Westcott 2810 Quick Start Guide

Softbox

™

Stripbank

™

Octabank

Quick Start Guide

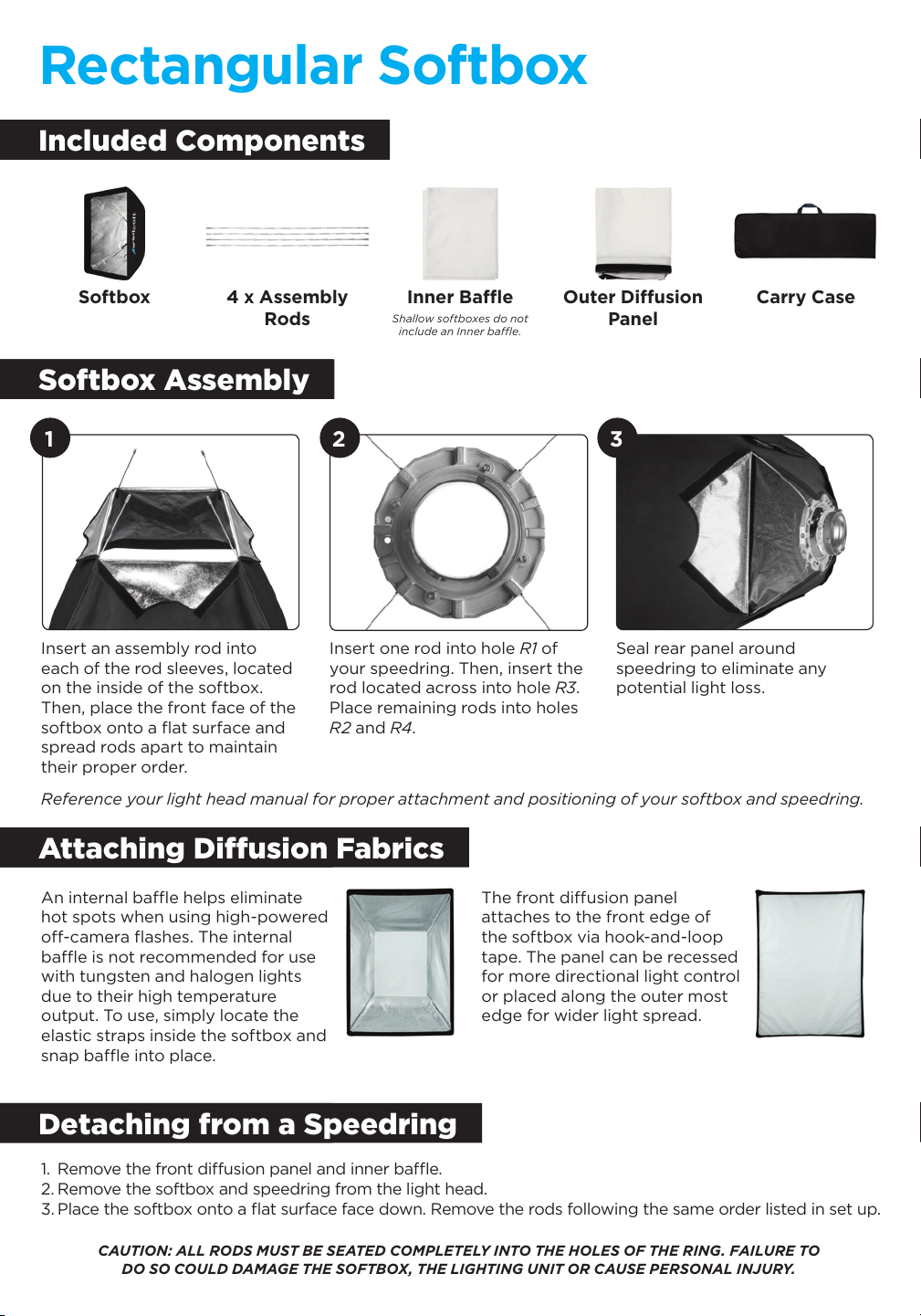

Seal rear panel around

speedring to eliminate any

potential light loss.

Insert one rod into hole R1 of

your speedring. Then, insert the

rod located across into hole R3.

Place remaining rods into holes

R2 and R4.

321

Insert an assembly rod into

each of the rod sleeves, located

on the inside of the softbox.

Then, place the front face of the

softbox onto a flat surface and

spread rods apart to maintain

their proper order.

An internal bae helps eliminate

hot spots when using high-powered

o-camera flashes. The internal

bae is not recommended for use

with tungsten and halogen lights

due to their high temperature

output. To use, simply locate the

elastic straps inside the softbox and

snap bae into place.

The front diusion panel

attaches to the front edge of

the softbox via hook-and-loop

tape. The panel can be recessed

for more directional light control

or placed along the outer most

edge for wider light spread.

Reference your light head manual for proper attachment and positioning of your softbox and speedring.

CAUTION: ALL RODS MUST BE SEATED COMPLETELY INTO THE HOLES OF THE RING. FAILURE TO

DO SO COULD DAMAGE THE SOFTBOX, THE LIGHTING UNIT OR CAUSE PERSONAL INJURY.

Softbox Assembly

Attaching Diusion Fabrics

Detaching from a Speedring

Included Components

Rectangular Softbox

Softbox 4 x Assembly

Rods

Inner Bae

Shallow softboxes do not

include an Inner bae.

Outer Diusion

Panel

Carry Case

1. Remove the front diusion panel and inner bae.

2. Remove the softbox and speedring from the light head.

3. Place the softbox onto a flat surface face down. Remove the rods following the same order listed in set up.

Loading...

Loading...