WERMA StockSAVER Instruction Manual

StockSAVER

Software version 2.1

WERMA Signaltechnik GmbH + Co. KG

D-78604 Rietheim-Weilheim

Telephone: +49 (0)7424 / 9557-222

Fax: +49 (0)7424 / 9557-44

support@werma.com

www.werma.com

310.865.005 0317_AA

Table of contents

StockSAVER manual - Software version 2.1

2

Table of contents

1 Introduction ........................................................................................................................................ 5

1.1 Target groups ..................................................................................................................................... 5

2 Safety information ............................................................................................................................. 6

2.1 Proper use ........................................................................................................................................... 6

2.2 General safety instructions .............................................................................................................. 6

3 Product description .......................................................................................................................... 7

3.1 Overview of hardware components ............................................................................................ 8

3.2 SensorBox ............................................................................................................................................ 9

3.3 Overview: SmartBox ....................................................................................................................... 10

3.3.1 SmartBox controls ...................................................................................................................... 10

3.3.2 SmartBox display messages ..................................................................................................... 10

3.3.3 SmartBox connections .............................................................................................................. 11

3.4 Overview: Transceiver .................................................................................................................... 12

3.5 Barcode scanner (optional) ......................................................................................................... 13

3.6 Software module overview ........................................................................................................... 14

4 Getting started: Overview of installation and commissioning ............................................... 15

5 Attaching the hardware to racks ................................................................................................ 16

5.1 Preparation ...................................................................................................................................... 16

5.1.1 Unpack devices and components ........................................................................................ 16

5.2 Installing the hardware .................................................................................................................. 17

5.2.1 Installing the sensors .................................................................................................................. 17

5.3 Installing a SensorBox ..................................................................................................................... 18

5.3.1 Wiring a SensorBox..................................................................................................................... 18

5.3.2 Wiring the bus ............................................................................................................................. 19

5.4 Installing the SmartBox ................................................................................................................... 20

5.5 Installing a Transceiver ................................................................................................................... 21

5.6 Functional test ................................................................................................................................. 22

5.7 Installing the software .................................................................................................................... 23

5.7.1 System requirements ................................................................................................................. 23

5.7.2 Network stability and security ................................................................................................. 25

5.7.3 Overview: System architecture ............................................................................................... 25

5.7.4 Installing WERMA StockSAVER ................................................................................................. 27

5.7.5 Advanced Server Installation .................................................................................................. 29

5.7.6 Installing a client on other PCs ................................................................................................ 30

5.8 Commissioning the hardware ...................................................................................................... 31

5.8.1 Wiring the racks .......................................................................................................................... 31

5.8.2 Connecting and configuring the Transceiver...................................................................... 31

5.8.3 Connecting and configuring the SmartBox ......................................................................... 33

5.8.4 Connect the SmartBox and Transceiver to the rack .......................................................... 36

Table of contents

StockSAVER manual - Software version 2.1

3

5.8.5 Configuring racks....................................................................................................................... 37

5.8.6 Configuring the bus cabling .................................................................................................... 38

6 System operation ............................................................................................................................ 39

6.1 Overview: Control Station ............................................................................................................. 39

6.2 Overview: Material Requirement List .......................................................................................... 40

6.2.1 Material Requirement List columns: Displaying a Single Location ................................... 40

6.2.2 Material Requirement List columns: Displaying Total Material .......................................... 41

6.3 Overview: Material Master ............................................................................................................ 42

6.4 Analysis .............................................................................................................................................. 43

6.4.1 Analysis and export function ................................................................................................... 47

6.4.2 Export to Excel ............................................................................................................................ 48

6.5 Configuring racks ............................................................................................................................ 49

6.6 Changing Settings .......................................................................................................................... 50

6.6.1 General........................................................................................................................................ 50

6.6.2 Views ............................................................................................................................................ 51

6.6.3 Devices ........................................................................................................................................ 52

6.6.4 Location ...................................................................................................................................... 52

6.6.5 Reports ......................................................................................................................................... 53

6.6.6 Functions ..................................................................................................................................... 53

6.7 System expansion ........................................................................................................................... 54

6.7.1 Changing the bus wiring .......................................................................................................... 54

6.8 Routing .............................................................................................................................................. 54

6.9 Connections ..................................................................................................................................... 56

6.10 CSV Interface ................................................................................................................................... 56

6.10.1 Exporting material movements to CSV ................................................................................. 56

6.10.2 Importing Material Master data from CSV ........................................................................... 59

6.10.3 Importing Location assignments from CSV ........................................................................... 61

6.11 XML interface ................................................................................................................................... 62

6.11.1 Configuring the Interface Service .......................................................................................... 62

6.11.2 XML import of Material Master data sets .............................................................................. 67

6.11.3 XML export of Material movements ........................................................................................... 70

6.11.4 Journal .............................................................................................................................................. 74

7 Software administration ................................................................................................................. 75

7.1 Uninstalling the software ................................................................................................................ 75

7.2 Installing updates ............................................................................................................................ 75

7.3 Unsupervised client installation .................................................................................................... 75

7.4 Administration console: Managing data ................................................................................... 75

7.4.1 Option: Manage data via the command line .................................................................... 76

7.5 Adjusting and synchronising the time ......................................................................................... 76

7.6 Alter the Server Service/database connection ........................................................................ 77

7.7 Firmware update ............................................................................................................................ 77

8 Troubleshooting ............................................................................................................................... 78

Table of contents

StockSAVER manual - Software version 2.1

4

8.1 Transceiver problems ..................................................................................................................... 78

8.2 SmartBox problems ......................................................................................................................... 79

8.3 SensorBox problems ........................................................................................................................ 79

8.4 Sensor problems .............................................................................................................................. 80

8.5 Software setup problems ............................................................................................................... 80

8.6 Software problems .......................................................................................................................... 80

8.7 Information on log files ................................................................................................................... 83

8.7.1 Request log files from the software ........................................................................................ 83

8.7.2 Activating detailed logging .................................................................................................... 83

8.7.3 Log file parameters ................................................................................................................... 83

9 Technical data ................................................................................................................................ 84

9.1 General ............................................................................................................................................. 84

9.2 Ratings ............................................................................................................................................... 84

9.3 Wireless .............................................................................................................................................. 85

Introduction

StockSAVER manual - Software version 2.1

5

1 Introduction

These instructions provide all the information required to operate the WERMA StockSAVER. The

instructions must be read by all persons assigned to work on this system.

1.1 Target groups

This manual is intended for:

− Production logisticians who will be working with the system.

− IT professionals who will be performing software configuration.

− Professional electricians who will be assembling the hardware components.

Safety information

StockSAVER manual - Software version 2.1

6

2 Safety information

2.1 Proper use

The device must be assembled and wired in accordance with the assembly instructions by a

professional electrician. Only use the components supplied.

The software must be configured by an IT professional.

The system must be commissioned and operated in accordance with this manual to ensure

the safety of operating personnel and protect the StockSAVER system from inc orre ct

operation.

Read the operating instructions carefully before assembly and commissioning. Keep these

operating instructions in a convenient place for future reference.

Special arrangements must be made if your production logistics processes involve returning

opened bins to storage from the withdrawal side to avoid irregularities in material requisition

and analysis functions.

Data is processed exclusively by the StockSAVER software. The system does not support direct

read or write access to the database content or alterations to the database structures by

other software. WERMA reserves the right to optimise the software and connected database.

Updates can lead to alterations, replacements and deletions in the database. Unauthorised

alterations can affect the operation of the software or individual functions.

2.2 General safety instructions

− The system must only be connected by a professional electrician taking into account the

operating instructions and the guidelines as well as standards applicable in the area of

use.

− Maintenance tasks must be performed by a professional electrician with the system

disconnected from the power supply.

− The operator is solely responsible for adherence to local safety regulations, for monitoring

and control of the StockSAVER system and for the results achieved using the system. The

purchaser must test the software thoroughly for applicability in their specific situation

before beginning productive use. The purchaser is obliged to make suitable provisions for

the eventuality that the system does not work properly either entirely or in part (e.g. by

backing up data, documenting the use of the software, fault diagnostics, regular testing

of results, emergency planning). It is the purchaser's responsibility to ensure the viability of

the system's working environment.

− When not in use, keep the WERMA StockSAVER system in the original packaging to ensure

optimum protection against damage.

− Modification of the system or improper use renders the guarantee void and invalidates

the manufacturer's responsibility.

− Usage that is not described in the manual is considered to be improper. The operator of

the product is liable for damage caused by improper use.

Product description

StockSAVER manual - Software version 2.1

7

3 Product description

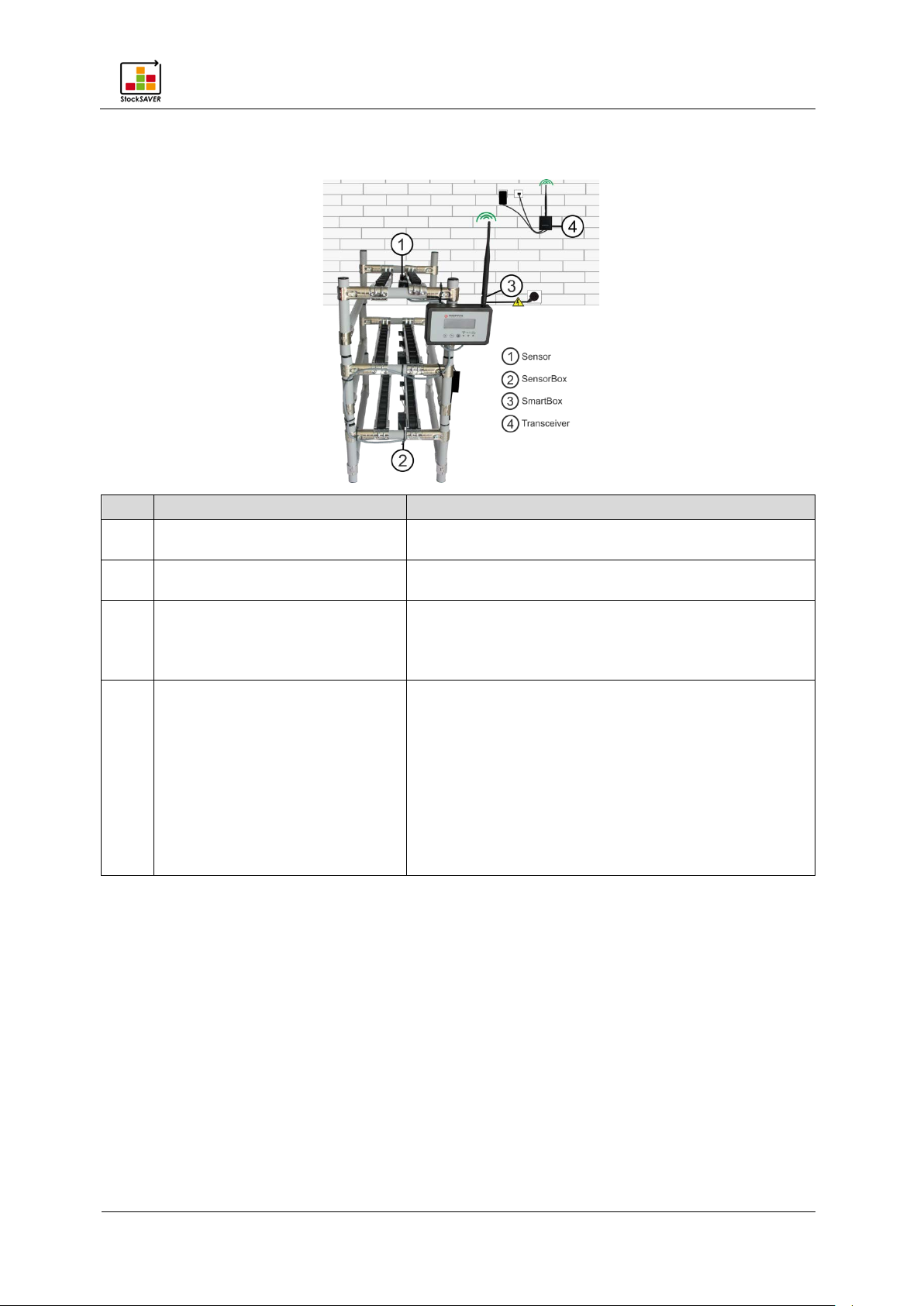

The StockSAVER system serves as a signal point in the logistics chain and monitors fill levels of

commercially-available FIFO flow racks. Fill levels are communicated wirelessly and visualised

in the StockSAVER software based on the intelligent interaction of the system components.

Sensors mounted in the racks record the fill levels. This status information is collected by the

SensorBox and transmitted to the SmartBox using a bus system. The data is transmitted

wirelessly to the Transceiver and written to the database by the software.

Misplaced replenishments can also be promptly detected if an optional barcode scanner is

employed.

StockSAVER software provides a wide range of functions for optimising work processes using

FIFO flow racks and the production logistics process.

The system sensor, SmartBox and SensorBox components and the mounting materials have

been developed for installation in FIFO flow racks. The following rack types have been tested

for compatibility:

− SSI Schäfer KDR live carton storage racks

− Creform pipe racks, Ø 28 mm series

− Bito live storage racks, type 36-33250

− Bosch Rexroth XLEAN material supply racks

Compatibility with other rack types and mounting options must be established before

installation.

Product description

StockSAVER manual - Software version 2.1

8

Item

Components

Function

the SensorBox.

location. Forwards the data to the bus system.

SmartBox also warns about misplaced products.

4

Transceiver

Receives statuses from up to 20 SmartBoxes.

range: 300 m (line-of-sight)

3.1 Overview of hardware components

1 Sensor Detects bins and forwards the status information to

2 SensorBox Receives the sensor status of up to 4 bins per

3 SmartBox Receives data from up to 50 SensorBoxes via the

bus system and transmits it to the Transceiver.

If the optional barcode scanner is used, the

Transfers data to the Server Service (Software). The

data is then stored the database and displayed on

client PCs.

Up to 4 Transceivers may be connected to a

database.

Power is supplied via the included mains plug-top

adapter. The Transceiver is connected to the

network via Ethernet cable. Maximum wireless

StockSAVER manual - Software version 2.1

9

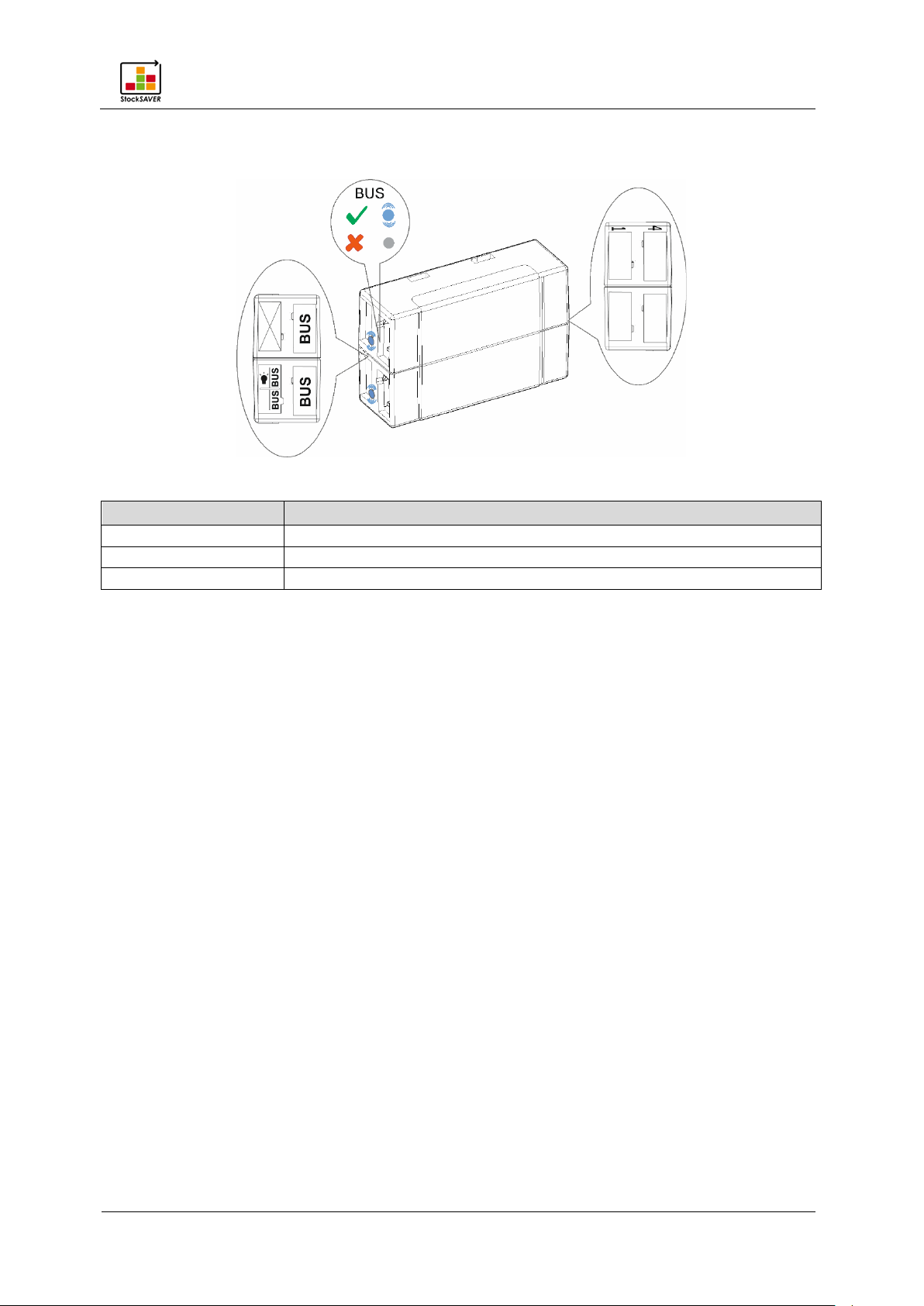

3.2 SensorBox

LED

Function

Bus LED flashes blue

Power supply present; bus connection interrupted

Bus LED off

No power supply and no bus connection

Bus LED steady blue

Power supply and bus connection present

Up to 4 sensors may be connected (see right)

Product description

StockSAVER manual - Software version 2.1

10

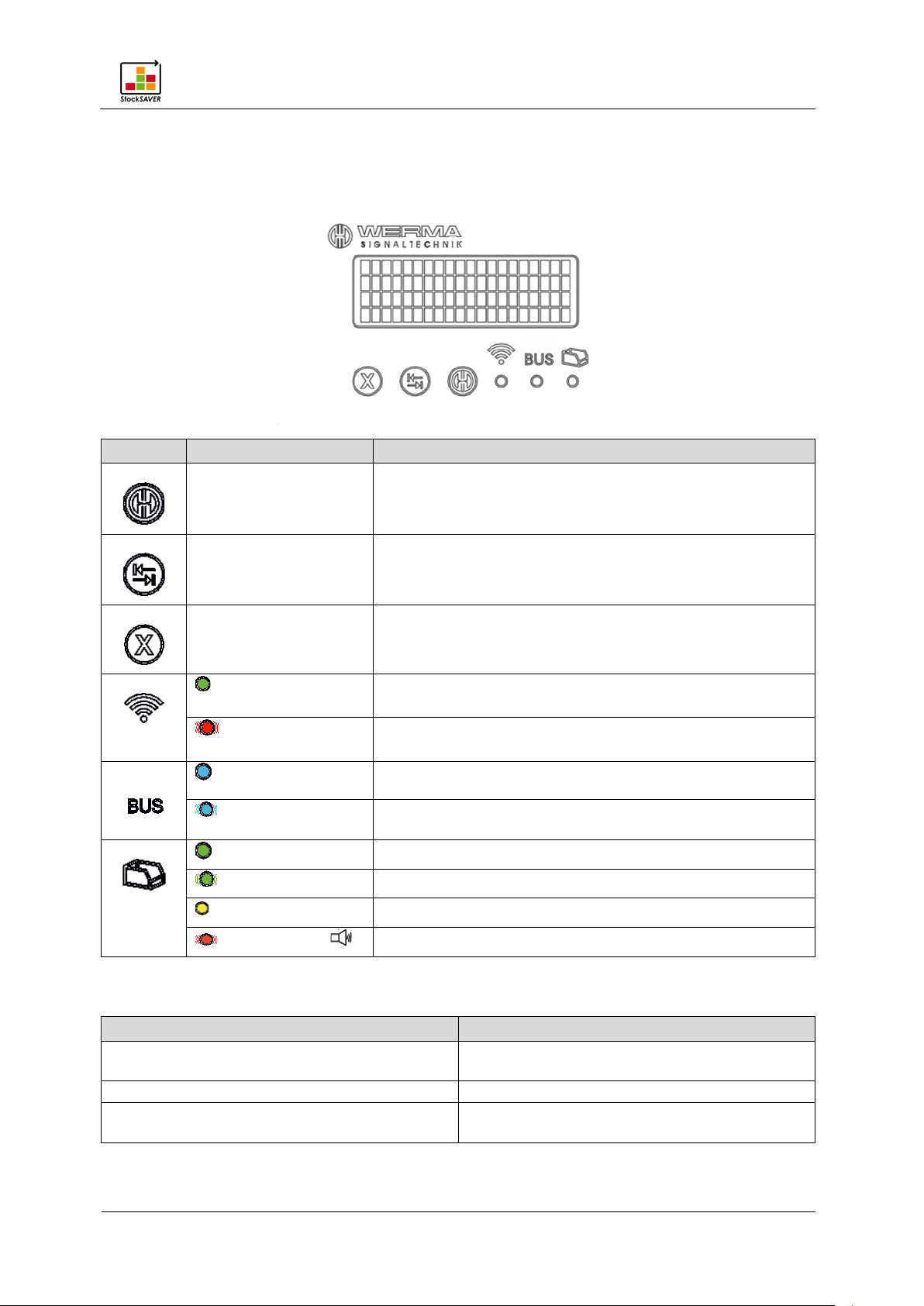

3.3 Overview: SmartBox

Icon

LED

Function

Hold down for approx. 5 s to access the volume menu.

Wireless connection present

Wireless connection not present

Bus connected to following SensorBox

Bus not connected to following SensorBox or no

SensorBox connected

Known material

Message

Cause

been initialised and is ready for operation.

Initialisation…

SmartBox is being initialised.

present.

3.3.1 SmartBox controls

Product description

Close the volume menu.

Increase the volume when in the volume menu

Reduce the volume when in the volume menu

If misplaced products are detected: Acknowledge

On (Green)

Flashes (Red)

On

Flashes

On (Green)

Flashes (Green)

On (Yellow) Unknown material

Flashes (Red)+ Misplaced Replenishment

correction of misplaced products

Database query running

3.3.2 SmartBox display messages

Ready... The system has a wireless connection, has

No connection… No wireless connection to the Transceiver is

Product description

StockSAVER manual - Software version 2.1

11

Message

Cause

Connecting and configuring a SmartBox.

displayed.

defined structure.

Material Master data.

SmartBox.

Error: SmartBox not initialised

SmartBox is not initialised.

Error: SensorBox full

Location has maximal load.

Error: Unknown reason

Unknown error. Repeat the process.

correctly.

Placement error

A product has been stored without first being

scanned.

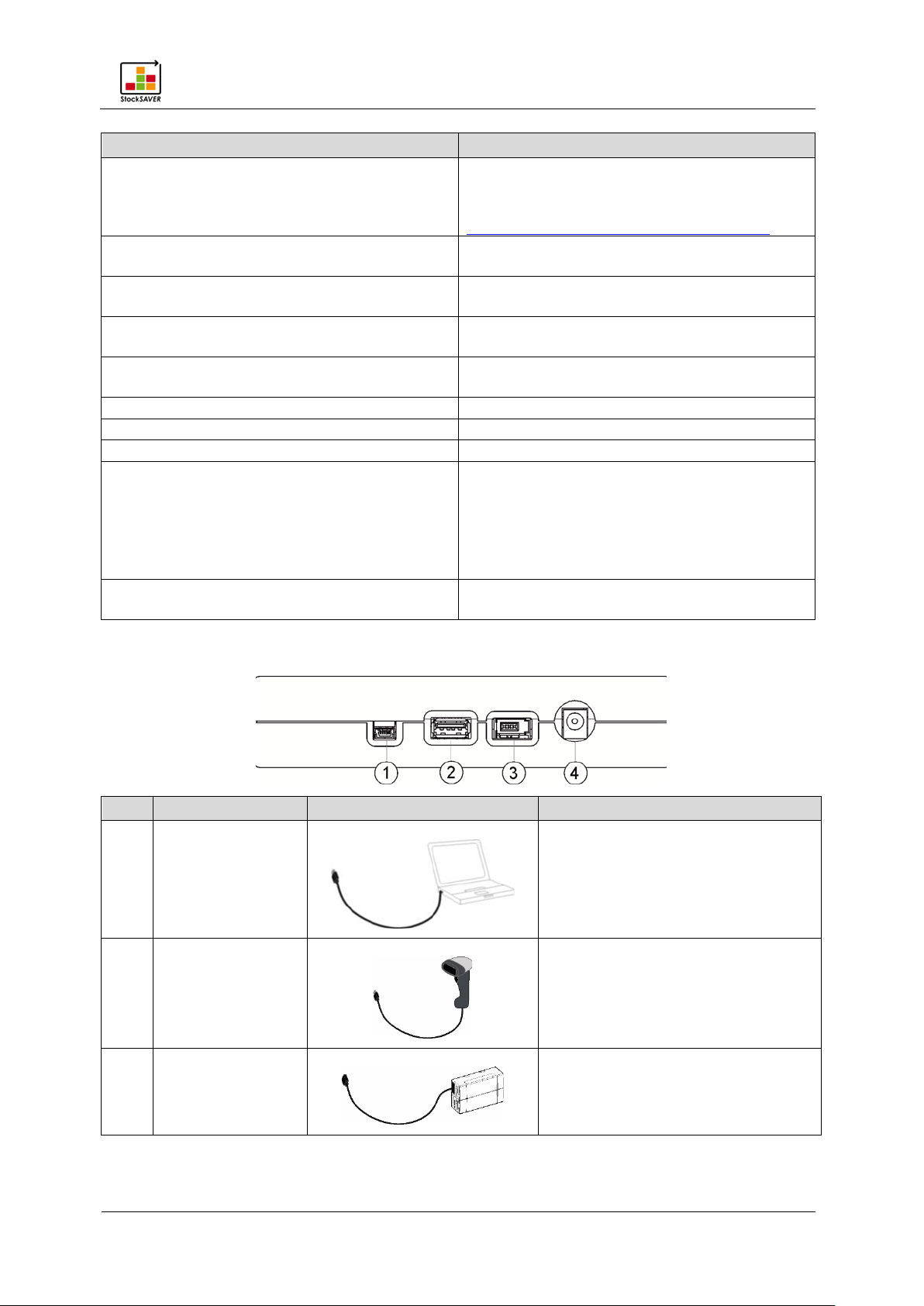

Item

Connector

Device

Comment

2

USB

Only for human interface devices

Not configured… SmartBox is not configured and cannot be

detected by the softw a re . S olutio n :

Configure the SmartBox via USB. See

Shelf Location is being detected and will be

Material not readable The Part Number does not correspond to the

Error: Material unknown The Part Number is not defined in the

Error: Material not available The Part Number is not available in this

Placement error Replenishment placed in the wrong Location

Solution:

Remove the material from the Location.

Press the X button.

Rescan the bins and place them in stock

3.3.3 SmartBox connections

1 Mini USB

3 BUS

Only required for configuration and

firmware updates

Connection to first SensorBox

Product description

StockSAVER manual - Software version 2.1

12

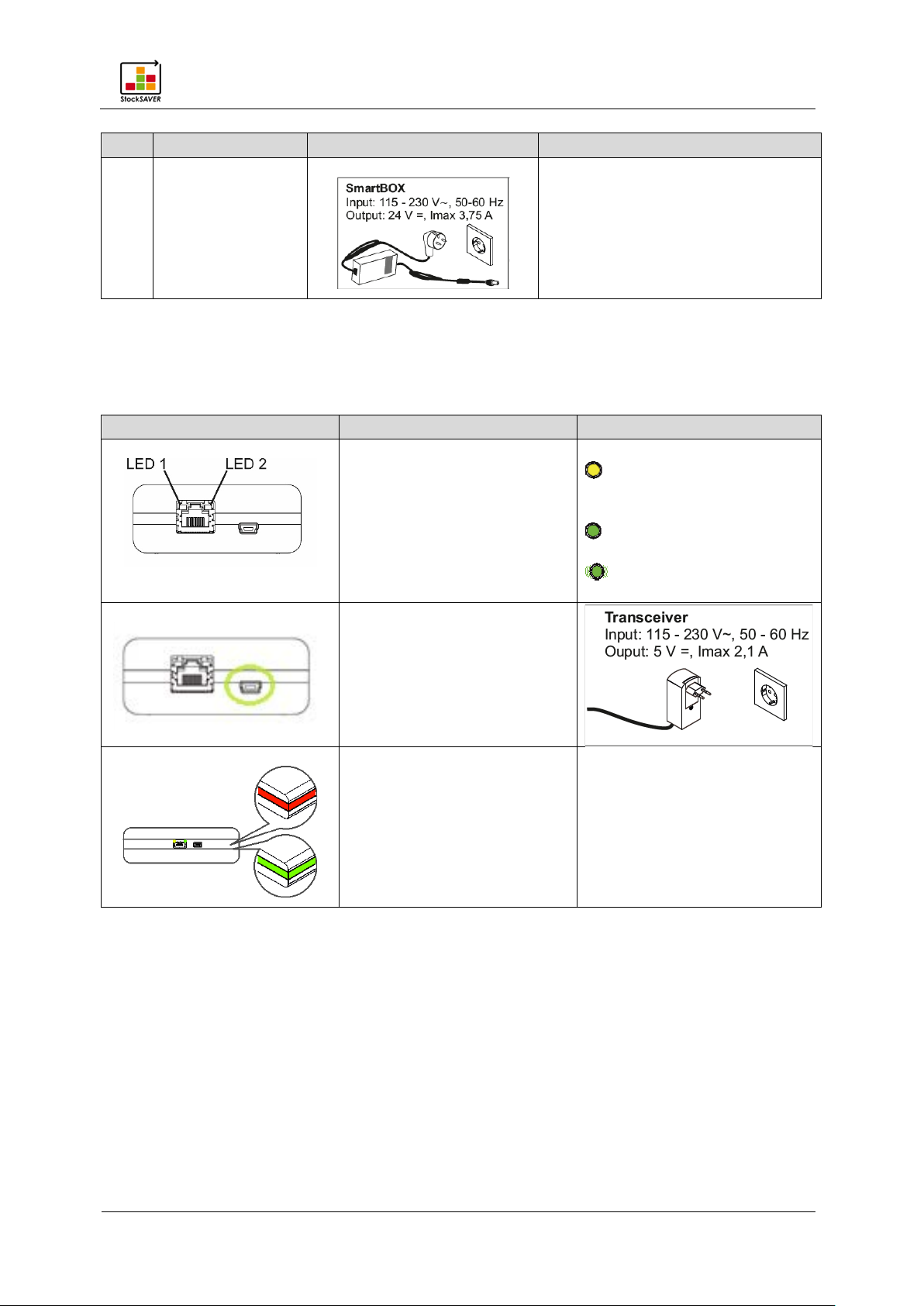

Item

Connector

Device

Comment

Components

Connector

LED

LED1

activity

Power supply/

Wireless connection

Red if no wireless connection

4 Power supply

3.4 Overview: Transceiver

Network

Input: 115-230 V

Output: 24 V

On (yellow) when

connected to the software

LED2

On (green) when

connected to the network

Flashes during network

commissioning hardware

is established with SmartBox

Green if wireless connection is

established with SmartBox

Product description

StockSAVER manual - Software version 2.1

13

Connector

Manufacturer

Type

RFID USB reader

I-keys RFID USB reader

RFID

Wired scanner

Motorola LS2208

Barcode

Wired scanner

Honeywell 1900

Barcode/2D

Wireless scanner

Motorola/Symbol LI4278

Barcode

Integrated scanner

Honeywell Quantum MS3580

Barcode

Bluetooth scanner

DataLogic

QuickScan QBT2131

Barcode

3.5 Barcode scanner (optional)

The optional barcode scanner enables the "SmartBox with identification" to be used to

identify and log misplaced material.

The scanner must be configured so that it is detected as a USB HID and the string ends with a

Carriage Return (0x0D) or with a Line Feed (0x0A). The keyboard layout language must also

be set to English (or German as required). Details of scanner configuration can be found in

the scanner instructions.

The scanner is not included and cannot be purchased from WERMA Signaltechnik. We have

tested the following barcode scanners for compatibility. Please contact us for the latest

overview.

Please contact your scanner supplier with any queries concerning barcode scanner

configuration. In some cases, it may not be possible to guarantee correct function with other

devices.

Scanning barcodes

1. Scan the barcode on the bin. The correct location is displayed on the SmartBox and the

green LED is activated on the corresponding SensorBox.

2. Place the bin on the correct location. The SmartBox will beep once.

3. If the bin is stored incorrectly, the SmartBox beeps several times. The system is blocked for

further stock placement.

4. Remove the misplaced product from the rack and then press X on the SmartBox to

acknowledge the misplaced product.

The last procedure is undone and the system becomes available for further stock

placement.

Product description

StockSAVER manual - Software version 2.1

14

Software modules

Description

Control Station

Displays requirements and errors from the racks.

Material Requirement

List

Displays current requirements and data related the stored

materials.

Material Master data

Users create the materials in use individually, import them as CSV

files, edit materials or delete materials.

Analysis

Statuses can be evaluated or exported in a different format.

software

3.6 Software module overview

The StockSAVER software is divided into modules. The modules are:

Configuration Configuration of the hardware and rack representation in the

Getting started: Overview of installation and commissioning

StockSAVER manual - Software version 2.1

15

4 Getting started: Overview of installation and commissioning

Before you can begin working with your StockSAVER, you must first install the devices and

software and configure the system using wireless connections and USB.

1. Attaching the hardware to racks.

2. Install the software.

− Install the server.

− Install the client.

3. Commission hardware using the commissioning wizard

− Configure the Transceiver.

− Configure the SmartBox.

− Connect the devices to the rack.

4. Configure the rack in the software

.

:

StockSAVER manual - Software version 2.1

16

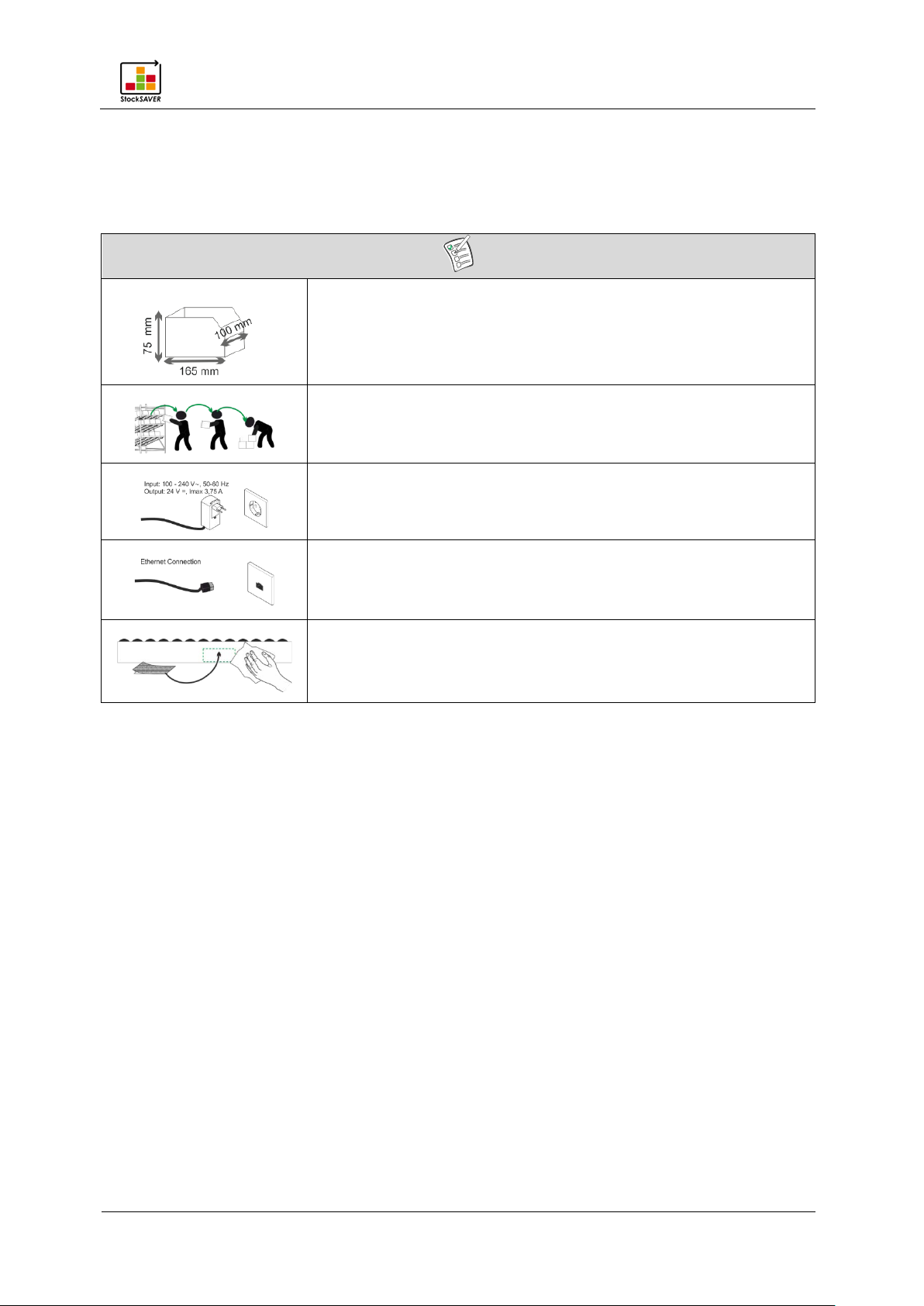

5 Attaching the hardware to racks

Note the minimum bin dimensions.

Remove all bins from the rack.

A power socket must be available nearby.

An Ethernet connection must be available.

Clean the rack using a cloth and a mild cleaning agent if

5.1 Preparation

Attaching the hardware to racks

necessary. Ensure it is free of grease or dust.

5.1.1 Unpack devices and components

1. Unpack the products and check for damage.

2. If damaged items are found, please inform WERMA Signaltechnik or the forwarding

agent.

3. Check the delivery against your order for:

− Delivered quantity

− Type and version of device according to type plate

− Accessories

− Quick guide

Attaching the hardware to racks

StockSAVER manual - Software version 2.1

17

5.2 Installing the hardware

The following tools are additionally required to install the hardware:

− Parallel action crimping pliers

− Stripping tool for the sensor cable: 3.30 mm - 4.40 mm Ø

− Stripping tool for the bus cable: 4.40 mm - 7 mm Ø

These tools are available as a set; part number 865 000 29

Tip: Installing the components can be simplified by removing the shelving rails from the rack, if

the rack structure allows.

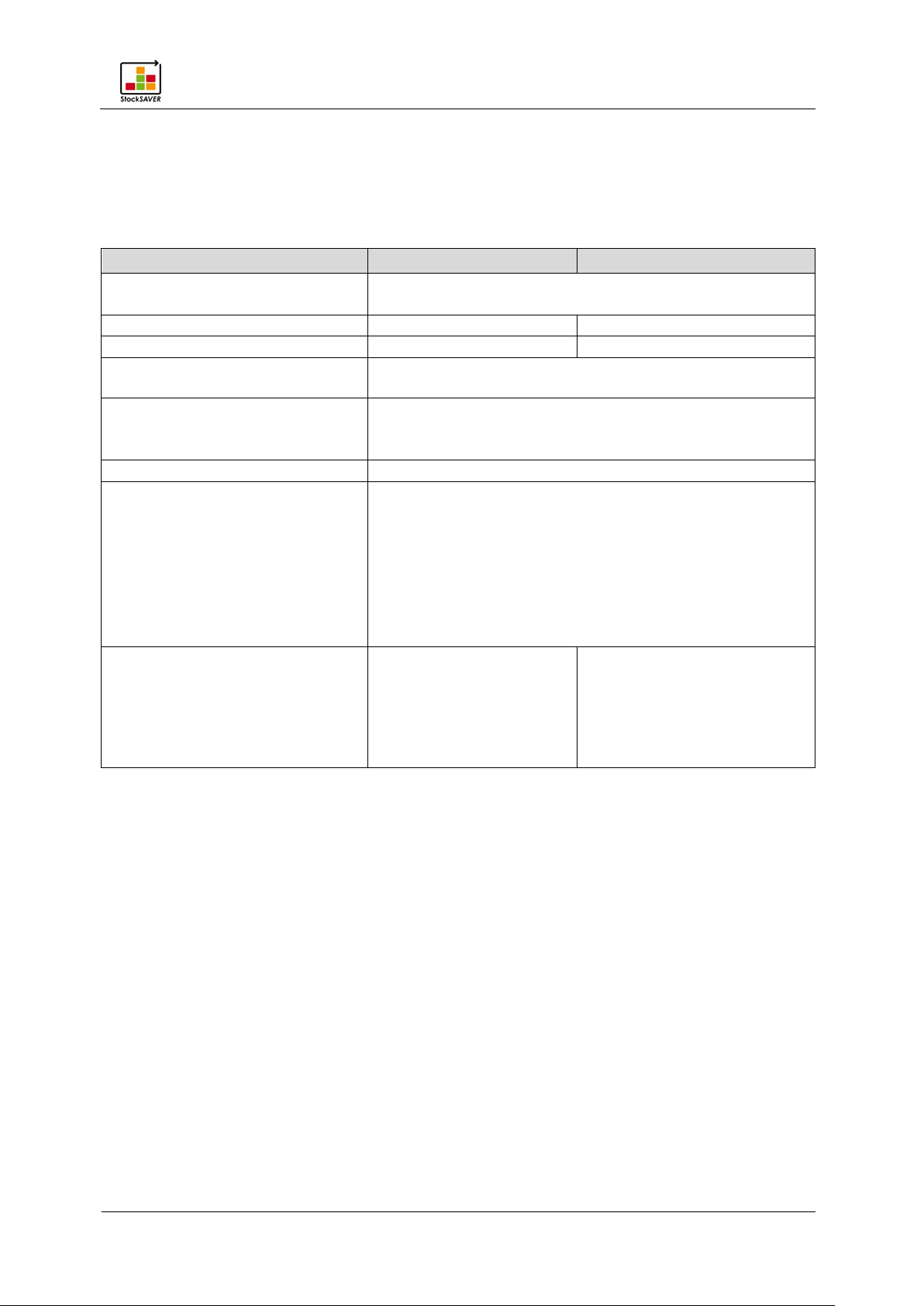

5.2.1 Installing the sensors

Tip: If a uniform bin size is used, we recommend pre-assembling the sensors (Installing the

cable and plug) outside the rack before actual assembly.

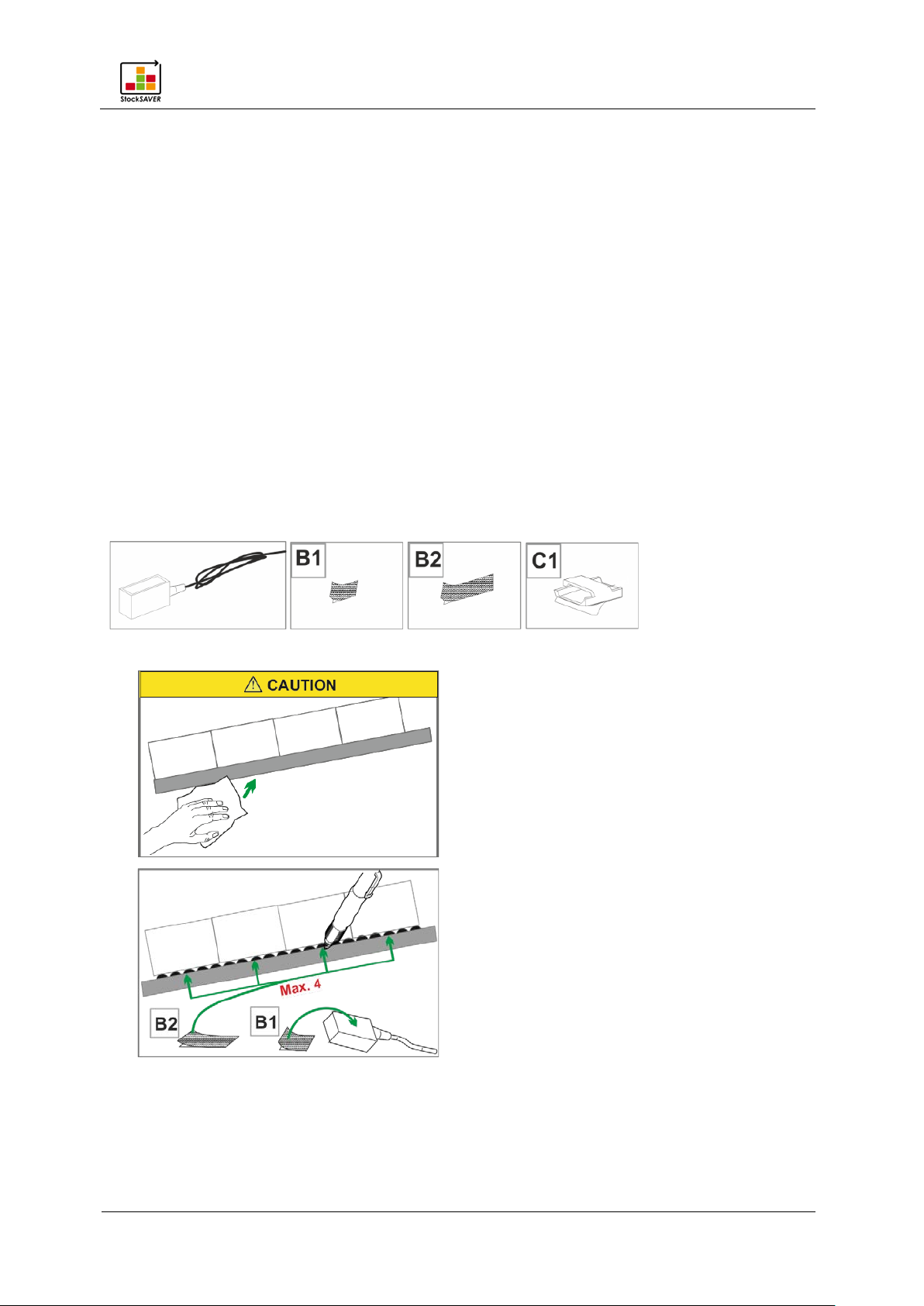

Required components

Procedure

1.

2.

Attaching the hardware to racks

StockSAVER manual - Software version 2.1

18

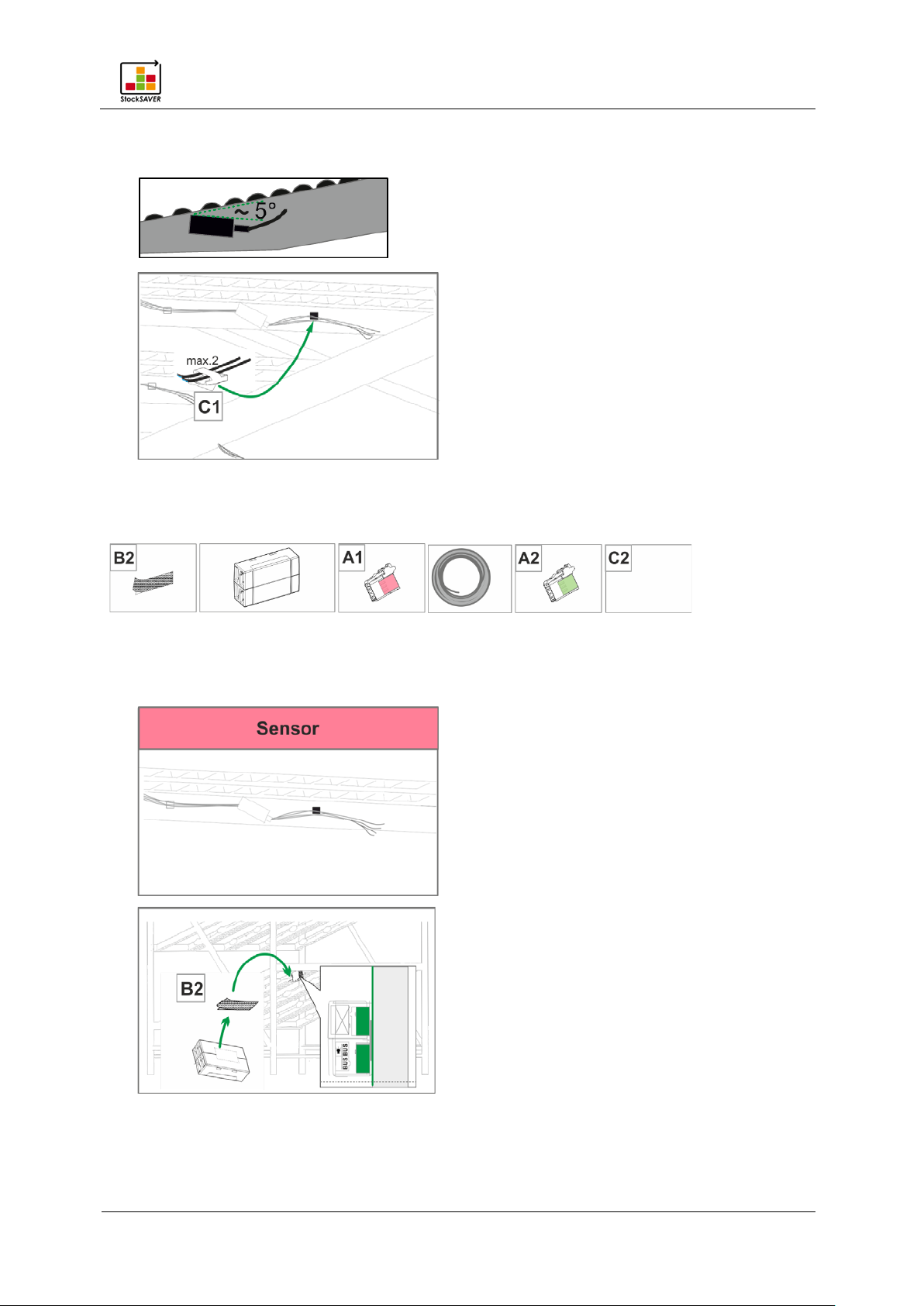

3. Attach the sensors tilted at an angle of 5° to prevent malfunction caused by reflective

surfaces. Clean sensors if they become heavily soiled during operation.

4.

5.3 Installing a SensorBox

Required components

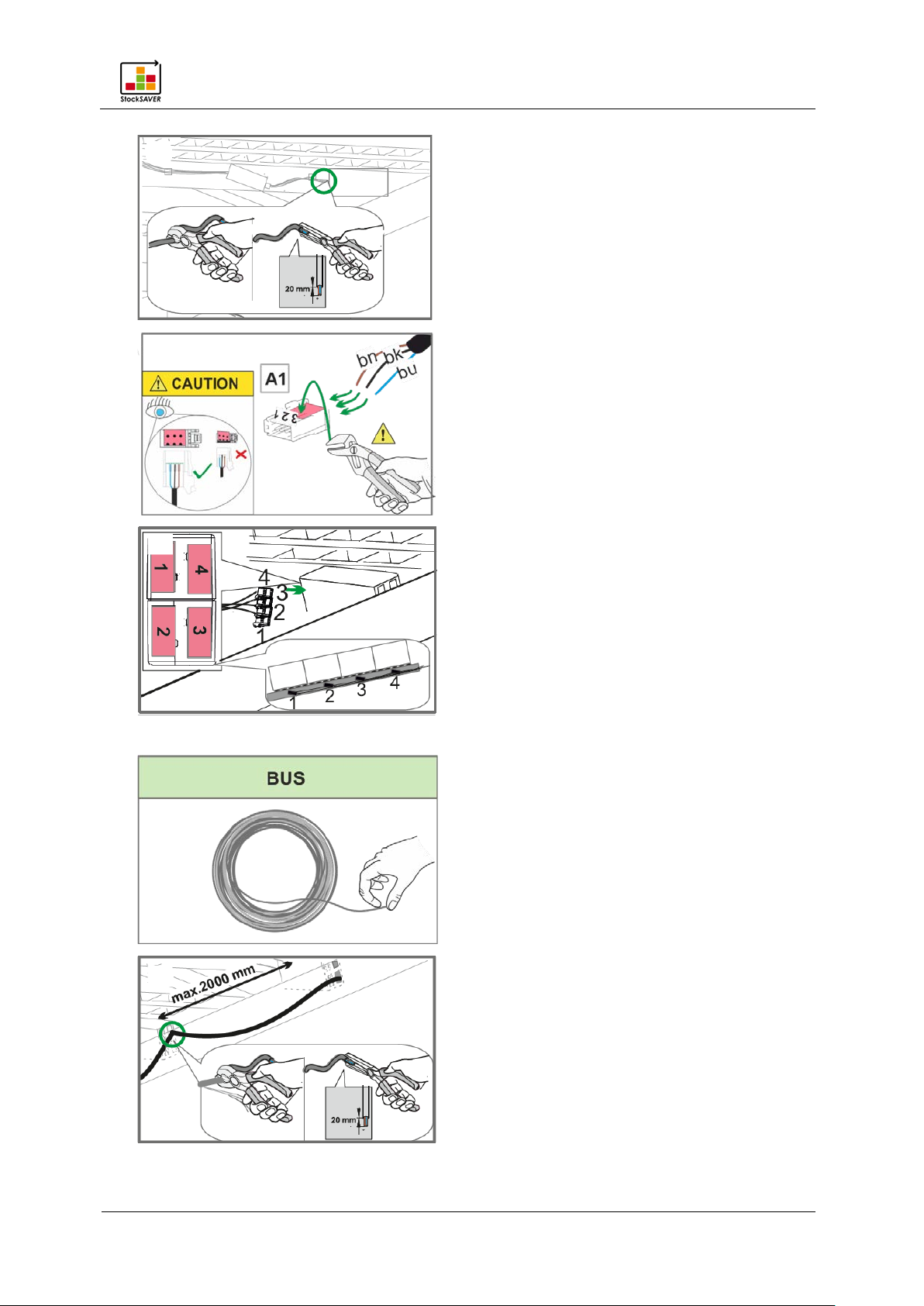

5.3.1 Wiring a SensorBox

Leave sufficient room (approx. 10 cm) between SensorBoxes and the rack crossbeam to

allow space for the bus wiring.

1.

2.

StockSAVER manual - Software version 2.1

19

3.

4.

Attaching the hardware to racks

5.

5.3.2 Wiring the bus

1.

2.

StockSAVER manual - Software version 2.1

20

3.

4.

Attaching the hardware to racks

5.

6.

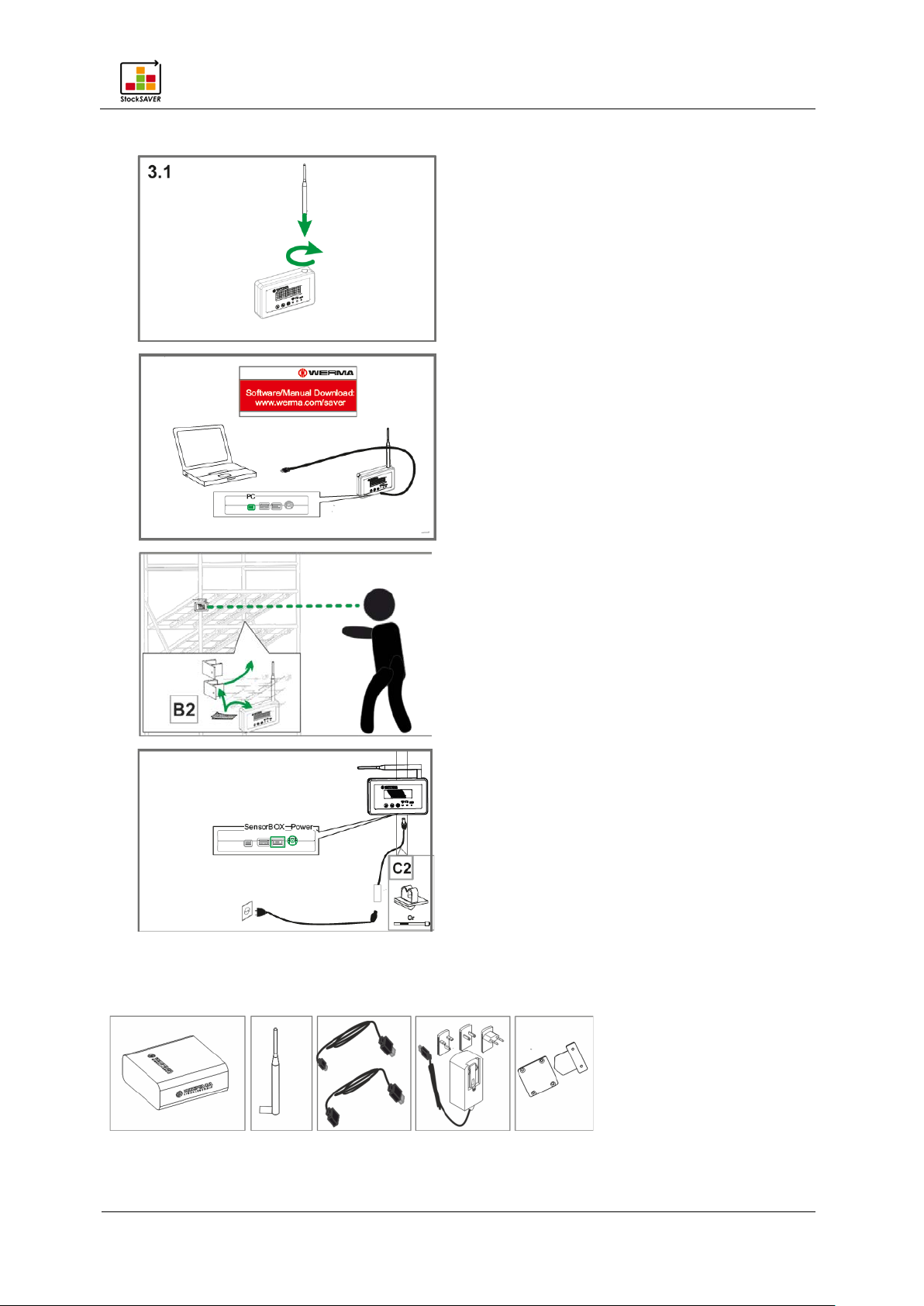

5.4 Installing the SmartBox

Required components

StockSAVER manual - Software version 2.1

21

Procedure

1.

2.

Attaching the hardware to racks

3.

4.

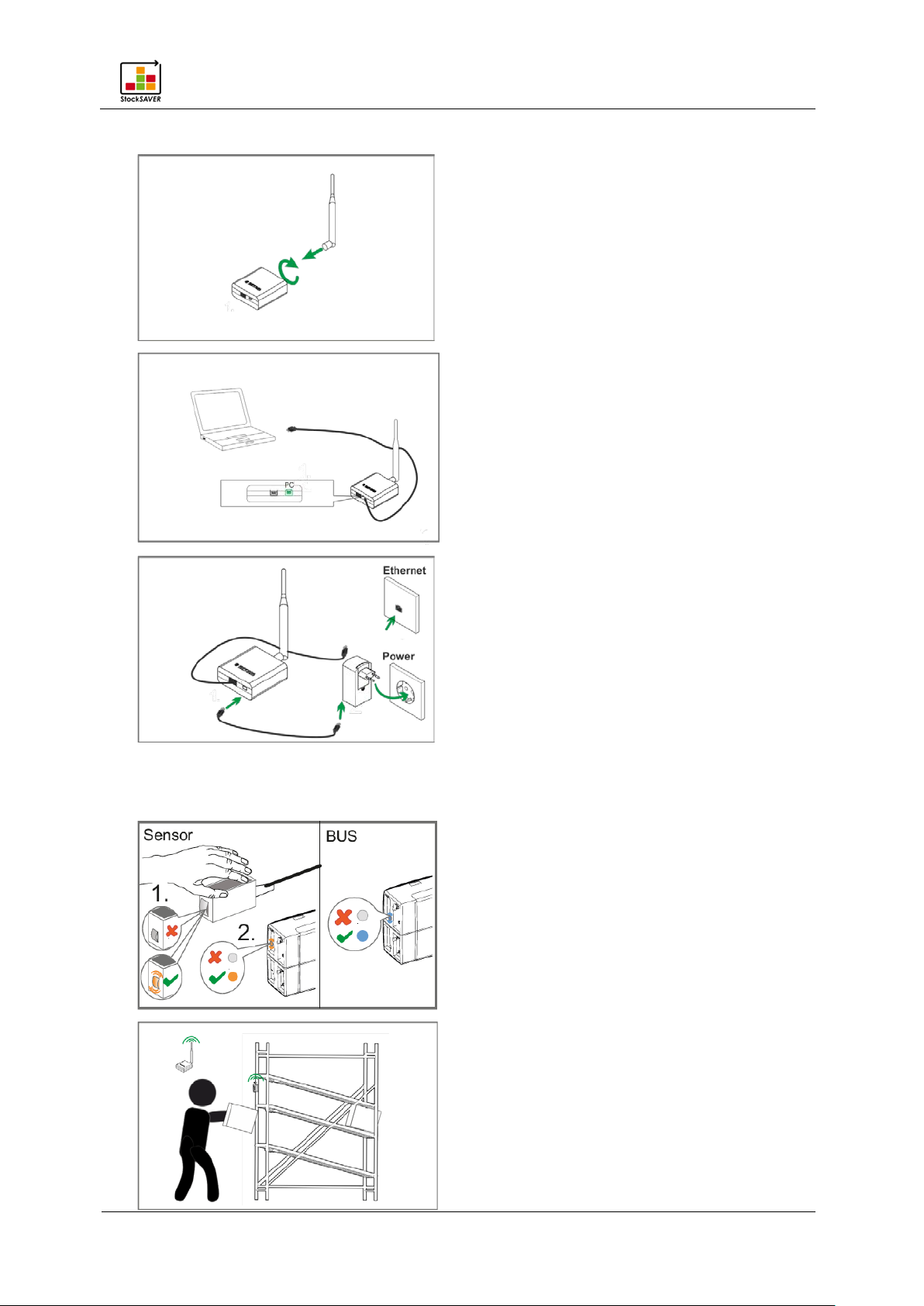

5.5 Installing a Transceiver

Required components

StockSAVER manual - Software version 2.1

22

Procedure

1.

2.

Attaching the hardware to racks

3.

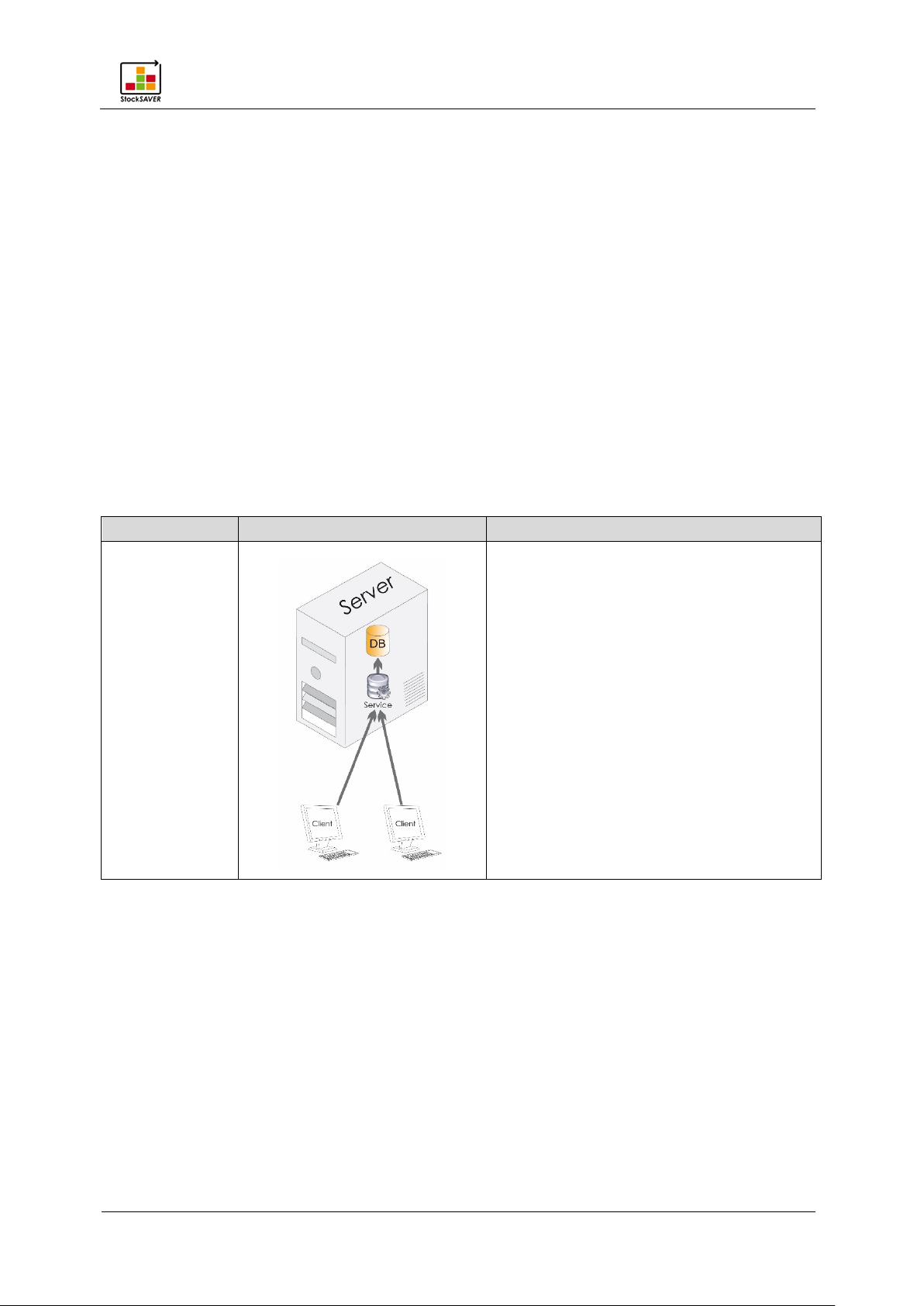

5.6 Functional test

1.

2.

Attaching the hardware to racks

StockSAVER manual - Software version 2.1

23

5.7 Installing the software

5.7.1 System requirements

System requirements for the server PC and the client are different.

Server PC

The following software components are installed on the server PC:

− WERMA StockSAVER Server Service

− Microsoft SQL server 2014 Express local DB

− WERMA StockSAVER client (user interface)

− USB device driver for the hardware

− WERMA StockSAVER administration console

Attaching the hardware to racks

StockSAVER manual - Software version 2.1

24

Name

Server PC

Client PC

Processor

Pentium-III-compatible processor or

fast dual-core processor recommended

Recommended RAM

3 GB

2 GB

Available hard drive memory

4.3 GB

1.8 GB

Configuration can be performed on the client PC

Monitor resolution

At least: 1280x1024

Text size scaling (DPI) up to 200% (192 DPI)

Microsoft .NET Framework 4.5.2

Automatically installed if not present

Supported operating systems

Windows 7 SP1

Windows server 2016

SP2

Client PCs

The following software components are installed on the client PC:

− WERMA StockSAVER client (user interface)

− USB device driver for the hardware

USB port Required for configuring the Transceiver and SmartBox.

Recommended from: 1920x1080

Windows 8

Windows 8.1

Windows 10

Windows server 2008 R2 SP1

Windows server 2012

Windows server 2012 R2

Supported SQL server Compatible from:

Microsoft SQL server 2008

SP4

Recommended:

Microsoft SQL server 2014

Note

− If not otherwise stated, both the 32-bit (x86) and 64-bit (x64) versions are supported.

− The latest service pack for Windows and Microsoft SQL server is supported.

− Windows server Core and Nano server installation is not supported.

− The Windows Remote Desktop Services server role is not supported on the server PC.

− Only the Express, Workgroup, Standard, Enterprise and Datacenter Microsoft SQL server

editions and the included Microsoft SQL server 2014 Express LocalDB are supported.

Attaching the hardware to racks

StockSAVER manual - Software version 2.1

25

Option

Visualisation

Comment

5.7.2 Network stability and security

We advise you to only operate WERMA StockSAVER in a reliable LAN environment (TCP/IP

network). An unstable or unsafe network can impair the function or performance of WERMA

StockSAVER.

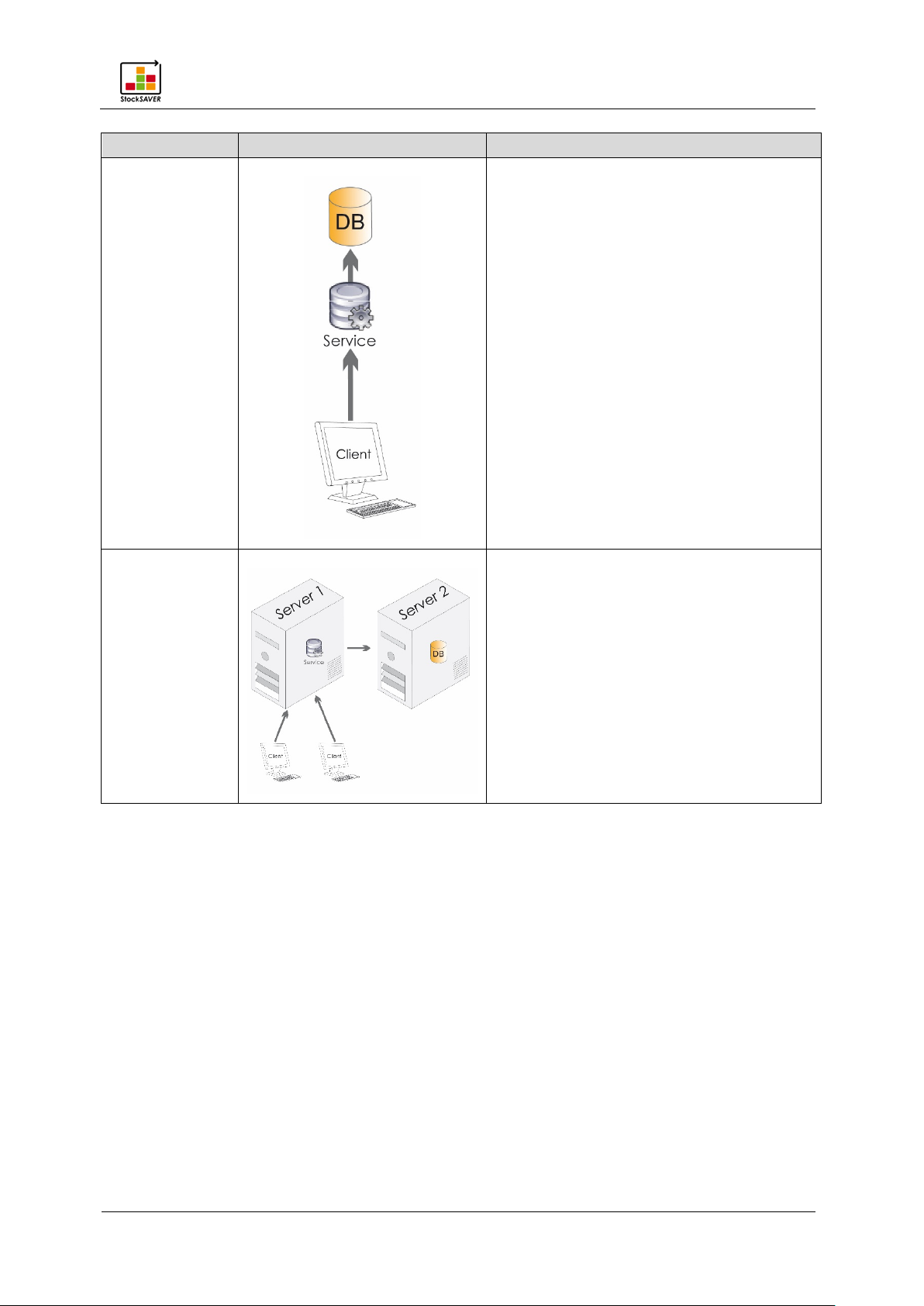

5.7.3 Overview: System architecture

The following points on system architecture must be observed:

− During installation, the Server Service is installed on the server. When the server is started,

the service is automatically started and executed in the background.

− Only one Server Service can be used per database.

− Only one Server Service can be used per server.

− Recommendation: Use a static IP address for the server PC.

− Data will be written to the database as long as the database and the Server Service are

started on the server. The software does not have to be running on the client PC to do so.

System architecture options

Standard

Install the Server Service and the

database on a server.

Install the client application on a

workstation PC.

Attaching the hardware to racks

StockSAVER manual - Software version 2.1

26

Option

Visualisation

Comment

Option A

Option B

Install the Server Service, client and

database on a workstation PC.

Not recommended during productive

operation.

Install the Server Service and database on

two different servers. A separate SQL

Server, e.g. SQL Server Express, must be

installed beforehand.

Install the client application on a

workstation PC.

Loading...

Loading...