Wells MOD-500T Installation Manual

ELECTRICAL

INSTALLATION INSTRUCTIONS

BUILT-IN MODULAR WARMERS

VOLTS WATTSMODELS SINGLE

MOD-500

MOD-500

MOD-500T

MOD-500T

ALL MODELS WITH A "D" OR "DM" SUFFIX HAVE THE SAME ELECTRICAL SPECIFICATIONS AS THE STANDARD MOD-500 OR MOD-500T MODELS.

240

208

6000

6200

AMPS PER LINE 3 PHASE

11.2

13.0

14.6

16.9 16.9

11.2

13.0

14.6

AMPS

PHASE

L3L2L1

21.615.0208 4500

FIELD WIRING GAUGE

3 PHASE 1 PHASE

12 AWB Cu

12 AWB Cu25.017.0

12 AWB Cu29.819.5

12 AWB Cu34.422.1240 8250

8 AWB Cu

8 AWB Cu

8 AWB Cu

8 AWB Cu

TEMP.

RATING

75°C

75°C

75°C

75°C

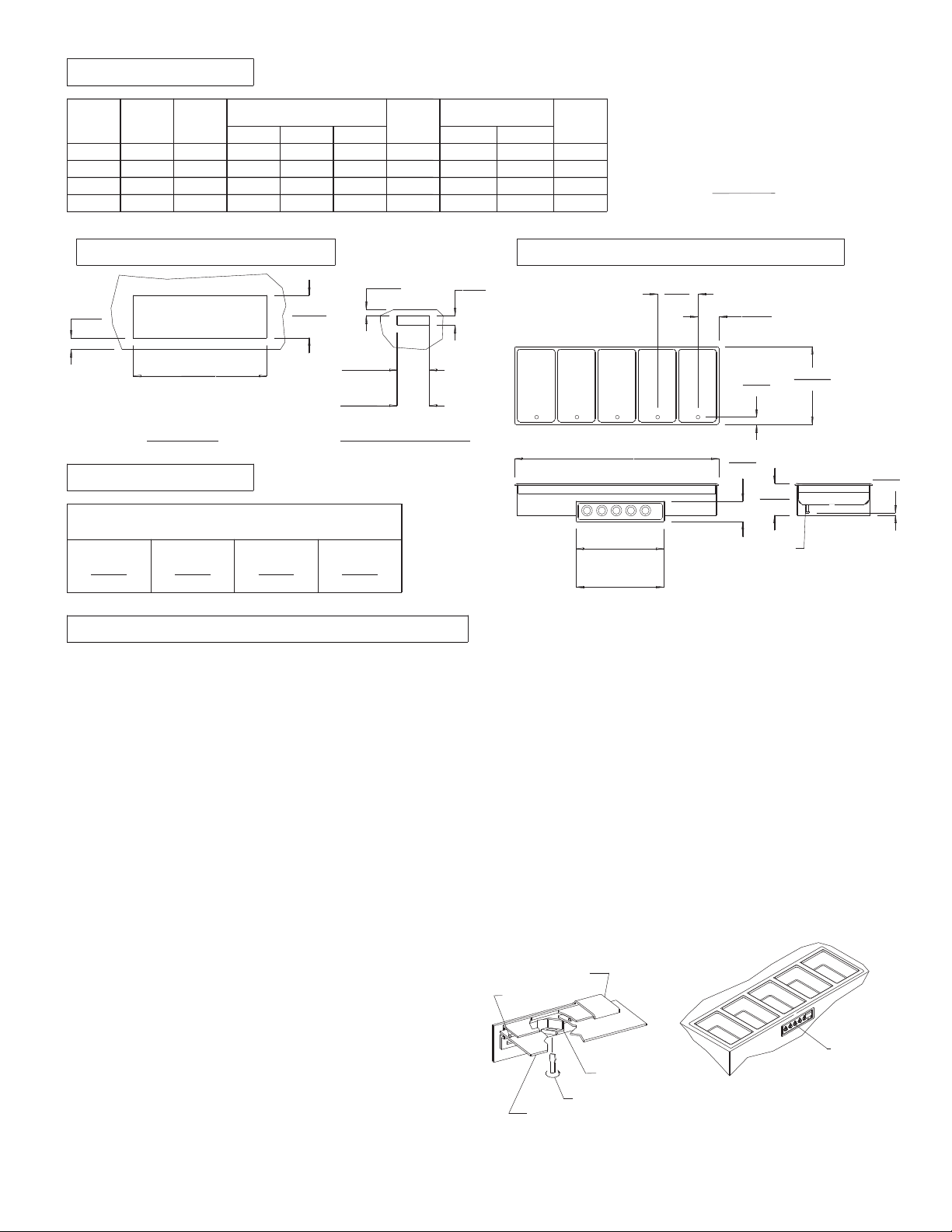

MOD 500 SERIES (T, TD, TDM)

INCHES

(MM)

CUTOUT DETAILS

3 1/8

6

(152)

22 1/2

(572)

70 1/2

(1791)

'T' MODELS

(79)

16 7/8

(430)

33 7/8

(860)

FRONT PANEL CUTOUTTOP CUTOUT

CLEARANCES

MINIMUM CLEARANCE REQUIRED FROM

UNIT TO THE NEAREST SURFACE

BACK SIDE BOTTOM FRONT

1 1 6 3/4 6

(25) (25) (171) (152)

INSTALLATION INSTRUCTIONS

NOTE: MOD-500 UNITS ARE SHIPPED THREE PHASE AND

ARE FIELD CONVERTIBLE TO SINGLE PHASE. THE DRAIN

MANIFOLD WITH 1" INTERNAL NPT VALVE IS SUPPLIED

FOR DM AND TDM MODELS ONLY.

INSTALLER MUST MEET CONDITIONS OF ACCEPTABILITY

OUTLINED BELOW UPON INSTALLATION:

1. Required Installation Clearances:

Wooden and Metal Installation: DO NOT install closer than

6 inches to front wall, 1 inch to back and side walls, and

6 3/4 inches to a surface below the unit.

2. Unit shall be accessible for servicing from the bottom.

3. If storage is to be used underneath the unit, it is

recommended that a baffle be placed 8 1/2 inches below

the unit to avoid contact with elevated temperatures.

TO FABRICATE:

1. Layout "cutout" dimensions on countertop and front

apron.

2. Layout and fabricate control panel holes in counter

apron using the control box as a template.

3. Cut out holes.

4. Unit shall be accessible for servicing from the bottom.

TO INSTALL:

IMPORTANT - DO NOT disconnect "lead wires" from the

Master Control Panel when making installation.

1. Tilt and pass Control Panel and electrical box through

counter top cutout, then through apron cutout. Lower

modular section into countertop cutout and position.

RECOMMENDATION: Before final seating of modular section

to countertop, apply a bead of silicone adhesive/sealant

to underside of gray gasket material supplied on mounting

flange.

2. From underneath, insert screwdriver into "slots" in

Wellslok frame and twist "ears" outward (clockwise) as

required to secure flange tightly to countertop.

3. Mount Control Box to apron cutout as shown in drawing.

PRODUCT DIMENSIONS

5

(127)

71 1/2

(1816)

18

(457)

35

(889)

4. Mount Control Panel onto electrical box using screws

supplied.

TO PLUMB:

1. A drain manifold complete with valve is supplied on all

Model "DM" and "TDM" units. Location of valve handle is at the

discretion of the fabricator. Install and tighten pipe plug in

one end of the manifold.

2. Models without manifold are supplied with individual 1/2''

female N.P.T. drains.

3. Connect 1'' drain connection to suitable drain line.

TO WIRE:

1. Final connection is accomplished by bringing proper power

supply leads (see 'wiring requirements' label) through conduit

knockout to terminal block supplied within the Master Control

Panel. Check nameplates for voltage and phase.

2. Do not connect to a circuit operating at more than 150

volts to ground.

NOTE: INSTALLATION MUST MEET LOCAL PLUMBING AND

ELECTRICAL CODES.

WARMER FLANGE

GASKET

WELLSLOK

SCREWDRIVER

COUNTERTOP

WELLS/BLOOMFIELD * VERDI, NV

14

(356)

'T' MODELS

IMPORTANT:

MOUNT APPLIANCE SO THAT BOTH

THE CONTROL PANEL AND DRAIN

MANIFOLD ARE LOCATED TO THE

FRONT OF THE FIXTURE.

7 3/4

(197)

2 1/4

(57)

6 1/4

(160)

9 3/4

(248)

1/2 INCH

INTERNAL N.P.T.

'D' MODELS ONLY

37099-5 REV (-)

23 5/8

(600)

MASTER

CONTROL

PANEL

1 3/4

(44)

Loading...

Loading...