Wells MOD-127TDWA Service Manual

MOD100E

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg.com

OWNERS MANUAL

BUILT-IN

SINGLE WELL

MODULAR

WARMERS

with

THERMOSTAT & DIGITAL

ELECTRONIC CONTROL

MODELS

MOD100T, TD, TDWA

MOD100E, ED, HE

MOD100HT, HTD

MOD127TD, TDWA

011C

Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

MOD100T

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

2M-308017 Rev. C

03/18

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be free from defects

in material and/or workmanship for a period of one [1] year from the

date of original installation, except as noted below. Defects that occur

as a result of normal use, within the time period and limitations defined

in this warranty, will at Wells’ discretion have the parts replaced or

repaired by Wells or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid .

CO NTAC T

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

RANTY EXCLUSIONS

WAR

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained, or

used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not liable

for any unit which has been mishandled, abused, misapplied, subjected

to chlorides, harsh chemicals, or caustic cleaners, damaged from

exposure to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have an altered

or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls,

air and gas burner/bypass/pilot adjustments, gas or electrical

system checks, voltage and phase conversions, cleaning

of equipment, or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety

controls, or reset buttons.

• Replacement of broken or damaged glass components, quartz heating

elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and

hotplates, including but not limited to burners, grates, and

radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily

cleaning routine. such as but not limited to silicone belts, PTFE nonstick sheets, knobs, control labels, bulbs, fuses, quartz heating

elements, baskets, racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been field-repaired instead [eg. field-welded fry pots].

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional and/or

extended warranties.

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

2 years 1 year

an d LLSC 1 1WA]

cast iron grates, burners, and burner

shields

original Wells parts sold to repair

Wells equipment

1 year

90 days

Service First 1 year

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z22393 • Rev A • 02.2018

TABLE OF CONTENTS

WARRANTY

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 3

INSTALLATION 4

OPERATION 6

MAINTENANCE INSTRUCTIONS 7

CLEANING INSTRUCTIONS 8

TROUBLESHOOTING SUGGESTIONS 10

EXPLODED VIEW & PARTS LIST 12-16

WIRING DIAGRAM 17

PARTS & SERVICE 20

CUSTOMER SERVICE DATA 21

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that it

gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for the

appliance in a manner which will ensure its optimum performance.

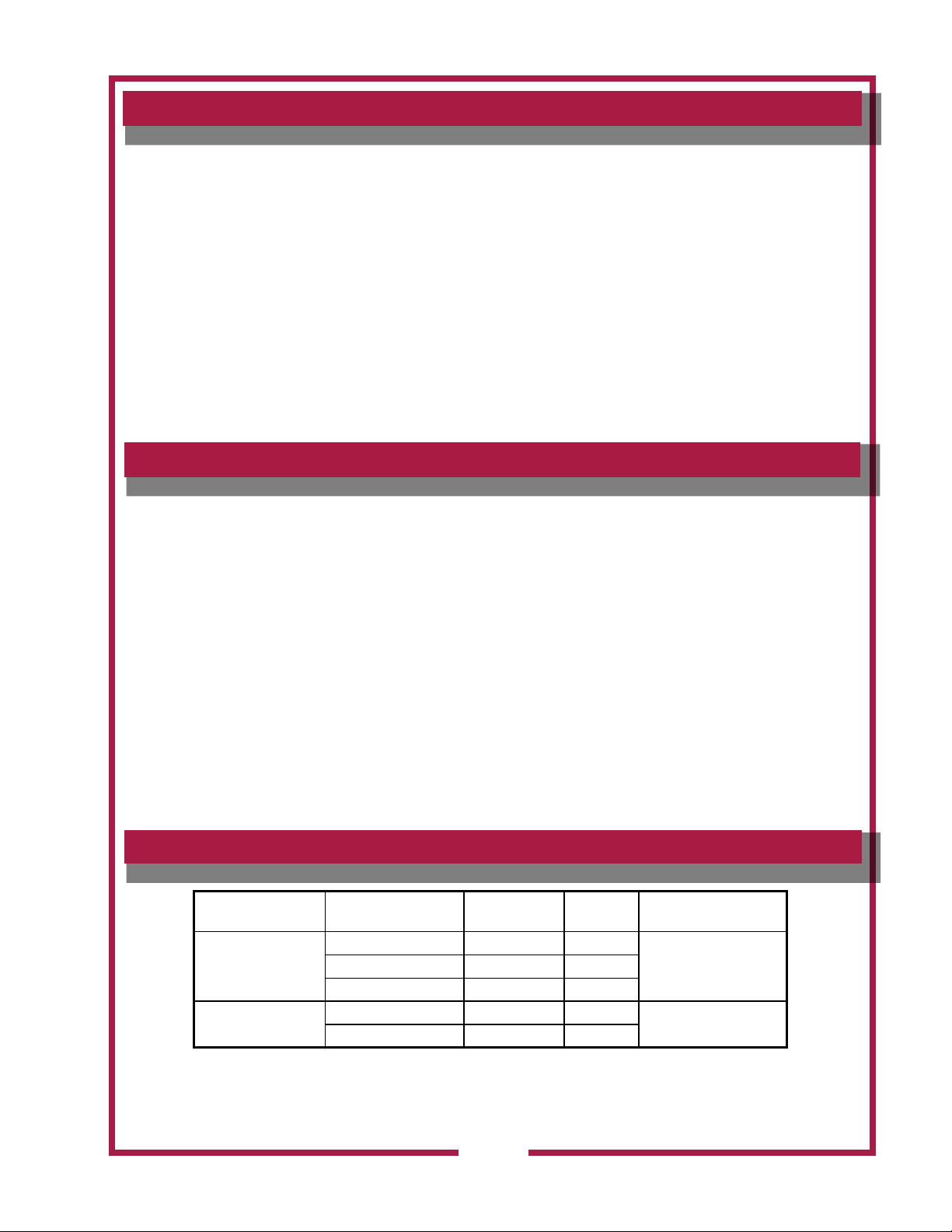

SPECIFICATIONS

2M-308017-011C Built-In Single Well Modular Warmer w/T-Stat Control

MODEL VOLTS AMPS WATTS

MOD100T,

MOD100TD

MOD127TD

120 VAC 1ø 13.8A 1600W

240 VAC 1ø 6.9A 1600W

208 VAC 1ø 6.0A 1240W

240 VAC 1ø 6.9A 1600W

1

POWER SUPPLY

CORD

NOT SUPPLIED208 VAC 1ø 6.0A 1240W

NOT SUPPLIED

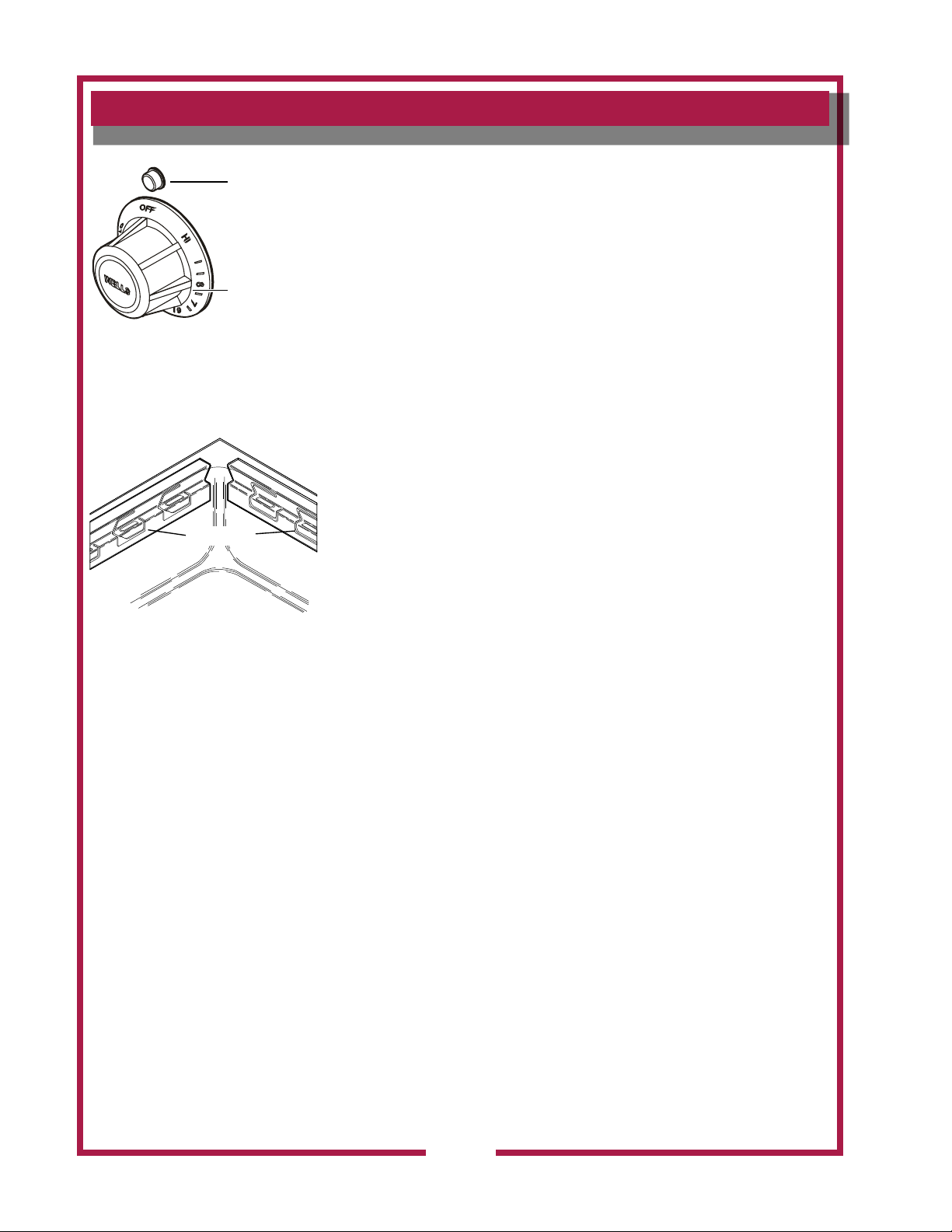

FEATURES & OPERATING CONTROLS

A. THERMOSTAT

INDICATOR

LIGHT

TEMPERATURE

CONTROL

KNOB

WELLSLOKS

IL2468

1. On thermostatically controlled warmers, power is applied to the

heating element according to the control knob position and the

actual temperature at the temperature sensing thermobulb.

2. The desired temperature is controlled by rotating the temperature

control knob. The knob has a numeric scale, where higher

numbers correspond to higher temperature.

3. On warmers equipped with an indicator light, the light will glow

when the thermostat is calling for heat (i.e. the element is

energized).

4. The TEMPERATURE CONTROL KNOB will rotate approximately

300º, and will reach a “stop” at both ends.

The OFF position is marked.

NOTE: The dial position is an indication of the temperature setting.

Actual temperature will vary depending upon the type of product

and food consistency.

B. MOUNTING

1. MOD-series built-in warmers may are equipped with wellsloks,

uniquely designed turnout tabs which help secure the warmer top

ange to the countertop.

2. See the Installation Instructions, supplied with the particular

appliance, for details.

IL2469

C. DRAINS

1. Sufx “D” units (e.g. MOD-300TD) have drains for each pan,

with each pan having an individual drain valve.

2M-308017-011C Built-In Single Well Modular Warmer w/T-Stat Control

2

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments only.

This appliance is intended to hold pre-heated food for human

consumption. No other use is recommended or authorized by the

manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

This appliance is not jet stream approved. Do not direct water jet or

steam jet at this appliance, or at any control panel or wiring.

Do not splash or pour water on, in or over any controls, control panel or

wiring.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Do not operate this appliance if the control panel is damaged. Call

your Authorized Wells Service Agent for service.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel.

Any procedure which requires the use of tools must be performed by a

qualied technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics,

parts breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance may result

if these instructions are not

followed.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

AGENCY LISTING INFORMATION

Refer to the product nameplate for the specic appliance for agency

listings. In general:

2M-308017-011C Built-In Single Well Modular Warmer w/T-Stat Control

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions.

UL Listed warmers are

U Listed under UL File E6070.

3

STD 4

E6070

UL Listed Warmers

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on

the inside front cover of this

manual.

WARNING:

RISK OF INJURY

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

CAUTION

FIRE HAZARD

Avoid storing ammable or

combustible materials in, on

or near the appliance.

IMPORTANT: For warmers

installed in plastic counter

tops, the counter material

must be protected from the

heat of the warmer in order to

prevent discoloration and/or

deterioration. Wellsloks are

not suitable for this purpose.

The installer should contact

the manufacturer or distributor

of the countertop material for

specic instructions.

IMPORTANT: Wellslok

Extension Kits must be used

ONLY with UL Listed warmers

approved for installation in

wood counter tops. Refer to

the Installation Instructions

provided with the warmer.

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic lm, packing materials and accessories from the Appliance

before connecting electrical power or otherwise performing any

installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before discarding

packing materials. Store all accessories in a convenient place for later

use.

INSTALLATION NOTES

1. Installation and start up of built-in warmers MUST be performed

by an authorized installation company.

2. It is the responsibility of the installer to verify that this warmer

installation is in compliance with the specications listed in this

manual and on the specication sheet provided.

3. It is the RESPONSIBILITY OF THE INSTALLER to check with the

authority having jurisdiction, in order to verify that this warmer

installation is in compliance with local code requirements.

4. Water supply and drain installation must meet all applicable local,

state and federal plumbing codes and ordinances.

5. Refer to Installation Instructions included with the warmer for

Underwriters Laboratories conditions of acceptability, electrical

requirements and other installation concerns.

BUILT-IN WARMERS

1. This is a GENERAL GUIDE. For specic cutout dimensions

and other installation details, refer to the Installation Instructions

supplied with the warmer.

2. Cutout dimensions for warmer units and control panels are listed

on the Installation Instructions provided with the warmer.

NOTE: Verify the dimensions are correct for the installation before

making the cutout.

2M-308017-011C Built-In Single Well Modular Warmer w/T-Stat Control

4

INSTALLATION

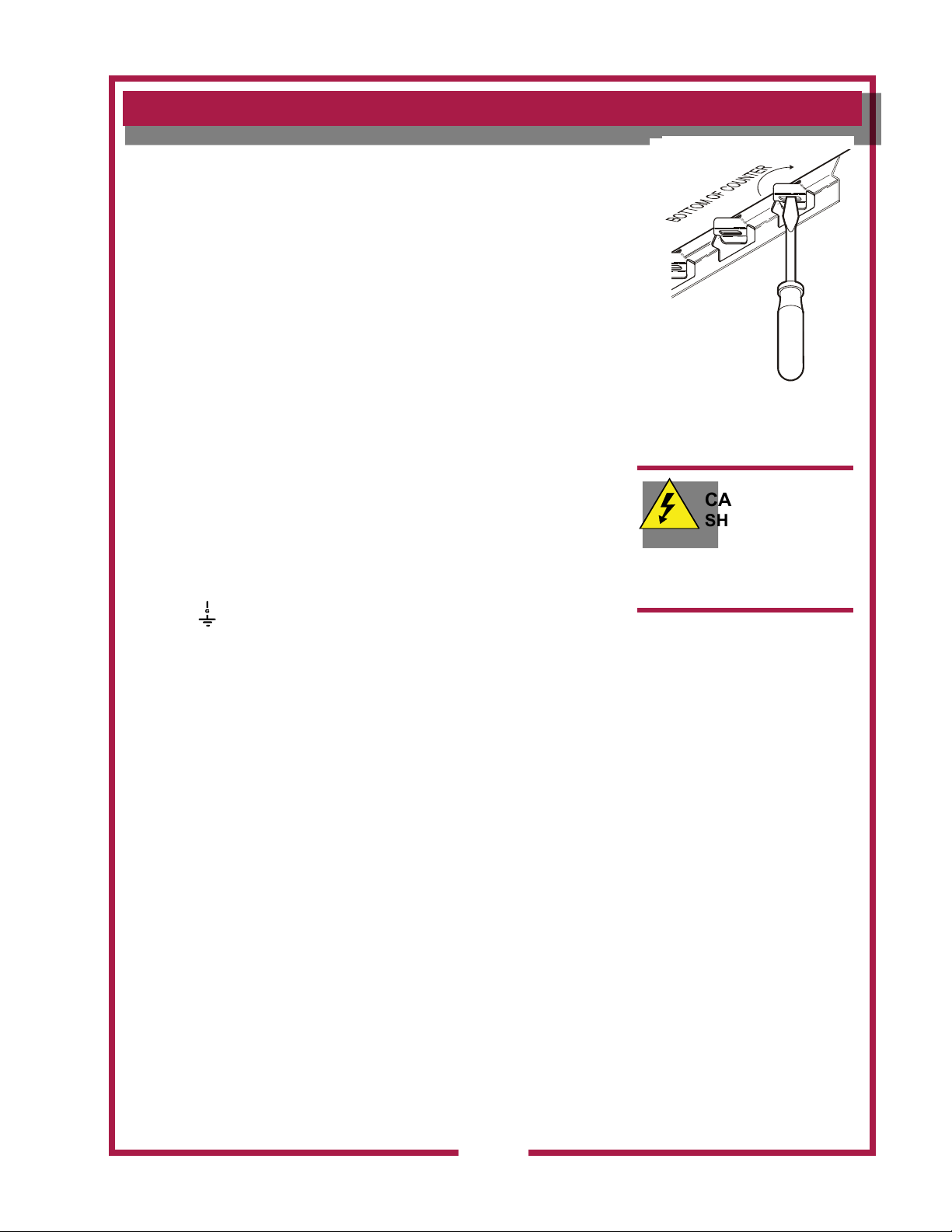

3. For “top-mounted” warmers (i.e. warmers mounted from above

the counter top):

a. Verify that provided sealants are applied to the underside

of the warmer top ange prior to setting the unit into the cutout.

b. After installation, verify that the tabs on the Wellsloks are turned

out to lock the warmer into the counter

c. Apply a thin bead of food-grade silicone sealant around the ange

to seal it to the counter.

d. Wellslok extension kits are available for installing warmers in

counter tops where the standard Wellslok would not normally

reach. The extension kit will adapt to counter tops up to 1¾” thick.

ELECTRICAL INSTALLATION

1. Refer to the product nameplate. Verify the electrical service

power. Voltage and phase must match the nameplate

specications. Wiring the warmer to the wrong voltage can

severely damage the unit or cause noticeably decreased

performance.

2. Available electrical service amperage must meet or exceed the

specications listed on the specication sheet provided with the

warmer.

3. Warmer and control unit must be connected to an appropriate

building ground. Ground connection will be marked “GND” or

” “ .

NOTE: Wire gauge, insulation type and temperature rating , as

well as type, size and construction of conduit, must meet or exceed

applicable specications of local codes and of the National

Electrical Code.

PLUMBING INSTALLATION

For use in the State of Massachusetts, this appliance must be

installed in compliance with Massachusetts Fuel Gas and

Plumbing Code CMR 248.

1. IMPORTANT: All plumbing installations must be performed by

a qualied plumber.

2. For units equipped with a DRAIN LINE: Some jurisdictions may

require an approved air gap or other back-ow prevention device

in the drain. It is the responsibility of the plumber to determine

2M-308017-011C Built-In Single Well Modular Warmer w/T-Stat Control

such requirement, to provide and properly install the required

device.

NOTE: Damage caused

by leaks due to improper

installation is NOT covered by

warranty.

CAUTION:

SHOCK HAZARD

The ground lug of this

appliance must be connected

to a suitable building ground.

IMPORTANT:

Contact a licensed electrician

to install and connect electrical

power to the appliance.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

IMPORTANT: Electrical

installation other than as

specied on the specication

sheet will void the UL listing,

and may void the warranty.

NOTE: Plumb connections

must be made in compliance

with all Federal, State and

Local Plumbing Codes and

Ordinances.

5

OPERATION

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

SHOCK HAZARD

DO NOT splash or pour water

onto control panel or wiring.

Always use an inset.

DO NOT place food directly

into the warmer.

Always pour hot water into the

warmer before it is preheated.

DO NOT pour water into a

dry, heated warmer. This may

damage the unit.

DO NOT put ice into a

warmer pan. This will cause

condensation on the inside of

the warmer. Damage caused

by condensation is NOT

covered by warranty.

Stir thick food items frequently

to keep food heated uniformly.

WET OR DRY OPERATION for WARMERS

1. Carefully read the description of the warmer operation on the

specication sheet.

2. a. Most warmers are designed for WET OR DRY operation.

b. Warmers may be used wet, or may be used dry. However

warmers may NOT be used wet-to-dry or dry-to-wet unless they

have been allowed to cool to room temperature between the

change in wet or dry operation.

c. Wells Manufacturing recommends operating WET for consistent

food heating.

d. If your wet-operation warmer is allowed to run dry, turn it OFF and

allow to cool to room temperature before adding water.

3. If the warmer is to be used for WET operation, add approximately

1” of hot tap water before turning the warmer ON. Use of hot water

will allow a faster preheat.

a. Check the water level frequently and add hot water as necessary

to prevent the warmer from running dry. Do not add water to the

warmer if it has run dry.

b. If your wet-operation warmer is allowed to run dry, turn it

OFF and allow to cool to room temperature before adding water.

4. Damage caused by allowing a wet-operation warmer to run dry,

is NOT covered by warranty. Damage caused by adding water

to a dry warmer when hot is NOT covered by warranty.

PRE-HEATING THE WARMER

1. Place desired pan(s) or inset(s) with appropriate adapter top on

warmer.

a. Insets are available as accessories in 2½ qt., 4qt., 7 qt., and 11 qt.

sizes with lids and adapter tops.

b. For dry operation, a 6” deep pan or inset is recommended.

2. Turn temperature control to HI or highest temperature setting.

3. Allow warmer to preheat for approximately 30 minutes, then set

the control for the desired temperature. Be sure to keep the warmer

covered during preheat and operation.

Keep insets covered to

maintain food quality and

temperature.

2M-308017-011C Built-In Single Well Modular Warmer w/T-Stat Control

6

Loading...

Loading...