Wells M4200 PARTS LIST

Convection Oven

Owner’s Manual

Models

M42004

This manual includes material

related to installation, use,

cleaning, and care. All available

parts list[s], wiring diagrams,

or specifi cations pertaining to the unit covered by this

manual are also included.

This manual must be read and understood by all

persons using or installing this appliance. Contact

your Wells dealer if you have any questions concerning

installation, use, or maintenance of this equipment.

This manual is for the exclusive use of licensees and

employees of McDonald’s Corporation as well as

employees of Wells Manufacturing.

DO NOT DISCARD THIS MANUAL.

M42004

2M-Z 19624 • Rev. C • 02.2018

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new M42004 ovens to be free from

defects in material and/or workmanship for a period of three [3] years

from the date of original installation, except as noted below. Defects

that occur as a result of any normal use or function, within the time

period and limitations defi ned in this warranty, will at Wells’ discretion

have the parts replaced or repaired by Wells or a Wells-authorized

service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specifi c

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid.

CO NTAC T

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

ARRANTY EXCLUSIONS

W

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained, or

used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not

liable for any unit which has been mishandled, abused, misapplied,

subjected to chlorides, harsh chemicals, or caustic cleaners, damaged

from exposure to hard water, modifi ed by unauthorized personnel,

damaged by fl ood, fi re, or other acts of nature [or God], or which

have an altered or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls,

air and gas burner/bypass/pilot adjustments, gas or electrical

system checks, voltage and phase conversions, cleaning

of equipment, or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety

controls, or reset buttons.

• Replacement of broken or damaged glass components, quartz

heating elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and

hotplates, including but not limited to burners, grates, and

radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform

service.

• Replacement of items subject to normal wear or items that can

easily be replaced during a daily cleaning routine, such as but not

limited to knobs, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been fi eld-repaired instead [eg. fi eld-welded fry pots].

• Any loss of business or profi ts.

ADDITIONAL WARRANTIES

Specialty/chain specifi c versions may also have additional and/or

extended warranties.

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

cast iron grates, burners, and burner

original Wells parts sold to repair

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty.

i

2 years 1 year

an d LLSC 11WA]

shields

Wells equipment

90 days

Service First 1 year

1 year

TABLE OF CONTENTS

Warranty i

Specifications iii

General Information 1

Safety Information 2

Installation Information 3

Oven Component Overview 4–5

Cleaning 6–7

Temperature Calibration 8

Troubleshooting 9

Daily Operation 10–11

U.S.A. Market Menu Items 12–14

Canada Market Menu Items 15

208 V and 240 V Single Phase Wiring Diagram 18

208 V and 240 V Three Phase (Delta) Wiring Diagram 19

230 V Three (Wye) Phase Wiring Diagram 20

Hinge Adjustment 21

Exploded Views 22–23

Parts List 24–26

Optional Equipment Setup 27

2M-Z19624 Rev C Owner’s Manual for M42004 Convection Oven

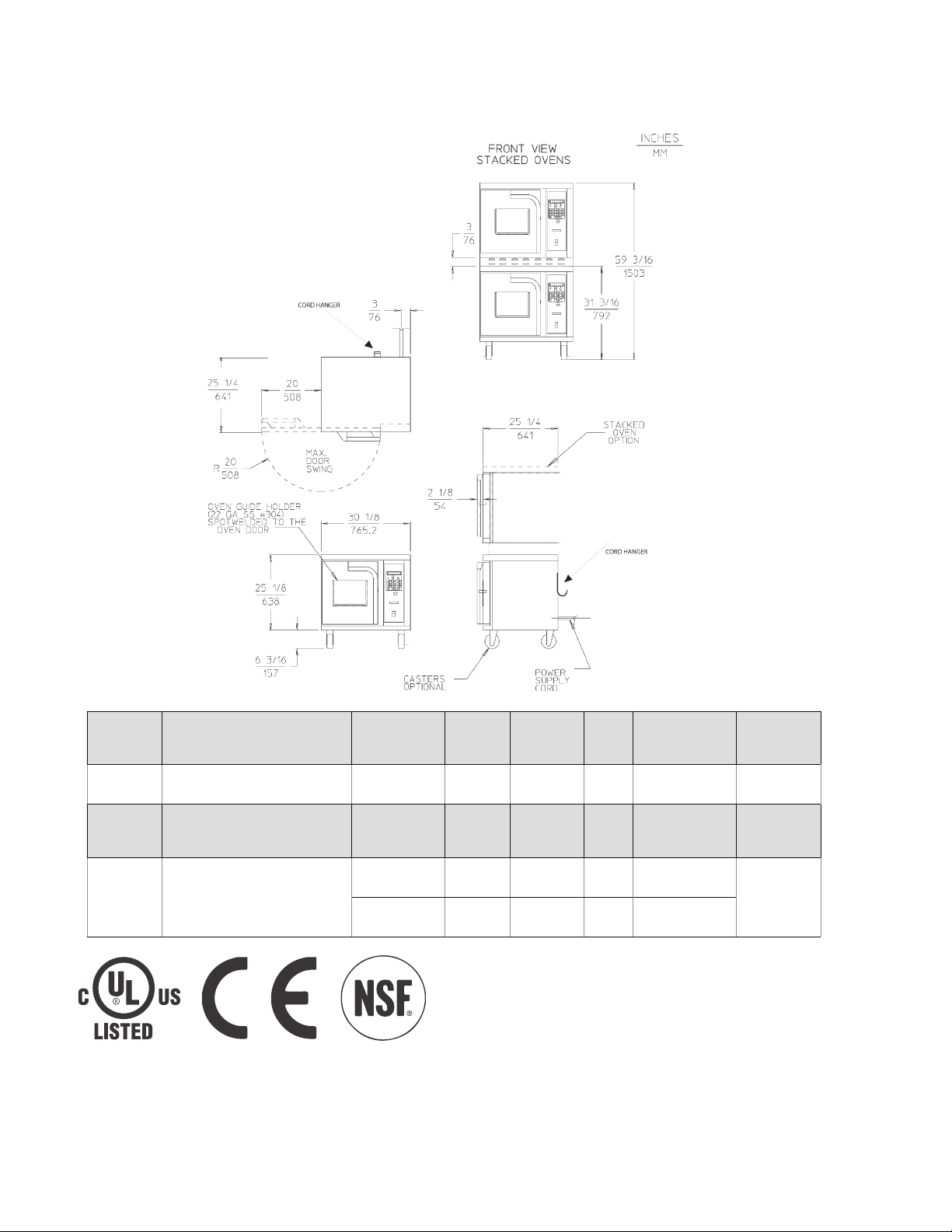

SPECIFICATIONS

Cord hanger is 2 in. (51 mm) wide.

Cord hanger does not come on all models.

Model

Number

W x D x H

(height without casters)

Voltage &

Phase

Watts Amps

1Ø

M42004 30-1/8” x 27-1/4” x 25-1/8”

765mm x 692mm x 639mm

Model

Number

W x D x H

(height without casters)

208V 1Ø

240V 1Ø

Voltage &

Phase

7500

8400

Watts Amps Per

3Ø

208V 3Ø

M42004

E6070 Standard 4

1 Applies to 208/240 V North American models only.

2 Applies to 380/415 V models only.

3 Complies to NSF 4 only if installed and maintained as instructed by this manual.

30-1/8” x 27-1/4” x 25-1/8”

765mm x 692mm x 639mm

1 2 3

240V 3Ø

380/415 3Ø 8400 12 12 12 1/4 NONE

7500

8400

Single

Phase

38

37

Line

L1 L2 L3

21 21 21

21 21 21

HP PLUG Weight

(Shipping)

1/4 253lbs

varies by

model version

115kg

HP PLUG Weight

(Shipping)

1/4 varies by

model version

253lbs

115kg

iii

2M-Z19624 Rev C Owner’s Manual for M42004 Convection Oven

SAFETY SYMBOLS

These symbols are intended to alert the user to the

presence of important operating and maintenance

instructions in the manual accompanying the appliance.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to ensure delivery of your unit

in perfect condition. However, there are instances in which the unit may be damaged in transit. In the

event you discover any type of damage to your product upon receipt, you must immediately contact

the transportation company who delivered the item to you and initiate your claim with that company.

If this procedure is not followed, it may aff ect the warranty status of the unit. If damage or loss is not

apparent until after equipment is unpacked, a request for inspection of concealed damage must be

made with carrier within 15 days. Please record the model number, serial number, voltage, and purchase

date in the area below at the time of receipt. Do not discard packaging until unit has been inspected

for hidden damage and tested for proper operation.

Model Number Restaurant [Number/Location]

Serial Number Service Company

Voltage Technician

Purchase Date Installation Date

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please have the

information in the above fi elds ready when you call to ensure a faster service.

Using any part other than genuine Wells factory supplied parts relieves the manufacturer of all liability.

Due to periodic changes in designs, methods, procedures, policies, and regulations, the specifi cations

contained in this document are subject to change without notice. Wells reserves the right to change

product specifi cations and design without notice. In regards to previously purchased equipment,

such revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements. While Wells Manufacturing exercises good faith eff orts to provide information that

is accurate, we are not responsible for errors or omissions in information provided or conclusions

reached as a result of using the specifi cations. By using the information provided, the user assumes

all risks in connection with such use.

PLEASE REFER TO THE WARRANTY PAGE FOR SPECIFIC WARRANTY INFORMATION.

AUTHORIZED SERVICE AGENT LISTING

Reference the listing provided with the unit or for an updated listing go to the website or call customer

service to fi nd an agent.

Business hours: 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone: 314-678-6314

Fax: 314-781-2714

Email: customerservice@star-mfg.com

Website: www.wells-mfg.com

1

GENERAL SAFETY INFORMATION

This equipment is designed and sold for commercial use only, and is intended for use by personnel

trained and experienced in its operation in order to prepare food for human consumption. This is not

sold for consumer use in and around the home nor for use directly by the general public in food service

locations.

Before using your new equipment, read and understand all the instructions and labels associated

with the unit prior to putting it into operation. Make sure all people associated with its use understand

the units operation and safety before they use the unit. If there is visible damage to any component,

including the control, the unit should not be used until after the damage has been repaired. Only

authorized, qualified technicians should perform repairs on this unit.

Proper cleaning and maintenance of this unit is essential to good sanitation. Read and follow all

included cleaning instructions and schedules, as well as any provided by your company, to ensure

the safety of the food product and the longevity of the oven.

Use caution, the exposed surfaces of this unit can be hot to the touch and direct contact with skin

may cause burns. Allow the oven to cool until it is 150° F (66° C) or less before performing any

cleaning procedure.

Do not immerse the unit in water or let the unit stand in water. Do not hose down the unit or use

any type of pressure or steam cleaner which would allow excess moisture to come in contact with

the oven’s electrical components.

2

2M-Z19624 Rev C Owner’s Manual for M42004 Convection Oven

GENERAL INSTALLATION INFORMATION

Installation and start up should be performed by an authorized, qualified personnel only and must

meet the requirements listed in this manual as well as any national and local codes. The oven will

have to be mounted over a non-combustible surface such as concrete, ceramic tile, terrazzo, or

metal. The installer is responsible for making certain all codes and other requirements are met.

Carefully remove the oven from its carton, making certain to remove all plastic film as well as any

flammable components which have been placed in the oven cavity for shipping purposes. The unit

is shipped with three [3] oven racks, two [2] rack supports, and one [1] fan bae. Make certain these

components as well as any optional parts [eg. casters, prep top kit, stacking kit, or vent duct] are

present when unpacking the unit. Also make sure to place any components that are packed with the

unit in a location where they will not be misplaced or discarded. Depending on the specific version

of the unit, it will be shipped with an attached cord or ready to hardwire. In any case, the oven must

be connected to an electrical connection adequate for its voltage and amp draw and in accordance

with the unit’s wiring diagram. If the unit does not properly power on and improper electrical supply

is suspected, contact a qualified electrician prior to using the unit. Should you require assistance,

contact your local authorized service agent for any service or required maintenance.

ELECTRICAL CONNECTION

Units that come with a factory attached cord simply need to be connected to a matching receptacle

rated for the proper amperage and phase. For units intended to be wired in the field, only a qualified

electrician should work on connecting this oven. They should be familiar with electrical installations

and all applicable electrical codes. The external wiring should be in conduit or an approved type

of flexible cable suitable for operation based on the power requirements of the unit and any local

or national codes. The strain relief supplied with the unit is intended for a metal conduit connection.

For other types of cords, an alternate strain relief will need to be used. Ensure 3-phase delta units and

3-phase wye units are hooked up properly based on the particular unit’s specific wiring requirements,

as shown in that unit’s wiring diagram. Improper grounding may result in personal injury or fatality.

The supply circuit should be properly fused and equipped with a means of disconnecting, as required

by local and federal electrical codes. Unless otherwise required, an approved all-pole power disconnect

switch, with at least 0.125 in. (3 mm) contact gap is recommended and should be installed in the fixed

wiring in an accessible location with close proximity to the appliance. Before any electrical connection

is made to this unit, check that the power supply is adequate for the voltage, amperage, and other

requirements stated on the nameplate. Make certain to disconnect the unit from the power source

before performing any maintenance or service, including installing or removing any parts.

VENTILATION

In order to cook proteins with this oven, a ventilation kit must be used and connected properly based

on all local and national requirements.

3

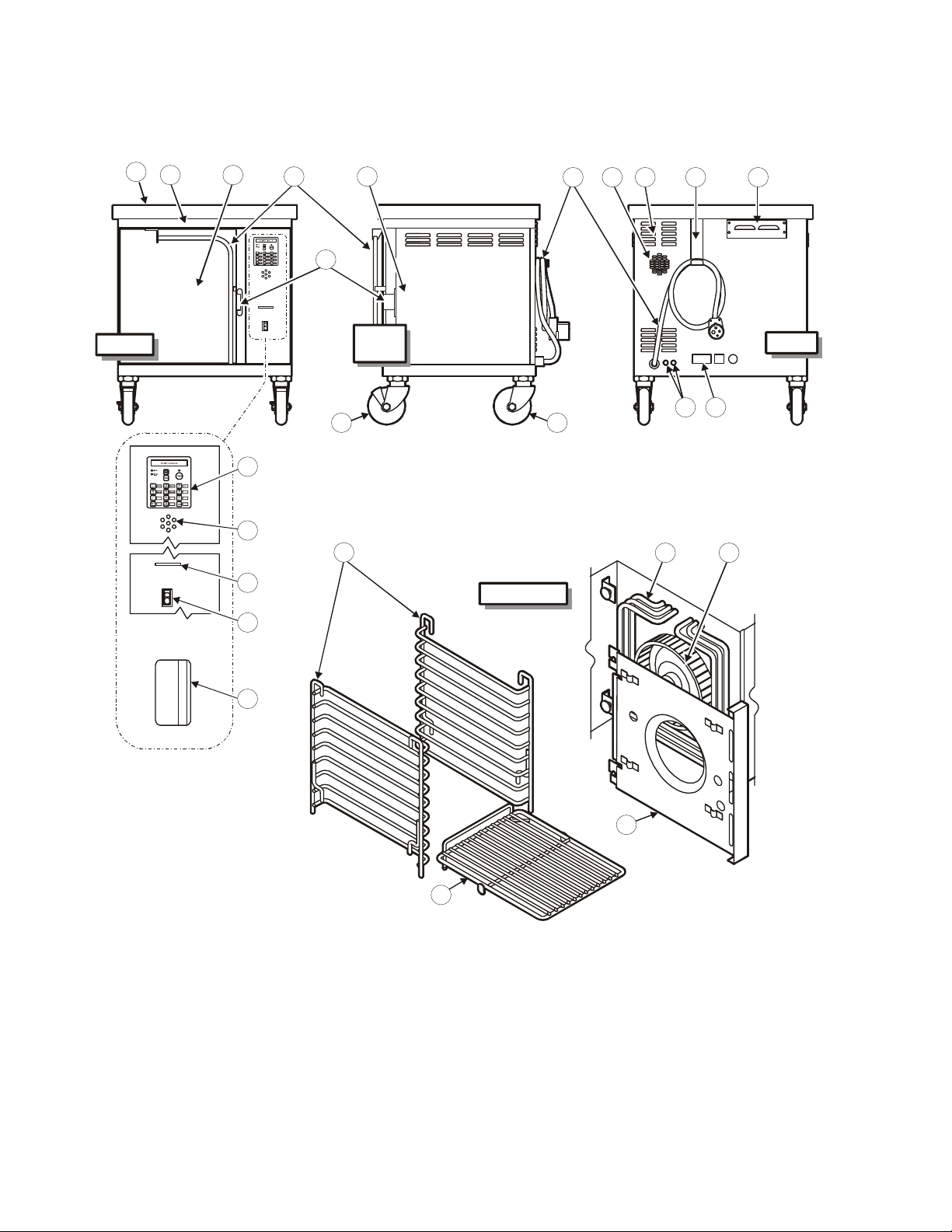

A

B C

D1 E

D2

F G1 G2 H I

FRONT

RIGHT

SIDE

J

N

O

S

P

Q

R

INTERIOR

K

L M

U V

REAR

W

T

4

2M-Z19624 Rev C Owner’s Manual for M42004 Convection Oven

REF COMPONENT ADDITIONAL DETAILS

A optional prep top optional add-on accessory that allows the top of the oven to be used as a work surface

B oven top covers top insulation [this panel should not be used as a work surface]

C oven door front oven cavity access

D1 door handle insulated handle to allow the door to be safely opened or closed

D2 door striker and latch holds door securely closed

E side panel

allows access to interior components during service

[excess moisture should be kept away from any opening in the body]

F power cord on applicable models only

G1 cooling fan inlet

G2 cooling louvers

[excess moisture should be kept away from any opening in the body]

louvers in side and rear panels allow air to move through the body of the oven to cool components

[excess moisture should be kept away from any opening in the body]

component cooling fan inlet

H cord hanger on applicable models only

I cavity vent vent out of oven cavity [vent kit and proper ventilation must be used when cooking proteins]

J optional front casters optional add-on accessory locking casters

K optional rear casters optional add-on accessory non-locking casters

L fuses protection for circuits that run from contactor/relay to power on/o switch

M nameplate shows data on model number, voltage, amperage, phase, certification[s], and serial number

N control board programmed control board with label and integrated display and speaker

O speaker grille front panel location that the speaker sound travels through

P card reader allows menu card to be used to reprogram product settings

Q power on/o switch used to power the unit on or o

R menu card stores product settings to easily and quickly reprogram control to accommodate changes to menu items

S rack support supports and locates product racks

T product rack supports product trays

U heating element energized to provide cooking heat

V fan circulates heated air for even temperature distribution

W fan bae covers fan for safety and to direct air around oven cavity

5

CLEANING

DO NOT USE COARSE SPONGES/PADS

WHICH WILL SCRATCH THE FINISH.

DO NOT USE CAUSTIC CLEANERS,

DEGREASERS, FLAMMABLE CLEANERS,

OR ANY OTHER CLEANER WHICH CAN

DAMAGE UNIT’S SURFACE.

DO NOT IMMERSE THE UNIT IN WATER

OR LET THE UNIT STAND IN WATER.

ALLOW THE OVEN TO COOL UNTIL IT IS

150° F (66° C) OR LESS BEFORE YOU

PERFORM ANY CLEANING PROCEDURE.

CLEANING & MAINTENANCE

Preventive maintenance consists of the following recommended cleaning procedures. To keep your

unit in its best operating condition, these steps should be performed on a regular basis as required.

The cooking area must be kept clean for the unit to function properly.

DAILY CLEANING

RECOMMENDED SUPPLIES

soft cloths

clean water

DO NOT ALLOW ANY CLEANER OR LIQUID

TO COLLECT ON THE TOP OF THE UNIT OR

TO ENTER THE OVEN THROUGH THE VENTS

ON THE SIDE OR REAR.

DO NOT HOSE DOWN THE UNIT OR USE ANY

TYPE OF PRESSURE OR STEAM CLEANER

WHICH WOULD ALLOW EXCESS MOISTURE

TO COME IN CONTACT WITH THE OVEN’S

ELECTRICAL COMPONENTS.

PROCEDURE

i. Use caution, as the oven will still be hot at this point. With the oven powered on, open the door.

ii. Press the “UTILITY” key. The display will now read “FAST COOL MODE” at this point.

iii. Press the “START” key. The display will now read “COOL DOWN” and the fan will start. Use caution at this

point as the fan will be on. At no point should you attempt to reach into the oven while the fan is running.

iv. When the oven has cooled down, flip the power switch to the “OFF” position. At this point, unplug the unit

or turn o the main power supply to the unit, depending on how the unit is connected, in order to prevent

accidentally powering the unit on during cleaning.

v. Wipe the interior of the oven and door thoroughly with a clean, soft cloth dampened with clean water.

vi. Next, wipe the interior of the oven and door thoroughly with a clean, soft, dry cloth.

vii. Wipe the exterior, including the control panel, with a clean, soft, dry cloth. Do not use a damp cloth on the

control or on any exterior panel that will allow moisture to enter the oven body or come into contact with

any electrical components.

6

Loading...

Loading...