Page 1

WHA900

Operating Instructions

Page 2

Table of Contents Page

WHA900 Detail View 1

Technical Data 1

1. Cautions! / Warnings! 2

2. Description 2

3. Placing Into Operation 2

4. Operating Guidelines 3

5. Accessories 3

6. Packing List 3

7. Nozzles 4,5,6

Page 3

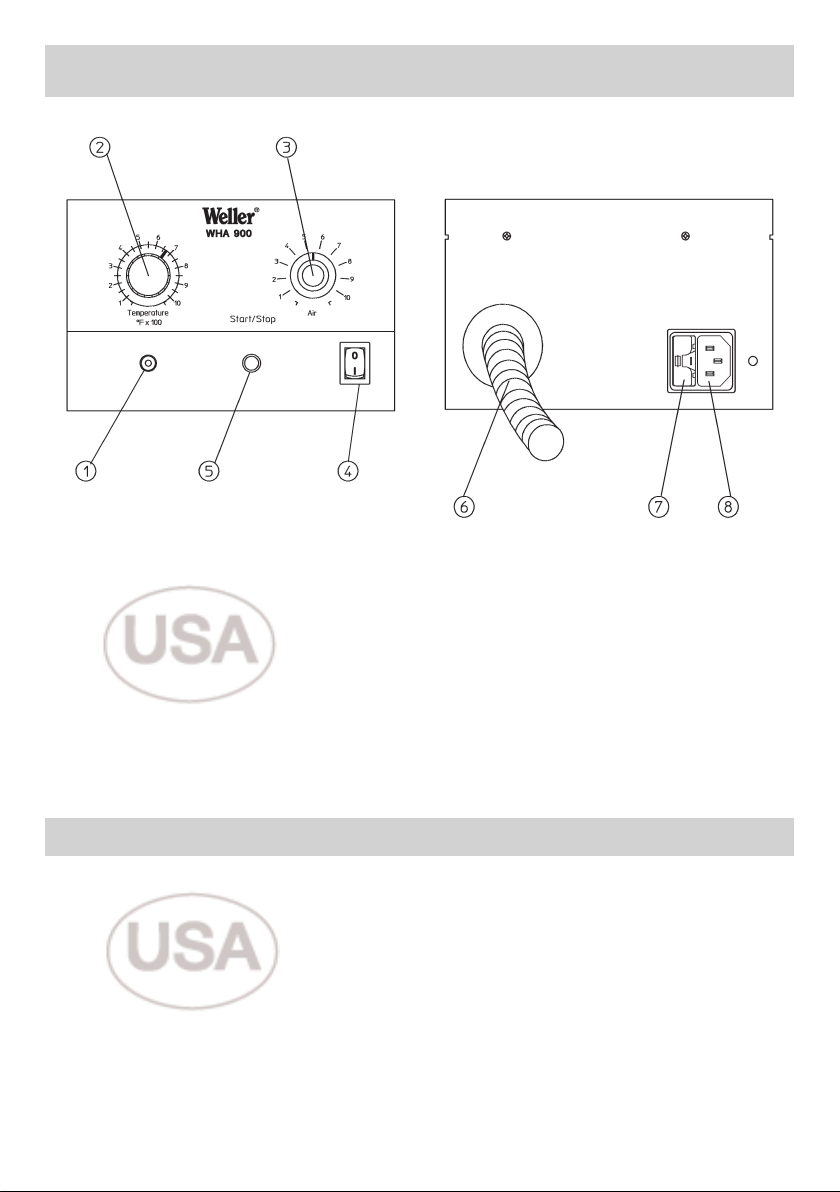

WHA900 Detailed View

1. LED Heater Control

2. VariableTemperature Control; Range 100°F and 1000°F

3. Air Flow Control; Range 5 to 50 l/minute

4. Power Switch

5. Start / Stop Push Button

6. Hot Air Pencil and Hose Assembly

7. Fuse T 10 Amp

8. Receptacle 120 VAC

Technical Data:

Dimensions: 8 3/16” L; 6 5/8” W; 4 1/4” H

Main Voltage: 120 VAC

Power consumption: 750 WATTS

Hot Air Pencil output: 700 WATTS

Fuse: T 10 AMP

Temperature Control: Variable between 100°F and 1000°F

Temperature Control accuracy: ± 54°F

Flow Control: Variable between 5 - 50 l/min

Noise Level: 56dB(A) distance 1m at max. airflow level

1

Page 4

nglish

E

Thank you for placing your trust in our company

by purchasing the Weller WHA900 Hot Air Station.

This product meets or exceeds the requirements

established by Weller for superior performance,

versatility and quality.

1. Cautions! / Warnings!

Please read these Operating Instructions and the

attached Safety Information carefully prior to initial

operation. Failure to observe the safety warnings

may result in accident, injury, or risk to health.

The manufacturer shall not be liable for damage

resulting from misuse of the machine or unauthorized alterations.

Warning: This product when used for soldering

and similar applications, produces chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

Safety Information:

● Always place the soldering iron in its original

holder

● Remove all inflammable objects from the proximity of the hot soldering tool.

● Use suitable protective clothing to prevent the

risk of burns associated with molten solder.

● Never leave a hot soldering iron unattended.

● Never work on electrically live circuits or com-

ponents.

● Always wear eye protection when working with

soldering and desoldering applications.

The Weller WHA900 Hot Air Station corresponds

to the EC Declaration of Conformity in accordance

with the basic safety requirements of Directives

89/336/EEC and 73/23EEC.

2. Description

The WHA900 hot air station was developed for

general soldering re-work on Surface Mount components. The temperature of the hot air is controlled electronically and is variable between

100°F and 1000°F. 120 VAC (8) is required to

operate the unit. The air flow is variable electronically within the range of approximately 5-50

l/minute and is generated by a self contained

pump. The hot air is activated using the Start/Stop

Push Button, (5) at the front of the unit.

2

The WHA900 is grounded through the 120 VAC

three wire power cord.

Standby mode:

This unit has a power-on function to activate a

Standby Mode (or secondary temperature airflow

setting). Before switching on the unit, choose the

Temperature and the Airflow settings that you

would prefer to use for the Standby Mode of operation.

Activating Standby:

Adjust the Temperature and Airflow control to the

desired Standby setting. Depress the Start/Stop

push button and hold while switching on the unit.

Keep the button depressed for approximately 5

seconds after turning the unit on. The pump will

start and the Standby function is activated. When

the unit is switched on, the Temperature and the

Airflow will be set to the Standby values. When

you depress the Start/Stop push button, the

Airflow and Temperature will go to the actual “Set”

values. The actual “Set” values should be set at a

normal Temperature and Airflow settings capable

of performing the rework application. Depress the

button again and the unit will go back to the

Standby values.

Note: To change the Standby settings, you must

first Deactivate Standby Mode as described

below.

Deactivating Standby:

If the Standby function is activated, depress the

Start/Stop push button while switching on the unit.

Keep the button depressed for about 5 seconds.

The unit is now in the original operating mode.

Repeat the “Activating Standby” directions to

assign new preferred settings.

3. Placing Into Operation

Note: Safety rest must be formed before tool use.

Place the hot air pencil in the formed safety rest

with the nozzle in a raised position to prevent

damage to w

ply voltage is consistent with the information on

the station label. Before connecting to the 120

VAC po

(2) and the air flow on (3) and switch on the unit

at the power switch (4). The LED will flash slowly

to indicate the unit has reached the Set

Temperature.

ork bench. Check to be sure the sup-

er source

w

, set the desired temper

ature

Page 5

nglish

E

The Airflow and Temperature are activated after

depressing the Start/Stop Push Button. Heat-up

time of the nozzle depends primarily on the size

of the nozzle and the air flow.

Temperature Offset

1. With the WHA900 off and the heater cooled down. Place Measuring Nozzle ( 0058736875 ) on to the

end of the Hot Air Pencil and fasten it with the set screw.

2. Insert the 0.5mm Type “K” Thermocouple, ( 0058736786 ) into the hole of the Measuring Nozzle and

place the Hot Air Pencil in the safety rest. Switch the device on.

3. Choose the temperature you want to adjust with the temperature knob.

4. Activate the unit with the Start / Stop push button. Set the Airflow Knob to 4. Wait approximately 5

minutes before continuing.

5. Read the temperature value indicated on the measuring instrument.

6. If the temperature has to be corrected, depress and hold the Start / Stop push button for approximately 15 seconds while the hot air is activated. The green LED (1) will light continuosly.

7. While the green LED (1) is continuosly lit, immediately turn the temperature knob slightly beyond center and rotate back to the center position (550 °F). This will be your “zero” point for adjustments. Rotate

clockwise for positive and counterclockwise for negative adjustments.

8 Adjust the temperature knob until the desired setting is indicated on the measuring device and has

stabilized. Depress the Start / Stop push button to confirm.

9. The Temperature Offset function is now complete. You may adjust the temperature knob to your original setting.

10. Repeat steps 3-9 if additional Offset is required.

Warning: Do not direct the hot air pencil at

people or inflammable objects.

4. Operating guidelines

Changing the nozzles;

The hot air nozzles are fixed to the heating element with a set/attachment screw. Loosen the

set/attachment screw to remove nozzles.

5. Accessories

For Nozzle range see “ Hot Air Nozzles “.

0051504899 - Multiple Rest for six nozzles.

0051504999 - Nozzle Exchange Tool

2.5 mm Hex Wrench

6. Packing List

WHA900 Control Unit

Power Cord

Safety Rest

( 1 ) Set / Attachment Screw

Operating Instructions

Safety Information

Subject to technical change without notice!

3

Page 6

ot Air Nozzles

H

Ø

1,7 x 45° mm

Ø

.067 x 45° in

0058736882

Ø 2.5 mm

Ø .098 in

0058736881

Ø 4 mm

Ø .157 in

0058736867

Ø 7 mm

Ø .280 in

0058736870

Made to

Order

4

RD11

Ø 2,5 x 9,5 mm

Ø .098 x .374 in

0058736883

Ø 11.5 mm

Ø .453 in

0058736836

Page 7

14,8 x 14,8 mm

.583 x .583 in

0058736818

11 x 11 mm

.433 x .433 in

0058736839

21,5 x 14.8 mm

.846 x .583 in

0058736840

19 x 12 mm

.748 x .472 in

0058736841

ot Air Nozzles

H

14 x 10 mm

.551 x .394 in

0058736842

10 x 8 mm

.394 x .315 in

0058736843

Measuring

Nozzle

0058736875

Adapter

0058750722

5

Page 8

ot Air Nozzles

H

31.3 x 31.3 mm

1.23 x 1.23 in

0058736833

26 x 26 mm

1.024 x 1.024 in

0058736804

20.5 x 20.5 mm

.807 x .807 in

0058736807

17.5 x 23.5 mm

.689 x .925 in

0058750721

18 x 18 mm

.709 x .709 in

0058736814

15.5 x 13 mm

.610 x .512 in

0058736837

14 x 10 mm

.551 x .394 in

0058736838

6

Page 9

Made To Order Nozzles ( Contact for Quote )

ot Air Nozzles

H

24 x 12 mm

.945 x .472 in

0058736880

43 x 43 mm

1.693 x 1.693 in

0058736890

36 x 36 mm

1.417 x 1.417 in

0058736891

27 x 14 mm

1.063 x .551 in

0058736892

29 x 17 mm

1.142 x .669 in

0058736877

35.5 x 23 mm

1.398 x .906 in

0058736998

48.5 x 30.5 mm

1.909 x 1.201 in

0058736999

44 x 32 mm

1.732 x 1.260 in

0058736858

48.5 x 38 mm

1.909 x 1.496 in

0058750709

61 x 38 mm

2.402 x 1.496 in

0058750714

7

Page 10

ot Air Nozzles

H

Made To Order Nozzles ( Contact for Quote )

12 x 27 mm

.472 x 1.063 in

0058736880

38 x 38 mm

1.496 x 1.496 in

0058736890

40 x 40 mm

1.575 x 1.575 in

0058736891

8

Page 11

wwwwww..ccooooppeerrhhaannddttoooollss..ccoom

m

UU..SS MMaaiilliinngg AAddddrreessss:

CCooooppeerr HHaanndd TToooolls

P.O. Box 728

Apex, NC 27502-0728

UU..SS SShhiippppiinngg AAddddrreessss:

1000 Lufkin Road

Apex, N.C. 27539

Tel: (919) 387-0099

Fax: (919) 387-2379

For inquiries concerning Technical /

Customer Service please call:

(800) 476-3030 Ext. 1

CCaannaaddaa SShhiippppiinngg AAddddrreessss:

CCooooppeerr TToooolls

164 Innisfil Street

Barrie, Ontario

Canada L4N 3B7

Attn: Repairs

Fax: 1-800-403-TOOL (8665)

Phone: 705-728-5564 Ext. 2026

:

s

:

:

s

Weller is a registered Trademark and registered Design of Cooper Industries, Inc.

005 XX XXX XX / 03.06 © 2006 Cooper Industries

Loading...

Loading...