WHA 3000P Hot Air Station

Operating Instructions

Version 2.3

Weller Tools GmbH

Carl-Benz-Str. 2, 74354 Besigheim, Germany

Tel: +49 (0) 7143 580- 0, Fax: +49 (0) 7143 580- 108

Table of contents Page

1. Description 5

Technical data 5

2. Placing in operation 6

2.1 Manual operating mode 6

2.2 Automatic operating mode 7

2.3 Setting temperature profile 8

2.4 Starting program 8

2.5 Control of the vacuum function 9

2.6 Saving and loading temperature-time profiles 9

3. External sensor 10

3.1 External sensor with measuring function "MEASURE MODE“

(factory setting) 10

3.2 Teach In Mode procedure 10

3.3 External sensor with control function "CONTROL MODE“ 10

4. Lock Mode 11

5. Switching Temperature Conversion 11

6. RS232 Interface 11

7. Work Instructions 11

8. Maintenance 11

9. Error Messages 12

10. Accessories 12

11. Items Supplied 12

12. Hot Air Nozzles 13

13. Quick Reference 14

Page 2 of 14

Operating instructions WHA 3000P

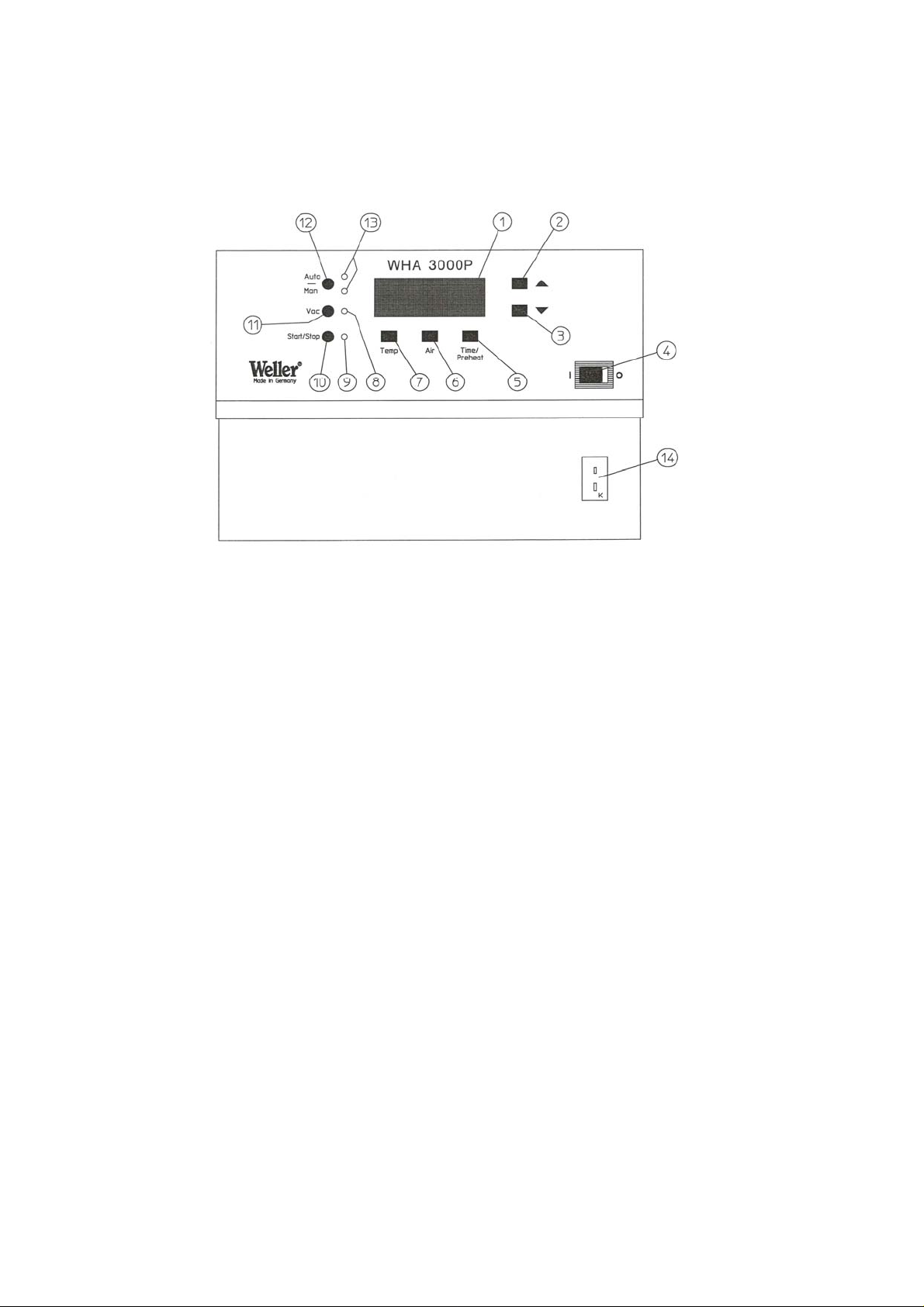

Front view WHA3000P

1 LCD Display

2 "UP" Control Key

3 "DOWN" Control Key

4 Mains Switch

5 "TIME"/"PREHEAT" Control Key (time setting auto. mode / pre-heating temperature)

6 "AIR" Control Key (air flow rate)

7 "TEMP" Control Key (hot air temperature)

8 LED Indicator, Vacuum

9 LED Indicator, START/STOP

10 "START/STOP" Control Key

11 "VAC" Control Key (activate Vacuum)

12 "AUTO" – "MAN" Control Key (changeover Automatic – Manual operating mode)

13 LED Indicators, Auto-Man operating mode

14 Connection for External Sensor Type K

Page 3 of 14

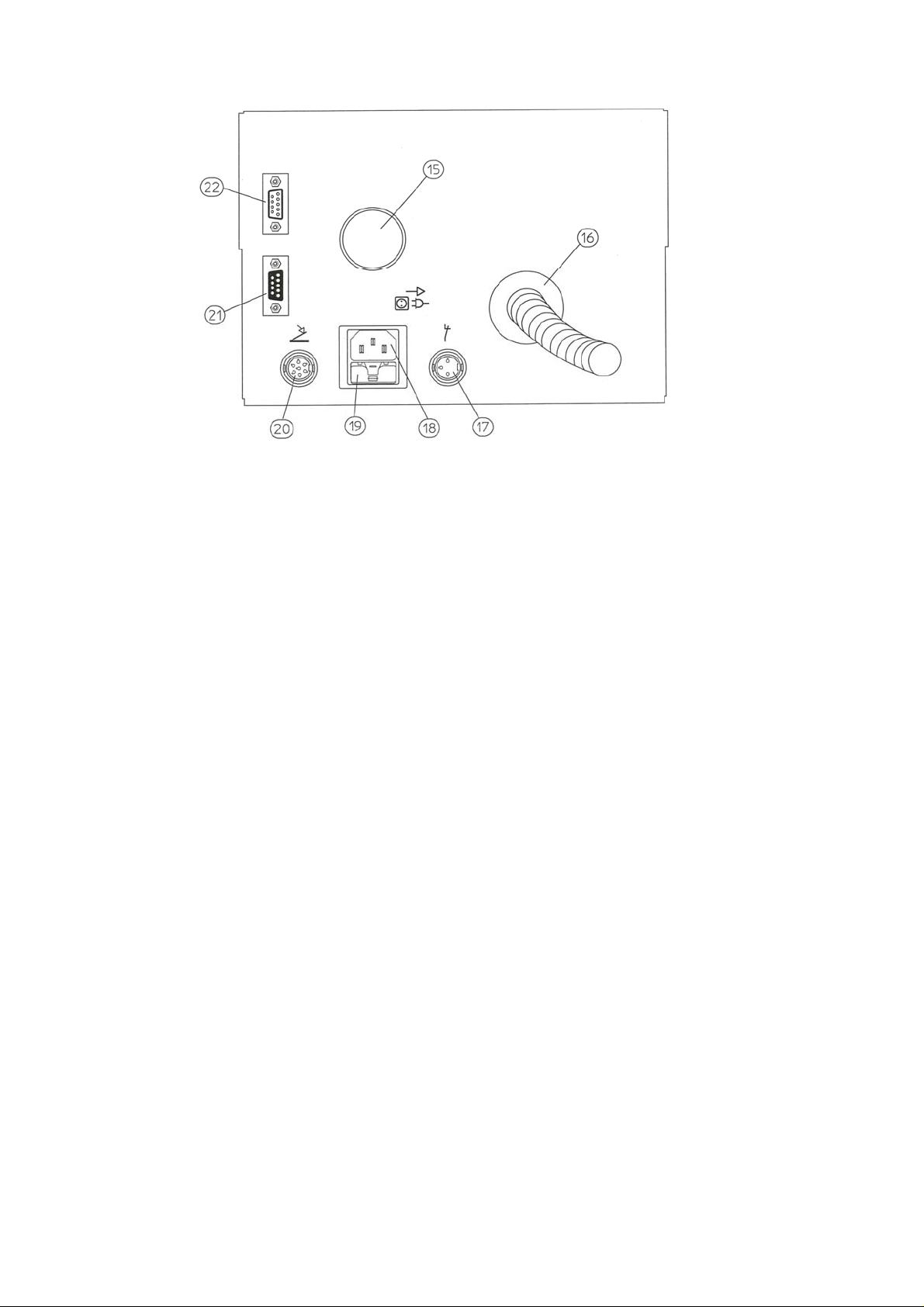

Rear view WHA3000P

15 Vacuum Pump Filter

16 Hand-piece Connecting Hose

17 Stand Switch Connection

18 Mains Connection

19 Mains Fuse

20 Connection for Manual Control Console; Foot Switch

21 PC Interface, RS232

22 Connection for WHP3000 (bottom heater), RS232 Interface

Page 4 of 14

We thank you for the confidence you have shown by purchasing the Weller WHA 3000P Hot Air

Station. During manufacturing, the strictest quality requirements are applied; these assure the

correct function of the device and make it possible to obtain optimal soldering results.

Warning!

Prior to placing the device in operation, please carefully read these operating instructions and the

safety instructions enclosed. If the safety instructions are not observed, there is a risk of injury.

The manufacturer accepts no liability for usage other than that described in the operating

instructions or for unauthorized modifications

The WELLER WHA 3000P Hot Air Station complies with the EU declaration of conformity as per the

essential safety requirements in the directives 2004/108/EC and 2006/95/EC

1. Description

The WHA 3000P Hot Air Station is suitable for difficult repairs on circuit boards with FINEPITCH

components. A thorough design concept combines maximum process safety with ease of use and

technically advanced application solutions. A comprehensive range of accessories adds to the

possible uses of this repair workstation.

The hot air temperature at the hand-piece can be adjusted over the range of 50°C – 550°C

(150°F – 999°F). The air flow rate is generated via an internal turbine and can be adjusted between

the range of 5 l/min – 50 l/min. Hot air temperature and air flow rate are digitally controlled.

The vacuum necessary for lifting the component is integrated into the nozzle system and can be

activated to suit the operating mode chosen. Two operating modes are provided:

A The "Manual“ operating mode (MAN) can be used for manual work at the hot air temperature

and air flow rate set. Hot air and vacuum can be activated using the foot switch, manual

remote control console or directly on the control Panel.

B The "Automatic“ operating mode (AUTO) establishes a program with a 3-step time/

temperature profile, and can be used in conjunction with the WHP 3000 Pre-Heat Plate

available as an accessory.

The parameters for hot air temperature, air flow rate, temperature of the optional WHP 3000

Pre-Heat Plate and vacuum function can be adjusted separately and can be saved as a Rework

Profile for the specific application.

The repair station can also be complemented with the optional matched WBH 3000S Circuit Board

Holder for X-Y alignment and a stand with Z-axis guide for the hot air hand-piece.

Page 5 of 14

Technical data

Dimensions (W X L X H): 240 (9.44) X 270 (10.63) X 170 (6.69) mm (inch)

Mains voltage: 230 V (120 V) AC

Power consumption: 600 W

Air flow rate: 5 – 50 l/min

Temperature range: 50°C –550°C (150°F – 999°F)

Accuracy: +/- 30°C (+/- 54°F)

Vacuum: - 0.6 bar

Mains fuse: 230 V / T6.3A (120 V / T8 A)

Protection class: 1 (Control Unit and Hand-Piece are hard grounded)

2. Placing in operation

Place the hand-piece, with the hot air nozzle installed, in the AKT30 safety stand. (The device

cannot be placed in operation without the safety stand or optional WBH 3000S Circuit Board

Holder.) Plug cable from safety stand or optional WBH 3000S Circuit Board Holder (proximity

switch), into socket (17). Check whether the mains voltage matches the information on the rating

plate. If the mains voltage is correct, connect the controller to the mains. When the device is

switched on, the device name "WHA 3000" and the software "Version" are displayed briefly. The

electronics then switch automatically to the default setting (Manual operating mode).

2.1 Manual operating mode

Information on display (1)

Nozzle Air Nozzle

Temp. Flow Rate Pre-Heating

in °C/°F in l/min ON/OFF

In the Manual operating mode the parameters for the nozzle temperature, air flow rate and switching

on or off the pre-heating can be set.

Select the parameter by pressing the Control Key:

• TEMP (7): Nozzle temperature in °C/°F

(see Switching Temperature Conversion page 11)

• AIR (6): Air flow rate in l/min

• TIME/

PREHEAT (5): Switch ON - OFF the nozzle pre-heating (standby) at 200°C/392°F with 5 l/min

airflow

After selection, the setting can be changed using the UP (2) or DOWN (3) Control Keys. Keeping the

Control Key depressed, rapidly changes the value.

The hot air and the nozzle vacuum are activated:

Directly on the Control Panel: Hot air START/STOP Control Key (10), Vacuum VAC Control

TEMP AIR PREHEAT

350°C 25 l OFF

Key (11)

Page 6 of 14

2-Position Foot Switch (20): Hot air-Position 1, Vacuum-Position 2

(hot air and vacuum are only active in the Manual Mode, when

the Foot Switch is depressed)

Manual Control Console (20): Hot Air "AIR“ Control Key, Vacuum "VAC“ Control Key

(Optional)

When the hand-piece is placed in the AKT30 Safety Stand (17), the hot air is switched off by a Mirco

Switch. If the nozzle pre-heating is active (PREHEAT ON), the device switches to the standby mode

with reduced temperature and air flow rate (200°C / 392°F – 5l/min).

Note: Hot air is automatically disabled after 999 sec for safety reasons.

2.2 Automatic operating mode

The Automatic operating mode has a 3-step temperature-time profile.

The temperature-time profile can be expanded by connecting an optional WHP 3000 bottom heater.

When the WHP 3000 is connected via the RS232 interface (22) the bottom heater is integrated into

the time profile.

The temperature profile is comprised of the following 3-steps:

Pre-heat phase, system Step 1 (ends with an audible tone)

Pre-heat phase, component Step 2

Reflow process (soldering) Step 3

The soldering process is normally started with the hot gas nozzle raised. At the end of step 1 there

is an audible tone, after this tone the nozzle should be placed over the component in the soldering

position. At the end of Step 3, raise or remove the nozzle from the application.

The following pre-settings must be made on the WHA 3000P controller to define a customer-specific

temperature-time profile.

Settings step 1 – step 3

Nozzle temperature 50°C – 550°C (150°F / 999°F)

Temperature, bottom heat 50°C – 400°C (150°F / 750°F) (optional with WHP 3000)

Air flow rate 5 l/min – 50 l/min

Time for the program step 0 sec. – 999 sec.

The Automatic operating mode can be selected by pressing the AUTO/MAN Control Key.

The light emitting diodes (LED‘s) (13) indicate the related operating state.

Page 7 of 14

Information on the display (1)

Nozzle

Pre-Heater

Nozzle

TEMP AIR TIME

210°C 40 l 100s

300°C 25 l 50s

210°C 30 l 15s

step 1

step 2

step 3

Nozzle or

bottom heater symbol

Temperature of the nozzle or

bottom heater (with WHP 3000)

Air flow rate in l/min

Time remaining for the

temperature profile step in sec.

2.3 Setting temperature profile

Select the parameters by pressing the Control Key:

• TEMP (7): Depressed Once : Nozzle temperature during the first step

Depressed Twice Temperature of the bottom heater during the first

step

(only with WHP 3000)

Repeat for Steps 1-3

Symbol for nozzle or bottom heater indicates which temperature is displayed.

• AIR (6): Depressed Once: Air flow rate in l/min during the first step

Repeat for Steps 1-3

• TIME/

PREHEAT (5) : Depressed Once: time remaining in the first step

Repeat for Steps 1-3

The active value is marked on the display and can be changed using the UP / DOWN (2) / (3)

Control Keys. Keeping the Control Key depressed, rapidly changes the value.

Page 8 of 14

2.4 Starting program

The soldering process and thus the 3-step temperature-time profile is started:

Directly on the Control Panel: START/STOP (10) Control Key, LED (9) illuminates.

2-Position Foot Switch (20): START/STOP corresponds to setting 1 of the foot switch

(hot air and vacuum are only active when pressed)

Foot Switch Position 1-Air, Position 2-Vacuum

Manual Control Console (20): START/STOP using the AIR Control Key

(Optional)

The nozzle temperature, air flow rate and the time remaining are indicated on the display (1). The

active program step is marked on the display.

When the hand-piece is placed in the safety stand, the program is interrupted and the hot air

switched off by an integrated contact. When the nozzle pre-heating is active (PREHEAT ON), the

device switches to the standby mode with reduced temperature and air flow rate.

Note: When using the WBH 3000S Circuit Board Holder (17), the WHA 3000P will

automatically turn “off” if the position of the Z-axis Head is moved from the “Locked” center

position. It must remain in position directly over the Hot Plate to allow for the WHA 3000P to

operate.

2.5 Control of the vacuum function

The nozzle vacuum are activated:

Directly on the Control Panel: VAC (11) Control Key, LED (8) illuminates.

2-Position Foot Switch (20): vacuum corresponds to Position 2 of the foot switch

Manual Control Console (20): using the VAC Control Key

(Optional)

If the VAC Control Key (11) is pressed prior to the start of a de-soldering process, the vacuum

integrated into the nozzle is activated automatically at the end of the process. The vacuum function

can also be enabled and disabled manually at any time during the soldering process. If the vacuum

is enabled during a soldering process, there is no automatic activation at the end of the process.

Note: If the nozzle temperature is above 250°C/482°F the vacuum is automatically disabled

after 90 sec for safety reasons.

2.6 Saving and loading temperature-time profiles

A total of 10 temperature-time profiles can be saved. A default profile is saved in the 10 program

memories in the factory.

Press UP/DOWN Control Keys (2)/(3) simultaneously until the following menu appears on the

display (1)

Page 9 of 14

PROGRAM 1

E X I T L O A D S A V E

The program memories 1 - 10 can be selected using the UP/DOWN Control Keys (2)/(3).

The preferred program can be selected by pressing the LOAD Control Key (6).

The indication on the display changes to the automatic mode and displays the selected parameters.

If a temperature-profile has been prepared, it can be saved in the selected program memory by

pressing the SAVE Control Key (5).

The menu can be exited without saving any changes using the EXIT Control Key (7).

UP

DOWN

PRESS AT

THE SAME

TIME

3. External Sensor

When using an external sensor (Thermocouple Type K), two different operating modes are

available. By pressing the Control Key "TIME" / "PREHEAT" (5) when switching on the unit (4), you

can toggle between the operating modes "MEASURE MODE" and "CONTROL MODE". The

following appears briefly in the display (1):

THERMOCOUPLE or THERMOCOUPLE

MEASURE MODE CONTROL MODE

Both operating modes only become active once the external sensor (14) has been connected.

3.1 External Sensor with measuring function "MEASURE MODE" (factory setting)

In this operating mode, the external sensor only has a measuring function. The temperature of the

external sensor is shown in the display (1). The Hot Air Tool temperature control regulates the

setpoint value for the nozzle temperature.

External sensor active in "MEASURE MODE"

TEMP AIR PREHEAT

250 °C 25 l OFF

Page 10 of 14

3.2 Teach In Mode procedure

During the sequence of an automatic temperature-time profile, it is possible to continue switching

the process stages 1-3 manually by pressing the Control Key "TIME" / "PREHEAT" (5). If the

external sensor is suitably positioned on the assembly or component, its temperature can be

monitored during the entire process sequence and can be continued to be switched when the

desired specified temperatures (stage 1-3) have been reached. The times determined in this manner

are shown after the soldering or desoldering process in the display (1) and can be saved.

3.3 External sensor with control function "CONTROL MODE"

The temperature of the external sensor is controlled in this operating mode. The external sensor

records the actual value (control variable) for the temperature control. The setting for the setpoint

value at the unit must therefore be adapted to the measured temperature (actual value) of the

external sensor. The actual value of the external sensor is shown in the display (1).

External sensor active in "CONTROL MODE"

TEMP AIR PREHEAT

A basic prerequisite for faultless application is direct contact of the sensor on the assembly or

component.

250 °C 25 l OFF

4. Lock Mode

The device can be locked by inserting and removing a coded plug in socket (20). The current

soldering parameters cannot be further changed. The WHA 3000P can only be operated using the

START/STOP (10) and VAC (11) Control Keys.

5. Switching Temperature Conversion

By pressing the Control Key "Temp" (7) when switching on the unit (4), you can toggle between the

operating modes "°C" and "°F". The following appears briefly in the display (1):

or

°F °C

6. RS232 interface

Using additional software, the device can be operated completely via the RS232 interface (21).

7. Work instructions

The hot air nozzle is designed such that the vacuum plate lies flat on the component. The vacuum

plate is also used for the transfer of heat. When the vacuum is enabled, the component can be lifted

after the solder has reflowed. Here it is important to pre-heat the vacuum plate to operating

temperature prior to de-soldering. As an option, it is possible to use a vacuum cup in place of the

vacuum plate.

Page 11 of 14

Nozzle change

Caution: Risk of burns! The hot air nozzle remains hot for some time after power off or

removal.

The hot air nozzles are fastened to the heating element using a clamping screw. To change the

nozzle, loosen the screw and remove the hot gas nozzle using the Nozzle Change Tool provided.

8. Maintenance

The vacuum filter (15) is soiled by flux residues and contaminants and must be replaced if the

vacuum drops.

9. Error messages

Error Description Rectification

ERROR 75 Offset entry on heating element change incorrect Repeat process

ERROR 76 Heating element faulty Replace heating element

ERROR 110 WHP3000 housing temperature exceeded Allow to cool down

REMOTE Input inhibited (can only be operated using PC) Operate using PC

LOCKED WHA locked (lock function) Unlock WHA

TOOL STAND AKT30 Stand (or WBH3000 Proximity Sensor) Connect to socket (17)

not connected

10. Accessories

0053119099 External sensor type K ∅ 0.5mm

0058754951 External sensor type K ∅ 0.25mm

0058757770 Foot switch

0058736780 Manual Control Console

0051504899 Stand for six hot air nozzles

WBH3000 Circuit board holder

WBH3000S Circuit board holder with hot air tool stand

WHP3000 Bottom heating plate

11. Items supplied

WHA3000P Controller with hand-piece

AKT30 Safety stand

0051504999 Nozzle exchange tool

Coded plug

Tool kit (2,5 mm hex wrench w/2 3 mm x 6 mm L screws provided)

0058750721 Hot air nozzle NQ30

Main power cord 120VAC

0058757770 Foot switch (Only USA Version)

Product CD- Rom (Operating instructions incl. WHA control software)

Subject to technical change without notice!

Page 12 of 14

12. Hot Air Nozzles

Hot Air Nozzles for HAP 3

Round Nozzles

Hot air nozzles 2-sides heated (Type ND)

Measuring nozzle 005 87 368 75 Hot air nozzles 4-sides heated (Type NQ))

005 87 368 39 NQT Hot air nozzle 22,0 x 22,0 mm

005 87 368 41 NQT10 Hot air nozzle 14,8 x 14,8 mm

005 87 368 42 NQT25 Hot air nozzle 18,0 x 18,0 mm

005 87 368 43 NQT Hot air nozzle 16,0 x 16,0 mm

Page 13 of 14

13. Quick Reference WHA3000P/V

• Changeover

auto-manual operating mode

• UP Control Key increase value

• DOWN Control Key decrease value

• Activating vacuum function

• Start/Stop soldering process

Respectively hot air function

• Setting hot air temperature

(manual mode)

• Setting hot air temperature and

bottom heater for step 1 – 3

(auto mode)

• Setting flow rate

(manual mode)

• setting flow rate for step 1 – 3

(auto mode)

• Time setting for step 1 – 3

(auto mode)

• Nozzle preheating ON/OFF

(manual mode)

• Save and load program

for temperature profiling

• Switching Temperature Conversion

(Pressing when switching on the WHA 3000P)

Auto

Man

Vac

Start/Stop

Temp

Air

Time

/

Preheat

Temp

+

Program

Page 14 of 14

Loading...

Loading...