Weller WD 1, WD 1000, WD 1000M Operating Manual

WD 1 (M) /

WD 1000 (M)

Operating Manual

DE

EN

FR IT ES PT NL SV DK FI GR TR CZ PL HU SK SL EE LV LT

WD 1 (M) / WD 1000 (M)

WD 1 (M)

WD 1000 (M)

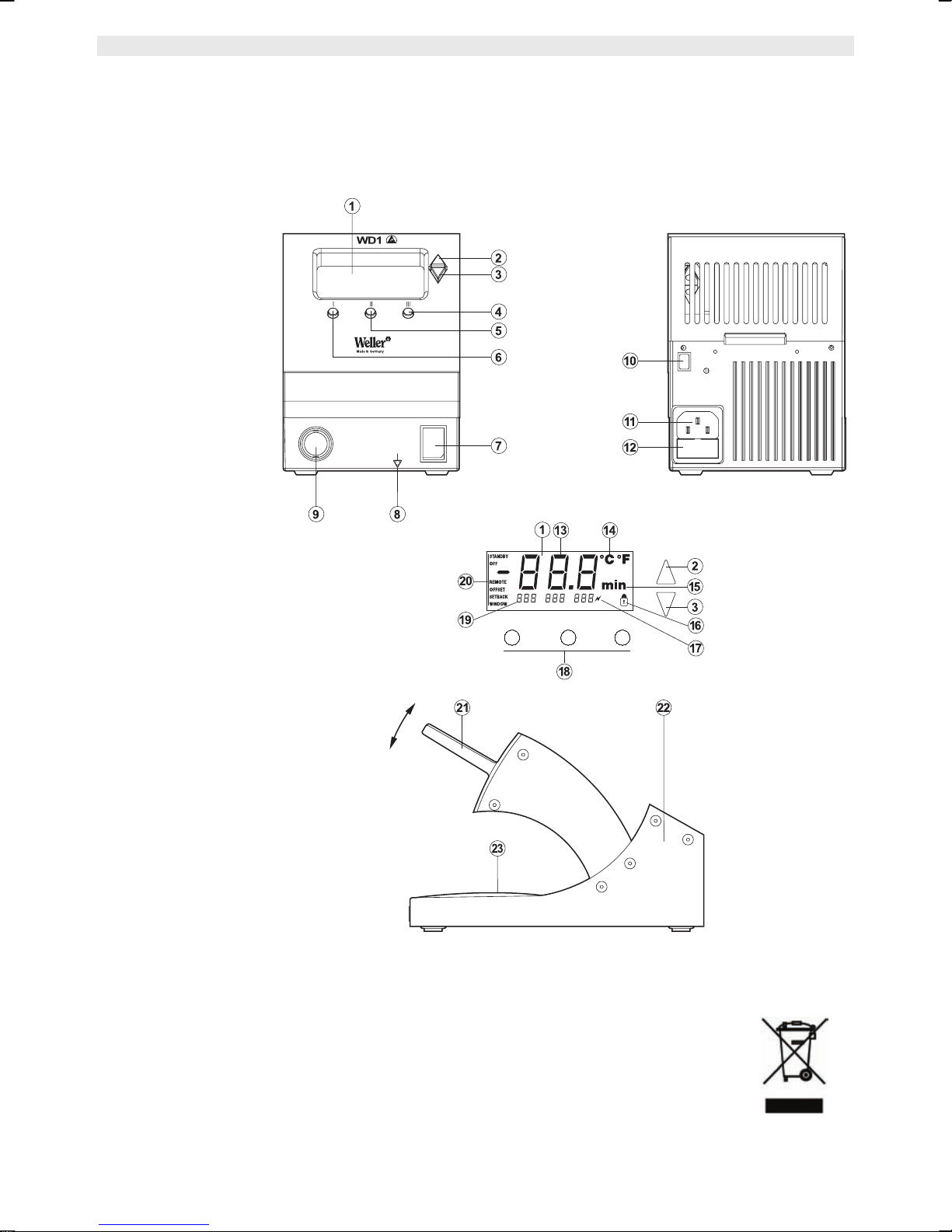

Equipment overview

1 Display

2 UP button

3 DOWN button

4 Temperature button III

5 Temperature button II

6 Temperature button I

7 Mains switch

8 Equipotential-bonding socket

9 Connecting socket for

soldering tool

10 USB interface, B-Mini

(WD 1M)

11 Mains connection

12 Mains system fuse

13 Temperature display

14 Temperature symbol

15 Time function

16 Lock

17 Optical control check

18 Temperature buttons

19 Fixed temperature display

20 Special functions

21 Funnel insert

22 Soldering tip compartment

23 Cleaning element

I II III

WD 1 (M) / WD 1000 (M) 3-18

Contents

About these instructions ............................................................ 3

1

2 For your safety ........................................................................... 4

3 Scope of supply ......................................................................... 4

4 Device description ..................................................................... 5

5 Starting up the device ................................................................ 7

6 Operating the device .................................................................. 8

7 Special functions ........................................................................ 9

8 Resetting to factory settings ...................................................... 17

9 WD 1 (M) / WD 1000 (M) care and maintenance ...................... 17

10 Fault messages and fault elimination ........................................ 17

11 Accessories ............................................................................... 18

12 Disposal ..................................................................................... 18

13 Warranty .................................................................................... 18

DE EN FR IT ES PT NL SV DK FI GR TR CZ PL HU SK SL EE LV LT

1 About these instructions

Thank you for placing your trust in our company by purchasing

the Weller WD 1 (M) / WD 1000 (M). The device has been

manufactured in accordance with the most rigorous quality

standards, which ensure that the device operates perfectly.

These instructions contain important information for safe and correct

initial operation of the WD 1 (M) / WD 1000 (M) soldering station,

including continued operation, maintenance and self-correction of

simple faults.

Z Read these instructions and the accompanying safety information

carefully before switching on the device and starting work with

the WD 1 (M) / WD 1000 (M) soldering station.

Z Make sure that all users have access to these instructions.

1.1 Applied directives

The Weller microprocessor-controlled WD 1 (M) / WD 1000 (M)

soldering station conforms to the specifications of the EC

Declaration of Conformity with Directives 2004/108/EC and

2006/95/EC.

1.2 Documents also applicable

− Operating instructions for soldering station

WD 1 (M) / WD 1000 (M)

− Safety information booklet accompanying these instructions

4-18 WD 1 (M) / WD 1000 (M)

r

r

2 For your safety

The WD 1 (M) / WD 1000 (M) soldering station has been

manufactured in accordance with state-of-the-art technology and

recognised technical safety regulations. There is nevertheless the

risk of personal injury and damage to property if you fail to observe

the safety information set out in the accompanying booklet and the

warnings given in these instructions. Always pass on the

WD 1 (M) / WD 1000 (M) soldering station to third parties together

with these operating instructions.

2.1 Specified use

Use the WD 1 (M) / WD 1000 (M) soldering station exclusively for

the purpose indicated in the operating instructions of soldering and

unsoldering under the conditions specified here. Specified use of the

WD 1 (M) / WD 1000 (M) soldering station also includes

− observing these operating instructions,

− observing all other accompanying documentation,

− observing locally applicable accident prevention regulations.

The manufacturer shall not be liable for damage resulting from

unauthorised alterations to the machine.

3 Scope of supply

WD 1 WD 1000 WD 1M WD 1000M

Control unit a a a a

Power cable a a a a

Jack connecto

Soldering iron a a a

Safety holde

USB cable a a

Operating

instructions

Safety information

booklet

a a a a

a a a

a a a a

a a a a

WD 1 (M) / WD 1000 (M) 5-18

4 Device description

The Weller WD 1 (M) / WD 1000 (M) is a versatile soldering station

for performing professional repair work on state-of-the-art electronic

assemblies in the industrial engineering sector as well as repair

workshops and laboratories.

Precise temperature control performance at the soldering tip is

guaranteed by the digital control electrotechnology together with

superior-quality sensor and heat-transfer technology. High-speed

measured-value acquisition provides for maximum temperature

precision and optimum dynamic temperature performance in load

situations.

All soldering irons (except for microtools) up to 80 Watts can be

connected to the WD 1. The temperature range is from 50 °C to

450 °C (150 °F to 850 °F). The WD 1M is multifunctional and all

soldering irons up to 150 Watts and microtools (WMRP & WMRT)

can be connected; the temperature range is from 50 °C to 450 °C

(150 °F to 850 °F). Setpoint and actual values are displayed in digital

from. Three temperature buttons are used to select fixed

temperatures directly. A flashing optical control check ("a" symbol

on display) indicates that the preselected tool temperature has been

reached.

The Weller WD 1 (M) / WD 1000 (M) soldering station also offers the

following functions:

− Automatic tool detection and activation of corresponding control

parameters

− Digital temperature control

− Option of inputting offset values

− Programmable temperature reduction (setback)

− Standby and lock functions

− Antistatic device design in accordance with ESD safety

− Different equipotential-bonding possibilities on the device

(standard configuration hard earthed)

− Customer-specific calibration function

− USB port for control, evaluation and documentation via PC

DE EN FR IT ES PT NL SV DK FI GR TR CZ PL HU SK SL EE LV LT

4.1 Safety holder

The funnel insert (21) for holding the soldering iron has four different

settings and can be adjusted to the most ergonomic position without

requiring tools. There is a compartment (22) on the back for storing

soldering tips. The base plate on the compartment contains a

cleaning element (23) for cleaning the soldering tip.

6-18 WD 1 (M) / WD 1000 (M)

A

A

4.2 Technical data WD 1 (M) / WD 1000 (M)

Dimensions L x W x H (mm): 134 x 108 x 147

L x W x H (inches): 5.27 x 4.27 x 5.77

Weight approx. 3.4 kg

Mains supply voltage 230 V, 50/60 Hz

120 V, 60 Hz

100 V, 50/60 Hz

Power consumption 95 W

Safety class I and III, housing antistatic

Fuse (12)

Only WD 1 / WD 1000

Fuse (12)

Only WD 1 M/ WD 1000M

Temperature control 50 °C – 450 °C (150 °F – 842 °F)

Temperature accuracy ± 9 °C (± 17 °F)

Temperature stability ± 5 °C (± 9 °F)

Soldering tip leakage

resistance (tip to ground)

Soldering tip leakage

current (tip to ground)

Equipotential bonding Via 3.5 mm pawl socket on back of

T 500 mA (230 V, 50 / 60 Hz)

T 1.0 A (120 V, 60 Hz)

T1.25

T 800 mA (230 V, 50 / 60 Hz)

T 1.6 A (120 V, 60 Hz)

T1.6

Complies with IPC-J-001D

Complies with IPC-J-001D

device (8).

(100 V, 50/60 Hz)

(100 V, 50 Hz)

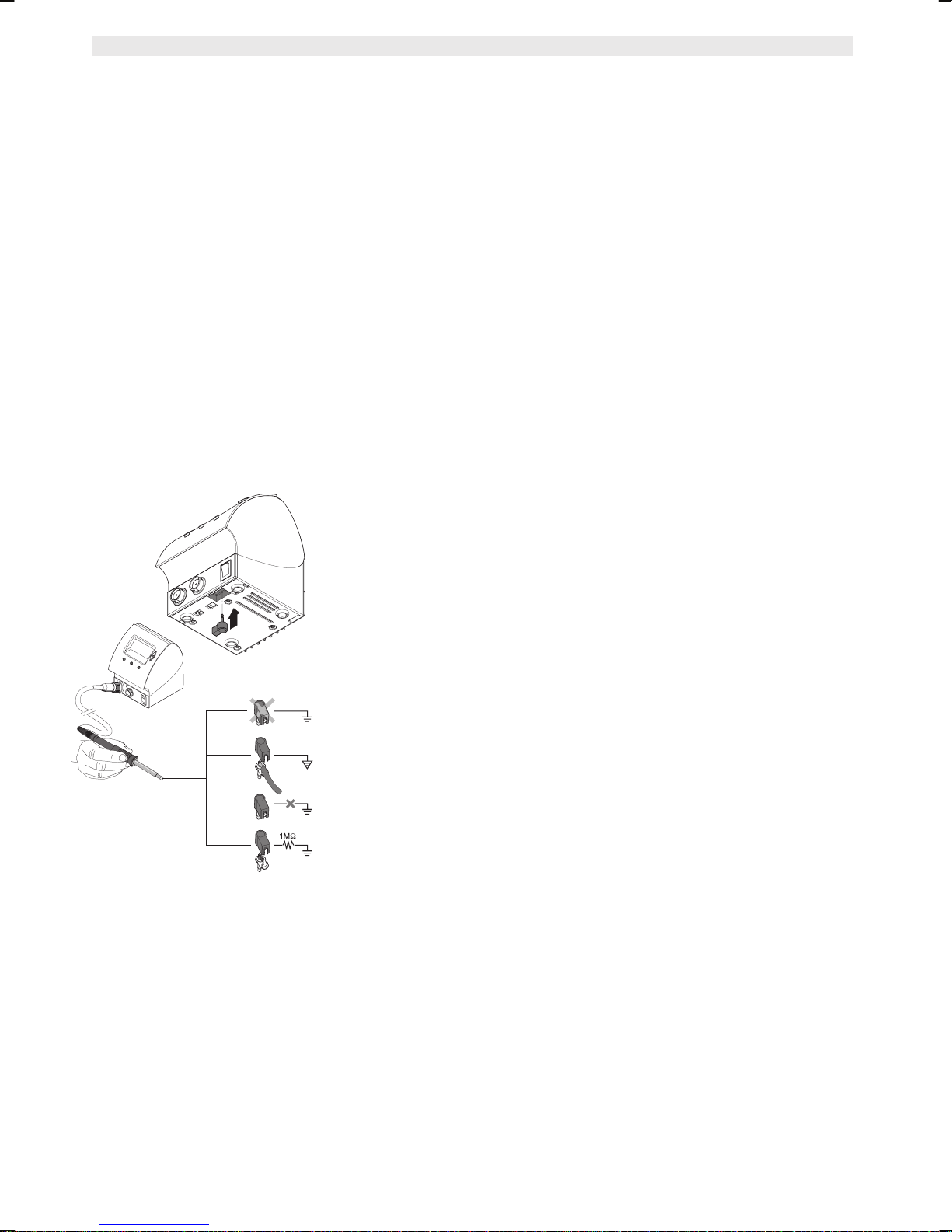

Equipotential bonding

4 variants are possible through connecting the 3.5 mm pawl

socket (8) differently:

− Hard earthed/grounded: without connector (delivery status)

− Equipotential bonding: with connector, bonding line at central

contact

− Floating: with connector

− Soft earthed/grounded: with connector and soldered resistor.

Earthing/grounding via the selected resistor

USB port

The control units WD 1M and WD 1000M are fitted with a mini USB

interface (10). For the purpose of using the USB port, Weller

software is available on a CD with which you

− can carry out a software update ("Firmware Updater“) on your

control unit and

− can remote-control the control unit and graphically display, store

and print temperature curves ("Monitor Software“).

Note Control units WD 1 and WD 1000 can be retrofitted with a USB

interface.

WD 1 (M) / WD 1000 (M) 7-18

WARNING!

5 Starting up the device

Electric shock and risk of burns

Connecting the control unit incorrectly poses a risk of injury and

damage to the device. Risk of burns from the soldering tool while

the control unit is operating.

Z Read the enclosed instructions, the safety instructions included

in these Operating Instructions as well as the instructions for

your control unit all the way through and observe the specified

precautionary measures before operating the control unit.

Z Always place the soldering tool in the safety holder when not in

use.

1. Carefully unpack the device.

2. Connect the soldering tools as follows:

Insert the soldering tool with connector into the connecting socket

(9) on the control unit and turn clockwise to lock.

3. Place the soldering tool in the safety holder.

4. Check whether the mains supply voltage matches that indicated

on the rating plate and whether mains power switch (7) is off.

5. Connect the control unit to the mains supply (11).

6. Switch on the device at the mains power switch (7).

After the device has been switched on, the microprocessor carries

out a self-test in which all the display elements are briefly in

operation. The preset temperature (setpoint) and the temperature

unit (°C / °F) are then displayed briefly. The electronics automatically

switch to the actual value display. The symbol "

the display (1) as an optical control check:

− Continuous illumination indicates that the system is warming up.

− Flashing light indicates that the preselected temperature has been

reached.

" (17) appears on

DE EN FR IT ES PT NL SV DK FI GR TR CZ PL HU SK SL EE LV LT

Note Please refer to the accessories section on page 18 for a list of tools

that can be connected to the WD 1 (M) / WD 1000 (M).

Loading...

Loading...