Page 1

MODEL MT1500L - MICROTOUCHPLUS-LOC SOLDERING STATION

WARNING: This product, when used for soldering and similar applications, produces chemicals known to the State of

California to cause cancer and birth defects or other reproductive harm.

PLEASE

Before using your new Weller® Microtouch MT1500LL unit, read this manual thoroughly. In only a few

minutes you will become familiar with your new station and be able to get the soldering performance youre

entitled to. Be sure to keep this manual in a handy place near the unit for reference.

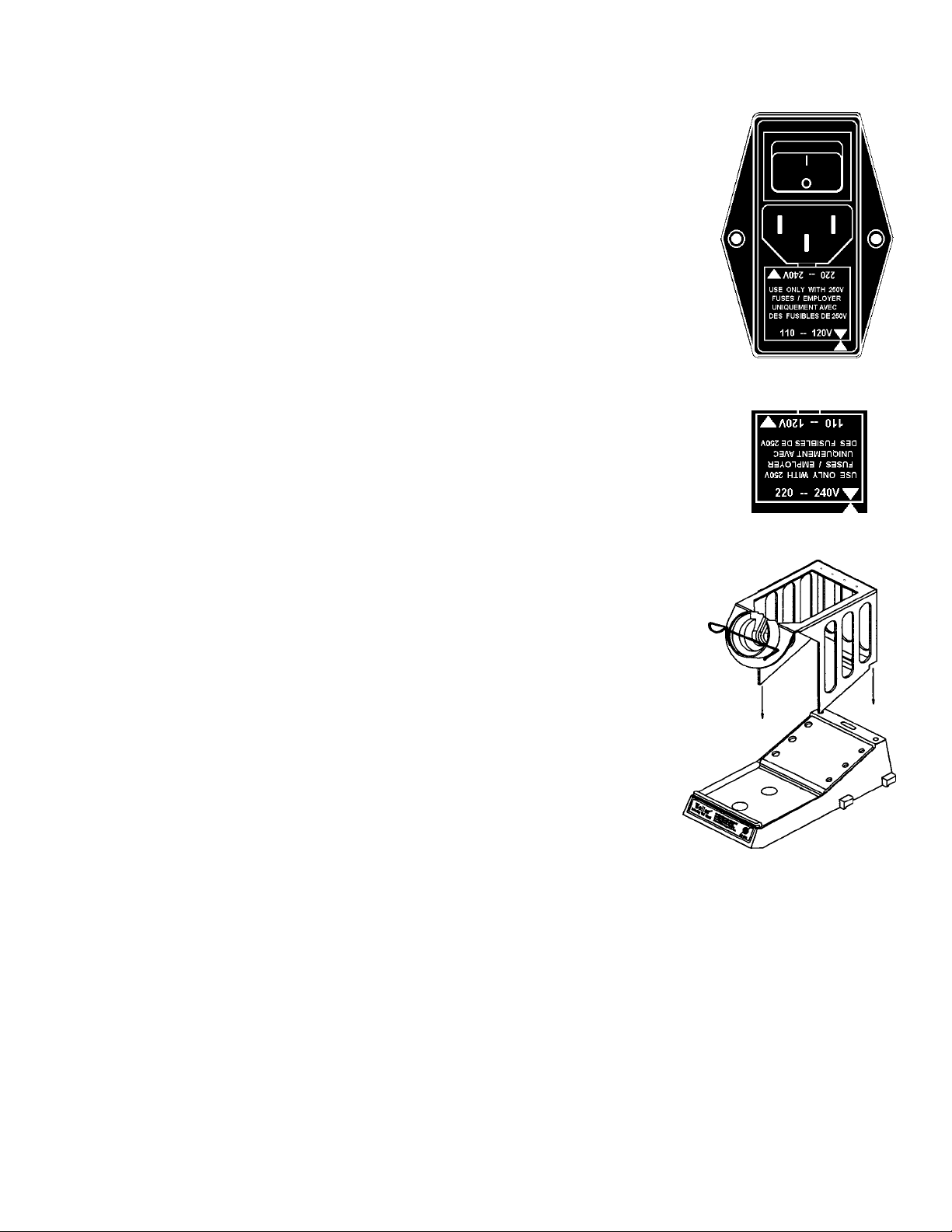

SETTING INPUT POWER

This soldering station can operate on 120 VAC or 230 VAC at *50/60 Hz. The fuse holder located under the

power cord receptacle on the back of the station also functions as a voltage selector.

Before plugging the power cord into its receptacle, be sure that the proper voltage has been selected. If

not, pull the fuse holder out of the station and line up the arrow next to the desired voltage with the arrow

located in the lower right hand corner of the receptacle housing. See figures on right. Push the fuseholder

back into its socket and press until the holder face is flush with the housing.

THE FUSE HOLDER MUST BE POSITIONED FOR THE CORRECT VOLTAGE RATING OR DAMAGE TO THE

STATION COULD OCCUR.

IF THE FUSES NEED TO BE REPLACED FOR ANY REASON, DO NOT SUBSTITUTE DIFFERENT RATED

FUSHES. The two fuses installed are different. The arrows on the fuseholder points toward the fuse used

for that voltage. The 120VAC fuse is a 3 amp time delay fuse (Bussmann® MDQ-3) and the 230VAC fuse is a

1 amp time delay fuse (Bussmann® GDC-1 or S504-1).

Insert universal end of line cord into the receptacle located on the back of the power unit, and insert the plug

end into a properly grounded AC receptacle.

Configuration for 110 - 120VAC

Configuration for 220 - 240VAC

THE MT1500L STATION IS EQUIPPED WITH AN INTERNAL AUTOMATIC RESETTING FUSE.

If the handle or tip were to short out, the fuse would heat up and switch off heater power. The

display and indicators would still light up but the heater power would stay off until the problem is

fixed and the station turned off for a few minutes to allow the fuse to cool. This fuse will also

switch off if an MT200 series tip is overworked.

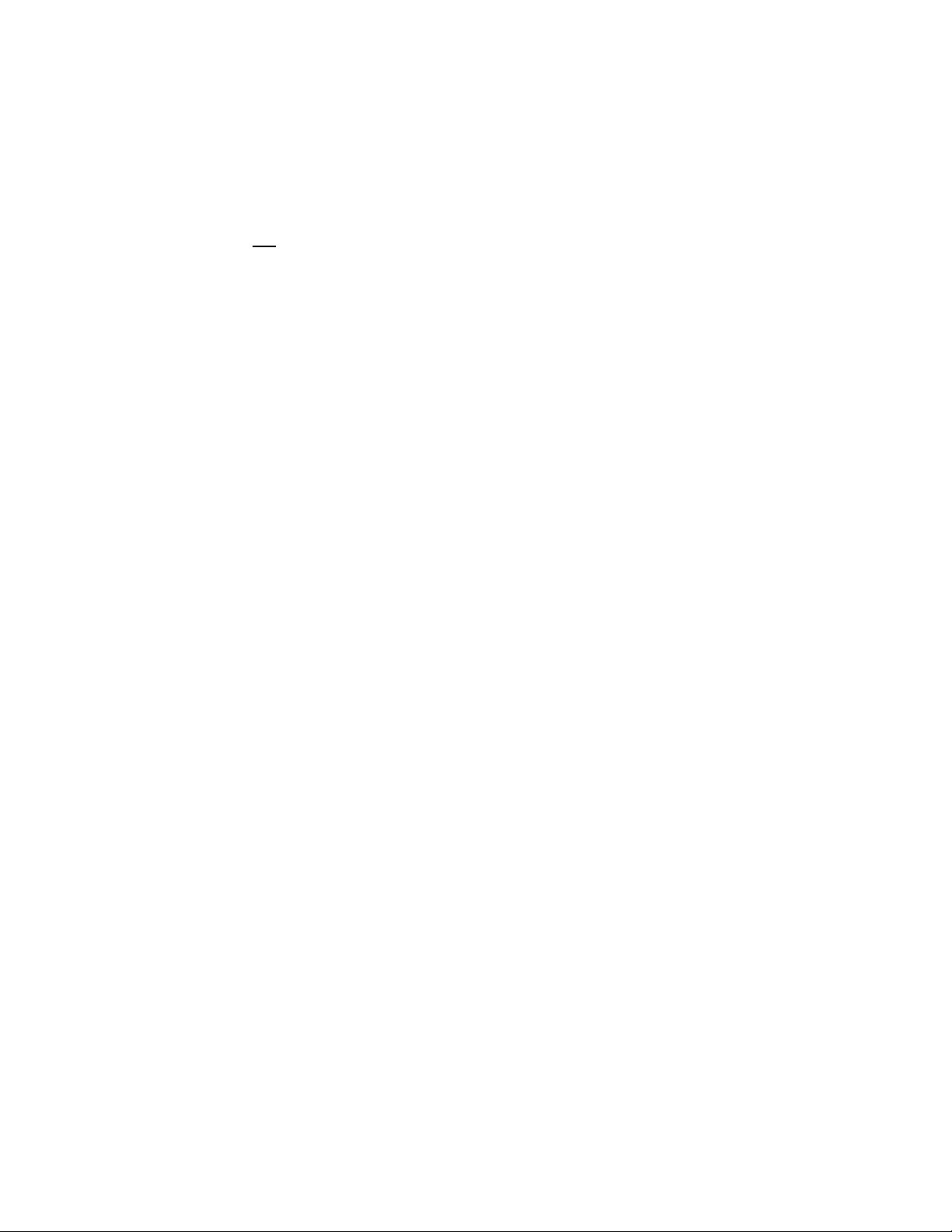

INTIAL SET-UP

Unpack the unit carefully. Assemble tool stand as shown in the figure at right. Fill reservoir with

water and wet sponge. Distilled water is preferred. Install the desired tip (TIPS NOT INCLUED

WITH STATION, SEE TIP SHEET FOR STYLES AVAILABLE) into the receptacle end of the

handpiece until it is well seated. Insert tool into holder and connect tool plug to receptacle located

on the left front panel of power unit; rotate plug cover to lock plug into place.

Choose a mode of operation with the mode switch located on the front of the power unit (see

Modes of Operation). Temperature keys for 600°F (315°C), 700°F (371°C), and 800°F (427°C)

are included with the MT1500LL station. Select a temperature key for the soldering tip temperature desired and plug into socket located on the right side of the front panel. If the desired

temperature key is not installed, the key may be changed while power is on. Turn the station

on with the power switch located on the back of the unit. When the red Tool Ready LED on

the front panel lights, the tip is at temperature and is ready to use.

MODES OF OPERATION

TOUCH MODE

The Touch Mode is primarily intended for soldering very small components with microtips and to extended tip life with larger tips. In Touch Mode,

the tip is heated only when the touch ring located at the front of the handpiece and the metallic portion of the rear of the handpiece are both

touched by the operators hand. When contact is broken, power is turned off to the heater and the tip will cool to ambient temperature. The Touch

Mode will maximize tip life by preventing the tip from sitting at high temperature for extended periods of time. Occasionally, dry hand will cause the

Touch Mode to malfunction. In this situation, the use of a moisturizing hand lotion is recommended.

IDLE MODE

The Idle Mode operates similar to the Touch Mode; however, it incorporates a delay before cooling to 400°F. When contact is broken, after

approximately a 1 minute delay, the tip will cool to 400°F (204°C). Idle Model operation allows larger tips to heat back to the desired temperature

faster. It can also be used in place of the Touch Mode, if desired.

CONTINUOUS MODE

In the Continuous Mode the tip will remain heated to the selected temperature as long as the unit is operating. Continuous Mode is suited for very

large surface mount style tips. This mode of operation may reduce tip life.

1

Page 2

TIP REPLACEMENT

WARNING: To prevent accidental burns, be sure the power is turned off when changing tips and use the tip gripper.

The Weller® Microtouch MT1500LL unit is made for sue with the new Weller® MT200, MT300, MT600, and MT1200 Series Tips only. These tips are

fitted with a special slip-fit connector that allows quick tip removal and attachment. Only handle the tips by the grip tube, because manipulating

the tips while holding other parts of it may damage the tip and/or cause burns.

To remove a tip, begin by turning the unit off. Wait a few seconds for the tip to cool, then using the tip gripper, grasp the tip grip tube and pull

straight off the handpiece. The iron stand has four holes located on top for convenient tip storage. To attach a tip, begin by making sure that the

unit is off. Grasp the tip grip tube, and push the tip straight on to the handpiece.

TIP GROUNDING

Most of the MT200 Series tips are not grounded. The MT203 Mil-Spec tip has a special lead grounding the tip through the probe handle. All of the

MT300, MT600, and MT1200 Series tips are grounded through the probe handle to the MT1500L station case.

TIPS

The different tip styles available are shown on a separate page included with this booklet. Four different series of tips are available for the

MT1500LL Station:

MT200 Series Micro Tips MT600 Series Macro Tips

MT300 Series Mini Tips MT1200 Series SMD Tips

CAUTION: The MT200 Series tips are not designed to be bent. If they are bent either by accident or on purpose the tip is

NOTE: The MT204 Conical and MT212 Screwdriver tips are non-wetting. They are unplated stainless steel so that solder will not stick to them.

CARE AND MAINTENANCE

TIP LIFE

The tips will last longer if you do not use them at high temperature settings for prolonged periods of time. However, you can extend tip life

significantly by making full use of the touch and idle modes. Keep the tip lightly coated with solder at all times. Rosin based fluxes are recommended for optimum cleaning of tip surfaces.

MIRCO TOUCH SOLDERING

Since very little heat is stored in the MT200 series tips, the energy needed to heat the solder joint must come form the tips heating element.

Because the tip senses loading almost instantaneously and can respond with maximum power, a lower tip temperature setting can be used

without danger of board or component overheating. The correct technique for Micro Touch Soldering with your MT1500LL is:

1. Tin the micro-tip with solder.

2. Touch the tip lightly to the pad; create a solder bridge with a small amount of additional solder.

3. Wait for solder to flow and wet components, add additional solder as necessary.

4. Remove tip and allow solder to solidify on connection.

This procedure should provide a quality solder joint with no overheating. Use very little pressure when soldering. Excess pressure will not

improve the result but will damage the tip by bending it.

damaged and can fail.

This allows them to be used to break solder bridges that may form between closely spaced pads.

SPECIFICAITONS

1. Power input: 120VAC ± 10%, (230VAC ± 10%) 50/60 Hz. 130 Watts.

2. Power unit output voltage: isolated 6 VAC, 12 VAC, and 24 VAC. (Tip Selected)

3. Line Cord: Detachable, 3 wire, U.L. recognized or CE approved.

4. Station Size: 6-5/8"W x 8-1/8"D x 3-7/8"H (16.8 cm W x 20.6 cm D x 9/8 cm H)

5. Weight: 8.2 lbs. (3.78 kg) with power cord.

6. Iron Handle: 1 oz. (28.4 g) without cord.

7. Iron Cord: 4 ft. (1.22 m) long.

8. Black ESD Silicone Rubber Jacket.

9. Tip temperature, key selected: 600°F, 700°F, and 800°F (315°C, 371°C, and 427°C). Keys provided with station.

10. Stability: ± 10°F (± 6°C).

11. Absolute accuracy: Average tip temperature is calibratable to ± 9°F (± 5°C) at idle with no load. Factory calibration is

made using the MT320 Minitip. (Other Calibration Tips include the MT220 Microtip and MT620 Macrotip.)

12. Ambient temperature range: 60°F to 110°F (16°C to 44°C).

13. MT1500LL units are U.L. listed and meet the requirements of: DOD-STD-2000, MIL-STD-2000, MIL-S-45743, W-S-6536,

W-S-570, DOD-STD-1686.

2

Page 3

TIP CALIBRATION

The MT1500LL is calibrated at the factory using the MT320 Calibration Tip. To calibrate a specific tip for a certain temperature, insert the desired

temperature Key into the panel socket and then measure the actual tip temperature. Adjust R57 (see below for location) to raise or lower the tip

temperature to match the temperature printed on the key.

STATION CALIBRATION

WARNING: HIGH VOLTAGES ARE LOCATED INSIDE THIS UNIT. SERVICE SHOULD BE PERFORMED BY QUALIFIED TECHNICIANS ONLY.

The MT1500LL is calibrated at the factory using the MT320 Calibration Tip. The following procedure will allow full calibration of the MT1500LL unit

for different series tips.

Tools needed: WA2000 Soldering Iron Analyzer (Recommended) to read tip temperature from the calibration tip, Digital Voltmeter (DVM), Phillips

screwdriver, small 1/16" wide blade screwdriver to adjust trimmer pots.

1. Remove power cord from rear receptacle. Remove six (6) screws holding cover on station. Remove cover. Use drawing at right to

locate adjustment pots. used for the procedure. Plug power cord back in.

2. Temperature measurements are done using a calibration tip from the same tip series as the tips you are using. If you are usin g the

MT200 Series Microtips use the MT220 calibration tip. For any of the MT300 Series Minitips use the MT320 calibration tip. For any of the

MT600 Series Macrotips use the MT620 calibration tip.

3. Set the front switch to Continuous Mode and remove any temperature key for minimum temperature setting. Turn station on.

4. Adjust trim pot R57 slowly until the tip temperature is steady at 400°F ± 2° (204°C ± 1°). R57 is located on the lower left side of the

angled front panel and is accessed through a small hole.

5. Insert the 800°F temperature key and adjust trim pot R56 until tip temperature is steady at 800°F ± 2° (427°C ± 1°).

6. MT200 Series tip operation is sensitive to the power line frequency. To calibrate station for 50 Hz or 60 Hz operation, replace

MT320calibration tip with a MT200 series tip. Set DVM to read DC volts. Connect DVM test leads to + or - test holes on the back of the

circuit board. (See drawing at right for location). For operation at 60 Hz, adjust trim pot R55 so that the voltage across the two test

points is 7.10 volts DC. For operation at 50 Hz set voltage to 6.70 volts DC.

7. MT200 series ungrounded tips. Set DVM to measure AC volts. Connect negative lead to DVM to measure AC volts. Connect negative lead

of DVM to green lead at ring terminal (case ground) and the other lead with an alligator clip to the tip. Insert 800°F temperature key.

Adjust trim pot. R32 for minimum voltage (less than 50mVAC).

8. Turn station Off. Unplug power cord. Place cover back on base. Line up front holes with screw threads and install front two

(2)screws. Push cover toward back of unit to line up rear two holes. Install remaining four (4) screws. Plug power cord back in .

TRIP POT. LOCATIONS AND TEST POINT HOLES ON CIRCUIT BOARD AS VIEWED FROM BACK OF CASE

3

Page 4

REPLACEMENT PARTS

PART NO. DESCRIPTION

MT1501 Replacement Handle

TC205 Sponge

* 600°F Temperature Key

* 700°F Temperature Key

* 800°F Temperature Key

*Contact Factory Repair Department for replacement keys.

ACCESSORIES

PART NO. DESCRIPTION

MT001 Leather Tip Gripper Pad

MT002 SMD Sponge Tool

MT220 Calibration Tip, Conical .030D

MT320 Calibration Tip, Screwdriver .047W

MT620 Calibration Tip, Screwdriver .070W

WA2000 Soldering Iron Analyzer

CUSTOMER SERVICE

Should your MT1500LL require service, it may be sent to the following address:

USA

Cooper Tools - Weller

1000 Lufkin Road

Apex, NC 27539

ATTN: Repair Department

Phone: 1-800-476-3030

FAX: 919-387-2640

CANADA

Cooper Tools

164 Innisfil Street

Barrie, Ontario, Canada L4N 3E7

ATTN: Repairs

Phone: 705-728-5564 Ext. 2026

FAX: 1-800-403-8665

S905

10/96

Rev. 3/03

*Station is set up for 60 Hz operation. To use MT200 Series tips at 50 Hz, see Calibration procedure on page 4 to adjust power

limiting circuit for 50 Hz operation.

4

Loading...

Loading...