Page 1

SERVICE MANUAL

Light Source Menu

Operation Manual

Int'l Operation Manual

for the

WELCH ALLYN

LX-150 LIGHT SOURCE

no.'s 45150,45250 (after 8/91),

45160, 45262, 45264, 45266, 45268

COPYRIGHT 1994 Service Manual 451621

WELCH ALLYN REV A

originator: RJS ECN#5-28314

Page 2

LX-150

TABLE OF CONTENTS

FORWARD - - - - - - - - - - - - - - - - - - - - - - - - - - i

SAFE SERVICE - - - - - - - - - - - - - - - - - - - - - - - ii

INDEX: FAILURE/CAUSE - - - - - - - - - - - - - - - - - - - 1 - 3

DIFFERENCES BETWEEN EARLY AND LATE MODELS - - - - - - - - - 3

INDEX: REMOVAL/REPLACEMENT ( R & R ) PROCEDURES - - - - - 4

REMOVAL/REPLACEMENT PROCEDURES - - - - - - - - - - - - - - 5 - 19

APPENDIX

SERVICE PARTS LIST AND EXPLODED DIAGRAM * * * * AA

WIRING DIAGRAM/SCHEMATIC DIAGRAM * * * * BB

REPAIR VERIFICATION TEST PROCEDURES * * * * CC

SET-UP AND OPERATION ( OWNER'S MANUAL ) * * * * DD

TOOLS (COMMON & SPECIAL) * * * * EE

PRODUCT UP-DATES * * * * FF

PRODUCT DESCRIPTION * * * * GG

Page 3

FORWARD

THIS MANUAL IS FOR WELCH ALLYN TECHNICIANS WHO ARE

TRAINED AND QUALIFIED

TO PERFORM ELECTRICAL REPAIRS.

This manual provides technical assistance to Welch Allyn

repair technicians for cleaning, disinfecting, diagnosing,

repairing, and testing the WELCH ALLYN LX-150 LIGHT SOURCE.

The manual's main content areas cover: faults/causes, step by step

removal and replacement of parts, and re-test.

The repair 'TASK' procedures ( R & R .. Removal and

Replacement ) are written to provide quick and easy reference for

different experience levels of repair technician. Required

specifications and materials are listed at each step where

applicable. When reading this manual for the first time, have an

LX-150 readily available for reference and practice. Read each

complete repair step on what to do (task statement), plus how to do

it ( technique statement ) before starting the repair or practice.

Training for the LX-150 should consist of detailed

demonstrations of required repair tasks, practice using repair

tooling and materials, and assessment of skill development through

observation of trainee practice on actual equipment. Set up

sessions to allow the trainee to practice the use of the

diagnostic, repair, adjustment, and re-testing procedures found in

this manual. The ability of the technician to develop and retain

new skills is in great part dependent on well prepared training

exercises. Each trainee must have the opportunity to practice the

procedure(s) after it has been demonstrated by the instructor.

More detailed background product information is found in the

APPENDIX section and as such will be a critical element in a

comprehensive service training program for technicians.

I M P O R T A N T :

Welch Allyn part numbers and 'M' (material) numbers appearing in

this manual are for the purpose of familiarizing new technicians

with Welch Allyn documentation conventions. Order replacement

parts, as always, by referencing your latest bill of materials,

parts catalog and assembly drawings. Part number changes, product

updates, or new test procedures should be noted on the appropriate

page of this manual by the manual owner. Notices announcing these

changes should be attached to Appendix FF, PRODUCT UPDATES.

HOW TO FIND CURRENT PART NUMBER INFORMATION:

REFER TO THE MOST RECENT ASSEMBLY DRAWING(S) FOR APPLICATION

INFORMATION ON PARTS, PROCESS, AND MATERIALS. FIND THE CURRENT PART

NUMBERS BY REFERRING TO THE CIRCLED NUMBERS ( 'BUBBLE' NUMBERS ) ON

CURRENT ASSEMBLY DRAWINGS. FIND CORRESPONDING PART NUMBER ON THE

MANUFACTURING OR REPAIR BILL OF MATERIALS.

i

Page 4

*** SAFE SERVICE ***

WEAR approved eye protection when servicing this product.

CLEAN AND DISINFECT as per normal operating procedure BEFORE

repairing, or adjusting all returned LX-150's. NEVER ASSUME IT HAS

BEEN DONE!! WIPE unit off with solution of 10% Clorox, 90% water.

DISCONNECT power cord from A.C. power source before cleaning or

disassembling LX-150. LET hot lamps cool before replacing them.

DO NOT OPERATE ANY UNITS UNTIL YOU HAVE DISASSEMBLED THEM AND

DETERMINED THAT THEY ARE SAFE TO TEST/OPERATE. VERIFY that the

circuits are same as appropriate assembly drawings circuits before

energizing the LX-150 Light Source.

COMPLY with all safety codes and practices for this product.

PERFORM recommended Welch Allyn test procedures AFTER SERVICING to

assure safe and reliable product operation, ie: ground continuity

testing, dielectric strength testing, leakage current testing, and

air pump output pressure testing.

EXAMINE AND REPAIR OR REPLACE as required, any and all worn or

questionable wiring, components, connections, connectors, warning

labels, insulation and other items necessary for the continued safe

operation of this product.

DO NOT TOUCH halogen lamps or nearby parts during or immediately

after operation. WAIT 20 MINUTES! High temperatures can cause

severe burns. Fractured or broken lamps may cause injury. Use a

cloth or other protection when removing questionable lamps.

DO NOT LOOK DIRECTLY AT halogen lamps during operation.

*** QUALITY SERVICE ***

MODIFY your Repair & Training Manual frequently by notating changes

and revisions of part numbers and procedures. Enter this new data

on the appropriate page and put the notice in Appendix FF.

READ AND UNDERSTAND customer comments and complaints on

accompanying documentation ( P.O. or other correspondence ).

IF AN INJURY OR ILLNESS TO PATIENT OR USER, OR HAZARDOUS

MALFUNCTION HAS OCCURRED OR IS SUSPECTED, DO NOT DISASSEMBLE,

REASSEMBLE, ALTER OR REPAIR THE PRODUCT IN ANY WAY...INSTEAD, GIVE

THE UNIT AND ALL ACCOMPANYING PAPERWORK TO YOUR REPAIR SUPERVISOR.

Appropriate action per approved Welch Allyn policy will be taken.

OPEN the light source and perform complete inspection. LOOK for:

product defects, damage, tampering, unsafe condition of wiring or

any component. ENTER findings and test data along with repair

status in the appropriate file.

ii

Page 5

INDEX OF FAILURES / CAUSES

SEE SCHEMATIC 451536,109P370, 451605 & ASSEMBLY DRAWINGS OF LX-150.

FAILURE or COMPLAINT: POSSIBLE CAUSE & CORRECTIVE ACTION:

UNIT COMPLETELY INOPERATIVE

( NO LIGHT, FAN, AIR ... not plugged in...PLUG IN TO MAINS

when lamp door is closed)... no voltage at MAINS (AC OUTLET).

CHECK and restore voltage.

... lamp access door ajar...LATCH DOOR.

... fuse(s) blown...CHECK FOR SHORT TO

GROUND OR OTHER HIGH CURRENT DRAW

CAUSE (LINE-TO-LINE SHORT.) RESTORE

CIRCUIT TO SPECIFICATIONS BEFORE

ENERGIZING UNIT. REPLACE FUSES, TEST.

... defective interlock switch...REPLACE

... bent interlock switch

actuation arm...REPLACE WHOLE SWITCH.

... loose wire connection...RESTORE

... defective power switch S1...REPLACE

... defective power cord...REPLACE CORD

... unit miswired...COMPARE TO SCHEMATIC

AND RESTORE CIRCUIT TO SPECIFICATION.

... interlock switch "normally closed"

contacts used instead of required

"normally open" contacts. CHECK AND

RESTORE CORRECT CONNECTIONS.

------------------------------------------------------------------FAN RUNS BUT NO LIGHT ... lamp loose in holder...RESEAT LAMP

WARNING:: ... burned out lamp...CHECK OLD LAMP FOR

ALLOW LAMP TO CORRECT VOLTAGE RATING (21 V).

COOL FOR 20 REPLACE LAMP WITH WELCH ALLYN PN04050

MINUTES BEFORE ... thermal protector over heated

TOUCHING !!! (above 95 degrees C)...LET COOL

... thermal protector cooled and stuck

open...REPLACE THERMAL PROTECTOR

... open transformer winding...REPLACE

... lamp turns off after short time...

wrong or defective thermal protector

REPLACE THERMAL PROTECTOR.

... unit miswired...COMPARE TO SCHEMATIC

AND RESTORE CIRCUIT TO SPECIFICATION.

-----------------------------------------------------------------LOW LIGHT OUTPUT ... lamp not seated...RESEAT LAMP

... bad lamp...REPLACE LAMP

WARNING:: ... lower wattage lamp installed...

ALLOW LAMP TO REPLACE WITH PNO4050 150 WATT LAMP.

COOL FOR 20 ... low transformer secondary

MINUTES BEFORE voltage...check wiring...REPLACE

TOUCHING !!! TRANSFORMER.

... unit miswired (wrong transformer

tap used)...COMPARE TO SCHEMATIC

AND RESTORE CIRCUIT TO SPECIFICATION.

... dirty reflector...CLEAN.

... shutter crank loose...ALIGN, TIGHTEN.

1

Page 6

LX-150 INDEX OF FAILURES / CAUSES, CONTINUED.....

FAILURE OR COMPLAINT: POSSIBLE CAUSE AND CORRECTIVE ACTION:

PUMP DOES NOT RUN ... defective " AIR" switch...REPLACE.

... poor electrical connection to

pump...RESTORE ELECTRICAL CONNECTION.

... defective pump...REPLACE PUMP.

... unit miswired...COMPARE TO SCHEMATIC

AND RESTORE CIRCUIT TO SPECIFICATION.

------------------------------------------------------------------PUMP RUNS, NO/LOW OUTPUT ... loose water bottle cap...TIGHTEN.

... tubing off of connector(s)...RESTORE

CONNECTION(S).

... tubing sharply bent..STRAIGHTEN TUBE.

... cracked panel mount connector...

REPLACE PANEL MOUNT CONNECTOR.

... cracked water bottle cap air fitting

REPLACE AIR FITTING ON WATER BOTTLE

- ... wrong tubing connections...RESTORE

------------------------------------------------------------------COOLING FAN INOPERATIVE ... bad electrical connection...RESTORE.

... defective fan motor...REPLACE FAN.

... fan obstructed...CLEAR OBSTRUCTION.

... unit miswired...COMPARE TO SCHEMATIC

AND RESTORE CIRCUIT TO SPECIFICATION.

------------------------------------------------------------------SIGMOIDOSCOPE CONNECTOR DOES

NOT PLUG IN ALL THE WAY ... ball detente jammed in down position

set screw too far in...LOOSEN SET

SCREW AND FREE UP THE BALL DETENT.

------------------------------------------------------------------SIGMOIDOSCOPE CONNECTOR DOES

NOT STAY IN THE PORT ... loose or missing ball detent or

spring...TIGHTEN SET SCREW AND PUSH

BALL INTO ITS HOLE TO CHECK FOR

SPRING.REPLACE WORN/MISSING PART.

------------------------------------------------------------------SHUTTER DOES NOT FUNCTION... knob is loose...TIGHTEN KNOB SET

SCREW.

... shutter crank is loose...TIGHTEN

SHUTTER CRANK 4-40X1/4" SET SCREW.

... bushing is broken...REPLACE BUSHING.

------------------------------------------------------------------BRIGHTNESS KNOB RATTLES ... knob shaft is loose...INSTALL SPRING

WASHER PN106142-1.

------------------------------------------------------------------SWITCH(S) PRODUCES ARC

OR FLASH WHEN ACTUATED ... switch is defective or wiring

connections are loose or intermittent

REPLACE CONNECTORS AND OR SWITCH.

------------------------------------------------------------------FAILS DIELECTRIC STRENGTH

TEST A00166 ... transformer/power cord assembly

defective...ISOLATE AND REPLACE.

2

Page 7

LX-150 INDEX OF FAILURES / CAUSES, CONTINUED.....

FAILURE OR COMPLAINT: POSSIBLE CAUSE AND CORRECTIVE ACTION:

FAILS GROUNDING CONTINUITY

TEST A00172 ... faulty connection in grounding

circuit between the power cord

receptacle ground pin and the

chassis. INSPECT AND TEST FOR GROUND

CONTINUITY, RESTORE AND OR REPLACE

FAULTY COMPONENT.

... if above inspection, test reveals

good circuit, then fault possible in

power cord assembly. REPLACE POWER

CORD.

------------------------------------------------------------------FAILS LEAKAGE CURRENT

TEST A00170 ... possible defective component:

transformer, pump, fan, cord

assembly. ISOLATE AND TEST

INDIVIDUAL COMPONENTS. REPLACE.

------------------------------------------------------------------NOTE: LX-15O UNITS MANUFACTURED AFTER JUNE 1991 INCORPORATE

FEATURES THAT DISTINGUISH THEM FROM MODELS MANUFACTURED

PRIOR TO THAT DATE. MOST NOTABLE ARE THE FOLLOWING:

ITEM: BEFORE 6/91: AFTER 6/91:

POWER CORD..... PERMANENTLY ATTACHED PLUG-IN TYPE

POWER CORD.

FUSES.......... FUSES MOUNTED INSIDE EXTERNAL ACCESS

UNIT ON FUSE BLOCK. AT POWER RECEPTACLE.

TRANSFORMER

MOUNTING....... TWO PHILLIPS HEAD TWO PHILLIPS HEAD

SCREWS, TWO MACHINE SCREWS, TWO TABS.

SCREWS W/ 1/4" HEAD.

RUBBER FEET.... ADHESIVE FASTENER

PNEUMATICS..... "T" FITTING BETWEEN PUMP OUTPUT GOES

PANEL MOUNT CONNECTOR DIRECTLY TO PANEL

AND AIR PUMP. MOUNT CONNECTOR.

T E C H N I C I A N N O T E S :

____________________________________________________________

3

Page 8

INDEX: REMOVAL AND REPLACEMENT ( R & R ) PROCEDURES

CAUTION : DISCONNECT LX-150 FROM A.C. POWER SOURCE

BEFORE SERVICING TO

AVOID ELECTRICAL SHOCK HAZARD

Component: Page:

A Lamp - - - - - 5

B.1 External fuses - - - - - 6

B.2 Internal fuses - - - - - 7

C Power cord - - - - - 8

D Power cord receptacle - - - - - 9

E Power and air switches - - - - - 10

F Fan assembly - - - - - 11

G Lamp holder - - - - - 12 - 13

H Lamp holder/heat sink assy. - - - - - 14

I Air pump - - - - - 15 - 16

J Transformer - - - - - 17

K Interlock switch - - - - - 18

L Shutter adjustment - - - - - 19

THIS MANUAL IS FOR AUTHORIZED WELCH ALLYN TECHNICIANS

WHO ARE TRAINED AND QUALIFIED TO WORK ON ELECTRICAL EQUIPMENT.

ALWAYS TEST TO VERIFY SAFE OPERATION.

4

Page 9

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

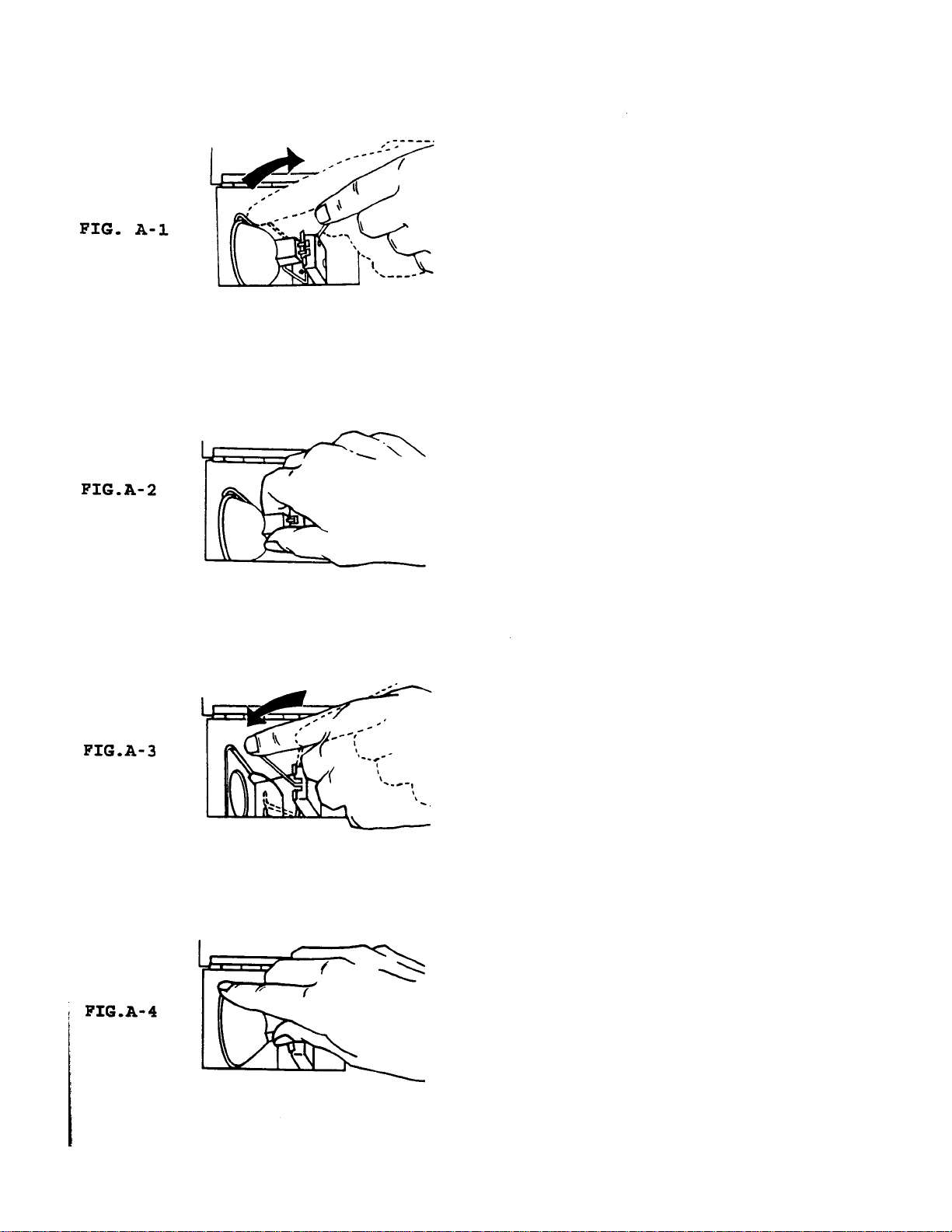

A HALOGEN LAMP REMOVAL AND REPLACEMENT (R & R) PN04050

( GE TYPE EJA 150 WATT 21 VOLTS )

D O N O T T O U C H H O T L A M P !

WARNING: ALLOW LAMP TO COOL OFF FOR 20 MINUTES BEFORE TOUCHING.

A 1. UNPLUG LX-150 AND OPEN LAMP ACCESS DOOR.

( ALSO REFER TO OPERATING INSTRUCTIONS PN451502.)

REMOVE POWER CORD FROM A.C. POWER SOURCE. UNCOUPLE

AIR INPUT HOSE AND UNCLIP WATER BOTTLE AND BRACKET FROM

THE SIDE OF THE UNIT. TURN THE UNIT UPSIDE DOWN. INSERT

A COIN IN THE SLOT OF THE LAMP-ACCESS-DOOR LATCH

( SLOTTED SCREW HEAD ON THE SIDE OF THE DOOR OPPOSITE THE

HINGE ) AND TURN THE LATCH ONE QUARTER TURN COUNTERCLOCKWISE. OPEN LAMP ACCESS DOOR.

D O N O T T O U C H H O T L A M P !

A 2. REMOVE LAMP.

AFTER COOLING DOWN PERIOD OF 20 MINUTES, LOCATE AND PULL

THE LAMP HOLDING LEVER TO RAISE THE BASE OF THE LAMP OUT

OF ENGAGEMENT WITH THE LAMP SOCKET AS SHOWN IN FIG. A-1.

PULL THE LAMP HOLDING LEVER TOWARD THE BACK OF THE UNIT

UNTIL LEVER IS ALMOST VERTICAL. REMOVE EXPIRED LAMP AS

SHOWN IN FIG. A-2.

CAUTION: EXERCISE CAUTION IF THE LAMP REFLECTOR OR THE QUARTZ

ENVELOPE ITSELF IS FRACTURED, CRACKED, OR HOT. USE A

CLOTH TO HOLD THE OLD LAMP WHEN PULLING OLD LAMP OUT OF

SOCKET. DO NOT TWIST LAMP...THIS WILL BREAK THE PINS

FROM THE LAMP. IF THE LAMP HAS FRACTURED, REMOVE ALL

FRAGMENTS FROM THE LX-150.

A 3. REPLACE WITH NEW LAMP PN04050.

RETURN THE LAMP HOLDING LEVER TO ITS ORIGINAL POSITION.

AS SHOWN IN FIG. A-3. NOTE: HOLD THE LAMP ON THE OUTSIDE

SURFACES ONLY. FINGER GREASE OR OTHER CONTAMINANTS WILL

DARKEN THE QUARTZ ENVELOPE CAUSING DISCOLORATION AND

PREMATURE FAILURE OF THE REPLACEMENT LAMP. REMOVE

PROTECTIVE CAP FROM LAMP. VERIFY PROPER ALIGNMENT OF

PINS IN LAMP SOCKET. PRESS DOWN INTO FULL ENGAGEMENT WITH

LAMP SOCKET. SEE FIG. A-4. LAMP WILL SNAP INTO PLACE.

A 4. RESTORE LAMP ACCESS DOOR TO ORIGINAL CLOSED AND LATCHED

POSITION.

CLOSE THE LAMP ACCESS DOOR AND LATCH THE FASTENER.

THE INTERLOCK SWITCH HAS BEEN CLOSED BY THIS ACTION.

A 5. TEST TO VERIFY SAFE OPERATION.

PLACE LX-150 IN UPRIGHT POSITION AND CONNECT TO POWER

SOURCE. LIGHT SHOULD COME ON. ALLOW NEW LAMP TO

OPERATE AT LEAST FIVE MINUTES TO 'BURN IN'.

5

Page 10

Page 11

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

B.1 NEWER UNITS .. EXTERNAL FUSES ( TWO ) R & R. SEE TABLE IN

PARTS CATALOG FOR CORRESPONDING PART NUMBER.

CAUTION: FOR UNITS RETURNED FOR SERVICE BECAUSE OF BLOWN FUSES,

OR RE-OCCURRING FUSE BLOWING, CHECK FOR SHORT TO GROUND

OR OTHER HIGH CURRENT DRAW CAUSE (LINE-TO-LINE SHORT.)

INSPECT WIRING AND COMPONENTS FOR BURN AND SMOKE MARKS,

AND DAMAGED INSULATION. REPLACE FAULTY COMPONENTS AND

RESTORE CIRCUIT TO SPECIFICATIONS BEFORE ENERGIZING UNIT.

REPLACE FUSES AND OPERATE UNIT.

LOOK FOR:

1. THE FAILURE OR DEFECT WHICH CAUSED THE FUSE TO

BLOW.

2. THE CAUSE OF THE FAILURE.

3. OTHER DAMAGE THAT MAY HAVE BEEN DONE BEFORE THE FUSE

BLEW.

B.1 1. REMOVE FUSE DRAWER.

DISCONNECT LX-150 FROM POWER SOURCE. REMOVE POWER CORD

FROM UNIT POWER CORD RECEPTACLE. INSERT THE FLAT BLADE

OF A SMALL SCREWDRIVER ( 1/8") INTO SLOT ON EITHER SIDE

OF FUSE DRAWER. UN-LATCH EACH SIDE OF THE FUSE DRAWER

AND REMOVE.

B.1 2. REMOVE FUSES FROM FUSE DRAWER.

PULL BOTH FUSES FROM FUSE DRAWER AND INSPECT. COMPARE

RATING ON END CAP TO CORRECT REPLACEMENT PART RATING.

FUSES CAN BE CHECKED VISUALLY. A BLOWN FUSE WILL HAVE

INFINITE RESISTANCE. ON DIGITAL V.O.M.'S SUCH AS BECKMAN

METERS, THE SYMBOL "OL" ( OPEN LEADS ) INDICATES AN

OPEN CIRCUIT, IN THIS CASE, A BLOWN FUSE.

B.1 3. INSTALL NEW FUSES IN FUSE DRAWER.

REPLACE FUSES IN MATCHED PAIRS EVEN WHEN ONE APPEARS TO

BE GOOD. ALIGN THE TAB ON THE BOTTOM OF THE FUSE DRAWER

WITH THE SLOT IN THE POWER CORD RECEPTACLE.

PRESS FUSE DRAWER INTO HOUSING.

B.1 4. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND PERFORM FULL FUNCTION

TEST.

T E C H N I C I A N N O T E S:

___________________________________________________________________

___________________________________________________________________

6

Page 12

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

B.2 OLDER UNITS ... INTERNAL FUSES ( TWO ) R & R. SEE TABLE IN

PARTS CATALOG FOR CORRESPONDING PART NUMBERS.

CAUTION: FOR UNITS RETURNED FOR SERVICE BECAUSE OF BLOWN FUSES,

OR RE-OCCURRING FUSE BLOWING, CHECK FOR SHORT TO GROUND

OR OTHER HIGH CURRENT DRAW CAUSE ( LINE TO LINE SHORT.)

INSPECT WIRING AND COMPONENTS FOR BURN AND SMOKE MARKS,

AND DAMAGED INSULATION. REPLACE FAULTY COMPONENTS AND

RESTORE CIRCUIT TO SPECIFICATIONS BEFORE ENERGIZING UNIT.

REPLACE FUSES AND OPERATE UNIT.

LOOK FOR:

1. THE FAILURE OR DEFECT WHICH CAUSED THE FUSE TO

BLOW.

2. THE CAUSE OF THE FAILURE.

3. OTHER DAMAGE THAT MAY HAVE BEEN DONE BEFORE THE FUSE

BLEW.

B.2 1. REMOVE UNIT COVER ( ON ALL UNITS ).

DISCONNECT LX-150 FROM POWER SOURCE. UNCOUPLE AIR INPUT

HOSE AND UNCLIP WATER BOTTLE AND BRACKET FROM THE SIDE OF

THE UNIT. REMOVE EIGHT ( 8 ) PHILLIPS HEAD SCREWS FROM

THE SIDES OF THE UNIT. REMOVE ONE ( 1 ) PHILLIPS HEAD

SCREW WITH ITS STAR WASHER ( FOR ELECTRICAL GROUNDING OF

THE ENTIRE CASE ) FROM THE BACK OF THE UNIT.

B.2 2. REMOVE FUSES FROM FUSE BLOCK.

PULL BOTH FUSES FROM FUSE BLOCK AND INSPECT. COMPARE

RATING ON END CAP TO CORRECT REPLACEMENT PART RATING.

FUSES CAN BE CHECKED VISUALLY. A BLOWN FUSE WILL HAVE

INFINITE RESISTANCE. ON DIGITAL V.O.M.'S SUCH AS BECKMAN

METERS, THE SYMBOL "OL" ( OPEN LEADS ) INDICATES AN

OPEN CIRCUIT, IN THIS CASE, A BLOWN FUSE.

B.2 3. INSTALL NEW FUSES IN FUSE BLOCK.

SECURELY INSERT A PAIR OF REPLACEMENT FUSES INTO THE

RECEPTACLES IN THE FUSE BLOCK.

B.2 4. INSTALL COVER ON UNIT. (LOCKTITE IS NOT USED ON SCREWS)

CAREFULLY SLIDE THE COVER OVER CHASSIS. ALIGN HOLES IN

COVER WITH SCREW HOLES IN CHASSIS. REPLACE EIGHT ( 8 )

PHILLIPS HEAD SCREWS ON THE SIDES OF THE UNIT. REPLACE

ONE ( 1 ) PHILLIPS HEAD SCREW AND STAR WASHER ON THE

BACK OF THE UNIT. THE STAR WASHER ESTABLISHES ELECTRICAL

CONTINUITY BETWEEN THE GROUNDED CHASSIS AND THE COVER.

B.2 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND PERFORM FULL FUNCTION

TEST.

7

Page 13

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

C POWER CORD ( for Pre 1991 units with permanently attached

cords ) R & R

C 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

C 2. REMOVE OLD POWER CORD.

UNSCREW GROUND WIRE FROM CHASSIS. REMOVE GROUND WIRE

SCREW AND STAR WASHER. ( STAR WASHER IS REQUIRED TO

CREATE CONTINUITY BETWEEN RING TERMINAL AND CHASSIS. SAVE

THIS WASHER FOR INSTALLATION BETWEEN RING TERMINAL AND

CHASSIS WHEN REASSEMBLING UNIT. )

DISCONNECT POWER CORD CONNECTORS FROM THE FUSE BLOCK.

REMOVE STRAIN RELIEF AND PULL OLD CORD OUT OF CHASSIS.

DISCARD OLD CORD AND STRAIN RELIEF.

C 3. INSTALL NEW POWER CORD.

ATTACH STRAIN RELIEF TO CORD AND PASS THROUGH THE HOLE IN

THE CHASSIS. ORIENT THE GROUND WIRE TOWARDS THE GROUND

SCREW HOLE. ATTACH THE GROUND RING TERMINAL TO THE

CHASSIS USING THE EXISTING SCREW WITH THE STAR WASHER

BETWEEN THE RING TERMINAL AND THE CHASSIS. TIGHTEN GROUND

SCREW. SEE ASSEMBLY DRAWING. CONNECT WHITE WIRE SPADE

CONNECTOR ( NEUTRAL WIRE ) TO THE FUSE BLOCK TERMINAL

THAT MATCHES THE BLUE WIRE. CONNECT BLACK WIRE SPADE

CONNECTOR ( LINE WIRE ) TO THE FUSE BLOCK TERMINAL THAT

MATCHES THE BROWN WIRE.

C 4. INSTALL COVER ON UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

C 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND PERFORM GROUND

CONTINUITY TEST AND ALL OTHER TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

8

Page 14

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

D POWER CORD RECEPTACLE ( for POST 1991 units with detachable

power cords ) R & R

D 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

D 2. REMOVE OLD POWER RECEPTACLE.

DISCONNECT THREE WIRES FROM THE TERMINALS ON THE BACK OF

THE POWER RECEPTACLE. DEPRESS SIDE LATCHES ON THE

RECEPTACLE TO ALLOW IT TO COME OUT OF THE CHASSIS CUTOUT.

DISCARD OLD POWER RECEPTACLE WITH CONTAINED FUSE TRAY AND

FUSES.

D 3. INSTALL NEW POWER RECEPTACLE.

ALIGN REPLACEMENT POWER RECEPTACLE WITH THE GROUND

( CENTER ) TERMINAL AT THE BOTTOM OF THE HOLE IN THE

CHASSIS. PRESS RECEPTACLE INTO CHASSIS CUTOUT. CONNECT

WIRES PER ASSEMBLY DRAWING. WHEN VIEWED FROM INSIDE THE

CHASSIS, THE LEFT RECEPTACLE TERMINAL IS THE LINE

TERMINAL.. CONNECT THE BROWN WIRE SPADE CONNECTOR TO THE

LINE TERMINAL. THE RIGHT TERMINAL IS THE NEUTRAL

TERMINAL...CONNECT THE BLUE WIRE SPADE CONNECTOR TO THE

NEUTRAL TERMINAL. THE CENTER TERMINAL IS THE GROUND

TERMINAL...CONNECT THE GREEN/YELLOW GROUND WIRE TO THE

GROUND TERMINAL.

D 4. INSTALL COVER ON UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

D 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND PERFORM GROUND

CONTINUITY TEST AND ALL OTHER TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

9

Page 15

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

E POWER AND AIR SWITCHES R & R

E 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

E 2. REMOVE OLD SWITCH(S). WEAR EYE PROTECTION!

DISCONNECT SPADE CONNECTORS FROM THE SWITCH TERMINALS.

CUT OFF THREE SPRING CLIP RETAINERS ON THE BACK CORNERS

OF THE SWITCH BODY TO ALLOW IT TO COME OUT OF THE CHASSIS

CUTOUT. ( TO CUT OFF CLIP RETAINERS ON THE SWITCH, PLACE

FLUSH CUTTING DIAGONAL CUTTERS ON THE CORNER OF THE

SWITCH AND CUT OFF THE CORNER WHERE THE SPRING CLIP IS

MOLDED TO THE BODY OF THE SWITCH. IT IS NECESSARY TO CUT

OFF AT LEAST THREE SPRING CLIPS TO EASE REMOVAL OF THE

SWITCH. ) DISCARD OLD SWITCH(S).

E 3. INSTALL NEW SWITCH.

ALIGN REPLACEMENT SWITCH WITH THE "O" SYMBOL AT THE

BOTTOM OF THE CHASSIS CUTOUT. PRESS SWITCH INTO CHASSIS

CUTOUT. CONNECT WIRES PER ASSEMBLY DRAWING.

E 4. INSTALL COVER OF UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

E 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND OPERATE SWITCHES.

PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

10

Page 16

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

F FAN ASSEMBLY R & R

A FAN, WHICH WHEN ISOLATED FROM THE CIRCUIT, AND DOES NOT

FUNCTION PROPERLY WHEN A PROTECTED POWER SOURCE SUPPLIES

CORRECT VOLTAGE TO ITS WIRES, IS CONSIDERED TO BE DEFECTIVE.

F 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

F 2. DISCONNECT FAN MOTOR WIRING.

CUT W IRE TIES FROM THE PAIR OF WIRES OF THE FAN MOTOR.

DISCONNECT FAN MOTOR SPADE CONNECTORS AT TRANSFORMER FOR

NEW UNITS, AND AT TERMINAL STRIP #S 4 AND 8 FOR OLDER

UNITS SO EQUIPPED.

F 3. REMOVE FAN.

REMOVE THE THREE 5/16" NUTS AND BOLTS WHICH HOLD THE FAN

HOUSING TO THE FAN/BAFFLE ASSEMBLY. USE 5/16" OPEN END

WRENCH AND 1/4" FLAT BLADE SCREWDRIVER. PULL THE FAN

WIRES THROUGH THE FAN/BAFFLE ASSEMBLY GROMMET AND DISCARD

THE OLD FAN IF DEFECTIVE.

F 4. INSTALL REPLACEMENT FAN ASSEMBLY.

POSITION REPLACEMENT FAN IN THE FAN/BAFFLE ASSEMBLY SO

THAT THE ARROW ON THE FAN HOUSING IS POINTING AWAY FROM

THE LAMP AND THE WIRES LEAVING THE FAN HOUSING ARE

CLOSEST TO THE GROMMET IN THE FAN/BAFFLE ASSEMBLY. PASS

WIRES OF REPLACEMENT FAN UNDER THE MOUNTING BOLT AND

THROUGH GROMMET. ATTACH WIRES TO TRANSFORMER ( OR

TERMINAL STRIP IF SO EQUIPPED AT TERMINALS 4 AND 8).

APPLY LOCKTITE TO THE ENDS OF THE BOLTS. SECURE THE FAN

IN PLACE WITH THE THREE ORIGINAL EQUIPMENT 5/16" NUTS AND

BOLTS. INSTALL NEW WIRE TIES AS PER ASSEMBLY DRAWING.

F 5. INSTALL COVER ON UNIT.

PERFORM INSPECTION TO VERIFY THAT THERE ARE NO

OBSTRUCTIONS TO FAN ROTATION.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

F 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON TO OPERATE

FAN. LAMP COOLING AIR WILL BLOW FROM FAN VENTS ON THE

SIDE OF THE UNIT. PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

11

Page 17

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

G LAMP HOLDER R & R

G 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

G 2. LAYOUT FOR ACCESS HOLE DRILLING OPERATION.

AN ACCESS HOLE WILL PERMIT EASY AND QUICK REMOVAL OF ONE

OF THE TWO LAMP HOLDER FASTENERS. THE OTHER IS

EASILY ACCESSIBLE. CENTER PUNCH AND DRILL 1/4" HOLE AT

LOCATION ON FAN/BAFFLE AS SHOWN IN THE PLAN VIEW ( TOP

VIEW OF THE LX-150 LIGHT SOURCE WITH COVER REMOVED )

BELOW. USE DRILL PRESS WITH 1/4" SHEET METAL DRILL BIT.

SET DRILL DEPTH TO 1/8". PROTECT SCREW HEAD WITH SHIM

STOCK UNDER THE AREA BEING DRILLED. VACUUM AND SHAKE ALL

CHIPS OUT OF THE LX-150.

___ ______________________________

. . . top surface of fan .

. . . baffle .

. . . .

FAN .<------- 1 7/16 "-----> + <--- drill 1/4" hole

. . . ^ .

. . . . .

. . . 1/2" UP .

. . ______________________________

. . lamp

. . holder

___ _________________________________________

. air pump .

____________________

G 3. REMOVE OLD LAMP HOLDER FROM LAMP BRACKET.

UNSCREW TWO 4-40 X 3/8" NUTS AND BOLTS.

CUT THE BUTT SPLICE OUT OF THE CIRCUIT. DISCONNECT LAMP

LEADS FROM THE TRANSFORMER. ( ON OLDER UNITS, DISCONNECT

BOTH SPADE CONNECTORS FROM TERMINALS ON THE TRANSFORMER.)

CUT WIRE TIE AND PULL LAMP LEADS THROUGH THE CUT OUT IN

THE FAN BAFFLE.

G4. ATTACH REPLACEMENT LAMP HOLDER TO LAMP BRACKET.

APPLY LOCKTITE TO BOTH 4-40 X 3/8" PHILLIPS HEAD

BOLTS. INSTALL AND TIGHTEN BOTH FASTENERS TO SECURE LAMP

HOLDER TO THE LAMP BRACKET. RESTORE WIRING CONNECTIONS

PER ASSEMBLY DRAWING.

G 5. INSTALL COVER OF UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

12

Page 18

G LAMP HOLDER R & R CONTINUED.....

G 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON AND CHECK FOR

LAMP OPERATION. PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

_____________________________________________________________

_________________________________________________________________

_______________________________________________________________

______________________________________________________________ _

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

13

Page 19

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

H LAMP HOLDER / HEAT SINK ASSEMBLY R & R

H 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

H 2. REMOVE OLD ASSEMBLY FROM UNIT.

NEW UNITS :

FOLLOW INSTRUCTIONS FOR FAN REMOVAL IN SECTION F PG 11

AND REMOVE FAN FROM CHASSIS. PLACE FAN OUT OF THE WAY.

REMOVE THREE ALLEN SCREWS FROM THE BEZEL ( USE 1/16" HEX

KEY ). REMOVE LAMP HOLDER / HEAT SINK ASSEMBLY.

OLD UNITS :

FOLLOW INSTRUCTIONS FOR FAN REMOVAL IN SECTION F PG 11

AND REMOVE FAN FROM CHASSIS. PLACE FAN OUT OF THE WAY.

REMOVE THREE ALLEN SCREWS FROM THE BEZEL ( USE 1/16" HEX

KEY ).

H 3. INSTALL REPLACEMENT LAMP HOLDER / HEAT SINK ASSEMBLY.

POSITION NEW ASSEMBLY IN CHASSIS WITH THE TEFLON SPACER

IN PLA CE BETWEEN THE INSIDE SURFACE OF THE FRONT PANEL

AND THE HEAT SINK. POSITION THE SHUTTER OVER THE PEG ON

THE SHUTTER CRANK BUSHING. TURN THE BRIGHTNESS KNOB TO

CHECK OPERATION OF THE SHUTTER. ATTACH THE LAMP HOLDER

HEAT SINK ASSEMBLY TO THE UNIT WITH THE THREE ALLEN KEYS.

USE 1/16" HEX KEY.

H 4. RESTORE ELECTRICAL CONNECTIONS.

NEW UNITS:

SLIDE A PIECE OF HEAT SHRINK OVER THE WIRES YOU ARE ABOUT

TO CONNECT WITH A BUTT CONNECTOR.

CONNECT LAMP HOLDER WIRE TO WIRE COMING FROM THERMAL

PROTECTOR USING BUTT SPLICE CONNECTOR AS SHOWN IN

ASSEMBLY DRAWING. COVER BUTT CONNECTOR WITH HEAT SHRINK.

ATTACH OTHER LEAD TO TRANSFORMER USING SPADE CONNECTOR AS

SHOWN IN ASSEMBLY DRAWING. INSTALL FAN PER SECT F PG 11.

OLD UNITS:

CONNECT SPADE CONNECTORS TO TRANSFORMER TERMINALS PER

ASSEMBLY DRAWING. INSTALL FAN PER SECT F PG 11.

H 5. INSTALL COVER OF UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

H 6. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON AND CHECK FOR

LAMP OPERATION. PERFORM ALL TESTS.

14

Page 20

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

I AIR PUMP PN451531 R & R.

I 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

I 2. REMOVE OLD AIR PUMP FROM BAFFLE.

STAND THE LX-150 ON ITS BACK TO FACILITATE PUMP REMOVAL.

THE FAN MUST BE UNFASTENED AND MOVED OUT OF THE WAY TO

REMOVE TWO OF THE AIR PUMP SCREWS. FOLLOW INSTRUCTIONS

FOR FAN REMOVAL IN SECTION F PG 11 BUT DO NOT CUT OR

DISCONNECT FAN WIRES. MOVE FAN ENOUGH TO GAIN ACCESS TO

TWO PUMP FASTENERS. CUT WIRE TIES HOLDING THE PUMP WIRES

IN PLACE. REMOVE THE FOUR PUMP MOUNTING NUTS ( 4-40 HEX

NUT ). USE 1/4" OPEN END WRENCH TO LOOSEN THEM. THEN

SPIN THEM OFF WITH A FINGER. WHEN ALL FOUR NUTS ARE

REMOVED, THE PUMP WILL FALL AWAY FROM THE BAFFLE.

DISCONNECT THE AIR LINE FROM THE PANEL MOUNT CONNECTOR.

REMOVE PUMP FROM LX-150.

I 3. INSTALL REPLACEMENT AIR PUMP* / BAFFLE ASSEMBLY.

*NOTE: THE ENOMOTO MODEL MV-610 IS AN ELECTROMAGNETIC VIBRATOR

PUMP. IT IS NOT REPAIRABLE. IT CONTAINS 2 SEPARATE BELLOWS PUMPS

WHICH ARE EACH DRIVEN BY THEIR RESPECTIVE PERMANENT MAGNET

ARMATURES. ELECTROMAGNETISM ALTERNATELY PULLS THE ARMATURE

PERMANENT MAGNETS BETWEEN THE TWO ELECTROMAGNET POLES AT LINE

VOLTAGE FREQUENCY (CPS). THE VIBRATING ARMATURES COMPRESS THE TWO

FLEXIBLE BELLOWS. EACH BELLOWS HAS AN INTAKE AND AN EXHAUST PORT.

AIR IS ADMITTED TO THE BELLOWS THROUGH AN INTAKE CHECK VALVE. AIR

LEAVES THROUGH THE EXHAUST CHECK VALVE. SEE FIG. I-1. THE OUTPUT

( EXHAUST ) OF THE FIRST BELLOWS IS FED INTO THE INTAKE OF THE

SECOND BELLOWS VIA A SHORT CONNECTOR TUBE. THE OUTPUT OF THE

SECOND BELLOWS IS FED TO THE PANEL MOUNT CONNECTOR. THE ENOMOTO

MV-610 PUMP GENERATES BETWEEN 258 AND 361.2 mmHG ( 6.6 PSIG ) AT A

FLOW RATE OF 7.2 L/MIN.. THE EXTERNAL LOOP OF TUBING CONNECTS THE

TWO BELLOWS AND MUST BE SECURELY CONNECTED TO THE CORRECT PORTS AS

SHOWN IN FIG. I-1. IF THE CONNECTOR TUBING IS LOOSE, MISSING, OR

ON THE WRONG NIPPLE, THE PUMP WILL NOT MEET SPECIFICATIONS.

CRIMP ON SPADE CONNECTORS IF PUMP DOES NOT HAVE THEM.

CHECK THE ROUTING OF ALL PUMP CONNECTOR TUBING.

CONNECT THE AIR OUTPUT TUBING SECURELY BETWEEN THE MV-610

OUTPUT AND THE PANEL MOUNT CONNECTOR. TUBES MUST BE FREE

OF CUTS, SHARP BENDS OR 'KINKS'. POSITION NEW PUMP ON

BAFFLE WITH THE WIRE LEADS ON TOP AND THE PUMP OUTPUT

TUBE ON THE BOTTOM. INSTALL ALL ORIGINAL VIBRATION

ISOLATION GROMMETS AND PLASTIC WASHERS. FASTEN PUMP TO

BAFFLE WITH NUTS AND BOLTS PROVIDED. ( EARLY MODELS HAVE

A "T" IN THE OUTPUT LINE TO THE PANEL MOUNT CONNECTOR.

15

Page 21

TUBING ARRANGEMENT FOR THE ENOMOTO MV-610 PUMP

CONTAINED IN THE LX-150 LIGHT SOURCE

ATMOSPHERE IN >>>> X X <<<< OUTPUT OF FIRST STAGE PUMP

_____________________________________<<<POWER CORD

__________________

MV-160 LABEL

__________________

_____________________________________

FROM FIRST STAGE>>> X X <<<FINAL OUTPUT OF PUMP TO

PANEL MOUNT CONNECTOR

FIGURE I - 1

Page 22

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

I AIR PUMP PN451531 R & R CONTINUED.....

THE PURPOSE OF THE "T" WAS TO PROVIDE A BLEED-OFF ORIFICE

TO LIMIT PUMP OUTPUT PRESSURE IF THAT PARTICULAR PUMP HAD

TOO MUCH OUTPUT PRESSURE. THE "T" WAS PLUGGED OFF IF THE

PUMP WAS ALREADY AT THE REQUIRED PRESSURE LIMIT.

THEREFORE DO NOT REMOVE THE "T" IF THE LX-150 EARLY MODEL

IS SO EQUIPPED.)

I 4. RESTORE ELECTRICAL CONNECTIONS.

(THE ELECTRICAL CONNECTIONS DIFFER SLIGHTLY BETWEEN OLDER

AND NEWER MODELS IN THAT ONE PUMP LEAD IS CONNECTED TO A

TERMINAL STRIP ON OLDER MODELS. PUMP LEAD ON NEWER

MODELS IS CONNECTED DIRECTLY TO THE TRANSFORMER VIA A

SPADE CONNECTOR.)

NEW UNITS:

CONNECT LEADS TO TRANSFORMER AND AIR SWITCH USING SPADE

CONNECTORS AS SHOWN IN ASSEMBLY DRAWING. INSTALL FAN PER

SECT F PG 11.

OLD UNITS:

CONNECT ONE PUMP LEAD SPADE CONNECTOR TO AIR SWITCH AND

THE OTHER LEAD TO THE TERMINAL STRIP PER ASSEMBLY

DRAWING. INSTALL FAN PER SECT F PG 11.

I 5. INSTALL COVER ON UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

I 6. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON AND CHECK FOR

CORRECT PUMP OPERATION. PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

16

Page 23

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

J TRANSFORMER R & R.

J 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

J 2. REMOVE OLD TRANSFORMER FROM UNIT.

REMOVE WIRE CONNECTORS FROM TRANSFORMER. REMOVE HOLD

DOWN FASTENERS ( TWO PHILLIPS SCREWS FOR NEW UNITS AND

TWO 1/4" HEX HEAD SCREWS AND TWO PHILLIPS HEAD SCREWS

FOR OLD UNITS ). REMOVE TRANSFORMER FROM CHASSIS.

J 3. INSTALL REPLACEMENT TRANSFORMER.

CHECK INTEGRITY OF JUMPER WIRES ON NEWER STYLE UNIT

TRANSFORMERS BY PULLING LIGHTLY ON JUMPERS WITH PLIERS.

BE CAREFUL THAT YOU DO NOT CUT INSULATION. REJECT ANY

TRANSFORMERS WITH LOOSE OR BROKEN SOLDER JOINTS.

NEWER STYLE:

POSITION TRANSFORMER WITH TERMINALS TOWARDS REAR OF UNIT.

PLACE TRANSFORMER FEET UNDER RAISED PUNCH OUT ON CHASSIS

AND SECURE OTHER TWO FEET WITH SCREWS.

OLDER STYLE:

POSITION TRANSFORMER WITH TERMINALS TOWARDS REAR OF UNIT.

PLACE TRANSFORMER FEET OVER THREADED HOLES IN CHASSIS AND

SECURE WITH TWO 1/4" HEX HEAD SCREWS AT THE REAR OF THE

TRANSFORMER AND TWO PHILLIPS HEAD SCREWS AT THE FRONT

FEET OF THE TRANSFORMER.

J 4. RESTORE ELECTRICAL CONNECTIONS.

CONNECT WIRING SPADE CONNECTORS TO TRANSFORMER

TERMINALS AS SHOWN IN ASSEMBLY DRAWING.

J 5. INSTALL COVER OF UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

J 6. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON AND CHECK FOR

OPERATION OF ALL COMPONENTS. PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

17

Page 24

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

K INTERLOCK SWITCH R & R.

NOTE: INTERLOCK SWITCH PN451562 MUST HAVE WIRING CONNECTED TO

THE NORMALLY OPEN CONTACTS (COMMON TERMINAL ON TOP OF

THE SWITCH AND TERMINAL LABELED #2). THIS WIRING

ARRANGEMENT WILL ENSURE THAT THE SWITCH WILL BE CLOSED

WHEN THE LAMP ACCESS DOOR IS SHUT AND THAT THE SWITCH

WILL "OPEN" WHEN THE DOOR IS OPENED. DO NOT USE CENTER

TERMINAL OF INTERLOCK SWITCH.

K 1. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

K 2. REMOVE OLD INTERLOCK SWITCH FROM CHASSIS.

REMOVE TWO NUTS AND BOLTS. USE OFFSET PHILLIPS

SCREWDRIVER OR PHILLIPS HEAD BIT IN RATCHET AND 1/4" OPEN

END WRENCH. WHEN THE FASTENERS HAVE BEEN REMOVED, LIFT

SWITCH UP AND AWAY FROM THE CHASSIS TO ENABLE YOU TO PULL

SPADE CONNECTORS OFF OF SWITCH TERMINALS. ( COMPARE THE

POSITION OF EACH OF THE TWO WIRES WITH RESPECT TO WHAT

THE ASSEMBLY DRAWING SHOWS. THERE SHOULD BE NO

DISCREPANCY. ) IF OLD INSULATOR REMAINS IN PLACE, DO NOT

REMOVE IT.

K 3. INSTALL REPLACEMENT INTERLOCK SWITCH.

CONNECT SPADE CONNECTORS TO REPLACEMENT SWITCH AS PER

ASSEMBLY DRAWING. FASTEN REPLACEMENT SWITCH TO CHASSIS

SO THAT THE INSULATOR IS BETWEEN THE SWITCH AND THE METAL

CHASSIS. UTILIZE THE ORIGINAL FASTENERS AND LOCKTITE.

OPEN AND CLOSE LAMP ACCESS DOOR TO VERIFY THAT THE

ACTUATING PIN ON THE DOOR CONTACTS THE ACTUATING ARM OF

THE SWITCH. INSTALL NEW WIRE TIES IF ANY HAVE BEEN

REMOVED DURING DISASSEMBLY.

K 4. INSTALL COVER ON UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

K 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON AND CHECK FOR

OPERATION OF INTERLOCK SWITCH. PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

18

Page 25

CAUTION: DISCONNECT LX-150 FROM POWER SOURCE BEFORE SERVICING.

L SHUTTER ADJUSTMENT.

L 1. INSPECT BRIGHTNESS CONTROL FUNCTION.

GRASP BRIGHTNESS KNOB AND MOVE IN ALL DIRECTIONS TO

DETECT LOOSENESS. TIGHTEN KNOB SET SCREW IF LOOSE.

USE A 1/8" FLAT BLADE SCREWDRIVER. IF SHAFT IS ROTATES

AND THE SHUTTER DOES NOT OPERATE, THEN A BROKEN BUSHING

PN451549 OR LOOSE SHUTTER CRANK MAY BE THE PROBLEM. TO

INSPECT THESE TWO COMPONENTS, THE COVER MUST BE REMOVED.

L 2. REMOVE COVER.

DISCONNECT LX-150 FROM POWER SOURCE.

FOLLOW INSTRUCTIONS IN SECT B.2-1 PG. 7 TO REMOVE COVER

FROM UNIT.

L 3. RESTORE OPERATION OF SHUTTER CAM.

IF BUSHING IS INTACT, AND CAM IS LOOSE ON SHAFT, TURN

BRIGHTNESS KNOB FULLY CLOCKWISE. THE SET SCREW IS NOW

ACCESSIBLE NEAR THE AIR SWITCH. TIGHTEN 4-40 X 1/4" SET

SCREW PN451519 IF LOOSE. USE .050" HEX KEY.

IF CUSTOMER COMPLAINT IS " KNOB RATTLES", INSTALL SPRING

WASHER PN106142-1 UNDERNEATH THE SHUTTER CRANK.

REPLACE BUSHING IF BROKEN OR MISSING. REMOVE PIECES

OF BROKEN BUSHING FROM CHASSIS BOTTOM.

MAKE SURE THAT THE BUSHING IS ON THE TOP OF ITS ARC OF

MOVEMENT WHEN THE KNOB POINTS UP.

L 4. INSTALL COVER ON UNIT.

FOLLOW INSTRUCTIONS IN SECTION B.2-4 PG 7 TO ATTACH THE

COVER TO THE LX-150.

L 5. TEST TO VERIFY SAFE OPERATION.

CONNECT LX-150 TO POWER SOURCE AND TURN ON AND CHECK FOR

OPERATION OF SHUTTER. PERFORM ALL TESTS.

T E C H N I C I A N N O T E S :

_________________________________________________________________

_________________________________________________________________

19

Page 26

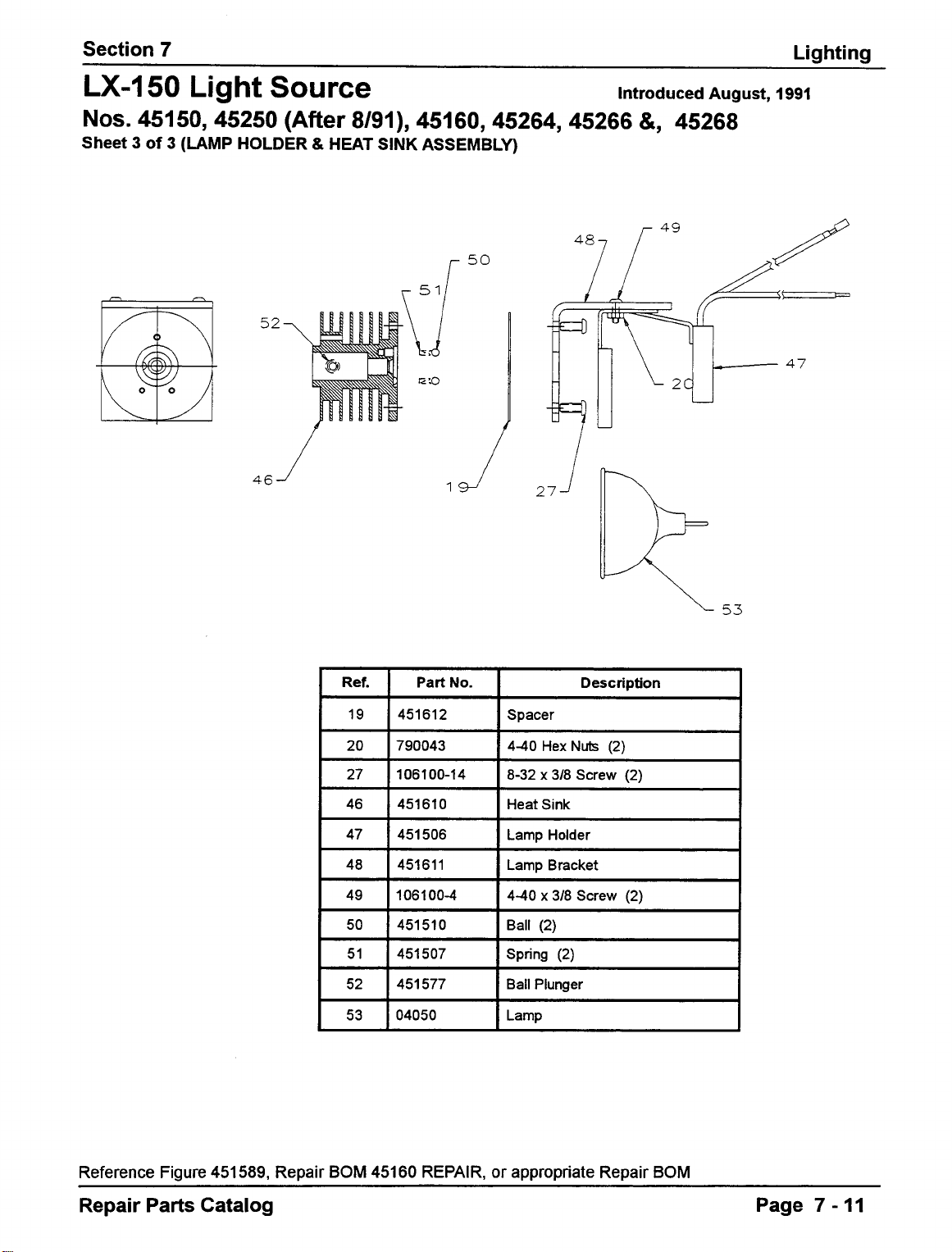

APPENDIX AA

LX-150 WITH PARTS LEGEND

(DRAWINGS 451589 THREE SHEETS)

Page 27

Page 28

Page 29

Page 30

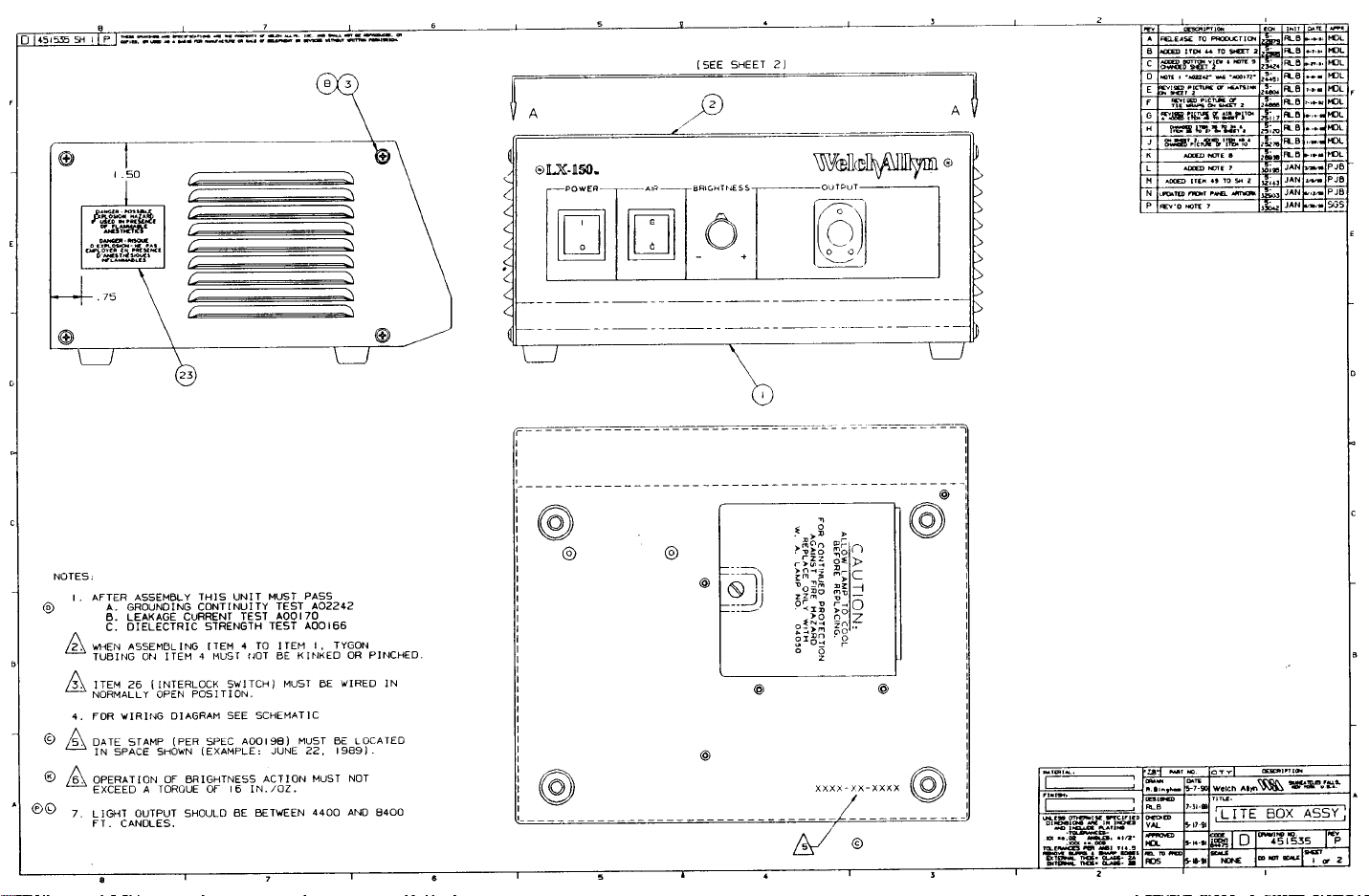

APPENDIX BB

WIRING DIAGRAM/SCHEMATIC LX-150

CIRCUIT CONNECTIONS/ SCHEMATICS SHOWN ON DRAWINGS:

DOMESTIC.......... 451535 AND 451536

INTERNATIONAL..... 451601 AND 451605

Page 31

Page 32

Page 33

Page 34

APPENDIX CC

REPAIR VERIFICATION TEST PROCEDURES

NOTE: This product is designed and manufactured to strict

specifications and safety regulations for medical products,

and should be serviced only by Welch Allyn trained

technicians.

Perform the following test procedures after repairs have been made

and prior to returning the LX-150 to the customer:

SEE A02353 FOR COMPLETE PROCEDURE WHICH INCLUDES THE FOLLOWING:

DIELECTRIC STRENGTH TEST (HIPOT) A00166

GROUNDING CONTINUITY TEST A00172

LEAKAGE CURRENT TEST A00170

LIGHT OUTPUT

PUMP OUTPUT

INTERLOCK SWITCH OPERATION

SHUTTER OPERATION

FAN OPERATION

Page 35

APPENDIX DD

SET-UP AND OPERATION

SEE ATTACHED : FX-100 FLEXIBLE SIGMOIDOSCOPE AND LX-150 LIGHT

SOURCE OPERATING INSTRUCTIONS PN339001

LX-150 LIGHT SOURCE OPERATING INSTRUCTIONS:

DOMESTIC........................ PN451502

INTERNATIONAL................... PN451602

Page 36

APPENDIX EE

The following items or their equivalent are required for the

complete repair and testing of the LX-150 Light Source:

COMMON TOOLS:

Item: Description: Catalog #:

1. Screwdrivers: Crescent #2502 Phillips #2

2. Screwdrivers: Offset Phillips #1 , #2

3. Screwdrivers: Flat blade: 1/4", 1/8",1/16"

4. Screwdrivers: Offset flat blade

5. Nut drivers:5/16", 1/2"

6. Combination wrenches: 5/16",1/4",1/2",5/8"

7. Pliers, long nose: Xcelite 51CG * cat. #51CG

8. Pliers, crimping: Klein 1005 ** cat. #1005

9. Wire cutter: Xcelite 107CG * cat. #107CG

10. Wire stripper: Xcelite 105SCG * cat. #105SCG

11. Hex keys 1/16" & .050" ** set cat. #BLX12

12. Volt-Ohm Meter ( with input impedance

above 1 megohm )BECKMAN 330*** cat. #330

13. Alligator test leads kit*** cat.#TL246A

14. Soldering iron:80W Ungar 3180 *** cat. #3180

15. Heat shrink heat gun.

TOOLS VENDORS:

* Cooper Tools, PO Box 728, Apex NC, 27502, (919)362-7510

catalog no. 55171

** Contact East Inc., 335 Willow Street, North Andover, MA

01845-5995, 1993 General Catalog, (508)682-2000

*** Marshall Catalog Co., Toll Free 1(800)522-0084

Nolan Supply, 115 Leo Ave., Syracuse, NY, (315)463-6241

TEST EQUIPMENT for 'A' Specs:

CONTACT WELCH ALLYN TECH.SERVICES FOR INFORMATION ON TEST EQUIPMENT

1. Dielectric strength tester: ASSOCIATED HY-POT, MODEL

AR404AT. Associated Research Co., 905 Carriage Park Ave.

Lake Bluff, Illinois, (312)295-3312

2. Power supply;DC output:Volts 0-10, Amps 0-10, Watts 0-100

KEPCO MSK-10-10M , Kepco Inc., 131-38 Sanford Ave.,

Flushing, NY, 11352, (718)461-7000

3. Current leakage tester circuit as described in A spec.

( Must be used in conjunction with volt meter with an

input impedance above 1 megohm: item #15 ABOVE

4. Illuminance meter: MINOLTA T-1, Item# 1519-206

Minolta Corp.,101 Williams Drive, Ramsey, NJ,

(201)825-4000

Page 37

APPENDIX FF

PRODUCT UP-DATES

FILE ALL UP-DATES IN THIS SECTION. MAKE THE APPROPRIATE CHANGES IN

THE MANUAL PERTAINING TO THESE UP-DATES.

Page 38

APPENDIX GG

PRODUCT DESCRIPTION

WELCH ALLYN LX-150 LIGHT SOURCE (domestic and international)

The LX-150 Light Source provides air, water, and light to a

fiber optic sigmoidoscope such as the FX-100. The metal housing

contains components such as transformer, fan, pump, light,

switches, power cord receptacle / fuse assembly, and circuits. A

fan cools the interior of the housing. See PN451502 instructions.

The sigmoidoscope connects to the LX-150 as follows:

1. The umbilical plug of the FX-100 connects to front panel

"OUTPUT" port on the LX-150.

2. The wa ter bottle connector "Air Input Hose" connects to the

right side panel CPC connector. This OUTPUT provides

approximately 6 P.S.I.G. to the water bottle.

3. The scope connects to the water bottle via the dual lumen

air/water line. It is color coded: White=Water,

Green=Air.

WARNING::::THE 150 WATT HALOGEN LAMP EMITS INTENSE LIGHT. DO NOT

LOOK DIRECTLY INTO THE LIGHT OUTPUT PORT LABELED "OUTPUT".

LIGHT is provided by a 150 watt halogen lamp. The operator

turns the lamp ON and the continuous "ON" cooling fan by depressing

the front panel mounted switch labeled "POWER". The operator

varies the light output by turning the front panel mounted knob

labeled "BRIGHTNESS". This knob is mechanically linked to a

continuous diaphragm. A thermal protector ( closed below 95

degrees C, 203 degrees F ) is wired in series with the lamp. It

automatically opens and thus disables the lamp when internal

temperatures rise above 95 C. The switch will close, thus enabling

lamp operation when temperatures fall below switch set point.

AIR PRESSURE is provided to the water bottle by an internal

pump. The operator turns on the pump by depressing the front panel

mounted switch labeled "AIR". Air pressure is not adjustable and

is approximately 6 P.S.I.G.. This air pressure is converted to

either air or water at the sigmoidoscope when the sigmoidoscope

operator uses the air/water button by covering it for air or

depressing it fully for water while the pump is operating.

WARNING!

FULL LINE VOLTAGE WILL BE PRESENT WITHIN THE LX-150 HOUSING WHEN

THE UNIT IS CONNECTED TO THE MAINS (EVEN IF THE LAMP DOOR IS OPEN).

REFER TO SCHEMATIC 109P371 B SIZE. THE LX-150 MUST BE UNPLUGGED

FROM POWER SOURCE B E F O R E OPENING THE LAMP ACCESS DOOR OR

PERFORMING ANY SERVICE PROCEDURES OR INSPECTIONS.

Lamps are removed and replaced through the bottom lamp access door.

UNPLUG the LX-150 before attempting to change the lamp.

A micro switch is mechanically actuated to interrupt voltage to the

transformer primary winding. If the lamp access door is open or

un-latched, a mechanically actuated micro switch 'opens' and

disables Light Source operation...HOWEVER, primary circuits ( most

of the circuits ) are still dangerous! Attempts to service a

plugged in unit are dangerous. Fuses are mounted in the modular

power cord receptacle for new units, and on an internal fuse block

for earlier models.

Loading...

Loading...