Page 1

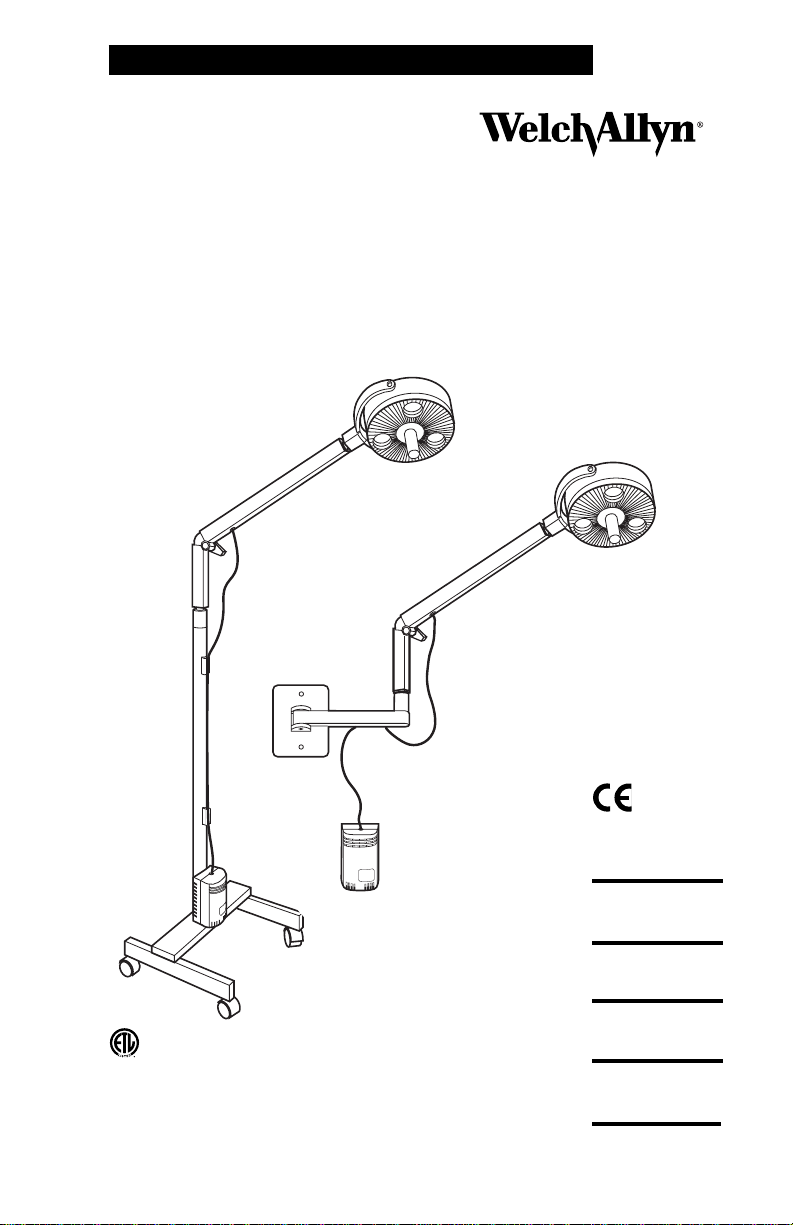

LS200™Procedure L ight

Exam/Procedure Lights

Service Manual

Lámpara para procedimientos LS200

Appareil d’éclairage articulé LS200

LS200™Untersuchungslampe

Lampada d’esame e per piccoli interventi LS200

™

™

™

Listed to: UL 544, CSA C22.2 No. 125 and IEC 601-1

Listados: UL 544, CSA C22.2 No. 125 y IEC 601-1

Agréé par: UL 544, CSA C22.2 No. 125 et IEC 601-1

Zulassung nach: UL 544 CSA C22.2 Nr. 125 und IEC 601-1

Approvazioni: UL 544, CSA C22.2 n. 125 e IEC 601-1

Owner’s Manual

English . . . . . . . . . . . .1

Manual del propietario

Español . . . . . . . . . .17

Manuel de l’utilisateur

Français . . . . . . . . . .33

Anleitungshandbuch

Deutsch . . . . . . . . . .49

Manuale dell’utente

Italiano . . . . . . . . . .65

Page 2

Page 3

Thank you for purchasing the Welch Allyn®LS200™Procedure

!!!

!1!

60cm

Light, designed by a leading worldwide manufacturer of illuminated diagnostic instrumentation. By following the use and care

guidelines given in this manual, you will be rewarded with years

of dependable, trouble-free service from your new LS200

Procedure Light. Read these instructions thoroughly before use.

WARNING

All users of this procedure light should be thoroughly trained in the

medical procedures appropriate to the equipment. Furthermore, they

should read and understand the instructions for all other equipment

used in conjunction with the LS200™ Procedure Light.

Lamps are extremely bright. DO NOT stare directly into lamps when lit.

DO NOT position luminaire in the upward direction with the lamps on.

CAUTION

Remove power cord from electrical outlet and allow lamps to cool

before replacing (replace with Welch Allyn Lamp #06400 only).

Accessible metal parts of this unit are electrically isolated from the

grounding conductor of the supply cord. If grounding of the accessible

parts is considered necessary, a separate grounding lead should be

employed.

To reduce the risk of electric shock, do not disassemble unit.

Refer servicing to qualified service personnel.

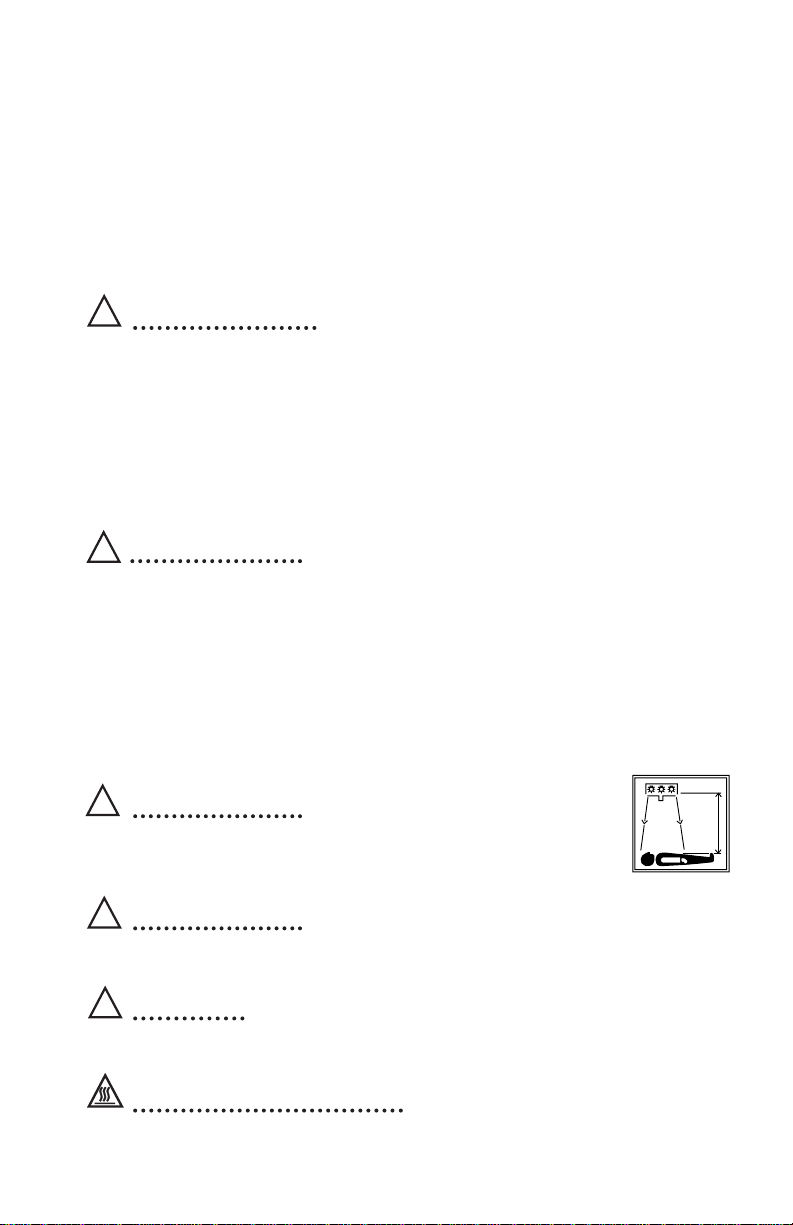

CAUTION

Operation at closer than 12" (30.5 cm) for

extended periods may result in erythema.

The designed working distance is 24" (60 cm).

CAUTION

The switch on luminaire is NOT a mains switch. Transformer energizes

when the light is plugged to mains.

DANGER

Risk of explosion if used in the presence of flammable anesthetics.

HOT SURFACE

The bezel in front of the lamps may be hot.

Page 4

TABLE OF CONTENTS

Components..............................................................3

Mounting....................................................................4

Mobile Stand Set-up ..........................................4

Wall Mount Set-up..............................................5

Mounting to Wood Stud ..............................5

Mounting to Concrete or Brick Wall............6

Transformer Mounting ........................................8

Operating Instructions ............................................8

Transport Instructions for Mobile Stand Unit......8

Arm Adjustment ..................................................9

Lamp Replacement ..................................................9

Fuse Replacement ................................................11

Cleaning ..................................................................12

Maintenance and Repair ........................................12

Warranty ..................................................................12

Electrical Specifications ........................................13

Operation Environment ..........................................14

Troubleshooting Guide..........................................15

2

Page 5

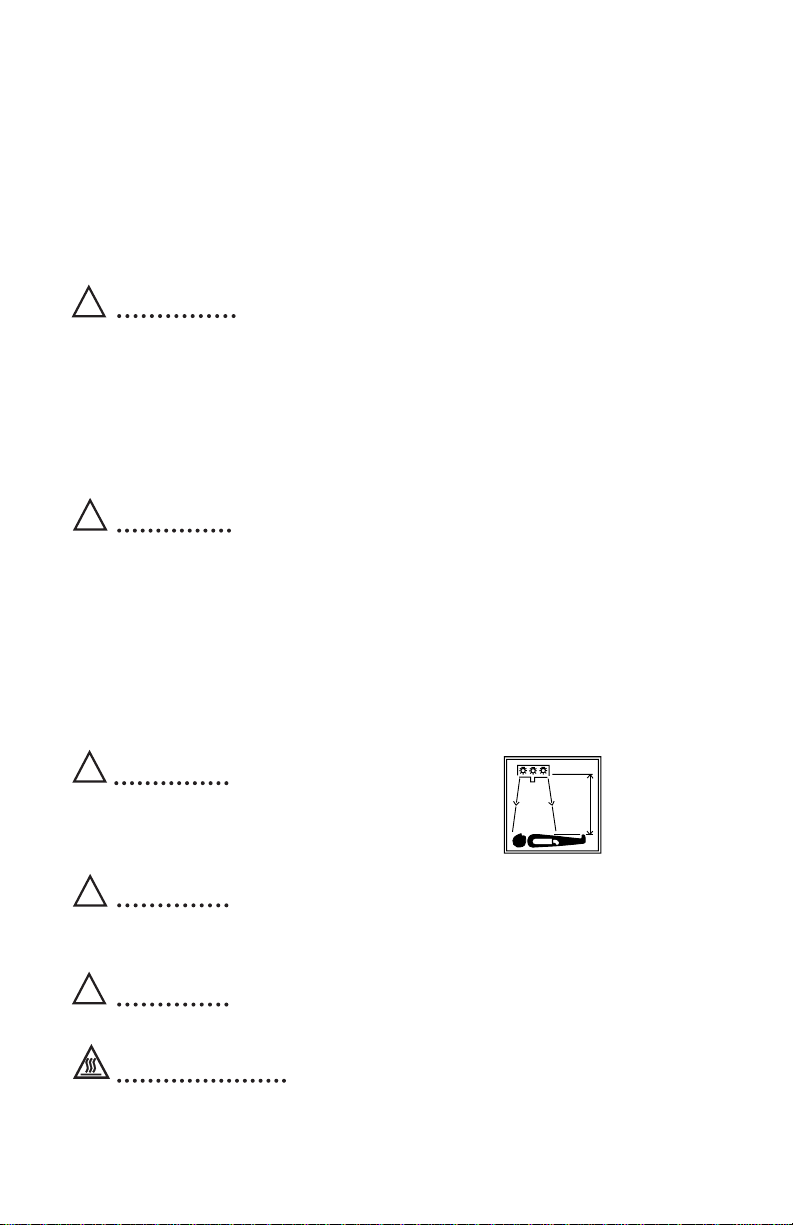

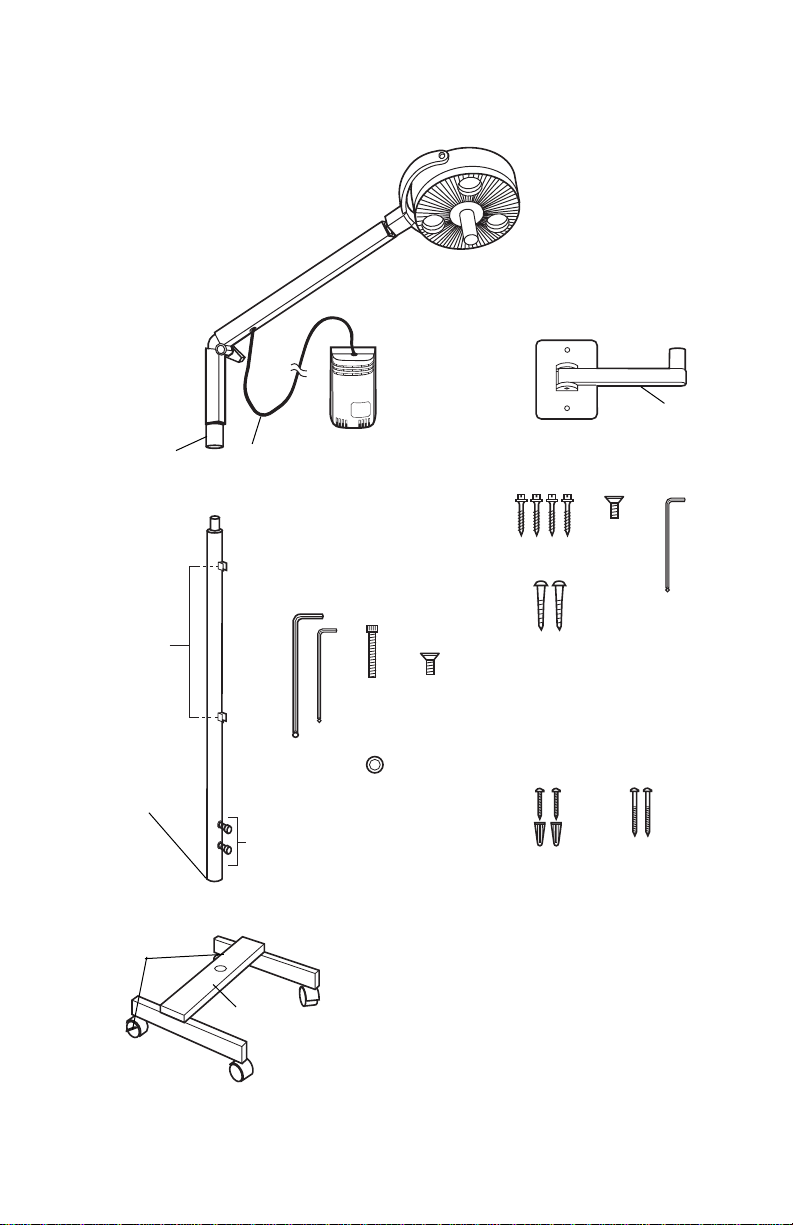

COMPONENTS

ARM/LUMINAIRE

ASSEMBLY

UNIVERSAL

CONNECTOR

(B)

POWER

CORD

(e)

TRANSFORMER

WALL MOUNT

WALL MOUNT

HARDWARE

EXTENSION

ARM (G)

POWER

CORD

CLIPS

(D)

POLE

END

(A)

MOBILE STAND

CASTER

LOCKS

MOBILE STAND

HARDWARE

ALLEN

WRENCHES

TRANSFORMER

MOUNTING

SCREWS

(C)

MOBILE

STAND BASE

CAP

HEAD

BOLT

(F)

LOCK

WASHER

(f)

FLAT

HEAD

SCREW

(b)

MASONRY

SCREWS

WOOD

SCREWS

FLAT

HEAD

SCREW

(b)

TRANSFORMER

HARDWARE

CONCRETE

SCREWS

SCREWS

WRENCH

WOOD

ALLEN

3

Page 6

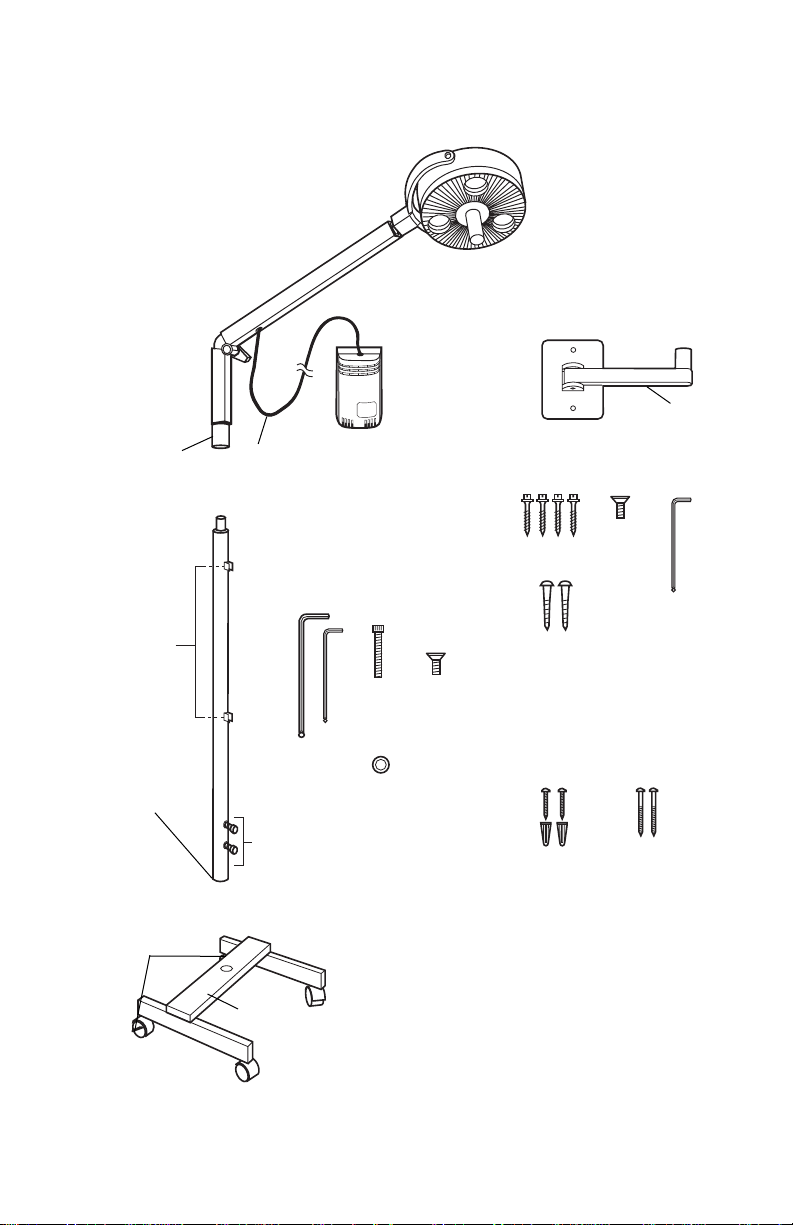

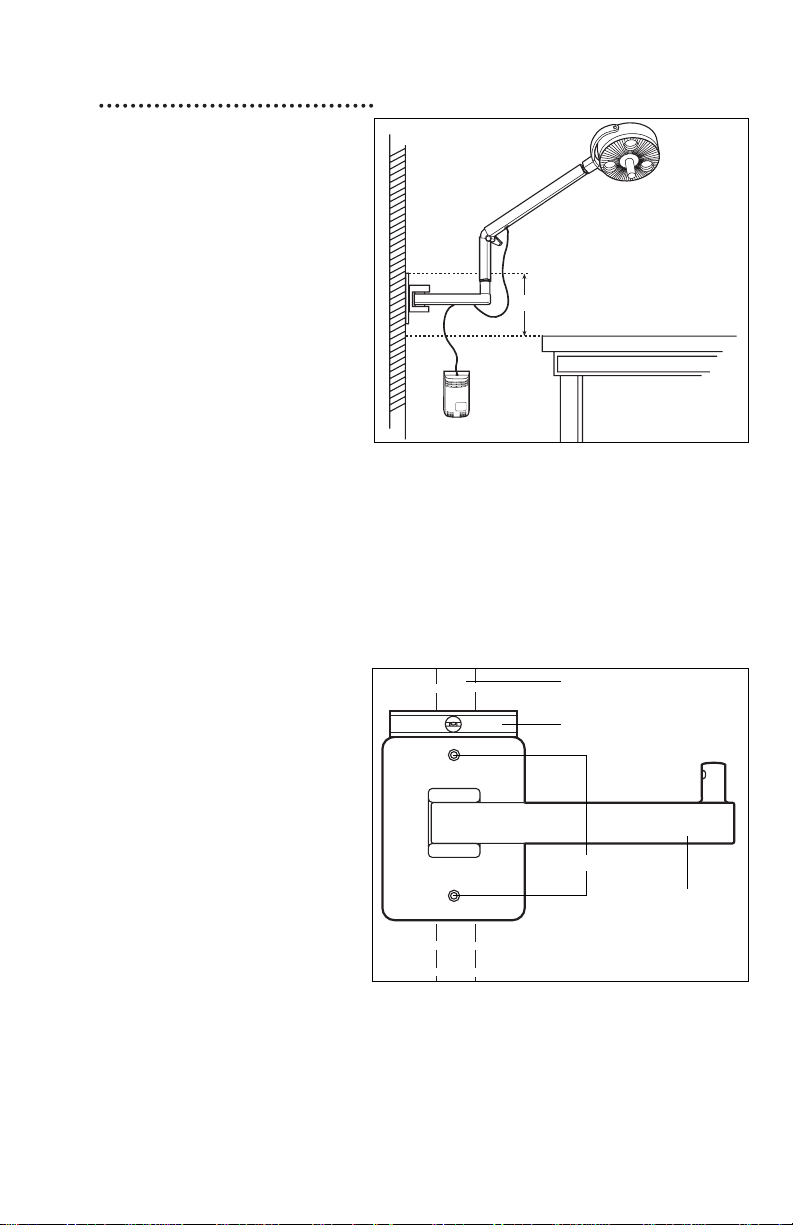

MOUNTING

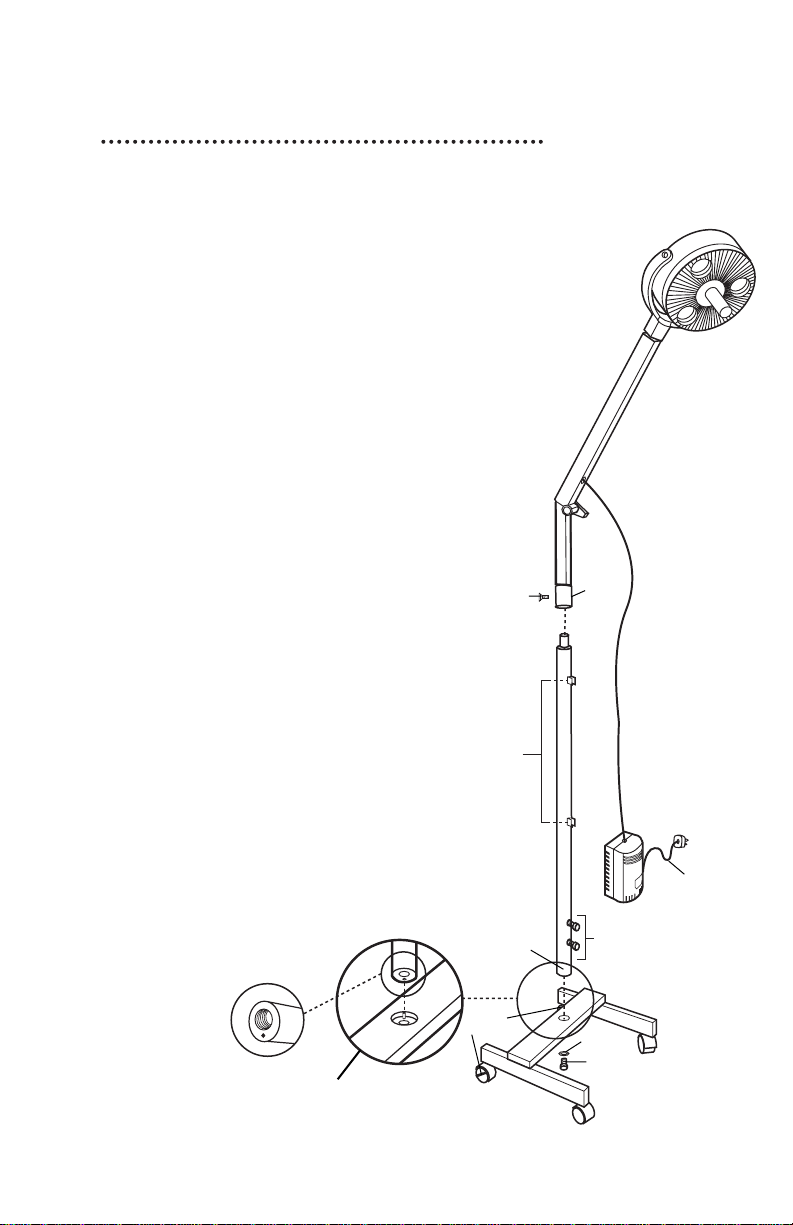

MOBILE STAND SET-UP

1. Remove stand base, pole and hardware kit from boxes.

2. Place stand base on floor with casters down

and lock casters.

3. Insert pole end (A) into hole in base of

mobile stand.

4. Rotate pole until it aligns with pin and drops

into place.

5. Insert cap-head bolt (F) with lock washer (f)

through stand cross member into pole

and tighten with 1/4" Allen wrench.

6. Carefully remove LS200 arm/luminaire

assembly from box. Hook transformer

onto the factory installed mounting screws

(C) on the pole and slide down until secure.

7. Place arm/luminaire assembly on pole by

sliding universal connector (B) onto top

end of the pole and align screw holes.

8. Insert 0.5" (13mm) flathead screw (b) into

hole on side of universal connector and

tighten with 5/32" Allen wrench.

9. Push power cord attached to transformer

into power cord clips (D) on pole,

ensuring enough slack for full range

of arm motion.

10. Attach power cord (e) to transformer.

11. To lock casters, push down on the tab

on the locking casters.

12. Before moving the LS200 Procedure Light,

refer to “Transport Instructions”

on Page 8.

(b)

(D)

(A)

(B)

(e)

(C)

ALIGN PIN IN

MOBILE STAND

WITH POLE END

CASTER

LOCKS

4

(f)

(F)

Page 7

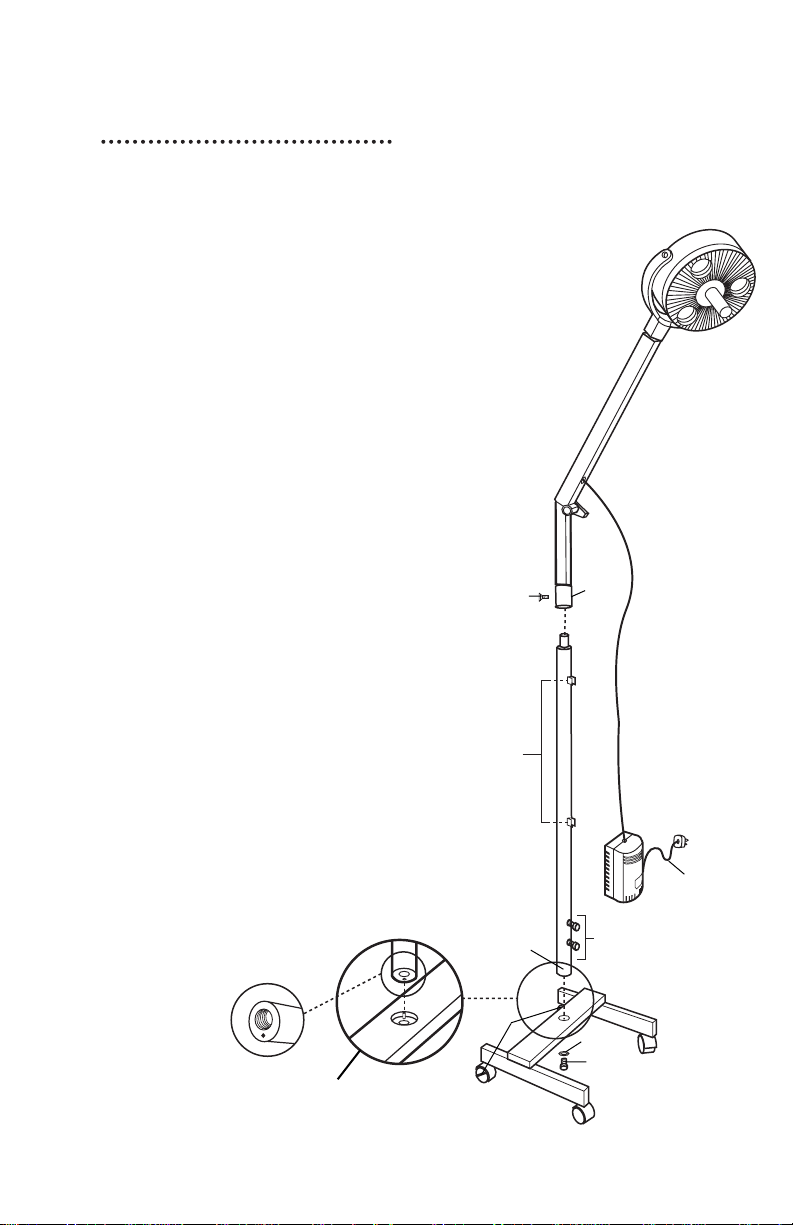

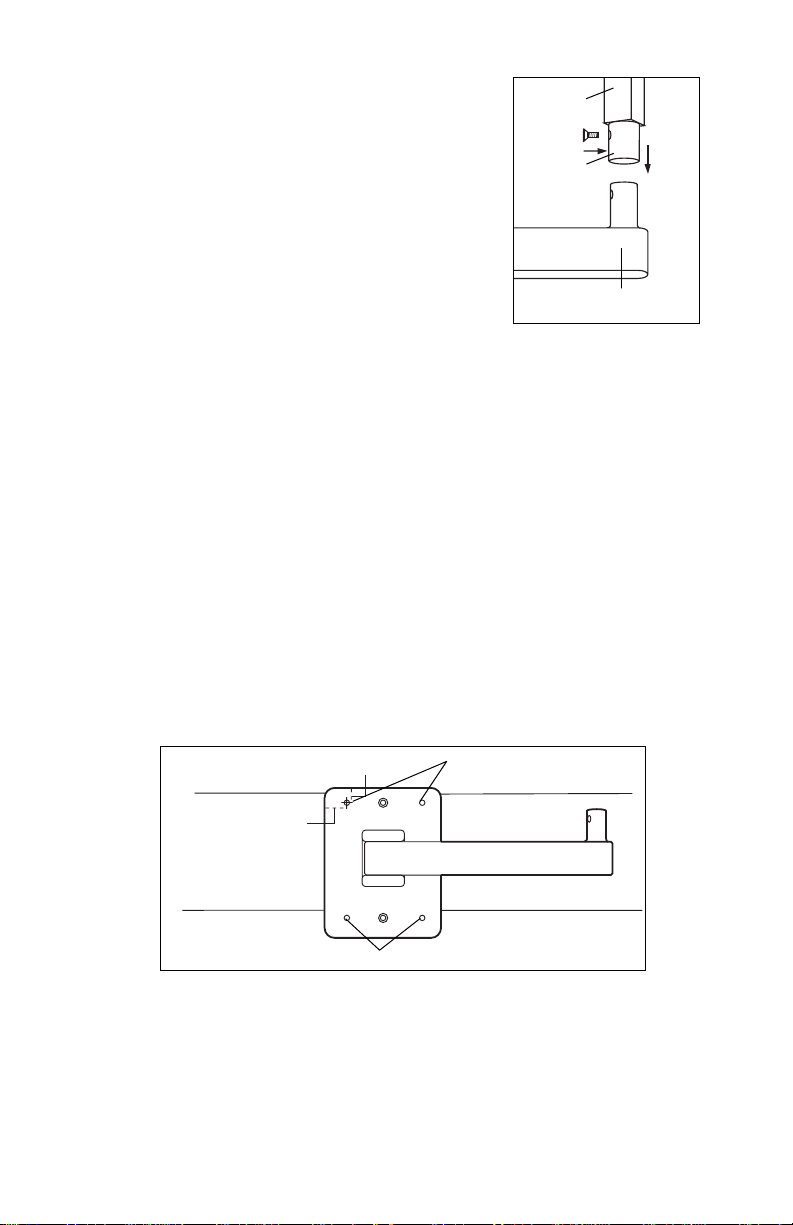

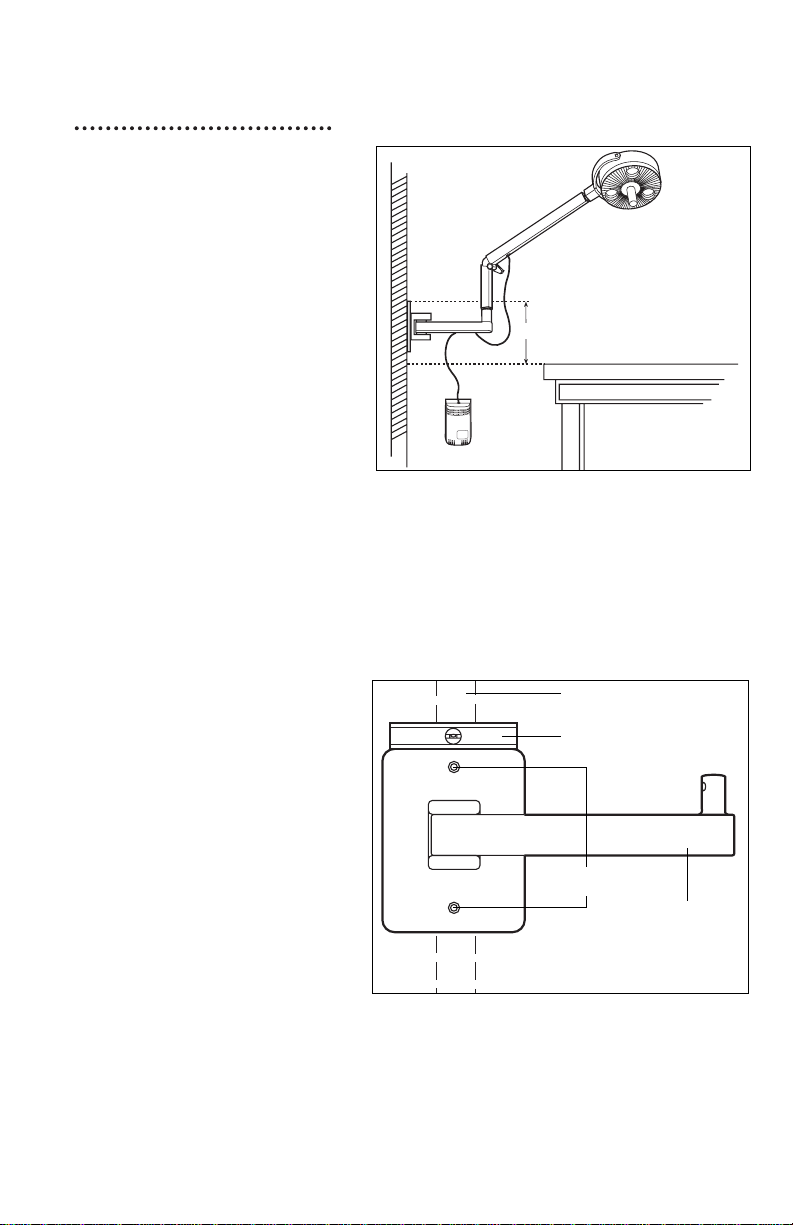

WALL MOUNT SET-UP

CAUTION: DO NOT mount

into sheetrock. Must be

mounted into stud.

The LS200 Procedure

Light arm is designed not to go

beyond 90˚ and the working

distance is 24" (60cm). To

ensure proper placement on

the wall, the top edge of the

4"

4"

wall plate should be located

4" (10cm) above the working

surface.

NOTE: Wall plate must be

leveled using a carpenter’s

level to ensure precise, drift-free movement.

Mounting to wood stud:

1. Remove wall mount assembly and hardware kit from box.

2. Select mounting location on a stud in the wall that is within 8'

(2.4m) of electrical outlet.

3. Using wall plate as a template, place on selected location on wall,

level plate and mark both holes.

4. Remove wall plate and drill pilot holes using 0.12" (3mm) drill bit.

5. Place wall plate on wall

and drive top 1.5" (3.8cm)

wood screw

wood stud

halfway

.

into

6. Align wall plate using

a level and secure at

bottom with 1.5" (3.8cm)

wood screw.

7. Tighten top wood screw.

8. Prepare for transformer

mounting by following

“Transformer Mounting”

instructions through

step 4 on page 8.

WOOD STUD

LEVEL

WOOD SCREW

EXTENSION

ARM (G)

5

Page 8

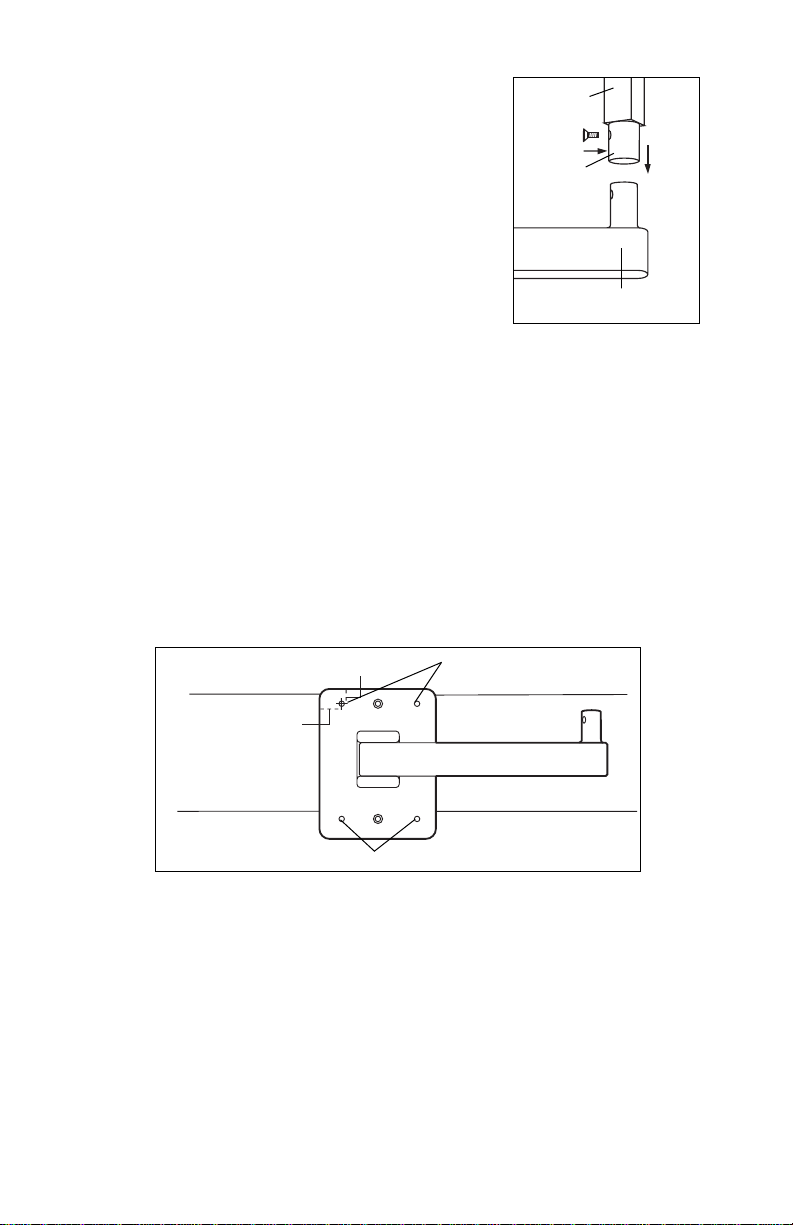

9. Carefully remove LS200 arm/luminaire

assembly from box. Complete transformer

mounting according to steps 5 and 6 of

instructions on page 8.

10. Place arm/luminaire assembly on exten-

ARM/

LUMINAIRE

ASSEMBLY

(b)

UNIVERSAL

CONNECTOR (B)

sion arm by sliding universal connector (B)

onto extension arm (G) and aligning screw

holes.

11. Insert 0.5" (13mm) flathead screw (b) into

hole on side of universal connector and

tighten. Move arm up and down to check

EXTENSION

ARM (G)

that mounting is secure.

12. Push cord into clips in underside of extension arm.

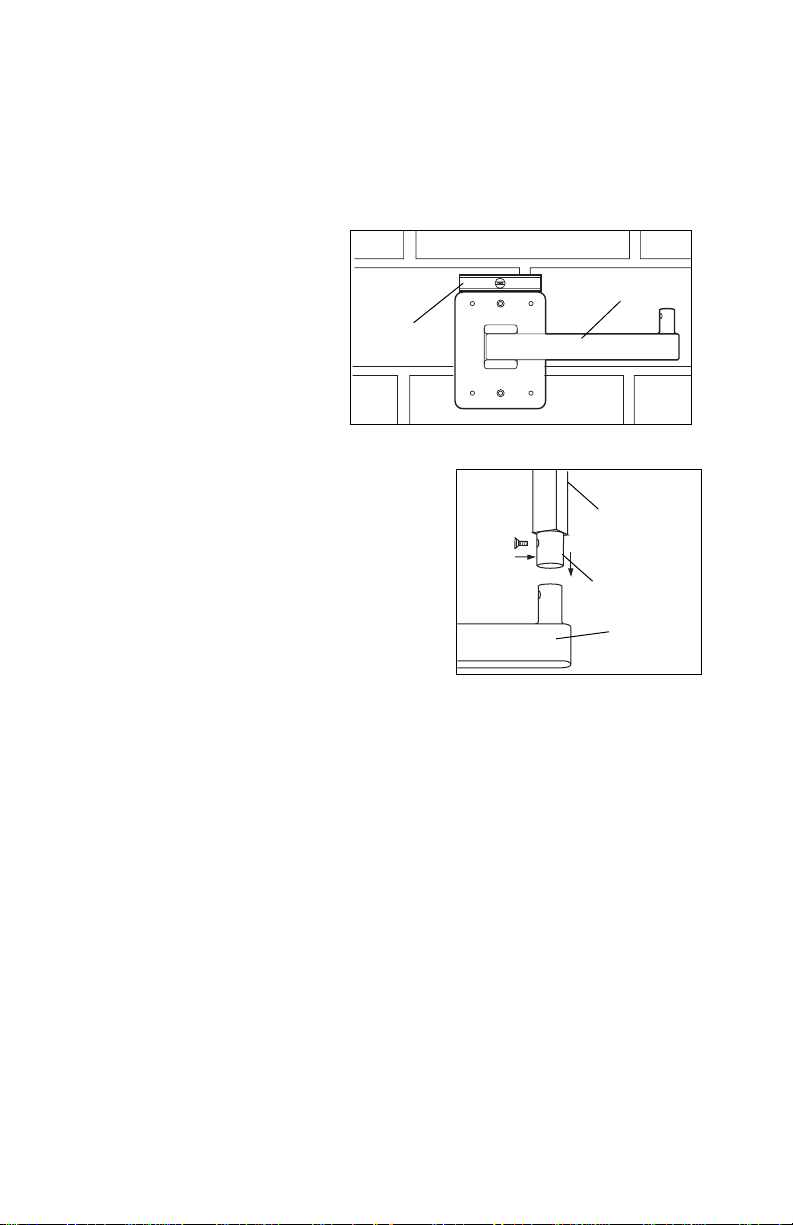

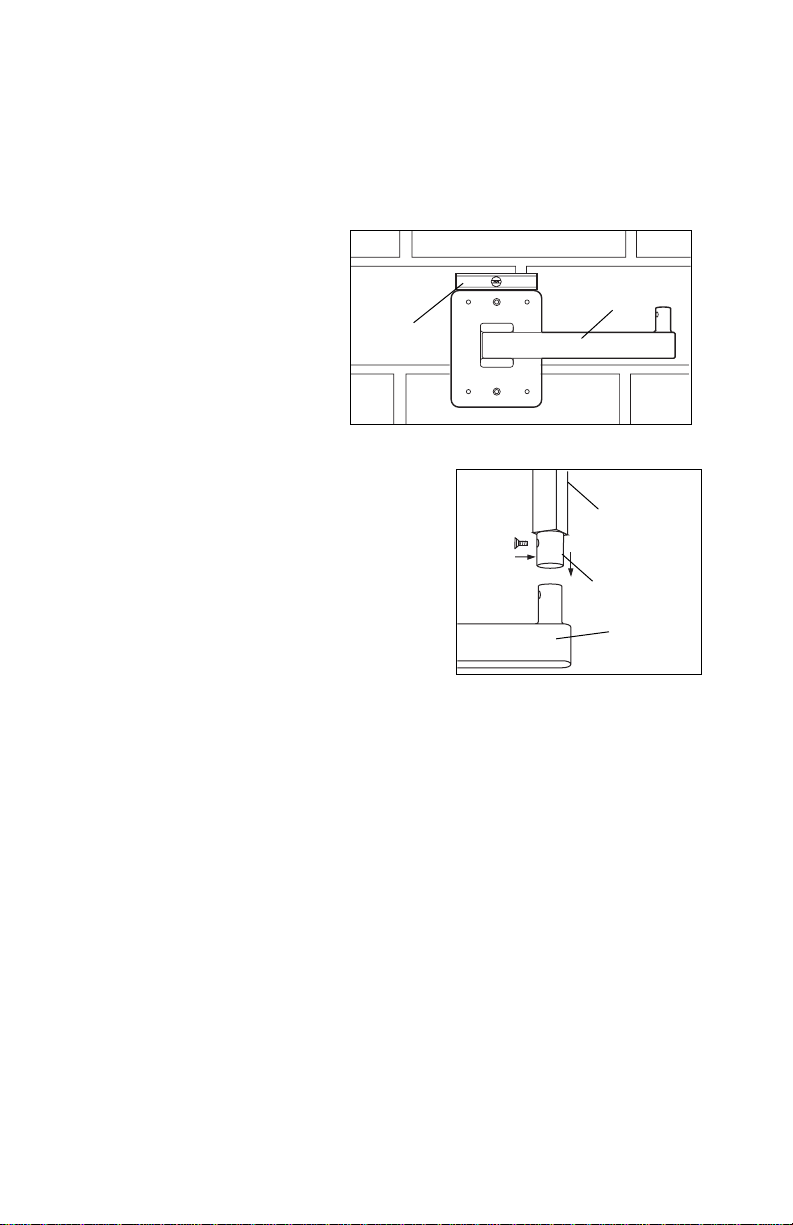

Mounting to concrete or brick wall:

1. Remove wall mount assembly and hardware kit from box.

CAUTION: DO NOT use the center two holes in the

wall plate for concrete walls. Additional holes must

be drilled for masonry surface mounting to assure

durable attachment.

2. Drill holes in wall plate:

a. Place wall plate flat on a wooden surface which can be

drilled into.

b. Mark four holes on wall plate 1" (2.5cm) from each edge

in corners of plate.

c. Use a center punch to start holes.

d. Drill four holes using a 13/64" (5.1mm) drill bit.

MASONRY HOLES

1"

(2.54 cm)

1" (2.54 cm)

MASONRY HOLES

3. Select mounting location on wall that is within 8' (2.4m) of

electrical outlet.

4. Using wall plate as a template, place on selected location on

wall and mark upper-left hole.

6

Page 9

5. Remove wall plate and use a center punch to start hole.

6. Using a hammer drill and 5/32" (4mm) masonry drill bit, drill

hole to a minimum of 1.5" (4cm) deep.

7. Place wall plate on wall and drive 1.25" (3.2cm) masonry

screw

halfway

into the wall.

8. Align wall plate using a level and secure by tightening screw.

9. Punch the next three

holes with wall plate

in place.

10. Drill remaining holes.

11. Fasten wall plate

LEVEL

EXTENSION

ARM (G)

with three remaining

screws.

12. Prepare for transformer

mountingby following

“Transformer Mounting”

instructions through step 4

on page 8.

13. Carefully remove LS200 arm/luminaire assembly from box. Complete

transformer mounting by following

steps 5 & 6 of instructions on page 8.

14. Place arm/luminaire assembly on

extension arm by sliding universal

(b)

ARM/

LUMINAiRE

ASSEMBLY

UNIVERSAL

CONNECTOR

(B)

EXTENSION

ARM (G)

connector (B) onto extension arm (G)

and aligning screw holes.

15. Insert 0.5" (13mm) flathead screw (b) into hole on

side of universal connector and tighten.

Move arm up and down to check that mounting is secure.

16. Push cord into clips in underside of extension arm.

7

Page 10

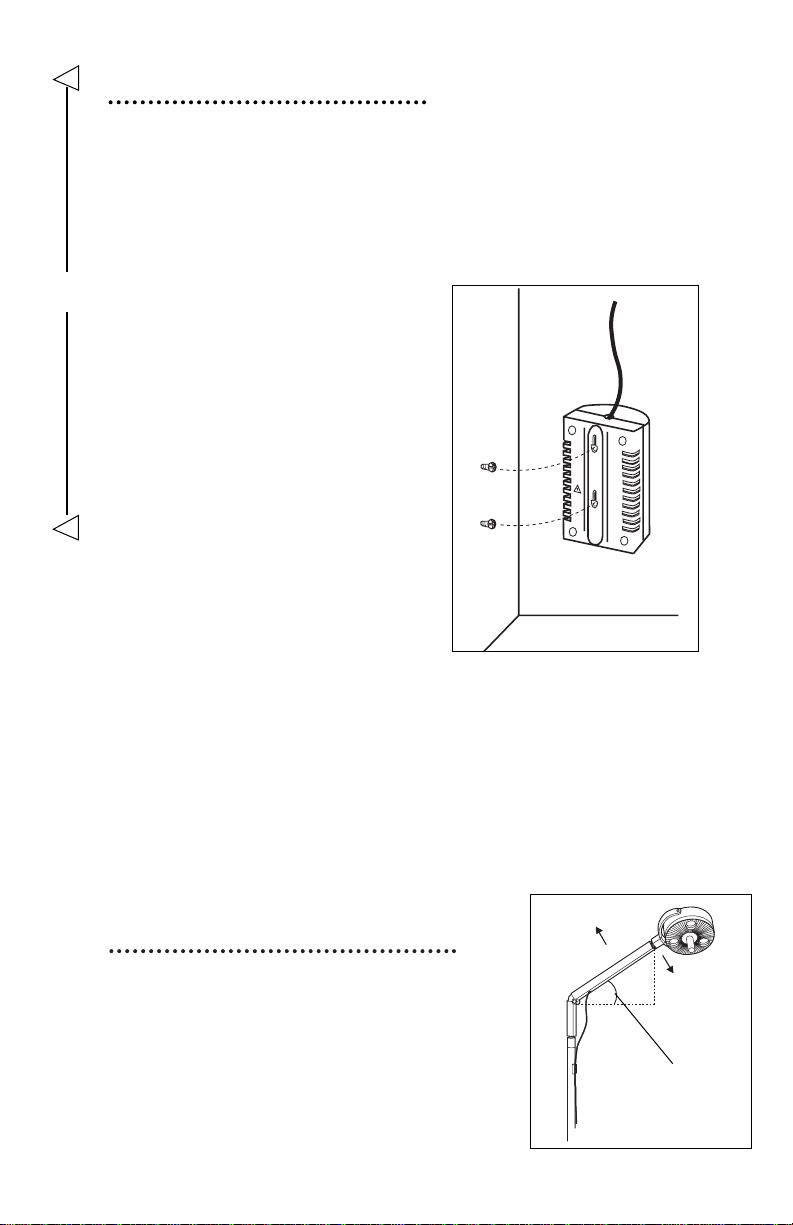

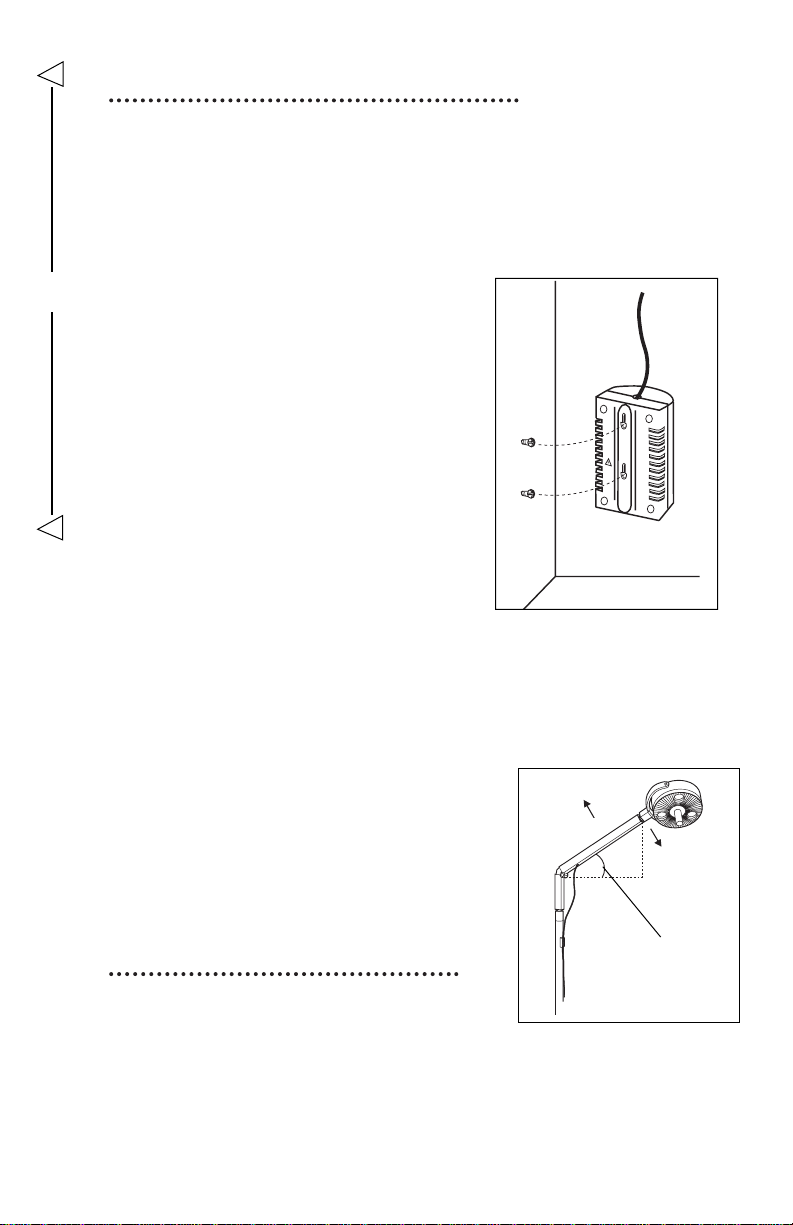

TRANSFORMER MOUNTING

1. Select proper mounting hardware from hardware kit in the

LS200 mounting option box: Choose 1" (2.5cm) wood screws

for mounting into wood stud and 1" (2.5cm) sheet metal screws

and plastic anchors for concrete or brick.

2. Select a location for the transformer that is within 8' (2.4m) of an

electrical outlet and within 1.5' (0.5m) of the wall mount plate to

3-1/8"

8cm

allow enough slack for full range of arm motion.

3. Using the template indicators on

left side of this page (3-1/8"

[8cm] on center), mark the location

for drill holes on the wall. Make

sure they are vertical.

For wooden walls:

No pilot hole is needed. Use

1.5" (3.8cm) wood screws

from transformer hardware kit.

For concrete walls:

Using a hammer drill and

3/16" (2.3mm) masonry

drill bit, drill holes for plastic

anchors to a minimum of

1" (2.5cm) deep. Tap in

plastic anchors from transformer hardware kit until flush.

4. Drive screws into the wall, allowing screw heads to protrude

11/32" (2.3mm).

5. Mount transformer by fitting round holes in the back of transformer over mounting screws on wall, then slide downward

until secure.

6. Attach power cord to transformer.

OPERATING INSTRUCTIONS

TRANSPORT INSTRUCTIONS

FOR MOBILE STAND UNIT

1. To prevent the light from tipping, position

arm at a 45˚ angle or greater, when rolling

the LS200 to a new place.

2. Center arm in range of motion.

3. Unlock casters by lifting up on the tabs and

hold unit at top of pole while moving it.

8

YES

NO

45°

Page 11

ARM ADJUSTMENT

The LS200 Procedure Light has been

designed to allow the user to adjust the

amount of resistance at the joints of the arm.

A

The main joint features a large knob for

easy adjustment of this key joint. Turn knob

to achieve required tension.

NOTE: There is no need to adjust knob

for every use. The set tension will be

maintained over multiple movements.

ADJUSTMENT

KNOB

NEVER completely unscrew large knob.

The top and lower joints have been preadjusted at Welch Allyn.

Should further adjustment be necessary, the joint resistance can

be increased or decreased by using a screwdriver to adjust the

set screws at point (A) or (B).

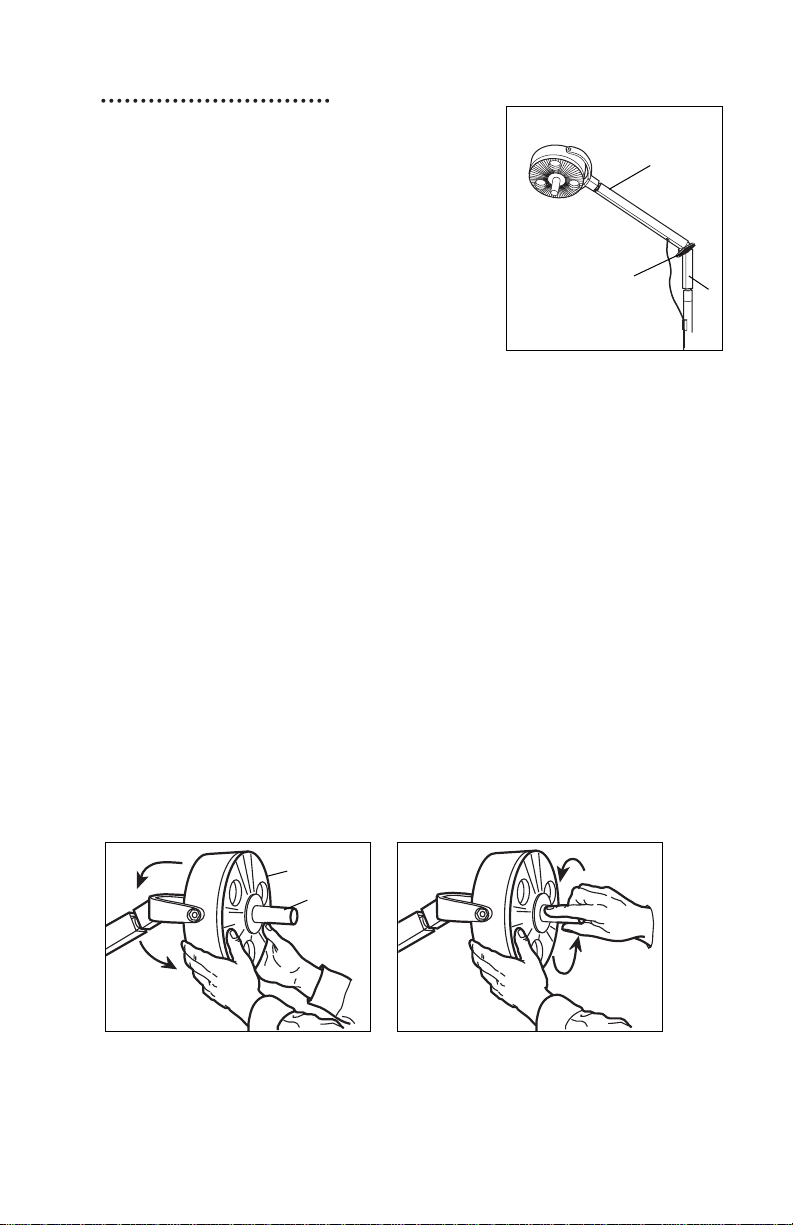

LAMP REPLACEMENT

WARNING: The lamps operate at high temperatures. DO NOT

attempt to replace lamps while they are hot. Wait until the lamps

are cool. Lamps may shatter under pressure, handle with care.

Replace with Welch Allyn lamp #06400 only.

1. Turn power switch to OFF position and unplug the power cord

from the electrical outlet.

2. Rotate luminaire so that the bezel and handle are facing

you (see A).

3. Turn handle counterclockwise to unscrew (see B). Remove

handle and carefully slide bezel out and allow to rest on wire

tether (see C).

4. Locate release lever on lamp holder and push downward (see D).

B

BEZEL

HANDLE

TURN

COUNTERCLOCKWISE

AB

9

Page 12

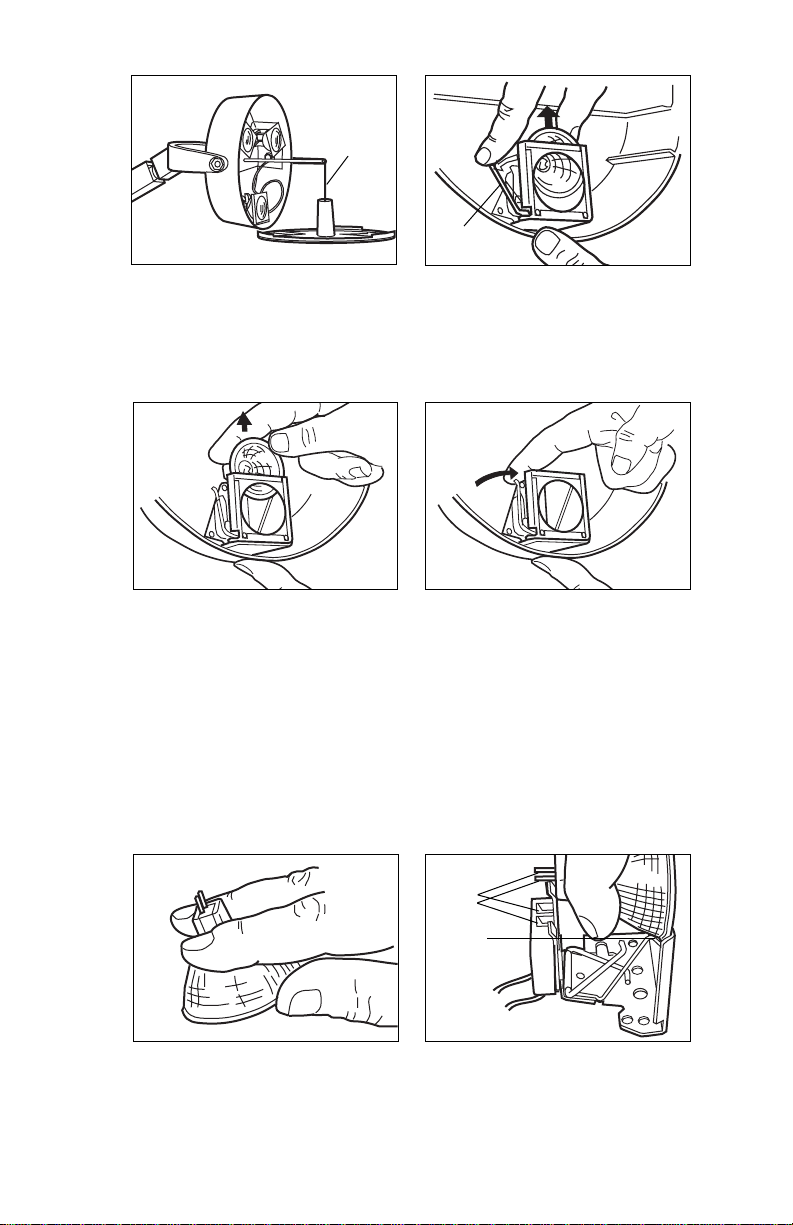

TETHER

RELEASE

LEVER

C

D

5. Grasp expired lamp by its base with two fingers and slide

out of lamp holder (see E).

6. Return release lever to upward position (see F).

EF

7. Remove Welch Allyn Replacement Lamp #06400 from

its package.

8. Grasp replacement lamp between your two forefingers (see G).

NOTE: Try not to touch the inside of reflector—dirt or oil can

cause reduced light output. Clean according to instructions on

page 12, if necessary.

9. Carefully slide the lamp into the lamp holder with two fingers,

making sure the two pins on the base of the lamp slide into the

socket and the reflector slides under the spring (see H).

ALIGN

SPRING

GH

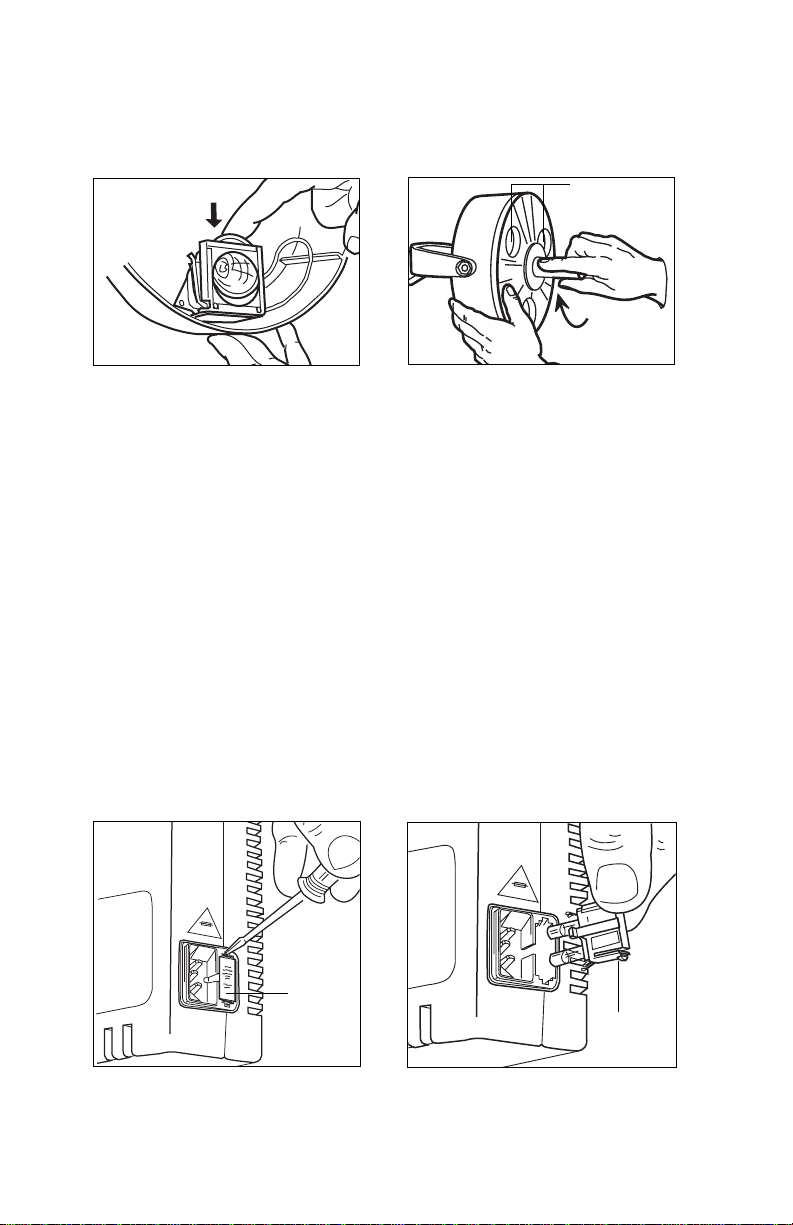

10. To assure proper placement in socket, gently push lamp into

socket until completely seated and snap into place (see I).

10

Page 13

11. Replace bezel. Be certain to align the three smooth “windows”

in bezel with lamps and tabs on edge of bezel with grooves in

white housing (see J).

12. Replace handle and rotate clockwise until secure (see J).

ALIGN SMOOTH

WINDOWS IN

BEZEL WITH

LAMPS

TURN

CLOCKWISE

IJ

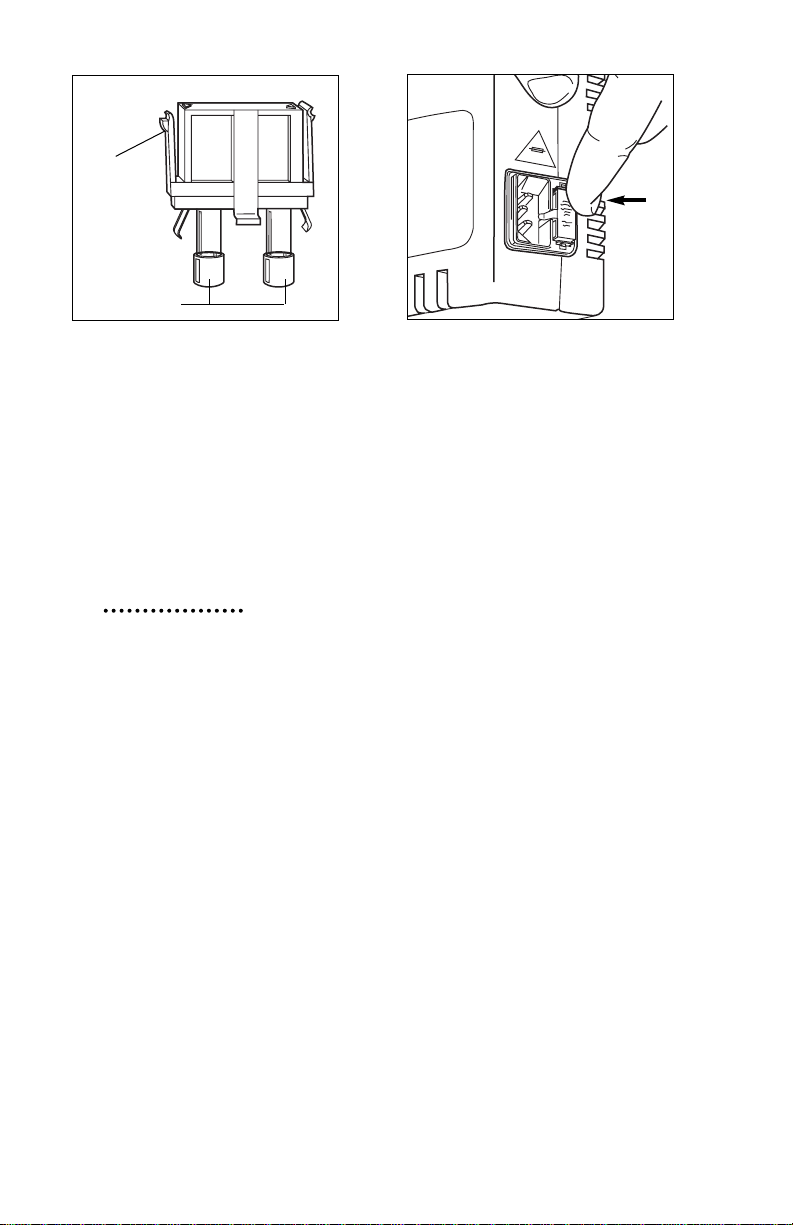

FUSE REPLACEMENT

There are two replaceable fuses located in the fuse drawer of the

transformer housing. If either one of these blows, the unit will not light.

Replace only with Welch Allyn part number 236706-3907 for model

44200 or 236706-3114 for models 44202, 44204 and 44206.

1. Turn the power switch to the OFF position and unplug the power

cord from the electrical outlet and transformer.

2. Using a small (1/8") screwdriver, remove the fuse drawer (a)

from the transformer housing by releasing the spring loaded snap

connection (b) on both sides of the component.

3. Pull out fuse drawer.

4. Remove and replace the blown fuse(s). There is no required

orientation of the fuses.

5. Reinsert the drawer by pressing it into the connector until it

snaps into place.

T 1A, 250V

REPLACE FUSES AS MARKED

(a)

FUSE

DRAWER

11

T 1A, 250V

REPLACE FUSES AS MARKED

(b)

SNAP

CONNECTION

Page 14

(a) FUSE DRAWER

(b)

SNAP

CONNECTION

FUSES

T 1A, 250V

REPLACE FUSES AS MARKED

CLEANING

Turn power switch to the OFF position and unplug the power cord from

the electrical outlet prior to cleaning.

The entire unit can be wiped down using a cloth dampened slightly with

a mild solution of detergent and water or glass cleaner. Be careful not to

allow the plug prongs to get wet. Wipe the unit dry with a clean, dry cloth.

DO NOT plug the LS200 Procedure Light into the electrical outlet until the

unit is thoroughly dry.

IMPORTANT

Be careful not to allow solution to drip into luminaire.

DO NOT spray solution directly into joints.

DO NOT sterilize any part of the unit.

DO NOT immerse any part of the unit in cleaning solutions.

MAINTENANCE AND REPAIR

For minor trouble, refer to the “Troubleshooting Guide” on page 15-16

for possible causes and corrective action.

Only qualified personnel should make electrical inspections of the

LS200 Procedure Light.

Repair: To locate qualified service personnel, contact your local, authorized

Welch Allyn distributor, or contact Welch Allyn directly at 800-535-6663.0.

WARRANTY

The LS200 Procedure Light is guaranteed by Welch Allyn against all

manufacturing defects. Welch Allyn will repair or replace, free of charge,

any parts of its own manufacture that prove to be defective for reasons

other than misuse, neglect, damage in shipment, or normal wear. This

warranty is in effect for three years from original date of purchase.

12

Page 15

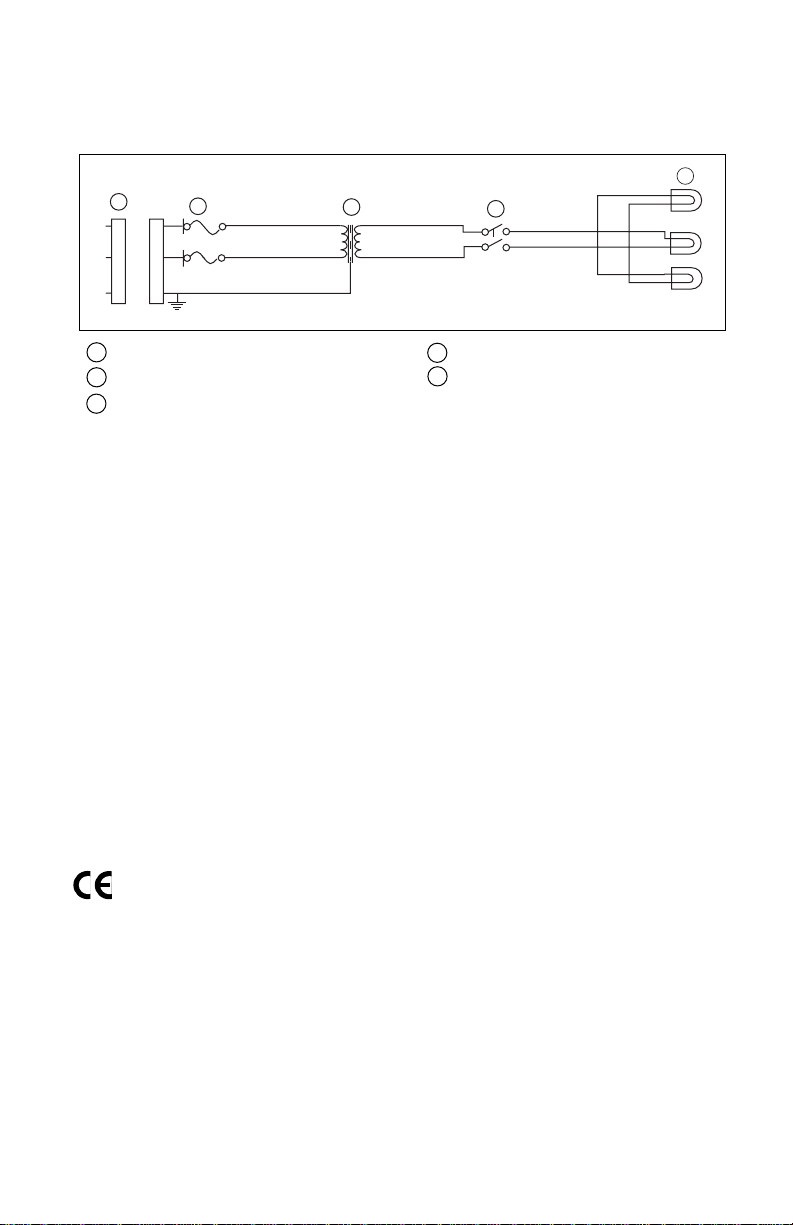

ELECTRICAL SPECIFICATIONS

A

D

B

E

C

Wiring Diagram

A

HOSPITALGRADE POWER CORD

B

FUSES

C

TRANSFORMER - STEP DOWN,

ISOLATED

Input/Output

Input:

Model 44200: 120 Vac, 60 Hz 0.70 A

(U.S.A./Canada/South America/Japan)

Model 44202: 230 Vac, 50 Hz 0.35 A (Europe, except

United Kingdom)

Models 44204, 44206: 240 Vac, 50 Hz 0.35 A (Australia, UK)

Output: 12.0 Vac @ 5.0 A (three 20-watt lamps)

ON-OFF SWITCH

D

E

LAMPS

Agency Approvals

Model 44200, listed to: UL 544 — Class 1 Medical Equipment

CSA 22.2-125 Class 2G Medical Equipment

Models 44202, 44204,

44206, listed to: IEC 601-1 — Class 1 Type B Medical

Equipment

The CE mark indicates this product has been tested to, and conforms

with, the provisions noted in both the 89/336/EEC Electromagnetic

Compatibility Directive and the 73/23/EEC Low Voltage Directive.

European Contact for Regulatory Compliance:

European Regulatory Manager

Welch Allyn Ltd., Kells Road, Navan, County Meath

Republic of Ireland Tel: 353 46 28122 Fax: 353 46 28536

Leakage Current

Less than 50 µA from any metal part

13

Page 16

Fuses User replaceable, both line and neutral.

Model 44200: 1A, 250 V slow-blow

Models 44202,

44204, 44206: T500 mA, L250V time lag (slow-blow),

low breaking capacity.

Key Measurements

Illumination: Intensity: 2,500 foot-candles average light

output (21,000 lux average) at 24" (60cm)

Color Temperature: 3,200˚ Kelvin

Working Distance: 24" (60cm)

Spot Size: 7" (18cm)

Depth of Field: 12" (30cm) total, ±6" (15cm)

Lamps: Dichroic Reflector, 3,000 hour average

lamp life

Cord Length: Output Cord: 4' (1.2m)

Input Cord (Detachable): 10' (3.0m)

Luminaire: Diameter: 9.5" (24cm)

Material: Lexan™ 940 Polycarbonate

Key Measurements: Arm: 20" (50cm)

Wall/Table Extension Arm: 10" (25cm)

Wall to Luminaire Center (90˚ to wall):

36" (90cm)

Mobile Stand Height: 46" (1.2m)

Mobile Stand Legs: 16" (40cm) long x 1"

(2.5cm) wide x 2" (5cm) high

Mobile Stand Base:

(45cm) wide x 2.5" (6cm) high

16" (40cm) long x 18"

OPERATION ENVIRONMENT

For Indoor Use Only

Ambient (room) temperature: 10˚C to 40˚C

Relative humidity range: 30% to 75%

Atmospheric pressure range: 700 hPa to 1060 hPa

Mode of operation: Continuous

Transport and Storage Environment:

Ambient temperature: -40˚C to 70˚C

Relative humidity: 10% to 100%

14

Page 17

TROUBLESHOOTING GUIDE

TROUBLE POSSIBLE CAUSE(S) CORRECTIVE ACTION

When switch

is activated

the light does

not turn on.

There has

been a

change in

spot

quality or a

decrease in

light intensity.

It’s difficult to

move the luminaire, the joints

are stiff.

Connection at

top of arm and

luminaire

At arm joint

Joint at bottom

of arm

Power cord is loose. Check connection at wall

outlet and at power supply.

A fuse is blown. Check fuse. Glass tube will be

blackened if a fuse is blown.

Replace if blown (according to

instructions starting on page 11).

No power at wall outlet. Try another outlet.

Power cord is damaged. Order replacement cord from

Welch Allyn.

Lamp is blown. Replace lamp (according to

instructions starting on page 9).

Lamp is not inserted Check lamps to ensure they

in socket properly. were properly installed

(according to instructions

starting on page 9).

Bezel on front of luminaire Make certain the clear

was not aligned properly. “windows” are lined up with

lamps (See instructions starting

on page 9).

Dirt or dust on bezel or on the Clean if necessary (see

glass filters behind the bezel. cleaning instructions on

page 12).

Set-screw at top of arm Loosen set screw (A)

is too tight. (see instructions on page 9).

Arm knob is too tight. Loosen knob.

Set-screw at bottom of Loosen set screw (B)

arm is too tight. (see instructions on page 9).

15

(Continued on next page.)

Page 18

TROUBLESHOOTING GUIDE

TROUBLE POSSIBLE CAUSE(S) CORRECTIVE ACTION

Luminaire does

not stay where

positioned.

The unit wobbles or parts

appear to not

be connected

properly.

Entire arm/

luminaire

assembly

Luminaire

Set-screw at top of arm Ensure screw (A) is in place

is too loose or has been and tighten according to

removed. instructions on page 9.

Arm knob is not tight Tighten knob.

enough.

Set-screw at bottom of Ensure screw (B) is in place

arm is too loose or has and tighten according to

been removed. instructions on page 9.

Unit is not mounted level. For wall mount, ensure unit is

mounted level. See mounting

instructions on page 5.

Screw (b) that attaches unit Check screw (b) and tighten.

to mounting option is not in

place or is too loose.

Arm knob is not tight enough. Tighten knob.

Mobile stand—small metal Reassemble according to

post in hole in mobile stand instructions on page 4.

base was not aligned

properly with hole in pole

during assembly.

Bezel on front of Check that tabs on bezel

luminaire is not attached are aligned with those

or installed properly. on white plastic housing.

(See lamp replacement instructions starting on page 9).

Transformer

mounting

attachment

Mobile stand

difficult to

move

Transformer housing is Push housing down as far as

not pushed down far possible on mounting screws

enough on screws. to make a tight connection.

Casters are locked. Unlock casters when moving

the unit.

Something is stuck to caster. Clean casters if necessary.

Caster is broken. Order replacement caster from

Welch Allyn.

16

Page 19

!

!!!

ESPAÑOL

!

60cm

Agradecemos su compra de la Lámpara para procedimientos

LS200

™

de Welch Allyn®, diseñada por un fabricante líder a nivel

mundial en cuanto a instrumental de diagnóstico iluminado.

Siguiendo las directrices de uso y cuidado que contiene este

manual, se verá recompensado con años de servicio fiable y sin

problemas por la nueva Lámpara para procedimientos LS200.

Lea estas instrucciones en su totalidad antes de usar la lámpara.

ADVERTENCIA

Todos los usuarios de esta lámpara para procedimientos deben estar

perfectamente capacitados en los procedimientos médicos que corresponden al

equipo. Además, deben leer y entender las instrucciones para todos los otros

equipos que se usan en conjunto con la Lámpara para procedimientos LS200™.

Las bombillas son sumamente brillantes. NO mire directamente las bombillas

cuando estén encendidas.

NO coloque la luminaria en la posición hacia arriba estando la bombilla encendida.

PRECAUCION

Retire el cable eléctrico del tomacorriente y deje enfriar la bombilla

antes de cambiarla (reemplácela por la bombilla Welch Allyn No. 06400 solamente).

Las piezas metálicas accesibles de esta unidad están eléctricamente aisladas

del conductor a tierra del cable de alimentación. Si se considera necesaria la

conexión a tierra de las piezas accesibles, se debe utilizar un cable de conexión a tierra separado.

Para reducir el riesgo de descarga eléctrica, no desarme la unidad. Solicite la

reparación al personal de servicio calificado.

PRECAUCION

La operación a menos de 12 pulgadas (30,5 cm) de distancia

durante períodos prolongados puede producir eritema.

La distancia contemplada en el diseño es de 24 pulgadas (60 cm).

PRECAUCION

El interuptor de la luminaria NO es un interruptor matriz. El transformador se

energiza cuando se conecta la luz está conectada a la matriz.

PELIGRO

Existe riesgo de explosión si se usa en la presencia de anestésicos

inflamables.

SUPERFICIE CALIENTE

El bisel delante de las bombillas puede estar caliente.

17

Page 20

TABLA DE CONTENIDO

Componentes..........................................................19

Montaje ..................................................................20

Instalación del pedestal móvil ..........................20

Instalación con montaje de pared ....................21

Montaje a un pilar de madera ..................21

Montaje a pared de concreto o ladrillo ....22

Montaje del transformador................................24

Instrucciones de operación ..................................24

Instrucciones de transporte para la unidad

con pedestal móvil ............................................24

Ajuste del brazo ................................................25

Recambio de la bombilla ......................................25

Recambio del fusible ............................................27

Limpieza ..................................................................28

Mantenimiento y reparación..................................28

Garantía ..................................................................28

Especificaciones eléctricas ..................................29

Ambiente de operación..........................................30

Guía para la solución de problemas ....................31

18

Page 21

COMPONENTES

CONJUNTO DEL

BRAZO/LUMINARIA

CONECTOR

UNIVERSAL

(B)

SUJETADORES

DEL CABLE

ELECTRICO

(D)

EXTREMO

DEL POSTE

(A)

CABLE

ELECTRICO

TRANSFORMADOR

TRANSFORMADOR

(e)

TORNILLERIA PARA

EL PEDESTAL MOVIL

LLAVES

ALLEN

TORNILLOS DE

MONTAJE DEL

(C)

PERNO

DE

CASQUETE

(F)

ARANDELA DE

SEGURIDAD (f)

TORNILLO

DE

CABEZA

PLANA

(b)

MONTAJE DE PARED

BRAZO DE

EXTENSION (G)

TORNILLERIA PARA EL

MONTAJE DE PARED

TORNILLO

TORNILLOS

DE

MAMPOSTERIA

TORNILLOS

PARAMADERA

DE

CABEZA

PLANA (b)

LLAVE ALLEN

TORNILLERIA DEL

TRANSFORMADOR

TORNILLOS

PARA

CONCRETO

TORNILLOS

PARAMADERA

PEDESTAL MOVIL

TRABA

DE LAS

RUEDAS

BASE DEL PEDESTAL MOVIL

19

Page 22

MONTAJE

INSTALACION DEL PEDESTAL MOVIL

1. Retire la base del pedestal, el poste y el juego de tornillería de las cajas.

2. Coloque la base del pedestal en el piso con las ruedas hacia

abajo y trabe las ruedas.

3. Inserte el extremo del poste (A) en el agujero en la base del

pedestal móvil.

4. Gire el poste hasta quedar alineado con

el pasador e insertarse en su lugar.

5. Inserte el perno de casquete (F) con la arandela

de seguridad (f) a través del travesaño del pedestal

en el poste y apriete con una llave Allen de 1/4”.

6. Cuidadosamente retire el conjunto del brazo/luminaria

LS200 de la caja. Enganche el transformador en los

tornillos de montaje instalados en la fábrica (C) en

el poste y deslícelo hacia abajo hasta quedar fijo.

7. Coloque el conjunto del brazo/luminaria

en el poste deslizando el conector

universal (B) en el extremo superior

del poste y alinee los agujeros de

los tornillos.

8. Inserte el tornillo de cabeza plana de

0.5” (13mm) (b) en el agujero del lado

del conector universal y apriete con

la llave Allen de 5/32”.

9. Presione el cable eléctrico conectado al

transformador en los sujetadores del

cable de energía (D) del poste, dejando

una holgura suficiente para que el brazo

tenga un movimiento de rango completo.

10. Conecte el cable eléctrico (e)

al transformador.

11. Para trabar las ruedas, presione hacia abajo

la lengüeta de las trabas de las ruedas.

12. Antes de mover la lámpara para

procedimientos LS200, consulte

las “Instrucciones de transporte”

en la página 24.

(b)

(D)

(A)

(B)

(C)

(e)

ALINEE EL PASADOR DEL

PEDESTAL MOVIL CON EL

EXTREMO DEL POSTE TRABAS

DE RUEDAS

20

TRABA

DE LAS

RUEDAS

(f)

(F)

Page 23

INSTALACION CON

MONTAJE DE PARED

PRECAUCION: NO monte la lám-

para en cartón de yeso. Debe montarse en el montante.

El brazo de la Lámpara para procedimientos LS200 está diseñado

para no pasar de 90° y la distancia

de trabajo es 24” (60cm). Para asegurar la ubicación adecuada en la

pared, el borde superior de la placa

de pared debe estar ubicado a 4”

(10cm) sobre la superficie de

trabajo.

NOTA: La placa de pared debe

nivelarse usando un nivel de

carpintero para asegurar un

movimiento preciso y sin

desviación.

Para montar al montante de madera:

1. Retire el conjunto para el montaje de pared y el juego de tornillería

de la caja.

2. Seleccione la ubicación del montaje en un montante de la pared que esté a

menos de 8’ (2.4m) del tomacorriente.

3. Usando la placa de pared como plantilla, colóquela en la ubicación

seleccionada en la pared, nivele la placa y marque ambos agujeros.

4. Retire la placa de la pared y

perfore agujeros guía usando

una broca de 0.12” (3mm).

5. Coloque la placa en la pared y

atornille hasta la mitad el tornillo

para madera superior de

1.5” (3.8cm) en el montante

de madera.

6. Alinee la placa de pared usando

un nivel y asegúrela en la parte

inferior con un tornillo

paramadera de 1.5” (3.8cm).

7. Apriete el tornillo para madera

superior.

8. Prepare el montaje del

transformador siguiendo las instrucciones bajo “Montaje del transformador”

hasta el paso 4 en la página 24.

4"

4"

MONTANTE DE MADERA

NIVEL

TORNILLO PARA

MADERA

BRAZO DE

EXTENSION

(G)

21

Page 24

9. Cuidadosamente retire el conjunto del brazo/

luminaria LS200 de la caja. Concluya el montaje

del transformador de acuerdo a los pasos 5 y 6

de las instrucciones en la página 24.

10.Ubique el conjunto del brazo/luminaria en el brazo

de extensión deslizando el conector universal (B)

CONJUNTO

DEL BRAZO/

LUMINARIA

(b)

CONECTOR

UNIVERSAL (B)

en el brazo de extensión (G) y alineando los

agujeros de los tornillos.

11.Inserte el tornillo de cabeza plana de 0.5” (13mm)

(b) en el agujero en el lado del conector universal

y apriete. Mueva el brazo hacia arriba y hacia

abajo para asegurar que el montaje esté firme.

BRAZO DE

EXTENSION (G)

12.Presione el cable en los sujetadores por debajo del brazo de extensión.

Montaje en pared de concreto o ladrillo:

1. Retire el conjunto del montaje de pared y el juego de tornillería de la caja.

PRECAUCION: NO use los dos agujeros centrales de la placa de la

pared para las paredes de concreto. Se deben perforar agujeros

adicionales para el montaje en superficies de mampostería a fin de

asegurar una instalación perdurable.

2. Perfore los agujeros en la placa de la pared:

a. Coloque la placa de la pared sobre una superficie de madera que se

pueda perforar.

b. Marque cuatro agujeros en la placa de la pared a 1” (2.5cm) de cada

borde en las esquinas de la placa.

c. Use un punzón de marcar para iniciar los agujeros.

d. Perfore cuatro agujeros usando una broca de 13/64” (5.1mm).

1" (2.54 cm)

1"

(2.54 cm)

AGUJEROS DE MAMPOSTERIA

AGUJEROS DE MAMPOSTERIA

3. Seleccione la ubicación del montaje en la pared que esté a menos de 8’

(2.4m) del tomacorriente.

4. Usando la placa de pared como plantilla, colóquela en la ubicación

seleccionada en la pared y marque el agujero izquierdo superior.

22

Page 25

5. Retire la placa de la pared y use un punzón de marcar para iniciar el

agujero.

6. Usando un taladro y una broca de mamposteria de 5/32” (4mm), perfore el

agujero a un mínimo de 1.5” (4cm) de profundidad.

7. Coloque la placa en la pared y atornille hasta la mitad los tornillos para

mampostería de 1.25” (3.2cm).

8. Alinee la placa de la pared

usando un nivel y asegúrela

apretando el tornillo.

9. Marque los tres agujeros

restantes con la placa de

la pared en su lugar.

NIVEL

BRAZO DE

EXTENSION

(G)

10.Perfore los agujeros

restantes.

11.Fije la placa de la pared con

los tres tornillos restantes.

12.Prepare el montaje del

transformador siguiendo las

instrucciones bajo “Montaje del

transformador” hasta el paso 4 en

la página 24.

13.Cuidadosamente retire el conjunto del

brazo/luminaria LS200 de la caja.

Concluya el montaje del transformador

de acuerdo a los pasos 5 y 6 de las

instrucciones en la página 24.

14.Coloque el conjunto del brazo/luminaria

(b)

CONJUNTO DEL

BRAZO/

LUMINARIA

CONECTOR

UNIVERSAL

(B)

BRAZO DE

EXTENSION

(G)

en el brazo de extensión deslizando el

conector universal (B) en el brazo de extensión (G) y alineando los agujeros

de los tornillos.

15.Inserte el tornillo de cabeza plana de 0.5” (13mm) (b) en el agujero del lado

del conector universal y apriete. Mueva el brazo hacia arriba y hacia abajo

para asegurar que el montaje está firme.

16.Presione el cable en los sujetadores por debajo del brazo de extensión.

23

Page 26

3-1/8"

8cm

MONTAJE DEL TRANSFORMADOR

1. Seleccione la tornillería de montaje apropiada del juego de tornillería en

la caja de opciones de montaje de la lámpara LS200: Elija tornillos para

madera de 1” (2.5cm) para el montaje en un pilar de madera; y tornillos

para lámina de metal de 1” (2.5cm) y anclajes de plástico para concreto

o ladrillo.

2. Seleccione una ubicación para el transformador que esté a 8’ (2.4m) de

un tomacorriente y a 1.5” de la placa de montaje de la pared para

permitir la holgura suficiente que requiere el brazo para un movimiento

de rango completo.

3. Usando los indicadores de la plantilla en el

lado izquierdo de esta página (3 1/8” [8cm]

en el centro), marque la ubicación para

perforar los agujeros en la pared. Verifique

que estén verticales.

Para paredes de madera:

No se necesita un agujero guía. Use los

tornillos para madera de 1.5” (3.8cm) del

juego de tornillería del transformador.

Para paredes de concreto:

Usando un taladro y una broca de mam

postería de 3/16” (2.3mm), perfore los

agujeros para los anclajes de plástico a un

mínimo de 1” (2.5cm) de profundidad.

Inserte los anclajes de plástico del juego

de tornillería del transformador hasta que queden al ras con respecto a

la superficie.

4. Atornille los tornillos en la pared, dejando sobresalir la cabeza de los

tornillos 11/32” (2.3mm).

5. Monte el transformador ajustando los agujeros en la parte posterior del

transformador sobre los tornillos de montaje en la pared, luego deslice

hacia abajo hasta que quede firme.

6. Conecte el cable eléctrico al transformador.

SI

INSTRUCCIONES DE

YES

OPERACION

INSTRUCCIONES DE

TRANSPORTE PARA LA

UNIDAD DE PEDESTAL MOVIL

1. Para evitar que se incline la lámpara, ubique

el brazo a un ángulo de 45° o más, cuando se

transporte la LS200 a una nueva ubicación.

2. Centre el brazo según el rango de movimiento.

3. Destrabe las ruedas levantando las lengüetas y tomando la unidad

desde la parte superior del poste mientras la está moviendo.

24

NO

NO

45°

Page 27

AJUSTE DEL BRAZO

La Lámpara para procedimientos LS200 ha sido

diseñada para permitir al usuario ajustar la

cantidad de resistencia en las articulaciones del

A

brazo. La articulación principal presenta un

perno largo para facilitar el ajuste de esta

articulación clave. Gire la perilla para lograr la

tensión requerida.

NOTA: No es necesario ajustar la perilla para

cada uso. La tensión fijada se conservará a

pesar de numerosos movimientos. NUNCA

PERILLA DE

AJUSTE

destornille el perno largo por completo.

Las articulaciones superior e inferior han sido

ajustadas previamente por Welch Allyn. Si resultase necesario un mejor

ajuste, puede aumentarse o disminuirse la resistencia de la articulación

usando un destornillador para ajustar el tornillo prisionero en el punto

(A) o (B).

REEMPLAZO DE LA BOMBILLA

ADVERTENCIA: Las bombillas operan a altas temperaturas. NO intente

cambiar las bombillas mientras están calientes. Espere hasta que las bombillas se hayan enfriado. Las bombillas se pueden romper bajo presión,

manipúlelas con cuidado. Reemplácela por la bombilla Welch Allyn No.

06400 solamente.

1. Mueva el interruptor de energía a la posición apagada OFF y

desenchufe el cable de energía del tomacorriente.

2. Gire la luminaria de manera que el bisel y el mango estén de cara hacia

usted (vea A).

3. Gire el mango en sentido opuesto a las manecillas del reloj para

desatornillar (vea B). Retire el mango y cuidadosamente deslice el bisel

hacia afuera, dejando que descanse en la resistencia del cable (vea C).

4. Ubique la palanca para aflojar en el portalámpara y presione hacia

abajo (vea D).

B

BISEL

MANGO

GIRE EN SENTIDO

OPUESTO A LAS

MANECILLAS DEL

RELOJ

A

B

25

Page 28

RESISTENCIA

PALANCAPARA

AFLOJAR

C

D

5. Tome la bombilla usada desde su base con dos dedos y deslícela hacia

afuera del portalámpara (vea E).

6. Vuelva a colocar la palanca para aflojar en su posición correcta (vea F).

EF

7. Retire la bombilla de recambio No. 06400 Welch Allyn del paquete.

8. Tome la bombilla de recambio entre sus dedos índice y medio (vea G).

NOTA: Procure no tocar el interior del reflector, la suciedad o el aceite

pueden causar una reducción en la intensidad de la luz. Limpie de

acuerdo a las instrucciones de la página 28, si es necesario.

9. Cuidadosamente deslice la bombilla en el portalámpara con los dos

dedos asegurándose de que los dos pasadores de la base de la

bombilla se deslicen en el receptáculo y que el reflector se deslice bajo

el resorte (vea H).

ALINEAR

RESORTE

GH

10. Para asegurar una colocación apropiada en el receptáculo, empuje

suavemente la bombilla en el mismo hasta quedar la bombilla totalmente asentada emitiendo un chasquido al fijarse en su lugar (vea I).

26

Page 29

11. Vuelva a colocar el bisel. Cerciórese de alinear las tres “ventanas” lisas

del bisel con las bombillas y lengüetas del borde del bisel con los

surcos de la carcasa blanca (vea J).

12. Vuelva a colocar el mango y gírelo en el sentido de las manecillas del

reloj hasta que quede firme (vea J).

ALINEE LAS

VENTANAS LISAS

DEL BISEL CON

LAS BOMBILLAS

GIRE EN EL

SENTIDO

DE LAS

MANECILLAS

DEL RELOJ

IJ

RECAMBIO DE LOS FUSIBLES

Hay dos fusibles reemplazables ubicados en el compartimiento de fusibles de la

caja del transformador. Si se funde cualquiera de éstos, la unidad no iluminará.

Reemplace sólo con la pieza Welch Allyn número 236706-3907 para el modelo

44200 ó 236706-3114 para los modelos 44202, 44204 y 44206.

1. Mueva el interruptor de energía a la posición apagada OFF y

desenchufe el cable eléctrico del tomacorriente y transformador.

2. Usando un destornillador pequeño (1/8”), retire la caja de fusibles (a)

desde la caja del transformador soltando la conexión a presión con

resorte (b) en ambos lados del componente.

3. Retire el compartimiento de fusibles.

4. Retire y reemplace el(los) fusible(s) fundido(s). No es necesario fijarse

en la orientación de los fusibles.

5. Vuelva a colocar el compartimiento presionándolo dentro del conector

hasta oír un chasquido al quedar fijo en su lugar.

T 1A, 250V

REPLACE FUSES AS MARKED

(a)

COMPARTIMIENTO DE

FUSIBLES

27

T 1A, 250V

REPLACE FUSES AS MARKED

(b)

CONEXION A

PRESION

Page 30

(a) COMPARTIMIENTO DE FUSIBLES

(b)

CONEXION A

PRESION

FUSIBLES

T 1A, 250V

REPLACE FUSES AS MARKED

LIMPIEZA

Coloque el interruptor de encendido en la posición apagada OFF y desenchufe

el cable eléctrico del tomacorriente antes de limpiar.

Puede limpiarse toda la unidad con un paño ligeramente humedecido con una

solución suave de detergente y agua o limpiavidrios. Tenga cuidado de no dejar

que se mojen las espigas del enchufe. Seque la unidad con un paño limpio y

seco. NO enchufe la Lámpara para procedimientos LS200 en el tomacorriente

hasta que esté totalmente seca.

IMPORTANTE

Tenga cuidado de no dejar escurrir la solución sobre la luminaria.

NO rocíe la solución directamente en las articulaciones.

NO esterilice ninguna parte de la unidad.

NO sumerja ninguna parte de la unidad en soluciones de limpieza.

MANTENIMIENTO Y REPARACION

Para problemas de menor importancia, consulte la “Guía para la solución

de problemas” en las páginas 31-32 para ver posibles causas y medidas

de corrección.

Las inspecciones eléctricas de la Lámpara para procedimientos LS2000 deben

realizarlas sólo el personal calificado.

Reparación: Para localizar al personal de servicio calificado, diríjase a su distribuidor autorizado local de Welch Allyn, o póngase en contacto con Welch

Allyn directamente al (315) 685-4560.

GARANTIA

La Lámpara para procedimientos LS200 está garantizada por Welch Allyn contra todo defecto de fabricación. Welch Allyn reparará o reemplazará, sin cargo

alguno, cualquier pieza fabricada por la misma fábrica que demuestre estar

defectuosa por razones que no sean maltrato, negligencia, daño durante el

envío o desgaste normal. Esta garantía se mantendrá vigente por tres años a

partir de la fecha original de compra.

28

Page 31

ESPECIFICACIONES ELECTRICAS

A

D

B

E

C

Diagrama de Cableado

CABLE ELECTRICO DE CALIDAD APTA PARA

A

HOSPITALES

FUSIBLES

B

TRANSFORMADORES -

C

REDUCTOR, AISLADO

Entrada/Salida

Entrada: 120 Vca, 60 Hz 0,70 A

Modelo 44200: (EE.UU./Canadá/América del Sur/Japón)

Modelo 44202: 230 Vca, 50 Hz 0.35 A(Europa, salvo el

Modelos 44204, 44206: 240 Vca, 50 Hz 0.35 A(Australia, Reino Unido)

Salida: 12.0 Vca @ 5.0 A(tres bombillas de 20 vatios)

Aprobaciones de Agencias

Modelo 44200, listado: US 544 — Equipo Médico Clase 1

Modelos 44202, 44204,

44206, listado: IEC 601-1 — Equipo Médico Clase 1 Tipo B

La marca CE indica que el producto ha sido probado y está en conformidad

con las disposiciones observadas dentro de la Directiva de compatibilidad

electromagnética 89/336/EEC y la Directiva de bajo voltaje 73/23/EEC.

Dirección del representante europeo autorizado:

European Regulatory Manager

Welch Allyn Ltd., Kells Road, Navan, County Meath

Republic of Ireland Tel: 353 46 28122 Fax: 353 46 28536

Filtración de Corriente

INTERRUPTOR DE ENCENDIDO/APAGADO

D

BOMBILLAS

E

Reino Unido)

CSA 22.2-125 Equipo Médico Clase 2G

Inferior a 50 uA por cualquier pieza metálica

29

Page 32

Fusibles Reemplazables por el usuario, tanto de línea

como neutros.

Modelo 44200: 1A, 250 V fundido lento

Modelos 44202,

44204, 44206: T500 mA, L250V de retraso (fundido lento),

capacidad de corte baja.

Dimensiones Claves

Iluminación: Intensidad: 2.500 bujías-pie de salida media de

Longitud del cable eléctrico: Cable de salida: 4’ (1.2m)

Luminaria: Diámetro: 9.5” (24cm)

Dimensions claves: Brazo: 20” (50cm)

luz (21.000 lux media) a 24” (60cm)

Temperatura de color: 3.200° Kelvin

Distancia de trabajo: 24” (60cm)

Tamaño de haz: 7” (18cm)

Profundidad de campo: 12” (30cm)

total, ±6” (15cm)

Bombillas: Reflector dicroico, 3.000 horas como

promedio de duración de las bombillas

Cable de entrada (Desprendible): 10’ (3m)

Material: Policarbonato Lexan

Brazo de extensión de pared/mesa: 10” (25cm)

Pared al centro de luminaria (90° a la pared):

36” (90cm)

Altura del pedestal móvil: 46” (1.2m)

Patas del pedestal móvil: 16” (40cm) de largo x

1” (2.5cm) de ancho x 2” (5cm) de alto

Base del pedestal móvil: 16” (40cm) de largo x

18” (45cm) de ancho x 2.5” (6cm) de alto

TM

940

AMBIENTE DE OPERACION

Para uso en Interiores Solamente

Temperatura ambiente: 10°C a 40°C

Humedad relativa: 30% a 75%

Presión atmosférica: 700 kPa a 1060 kPa

Modo de operación: Continuo

Transporte y ambiente de almacenamiento:

Temperatura ambiente: -40°C a 70°C

Humedad relativa: 10% a 100%

30

Page 33

GUIA PARA LA SOLUCION DE PROBLEMAS

PROBLEMA

Cuando se

activa el interruptor, la luz

no se enciende.

Ha habido un

cambio en la

calidad del haz

o ha disminuido

la intensidad do

la luz.

Es difícil mover

la luminaria, las

articulaciones

están rígidas.

POSIBLE(S) CAUSA(S)

El cable eléctrico está flojo. Revise la conexión del tomacorriente

Se ha fundido un fusible. Verifique el fusible. El tubo de vidrio

No hay electricidad en el Pruebe con otro tomacorriente.

tomacorriente.

El cable eléctrico está Pida un cable eléctrico a Welch Allyn.

dañado.

La bombilla está fundida.

La bombilla no está insertada debidamente en el portalámpara.

El bisel delante de la luminaria no se alineó debidamente.

Hay suciedad o polvo en el

bisel o en los filtros de vidrio

tras el bisel.

CORRECCION

de la pared y en la red eléctrica.

estará ennegrecido si se ha fundido

un fusible. Reemplácelo si está fundido

(según las instrucciones de la

página 27).

Reemplace las bombillas para asegurar que se instalen bien (según las

instrucciones que comienzan en la

página 25).

Verifique las bombillas para asegurar

que se instalaron bien (según las

instrucciones que comienzan en la

página 25).

Asegúrese de que las “ventanas”

transparentes estén alineadas con

las bombillas (Vea las instrucciones

que comienzan en la página 25).

Limpie si es necesario (vea las

instrucciones de limpieza de la

página 28).

Conexión en la

parte superior del

brazo y la luminaria

En la articulación

del brazo.

Articulación en la

parte inferior del

brazo

El perno prisionero en el

extremo superior del brazo

está demasiado apretado.

La perilla del brazo está

demasiado apretada.

El perno prisionero en la

parte inferior del brazo está

demasiado apretado.

31

Suelte el perno prisionero (A) (vea

las instrucciones de la página 25).

Suelte la perilla.

Suelte el perno prisionero (B) (vea

las instrucciones de la página 25).

(Continue en la siguiente página.)

Page 34

GUIA PARA LA SOLUCION DE PROBLEMAS

PROBLEMA

La luminaria no

se queda donde

se la coloca.

La unidad se

tambalea o las

piezas parecen no

estar conectadas

correctamente.

Todo el conjunto

del brazo/

luminaria

Luminaria

Accesorio para el

montaje del transformador

El pedestal

móvil es difícil

de mover

POSIBLE(S) CAUSA(S)

El perno prisionero de la

parte superior del brazo está

demasiado suelto o ha sido

retirado.

La perilla del brazo no está

bien apretada.

El perno prisionero de la

parte inferior del brazo está

demasiado suelto o ha sido

retirado.

La unidad no está montada

niveladamente.

El tornillo (b) que conecta la

unidad a la opción de montaje no está en su lugar o

está demasiado suelta.

La perilla del brazo no está

suficientemente apretada.

El pedestal móvil—el poste

metálico pequeño en el agujero de la base del pedestal

móvil no se alineó debidamente con el agujero en

el poste durante el

ensamblaje.

El bisel delante de la luminaria no está conectado o

instalado debidamente.

La carcasa del transformador no está bien empujada hacia abajo sobre los

tornillos.

Las ruedas están trabadas.

Hay algo pegado a la rueda.

La rueda está rota.

32

CORRECCION

Asegúrese de que el tornillo (A) esté

en su lugar y apriete de acuerdo a las

instrucciones de la página 25.

Apriete la perilla.

Asegúrese de que el tornillo (B) esté

en su lugar, y apriételo según las

instrucciones de la página 25.

Para el montaje en la pared,

asegúrese de que la unidad esté

montada nivelada. Vea las instrucciones de montaje de la página 21.

Verifique el tornillo (b) y apriételo.

Apriete la perilla.

Vuelva a ensamblar según las

instrucciones de la página 20.

Verifique que las lengüetas del bisel

estén alineadas con las de la caja

plástica blanca. (Vea las instrucciones para el recambio de la bombilla que comienzan en la página 25).

Empuje la carcasa hacia abajo todo

lo posible sobre los tornillos de montaje para lograr una conexión firme.

Destrabe las ruedas cuando mueva la

unidad.

Limpie las ruedas si es necesario.

Pida una rueda de recambio a

Welch Allyn.

Page 35

!!!

!

FRANÇAIS

60cm

!

Nous vous remercions d’avoir acheté l’appareil d’éclairage

articulé Welch Allyn LS200

™

, conçu par un chef de file mondial dans la fabrication d’instruments de diagnostic avec

éclairage.Veuillez suivre les instructions d’emploi et d’entretien

contenues dans ce manuel; vous serez assuré d’obtenir de

nombreuses années de fonctionnement fiable de votre nouvel

appareil d’éclairage articulé LS200. Lisez attentivement ces

instructions avant l’emploi.

AVERTISSEMENT

Tous les utilisateurs de cet appareil d’éclairage doivent posséder une formation

complète des procédures médicales appropriées à l’équipement. Par ailleurs,

ils doivent lire et assimiler les instructions concernant tout autre équipement

utilisé conjointement avec l’appareil d’éclairage articulé LS200™.

La lumière des lampes est extrêmement vive. NE PAS regarder les lampes

directement lorsqu’elles sont allumées.

NE PAS placer le luminaire vers le haut lorsque les lampes sont allumées.

ATTENTION

Débrancher le cordon d’alimentation de la prise secteur et laisser les lampes

refroidir avant de les remplacer (ne les remplacer que par des lampes Welch

o

Allyn n

Les parties métalliques accessibles de cette unité sont isolées du conducteur de

mise à la terre du cordon d’alimentation. Si la mise à la terre des parties accessibles est jugée nécessaire, employer un cordon de mise à la terre séparé.

Pour réduire le risque d’électrocution, ne pas démonter l’unité. Confier les réparations au personnel technique qualifié.

06400).

ATTENTION

L’utilisation à une distance de moins de 12 pouces (30,5 cm) pour

des périodes de temps prolongées peut causer de l’érythème.

La distance correcte d’utilisation est de 24 pouces (60 cm).

ATTENTION

L’interrupteur sur la luminaire n’est PAS un interrupteur principal. Le transformateur s’amorce quand la lumière est branchée sur le circuit principal.

DANGER

Risque d’explosion en présence d’anesthésiques inflammables.

SURFACE BRULANTE

L’enjoliveur situé à l’avant des lampes risque d’être brûlant.

33

Page 36

TABLE DES MATIÈRES

Eléments..................................................................35

Montage ..................................................................36

Sur socle mobile ..............................................36

Sur support mural ............................................37

Fixation à la tige en bois ..........................37

Fixation à un mur en béton ou en brique 38

Transformateur ................................................40

Instructions de fonctionnement............................40

Instructions de transport de l’unité

sur socle mobile ..............................................40

Réglage du bras ..............................................41

Remplacement d’une lampe..................................41

Remplacement d’une fusible ................................43

Nettoyage ................................................................44

Entretien et réparations ........................................44

Garantie ..................................................................44

Caractéristiques électriques..................................45

Environnement de fonctionnement ......................46

Guide de dépannage ..............................................47

34

Page 37

ÉLÉMENTS

ENSEMBLE

BRAS/LUMINAIRE

CONNECTEUR

UNIVERSEL

(B)

BAGUES

DE

SERRAGE

(D)

CORDON

D’ALIMEN-

TATION

(e)

OUTILLAGE DE

MONTAGE DU

SOCLE MOBILE

CLÉS ALLEN

TRANSFORMATEUR

BOULON

À CHA-

PEAU

(F)

VIS À

TÊTE

PLATE

(b)

SUPPORT MURAL

BRAS DE

RALLONGE

(G)

OUTILLAGE DE MONTAGE

DU SUPPORT MURAL

VIS À

VIS À

MAÇONNERIE

VIS À BOIS

TÊTE

PLATE

(b)

CLÉ ALLEN

OUTILLAGE DE

MONTAGE DU

TRANSFORMATEUR

EXTRÉMITÉ

DU

PIED

(A)

SOCLE MOBILE

VERROUILLAGE

DES ROULETTES

VIS DE MONTAGE DU

TRANSFORMATEUR

(C)

BASE DU

SOCLE MOBILE

RONDELLE DE

BLOCAGE

(f)

35

VIS À

BÉTON

VIS À

BOIS

Page 38

MONTAGE

SUR SOCLE MOBILE

1. Retirer le socle, le pied et le kit d’outillage de leurs boîtes.

2. Placer le socle sur le sol, les roulettes abaissées, et verrouiller les

roulettes.

3. Insérer l’extrémité (A) du pied dans le trou ménagé dans le socle

mobile.

4. Faire tourner le pied jusqu’à ce qu’il soit aligné sur

la tige et se mette en place.

5. Insérer le boulon à chapeau (F) et la rondelle de

blocage (f) dans la traverse du socle, puis dans le pied ;

serrer à l’aide d’une clé Allen de 6,35 mm (1/4 po).

6. Retirer avec précaution l’ensemble bras/

luminaire LS200 de la boîte. Accrocher le

transformateur sur les vis de montage

installés en usine (C), situées sur le pied,

et le faire glisser jusqu’à ce qu’il soit

solidement fixé.

7. Placer l’ensemble bras/luminaire sur le

pied en faisant glisser le connecteur universel (B) sur l’extrémité supérieure du

pied et aligner les trous des vis.

8. Insérer la vis à tête plate (b) de 13 mm

(0,5 po) dans le trou ménagé sur le côté

du connecteur universel, puis serrer à

l’aide de la clé Allen de 4 mm (5/32 po).

9. Pousser le cordon d’alimentation du

transformateur dans les bagues de

serrage (D) du pied, en laissant une

longueur suffisante pour permettre le

mouvement complet du bras.

10. Fixer le cordon d’alimentation (e) au

transformateur.

11. Pour verrouiller les roulettes, enfoncer

leur patte de verrouillage.

12. Avant de déplacer l’éclairage de procédure

LS200, se reporter aux “Instructions de

transport”, page 40.

(b)

(D)

VERROUILLAGE

DES

ROULETTES

(A)

(B)

(e)

(C)

ALIGNER LA

TIGE DU SOCLE

MOBILE SUR

L’EXTRÉMITÉ

DU PIED.

(f)

(F)

36

Page 39

MONTAGE SUR SUPPORT MURAL

ATTENTION : NE PAS monter

dans du placoplâtre. Monter

dans la tige.

Le bras de l’appareil

d’éclairage articulé LS200 est

conçu pour ne pas dépasser

90°; la distance de travail

est de 60 cm (24 po).

Pour assurer son

positionnement correct

4"

4"

sur le mur, placer le bord

supérieur de la plaque murale à

10 cm (4 po) au-dessus de la

surface de travail.

REMARQUE : mettre la plaque

murale à l’horizontale à l’aide

d’un niveau de menuisier pour

assurer un déplacement précis

sans dérive.

Fixation à la tige en bois :

1. Retirer l’ensemble de montage mural et le kit d’outillage de la boîte.

2. Choisir un emplacement de montage mural de la tige à moins de 2,4 m

(8 pieds) de la prise secteur.

3. En utilisant la plaque murale comme gabarit, la placer à l’endroit choisi

du mur, la positionner à l’horizontale et marquer les deux trous.

4. Enlever la plaque murale et forer

des trous de guidage à l’aide

d’un foret de 3 mm (0,12 po).

5. Placer la plaque murale

contre le mur et insérer

à moitié

la vis à bois

supérieure de 3,8 cm

(1,5 po) dans la tige en bois.

6. Mettre la plaque murale à

l’horizontale l’aide d’un

niveau et la fixer au bas

au moyen de la vis à bois

de 3,8 cm (1,5 po).

7. Serrer la vis à bois

supérieure.

8. Préparer le montage du

transformateur en

suivant les instructions

intitulées “Montage

du transformateur”, page 40,

étapes 1 à 4.

TIGE EN BOIS

NIVEAU

VIS A BOIS

BRAS DE

RALLONGE (G)

37

Page 40

9. Retirer avec précaution l’ensemble bras/luminaire LS200 de la boîte. Terminer le montage

du transformateur en suivant les étapes 5 et

6 des instructions, page 40.

10. Placer l’ensemble bras/luminaire sur le bras

ENSEMBLE

BRAS/LUMINAIRE

(b)

CONNECTEUR

UNIVERSEL (B)

de rallonge en faisant glisser le connecteur

universel (B) sur le bras de rallonge (G) et en

alignant les trous des vis.

11. Insérer la vis à tête plate (b) de 13 mm (0,5

po) dans le trou ménagé sur le côté du connecteur universel, puis la serrer. Déplacer le

bras vers le haut et le bas pour s’assurer que

BRAS DE

RALLONGE (G)

le montage est solide.

12. Pousser le cordon d’alimentation dans les bagues de serrage de la face

inférieure du bras de rallonge.

Fixation à un mur en béton ou en brique :

1. Retirer l’ensemble de montage mural et le kit d’outillage de la boîte.

ATTENTION : NE PAS utiliser les deux trous centraux de la plaque

murale sur des murs en béton. Forer des trous supplémentaires

pour le montage sur des surfaces en maçonnerie afin d’assurer

une fixation durable.

2. Forer des trous dans la plaque murale en procédant comme suit:

a. Placer la plaque murale sur une surface en bois pouvant être

forée.

b. Aux coins de la plaque murale, marquer quatre trous à 2,5 cm

(1 po) de chaque bord.

c. Utiliser un centreur pour commencer les trous.

d. Forer quatre trous à l’aide d’un foret de 5,1 mm (13/64 po).

TROUS DE MAÇONNERIE

2,54 cm

(1 PO)

2,54 cm (1 PO)

TROUS DE MAÇONNERIE

3. Choisir un emplacement de montage mural situé à moins de 2,4 m

(8 pieds) de la prise secteur.

4. En utilisant la plaque murale comme gabarit, la placer à l’endroit choisi

du mur et marquer le trou supérieur gauche.

38

Page 41

5. Enlever la plaque murale et utiliser un centreur pour commencer le

trou.

6. À l’aide d’un marteau perforateur et d’un foret de maçonnerie de

4 mm (5/32 po), forer un trou d’une profondeur minimum de 4 cm

(1,5 po).

7. Placer la plaque murale contre le mur et insérer

à moitié

la vis de

maçonnerie de 3,2 cm

(1,25 po) dans le mur.

8. Mettre la plaque

murale à l’horizontale

à l’aide d’un niveau et

la fixer en serrant la

vis.

NIVEAU

BRAS DE

RALLONGE (G)

9 La plaque murale étant

en place, percer les

trois trous restants.

10. Forer les trous

restants.

11. Fixer la plaque murale

à l’aide des trois vis

restantes.

12. Préparer le montage du transformateur en suivant les instructions

intitulées “Montage du transforma-

(b)

ENSEMBLE

BRAS/

LUMINAIRE

CONNECTEUR

UNIVERSEL (B)

teur”, page 40, étapes 1 à 4.

13. Retirer avec précaution l’ensemble

bras/luminaire LS200 de la boîte.

BRAS DE

RALLONGE

(G)

Terminer le montage du transformateur en suivant les étapes 5 et 6 des

instructions, page 40.

14. Placer l’ensemble bras/luminaire sur le bras de rallonge en faisant

glisser le connecteur universel (B) sur le bras de rallonge (G) et en

alignant les trous des vis.

15. Insérer la vis à tête plate (b) de 13 mm (0,5 po) dans le trou ménagé

sur le côté du connecteur universel, puis la serrer. Déplacer le bras

vers le haut et le bas pour s’assurer que le montage est solide.

16. Pousser le cordon d’alimentation dans les bagues de serrage de la

face inférieure du bras de rallonge.

39

Page 42

3-1/8 po

8 cm

MONTAGE DU TRANSFORMATEUR

1. Choisir l’outillage de montage approprié dans le kit d’outillage de la

boîte de montage en option du LS200 : choisir des vis à bois de 2,5 cm

(1 po) pour le montage dans la tige en bois et des vis à métaux de 2,5

cm (1 po) ainsi que des fixations en plastique pour le montage sur un

mur en béton ou en brique.

2. Choisir un emplacement de transformateur qui soit situé à moins de

2,4 m (8 pieds) d’une prise secteur et à moins de 3,81 cm (1,5 po) de la

plaque de montage murale, afin de laisser une longueur suffisante pour

le mouvement complet du bras.

3. En utilisant le gabarit illustré à

gauche de cette page (8 cm [3/8 po]

au centre), marquer l’emplacement

des trous de forage sur le mur.

Veiller à ce qu’ils soient verticaux.

Murs en bois:

Aucun trou de guidage n’est

nécessaire. Utiliser les vis

à bois de 3,8 cm (1,5 po)

du kit d’outillage du

transformateur.

Murs en béton:

A l’aide d’un marteau

perforateur et d’un foret à

maçonnerie de 2,3 mm

(3/16 po), forer les trous des

attaches en plastique à une

profondeur de 2,5 cm (1 po)

minimum. Enfoncer les

attaches en plastique du kit d’outillage du transformateur

jusqu’à ce qu’elles soient à ras.

4. Enfoncer les vis dans le mur, jusqu’à ce que leurs têtes fassent saillie à

2,3 mm (11/32 po).

5. Monter le transformateur en plaçant les trous ronds ménagés à l’arrière

sur les vis de montage du mur, puis le glisser vers le bas jusqu’à ce

qu’il soit solidement fixé.

6. Fixer le cordon d’alimentation au transformateur.

INSTRUCTIONS DE FONCTIONNEMENT

INSTRUCTIONS DE TRANSPORT

DE L’UNITE SUR SOCLE MOBILE

YES

OUI

1. Afin d’empêcher l’éclairage de se renverser,

placer le bras à un angle de 45° ou plus pour

déplacer l’appareil sur ses roulettes.

2. Centrer le bras dans son rayon d’action.

3. Déverrouiller les roulettes en relevant les pattes

et tenir l’unité par le haut du pied pour la

déplacer.

40

NO

NON

45

˚

Page 43

RÉGLAGE DU BRAS

L’appareil d’éclairage articulé LS200 a été conçu

pour permettre le réglage de la résistance

aux articulations du bras.

L’articulation principale comporte un grand

A

bouton, qui en facilite le réglage. Tourner ce

bouton pour obtenir la tension nécessaire.

REMARQUE: il n’est pas nécessaire de

régler ce bouton à chaque utilisation.

Le réglage de la tension reste le même

pendant de nombreux mouvements.

BOUTON DE

RÉGLAGE

Ne JAMAIS dévisser complètement le

bouton. Les articulations supérieure

et inférieure ont déjà été réglées chez

Welch Allyn. Si d’autres réglages s’avèrent nécessaires, un

tournevis permet d’augmenter ou de diminuer la résistance des

articulations en réglant les vis d’arrêt au point (A) ou (B).

REMPLACEMENT D’UNE LAMPE

AVERTISSEMENT : les lampes fonctionnent à haute température. NE PAS

tenter de les remplacer pendant qu’elles sont brûlantes. Attendre qu’elles

aient refroidi. Les manipuler avec précaution, car elles peuvent se briser

sous pression. Ne les remplacer que par les lampes Welch Allyn n

1. Mettre le commutateur marche/arrêt en position OFF et débrancher

le cordon d’alimentation de la prise secteur.

2. Tourner le luminaire de manière à ce que l’enjoliveur et la poignée

soient face à l’utilisateur (voir A).

3. Tourner la poignée dans le sens inverse des aiguilles d’une montre pour

la dévisser (voir B). Retirer la poignée et faire glisser l’enjoliveur avec

précaution pour l’enlever; le laisser sur son fil d’attache métallique (voir

C).

4. Repérer le levier de dégagement situé sur le porte-lampe et le pousser

vers le bas (voir D).

o

06400.

B

A

ENJOLIVEUR

POIGNÉE

41

TOURNER DANS

LE SENS INVERSE

DES AIGUILLES

D’UNE MONTRE

B

Page 44

FIL D’ATTACHE

LEVIER DE

DÉGAGEMENT

C

D

5. Saisir la lampe usée par sa base entre le pouce et l’index et la faire

glisser en dehors du porte-lampe (voir E).

6. Remettre le levier de dégagement en position relevée (voir F).

EF

7. Sortir la lampe de rechange Welch Allyn n

o

06400 de son

emballage.

8. Saisir la lampe de rechange entre le pouce et l’index (voir G).

REMARQUE: essayer de ne pas toucher l’intérieur du réflecteur

—

la saleté ou l’huile peuvent réduire la luminosité. Nettoyer en suivant

les instructions de la page 44, si nécessaire.

9. Faire glisser la lampe avec précaution dans le porte-lampe en la tenant entre le pouce et l’index ; veiller à insérer la base de la lampe

dans la douille et le réflecteur sous le ressort (voir H).

ALIGNER

RESSORT

GH

10. Pour positionner correctement la lampe dans la douille, enfoncer délicate ment la lampe jusqu’à ce qu’elle soit bien calée et en place

(voir I).

42

Page 45

11. Remettre l’enjoliveur en place. Veiller à aligner les trois “fenêtres”

lisses de l’enjoliveur avec les lampes et les languettes sur

le bord de l’enjoliveur avec les rainures situées dans le boîtier

blanc (voir J).

12. Remettre la poignée en place et la tourner dans le sens des aiguilles

d’une montre jusqu’à ce qu’elle soit bien serrée. (voir J).

ALIGNER LES

FENÊTRES DE

L’ENJOLIVEUR

AVEC LES LAMPES

TOURNER

DANS LE SENS

DES AIGUILLES

D’UNE

MONTRE

I

J

REMPLACEMENT D’UN FUSIBLE

Deux fusibles remplaçables sont contenus dans le porte-fusibles du boîtier

du transformateur. Si l’un ou l’autre fusible saute, l’unité ne s’allume pas. Ne

remplacer les fusibles que par des pièces Welch Allyn, numéro de référence

236706-3907 pour le modèle 44200, ou 236706-3114 pour les modèles

44202, 44204 et 44206.

1. Mettre le commutateur marche/arrêt en position OFF et

débrancher le cordon d’alimentation de la prise secteur.

2. A l’aide d’un petit tournevis de 8 mm (1/8 po), retirer le

porte-fusibles (a) du boîtier du transformateur en relâchant les

raccords à ressort (b) situés des deux côtés de l’élément.

3. Retirer le porte-fusibles.

4. Enlever le ou les fusibles sautés et les remplacer. Il n’est pas néces-

saire de les orienter d’une certaine manière.

5. Réinsérer le porte-fusibles en l’enfonçant dans le connecteur jusqu’à

ce qu’un déclic se produise.

T 1A, 250V

REPLACE FUSES AS MARKED

(a)

PORTEFUSIBLES

43

T 1A, 250V

REPLACE FUSES AS MARKED

(b)

RACCORD À

RESSORT

Page 46

(a) PORTE-FUSIBLES

(b)

RACCORD À

RESSORT

FUSIBLES

T 1A, 250V

REPLACE FUSES AS MARKED

NETTOYAGE

Avant de procéder au nettoyage, mettre le commutateur marche/arrêt en

position OFF et débrancher le cordon d’alimentation de la prise secteur.

Nettoyer toute l’unité avec un chiffon légèrement imbibé d’une faible solution de

détergent et d’eau ou de produit de nettoyage pour verre. Veiller à ne pas

mouiller les griffes de la prise. Essuyer l’unité avec un chiffon propre et sec.

NE PAS brancher l’appareil d’éclairage articulé LS200 sur la prise secteur tant

qu’il n’est pas complètement sec.

IMPORTANT

Veiller à ne pas laisser de solution goutter dans le luminaire.

NE PAS vaporiser de solution directement dans les articulations.

NE PAS stériliser les éléments de l’unité.

NE PAS immerger de partie de l’unité dans des solutions de nettoyage.

ENTRETIEN ET RÉPARATIONS

Pour les petits problèmes, se reporter au “Guide de dépannage”, page 47-48,

pour les causes possibles et les mesures à prendre.

Ne confier les inspections électriques de l’appareil d’éclairage articulé LS200

qu’au personnel technique agréé.

Réparations: pour contacter le personnel technique qualifié, s’adresser au

concessionnaire local agréé Welch Allyn, ou contacter directement Welch Allyn

en téléphonant au (315) 685-4560.

GARANTIE

L’appareil d’éclairage articulé LS200 est garanti par Welch Allyn contre tout

défaut de fabrication. Welch Allyn réparera ou remplacera gratuitement toutes

les pièces de sa fabrication jugées défectueuses, pour des raisons autres que

l’abus, la négligence, les dégâts survenus pendant le transport ou l’usure normale. Cette garantie est valable trois ans à partir de la date d’achat.

44

Page 47

CARACTÉRISTIQUES ÉLECTRIQUES

A

D

B

E

C

Schéma de câblage

CORDON D’ALIMENTATION

A

POUR HÔPITAUX

FUSIBLES

B

TRANSFORMATEUR -

C

ABAISSEUR, ISOLÉ

Entrée/sortie

Homologations

La marque CE figurant sur ce produit indique que les résultats des tests

auxquels il a été soumis sont conformes aux dispositions de la Directive

89/336/EEC sur la compatibilité électromagnétique et de la Directive

73/23/EEC sur les basses tensions.

Adresse du représentant européen agréé :

Courant de fuite

COMMUTATEUR MARCHE-

D

ARRÊT

E

LAMPES

Entrée :

Modèle 44200 : 120 Vca, 60 Hz 0,70 A

Modèle 44202 : 230 Vca, 50 Hz 0,35 A (Europe, sauf

Modèles 44204,

44206 : 240 Vca, 50 Hz 0,35 A(Australie,

Sortie: 12,0 Vca @ 5,0 A (trois lampes de

Modèle 44200 : UL 544 — Equipement médical de

Modèles 44202,

44204, 44206 : IEC 601-1 - Equipement médical

European Regulatory Manager

Welch Allyn Ltd., Kells Road, Navan, County Meath

Republic of Ireland Tél : 353 46 28122 Télécopieur : 353 46 28536

(É.-U./Canada/Amérique du Sud/Japon)

Royaume-Uni)

Royaume-Uni)

20 watts)

catégorie 1 CSA 22.2-125

médical de catégorie 2G

de catégorie 1, type B

Moins de 50 µA de n’importe quelle

pièce métallique

45

— Equipement

Page 48

Fusibles Remplaçables par l’utilisateur (ligne

et neutre).

Modèle 44200 : 1 A, 250 V, action retardée.

Modèles 44202,

44204, 44206 : (Fusible) T500 mA, L250V retard (slow-

blow), basse capacité de rupture.

Caractéristiques principales

Illumination : Intensité : rendement moyen de 2 500

Longueur du

cordon : Cordon de sortie : 1,2 m (4 po)

Luminaire : Diamètre : 24 cm (9,5 po)

Dimensions principales : Bras : 50 cm (20 po)

unités d’éclairage (moyenne 21 000

lux) à 60 cm (24 po)

Température de couleur : 3 200° Kelvin

Distance de travail : 60 cm (24 po)

Diamètre du spot : 18 cm (7 po)

Profondeur de champ : 30 cm (12 po)

total, ± 15 cm (6 po)

Lampes : réflecteur dichroïque,

durée de vie moyenne de lampe :

3 000 heures

Cordon d’entrée (détachable) : 3,0 m

(10 po)

Matériau: polycarbonate Lexan™ 940

Bras de rallonge mur/table : 25 cm (10 po)

Du mur au centre du luminaire (à 228,6

cm [90 po] du mur) : 90 cm (36 po)

Hauteur du socle mobile : 1,2 m (46 po)

Pieds du socle mobile : longueur

40 cm (16 po) x largeur 2,5 cm

(1 po) x hauteur 5 cm (2 po)

Base du socle mobile : longueur 40 cm

(16 po) x largeur 46 cm (18 po) x

hauteur 6 cm (2,5 po)

ENVIRONNEMENT DE

FONCTIONNEMENT

Usage intérieur uniquement

Température ambiante : de 10°C à 40°C

Humidité relative : de 30% à 75%

Pression atmosphérique : de 700 hPa à 1060 hPa

Mode de fonctionnement : continu

Environnement de transport et de stockage :

Température ambiante : de -40°C à 70°C

Humidité relative : De 10% à 100%

46

Page 49

GUIDE DE DÉPANNAGE

PROBLEME

La lumière ne

s’allume pas

lorsque le

commutateur

est actionné.

Changement

de qualité de

spot

ou diminution

d’intensité de

l’éclairage.

CAUSE(S) POSSBLE(S)

Cordon d’alimentation

desserré.

Un fusible a sauté.

Pas d’alimentation à la prise

murale.

Cordon d’alimentation

endommagé.

Une lampe a sauté.

Une lampe n’est pas insérée

correctement dans sa douille.

L’enjoliveur situé à l’avant du

luminaire n’a pas été aligné

correctement.

SOLUTION

Vérifier le branchement à la

prise murale et à l’alimentation électrique.

Vérifier le fusible. Le tube en

verre est noirci si un fusible

a sauté. Remplacer le fusible