Page 1

LS-135 & LS-150 Halogen Exam Lights

INTRODUCTION

Thank you for purchasing your new Halogen Exam Light by Welch Allyn, the worldwide le ader in illuminated medical diagnostic

instrumentation. By following the use and care guidelin es given in this booklet, you will enjoy years of dependable, trouble-free

service from your new exam light.

This exam light can be used for topical examinat ions of the skin such as abrasions, foreign body removal, and other similar

applications.

SYMBOLS

Protective shield. Replace any cracked protective shield.

Tungsten Halogen Lamp On or full light intensity position.

“INDOOR”

Indoor use only. On or low light intensity position (LS-135

WARNINGS & CAUTIONS

CAUTION: All users of this exam light should be thoroughly t rained in the medical examinations appropriate to the

equipment. Furthermore, they should read and understand the instructions contained within this manual before use.

Failure to do so may result in injury to the patient or damage to the equipment.

CAUTION: Do not use the LS-135 or LS-150 for tran sillumination, as erythema may result. Co ntact Welch Allyn regarding appropriate lights for transillumination a pplications.

INTENSE LIGHT: Lamp is extremely bright. Do not stare at the lamp when in use. May be harmful to eyes.

CAUTION: Remove power cord from electrical outlet and allow lamp to cool 10 minutes before replacing with Welch

Allyn lamp. For the LS-135 use lamp No.: 04430 and for the LS-150 use lamp No.: 04450.

DANGER: Electric Shock Hazard - do not disassemble the instrument. Refer servicing to qualified service personnel. There are no user serviceable part s other than the lamp.

CAUTION: Use the examination light in its intended working range of 12 t o 36 inches. Exposures at closer distances may be harmful to skin.

DANGER: Risk of explosion if used in the presence of flammab le anesthetics.

IPXØ: Not protected against the ingress of wate r.

HOT SURFACE: Lamp surface is hot. May be harmful to skin if touched.

Guidelines for the safe use of the LS-135 & LS-150 include:

General good practices to mi nimize risk of harm to the skin from optical radiation hazards include: minimizing illumination intensity

at the tissue examination site, minimizing expo sure times, and taking additional precautions when skin sensitivity has been alt ered

through tissue trauma or the use of anesthesi a.

General good practices to minimize risk of h arm to the eyes from optical radiation hazards include: avoiding looking at

bright light sources and their reflections, and p rotecting eyes where normal pupil sizes and aversion responses are not

present.

NOTE: This product complies with current required standards for electromagnetic interference and should not

interfere with other equipment or be affected by other compliant devices. As a precaution, avoid using this

device in close proximity to other equipment.

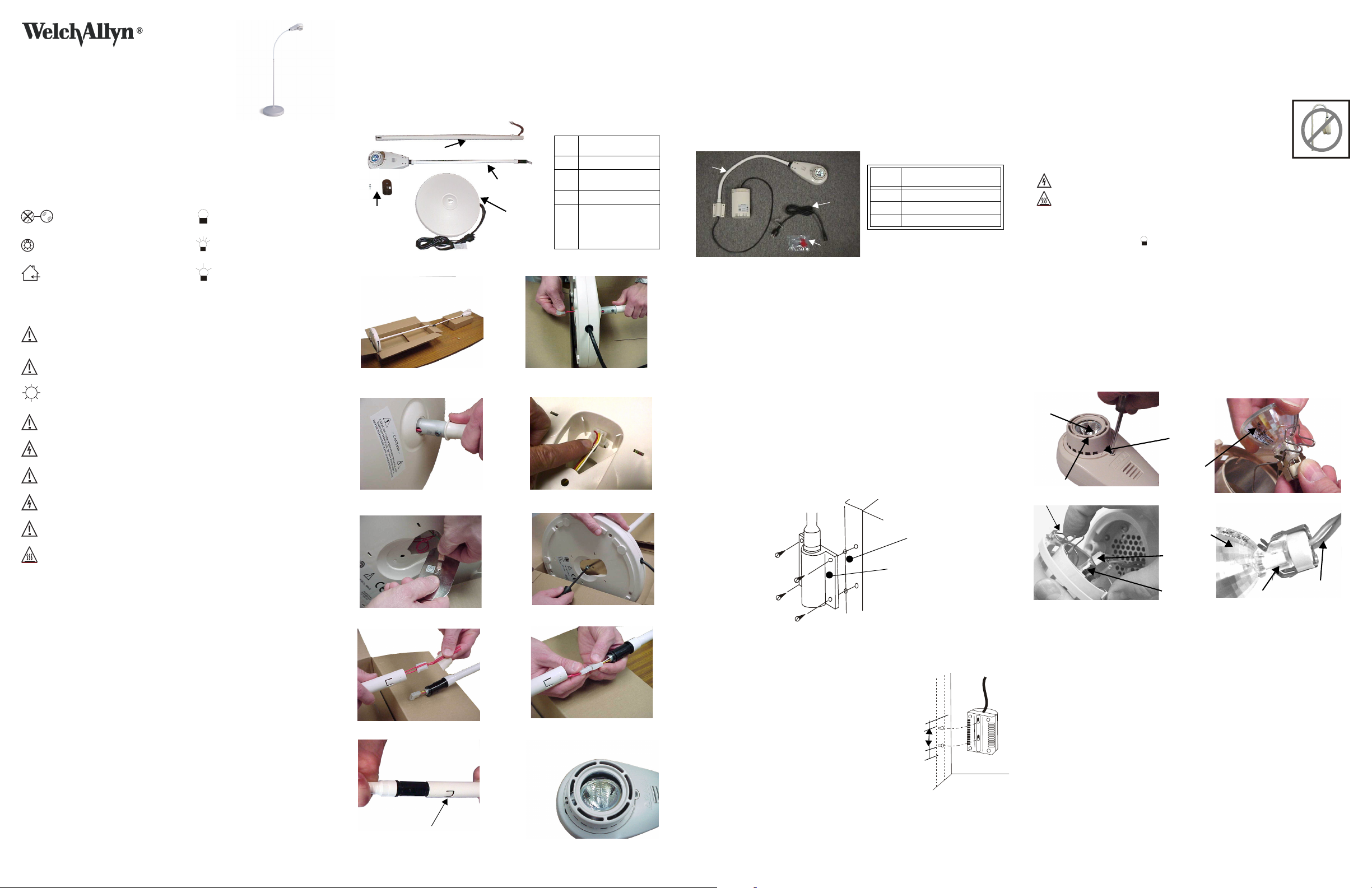

ASSEMBLY INSTRUCTIONS FOR LS-135 & LS-150

FLOOR STAND MODELS

NOTE: Follow the assembly instructions listed below and their corresponding photographs.

Required tools for assembly: Phillips #2 or #3 screwdriver.

1. Remove all items from the shipping ca rton. Check for damage or missing components. Refer to photo 1 and table 1. Notify

Welch Allyn, or your nearest Service Center of any dam age or missing parts using the appropriate phone number listed on

the back.

2. Using the shipping box as an assembly aid; place the base (item 1) on its side oriented in the box as shown in photo 2a.

3. Obtain the pole (item 3). Identify a nd orient the pole’s flange end with wire harness to the base and fe ed wire harness

through base center hole as shown in photo 2b. Align wire harness into notch in base as shown in photo 3, then seat pole

into base. EXERCISE CARE WHEN INSERTING POLE AND HARNESS INTO BASE. DO NOT PINCH WIRES.

4. Connect pole’s wire harness connector to the corresponding connecto r in the base as shown in photo 4. Align and press firmly into place.

5. From the parts kit, obtain the base cover pla te and attach the remaining wire connector to the corresponding tab loca ted on the cover plate. Refer to photo 5.

6. From the parts kit, obtain the screw and external lockwasher and install through the plate, place the plate into the b ase, threading screw clockwise into pole. Tighten firmly, using screwdriver. Refer to photo 6.

Off position when rocker switch is oriented towards this marking.

only).

7. With the base/pole still lying on its side, gently pull the e lectrical connector from inside of the pole using the twist tie.

Remove and discard twist tie. Refer to p hoto 7. Orient the Luminaire-flexible arm assembly’s electrical connector to the

remaining pole electrical connector and conne ct each by firmly pressing together. Refer to photo 8.

8. Connect the flexible arm to the pole b y lining up the slots on the black plastic con nector (nearest the electrical connector) above the pole cut outs. Push flexible arm into pole until it clicks into place. Refer to photo 9.

9. Prior to plugging the unit into t he appropriate outlet, inspect the lamp to insure that it has not become u nseated during

shipment (Refer to photo 10). If the lamp is not properly seate d in the lamp housing, use your fingertips to gently press

against the protective cover glass of the lamp to spring the lam p back into the proper position. If the lamp can not be easily

reseated by this method, refer to the Lamp Replacement instructions to open the Lamp Housing and reseat the la mp.

10. Stand light assembly up onto its base and plug into an appropriate outlet. Please refer to warnings and ca ution section as well as the operations section prior to use.

3

2

4

#1

#2A

#3

#5

#7

Pole Cut Out

#9

1

No. Description

1 Base Assembly

2 Luminaire-Flexible Arm

Assembly

3 Pole Assembly

4 Parts Kit

• Base Cover Plate

• Screw 1/4-20 x 1” Phillips

•1/4” External Lockwasher

(443062-501)

Table #1

#2B

#4

#6

#8

#10

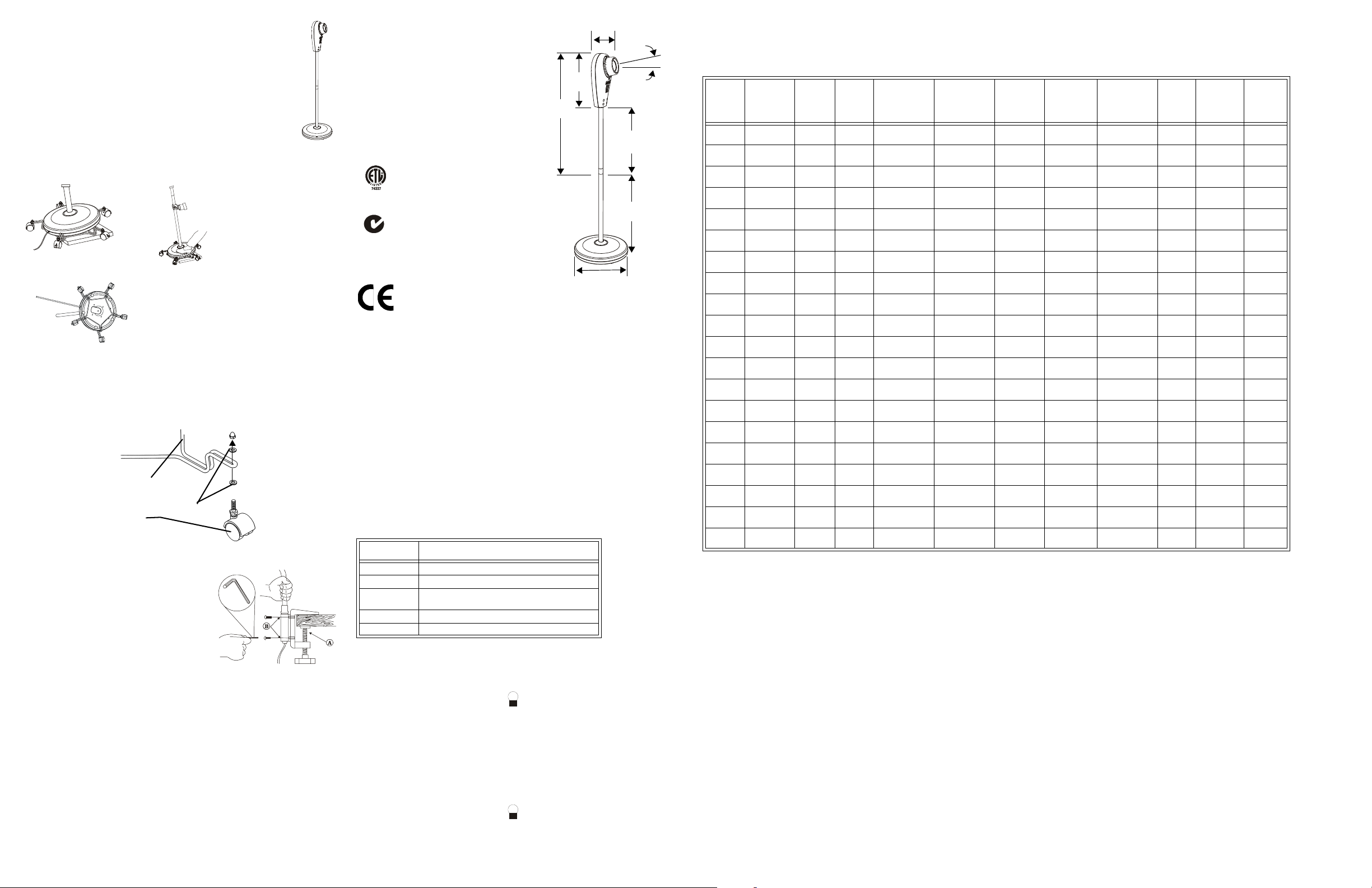

ASSEMBLY INSTRUCTIONS FOR LS-135 & LS-150

WALL MOUNT MODELS

Required tools for assembly: Electric drill, 3mm (1/ 8”) and 4.7mm (3/16”) diameter drill bits, #2 phillips screwdriver, bubble level,

linear scale.

Wall Unit

1. Remove all items from shipping carton and check for damage. Refer to photo and table. Notify Welch Allyn or your nearest Service Center of any damage or missing parts using the appropriate phone number listed on the back.

2. Identify the type of wall construction you intend to mount the wall unit onto (and if applicable, transformer). Generally wall types can be described as follows:

• Dry wall (gypsum or plaster) with wood studs OR metal studs

•Masonry

• Wood (solid or heavy 19mm (3/4”) thick veneer)

1

NO. Description

2

3

3. Identify the desired location for ligh t (and if applicable, transformer). In general, the wall unit must be installed so that at

least two of its four fasteners extend into the walls structural members (studding or structural masonry). The cable length

between the light and transformer is 1.1m (3.5’) and power cord length is 2.4m (8’).

4. Position the unit’s mounting bracket onto the wall and level. Using t he bracket as a template, mark the four mount hole locations. Locate parts kit containing screws and plastic anchors. Mount as follows:

• For studded dry wall:

1. Pre-drill two 3mm (1/8”) holes 19mm (3/4”) deep that are located over the structural studding (one side of the bracket).

2. Pre-drill two 4.7mm (3/16”) holes just through the drywall surface located op posite the previous holes. Install two plastic anchors into these holes.

3. Place mounting bracket over the holes and :

• Install two #8-1.5” tapping screws through bracket and into the holes drilled in step 1.

• Install two #8- 1.5” t apping screws through bracket and into the plastic anchors installed in

step 2.

• For masonry type walls:

• For wood walls:

• Tighten all four screws.

• Tighten all four screws.

1. Pre-drill four 4.7mm (3/16”) holes 38 mm (1.5”) deep. Install four plastic anchors into these holes.

2. Place mounting bracket over the holes and :

• Install four #8-1 .5” tapping screws through the bracket and into the plastic anchors installed in

step 1.

• Tighten all four screws.

1. Pre-drill four 3mm (1/8”) holes 25 mm (1”) deep.

2. Place mounting bracket over the holes and :

• Install four #8 -1.5” tapping screws through bracket and into the wall.

TRANSFORMER

Mount the transformer to the wall using the hardware provided and integral brackets on the back of the transformer. Locate the

transformer an appropriate distance fr om the light assembly, but within 2.4m (8’) from a suitable outlet.

NOTE: For studded dry wall, identify a stud location (p referably on the

same stud used to mount the light assembly). If a stud location is not

available, you can use drywall only mounting as described below.

1. Place the transformer at the desired height and mark a short horizontal line corresponding to the top of the transformer. From this line, mark a vertical and plumb line down approximately 12cm (5”).

2. Mark hole location one 1.9 cm (3/4”) down from the horizont al line. Mark hole location two 8 cm (3 1/8”) down from hole location one. Refer to figure.

• For dry wall over a stud or wood:

1. Pre-drill two 3mm (1/8”) holes 19mm (3/4”) deep that are located over the structural studd ing.

2. Screw two #8 1.5” tapping screws into wall

allowing the screw heads to protrude 2. 3mm (11/

• For dry wall only or masonry:

32”).

1. Pre-drill two 4.7mm (3/16”)holes just through the drywall surface or 38mm (1.5”) into masonry. Install two plastic anchors into these holes.

2. Install two #8-1.5” tapping screws into the p lastic anchors allowing the screw heads to protrude 2.3mm (11/32”).

1 Light/Transformer Assembly

2 Power Cord

3 Mounting Hardware (443184-501)

Structural Stud

Mounting Bracket

1.9 cm (3/4”)

8 cm (3 1/8”)

OPERATION OF FLEXIBLE ARM

Your new LS-135 & LS-150 light has been carefully designed to give you opt imum performance to enable you to easily articulate

and place the light exactly where you need it . These design attributes include:

• The lamp has been offset at a 12° angle relative to the Lumin aire housing, allowing the physician an unobstructed view

of the field of interest.

• A pole to flexible arm joint that allows the flexible arm to be freely rotated about the pole 270°.

• A flexible arm to Luminaire joint that allows rotation of the Luminaire about the flexible arm 300°.

• A 24” flexible arm that allows you to easily a rticulate and hold the Luminaire in an infinite number of positions.

Please use the following guidelines for proper articulation of the flexible arm:

• The flexible arm should be articulated (bent), NOT TWISTED. Twisting of the flexible arm

beyond its rotation stops will decrease the life of the arm and can cause it to lose its ability

to hold position.

• Failure of the flexible arm due to twisting may void the warranty.

Special Note: We recommend that you DO NOT acutely bend the flexible arm as shown to the right.

LAMP REPLACEMENT

Disconnect power cord from electrical ou tlet prior to replacement.

Allow lamp to cool 10 minutes prior t o replacement.

1. Exposing the Lamp (Refer to photo 1)

• Turn power switch to the off (“ ”) position and unplug power cord from outlet.

• Rotate Light Assembly (A) so that the lamp points up (towards ceiling).

• Completely loosen screw in Lamp Housing (B) and lift to expose the Lamp (C).

2. Freeing the Lamp and Lamp Socket (Refer to pho to 2)

• Release the Lamp Retaining Wire (E) from the Lamp Housing (B) by pushing on wire “ears” towards Lamp Socket and

swing out as shown to free the Lamp (C) and Lamp Socket (D).

3. Removing the Lamp Socket (Refer to photos 3 and 4)

• Hold the Lamp (C) by its outer rim. Grasp the w hite sides of the Lamp Socket (D) as shown, pull on the Lamp Socket (D)

while rocking it slightly to remove it from the Lamp (C). Do not p ull on Lamp Socket Wires (G).

4. Install the new Lamp

• Verify that the lamp number located on the meta l plate inside the Light Assembly (H) (photo #2) matches the

replacement lamp number.

• Replace Lamp (C) and reattach Lamp Retaining Wire (E) to Lamp Housing (B).

• Align Lamp pins to Lamp Socket holes and reconnect Lamp Socket.

• Reinstall Lamp Housing (B) onto Light Assembly (A) by first engaging Lamp Housing tab (opposite screw) into Light

Assembly. Fully tighten screw.

• Reconnect Power cord and verify Lamp oper ation.

# 1

(B)

# 2 # 4

(H)

(D)

# 3

(C)

(C)

(G)

(D)

(C)

(A)

(E)

CLEANING

1. Unplug the unit prior to cl eaning.

2. The entire unit can be wiped down with a cloth slightly dampened with a mild solution of detergent and water. Wipe the unit dry with a clean, dry cloth. Be careful not to allow moisture to enter into the unit or allow the plug prongs to get wet.

3. Do not plug the light back into the elect rical outlet until the light is thoroughly dry.

NOTE: Do not sterilize the unit.

CAUTION: Do not immerse in cleaning solutions.

WARRANTY

Welch Allyn warrants that the LS135 and LS-150 Exam Light products meet the labeled specification s of the products and will be

free from defects in materials and workmansh ip that occur within one year after the date of purchase.

The date of purchase is: 1) the date specified in our records if you purchased the Product directly from us, 2) the date specified in

the warranty registration card that we ask you to send to us, or 3) the date of purchase of product from the authorized Welch Allyn

distributor as documented from a receipt from said distributor.

This warranty does not cover damage caused by: 1)ha ndling during shipping, 2) use or maintenance contrary to labeled instructions,

3) alteration or repair by anyone not authorized by Welch Allyn, and 4) accidents.

If a Product or accessory covered by this warranty is determined to be defective because of defective materials, components, or

workmanship, and the warranty claim is made within the warranty period described above, Welch Allyn will, at its discretion, repair

or replace the defective Product or accessory free of charge. If your Product requires repairs covered by this warranty, upon your

request Welch Allyn will loan to you, at no cost, a substitu te Product for use until your repaired Product is returned.

You must obtain a service notification number from Welch Allyn to return your Product before you send it to Welch Allyn’s

designated service center for repair. Contact Welch Allyn Technical Support.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITE D TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. WELCH ALLYN’S OBLIGATION UNDER THIS

WARRANTY IS LIMITED TO REPAIR OR REPLACEMENT OF PRODUCTS CONTAINING A DEFECT. WELCH ALLYN IS NOT

RESPONSIBLE FOR ANY INDIRECT OR CONSEQUENTIAL DAMAGES RESULTING FROM A PRODUCT DEFECT COVERED BY THE

WARRANTY.

Page 2

CASTER BASE ACCESSORY ASSEMBLY INSTRUCTIONS

NOTE: The Exam Light must be assembled before the Caster Base Accessory is attached.

Attachment Instructions:

Place styrofoam block from accessory packaging box on floor. Then place Caster Base Accessory on

center of block so that casters are not touching the floo r.

Position the Exam Light flexibl e arm in neutral position as shown in Figure 1.

Place the Exam Light base into Caster Base Accessory centering power cord between two wire

frame legs, as shown in Figure 2. The Ex am Light base should rest on top of bent legs on the

opposite side.

Place hand and foot as shown in Figure 3. Use your foot to push the Exam Light base down firmly

until the base engages into the wi re frame.

NOTE: Do not force base into plac e by pushing down on the Light pole or pulling on flexible arm.

Check to insure that the Exam Light is assembled correctly with the Caster Base Accessory. To do this, lay the Exam light over on its

side and verify that the Caster Base Assembly’s wire frame is interlocked into t he notches of the Exam Light Base (see Figure 4). If

they are not interlocked, grasp the Exam Ligh t Base with one hand and one leg of the Caster Base Accessory with the other hand,

and turn in opposite directions until the Caster Base Accessory locks into the Exam Light Base notches.

Figure 2. Base fitted into two bent legs

Figure 3. Push base into place with foot.

Do not force using pole.

Figure 4. Caster Base Accessory assembled

correctly with Exam Light Base.

Figure 1.

Flexible arm in

neutral position

Detachment Instructions:

Place locking casters in locked positi on.

Place foot on one of the five legs of t he metal frame. Then hold pole at the top near flexible arm and pole connection.

Simultaneously, lift and push the LS-135 & LS-150 Exam Light away from you, releasing the base from the Caster Base Accessory.

NOTE: Do not place foot on base while pushing and pullin g. Do not pull on flexible arm.

When ordering replacement parts for your Caster Base Accessor y, please use the following numbers:

Caster Base Frame

440094 Caster with brake

OR

440095 Caster without brake

No. 440094 Caster with brake, Acorn Nut and tw o Washers

No. 440095 Caster without brake, Acorn Nut and two Washers

Washers

TABLE CLAMP ACCESSORY ASSEMBLY

1. Securely tighten the clamp (A) to the chosen mounting surface.

2. Align the holes in the mounting bracket (B) on the light with the holes in the table clamp.

Using the wrench provided, install the four screw s provided and tighten.

SPECIFICATIONS Approximate Physical Dimensions

Leakage Current: The products listed within this manual co mply with

the agency requirements listed below.

Environment:

Transport/Storage: Operating:

-20°C - 49°C, 10°C - 35°C

10% - 95% R.H. Max, 30% - 75% R.H. Max,

500hPa - 1060hPa Altitude 500hPa - 1060hPa Altitude

Safety Class I Equipment

Continuous Operation

ETL listed:

UL2601-1,

US

C

CSA C22.2 No. 601.1,

IEC 60601-1, AS 3200.1.

IEC 60601-1-2

Australia EMC Framework Compliance

N344

The CE mark on this product indicates that it h as been tested to and conforms with the provisions noted within

the 89/336/EEC Electromagnetic Compatibility Directive.

Authorized European Representative Address:

European Regulatory Manager

Welch Allyn, LTD.

Navan Business Park,

Dublin Road

Navan, County Meath, Republic of Ireland

Tel: +353 46 90 67700

Fax: +353 46 90 67755

86 cm (34”)

9.5 cm (3.75”)

23 cm (9”)

63 cm (25”)

89 cm (35”)

Ø 36 cm

(Ø14”)

12°

SERVICE INFORMATION

For Technical Support or to obtain return instructions, please contact your nearest Welch Allyn service center listed below:

USA + 1 315 685 4560

800 535 6663

Canada 800 561 8797 China + 86 216 327 9631

European Call Center + 353 46 906 7790 France + 331 6009 3366

Germany + 49 747 792 7186 Japa n + 81 33 219 0071

Latin America + 1 305 669 9003 Netherlands + 31 15 750 5000

Singapore + 65 6419 8100 South Africa + 27 11 777 7555

United Kingdom + 44 207 365 6780 Sweden + 46 85 853 6551

Australia + 61 29 638 3000

800 074 793

ORDERING INFORMATION

Catalog #

04450 Halogen replacement lamp for LS-1 50 Halogen Exam Light

04430 Halogen replacement lamp for LS-1 35 Halogen Exam Light

44350 Caster base accessory, LS-135 & LS-150 Halogen Exam Light

44101 Table Clamp Accessories (Wall mount Models Only)

44301 Rail Mount Accessory (Wall mount Models Only)

(Floor Stand Models Only)

Description

DISASSEMBLY INSTRUCTIONS

When not in use, wrap the power cord and use a twist tie to hold it together. Place the power cord on top of the base.

To return a floor stand unit for service:

NOTE: This product contains no materials classified as hazardous. Therefore, its disposal is not deemed as

harmful to the environment or health risk to individuals disposing of the product. As a precaution, it is

recommended you contact your local disposal and/or recycling authority for information regarding the disposal of

the equipment.

Model Input Output

44300 120v~60Hz,

44302 230v~50Hz,

44303 100v~50/60Hz,

44304 230/240v~50Hz,

44306 240v~50Hz,

44310 120v~60Hz,

44312 230v~50Hz,

44313 100v~50/60Hz,

44314 230/240v ~50Hz,

44316 240v~50Hz,

44500 120v~60Hz,

44502 230v~50Hz,

44503 100v~50/60Hz,

44504 230/240v~50Hz,

44506 240v~50Hz,

44510 120v~60Hz,

44512 230v~50Hz,

44513 1000v~50/

44514 230/240v ~50Hz,

44516 240v~50Hz,

(1) Full intensity (2) Recommended m inimum working distance, see cautions regarding skin exposure. (3) Non-user se rviceable in-line single acting type. (4) Lamp life m ay vary slightly due to usage patterns.

400mA

250mA

500mA

250mA

250mA

400mA

250mA

250mA

500mA

250mA

600mA

350mA

750mA

350mA

350mA

600mA

350mA

60Hz,750mA

350mA

350mA

12v~2.9A 250v, 500mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 315mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 630mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 315mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 315mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 500mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 315mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 630mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 315mA 35w 525fc (1) 2 9 cm

12v~2.9A 250v, 315mA 35w 525fc (1) 2 9 cm

12v~4.2A 350v, 800mA 50w 576fc 33 cm

12v~4.2A 250v, 500mA 50w 576fc 33 cm

12v~4.2A 250v,

12v~4.2A 250v, 500mA 50w 576fc 33 cm

12v~4.2A 250v, 500mA 50w 576fc 33 cm

12v~4.2A 250v, 800mA 50w 576fc 33 cm

12v~4.2A 250v, 500mA 50w 576fc 33 cm

12v~4.2A 250v,

12v~4.2A 250v, 500mA 50w 576fc 33 cm

12v~4.2A 250v, 500mA 50w 576fc 33 cm

Fuse

(3)

1000mA

1000mA

Wattage Intensity

50w 576fc 33 cm

50w 576fc 33 cm

Spot Size

@ 65 cm

(24”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(11.4”)

(13”)

(13”)

(13”)

(13”)

(13”)

(13”)

(13”)

(13”)

(13”)

(13”)

Working

Distance

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

30.5 cm min (12” min) (2)

Color

Temperature

3000K 5,000 hrs (4) 7.8 kg

3000K 5,000 hrs (4) 7.8 kg

3000K 5,000 hrs (4) 7.8 kg

3000K 5,000 hrs (4) 7.8 kg

3000K 5,000 hrs (4) 7.8 kg

3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

3000K 5,000 hrs (4) 3.3 kg (7.3lbs) 2.4M (8’)

4700K 3,000 hrs (4) 7.9 kg

4700K 3,000 hrs (4) 7.9 kg

4700K 3,000 hrs (4) 7.9 kg

4700K 3,000 hrs (4) 7.9 kg

4700K 3,000 hrs (4) 7.9 kg

4700K 3,000 hrs (4) 3.4kg

4700K 3,000 hrs (4) 3.4kg

4700K 3,000 hrs (4) 3.4kg

4700K 3,000 hrs (4) 3.4kg

4700K 3,000 hrs (4) 3.4kg

Lamp

Life

Tot al

Weight

(17.3 lbs)

(17.3 lbs)

(17.3 lbs)

(17.3 lbs)

(17.3 lbs)

(17.4 lbs)

(17.4 lbs)

(17.4 lbs)

(17.4 lbs)

(17.4 lbs)

(7.4 lbs)

(7.4 lbs)

(7.4 lbs)

(7.4 lbs)

(7.4 lbs)

Cord

Length

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.9 M (9.5’)

2.4M (8’)

2.4M (8’)

2.4M (8’)

2.4M (8’)

2.4M (8’)

1. Turn the power switch to the OFF position ( ) and unplug the cord from the outle t.

2. Using a small flat head screwdrive r, CAREFULLY pull back the tabs at the top of the pole slightly - just enough to disengage them from the black plas tic insert in the pole.

3. Pull up on the bottom end of the flexible arm. Unplug the electrical connector and remove Luminaire-Flexible Arm assembly from the pole.

4. Tilt the pole/base onto its side and unscrew the large phillips head screw located on the bottom center of the base.

5. Remove the metal base cover plate and d isconnect the connector attached to it.

6. Disconnect the remaining electrical connector fr om the base and pull the pole out of the base.

7. Securely wrap the three components (base, pole, an d Luminaire assembly) and loose parts in suitable protective packaging for shipment to your authorize d service center.

To return a wall mount unit for service:

1. Turn the power switch to the OFF position ( ) and unplug the cord from the outle t.

2. Pull up on transformer to remove it from its mounting screws.

3. Unscrew the four screws mounting the un it to the wall. For units fitted with the table clamp accessory, simply remove clamp from the table.

4. Securely wrap the components (lamp assembly and t ransformer) in suitable protective packaging for shipment to your authorized service center.

80012404 Ver. A

(English)

Loading...

Loading...