Page 1

LC101 CO2 Module

OEM Implementation Manual

Page 2

P

W

W

LC101 CO

Cop yright © 2002 by Welch Allyn OEM Technologies. Welch Allyn

Module OEM Implementation Man ual

2

®

is a registered tr ademark,

and Pryon™ is a trademark of Welch Allyn, Inc. Welch Allyn, Inc. is protected under various

patents and patents pending. Welch Allyn OEM Technologies is a division of Welch Allyn, Inc.

Disc laimers: Welch Allyn OEM Technologies cautions the reader of this manual:

• This manual may be wholly or partially subject to change without notice.

• All rights are reserved. No one is permitted to reproduce or duplicate, in any form, the

whole or part of this manual without permission from Welch Allyn OEM Technologies.

For inf ormation concerning this document, contact:

elch Allyn OEM Technologies

8500 SW Creekside Place

Beaverton, OR 97008-7107 U.S.A

(503) 530-7900 • Fax: (503) 526-4901

PN 000.91161 Rev. 1, September, 2002

age 2

Confi dential

elch Allyn OEM T echnologies

Page 3

W

C

P

T

LC101 CO

Module OEM Implementation Man ual

2

able of Contents

Section 1

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mainstream vs. Sidestream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measuring Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measurement Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Measurement Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LC101 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sidestream Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 2

LC101 Module Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

LC101 Main Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

LC101 Module Interface Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Watertrap Switch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Watertrap Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Watertrap Receiver Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Exhaust Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 3

LC101 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Zero Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Two-Point User Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Two-Point User Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

elch Allyn OEM T echnologies

onfi dential

age 3

Page 4

P

W

LC101 CO

Module OEM Implementation Man ual

2

Section 4

Host/Module Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Host Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Simple Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuration Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Calibration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Module Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Status Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mode Command Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Simple Command Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Configuration Command Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Calibration Command Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Software Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Packets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Module Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

System Behaviors - Dynamic Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Section 5

Pneumatic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Normal Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Pneumatic Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Total Inlet Occlusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Partial Inlet Occlusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Total Exhaust Occlusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Partial Exhaust Occlusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Barometric Out Of Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Unexpected Reverse Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Unexpected Forward Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Internal Disconnects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Watertrap Receptacle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Sensor Inlet/Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Flow Control Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pump Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pump Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pump Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Low Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

High Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

No Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Section 6

Regulatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

IEC 601-1-2 (EN 60601-1-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Welch Allyn OEM Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

OEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

age 4

Confi dential

elch Allyn OEM T echnologies

Page 5

W

C

P

LC101 CO

Electromagnetic Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Electromagnetic Susceptibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Compliance Testing Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ISO 9918 and EN 864 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Module OEM Implementation Man ual

2

Appendix A

Software Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

O2/N2O/Desflurane Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Correction For O2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Correction For N2O & O2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Correction For Desflurane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Summary of O2, N2O, and Desflurane Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Percent CO2 Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Zero Calibration Sequence Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Two-Point User Calibration Sequence Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Example of Verification Using Dry Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

CRC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

CCITT/CRC Code Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Software Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix B

EEPROM Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

System EEPROM Map Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix C

Error Messages & Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Advisories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

LC101 Advisories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Pneumatic System Advisories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Calibration Advisories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Soft Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Calibration Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Sensor Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

System Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Appendix D

Welch Allyn OEM Technologies

Part Numbers and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Module Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Accessories Available From Welch Allyn OEM Technologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Appendix E

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

LC101 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

CO2 Absorber Material Safety Data Sheet (MSDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

elch Allyn OEM T echnologies

onfi dential

age 5

Page 6

P

W

LC101 CO

Module OEM Implementation Man ual

2

Appendix F

CO2 Developer’s Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Menu Options Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

CO2 Evaluation Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

age 6

Confi dential

elch Allyn OEM T echnologies

Page 7

W

C

P

w

LC101 CO

Module OEM Implementation Man ual

2

Section 1

Functional Description

Intr oduction

The LC101 Module is designed to control and acquire data from an inter nal Welch Allyn OEM

Technologies CO

CO

concentr ation in the patient’s expired respiratory gas can be obtained. The sidestream

2

system includes an internal sidestream CO

The LC101 Module calculates CO

CO

aveform to the host system via a serial communications interface.

2

bench. Utilizing a pump to aspirate the patient sample to the CO

2

bench, electronics and pneumatic components .

2

measurements and respir atory rate and outputs this data with

2

bench, the

2

Intended Use

The LC101 Module is intended f or use as a subsystem within a medical instrument or device.

The Module measures levels of CO

Module has been designed to be used on both intubated and non-intubated patients. The Module

and its accessories should always be used as described in the host system’s operator’s manual

and only for the purpose(s) intended. Areas of intended use include:

• Hospital Intensive Care Units (ICU)

• Hospital Emergency Department/EMS (ED/EMS)

• Surgical Operating Rooms (Anesthesia)

• Hospital Post Anesthesia Care Units (PACU)

• Outpatient Surgical Units

contin uously or intermittently in the sidestream mode. The

2

• Skilled Nursing Facilities / Subacute Care

•Transport (Air, Ground and Sea)

• Home Care / Traditional Health Care

The most common user will be a nurse or skilled healthcare professional (such as an EMT,

paramedic, respiratory therapist, clinical engineer, etc.).

elch Allyn OEM T echnologies

onfi dential

age 7

Page 8

LC101 CO

Module OEM Implementation Manual

2

Terminology

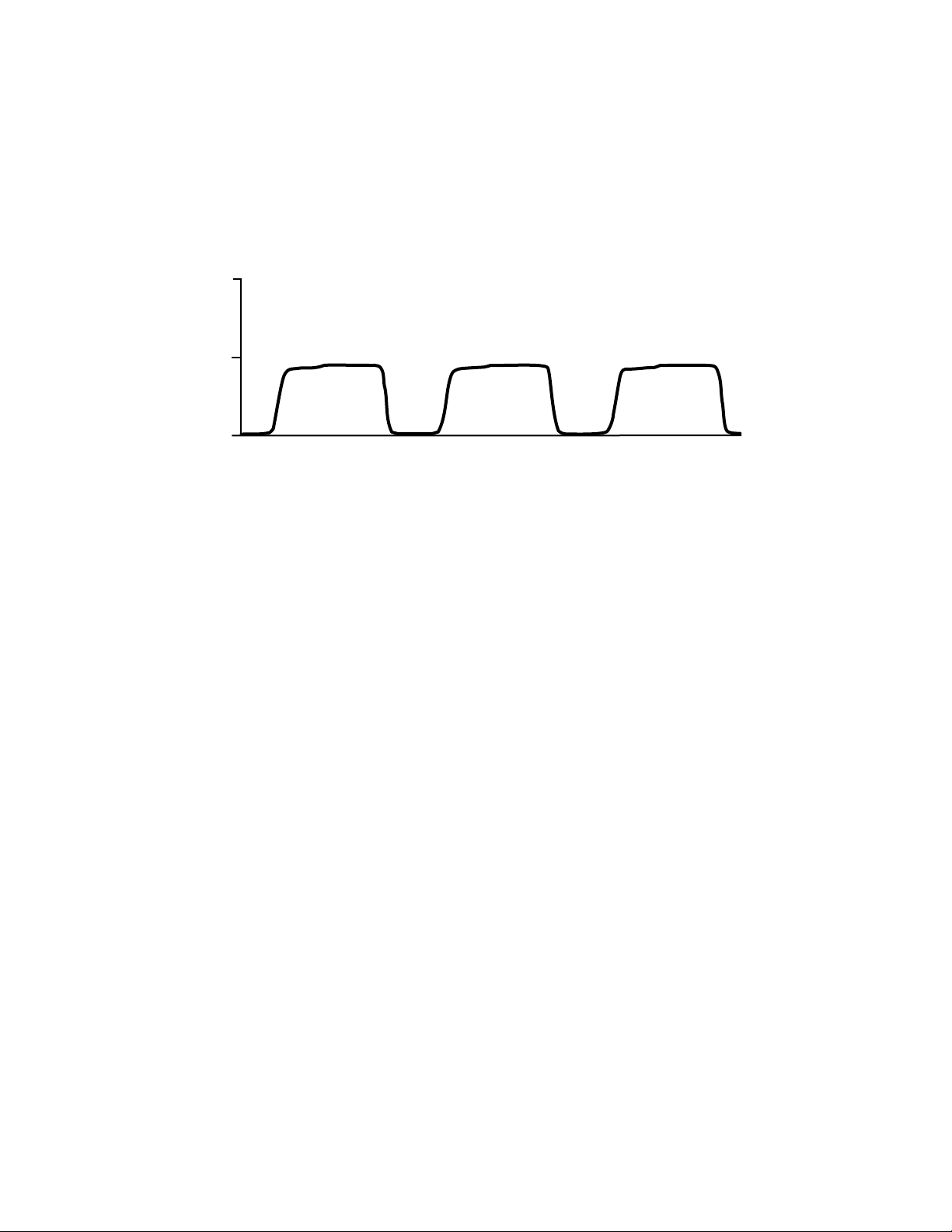

Capnography is the noninvasive measurement and graphic display of airway CO2 concentration

as a function of time. The resulting waveform is called a capnogram. The evaluation of the

capnogram is useful in the assessment of the adequacy of carbon dioxide exchange in the lungs,

integrity of the patient’s airway, cardiopulmonary function and ventilator function.

76

CO

2

40

(mmHg)

0

Capnogram Components

CD

AB

Time

E

Monitoring of CO2 concentration at the end of expiration (point D) is referred to as End-Tidal CO2

(ETCO2) monitoring.

Mainstream vs. Sidestream

The patient’s expired gas may be sampled either directly off the patient airway external to the

LC101 Module or aspirated from the patient through a cannula into the Module. The method used

is dependent on the patient’s airway status.

Mainstream capnography is typically used on intubated or tracheostomy patients and requires

the use of an external mainstream sensor. Intubation is the process of inserting a tube into the

patient’s trachea to deliver gases to the lungs.

Sidestream capnography is used on patients who are intubated or non-intubated. The patient’s

expired gas is aspirated from the airway and transported to the LC101 Module through a sample

line. The sidestream sample chamber and sensor are embedded within the LC101 Module.

Signal acquisition and measurement calculation are performed by the LC101 Module.

Measuring Principle

CO2 measurement is based on the Infra-Red (IR) absorption characteristics of CO2 molecules.

The CO

present in the sample gas. CO2 gas has a unique absorption band which is related to a CO2

molecule’s composition and mass. CO2 gas concentration is measured by detecting absorption in

this band. Due to the nature of the measurement technique employed, user calibration is

necessary with this system.

sensor uses non-dispersive IR spectroscopy to measure the number of CO2 molecules

2

Page 8 Confidential Welch Allyn OEM Technologies

Page 9

LC101 CO2 Module OEM Implementation Manual

Section 1 - Functional Description

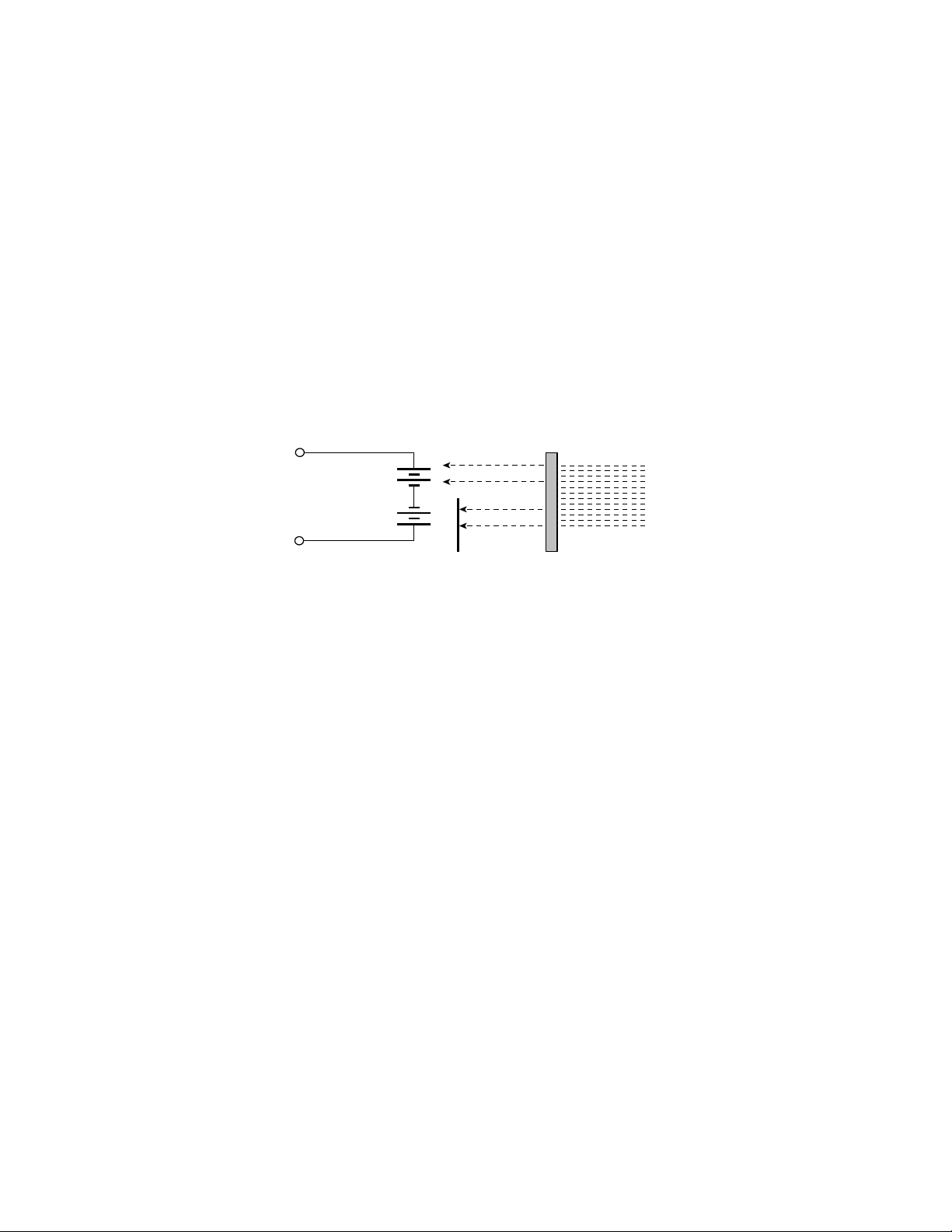

The basic components of the CO2 sensor (C-Cap bench) include

• IR source

• Dual element IR detector

• optical filter

• non-volatile memory

The IR source emits energy that is directed toward a dual element thermopile IR detector. The

dual element design uses two opposing thermopiles connected in series. As the ambient

temperature changes, the two elements change in similar fashion resulting in an output near

zero. Only one element is exposed to energy from the IR source, resulting in a voltage change

due to only that energy. The detector generates a voltage based on the amount of energy it

receives. In the IR path between the IR source and the detector is an

optical filter which allows

only a specific IR wavelength to pass and the gas sample within the sensor chamber.

Dual Element Thermopile

+

detector

output

element 1

element 2

+

narrowband

IR pass filter

energy

from IR

source

foil cover

CO2 Measurement Method

A temperature sensor is attached to the detector housing for temperature compensation beyond

the thermopile’s designed compensation, including temperature changes in the system

sensitivity. The detector generates a voltage in the mV range and an Op-amp on the circuit board

amplifies the signal.

The non-volatile memory is an EEPROM containing calibration and manufacturing data specific

to the CO

sensor.

2

Measurement Calculation

Measurements provided to the host system by the LC101 Module include ETCO2, Inspiratory

(InsCO2) and respiratory rate (RR). These three measurements are collectively referred to

CO

2

as breath data. A proprietary breath algorithm is used to calculate the breath data.

Breath Algorithm

Welch Allyn OEM Technologies’s breath algorithm incorporates an initial learning period which,

based on certain assumptions of CO

for threshold determinations. A sliding window is used to detect a stable maximum, or ETCO

waveform morphology, establishes CO2 reference points

2

2

value, and a baseline, or InsCO2 value. Thresholds are updated in real time with each breath. A

signal averaging technique is used to calculate the RR based on this set of measurements.

By incorporating these adaptive and signal averaging techniques, the breath algorithm effectively

reports accurate CO

measurements while maintaining a high level of noise immunity.

2

Welch Allyn OEM Technologies Confidential Page 9

Page 10

LC101 CO2 Module OEM Implementation Manual

Measurement Compensation

IR absorption in the CO2 wavelength band may be affected by a number of factors that alter the

measurement. The LC101 Module automatically compensates for some of these factors

CO

2

while others may be disabled by the host system.

These factors include

•water vapor

• pressure broadening

• gas mixing

•oxygen, nitrous oxide and desflurane or O2/N2O/desflurane

• Body Temperature, ambient Pressure and Saturated with water vapor or BTPS

Water Vapor

Water vapor compensation accounts for the effect that water vapor has on the IR absorption

characteristics of CO

adjusted mathematically to compensate for this effect.

molecules. During normal sidestream operation, CO2 measurements are

2

The host may choose to disable this compensation when performing dry gas measurements in

which the gas does not contain water vapor. Dry gas procedures may include steady state

measurements and calibration procedures. Steady state measurements are performed only

when background CO

of a steady state measurement is measuring the CO

, or CO2 present in the immediate environment, is measured. An example

2

content inside an incubator. Calibration

2

procedures use calibrated gas which is free of water vapor, or dry, as well.

The water vapor compensation is ON by default and may be enabled or disabled via a host

system command.

Pressure Broadening

Pressure broadening compensation accounts for the effect that barometric pressure has on CO2

molecule distribution and is used in both measurement and autorun modes.

The pressure broadening compensation is ON by default and cannot be disabled by the host

system.

Gas Mixing

A small amount of gas “mixing” occurs as the CO2 sample travels through the tubing to the

sample chamber. Gas mixing compensation accounts for the effect that low level gas mixing has

on the baseline, or InsCO2 measurement in both measurement and autorun modes. The gas

mixing, or baseline, compensation is ON by default and can be disabled by the host system.

Page 10 Confidential Welch Allyn OEM Technologies

Page 11

LC101 CO2 Module OEM Implementation Manual

O2/N2O/desflurane

O2/N2O/desflurane compensations account for the effects that these gases have on the IR

absorption characteristics of CO

description of this effect and a recommendation for enabling these compensations.

The O2/N2O/desflurane compensations are OFF by default and may be enabled or disabled via a

host system command.

BTPS

Often the clinician’s intent is to determine the CO2 levels within the patient’s lungs where gas

exchange is taking place. BTPS compensation corrects for the environmental differences

between the measurement site (i.e. the bench) and “deep lung” CO2.

The BTPS compensation is ON by default and may be enabled or disabled via a host system

command.

molecules. Refer to Appendix A Software Procedures for a

2

Section 1 - Functional Description

Hardware Components

LC101 Main Board

The LC101 Main Board provides the interface to the host system, manages power requirements,

calculates measurements, and regulates pump flow.

The functional components of the Main Board include

• 68HC11 microprocessor with external memory

• reset circuit

•primary power supplies

• analog to digital (A/D) converter

• digital to analog (D/A) converter

• source hybrid

• pressure transducers

68HC11 Microprocessor

The microprocessor controls feedback to the pump and to the temperature and pressure

transducer. The microprocessor also provides the communication interface to the host system

and interfaces to the external A/D and D/A converters and sensor EEPROM memory. An internal

multiplexed A/D converter is used for digital conversion and for monitoring some of the power

supplies for fault determinations.

All address decoding is performed by a microprocessor. The software code is stored in FLASH

memory and is supplemented by an external static RAM chip. The boot mode of the

microprocessor is used to install new software into the FLASH device.

Welch Allyn OEM Technologies Confidential Page 11

Page 12

LC101 CO2 Module OEM Implementation Manual

Reset Circuit

The first section of a 556 timer is connected to a serial receive data line such that the

microprocessor is forced into reset if the data line is held in a break condition for greater than 10

msec. A second timer section is used to determine if the break condition is maintained for more

than 500 msec.

Holding the receive data line in a break condition for a period of time greater than 10 msec and

less than 500 msec is referred to as a reset.

A hard reset occurs when the break condition is held longer than 500 msec. This condition

forces the microprocessor to enter the boot mode after the break is released.

Power ON, reset and low voltage lockouts are performed by a reset controller. Undervoltage

lockout is set to approximately 4.5 V. On power up, the microprocessor is held in reset for about

100 msec after the supply rises above 4.5 V.

Primary Power Supplies

All primary power supplies run off a single voltage power source and are converted on the Main

Board to various levels. The power source is derived from the (+5 V or +5.75 to +14.5 Vdc) Vin

power supplied by the host system.

A/D Converter

The 8 channel 12 bit serial A/D converter converts the following analog signals into a binary data

stream for the microprocessor: analog waveform from the optical bench, temperature of optical

bench, barometric pressure and pneumatic flow rate.

D/A Converter

The 12 bit serial interface D/A converter provides bench source current selection and bench

detector bias circuit control.

Source Hybrid

The optical bench requires that the IR source be current-regulated. The current-sensing circuitry

is located on a ceramic hybrid module, or source hybrid. A regulator is used that adjusts the

output voltage to maintain a constant current.

Pressure Transducers

The pressure circuitry monitors pressure via transducers in order to compensate for the effect of

pressure variation on the CO

measurement. The transducers include

2

• an absolute pressure transducer which initially provides an ambient pressure

measurement and then continuously monitors internal bench pressures during pump

operation.

•a differential pressure transducer which is used for pump flow regulation.

Due to the use of a single absolute pressure transducer, the ambient pressure

measurement is only updated at power on and watertrap replacement.

Page 12 Confidential Welch Allyn OEM Technologies

Page 13

LC101 CO2 Module OEM Implementation Manual

Section 1 - Functional Description

Sidestream Components

The functional components necessary for sidestream operation include

• pump

•watertrap and watertrap receiver assembly

• inlet and exhaust tubing

•CO2 sample line

• cannula

The flow control circuitry regulates flow by using a fixed orifice flow sensor that provides

feedback to a circuit that controls power to the pump. A differential pressure transducer

measures the pressure drop across a restrictor and this is used as feedback to adjust the pump

speed. The pump power supply steps down the raw voltage applied to the board to a level

appropriate for maintaining the desired pump flow rate.

The pump connector provides the electrical connection for the pump to the Main Board.

The watertrap receiver assembly connector provides the electrical connection for the

watertrap switch to the Main Board.

Pump

The electrically driven miniature oil-free diaphragm pump is mounted on the Main Board. The

pump draws the sample through the sample line to the sample chamber by creating a vacuum.

Fault states such as exhaust and watertrap occlusions are recognized by the flow control

circuitry. Refer to Section 5, Pneumatic Operation, for additional information on pump function.

Watertrap and Watertrap Receiver Assembly

NOTE The watertrap, watertrap receiver and receiver switch are not included with the LC101

Module and each may be ordered separately from Welch Allyn OEM Technologies or

supplied by the OEM.

The watertrap is a user-supplied cartridge that removes excess moisture in the sample line

before the sample is delivered to the sample chamber. The watertrap includes a built-in shutoff

pellet which is designed to fully occlude once the filter is saturated.

The functional components of the watertrap assembly include the watertrap receiver and

receiver switch.

The watertrap receiver is a receptacle for the watertrap and can be molded by the OEM into the

main housing of the host monitor (or purchased from Welch Allyn OEM Technologies as an

accessory). The external end of the watertrap is connected to the sample line.

The watertrap receiver switch provides a signal that is used for detection of a properly inserted

watertrap into the watertrap receiver before the pump begins operation. This eliminates the

possibility of the user bypassing the watertrap.

Welch Allyn OEM Technologies Confidential Page 13

Page 14

LC101 CO2 Module OEM Implementation Manual

Inlet and Exhaust Tubing

The internal inlet tubing provides the means to transport the gas sample from the watertrap

receiver to the sidestream bench. The inlet tubing includes the tubing, connectors and a

secondary shutoff pellet. Attachment of the inlet tubing to the watertrap receiver is via a Luer®

connector. A secondary shutoff pellet is attached in line with the inlet tubing to provide additional

backup.

The exhaust tubing provides the means to expel the exhaust gas. A 5 µm screen, or filter, is

positioned in line with the exhaust tubing to muffle, or reduce the pump noise.

CO2 Sample Line and Cannula

The CO2 sample line, or sample line, is used to transport the gas sample from the patient to the

watertrap assembly.

NOTE The sample line is not included with the LC101 Module and may be ordered separately

from Welch Allyn OEM Technologies or other suppliers.

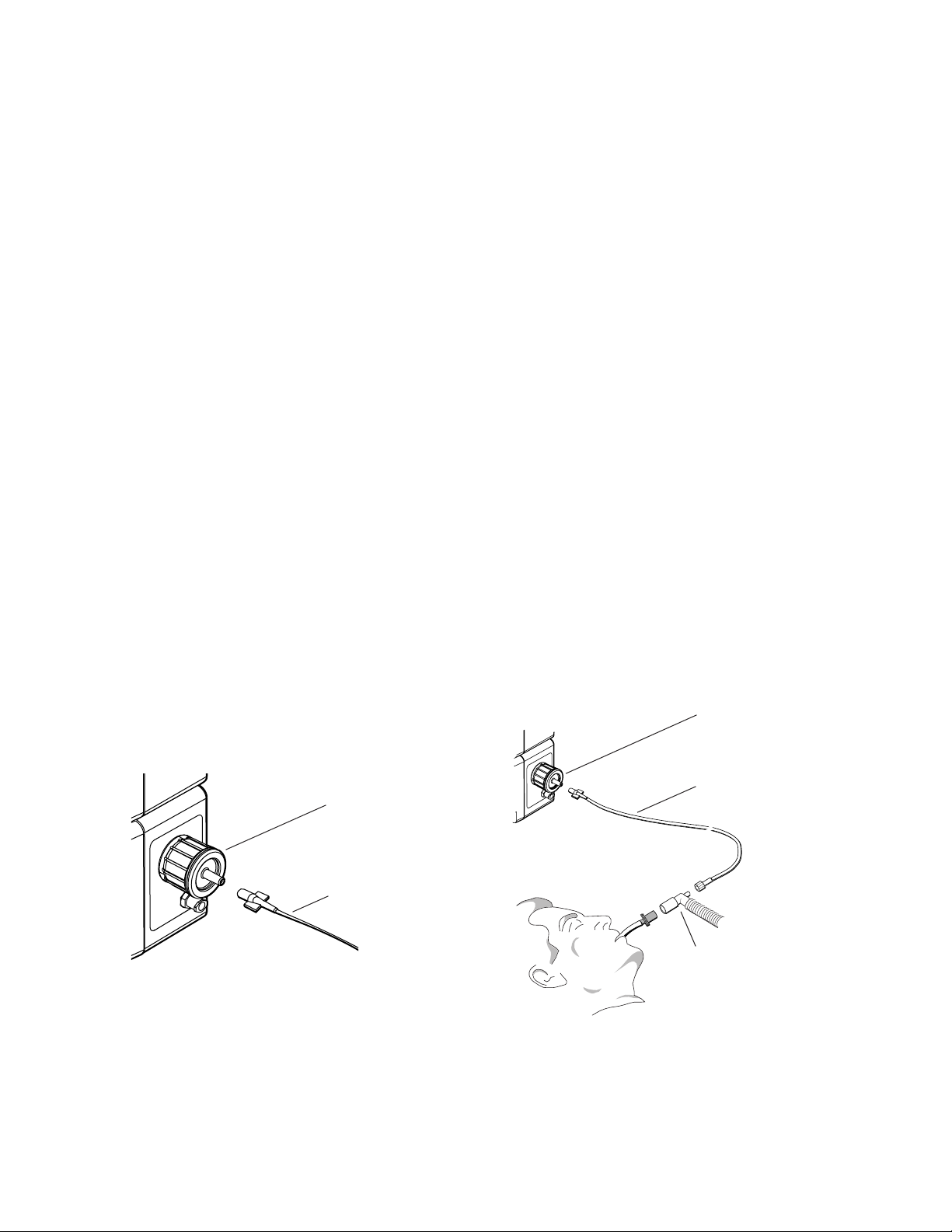

For a non-intubated patient, the sample line connects to a cannula that is positioned on the

patient. A variety of cannulas are available to accommodate patient requirements. Nasal, oral/

nasal and divided cannulas which deliver oxygen and sample CO

simultaneously may be used.

2

NOTE Cannulas are not included with the LC101 Modules and may be ordered separately

from Welch Allyn OEM Technologies or other suppliers.

For an intubated patient, the sample line connects to the patient’s breathing circuit.

Sample connections for both intubated and non-intubated patients are shown below.

Watertrap

Sample line

Watertrap

Sample line

To cannula

Elbow connector

to breathing

apparatus

Typical Connection to Non-Intubated Patient

Typical Connection to Intubated Patient

Page 14 Confidential Welch Allyn OEM Technologies

Page 15

LC101 CO2 Module OEM Implementation Manual

Section 2

LC101 Module Interface

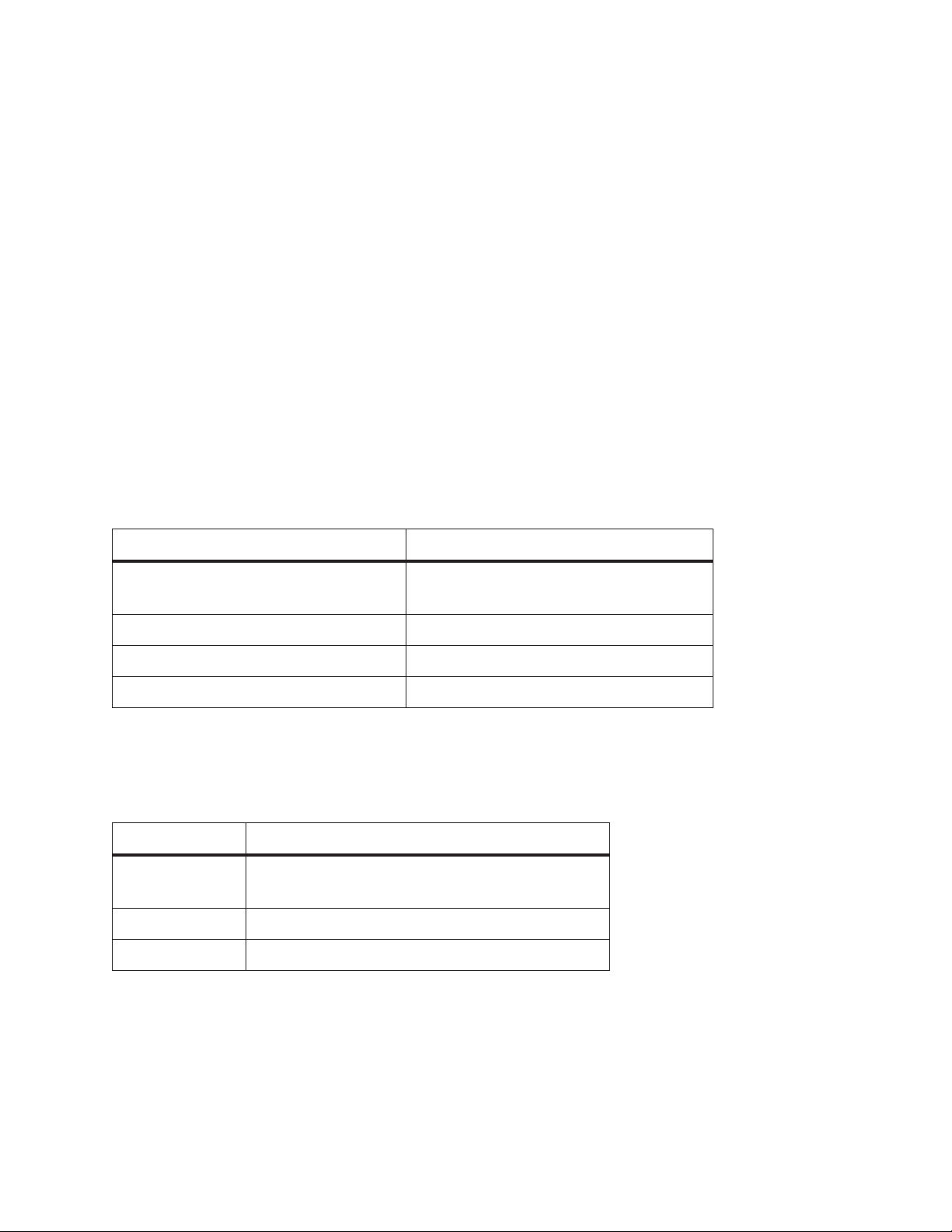

Power Requirements

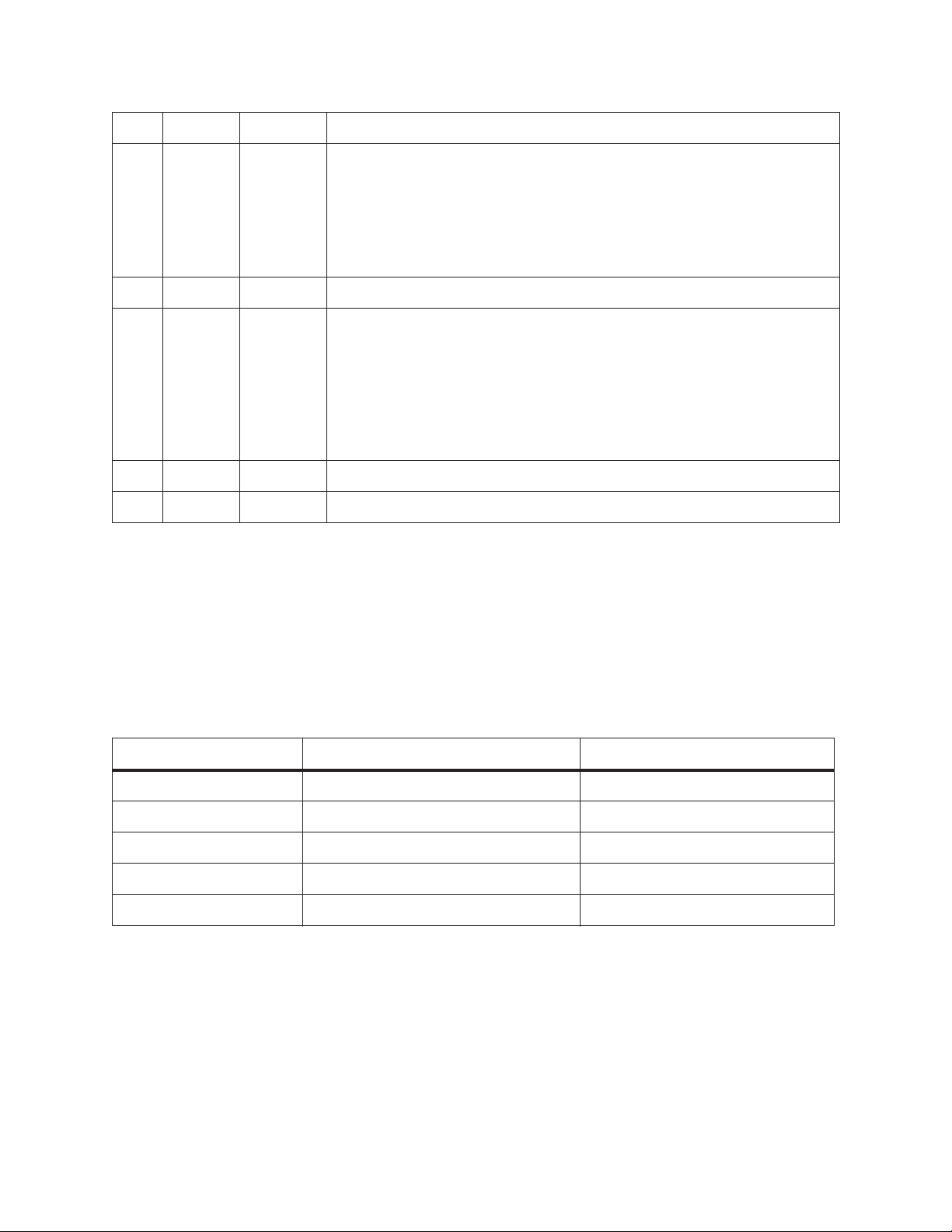

Description Typical

Input voltage range 5 V regulated, or +5.75 to +14.50 Vdc

Ripple 100 mV peak-to-peak

Typical non-measurement mode power 570 mW at 8 Vdc

Typical operating power 1.3 W at 8 Vdc

Typical occluded power 1.5 W at 8 Vdc

LC101 Main Board

Description Specification

Dimensions 3.15 in. L x 3.90 in. W x 1.00 in. H

(80.3 mm × 99.3 mm × 25mm)

Orientation No limitations

Weight < 1 lb (454 gm)

Welch Allyn OEM Technologies Confidential Page 15

Page 16

LC101 CO2 Module OEM Implementation Manual

LC101 Module Interface Connector

The LC101 Module interface connector is a 4-pin connector (Molex P/N 22-11-2042). The host

may use a 4-pin polarized housing (Molex P/N 22-01-3047 with Molex 2759 series terminals) or

equivalent.

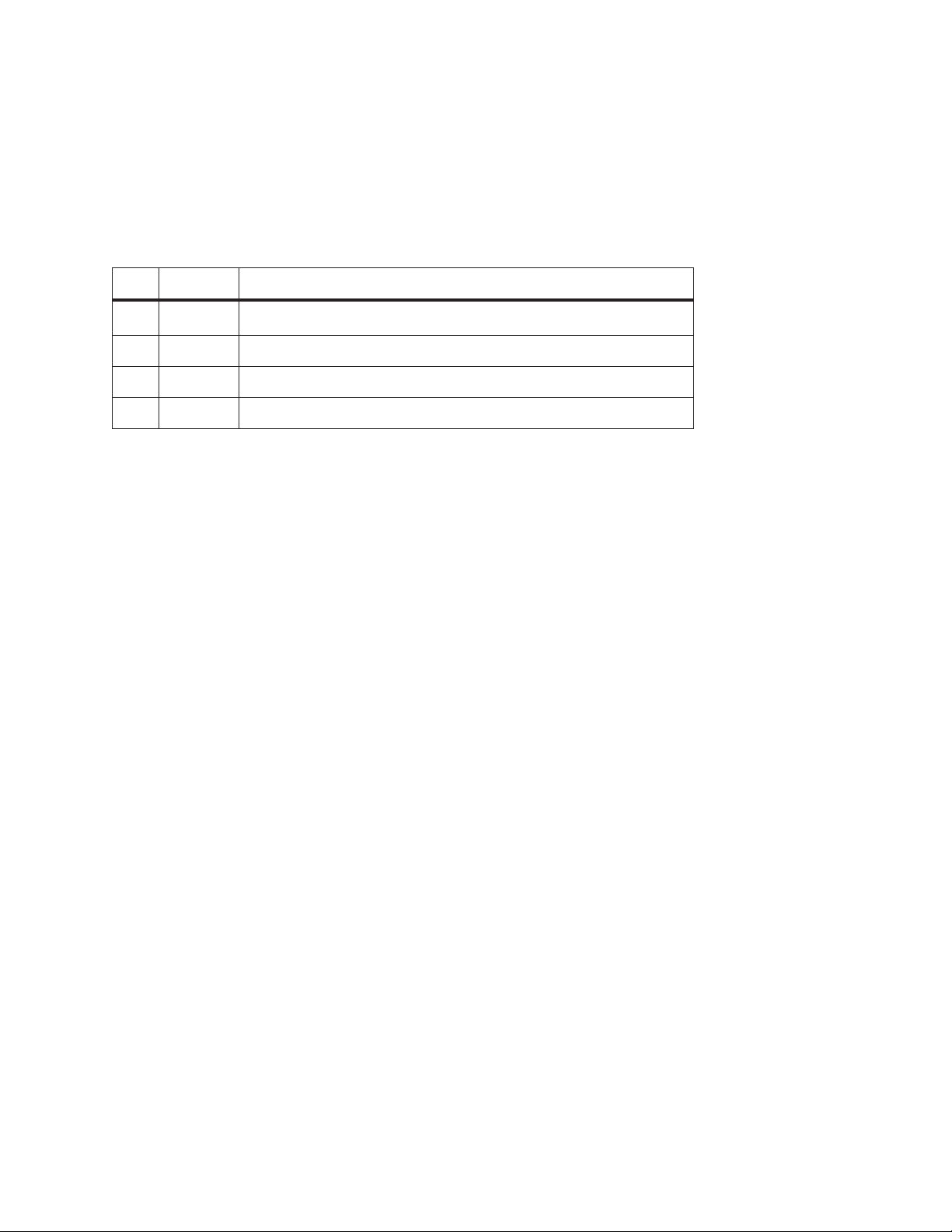

Pin Signal Signal Description

Vin

a

input power

1

2 gnd ground

3 TXD data from Main Board to host system

4 RXD data from host system to Main Board

a. The “square” plated through-hole designates pin 1 on the Main Board.

Watertrap Switch Connection

Watertrap switch connection is via a 2-pin Molex connector on the Main Board.

Pump

The pump is mounted on the Main Board. The pump wiring harness is connected to the Main

Board via a 2-pin connector (Molex P/N 22-01-3027).

The pump wiring meets typical insulation standards but does not meet patient isolation

requirements. If the pump must be moved to a different location, patient isolation requirements

must not be compromised. Refer to Section 6, Regulatory, for additional regulatory and safety

information.

Watertrap Receiver

The internal space available in the host monitor must be considered when incorporating the

watertrap receiver into the host system design. To accommodate various OEM dimensions, two

watertrap receivers are offered: long and short. The long watertrap receiver requires more

intrusion into the host monitor but the watertrap does not protrude as far externally from the host

chassis than with the short watertrap receiver.

Page 16 Confidential Welch Allyn OEM Technologies

Page 17

LC101 CO2 Module OEM Implementation Manual

Section 2 - LC101 Module Interface

Watertrap Receiver Switch

The watertrap receiver switch is wired in the “normally open” configuration.

The watertrap receiver switch connects directly to the Main Board via a wiring harness and

connector. The watertrap receiver switch assembly is equipped with a 2 pin connector (Molex

P/N 22-01-3027) which electrically connects directly to the Main Board at J102.

The watertrap receiver switch wiring meets typical insulation standards but does not meet patient

isolation requirements. When applicable, harness routing must not violate patient isolation

requirements. Refer to Section 6, Regulatory, for additional regulatory and safety information.

Exhaust Tubing

In the event of an exhaust tubing malfunction, gas buildup can occur within the host system.

WARNING To protect against potentially flammable gas buildup, the tubing must be

single-fault protected. Refer to Section 6, Regulatory, for additional regulatory

and safety information.

Welch Allyn OEM Technologies Confidential Page 17

Page 18

LC101 CO2 Module OEM Implementation Manual

Page 18 Confidential Welch Allyn OEM Technologies

Page 19

LC101 CO2 Module OEM Implementation Manual

Section 3

LC101 Calibration

The LC101 Module requires periodic user calibration to adjust offset voltages and calibration

constants used by the internal C-Cap bench. There are two types of calibration, each supported

in the LC101 software protocol:

• Zero Calibration

•Two-Point User Calibration

Zero Calibration

The Zero Calibration adjusts the offset voltage used by the C-Cap to generate the CO2 values

and the IR source current. The required frequency of Zero Calibration depends on the amount

and type of usage, and may be typically required every two weeks. The LC101 does not monitor

the elapsed time between calibrations, nor does it alert the host when calibration is needed. It is

up to the host system and the end-user to determine when calibration is required.

The procedure requires the use of clean, dry air (0% CO2) at room/ambient temperature. In

order to provide the 0% CO

used to absorb CO

eliminates CO

Allyn OEM Technologies.

The scrubber is designed to be attached directly to the Welch Allyn OEM Technologies watertrap

by the user before a Zero Calibration. The scrubber is removed after successful calibration. The

scrubber has a shelf life of approximately one year. Although the scrubber is considered reusable, its effective life depends on application and exposure to CO

concentration in the zero reference gas and will alert the host system, when polled for

CO

2

status, if a problem exists with the sample zero gas.

from room air. The scrubber contains a chemical which reacts with and

2

as it is drawn through the scrubber. The CO2 scrubber is available from Welch

2

, an external device, called a “CO2 scrubber” (or CO2 absorber), is

2

. The LC101 monitors the

2

Welch Allyn OEM Technologies Confidential Page 19

Page 20

LC101 CO2 Module OEM Implementation Manual

To get an accurate calibration, the LC101 needs to be operating for at least 5 minutes in

measurement or autorun mode with the scrubber installed. The LC101 internally monitors the

run time and will not allow a Zero Calibration if the run time requirement has not been met.

The LC101 monitors the calibration progress and provides a “Calibration OK” (or “not OK”)

message to the host system when polled for status. See the LC101 Software Protocol and the

Zero Calibration Commands and Responses for more detail. After a successful Zero Calibration,

the LC101 updates the zero residual offset constants located in the LC101 C-Cap EEPROM

Memory and the IR source current.

Zero Calibration Procedure

Equipment needed:

• watertrap

•CO2 scrubber (or 0% CO2 medical-grade gas source; see the Two-Point User

Calibration procedure for pressurized gas setup)

To Perform a Zero Calibration:

The user is required to apply a 0% CO2 gas, or “zero” gas, during the steps of a Zero Calibration.

To perform Zero Calibration, the user must follow the Original Equipment Manufacturer’s

procedure typically provided in the Operator’s Guide or User Service Manual.

1. Select a well ventilated room to perform the calibration.

2. Make sure the LC101 has been operating for at least 5 minutes prior to the Zero Calibration.

3. Attach the CO2 scrubber to the watertrap inlet according to the CO2 scrubber “Directions for

Use” (or attach a 0% medical-grade gas source). Now let the LC101 operate for one

minute.

4. After approximately one minute, observe the CO2 reading. The CO2 reading should be

between 0.0% - 0.3% with well-ventilated room air.

5. Proceed with the zero gas phase of the calibration as defined by the host system.

6. Disconnect the CO2 scrubber (or gas source) from the watertrap after the zero gas calibration.

Page 20 Confidential Welch Allyn OEM Technologies

Page 21

LC101 CO2 Module OEM Implementation Manual

Section 3 - LC101 Calibration

Two-Point User Calibration

NOTE Before performing a Two-Point User Calibration, a separate Zero Calibration must be

performed first. It is also recommended that both calibrations be performed at 75ºF in

order to maintain accuracy over the Module’s operating temperature range.

The Tw o-Point User Calibration, or User Calibration, updates two of the gas calculation constants

used to generate the CO

amount and type of usage. Typically it may be required every six months. The LC101 does not

monitor time between calibrations, nor does it alert the host when calibration is needed. It is up

to the host system and the end-user to determine when calibration is required.

To get an accurate User Calibration, the LC101 needs to be operating for at least 5 minutes in

measurement or autorun mode. The LC101 internally monitors the run time and will not allow a

User Calibration if the run time requirement has not been met.

To perform the User Calibration, the host is required to supply a calibration date, a span gas

concentration, and indicate the gas concentration being applied to the LC101 Module (0% or the

span gas).

values. The required frequency of User Calibration depends on the

2

The OEM typically provides a User Calibration Kit to the end user containing a CO2 reference

gas with regulator, scrubber, directions for use, adapter, and tubing.

The LC101 monitors the User Calibration progress and provides a “Calibration OK” (or “not OK”)

message to the host system after successful calibration when polled for status. See the LC101

Software Protocol and the User Calibration Commands and Responses for more detail. After a

successful User Calibration, the LC101 updates the User Calibration History Queues located in

the LC101 C-Cap EEPROM Memory.

Zero and User Calibration dates should be user accessible via a host service screen or other

means.

Welch Allyn OEM Technologies Confidential Page 21

Page 22

LC101 CO2 Module OEM Implementation Manual

Two-Point User Calibration Procedure

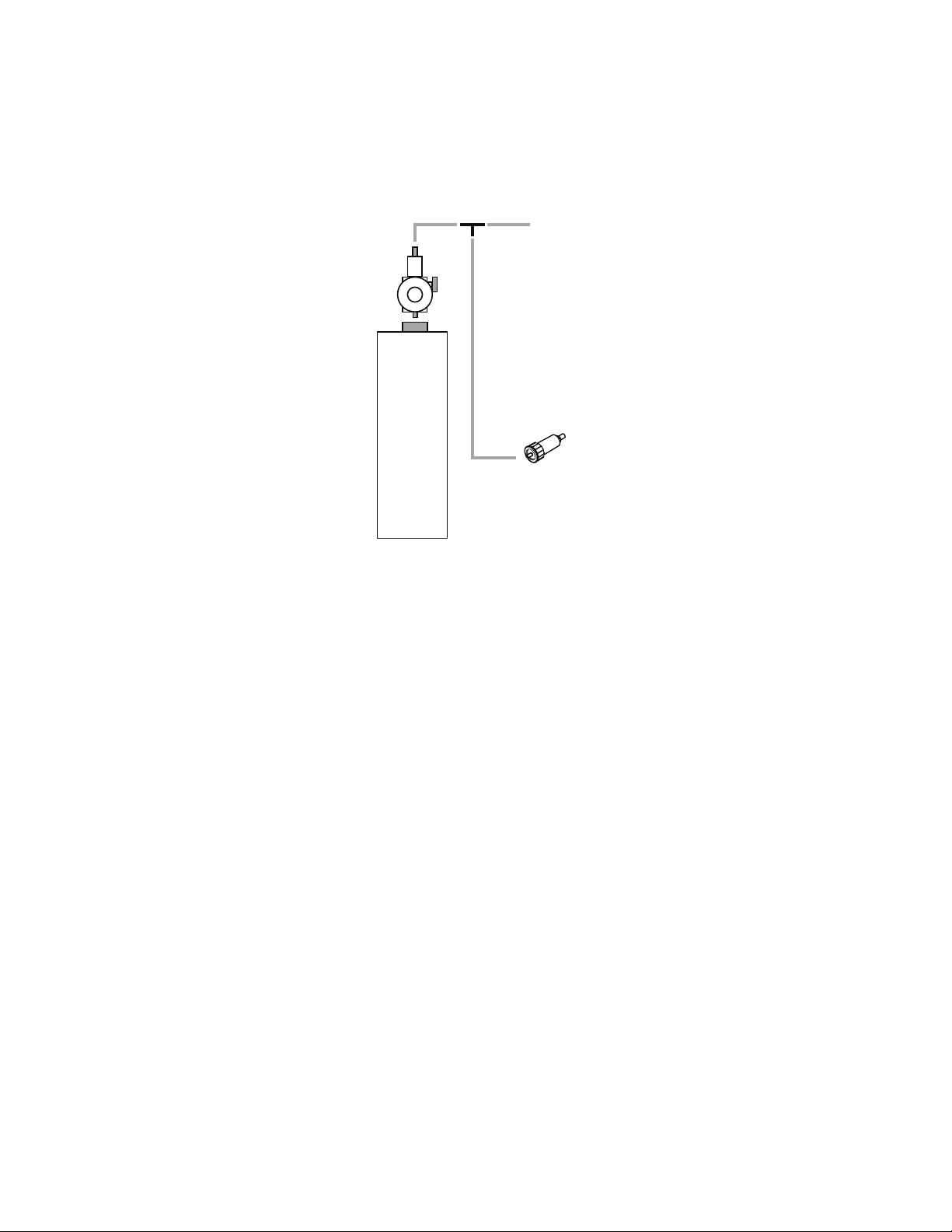

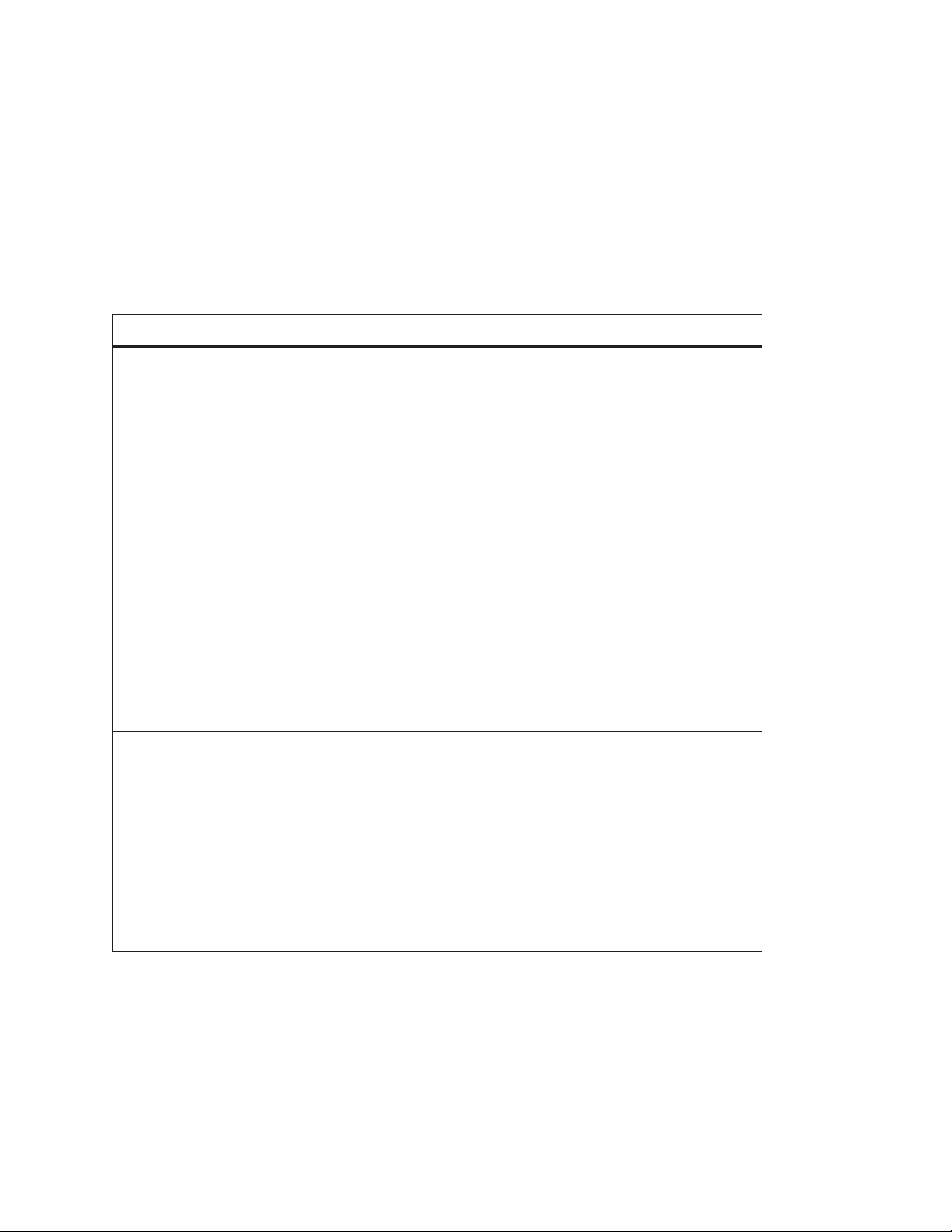

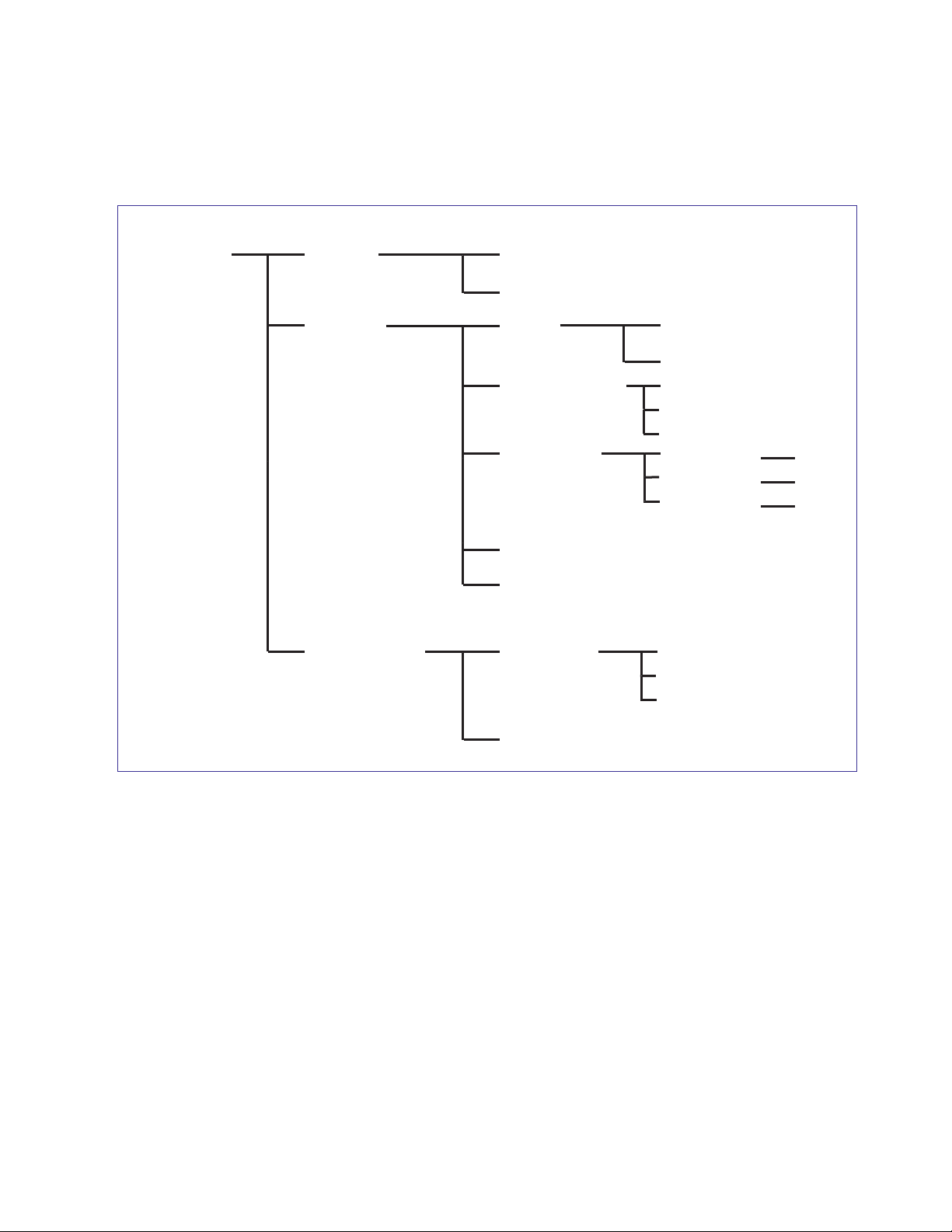

Illustration of gas canister,

regulator and pneumatic circuit

Equipment needed:

• calibration gas canister (8 – 12% CO2, ±0.02%, balance air or nitrogen)

Regulator

Te e

On/Off

10%

CO2

Bal. N2

Free Flow Away

From Monitor Input

Water Trap

To Monitor

Two-Point User Calibration Equipment Setup

• gas valve and non-silicon tubing

• sample elbow or tee

•flow meter

• sample line

•watertrap

•CO2 scrubber (or 0% CO2 medical-grade gas source)

CAUTION Make sure that the tubing used to connect the gas supply to the LC101 does

NOT contain silicon. Silicon tubing absorbs CO

and affects the stability of

2

the gas concentration, thereby reducing the accuracy of the procedure.

Page 22 Confidential Welch Allyn OEM Technologies

Page 23

LC101 CO2 Module OEM Implementation Manual

Section 3 - LC101 Calibration

To Perform a Two-Point User Calibration:

The user is required to apply a 0% CO2, or “zero” gas, and also apply a gas of known CO2

concentration (referred to as “span” gas) during the various steps of a Two-Point User

Calibration. The user is required to manually enter the value of the Span Gas applied into the

Monitor.

To perform the Two-Point User Calibration, the user must follow the Original Equipment

Manufacturer’s procedure typically provided in the Operator’s Guide or User Service Manual.

(Refer to illustration on

page 22.)

1. Select a well-ventilated room to perform the calibration.

2. Let the LC101 run for at least 5 minutes prior to calibration.

3. For the “Sample Zero Reference Gas” step, attach the CO2 scrubber to the watertrap inlet

according to the CO

scrubber “Directions for Use” (or use a 0% medical-grade gas source).

2

4. Proceed with the zero gas phase of the calibration as defined by the host system. Disconnect CO2 scrubber (or 0% gas source) from the watertrap after the zero gas phase and prior

to the next calibration step.

5. For the “Sample Span Reference Gas” phase of the calibration, provide a medical-grade

gas source with a known CO

concentration between 8% and 12%, regulated to a pressure

2

between 5 and 7 psi.

NOTE Do not apply any pressure directly to the Module inlet or outlet.

6. Introduce a steady stream of CO2 gas. Set and monitor the flow rate to approximately

liter/minute (±10%). To verify flow, place the bleed line of the calibration sample line in a

1

glass of water. If bubbles emerge, gas supply is sufficient. If no bubbles emerge, there is an

insufficient supply of gas.

7. Connect a sample line from the sample elbow, or Tee, as shown above, to the Monitor’s

watertrap inlet. Make sure the bleed line is directed away from the monitor. Allow the refer

ence gas to flow for at least one minute.

8. Sample the Span Reference Gas.

9. After the Two-Point User Calibration steps have been followed, disconnect the LC101 from

the gas supply and test setup.

10. A verification may be performed using the same gas delivery set up. Verify the observed

CO

gas reading is within 3 mmHg or 10%, whichever is greater, of the CO2 value of the test

2

gas supplied. (If not, refer the user to the appropriate troubleshooting information.)

-

Welch Allyn OEM Technologies Confidential Page 23

Page 24

Troubleshooting

• Make sure that the room is well ventilated. CO2 readings may be elevated in a closed

room.

• Confirm that the calibration gas is of known concentration. If the CO2 readings are

consistently elevated or depressed, the calibration gas may be suspect. Try another

gas source.

• Make sure that the CO2 module was properly set up and operating for the required

minimum period before testing.

• Check for air leaks in the pneumatic tubing and connections. Repair or replace as

needed.

• Confirm that the sample gas flow rate is greater than the CO2 module’s pump flow

rate.

• Confirm that silicon tubing is not used in the procedure (silicon absorbs CO2 which

affects the gas concentration stability and accuracy of the procedure).

LC101 CO2 Module OEM Implementation Manual

Page 24 Confidential Welch Allyn OEM Technologies

Page 25

LC101 CO2 Module OEM Implementation Manual

Section 4

Host/Module Communications

The LC101 Module is a command driven slave device capable of communicating with a host

system over an asynchronous serial communication line. After the host system commands the

LC101 Module to begin transmission of CO

sends periodic packets without additional intervention by the host system. The host system must

initiate all other communication with the LC101 Module.

waveform and breath data packets, the Module

2

The LC101 Module and the host system are referred to as the “Module” and “host” in the

remainder of this section.

Communication Interface

• 9600 baud rate

• full duplex

• asynchronous using standard non return to zero (NRZ) format.

{1 start bit 7 or 8 data bits even parity 1 stop bit}

• Receive data input (RxD) is the buffered input of a 74HC14. A pull up is provided on

the Module so it can be driven by an open collector source.

•Transmit data output (TxD) is the collector of a 2N4401 transistor driven with a 10 K

base resistor from the output of a 74HC14. A weak pull up is provided to source a

CMOS load.

• Module power and communications are provided at J101.

Welch Allyn OEM Technologies Confidential Page 25

Page 26

LC101 CO2 Module OEM Implementation Manual

System EEPROM

The system EEPROM contains manufacturing and operational data that is necessary for the

LC101 Module to function. A limited number of these system parameters may be specified by the

OEM. These include

• data format

• start up mode

• initial pump flow rate

The data format options are 7 and 8 data bits (default is 7E1).

The start up mode options are auto run, measurement, standby and fault (default is standby).

The initial pump flow rate option allows the host to specify the default pump flow rate in

milliliters per minute (default is 150 ml/min).

Packet Structure

Transmission of host commands and Module responses is via packets. The following byte

structure represents a packet.

Packet format:

< start of text (STX) 02h

X identifier 1*(ASCII)

n

xx

yy CCITT/CRC code 2*(ASCII)

> end of text (ETX) 03h

ASCII characters have values in the range of 00h to 7Fh. The identifier is case sensitive.

Characters between 00h and 20h are reserved as control characters.

Tr ansmission of all packets starts with a “<” STX control character and ends with a CCITT/CRC

code and “>” ETX control character. Between STX and ETX is an identifier and n bytes of ASCII

data. The length of the packet is defined by the identifier character. Packet length cannot exceed

25 bytes with a maximum of 20 bytes of data allowed. Packets without the STX control character

are ignored. The CCITT/CRC code is calculated on values between STX and CCITT/CRC code.

data n(hex char)

Example:

02h X xxn yy 03h

Page 26 Confidential Welch Allyn OEM Technologies

Page 27

LC101 CO2 Module OEM Implementation Manual

Section 4 - Host/Module Communications

Host Commands

The host communicates to the Module via commands. These include:

• mode commands to request a change in the operating mode.

• simple commands to request data or a status change. Data is not sent with these

commands.

• configuration commands to specify custom system settings. Data is sent with these

commands.

• calibration commands to request a Zero or User Calibration sequence. Data is sent

with these commands.

Mode Commands

Mode commands allow the host to put the Module into one of the three operating modes.

Host Command Description

<M24> Enter auto run mode

To start automatic sampling and data packet transmission at default

intervals of realtime CO2 waveform and breath data. A watertrap

removal causes the Module to wait for a watertrap insertion. This is

the preferred operating mode since temporary watertrap

removal and replacement is typical in normal operation.

<M23> Enter measurement mode

Same as auto run mode except for sidestream watertrap removals.

Instead of waiting for watertrap insertion, the sensor’s activity is

halted and the Module reverts to the standby mode and requires a

new <M23> host command to restart measurement.

<M21> Enter standby mode

Used when a low power standby state for the Module is desirable.

This prolongs the life expectancy of the IR source, since this component is disabled in this mode.

No more than two mode commands should be issued in any five-second period.

The Module automatically reverts to fault mode if a Module or sensor fault occurs. A fault

message is sent via the status response by the Module to the host when polled for status.

Welch Allyn OEM Technologies Confidential Page 27

Page 28

LC101 CO2 Module OEM Implementation Manual

Simple Commands

Simple commands instruct the Module to send Module data or EEPROM data and to reset the

Module software or reset sensor error.

Host Command Description

<C00> Request and confirm operating mode and Module status

<C20> Request software version

<C21> Request hardware version

<C22> Request ambient barometric pressure

<C23> Request sensor temperature

<C26> Request single CO2 measurement

<C27> Request single breath data packet

<C2E> Request current set flow rate

<C31> Request sensor EEPROM revision #

<C32> Request sensor manufacturer code

<C33> Request sensor serial #

<C3A> Request last calibration date

Page 28 Confidential Welch Allyn OEM Technologies

Page 29

LC101 CO2 Module OEM Implementation Manual

Section 4 - Host/Module Communications

Configuration Commands

Configuration commands instruct the Module to temporarily modify specific default settings for

measurement criteria. A new pump flow rate may also be specified. The host does not have to

command the Module into the unprotected mode prior to issuing a new flow rate command.

A description of these commands is included in the following table.

Host Command Description

<Nxx> Change CO2 waveform update rate

Allows the host to specify how often the Module sends a CO2 waveform data packet. The Module generates a CO2 measurement every

31msec. The maximum update rate is 31 msec. The host may program the rate to xx increments, where xx is the number of 31msec

increments per packet.

<Nxx> where xx (ASCII) defines the CO2 waveform update rate

based on the number of 31msec increments.

xx range 00h to FFh

xx default 01h, 31 msec interval

Examples:

<N01> send a CO2 waveform data packet every 31 msec (1 × 31

msec)

<N05> send a CO2 waveform data packet every 155 msec (5 ×

31 msec)

<NFF> send a CO2 waveform data packet every 7.9 seconds

(255 × 31 msec)

<N00> stop sending waveform data

<Axx> Change breath data clear rate

Allows the host to specify how long the Module waits for a new

breath data packet before clearing the breath data (ETCO2 = 00h /

RR = 00h / InsCO2 = 00h).

<Axx> where xx (ASCII) defines the “no breath” timeout in sec-

onds

xx range 10 to 60 s (0Ah to 3Ch)

xx default 0Fh, clear breath data after 15 s of “no breath”

Example:

<A0A> clear the breath data after 10 seconds of “no breath”

Welch Allyn OEM Technologies Confidential Page 29

Page 30

LC101 CO2 Module OEM Implementation Manual

<Oxx> Change breath data update rate

Allows the host to specify how often the Module sends a breath

data packet.

<Oxx> where xx (ASCII) is converted to a 8 bit binary number (yyzz

zzzz) with yy defining how often the breath data is

updated.

If yy = 00 binary, Breath data packet update rate is defined by

zzzzzz, where zzzzzz is in tenths of seconds. The 6

lower bits = (seconds × 10).

to even values.

If yy = 01 binary, Breath data packet update rate is every breath

where zzzzzz = doesn’t matter.

Exception: If the “no breath” condition occurs, data is sent

at 1 second increments.

If yy = 10 binary, Breath data update rate is when the data changes,

where zzzzzz = doesn’t matter.

Exception: If after 15 seconds the breath data has not

changed, data is sent after the next breath. This does not

guarantee a 15 second update; however, if the “no breath”

condition has occurred, the “no breath” timeout takes precedence.

Exception: If the “no breath” condition occurs, data is sent

at 1 second increments.

If yy = 11 binary, Not defined.

Examples

<O05> send a breath data packet at .6 s interval (Odd values

<O40> send a breath data packet every breath

<O80> send a breath data packet every time the data changes

Special case:

<O00> no breath data sent (Note: Continuous CO2 mode would

:

rounded up)

use this command.)

Odd values are rounded up

Page 30 Confidential Welch Allyn OEM Technologies

Page 31

LC101 CO2 Module OEM Implementation Manual

<Qxxy> Function enable

Allows the host to enable or disable functions listed below.

<Qxxy> where xx (ASCII) is the compensation and y (ASCII) is

ON/OFF status.

xx =

00h O2 compensation

01h N2O compensation

02h desflurane compensation

08h water vapor compensation

09h BTPS compensation

0Ah baseline compensation

7Fh protect mode

y =

00 binary ON

01 binary OFF

3Fh current ON/OFF status

Example

<Q011> compensate the CO2 waveform data for N2O

<Q7F0> turn off protect mode (to allow certain commands)

Section 4 - Host/Module Communications

<F20yy> Change pump flow rate

Allows the host to specify the pump flow rate in milliliters per

minute.

<F20yy> where yy (8 bit) is the current pump flow rate.

yy range 90 – 200 ml/min (5Ah – C8h)

yy default 175 ml/min (AFh)

Example

<F205A> set the pump flow rate to 90 ml/minute

Note: Using this command to set a desired flow rate, the pump flow

rate will revert back to default settings upon power up. The flow rate

can be fixed in the EEPROM to a specific default setting. See

EEPROM Map for location details.

<C80> Request software reset

Allows the host to reset the Module. This command is only

accepted if the Module is in the unprotected mode. See Function

enable <Qxxy>.

Welch Allyn OEM Technologies Confidential Page 31

Page 32

LC101 CO2 Module OEM Implementation Manual

Calibration Commands

Calibration commands instruct the Module to update the gas calculation or the zero offset

constants used to generate the CO

are stored in EEPROM memory. Data is required with these commands. There are two types of

calibration: Two-Point User Calibration and Zero Calibration.

Two-Point User Calibration

TheTw o-Point User Calibration updates two of the gas calculation constants used to generate the

CO

values. To perform a User Calibration, the host is required to supply a calibration date and a

2

span gas concentration.

When performing a User Calibration, the LC101 Module must first be in either Unprotected

'Measurement' or 'Autorun' mode. During the calibration, CO

be sent to the host.

To get an accurate calibration, the LC101 Module needs to be operating for at least 5 minutes in

measurement or autorun modes. The LC101 will not allow a calibration if this requirement has

not been met. In addition, the calibration should be performed at room/ambient temperature.

values. At the end of a successful calibration, new constants

2

waveform and Breath data will still

2

Host Command Description

<Lmmddyyyy> Update calibration date.

Allows the host to enter a new calibration date from user input into

EEPROM memory.

<Lmmddyyyy> mm = month, dd= day, yyyy= year

Note: The mmddyyyy fields are decimal values.

Example

<L01012000> calibration date = January 1, 2000

<Gxx> Update span gas concentration.

Allows the host to enter a gas concentration value from user input.

<Gxx> xx = percent CO2 x 16.

Example

<GA8> span gas concentration = 10.5%

<C10> Sample zero reference gas.

<C11> Sample span reference gas.

<C13> Abort calibration

:

:

After a successful calibration, the Module updates the User Calibration History Queues located

in the

C-Cap EEPROM Memory Map

.

Page 32 Confidential Welch Allyn OEM Technologies

Page 33

LC101 CO2 Module OEM Implementation Manual

Zero Calibration

The Zero Calibration adjusts the IR source current to compensate for detector output changes.

The host is required to inform the LC101 Module when to start sampling 0% CO

When performing a Zero Calibration, the LC101 Module must first be in either Unprotected

'Measurement' or 'Autorun' mode. During the calibration, CO

be sent to the host.

To get an accurate calibration, the LC101 Module needs to be operating for at least 5 minutes in

measurement or autorun modes. The LC101 will not allow a calibration if this requirement has

not been met. In addition, the calibration should be performed at room/ambient temperature.

Host Command Description

<C12> Perform Zero Calibration

<C13> Abort Calibration

Section 4 - Host/Module Communications

gas.

2

waveform and Breath data will still

2

After a successful Zero Calibration, the Module updates the zero residual offset constants

located in the

C-Cap EEPROM Memory Map

.

Module Responses

The host must initiate all communication with the Module with the exception of periodic CO2

waveform and breath data packets. The type of response sent is determined by the type of host

command. Responses include:

• status responses

• mode command responses

• simple command responses

• configuration command responses

• calibration command responses

Welch Allyn OEM Technologies Confidential Page 33

Page 34

LC101 CO2 Module OEM Implementation Manual

Status Responses

Status responses are data packets that communicate Module, sensor and system status. The

status response also serves as an acknowledgement for mode commands.

Status response packet format:

< STX 02h

X identifier 1*(ASCII)

xx mode 2*(ASCII)

yy message 2*(ASCII)

zz CCITT/CRC code 2*(ASCII)

> ETX 03h

NOTE: To simplify the Module status response examples that follow, the CRC data (zz) is

assumed to be included with the ETX character (>).

Status Response Mode Byte

The format of the Mode byte is as follows:

<Sxxyy> where S = Identifier

xx = Mode

yy = Status message

(1 byte = 1 ASCII character)

(2 Hex digits = 2 ASCII characters)

(2 Hex digits = 2 ASCII characters)

Status Response Mode Byte - Format Summary

bit 7* bit 6* bit 5* bit 4** bit 3** bit 2 bit 1 bit 0

Status

Response xx

<S61yy> Standby 0 1 1 0 0 0 0 1

<S63yy> Measurement 0 1 1 0 0 0 1 1

<S64yy> Autorun 0 1 1 0 0 1 0 0

<S65yy> Fault 0 1 1 0 0 1 0 1

Mode

8 4 2 1 8 4 2 1

*Bits 5 and 6 will always be set to 1; Bit 7 will always be set to 0.

**Bits 3 and 4 are always zero as there are only 4 modes (values 0, 2, and 6 to 31 are undefined).

Page 34 Confidential Welch Allyn OEM Technologies

Page 35

LC101 CO2 Module OEM Implementation Manual

Section 4 - Host/Module Communications

Status Response Message Byte

<Sxxyy> where yy =

Status message (2 Hex digits = 2 ASCII characters)

Status Response message byte (yy) contains:

• generic status messages (00h – 06h)

•fault status messages (10h – 85h)

Refer to the Status Message Table at the end of this section for message descriptions. More

detailed information about fault messages is also available in Appendix C, Error Messages &

Recovery.

Mode Command Responses

Host Command Module Response Module Response Format

<M21>

Enter standby mode

<M23>

Enter measurement mode

<M24>

Enter auto run mode

<S6106> xx = mode

yy = message

Example:

<S6106>

61= Standby mode

06= Acknowledge mode command

<S6306> xx = mode

yy = message

Example:

<S6306>

63= Measurement mode

06= Acknowledge mode command

<S6406> xx = mode

yy = message

Example:

<S6406>

64= Autorun mode

06= Acknowledge mode command

Welch Allyn OEM Technologies Confidential Page 35

Page 36

LC101 CO2 Module OEM Implementation Manual

Simple Command Responses

Host Command Module Response Module Response Format

<C00>

Request Module status

<C20>

Request software version

<C21>

Request hardware version

<C22>

Request stored ambient baro-

metric pressure reading from

absolute pressure transducer

<Sxxyy> xx = mode

yy = message

Example:

<S6400>

64= Autorun mode

00= OK status

<Vxxxmmddyyyy> xxx = version #

mm = version month

dd = version day

yyyy = version year

Example:

<V13010231998>

version = 1.30

date = 10-23-1998

<Hxx> xx = hardware version

Example:

<H25>

hardware version = 2.5

<Lxxxx> xxxx = amb baro pressure mmHg

Examples:

<L02E9>

amb baro pressure = 745 mmHg

<L02F8>

amb baro pressure = 760 mmHg

<C23>

Request sensor temperature

<Txx>

xx = (temperature x 4) oC

Example:

<T2A>

temperature = (42/4) = 10.5oC

<C26>

Request single CO2 packet

<wxxyy> xxyy = ppCO2 x 256

CO2 = 16 bit binary integer

Example:

<w1C5B>

waveform = 28.35

Page 36 Confidential Welch Allyn OEM Technologies

Page 37

LC101 CO2 Module OEM Implementation Manual

Section 4 - Host/Module Communications

<C27>

Request single breath packet

<C2E>

Request current pump flow rate

<C31>

Request sensor EEPROM revi-

sion #

<zxxyyww> xx = ETCO2 mmHg

yy = RR bpm

ww = InsCO2 mmHg

Example:

<z201500>

ETCO2= 32

RR= 21

InsCO2= 0

<Bxxxx> xxxx = pump flow rate ml/min

Example:

<B0096>

flow rate = 150 ml/min

<Rxx> xx = revision #

Example:

<R02>

revision # = 2

<C32>

Request sensor customer code

<C33>

Request sensor serial #

<C3A>

Request last calibration date

<Ixx> xx = customer code

Example:

<I00>

customer code = 00

<Nxxxx> xxxx = serial #

Example:

<N34C2>

serial # = 13506

<Dmmddyyyy> mm = month

dd = day

yyyy = year

Example:

<D06041998>

last cal date= 6/4/1998

Welch Allyn OEM Technologies Confidential Page 37

Page 38

LC101 CO2 Module OEM Implementation Manual

Configuration Command Responses

Configuration responses are data packets sent by the Module to the host at programmed

intervals. A single host measurement or auto run mode command initiates unsolicited

transmission of CO

packets is either defined by the host via a configuration command or the host may use the default

setting.

Module Response Module Response Format

waveform and breath data packets. The programmed interval between

2

<Wxxyy>

Unsolicited CO2 waveform packet at programmed interval

<Zxxyyzz>

Unsolicited breath data packet at programmed interval

see below

see below

<Wxxyy>, CO2 Waveform Data

Includes 4 bytes of CO2 waveform data that are sent at the programmed interval during

measurement and auto run modes.

<Wxxyy> where xxyy:

xxyy CO2 waveform data mmHg × 256 4*(ASCII)

range: 0 – 99.996 mmHg (0000h – 63FFh)

Example:

CO2 = 37.50 mmHg

{STX} “W” xx yy CCITT/CRC {ETX} waveform byte string

0x25 0x80 0x79 {STX}W258079{ETX}

02h 57h 32h35h 38h30h 37h39h 03h

Page 38 Confidential Welch Allyn OEM Technologies

Page 39

LC101 CO2 Module OEM Implementation Manual

Section 4 - Host/Module Communications

<Zxxyyzz>, Breath Data

Includes 6 bytes of breath data that are sent at the programmed interval during measurement

and auto run modes.

<Zxxyyzz> where xxyyzz:

xx ETCO2 mmHg 2*(ASCII)

yy RR bpm 2*(ASCII)

zz InsCO2 mmHg 2*(ASCII)

Range:

ETCO

2

0 – 99 mmHg (00h – 63h)

RR 0 – 250 bpm (00h – FAh)

InsCO

Example:

2

0 – 99 mmHg (00h – 63h)

ETCO2 = 39 mmHg / RR = 12 bpm / InsCO2 = 0 mmHg

{STX} “Z” xx yy zz CCITT/CRC {ETX} breath byte string

0x27 0x0C 0x00 0x1A {STX}Z270C001A{ETX}

02h 5Ah 32h37h 30h43h 30h30h 31h41h 03h

Additional Configuration Command Responses

Host Command Module Response Description

<Axx>

Change breath data clear rate

<Nxx>

Change waveform update rate

<axx> response = echo data field

<nxx> response = echo data field

<Oxx>

Change breath data update rate

<Qxxy>

Function enable

<F20yy>

Change pump flow rate

<C80>

Request software reset

<oxx> response = echo data field

<qxxy> response = echo new/current status

<F20yy> response = echo data field

no response

Welch Allyn OEM Technologies Confidential Page 39

Page 40

LC101 CO2 Module OEM Implementation Manual

Calibration Command Responses

Host Command Module Response Module Response Format

<Lmmddyyyy>

Update calibration date

<Gxx>

Update span gas concen-

tration

<C10>

Sample zero reference gas

<Sxxyy> xx = mode

yy = message

Example:

<S6424>

64= Autorun mode

24= Cal. ready for next step

Example:

<S6421>

64= Autorun mode

21= Cal. already in progress

<Sxxyy> xx = mode

yy = message

Example:

<S6424>

64= Autorun mode

24= Cal. ready for next step

Example:

<S6422>

64= Autorun mode

22= Cal. not in progress

<Sxxyy> xx = mode

yy = message

Example:

<S6425>

64= Autorun mode

25= Cal. in progress

<C11>

Sample span gas

<Sxxyy> xx = mode

yy = message

Example:

<S6425>

64= Autorun mode

25= Cal. in progress

<C13>

Abort calibration

<Sxxyy> xx = mode

yy = message

Example:

<S6400>

64= Autorun mode

00= OK (operation aborted)

Refer to the Status Message Code Table and the Host Command/Module Response Overview

Ta ble at the end of this section for message descriptions.

Page 40 Confidential Welch Allyn OEM Technologies

Page 41

LC101 CO2 Module OEM Implementation Manual

Software Protocol

Packets

• Module must respond within 1 second after receiving a host command (50 msec

typical response time).

• There is no minimum time interval between packets.

• Host must request Module status periodically to confirm the fault/OK status of the

Module and sensor.

• Host must either receive a Module response or have exceeded the Module response

timeout of 1 second before issuing a new command.

• There are no restrictions when switching from mode to mode.

•A packet that interrupts another packet causes the interrupted packet to be ignored.

• An incomplete or incorrectly formatted packet is ignored.

• Status messages have identical meanings in all operating modes.

Section 4 - Host/Module Communications

Faults

WARNING The host should not assume that the Module is faultless if CO2 waveform and

breath data is being sent. Data response packets may be communicated when

the Module is in a non-fatal fault, or soft fault state.

• If a fault occurs and the host issues a new mode command that is different from the

current mode, the Module responds with either a hard fault status and ignores the

mode command, or retries by attempting to clear the fault.

• If the Module is in a soft fault state, the host should issue a new measurement mode

command to attempt to clear the fault.

•A fault condition may leave the Module in the fault mode indicated by a <Sz5yy> status

response. For <Sz5yy>, yy is the status message and z is the other status.

Module Resets

External Resets (Initiated by the Host System)

• Software Reset - The host may command a software reset using the <C80>

command while the Module is unprotected. After the reset, the Module returns to its

EEPROM default settings.

• Reset - If the host holds the receive data line in a break condition for greater than 10

msec, but less than 500 msec, the microprocessor is forced into reset. After the reset,

the Module returns to its EEPROM default settings and starts up in the standby mode.

The Module can respond to host communication 2 seconds after a reset.

Welch Allyn OEM Technologies Confidential Page 41

Page 42

LC101 CO2 Module OEM Implementation Manual

• Hard Reset - If the host holds the receive data line in a break condition for more than

500 msec, the microprocessor is forced to enter the boot mode when the break

condition is released. The microprocessor boot mode is used to install new software

into the FLASH device.

Internal Resets (Initiated within the LC101 Module)

• Watchdog Reset - Watchdog reset is caused by a watchdog timeout. After a

watchdog reset, the Module responds to a <C00> Request Status command with the

status response <S6540> (fault mode, watchdog timeout). The host must issue a reset

to recover from a watchdog reset.

• Self Reset - Caused by a condition other than watchdog timeout. After self reset, the

Module responds to a <C00> Request Status command with status response

<S6500> (fault mode, status OK). The host must issue a reset to recover from self

reset.

System Behaviors - Dynamic Communications

Status Requests

The host must poll the LC101 Module periodically to determine status.

requests, the host can report any problems seen by the LC101 Module.

By sending status

WARNING The host should NOT assume that if waveform data is being sent by the LC101