Page 1

Gas-fired

water boiler

PFG

Series 7

Control Supplement

Universal Control Systems (UCS)

To complete boiler installation,

follow:

• General Information 2

• Boiler Wiring 3-5

• Vent Damper Installation 6

• Check-out Procedure 7

• Operating Instructions 8-10

For additional help, see:

• Troubleshooting 11-15

• Parts List 16

Controls must only be installed by and Control Supplement used by a qualified

installer/service technician. Read all instructions before installing. Failure to

follow all instructions in proper order can cause severe personal injury, death

or substantial property damage.

Part No. 550-110-643/0605

Page 2

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

GENERAL INFORMATION:

This system is used on natural gas-red boilers with or without

dampers as shipped from the factory.

This system is not offered for retrot,

or conver sion fr om sta nding pilot

systems. Any attempt to apply the system

components to boilers shipped for use

with a different control system will not

be covered under boiler warranty and

can cause severe personal injury, death

or substantial property damage.

IMPORTANT: When calling or writing about the boiler,

PLEASE GIVE THE MODEL listed on the boiler rating label

AND THE CP NUMBER found next to the rating label.

The following dened terms are used throughout this manual.

They bring attention to the presence of hazards of various risk

levels, or to important information concerning the life of the

product.

indicates presence of hazard which will

cause severe personal injury, death or

substantial property damage if ignored.

indicates presence of hazard which can

cause severe personal injury, death or

substantial property damage if ignored.

indicates presence of hazard which will

or can cause minor personal injury or

property damage if ignored.

indicates special instructions on

installation, operation, or maintenance

which are important but not related to

personal injury hazards.

2

Part Number 550-110-643/0605

Page 3

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

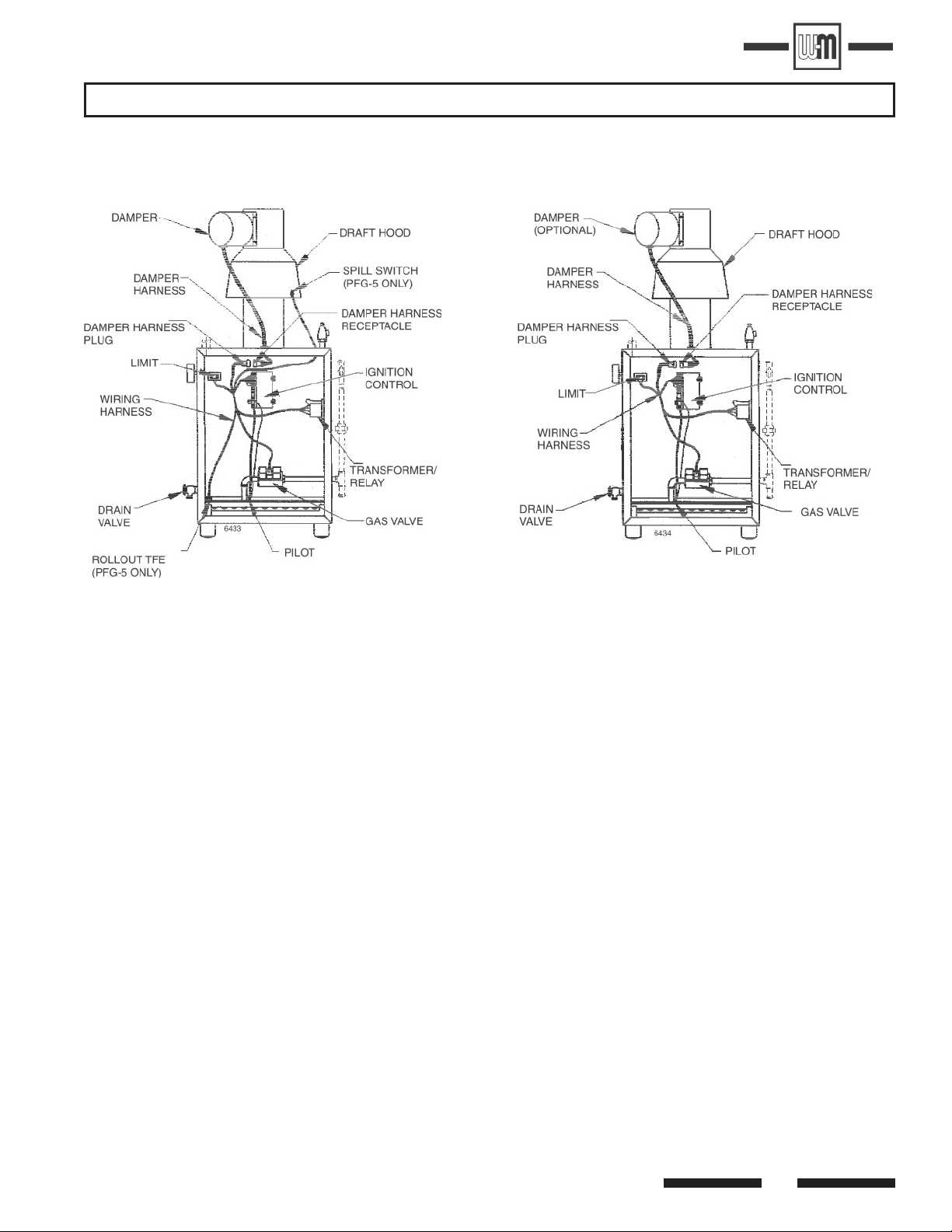

Section A: Installation

1. Bring supply wiring to boiler. Must be 14 ga. or heavier. See pages listed below each Figure for appropriate wiring diagram.

2. Proceed to page 6.

PFG 5 Boiler

Figure 1,

see page 4

PFG 6 thru 8 Boilers

Figure 2,

see page 5

Part Number 550-110-643/0605

3

Page 4

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

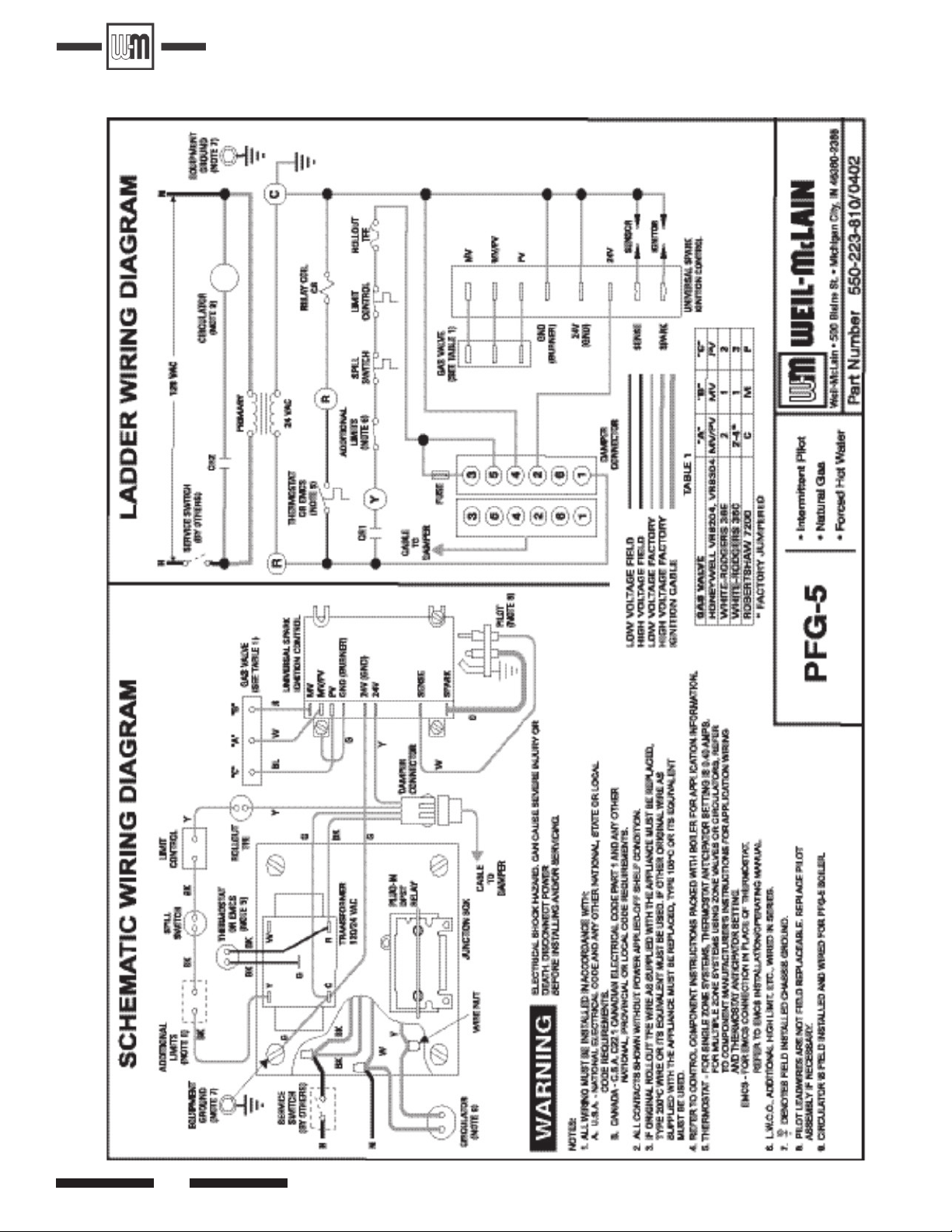

PFG-5

4

Part Number 550-110-643/0605

Page 5

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

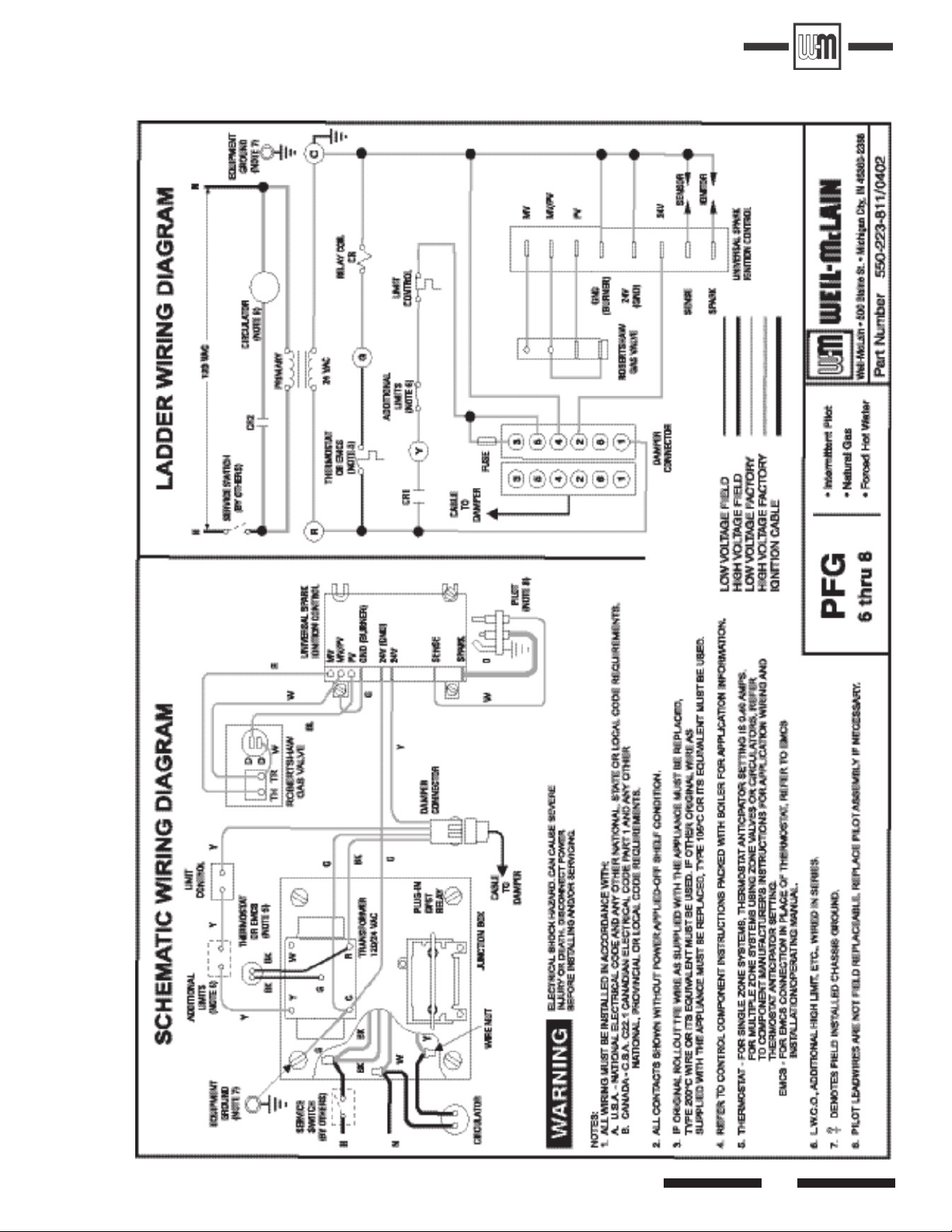

PFG 6 thru 8

Part Number 550-110-643/0605

5

Page 6

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

These boilers must have vent dampers:

• PFG 5 (U.S. only)

These boilers may have vent dampers:

• PFG 6-8 (U.S. only)

• PFG 5-7 (Canadian)

These boilers must not have vent damper:

• PFG 8 (Canadian)

If not installing damper, proceed to page 7.

1.

Only dampers listed on page 16 are

2. Efkal and Johnson dampers - install plug (packed in damper

carton of 4” thru 8” dampers) in hole in damper blade.

3. Minimum clearances:

Once damper is installed on boiler,

boiler will not operate without

damper installed.

approved for use on PFG Series 6 &

7 boilers. Any other damper installed

can cause severe personal injury or

death.

Section B: Damper Installation

Where screws or rivets are used to secure damper to draft

hood, they must not interfere with free movement of damper

blade.

5. Install damper harness between damper actuator and knock-

out in jacket top panel. Use strain relief connectors and

locknuts to secure both ends of damper harness. See Figure

1 or 2.

Keep wiring harness clear of all hot

surfaces.

PFG - 48” between jacket top and combustible ceiling.

DO NOT modify draft hood or

damper, or make another connection

between draft hood and damper

or boiler. This will void C.S.A.

certication and will not be covered

by Weil-McLain warranty. Any

changes will cause severe personal

injury, death or substantial property

damage.

4. PFG - Damper must be installed directly on top of draft

hood so that it serves only one boiler and so that damper

blade indicator is visible to homeowner. See Figure 1 or 2

and Figure 3 or 4.

6. Remove dummy receptacle from damper plug in boiler wiring

harness. Plug damper harness receptacle into damper harness

plug. See Figure 1 or 2.

Bypassing (jumpering) damper will

cause ue products such as carbon

monoxide to escape into house. This

will cause severe personal injury or

death.

After boiler has operated once, if

either end of harness is disconnected,

system shutdown will occur. Boiler

will not operate until harness is

reconnected.

7. Efkal damper - damper “Hold Open” switch must be in “Au

tomatic Operation” position for system to operate properly.

8. Apply label shown in step 5 to damper, so that it is visible

after installation.

9. Proceed to page 7.

-

Efkal Damper

Figure 3

6

Johnson Damper

Figure 4

Part Number 550-110-643/0605

Page 7

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

Section C: Check-Out

1. See Figure 5 for operating instructions page numbers. Raise

room thermostat to call for heat. Damper actuator will slowly

open damper (if provided).

2. When damper (if provided) is fully open, ignition control

powers spark generator and opens pilot valve.

Damper must be in open position when

appliance main burners are operating.

If damper is not in open position, ue

products will escape into house, causing

severe personal injury or death.

3. a. If pilot does not light within 15 seconds, pilot valve is closed

and spark generator is turned off. The ignition control initi-

ates a ve minute wait period. If call for heat exists after

ve minutes, ignition sequence starts at Step 2.

b. If pilot lights and ignition control senses ame current,

main valve opens and spark generator is turned off.

Figure 5

4. During main burner operation:

a. Ignition control monitors pilot ame current. If signal is

lost, main valve is closed, spark generator activated, and

sequence returns to Step 3.

b. If power is interrupted, the control system shuts off pilot

and main gas valves and restarts at Step 1 when power is

restored.

5. Thermostat is satised: pilot and main gas valves are closed.

Damper (if provided) will close.

6. Boiler is now in the off cycle.

7. Repeat steps 1-6 several times to verify operation.

8. Return thermostat to normal setting.

9. Set thermostat heat anticipator setting indicated in notes on

wiring diagram.

Part Number 550-110-643/0605

7

Page 8

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

PFG-5 WITH HONEYWELL VR8204/VR8304 GAS VALVE

8

Part Number 550-110-643/0605

Page 9

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

PFG-5 WITH WHITE-RODGERS 36C GAS VALVE

Part Number 550-110-643/0605

9

Page 10

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

PFG 6-8 WITH ROBERTSHAW 7000 DERHC GAS VALVE

10

Part Number 550-110-643/0605

Page 11

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

Section D: Troubleshooting

VERIFY PROPER OPERATION AFTER SERVICING

Never jumper (bypass) any device except

for momentary testing as outlined in

Troubleshooting Charts. Substantial

property damage and/or severe personal

injury could occur.

Label all wires prior to disconnection

when servicing controls. Wiring errors

can ca use improper and dan gerous

operation.

1. Before troubleshooting.

a. Have a voltmeter that can check 120VAC, 24VAC, a

microammeter with minimum scale range of 0-25, and a

continuity tester.

b. Check for 120VAC (min. 102 - max. 132) to boiler.

c. Check for 24VAC at secondary side of transformer.

d. Make sure thermostat is calling for heat and contacts

(including appropriate zone controls) are closed. Check for

24VAC between thermostat wire nuts and ground.

IN EVENT OF ACTUATOR FAILURE

–EFFIKAL DAMPER

If troubleshooting chart recommends replacing actuator, and

actuator is not immediately available, damper blade can be

xed in an open position to allow boiler operation.

Manually turning blade can cause actuator damage. Follow these

instructions only in case of no heat or damper actuator malfunc-

tion. See Figure 6.

1. Move damper service switch to “HOLD DAMPER OPEN”

position. Apply “call for heat” to boiler. Damper blade should

then rotate to open position and boiler will re.

2. If Step 1 above does not open damper, manually rotate

damper blade to open position using wrench or pliers on at

shaft between damper and actuator. Boiler will re. Verify

that damper service switch is in “HOLD DAMPER OPEN”

position.

3. Do not leave damper permanently in this position. Replace

actuator immediately. If damper is left in open position, boiler

will not operate at published efciencies.

Figure 6

JOHNSON DAMPER

If troubleshooting chart recommends replacing actuator, and

actuator is not immediately available, damper blade can be xed

in open position to allow boiler operation. Follow these instruc-

tions only in case of no heat or damper actuator malfunction.

See Figure 7.

1) Turn off power to boiler.

Failure to turn off power to boiler can result

in severe personal injury, death or substantial

property damage.

2) Remove damper actuator cover.

3) On PC board, move wire from A to B.

4) Turn on power to boiler.

5) Using wrench or pliers on at shaft section, manually rotate

damper blade until green light turns on. Boiler will re.

6) Do not leave damper permanently in this position. Replace

actuator immediately. If damper is left in open position, boiler

will not operate at published efciencies.

See damper manufacturer’s instructions packed with

damper for additional information.

See damper manufacturer’s instructions packed with

damper for additional information.

Part Number 550-110-643/0605

Figure 7

11

Page 12

Check for open thermostat or circ. relay

(where used) or check for loose wire

connections, defective spill switch or

rollout thermal fuse element, or open

LWCO or limit contacts.

If LWCO, spill switch or

rollout thermal fuse element

contacts are open, determine cause

and correct condition. Failure to do so

will cause severe personal injury, death,

or substantial property damage.

Open thermostat contacts for 15 seconds. Close thermosta t

contacts - is 24 VAC across terminals PV & MV/PV?

No Yes

Replace ignition control.

Is 24VAC present across Terminals 24V & 24V(GND)?

No Yes

VISUALLY CHECK - is ground wire connected from

"GND(Burner)" to ignition control mounting screw;

and ground wire connected from transformer

Terminal "C" to case ground?

No Yes

Correct by making connections.

Turn

OFF

supply voltage.

Check spark wire. Is it securely connected

to spark transformer?

No Yes

Securely connect, then turn ON supply voltage and re-test.

Is condition of spark wire good (not cut,

brittle, burned, or cracked)?

No Yes

Is spark gap 0.125" and isolated in pilot gas steam?

No Yes

Replace pilot assembly.

Replace pilot assembly, turn ON supply

voltage, operate system several complete

heat cycles.

Replace ignition control.

Replace pilot assembly, turn ON supply

voltage, operate system several

complete heat cycles.

TABLE I: No Spark, System Does Not Work

Without Vent Damper

Is spark electrode ceramic cracked?

No Yes

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

12

Part Number 550-110-643/0605

Page 13

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

Check for open thermostat or circ. relay (where used) or check for

loose wire connections, defective spill switch or rollout thermal fuse

element, or open LWCO or hight limit contacts.

If LWCO, spill switch or rollout thermal fuse element

contacts are open, determine cause and correct

condition. Failure to do so will cause severe personal injury, death,

or substantial property damage.

Is damper harness securely plugged in at both

ends?

No

Yes

Secure connections.

TABLE II: No Spark, System Does Not Work

With Vent Damper

Is 24VAC present across terminals C and Y on

transformer?

No Yes

Check for loose wire connections

or bad relay on transformer.

Is 24VAC present across terminal C and yellow wire

between damper connector and rollout thermal fuse

element?

No Yes

Replace actuator.

Check for out of round stack section.

Does motor rotate open?

No Yes

Is damper rotated open?

No Yes

Open thermostat contacts for 30

seconds. Damper will rotate to closed

position. Close thermostat contacts.

Damper will rotate to open position..

Is 24VAC present across terminals PV

and MV/PV?

No Yes

Is 24VAC present at Terminals

PV and MV/PV?

No Yes

Is spark present now?

Yes No

Re-test.

Turn

OFF

supply voltage.

Check continuity of each wire in wiring

harness to damper. Does continuity exist

for each wire?

No Yes

Replace damper

wiring harness.

Securely connect and

turn ON supply voltage.

Re-test.

Check spark wire. Is it securely

connected to ignition control?

No Yes

Is condition of spark

wire good (not brittle,

burned or cracked)?

No Yes

Remove damper harness from boiler

wiring harness. TEMPORARILY install

jumper between terminal 2 and

terminal 5 on damper plug in boiler

wiring harness. See Figure 10. Does

boiler fire?

No Yes

Replace pilot assembly.

Replace ignition control.

Replace actuator.

Is spark gap 0.125" and

located in pilot gas stream?

No Yes

Replace pilot assembly.

Replace ignition

control.

Is spark electrode ceramic

cracked?

No Yes

Replace pilot assembly.

Turn ON supply voltage

and operate system

several complete cycles.

Part Number 550-110-643/0605

13

Page 14

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

TABLE III: Pilot Lights, Main Valve Will Not Come On

With or Without Vent Damper

Correct wiring.

Make sure sense wire is not wrapped

around any pipe or accessories.

Is sense wire securely attached to sense

terminal and pilot assembly?

No Yes

Correct.

Replace pilot

assembly.

Replace

valve.

Check for continuity of sense wire

and condition of insulation.

Not OK OK

Check for proper gas pressure, clean pilot assembly

tight mechanical and electrical connections.

Also check for proper system grounding.

See additional information on page 15.

Does spark stay on for more than a few seconds after pilot is established?

No

Yes

Is sensing probe ceramic

cracked?

No Yes

Replace pilot

assembly.

Is sense wire or sensing

probe shorted out to

metal surface?

No Yes

Correct.

Replace ignition control.

Replace ignition

control.

Is 24VAC between Terminals

MV and MV/PV on ignition control?

No Yes

Contact gas supplier to

correct.

Is inlet gas pressure at least

5.0"W.C. and not over

14"W.C.?

No

Yes

Is main valve wiring secure

at terminals?

No Yes

No

Yes

Does system have proper flame signal?

Set up microammeter to measure

output current in flame sensor circuit

as follows:

a. Detach sense lead from ignition

control. Attach negative lead

from microammeter to sense

terminal on ignition control.

b. Attach positive lead to sense wire

from pilot assembly.

c. Disconnect main valve lead from

Terminal "MV" on ignition control.

d. Energize the system. Spark should

ignite the pilot. As soon as pilot is

burning, microammeter should

read at least 1.0 microamp for

Honeywell S8620C, 0.1 microamp

for U.T. 1003-510.

e. Is flame current signal less than the

minimum specified in "d" above?

14

Part Number 550-110-643/0605

Page 15

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

TABLE IV: Spark is Present, Pilot Will Not Light

With or Without Vent Damper

Connect securely to Terminals PV

and MV/PV on ignition control.

Are pilot valve connections CORRECT and securely fastened?

No

Yes

Open manual hand valve.

Is manual hand valve open?

No Yes

Is inlet gas pressure at least 5.0"W.C. and not over 14.0"W.C.?

No Yes

Contact gas supplier to

correct gas pressure.

Is gas present at pilot burner assembly? CAUTION Remove MV wire from ignition control, use a match

taped to a long screwdriver or pilot lighter rod and

manually light pilot.

No Yes

Make sure gas cock is in "ON" position and pilot line is

not kinked or obstructed. Check for clean pilot orifice.

If OK, replace gas valve.

Replace pilot assembly.

Block any draft around boiler. Check for clean pilot orifice.

Is spark gap 0.125" and located in pilot gas stream?

No Yes

TO CHECK IGNITION SYSTEM GROUNDING FOR TABLE III, PAGE 14.

Nuisance shutdowns are often caused by poor or erratic ground.

• Check for good metal-to-metal contact between pilot burner bracket

and main burner, and between main burner and burner rest.

control mounting screw, and from "C" on transformer to transformer case ground.

Make sure connections are clean and tight. If wire is damaged or deteriorated,

replace with No. 18 ga. moisture-resistant, thermosplastic insulated wire with

105°C minimum rating.

• Check ground lead from GND (BURNER) terminal on ignition control to ignition

Pilot assembly and ignition control must share common ground with main burner.

Part Number 550-110-643/0605

15

Page 16

Section E: Parts

Part Description Vendor Part Number W-M

Part No.

Damper Assembly

PFG-5)

8" (PFG-6)

9" (PFG 7-8)

Effikal RVGP-KS-7BKF

Johnson Q35GH-2 consisting of M35BC actuator and Y15 vent

pipe

Effikal RVGP-KS-8BFK

Johnson Q35GK-2 consisting of M35BC actuator and Y15 vent

pipe

Effikal RVGP-KS-9BF**

Johnson Q35GM-2 consisting of M35BC actuator and Y15 vent

pipe**

381-800-477

381-800-478

381-800-445

Damper Actuator Effikal RVGP (Effikal Only)

Johnson M35BE-1C (Johnson Only)

510-512-337

510-312-255

Damper Harness Weil-McLain 591-391-795

UCS Ignition Control Honeywell S8620C1003

United Technologies 1003-511

511-330-097

Pilot Burner Assembly Johnson Controls Q90GE-1 consisting of J981LYW pilot and

Y75AA-3 flame sensor

511-330-218

Boiler Wiring Harness, PFG-5

Boiler Wiring Harness, PFG 6-8

Weil-McLain

Weil-McLain

591-391-878

591-391-880

Gas Valve 3/4"

X

3/4"

PFG 5

Gas Valve 3/4"

X

1"

PFG 6-7

Gas Valve 1"

X

1"

PFG-8

Honeywell VR8304P4348

White-Rodgers 36C74-474

Robertshaw 7000 DERHC-S7C

Robertshaw 7000 DERHC-S7C

511-044-382

511-044-286

511-044-287

PFG SerieS 7 GaS-Fired Water Boiler – UniverSal Control SyStemS

**Not for use on Canadian PFG-8 boilers.

Only dampers listed above are approved for use on and PFG Series 6 & 7 boilers.

Any other damper installed can cause severe personal injury or death.

16

Part Number 550-110-643/0605

Loading...

Loading...