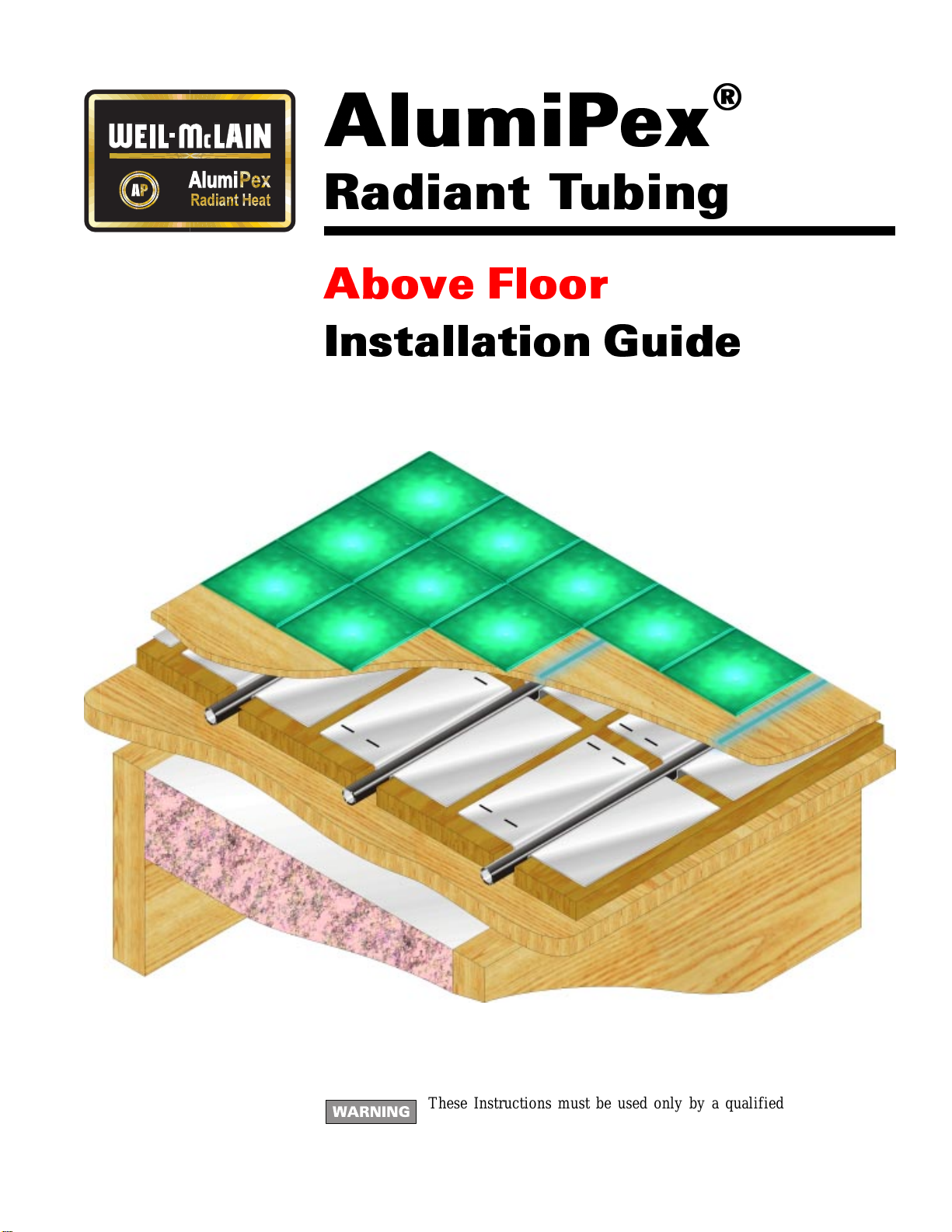

Page 1

®

AlumiPex

Radiant Tubing

Above Floor

Installation Guide

These Instructions must be used only by a qualified installer/service

technician. Read these instructions completely before beginning. Failure to

follow these instructions can cause severe personal injury, death or substantial

property damage.

Part No. 650-000-221/0298

Page 2

AlumiPe x Radiant Tubing

Hazard Definitions

Indicates presence of hazards that will cause

severe personal injury, death or substantial

property damage.

Indicates presence of hazards that will or can

cause minor personal injury or property

damage.

Codes and Standards

• This guide is provided for general information only.

The building or heating system designer is responsible

for all design details and for compliance with all

building codes, local and national.

• Refer to AlumiPex Technical Information sheets for

specific approvals and listings of AlumiPex Radiant

Tubing.

Indicates presence of hazards that can cause

severe personal injury, death or substantial

property damage.

Indicates special instructions on installation,

operation or maintenance that are important

but not related to personal injury or property

hazards.

• AlumiPex Radiant Tubing is not approved for potable

water applications.

• Consult local requirements before installing a radiant

heating system. Install AlumiPex tubing following all

of the applicable codes and all specifications and

methods prescribed by the building designer and

heating system designer.

Do not use AlumiPex Radiant Tubing to

conduct natural gas. Such an application

could result in severe personal injury, death

or substantial property damage.

Do not expose AlumiPex Radiant Tubing to

petroleum products or solvents.

Do not weld or glue AlumiPex.

Do not secure AlumiPex tubing permanently

with adhesive tape.

The tubing could be damaged, resulting in

risk of severe personal injury, death or

substantial property damage.

Finished Flooring: Use only finished

flooring rated by the flooring manufacturer

for use with heated floors. Failure to follow

this guideline could result in substantial

property damage.

Do not use AlumiPex Radiant Tubing in

potable water or combination space heating/

potable water heating applications.

The tubing is not approved for domestic

water use.

In combination space heating/potable water

heating applications, chemical or biological

contamination in the system water is possible

and could result in severe personal injury,

death or substantial property damage.

Use only AlumiPex Fittings with AlumiPex

Tubing. Use of any other method can result in

severe personal injury, death or substantial

property damage.

This installation guide covers both new

construction and retrofit. For retrofit of a

completed building review the Trade Guides

with the building owner if there is no general

contractor involved in the remodeling project.

2

Part Number 650-000-221/0298

Page 3

Above Floor Installation Guide

ALUMIPEX STEP-BY-STEP - - ABOVE FLOOR INSTALLATION

Page CONTENTS

4

7

8

9

10

11

11

12

Tube Layouts for Radiant Heating

Obtain Tube Layout Drawing

Meet with General Contractor

Obtain Materials

Obtain Special Equipment

Pre-Installation Check List

Mark Tube Layout on Subfloor

Mount Manifold(s)

Heating

Contractor

!

Set Tube Layout

!

Review Plans and

Trade Guides with

General Contractor

!

Purchase materials

and equipment

TYPICAL SEQUENCE

Others

Calculate heat loss

!

and design radiant

system

Site Preparation

!

Rough in utilities

!

Pour Foundation &

!

Main Slab

Building Closure

!

Interior Framing,

!

Plumbing, Electrical

14

17

18

18

18

19

19

Part Number 650-000-221/0298

Install the Tubing

Pressure Test Tubing

Connect System Piping

Pressurize Tubing for Observation

Before Leaving the Jobsite . . .

Inspect Tubing Before Flooring Inst.

Inspection, Repair & Troubleshooting

Install and Test

!

AlumiPex Manifolds

and Tubing

Install System Piping

!

& Heating

Components

! Inspect and Test

System After

Building Completion

Drywall

!

Finish Carpentry

!

Finish Flooring

!

3

Page 4

AlumiPe x Radiant Tubing

A. Tube Layouts for Radiant Heating

1. Radiant Floor Heatng

a. Hot water flowing in the radiant tubing under the

finished flooring heats the flooring and the heat

emission plates. The heat emission plates help

spread the heat evenly across the flooring.

b. Heat must pass through the flooring and the

coverings on the floor (low pile carpeting and

thermal pads, for example). See Figure 1.

• The more the flooring and coverings act as

insulators, the higher the tube water

temperature has to be to cause the floor surface

to heat up.

• Heavy carpeting and pads resist heat transfer

and are not recommended for use in radiant

floor heating.

c. Heat will also try to move downward.

• In suspended floor applications, heat will try

to pass to the space underneath. So insulation

is needed under the floor to prevent this heat

movement.

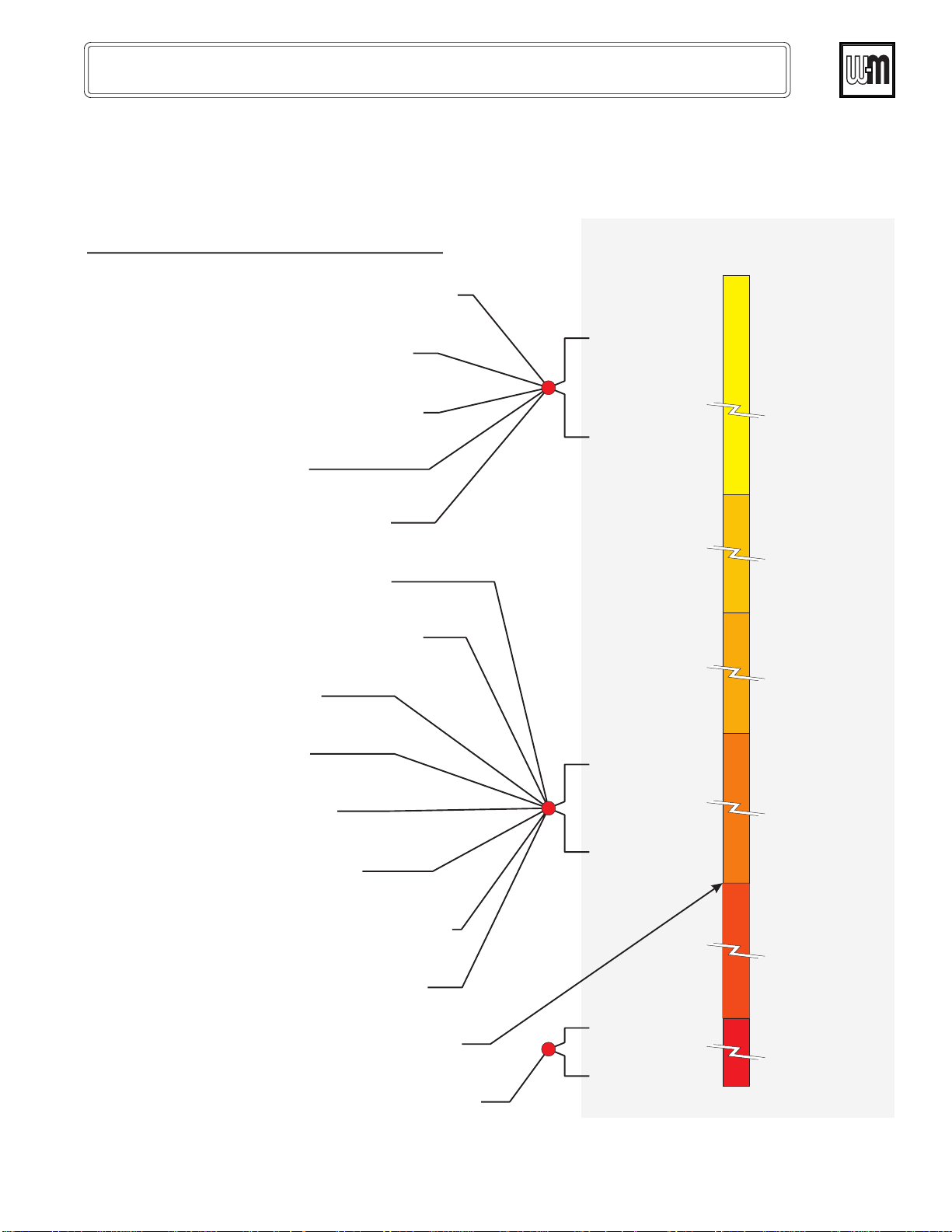

2. Heat Output from Radiant Floors

a. The floor surface is usually heated to a maximum

temperature of about 85 oF - the surface

temperature of human skin.

• Higher floor temperatures in occupied areas

could be uncomfortable.

• Floor surface temperatures up to 92 oF are

often used around the outside perimeter of

rooms and in other areas where foot contact is

limited.

b. The heat given off by the floor depends on the

difference between the room temperature and the

floor temperature - the larger the difference in

temperature, the greater the heat.

• With the floor at 85 oF and room temperature at

70 oF, each square foot of the heated floor will

give off about 30 Btu’s per hour.

c. The spacing of tubes affects how much heat can be

moved through the floor.

• Closer spacing increases the heat per square

foot of floor.

• This is why tubes are often spaced closer

together along outside walls with high heat

losses - like next to large windows or patio

doors.

Figure 1 - Heat flow from tube through slab

CarpetCarpet

PadPad

SubfloorSubfloor

SleepersSleepers SleepersSleepers

SubfloorSubfloor

InsulationInsulation

TubeTube

Heat Emission PlateHeat Emission Plate

JoistJoist

3. Radiant Floor Heating Design

a. The heating system designer must determine:

• The heat loss for each room.

• Square feet of room floor surface available for

floor heating.

• The water temperature in the tubing and

spacing between tubes - to match the heat

given off by the floor to the heat lost from the

room.

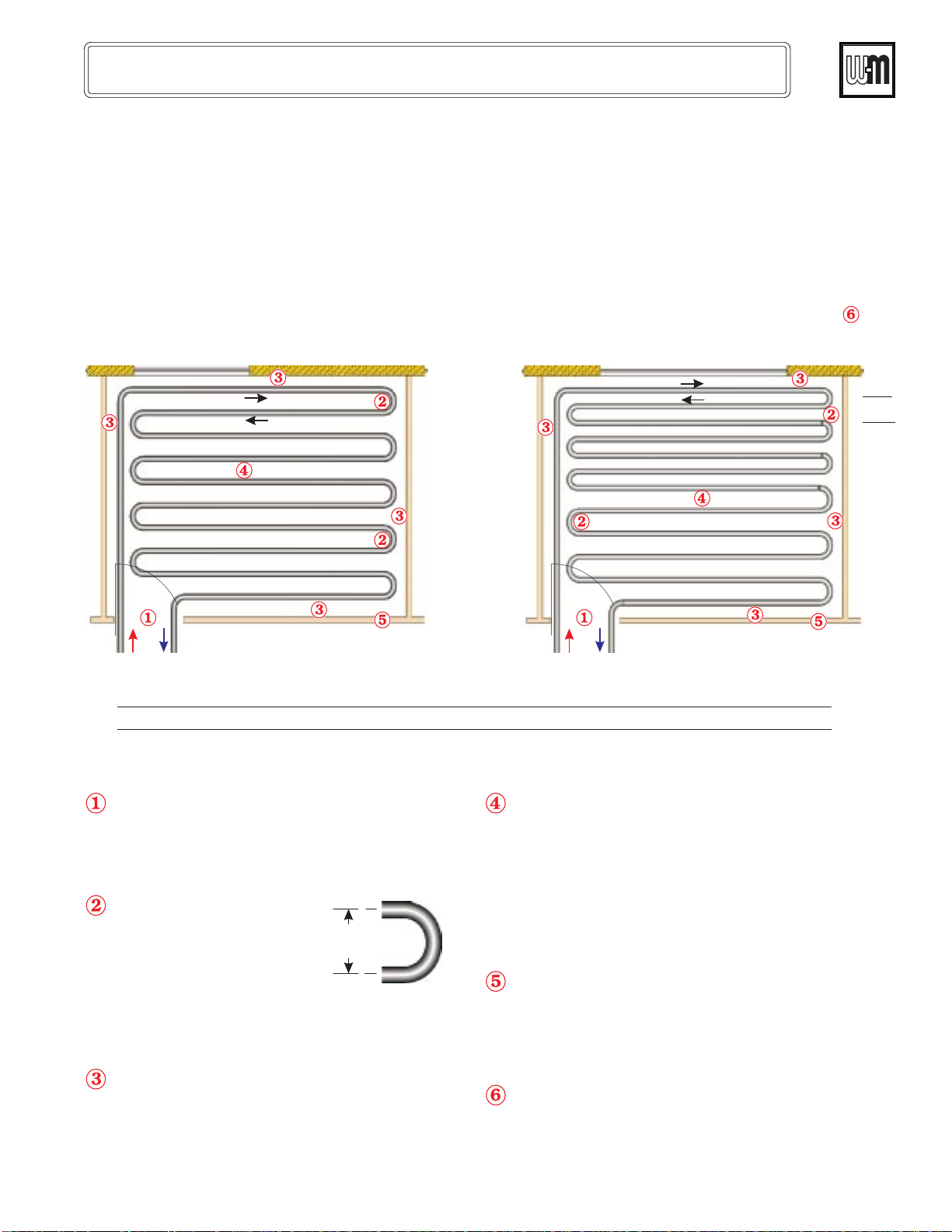

4. Tube Layout Patterns

a. The routing of the tubing in the room affects room

comfort and effectiveness of the floor heating

system.

b. Figure 2 shows typical tube layouts for above floor

installations.

• Where possible, the hottest water is usually

routed along the outside walls.

• Tube routing in above floor installations is

limited by the practicality of variations in

sleeper layouts. Sleepers are the boards used to

separate the tubing and support the flooring.

c. Where the outside wall loss is particularly high,

such as caused by patio doors, the tubing will

sometimes be spaced closer together for a few feet

out from the wall as shown in Figure 2.

b. Pay close attention to the key information given in

these illustrations, such as:

• flow direction

• minimum bend diameters

• spacing to walls

• heat emission plates

• passage under walls

• use of closer spacing

4

Part Number 650-000-221/0298

Page 5

Above Floor Installation Guide

Figure 2 - Typical tube routing for an above floor installation

ABOVE FLOOR INSTALLATION

(One-Way Serpentine Patterns - Typical)

Outside Wall

Interior Partition

Supply

Constant Spacing

Outside Wall Concentrated Spacing

(Wall with large window area or cool wall)

Outside Wall

Interior Partition

Interior Partition

Return

These drawings are conceptual only. Consult Weil-McLain Radiant Guides or Software for actual project layout.

Interior Partition

Supply

Interior Partition

Return

Interior Partition

NOTE FLOW DIRECTION

!

The warmest water is directed next to the outside wall.

BEND DIAMETER

Maintain a MINIMUM bend

diameter of:

!

1/2“ Tube - 6 inches

5/8“ Tube - 7 inches

!

3/4“ Tube - 8 inches

!

DISTANCE TO WALL

!

Keep the tubing 4 to 6 inches from the walls.

This will reduce the chance of damage due to drilling,

!

sawing or nailing.

Part Number 650-000-221/0298

Bend

Diameter

USE HEAT EMISSION PLATES

!

Snap the tubing into AlumiPex Heat Emission Plates

placed on the sleepers.

These plates spread the heat evenly to the floor and ensure

!

that the tubing is maintained in tight contact with the

flooring above.

Staple the heat emission plates to the sleepers on one side

!

only to allow the plates to conform as the flooring or

subfloor is installed.

PASSAGE UNDER WALLS

!

Avoid running tube under walls if possible.

Where tubing must run under a wall, mark the framing

!

above for 6 inches on either side of this location so no

fasteners will be driven into the framing near the tubing.

CLOSER SPACING

!

Tubing is often spaced closer near outside walls with cool

surface temperatures or large window areas.

5

Page 6

AlumiPe x Radiant Tubing

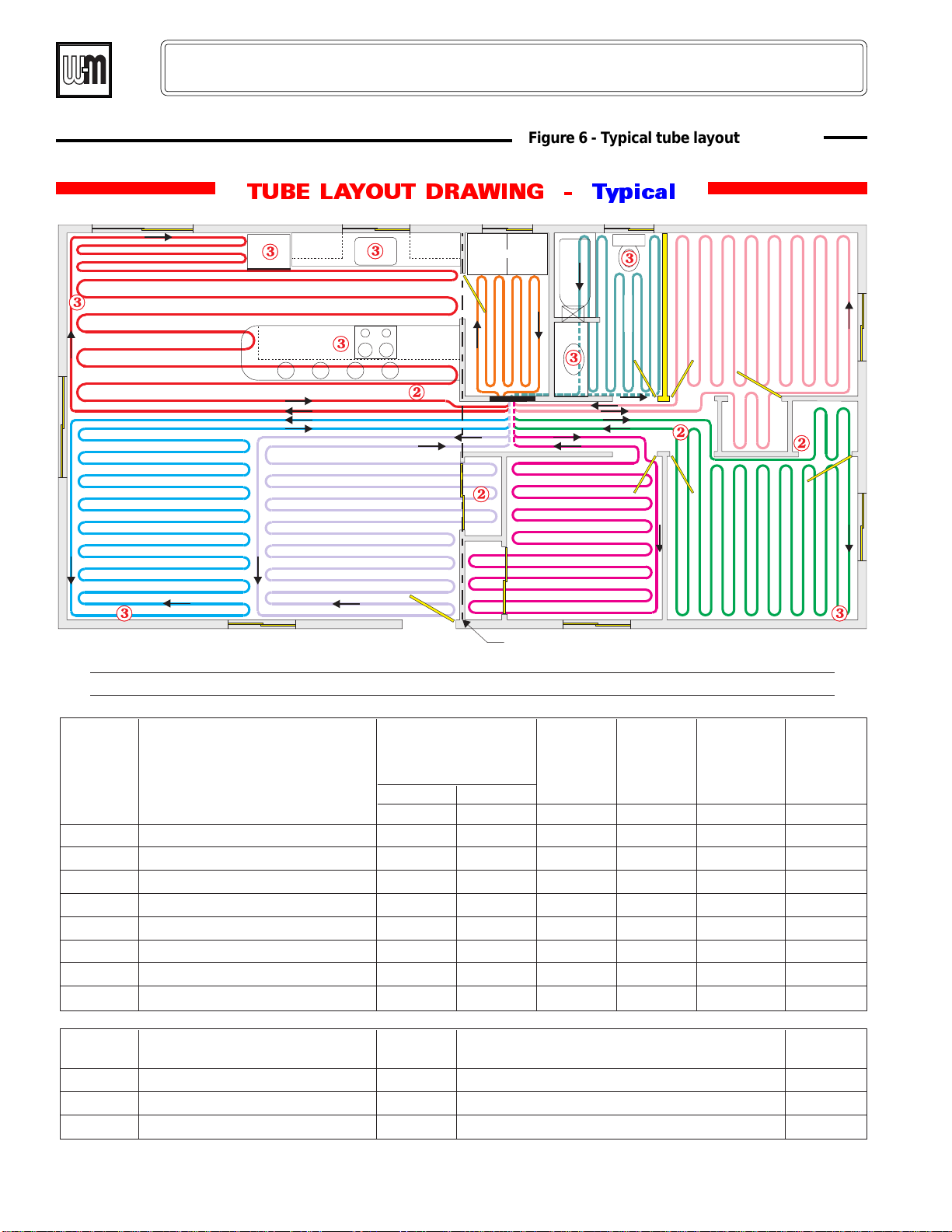

Figure 6 - T ypical tube layout drawing

TUBE LAYOUT DRAWING - Typical

washer / dryer

DINING

LR1

KITCHEN

DK

LIVING ROOM

LR2

U

T

I

L

I

T

UT

Y

Slab Control Joint

MANIFOLD

BEDROOM

BR1

BT

B

A

T

H

BEDROOM

This drawing is conceptual only. Consult Weil-McLain Radiant Guides or Software for actual project layout.

BR3

BEDROOM

BR2

Tubing

Circuit

Finished

Flooring

Tube Spacing

(Center to Center)

Circuit

Length

Leader

Length

Length

Allowance

Normal Close

Inches Inches Feet Feet Feet Feet

LR1 Low pile carpet w/ thermal pad 8.5 178 43 10 231

LR2 Low pile carpet w/ thermal pad 8.5 6.5 192 22 10 224

DK Laminatedhardwood 12.5 6.5 227 28 10 265

UT Ceramic tile 6.5 45 4 10 59

BT Ceramic tile 6.5 79 12 10 101

BR1 Laminated hardwood 8.5 6.5 141 22 10 173

BR2 Laminated hardwood 8.5 6.5 163 22 10 195

BR3 Laminated hardwood 8.5 6.5 156 19 10 185

Coil

Number

Coil Length Tube Size

1 1000 feet 1/2" 974

2 300 feet 1/2" 286

3 300 feet 1/2" 173

Use for Circuits Listed

LR1, LR2, DK, UT & BR2

BT & BR3

BR1

Total

Tube

Length

Total

Length

6

Part Number 650-000-221/0298

Page 7

Above Floor Installation Guide

B. Obtain Tube Layout Drawing

Floor Plan/Layout Should . . . . . . . . . .

!

Be drawn to scale using a CAD program so tube

lengths can be calculated by the program.

!

Show complete floor plan, including all

appliances, cabinets, fireplaces and any other

details which could affect the routing of the

tubing.

!

Show complete layout of all circuits.

!

Provide length of each circuit, including leader

length. are the tubing runs connecting

Leaders

from the room circuits to the manifold(s).

The heating system designer may add an

allowance to the total length to account for

variations in actual installation. This might range

from 3 to 10% depending on the type of

installation. In the example shown at left, the

designer used a length allowance of 10 feet.

!

Show tube spacing and flow directions.

!

State finished flooring assumed for each space.

Note Tube Routing

!

Run leaders (connecting tubing from manifolds to

circuits) through hallways.

!

Run leaders and tubing under doorways.

!

Avoid running under walls to reduce chances of

damage from fasteners.

!

Mark the framing above where tubing runs under

walls so all trades will be aware.

!

If tubing must penetrate a firewall, follow local

codes regarding sleeving and fire stopping

requirements.

1. Do not start a radiant heating installation without a

detailed tube layout drawing.

• It provides critical information on:

• tube routing

• tube lengths

• areas to be avoided

• materials needed

2. Figure 3 includes the information and drawing detail

for a typical tube layout drawing.

3. A complete, accurate drawing of the tube layout is the

most important key to a successful job.

DO NOT Run Tubing:

!

Under cabinets, refrigerators, ranges, freezers.

These items "block" the heat and the tubing would

be wasted.

!

Within 8 inches of toilet flanges. The wax ring

seal may soften and fail from the heat.

!

Under fireplaces, ovens, appliances or other heat

sources.

!

Closer than 4" from walls.

!

Closer than 6" from appliance vents or flues.

Part Number 650-000-221/0298

7

Page 8

AlumiPe x Radiant Tubing

C. Meet with General Contractor

1. W e suggest you meet with the general contractor

and follow this checklist:

q Review the AlumiPex Trade Guides with the

general contractor and ask him to provide the

information and copies to each of the trades

involved.

q Verify that the flooring system is rated by the

flooring manufacturer for use with heated floors.

q Verify architectural details affected by the

flooring system. Verify that the building designer

has allowed for the following:

The rough openings for doors and windows

allow for the height of the flooring system.

Stair risers include allowance for the height

of the flooring system.

q Ensure that the tubing will be stored inside until

time for use.

AlumiPex is specially designed to protect the

tubing from damaging ultraviolet rays.

However, avoid exposing the tubing to direct

sunlight for extremely long periods.

Do not install AlumiPex tubing in

applications which will continuously expose

the tubing to direct sunlight.

q Discuss the tube layout drawing with the general

contractor and verify:

q If the tubing passes under any interior walls, you

should mark these locations on the framing

above.

Ask the general contractor to notify other

trades to watch for these markings to ensure

tubing will not be damaged by fasteners.

q If the tubing passes through stud walls, the

framing carpenters should apply nail stops on

both sides of the stud at these locations.

Ask the general contractor to notify other

trades to watch for these locations to ensure

tubing will not be damaged by fasteners.

q A copy of the tube layout drawing should be

given to the general contractor to ensure a

trouble-free installation.

You will probably want to provide a final

copy after the installation is complete.

The final copy should show special

notations, any changes from the original

plan, and locations of any repairs.

floor plan design has not been changed.

finished floorings (and coverings) shown by

heating system designer are correct per final

design.

8

Part Number 650-000-221/0298

Page 9

Above Floor Installation Guide

D. Obtain Materials

1. AlumiPex Tubing

• In rolls and sizes specified on tube layout drawing.

2. AlumiPex Tube Fittings

• Refer to AlumiPex Fitting Instructions for part

numbers and procedures.

Use only AlumiPex Fittings with AlumiPex

Tubing. Use of any other method can result in

severe personal injury, death or substantial

property damage.

Refer to AlumiPex Fitting Instructions for

selection and application of fittings.

3. AlumiPex Manifolds

• Available in three sizes (2, 3 and 4 takeoff) in

nickel-plated brass (shown above), with or without

integral balancing valves .

• Copper manifolds (not shown) are also available.

• Refer to AlumiPex Manifold Instructions for part

numbers and procedures.

4. Additional Materials

a. AlumiPex Heat Emission Plates

• These are sized and designed specifically for

use with AlumiPex ½” tubing.

• See Figure 11, Page 16.

• Do not apply tubing in above floor

installations without heat emission plates.

Heat will be uneven and could cause

shrinkage or damage to flooring.

b. Staples

• Use staples sized so as not to penetrate deeper

than the subfloor. Usually, 5/8” staples will

work well.

c. Poly-wrapped insulation (if not already installed in

joist bays below)

e. Manifold Enclosure(s) (Optional)

• 30” x 27” or 30” x 37”.

Part Number 650-000-221/0298

9

Page 10

AlumiPe x Radiant Tubing

E. Obtain Special Equipment

3. AlumiPex Reamer/Sizer(s)

The reamer/sizer is specific to tube diameter.

Make sure to have the right reamer/sizer for each

size of tubing being installed.

1. Tubing Uncoiler

Assists in tube installation.

2. AlumiPex Tube Cutter

4. Pressure Gauge

With a scale range of 150 psig.

For pressure testing and tubing pressurization.

10

Part Number 650-000-221/0298

Page 11

Above Floor Installation Guide

F. Pre-Installation Check List

q Subfloor must be installed.

q Make provision for pressure testing:

• W ater if no freeze concern.

q Interior framing should be completed, but drywall

and finish carpentry not in place if possible.

• Otherwise, air compressor and hoses for air test and

pressurization.

q Read this installation guide, the AlumiPex Fitting

q Review AlumiPex T rade Guides with general

contractor to ensure other trades will be informed.

Instructions and AlumiPex Manifold Instructions

thoroughly .

G. Mark Floor Plan and Tube Layout on Subfloor

1. Use the T ube Layout Plan to mark the following on

the subfloor . Use several colors if possible to define

different elements and circuits.

See Figure 7 for typical layout markings for the

system shown in Figure 6, page 6.

Mark wall lines and door openings (if interior

framing is not already installed).

Mark outlines of kitchen and bath cabinets,

appliances, etc.

Mark areas to be avoided (fireplaces, toilet

flanges, etc.).

Then mark key portions of the tube layout,

showing tube bend locations and flow direction.

• Mark locations of penetration holes in rooms

and hallways, if any.

Figure 7 - Possible layout markings on subfloor for portion of system shown in Figure 6

Penetration Hole (Typical)

Areas (Typical)

Areas (Typical)

Counters and Avoidance

Counters and Avoidance

Leader Routing

(typical)

Return Bends (typical)

(Typical)

Penetration Holes

Manifold

Leader Routing

(typical)

Return Bends (typical)

Part Number 650-000-221/0298

This drawing is conceptual only. Consult heating system designer for actual job details.

11

Page 12

AlumiPe x Radiant Tubing

H. Mount Manifold(s)

1. Accurately measure the location of the manifold

mounting wall (if not already installed).

Placement of the manifold and the tube

penetrations is critical.

Take extra care in laying out these locations so all

items will be in proper position for the interior

framing of the building.

2. Attach the manifold to a plywood panel.

Size the panel to fit between the finished studs if

the panel is to be recess mounted.

Longer manifolds will require spanning more than

one stud spacing.

For a complete metal cabinet enclosure, use

AlumiPex Wall Cabinets.

See Figure 8 for a typical manifold mounting

arrangement.

3. Prepare holes for tube routing.

Drill 1½” holes through the studs to route tubing

to upper floors. See Figure 9 for drilling

penetration holes in the rooms above.

Drill 1½” holes through the sole plate in the

manifold stud cavity for penetrations to route

tubing to same floor or lower floor heating circuits.

Route same floor tubing through the joist bays

below and then up through holes in each room

unless the tubing will be routed through a hallway

as in Figure 6. Here, the tubing would be routed to

the joist bay below, then up to the proper locations

in the hallway to route to the rooms. This method

provides a neat installation while allowing ample

room for tube bending.

When drilling the holes for tube penetration into

the rooms or hallway, drill the holes at a 45 degree

angle to provide the proper minimum bend

diameter for the tubing. See Figure 9, Page 14.

12

Part Number 650-000-221/0298

Page 13

Above Floor Installation Guide

Figure 8 - Mounting of manifold(s), typical

MANIFOLD MOUNTING

4“

Cover

(Above Floor System)

RETURN

SUPPLY

RETURNRETURN

SUPPLYSUPPLY

Studs

24“

Min

Dry Wall

Dry Wall

Joists

AlumiPex Manifold, Typical

!

Refer to AlumiPex Manifold Instructions for details of

mounting, assembly and application.

Mounting Configuration

!

The installed depth of the manifold assembly is

approximately 4 inches.

!

If mounted on 3/4“ plywood as shown, the complete

assembly would fit in a 5” deep enclosure.

!

This can be done by using 2 x 6 studs in the vicinity of the

manifold or building out from 2 x 4 studs.

Part Number 650-000-221/0298

Lower Plate

Subfloor

Joist Bays

The details shown are representative only. Other mounting configurations are possible.

Junction Box

!

Junction box for manifold valve actuator wiring, if needed.

Protect Tubing at Penetrations

!

Where tubing passes through stud walls, make sure nail

stoppers are installed on both sides of the stud to protect

tubing from damage by fasteners.

!

Make sure the drywall installers and finish carpenters are

aware of the tubing in the walls and floors.

AlumiPex Manifold Fittings

!

Refer to AlumiPex Fitting Instructions for selection and

application of AlumiPex fittings.

13

Page 14

AlumiPe x Radiant Tubing

I. Install the T ubing

Always wear safety glasses for eye protection

when handling AlumiPex tubing. The tubing

can spring back when pulled. Failure to follow

this guideline could result in serious personal

injury.

1. Install the sleepers.

Beginning from one side of each room, use your

floor markings and the tube layout drawing to

place the sleepers.

Glue and nail each sleeper in place as shown in

Figure 10.

Bend routing sleepers can be made using a router

and fixture as shown or using a saber saw to cut

semicircles.

2. Drill tube penetration holes.

If the tubing will penetrate the floor in the room,

drill a 1½” hole at a 45 degree angle for each

penetration as shown in Figure 9.

Make sure the tube can be routed through the hole

from below and provide a minimum 6 inch bend

diameter (3 inch bend radius) for 1/2” tubing.

3. Install heat emission plates.

Install AlumiPex Heat Emission Plates in the

sleeper spaces, centered in the 1” gap.

Secure heat emission plates on one side only to the

sleeper below using 5/8” staples.

Leave the other side of the heat emission plates

free to move so the plates can conform to the floor

as the upper subfloor or finished flooring is

installed.

See Figure 11 for typical details.

7. Attach tube fitting to manifold SUPPLY connection

(bottom manifold).

8. Feed the tubing to the room as shown on the heating

system designer’s tube layout drawing, feeding the

outer (SUPPL Y) tubing first.

9. Complete the layout for the circuit and route the

tubing back to the return manifold as shown on the

tube layout drawing.

10. Carefully cut the tubing to the correct height at the

return manifold. Apply an AlumiPex fitting for

attachment to the manifold.

11. Then attach the fitting to the RETURN (top) manifold.

12. Continue the process for each circuit.

13. See Figure 11, page 16, for an above floor

construction example.

Figure 9 - Tubing penetration hole, typical

45

degrees

Drill penetration holes

1½" diameter on 45

degree angle.

4. Place tube roll on uncoiler.

5. Route free end of tubing to manifold.

Feed the free end of the tubing through any

penetration holes to the manifold.

6. Install manifold fitting on free end of tube.

a. AlumiPex Nickel-Plated Brass Manifolds:

Use only AlumiPex Euro conical fittings.

Refer to AlumiPex Manifold Instructions for

details and part numbers.

b. AlumiPex Copper Manifolds:

Use only AlumiPex tubing to NPT connectors.

14

SleeperSleeper

SubfloorSubfloor

1/2" Tubing, Typical

(With 6" bend diameter)

Joist, Typical

Part Number 650-000-221/0298

Page 15

Above Floor Installation Guide

Figure 10 - T ypical sleeper layout and installation

SLEEPER LAYOUT - ABOVE FLOOR

(Typical)

5

3

4

1

4

1

4

1

4

3

1

2

4

2

1

4

1

4

4

1

4

5 5

These drawings are conceptual only. Consult Weil-McLain Radiant Guides or Software for actual project layout.

1

SLEEPERS

!

Typically sleepers are 1 x __ lumber or .

(Width of sleeper is equal to the required tube spacing less

1 inch.)

!

Space 1" apart as shown to provide room for heat emission

plate tubing channel and for thermal expansion.

!

Begin at one side of the room. Place a 1 x 4 spacer (item 3)

" from wall as shown.

¼

!

Leave a 1" gap between spacer and first sleeper. Then glue

and nail sleepers in place.

2

END SUPPORT SLEEPERS

!

Typically cut from 3/4" plywood.

should equal tube bend radius plus 4 inches.)

!

Use a router and circle cutting template or fixture to route

3/4" wide x 5/8" deep channels as shown..

!

Place the end supports about " from the wall to allow

room for expansion. Then glue and nail in place.

Part Number 650-000-221/0298

¾" CDX plywood

(Width of end sleepers

¼

3

SPACERS

!

Typically 1 x 4 furring strips.

!

Place spacers about from the wall to allow room

for expansion. Then glue and nail in place.

!

Use a spacer between the wall and one of the end

support sleepers to provide a channel for the tubing to

leave the room as shown.

4

TUBING PATH

!

Provide a 1" gap between spacer and end support

sleeper for routing tubing out of room. This will allow

placement of a heat emission plate along this route.

5

PROVIDE GAP AROUND PERIMETER

!

Provide " gap around entire perimeter of room to

allow for expansion.

¼

¼"

15

Page 16

AlumiPe x Radiant Tubing

Figure 11 - Typical above floor installation

ABOVE FLOOR INSTALLATION

J

E

I

F

G

This drawing is conceptual only. Consult Weil-McLain Radiant Guides or Software for actual project layout.

AlumiPex Tubing, 1/2”

A

!

Use AlumiPex tubing, 1/2”, commonly spaced on 6½-inch

centers as shown (equal to 5½" for the sleeper plus 1" gap).

B

AlumiPex Heat Emission Plates

!

Use AlumiPex Heat Emission Plates to distribute the heat

evenly to the floor above. Space plates from 1/4” to 1”

apart end to end to allow for thermal expansion.

C

Sleepers

!

Glue and nail 1 x __ wood sleepers to the subflooring,

starting from one side of the room and working toward the

other.

Leave a 1" gap between sleepers to provide room for the

!

heat emission plate groove.

Staples

D

!

Secure each 2-foot long plate to the sleepers with 5/8"

staples. Staple one side only to allow the plates to level

out as the top subfloor or finish wood flooring is

applied..

C

B

A

E

F

G

H

I

J

D

H

Cover Sheet

!

A cover sheet must be used if the finished flooring will

be carpet, tile, vinyl or laminated hardwood.

Mark the Tubing Locations

!

Always mark the top subfloor with a chalk line or other

mark to clearly show the location of the tubing

underneath, ensuring the tubing won't be penetrated by

fasteners.

Pay extra attention to marking the tubing bend

!

locations as well.

Poly-wrapped Insulation

Joists

Subflooring

Finished Flooring

16

Part Number 650-000-221/0298

Page 17

Above Floor Installation Guide

J . Pressure T est the Finished Tubing Installation

1. After all tubing has been routed and connected to the

manifold, pressure test all tubing circuits before

finished flooring is installed. Refer to AlumiPex

Manifold Instructions.

2. Isolate the AlumiPex manifolds and tubing from any

other piping.

3. Attach a pressure gauge with a 150 psig scale range

to the manifold using a high pressure hose.

• Locate the gauge so it can be read during all

phases of construction.

4. Fill the system for pressure test with water only if

there is no freeze potential.

• You will need to keep the system pressurized as

discussed in the next section.

• So the fluid used for testing would have to remain

in place.

• You must be sure, if using water, that no freeze

potential would exist from time of installing pipe

until time for you to complete the system piping

and fill the system for start-up.

5. If there is freeze potential, fill the system with air and

perform the pressure test using air .

• If using air, remove all air vents from the manifolds

and plug the openings.

b. The pressure should not drop unless testing with

air on a cold day.

• On cold days, air pressure testing will show

a drop as the air in the tubing cools off. But

the pressure should reach a steady level and

drop no further.

• If the pressure does drop, check the

connections at the manifolds first.

c. Examine the system for leaks. Repair any leaks

found and repeat the test.

d. Check threaded joints with leak detection fluid

(soap mixture if using air).

When pressure testing with air, or when air is

left anywhere in the system being pressurized,

there is a risk of explosive discharge of

compressed air or water if a leak or break

occurs.

Do not leave these pressure tests unattended

while others are present.

Remove all non-essential persons from the

area during pressure testing.

Failure to follow these guidelines could lead

to severe personal injury, death or substantial

property damage.

6. Pressurize the system to between 70 and 100 psig for

30 minutes.

a. Observe the pressure on the gauge.

Failure to check for and repair leaks can result

in damage to system components and the

premises, causing severe personal injury, death

or substantial property damage.

Part Number 650-000-221/0298

17

Page 18

AlumiPe x Radiant Tubing

L. Connect System Piping & Heating System Components

1. Install piping and heating system components if

framing is in place.

3. Don’t solder within 18 inches of tubing.

3. Cover tubing to protect it from solder drip.

K. Pressurize T ubing for Observation

1. After the system has been proven leak free, pressurize

all tubing circuits to 30 psig.

Maintain this pressure on the tubing for the

remainder of the building construction.

Pressurizing the tubing allows use of the pressure

gauge to verify the integrity of the tubing and

connections.

4. Never apply an open flame to AlumiPex tubing.

5. Pressure test sytem piping to verify there are no

leaks.

Periodically observe the pressure gauge to make

sure no major drop in pressure occurs. A pressure

drop would indicate a puncture or leak.

M. Before Leaving the Jobsite . . .

1. Before leaving the jobsite, we recommend you meet

with the general contractor to review the AlumiPex

T rade Guides.

q Make special note of the pressure gauge. It can be

used by all trades to check the integrity of the

tubing throughout the construction of the

building.

q Review traffic recommendations.

q Ask for early notification of the schedule for

installing finished flooring so you can inspect the

installation a day before this starts.

q If possible, get an agreement that the flooring

won’t be installed until you have inspected the

installation and given your release.

2. Make a record of your installation

We suggest you take photographs of the tubing

and manifolds.

Use the photographs and notes on the tube layout

drawing to document installation details.

18

Part Number 650-000-221/0298

Page 19

Above Floor Installation Guide

N . Inspect T ubing Before Finished Flooring Installation

1. Arrange to inspect the installation a day before the

scheduled finished flooring installation starts.

q Check the pressure gauge to verify the system is

still pressurized at or near 30 psig.

q Visually inspect all tubing to verify there is no

damage.

q Repair any damage you find.

q Advise the general contractor of your findings and

release for finished flooring installation.

O. Inspection, Repair and T roubleshooting

1. Inspect the tubing connections and piping as the job

is completed.

2. Perform a final pressure test on the system after all

flooring is in place and building is ready for

occupancy to verify all joints are tight and no

damage has occurred to the tubing during

construction.

3. Repair of kinked or crushed tubing:

Use a copper pipe truer to restore the tubing

roundness.

If the damage is so severe that this cannot be done,

cut out the damaged section of tubing.

• Cut a new length of tubing long enough to

span the gap.

• At each end of the splice section, install an

AlumiPex coupling.

• Slip a length of heat shrink tubing over each

end before tightening the couplings.

• Tighten couplings. Then seal them with the

heat shrink tubing.

• Route a groove in the subflooring deep

enough to accommodate the finished repair

section.

• Mark the location of any such repairs on the

tube layout drawing

Part Number 650-000-221/0298

19

Page 20

AlumiPe x Radiant Tubing

20

Part Number 650-000-221/0298

Loading...

Loading...