Page 1

Safety Stop Function

Función Parada Segura

Função de Parada de Segurança

CFW-11, CFW-11M, CFW70X

Installation, Configuration and Operation Guide

Guía de Instalación, Configuración y Operación

Guia de Instalação, Configuração e Operação

Motors | Automation | Energy | Transmission & Distribution | Coatings

Page 2

Page 3

Summary / Índice

ENGLISH

1. GENERAL INFORMATION ..................................................................................................5

2. INSTALLATION .....................................................................................................................8

3. OPERATION ........................................................................................................................10

3.1 Truth Table ............................................................................................................................... 10

3.2 State of Inverter, Fault and Alarm Related to Safety Stop Function .................................. 10

3.3 STO Status Indication ............................................................................................................ 11

3.4 Periodic Test............................................................................................................................ 11

4. EXAMPLES OF WIRING DIAGRAMS OF INVERTER CONTROL SIGNAL ...................12

5. TECHNICAL SPECIFICATIONS ........................................................................................13

5.1 Electrical Control Characteristics ......................................................................................... 13

5.2 Operational Safety Characteristics ...................................................................................... 13

APPENDIX .............................................................................................................................. 32

ESPAÑOL

1. INFORMACIONES GENERALES ......................................................................................14

2. INSTALACIÓN ....................................................................................................................17

3. PUESTA EN MARCHA .......................................................................................................19

3.1 Tabla-Verdad ........................................................................................................................... 19

3.2 Estado del Convertidor de Frecuencia, Fallos y Alarmas Relacionados a la Función de

Parada de Seguridad .................................................................................................................... 19

3.3 Señalización del estado de la función “Safety Stop” .......................................................... 20

3.4 Teste Periódico .......................................................................................................................20

4. EJEMPLOS DE DIAGRAMAS DE CONEXIÓN DE LAS SEÑALES DE CONTROL DEL

CONVERTIDOR ......................................................................................................................21

5. ESPECIFICACIONES TÉCNICAS .................................................................................... 22

5.1 Características Eléctricas de Control ................................................................................... 22

5.2 Características de Seguridad Operacional .......................................................................... 22

ANEXO .................................................................................................................................... 32

PORTUGUÊS

1. INFORMAÇÕES GERAIS .................................................................................................. 23

2. INSTALAÇÃO ..................................................................................................................... 26

3. COLOCANDO EM FUNCIONAMENTO ........................................................................... 28

3.1 Tabela-Verdade ....................................................................................................................... 28

3.2 Estado do Inversor, Falha e Alarme Relacionados à Função de Parada de Segurança .28

3.3 Indicação do Estado da Função Safety Stop....................................................................... 29

3.4 Teste Periódico .......................................................................................................................29

4. EXEMPLOS DE ESQUEMAS DE LIGAÇÃO DOS SINAIS DE CONTROLE DO

INVERSOR ............................................................................................................................. 30

5. ESPECIFICAÇÕES TÉCNICAS .........................................................................................31

5.1 Características Elétricas de Controle ................................................................................... 31

5.2 Características de Segurança Operacional ......................................................................... 31

ANEXO .................................................................................................................................... 32

Page 4

Page 5

Safety Stop Function

CFW-11, CFW-11M, CFW70X | 5

English

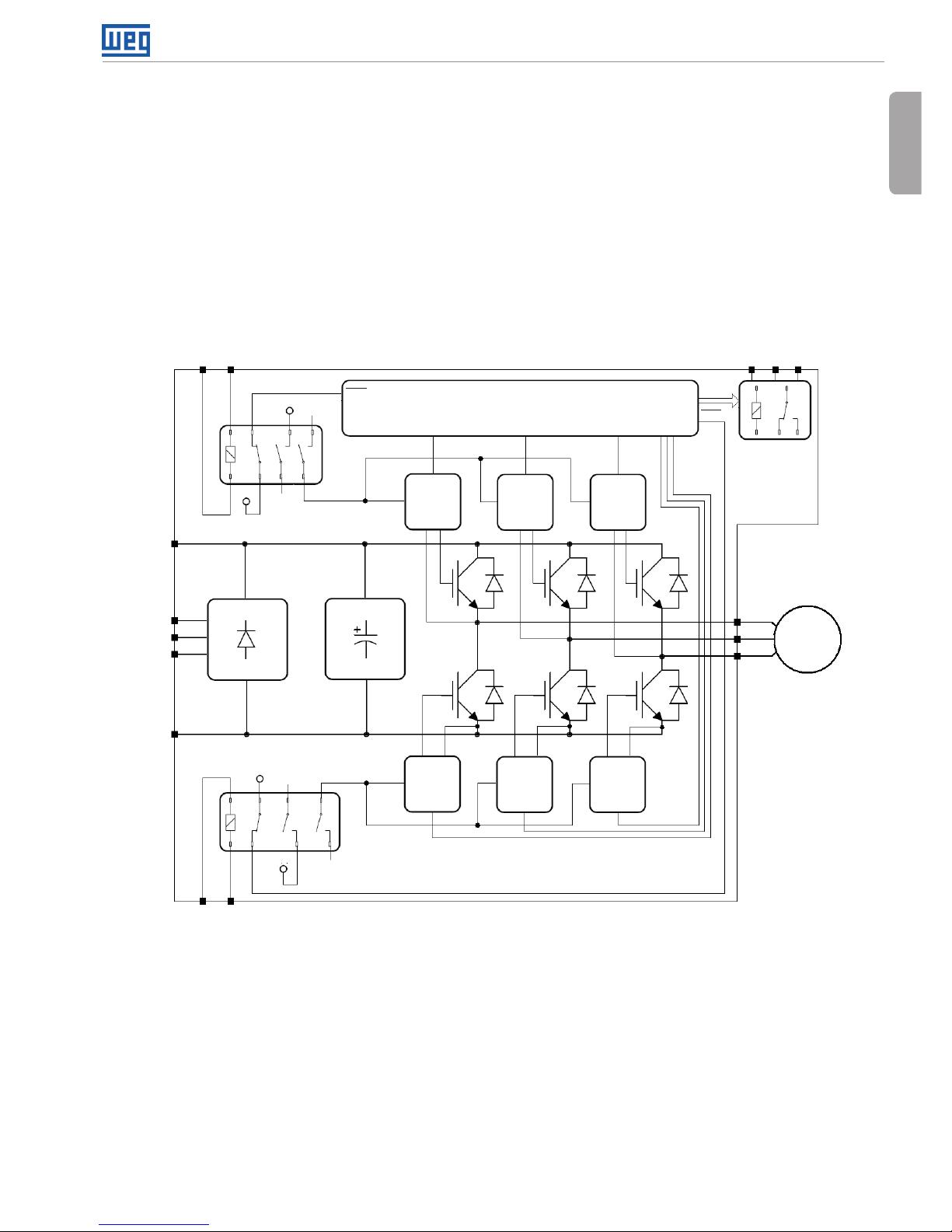

1. GENERAL INFORMATION

Inverters with safety stop option have suffix Y (CFW-11 and CFW-11M inverters) or suffix Y1 (CFW70x

inverters) on its nomenclature. Control units of CFW-11M with safety stop option also have suffix

Y on its name (e.g.: UC11-1340T5OYZ).

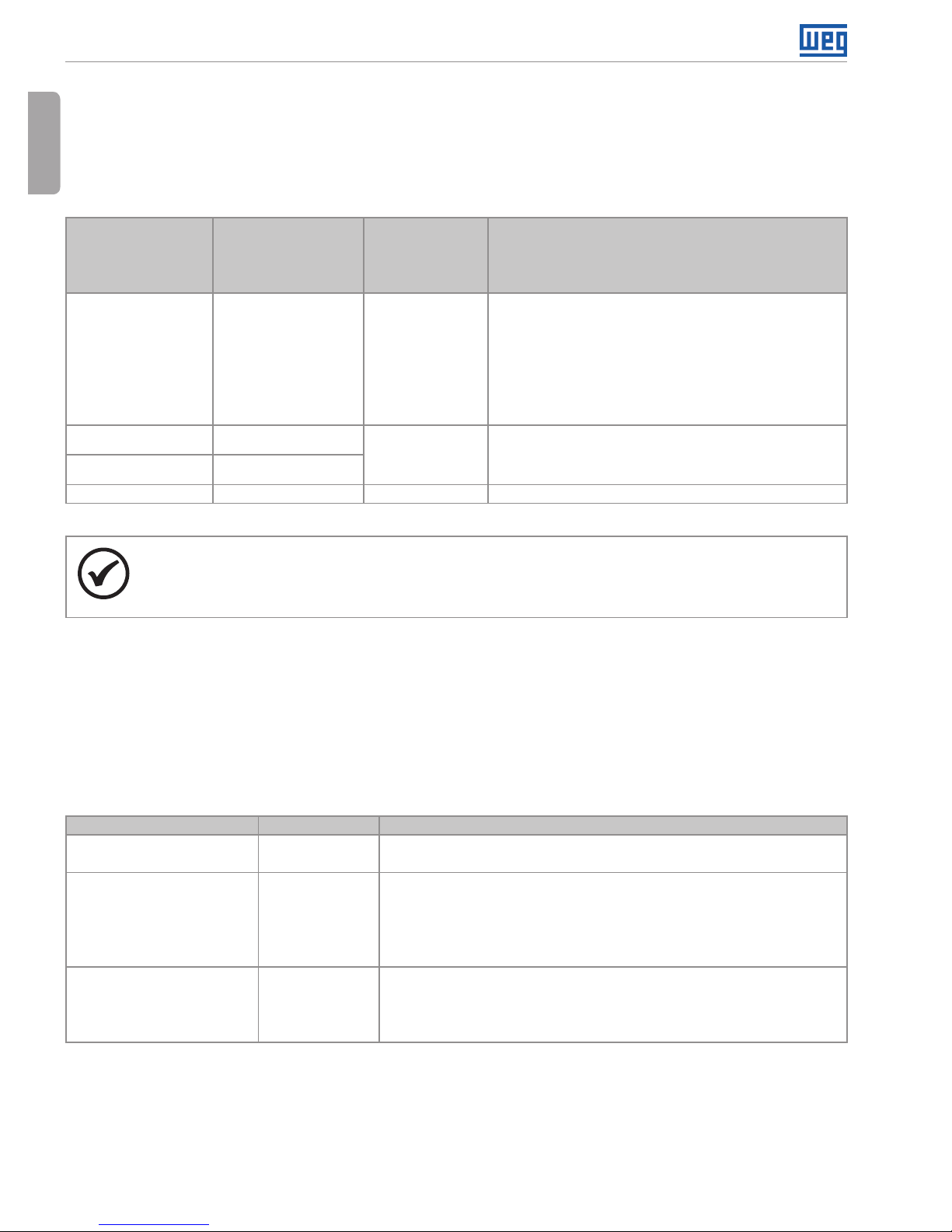

Those inverters have an additional board (SRBXX) with two safety relays (K1 and K2) that actuate

directly on the power circuit of the inverter (more specifically on the IGBT gate drivers power supply,

for further information see the figure 1) and guarantee that the IGBTs remain switched off while

safety stop function is activated, even in case of an internal single failure. The position of SRBXX

board and XC25 terminals (safety stop terminals) on the inverter is shown in figure 2.

Control Circuit (Microcontroller+EPLD)

Gate

Driver

Circuit

Gate

Driver

Circuit

XC25:1

XC25:3

2

V1

V1

S1

S1

K1

K2

S2

S2

+5V

+5V

4

PWM1

PWM3

PWM5

Rectifier

DC Link

Capacitors

Gate

Driver

Circuit

Gate

Driver

Circuit

Gate

Driver

Circuit

Gate

Driver

Circuit

Digital (Relay)

Outputs

XC1

X1

X1:

X1:

X1:

DC+

DC-

U/T1

R/L1

V/T2

S/L2

Motor

W/T3

T/L3

SR1

PWM6

PWM4

PWM2

SR2

Notes:

V1 = inverter internal voltage.

CFW-11M (more specifically power units) do not have R/L1, S/L2 and T/L3 terminals, They are fed by a DC voltage only,

SRBXX board is located on the control unit – in this case, K1 and K2 safety relays actuate on the fiber optic transceivers that

send PWM pulses to power units (UP11-XX) for firing the IGBTs.

Figure 1: Basic block diagram of safety stop function available in CFW-11, CFW-11M and CF W70x

inverter series

Page 6

Safety Stop Function

6 | CFW-11, CFW-11M, CFW70X

English

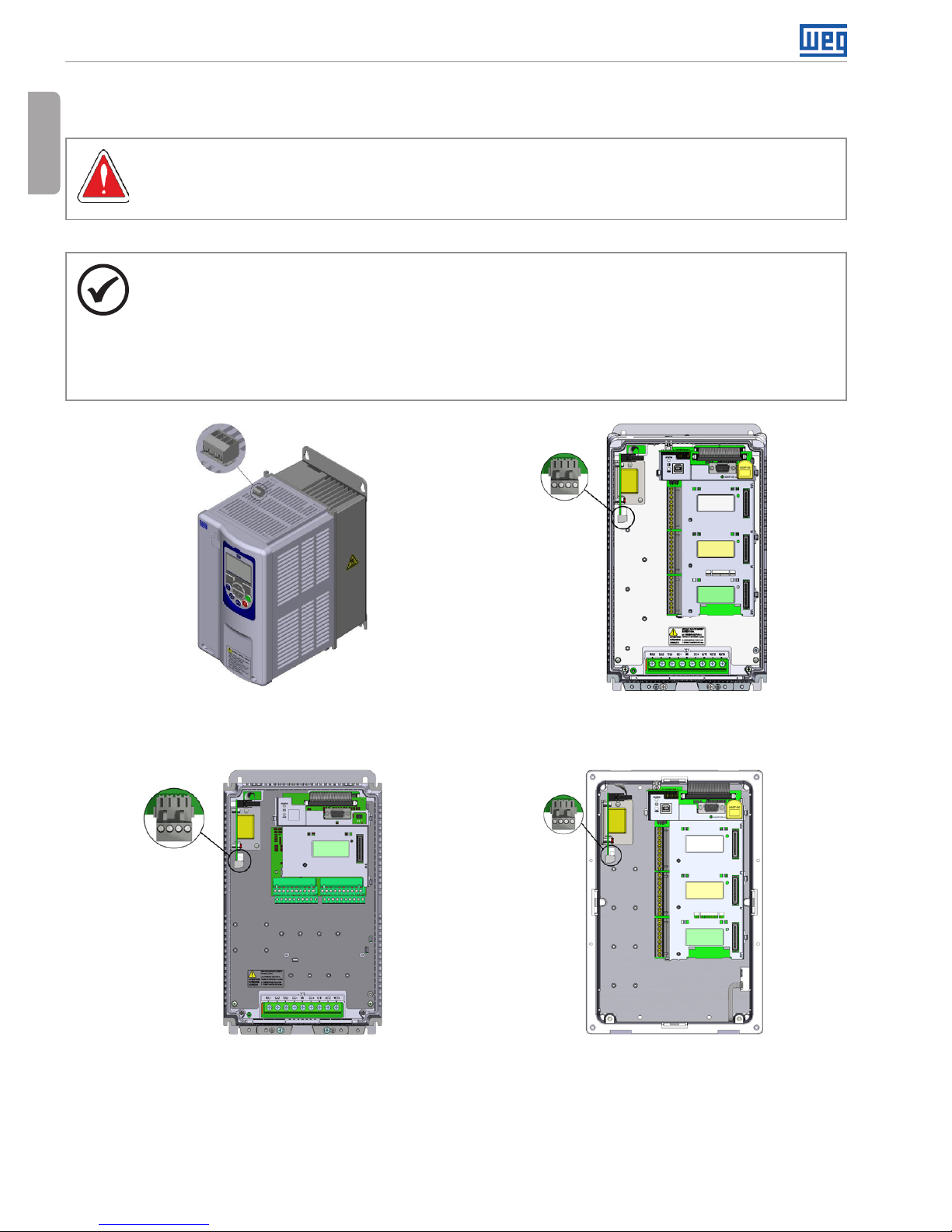

Safety stop function prevents the motor starting accidentally.

DANGER!

The activation of the safety stop function does not guarantee electrical safety of the motor

terminals they are not isolated from the power supply in this condition.

NOTE!

Inverter safety stop function is only one component of the safety control system of a

machine and/or process. When inverter and its safety stop function is correctly used

and with other safety components, it’s possible to fulfill the requirements of standard

EN 954-1 / ISO 13849-1, Category 3 (machine safety) and IEC/EN 61508, SIL2 (safety

control/signalling applied to processes and systems).

XC25

XC25

(a) CFW-11 and CFW70x frame A inverters –

SRB1A.00 board

(b) CFW-11 frame B and C inverters –

SRB2A.00 board

XC25

XC25

(c) CFW70x frame B and C inverters – SRB2A.00

board

(d) CFW-11 frame D and E inverters and

CFW-11M (UC11) inverters – SRB2A.00 board for

200...240 V / 220...230 V and 380...480 V models

and SRB4.00 for 500...690 V models

Figure 2: SRBXX board (safety stop function)

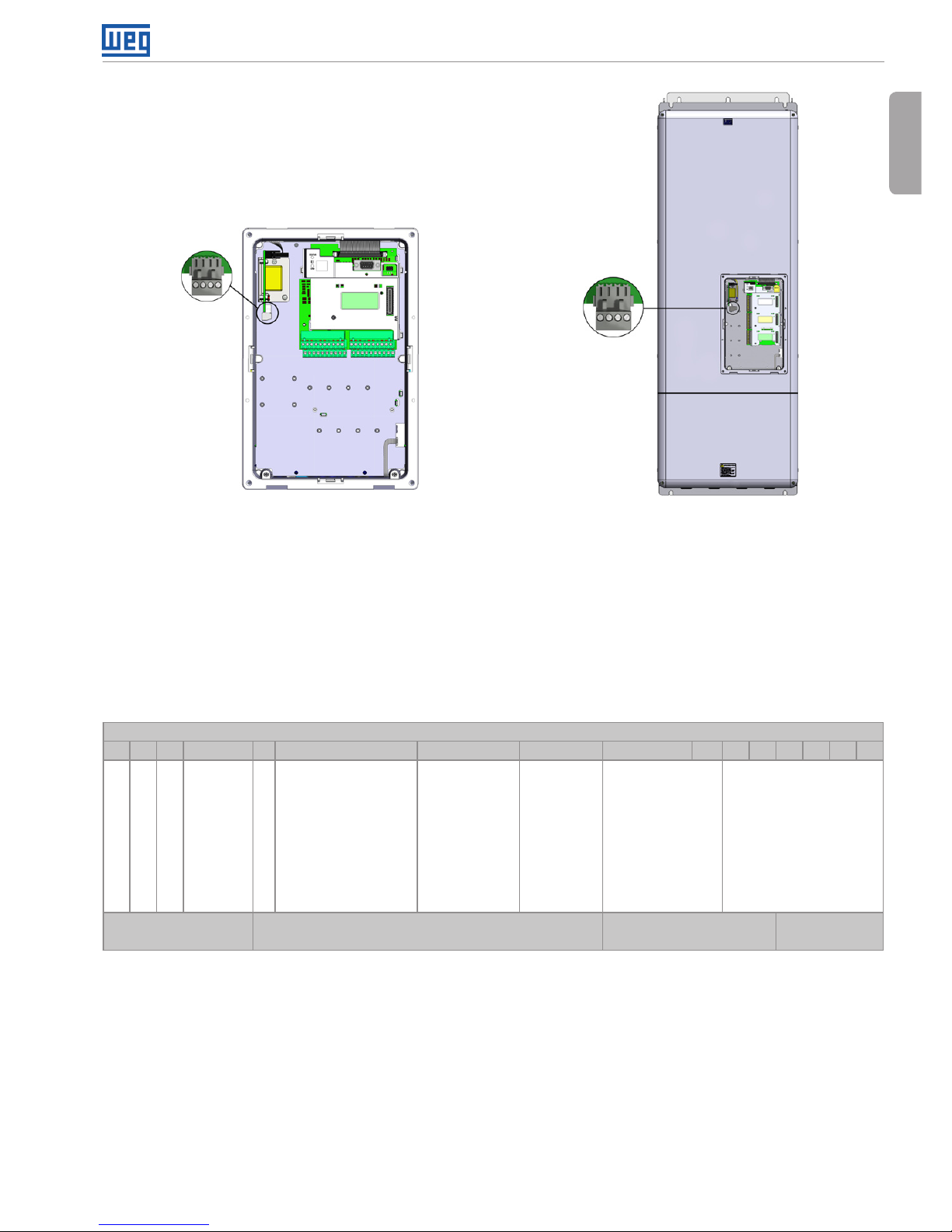

Page 7

Safety Stop Function

CFW-11, CFW-11M, CFW70X | 7

English

XC25

XC25

(e) CFW70x frame D and E inverters –

SRB2A.00 board for 200...240 V / 220...230 V and

380...480 V models and SRB4.00 for 500...600 V

models

(f) CFW-11 frame F and G inver ters –

SRB3.00 board

Figure 2 (cont.): SRBXX board (safety stop function)

Bit 9 of parameter P0029 content shows if the inverter have identified correctly SRBXX board.

Refer to table 1 for further information.

Table 1: Content of P0029 parameter

Bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 1 0 0 = With

braking

IGBT

1 =

Without

braking

IGBT.

0 0 = control circuit

is supplied from an

external +24 Vdc

power supply

1 = control circuit

is fed by the

inverter SMPS.

0 = Inverter

without

safety stop

option

1 = Inverter

with safety

stop option.

0 =

Inverter

without

RFI filter

1= Inverter

with RFI

filter.

Voltage rating of

the inverter:

00 = 200...240 V

/ or 220/230 V

01 = 380...480 V

10 = 500...600 V

11 = 500...690 V

or 660/690 V

Inverter output rated

current.

Hexadecimal

digit #4

Hexadecimal

digit #3

Hexadecimal

digit #2

Hexadecimal

digit #1

Page 8

Safety Stop Function

8 | CFW-11, CFW-11M, CFW70X

English

2. INSTALLATION

Table 2: XC25 terminals (safety stop terminals) signals

XC25 terminals Function Specifications

1 STO1

Terminal 1 of

safety relay K1 coil.

Coil rated voltage: 24 V, range: 20…30 Vdc

Coil resistance: 960 Ω ± 10 % @ 20 °C (68 °F).

2 GND1

Terminal 2 of

safety relay K1 coil.

3 STO2

Terminal 1 of

safety relay K2 coil.

Coil rated voltage: 24 V, range: 20…30 Vdc

Coil resistance: 960 Ω ± 10 % @ 20 °C (68 °F).

4 GND2

Terminal 2 of

safety relay K2 coil.

NOTE!

XC25:2 and XC25:4 terminals are not connected internally to inverter +24 V power supply

reference. In most of cases, those terminals are connected to XC1:11 control terminal in

CFW-11 and CFW-11M inverters and to XC1:36 in CFW70X inverters.

NOTE!

Follow the instructions provided on item 3.2.5 (CFW-11 and CFW70x) or 3.4.8

(CFW-11M) of User’s Manual.

For XC25 control cabling consider the following:

Use wire gauge from 0.5 mm

2

(20 AWG) to 1.5 mm2 (14 AWG) and maximum tightening torque

of maximum 0.50 N.m (4.50 lbf.in).

Use shielded cables connected to ground only on inverter side (use the provided metallic pieces

as shown on figure 3).

Run the cables separated from the remaining circuits (power, 110 V/220 Vac control, etc.).

Page 9

Safety Stop Function

CFW-11, CFW-11M, CFW70X | 9

English

Figure 3: Example of connection of shielding of control cable (in this case it was presented an example of

cables connected on XC1 terminals, but the same applies to XC25 terminals)

If the degree of protections of the used inverter is lower than IP54, it must be installed inside an

IP54 (minimum) cabinet.

Page 10

Safety Stop Function

10 | CFW-11, CFW-11M, CFW70X

English

3. OPERATION

3.1 TRUTH TABLE

Table 3: Safety stop function operation

STO1 logic level

(voltage between

XC25:1-3

terminals)

STO2 logic level

(voltage between

XC25:2-4

terminals)

Safety stop

function

Inverter behavior

0 (0 V) 0 (0 V)

Activated

(enabled)

Inverter remains in STO state and does not

accept commands. In CFW70x inverters with

software version V1.02 or higher, it’s indicated

A170 (activation of safety stop function advice)

on the keypad. In order to escape this condition,

it’s required to have STO1 = 1 and STO2 = 1

simultaneously.

0 (0 V) 1 (24 V)

Fault

Inverter is tripped by F160 fault (safety stop

function related fault). To escape this condition,

it’s required to reset the inverter.

1 (24 V) 0 (0 V)

1 (24 V) 1 (24 V) Disabled Inverter accepts commands normally.

NOTE!

Maximum delay between STO1 and STO2 signals: 100 ms (otherwise inverter will be

tripped by F160 fault).

Safety stop function takes priority over all other functions of the inverter.

This function should not be used as a control for starting and/or stopping the inverter.

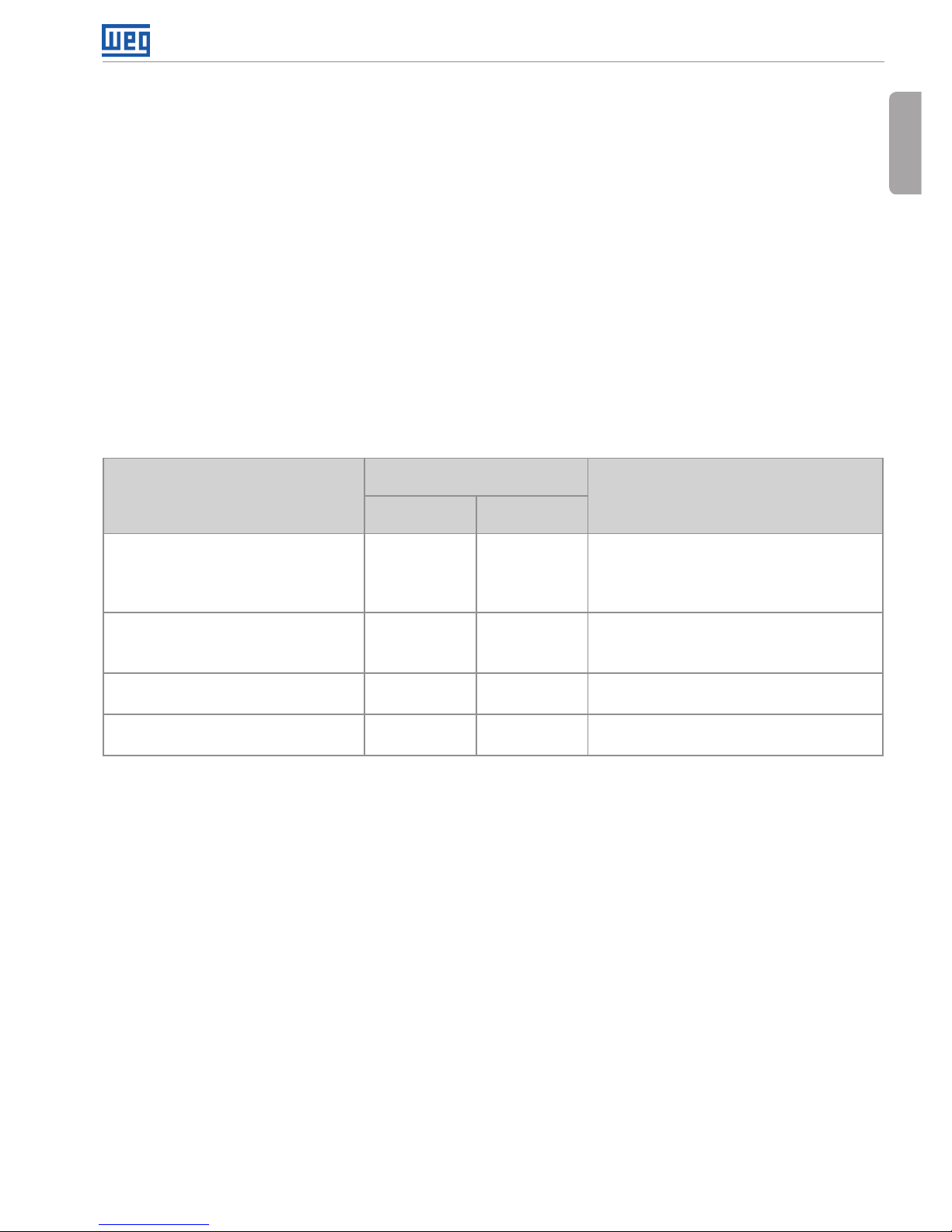

3.2 STATE OF INVERTER, FAULT AND ALARM RELATED TO SAFETY STOP FUNCTION

Table 4: State of inverter, fault and alarm related to safety stop function

State / fault / alarm Description Cause

STO state Safety stop

activated

Voltage between terminals 1 and 3 (relay K1 coil) and between

terminals 2 and 4 (relay K2 coil) of XC25 higher than 17 V.

F160 fault Safety stop

function fault

It’s applied voltage to relay K1 coil (STO1) but it’s not applied

voltage to relay K2 coil (STO2) or vice-versa or there is a delay

of more than 100ms between one signal and the other. To solve

it, correct the external circuit that generates STO1 and STO2

signals.

A170 alarm (only on

CFW70x inverters with

software version V1.02

or higher)

Safety stop

activated

Only for keypad indication purpose, this alarm is indicated in

CFW70x inverters when the state of inverter is switched to STO.

Page 11

Safety Stop Function

CFW-11, CFW-11M, CFW70X | 11

English

3.3 STO STATUS INDICATION

State of the inverter is shown on the left upper side of the display of the keypad of CFW-11 and

CFW-11M series, on the mid upper region of keypad of CFW70x series (not all states of the inverter

are indicated on the keypad of CFW70x) and in parameter P0006.

Possible states of the inverter: ready, run (inverter enabled), undervoltage, fault, self-tunning,

configuration, DC braking and STO (safety stop function activated).

It’s possible to set one or more digital and relay outputs of the inverter to indicate that safety stop

function is activated (state of the inverter = STO), if the inverter is or not on a fault state and more

specifically if the inverter was tripped by F160 fault (safety stop function fault). For that set the

parameters P0275 (DO1), P0276 (DO2), P0277 (DO3), P0278 (DO4) and P0279 (DO5) according

to table 5.

Table 5: P0275...P0279 options for indication of state of inverter or faults on DOx digital outputs

DOx digital output function

Value to be set

on P0275...P0279

Comment

CFW-11 and

CFW-11M

CFW70x

State of the inverter = STO

(safety stop function activated).

33 30 Safety stop function disabled:

relay/transistor OFF.

Safety stop function activated:

relay/transistor ON.

F160 fault

(inverter tripped by safety stop

function fault actuation).

34 31 Without F160 fault: relay/transistor OFF.

With fault F160: relay/transistor ON.

Fault (inverter tripped by

actuation of any fault).

13 13 Without fault: relay/transistor OFF.

With fault: relay/transistor ON.

Without fault

(state of the inverter is not fault).

26 24 With fault: relay/transistor OFF.

Without fault: relay/transistor ON.

Refer to CFW-11 inverter programming manual for a complete list of options for parameters

P0275...P0279.

3.4 PERIODIC TEST

Safety stop function, alternatively safety stop inputs (STO1 and STO2), must be activated at least

once a year for preventive maintenance purposes. Inverter power supply must be switched off

and then on again before carrying out this preventive maintenance. If during testing the power

supply to the motor is not switched off, safety integrity is no longer assured for the safety stop

function. The drive must therefore be replaced to ensure the operational safety of the machine or

of the system process.

Page 12

Safety Stop Function

12 | CFW-11, CFW-11M, CFW70X

English

4. EXAMPLES OF WIRING DIAGRAMS OF INVERTER CONTROL SIGNAL

It’s recommended to use inverter DI1 and DI2 digital inputs set as 3-wire start/stop commands

and the wiring diagrams of inverter control signal according to figure 4.

XC1:11 - DGND*

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:12 - COM

XC1:13 - +24V

XC1:15 - DI1

XC1:16 - DI2

Stop

Start

Emergency

Stop

CFW-11/

CFW-11M

XC1:36 - GND(24V)

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:35 - COM

XC1:34 - +24V

XC1:37 - DI1

XC1:38 - DI2

Stop

Start

Emergency

Stop

CFW70X

(a) STO or SS0 safety function with

CFW-11 and CFW-11M inverters

(b) STO or SS0 safety function with CFW70x

inverters

External

XC1:11 - DGND*

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:12 - COM

XC1:13 - +24V

XC1:15 - DI1

A1 A2

XC1:16 - DI2

Stop

Start

Safety Relay

CFW-11/

CFW-11M

14 24 48 58

13 23 47 57

(c) SS1 safety function with CFW-11 and CFW-11M inverters

(*)

External

XC1:36 - GND(24V)

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:35 - COM

XC1:34 - +24V

XC1:37 - DI1

XC1:38 - DI2

Stop

Start

Safety Relay

CFW70X

13 23 47 57

14 24 48 58

A1 A2

(d) SS1 safety function with CFW70x inver ters

(*)

(*) For specifications of external safety relay that is required to realize SS1 (stop category 1) refer to item 5.

Figure 4: Inverter control wiring examples (XC1 and XC25 terminals) to realize STO (or SS0, i.e., stop category 0)

and SS1 (stop category 1) safety functions according to IEC/EN 61800-5-2 and IEC/EN 60204-1 standards –

DI1 and DI2 inputs set as 3-wire start/stop commands

Page 13

Safety Stop Function

CFW-11, CFW-11M, CFW70X | 13

English

Circuit operation of SS1 function (figures 4c and 4d):

In this case, when the activation command is given to the external safety relay, safety relay

opens inverter DI2 signal (via terminals 23 to 24) and motor is decelerated first by the inverter (via

deceleration ramp). When the time delay set at the external safety relay expires (this delay must

be higher than required time to stop the motor, taking into account deceleration time set on the

inverter and inertia of the motor load), the safety relay delayed contacts (terminals 47 to 48 and

57 to 58) opens inverter STO1 and STO2 signals and the inverter safety stop function is activated.

The motor stops according to category 1 (SS1) of standard IEC/EN 60204-1. In order to drive the

motor again, it’s required to apply STO1 and STO2 signals again (to close terminals 13 to 23 and

23 to 24) and to have a pulse on inverter DI1 input (to apply a pulse on START switch).

5. TECHNICAL SPECIFICATIONS

5.1 ELECTRICAL CONTROL CHARACTERISTICS

Safety stop function inputs XC25:1-2, XC25:3-4 2 independent inputs for safety stop function.

Power supply: 24 Vdc (max. 30 V)

Impedance: 960 Ω

State 0 if < 2 V, state 1 if > 17 V

External

safety relay specifications

(only when SS1 function is

required according to IEC/

EN 61800-5-2 and IEC/EN

60204-1 standards – refer

to figures 4c/4d).

General requirements IEC 61508 and/or EN 954-1 and/or ISO 13849-1

Output requirements No. of current paths: 2 independent paths (one for

each STO path)

Switching voltage capability: 30 Vdc per contact

Switching current capability: 100 mA per contact

Maximum switching delay between contacts: 100 ms.

Example Type/manufacturer: WEG / Instrutech CPt-D.

5.2 OPERATIONAL SAFETY CHARACTERISTICS

Protection Of the machine Safety stop function which forces stopping and/or

prevents the motor from restarting unintentionally,

conforming to EN 954-1 / ISO 13849-1 category 3,

IEC/EN 61800-5-2 and IEC/EN 60204-1.

Of the system process Safety stop function which forces stopping and/or

prevents the motor from restarting unintentionally,

conforming to IEC/EN 61508 level SIL2 and

IEC/EN 61800-5-2.

NOTE!

Certification of the product is in annex.

Page 14

Función Parada Segura

14 | CFW-11, CFW-11M, CFW70X

Español

1. INFORMACIONES GENERALES

Los convertidores de frecuencia con la opción parada de seguridad poseen en su nomenclatura

el sufijo Y (CFW-11 y CFW-11M) o el sufijo Y1 (CFW70x). La unidad de control del CFW-11M con

el accesorio opcional parada de seguridad también posee el sufijo Y en su nombre (ejemplo:

UC11-1340T5OYZ).

Estos convertidores poseen una tarjeta adicional (SRBXX) con dos relés de seguridad (K1 y K2) que

actúan directamente en el circuito de potencia del convertidor de frecuencia (más específicamente

en la alimentación de los “Gate Drivers” del IGBT; para mayores detalles consultar la figura 1) y se

garantiza que los IGBTs permanezcan deshabilitado cuando la función parada de seguridad se

encuentra activa, mismo que ocurra un fallo o defecto interno. La posición de la tarjeta SRBXX y

de los terminales XC25 (conector de la parada de seguridad) en el convertidor de frecuencia es

presentada en la figura 2.

Circuito

del Gate

Driver

Circuito

del Gate

Driver

XC25:1

XC25:3

2

V1

V1

S1

S1

K1

K2

S2

S2

+5V

+5V

4

Rectificador

Condensadores

del link CC

Circuito

del Gate

Driver

Circuito

del Gate

Driver

Circuito

del Gate

Driver

Circuito

del Gate

Driver

Salidas

digitales

a rele

XC1

X1

X1:

X1:

X1:

DC+

DC-

U/T1

R/L1

V/T2

S/L2

Motor

W/T3

T/L3

SR1

SR2

Circuito del control (Microcontrolador + EPLD)

PWM1

PWM3

PWM5

PWM6

PWM4

PWM2

¡Notas!

V1 = tensión interna del convertidor de frecuencia.

Los modelos CFW-11M (más específicamente las unidades de potencia) no poseen los terminales R/L1, S/L2 y T/L3, Son

alimentados solamente con tensión CC, la tarjeta SRBXX se queda en la unidad de control – en ese caso, los relés de

seguridad K1 y K2 actúan en los transmisores de fibra óptica que envían los pulsos PWM para los disparos de los IGBTs

hasta las unidades de potencia (UP11-XX).

Figura 1: Diagrama de bloques básico de la función parada de seguridad de los convertidores

CFW-11, CFW-11M y CFW70x

Page 15

Función Parada Segura

CFW-11, CFW-11M, CFW70X | 15

Español

La función parada de seguridad evita que el motor sea accidentalmente accionado.

¡PELIGRO!

La activación de la función parada de seguridad no garantiza la seguridad eléctrica de los

terminales del motor. Estos, no se quedan aislados de la red eléctrica en esta condición.

¡NOTA!

La función parada de seguridad del convertidor de frecuencia es solamente una parte del

sistema de seguridad de una máquina y/o proceso. Cuando el convertidor de frecuencia

y esa función son correctamente utilizados y en conjunto con otros componentes de

seguridad, es posible cumplir con la normativa EN 954-1 / ISO 13849-1, Categoría 3.

XC25

XC25

(a) Convertidores de Frecuencia CFW-11 y CFW70x

talla A – tarjeta SRB1A.00

(b) Convertidor de Frecuencia CFW-11 talla B y C –

tarjeta SRB2A.00

XC25

XC25

(c) Convertidores de Frecuencia CFW70x talla

B y C – tarjeta SRB2A.00

(d) Convertidores de Frecuencia CFW-11 tamaño

D y E CFW11M (UC11) - tarjeta SRB2A.00 para

modelos 200...240 V / 220...230 V y 380...480 V y

tarjetas SRB4.00 para modelos 500...690 V

Figura 2: Tarjeta SRBXX (función de seguridad de parada)

Page 16

Función Parada Segura

16 | CFW-11, CFW-11M, CFW70X

Español

XC25

XC25

(e) Convertidores de Frecuencia CFW70x

tamaño D y E - tarjeta SRB2A.00 para

modelos 200...240 V / 220...230 V y 380...480

V y tarjetas SRB4.00 para modelos 500...600 V

(f) Convertidores de Frecuencia CFW-11 talla

F y G – tarjeta SRB3.00

Figura 2 (cont.): Tarjeta SRBX X (función de seguridad de parada)

El bit 9 del contenido del parámetro P0029 señaliza si el convertidor de frecuencia identificó

correctamente la tarjeta SRBXX. Para mayores detalles consultar la tabla 1.

Tabla 1: Contenido del parámetro P0029

Bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 1 0 0 = Con

IGBT de

frenado

1 = Sin

IGBT de

frenado.

0 0 = Alimentación

independiente del

circuito de control

vía fuente 24 Vcc

1 = Control

alimentado

vía tarjeta de

potencia.

0 =

Convertidor

de

frecuencia

sin la tarjeta

opcional

parada de

seguridad

1 =

Convertidor

de

Frecuencia

con la

tarjeta

opcional

parada de

seguridad.

0 =

Convertidor

de

frecuencia

sin filtro RFI

1=

Convertidor

de

frecuencia

con filtro

RFI.

Rango de

tensión del

convertidor de

frecuencia:

00 = 200...240 V

o 220/230 V

01 = 380...480 V

10 = 500...600 V

11 = 500...690 V

o 660/690 V

Corriente nominal

del convertidor de

frecuencia.

Dígito

hexadecimal #4

Dígito

hexadecimal #3

Dígito

hexadecimal #2

Dígito

hexadecimal #1

Page 17

Función Parada Segura

CFW-11, CFW-11M, CFW70X | 17

Español

2. INSTALACIÓN

Tabla 2: Señales en los bornes XC25 (conector de la parada de seguridad)

Bornes XC25 Función Especificaciones

1 STO1

Terminal 1 de la

bobina del relé K1.

Tensión nominal de la bobina: 24 V,

rango de 20 a 30 Vcc

Resistencia de la bobina: 960 Ω ± 10 % @ 20 °C

2 GND1

Terminal 2 de la

bobina del relé K1.

3 STO2

Terminal 1 de la

bobina del relé K2.

Tensión nominal de la bobina: 24 V,

rango de 20 a 30 Vcc

Resistencia de la bobina: 960 Ω ± 10 % @ 20 °C

4 GND2

Terminal 2 de la

bobina del relé K2.

¡NOTA!

Los terminales XC25:2 y XC25:4 no están interconectados internamente a la referencia

de la fuente +24 V del convertidor de frecuencia. En la mayoría de las veces se conecta

estos terminales al terminal de controle XC1:11 en los inversores CFW-11 y CFW-11M y

al XC1:36 para el inversor CFW70X.

¡NOTA!

Seguir las recomendaciones del ítem 3.2.5 (CFW-11 y CFW70x) o 3.4.8 (CFW-11M) del

manual del usuario.

Consideraciones para el cableado en XC25:

Utilizar calibre de los cables en el rango de 0.5 mm

2

(20 AWG) a 1.5 mm2 (14 AWG) y par (torque)

de aprieto máximo de 0.5 N.m (4.50 lbf.in).

Utilizar cable blindado puestos a tierra solamente del lado del convertidor de frecuencia (utilizar

piezas metálicas de puesta a tierra de los cables de control conforme presentado en la figura 3).

Separar de los demás cableados (potencia, mando en 110 V/220 Vca, etc).

Page 18

Función Parada Segura

18 | CFW-11, CFW-11M, CFW70X

Español

Figura 3: Ejemplo de conexión del blindaje de los cables de control (en ese caso fue presentado el ejemplo de

cables conectados en XC1, más el mismo se aplica a los cables conectados en XC25)

Si el grado de protección del inversor utilizado es inferior a IP54, debe ser instalado dentro de un

armario IP54 (mínimo).

Page 19

Función Parada Segura

CFW-11, CFW-11M, CFW70X | 19

Español

3. PUESTA EN MARCHA

3.1 TABLA-VERDAD

Tabla 3: Funcionamiento de la función parada de seguridad

STO1 nivel lógico

(tensión entre

XC25:1-3)

STO2 nivel lógico

(tensión entre

XC25:2-4)

Función parada

de seguridad

Comportamiento del Convertidor de

Frecuencia

0 (0 V) 0 (0 V) Activa

Convertidor de frecuencia se queda en estado

STO y no acepta comandos. En el caso del

CFW70x con versión de software V1.02 o

superior, también es indicado A170 (aviso de

actuación de la función parada de seguridad) en

la HMI. Para salir de esa condición, basta hacer

STO1 = 1 y STO2 = 1 simultáneamente.

0 (0 V) 1 (24 V)

Fallo

Convertidor de frecuencia es bloqueado por

F160 (falla relacionada a la función parada de

seguridad). Para salir de esa condición, es

necesario resetear el convertidor de frecuencia.

1 (24 V) 0 (0 V)

1 (24 V) 1 (24 V) Inactiva

Convertidor de frecuencia acepta mandos

normalmente.

¡NOTA!

Retraso máximo entre señales STO1 y STO2: 100 ms (caso contrario el convertidor de

frecuencia será bloqueado por F160).

La función parada de seguridad es prioritaria sobre todas las otras funciones del convertidor de

frecuencia.

Esa función no debe ser usada para controlar el arranque y/o parada del convertidor de frecuencia.

3.2 ESTADO DEL CONVERTIDOR DE FRECUENCIA, FALLOS Y ALARMAS RELACIONADOS

A LA FUNCIÓN DE PARADA DE SEGURIDAD

Tabla 4: Estado del convertidor de frecuencia, fallos y alarmas relacionados a la función de parada de seguridad

Estado / fallo / alarma Descripción Causa

Estado STO Función parada

de seguridad

activa.

Tensión entre los terminales 1 y 3 (bobina del relé K1) y entre los

terminales 2 y 4 (bobina del relé K2) de XC25 mayor que 17V.

Fallo F160 Fallo de la

función de

parada de

seguridad.

Se aplicada tensión en la bobina del relé K1 (STO1) más no se

aplicada tensión en la bobina del relé K2 (STO2) o viceversa o

existe una diferencia de más de 100 ms entre el accionamiento

de un relé y del otro. Para solucionar eso, arreglar las lógica

externa que genera las señales STO1 y STO2.

Alarma A170

(solamente en los

convertidor de frecuencia

CFW70x con versión de

software V1.02 o superior).

Función parada

de seguridad

activa.

Para fines de señalización en la HMI, esa alarma es presentada

en el CFW70x cuando el estado del convertidor de frecuencia

es igual a STO.

Page 20

Función Parada Segura

20 | CFW-11, CFW-11M, CFW70X

Español

3.3 SEÑALIZACIÓN DEL ESTADO DE LA FUNCIÓN “SAFETY STOP”

El estado del convertidor de frecuencia es presentado en el canto izquierdo superior del display de la

HMI del CFW-11 y CFW-11M, en el área central superior de la HMI del CFW70x (ni todos los estados

del convertidor de frecuencia son señalados en la HMI del CFW70x) y en el parámetro P0006.

Estados posibles: ready (listo), run (convertidor de frecuencia habilitado), subtensión, fallo,

autoajuste, configuración, frenado CC y STO (función parada de seguridad activa).

Es posible programar una o más salidas a relé y digitales del convertidor de frecuencia para

señalizar que la función parada de seguridad está activa (estado del convertidor de frecuencia

= STO), si el convertidor de frecuencia está o no en estado de fallo y más específicamente si el

convertidor de frecuencia fue bloqueado por F160 (fallo de la función parada de seguridad). Eso

es hecho ajustándose el contenido de los parámetros P0275 (DO1), P0276 (DO2), P0277 (DO3),

P0278 (DO4) y P0279 (DO5) de acuerdo con la tabla 5.

Tabla 5: Opciones de P0275...P0279 para señalización del estado y fallos del convertidor de frecuencia en las

salidas digitales DOx

Función de la salida digital DOx

Valor a ser ajustado en

P0275...P0279

Comentario

CFW-11 y

CFW-11M

CFW70x

Estado del convertidor de

frecuencia = STO (función parada

de seguridad activa).

33 30 Función parada de seguridad inactiva:

relé/transistor OFF.

Función parada de seguridad activa:

relé/transistor ON.

Fallo F160 (convertidor de

frecuencia bloqueado por la

actuación del fallo de la función de

parada de seguridad).

34 31 Sin fallo F160: relé/transistor OFF.

Con fallo F160: relé/transistor ON.

Fallo (convertidor de frecuencia

fue bloqueado por la actuación de

cualquier fallo).

13 13 Sin fallo: relé/transistor OFF.

Con fallo: relé/transistor ON.

Sin fallo (ninguno fallo del

convertidor de frecuencia fue

activada).

26 24 Con fallo: relé/transistor OFF.

Sin fallo: relé/transistor ON.

Para una lista completa de opciones de los parámetros P0275...P0279 consultar el manual de

programación del convertidor de frecuencia CFW-11.

3.4 TESTE PERIÓDICO

La función Parada de Seguridad debe ser activada por lo menos una vez al año con el objetivo

de mantenimiento preventivo. Este procedimiento es realizado a través de las entradas STO1 y

STO2 conforme es presentado en la tabla 3. La alimentación del convertidor debe ser retirada y

entonces conectada nuevamente, antes de ejecutar el mantenimiento preventivo. La función Parada

de Seguridad estará funcionando correctamente si durante el test es interrumpida la alimentación

del motor (el motor debe parar) y no ocurre la actuación de fallas en el convertidor. En caso de que

el convertidor no pase en ese test, es necesario sustituirlo para garantizar la seguridad operacional

de la máquina o del proceso en cuestión.

Page 21

Función Parada Segura

CFW-11, CFW-11M, CFW70X | 21

Español

4. EJEMPLOS DE DIAGRAMAS DE CONEXIÓN DE LAS SEÑALES DE CONTROL

DEL CONVERTIDOR

Se sugiere utilizar las entradas digitales DI1 y DI2 del convertidor de frecuencia programadas

como mandos “start” y “stop” 3 cables y el diagrama de conexiones de las señales de control del

convertidor de frecuencia conforme la figura 4.

XC1:11 - DGND*

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:12 - COM

XC1:13 - +24V

XC1:15 - DI1

XC1:16 - DI2

Stop

Start

Emergency

Stop

CFW-11/

CFW-11M

XC1:36 - GND(24V)

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:35 - COM

XC1:34 - +24V

XC1:37 - DI1

XC1:38 - DI2

Stop

Start

Emergency

Stop

CFW70X

(a) Parada tipo STO o SS0 para los convertidores

de frecuencia CFW-11 y CFW-11M

(b) Parada tipo STO o SS0 para los convertidores

de frecuencia CFW70x

External

XC1:11 - DGND*

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:12 - COM

XC1:13 - +24V

XC1:15 - DI1

A1 A2

XC1:16 - DI2

Stop

Start

Safety Relay

CFW-11/

CFW-11M

14 24 48 58

13 23 47 57

(c) Parada tipo SS1 con Convertidor de Frecuencia CFW-11 y CFW-11M (*)

External

XC1:36 - GND(24V)

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:35 - COM

XC1:34 - +24V

XC1:37 - DI1

XC1:38 - DI2

Stop

Start

Safety Relay

CFW70X

13 23 47 57

14 24 48 58

A1 A2

(d) Parada tipo SS1 con Convertidor de Frecuencia CFW70x (*)

¡Nota! (*) Para especificar el relé de seguridad externo es necesario para implementar la parada tipo SS1 consultar el ítem 5.

Figure 4: Ejemplos de conexiones de las señales de control del convertidor de frecuencia (bornes XC1 y

XC25) para implementar las funciones de parada de seguridad tipo STO (o SS0, i.e., categoría de parada 0) y

SS1 (categoría de parada 1) conforme las normativas IEC/EN 61800-5-2 y IEC/EN 60204-1 respectivamente –

entradas DI1 y DI2 programadas como mandos start/stop 3 cables

Page 22

Función Parada Segura

22 | CFW-11, CFW-11M, CFW70X

Español

Operación del circuito de la parada tipo SS1 (figuras 4c y 4d):

En ese caso, cuando un mando de activación es enviado al relé de seguridad externo, el relé abre la

señal de la entrada DI2 del convertidor de frecuencia (vía terminales 23-24) y el motor es inicialmente

desacelerado por el convertidor de frecuencia (vía rampa de desaceleración). Cuando el intervalo

de tempo ajustado en el relé de seguridad se cumple (ese intervalo debe ser mayor que el tiempo

necesario para parar el motor, considerando la rampa de desaceleración ajusta y la inercia del

motor), los contactos de retraso del relé de seguridad (terminales 47-48 y 57-58) abren las señales

STO1 y STO2 y la función parada de seguridad del convertidor de frecuencia es activada. El motor

para de acuerdo con la categoría 1 (SS1) de la normativa IEC/EN 60204-1. Para accionar el motor

nuevamente, es necesario aplicar señales en STO1 y STO2 (cerrar los terminales 13-14 y 23-24) y

tener un pulso en la entrada DI1 del convertidor de frecuencia (aplicar un pulso en la llave START).

5. ESPECIFICACIONES TÉCNICAS

5.1 CARACTERÍSTICAS ELÉCTRICAS DE CONTROL

Entradas de la función

parada de seguridad.

XC25:1-2, XC25:3-4. 2 entradas independientes para función parada de

seguridad.

Alimentación: 24 Vcc (máx. 30 V)

Impedancia: 960 Ω

Nivel 0 si < 2 V, nivel 1 si > 17 V

Especificaciones del relé

de seguridad externo

(solamente cuando es

necesario la función SS1

conforme las normativas

IEC/EN 61800-5-2 y IEC/

EN 60204-1 – ver figuras

4c/4d).

Generales. IEC 61508 y/o EN 954-1 y/o ISO 13849-1

Especificaciones de salida. Número de circuito de corriente: 2 circuitos

independientes (una para STO1 y otro para STO2).

Capacidad de conmutación de tensión: 30 Vcc por

contacto.

Capacidad de conmutación de corriente: 100 mA

por contacto.

Máximo retraso entre los contactos: 100 ms.

Ejemplo. Tipo/fabricante: WEG / Instrutech CPt-D

5.2 CARACTERÍSTICAS DE SEGURIDAD OPERACIONAL

Protección. De la máquina. Función parada de seguridad que garantiza la parada

y/o evita el accionamiento no deseado del motor

conforme la normativa EN 954-1 / ISO 13849-1

categoría 3, IEC/EN 61800-5-2 y IEC/EN 60204-1.

Del sistema del proceso. Función parada de seguridad que garantiza la

parada y/o evita el accionamiento no deseado del

motor conforme la normativa IEC/EN 61508 nivel

SIL2 y IEC/EN 61800-5-2.

¡NOTA!

Certificación del producto es encontrada en el anexo.

Page 23

Função de Parada de Segurança

CFW-11, CFW-11M, CFW70X | 23

Português

1. INFORMAÇÕES GERAIS

Os inversores com a opção parada de segurança possuem na sua nomenclatura o sufixo Y

(inversores CFW-11 e CFW-11M) ou o sufixo Y1 (inversores CFW70x). A unidade de controle do

CFW-11M com o opcional parada de segurança também possui o sufixo Y no seu nome

(ex: UC11-1340T5OYZ).

Esses inversores têm um cartão adicional (SRBXX) com dois relés de segurança (K1 e K2) que

atuam diretamente no circuito de potência do inversor (mais especificamente na alimentação dos

gate drivers do IGBT, para maiores detalhes veja a figura 1) e garantem que os IGBTs permaneçam

desligados quando a função parada de segurança estiver ativa, mesmo que ocorra uma falha ou

defeito interno. A posição do cartão SRBXX e dos bornes XC25 (conector da parada de segurança)

no inversor é apresentada na figura 2.

Circuito

de Gate

Driver

Circuito

de Gate

Driver

XC25:1

XC25:3

2

V1

V1

S1

S1

K1

K2

S2

S2

+5V

+5V

4

Retificador

Capacitores

do Link CC

Circuito

de Gate

Driver

Circuito

de Gate

Driver

Circuito

de Gate

Driver

Circuito

de Gate

Driver

Saídas

Digitais a

Relé

XC1

X1

X1:

X1:

X1:

DC+

DC-

U/T1

R/L1

V/T2

S/L2

Motor

W/T3

T/L3

SR1

SR2

Circuito de Controle (Microcontrolador + EPLD)

PWM1

PWM3

PWM5

PWM6

PWM4

PWM2

Notas:

V1 = tensão interna do inversor.

Os modelos CFW-11M (mais especificamente as unidades de potência) não têm os terminais R/L1, S/L2 e T/L3, São

alimentados somente com tensão CC, o cartão SRBXX fica na unidade de controle – nesse caso, os relés de segurança

K1 e K2 atuam nos transmissores de fibra óptica que enviam os pulsos PWM para disparo dos IGBTs até as unidades de

potência (UP11-XX).

Figura 1: Diagrama de blocos básico da função parada de segurança dos inversores

CFW-11, CFW-11M e CFW70x

Page 24

Função de Parada de Segurança

24 | CFW-11, CFW-11M, CFW70X

Português

A função parada de segurança evita que o motor seja acidentalmente acionado.

PERIGO!

A ativação da função parada de segurança não garante segurança elétrica dos terminais

do motor. Estes, não estão isolados da rede elétrica nesta condição.

NOTA!

A função parada de segurança do inversor é somente uma parte do sistema de

segurança de uma máquina e/ou processo. Quando o inversor e essa função forem

corretamente utilizados e em conjunto com outros componentes de segurança, é

possível o atendimento da norma EN 954-1 / ISO 13849-1, Categoria 3.

XC25

XC25

(a) Inversores CFW-11 e CFW70x mecânica A –

car tão SRB1A.00

(b) Inversores CFW-11 mecânicas B e C –

car tão SRB2A.00

XC25

XC25

(c) Inversores CFW70x mecânicas B e C –

car tão SRB2A.00

(d) Inversores CFW-11 mecânicas D e E e

inversores CFW-11M (UC11) – cartão SRB2A.00

para modelos 200...240 V / 220...230 V e 380...480 V

e car tão SRB4.00 para modelos 500...690 V

Figura 2: Cartão SRBXX (função de parada de segurança)

Page 25

Função de Parada de Segurança

CFW-11, CFW-11M, CFW70X | 25

Português

XC25

XC25

(e) Inversores CFW70x mecânicas D e E –

car tão SRB2A.00 para modelos 200...240 V

/ 220...230 V e 380...480 V e cartão SRB4.00

para modelos 500...600 V

(f) Inversores CFW-11 mecânicas F e G –

car tão SRB3.00

Figura 2 (cont.): Cartão SRBXX (função de parada de segurança)

O bit 9 do conteúdo do parâmetro P0029 indica se o inversor identificou corretamente o cartão

SRBXX. Para maiores detalhes ver tabela 1.

Tabela 1: Conteúdo do parâmetro P0029

Bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 1 0 0 = Com

IGBT de

frenagem

1 = Sem

IGBT de

frenagem.

0 0 = Alimentação

independente

do circuito de

controle via fonte

24 Vcc

1 = Controle

alimentado

via cartão de

potência.

0 = Inversor

sem

opcional

parada de

segurança

1 = Inversor

com

opcional

parada de

segurança.

0 = Inversor

sem filtro

RFI

1= Inversor

com filtro

RFI.

Range de

tensão do

inversor:

00 = 200...240 V

ou 220/230 V

01 = 380...480 V

10 = 500...600 V

11 = 500...690 V

ou 660/690 V

Corrente nominal do

inversor.

Dígito

hexadecimal #4

Dígito

hexadecimal #3

Dígito

hexadecimal #2

Dígito

hexadecimal #1

Page 26

Função de Parada de Segurança

26 | CFW-11, CFW-11M, CFW70X

Português

2. INSTALAÇÃO

Tabela 2: Sinais nos bornes XC25 (conector da parada de segurança)

Bornes XC25 Função Especificações

1 STO1 Terminal 1 da bobina do relé K1.

Tensão nominal da bobina: 24 V, faixa de 20 a 30 Vcc

Resistência da bobina: 960 Ω ± 10 % @ 20 °C

2 GND1 Terminal 2 da bobina do relé K1.

3 STO2 Terminal 1 da bobina do relé K2.

Tensão nominal da bobina: 24 V, faixa de 20 a 30 Vcc

Resistência da bobina: 960 Ω ± 10 % @ 20 °C

4 GND2 Terminal 2 da bobina do relé K2.

NOTA!

Os terminais XC25:2 e XC25:4 não estão ligados internamente à referência da fonte +24 V

do inversor. Na maioria das vezes conecta-se estes terminais ao terminal de controle

XC1:11 nos inversores CFW-11 e CFW-11M e ao XC1:36 para o inversor CFW70X.

NOTA!

Seguir recomendações do item 3.2.5 (CFW-11 e CFW70x) ou 3.4.8 (CFW-11M) do

manual do usuário.

Considerações para fiação em XC25:

Utilizar bitola dos cabos na faixa de 0.5 mm

2

(20 AWG) a 1.5 mm2 (14 AWG) e torque de aperto

de no máximo 0.5 N.m (4.50 lbf.in).

Utilizar cabo blindado aterrado somente do lado do inversor (utilizar peças metálicas de

aterramento dos cabos de controle conforme apresentado na figura 3).

Separar das demais fiações (potência, comando em 110 V/220 Vca, etc).

Page 27

Função de Parada de Segurança

CFW-11, CFW-11M, CFW70X | 27

Português

Figura 3: Exemplo de conexão da blindagem dos cabos de controle (nesse caso foi apresentado exemplo de

cabos ligados em XC1, mas o mesmo se aplica aos cabos ligados em XC25)

Page 28

Função de Parada de Segurança

28 | CFW-11, CFW-11M, CFW70X

Português

3. COLOCANDO EM FUNCIONAMENTO

3.1 TABELA-VERDADE

Tabela 3: Funcionamento da função parada de segurança

STO1

(tensão entre

XC25:1-3)

STO2

(tensão entre

XC25:2-4)

Função parada

de segurança

Comportamento do inversor

0 0 Ativa.

Inversor fica em estado STO e não aceita

comandos. No caso do CFW70x com versão

de software V1.02 ou superior, também é

indicado A170 (aviso de atuação da função

parada de segurança) na HMI. Para sair dessa

condição, basta fazer STO1 = 1 e STO2 = 1

simultaneamente.

0 1 (24V)

Falha.

Inversor é bloqueado por F160 (falha relacionada

à função parada de segurança). Para sair dessa

condição, é necessário resetar o inversor.

1 (24V) 0

1 (24V) 1 (24V) Inativa. Inversor aceita comandos normalmente.

NOTA!

Atraso máximo entre sinais STO1 e STO2: 100 ms (caso contrário o inversor será

bloqueado por F160).

A função parada de segurança é prioritária sobre todas as outras funções do inversor.

Essa função não deve ser usada para controlar a partida e/ou parada do inversor.

3.2 ESTADO DO INVERSOR, FALHA E ALARME RELACIONADOS À FUNÇÃO DE PARADA

DE SEGURANÇA

Tabela 4: Estado do inversor, falha e alarme relacionados à função de parada de segurança

Estado /

falha / alarme

Descrição Causa

Estado STO. Função parada

de segurança

ativa.

Tensão entre terminais 1 e 3 (bobina do relé K1) e entre terminais

2 e 4 (bobina do relé K2) de XC25 maior que 17V.

Falha F160. Falha da função

de parada de

segurança.

É aplicada tensão na bobina do relé K1 (STO1) mas não é

aplicada tensão na bobina do relé K2 (STO2) ou vice-versa ou

há uma diferença de mais de 100 ms entre o acionamento de

um relé e do outro. Para resolver isso, acertar lógica externa que

gera os sinais STO1 e STO2.

Alarme A170

(somente nos inversores

CFW70x com versão

de software V1.02 ou

superior).

Função parada

de segurança

ativa.

Para fins de indicação na HMI, esse alarme é indicado no

CFW70x quando o estado do inversor é igual a STO.

Page 29

Função de Parada de Segurança

CFW-11, CFW-11M, CFW70X | 29

Português

3.3 INDICAÇÃO DO ESTADO DA FUNÇÃO SAFETY STOP

O estado do inversor é apresentado no canto esquerdo superior do display da HMI do CFW-11

e CFW-11M, na área central superior da HMI do CFW70x (nem todos os estados do inversor são

indicados na HMI do CFW70x) e no parâmetro P0006.

Estados possíveis: ready (pronto), run (inversor habilitado), subtensão, falha, auto-ajuste,

configuração, frenagem CC e STO (função parada de segurança ativa).

É possível programar uma ou mais saídas a relé e digitais do inversor para indicar que a função

parada de segurança está ativa (estado do inversor = STO), se o inversor está ou não em estado

de falha e mais especificamente se o inversor foi bloqueado por F160 (falha da função parada de

segurança). A programação é feita ajustando o conteúdo dos parâmetros P0275 (DO1), P0276

(DO2), P0277 (DO3), P0278 (DO4) e P0279 (DO5) conforme a tabela 5.

Tabela 5: Opções de P0275...P0279 para indicação do estado e falhas do inversor nas saídas digitais DOx

Função da saída digital DOx

Valor a ser ajustado em

P0275...P0279

Comentário

CFW-11 e

CFW-11M

CFW70x

Estado do inversor = STO

(função parada de segurança ativa).

33 30 Função parada de segurança inativa:

relé/transistor OFF.

Função parada de segurança ativa: relé/

transistor ON.

Falha F160 (inversor bloqueado

pela atuação da falha da função de

parada de segurança).

34 31 Sem falha F160: relé/transistor OFF.

Com falha F160: relé/transistor ON.

Falha (inversor foi bloqueado pela

atuação de qualquer falha).

13 13 Sem falha: relé/transistor OFF.

Com falha: relé/transistor ON.

Sem falha (nenhuma falha do

inversor foi ativada).

26 24 Com falha: relé/transistor OFF.

Sem falha: relé/transistor ON.

Para uma lista completa de opções dos parâmetros P0275...P0279 consultar o manual de

programação do inversor CFW-11.

3.4 TESTE PERIÓDICO

A função parada de segurança, deve ser ativada pelo menos uma vez ao ano com o objetivo

de manutenção preventiva. Este procedimento é realizado através das entradas STO1 e STO2

conforme apresentado na tabela 3. A alimentação do inversor deve ser retirada e então conectada

novamente antes de executar essa manutenção preventiva. A função parada de segurança estará

funcionando corretamente se durante o teste a alimentação do motor for interrompida (o motor

deve parar) e não ocorrer a atuação de falhas no inversor. Caso o inversor não passar nesse teste

é necessário substituí-lo para garantir a segurança operacional da máquina ou do processo em

questão.

Page 30

Função de Parada de Segurança

30 | CFW-11, CFW-11M, CFW70X

Português

4. EXEMPLOS DE ESQUEMAS DE LIGAÇÃO DOS SINAIS DE CONTROLE DO

INVERSOR

Sugere-se utilizar as entradas digitais DI1 e DI2 do inversor programadas como comandos start e

stop 3 fios e esquemas de ligação dos sinais de controle inversor conforme figura 4.

XC1:11 - DGND*

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:12 - COM

XC1:13 - +24V

XC1:15 - DI1

XC1:16 - DI2

Stop

Start

Emergency

Stop

CFW-11/

CFW-11M

XC1:36 - GND(24V)

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:35 - COM

XC1:34 - +24V

XC1:37 - DI1

XC1:38 - DI2

Stop

Start

Emergency

Stop

CFW70X

(a) Parada tipo STO ou SS0 com inversores CFW-11 e CFW-11M (b) Parada tipo STO ou SS0 com inversores CFW70x

External

XC1:11 - DGND*

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:12 - COM

XC1:13 - +24V

XC1:15 - DI1

A1 A2

XC1:16 - DI2

Stop

Start

Safety Relay

CFW-11/

CFW-11M

14 24 48 58

13 23 47 57

(c) Parada tipo SS1 com inversores CFW-11 e CFW-11M

(*)

External

XC1:36 - GND(24V)

XC25:2 - GND(R1-)

XC25:1 - STO1(R1+)

XC25:3 - STO2(R2+)

XC25:4 - GND(R2-)

XC1:35 - COM

XC1:34 - +24V

XC1:37 - DI1

XC1:38 - DI2

Stop

Start

Safety Relay

CFW70X

13 23 47 57

14 24 48 58

A1 A2

(d) Parada tipo SS1 com inversores CFW70x

(*)

(*) Para especificações do relé de segurança externo é necessário para implementar parada tipo SS1 ver item 5.

Figura 4: Exemplos de conexões de controle do inversor (bornes XC1 e XC25) para implementar funções de

segurança tipo STO (ou SS0, i.e., categoria de parada 0) e SS1 (categoria de parada 1) conforme normas IEC/EN

61800-5-2 e IEC/EN 60204-1 respectivamente – entradas DI1 e DI2 programadas como comandos start stop 3 fios

Page 31

Função de Parada de Segurança

CFW-11, CFW-11M, CFW70X | 31

Português

Operação do circuito da parada tipo SS1 (figuras 4c e 4d):

Nesse caso, quando um comando de ativação é dado ao relé de segurança externo, o relé abre

o sinal da entrada DI2 do inversor (via terminais 23-24) e o motor é inicialmente desacelerado pelo

inversor (via rampa de desaceleração). Quando o intervalo de tempo ajustado no relé de segurança

expirar (esse intervalo deve ser maior que o tempo necessário para parar o motor, considerando a

rampa de desaceleração ajusta e a inércia do motor), os contatos retardados do relé de segurança

(terminais 47-48 e 57-58) abrem os sinais STO1 e STO2 e a função parada de segurança do inversor

é ativada. O motor para de acordo com a categoria 1 (SS1) da norma IEC/EN 60204-1. Para acionar

o motor novamente, é necessário aplicar sinais em STO1 e STO2 (fechar os terminais 13-14 e 23-24)

e ter um pulso na entrada DI1 do inversor (aplicar um pulso na chave START).

5. ESPECIFICAÇÕES TÉCNICAS

5.1 CARACTERÍSTICAS ELÉTRICAS DE CONTROLE

Entradas da função parada

de segurança.

XC25:1-2, XC25:3-4 2 entradas independentes para função parada de

segurança.

Alimentação: 24 Vcc (máx. 30 V)

Impedância: 960 Ω

Nível 0 se < 2 V, nível 1 se > 17 V

Especificação do relé

de segurança externo

(somente quando for

necessário a função SS1

conforme normas IEC/

EN 61800-5-2 e IEC/EN

60204-1 – veja figuras

4c/4d).

Gerais. IEC 61508 e/ou EN 954-1 e/ou ISO 13849-1

Exemplo. Número de caminhos de corrente: 2 caminhos

independentes (uma para STO1 e outro para STO2).

Capacidade de chaveamento de tensão: 30 Vcc

por contato.

Capacidade de chaveamento de corrente: 100 mA

por contato.

Máximo atraso entre contatos: 100 ms.

Exemplo. Tipo/fabricante: WEG / Instrutech CPt-D.

5.2 CARACTERÍSTICAS DE SEGURANÇA OPERACIONAL

Proteção. Da máquina. Função parada de segurança que garante a parada

e/ou evita o acionamento não desejado do motor

conforme EN 954-1 / ISO 13849-1 categoria 3, IEC/

EN 61800-5-2 e IEC/EN 60204-1.

Do sistema de processo. Função parada de segurança que garante a parada

e/ou evita o acionamento não desejado do motor

conforme IEC/EN 61508 nível SIL2 e IEC/EN

61800-5-2.

NOTA!

Certificação do produto se encontra no anexo.

Page 32

APPENDIX

ANEXO

Page 33

USER NOTES / ANOTACIONES / ANOTAÇÕES DO USUÁRIO

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

Page 34

USER NOTES / ANOTACIONES / ANOTAÇÕES DO USUÁRIO

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

Page 35

Page 36

Document: 10000933196 / 00

WEG Drives & Controls - Automação LTDA.

Jaraguá do Sul - SC - Brazil

Phone 55 (47) 3276-4000 - Fax 55 (47) 3276-4020

São Paulo - SP - Brazil

Phone 55 (11) 5053-2300 - Fax 55 (11) 5052-4212

automacao@weg.net

www.weg.net

11863264

Loading...

Loading...