Page 1

Anybus-CC

CFW-11

User’s Manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

Anybus-CC User’s Manual

Series: CFW-11

Language: English

Document Number: 0899.5750 / 06

Publication Date: 09/2013

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

CONTENTS

CONTENTS ......................................................................................................................... 3

ABOUT THE MANUAL ....................................................................................................... 6

ABBREVIATIONS AND DEFINITIONS ......................................................................................................... 6

NUMERICAL REPRESENTATION ............................................................................................................... 6

1 INTRODUCTION TO THE FIELDBUS .......................................................................... 7

2 ACCESSORY KITS ....................................................................................................... 8

2.1 DEVICENET ........................................................................................................................................ 8

2.1.1 DEVICENET-05 Accessory ........................................................................................................ 8

Connector Pin Function ........................................................................................................................................ 8

Power Supply ......................................................................................................................................................... 8

Indications ............................................................................................................................................................. 9

2.1.2 Installation of the DeviceNet network ..................................................................................... 9

Communication Rate ............................................................................................................................................ 9

Address in the DeviceNet network .................................................................................................................... 10

Termination resistors .......................................................................................................................................... 10

Cables .................................................................................................................................................................. 10

Installation recommendations ........................................................................................................................... 10

2.1.3 Configuration of the Communication .................................................................................... 11

2.1.4 Access to Parameters – Acyclic messages .......................................................................... 11

2.2 PROFIBUS ........................................................................................................................................ 12

2.2.1 PROFIBUS-05 Accessory ........................................................................................................ 12

Connector Pin Function ...................................................................................................................................... 12

Indications ........................................................................................................................................................... 12

2.2.2 Installation of the Profibus network ....................................................................................... 13

Communication Rate .......................................................................................................................................... 13

Address ................................................................................................................................................................ 13

Termination resistors .......................................................................................................................................... 13

Cables .................................................................................................................................................................. 13

Connectors .......................................................................................................................................................... 13

Installation recommendations ........................................................................................................................... 13

2.2.3 Configuration of the Module ................................................................................................... 14

2.2.4 Access of the Parameter – Acyclic Messages ...................................................................... 15

2.3 ETHERNET/IP .................................................................................................................................. 15

2.3.1 ETHERNETIP-05 and ETHERNET-2P-05 Accessory ............................................................ 15

Connector ............................................................................................................................................................ 15

Indications ........................................................................................................................................................... 15

2.3.2 Installation of the Ethernet network ...................................................................................... 16

Communication Rate .......................................................................................................................................... 16

MAC Address ....................................................................................................................................................... 16

Address in the Ethernet network ....................................................................................................................... 16

Cables .................................................................................................................................................................. 16

Installation recommendations ........................................................................................................................... 16

2.3.3 Configuration of the Ethernet Interface................................................................................. 17

HMS Anybus IPconfig ......................................................................................................................................... 17

Web Browser ....................................................................................................................................................... 18

2.3.4 Configuration of the Communication .................................................................................... 19

2.3.5 Access to Parameters – Acyclic messages .......................................................................... 19

2.4 MODBUS TCP .................................................................................................................................. 20

2.4.1 MODBUSTCP-05 Accessory ................................................................................................... 20

Connector ............................................................................................................................................................ 20

Indications ........................................................................................................................................................... 20

2.4.2 Installation of the Ethernet Network ...................................................................................... 20

2.4.3 Configuration of the Ethernet Interface................................................................................. 21

2.4.4 Configuration of the Communication .................................................................................... 21

2.4.5 Addressing of the data ............................................................................................................ 22

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

2.5 PROFINET ........................................................................................................................................ 22

2.5.1 PROFINETIO-05 Accessory .................................................................................................... 22

Connector ............................................................................................................................................................ 22

Indications ........................................................................................................................................................... 23

2.5.2 Installation of the Ethernet Network ...................................................................................... 24

2.5.3 Configuration of the Ethernet Interface................................................................................. 24

2.5.4 Configuration of the Communication .................................................................................... 24

2.5.5 Access to Parameters – Acyclic messages .......................................................................... 24

2.6 RS232................................................................................................................................................ 25

2.6.1 RS232-05 Accessory ................................................................................................................ 25

Connector Pin Function ...................................................................................................................................... 25

Indications ........................................................................................................................................................... 25

Connection with the Network ............................................................................................................................ 25

2.7 RS485................................................................................................................................................ 25

2.7.1 RS485-05 Accessory ................................................................................................................ 25

Connector Pin Function ...................................................................................................................................... 25

Indications ........................................................................................................................................................... 26

Connection with the Network ............................................................................................................................ 26

3 PROGRAMMING ........................................................................................................ 27

3.1 SYMBOLS FOR THE PROPERTIES DESCRIPTION ...................................................................... 27

P0105 – 1ST/2ND RAMP SELECTION .......................................................................................................... 27

P0220 – LOCAL/REMOTE SELECTION SOURCE .................................................................................... 27

P0221 – SPEED REFERENCE SELECTION – LOCAL SITUATION ......................................................... 27

P0222 – SPEED REFERENCE SELECTION – REMOTE SITUATION ...................................................... 27

P0223 – FORWARD/REVERSE SELECTION – LOCAL SITUATION ........................................................ 27

P0224 – RUN/STOP SELECTION – LOCAL SITUATION .......................................................................... 27

P0225 – JOG SELECTION – LOCAL SITUATION ..................................................................................... 27

P0226 – FORWARD/REVERSE SELECTION – REMOTE SITUATION .................................................... 27

P0227 – RUN/STOP SELECTION – REMOTE SITUATION ...................................................................... 27

P0228 – JOG SELECTION – REMOTE SITUATION .................................................................................. 27

P0313 – COMMUNICATION ERROR ACTION .......................................................................................... 27

P0680 – STATUS WORD ............................................................................................................................ 28

P0681 – MOTOR SPEED IN 13 BITS ......................................................................................................... 29

P0686 – ANYBUS-CC CONTROL WORD .................................................................................................. 30

P0687 – ANYBUS-CC SPEED REFERENCE ............................................................................................. 31

P0695 – DIGITAL OUTPUT SETTING ........................................................................................................ 31

P0696 – VALUE 1 FOR ANALOG OUTPUTS ............................................................................................. 32

P0697 – VALUE 2 FOR ANALOG OUTPUTS ............................................................................................. 32

P0698 – VALUE 3 FOR ANALOG OUTPUTS ............................................................................................. 32

P0699 – VALUE 4 FOR ANALOG OUTPUTS ............................................................................................. 32

P0723 – ANYBUS IDENTIFICATION ......................................................................................................... 33

P0724 – ANYBUS COMMUNICATION STATUS ...................................................................................... 33

P0725 – ANYBUS ADDRESS .................................................................................................................... 34

P0726 – ANYBUS COMMUNICATION RATE ........................................................................................... 34

P0727 – ANYBUS I/O WORDS .................................................................................................................. 35

P0728 – ANYBUS READING #3 ................................................................................................................. 36

P0729 – ANYBUS READING #4 ................................................................................................................. 36

P0730 – ANYBUS READING #5 ................................................................................................................. 36

P0731 – ANYBUS READING #6 ................................................................................................................. 36

P0732 – ANYBUS READING #7 ................................................................................................................. 36

P0733 – ANYBUS READING #8 ................................................................................................................. 36

P0734 – ANYBUS WRITING #3 .................................................................................................................. 37

P0735 – ANYBUS WRITING #4 .................................................................................................................. 37

P0736 – ANYBUS WRITING #5 .................................................................................................................. 37

P0737 – ANYBUS WRITING #6 .................................................................................................................. 37

P0738 – ANYBUS WRITING #7 .................................................................................................................. 37

P0739 – ANYBUS WRITING #8 .................................................................................................................. 37

P0799 – I/O UPDATE DELAY ..................................................................................................................... 37

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

4 FAULTS AND ALARMS RELATED TO THE ANYBUS-CC COMMUNICATION ....... 39

A129/F229 – ANYBUS-CC MODULE OFFLINE ........................................................................................ 39

A130/F230 – ANYBUS-CC MODULE ACCESS ERROR ........................................................................... 39

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 6

ABOUT THE MANUAL

This manual provides the necessary information for the operation of the CFW-11 frequency inverter using the

Anybus-CC modules. This manual must be used together with the CFW-11 user manual.

ABBREVIATIONS AND DEFINITIONS

ASCII

American Standard Code for Information Interchange

CAN

Controller Area Network

CIP

Common Industrial Protocol

CSMA/CD

Carrier Sense Multiple Access/Collision Detection

DP

Decentralized Periphery

FMS

Fieldbus Message Specification

HMI

Human Machine Interface

IP

Internet Protocol

MAC

Medium Access Control

MS

Module Status

NS

Network Status

ODVA

Open DeviceNet Vendor Association

OP

Operation Mode

PI

Profibus International

PLC

Programmable Logic Controller

ST

Status

TCP

Transmission Control Protocol

UDP

User Datagram Protocol

NUMERICAL REPRESENTATION

Decimal numbers are represented by means of digits without suffix. Hexadecimal numbers are represented with

the letter ‘h’ after the number. Binary numbers are represented with the letter ‘b’ after the number.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 7

1 INTRODUCTION TO THE FIELDBUS

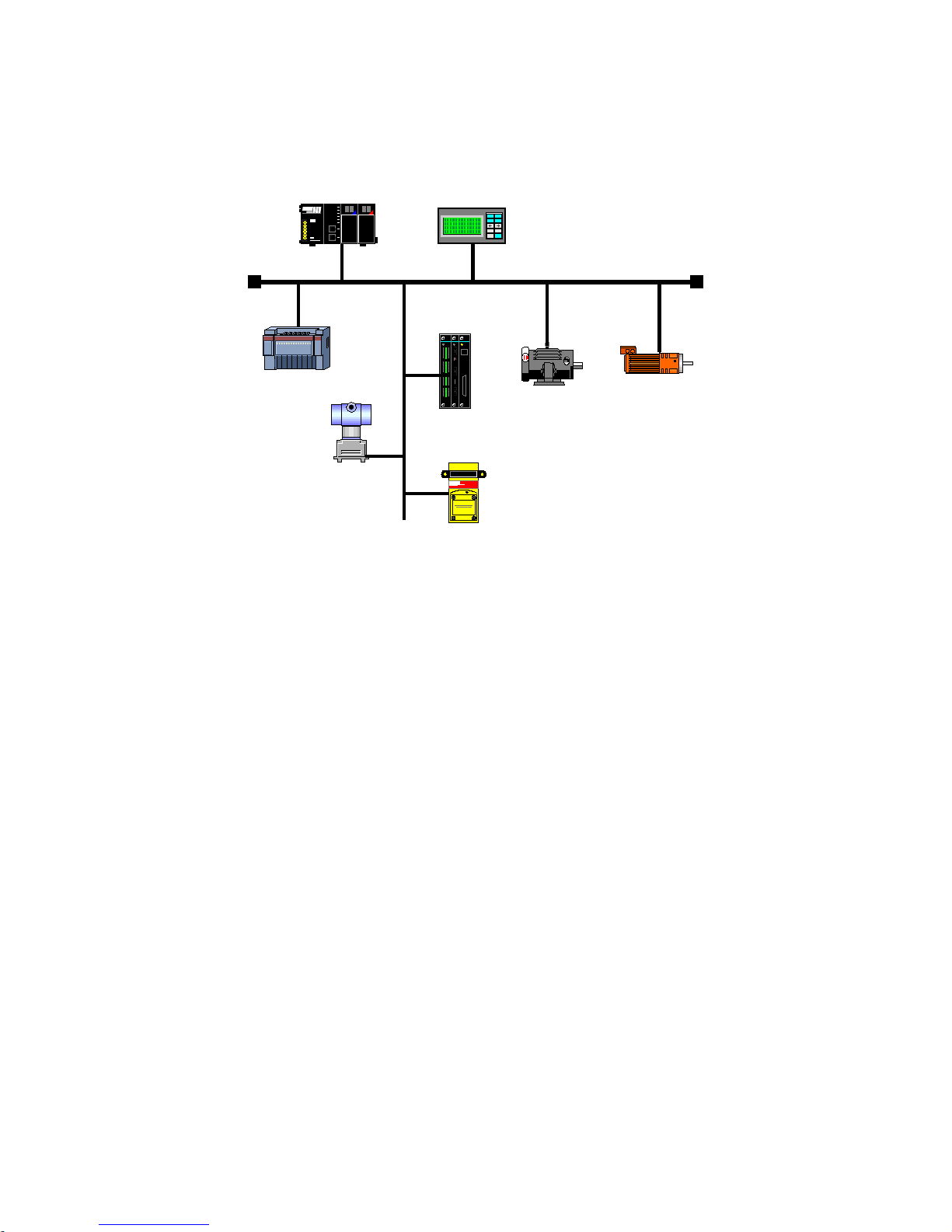

The Fieldbus is a digital communication system used in the industry to interconnect automation primary

elements, such as PLC’s, drives, valves, sensors, actuators, etc., as illustrated in the figure below.

Figure 1.1: Illustration of a Fieldbus network

Nowadays, there is a great variety of protocols in the market, each one with its advantages and disadvantages.

It is up to the user/project designer to evaluate what the necessary requirements for the application are, and

choose among the available options.

Rega

rdless of the choice, the main advantages of the industrial networks are:

Significant reduction in cable and installation costs;

Reduction in the

start-up

time;

More reliability and efficiency;

Addition, removal and replacement of equipment with the network under load (supply);

Integration of several suppliers (standardization);

Effective process monitoring;

Configuration of devices via the network.

By

means of the Anybus-CC communication modules, the CFW-11 supports protocols widely spread in the

industry, like DeviceNet, Profibus DP-V1, EtherNet/IP, Modbus TCP and PROFINET IO. Besides this, by means

of passive modules, RS232 and RS485/422 interfaces are also available.

Follo

wing, the characteristics for Anybus-CC modules available for the frequency inverter CFW-11 are

presented.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 8

2 ACCESSORY KITS

Frequency inverter CFW-11 features as accessory the Anybus-CC communication modules. Anybus-CC

modules are divided into two types: active and passive.

Active Module:

it has all the required hardware and software to perform the communication. The following

active modules are available for CFW-11:

DeviceNet

Profibus DP-V1

EtherNet/IP

Modbus TCP

PROFINET IO

Passive Module

: these passive devices work only as physical layer, not performing any processing over the

data flow. CFW-11 features the following interfaces:

RS232

RS485/422

NOTE!

For the passive modules, communication is performed through the serial interface of the product.

Therefore, the manual of serial communication Modbus RTU User’s Manual

must be referred to in

order to obtain information about how to configure and operate the product using this interface.

2.1 DEVICENET

2.1.1 DEVICENET-05 Accessory

WEG part number: 11008158.

Composed by the Anybus ABCC-DEV communication module,

mounting instructions and a “torx” screw driver for fixing the

module.

ODVA certified interface.

It allows the programming of the Frequency inverter via network

configuration software.

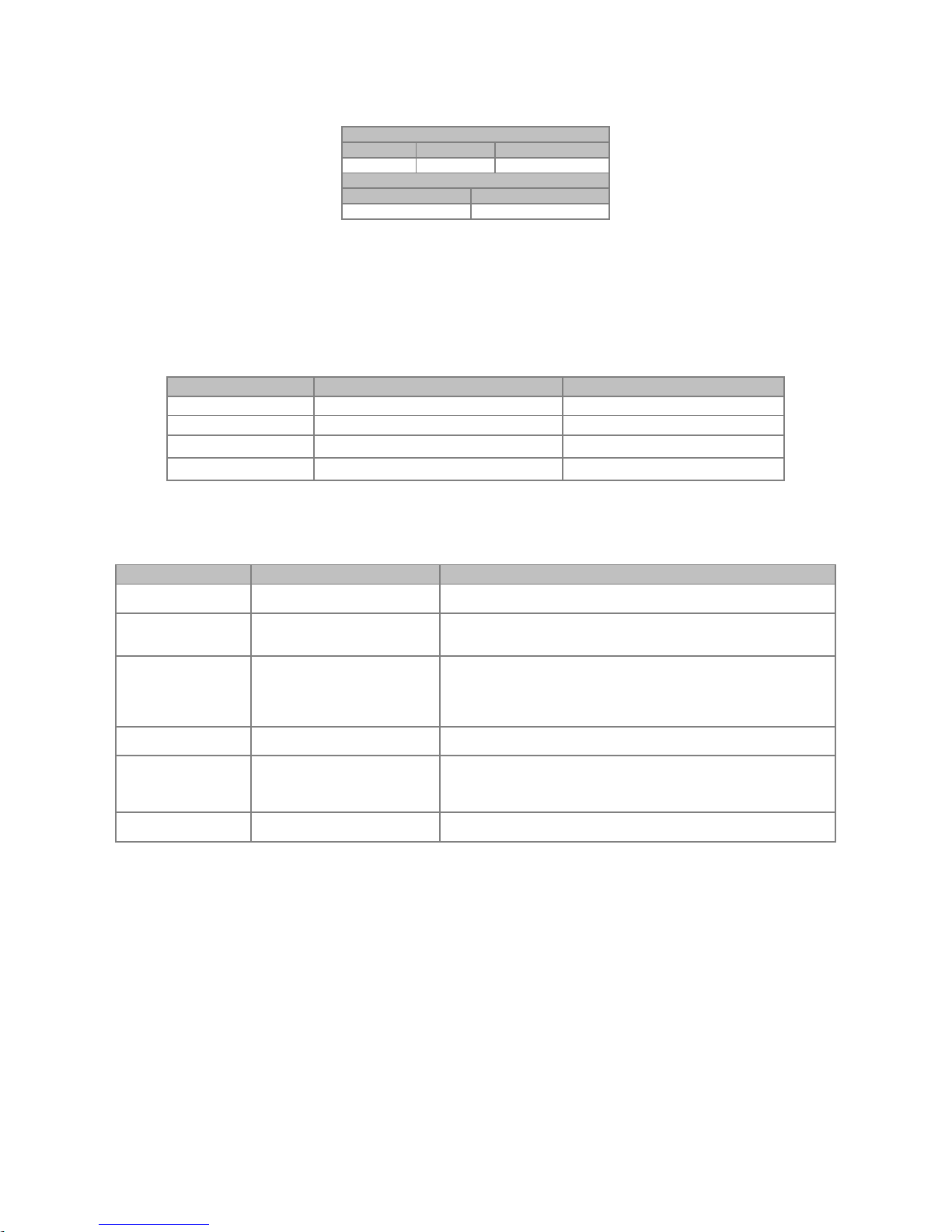

Connector Pin Function

The DeviceNet communication module presents a male

plug-in

connector with the following pin assignment:

Table 2.1: DeviceNet plug-in connector pin assignment

Pin Name Function

1

V-

Power supply negative pole

2

CAN_L

CAN_L signal

3

Shield

Cable shield

4

CAN_H

CAN_H signal

5

V+

Power supply positive pole

Power Supply

The power supply of the network must be able to supply enough current to power up the equipment and

interfaces connected to the network. The data for individual consumption and input voltage for the DEVICENET05 accessory are presented in table 2.2.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

Table 2.2: Characteristics of power supply for the interface

Power Supply (VDC)

Minimum

Maximum

Recommended

11

25

24

Current (mA)

Typical

Maximum

36

38

Indications

DeviceNet defines two LEDs for state indication: one for the communication module (MS) and another for the

network (NS).

The MS LED indicates the conditions of the module itself. That is, whether it is able to work or not. The table

below shows the possible states:

Table 2.3: State of the DeviceNet module

LED Status Description Comments

Off Without power supply -

Green Module operating and in normal conditions -

Red Module in error Reinitializing the equipment is required.

Flashing green/red Equipment performing self-diagnosis It occurs during initialization.

The NS LED provides information about the status of the DeviceNet network. The table below presents the

description of those states.

Table 2.4: Status of the DeviceNet network

LED Status Description Comments

Off

Without power supply or not

online

Equipment is not connected to a DeviceNet network with other equipment

at the same communication rate.

Green

Online

, connected

Master has allocated a set of I/O type connection with the slave. In this

stage data exchange by means of I/O type connections does effectively

occur.

Flashing green

Online

, not connected

Slave has successfully completed the Mac ID verification procedure. This

means that the configured communication is correct (or was detected

correctly in the case of use of autobaud) and that there are no other nodes

in the network with the same address. However, in this stage, there is not a

set of I/O type connections established.

Flashing red

One or more I/O type connections

have expired

The I/O data exchange has been interrupted.

Red Serious fault in the link

It indicates that the slave cannot enter the network because of addressing

problems or due to the occurrence of

bus off

. Verify if the address is being

used by another device

, if the chosen communication rate is correct or if

there are installation problems.

Flashing green/red

Equipment performing selfdiagnosis

It occurs during initialization.

2.1.2 Installation of the DeviceNet network

For the connection of the frequency inverter using the DeviceNet interface, the following points must be

observed:

Communication Rate

Equipment with Anybus-CC interface in general allow to configure the desired communication rate, which may

vary from 125 Kbit/s to 500 Kbit/s. A communication rate (baud rate) that can be used by a device also

depends on the length of the cable used in the installation. It worth to mention that, in order to allow the

disconnection of the element from the network without damaging the bus, it is interesting to put active

terminations, which are elements that only play the role of the termination. Thus, any equipment in the network

can be disconnected from the bus without damaging the termination. The table 2.5 shows the relation between

the communication rates and the maximum lengths of the cable which can be used in the installation, according

to the recommendation of ODVA.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 10

Table 2.5: Communication rates supported and cable length

Communication

Rate

Length of the

cable

500 Kbit/s

100 m

250 Kbit/s

250 m

125 Kbit/s

500 m

All the equipment of the network must be set to use the same communication rate.

Address in the DeviceNet network

Every device in the Anybus-CC network must have an address, or MAC ID, between 0 and 63. This address

must be different for each device.

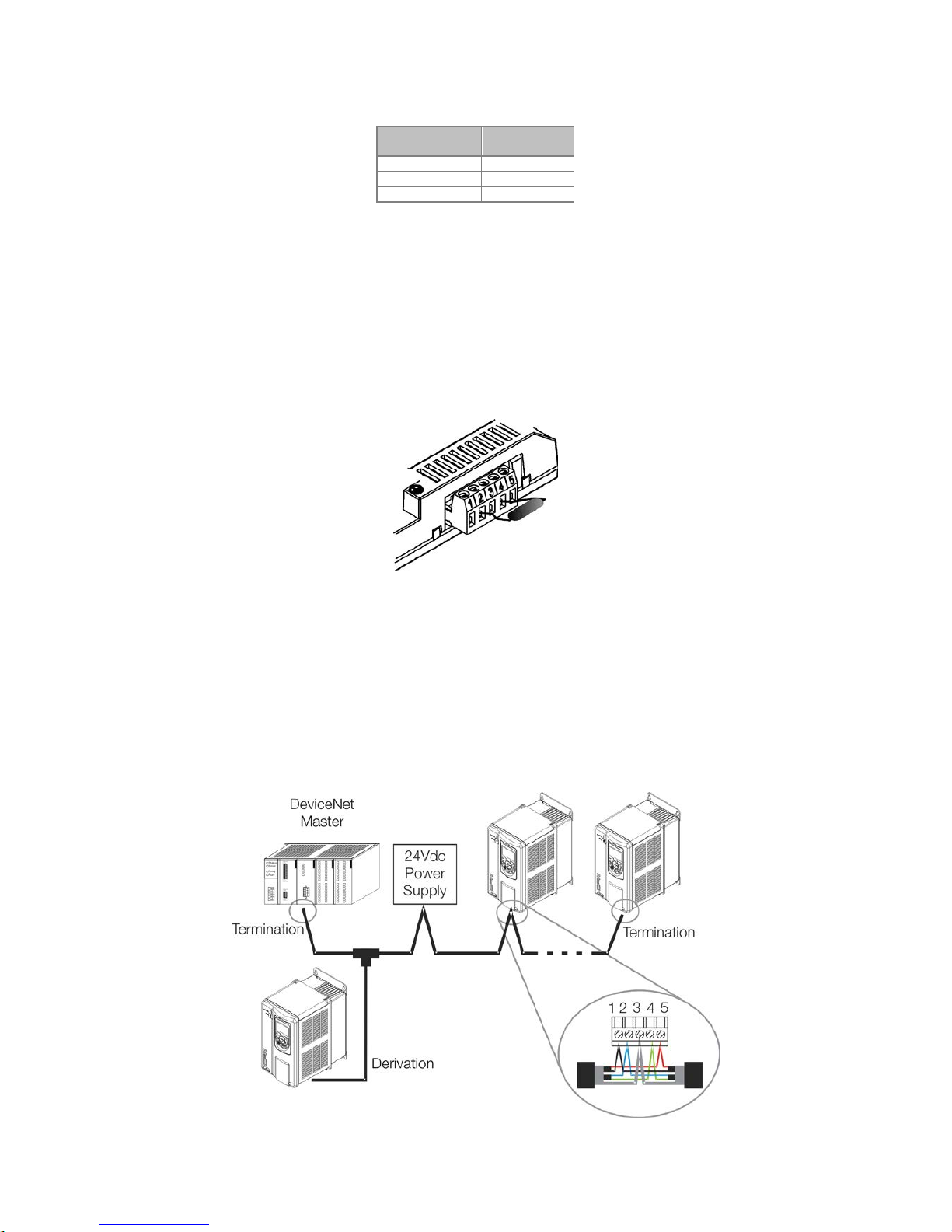

Termination resistors

The use of termination resistors at the ends of the CAN bus is essential to prevent reflection in the line, which

may damage the signal transmitted and cause errors in the communication. Termination resistors of 121 Ω /

0.25 W must be connected between the signals CAN_H and CAN_L at the ends of the main bus.

Figure 2.1: Example of installation of the termination resistor

Cables

A shielded cable must be used with two pairs of wires, as specified in the DeviceNet protocol.

Installation recommendations

In order to interconnect the network nodes, it is recommended the connection of the equipment directly from

the main line, without the use of derivations. If you use derivations, the limits of length for derivation defined by

the DeviceNet specification must be observed. During the installation of the cables, you must avoid passing

them close to power cables, since that can cause errors during the transmission due to electromagnetic

interference.

Figure 2.2: Example of installation in DeviceNet network

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 11

The grounding of the cable shield must be done only in one point, thus avoiding long current loops. This point is

normally the network own power supply. It is recommended that the network be powered in only one point, and

the power supply signal be taken to all devices by means of the cable. In case more than one power supply is

required, they must have the same point as reference.

2.1.3 Configuration of the Communication

In order to configure and use the DeviceNet module, follow the steps below:

With the module installed, during the recognition stage, a warning message will be displayed on the product

HMI, and the MS and NS LEDs test routine performed. After this stage, the MS LED must turn on in green.

Observe the content of parameter P0723. Check if the module was recognized. The detection is done

automatically and does not require the user’s intervention.

Set the parameters as desired for the application:

Address: the address of the equipment is set in parameter P0725.

Communication rate: the communication rate is set in parameter P0726.

I/O configuration: program in P0727 the number of words to be exchanged with the network master.

This same value must be set in the DeviceNet master. For this adjustment being complete, it is

necessary to program a value different from 0 (zero) in parameters P0728 to P0739 (see item 3).

Once the parameters are set, if any of the parameters described in the previous item were changed, it is

necessary to restart the equipment.

Once the equipment is set, it is necessary to configure the communication in the network master:

EDS file: register the EDS file in the network configuration tool. The EDS configuration file is supplied in a CD

together with the product. It is necessary to observe the equipment software version in order to use an EDS

file which is compatible with this version.

I/O data setting: during the configuration of the network, it is necessary to define the quantity of I/O data

communicated between master and slave, as well as the transmission method of these data. The

DeviceNet protocol defines different methods of dada exchange, seeing that the module supports the

following methods:

Polled:

communication method in which the master sends a telegram to each of the slaves of its list

(

scan list

). As soon as it receives the request, the slave immediately answers the request of the master.

This process is repeated until all slaves are polled, restarting the cycle.

Bit-strobe:

communication method in which the master sends a telegram to the network containing 8

bytes of data. Each bit of these 8 bytes represents one slave that, if addressed, answers according to

the programmed.

Change of State:

communication method in which the data exchange between master and slave only

occurs when there are changes in the values monitored/controlled up to a certain time limit. When this

limit is reached, the transmission and reception will take place even if changes have not occurred.

Cyclic:

another communication method very similar to the previous one. The only difference is the

production and consumption of messages. In this type of communication, every data exchange occurs

at regular time intervals, no matter if they have been changed or not.

If everything is correctly configured, the NS LED of the module will be on in green. It is in this condition that

cyclic data exchange effectively occurs between the slave and the master of the network.

2.1.4 Access to Parameters – Acyclic messages

Besides the I/O data (cyclic) communication, the DeviceNet protocol also defines a kind of acyclic telegram

(

explicit messages

), used especially in asynchronous tasks, such as parameter setting and configuration of the

equipment.

After the registration of the EDS file in the network configuration software, the user will have access to the full

parameter list of the equipment, which can be accessed via

explicit messages

. Each parameter is accessed

using an addressing based on class, instance and attribute. The table 2.6 shows how to address the

parameters of the CFW-11.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 12

Table 2.6: Addressing of the parameters

Parameter

Class

Instance

Attribute

P0001

Class 162 (A2h)

1 5 P0002

Class 162 (A2h)

2 5 P0003

Class 162 (A2h)

3 5 ...

...

...

...

P0400

Class 162 (A2h)

400 5 ...

...

...

...

2.2 PROFIBUS

2.2.1 PROFIBUS-05 Accessory

WEG part number: 11008107.

It is composed by the Anybus ABCC-

DPV1 communication

module, mounting instructions and a “torx” screw driver for fixing

the module.

Interface certified by Profibus International.

It supports DP-V1 (acyclic messages).

Connector Pin Function

The Profibus DP-V1 communication module has a female DB9 connector with the following pin assignment:

Table 2.7: Profibus female DB9 connector pin assignment

Pin

Name

Function

1

- - 2

- - 3

B-Line (+)

RxD/TxD positive

4

RTS

Request To Send

5

GND

Reference (0 V) of the RS485 interface (isolated)

6

+5 V

+5 V for active termination (RS485 isolated power supply)

7

- - 8

A-Line (-)

RxD/TxD negative

9

-

-

Indications

Profibus defines two LEDs for status indication: one for the communication module (ST) and another for the

operating mode (OP).

The ST LED indicates the conditions of the module itself. That is, whether it is able to work or not. The table 2.8

shows the possible states:

Table 2.8: Status of the Profibus DP-V1 module

LED Status Description Comments

Off Without power supply or not initialized -

Green Module initialized -

Flashing green Initialized, but in event diagnosis

It indicates that a problem was diagnosed in the

module and an alarm was generated.

Red

In error

Reinitializing the equipment is required.

The OP LED provides information about the status of the Profibus network. The table 2.9 presents a brief

description of those states.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 13

Table 2.9: Status of the operating mode

LED Status Description Comments

Off Without power supply or not

online

-

Green Device

online

In this state, data exchange effectively occurs.

Flashing green

Online

but in the

clear

sate

In this state, data exchange occurs, but the

outputs are not updated.

Flashing red (1 flash) Error in parameter setting

Incorrect configuration of the Profibus

communication properties in the master of the

network.

Flashing red (2 flashes) Error in the Profibus configuration

It indicates that the quantity of I/O words (or the

order of these words) set in the master is different

from that set in the equipment.

2.2.2 Installation of the Profibus network

For the connection of the frequency inverter using the Profibus interface, the following points must be observed:

Communication Rate

It is not necessary to set the communication rate of the Profibus module because it features autobaud and,

therefore, this configuration is done in the master of the network.

Address

Every device in the Profibus network, master or slave, is identified in the network by means of an address. This

address must be different for each device. Valid values: 1 to 126.

Termination resistors

For each segment of the Profibus DP network, it is necessary to enable a termination resistor at the ends of the

main bus. Connectors suitable for the Profibus network that feature a switch to enable the resistor may be used,

but the switch must only be enabled (ON position) if the equipment is the first or last element in the segment. It

is worth to mention that, in order to allow the disconnection of the element from the network without damaging

the bus, it is interesting to put active terminations, which are elements that only play the role of the termination.

So any equipment in the network can be disconnected from the bus without damaging the termination.

Cables

It is recommended that the installation be done with A-type cable, whose features are described in table 2.10.

The cable has a pair of wires that must be shielded and twisted in order to guarantee greater immunity to

electromagnetic interference.

Table 2.10: Properties of cable A-type cable

Impedance

135 to 165 Ω

Capacitance

30 pf/m

Resistance in loop

110 Ω/km

Diameter of the cable

> 0.64 mm

Cross section of the wire

> 0.34 mm

Connectors

There are different types of connectors specifically designed for applications in the Profibus network. For CFW-

11 frequency inverter, it is recommended to use connectors with cable connection in 180 degrees, because, in

general, connectors with different angles can not be used due to mechanical characteristics of the product.

Installation recommendations

The Profibus DP protocol, using physical medium RS485, allows the connection of up to 32 devices per

segment, without the use of repeaters. With repeaters, up to 126 addressable devices can be connected to the

network. Each repeater must also be included as a device connected to the segment, although it will not take

an address in the network.

It is recommended that the connection of all the devices present in the Profibus DP network be done from the

main bus. In general, the connector of the Profibus network itself has one input and one output for the cable,

allowing the connection to be taken to the other points of the network. Derivations from the main line are not

recommended, especially for communication rates over or equal to 1.5Mbps.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 14

Figure 2.3: Example of installation of the Profibus DP network

The Profibus DP network cables must be laid separately (and far away if possible) from the power cables. All the

drives must be properly grounded, preferably at the same ground point. The Profibus cable shield must also be

grounded. The DB9 connector itself already has a connection with the protective ground and, therefore, makes

the connection of the shield to the ground when the Profibus cable is connected to the drive. However a better

connection, implemented by clamps that connect the shield to a ground point, is also recommended.

2.2.3 Configuration of the Module

In order to configure and use the Profibus DP-V1 module, follow the steps below:

With the module installed, during the acknowledgement stage, a warning message will be displayed on the

product HMI, and the ST and OP LEDs test routine performed. Then the ST LED of the module must turn

on in green.

Observe the content of parameter P0723. Check if the module was recognized. The detection is done

automatically and does not require the user’s intervention.

Set the parameters as desired for the application:

Address: the address of the equipment is set in parameter P0725.

I/O configuration: Program in P0727 the number of words to be exchanged with the network master.

This same value must be set in the Profibus master. For this adjustment being complete, it is necessary

to program a value different from 0 (zero) in parameters P0728 to P0739 (see item 3).

Once the parameters are set, if any of the parameters described in the previous item are changed, it is

necessary to restart the equipment.

Once the equipment is set, it is necessary to configure the communication in the master of the network:

GSD file: every element of the Profibus DP network has an associated configuration file with extension GSD.

This file describes the features of each device and it is used by the configuration tool of the master of the

Profibus DP network. During the configuration of the master, the GSD configuration file, supplied with the

equipment, must be used. This file must be registered in the master of the Profibus DP network. The

module will be recognized as “

Anybus CompactCom DPV1

” in the category “

General

”.

I/O data setting: add the CFW-11 to the device list of the master, setting the number of I/O words

according to parameter P0727.

If everything is correctly configured, the OP LED of the module will be on in green. It is in this condition that

cyclic data exchange effectively occurs between the drive and the master of the network.

NOTE!

In the configuration software of the Profibus network, first you must select all the input words (

inputs

)

and then select the output words (

outputs)

, according to parameter P0727.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 15

NOTE!

For further information on the parameters mentioned above, refer to item 3.

2.2.4 Access of the Parameter – Acyclic Messages

The PROFIBUS-05 communication kit allows parameter reading/writing services by means of DP-V1 acyclic

functions. The parameter mapping is done based on the slot and index addressing, as showed in the formula

below:

Slot: (parameter number - 1) / 255.

Index: (parameter number - 1) MOD 255.

NOTE: MOD represents the remainder of the integer division.

2.3 ETHERNET/IP

2.3.1 ETHERNETIP-05 and ETHERNET-2P-05 Accessory

Ethernet-05 part number: 10933688 (1 Ethernet port).

Ethernet-2P-05 part number: 12272760 (2 Ethernet ports with

integrated switch).

Composed by the Anybus ABCC-EIP communication module,

mounting instructions and a “torx” screw driver for fixing the

module.

Standard RJ45 connector.

ODVA certified interface.

Connector

The EtherNet/IP communication module has a standard female RJ45 connector (T-568A or T-568B).

Indications

EtherNet/IP defines two LEDs for status indication: one for the communication module (MS) and another for the

network (NS).

The MS LED indicates the conditions of the module itself. That is, whether it is able to work or not. The table

below shows the possible states:

Table 2.11: State of the EtherNet/IP module

LED Status Description Comments

Off Without power supply -

Green Module controlled by a scanner in RUN mode. In this state, data exchange effectively occurs.

Flashing green Not configured or scanner in IDLE mode

In this stage there is no cyclic data communication

with the scanner, or the scanner is in IDLE mode.

Red Major fault

Internal error of the module. Equipment must be

reinitialized.

Flashing red Recoverable fault

Internal error of the module, but the return to the

normal state occurs automatically after the cause of

the fault is corrected.

Flashing green/red

Equipment performing self-diagnosis

It occurs during initialization.

The NS LED indicates the conditions of the EtherNet/IP network.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 16

Table 2.12: Status of the EtherNet/IP network

LED Status Description Comments

Off Without power supply or IP address

The software IPconfig must be used to configure the

communication module address.

Green

Online

, connected

Master has allocated a set of I/O type connection

with t

he slave. In this stage data exchange by means

of I/O type connections does effectively occur.

Flashing green

Online

, not connected

In this stage, there is not a set of I/O type

connections established.

Red Major fault or duplicated IP address

Equipment must be reinitialized to exit the fault state.

Check the IP addresses in the network.

Flashing red

One or more I/O type connections

have expired

The I/O data exchange has been interrupted.

Flashing green/red

Equipment performing self-diagnosis

It occurs during initialization.

The LINK LED indicates the state of the physical connection of the network, as well as the activity in the bus.

Table 2.13: Status of the connection

LED Status Description Comments

Off Without link Without connection, without activity

Green Link Ethernet link established but without data exchange.

Flashing green Activity in the bus

It effectively indicates that there is exchange of

telegrams with the network.

2.3.2 Installation of the Ethernet network

For the connection of the frequency inverter using the Ethernet interface, the following points must be observed:

Communication Rate

The Ethernet interfaces of the Anybus-CC communication cards can communicate using the 10 or 100 Mbps

rates in

half

or

full

duplex mode. As default, the modules are configured with automatic detection of the

communication rate.

MAC Address

Each Anybus-CC module has a unique MAC address, which is indicated on a label in its lower part. This MAC

address may be useful during the stage of configuration of the interface, when it may be necessary to make a

differentiation in case several modules are simultaneously configured, and it must be written down before its

installation.

Address in the Ethernet network

Every device in an Ethernet network needs an IP address and subnet mask.

The IP addressing is unique in the network, and each device must have a different IP. The subnet mask is used

to define which IP address range is valid in the network.

These attributes can be automatically configured by means of a DHCP server present in the network, as long as

this option is enabled in the Anybus-CC module.

Cables

To perform the installation, it is recommended the use of shielded Ethernet cables specific for use in industrial

environment.

Installation recommendations

Each cable segment must have at most 90 m.

It must be used a direct cable to connect the module to a concentrating element (

switch

), or a

cross-over

cable for direct connection between the module and the PC/CLP.

As for topology, there are two models of Anybus-CC card: with one or two Ethernet ports.

For the models with one port, the most usual topology is star, exactly as it is done with computer

networks. In this case all the equipment must be connected to a concentrating element (switch).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 17

Figure 2.4: Star topology.

The models with two ports have an integrated switch. Thus, besides the connection of the equipment in

star for a concentrating element, it is also possible to make the connection in

daisy chain

, allowing a

topology equivalent to a bus.

Figure 2.5: D

aisy chain topology.

2.3.3 Configuration of the Ethernet Interface

In order to configure the Ethernet interface of the communication modules, it is necessary to connect the

module to a PC to use the following software:

HMS Anybus IPconfig

This software is used to program the IP address of the module. When you execute this software, it will

automatically scan the network in order to find out which modules are connected. The modules found will be

listed, showing the information of IP address, subnet, gateway, etc. If more than a module is found, it is

necessary to make the differentiation through the MAC address indicated in the lower part of the Anybus-CC

module.

Figure 2.6: HMS Anybus IPconfig.

To edit this information, you just click twice on the desired module to open new window, where you can modify

these fields.

PC

(192.168.0.2)

CLP

EtherNet/IP module

(192.168.0.1)

Switch

HMI

(192.168.0.5)

Remote I/O

(192.168.0.4)

Drive

(192.168.0.3)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 18

Figure 2.7: IPconfig software information editing.

Web Browser

In case the IP address is known, it is possible to use a web browser to access the data configuration of the

Anybus-CC module. Typing the IP address in the address bar of the browser, you will see a webpage with links

for the configurations of the interface or for the data of the equipment.

In the interface configurations, you will find several fields to program IP address, subnet, DHCP, among others.

Figure 2.8: Webpage of interface configuration

The data mapped in the input/output (I/O) areas can also be accessed by means of the web browser through

the link “Parameter Data”. Through this page, it is possible to read the monitoring data, as well as to modify the

equipment control data.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 19

Figure 2.9: Web page with input/output data

NOTE!

If there is cyclic communication between the module and the master of the network, the control data

sent by the master will overwrite the data sent through this page. Thus, the commands sent by this

page will only be executed in case the module is in the offline state.

2.3.4 Configuration of the Communication

In order to configure and use the EtherNet/IP module, follow the steps below:

With the module installed, during the recognition stage, a warning message will be displayed on the product

HMI, and the MS and NS LEDs test routine performed. After this stage, the MS LED must turn on in green.

Observe the content of parameter P0723. Check if the module was recognized. The detection is done

automatically and does not require the user’s intervention.

Set the parameters as desired for the application:

Configurations of IP address and communication rate are explained in item 2.3.3.

I/O configuration: program in P0727 the number of words to be exchanged with the network master.

This same value must be set in the EtherNet/IP scanner. For this adjustment being complete, it is

necessary to program a value different from 0 (zero) in parameters P0728 to P0739 (see item 3).

Once the parameters are set, if any of the parameters described in the previous item are changed, it is

necessary to restart the equipment.

Once the equipment is set, it is necessary to configure the communication in the master of the network:

EDS file: register the EDS file in the network configuration file. The EDS configuration file is supplied in a CD

together with the product.

For the configuration of the master, besides the IP address used by the EtherNet/IP module, it is necessary

to indicate a number of the instances of I/O and the quantity of data exchanged with the master in each

instance. For the EtherNet/IP communication module, the following values must be programmed:

Input instance (input): 100

Output instance (output): 150

The EtherNet/IP module is described in the network as “Generic Ethernet Module”. Using these

configurations it is possible to program the master of the network to communicate with the equipment.

If everything is correctly configured, the NS LED of the module will be on in green. It is in this condition that

cyclic data exchange effectively occurs between the slave and the master of the network.

2.3.5 Access to Parameters – Acyclic messages

Besides the cyclic data communication, the EtherNet/IP protocol also defines a kind of acyclic telegram, used

especially in asynchronous tasks, such as parameter setting and configuration of the equipment. The table 2.6

brings the class, instance and attribute for the access of the parameters of the equipment.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 20

2.4 MODBUS TCP

2.4.1 MODBUSTCP-05 Accessory

WEG part number: 11550476.

Composed by the Anybus ABCC-EIT communication module,

mounting instructions and a “torx” screw driver for fixing the

module.

Standard RJ45 connector.

Connector

The Modbus TCP communication module has a standard female RJ45 connector (T-568A or T-568B).

Indications

Modbus TCP defines two LEDs for status indication: one for the communication module (MS) and another for

the network (NS).

The M

S LED indicates the conditions of the module itself. That is, whether it is able to work or not. Table 2.14

shows the possible states:

Table 2.14: Status of the Modbus TCP module

LED Status Description Comments

Off Without power supply -

Green Normal operation -

Red Serious fault.

Internal error of the module. Equipment must be

reinitialized.

Flashing red

Recoverable fault or c

onflict of IP

address

Internal error of the module, but the return to the

normal state occurs automatically after the cause of

the fault is corrected.

Check the IP addresses in the network.

Flashing green/red

Equipment performing self-diagnosis

It occurs during initialization.

The N

S LED indicates the conditions of the Modbus TCP network.

Table 2.15: Status of the Modbus TCP network

LED Status Description Comments

Off Without power supply or IP address

The software IPconfig must be used to configure the

communication module address.

Green Module is in Process Active or Idle state -

Flashing green Waiting for connections -

Red Major fault or conflict of IP address

Equipment must be reinitialized to exit the fault state.

Check the IP addresses in the network.

Flashing red

Timeout

The data exchange has been interrupted.

Flashing green/red

Equipment performing self-diagnosis

It occurs during initialization.

The

LINK LED indicates the state of the physical connection of the network, as well as the activity in the bus.

Table 2.16: Status of the connection

LED Status Description Comments

Off Without link Without connection, without activity

Green Link

Ethernet link established but without data exchange

between master and slave.

Flashing green Activity in the bus

It effectively indicates that there is data exchange

between the master and the slave.

2.4.2 Installation of the Ethernet Network

For the connection of the frequency inverter using the Ethernet interface, refer to item 2.3.2.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 21

2.4.3 Configuration of the Ethernet Interface

To configure the Ethernet interface of the communication module, refer to item 2.3.3.

2.4.4 Configuration of the Communication

In order to configure and use the Modbus TCP, follow the steps below:

With the module installed, during the recognition stage, a warning message will be displayed on the product

HMI, and the MS and NS LEDs test routine performed. After this stage, the MS LED must turn on in green.

Observe the content of parameter P0723. Check if the module was recognized. The detection is done

automatically and does not require the user’s intervention.

Set the parameters as desired for the application:

Configurations of IP address and communication rate are explained in item 2.3.3.

I/O configuration: program in P0727 the number of words to be exchanged with the network master.

For this adjustment being complete, it is necessary to program a value different from 0 (zero) in

parameters P0728 to P0739 (see item 3).

Once the parameters are set, if any of the parameters described in the previous item are changed, it is

necessary to restart the equipment.

Once the equipment is set, it is necessary to configure the communication in the master of the network:

Configure the master to access the Anybus I/O words as per the memory map presented in item 2.4.5.

To configure the timeout of the communication and order of the bytes, use the web browser according to

the figure 2.10.

Figure 2.10: Webpage with configuration of the timeout and order of the bytes

The field “Comm tmo” is used to configure the timeout of the TCP connection and the field Process tmo

allows to program the time for the detection of communication error.

The field “Word order” configures the order of the

bytes

of each word in

little endian

(byte 1 most significant)

or

big endian

(byte 0 least significant).

Connect the network cable to the module.

If everything is correctly configured, the NS LED of the module will be on in green and the LINK LED will

start to flash indicating normal activity in the network.

NOTE!

For further information on the parameters mentioned above, refer to item 3.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 22

2.4.5 Addressing of the data

Modbus TCP does not define a channel of cyclic data dedicated like in other networks. However, in the AnybusCompactCom module, the I/O words can be accessed by the network by means of dedicated registers.

The I

/O words can be accessed as bits (Coils and Discrete Inputs) or as registers of 16 bits (Holding Registers

and Input Registers).

The p

arameters of the drive can be accessed only as holding registers.

The M

odbus mapping is presented in the table below:

Table 2.17: Addressing for Holding Registers

Address range Description

0000h ... 00FFh Anybus Writing Words

0100h ... 01FFh Anybus Reading Words

0210h ... FFFFh

Parameters of the drive

To find the address of the register corresponding to

the parameter:

ADDR = 210h + (Parameter Number – 1)

Examp

le:

P0003 = 210h + (3h – 1h) = 212h

P0100 = 210h + (64h – 1h) = 273h

Table 2.18: Addressing for Input Registers

Address range Description

0000h ... 00FFh Anybus Reading Words

Table 2.19: Addressing for Coils

Address range Description

0000h ... 0FFFh Anybus Writing Words

Table 2.20: Addressing for Discrete Inputs

Bit address range Description

0000h ... 0FFFh Reading Words Anybus

NOTE!

Writings in reading words will have no effect, and the reading of not used registers will return to value

zero.

2.5 PROFINET

2.5.1 PROFINETIO-05 Accessory

WEG part number: 11550548.

Composed by the Anybus ABCC-EIT communication module,

mounting instructions and a “torx” screw driver for fixing the

module.

Two Standard RJ45 connectors.

Connector

The PROFINET IO communication module has two standard female RJ45 connectors (T-568A or T-568B). It

features integrated switch, enabling the connection in

daisy chain

.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 23

Indications

PROFINET IO defines two LEDs for status indication: one for the communication module (MS) and another for

the network (NS). Figure 2.11 describes the indication LEDs.

Figure 2.11: Description of the indication LEDs of the PROFINET module

The MS LED (2) indicates the conditions of the module itself. Table 2.21 shows the possible states:

Table 2.21: Status of the operating mode

Status Description COMMENTS

Off Without power supply -

Green Normal operation -

Flashing green - flashes

once

Present diagnosis No used.

Flashing green - flashes

twice

acknowledgement

Signaling used by an engineering tool to recognize

the equipment in the network.

Red Major fault

Internal error in the communication between the

Anybus-CC module

and drive (Exception).

Equipment must be reinitialized.

Flashing red - flashes once Configuration error

It indicated that the quantity of I/O words (or the

order of these words) was not correctly configured in

the master of the network.

Flashing red - flashes once IP address not configured

The software IPconfig must be used to configure the

communication module address or use the

PROFINET master to choose the automatic

configuration of the IP address.

Flashing red - flashes three

times

Station name not configured

The equipment must be configured in a PROFINET

network so that the station name is attributed by the

master of the network.

Flashing red - flashes three

times

Internal error Equipment must be reinitialized.

Flashing green/red

Equipment performing self-diagnosis

It occurs during initialization.

The NS LED (1) indicates the conditions of the PROFINET network.

Table 2.22: Status of the PROFINET network

LED Status Description Comments

Off Offline

Module without power supply

Without connection with the master of the network.

Green Online (RUN)

Connection with the master of the network

established.

Master of the network in RUN.

Flashing green Online (STOP)

Connection with the master of the network

established.

Master of the network in STOP.

The LINK LEDs (5 and 6) indicates the state of the physical connection of the network, as well as the activity in

the bus.

Table 2.23: Status of the connection

LED Status Description Comments

Off Without link Without connection, without activity.

Green Link

Ethernet link established but without data exchange

between master and slave.

Flashing green Activity in the bus

It indicates that there is data exchange between the

master and the slave.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 24

2.5.2 Installation of the Ethernet Network

For the connection of the frequency inverter using the Ethernet interface, refer to item 2.3.2.

2.5.3 Configuration of the Ethernet Interface

To configure the Ethernet interface of the communication module, refer to item 2.3.3.

2.5.4 Configuration of the Communication

In order to configure and use the PROFINET IO module, follow the steps below:

With the module installed, during the recognition stage, a warning message will be displayed on the product

HMI, and the MS and NS LEDs test routine performed. After this stage, the MS LED must turn on in green.

Observe the content of parameter P0723. Check if the module was recognized. The detection is done

automatically and does not require the user’s intervention.

Set the parameters as desired for the application:

Configurations of IP address and communication rate are explained in item 2.3.3.

I/O configuration: program in P0727 the number of words to be exchanged with the network master.

This same value must be set in the PROFINET master. For this adjustment being complete, it is

necessary to program a value different from 0 (zero) in parameters P0728 to P0739 (see item 3).

Once the parameters are set, if any of the parameters described in the previous item are changed, it is

necessary to restart the equipment.

Once the equipment is set, it is necessary to configure the communication in the master of the network:

GSD file: register the GSD file for PROFINET (GSDML) in the configuration software of the network. The

GSD configuration file is supplied in a CD together with the product. The module will be recognized as

“

Anybus CompactCom PRT 2-Port

” in the category “

General

”.

For the configuration of the master, the following points must be observed:

The same quantity of data set in the slave must be set in the master. These data must be programmed

observing the following order: first all input words and then all output words

;

The IP address of the slave can be configured manually (via IPconfig) or attributed automatically by the

PROFINET master (in case it has this function);

The network topology must be informed, indicating precisely the connections between the PROFINET

equipment.

NOTE!

For further information on the parameters mentioned above, refer to item 3.

2.5.5 Access to Parameters – Acyclic messages

Besides the cyclic communication, the PROFINET protocol also allows to perform acyclic requests used

especially to transmit diagnosis data, parameter setting and configuration of the equipment. For the drive which

uses the Anybus module, practically all the parameters can be accessed by means of this way of

communication.

The PROFINET protocol defines the following structures for the addressing of the components used in the

configuration of the network:

AR (Application Relation);

API (Application Process Identifier);

Slot;

Subslot.

AR and API are used to identify the Anybus module during the stage of configuration of the network.

Slot/Subslot are not relevant for acyclic access of the data for the drive. Once the module is identified, the

parameters are accessed indicating the Index and the size of the data (Length) accessed:

Index: it represents the number of the parameter;

Length: the size of the data accessed. All the parameters of the drive are accessed as Word (2 bytes).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 25

2.6 RS232

2.6.1 RS232-05 Accessory

WEG part number: 11008160.

Composed by the Anybus ABCC-

RS232 communication

module, mounting instructions and a “torx” screw driver for

fixing the module.

It allows transmission rates up to 57.6 kbps.

Connector Pin Function

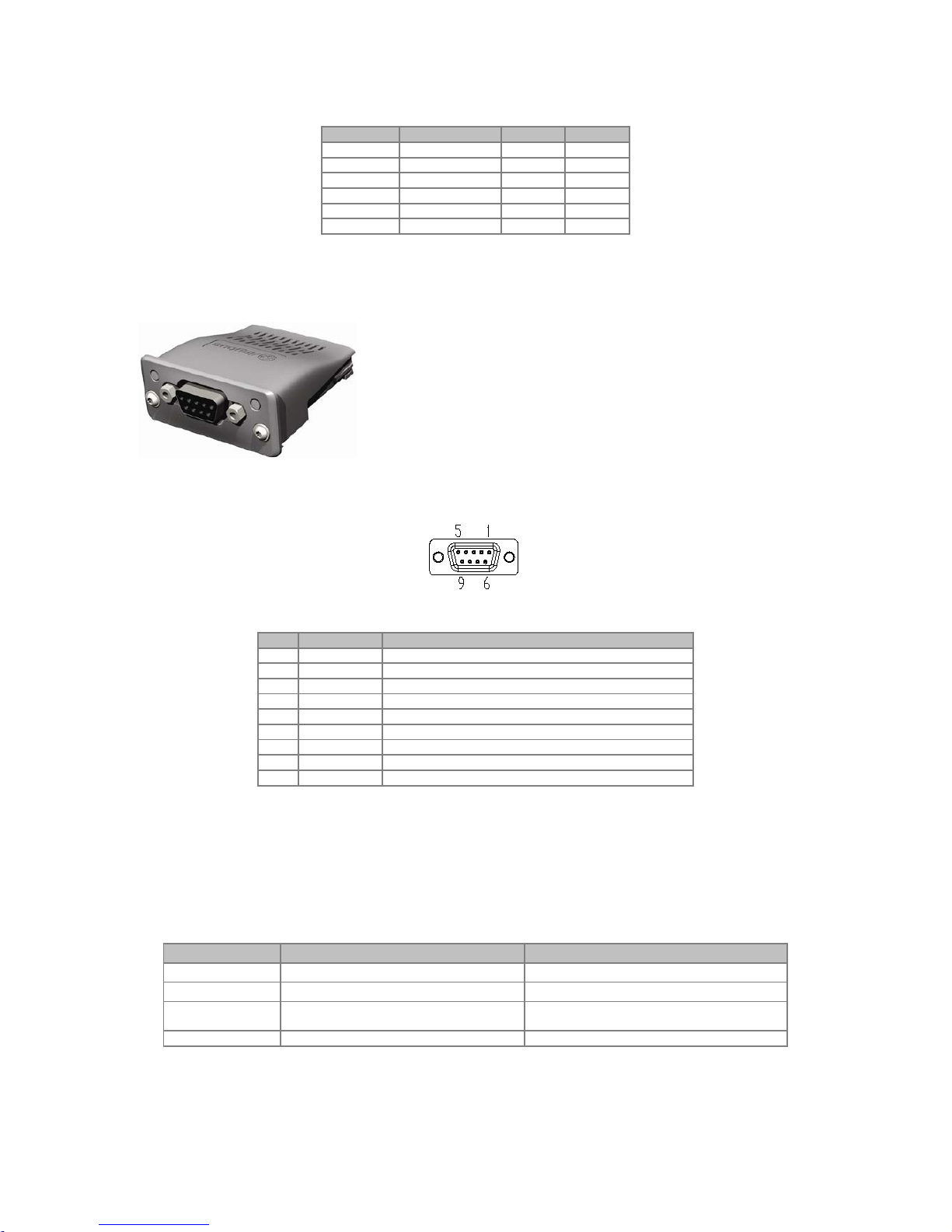

The RS232 communication module presents a male DB9 connector with the following pin assignment:

Table 2.24: RS232 DB9 male connector pin assignment

Pin Name Function

1

-

-

2

RxD

RS232 data reception

3

TxD

RS232 data transmission

4

- - 5

GND

Reference (0 V) of the interface

6

-

-

7

RTS

Request To Send

8

-

-

9

-

-

Indications

PWR LED: Green LED. When on, it indicates that the module is powered.

Connection with the Network

For the connection of the device using the passive RS232 interface, the following points must be observed:

Use good quality cables, preferably shielded.

Keep the cable length within the limits stipulated by the standard, normally about 10m.

Avoid passing the cables close to power cables.

2.7 RS485

2.7.1 RS485-05 Accessory

WEG part number: 11008161.

Composed by the Anybus ABCC-RS485, mounting instructions

and a “torx” screw driver for fixing the module.

It allows transmission rates up to 57.6 kbps.

Connector Pin Function

The RS485/422 interface module presents a female DB9 connector with the following pin assignment:

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 26

Table 2.25: RS485/422 female DB9 connector

Pin

RS422 Mode

RS485 Mode

Function

1

Term Pwr

Term Pwr

+5 V for active termination (isolated)

2

-

-

-

3

-

-

-

4

Mode Select

Mode Select

Not connected: RS485 mode

Connected to GND: RS422 mode

5

GND

GND

Reference (0 V) for the interface circuit (isolated)

6

RxD

-

Data reception line in RS422 mode

Not connected in RS485 mode

7

RxD (inverted)

-

8

TxD

RxD/TxD

Data transmission line in RS422 mode

Bidirectional data line in RS485 mode.

9

TxD (inverted)

RxD/TxD (inverted)

Indications

PWR LED: Green LED. When on, it indicates that the module is powered.

Connection with the Network

For the connection of the device using the passive RS485 interface, the following points must be observed:

Use

good quality shielded cables.

Keep the cable length within the limits stipulated by the standard, normally about 1000 meters.

Avoid passing the communication cables close to power cables.

Put termination resistors between the data signal wires (RxD/TxD and TxD/RxD) at the network extreme

nodes. This will avoid reflections in the line.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 27

3 PROGRAMMING

Next, only the CFW-11 frequency inverter parameters related to the Anybus-CC communication will be

presented.

3.1 SYMBOLS FOR THE PROPERTIES DESCRIPTION

RO

Read-only parameter

CFG

Parameter that can be changed only with a stopped motor

NET

Parameter visible on the HMI if the device has the network interface installed – RS232, RS485, CAN,

Anybus-CC, Profibus – or if the USB interface is connected

P0105 – 1ST/2ND RAMP SELECTION

P0220 – LOCAL/REMOTE SELECTION SOURCE

P0221 – SPEED REFERENCE SELECTION – LOCAL SITUATION

P0222 – SPEED REFERENCE SELECTION – REMOTE SITUATION

P0223 – FORWARD/REVERSE SELECTION – LOCAL SITUATION

P0224 – RUN/STOP SELECTION – LOCAL SITUATION

P0225 – JOG SELECTION – LOCAL SITUATION

P0226 – FORWARD/REVERSE SELECTION – REMOTE SITUATION

P0227 – RUN/STOP SELECTION – REMOTE SITUATION

P0228 – JOG SELECTION – REMOTE SITUATION

These parameters are used in the configuration of the command source for the CFW-11 frequency inverter local

and remote situations. In order that the device be controlled through the Anybus-CC interface, the options

‘Anybus-CC’ available in these parameters, must be selected.

The detailed description of these parameters is found in the CFW-11 programming manual.

P0313 – COMMUNICATION ERROR ACTION

Range: 0 = Inactive Default: 1

1 = Disable via Run/Stop

2 = Disable via General Enable

3 = Change to Local

4 = Change to Local keeping commands and reference

5 = Causes a Fault

Properties: CFG

Access groups 01 PARAMETER GROUPS

via HMI: ∟49 Communication

∟111 Status and commands

Description:

It allows the selection of the action to be executed by the device, if it is controlled via network and a

communication error is detected.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 28

Table 3.1: P0313 options

Options

Description

0 = Inactive

No action is taken and the drive remains in the existing status.

1 = Disable via Run/Stop

A stop command with deceleration ramp is executed and the

motor stops according to the programmed deceleration ramp.

2 = Disable via General Enable

The drive is disabled by removing the General Enabling and the

motor coasts to stop.

3 = Change to Local

The drive commands change to Local.

4 = Change to Local keeping

commands and reference

The drive commands change to Local, but the status of the

enabling and speed reference commands received via network

are kept, providing that the drive has been programmed to use in

Local mode the commands via HMI, or 3-

wire start/stop and

speed reference via either HMI or electronic potentiometer.

5 = Causes a Fault

Instead of an alarm, the communication error causes an drive

fault, so that a drive fault reset

becomes necessary in order to

restore normal operation.

The following events are considered communication errors:

Anybus-CC communication:

A129 alarm/F229 fault: Anybus is offline

A130 alarm/F230 fault: Anybus access error

The actions described in this parameter are executed by means of the automatic writing of the selected actions

in the respective bits of the interface control words. Therefore, in order that the commands written in this

parameter be effective, it is necessary that the device be programmed to be controlled via the used network

interface (with exception of option “Causes a Fault”, which blocks the equipment even if it is not controlled by

network). This programming is achieved by means of parameters P0220 to P0228.

P0680 – STATUS WORD

Range: 0000h to FFFFh Default: Properties: RO

Access groups 01 PARAMETER GROUPS

via HMI: ∟49 Communication

∟111 Status and commands

Description:

It allows the device status monitoring. Each bit represents a specific status:

Bits

15

14

13

12

11

10 9 8 7 6 5 4

3 to 0

Function

Fault condition

(PID) Automatic

Undervoltage

LOC/REM

JOG

Speed direction

Active General

Enable

Motor Running

Alarm condition

In configuration

mode

Second ramp

Active fast stop

Reserved

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 29

Table 3.2: P0680 parameter bit functions

Bits

Values

Bits 0 to 3

Reserved.

Bit 4

Active quick stop

0: The fast stop command is not active.

1: The drive is executing the fast stop command.

Bit 5

Second ramp

0: The drive is configured to use the first ramp values, programmed in P0100 and P0101, as the motor

acceleration and deceleration ramp times.

1: The drive is configured to use the second ramp values, programmed in P0102 and P0103, as the motor

acceleration and deceleration ramp times.

Bit 6

In configuration mode

0: The drive is operating normally.

1: The drive is in the configuration mode. It indicates a special condition during which the drive cannot be

enabled:

Executing the self-tuning routine

Executing the oriented start-up routine

Executing the HMI copy function

Executing the flash memory card self-guided routine

There is a parameter setting incompatibility

There is no power at the drive power section

Bit 7

Alarm condition

0: The drive is not in alarm condition.

1: The drive is in alarm condition.

Note: The alarm number can be read by means of the parameter P0048 – Present Alarm.

Bit 8

Motor Running

0: The motor is stopped.

1: The drive is running the motor at the set point speed, or executing either the acceleration or the

deceleration ramp.

Bit 9

Active General Enable

0: General Enable is not active.

1: General Enable is active and the drive is ready to run the motor.

Bit 10

Speed direction

0: The motor is running in the reverse direction.

1: The motor is running in the forward direction.

Bit 11

JOG

0: Inactive JOG function.

1: Active JOG function.

Bit 12

LOC/REM

0: Drive in Local mode.

1: Drive in Remote mode.

Bit 13

Undervoltage

0: No Undervoltage.

1: With Undervoltage.

Bit 14

Manual/ Automatic

0: PID in manual mode.

1: PID in Automatic mode.

Bit 15

Fault condition

0: The drive is not in a fault condition.

1: The drive has detected a fault.

Note: The fault number can be read by means of the parameter P0049 – Present Fault.

P0681 – MOTOR SPEED IN 13 BITS

Range: - 32768 to 32767 Default: Properties: RO

Access groups 01 PARAMETER GROUPS

via HMI: ∟49 Communication

∟111 Status / Commands

Description:

It allows monitoring the motor speed. This word uses 13-bit resolution with signal to represent the motor

synchronous speed:

P0681 = 0000h (0 decimal) → motor speed = 0

P0681 = 2000h (8192 decimal) → motor speed = synchronous speed

Int

ermediate or higher speed values in rpm can be obtained by using this scale. E.g. for a 4 pole motor and

1800 rpm of synchronous speed if the value read is 2048 (0800h), then, to obtain the speed in rpm one must

calculate:

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 30

8192 => 1800 rpm

2048 => Speed in rpm

Speed in rpm = 1800 × 2048

8192

Speed in rpm = 450 rpm

Negative values in this parameter indicate that the motor is running in the reverse direction.

P0686 – ANYBUS-CC CONTROL WORD

Range: 0000h to FFFFh Default: 0000h

Properties: Access groups 01 PARAMETER GROUPS

via HMI: ∟49 Communication

∟111 Status and commands

Description:

It is the device Anybus-CC interface control word. This parameter can only be changed via Anybus-CC

interface. For the other sources (HMI, etc.) it behaves like a read-only parameter.

In order to have those commands executed, it is necessary to program the equipment to be controlled via