WEG CFW100A01P6S220, CFW100C04P2S220, CFW100B02P6S220 Quick Installation Manual

Quick Installation Guide

CFW100 Micro Drive

1 SAFETY INSTRUCTIONS

This quick ins tallation guide c ontains the basic i nformation nec essary to commi ssion the CFW100. It has

been writte n to be used by qualifi ed personnel w ith suitable tr aining or techni cal qualifica tion for operati ng

this type of equ ipment. The personnel sh all follow all the safety inst ructions described in th is manual

defined by the loc al regulations. F ailure to comply wi th the safety instr uctions may resul t in death, serious

injury, and/or equipment damage.

2 SAFETY WAR NINGS IN THE MANUAL

NOTE!

It is not the intenti on of this guide to present a ll the possibilitie s for the application of th e

CFW100, as well as WEG c annot take any liabil ity for the use of the CF W100 which is not

based on this guide.

For further information about installation, full parameter list and recommendations, visit the

website www.weg.net.

DANGER!

The procedur es recommended in this war ning have the purpose of protec ting the user

against death, serious injuries and considerable material damage.

ATTENTION!

The procedur es recomme nded in this wa rning have the p urpose of avoi ding materia l damage.

NOTE!

The informati on mentioned in this wa rning is important f or the proper underst anding and

good operation of the product.

High voltage s are present.

Components sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to the protective ground (PE).

Connection of the shield to the ground.

3 PRELIMINARY RECOMMENDATIONS

DANGER!

Always disconnect the main power supply before touching any electrical component

associated to th e inverter. Several comp onents can remain c harged with high vol tages or

remain in movem ent (fans) even af ter the AC power is disc onnected or swi tched off. Wait at

least ten minu tes after turning of f the input power fo r the complete disch arge of the power

capacitors. Always connect the grounding point of the inverter to the protection earth (PE).

Connectors XCA and XCB do not present USB compatibility; therefore, they cannot be

connected to USB doors.

These conne ctors serve only as inter face between the CFW100 freq uency inverter and

its accessories.

NOTE!

Frequency Inve rter may interfere w ith other electronic e quipment. Follow the pr ecautions

recommended in manual available in www.weg.net.

Do not perfo rm any withstan d voltage test!

If necessary, contact the manufacturer.

ATTENTION!

Electronic boards have components sensitive to electrostatic discharges.

Do not touch directly on components or connectors. If necessary, first touch the grounding

point of the inver ter, which must be con nected to the protecti on earth (PE) or us e a proper

grounding strap.

ATTENTION!

When the inver ter is stored for a l ong period, i t becomes ne cessary to p erform the c apacitor

reforming. Ref er to the procedure re commended in www.weg.net.

4 ABOUT THE CF W100

The CFW100 frequency inverter is a high-performance product which allows speed and torque

control of three-phase induction motors. This product provides the user with the options of vector

(VVW ) or scalar (V/f) control, both programmable according to the application.

5 TERMINOLOGY

Table 1: Terminology of th e CFW100 inverters

Product

and

Series

Model Identification

Degree of

Protection

Hardware

Version

Software

Version

Frame

Size

Rated

Current

Phase

Number

Rated

Voltage

E.g.: CFW10 0 A 01P6 S 2 20 --- ---

Available options

CFW100

A 01P6 = 1.6 A

S = single-phase

supply

2 = 200...240 V

Blank =

standard

B 02P6 = 2.6 A

Sx =

special

software

C 04P2 = 4.2 A

20 = IP20

Blank = standard

Hx = special hardware

6 RECEIVING AND STORAGE

The CFW100 is supp lied packed in a card board box. There is an i dentification la bel affixed to the out side

of the package, id entical to the one af fixed to the side of the inv erter.

Verify whether:

The CFW100 ident ification labe l corresponds to th e purchased mode l.

Any damage occurred during transportation.

Report any damage immediately to the carrier.

If the CFW100 is not in stalled soon, store it i n a clean and dry lo cation (temperatur e between -25 ºC and

60 ºC (-13 ºF and 140 ºF)), with a cover to p revent dust accumu lation inside it.

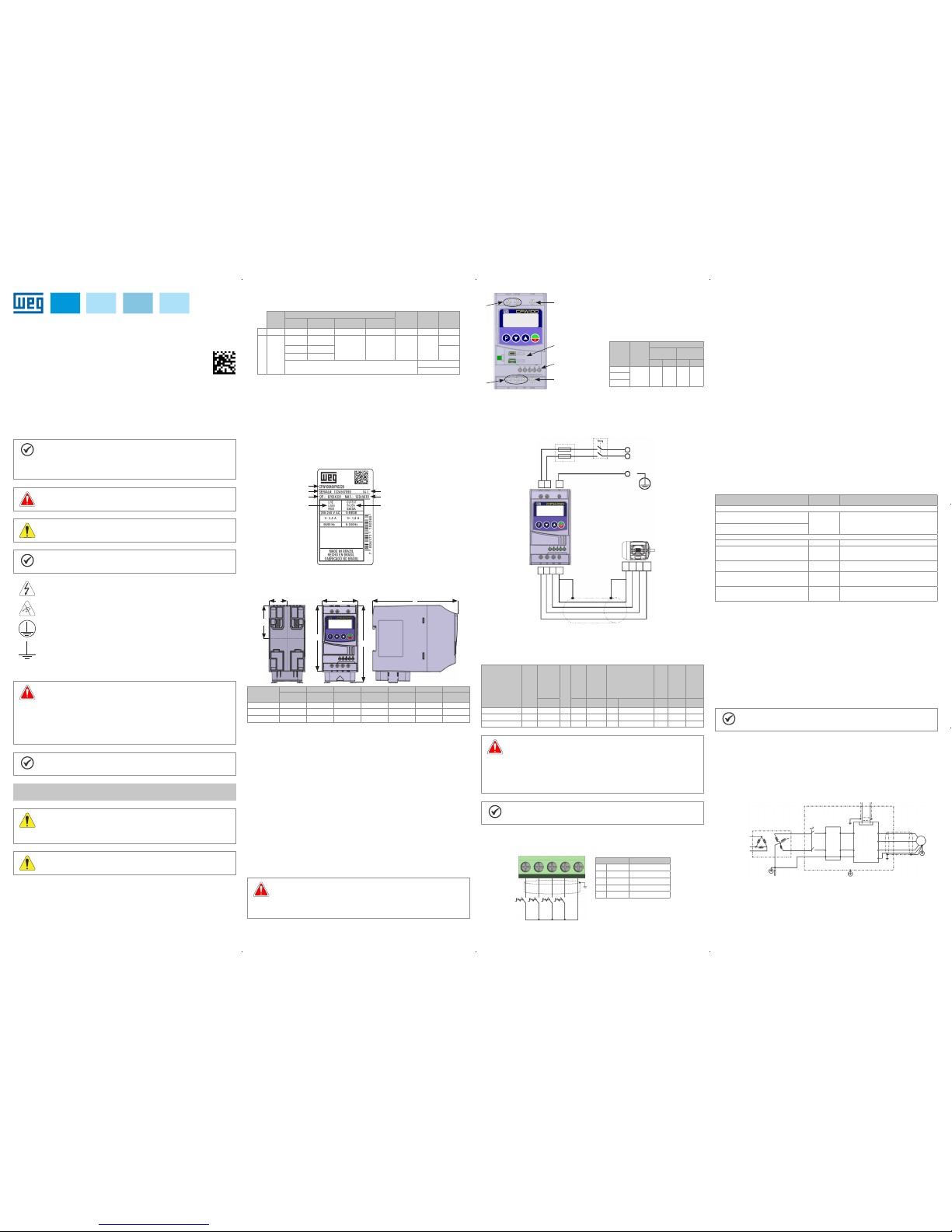

7 IDENTIFICATION LABEL

Production order

Rated input data

(voltage, curren t and

frequency)

Serial number

Manufacturing date (14 corresponds

to the week and I to the year )

Rated output data

(voltage, curren t and frequency)

WEG stock item

Model (Inverte r

intelligent code)

Figure 1: Description of the CFW100 ident ification labe l

8 DIMENSIONS

VIEW OF THE MOUNTI NG BASE

FRONT VIEW

SIDE VIEW

PLB

A

H1

H2

Frame

Size

A B H1 H2 L P Weight

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

mm

(in)

kg

(lb)

A 50 (1.97 ) 28 (1 .10) 100 (3.94) - 5 5 (2 .17) 129 (5.08 ) 0.48 (1. 05)

B 50 (1.97 ) 28 (1.1 0) - 117 (4.6 0) 5 5 (2 .17) 129 ( 5.08 ) 0.57 (1.25)

C 50 (1.97 ) 28 (1.1 0) - 125 .6 (4.9 4) 5 5 (2 .17) 129 (5.08 ) 0.61 (1. 34)

Dimension tolerance: ±1,0 mm (±0,039 in)

Figure 2: Inverter dimensions for mechanical installation

9 INSTALLATION AND CONNECTION

Environmental Conditions

Avoid:

Direct expos ure to sunlight, rain, h igh humidity or s ea-air.

Inflammable or corrosive gases or liquids.

Excessive vibration.

Dust, metalli c particles or oi l mist.

Environment conditions permitted for the operation of the inverter:

Temperature surr ounding the inver ter: 0 ºC to 50 ºC ( 32 ºF to 122 ºF) – I P20.

For temperatur es surroundin g the inverter hig her than the spec ifications above , it is necessar y to apply

of 2 % of current der ating for each degr ee Celsius, limite d to an increase of 10 ºC (50 º F).

Air relative hu midity: 5 % to 95 % non-c ondensing.

Maximum al titude: up to 1000 m (3.300 f t) - rated condition s.

From 1000 m to 4000 m (3.3 00 ft to 13.200 ft) – 1 % of curren t derating for each 100 m above 1000 m

of altitude.

Pollution deg ree: 2 (according to EN5 0178 and UL508C), with non-co nductive pollu tion. Condensa tion

must not originate conduction through the accumulated residues.

10 ELECTRICAL INSTALLATION

DANGER!

The following information is merely a guide for proper installation. Comply with applicable

local regulations for electrical installations.

Make sure the AC power supply is disconnected before starting the installation.

T he CFW100 must not be used as a n emergency stop device . Provide other devices

for that purpose.

1

1

2

2

4

3

1 - Power terminals

2 - Grounding points

3 - Accessory

connectors

4 - Control termina ls

Frame

Size

Power

Supply

Recommended Torque

Grounding

Points

Power

Terminals

N.m Lbf.in N.m Lbf.in

A

200...

240 V

1.4 12.4 1.4 12.4B

C

Figure 3: Power terminals, grounding points and recommended tightening torque

10.1 POWER CONNECTIONS

Descriptio n of the power terminal s:

L/L1 and N/L2 : AC power supply must b e connected to L/ L1 and N/L2.

U, V and W: connection for the motor.

PE: grounding connection.

Shield

PE

PEL2L1

Disconnecting

switch

Fusibles

Power supply

PE W V U

L1/L

L2/N

U V W PE

Figure 4: Power and grounding connections

The CFW100 is suit able for application in a ci rcuit able to supply not more th an 30.000 symetric A

rms

maximum of 240V, when p rotected by fuses cla ssified as indica ted below:

Table 2: List of mode ls of CFW100 series, ma in electrical s pecification s

Inverter

Number of Input

Phases

Power Supply

Rated

Voltage

Frame Size

Output

Rated

Current

Maximum

Motor

Circuit

Breaker

Recommended

J Type Fuse

Power Wire

Size

Grounding

Wire Size

[Vrms] [Arms] [HP/ kW] [A] WEG [A]

mm2

(AWG)

mm2

(AWG)

CFW100A01P6S220 1 200 ... 240 A 1.6 0.25/0.18 5.5 MPW25-3-D063 6 1. 5 (16) 2.5 (14)

CFW100 B02P6 S220 1 2 00 ... 240 B 2.6 0.5/0.37 9.0 MPW25-3-U010 10 1.5 (16 ) 2.5 (14)

CFW100C04P2S220 1 20 0 ... 240 C 4.2 1/0.75 13.5 MPW25-3-U016 17.5 1.5 ( 16) 2.5 (14)

DANGER!

The inverter m ust be connected to a p rotective ground (PE ).

Use a minimum wi re gauge for ground c onnection equa l to the indicated in Table 2.

Connect the inverter grounding connections to a ground bus bar, to a single ground point

or to a common grou nding point (impe dance ≤ 10 Ω).

The neuter con ductor of the line tha t feeds the inverte r must be solidly g rounded; however

this conducto r must not be used to grou nd the inverter.

Do not share the gr ounding wiring with oth er equipment that opera te with high currents

(e.g.: high voltage moto rs, welding machi nes, etc.).

NOTE!

The wire gauge s listed in Table 2 are g uiding valu es. Installa tion conditi ons and the ma ximum

permitted voltage drop must be considered for the proper wiring sizing.

10.2 CONTROL CONNECTIONS

DI11DI2

2

S2S1 S3 S4

DI33DI4

GND

4 5

Connector Description

(**)

1 DI1 Digital input 1

2 DI2 Digital input 2

3 DI3 Digital input 3

(*)

4 DI4 Digital input 4

5 GND Reference 0 V

(*) The digital input 3 (DI3) can also be used as input in fre quency (FI).

Figure 5: Signals of control card co nnector of the C100A-20

For the corr ect connec tion of the con trol, use:

1. Gauge of the cable s: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG).

2. Maximum torqu e: 0.5 N.m (4.50 lbf.in).

3. Wiring of the co nnector of the control bo ard with shielded ca ble and separated from t he other wiring

(power, command in 110 V / 220 Vac, etc.)

10.3 INSTALLATIONS ACCORDING TO EUROPEAN DIRECTIVE OF ELECTROMAGNETIC

COMPATIBILITY

The CFW100 inver ter series, wh en properly ins talled, meet th e requirements o f the directive of th e

electromagnetic compatibility.

These inverters were developed for professional applications only. Therefore, the emission limits of

harmonic cur rents by the standa rds EN 61000-3-2 and EN 61000 -3-2/A 14.

10.3 .1 Conformal Installation

1. Shielded outpu t cables (motor c ables) with shi eld connecte d at both ends, moto r and inverter, by mea ns

of a low impedanc e to high frequency conn ection. Maximum moto r cable length and cond uced and

radiated emission levels according to Table 5. For more information (RFI filter commercial reference,

motor cable len gth and emission l evels) refer to the Table 5.

2. Shielded control cables, keeping the separation distance from other cables according to Table 3.2 the

user's manual.

3. Grounding of th e inverter acc ording to instr uction of the 3.2.4 Gro unding Conn ections the us er's manual.

4. Grounded powe r supply.

5. The inverter a nd external fil ter must be mounted on a c ommon metal plate.

6. The wiring be tween filter and i nverter must be as s hort as possibl e.

7. The grounding must be done according to recommendation of the CFW100 user's manual.

8. Use short wi ring to ground the exte rnal filter or inve rter.

9. Ground the moun ting plate using a flexible br aid as short as possible. Fl at conductors have lower

impedance at high frequencies.

10. Use sleeves for cable conduits whenever possible.

10.3.2 Emission and Immunity Levels

Table 3: Emission and immunity levels

EMC Phenomenon

Basic

Standard

Level

Emission:

Mains terminal disturbance voltage

Frequency range: 150 kH z to 30 MHz)

IEC/EN 61800-3

It depends on the in verter model on th e length of the

motor cable. Refer to Table 5

Electromagnetic radiation disturbance

Frequency Rang e: 30 MHz to 1000 MHz)

Immunity:

Electrostatic discharge (ESD) IEC 61000-4-2 4 kV fo r contact discha rge and 8 kV for air disc harge

Fast transient-Burst IEC 61000-4-4

2 kV / 5 kHz (coupling ca pacitor) input ca bles

1 kV / 5 kHz control cabl es and remote HMI ca bles

2 kV / 5 kHz (coupling ca pacitor) motor cab les

Imunidade conduzida ("Conducted radiofrequency common mode")

IEC 61000-4-6

0.15 to 80 MHz; 10 V; 80 % AM (1 kHz)

Motor, control and HMI cables

Surges IEC 61000-4-5

1.2/50 μs, 8/20 μs

1 kV line-to-line coupling

2 kV line-to-ground coupling

Radio-frequency electromagnetic field IEC 61000-4-3

80 to 1000 MHz

10 V/m

80 % AM (1 kHz)

Definiti on of Standar d IEC/EM 61800 -3: “Adjusta ble Speed El ectrical Pow er Drives Sys tems”

Environments:

First Environment: environments that include domestic installations, as well as establishments directly

connected without intermediate transformer to a low-voltage power supply network which supplies

buildings used for domestic purposes.

Second Environment: includes all establishments other than those directly connected to a low voltage

power supply network that supplies buildings used for domestic purposes.

Categories:

Category C1: inverters with a vol tage rating le ss than 1000 V and i ntended for us e in the First Env ironment.

Category C2: inverters wit h a voltage rating less t han 1000 V intended for us e in the First Environm ent,

not provided with a plug connector or movable installations. They must be installed and commissioned by

a professional.

NOTE!

A professional is a person or organization familiar with the installation and/or commissioning

of inverters, i ncluding their EM C aspects.

Category C3: inverters w ith a voltage rating le ss than 1000 V and inten ded for use in the Sec ond

Environment only (not designed for use in the First Environment).

10.3.3 Characteri stics of the R FI Filter

The CFW100 inver ters, when installed wit h external filter, are used to reduc e the conducted from the

inverter to the po wer line in the high f requency band (>150). It is neces sary to meet the ma ximum levels of

conducted emission of electromagnetic compatibility standards, such as EN 61800-3 and EN 55011.

For further i nformation abou t the RFI filter model, re fer to Table 4.

The figure below demonstrate the connection of the filter to the inverter:

Protective ground

Metal panel (when necessary)

Grounding

rod

External

input

RFI filter

PE

PE

PE

W

V

U

Signal and control wiring

Transformer

L1/L L1

L1/L

1...5

XC1

PE PE

L2/N L2 L2/N

CFW100

Motor

Power supply

Figure 6: Connection of the RFI fil ter - general con ditions

English

13230 453

Table 4: Exter nal RFI filter mod els for CFW100

WEG Item Name Description

13128410 CFW100-KFABC External RFI filte r kit WEG

- - Filter B84142A0010R000 Epco s (*)

(*) For Electrodiagnostica Radiation Disturbance use choke (T60006- L2016-W403 – VACUUMSCHMELZE).

Table 5: Conducte d and radiated emis sion levels, and add itional informa tion

Inverter Model

Conducted Emission – Maximum Motor Cable

Length

Radiated Emission

Category C2 Category C3 Category C3

1 CFW100A01P6S220

1 m (39 in) 10 m (393 in) 10 m (393 in)

2 CFW 100B02 P6S220

3 CFW100C04P2S220

(1) The switchi ng frequency is 5 KH z.

10.4 ACCESSORIES

The accesso ries are hardware r esources that ca n be added in the appli cation with the CF W100.

The accesso ries are inco rporated to the inve rters in an ea sy and quick way by us ing the conce pt “Plug and

Play”. The accesso ry must be install ed or modified with the i nverter de-ener gized. They may be orde red

separately, and a re sent in their own package con taining the components an d manuals with detailed

instructions for their installation, operation and setting.

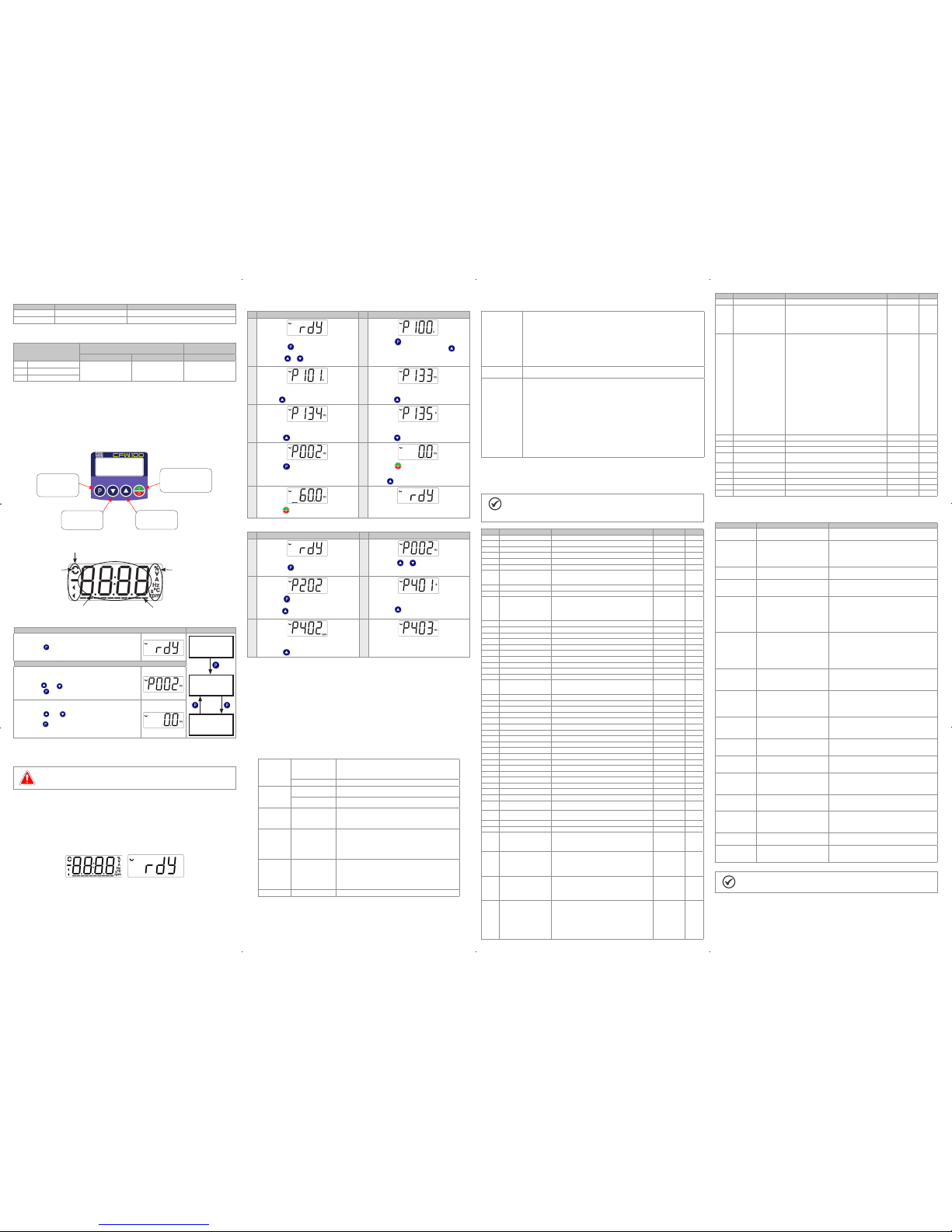

11 USE OF THE K EYPAD TO OPERATE THE INV ERTER

Selects (toggles)

display between th e

parameter number

and its value (position/

content).

Decreases the

frequency, parameter

number or parameter

value.

Increases the

frequency, parameter

number and parameter

value.

Enables/disables the inverter

via acceleration/deceleration

ramp (start/stop, according to

P229). Resets the inver ter after

a fault event.

11.1 INDICATIONS OF DISPLAY

Inverter status

Direction of

rotation

Unit of measurement

(it refers to the valu e

of the main display)

Bar to monitor

the variable

Main display

11.2 OPERATING MODES OF THE HMI

Initialization Mode

It is the initial state o f the HMI after i ts successf ul power-up (with out

the occurrence of faults, alarms or undervoltage).

Press key to go to level 1 o f the parameterization mo de –

selection of par ameters. Pressi ng any other key also sw itches to

parameterization mode.

Monitoring

Parameterization

Level1

Parameterization

Level 2

Parameterization Mode

Level 1:

This is the first le vel of the param eterization m ode. The para meter

number is shown on the main display.

Use keys and to fin d the desired para meter.

Press key to go to level 2 o f the parameterization mo de -

change of the para meter values.

Level 2:

The parameter val ue is shown on the mai n display.

Use keys and to s et the new value in the selected

parameter.

Press key to confi rm the modification (s ave the new value).

After confirm ing the modifi cation, the HMI re turns to level 1 of the

parameterization mode .

Figure 7: HMI operating modes

12 START-UP PREPARATION

DANGER!

Always disconnect the main power supply before making any connection.

1. Check if the power, grounding and control connections are correct and firm.

2. Remove all the mate rials left beh ind from the install ation work from ins ide the inverter or t he cabinet.

3. Verify the moto r connections an d if its voltage and cu rrent are within the i nverter rated valu e.

4. Mechanica lly uncouple the motor from th e load. If the motor cannot be unc oupled, make sure that

any speed dire ction (forward or r everse) will not resu lt in personnel i njury and/or equ ipment damage.

5. Close the inver ter or cabinet cove rs.

6. Measure the po wer supply and ver ify if it is within th e allowed range.

7. Apply power to the input: c lose the input disc onnecting switc h.

8. Check the res ult of the first time p ower-up:

The HMI display indicates:

12.1 BASIC APPLICATION

The following table contains the basic programming to operate the CFW100 via product HMI:

Seq Display Indication/Action Seq Display Indication/Action

1

2

Initialization mode.

Press key to enter the fir st level of the

parameterization mode.

Press keys or to se lect the para meter P100.

Press key if you need to change t he content of

P100 – “Acceleration Tim e” or press key for the

next parameter.

3 4

If necessar y, change the conte nt of “P101 -

Deceleration Time”.

Use key to select the parameter P133.

If necessar y, change the conten t of “P133 - Minimum

Spe ed”.

Press key for the next parameter.

5 6

If necessar y, change the conte nt of “P134 - Maximu m

Spe ed”.

Press key for the next parameter.

If necessar y, change the content of “P135 - Outpu t

Maximum Current”.

Press key to select parameter P 002.

7 8

Press key to view the parameter c ontent.

Press key that the motor will accel erate up to

3.0 Hz (factory defau lt setting of P133 - Minimum

Frequenc y).

Press an d hold it until it reac hes 60.0 Hz.

9 10

Press key . The motor will decel erate to a stop.

When the motor stops, th e display will indicate

“rea dy”.

12.2 TY PE OF CONTROL V/f (P 202 = 0)

Seq Display Indication/Action Seq Display Indication/Action

1

2

Initialization mode.

Press key to enter the fir st level of the

parameterization mode.

Press keys or to se lect parameter P2 02.

3

4

Press key if you need to change t he content of

“P202 – Type of Control” for P2 02 = 0 (V/f).

Press key to select paramete r P401.

If necessary, cha nge the conten t of parameter “P401

– Motor Rated Current ” according to the n ameplate.

Press key for the next parameter.

5

6

If necessar y, change the content of “P402 - Motor

Rated Speed”.

Press key for the next parameter.

If necessar y, change the content of “P403 - Motor

Rated Frequency”.

13 TECHNICAL SPECIFICATIONS

POWE R DATA

Power Supply:

Tolerance: -15 % to +10 %.

Frequency: 50/6 0 Hz (48 Hz to 62 Hz).

Phase imbala nce: ≤ 3 % of the rated phase -to-phase input vol tage.

Overvolta ge according to Categ ory III (EM 61010/UL 508C).

Transient voltages according to Category III.

Maximum of 10 con nections per hou r (1 every 6 minutes).

Typical effic iency: ≥ 97 %.

14 ELECTRONICS/GENERAL DATA

Table 6: Electronics/general data

Control Method Types of control:

- V/f (Scalar)

- VVW: voltage vector control

PWM SVM (Space Vector Modulation)

Output frequency 0 to 300 Hz, res olution of 0.1 Hz

Performance V/f Control Speed reg ulation: 1 % of the rated s peed (with slip co mpensation)

Speed variatio n range: 1:20

Vector control (VVW) Spe ed regulation: 1 % of the r ated speed

Speed variatio n range: 1:30

Inputs Digital 4 isolated inputs

Maximum inpu t voltage of 30 Vdc

Input current: - 11 mA

Maximum inpu t current: -20 mA

Safety Protection Output overcurrent/short-circuit

Under/overvoltage

Motor overload

Overtempera ture in the power modu le (IGBTs)

Fault / external a larm

Programming error

Integral keypad

(HMI)

Standard keypad 4 keys: Start/Stop, Up a rrow, Down arrow and Prog ramming

LCD Display

View/edition of parameters

Indication accuracy:

- current: 5 % of the rated c urrent

- speed resoluti on: 0.1 Hz

Enclosure IP20 Fra me Sizes A, B and C

15 CONSIDERED STANDARDS

Table 7: Considered standards

Safety

standards

UL 508C - power conver sion equipmen t

UL 840 - insulation coordination including clearances and creepage distances for electrical

equipment

EN61800-5-1 - safety requirements electrical, thermal and energy

EN 50178 - electronic equip ment for use in power in stallations

EN 60204-1 - safety of machi nery. Electric al equipment of ma chines. Part 1: gen eral requireme nts

Note: the final assem bler of the machine is re sponsible for insta lling a safety stop dev ice and a

supply disconnecting device

EN 60146 (IEC 146) - semiconducto r converters

EN 61800-2 - adjustabl e speed elec trical power d rive systems - Pa rt 2: genera l requireme nts - rating

specifications for low voltage adjustable frequency AC power drive systems

Mechanical

standards

EN 60529 - degrees of pr otection provide d by enclosures (IP c ode)

UL 50 - enclosures f or electrical eq uipment

Electromagnetic

compatibility

(EMC)

standards

(*)

EN 61800-3 - adjustabl e speed electrical p ower drive systems - part 3: EM C product standard

including specific test methods

EN 55011 - limits and methods of me asurement of radi o disturbance cha racteristics of ind ustrial,

scientific and medical (ISM) radio-frequency equipment

CISPR 11 - industrial, scie ntific and medical ( ISM) radio-frequenc y equipment - electro magnetic

disturbance ch aracteristics - l imits and methods of m easurement

EN 61000-4-2 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 2: electrostatic discharge immunity test

EN 61000-4-3 - electr omagnetic co mpatibilit y (EMC) - part 4: test ing and measu rement techn iques

- section 3: radiated, radio-frequency, electromagnetic field immunity test

EN 61000-4-4 - electr omagnetic co mpatibilit y (EMC) - part 4: test ing and measu rement techn iques

- section 4: electrical fast transient/burst immunity test.

EN 61000-4-5 - electr omagnetic co mpatibilit y (EMC) - part 4: tes ting and measu rement techn iques

- section 5: surge imm unity test.

EN 61000-4-6 - elect romagnetic co mpatibilit y (EMC) - part 4: tes ting and measu rement techn iques

- section 6: immuni ty to conducted dis turbances, indu ced by radio-freq uency fields.

(*) Standards met with t he installation of t he external RFI fil ter. For further detai ls refer to www.weg.net.

16 MAIN PAREMETERS

The table bel ow contains the mai ns parameters of the C FW100.

NOTE!

ro = read only para meter.

V/f = parameter avai lable in V/f mode.

cfg = configur ation parameter, value c an only be change d with the motor stoppe d.

Param. Description Adjustable Range Factory Setting Prop.

P000 Access to Parameters 0 to 9999 1

P001 Speed Reference 0 to 9999 ro

P002 Outpu t Speed (Motor) 0 to 9999 ro

P003 Motor Current 0.0 to 10.0 A ro

P004 DC Link Vo ltage (Ud) 0 to 524 V ro

P005 Outpu t Frequency (Motor) 0.0 to 3 00.0 Hz ro

P006 Inverter Statu s 0 = Ready

1 = Run

2 = Undervoltage

3 = Fault

4 = Not Used

5 = Configuration

ro

P007 Output Voltage 0 to 240 V ro

P011 Active Current -10.0 to 10.0 A ro

P012 DI8 to DI1 Status 0 to FF (hexa)

Bit 0 = DI1

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

ro

P022 FI Value in H z 1 to 3000 Hz ro

P023 Main SW Ver sion 0.00 to 99.99 ro

P030 Module Temperature -200.0 to 200.0 ºC ro

P037 Moto r Overload Ixt 0.0 to 100.0 % ro

P047 CONFIG Status 0 to 999 ro

P048 Present Alarm 0 to 999 ro

P049 Present Fault 0 to 999 ro

P050 Last Fa ult 0 to 999 ro

P100 Acceleration Time 0.1 to 999.9 s 5.0

P101 D eceleration Time 0.1 to 999.9 s 10.0

P120 Speed Ref. Backup 0 = Inactive

1 = Active

2 = Backup by P121

1

P121 Reference via HMI 0.0 to 300.0 Hz 3.0 H z

P124 Multispeed Ref. 1 -300.0 to 300.0 Hz 3.0 Hz

P125 Multispeed Ref. 2 -300.0 to 300.0 Hz 10.0 (5.0) Hz

P126 Multispeed Ref. 3 -300.0 to 300.0 Hz 20.0 (10.0) Hz

P127 Multispeed Ref. 4 -300.0 to 300.0 Hz 30.0 (20.0) Hz

P128 Multispeed Ref. 5 -300.0 to 300.0 Hz 40.0 (30.0) Hz

P129 Multispeed Ref. 6 -300.0 to 300.0 Hz 50.0 (40.0) Hz

P130 Multispeed Ref. 7 -300.0 to 300.0 Hz 60.0 (50.0) Hz

P131 Multispeed Ref. 8 -300.0 to 300.0 Hz 66.0 (55.0) Hz

P133 Minimum Frequency 0.0 to 300.0 Hz 3.0 Hz

P134 Maximum Frequency 0.0 to 300.0 Hz 66.0 (55.0) Hz

P135 Maximum Output Current 0.0 to 10.0 A 1.5xI

nom

P136 Manual Torque Boost 0.0 to 30.0 % 0.0 % V/f

P137 Automatic Torque Boost 0.0 to 30.0 % 0.0 % V/f

P138 Slip Compensation -10.0 to 10.0 % 0.0 % V/f

P139 Output Current Filter 0 to 9.999 s 0.005 s

P140 Slip Com. Filter 0 to 9.999 s 0.5 s VVW

P142 Maximum Output Voltage 0.0 to 100.0 % 100 .0 % cf g, V/f

P143 Intermediate Output

Voltage

0.0 to 100.0 % 50.0 % cfg, V/f

P145 Field Weakening Start

Frequency

0.0 to 300.0 Hz 60.0 (50.0) Hz cfg, V/f

P146 Intermediate Frequ ency 0.0 to 30 0.0 Hz 30.0 (25.0) Hz c fg, V/f

P156 Overload Current 0.1 to 2xI

nom

1.2xI

nom

P202 Type of Contr ol 0 = V/f

1 = V/f Quadratic

2 to 4 = Not Used

5 = VV W

0 cfg

P204 Load/Save Parameters 0 to 4 = N ot Used

5 = Load 60 Hz

6 = Load 50 Hz

7 = Load User

8 = Not Used

9 = Save User

10 = Not Used

11 = Load Default SoftPLC

12 to 13 = Reserved

0 cfg

P220 LOC/REM Selection

Source

0 = Always Local

1 = Always Remote

2 to 3 = Not Used

4 = DIx

5 = Serial/USB (LOC )

6 = Serial/USB (R EM)

7 to 8 = Not Used

9 = CO/DN (LOC)

10 = CO/DN (REM)

11 = SoftPLC

0 cfg

P221 LOC Reference Sel. 0 = HMI Keys

1 = AI1

2 to 3 = Not Used

4 = FI

5 to 6 = Not Used

7 = E.P.

8 = Multispeed

9 = Serial/USB

10 = Not Used

11 = CO/DN

12 = SoftPLC

13 = Not Used

14 = AI1 > 0

15 to 16 = Not Used

17 = FI > 0

0 cfg

Param. Description Adjustable Range Factory Setting Prop.

P222 REM Refer ence Sel. See opti ons in P221 2 cfg

P223 LOC Rotation Sel. 0 = Always FWD

1 = Always REV

2 = Not Used

3 = Not Used

4 = DIx

5 = Serial/USB (F WD)

6 = Serial/USB (R EV)

7 to 8 = Not Used

9 = CO/DN (FWD)

10 = CO/DN (REV)

11 = Not Used

12 = SoftPLC

0 cfg

P263 DI1 Input Function 0 = Not Used

1 = Run/Stop

2 = General Enabl e

3 = Quick Stop

4 = Forward Run

5 = Reverse Run

6 = Start

7 = Stop

8 = FWD/REV

9 = LOC/REM

10 = JOG

11 = Increase E.P.

12 = Decelerate E.P.

13 = Multispeed

14 = 2nd Ramp

15 to 17 = Not Used

18 = No Ext. Alarm

19 = No Ext. Fault

20 = Reset

21 to 23 = Not Used

24 = Disab. Flying Star t

25 = Regul. DC Link

26 = Lock Prog.

27 to 31 = Not Used

32 = 2nd Ramp Multispeed

33 = 2nd Ramp E.P. Ac.

34 = 2nd Ramp E.P. De.

35 = 2nd Ramp FRW Run

36 = 2nd Ramp Rev Run

37 = Turn ON / Ac. E.P.

38 = De. E.P. / Turn OFF

39 = Stop

40 = Safety Switch

41 = Function 1 Application

42 = Function 2 Application

43 = Function 3 Application

44 = Function 4 Application

45 = Function 5 Application

46 = Function 6 Application

47 = Function 7 Application

48 = Function 8 Application

1 cfg

P264 DI2 Input Function See options i n P263 8 cfg

P265 DI3 Input Function See opti ons in P263 0 cfg

P266 DI4 Input Function See opti ons in P263 0 cfg

P295 Inv. Rated Cu rrent 1.6 to 15.2 A According to

inverter model

ro

P296 Line Rated Voltage 0 to 1 = Reser ved

2 = 200 - 240 V

2 ro, cfg

P297 Switching Frequency 2.5 to 15.0 kHz 5.0 k Hz

P401 Mo tor Rated Current 0.0 to 10.0 A 1.4 A cfg

P402 M otor Rated Speed 0 to 9999 rpm 1720 (1310) rpm cfg

P403 M otor Rated Frequency 0 to 300 Hz 60 (50 ) Hz cfg

17 FAULTS AND ALARMS

Most common faults and alarms

Fault / Alarm Description Possible Causes

A046

Motor Overload

Motor overload alarm Settin gs of P156 is too low for the used moto r

Overload on the moto r shaft

A050

Power Module

Overtemperature

Overtemperature alarm from the

power module temperature sensor

(NTC)

High temperatur e at IGBTs (P030 > 110 °C)

High ambient tem perature around the inve rter (>50 °C (>

122 °F)) and high output c urrent

Blocked or defec tive fan

Heatsink is too dir ty, preventing the air f low

A090

External Alarm

External ala rm via DIx (option “No

External Ala rm” in P26x)

Wiring on DI1 to DI4 input s are open or have poo r contact

A700

Remote HMI

Communication Fault

No communication with remote HMI,

but here is freque ncy command or

reference for this s ource

Check if the communication interface with the HMI is

properly conf igured in paramete r P312

HMI cable disconnected

F021

Undervoltage on the

DC Link

Undervoltage fault on the intermediate

circuit

Wrong voltage supply; check if the data on the inverter

label comply with the power supply and parameter P296

Supply voltage to o low, producing voltag e on the DC link

below the minimum v alue (in P004):

Ud < 200 Vdc in 200 / 240 Vac

Phase fault in the in put

Fault in the pre-ch arge circuit

F022

Overvoltage on the

DC Link

Overvoltage fault on the intermediate

circuit

Wrong voltage supply; check if the data on the inverter

label comply with the power supply and parameter P296

Supply voltage is too high, producing voltage on the DC

link above the max imum value (in P00 4):

Ud > 410 Vdc in 200 / 240 Vac

Load inertia is to o high or decelera tion ramp is too fast

P151 setting is too high

F031

Fault of

communication with

the accessory

Main control can not establish the

communication link with accessory

Accessory damaged

Poor connection of the accessory

Problem in the iden tificatio n of the access ory; refer to P027

F051

IGBTs

Overtemperatures

Overtemperature fault measured

on the temperature s ensor of the

power pack

High temperatur e at IGBTs (P030 > 120 °C)

High ambient tem perature around the inverte r (>50 °C

(>122 °F)) and high output curre nt

Blocked or defec tive fan

Heatsink is too dir ty, preventing the air f low

F070

Overcurrent/

Shortcircuit

Overcurrent or short-circuit on the

output, DC link or br aking resistor

Short-circuit between two motor phases

IGBTs module in short-circuit or damaged

Start with too sho rt accelerati on ramp

Start with motor spinning without the Flying Start function

F072

Motor Overload

Motor overload faul t

(60 s in 1.5 x Inom)

P156 setting is too low in rel ation to the motor operatin g

current

Overload on the moto r shaft

F080

CPU Fault

(Watchdog)

Fault related to the supervision

algorithm of the in verter main CPU

Electric noise

Inverter firmware fault

F081

Fault on the Save

User function

Fault in the attempt to s ave the user

parameter table

Attempt to save (P204 = 9) mo re than 32 parameters

(with values dif ferent from the fa ctory default) on t he User

parameter table

The function Saves User is blocked

F082

Fault in the Copy

Function (MMF)

Fault in the copy of par ameters Attem pt to copy the parameters fr om the Flash Memory

Module to the inver ter with differe nt software vers ions

F084

Auto-diagnosis

Fault

Fault related to the automatic

identification algorithm of the inverter

hardware

Poor contact in the connection between the main control

anthe power pack

Hardware not compatible with the firmware version

Defect on the inter nal circuits of the inv erter

F091

External Fault

External fau lt via DIx (“No Exte rnal

Fault” in P26x)

Wiring on DI1 to DI4 input s are open or have poo r contact

F701

Remote HMI

communication fault

No communication with the remote

HMI; however, there is com mand or

frequency refe rence for this sourc e

Check that the HMI communication interface is properly

configured in pa rameter P312

HMI cable disconnected

NOTE!

For further information, refer www.weg.net.

Document: 1000 3540581 / 00

Loading...

Loading...