Page 1

Frequency Inverter

CFW-09

Convertidor de Frecuencia

CFW-09

Inversor de Freqüência

CFW-09

Frequenzumrichter

CFW-09

Variateur de Vitesse

CFW-09

Frequentie-Omzetter

CFW-09

Frekvensomriktare

CFW-09

Преобразователь частоты

CFW-09

User´s Guide

Manual del Usuario

Manual do Usuário

Bedienungsanleitung

Guide d'instalation et d'exploitation

Installatie en gebruikshandleiding

Bruksanvisning

Руководство по эксплуатации

Motors | Automation | Energy | Coatings

Page 2

FREQUENCY

INVERTER

MANUAL

ATTENTION!

It is very important to check if the

inverter software version is the same

as indicated above.

09/2008

Series:

CFW-09

Software:

version 4.0X

Language:

English

Document:

0899.5306 / 12

Page 3

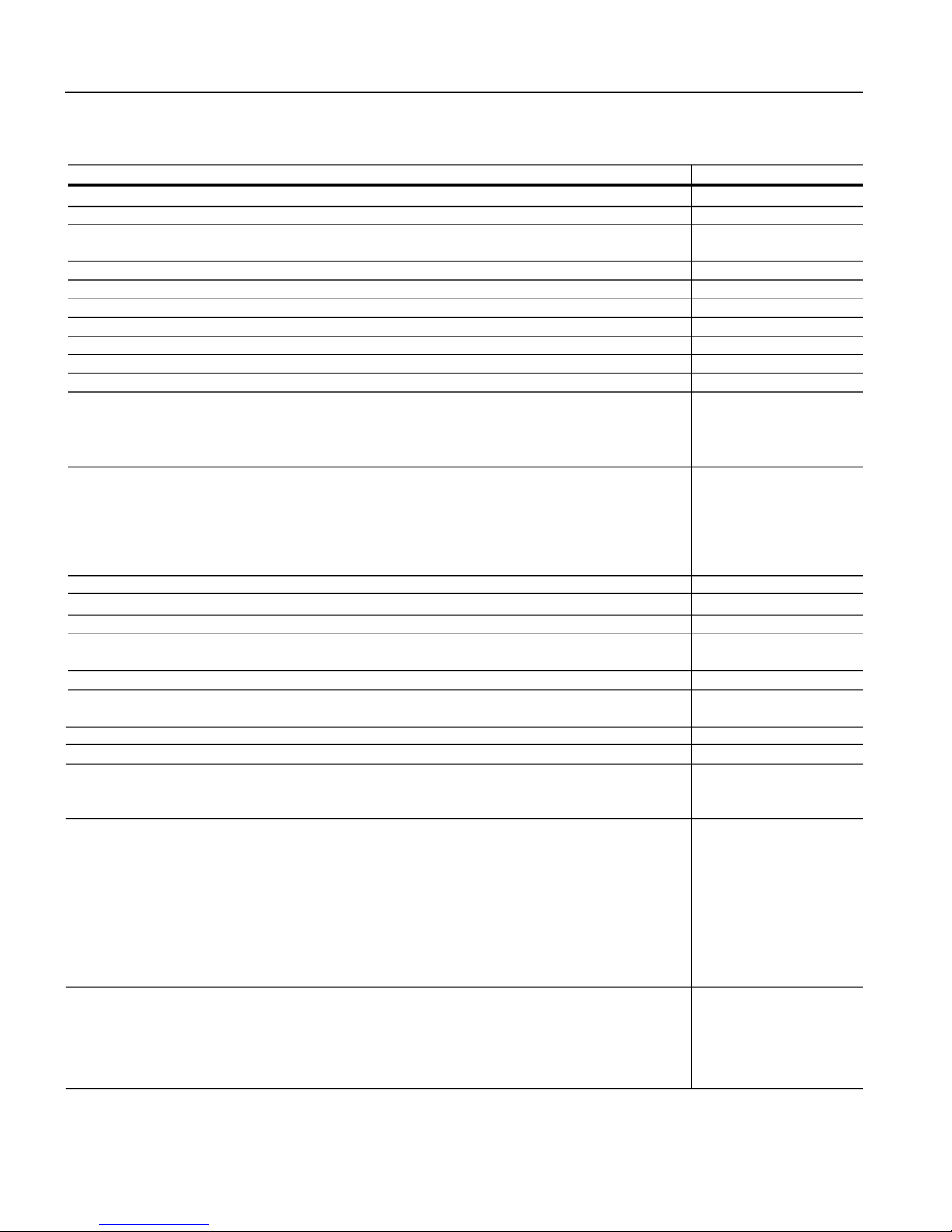

Revision

Description

Section

1

FirstEdition.

-2Inclusion of the functions Fieldbus and Serial Communication.

Refer to item

8.12 and 8.13

2

Inclusion of the Spare Part List.

Refer to item

7.52DimensionChanging.

Refer to item

3.1.2 and 9.4

3

Inclusion of thePID Regulator.

Refer to

item 6

4

Inclusion of the German Language - Ride-through and Flying

S

tart functions.

Refer to

item 6

4

Inclusionof DBW-01;KITKME; DC LinkInductor.

Refer to

item 8

5

Inclusion of

I

tem 3.3 -CE Installation.

Refer to

item 3

5

Inclusion of new functions such as Ride-Through for Vector Control, Motor Phase Loss.

Refer to item 6

5

New I/O Expansion Boards EBB.04 and EBB.05.

Refer to item 8

6

General Revision.

-7Inclusion of the models from 2.9 to 32 A / 500-600 V.

Refer to items 2.4; 3.1;

3.2.1; 3.3; 4.2; 6.2; 6.3; 7.1;

7.2; 7.4; 7.5; 8.7.1; 8.10.1;

9.1 and 9.1.3

8

Inclusion of new functions:

Refer to item 6

Control Type of the Speed Regulator, SpeedRegulator Differential Gain, Stop Mode Selection,

Access to the parameters with different content than default, Hysteresis for Nx/Ny, kWh

Counter,Load User 1 and 2 the factory Hours Hx, via DIx, Parameter Setting Disable via DIx,

Help Message for E24, “P406 = 2 in Vector Control”, Automatic SensorLess Set of P525, Last

10 errors indication, Motor Torque indication via AOx.

8

New optional boards: EBC and PLC1.

Refer to

item 8

8

Newmodel CFW-09 SHARKNEMA 4X/IP56.

Refer to item 8

8

New models for voltages, currents and powers: Models 500-600 V.

Refer to items 1 to 9

8

Inclusion of the items 8.14 Modbus-RTU,8.17 CFW-09 Supplied by the DC Link - Line HD,

Refer to item 8

8.18 CFW-09 RB Regenerative Converter.

8

Updating of the SparePart List.

79Inclusion of new functions:

-

Overcurrent Protection, Default factory reset 50 Hz, Timer Relay, Ramp Holding.

9

New lines of the current and

power supply

.-9

PID Regulator to “Academic” Changing.

-10General revision and update of the software version (2.6X to 3.1X):

-

Change on the maximum value of P156 and P401 for some models; Change on the maximum

value of P331; Change on the factory default value of P404.

11

New functions;

Incorporation of the Mechanical Brake Logic for cranes, Load Detection Logic and addition of

Refer to items I, 6, 7 and 8

option “Indication of Torque Current Polarity” at the DOx and RLx outputs; VVW Control; DC

Braking for VVW and Sensorless; Flying Start function for the Sensorless Control; support for

EtherNet/IP communication board; read/write function for the PLC board parameters through

Modbus; Indication of the Analog Outputs values in read only parameters P027 to P030;

Simultaneous indication of the speed and current in parameter P070; P313 = 4 (Changes to

LOCAL mode keeping the commands);Regulation of the maximum torque current through

options AI1+AI2 and AI2+AI3; function F > Fx; function ready 2.

12

Updating of the software version to V4.0X.

-

Updating of the parameters P309 and P313.

Addition of new parameters: P335, P336, P337, P338, P340, P341, P342, P343, P344 and P346.

New options for fault Reset.

General revision.

Summaryof Revisions

The table below describes all revisions made to this manual.

Page 4

Summary

Quick Parameter Reference, Fault and Status Messages

I.

Parameters

.......................................................................................

09

II.

FaultMessages

....................................................................................

33

III.Other Messages

.................................................................................

34

CHAPTER

1

Safety Notices

1.1 Safety Notices in the Manual

.............................................................

35

1.2 Safety Notices on the Product

...........................................................

35

1.3PreliminaryRecommendations

..........................................................

35

CHAPTER

2

General Information

2.1About this Manual

..............................................................................

37

2.2SoftwareVersion

................................................................................

37

2.3About the CFW-09

.............................................................................

37

2.4CFW-09IdentificationLabeland CodeNumber

..................................

39

2.5ReceivingandStorage

.......................................................................

41

CHAPTER

3

Installation and Connection

3.1Mechanical Installation

......................................................................

42

3.1.1EnvironmentConditions

...............................................................

42

3.1.2Dimensionalof CFW-09

...............................................................

42

3.1.3Mounting Specifications

...............................................................

43

3.1.3.1Mounting Inside a Panel

.....................................................

44

3.1.3.2Mounting onSurface

..........................................................

45

3.1.3.3Mounting withthe Heatsink Through aSurface

..................

46

3.1.4Keypad(HMI)andCoverRemoval

................................................

48

3.2 Electrical Installation

..........................................................................

49

3.2.1Power/GroundingTerminals

.........................................................

49

3.2.2Locationof thePower/Grounding/ControlConnections

................

51

3.2.3 RatedVoltageSelection

..............................................................

53

3.2.4

Power/GroundingWiringand Fuses

............................................

54

3.2.5

PowerConnections

.....................................................................

57

3.2.5.1AC InputConnection

...........................................................

57

3.2.5.2Output Connections

............................................................

58

3.2.5.3GroundingConnections

.......................................................

58

3.2.5.4ITNetworks

.........................................................................

59

3.2.6

ControlWiring

..............................................................................

61

3.2.7

TypicalTerminalConnections

......................................................

64

3.3EuropeanEMC Directive- Requirementsfor ConformingInstallations

67

3.3.1Installation

...................................................................................

67

3.3.2 Epcos Filters

...............................................................................

68

3.3.3Schaffner Filters

...........................................................................

71

3.3.4 EMC Filter Characteristics

...........................................................

74

Page 5

Summary

CHAPTER

4

Keypad (HMI) Operation

4.1 D

e

scription of the Keypad

..................................................................

86

4.2 Useof theKeypad(HMI)

....................................................................

88

4.2.1

KeypadOperation

........................................................................

88

4.2.2

"Read-Only"Variablesand Status

...............................................

89

4.2.3

ParameterViewingandProgramming

.........................................

90

CHAPTER

5

Start-up

5.1

Pre-Power Checks

............................................................................

93

5.2

InitialPower-up

.................................................................................

93

5.3

Start-up

.............................................................................................

98

5.3.1

Type of Control:V/F60 Hz - Operation via Keypad(HMI)

............

99

5.3.2Typeof Control: Sensorless or Vector with Encoder

(OperationVia Keypad(HMI))

.....................................................

102

5.3.3

TypeofControl: VVW - KeypadOperation

.................................

109

CHAPTER

6

Detailed Parameter Description

6.1Access and Read Only Parameters - P000 to P099

.........................

118

6.2 RegulationParameters - P100 to P199

.............................................

124

6.3Configuration Parameters-P200 to P399

.........................................

147

6.3.1

ParametersforCraneApplicationsand forTorqueMaster/Slave

Function - P351 to P368

..........................................................

208

6.4 Motor Parameters - P400 to P499

....................................................

214

6.5 SpecialFunctions Parameters - P500 to P699

.................................

220

6.5.1

PIDRegulator

.............................................................................

220

6.5.2

Description

.................................................................................

220

CHAPTER

7

Diagnostics and Troubleshooting

7.1 Faults and Possible Causes

.............................................................

228

7.2Troubleshooting

................................................................................

233

7.3 ContactingWEG

...............................................................................

235

7.4PreventiveMaintenance

....................................................................

235

7.4.1CleaningInstructions

..................................................................

236

7.5 SparePart List

..................................................................................

237

CHAPTER

8

CFW-09 Options and Accessories

8.1 I/O ExpansionBoards

.......................................................................

248

8.1.1 EBA(I/O Expansion BoardA)

.....................................................

248

Page 6

Summary

8.1.2 EBB (I/O Expansion Board B)

....................................................

251

8.1.3 EBE

............................................................................................

254

8.2IncrementalEncoder

.........................................................................

254

8.2.1 EBA/EBB Boards

.......................................................................

254

8.2.2EBC1 Board

................................................................................

256

8.3 Keypad with LEDs Only

....................................................................

258

8.4RemoteKeypad and Cables

.............................................................

258

8.5Blank Covers

....................................................................................

262

8.6RS-232 PC Communication Kit

........................................................

262

8.7Line Reactor/DC BusChoke

.............................................................

263

8.7.1Application Criteria

......................................................................

264

8.7.2 DC Link Inductor Built in

.............................................................

266

8.8Load Reactor

....................................................................................

267

8.9 RFIFilter

...........................................................................................

267

8.10Dynamic Braking

............................................................................

268

8.10.1 DB Resistor Sizing

..................................................................

268

8.10.2Installation

...............................................................................

270

8.10.3DynamicBraking Module-DBW-01and DBW-02

.....................

271

8.10.3.1DBW-01and DBW-02 IdentificationLabel

...................

272

8.10.3.2Mechanical Installation

................................................

272

8.10.3.3Installation/Connection

................................................

275

8.11

ThroughSurfaceMountingKit

.........................................................

277

8.12

Fieldbus

...........................................................................................

277

8.12.1 Installation of the

Fieldbus

Kit

.................................................

278

8.12.2Profibus DP

.............................................................................

281

8.12.3ProfibusDP-V1

.......................................................................

283

8.12.4DeviceNet

................................................................................

284

8.12.5DeviceNetDriveProfile

............................................................

286

8.12.6EtherNet/IP

.............................................................................

287

8.12.7Use to the Fieldbus/RelatedParameters of the CFW-09

.........

294

8.12.7.1VariablesReadfrom the Inverter

..................................

294

8.12.7.2VariablesWritten inthe Inverter

...................................

296

8.12.7.3 Fault Indications

..........................................................

298

8.12.7.4Addressing of the CFW-09Variables in the

FieldbusDevices

.........................................................

299

8.13SerialCommunication

.....................................................................

300

8.13.1Introduction

.............................................................................

300

8.13.2InterfacesDescription

..............................................................

301

8.13.2.1RS-485

.........................................................................

301

8.13.2.2RS-232

.........................................................................

302

8.13.3Protocol Definitions

.................................................................

302

8.13.3.1UsedTerms

..................................................................

302

8.13.3.2Parameters/VariablesResolution

..................................

303

8.13.3.3CharactersFormat

........................................................

303

8.13.3.4Protocol

........................................................................

303

8.13.3.5

Execution

andTelegram Test

.......................................

305

8.13.3.6TelegramSequence

......................................................

306

8.13.3.7Variable Code

...............................................................

306

8.13.4Telegram Examples

.................................................................

306

8.13.5Variablesand Errorsof the Serial Communication

..................

307

8.13.5.1 Basic Variables

............................................................

307

8.13.5.2Examples of Telegrams withBasic Variables

...............

310

8.13.5.3Parameters Related tothe Serial Communication

........

311

8.13.5.4Errors Related to theSerial Communication

.................

312

Page 7

Summary

8.13.6Timesfor Read/Writeof Telegrams

..........................................

312

8.13.7 PhysicalConnectionof theRS-232and RS-485Interface

........

313

8.14

Modbus-RTU

....................................................................................

314

8.14.1Introductionin theModbus-RTU Protocol

................................

314

8.14.1.1TransmissionModes

....................................................

314

8.14.1.2Message Structurein RTUMode

..................................

314

8.14.2Operationof theCFW-09 inthe Modbus-RTUNetwork

...........

316

8.14.2.1Interface RS-232andRS-485Description

.....................

316

8.14.2.2InverterConfigurationinthe Modbus-RTUNetwork

......

317

8.14.2.3Access to the Inverter Data

...........................................

317

8.14.3Detailed FunctionDescription

...................................................

320

8.14.3.1 Function 01- Read Coils

..............................................

321

8.14.3.2Function 03 -Read Holding Register

............................

321

8.14.3.3 Function 05 - Write Single Coil

.....................................

322

8.14.3.4 Function 06 - Write SingleRegister

..............................

323

8.14.3.5 Function 15 - Write Multiple Coils

.................................

324

8.14.3.6 Function 16 - Write Multiple Registers

.........................

325

8.14.3.7Function43 - ReadDevice Identification

.......................

326

8.14.4CommunicationErrors

.............................................................

327

8.14.4.1Error Messages

............................................................

327

8.15KIT KME (for ExtractableMounting)

................................................

329

8.16CFW-09 SHARKNEMA4X

.............................................................

330

8.16.1Enclosure Specifications

.........................................................

330

8.16.2Mechanical Installation

............................................................

330

8.16.3 Electrical Installation

...............................................................

332

8.16.4Closingthe

Inverter

..................................................................

332

8.16.5 How to Specify

........................................................................

333

8.17 CFW-09 Supplied by the DC Link - Line HD

...................................

333

8.18CFW-09RBRegenerativeConverter

...............................................

333

8.19PLC Board

......................................................................................

335

CHAPTER 9

Technical Specification

9.1Power Data

......................................................................................

336

9.1.1

PowerSupplySpecifications

......................................................

336

9.1.2220-230V Power Supply

............................................................

337

9.1.3380-480V Power Supply

............................................................

337

9.1.4500-600V Power Supply

............................................................

338

9.1.5660-690V Power Supply

............................................................

340

9.2Electronics/General Data

..................................................................

343

9.2.1Applicable Standards

..................................................................

344

9.3OptionalDevices

...............................................................................

345

9.3.1 I/O Expansion Board EBA

..........................................................

345

9.3.2 I/O Expansion Board EBB

..........................................................

345

9.4Mechanical Data

...............................................................................

346

Page 8

CFW-09-

QUICKPARAMETER REFERENCE

9

QUICK PARAMETER REFERENCE, FAULT AND STATUS MESSAGES

Software:V

4.0X

Application:

CFW-09 Model:

SerialNumber:

Responsible:

Date:

//.

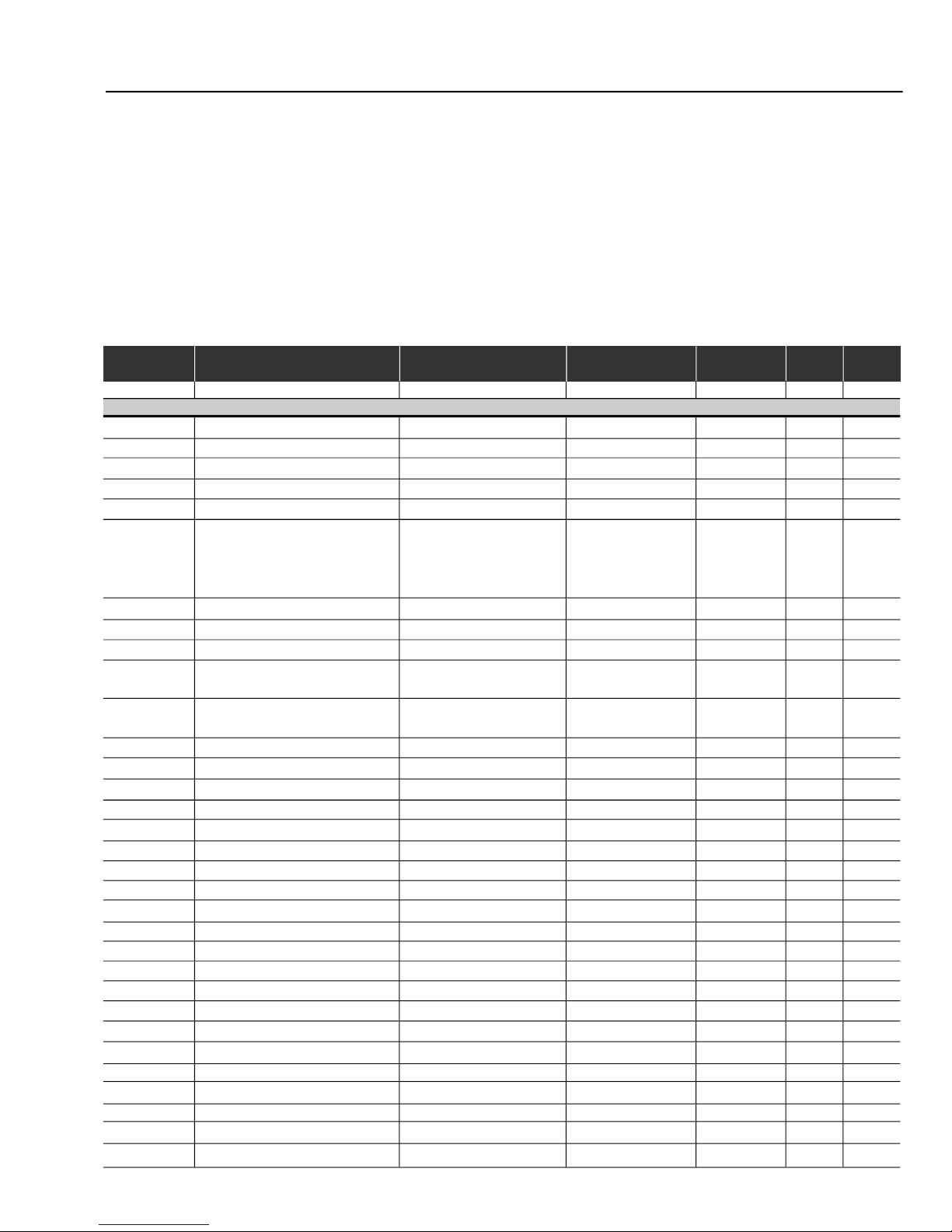

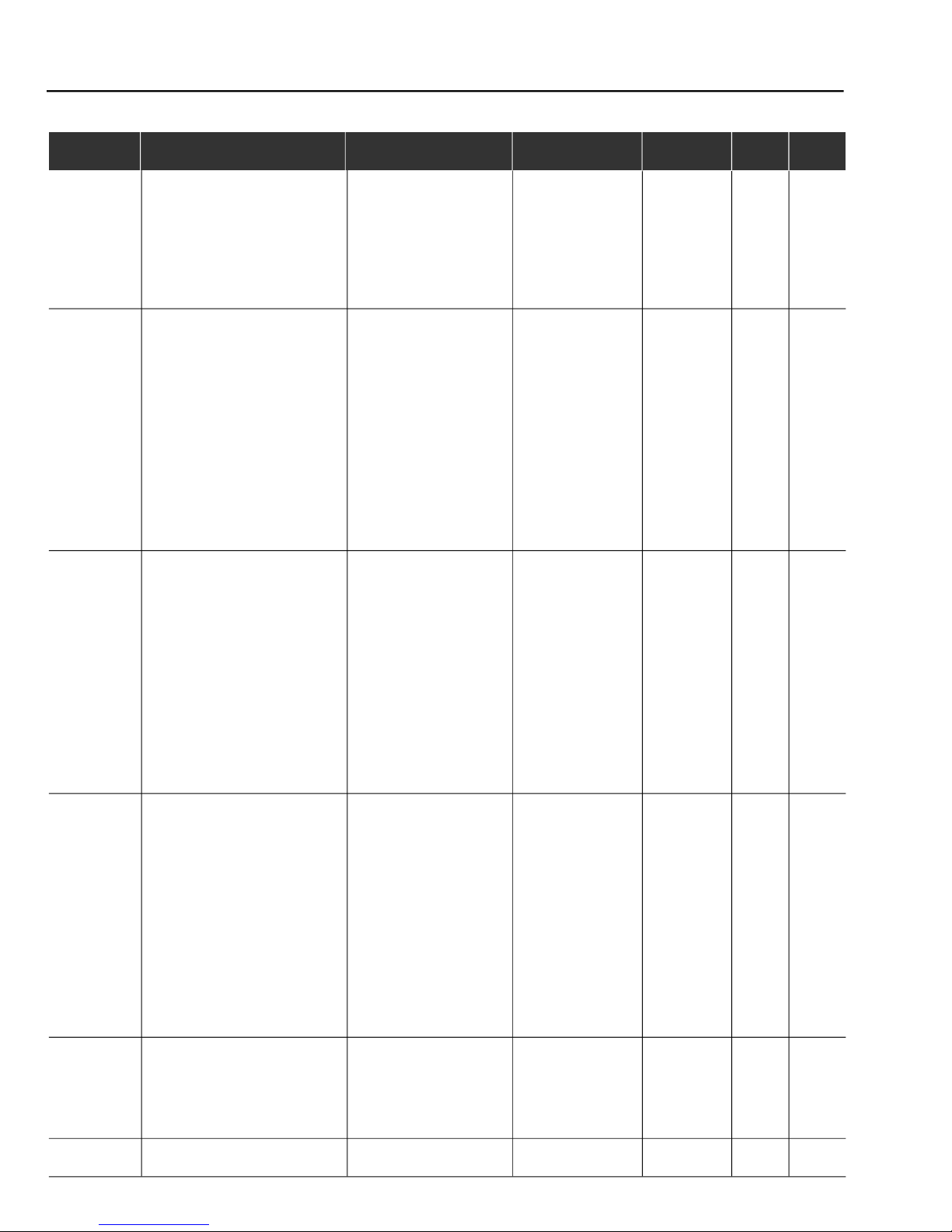

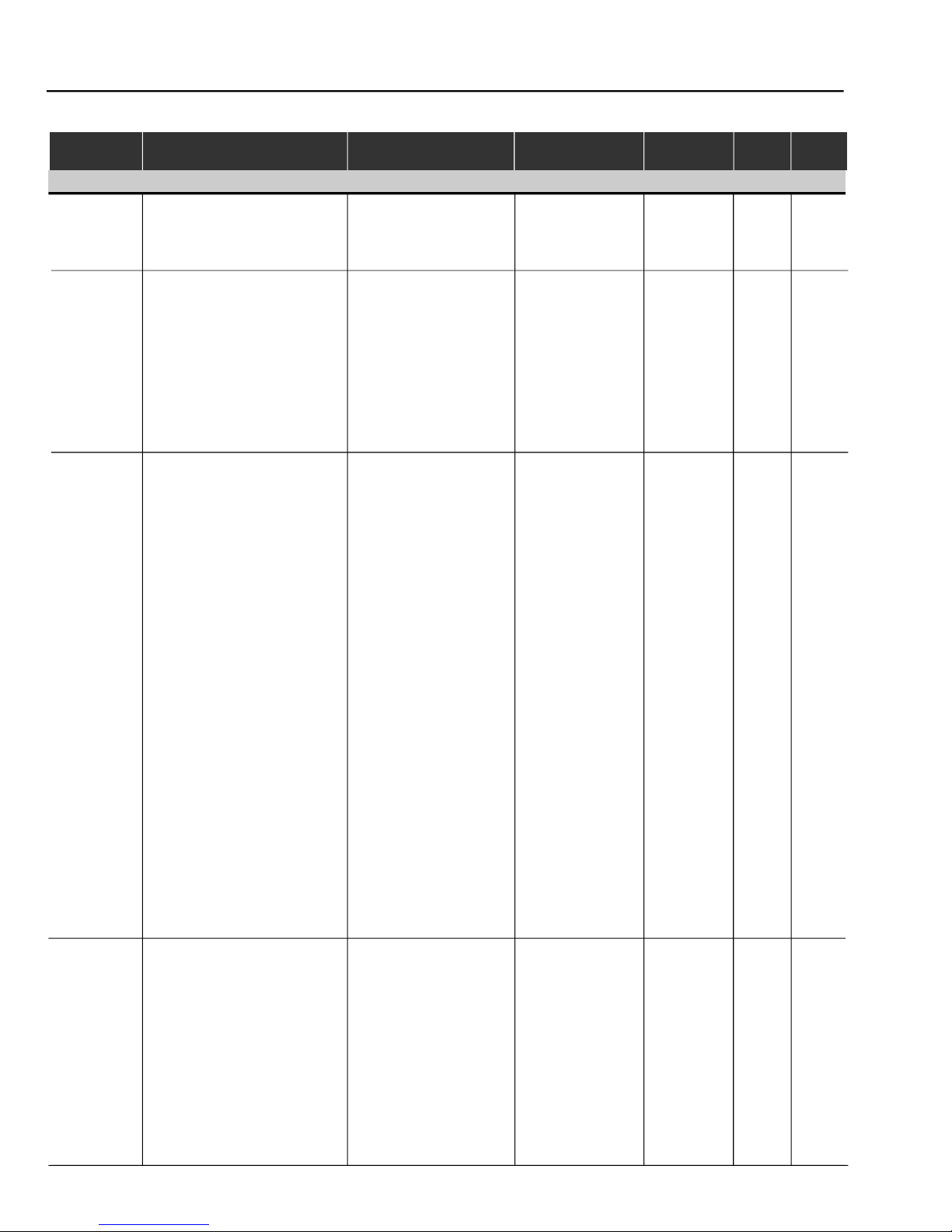

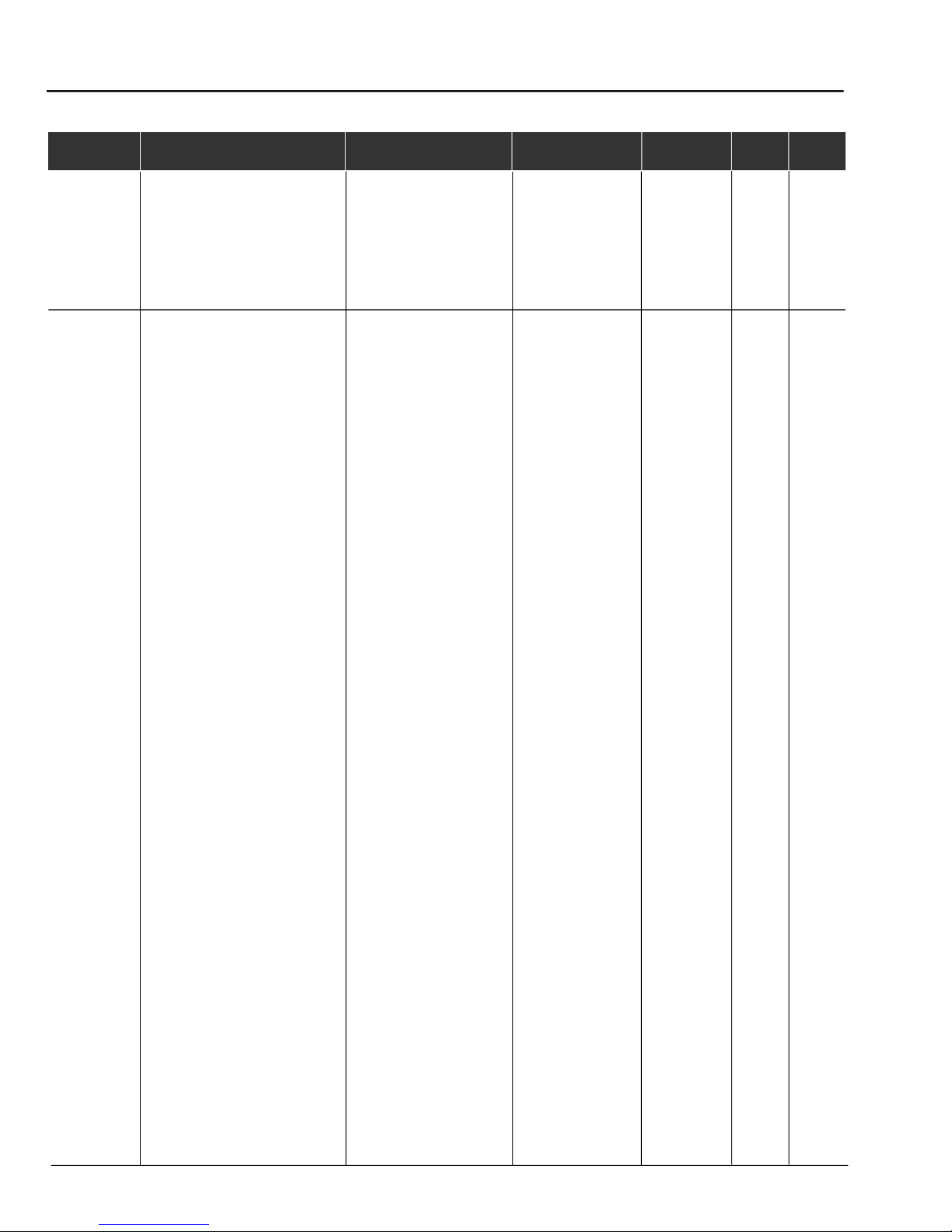

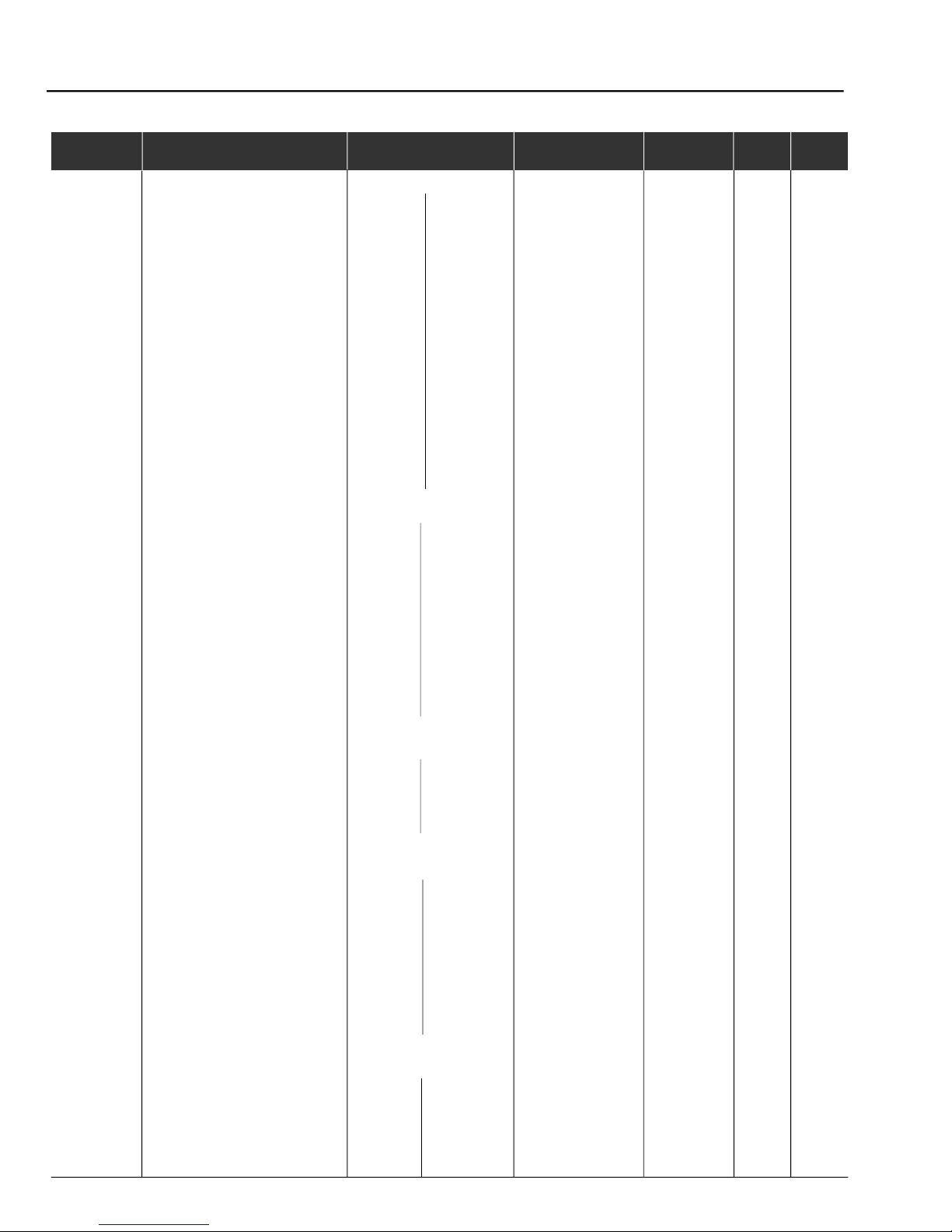

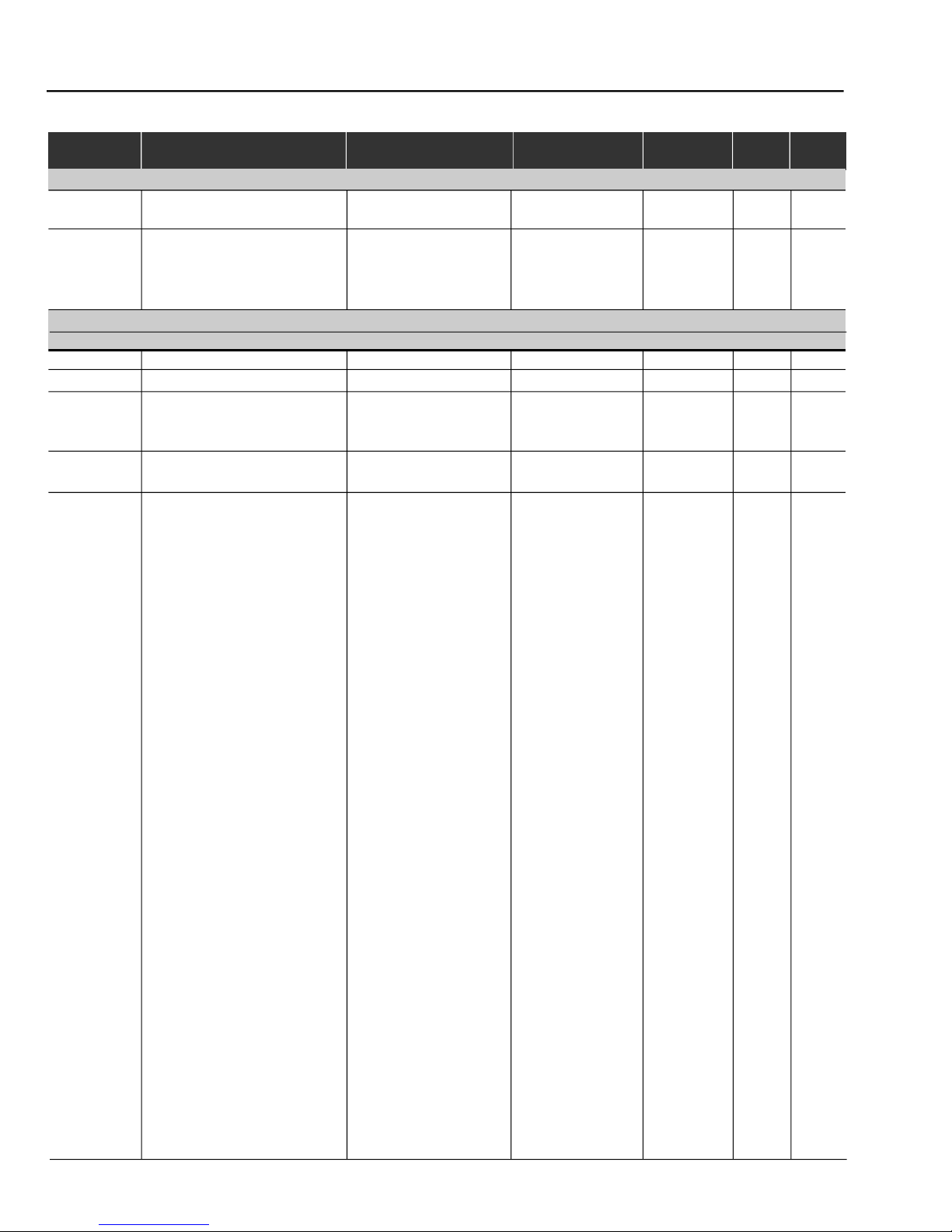

I.Parameters

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

P000

Parameter Access

0 to 999

0-118

READONLY PARAMETERS

P001 to

P099

P001

Speed Reference

0.0 to P134

rpm

118

P002

MotorSpeed

0.0 to P134

rpm

118

P003

Motor Current

0.0 to 2600

A (rms)

118

P004

DCLink Voltage

0.0 to 1235

V

119

P005

Motor Frequency

0.0 to 1020

Hz

119

P006

Inverter Status

rdy-119

run

Sub

Exy

P007

Motor Voltage

0 to 800

V

119

P009

Motor Torque

0.0 to 150.0

%

119

P010

Output Power

0.0 to

3276kW119

P012

DigitalInputsDI1 ... DI8Status

0 = Inactive (Open)

-

119

1 = Active (Closed)

P013

DigitalandRelayOutputsDO1,DO2,

0 = Inactive (Dropped-out)

-

120

RL1, RL2, and RL3 Status

1 = Active (Picked-up)

P014

Last Fault

0 to 71

-

121

P015

Second Previous Fault

0 to 71

-

121

P016

Third Previous Fault

0 to 71

-

121

P017

Fourth Previous Fault

0 to 71

-

121

P018

Analog InputAI1’ Value

-100 to +100

%

121

P019

Analog InputAI2’ Value

-100 to +100

%

121

P020

Analog InputAI3’ Value

-100 to +100

%

121

P021

Analog InputAI4’ Value

-100 to +100

%

121

P022

WEGUse

--121

P023

Software Version

V4.0X

-

121

P024

A/D Conversion Value of AI4

-32768 to +32767

-

121

P025

A/D Conversion Value of Iv

0 to 1023

-

121

P026

A/D Conversion Value of Iw

0 to 1023

-

121

P027

AO1 Value

0.0 to 100

%

122

P028

AO2 Value

0.0 to 100

%

122

P029

AO3 Value

-100 to +100

%

122

P030

AO4 Value

-100 to +100

%

122

P040

PID Process Variable

0 to 100

%

122

P042

Powered Time

0 to 65535

h

122

P043

Enabled Time

0 to 6553.5

h

122

P044

kWh Counter

0 to 65535

kWh

123

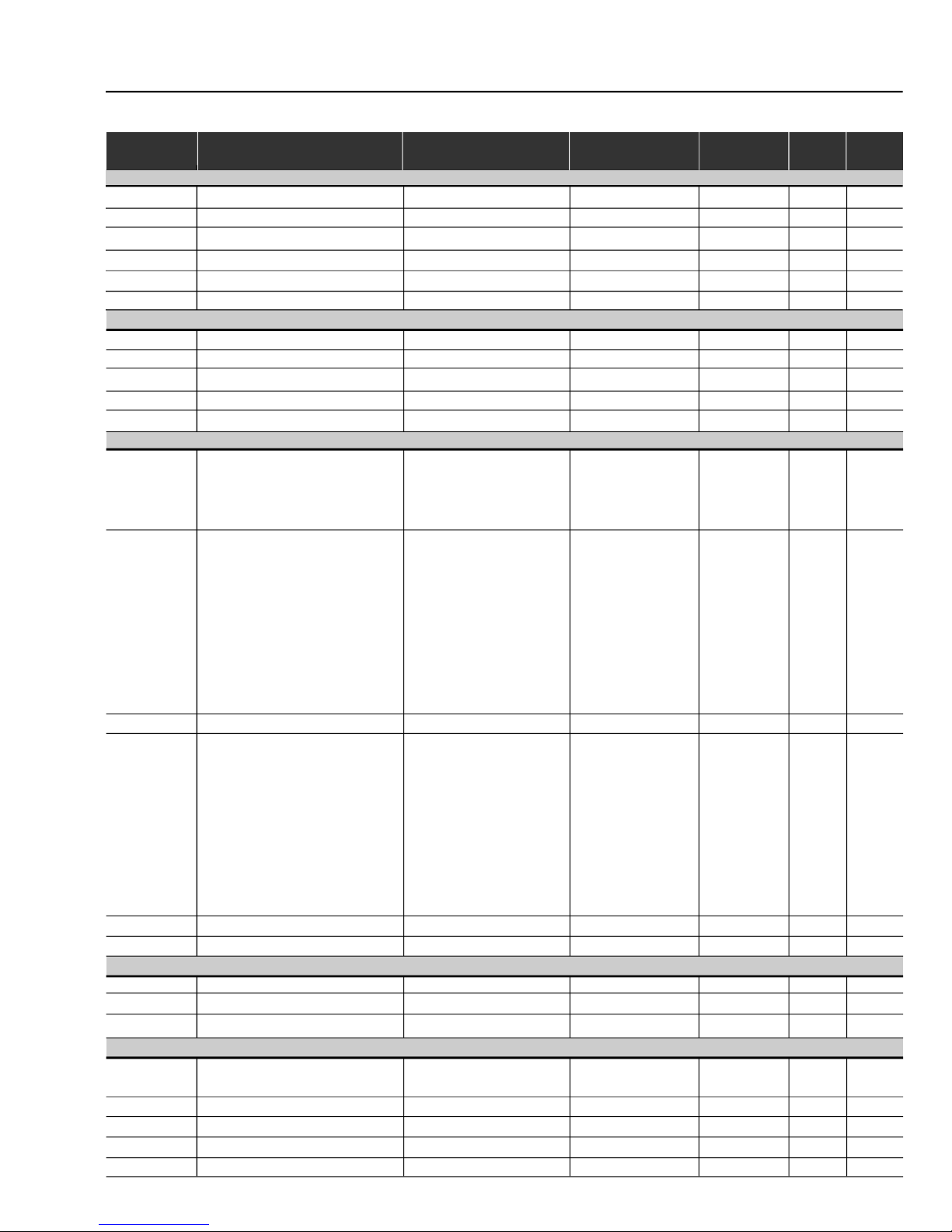

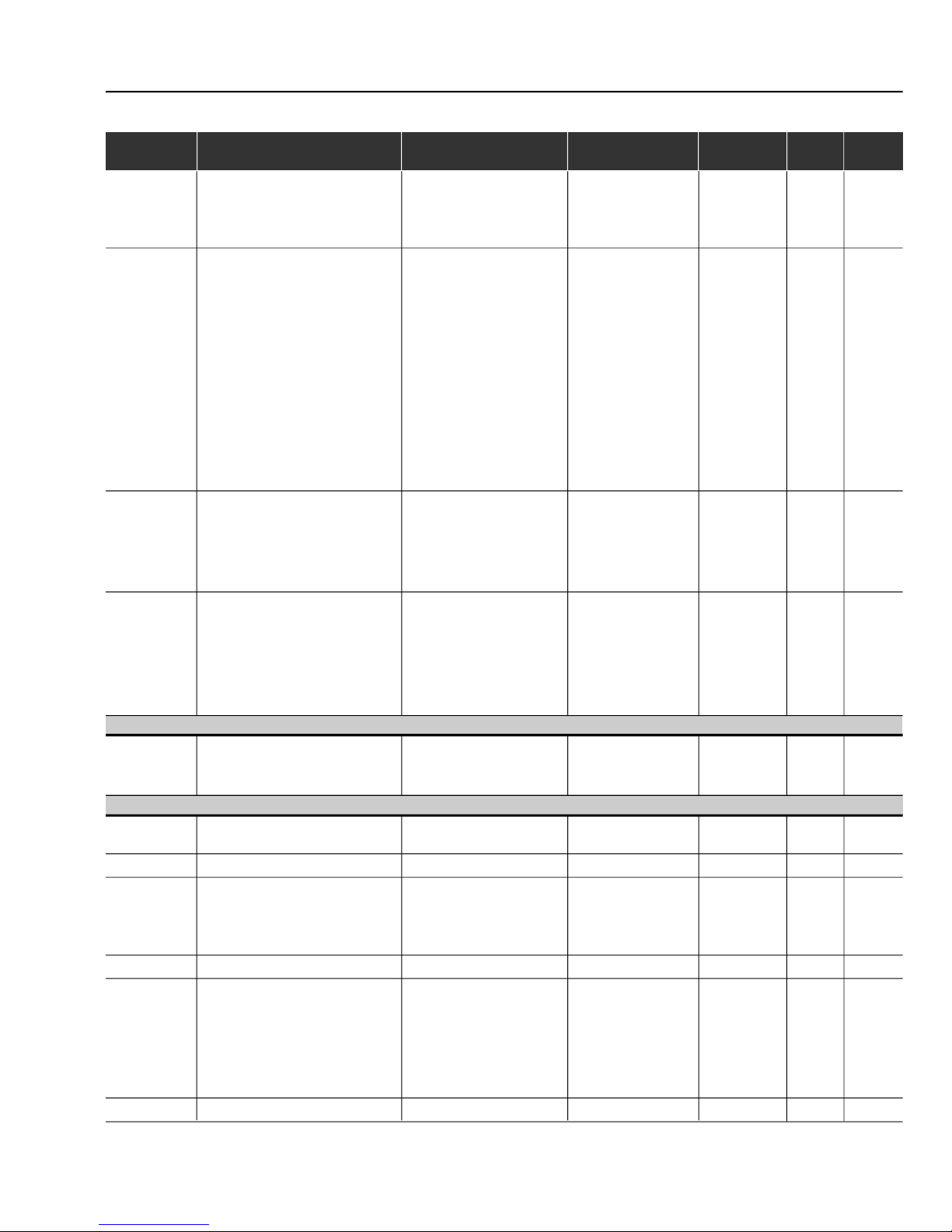

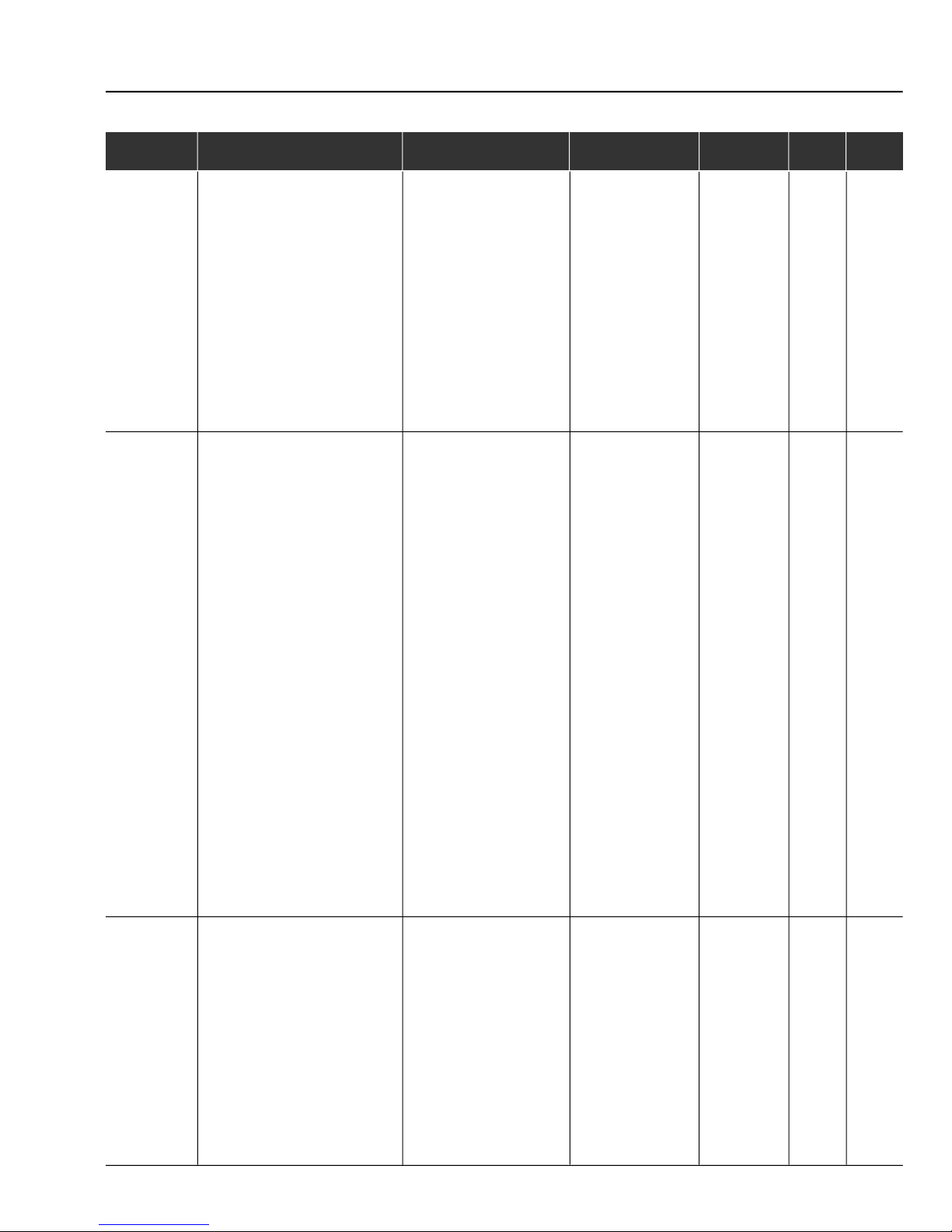

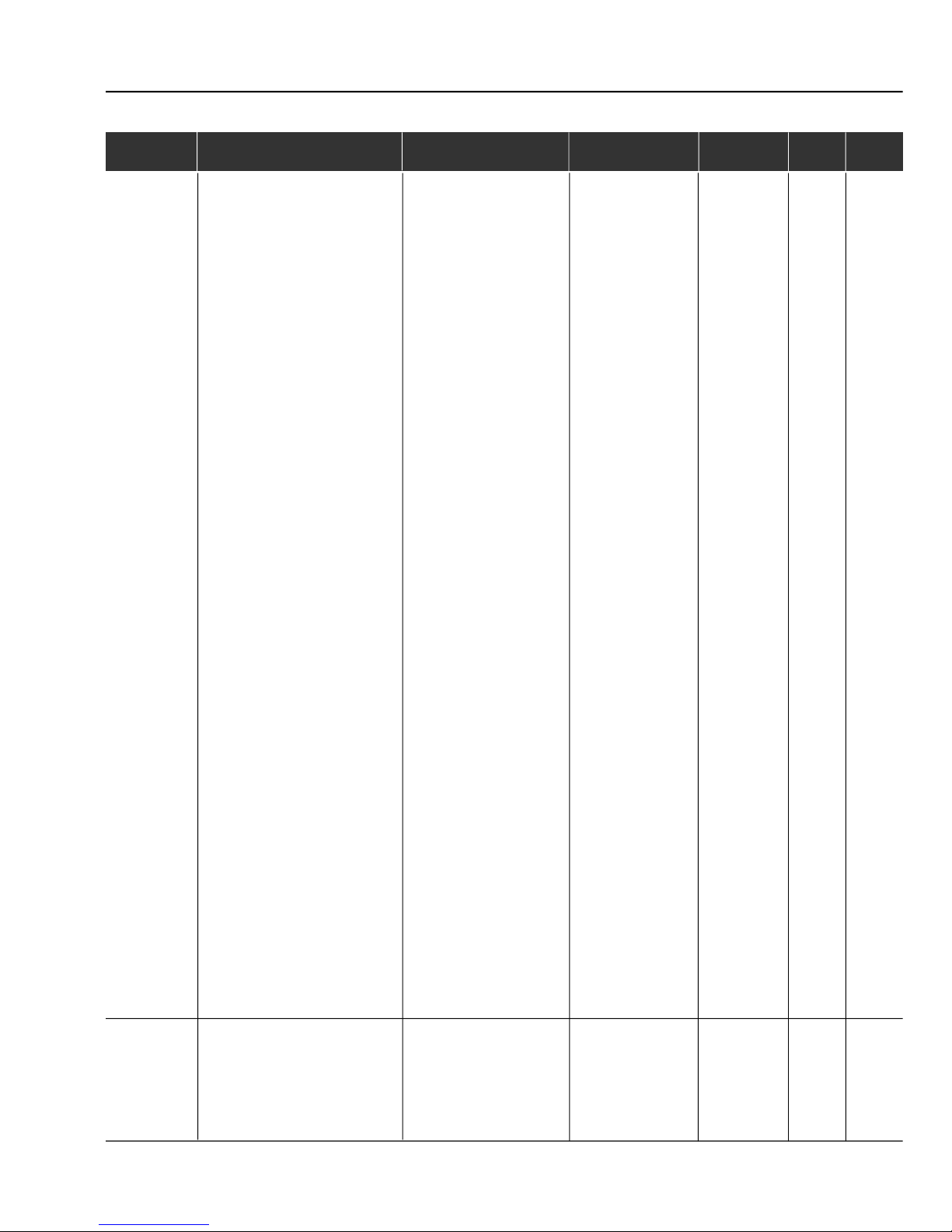

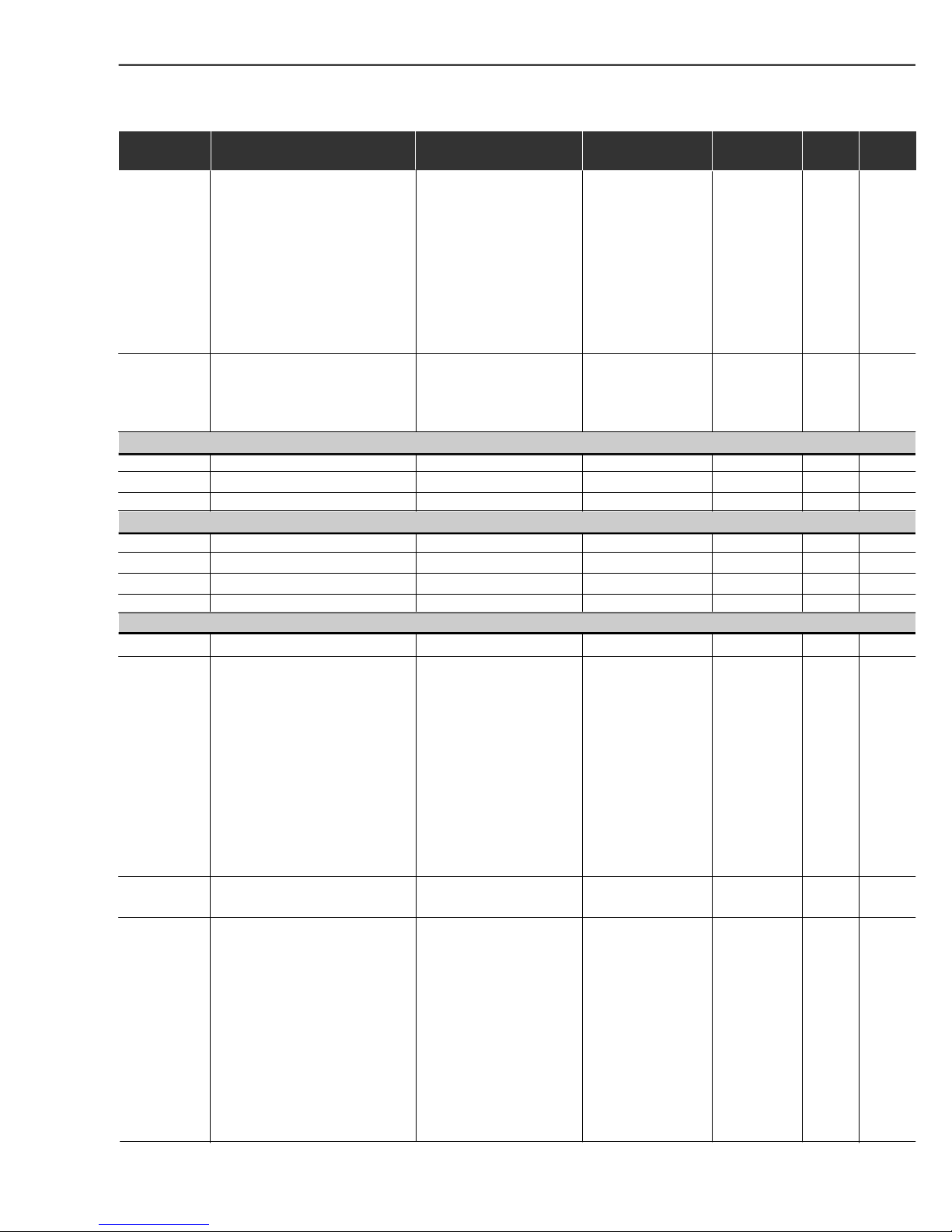

Page 9

CFW-09-

QUICKPARAMETER REFERENCE

10

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

(*)

P136 has different functions for V/F and Vector Control.

P060

Fifth Error

0 to 71

-

123

P061

Sixth Error

0 to 71

-

123

P062

Seventh Error

0 to 71

-

123

P063

EighthError

0 to 71

-

123

P064

Ninth Error

0 to 71

-

123

P065

Tenth Error

0 to 71

-

123

P070

Motor Current and Motor Speed

0 to 2600

A (rms)

123

0 to P134

rpm

P071

CommandWord

0 a 65535

-

123

P072

Fieldbus Speed Reference

0 a 65535

-

123

REGULATIONPARAMETERS

P100 to P199

Ramps

P100

Acceleration Time

0.0 to 999

20.0s124

P101

DecelerationTime

0.0 to 999

20.0s124

P102

Acceleration Time 2

0.0 to 999

20.0s124

P103

DecelerationTime 2

0.0 to 999

20.0s124

P104

SRamp

0 = Inactive (Linear)

0 = Inactive

-

124

1 = 50 %

2 = 100 %

Speed References

P120

Speed Reference Backup

0 = Inactive

1 = Active

-

124

1 = Active

P121

Keypad Speed Reference

P133 to P134

90

rpm

125

P122

(2)(11)

JOG or JOG+ Speed Reference

00 to P134

150 (125)

rpm

125

P123

(2)(11)

JOG- Speed Reference

00 to P134

150 (125)

rpm

125

P124

(2)(11)

Multispeed Reference 1

P133 to P134

90 (75)

rpm

126

P125

(2)(11)

Multispeed Reference 2

P133 to P134

300 (250)

rpm

126

P126

(2)(11)

Multispeed Reference 3

P133 to P134

600 (500)

rpm

126

P127

(2)(11)

Multispeed Reference 4

P133 to P134

900 (750)

rpm

126

P128

(2)(11)

Multispeed Reference 5

P133 to P134

1200 (1000)

rpm

126

P129

(2)(11)

Multispeed Reference 6

P133 to P134

1500 (1250)

rpm

126

P130

(2)(11)

Multispeed Reference 7

P133 to P134

1800 (1500)

rpm

126

P131

(2)(11)

Multispeed Reference 8

P133 to P134

1650 (1375)

rpm

126

Speed Limits

P132

(1)

Maximum Overspeed Level

(0 to 99) x P134

10%127

100 = Disabled

P133

(2)(11)

MinimumSpeedReference

0 to (P134-1)

90 (75)

rpm

127

P134

(2)(11)

Maximum Speed Reference

(P133+1) to (3.4 x P402)

1800 (1500)

rpm

127

I/F Control

P135

(2)

Speedtransition to I/F Control

0 to 90

18

rpm

128

P136

(*)

Current Reference (I*)

0= Imr1 = 1.11 x I

mr

-

128

for I/F Control

1 = 1.11 x I

mr

2 = 1.22 x I

mr

3 = 1.33 x I

mr

4 = 1.44 x I

mr

5 = 1.55 x I

mr

6 = 1.66 x I

mr

7 = 1.77 x I

mr

8 = 1.88 x I

mr

9 = 2.00 x I

mr

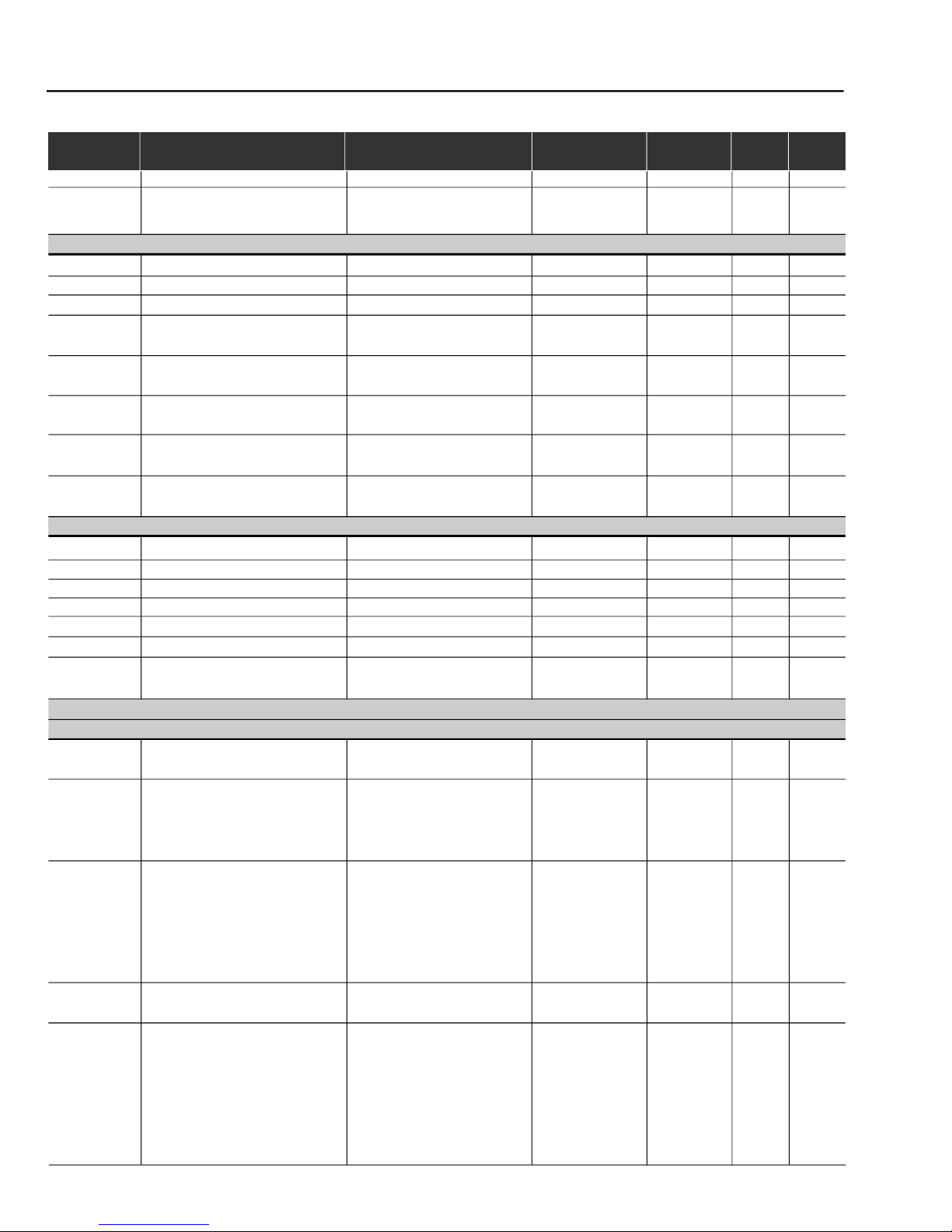

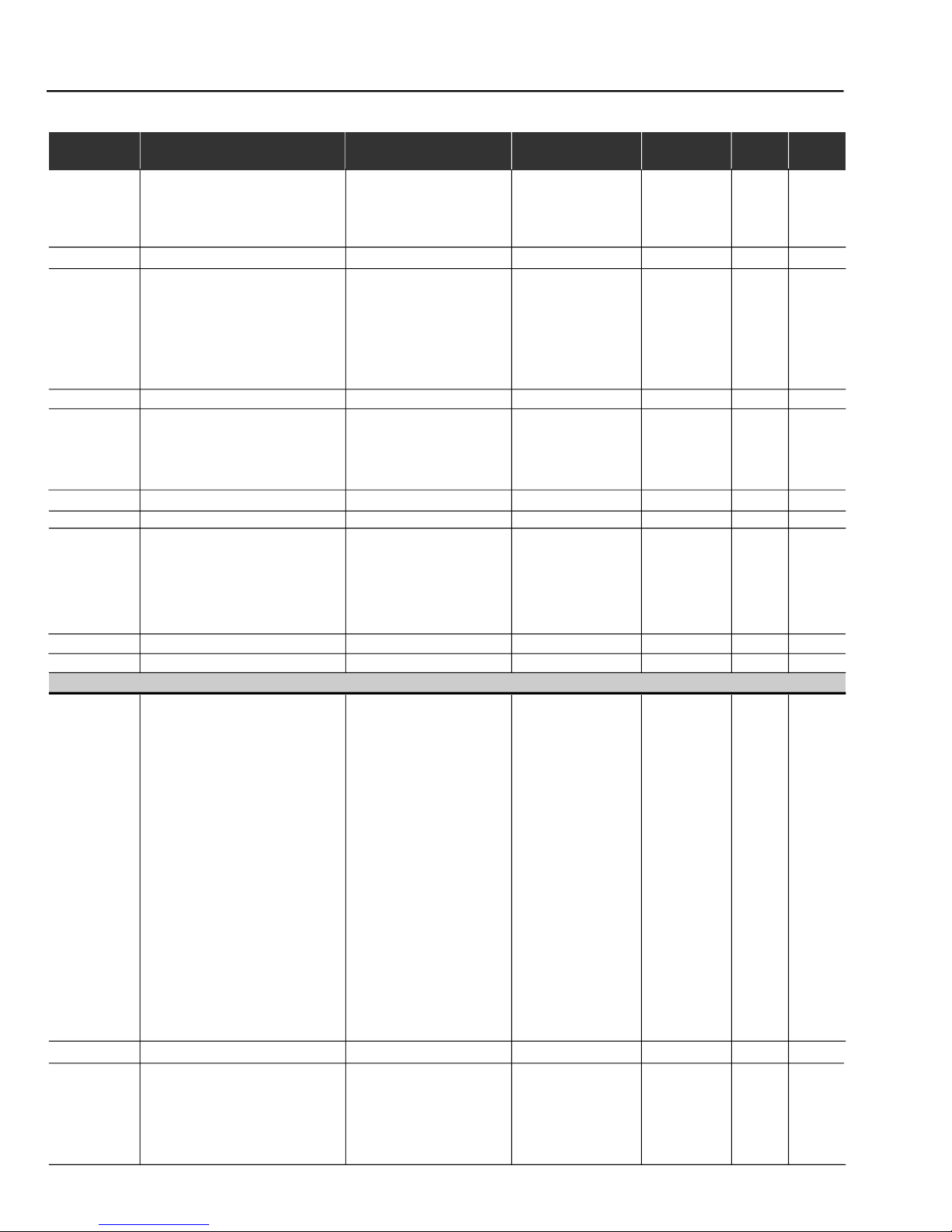

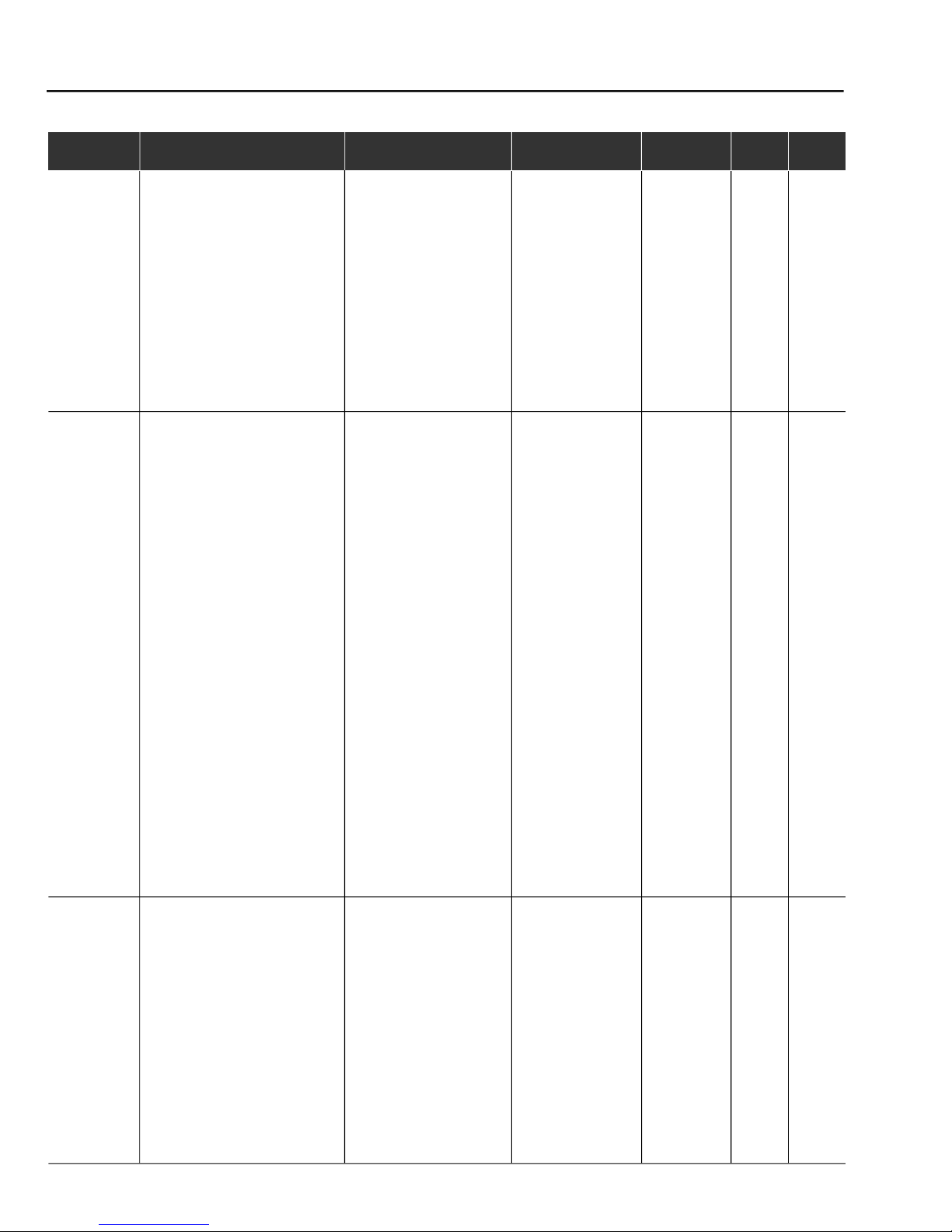

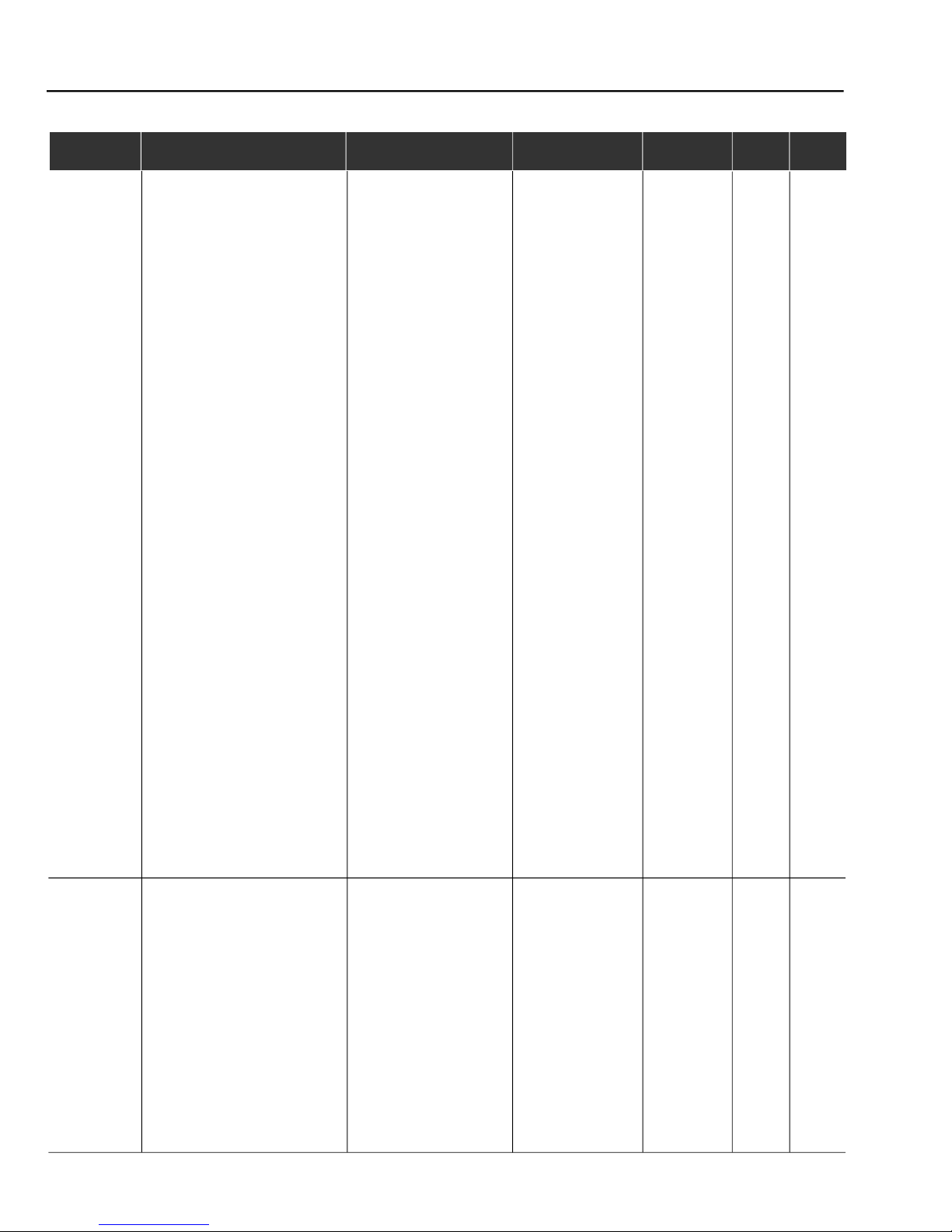

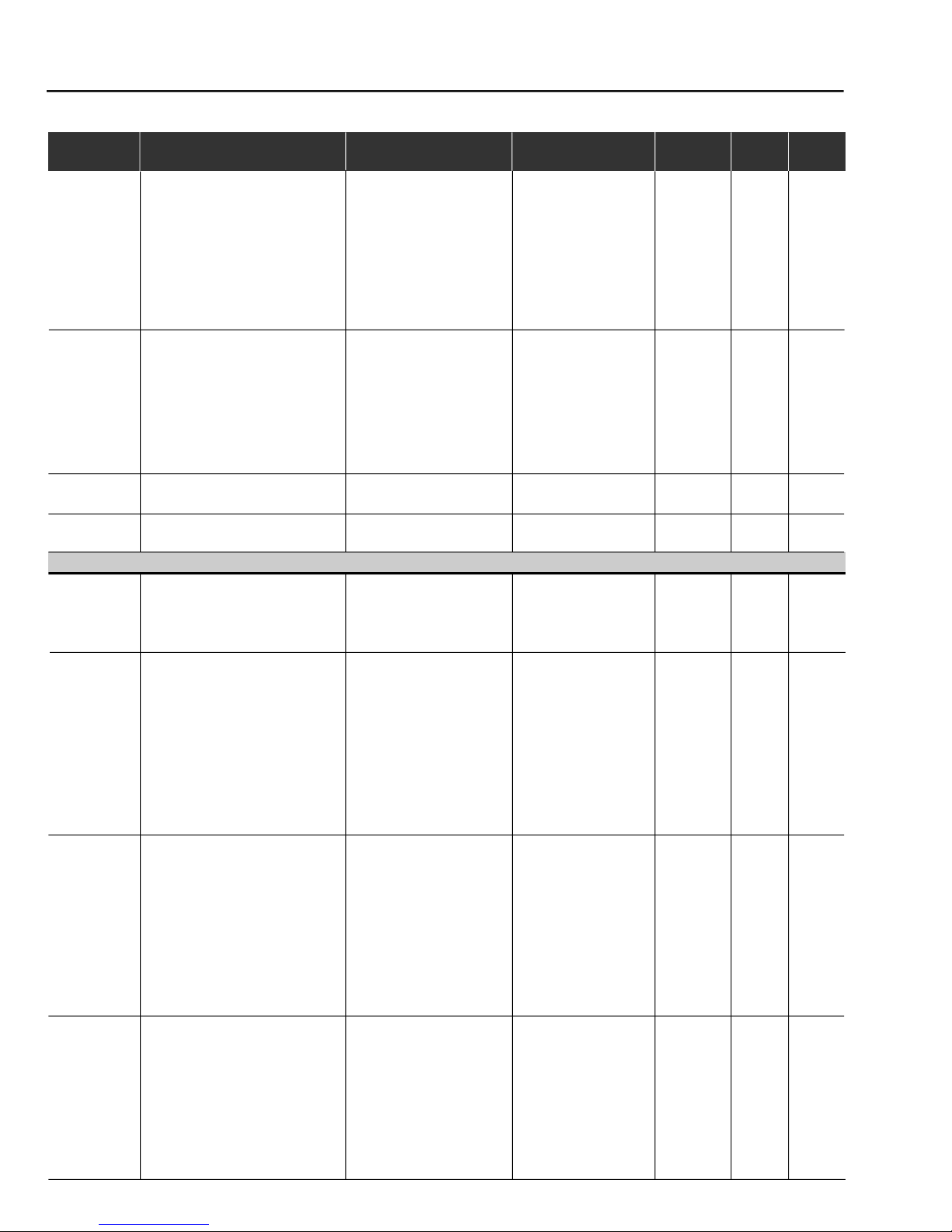

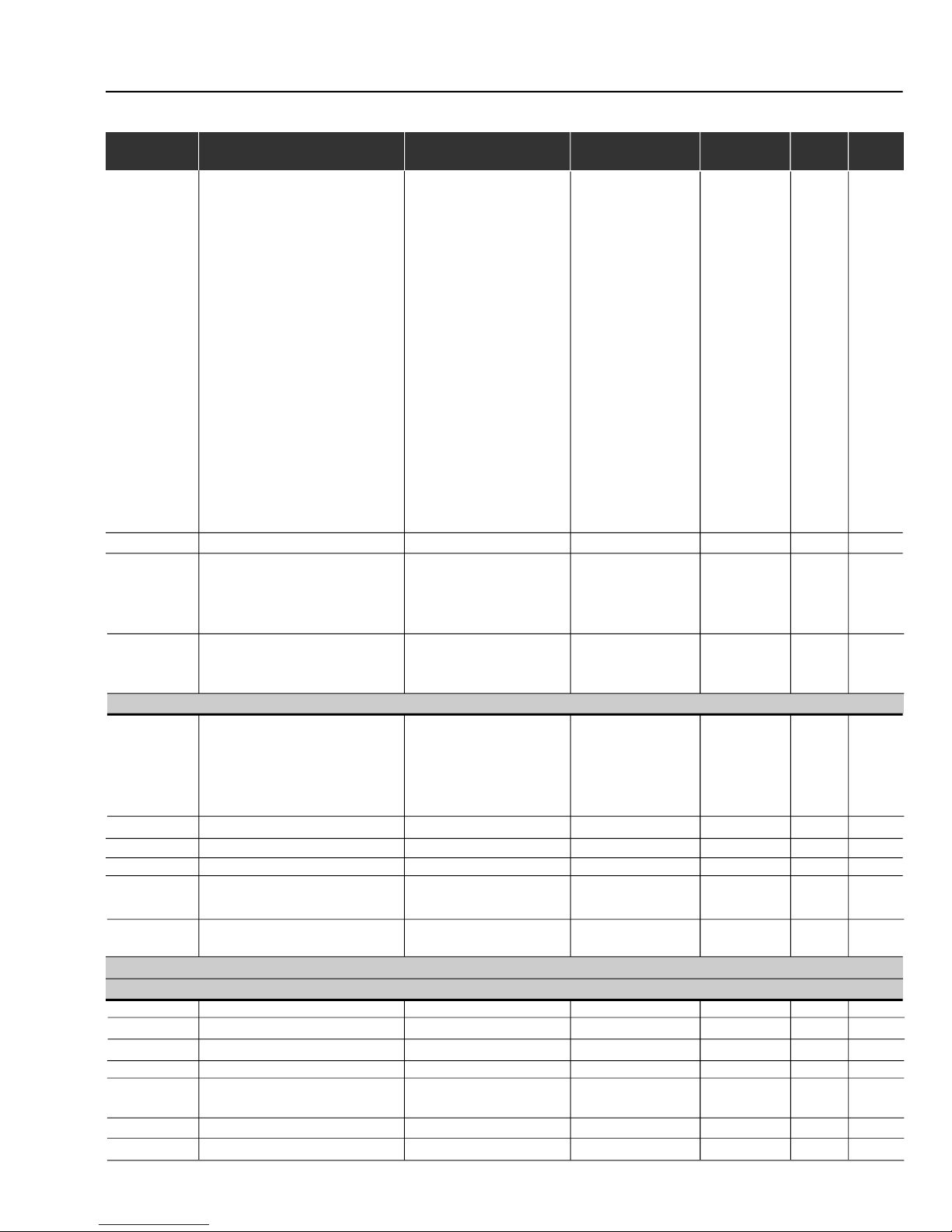

Page 10

CFW-09-

QUICKPARAMETER REFERENCE

11

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

(*)

P151 has different function for V/F or Vector Control.

V/F Control

P136

(*)

Manual Boost Torque

0 to 9

1-129

P137

Autommatic Torque Boost

0.00 to 1.00

0.00-130

P138

SlipCompensation

-10.0 to +10.0

0.0%130

P139

Output Current Filter

0.00 to 16.00

1.00s131

P140

Dwell Time at Start

0.0 to 10.0

0.0s131

P141

Dwell Speed at Start

0 to 300

90

rpm

131

Adjustable V/F

P142

(1)

MaximumOutputVoltage

0.0 to 100.0

100.0

%

132

P143

(1)

Intermediate Output Voltage

0.0 to 100.0

50.0%132

P144

(1)

Output Voltage at 3 Hz

0.0 to 100.0

8.0%132

P145

(1)

FieldWeakeningSpeed

P133 (> 90) to P134

1800

rpm

132

P146

(1)

IntermediateSpeed

90 to P145

900

rpm

132

DC Link Voltage Regulation

P150

(1)

DCLink VoltageRegulationMode

0 = With Losses

1 = Without Losses

-

133

1 = Without Losses

2= Enable/Disable

viaDI3...DI8

P151

(6) (*)

DC Link VoltageRegulation Level

339 to 400 (P296 = 0)

400V133 and

(V/F Control / Vector Control

585 to 800 (P296 = 1)

800

136

with optimal braking)

616 to 800 (P296 = 2)

800

678 to 800 (P296 = 3)

800

739 to 800 (P296 = 4)

800

809 to 1000 (P296 = 5)

1000

885 to 1000 (P296 = 6)

1000

924 to 1000 (P296 = 7)

1000

1063 to 1200 (P296 = 8)

1200

P152

ProportionalGain

0.00 to 9.99

0.00-137

P153

(6)

Dynamic Braking Level

339 to 400 (P296 = 0)

375V137

585 to 800 (P296 = 1)

618

616 to 800 (P296 = 2)

675

678 to 800 (P296 = 3)

748

739 to 800 (P296 = 4)

780

809 to 1000 (P296 = 5)

893

885 to 1000 (P296 = 6)

972

924 to 1000 (P296 = 7)

972

1063 to 1200 (P296 = 8)

1174

P154

Dynamic Braking Resistor

0.0 to 500

0.0138

P155

DB Resistor Power Rating

0.00 to 650

2.60kW138

Overload Currents

P156

(2)(7) (12)

Overload Current 100 % Speed

P157 to 1.3 x P295

1.1 x P401

A

139

P157

(2) (7)

Overload Current 50 % Speed

P156to P158

0.9 x P401

A

139

P158

(2) (7)

Overload Current 5 % Speed

(0.2 x P295) to P157

0.55 x P401

A

139

Speed Regulator

P160

(1)

Optimization of the

0= Normal

0= Normal

-

140

SpeedRegulator

1 = Saturated

P161

(3)

ProportionalGain

0.0 to 63.9

7.4-142

P162

(3)

IntegralGain

0.000 to 9.999

0.023

-

142

P163

Local Speed Reference Offset

-999 to +999

0-143

P164

Remote Speed Reference Offset

-999 to +999

0-143

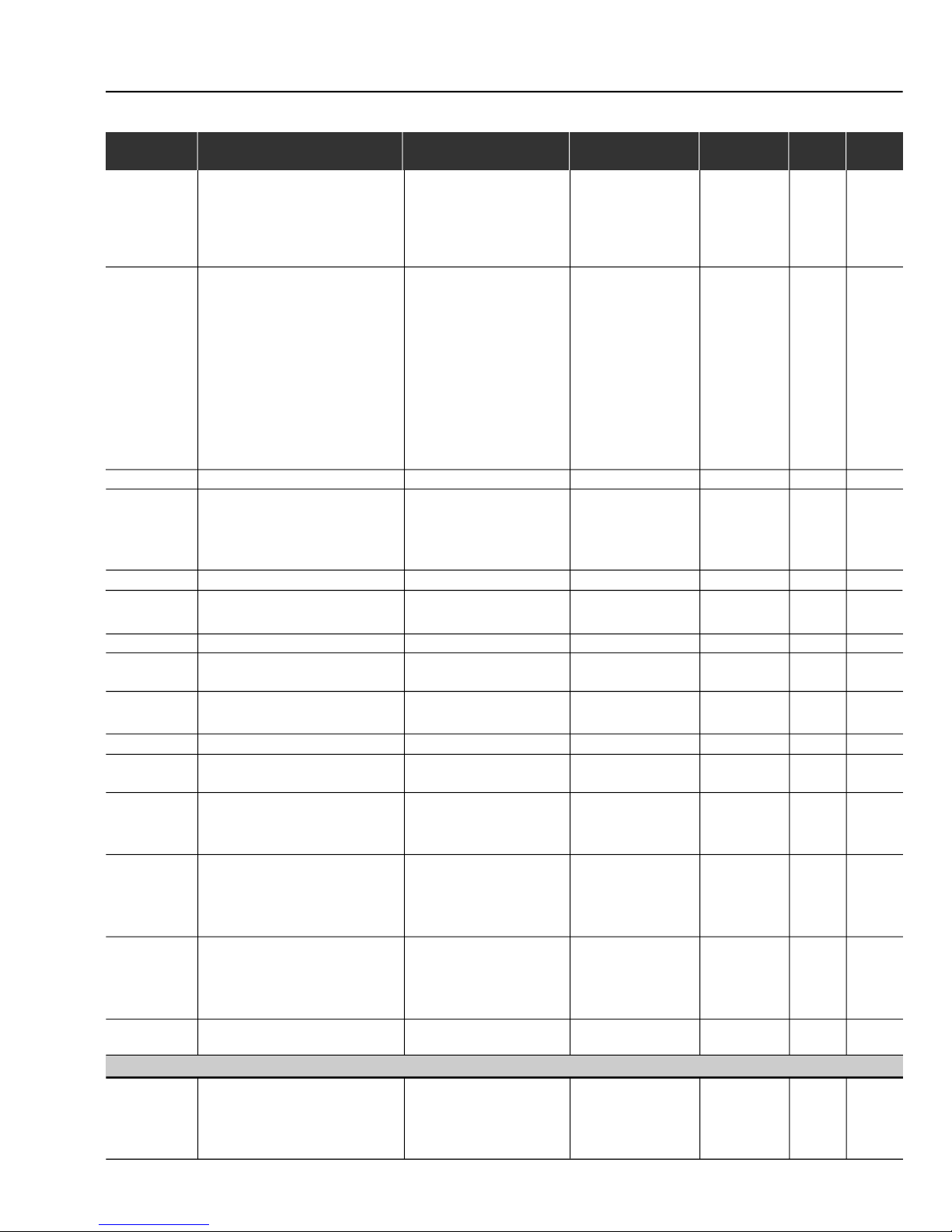

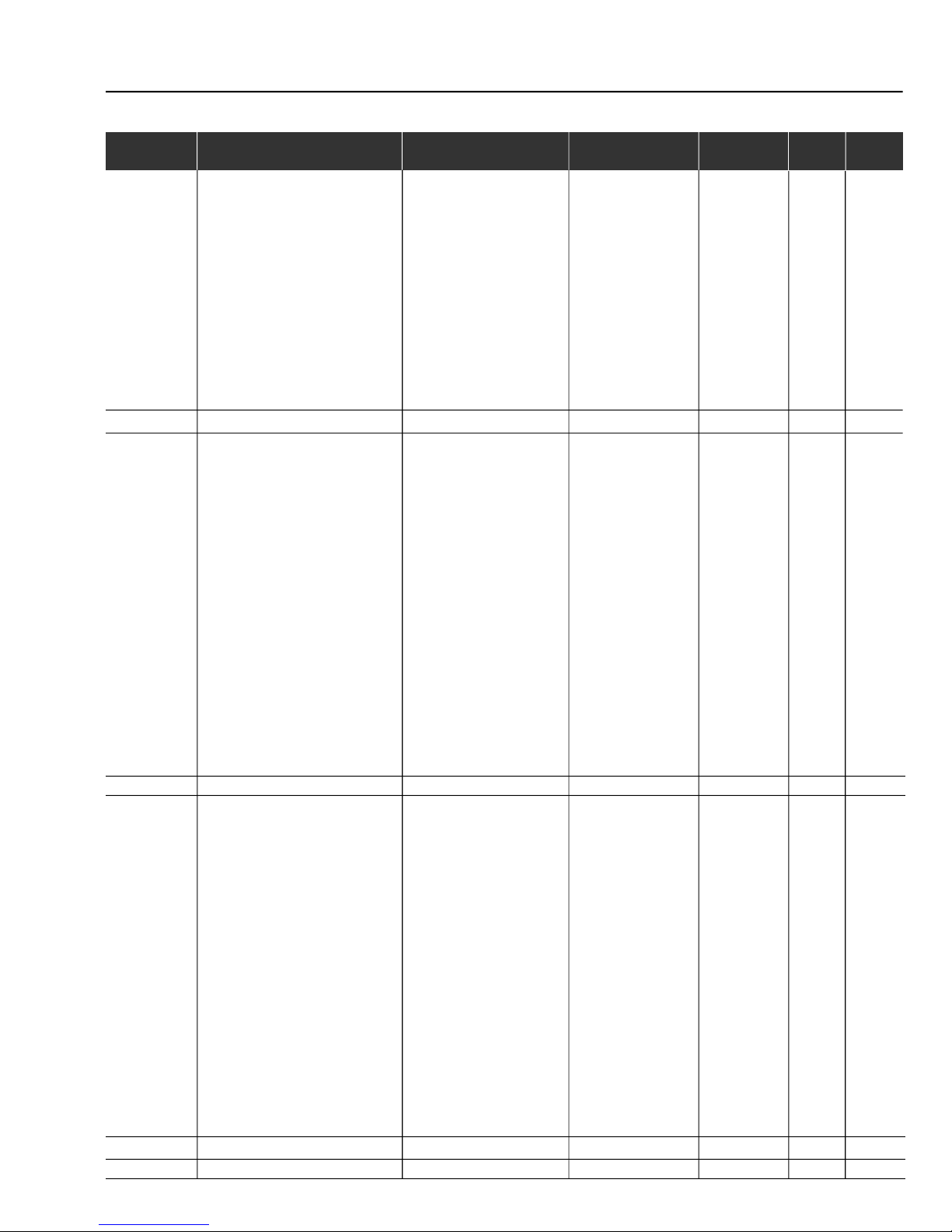

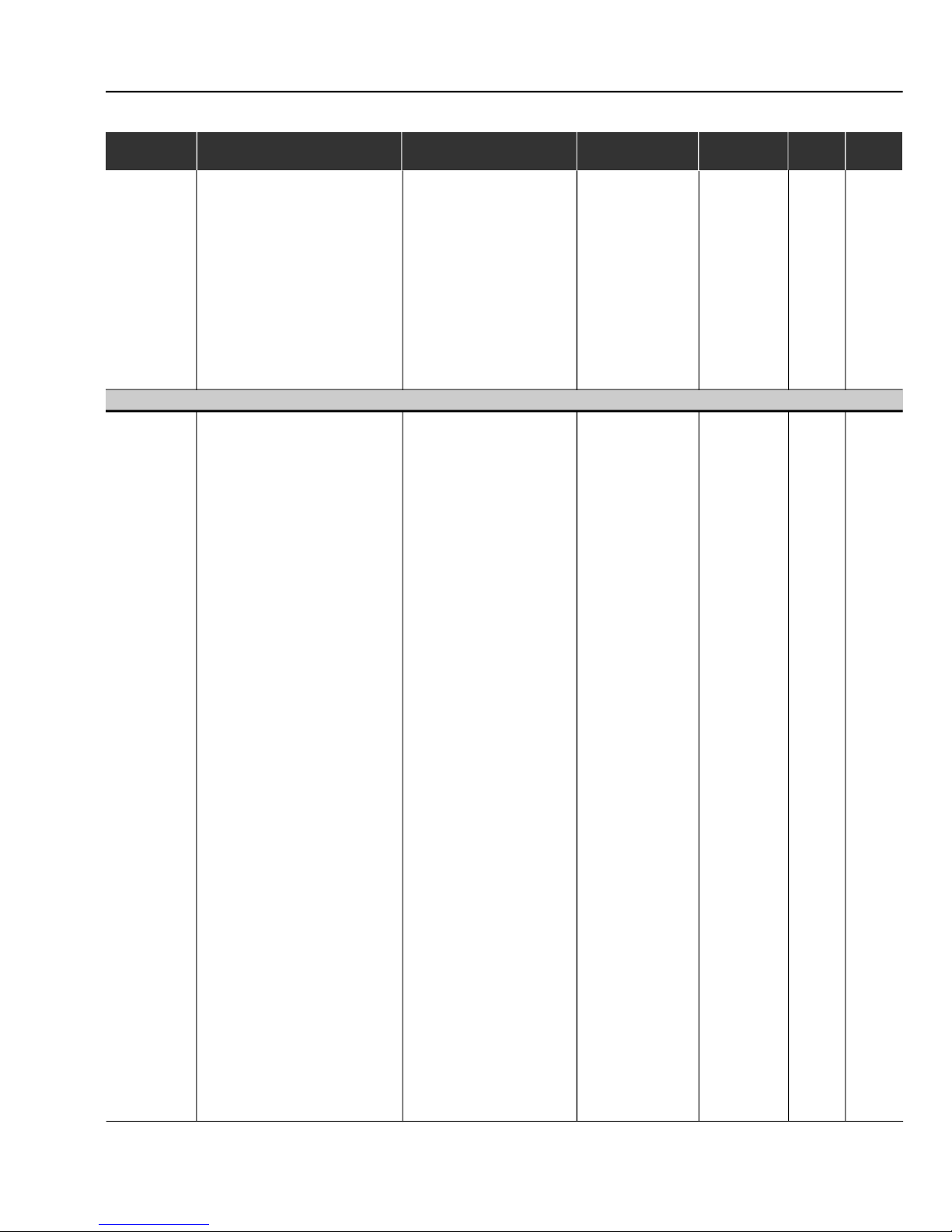

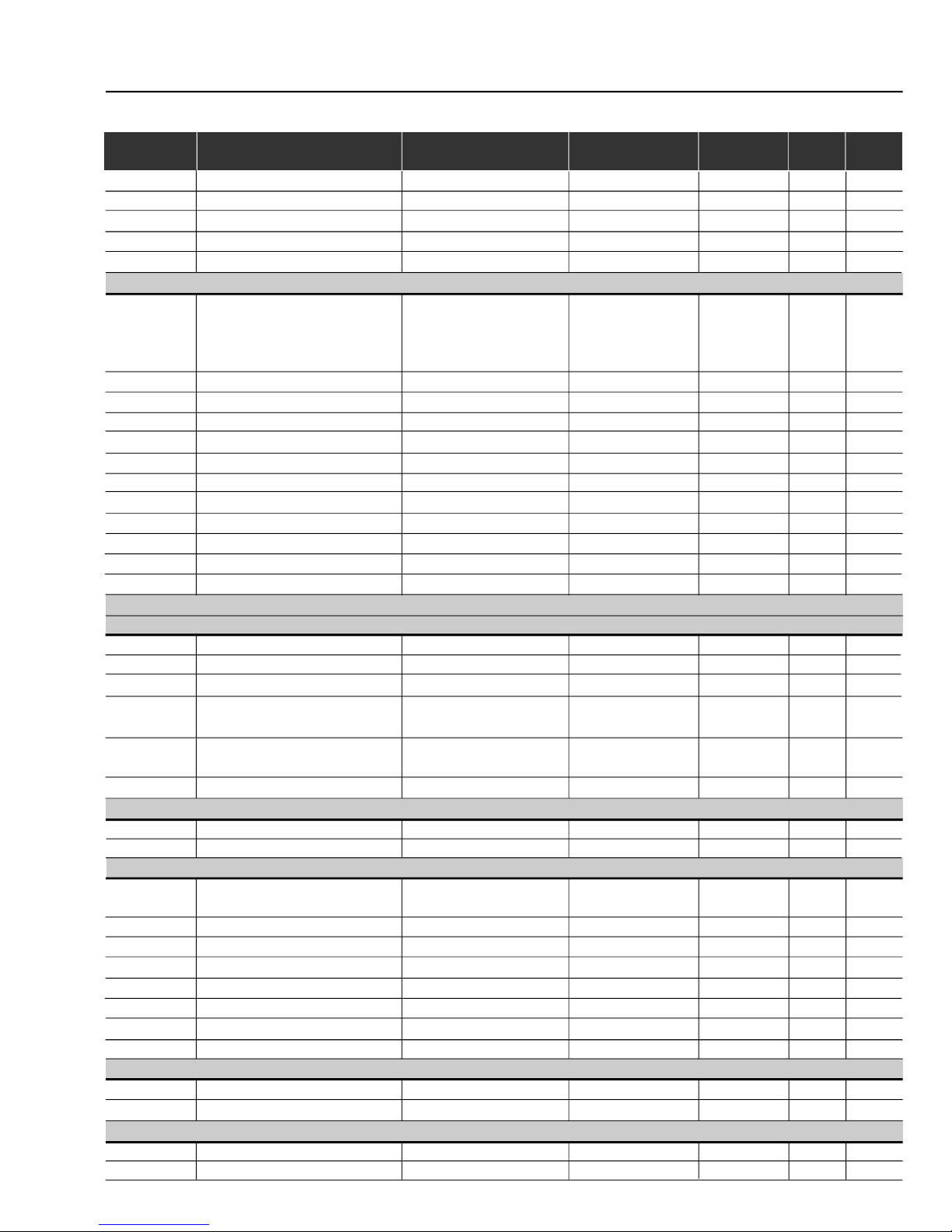

Page 11

CFW-09-

QUICKPARAMETER REFERENCE

12

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

P165

SpeedFilter

0.012 to 1.000

0.012

s

143

P166

Speed Regulator Differential Gain

0.00 to 7.99

0.00 (without

-

143

differential action)

Current Regulator

P167

(4)

ProportionalGain

0.00 to 1.99

0.50-143

P168

(4)

IntegralGain

0.000 to 1.999

0.010

-

143

P169

(*) (7)

Maximum Output Current(V/FControl)

(0.2 x P295) to

(1.8 x P295)

1.5 x P295

A

144

P169

(*) (7)

Maximum Forward Torque Current

0 to 180

125%144

(Vector Control)

P170

Maximum Reverse Torque Current

0 to 180

125%144

(Vector Control)

P171

Maximum ForwardTorque Current at

0 to 180

125%145

MaximumSpeed(P134)

P172

Maximum Reverse Torque Current at

0 to 180

125%145

MaximumSpeed(P134)

P173

Curve Type of the Max. Torque

0= Ramp

0= Ramp

-

145

1 = Step

Flux Regulator

P175

(5)

ProportionalGain

0.0 to 31.9

2.0-146

P176

(5)

IntegralGain

0.000 to 9.999

0.020

-

146

P177

MinimumFlux

0 to 120

0%146

P178

NominalFlux

0 to 120

100%146

P179

MaximumFlux

0 to 120

120%146

P180

FieldWeakenigStartPoint

0 to 120

95%146

P181

(1)

MagnetizationMode

0 = General Enable

0 = General Enable

-

146

1 = Start/Stop

CONFIGURATION PARAMETERS

P200 to P399

Generic Parameters

P200

Password

0 = Off

1 = On

-

147

1 = On

P201

(11)

Language Selection

0 = Português

0, 1, 2, 3

(11)

-

147

1= English

2 = Español

3 = Deutsch

P202

(1)(2) (11)

Type of Control

0 = V/F 60 Hz

0 (1)-147

1 = V/F 50 Hz

2 = V/F Adjustable

3 = Sensorless Vector

4 = Vector with Encoder

5 = VVW (Voltage Vector WEG)

P203

(1)

SpecialFunction Selection

0 = None

0 = None

-

147

1= PID Regulator

P204

(1)(10)

Load/Save Parameters

0 = Not Used

0 = Not Used

-

148

1 = Not Used

2 = Not Used

3 = Reset P043

4 = Reset P044

5 = LoadsFactory Default-60Hz

6 = LoadsFactory Default-50Hz

(*)

P169 has different function for V/F or Vector Control.

Page 12

CFW-09-

QUICKPARAMETER REFERENCE

13

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

7 = Loads User Default 1

8 = Loads User Default 2

9 = Not Used

10 = Save User Default 1

11 = Save User Default 2

P205

Display Default Selection

0=P005 (Motor Frequency)

2 = P002

-

149

1 = P003 (Motor Current)

2 = P002 (Motor Speed)

3 = P007 (Motor Voltage)

4 = P006 (Inverter Status)

5 = P009 (Motor Torque)

6 = P070

(Motor Speed and

Motor Current)

7 = P040

(PID Process

Variable)

P206

Auto-Reset Time

0 to 255

0s150

P207

Reference Engineering Unit 1

32 to 127 (ASCII)

114= r

-

150

A, B, ... , Y, Z

0, 1, ... , 9

#, $, %, (, ), *, +, ...

P208

(2)(11)

Reference Scale Factor

1 to 18000

1800 (1500)

-

150

P209

(1)

Motor Phase Loss Detection

0 = Off

0 = Off

-

151

1 = On

P210

DecimalPoint of the SpeedIndication

0 to 3

0-151

P211

(1)

Zero Speed Disable

0 = Off

0 = Off

-

151

1 = On

P212

Condition to Leave Zero

0 = N* or N>P291

0 = N* or N>P291

-

152

SpeedDisable

1= N*>P291

P213

Time Delay for Zero Speed Disable

0 to 999

0s152

P214

(1) (9)

Line Phase Loss Detection

0 = Off

1 = On

-

152

1 = On

P215

(1)

Keypad Copy Function

0 = Off

0 = Off

-

152

1 = Inverter Keypad

2 = Keypad Inverter

P216

Reference Engineering Unit 2

32 to 127 (ASCII)

112= p

-

154

A, B, ... , Y, Z

0, 1, ... , 9

#, $, %, (, ), *, +, ...

P217

Reference Engineering Unit 3

32 to 127 (ACSII)

109 = m

-

154

A, B, ... , Y, Z

0, 1, ... , 9

#, $, %, (, ), *, +, ...

P218

LCD Display Contrast

0 to 150

127-154

Adjustment

Local/Remote Definition

P220

(1)

Local/Remote Selection Source

0 = Always Local

2 = Keypad

-

154

1 = Always Remote

(Default Local)

2 = Keypad (Default Local)

3 = Keypad (

DefaultRemote

)

Page 13

CFW-09-

QUICKPARAMETER REFERENCE

14

4 = DI2 to DI8

5 = Serial (L)

6 = Serial (R)

7 = Fieldbus (L)

8 = Fieldbus (R)

9 = PLC (L)

10 = PLC (R)

P221

(1)

Local Speed Reference Selection

0 = keypad

0 = Keypad

-

155

1 = AI1

2 = AI2

3 = AI3

4 = AI4

5 =Add AI > 0

6 =Add AI

7=E.P.

8 = Multispeed

9 = Serial

10 = Fieldbus

11= PLC

P222

(1)

Remote SpeedReference

0 = keypad

1 = AI1

-

155

Selection

1 = AI1

2 = AI2

3 = AI3

4 = AI4

5 =Add AI > 0

6 =Add AI

7= E.P.

8 = Multispeed

9 = Serial

10 = Fieldbus

11= PLC

P223

(1) (8)

LocalFWD/REV Selection

0 = Always Forward

2 = Keypad

-

156

1 = Always Reverse

(DefaultFWD)

2 = Keypad (Default FWD)

3 = Keypad (Default REV)

4= DI2

5 = Serial (Default FWD)

6 = Serial (Default REV)

7 = Fieldbus (Default FWD)

8 = Fieldbus (Default REV)

9 = PolarityAI4

10= PLC (FWD)

11= PLC(REV)

P224

(1)

Local Start/Stop Selection

0 = [I] and [O] Keys

0 = [I] and [O] Keys

-

156

1 = DIx

2 = Serial

3 = Fieldbus

4=PLC

P225

(1) (8)

Local JOG Selection

0 = Disable

1 = Keypad

-

156

1 = Keypad

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

Page 14

CFW-09-

QUICKPARAMETER REFERENCE

15

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

2 = DI3 to DI8

3 = Serial

4 = Fieldbus

5=PLC

P226

(1) (8)

RemoteFWD/REVSelection

0 = Always Forward

4= DI2

-

157

1 = Always Reverse

2 = Keypad (Default FWD)

3 = Keypad (Default REV)

4= DI2

5 = Serial (Default FWD)

6 = Serial (Default REV)

7 = Fieldbus (Default FWD)

8 = Fieldbus (Default REV)

9 = PolarityAI4

10= PLC (FWD)

11= PLC(REV)

P227

(1)

RemoteStart/StopSelection

0 = [I] and [O] Keys

1 = DIx

-

157

1 = DIx

2 = Serial

3 = Fieldbus

4=PLC

P228

(1) (8)

RemoteJOG Selection

0 = Disable

2 = DI3 to DI8

-

157

1 = Keypad

2 = DI3 to DI8

3 = Serial

4 = Fieldbus

5=PLC

Stop Model Definition

P232

(1)

StopMode Selection

0 =

Ramp to Stop

0 = Ramp to Stop

-

163

1 = Coast to Stop

2 =

Fast Stop

Analog Inputs

P233

Analog Inputs Dead Zone

0 = Off

0 = Off

-

163

1 = On

P234

Analog Input AI1 Gain

0.000 to 9.999

1.000

-

164

P235

(1)

Analog Input AI1 Signal

0 = (0 to 10) V / (0 to 20) mA

0 = (0 to 10) V /

-

165

1 = (4 to 20) mA

(0 to 20) mA

2 = (10 to 0) V / (20 to 0) mA

3 = (20 to 4) mA

P236

Analog Input AI1 Offset

-100.0 to +100.0

0.0%165

P237

(1) (8)

Analog Input AI2 Function

0= P221/P222

0= P221/P222

-

165

1 = N* without ramp

2=MaximumTorqueCurrent

3 = PID Process Variable

4=MaximumTorqueCurrent

(AI2 + AI1)

P238

Analog Input AI2 Gain

0.000 to 9.999

1.000

-

166

Page 15

CFW-09-

QUICKPARAMETER REFERENCE

16

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

P239

(1)

Analog Input AI2 Signal

0 = (0 to 10) V / (0 to 20) mA

0 = (0 to 10) V /

-

166

1 = (4 to 20) mA

(0 to 20) mA

2 = (10 to 0) V / (20 to 0) mA

3 = (20 to 4) mA

P240

Analog Input AI2 Offset

-100.0 to +100.0

0.0%167

P241

(1) (8)

Analog Input AI3 Function

0= P221/P222

0= P221/P222

-

167

(Requires Optional I/O Expansion

1 = Without ramp

Board EBB)

2 =

MaximumTorqueCurrent

3 = PID Process Variable

4=MaximumTorqueCurrent

(AI3 + AI2)

P242

Analog Input AI3 Gain

0.000 to 9.999

1.000

-

168

P243

(1)

Analog Input AI3 Signal

0 = (0 to 10) V / (0 to 20) mA

0 = (0 to 10) V /

-

168

1 = (4 to 20) mA

(0 to 20) mA

2 = (10 to 0) V / (20 to 0) mA

3 = (20 to 4) mA

P244

Analog Input AI3 Offset

-100.0 to +100.0

0.0%168

P245

Analog Input AI4 Gain

0.000 to 9.999

1.000

-

168

P246

(1)

Analog Input AI4 Signal

0 = (0 to 10) V / (0 to 20) mA

0 = (0 to 10) V /

-

168

(Requires Optional I/O Expansion

1 = (4 to 20) mA

(0 to 20) mA

Board EBA)

2 = (10 to 0) V / (20 to 0) mA

3 = (20 to 4) mA

4 = (-10 to +10) V

P247

Analog Input AI4 Offset

-100.0 to +100.0

0.0%169

P248

InputFilterAI2

0.0 to 16.0

0.0s169

Analog Outputs

P251

Analog OutputAO1 Function

0 = Speed Reference

2 = Real Speed

-

169

(CC9 or EBB board)

1 = Total Reference

2 = Real Speed

3 = Torque Current

Reference (Vector)

4=Torque Current (Vector)

5 = Output Current

6 = PID Process Variable

7 = Active Current (V/F)

8 = Power (kW)

9= PID Setpoint

10=PositiveTorque Current

11= Motor Torque

12= PLC

13 =

Dead Zone for

SpeedIndication

14 = Motor Voltage

P252

Analog Output AO1 Gain

0.000 to 9.999

1.000

-

169

P253

Analog OutputAO2 Function

0 = Speed Reference

5 = Output Current

-

169

(CC9 or EBB board)

1 = Total Reference

2 = Real Speed

3 = Torque Current

Reference (Vector)

Page 16

CFW-09-

QUICKPARAMETER REFERENCE

17

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

4 = Torque Current (Vector)

5 = Output Current

6 = PID Process Variable

7 = Active Current (V/F)

8 = Power (kW)

9= PID Setpoint

10=PositiveTorque Current

11= Motor Torque

12= PLC

13 = Dead Zone for

SpeedIndication

14 = Motor Voltage

P254

Analog Output AO2 Gain

0.000 to 9.999

1.000

-

169

P255

Analog Output AO3 Function

0 = Speed Reference

2 = Real Speed

-

169

(Requires Optional I/O Expansion

1 = Total Reference

Board EBA)

2 = Real Speed

3 = Torque Current

Reference (Vector)

4=Torque Current (Vector)

5 = Output Current

6 = PID Process Variable

7 = Active Current (V/F)

8 = Power (kW)

9= PID Setpoint

10

=PositiveTorqueCurrent

11= Motor Torque

12= PLC

13 =

Not Used

14 = Motor Voltage

15to 63= ExclusiveWEG use

P256

Analog Output AO3 Gain

0.000 to 9.999

1.000

-

170

P257

Analog Output AO4 Function

0 = Speed Reference

5 = Output Current

-

170

(Requires optional I/O Expansion

1 = Total Reference

Board EBA)

2 = Real Speed

3 = Torque Current

Reference (Vector)

4 = Torque Current (Vector)

5 = Output Current

6 = PID Process Variable

7 = Active Current (V/F)

8 = Power (kW)

9= PID Setpoint

10=PositiveTorqueCurrent

11= Motor Torque

12= PLC

13 = Not Used

14 = Motor Voltage

15to 63= ExclusiveWEG use

P258

Analog Output AO4 Gain

0.000 to 9.999

1.000

-

170

P259

Dead Zone for Speed Indication

0 to P134

1000

rpm

171

Page 17

CFW-09-

QUICKPARAMETER REFERENCE

18

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

Digital Inputs

P263

(1)

DigitalInput DI1 Function

0 = Not Used

1 = Start/Stop

-

172

1 = Start/Stop

2 = General Enable

3 = Fast Stop

P264

(1)

DigitalInput DI2 Function

0=FWD/REV

0=FWD/REV

-

172

1= Local/Remote

2 = Not Used

3 = Not Used

4 = Not Used

5 = Not Used

6 = Not Used

7 = Not Used

8 = Reverse Run

P265

(1) (8)

DigitalInput DI3 Function

0 = Not Used

0 = Not Used

-

172

1 = Local/ Remote

2 = General Enable

3 = JOG

4 = No ExternalFault

5 = Increase E.P.

6 = Ramp 2

7 = Not Used

8 = Forward Run

9 = Speed/Torque

10= JOG+

11= JOG-

12 = Reset

13 = Fieldbus

14 = Start (3 wire)

15 = Man/Auto

16 = Not used

17 = Disables Flying Start

18 = DC VoltageRegulator

19 = Parameter Setting

Disable

20 = Load user

21 = Timer (RL2)

22 = Timer (RL3)

P266

(1)

DigitalInput DI4 Function

0 = Not used

0 = Not Used

-

172

1 = Local/ Remote

2 = General Enable

3 = JOG

4 = No external Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Multispeed (MS0)

8 = Reverse Run

9 = Speed/Torque

10= JOG+

Page 18

CFW-09-

QUICKPARAMETER REFERENCE

19

11= JOG-

12 = Reset

13 = Fieldbus

14 = Stop (3 wire)

15 = Man/Auto

16 = Not used

17 = Disables Flying Start

18 = DC voltage regulator

19 = Parameter Setting

Disable

20 = Load User

21 = Timer (RL2)

22 = Timer (RL3)

P267

(1)

DigitalInput DI5 Function

0 = Not Used

3 = JOG

-

172

1 = Local/ Remote

2 = General Enable

3 = JOG

4 = No ExternalFault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS1)

8 = Fast Stop

9 = Speed/Torque

10= JOG+

11= JOG-

12 = Reset

13 = Fieldbus

14 = Start (3 wire)

15 = Man/Auto

16 = Not Used

17 = Disables Flying Start

18 = DC VoltageRegulator

19 = Parameter Setting

Disable

20 = Load User

21 = Timer (RL2)

22 = Timer (RL3)

P268

(1)

DigitalInput DI6 Function

0 = Not Used

6 = Ramp 2

-

173

1 = Local/ Remote

2 = General Enable

3 = JOG

4 = No ExternalFault

5 = Decrease E.P.

6 = Ramp 2

7 = Multispeed (MS2)

8 = Fast Stop

9 = Speed/Torque

10= JOG+

11= JOG-

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

Page 19

CFW-09-

QUICKPARAMETER REFERENCE

20

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

12 = Reset

13 = Fieldbus

14 = Stop (3 wire)

15 = Man/Auto

16 = Not Used

17 = Disables Flying Start

18 = DC voltage regulator

19 = Parameter setting

disable

20 = Load user

21 = Timer (RL2)

22 = Timer (RL3)

P269

(1)

DigitalInput DI7 Function

0 = Not Used

0 = Not used

-

173

(Requiresoptional I/O

1 = Local/ Remote

expansion board EBA or EBB)

2 = General Enable

3 = JOG

4 = No ExternalFault

5 = Not Used

6 = Ramp 2

7 = Not Used

8 = Fast Stop

9 = Speed/Torque

10= JOG+

11= JOG-

12 = Reset

13 = Fieldbus

14 = Start (3 wire)

15 = Man/Auto

16 = Not Used

17 = Disables Flying Start

18 = DC VoltageRegulator

19 = Parameter Setting

Disable

20 = Load User

21 = Timer (RL2)

22 = Timer (RL3)

P270

(1)

DigitalInput DI8 Function

0 = Not used

0 = Not used

-

173

(Requiresoptional I/O

1= Local/Remote

expansion board EBA or EBB)

2 = General Enable

3 = JOG

4 = No ExternalFault

5 = Not Used

6 = Ramp 2

7 = Not Used

8 = Fast Stop

9 = Speed/Torque

10= JOG+

11= JOG-

12 = Reset

Page 20

CFW-09-

QUICKPARAMETER REFERENCE

21

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

13 = Fieldbus

14 = Stop (3 wire)

15 = Man/Auto

16 = Motor Thermistor

17 = Disables Flying Start

18 = DC VoltageRegulator

19 = Parameter Setting

Disable

20 = Not Used

21 = Timer (RL2)

22 = Timer (RL3)

Digital Outputs

P275

(1)

DigitalOuputDO1Function

0 = Not used

0 = Not Used

-

180

(requires optional I/O

1 = N* > Nx

expansion board EBA or EBB)

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

6 = Is > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10= Remote

11= Run

12 = Ready

13 = No Fault

14 = No E00

15= NoE01+E02+E03

16 = No E04

17 = No E05

18 = (4 to 20) mA OK

19 = Fieldbus

20= FWD

21 = Proc.Var. > VPx

22 = Proc. Var. < VPy

23 = Ride-Through

24 = Pre-charge OK

25 = Fault

26 = Enabled Hours > Hx

27 = Not Used

28 = Not Used

29 = N > Nx and Nt > Nx

30 = Brake (Actual Speed)

31 =

Brake (Total Reference)

32 = Overweight

33 = Slack Cable

34 = Torque Polarity +/-

Page 21

CFW-09-

QUICKPARAMETER REFERENCE

22

35 = Torque Polarity -/+

36 = F > Fx _ 1

37 = F > Fx _ 2

38 = Set Point = Process

Variable

39 = No E32

40 = Ready 2

P276

(1)

DigitalOutputDO2 Function

0 = Not Used

0 = Not used

-

180

(Requiresoptional I/O

1 = N* > Nx

expansion board EBA or EBB)

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

6 = Is > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10= Remote

11= Run

12 = Ready

13 = No Fault

14 = No E00

15= NoE01+E02+E03

16 = No E04

17 = No E05

18 = (4 to 20) mA OK

19 = Fieldbus

20= FWD

21 = Proc.Var. > VPx

22 = Proc. Var. < VPy

23 = Ride-Through

24 = Pre-charge OK

25 = Fault

26 = Enabled Hours > Hx

27 = Not Used

28 = Not Used

29 = N > Nx and Nt > Nx

30 = Brake (Actual Speed)

31 = Brake

(Total Reference)

32 = Overweight

33 = Slack Cable

34 = Torque Polarity +/-

35 = Torque Polarity -/+

36 = F > Fx _ 1

37 = F > Fx _ 2

38 = Set Point = Process

Variable

39 = No E32

40 = Ready 2

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

Page 22

CFW-09-

QUICKPARAMETER REFERENCE

23

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

P277

(1)

Relay Output RL1 Function

0 = Not Used

13 = No Fault

-

180

1 = N* > Nx

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

6 = Is > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10= Remote

11= Run

12 = Ready

13 = No Fault

14 = No E00

15= NoE01+E02+E03

16 = No E04

17 = No E05

18 = (4 to 20) mA OK

19 = Fieldbus

20= FWD

21 = Proc.Var. > VPx

22 = Proc. Var. < VPy

23 = Ride-Through

24 = Pre-charge OK

25 = Fault

26 = Enabled Hours > Hx

27= PLC

28 = Not Used

29 = N > Nx and Nt > Nx

30 = Brake (Actual Speed)

31 = Brake

(Total Reference)

32 = Overweight

33 = Slack Cable

34 = Torque Polarity +/-

35 = Torque Polarity -/+

36 = F > Fx _ 1

37 = F > Fx _ 2

38 = Set Point = Process

Variable

39 = No E32

40 = Ready 2

P279

(1)

Relay Output RL2 Function

0 = Not used

2 = N > Nx

-

180

1 = N* > Nx

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

Page 23

CFW-09-

QUICKPARAMETER REFERENCE

24

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

6 = I

s > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10= Remote

11= Run

12 = Ready

13 = No Fault

14 = No E00

15= NoE01+E02+E03

16 = No E04

17 = No E05

18 = (4 to 20) mA OK

19 = Fieldbus

20= FWD

21 = Proc.Var. > VPx

22 = Proc. Var. < VPy

23 = Ride-Through

24 = Pre-charge OK

25 = Fault

26 = Enabled Hours > Hx

27= PLC

28= Timer

29 = N > Nx and Nt > Nx

30 = Brake (Actual Speed)

31 = Brake

(Total Reference)

32 = Overweight

33 = Slack Cable

34 = Torque Polarity +/-

35 = Torque Polarity -/+

36 = F > Fx _ 1

37 = F > Fx _ 2

38 = Set Point = Process

Variable

39 = No E32

40 = Ready 2

P280

(1)

Relay Output RL3 Function

0 = Not used

1 = N* > Nx

-

180

1 = N* > Nx

2 = N > Nx

3 = N < Ny

4 = N = N*

5 = Zero Speed

6 = Is > Ix

7 = Is < Ix

8 = Torque > Tx

9 = Torque < Tx

10= Remote

11= Run

12 = Ready

13 = No Fault

Page 24

CFW-09-

QUICKPARAMETER REFERENCE

25

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

14 = No E00

15= NoE01+E02+E03

16 = No E04

17 = No E05

18 = (4 to 20) mA OK

19 = Fieldbus

20= FWD

21 = Proc.Var. > VPx

22 = Proc. Var. < VPy

23 = Ride-Through

24 = Pre-charge OK

25 = Fault

26 = Enabled Hours > Hx

27= PLC

28= Timer

29 = N > Nx and Nt > Nx

30 = Brake (Actual Speed)

31 = Brake

(Total Reference)

32 = Overweight

33 = Slack Cable

34 = Torque Polarity +/-

35 = Torque Polarity -/+

36 = F > Fx _ 1

37 = F > Fx _ 2

38 = Set Point = Process

Variable

39 = No E32

40 = Ready 2

P283

Time for RL2ON

0.0 to 300

0.0s186

P284

Timefor RL2 OFF

0.0 to 300

0.0s186

P285

Time for RL3ON

0.0 to 300

0.0s186

P286

Timefor RL3 OFF

0.0 to 300

0.0s186

Nx, Ny, Ix, Zero Speed Zone, N = N* and Tx

P287

Hysteresis for Nx/Ny

0.0 to 5.0

1.0%193

P288

(2)(11)

Nx Speed

0 to P134

120 (100)

rpm

193

P289

(2)(11)

Ny Speed

0 to P134

1800 (1500)

rpm

193

P290

(7)

Ix Current

(0 to 2.0) x P295

1.0 x P295

A

193

P291

Zero Speed Zone

1 to 100

1%193

P292

N = N* Band

1 to 100

1%193

P293

Tx Torque

0 to 200

100%193

P294

Hours Hx

0 to 6553

4320h193

Inverter Data

P295

(1)

Inverter Rated Current

According to

-

194

Inverter Model

3 = 6 A

4 = 7 A

6 = 10 A

7 = 13 A

8 = 16 A

9 = 24 A

220-230 V Models

10 = 28 A

13 = 45 A

14 = 54 A

16 = 70 A

17 = 86 A

18 = 105 A

19 = 130 A

Page 25

CFW-09-

QUICKPARAMETER REFERENCE

26

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

0 = 3.6 A

1 = 4 A

2 = 5.5 A

5 = 9 A

7 = 13 A

8 = 16 A

9 = 24 A

11= 30 A

12 = 38 A

13 = 45 A

15 = 60 A

16 = 70 A

17 = 86 A

18 = 105 A

20 = 142 A

21 = 180 A

55 = 211A

22 = 240 A

67 = 312 A

23 = 361 A

24 = 450 A

69 = 515 A

25 = 600 A

33 = 686 A

34 = 855 A

35 = 1140A

36 = 1283 A

37 = 1710 A

82 = 1468 A

39 = 2.9 A

40 = 4.2 A

4 = 7 A

6 = 10 A

41 = 12 A

42 = 14 A

43 = 22 A

44 = 27 A

45 = 32 A

46 = 44 A

47 = 53 A

48 = 63 A

49 = 79 A

25 = 600 A

72 = 652 A

73 = 794 A

76 = 897 A

78 = 978 A

79 = 1191A

81 = 1345 A

51 = 107 A

53 = 147 A

55 = 211A

57 = 247 A

60 = 315 A

62 = 343 A

63 = 418 A

65 = 472 A

50 = 107 A

52 = 127 A

54 = 179 A

56 = 225 A

58 = 259 A

59 = 305 A

61 = 340 A

64 = 428 A

68 = 492 A

70 = 580 A

71 = 646 A

74 = 813 A

75 = 869 A

77 = 969 A

80 = 1220 A

38 = 2 A

66 = 33 A

26 = 200 A

27 = 230 A

28 = 320 A

SpecialModels

29 = 400 A

30 = 570 A

31 = 700 A

32 = 900 A

380-480 V

Models

500-600 V

Models

500-690 V

Models

660-690 V Models

Page 26

CFW-09 -

QUICK PARAMETER REFERENCE

27

Parameters

Function

Adjustable Range

Factory

Unit

User's

Page

Setting

Setting

0 = for models

220-230 V

3 = for models

380-480 V

6 = for models

500-600 V and

500-690 V

8 = for models

660-690 V

P296

(1) (11)

Inverter Rated Voltage

0 = 220-230 V

-

195

(Rated Input Voltage)

1 = 380 V

2 = 400-415 V

3 = 440-460 V

4 = 480 V

5 = 500-525 V

6 = 550-575 V

7 = 600 V

8 = 660-690 V

P297

(1) (2)

Switching Fr equency

0 = 1.25

2 = 5.0

kHz

195

1 = 2.5

2 = 5.0

3 = 10.0

DC Br aking

P300

DC Braking Time

0.0 to 15.0

0.0s196

P301

DC Braking Start Speed

0 to 450

30

rpm

197

P302

DC Braking Voltage

0.0 to 10.0

2.0%197

Skip Speed

P303

Skip Speed 1

P133 to P134

600

rpm

197

P304

Skip Speed 2

P133 to P134

900

rpm

197

P305

Skip Speed 3

P133 to P134

1200

rpm

197

P306

Skip Band

0 to 750

0

rpm

197

Serial Communication

P308

(1)

Inverter Address

1 to 30

1-198

P309

(1)

Fieldbus

0 = Disable

0 = Disable

-

198

1 = Profibus DP/DP-V1 2 I/O

2 = Profibus DP/DP-V1 4 I/O

3 = Profibus DP/DP-V1 6 I/O

4 = DeviceNet 2 I/O

5 = DeviceNet 4 I/O

6 = DeviceNet 6 I/O

7 =EtherNet/IP 2 I/O

8 =EtherNet/IP 4 I/O

9 =EtherNet/IP 6 I/O

10 = DeviceNet Drive Profile

P310

(1)

STOP Detection in a Profibus

0 = Off

0 = Off

198

Networ k

1 = On

P312

(1)

Type of Serial Protocol

0 = WBUS Protocol

0 = W EG Protocol

-

199

1 = Modbus-RTU, 9600 bps,

no parity

2 = Modbus-RTU, 9600 bps,

odd parity

3 = Modbus-RTU, 9600 bps,

even parity

4 = Modbus-RTU, 19200 bps,

no parity

5 = Modbus-RTU, 19200 bps,

odd parity

Attention!

Refer to

item

3.2.3 to

do the

voltage

selection

Page 27

CFW-09-

QUICKPARAMETER REFERENCE

28

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

6= Modbus-RTU,19200bps,

even parity

7= Modbus-RTU,38400bps,

no parity

8= Modbus-RTU,38400bps,

odd parity

9= Modbus-RTU,38400bps,

even parity

P313

(1)

Typeof disabling by E28/E29/E30

0 = Disable via Start/Stop

0 = Disablevia Start/Stop

-

199

1 = Disable via General

Enable

2 = Not Used

3 = Changes to LOCAL 1

4 = Changes to LOCAL 2

5 = Causes Fatal Error

P314

(1)

Time for Serial Watchdog

0.0 = Disable

0.0 = Disabled

s

200

Action

0.1 to 999.0 = Enable

P318

Watchdog detection for the

0 = Off

0 = Off

200

PLCboard

1 = On

Flying Start/Ride-Through

P320

(1)

FlyingStart/Ride-Through

0 = Inactive

0 = Inactive

-

200

1 = Flying Start

2 =

FlyingStart/Ride-Through

3 = Ride-Through

P321

(6)

Ud Line Loss Level

178 to 282 (P296 = 0)

252V200

307 to 487 (P296 = 1)

436

324 to 513 (P296 = 2)

459

356 to 564 (P296 = 3)

505

388 to 615 (P296 = 4)

550

425 to 674 (P296 = 5)

602

466 to 737 (P296 = 6)

660

486 to 770 (P296 = 7)

689

559 to 885 (P296 = 8)

792

P322

(6)

UdRide-Through

178 to 282 (P296 = 0)

245V201

307 to 487 (P296 = 1)

423

324 to 513 (P296 = 2)

446

356 to 564 (P296 = 3)

490

388 to 615 (P296 = 4)

535

425 to 674 (P296 = 5)

588

466 to 737 (P296 = 6)

644

486 to 770 (P296 = 7)

672

559 to 885 (P296 = 8)

773

P323

(6)

Ud Line Recover Level

178 to 282 (P296 = 0)

267V202

307 to 487 (P296 = 1)

461

324 to 513 (P296 = 2)

486

356 to 564 (P296 = 3)

534

388 to 615 (P296 = 4)

583

425 to 674 (P296 = 5)

638

466 to 737 (P296 = 6)

699

486 to 770 (P296 = 7)

729

Page 28

CFW-09-

QUICKPARAMETER REFERENCE

29

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

559 to 885 (P296 = 8)

838

P325

Ride-ThroughProportional Gain

0.0 to 63.9

22.8-203

P326

Ride-ThroughIntegralGain

0.000 to 9.999

0.128

-

203

P331

VoltageRamp

0.2 to 60.0

2.0s204

P332

DeadTime

0.1 to 10.0

1.0s204

DeviceNet Drive Profile

P335

DeviceNet I/O Instances

0 = Instances 20/70

0 = Instances 20/70

-

206

1 = Instances 21/71

2 = Instances 100/101

3 = Instances 102/103

P336

Input Word #3

0 to 749

0-206

P337

Input Word #4

0 to 749

0-206

P338

Input Word #5

0 to 749

0-206

P339

Input Word #6

0 to 749

0-206

P340

Input Word #7

0 to 749

0-206

P341

Output Word #3

0 to 749

0-207

P342

Output Word #4

0 to 749

0-207

P343

Output Word #5

0 to 749

0-207

P344

Output Word #6

0 to 749

0-207

P345

Output Word #7

0 to 749

0-207

P346

I/O Words Quantity

2 to 7

2-207

PARAMETERS FOR CRANEAPPLICATIONS AND FOR MASTER/SLAVE FUNCTION

- P351 to P399

Logic for the Mechanical Braking Operation

P351

(1)

Delay for E33

0.0 to 99.9

99.9s208

P352

(1)

Delay for E34

0 to 999

999s208

P353

(1)

Delay for N < Nx - Brake Activation

0.0 to 20.0

0.0s208

P354

(1)

Delay for Resetting the Integrator

0.0 to 10.0

2.0s208

of the Speed Regulator

P355

(1)

Delay for Accepting New

0.0 to 10.0

1.0s208

“Start/Stop”Commands

P356

(1)

Delayfor Ramp Enable

0.0 to 10.0

0.0s209

Indication of the Torque Current Polarity

P357

(1)

Torque Current (Iq) Filter

0.00 to 9.99

0.00s209

P358

(1)

Torque Current (Iq) Hysteresis

0.00 to 9.99

2.00%209

Parameters for Load Detection

P361

(1)

Load Detection

0 = Off

0 = Off

-

209

1 = On

P362

(1)

StabilizationSpeed

0 to P134

90

rpm

209

P363

(1)

StabilizationTime

0.1 to 10.0

0.1s210

P364

(1)

SlackCableTime

0.0 to 60.0

0.0s210

P365

(1)

Slack Cable Level

0.0 to 1.3 x P295

0.1 x P295

A

210

P366

(1)

Lightweight Level

0.0 to 1.3 x P295

0.3 x P295

A

210

P367

(1)

Overweight Level

0.0 to 1.8 x P295

1.1 x P295

A

210

P368

(1)

Speed Reference Gain

1.000 to 2.000

1.000

-

210

Fx

P369

(2)

(11)

Frequency Fx

0.0 to 300.0

4.0Hz210

P370

Hysteresis for Fx

0.0 to 15.0

2.0Hz213

DC Braking

P371

DCBrakingTime at Start

0.0 to 15.0

0.0s213

P372

DC Braking Current Level

0.0 to 90.0

40.0%213

Page 29

CFW-09-

QUICKPARAMETER REFERENCE

30

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

According to

the motor rated

power factor

(P404)

VVW Control

P398

(1)

SlipCompensationDuring

0 = Off

1 = On

-

213

Regeneration

1 = On

P399

(1)

(2)

Motor Rated Efficiency

50.0 to 99.9

%

213

MOTORPARAMETERS

P400 to P499

Motor Nameplate Data

P400

(1) (6)

Motor Rated Voltage

0 to 690

P296V214

P401

(1)(12)

Motor Rated Current

(0.0 to 1.30) x P295

(12)

1.0 x P295

A

214

P402

(1)(2) (11)

MotorRatedRPM

0 to 18000

1750 (1458)

rpm

214

(P202 = 0, 1, 2 and 5)

0 to 7200 (P202 = 3 and 4)

P403

(1)(11)

Motor Rated Frequency

0 to 300 (P202 = 0,1,2 and5)

60 (50)

Hz

214

30 to 120 (P202 = 3 and 4)

P404

(1)

Motor Rated hp

0 = 0.33 hp/0.25 kW

4 = 1.5 hp/1.1 kW

-

214

1 = 0.50 hp/0.37 kW

2 = 0.75 hp/0.55 kW

3 = 1.0 hp/0.75 kW

4 = 1.5

hp

/1.1 kW

5 = 2.0

hp

/1.5 kW

6 = 3.0

hp

/2.2 kW

7 = 4.0

hp

/3.0 kW

8 = 5.0

hp

/3.7 kW

9 = 5.5

hp

/4.0 kW

10 = 6.0

hp

/4.5 kW

11= 7.5

hp

/5.5 kW

12 = 10.0

hp

/7.5 kW

13 = 12.5

hp

/9.0 kW

14 = 15.0

hp

/11.0kW

15 = 20.0

hp

/15.0 kW

16 = 25.0

hp

/18.5 kW

17 = 30.0

hp

/22.0 kW

18 = 40.0

hp

/30.0 kW

19 = 50.0

hp

/37.0 kW

20 = 60.0

hp

/45.0 kW

21 = 75.0

hp

/55.0 kW

22 = 100.0

hp

/75.0 kW

23 = 125.0

hp

/90.0 kW

24 = 150.0

hp

/110.0kW

25 = 175.0

hp

/130.0 kW

26 = 180.0

hp

/132.0 kW

27 = 200.0

hp

/150.0 kW

28 = 220.0

hp

/160.0 kW

29 = 250.0

hp

/185.0 kW

30 = 270.0

hp

/200.0 kW

31 = 300.0

hp

/220.0 kW

32 = 350.0

hp

/260.0 kW

Page 30

CFW-09-

QUICKPARAMETER REFERENCE

31

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

According to the

motor rated power

(P404)

33 = 380.0

hp

/280.0 kW

34 = 400.0

hp

/300.0 kW

35 = 430.0 hp/315.0 kW

36 = 440.0 hp/330.0 kW

37 = 450.0

hp

/335.0 kW

38 = 475.0 hp/355.0 kW

39 = 500.0

hp

/375.0 kW

40 = 540.0 hp/400.0 kW

41 = 600.0

hp

/450.0 kW

42 = 620.0 hp/460.0 kW

43 = 670.0 hp/500.0 kW

44 = 700.0

hp

/525.0 kW

45 = 760.0

hp

/570.0 kW

46 = 800.0

hp

/600.0 kW

47 = 850.0 hp/630.0 kW

48 = 900.0 hp/670.0 kW

49 = 1100.0 hp/820.0 kW

50 = 1600.0 hp/1190.0 kW

P405

(1)

Encoder PPR

250 to 9999

1024

ppr

215

P406

(1)

Motor Ventilation Type

0 = Self Ventilated

0 = Self Ventilated

-

215

1 = Separate Ventilation

2= Optimal Flux

3 = Increased Protection

P407

(1) (2)

Motor Rated Power Factor

0.50 to 0.99

-

216

Measured Parameters

P408

(1)

Self-Tuning

0 = No

0 = No

-

216

1 = No Rotation

2 = Run for I

mr

3 = Run for Tm

4=EstimateTm

P409

(1)

Motor Stator Resistance (Rs)

0.000 to 77.95

0.000

217

P410

Motor Magnetizing Current (I

mr

)

(0.0 to 1.25) x P295

0.0A218

P411

(1)

MotorFluxLeakage Inductance( LS)

0.00 to 99.99

0.00mH218

P412

LR/RRConstant(RotorTime

0.000 to 9.999

0.000

s

218

Constant (Tr))

P413

(1)

Tm

Constant(MechanicalTime

0.00 to 99.99

0.00s219

Constant)

SPECIAL FU

NCTION PARAMETERSP520

to

P538

PID Regulator

P520

PIDProportionalGain

0.000 to 7.999

1.000

-

223

P521

PIDIntegralGain

0.000 to 7.999

0.043

-

223

P522

PIDDifferentialGain

0.000 to 3.499

0.000

-

223

P523

PIDRampTime

0.0 to 999

3.0s223

P524

(1)

Selection of PIDFeedback

0 = AI2 (P237 to P240)

0=AI2 (P237toP240)

-

223

1 = AI3 (P241 to P244)

P525

PIDSetpoint

0.0 to 100.0

0.0%224

P526

Process Variable Filter

0.0 to 16.0

0.1s224

Page 31

CFW-09-

QUICKPARAMETER REFERENCE

32

Parameters

Function

AdjustableRange

Factory

Unit

User's

Page

Setting

Setting

P527

PIDAction

0 = Direct

0 = Direct

-

224

1 = Reverse

P528

Process Variable Scale Factor

0 to 9999

1000-225

P529

Decimal Point of Proc. Var.

0 to 3

1

225

P530

Engineering Unit of Proc. Var. 1

32 to 127 (ASCII)

37 = %

-

226

A, B, ... , Y, Z

0, 1, ... , 9

#, $, %, (, ), *, +, ...

P531

Engineering Unit of Proc. Var. 2

32 to 127 (ASCII)

32 = blank

-

226

A, B, ... , Y, Z

0, 1, ... , 9

#, $, %, (, ), *, +, ...

P532

Engineering Unit of Proc. Var. 3

32 to 127 (ASCII)

32 = blank

-

226

A, B, ... , Y, Z

0, 1, ... , 9

#, $, %, (, ), *, +, ...

P533

Value of Proc. Var. X

0.0 to 100

90.0%226

P534

Value of Proc. Var. Y

0.0 to 100

10.0%226

P535

Wake Up Band

0 to 100

0%227

P536

(1)

Automatic Setting of P525

0 = Active

0 = Active

-

227

1 = Inactive

P537

Hysteresis for Set point =

1 to 100

1%227

Process Variable

P538

Hysteresis for VPx/VPy

0.0 to 50.0

1.0%227

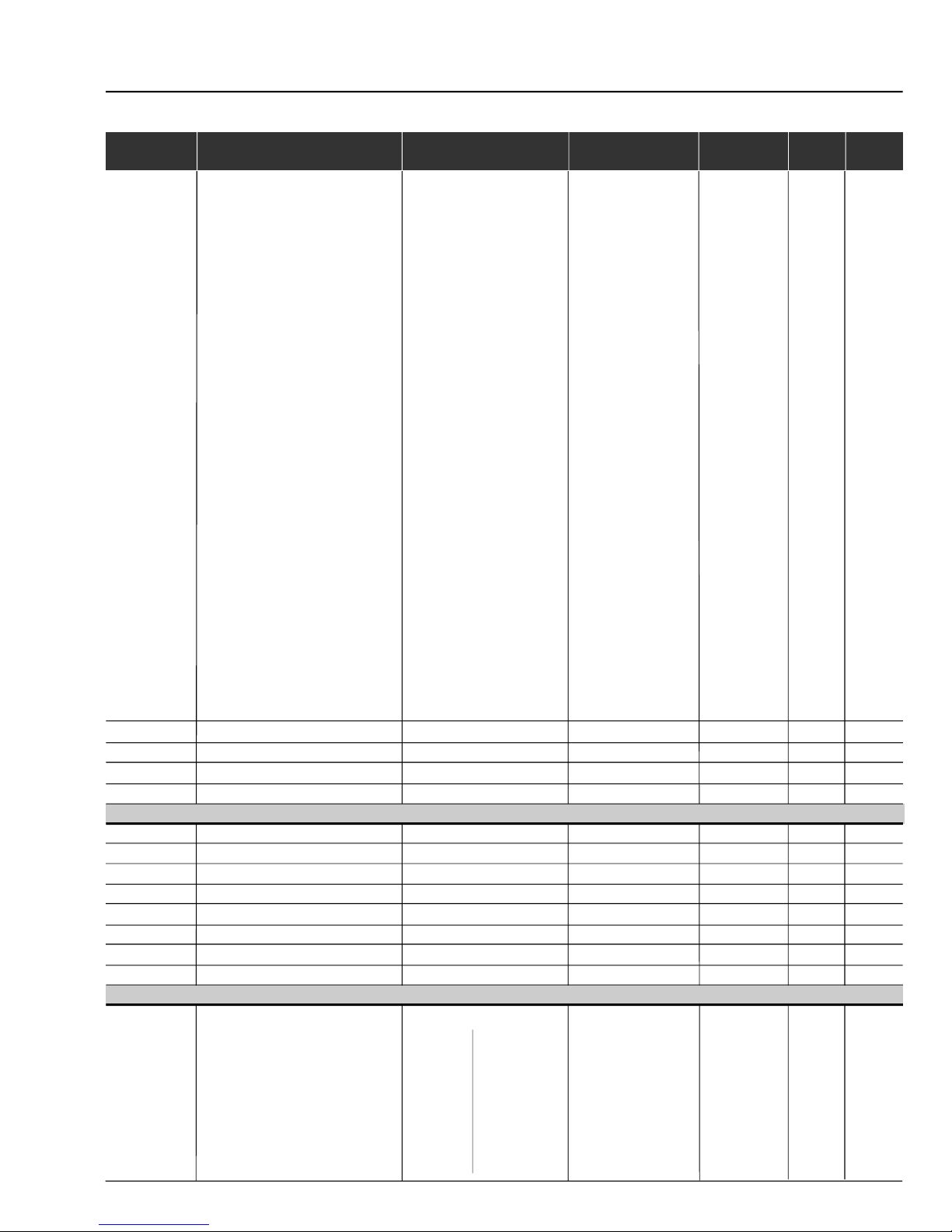

Notes presented on Quick Parameter Description:

(1)

Parameter can be changed only with the inverter disabled

(motor stopped).

(2)

Values may change as a function of the “Motor Parameters”.

(3)

Values may change as a function of P413 (Tm Constant - obtained during

Self-tuning).

(4)

Values may change as a function of P409 and P411 (obtained during Self-

tuning).

(5)

Values may change as a function of P412 (Tr Constant - obtained during

Self-tuning).

(6)

Values may change as a function of P296.

(7)

Values may change as a function of P295.

(8)

Values may change as a function of P203.

(9)

Values may change as a function of P320.

(10)

User’s Standard (for new inverters) = without parameter.

(11)

The inverter will be delivered with settings according to the market,

consideringthe HMI language,V/F 50 Hz or 60 Hz and the required voltage.

Thereset of the standard factorysetting may changethe parameters related

to the frequency (50 Hz/60 Hz). Valueswithin parenthesis mean the factory

setting for 50 Hz.

(12)

The maximum value of P156 and P401 is 1.8 x P295 for model 4.2 A/500-

600 V and 1.6 xP295 for models 7 Aand 54A/220-230 V; 2.9A and7 A/500-

600V;107A, 147A and 247A/500-690 V;100A, 127Aand340A/660-690V.

Page 32

CFW-09-

QUICKPARAMETER REFERENCE

33

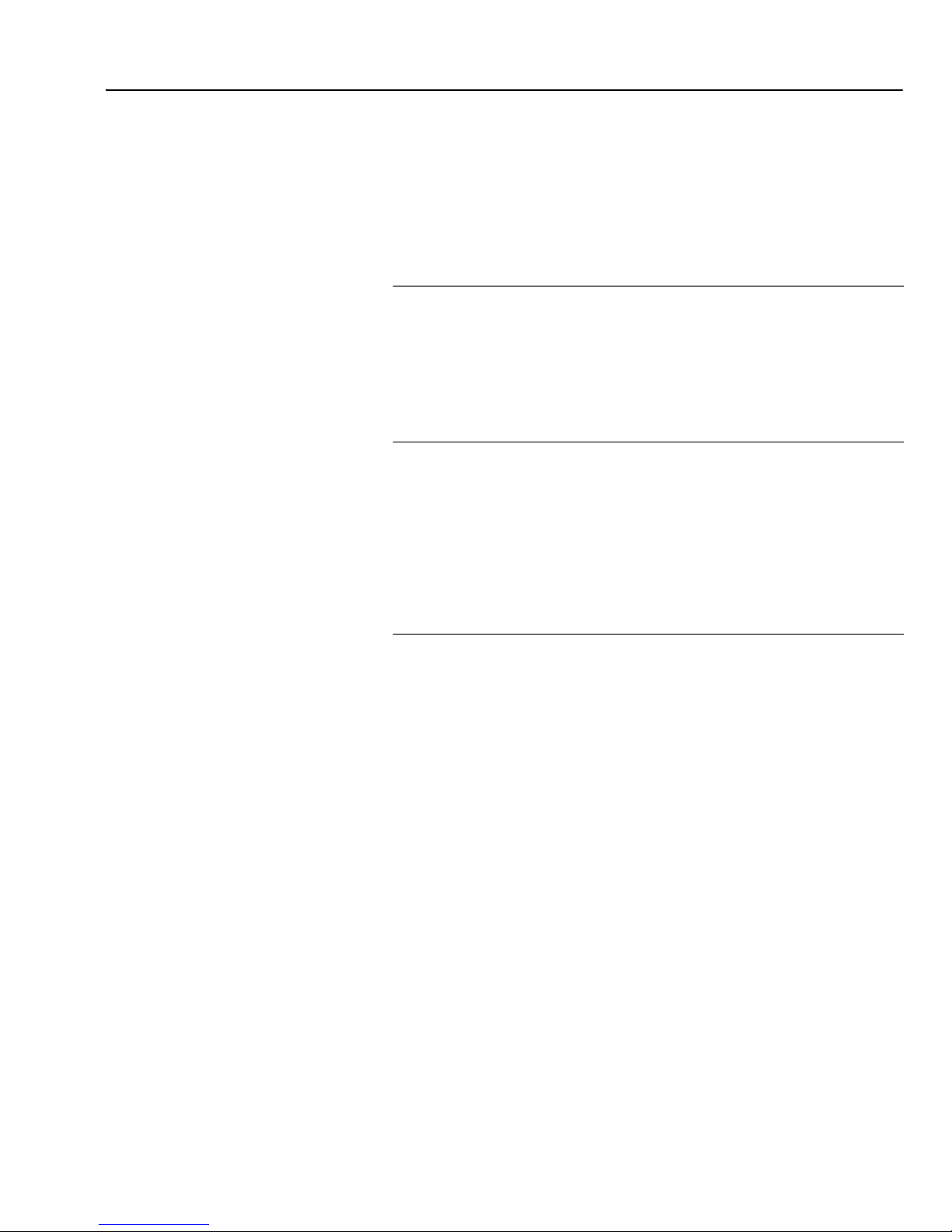

Table 1

- Interdependence among parameters: parameters that change the settings of

others when modified versus parameters that are automatically modified as a function of a

parameter setting (during start-up and/or normal operation)

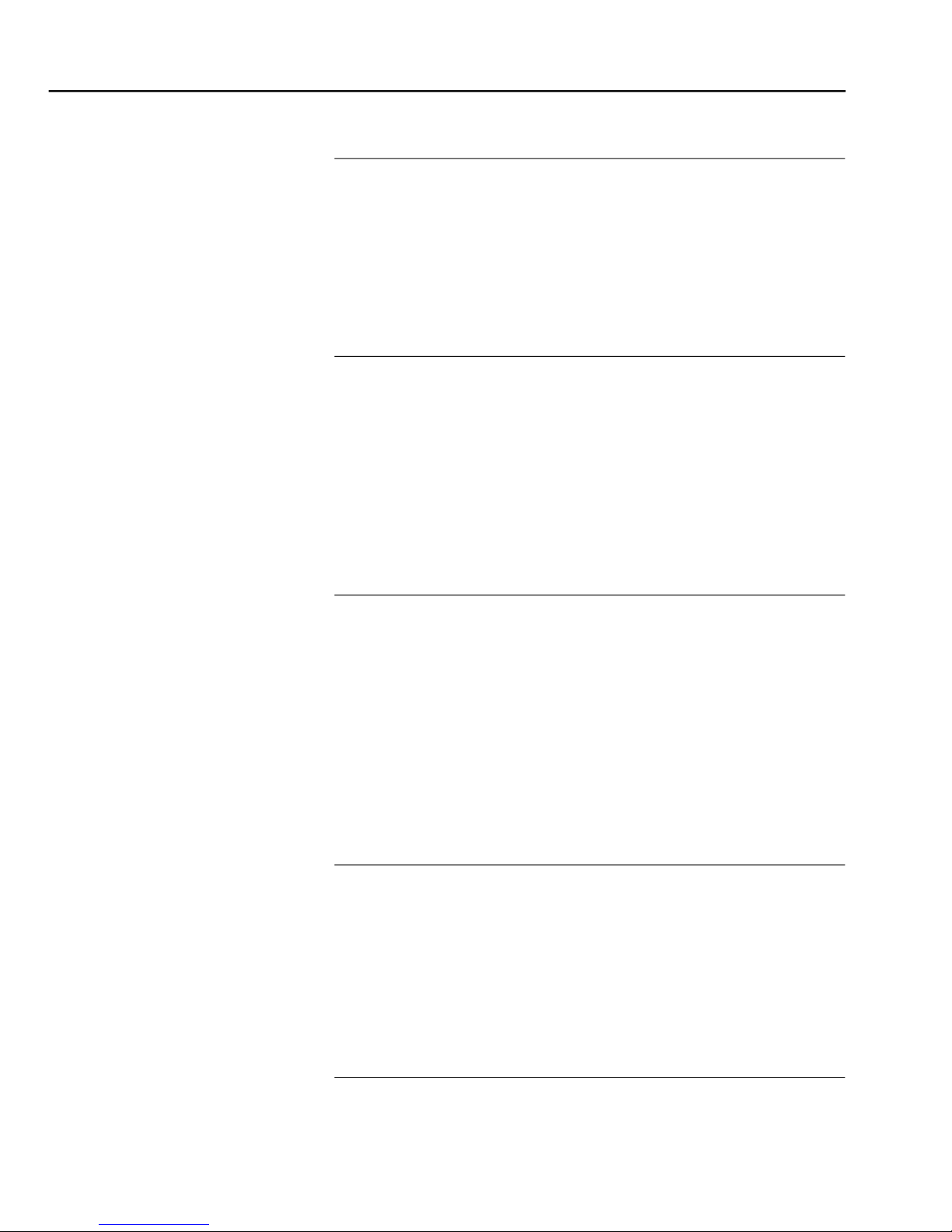

II.FaultMessages

Display

Description

Page

E00

Output Overcurrent/Short-Circuit

228

E01

DC Link Overvoltage

228

E02

DCLink Undervoltage

228

E03

Power Supply Undervoltage/Phase Loss

229

E04

(*)