Page 1

Page 2

08/2003

FREQUENCY

INVERTER

MANUAL

Series: CFW-08

Software: version 3.9X

0899.4690 E/5

ATTENTION!

It is very important to check if the

inverter software version is the

same as indicated above.

Page 3

Summary of Revisions

The table below describes all revisions made to this manual.

Revision Description Section

1 First Edition 2 Item 3.3 - CE Installation Included See item 3.3

3 General Revision -

4

External Parallel Keypad and

See item 8.3

Fixs Kit Included and

and 8.12

General Revision

5 General Revision -

6

Description changed of the Parallel Cable

See item 8.5

for the External Parallel Keypad.

and 6.3.5

Item 7.5 (Spare Part List) Removed.

Parameter 536 included

and General Revision

Page 4

CONTENTS

Quick Parameter Reference,

Fault and Status Messages

1 Parameters .................................................................................07

2 Fault Messages ..........................................................................14

3 Other Messages ......................................................................... 14

CHAPTER 1

Safety Notices

1.1 Safety Notices in the Manual .................................................15

1.2 Safety Notice on The Product ................................................15

1.3 Preliminary Recommendations...............................................15

CHAPTER 2

General Information

2.1 About this Manual..................................................................17

2.2 Version of Software ................................................................17

2.3 About the CFW-08 .................................................................18

2.3.1 Differences between the Old µline and the New CFW-0821

2.4 CFW-08 Identification ............................................................. 25

2.5 Receiving and Storing.............................................................27

CHAPTER 3

Installation

3.1 Mechanical Installation...........................................................28

3.1.1 Environment ..................................................................28

3.1.2 Mounting Specifications ................................................29

3.2 Electrical Installation ..............................................................32

3.2.1 Power/Grounding Connections ......................................32

3.2.2 Power T erminals............................................................35

3.2.3 Location of the Power/Grounding/Control Connections ..36

3.2.4 Control Wiring ...............................................................37

3.2.5 Typical Terminal Connections ........................................40

3.3 European EMC Directive ........................................................43

3.3.1 Installation .....................................................................43

3.3.2 Inverter Models and Filters .............................................44

3.3.3 EMC Categories Description.......................................... 46

3.3.4 EMC Categories Characteristics Filters .........................47

CHAPTER 4

Start-up

4.1 Pre-Power Checks .................................................................52

4.2 Initial Power-up ......................................................................52

4.3 Start-up .................................................................................. 53

4.3.1 Start-up Operation via Keypad (HMI)

Type of Control: Linear V/F (P202=0).............................53

4.3.2 Start-up Operation via T erminals -

Type of Control: Linear V/F (P202=0).............................55

4.3.3 Start-up - Operation via Keypad (HMI)

Type of Control: V ector (P202=2) ...................................56

Page 5

CONTENTS

CHAPTER 5

Keypad (HMI) Operation

5.1 Keypad (HMI) Description ........................................................ 60

5.2 Use of the Keypad (HMI) .......................................................... 61

5.2.1 Keypad Operation ........................................................... 62

5.2.2 Inverter Status ................................................................. 63

5.2.3 Read-Only V ariables........................................................ 63

5.2.4 Parameter Viewing and Programming.............................. 64

CHAPTER 6

Detailed Parameter Description

6.1 Symbols .................................................................................. 66

6.2 Introduction .............................................................................. 66

6.2.1 Control Modes................................................................. 66

6.2.2 V/F Control...................................................................... 66

6.2.3 Vector Control (VVC)....................................................... 67

6.2.4 Frequency Reference Sources ........................................ 67

6.2.5 Commands...................................................................... 70

6.2.6 Local/Remote Operation Modes ...................................... 70

6.3 Parameter Listing ..................................................................... 71

6.3.1 Access and Read Only Parameters - P000...P099.......... 72

6.3.2 Regulation Parameters - P100...P199 ............................. 73

6.3.3 Configuration Parameters - P200...P398.......................... 81

6.3.4 Motor Parameters - P399...P499................................... 101

6.3.5 Special Function Paramaters - P500...P599.................. 104

6.3.5.1 PID Introduction ............................................... 104

6.3.5.2 PÌD Description ................................................ 104

6.3.5.3 PID Start-up Guide ........................................... 106

CHAPTER 7

Diagnostics and Troubleshooting

7.1 Faults and Possible Causes ...................................................110

7.2 Troubleshooting.......................................................................112

7.3 Contacting WEG .....................................................................113

7.4 Preventive Maintenance...........................................................113

7.4.1 Cleaning Instructions......................................................114

CHAPTER 8

CFW-08 Options and Accessories

8.1 HMI-CFW08-P.........................................................................116

8.1.1 Instructions for Insertion - Removing of HMI-CFW08-P....117

8.2 TCL-CFW08 ............................................................................117

8.3 HMI-CFW08-RP ......................................................................117

8.3.1 HMI-CFW08-RP Installation............................................118

8.4 MIP-CFW08-RP ......................................................................118

8.5 CAB-RP-1, CAB-RP-2, CAB-RP-3, CAB-RP-5, CAB-RP-7.5,

CAB-RP-10 .............................................................................119

8.6 HMI-CFW08-RS ......................................................................119

8.6.1 HMI-CFW08-RS Installation........................................... 120

8.6.2 HMI-CFW08-RS Start-up ............................................... 120

8.6.3 Keypad Copy Function.................................................. 121

8.7 MIS-CFW08-RS ..................................................................... 121

Page 6

CONTENTS

8.8 CAB-RS-1, CAB-RS-2, CAB-RS-3, CAB-RS-5, CAB-RS-7.5

CAB-RS-10 ............................................................................ 121

8.9 KCS-CFW08.......................................................................... 122

8.9.1 Instruction and Removing Instructions for KCS-CFW08 12 3

8.10 KSD-CFW08.......................................................................... 123

8.1 1 KMD-CFW08-M1.................................................................... 124

8.12 KFIX-CFW08-M1, KFIX-CFW08-M2 ........................................ 125

8.13 KN1-CFW08-M1, KN1-CFW08-M2 ......................................... 126

8.14 MIW-02 .................................................................................. 126

8.15 RFI Filters.............................................................................. 127

8.16 Line Reactor .......................................................................... 128

8.16.1 Application Criteria ...................................................... 128

8.17 Load Reactor ......................................................................... 129

8.18 Dynamic Braking.................................................................... 131

8.18.1 Resistor Sizing............................................................ 131

8.18.2 Installation................................................................... 132

8.19 Serial Communication ............................................................ 133

8.19.1 Introduction ................................................................. 133

8.19.2 Interfaces Description.................................................. 134

8.19.2.1 RS-485........................................................... 134

8.19.2.2 RS-232........................................................... 136

8.19.3 Definitions ................................................................... 136

8.19.3.1 Used T erms.................................................... 136

8.19.3.2 Parameters/V ariables Resolution.................... 136

8.19.3.3 Character Format ........................................... 136

8.19.3.4 Protocol ......................................................... 137

8.19.3.4.1 Reading Message .......................... 137

8.19.3.4.2 Writing Message ........................... 138

8.19.3.5 Execution and Message Test ......................... 138

8.19.3.6 Message Sequence ....................................... 139

8.19.3.7 V araiables Code ....................................................... 139

8.19.4 Message Examples..................................................... 139

8.19.5 Variables and Errors of the Serial Communication ....... 140

8.19.5.1 Basic V ariables .............................................. 140

8.19.5.1.1 V00 (Code 00700) .......................... 140

8.19.5.1.2 V02 (Code 00702) .......................... 140

8.19.5.1.3 V03 (Code 00703) .......................... 141

8.19.5.1.4 V04 (Code 00704) .......................... 142

8.19.5.1.5 V05 (Code 00705) .......................... 142

8.19.5.1.6 Message Examples with

Basic Variables .............................................. 142

8.19.5.2 Parameters Related to the Serial Communication143

8.19.5.3 Errors Related to the Serial Communication ... 144

8.19.6 Times for Read/Write of Messages.............................. 144

8.19.7 Physical Connection of RS-232 and RS-485 Interface.. 145

8.20 Modbus-RTU ...................................................................... 146

8.20.1 Introduction in the Modbus-RTU Protocol..................... 146

8.20.1.1 Transmission Modes ...................................... 146

8.20.1.2 Message Structure in RTU Mode.................... 146

8.20.1.2.1 Address ......................................... 147

8.20.1.2.2 Code Function ............................... 147

8.20.1.2.3 Dat a Field...................................... 14 7

8.20.1.2.4 CRC............................................... 147

8.20.1.3 Time between messages.......................................... 148

8.20.2 Operation of the CFW-08 in the Modbus-RTU Network 14 8

8.20.2.1 Interface Description....................................... 148

8.20.2.1.1 RS-232 .......................................... 149

Page 7

CONTENTS

8.20.2.1.2 RS-485 .......................................... 149

8.20.2.2 Inverter Configuration in the

Modbus-RTU Network..................................... 149

8.20.2.2.1 Inverter address in the Network ...... 149

8.20.2.2.2 Transmission Rate and Parity ........ 149

8.20.2.3 Access to the Inverter Data ............................ 149

8.20.2.3.1Available Functions and

Response Times ............................................ 150

8.20.2.3.2 Register addressing and Offset ...... 150

8.20.3Detailed Function Description ...................................... 152

8.20.3.1 Function 01 - Read Coils ................................ 15 3

8.20.3.2 Function 03 - Read Holding Register .............. 153

8.20.3.3 Function 05 - Write Single Coil ....................... 154

8.20.3.4 Function 06 - Write Single Register ................ 155

8.20.3.5 Function 15 - Write Multiple Coils................... 15 5

8.20.3.6 Function 16 - Write Multiple Registers............ 15 6

8.20.3.7 Function 43 - Read Device Identification ......... 157

8.20.4Communication Errors ................................................. 159

8.20.4.1 Error Messages.............................................. 159

CHAPTER 9

Technical Specifications

9.1 Power Data ............................................................................ 161

9.1.1 200 - 240V Power Supply.............................................. 161

9.1.2 380 - 480V Power Supply.............................................. 161

9.2 General Electronic Data ......................................................... 163

9.3 WEG Standard IV Pole Motor Data ........................................ 164

CHAPTER 10

Warranty

Warranty Terms for Frequency Inverters - CFW-08 ........................ 165

Page 8

7

CFW-08 -

QUICK PARAMETER REFERENCE

Software: V3.9X

Application:

Model:

Serial Number:

Responsible:

Date: / / .

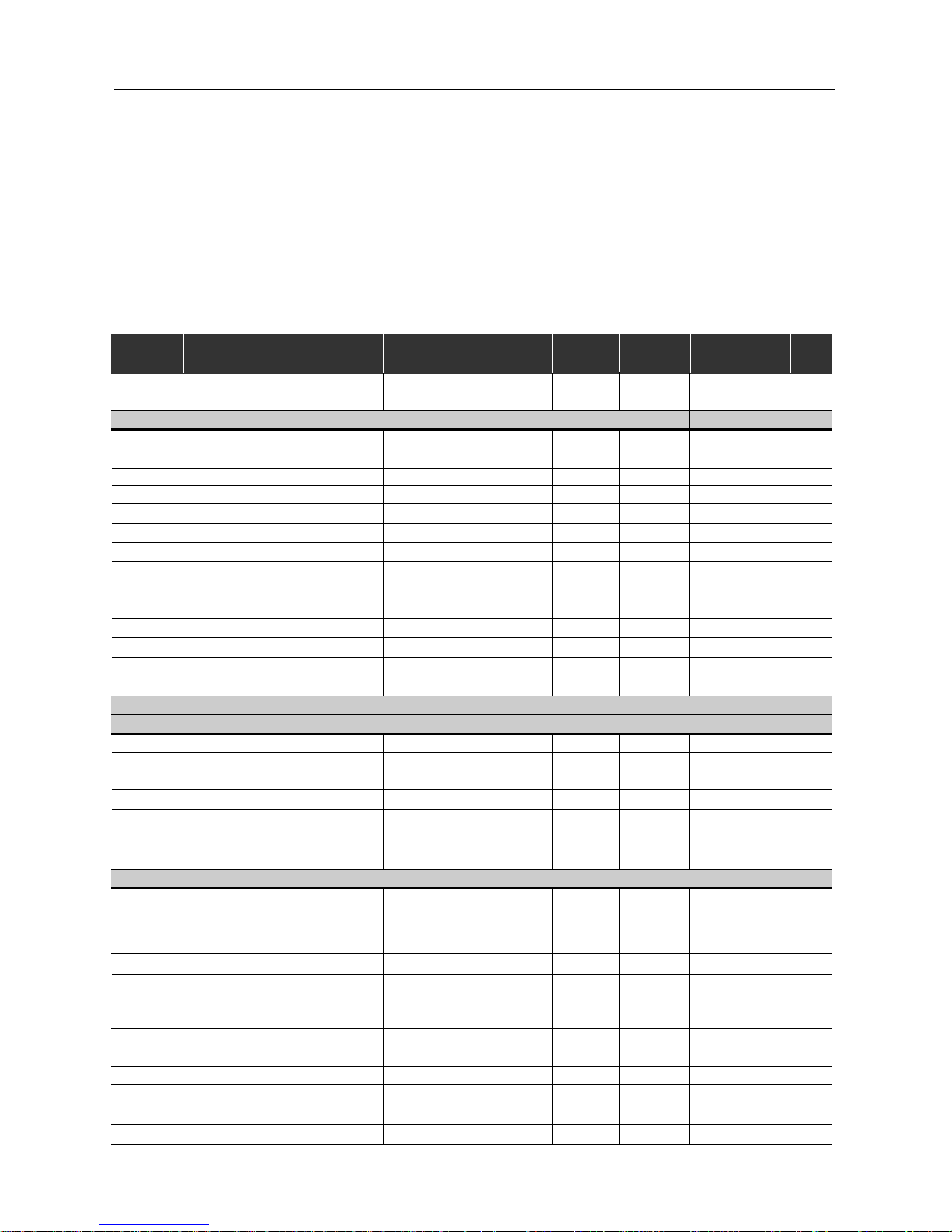

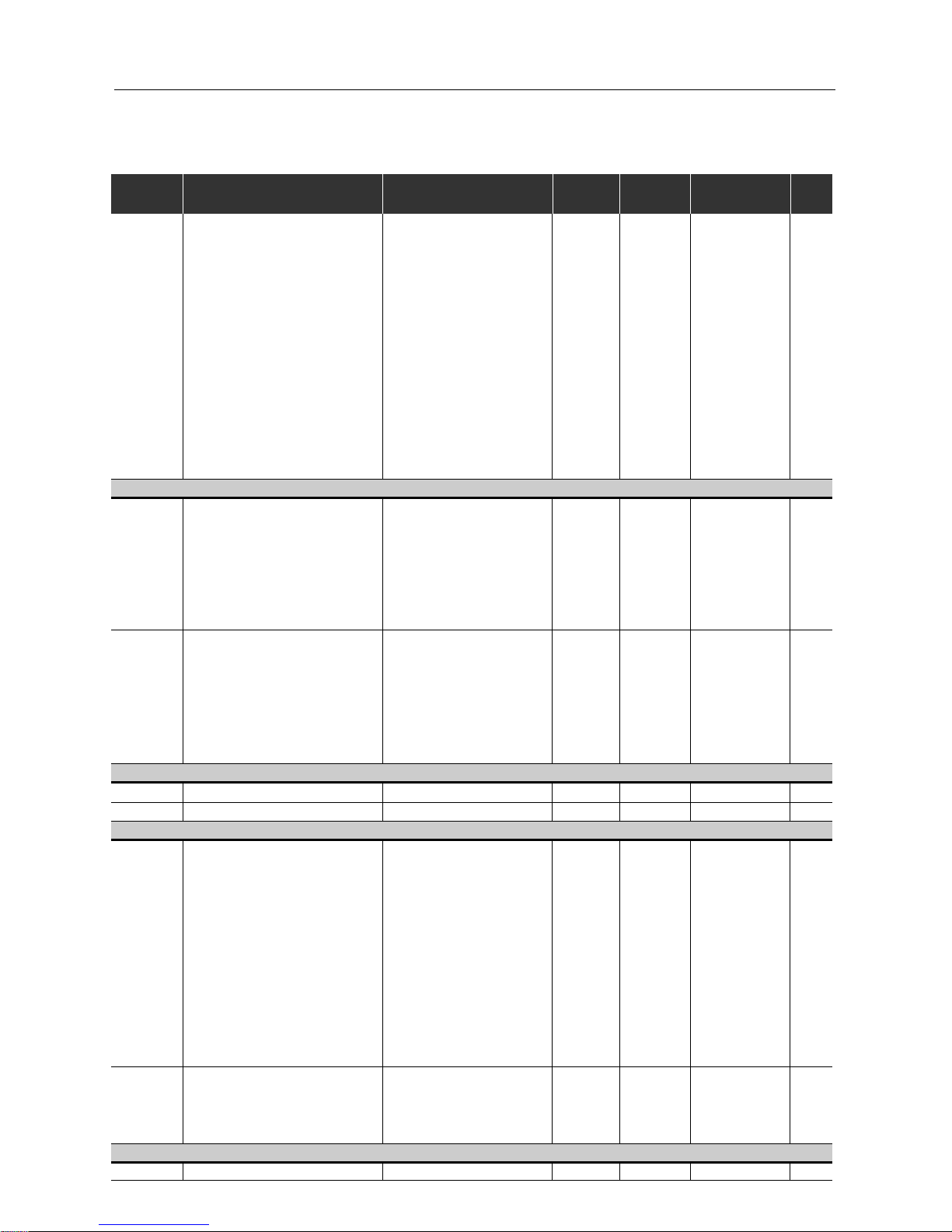

1. Parameters

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

P000 Parameter Access

0 ... 4, 6 ... 999 = Read

0- 72

5 = Alteration

READ ONL Y P ARAMETERS (P002 ... P099)

P002

Fequency Proportional Value

0 ... 6553 - - 72

(P208xP005)

P003 Motor Current 0 ... 1.5xI

nom

-- 72

P004 DC Link Voltage 0 ... 862V - - 72

P005 Motor Frequency 0.00 ... 99.99, 100.0 ... 300.0Hz - - 72

P007 Motor Voltage 0 ... 600V - - 72

P008 Heatsink Temperature 25 ... 110°C - - 72

P009 Motor Torque 0.0 ... 150.0% - -

Only avaliable

in vector control 72

mode (P202=2)

P014 Last Fault 00 ... 41 - - 72

P023 Software Version x . y z - - 73

P040

PID Process Variable

0 ... 6553 - - 73

(Value % x P528)

REGULATION PARAMETERS (P100 ... P199)

Ramps

P100 Acceleration Time #1 0.1 ... 999s 5.0 73

P101 Deceleration Time #1 0.1 ... 999s 10.0 73

P102 Acceleration Time #2 0.1 ... 999s 5.0 73

P103 Deceleration Time #2 0.1 ... 999s 10.0 73

P104

0 = Inactive

073

S Ramp 1 = 50%

2 = 100%

Frequency Reference

0 = Inactive

1 = Active 1 74

P120 Digital Reference Backup 2 = Backup by P121

(or P525 - PID)

P121 Keypad Reference P133 ... P134 3.00 74

P122 JOG Speed Reference 0.00 ... P134 5.00 74

P124 Multispeed Reference 1 P133 ... P134 3.00 75

P125 Multispeed Reference 2 P133 ... P134 10.00 75

P126 Multispeed Reference 3 P133 ... P134 20.00 75

P127 Multispeed Reference 4 P133 ... P134 30.00 75

P128 Multispeed Reference 5 P133 ... P134 40.00 75

P129 Multispeed Reference 6 P133 ... P134 50.00 75

P130 Multispeed Reference 7 P133 ... P134 60.00 75

P131 Multispeed Reference 8 P133 ... P134 66.00 75

QUICK P ARAMETER REFERENCE, F AUL T AND ST ATUS MESSAGES

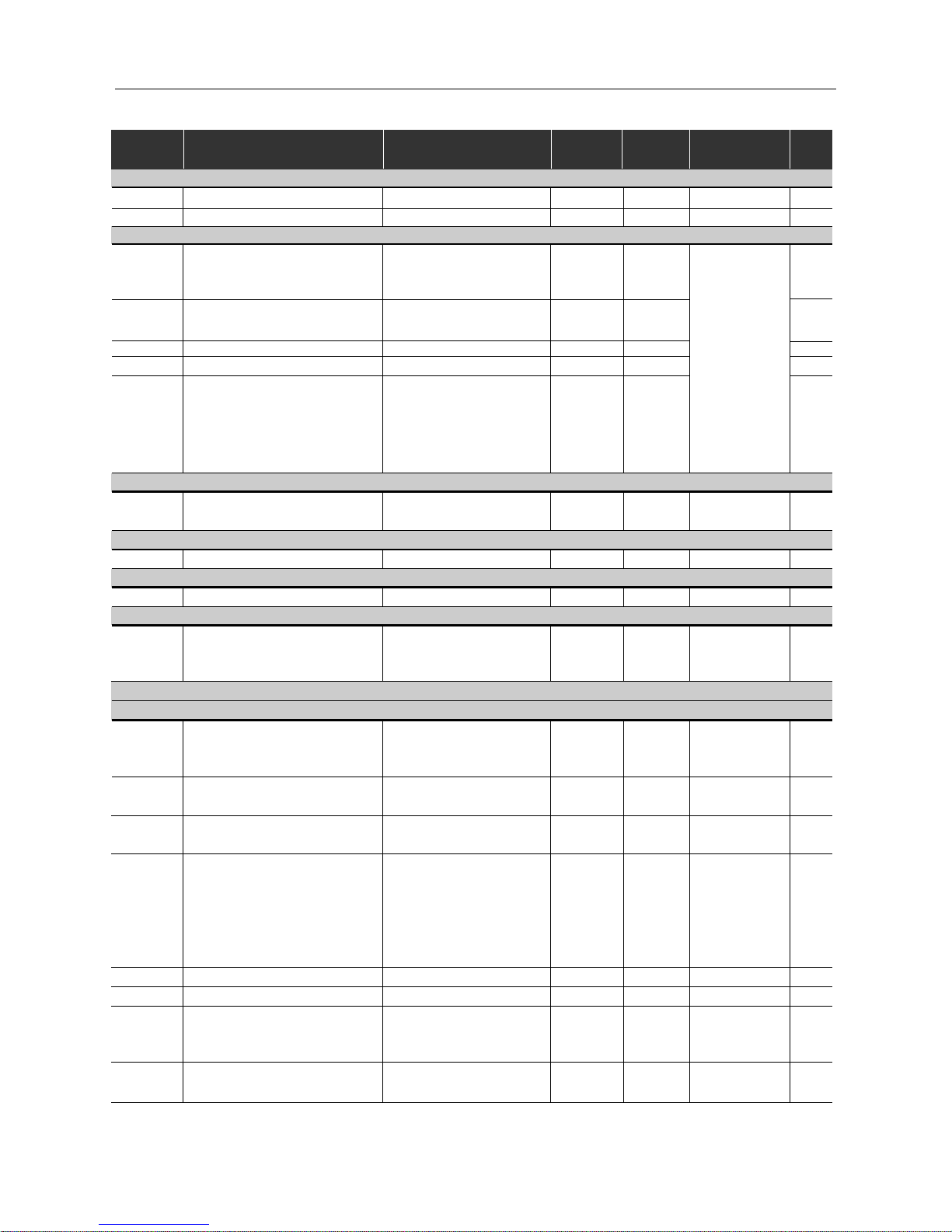

Page 9

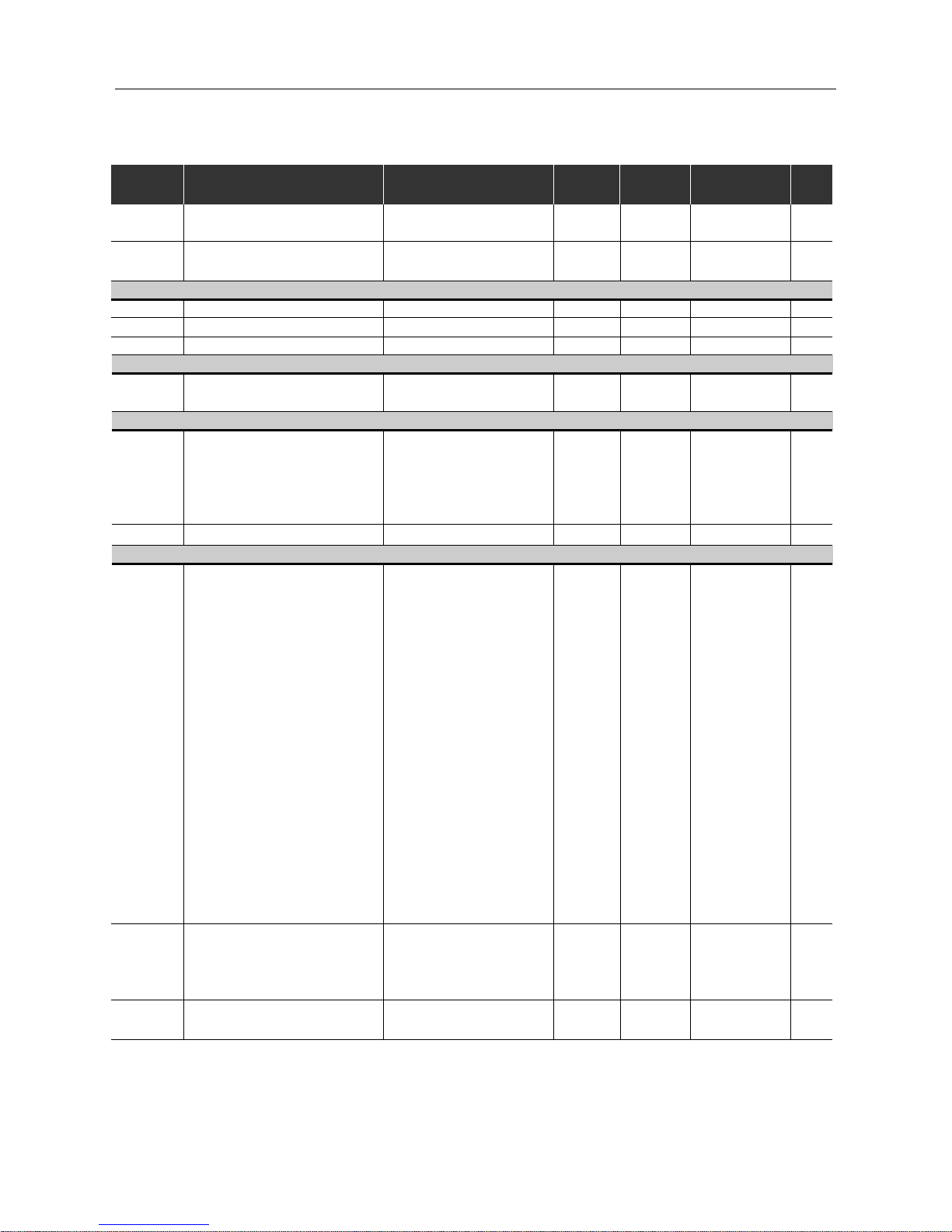

8

CFW-08 -

QUICK PARAMETER REFERENCE

Speed Limits

P133 Minimum Frequency (F

min

) 0.00 ... P134 3.00 7 6

P134 Maximum Frequency (F

max

) P133 ... 300.0Hz 66.00 76

V/F Control

P136

Manual Torque Boost

0.0 ... 30.0%

5.0 or

Only available

76

(IxR Compensation)

2.0 or

in V/F co n trol

1.0

(2)

Control Mode

P137

Aut. Torque Boost

0.00 ... 1.00 0.00

P202=0 or 1.

76

(aut. IxR compensation)

P138 Slip Compensation 0.0 ... 10.0% 0.0 77

P142

(1)

Maximum Output Voltage 0.0 ... 100% 100 78

P145

(1)

Field Weakening

P133 ... P134

50.00Hz or

78

Frequency (F

nom

)

60.00Hz

depending

on the

market

DC Link Volt age Regulation

P151 DC Link Regulation Level

200V models: 325 ... 410V 380V

79

400V models: 564 ... 820V 780V

Overload Current

P156 Motor Overload Current 0.2xI

nom

... 1.3xI

nom

1.2xP401 79

Current Limitation

P169 Maximum Output Current 0.2xI

nom

... 2.0xI

nom

1.5xI

nom

80

Flux Control

P178 50.0 ... 150% 100

Only available

80

Rated Flux in V/F control

mode (P202=2).

CONFIGURATION PARAMETERS (P200 ... P398)

Generic Parameters

P202

(1)

Control Mode

0 = Linear V/F Control

081

1 = Quadratic V/F Control

2 = Sensorless Vector

P203

(1)

Special Function Selection

0 = No function

082

1 = PID Regulator

P204

(1)

Load Factory Setting

0 ... 4 = No Function

0- 82

5 = Loads Factory Default

P205 Display Default Selection

0 = P005

282

1 = P003

2 = P002

3 = P007

4, 5 = Not used

6 = P040

P206 Auto-Reset Time 0 ... 255s 0 82

P208 Reference Scale Factor 0.00 ... 99.9 1.00 83

0 = Off

0

Only available

83

P215

(1)

Keypad Copy Function 1 = Copy (inverter to keypad) via HMI-CFW08-RS

2 = Paste (keypad to inverter) keypad.

P219

(1)

Switching Frequency

0.00 ... 25.00Hz 6.00 84

Reduction Point

(1)

This parameter can be changed only with the inverter disabled (motor stopped).

(2)

The factory default of Parameter P136 depends on the inverter model as follows:

- models 1.6-2.6-4.0-7.0A/200-240V or 1.0-1.6-2.6-4.0A/380-480V: P136=5.0%;

- models 7.3-10-16A/200-240V or 2.7-4.3-6.5-10A/380-480V: P136=2.0%;

- models 13-16A/380-480V: P136=1.0%.

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

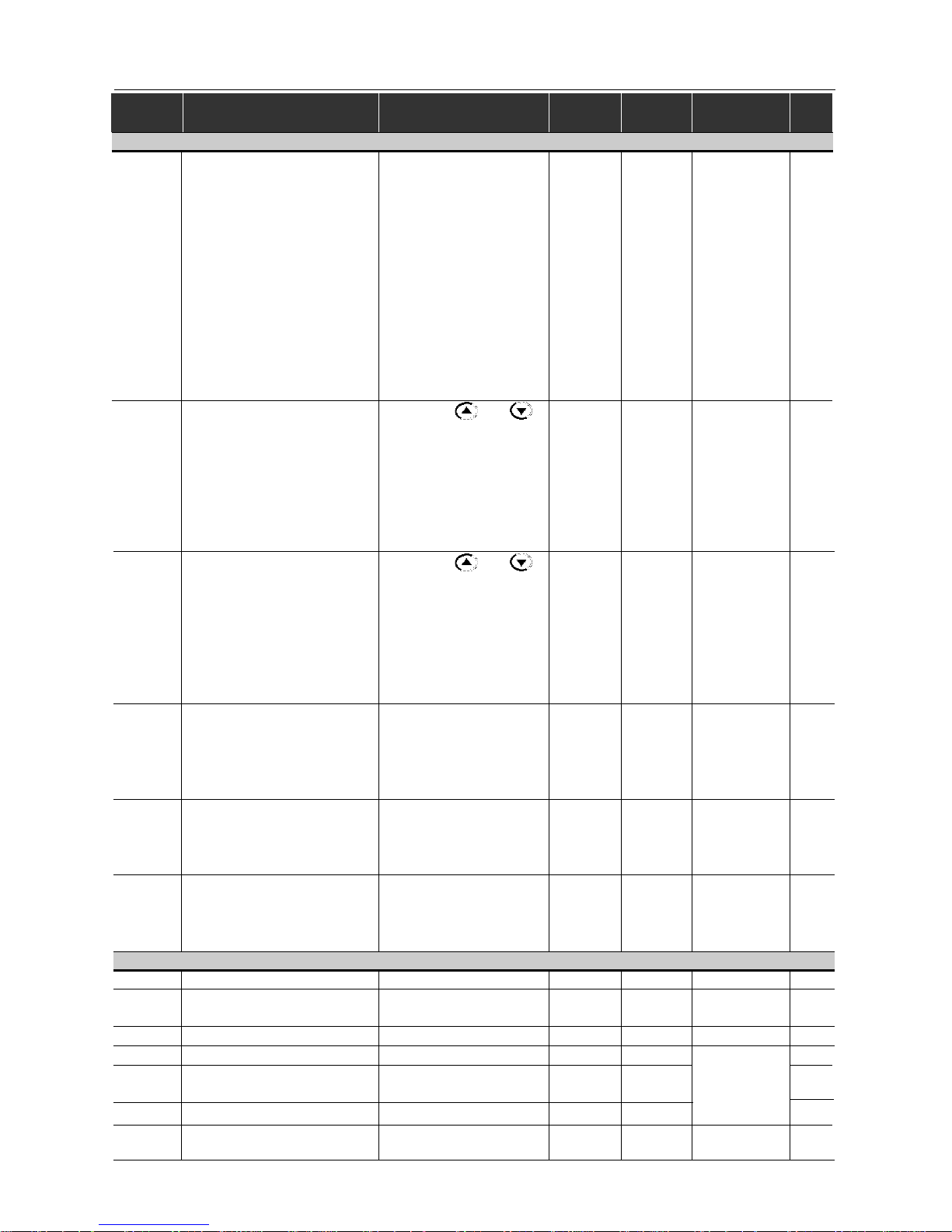

Page 10

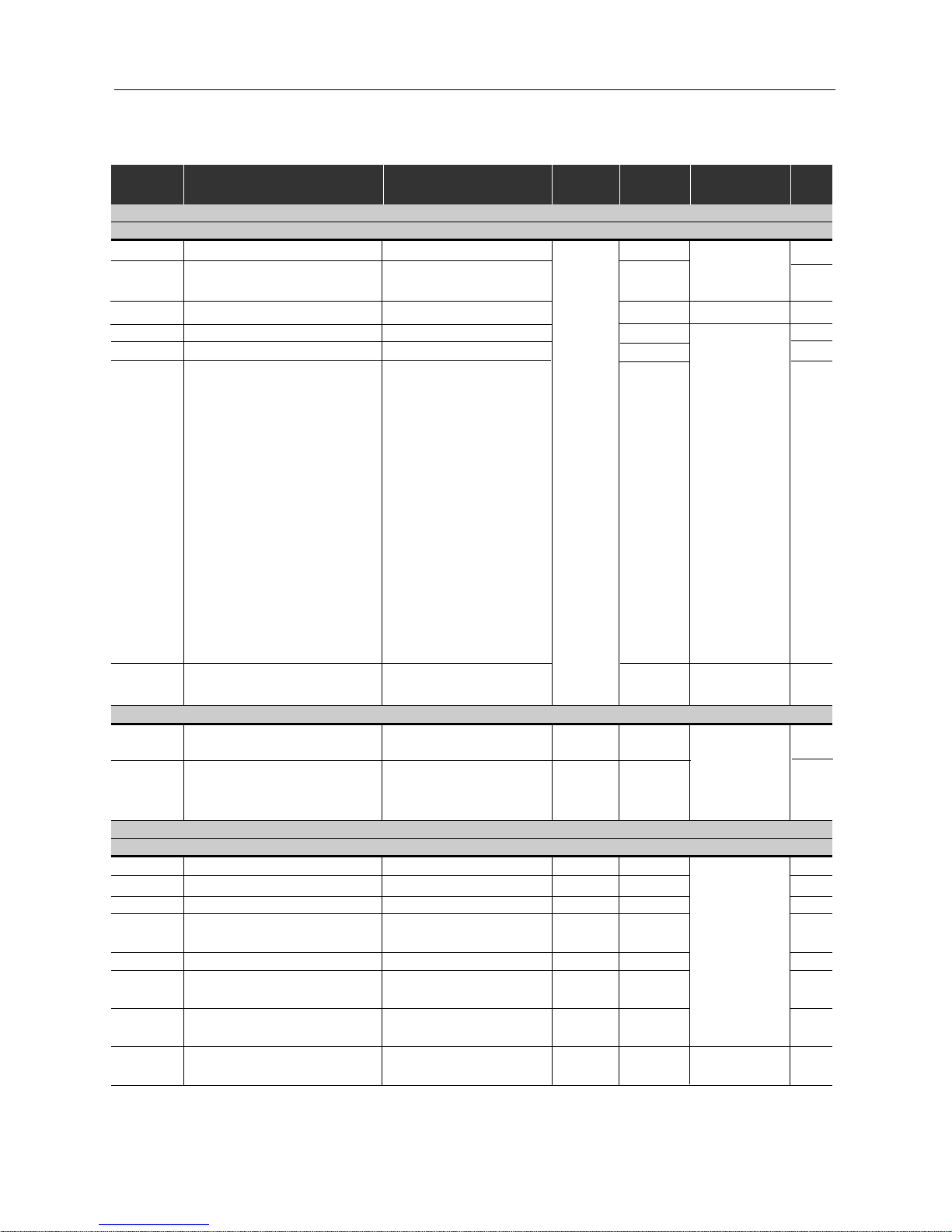

9

CFW-08 -

QUICK PARAMETER REFERENCE

(1)

This parameter can be changed only with the inverter disabled (motor stopped).

Only available

in CFW-08

Plus Version

Local/Remote Definition

P220

(1)

Local/Remote

0 = Always Local

285

Selection Source

1 = Always Remote

2 = HMI-CFW08-P or

HMI-CFW08-RP keypad

(default: local)

3 = HMI-CFW08-P or

HMI-CFW08-RP keypad

(default: remote)

4 = DI2 ... DI4

5 = Serial or HMI-CFW08-RS

keypad (default: local)

6 = Serial or HMI-CFW08-RS

keypad (default: remote)

0 = Keypad and

86

1 = AI1

2, 3 = AI2

P221

(1)

Local Reference Selection 4 = E.P. (Electronic Pot.)

0

5 = Serial

6 = Multispeed

7 = Add AI>=0

8 = Add AI

0 =Keypad and

86

1 = AI1

2, 3 = AI2

P222

(1)

Remote Reference Selection 4 = E.P. (Eletronic Pot.)

1

5 = Serial

6 = Multispeed

7 = Add AI>=0

8 = Add AI

0 = HMI-CFW08-P or

86

P229

(1)

Local Command Selection HMI-CFW08-RP keypad

1 = Terminals

0

2 = Serial or HMI-CFW08-RS

keypad

0 = HMI-CFW08-P or

86

P230

(1)

Remote Command Selection HMI-CFW08-RP keypad

1 = Terminals

1

2 = Serial or

HMI-CFW08-RS keypad

P231

(1)

Forward/Reverse Selection

0 = Forward

86

1 = Reverse 2

2 = Commands

Analog Input(s)

P234 Analog Input A I1 Gain 0.00 ... 9.99 1.00 86

P235

(1)

Analog Input AI1 Signal

0 = 0-10V/0-20mA

0

87

1 = 4-20mA

P236 Analog Input AI1 Offset -120 ... 120% 0.0 8 8

P238 Analog Input A I2 Gain 0.00 ... 9.99 1.00 88

P239

(1)

Analog Input AI2 Gain

0 = 0-10V/0-20mA

0

87

1 = 4-20mA

P240 Analog Input AI2 Offset -120 ... 120% 0.0 8 8

P248

Analog Inputs Filter

0 ... 200ms 20 0 8 8

Time Constant

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

Page 11

10

CFW-08 -

QUICK PARAMETER REFERENCE

Only available

in CFW-08

Plus version.

Analog Output

0 = Output Frequency (Fs)

1 = Input Reference (Fe)

2 = Output Current (Is)

3, 5, 8 = Not used 88

P251 Analog Output 4 = Motor Torque 0

AO Function 6 = Process Variable

(PID)

7 = Active Current

9 = PID Setpoint

P252 Analog Output AO Gain 0.00 ... 9.99 1.00 88

Digital Inputs

P263

(1)

Digital Input DI1 Function

0 = No Function or

089

General Enable

1 ... 7 and 10 ... 12 =

General Enable

8 = Forward Run

9 = Start/S top

13 = FWD Run Using

Ramp #2

14 = Start (3-wire)

P264

(1)

Digital Input DI2 Function

0 = Forward/Reverse

089

1 = Local/Remote

2 ... 6 and 9 ... 12 = Not used

7 = Multispeed (MS2)

8 = Reverse

13 = REV Run - Ramp #2

14 = Stop (3-wire)

P265

(1) (2)

Digital Input DI3 Function

0 = Forward/Reverse

10 89

1 = Local/Remote

2 = General Enable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp #2

7 = Multispeed (MS1)

8 = No Function or

Start/Stop

9 = Start/S top

10 = Reset

11, 12 = Not used

13 = Flying Start Disable

14 = Multispeed (MS1)

Using Ramp #2

15 = Manual/Automatic PID)

16 = Increase E.P. with

Ramp #2

P266

(1)

Digital Input DI4 Function

0 = Forward/Reverse

889

1 = Local/Remote

2 = General Enable

(1)

This parameter can be changed only with the inverter disabled (motor stopped).

(2)

Value may change as a function of P203.

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

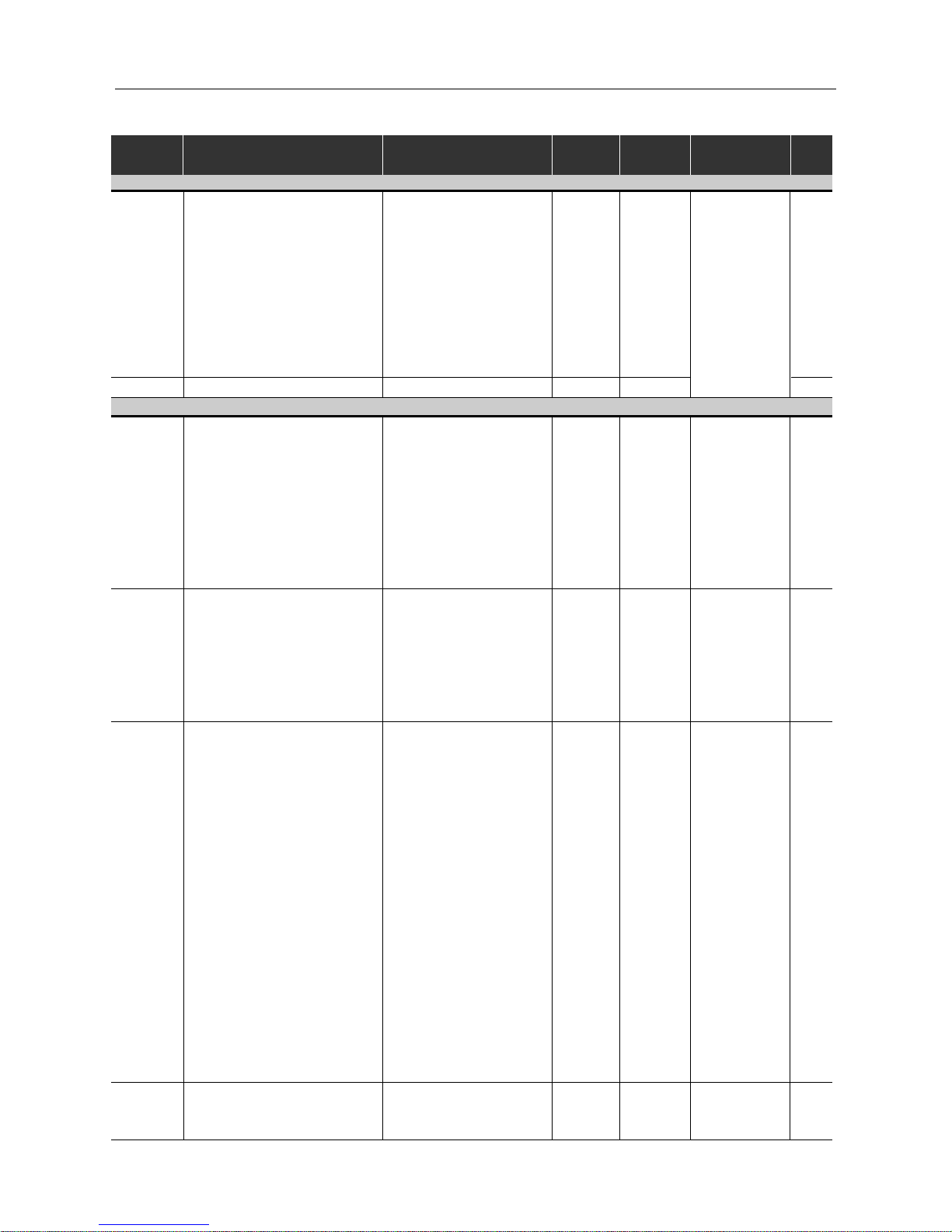

Page 12

11

CFW-08 -

QUICK PARAMETER REFERENCE

According

to the

inverter

model

Only available

in CFW-08

Plus version.

In vector control

mode (P202=2)

it is not possible

to set P297=7

(15kHz).

3 = JOG

4 = No Extrernal Fault

5 = Decrease E.P.

6 = Ramp #2

7 = Multispeed (MS0)

8 = Not used or

Start/Stop

9 = Start/S top

10 = Reset

11, 12, 14 and 15 =

Not Used

13 = Flying Start Disable

16 = Decrease E.P. with

Ramp #2

Digital Output(s)

P277

(1)

Relay Output RL1 Function

0 = Fs>Fx

794

1 = Fe>Fx

2 = Fs=Fe

3 = Is>Ix

4 and 6 = Not used

5 = Run

7 = No Fault

P279

(1)

Relay Output RL2 Function

0 = Fs>Fx

0

94

1 = Fe>Fx

2 = Fs=Fe

3 = Is>Ix

4 and 6 = Not used

5 = Run

7 = No Fault

Fx and Ix

P288 Fx Frquency 0.00 ... P134 3.00 95

P290 Ix Current 0 ... 1.5xI

nom

1.0xI

nom

95

Inverter Data

P295

(1)

Rated Inverter

300 = 1.0A

95

Current (I

nom

)

301 = 1.6A

302 = 2.6A

303 = 2.7A

304 = 4.0A

305 = 4.3A

306 = 6.5A

307 = 7.0A

308 = 7.3A

309 = 10A

310 = 13A

311 = 16A

P297

(1)

Switching Frequency

4 = 5.0kHz

4

96

5 = 2.5kHz

6 = 10kHz

7 = 15kHz

DC Braking

P300 DC Braking Time 0.0 ... 15.0s 0.0 9 7

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

(1)

This parameter can be changed only with the inverter disabled (motor stopped).

Page 13

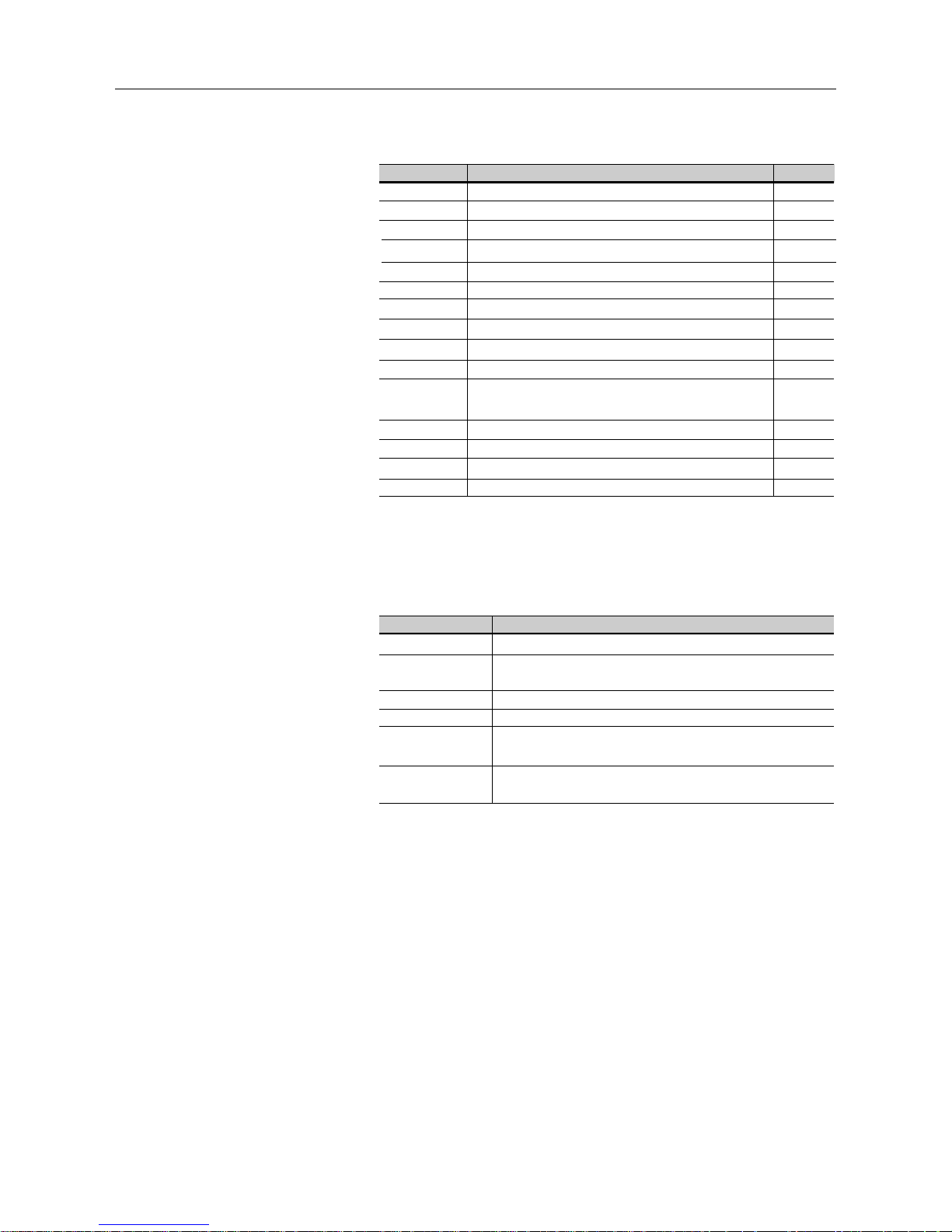

12

CFW-08 -

QUICK PARAMETER REFERENCE

Serial Communication Interface I

P308

(1)

Inverter Address

1 ... 30 (Serial WEG)

198

1 ... 247 (Modbus-RTU)

Flying Start and Ride-Through

P310

(1)

Flying Start and Ride-Through

0 = Inactive

099

1 = Flying Start

2 = Flying Start and

Ride-Through

3 = Ride-Through

P311 Voltage Ramp 0.1 ... 10.0s 5.0 100

Serial Communication Interface II

P312

(1)

Serial Interface Protocol

0 = Serial WEG

0 100

1 = Modbus-RTU 9600 bps

without parity

2 = Modbus-RTU 9600 bps

with odd parity

3 = Modbus-RTU 9600 bps

with even parity

4 = Modbus-RTU 19200 bps

without parity

5 = Modbus-RTU 19200 bps

with odd parity

6 = Modbus-RTU 19200 bps

with even parity

7 = Modbus-RTU 38400 bps

without parity

8 = Modbus-RTU 38400 bps

with odd parity

9 = Modbus-RTU 38400 bps

with even parity

P313

Serial Interface Watchdog

0 = Desabling by ramp

2 100

Action

1 = General disable

2 = Shows only E28

3 = Goes to local mode

P314

Serial Interface Watchdog 0.0 = Desables the function

0.0 100

Timeout 0.1 ...99.9s = Set value

(1)

This parameter can be changed only with the inverter disabled (motor stopped).

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

P301

DC Braking Start

0.00 ... 15.00Hz 1.00 97

Frequency

P302

DC Braking

0.0 ... 130% 0.0 97

Current

Skip Frequencies

P303 Skip Frequency 1 P133 ... P134 20.00 98

P304 Skip Frequency 2 P133 ... P134 30.00 98

P306 Skip Band Range 0.00 ... 25.00Hz 0.00 9 8

Page 14

13

CFW-08 -

QUICK PARAMETER REFERENCE

Only available in

vector mode

(P202=2).

Only available

in vector mode

(P202=2).

Only available

in vector mode

(P202=2).

According

to inverter

model

(1)

This parameter can be changed only with the inverter disabled (motor stopped).

MOTOR P ARAMETERS (P399 ... P499)

Rated Parameters

P399

(1)

Rated Motor Efficiency 50.0 ... 99.9% 101

P400

(1)

Rated Motor Voltage

0 ... 600V 101

P401 Rated Motor Current 0.3xI

nom

... 1.3xI

nom

101

P402 Rated Motor Speed 0 ... 9999rpm 10 1

P403

(1)

Rated Motor Frequency 0.00 ... P134 101

P404

(1)

Rated Motor Power

0 = 0.16HP / 0.12kW

1 = 0.25HP / 0.18kW

2 = 0.33HP / 0.25kW

3 = 0.50HP / 0.37kW

4 = 0.75HP / 0.55kW

5 = 1HP / 0.75kW 102

6 = 1.5HP / 1.1kW

7 = 2HP / 1.5kW

8 = 3HP / 2.2kW

9 = 4HP / 3.0kW

10 = 5HP / 3.7kW

11 = 5.5HP / 4.0kW

12 = 6HP / 4.5kW

13 = 7.5HP / 5.5kW

14 = 10HP / 7.5kW

15 = 12.5HP / 9.2kW

P407

(1)

Rated Motor Power

0.50 ... 0.99 102

Factor

Measured Parameters

P408

(1)

Self-Tuning

0 = No

0- 102

1 = Yes

P409 Motor Stator Resistance 0.00 ... 99.99Ω 103

SPECIAL FUNCTION (P500 ... P599)

PID Regulator

P520 PID Proportional Gain 0.000 ... 7.999 1.000 109

P521 PID Integral Gain 0.000 ... 9.999 1.000 10 9

P522 PID Differential Gain 0.000 ... 9.999 0.000 10 9

P525

Setpoint Via Keypad of the

0.00 ... 100.0% 0.00 109

PID Regulator

P526 Process Variable Filter 0.01 ... 10.00s 0.10 109

P527 PID Action

0 = Direct

0109

1 = Reverse

P528

Process Variable

0.00 ... 99.9 1.00 109

Scale Factor

P536 Automatic Setting of P525

0=Active

0109

1=Inactive

According

to inverter

model

(motor

matched

to the

inverter see item

9.3)

and sales

market

Parameter Function

Adjustable Range

Factory User

Note Page

Setting Setting

Page 15

14

CFW-08 -

QUICK PARAMETER REFERENCE

Display Description Page

E00 Output Overcurrent/Short-Circuit 110

E01 DC Link Overvoltage 110

E02 DC Link Undervoltage 110

E04 Inverter Overtemperature 111

E05 Output Overload (Ixt Function) 11 1

E06 External Fault 111

E08 CPU Error (Watchdog) 111

E09 Program Memory Error (Checksum) 111

E10 Keypad Copy Function Error 111

E14 Self-tuning Fault 111

E22, E25

Serial Communication Error 111

E26 and E27

E24 Programming Error 111

E28 Serial Interface Watchdog Timeout Error 111

E31 Keypad Connection Fault (HMI-CFW08-RS) 111

E41 Self-Diagnosis Fault 111

2. Fault Messages

3. Other Messages

Display Description

rdy Inverter is ready to be enabled

Sub

Power suplly voltage is too low for the inverter operation

(Undervoltage)

dcbr Inverter in DC braking mode

auto Inverter is running self-tuning routine

copy

Keypad Copy Function in Progress (only available in

the HMI-CFW08-RS) - inverter to keypad

past

Keypad Copy Function in Progress (only available in

the HMI-CFW08-RS) - Keypad to Inverter

Page 16

15

CHAPTER 1

SAFETY NOTICES

This Manual contains necessary information for the correct use of the

CFW-8 V ariable Frequency Drive.

This Manual has been written for qualified personnel with suitable training

and technical qualification to operate this type of equipment.

The following Safety Notices will be used in this Manual:

DANGER!

If the recommended Safety Notices are not strictly observed, it can lead

to serious or fatal injuries of personnel and/or material damage.

ATTENTION!

Failure to observe the recommended Safety Procedures can lead to

material damage.

NOTE!

The content of this Manual supplies important information for the correct

understanding of operation and proper performance of the equipment.

The following symbols may be attached to the product, serving as Safety

Notice:

High V olt ages

Components sensitive to electrostatic discharge. Do not touch them

without proper grounding procedures.

Mandatory connection to ground protection (PE)

Shield connection to ground

DANGER!

Only qualified personnel should plan or implement the installation,

start- up, operation and maintenance of this equipment. Personnel must

review entire Manual before attempting to install, operate or troubleshoot

the CFW-08.

DANGER!

The inverter control circuit (ECC2, DSP) and the HMI-CFW08-P are not

grounded. They are high voltage circuits.

1.3 PRELIMINARY

RECOMMENDATIONS

1.2 SAFETY NOTICE ON THE

PRODUCT

1.1 SAFETY NOTICES IN THE

MANUAL

Page 17

16

SAFETY NOTICES

These personnel must follow all safety instructions included in this Manual

and/or defined by local regulations.

Failure to comply with these instructions may result in personnel injury and/or

equipment damage.

NOTE!

In this Manual, qualified personnel are defined as people that are trained to:

1. Install, ground, power up and operate the CFW-08 according to this

Manual and the local required safety procedures;

2. Use of safety equipment according to the local regulations;

3. Administer Cardio Pulmonary Resuscitation (CPR) and First Aid.

DANGER!

Always disconnect the supply voltage before touching any electrical component

inside the inverter.

Many components are charged with high voltages, even after the incoming AC

power supply has been disconnected or switched OFF. Wait at least 10

minutes for the total discharge of the power capacitors.

Always connect the frame of the equipment to the ground (PE) at the suitable

connection point.

ATTENTION!

All electronic boards have components that are sensitive to electrostatic

discharges. Never touch any of the electrical components or connectors without

following proper grounding procedures. If necessary to do so, touch the properly

grounded metallic frame or use a suitable ground strap.

NOTE!

Inverters can interfere with other electronic equipment. In order to reduce this

interference, adopt the measures recommended in Section 3 “Installation”.

NOTE!

Read this entire Manual carefully and completely before installing or operating

the CFW-08.

Do not apply High V oltage (High Pot) Test on the Inverter!

If this test is necessary, contact the Manufacturer.

Page 18

CHAPTER 2

GENERAL INFORMA TION

This chapter defines the contents and purposes of this manual and

describes the main characteristics of the CFW-08 frequency inverter.

Identification, receiving inspections and storage requirements are also

provided.

2.1 ABOUT THIS MANUAL

This Manual is divided into 10 Chapter, providing infornation to the user on

how receive, install, start-up and operate the CFW-08:

Chapter 1 - Safety Notices;

Chapter 2 - General Information;

Chapter 3 - Installation;

Chapter 4 - Start-up;

Chapter 5 - Keypad HMI) Operation;

Chapter 6 - Detailed Parameter Description;

Chapter 7 - Diagnostic and Troubleshooting;

Chapter 8 - CFW-08 Options and Accessories;

Chapter 9 - Technical S pecifications;

Chapter 10 - Warranty Policy.

This Manual provides information for the correct use of the CFW-08. The

CFW-08 is very flexible and allows for the operation in many different

modes as described in this manual.

As the CFW-08 can be applied in several ways, it is impossible to describe

here all of the application possibilities. WEG does not accept any

responsibility when the CFW-08 is not used according to this Manual.

No part of this Manual may be reproduced in any form, without the written

permission of WEG.

2.2 SOFTWARE VERSION

It is important to note the Software V ersion installed in the V ersion CFW08, since it defines the functions and the programming parameters of the

inverter.

This Manual refers to the Software version indicated on the inside cover.

For example, the Version 3.0X applies to versions 3.00 to 3.09, where “X”

is a variable that will change due to minor software revisions. The operation

of the CFW-08 with these software revisions are still covered by this version

of the Manual.

The Software V ersion can be read in the Parameter P023.

Page 19

18

GENERAL INFORMATION

2.3 ABOUT THE CFW-08

The CFW-08 is a high performance V ariable Frequency Drive that permits

the control of speed and torque of a three-phase AC induction motor . T wo

types of control are available in the same product:

Programmable scalar (Volts/Hz) control;

Sensorless Vector Control (VVC: V oltage V ector Control).

In the vector control mode, the motor performance is optimized relating to

torque and speed regulation.

The "Self-Tuning" function, available in vector control, permits the automatic

setting of the inverter parameter from the identification (also automatic) of

the parameters of the motor connected at the inverter output.

The V/F (scalar) mode is recommended for more simple applications

such as pump and fan drives. In these cases one can reduce the motor

and inverter losses by using the "Quadratic V/F" option, that results in

energy saving.

The V/F mode is also used when more than one motor should be driven

simultaneously by one inverter (multimotor application).

There are two CFW-08 versions:

Standard: it has 4 digit al inputs (DIs), 1 analog input (AI) and 1 relay

output.

CFW-08 Plus: compared to the standard version it has one additional

analog input and one additional relay output. It has also an analog

output (AO).

For power ratings and further technical information, see Chaper 9.

Page 20

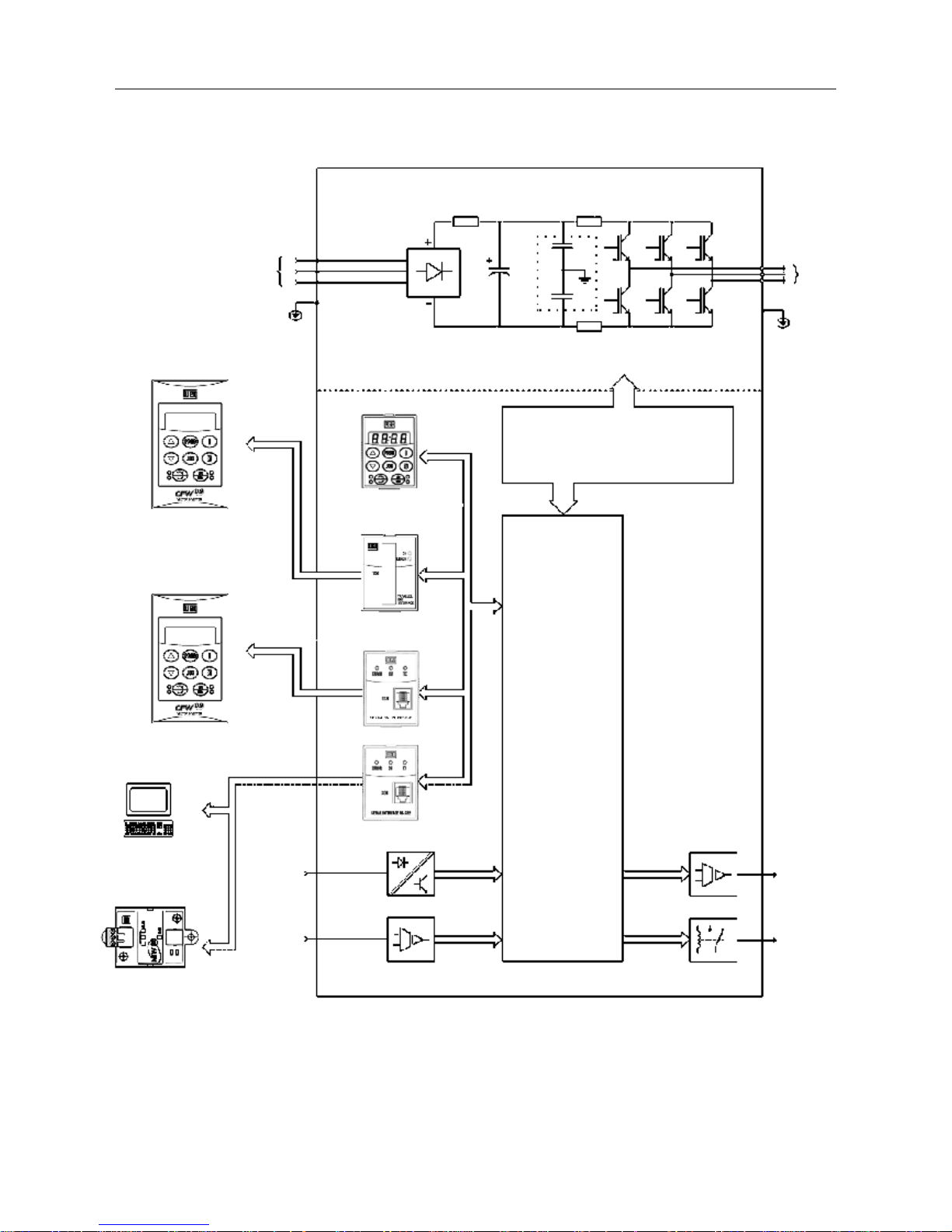

19

GENERAL INFORMATION

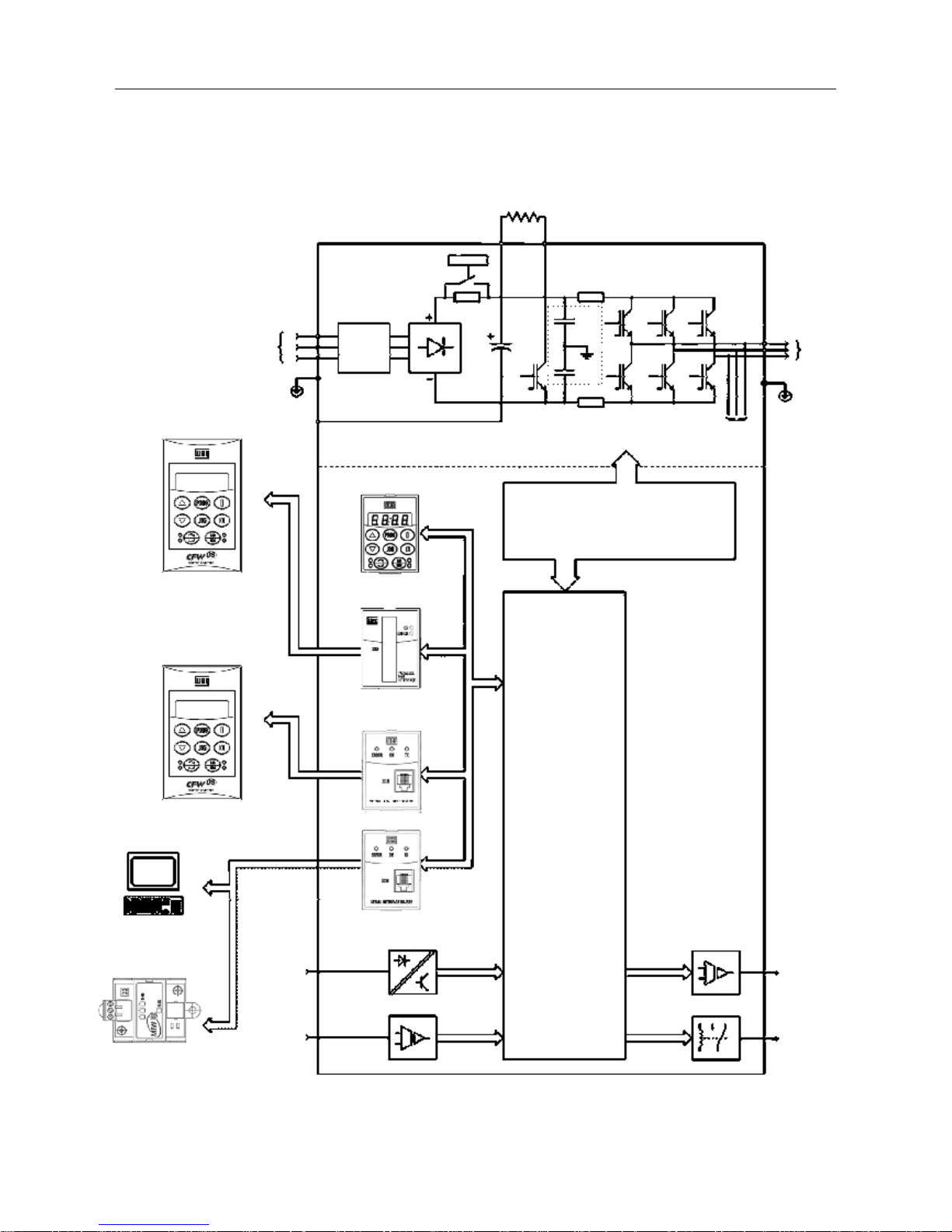

Figure 2.1 - Block diagram for the models:

1.6-2.6-4.0-7.0A/200-240V and 1.0-1.6-2.6-4.0A/380-480V

Power

Supply

R

S

T

P E

PC-Software

SuperDrive

or

RS-485

MIW-02

Analog

Inputs

(AI1 and

AI2)

Digital

Inputs

(DI1 to DI4)

POWER

CONTROL

POWER SUPPLIES AND

CONTROL / POWER INTERF ACES

"ECC2"

CONTROL BOARD

WITH DSP

Analog

Output

(AO)

Relay

Output

(RL1 and

RL2)

Motor

U

V

W

Rsh2

Rsh1

NTC

PE

RFI Filter

Interface

RS-232 KCS-CFW08

Interface

MIS-CFW08-RS

HMI-CFW08-P

Interface

MIP-CFW08-RP

or

or

or

HMI-CFW08-RS

HMI-CFW08-RP

Page 21

20

GENERAL INFORMATION

Figura 2.2– Block diagram for the models:

7.3-10-16A/200-240V and 2.7-4.3-6.5-10-13-16A/380-480V

Note: Model 16A/200-240V is not fitted with RFI filter (optional).

Power

Supply

R

S

T

RFI

Suppressor

Filter

(optional)

PC-Software

SuperDrive

or

RS-485

MIW-02

Analog

Inputs

(AI1 and AI2)

Digital

Inputs

(DI1 to DI4)

POWER

CONTROL

POWER SUPPLIES AND CONTROL /

POWER INTERFACES

"ECC2"

CONTROL BOARD

WITH DSP

Analog

Output

(AO)

Relay

Output

(RL1 and

RL2)

Motor

U

V

W

Rsh2

Rsh1

RPC

Pré-Carga

Braking

Resistor (External and Optional)

BR

+VD

PE

-UD

Voltage

Feedback

PE

RFI

Filter

HMI-CFW08-RS

HMI-CFW08-RP

Interface

RS-232 KCS-CFW08

Interface

MIS-CFW08-RS

HMI-CFW08-P

Interface

MIP-CFW08-RP

or

or

or

Page 22

21

GENERAL INFORMATION

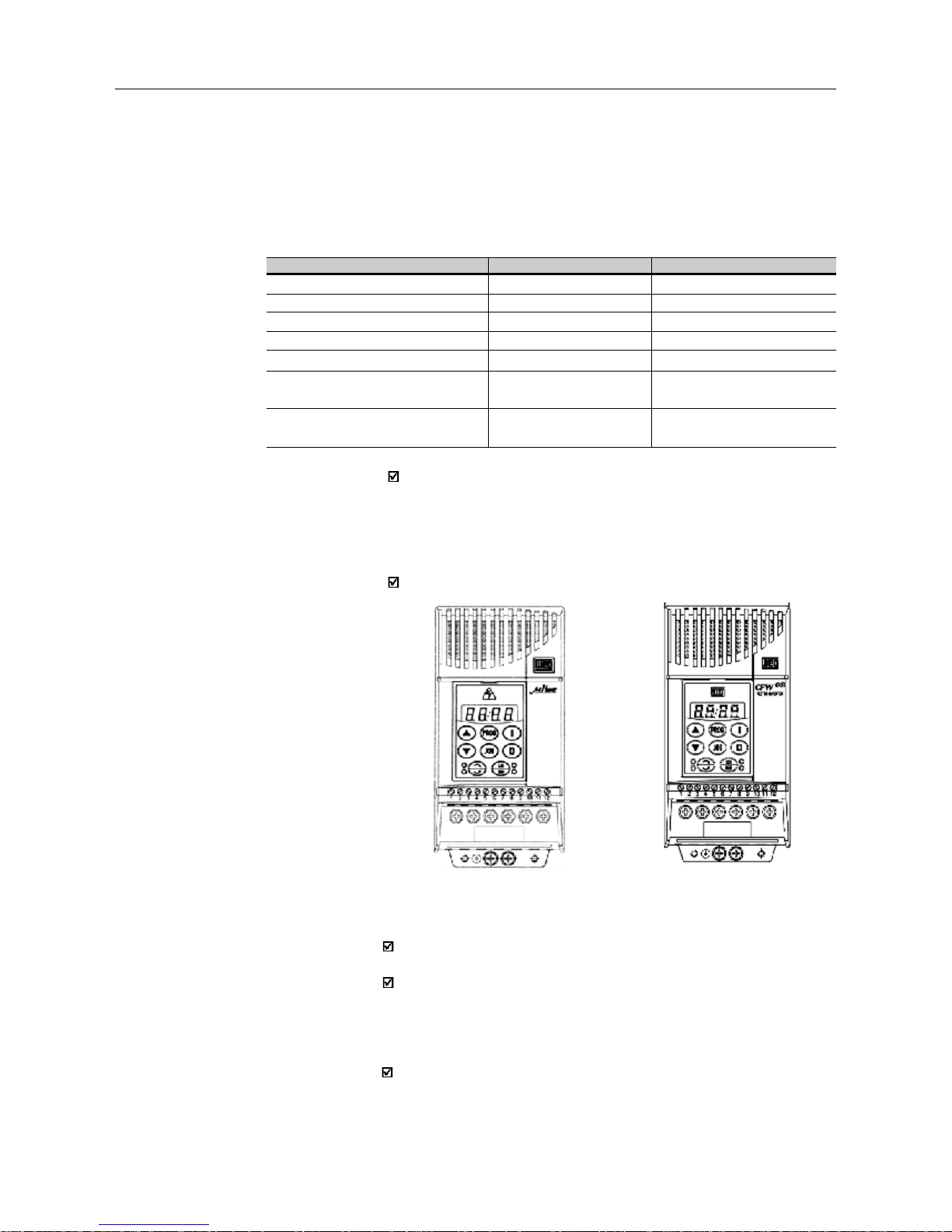

Product Appearance

Besides the internal electronics, also the exterrnal product appearance

have changed, which are:

- the frontal lettering on the plastic covers (formerly: µline, now:

CFW-08 vector inverter);

- WEG logo is now indicated on all accessories of the CFW-08 line

(keypad, communication modules etc).

Figure below makes a comparison:

2.3.1Differences between the

old

µ

line and

the new

CFW-08

(a)

µline

(b) CFW-08

Figure 2.3 - Comparison between µline a CFW-08 appearance

Version of Software

The new CFW-08 starts with Software V ersion V3.00. Thus, the software

Versions V1.xx and V2.xx are exclusive for µline.

Besides the inverter control has been implemented in a DSP (Digital

Signal Processor), which enables a more sophisticated control with

more parameters and functions.

Accessories

With the migration from the 16 bits microcontroller to the DSP of the

new CFW-08, the power supply of the electronic circuits had to be

changed from 5V to 3.3V . Consequently , the accesories (keyp ads,

communication modules, etc) of the old µline CAN NOT BE USED

with the new CFW-08 line. As general rule, use only accessories with

WEG logo, as already informed above.

This section aims at showing the differences between the old µline and

the new CFW-08. The information below are addressed to user that are

used to µline.

Table below shows the equivalence between the accessories of the old

µline an the new CFW-08.

Acessoriy

Local Keypad (parallel)

Remote serial Keypad

Remote parallel Keypad

Interface for remote serial Keypad

Interface for remote parallel Keypad

Interfaces for serial communication

RS-232

Interface for RS-485

serial communication RS-485

µline

IHM-8P (417100258)

IHM-8R (417100244)

-

MIR-8R (417100259)

-

MCW-01 (417100252)

MCW-02 (417100253)

CFW-08

HMI-CFW08-P (417100868)

HMI-CFW08-RS (417100992)

HMI-CFW08-RP (417100991)

MIS-CFW08-RS (417100993)

MIP-CFW08-RP (417100990)

KCS-CFW08 (417100882)

KCS-CFW08 (417100882) +

MIW-02 (417100543)

Page 23

22

GENERAL INFORMATION

Expansion of the Power Range

The power range of the old µline (0.25-2HP) has been expanded to

(0.25-10HP) with the new CFW-08 line.

Control Modes

Only the CFW-08 line has:

- Volt age Vector Control (VVC) that improves the inverter performance

considerably - adding the parameters P178, P399, P400, P402,

P403, P404, P407, P408 e P409;

- the quadratic curve V/F improves the systema energy saving capability

when loads with quadratic torque x speed characteristics are driven,

like pumps and fans.

Frequency Resolution

The new CFW-08 has a frequency resolution 10 times higher than the

old µline, i.e., it has a resoltion of 0.01Hz for frequencies up to 100.0Hz

and of 0.1Hz for frequencies higher than 99.99Hz.

Switching Frequencies of 10 and 15kHz

When the new CFW-08 is used, one can set the inverter switching

frequency to 10 and 15kHz, which enables an extremly quiet operation.

The audible noise level generated by the motor with 10 kHz is lower

with the CFW-08, when compared with the µline. This is due to the

PWM modulation improvements of the CFW-08.

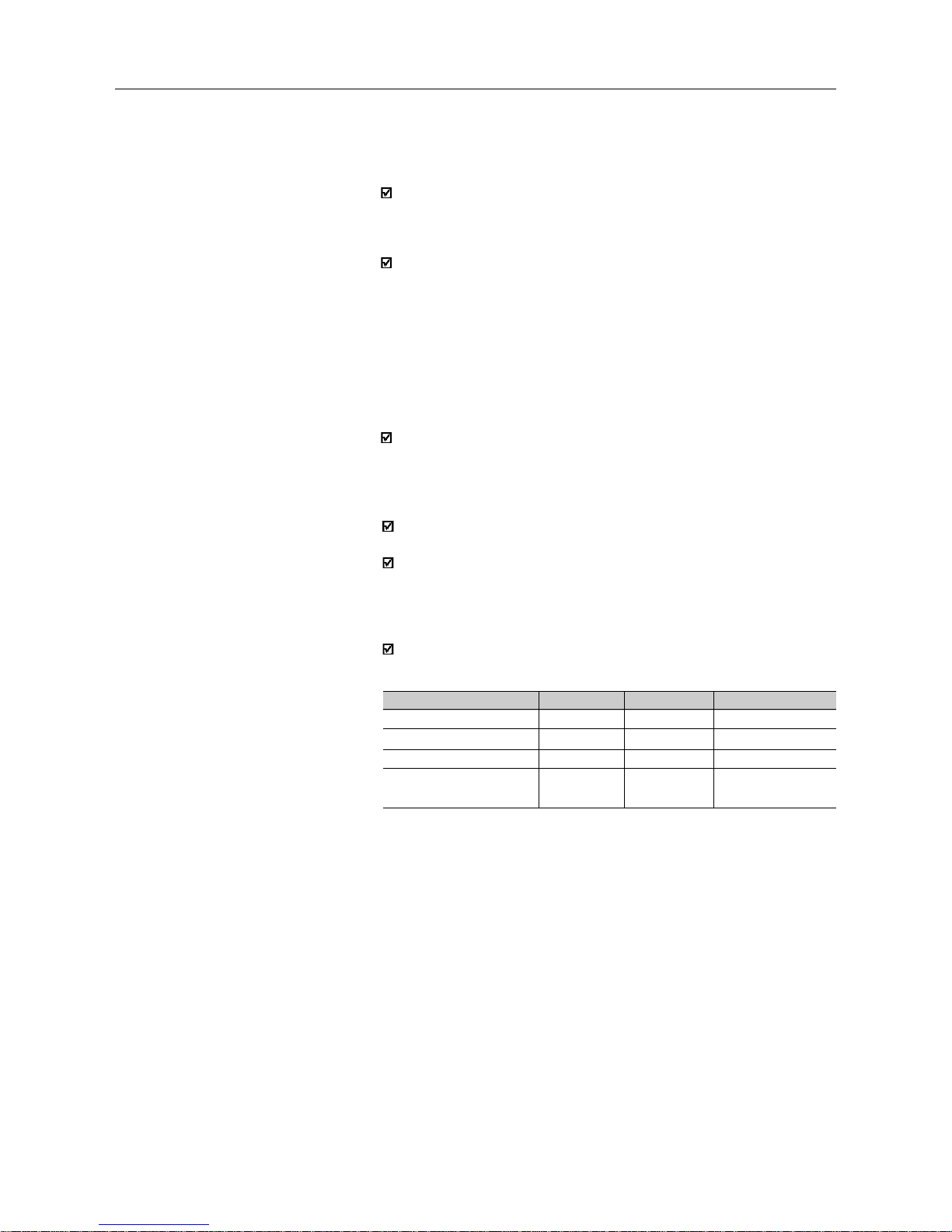

Inputs and Outputs (I/Os)

The CFW-08 Plus line has more I/Os than the old µline, while the

CFW-08 is equivalent to the µline in terms of of I/Os. See table below:

I/O

Digital Inputs

Analog Input(s)

Analog Outputs

Relay Outputs

µline

4

1

-

1

(REV contatct)

CFW-08

4

1

-

1

(REV contact)

CFW-08 Plus

4

2

1

2 (1 NO contact,

1 NC contact)

Page 24

23

GENERAL INFORMATION

I/O

Digital Input DI1

Digital Input DI2

Digital Input DI3

Digital Input DI4

0V for Digital Inputs

+10V

Analog Input AI1 voltage signal

Analog Input AI1 current signal

0V for analog

input(s)

Analog Input AI2 voltage signal

Analog Input AI2 current signal

Saída Analógica AO

Relay Ouput RL1

Relay Output RL2

µline

1

2

3

4

5

6

7

9

8

not

available

not

available

not

availablel

10(NF), 11(C)

and 12(NA)

not

available

CFW-08

1

2

3

4

5

6

7 with switch

S1:1 at pos. OFF

7 with switch

S1:1 at pos. ON

5

not

available

not

available

not

available

10(NF), 11(C)

and 12(NA)

not

available

CFW-08 Plus

1

2

3

4

5

6

7 with switch S1:1

at position OFF

7 with switch S1:1

at position ON

5

8 with switch S1:2

at position OFF

8 with switch S1:2

at position ON

9

11-12(NO)

10-11(NC)

Parameters and Functions

Parameters that are already used in

µµ

µµ

µline but have been changed

a) P136 - Manual T orque Boost (IxR Compensation)

Besides the parameter name, also the way the user enters the IxR

compensation value has been changed. In the old µline, the

parameter P136 had a family of 10 curves (value range: 0 to

9). In the new CFW-08, the IxR Compensation is set by entering a

percent (relating to the input voltage) that defines the output voltage

for an output frequency equal to zero. So larger curve set and a

larger variation range is obtained.

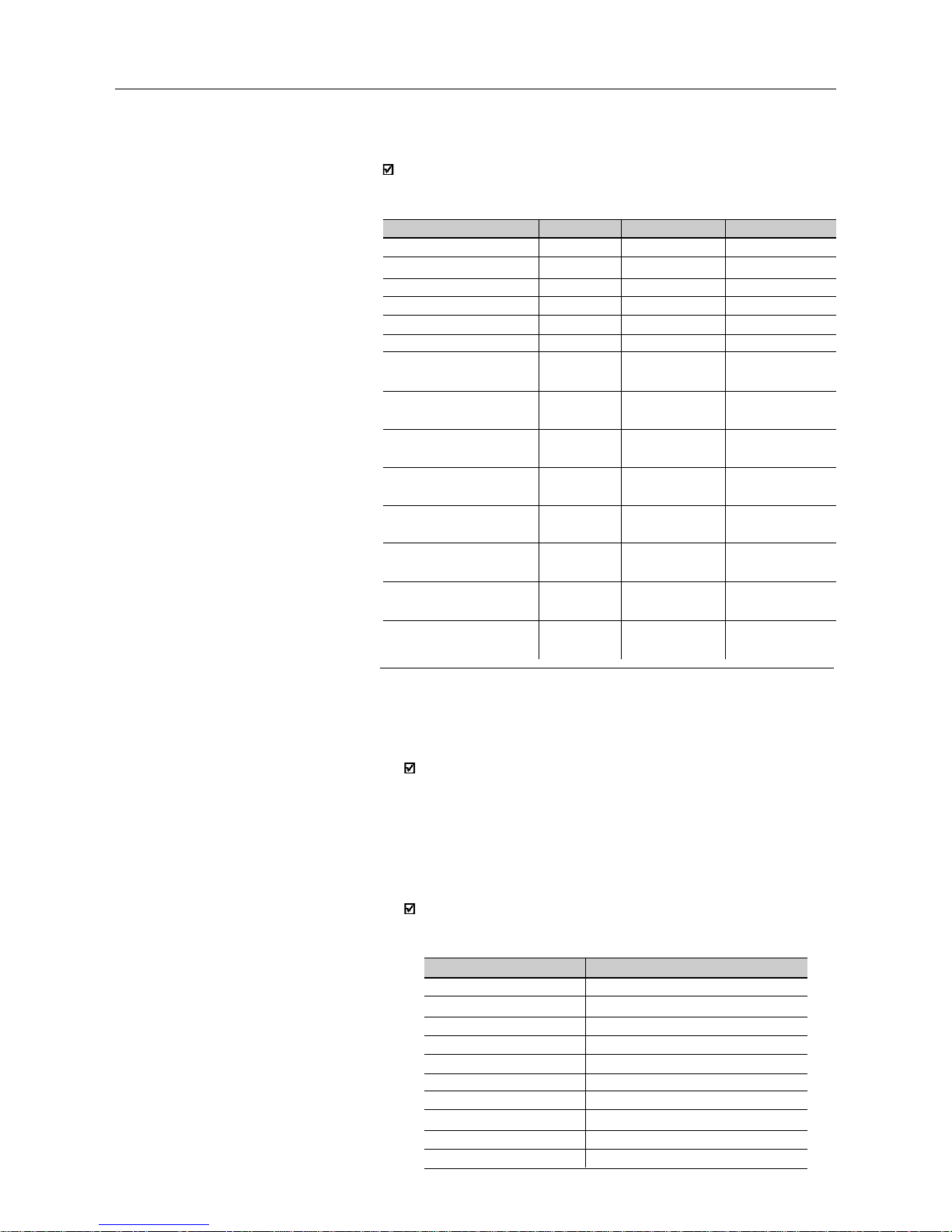

T able below shows the equivalence between which was programmed

in the old µline and which must be programmed in the new CFW08 to obtain the same result.

P136 set in µline

0

1

2

3

4

5

6

7

8

9

P136 to be set in the CFW-08

0.0

2.5

5.0

7.5

10.0

12.5

15.0

17.5

20.0

22.5

But the control connections (terminals XC1) differ between the µline

and the CFW-08 line. T able below shows theses pin dif ferences:

Page 25

24

GENERAL INFORMATION

b) Automatic T orque Boost (Automatic IxR Compensation) and Slip

Compensation

In the µline only the rated motor current (P401) was used in

the Automatic IxR Compensation and the Slip Compensation

functions. In the µline the rated motor power factor of the motor

was considered as a fixed value and equal to 0.9 .

Now in the new CFW-08, are used the parameters P401 and P407

(rated motor power factor). Thus:

Example: When in an application with the µline the following setting

was required: P401=3.8A, now with the new CFW-08 you must perform

the following setting: P401=3.8A and P407=0.9

or

P407= rated cos ∅ of the used motor and P401=3.8 x

0.9

P407

Parameters existing only in Special Software Versions of the

µµ

µµ

µline

a) Quick Inputs

In the new CFW-08, the response time of the the digital inputs is

10ms (max.).

In addition, the minimum acceleration and deceleration time was

reduced from 0.2s (µline) to 0.1s (CFW-08). Besides the DC braking

process can be interrupted before it has been concluded, for

instance, when a new enabling is required.

b) Other changes

P120=2 - digital reference backup via P121 independently of the

reference source.

P265=14 - DI3: multispeed using ramp #2.

New Parameters and Functions

The reference 1 of the multispeed that was in Parameter P121 (in

µline) is now in Parameter P124 (in CFW-08).

The DC link regulation level (ramp holding) can now be

programmed in Parameter P151 - in the µline this level was fixed to

377V for the 200-240V line and 747V for the 380-480V line.

Also the programming way of Parameter P302 has changed. In the

µline P302 was related to the voltage applied to the output during the

D Cbraking, now in the new CFW-08, P302 defines the DC Braking

Current.

PID regulator.

Suammarizing, the new parameters are: P009, P040, P124, P151,

P178, P202, P203, P205, P219, P238, P239, P240, P251, P252, P279,

P399, P400, P402, P403, P404, P407, P408, P409, P520, P521, P522,

P525, P526, P527 e P528.

P401

uline

. 0.9 = P401 x P407

CFW-08

Page 26

25

GENERAL INFORMATION

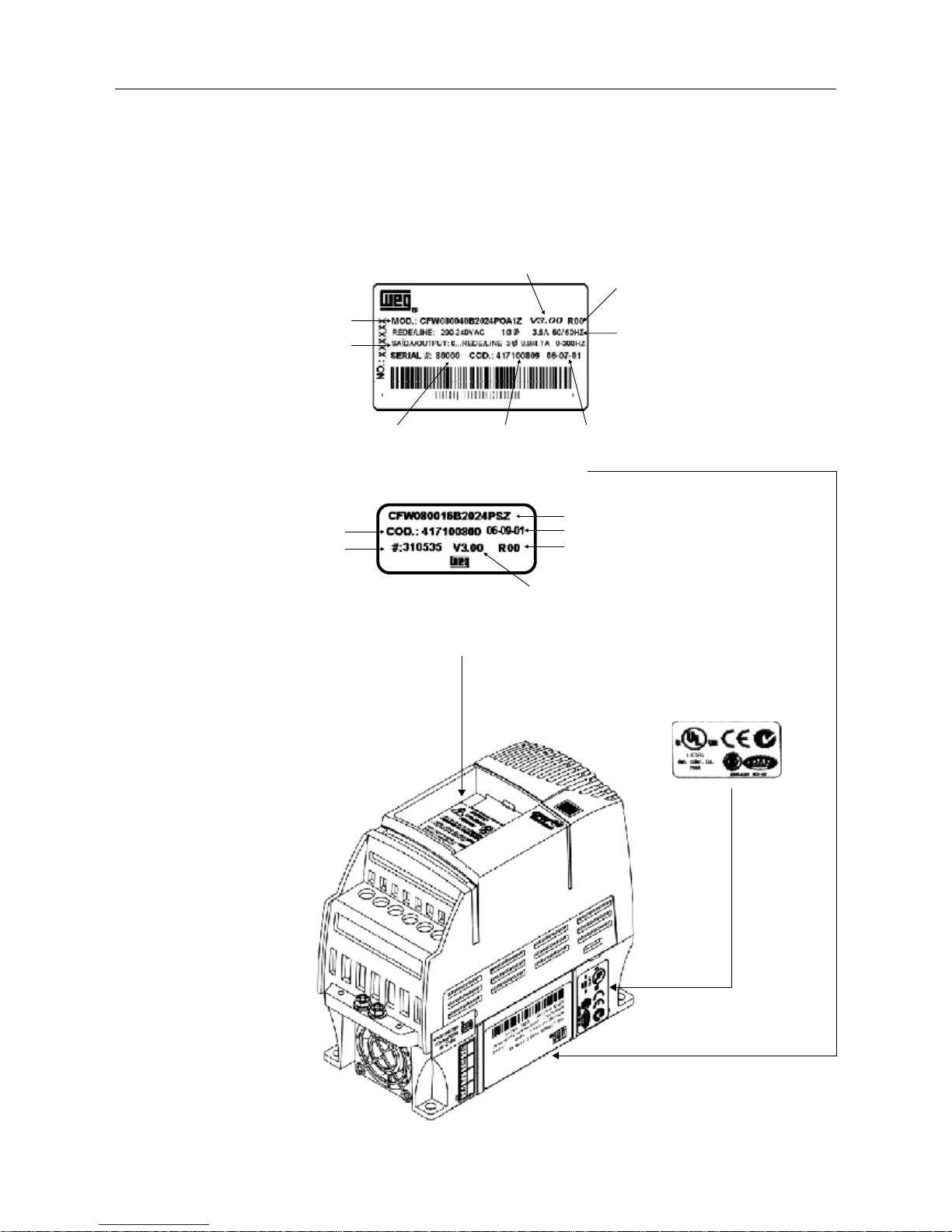

2.4 CFW-08 IDENTIFICA TION

Figure 2.4 - Description and location of the nameplates

Software

Version

Hardware

Revision

Rated Input Data

(Voltage, Number of

Phases Current,

Frequency)

Manufacturing DateWEG Part NumberSerial Number

CFW-08 Model

Rated Output Data

(Voltage, Frequency)

Lateral Nameplate of the CFW-08

Frontal Nameplate of the CFW-08 (under the keypad)

Note: T o remove the

keypad, see instructions

in 8.1.1 (Figure 8.2).

WEG Part Number

Seriel Number

CFW-08-Model

Manufacturing Date

Hardware Revision

Software Version

Page 27

26

GENERAL INFORMATION

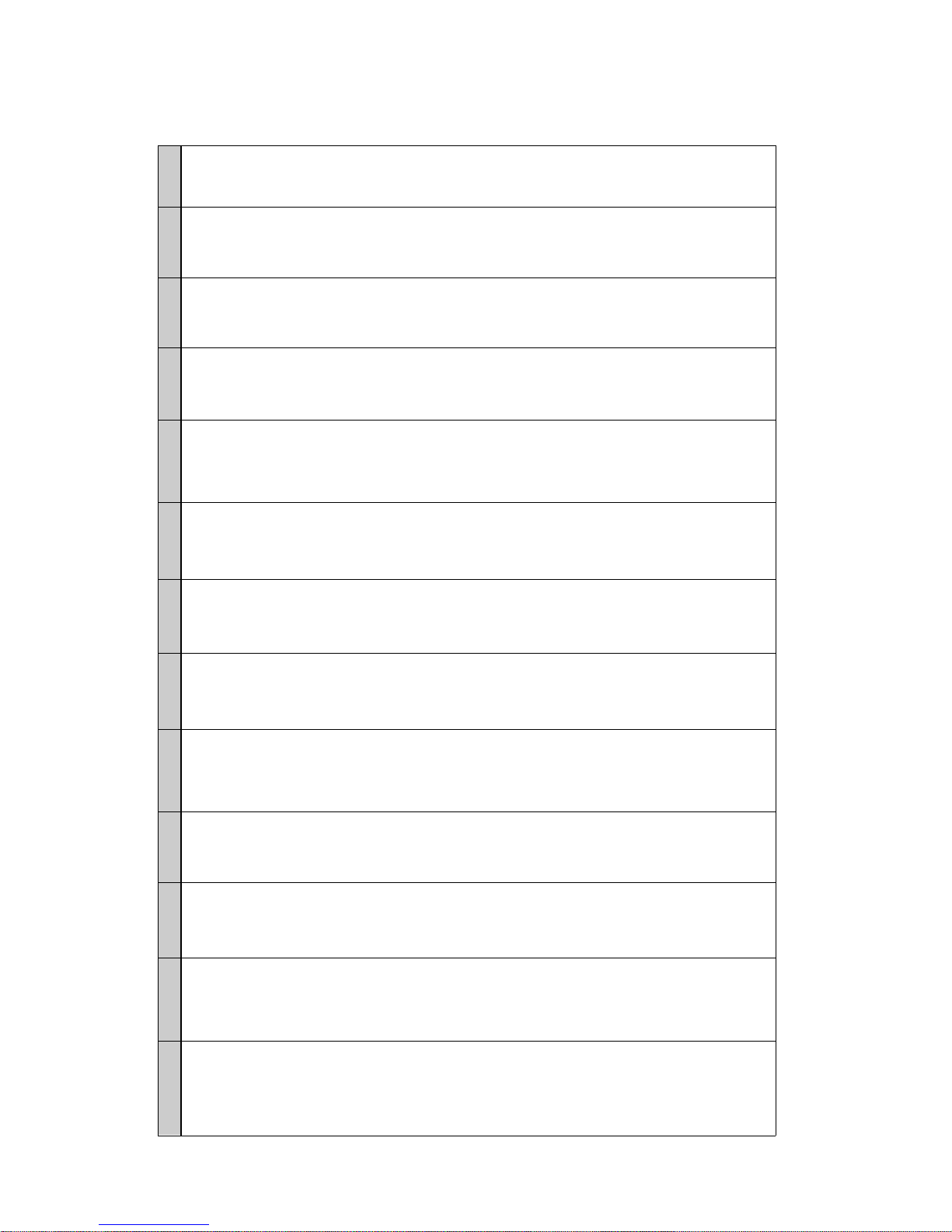

CFW-08 0040 B 2024 P O 00 00 00 00 00 00 Z

Rated Output

Current for

200 to 240V:

0016=1.6A

0026=2.6A

0040=4.0A

0070=7.0A

0073=7.3A

0100=10A

0160=16A

380 to 480V:

0010=1.0A

0016=1.6A

0026=2.6A

0027=2.7A

0040=4.0A

0043=4.3A

0065=6.5A

0100=10A

0130=13A

0160=16A

Number of

phases of

the power

supply:

S=single

phase

T=three

phase

B=single

phase or

three phase

Manual

Language:

P= Portug.

E= English

S= Spanish

F= French

G= German

Power

Supply:

2024 =

200 to 240V

3848 =

380 to 480V

Options:

S= standard

O= with

optiions

Degree of

Protection:

Blank =

standard

N1= Nema 1

Human

Machine

Interface:

blank

standard

SI= without

interface

(with dummy

panel)

WEG

Series 08

Frequency

Inverter

Control Board:

Blank =

standard

control

A1= control 1

(Plus Version)

Special

Software:

00 = none

End Code

RFI Filter:

Blank=

without

filter

FA=

Class A

RF I filter

(internal or

footprint)

Special

Hardware:

00 = none

HOW TO SPECIFY THE CFW-08 MODEL:

Page 28

27

GENERAL INFORMATION

2.5 Receiving and

Storing

NOTE!

The Option field (S or O) defines if the CFW-08 is a standard version or

if it will be equipped with any optional devices. If the standard version

is required, the specification code ends here.

The model number has always the letter Z at the end. For example:

CFW080040S2024ESZ = standard 4.0A CFW-08 inverter, single-phase

at 200...240V input with manual in English.

For the effect of this code, the standard product is conceived as follows:

- CFW-08 with standard control board.

- Degree of protection: NEMA 1 for the models 13 and 16A/380-480V;

IP20 for the other models.

If the CFW-08 is equipped with any optional devices, you must fill out

all fields in the correct sequence up to the last optional device, the

model number is completed with the letter Z. It is not necessary to

indicate the code number 00 for those optional devices that are standard

or that will not be used.

Thus, for instance if the product above is required with NEMA 1 degree

of protection:

CFW080040S2024EON1Z = CFW-08 inverter, 4A, single-phase,

200...240V input, with manual in English language and with kitf fo r

NEMA 1 degree of protection.

The CFW-08 Plus is formed by the inverter and the control board 1.

Example: CFW080040S2024EOA1Z.

7.0 and 16.0A/200-240V and for all 380-480V models are just available

with three-phase power supply.

A RFI Class A filter (optional) can be installed inside the inverter in

models 7.3 and 10A/200-240V (single-phase) and 2.7, 4.3, 6.5, 10, 13

and 16A/380-480V . Models 1.6, 2.6 and 4.0A/200-240V (single-phase)

and 1.0, 1.6, 2.6 and 4.0A/380-480V can be provided mounted on a

footprint RFI Class A filter (optional).

The listing of the existing models (voltage/current) is shown in item 9.1.

The CFW-08 is supplied in cardboard boxes.

The outside of the packing box has a nameplate that is identical to that

on the CFW-08.

Please check if the CFW-08 is the one you ordered.

Check if the:

CFW-08 nameplate data matches with your purchase order .

The equipment has not been damaged during transport.

If any problem is detected, contact the carrier immedately .

If the CFW-08 is not installed immediately, store it in a clean and dry

room (storage temperatures between –25°C and 60°C). Cover it to

protect it against dust, dirt or other contamination.

Page 29

28

CHAPTER 3

INST ALLATION

3.1 MECHANICAL

INST ALLA TION

This chapter describes the procedures for the electrical and mechanical

installation of the CFW-08.

These guidelines and suggestions must be followed for proper CFW-08

operation.

3.1.1 Environment

The location of the inverter installation is an important factor to assure

good performance and high product reliability . For proper installation, we

make the following recommendations:

Avoid direct exposure to sunlight, rain, high moisture and sea air .

Avoid exposure to gases or explosive or corrosive liquids;

Avoid exposure to excessive vibration, dust, oil or any conductive

particles or materials.

Environmental Conditions:

T emperature : 32...104ºF (0 ... 40ºC) - nominal conditions. 32...122ºF

(0 ... 50ºC) - with 2% current derating for each 1.8ºF (1ºC) degree

above 104ºF (40ºC).

Relative Air Humidity: 5% to 90% - non-condensing.

Maximum Altitude: 3,300 f t (1000m) - nominal conditions.

3,300...13,200 ft (1000 ... 4000m) - with 10% current reduction for

each 3,300 ft (1000m) above 3,300 ft (1000m).

Pollution Degree: 2 (according to EN50178 and UL508C)

NOTE!

When inverters are installed in panels or in closed metallic boxes, adequate

cooling is required to ensure that the temperature arounds the inverter will

not exceed the maximim allowed temperature. See Dissipated Power in

Section 9.1.

Page 30

29

INSTALLATION AND CONNECTION

Table 3.1 - Recommended free spaces

Install the inverter in vertical position.

Leave free space around the inverter as indicated in T able 3.1.

Do not install heat sensitive components immediately above the

inverter.

When inverters are installed side by side, maintain the minimum

recommended distance B.

When inverters are installed top and bottom, maintain the minimum

recommended distance A + C and deflect the hot air coming from

the inverter below.

Install the inverter on a flat surface.

External dimensions and mounting holes are according to Fig. 3.2.

For CFW-08 installation procedures, see Fig. 3.3.

Provide independent conduits for signal, control and power

conductors. (Refer to Electrical Installation). Separate the motor

cables from the other cables.

CFW-08 Model

1.6A / 200-240V

2.6A / 200-240V

4.0A / 200-240V

7.0A / 200-240V

1.0A / 380-480V

1.6A / 380-480V

2.6A / 380-480V

4.0A / 380-480V

7.3A / 200-240V

10.0A / 200-240V

16.0A / 200-240V

2.7A / 380-480V

4.3A / 380-480V

6.5A / 380-480V

10.0A / 380-480V

13.0A / 380-480V

16.0A / 380-480V

ABCD

30 mm 1.18 in 5 mm 0.20 in 5 0 mm 2 in 50 mm 2 in

35 mm 1.38 in 15 mm 0.59 in 5 0 mm 2 in 50 mm 2 in

40 mm 1.57 in 30 mm 1.18 in 5 0 mm 2 in 50 mm 2 in

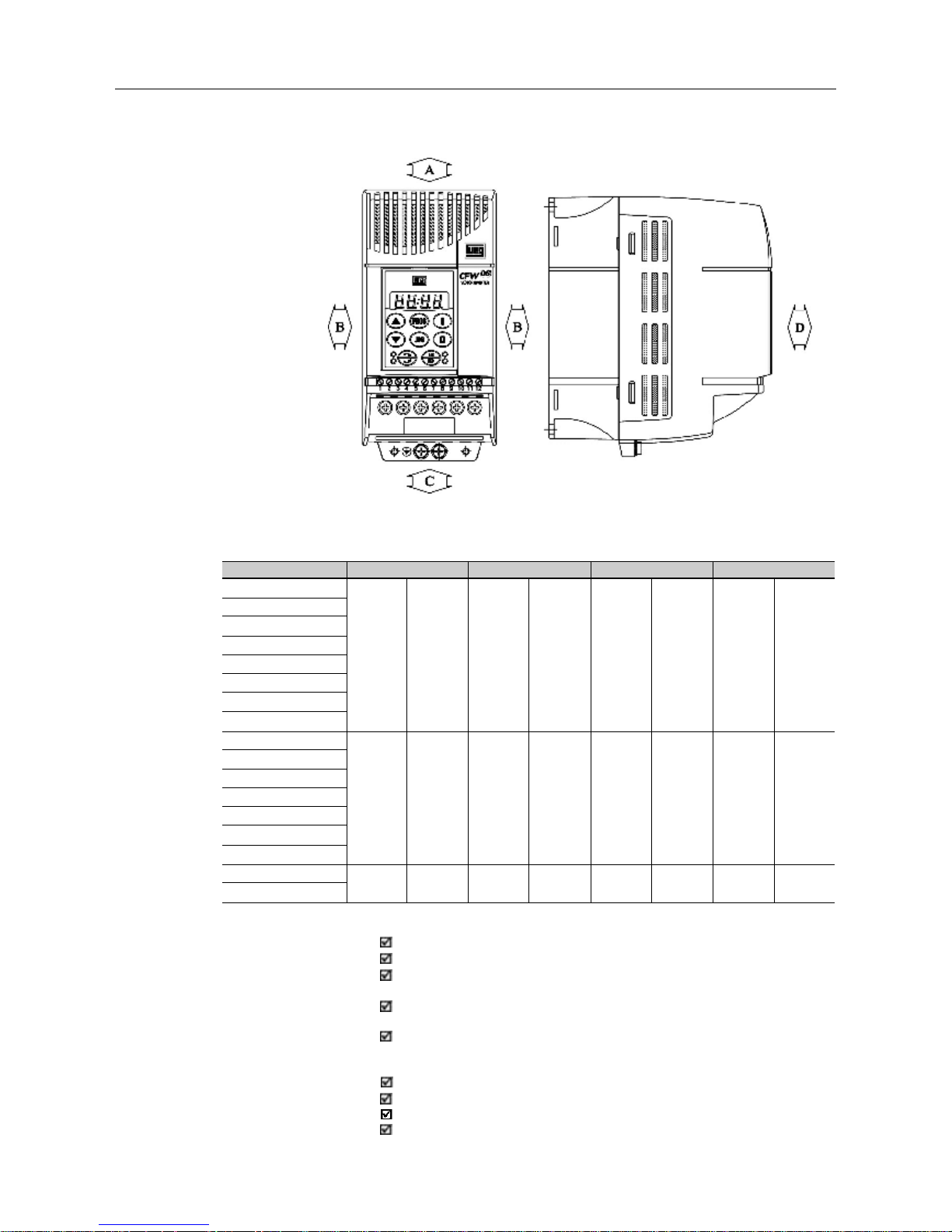

3.1.2 Mounting Specification

Figure 3.1 - Free Space for Cooling

Page 31

30

INSTALLATION AND CONNECTION

Figure 3.2 - Dimensional Drawings of the CFW-08

VIEW OF THE

MOUNTING BASE

FRONTAL

VIEW

LATERAL VIEW

Page 32

31

INSTALLATION AND CONNECTION

Inverter

Model

1.6A / 200-240V

2.6A / 200-240V

4.0A / 200-240V

7.0A / 200-240V

7.3A / 200-240V

10A / 200-240V

16A / 200-240V

1.0A / 380-480V

1.6A / 380-480V

2.6A / 380-480V

2.7A / 380-480V

4.0A / 380-480V

4.3A / 380-480V

6.5A / 380-480V

10A / 380-480V

13A / 380-480V

16A / 380-480V

Width L

in

(mm)

2.95

(75)

2.95

(75)

2.95

(75)

2.95

(75)

4.53

(115)

4.53

(115)

4.53

(115)

2.95

(75)

2.95

(75)

2.95

(75)

4.53

(115)

2.95

(75)

4.53

(115)

4.53

(115)

4.53

(115)

5.63

(143)

5.63

(143)

Height H

in

(mm)

5.95

(151)

5.95

(151)

5.95

(151)

5.95

(151)

7.87

(200)

7.87

(200)

7.87

(200)

5.95

(151)

5.95

(151)

5.95

(151)

7.87

(200)

5.95

(151)

7.87

(200)

7.87

(200)

7.87

(200)

7.99

(203)

7.99

(203)

Depth P

in

(mm)

5.16

(131)

5.16

(131)

5.16

(131)

5.16

(131)

5.91

(150)

5.91

(150)

5.91

(150)

5.16

(131)

5.16

(131)

5.16

(131)

5.91

(150)

5.16

(131)

5.91

(150)

5.91

(150)

5.91

(150)

6.50

(165)

6.50

(165)

A

in

(mm)

2.52

(64)

2.52

(64)

2.52

(64)

2.52

(64)

3.98

(101)

3.98

(101)

3.98

(101)

2.52

(64)

2.52

(64)

2.52

(64)

3.98

(101)

2.52

(64)

3.98

(101)

3.98

(101)

3.98

(101)

4.76

(121)

4.76

(121)

B

in

(mm)

5.08

(129)

5.08

(129)

5.08

(129)

5.08

(129)

6.97

(177)

6.97

(177)

6.97

(177)

5.08

(129)

5.08

(129)

5.08

(129)

6.97

(177)

5.08

(129)

6.97

(177)

6.97

(177)

6.97

(177)

7.09

(180)

7.09

(180)

C

in

(mm)

0.20

(5)

0.20

(5)

0.20

(5)

0.20

(5)

0.28

(7)

0.28

(7)

0.28

(7)

0.20

(5)

0.20

(5)

0.20

(5)

0.28

(7)

0.20

(5)

0.28

(7)

0.28

(7)

0.28

(7)

0.43

(11)

0.43

(11)

D

in

(mm)

0.24

(6)

0.24

(6)

0.24

(6)

0.24

(6)

0.20

(5)

0.20

(5)

0.20

(5)

0.24

(6)

0.24

(6)

0.24

(6)

0.20

(5)

0.24

(6)

0.20

(5)

0.20

(5)

0.20

(5)

0.39

(10)

0.39

(10)

Mounting

Screw

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

5/32

(M4)

3/16

(M5)

3/16

(M5)

Weigth

lb

(kg)

2.2

(1.0)

2.2

(1.0)

2.2

(1.0)

2.2

(1.0)

4.4

(2.0)

4.4

(2.0)

4.4

(2.0)

2.2

(1.0)

2.2

(1.0)

2.2

(1.0)

4.4

(2.0)

2.2

(1.0)

4.4

(2.0)

4.4

(2.0)

4.4

(2.0)

5.5

(2.5)

5.5

(2.5)

Degree of

Protection

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

IP20 / NEMA1

NEMA1

NEMA1

Dimensions Fixing base

Table 3.2 - Installation data (dimensions in mm) - Refer to Section 9.1

Figure 3.3 - Mounting procedures for CFW-08

AIR FLOW

Page 33

32

INSTALLATION AND CONNECTION

(a) Models 1.6-2.6-4.0-7.0A / 200-240V and 1.0-1.6-2.6-4.0A / 380-480V

PE

R

S

T

Power

Supply

Disconnect (*)

PE

T

Q1

R

S

TUVW

PE

PE WVU

DANGER!

AC input disconnection: provide and AC input disconnecting switch to

switch OFF the input power to the inverter.

This device shall disconnect the inverter from the AC input supply when

required (e.g. during maintenances services).

DANGER!

This AC input disconnecting switch can not be used as an emergency

stop device.

DANGER!

Be sure that the AC input power is disconnected before making any terminal connection.

DANGER!

The information below will be a guide to achieve a proper installation.Follow

also all applicable local standards for electrical installations.

ATENTION!

Provide at least 10 in (0.25m) spacing between the equipment and sensitive

wirings and betwen the cables of the inverter and motor. For instance:

PLCs, temperature monitoring devices, thermocouples, etc.

3.2 ELECTRICAL INST ALLA TION

3.2.1Power / Grounding

Connections

Page 34

33

INSTALLATION AND CONNECTION

NOTE!

Do not use the neutral conductor for grounding purposes.

Figure 3.5 - Grounding connections for more than one inverter

GROUNDING BAR

INTERNAL TO THE PANEL

DANGER!

The inverter must be grounded to a protective earth for safety purposes (PE).

The earth or ground connection must comply with the local regulations.For

grounding, use cables with cross sections as indicated in Table 3.3.

Make the ground connection to a grounding bar or to the general grounding

point (resistance 10 < ohms). Do not share the ground wiring with other

equipment that operate with high currents (for instance: high voltage

motors, welding machines, etc). If several inverters are used together,

refer to Figure 3.5.

Figure 3.4 - Power / Grounding Connections

(b) Models 7.3-10-16A / 200-240V e 2.7-4.3-6.5-10-13-16A / 380-480V

Note: (*) In case of single-phase power supply with phase and neutral cable, connect only the phase cable to the

disconnecting switch.

PE

R

S

T

Power

Supply

PE

T

Q1

RS

TUVW

PE

Shielding

PE W V

U

-UdBR

+Ud Braking

Resistor

(see item 8.17)

Disconnect (*)

Page 35

34

INSTALLATION AND CONNECTION

Table 3.3 - Recommended wiring and circuit-breakers - use 70ºC copper wires only

Amp

Rating

[ A ]

1.0

1.6 (200-240V)

1.6 (380-480V)

2.6 (200-240V)

2.6 (380-480V)

2.7

4.0 (200-240V)

4.0 (380-480V)

4.3

6.5

7.0

7.3

10.0

13.0

16.0

Power Cables

[ mm

2

]

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

2.5

2.5

2.5

2.5

2.5

2.5

Grounding Cables

[ mm

2

]

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

4.0

4.0

4.0

4.0

4.0

4.0

Current

[ A ]

4

10

4

10

6

6

15

10

10

15

10

20

30

30

35

WEG

Model

DMW25-4

DMW25-6,3

DMW25-4

DMW25-10

DMW25-6.3

DMW25-6.3

DMW25-16

DMW25-10

DMW25-10

DMW25-16

DMW25-10

DMW25-20

DW125H-32

DW125H-25

DW125H-32

Circuit-Breaker

ATTENTION!

The AC input for the inverter must have a grounded neutral conductor .

NOTE!

The AC input voltage must be comp atible with the inverter rated voltage.

The requirements for use of line reactors depends on several application

factors. Refer to Section 8.15.

Capacitors for power factor correction are not required at the input

(L/L1, N/L2, L3 or R, S, T ) and they must not be connected at the

output (U, V and W).

When inverters with dynamic braking (DB) are used, the DB resistor

shall be mounted externally . Figure 8.21 shows how to connect the

braking resistor. Size it according to the application, not exceeding

the maximum current of the braking circuit. For the connection between

inverter and the braking resistor, use twisted cable. Provide physical

separation between this cable and the signal and control cables. When

the DB resistor is mounted inside the panel, consider watt loss generated

when the enclosure size and required ventilation are calculated.

When electromagnetic interference (EMI), generated by the inverter,

interfers in the performance of other equipment, use shielded wires, or

install the motor wires in metallic conduits.Connect one end of the

shielding to the inverter grounding point and the other end to the motor

frame. Always ground the motor frame. Ground the motor in the p anel

where the inverter is installed or ground it to the inverter . The inverter

output wiring must be laid separately from the input wiring as well as

from the control and signal cables.

The inverter is provided with electronic protection against motor overload.

This protection must be set according to the specific motor. When the

same inverter drives several motors, use individual overload realays for

each motor. Maint ain the electrical continuity of the motor cable shield.

If a disconnect switch or a contactor is inserted in the motor supply

line, do not operate them with motor running or when inverter is enabled.

Maintain the electrical continuity of the motor cable shield.

Use wire sizing and circuit breakers as recommended in Table 3.3.

Tightening torque is as indicated in T able 3.4. Use (70ºC) copper wires only .

Page 36

35

INSTALLATION AND CONNECTION

NOTE!

Supply line capacity:

The CFW-08 is suitable for use in circuits capable of supplying not more

than symmetrical 30.000Arms (240/480V).

The CFW-08 can be installed on power supplies with a higher fault level if

an adequate protection is provided by fuses or circuit breaker.

3.2.2 Power T erminals

Description of the power terminals:

L/L1, N/L2 and L3 (R, S and T) : AC supply line

200-240 V models (except 7.0A and 16A) can be opeated

with two phases (single-phase operation) without current derating. In

this case, the AC supply can be connected to any 2 of the 3 input

terminals.

U, V and W: Motor connection.

-UD: Negative pole of the DC link circuit.

Not available on the models 1,6-2,6-4,0-7,0A/200-240V and on the

models 1.0-1.6-2.6-4.0A/380-480V . This pole is used when inverter

shall be supplied with DC voltage (jointly with the +UD terminal).

T o avoid wrong connection of the braking resistor (mounted outside

the inverter), inverter is supplied with a rubber plug on this terminal

that must be removed when the use of the -UD terminal is required.

BR: Connection for Dynamic Braking Models (DB).

Not available on types 1.6-2 .6-4 .0-7.0A/200-240V and on models

1.0-1.6-2.6-4.0A/380-480V.

+UD: Positive pole of the DC link ciruit.

Not available on models 1.6- 2.6-4 .0-7.0A/200-240V and on models

1.0-1.6-2.6-4.0A/380-480V . This terminal is used to connect the

dynamic braking (DB) (jointly with the BR terminal) or when inverter

shall be supplied with DC voltage (jointly with the -UD terminal).

NOTE!

The wire sizing indicated in T able 3.3 are reference values only . The exact

wire sizing, depends on the installation conditions and the maximum

acceptable line voltage drop.

Inverter Model

1.6A / 200-240V

2.6A / 200-240V

4.0A / 200-240V

7.0A / 200-240V

7.3A / 200-240V

10.0A / 200-240V

16.0A / 200-240V

1.0A / 380-480V

1.6A / 380-480V

2.6A / 380-480V

2.7A / 380-480V

4.0A / 380-480V

4.3A / 380-480V

6.5A / 380-480V

10.0A / 380-480V

13.0A / 380-480V

16.0A / 380-480V

Grounding Wiring

N.m Lbf.in

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

0.4 3.5

Power Cables

N.m Lbf.in

1.0 8.68

1.0 8.68

10 8.68

1.0 8.68

1.76 15.62

1.76 15.62

1.76 15.62

1.2 100

1.2 10.0

1.2 10.0

1.76 15.62

1.2 10.0

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15 .62

Table 3.4 - Recommended tightening torque for power and grounding

connections

Page 37

36

INSTALLATION AND CONNECTION

3.2.3 Location of the Power,

Grounding and Control

Connections

(a) Models 1.6-2.6-4.0-7.0-7.3-10-16A/200-240V and 1.0-1.6-26-2.7-40-

4.3-65-10A/380-480V

Control (XC1)

Power

Grounding

(b) models 7.3-10-16A/200-240V and 2.7-4.3-6.5-10A/380-480V

UVW

-Ud BR +Ud

(a) models 1.6-2.6-4.0-7.0A/200-240V and 1.0-1.6-2.6-4.0A/380-480V

L3 U V W

L/L1

Figure 3.6 - Power terminals

(c) models 13-16A/380-480V

N/L2

L3L/L1

N/L2

Page 38

37

INSTALLATION AND CONNECTION

3.2.4Control

Wiring

The control wiring (analog inputs/outputs, digital inputs and relay outputs

is made on the XC1 connector of control board (see location in Figure 3.7,

Section 3.2.3).

There are two configurations for the control board: standard version

(CFW-08 line) and Plus version (CFW-08 Plus line), as shown below:

Figure 3.8 - XC1 control terminal description (standard control board - CFW-08)

Note: NC = Normally Closed Contact, NO = Normally Open Contact

Figure 3.7 - Location of the power/grounding and control connections

(b) Models 13-16A/380-480V

Control XC1

Power

Grounding

XC1 Terminal

1DI1

2DI2

3DI3

4DI4

5 GND

6 AI1

7 +10V

8

9

10 NC

11 Commom

12 NO

Description

Factory Default Function

Digital Input 1

General Enable (remote mode)

Digital Input 2

FWD / REV (remote mode)

Digital Input 3

Reset

Digital Input 4

Start / Stop (remote mode)

0V Reference

Analog Input 1

Frequency / Speed Reference

(remote mode)

Potentiometer reference

Not used

Not used

Relay Output 1 - NC contact

No Fault

Relay Output 1 - common point

Relay Output 1 - NO contact

No Fault

Specifications

4 isolated digital inputs

Minimum High Level: 10VDC

Maximum Low Level: 3VDC

Input current: -11mA @ 0V

Max. input current: -20 mA

Not connected to PE

0 to 10VDC or 0(4) to 20mA (fig. 3.10).

Impedance: 100kΩ (0...10V input),

500Ω (0/4...20mA input).

Resolution: 7bits.

Max. input voltage: 30 VDC

+10VDC ± 5%, capacity: 2mA

Contact capacity:

0.5A / 250V AC

Relé 1

CW

CCW

≥

5k

Ω

10 12

11

Page 39

38

INSTALLATION AND CONNECTION

Figure 3.9 - XC1 control terminal description of the control board 1 (CFW-08 Plus)

Figure 3.10 - Dip switch position for 0 ...10V/4 ... 20mA selection

S1

2

1

OFF

ON

Conector XC1

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

6 AI1

7 +10V

8 AI2

9AO

10 NF

11 Comum

12 NA

Description

Factory Default Function

Digital Input 1

General Enable (remote mode)

Digital Input 2

FWD / REV (remote mode)

Digital Input 3

Reset

Digital Input 4

Start/Stop (remote mode)

0V Reference

Analog input 1

Frequency/Speed reference (remote mode)

Potentiometer reference

Analog input 2

Not used

Analog output

Output Frequency (Fs)

Relay Output 2 - NC contact

Fs>Fx

Relay outputs common points

Relay Output 1 - NO contact

No Fault

Specifications

4 isolated digital inputs

Minimum High Level: 10VDC

Maximum Low Level: 3VDC

Input Current: -11mA @ 0V

Max. Input Current: -20 mA

Not connected to PE

0 to 10VDC or 0(4) to 20mA (fig. 3.10).

Impedance: 100kΩ (0...10V input), 500Ω

(0/4...20mA input).

Resolution: 7bits.

Max. input voltage: 30VDC

+10VDC,

±

5%, capacity: 2mA

0 to 10VDC or 0(4) to 20mA (fig. 3.10).

Impedance: 100kΩ (0...10V input), 500Ω

(0/4...20mA input).

Resolution: 7bits.

Max. input voltage: 30Vdc

0 to 10VDC, RL ≥ 10k Ω

Resolution: 8bits

Contact capacity:

0.5A / 250VAC

CW

CCW

≥

10k

Ω

RPM

-

+

Relé 1

11

Relé 2

12 10

CCW

CW

≥

10k

Ω

Page 40

39

INSTALLATION AND CONNECTION

Analog Input

AI1

AI2

Factory Deafult Setting

Frequency / Speed

Reference (remote mode)

No function

Dip

Switch

S1.1

S1.2

Selection

OFF: 0 ... 10V

ON: 4 ... 20mA or 0 ... 20mA

OFF: 0 ... 10V

ON: 4 ... 20mA or 0 ... 20mA

Table 3.5 - Dip switch configuration

NOTE!

Jumpers S1 are factory set to OFF position (0 ... 10V signal).

If it's used a 4 ... 20mA signal, set parameter P235 and/or P239, that

defines the signal type at AI1 and AI2, respectively .

The parameters related to the analog inputs are: P221, P222, P234,

P235, P236, P238, P239 e P240. For more details, please refer to

Chapter 6.

During the signal and control wire installation note please the following:

1) Cable cross section: 20 ... 14 A WG (0.5...1.5mm²).

2) Max. T orque: 0.50 N.m (4.50 lbf.in).

3) XC1 wiring must connected with shielded cables and installed

separately at a distance of 10 cm each other for lengths up to 100m

and at distance of 25cm each other for lengths over 100m. If the crossing

of these cables is unavoidable, install them perpendicular , maintaining

a mimimum separation distance of 2 in (5 cm) at the crossing point.

Connect the shield as shown below:

Figure 3.11 - Shield connection

Connect to earth: bolts are located on heatsink

Do not

ground

Inverter

side

Insulate with tape

4) For wiring distances longer than 150 ft ( 50 m), it's necessary to use

galvanic isolators for the XC1:5...9 analog signals.

As a default the analog input(s) is(are) selected as 0...10V . This can be

changed using dip switch S1 on the control board and parameters P235

and P239 (see note below).

Page 41

40

INSTALLATION AND CONNECTION

5) Relays, contactors, solenoids or eletromagnetic braking coils installed

near inverters can generate interferences in the control circuit. T o

eliminate this interference, connect RC suppressor in parallel with the

coils of AC relays. Connect free-wheeling diode in case of DC relays.

6) When external keypad (HMI) is used (refer to Chapter 8), separete

the cable that connects the keypad to the inverter from other cables,

maintaining a minimum distance of 4 in (10 cm) between them.

7) When analog reference (AI1 or AI2) is used and the frequency

oscillates (problem caused by eletromagnetic interference)

connect XC1:5 to the inverter heatsink.

3.2.5 Typical T erminal

Connections