Page 1

W

W

E

B

E

R

W

E

B

E

R

W

E

B

E

R

W

E

B

E

R

SUMMIT

TM

425 & 625

SUMMIT

TM

450 & 650

Step-By-Step Guide

Natural Gas Barbecues

Summit 425 NG

Summit 650 NG

Summit 625 NG

Summit 450 NG

92773 10/98

W

E

B

E

R

W

E

B

E

R

W

E

B

E

R

W

E

B

E

R

R

A P P R O V E D

CANADIAN

GAS ASSOCIATION

®

WARNING

1. Do not store spare LP Cylinder within

10 feet (3m) of this appliance.

2. Do not store or use gasoline or other

flammable liquids or vapors within 25

feet (8m) of this appliance.

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, Keep away from the

appliance and immediately call your

gas supplier or your fire department.

Leaking gas may cause a fire or explosion

which can cause serious bodily injury or

death or damage to property.

NOTICE TO INSTALLER: These instructions

must be left with the owner and the owner

should keep them for future use.

WARNING: Follow all leak check procedures

carefully in this manual prior to barbecue

operation. Do this even if barbecue was

dealer assembled.

WARNING: Do not try to light this appliance

without reading "Lighting" instructions

section of this manual.

THIS GAS APPLIANCE IS DESIGNED FOR

OUTDOOR USE ONLY.

Page 2

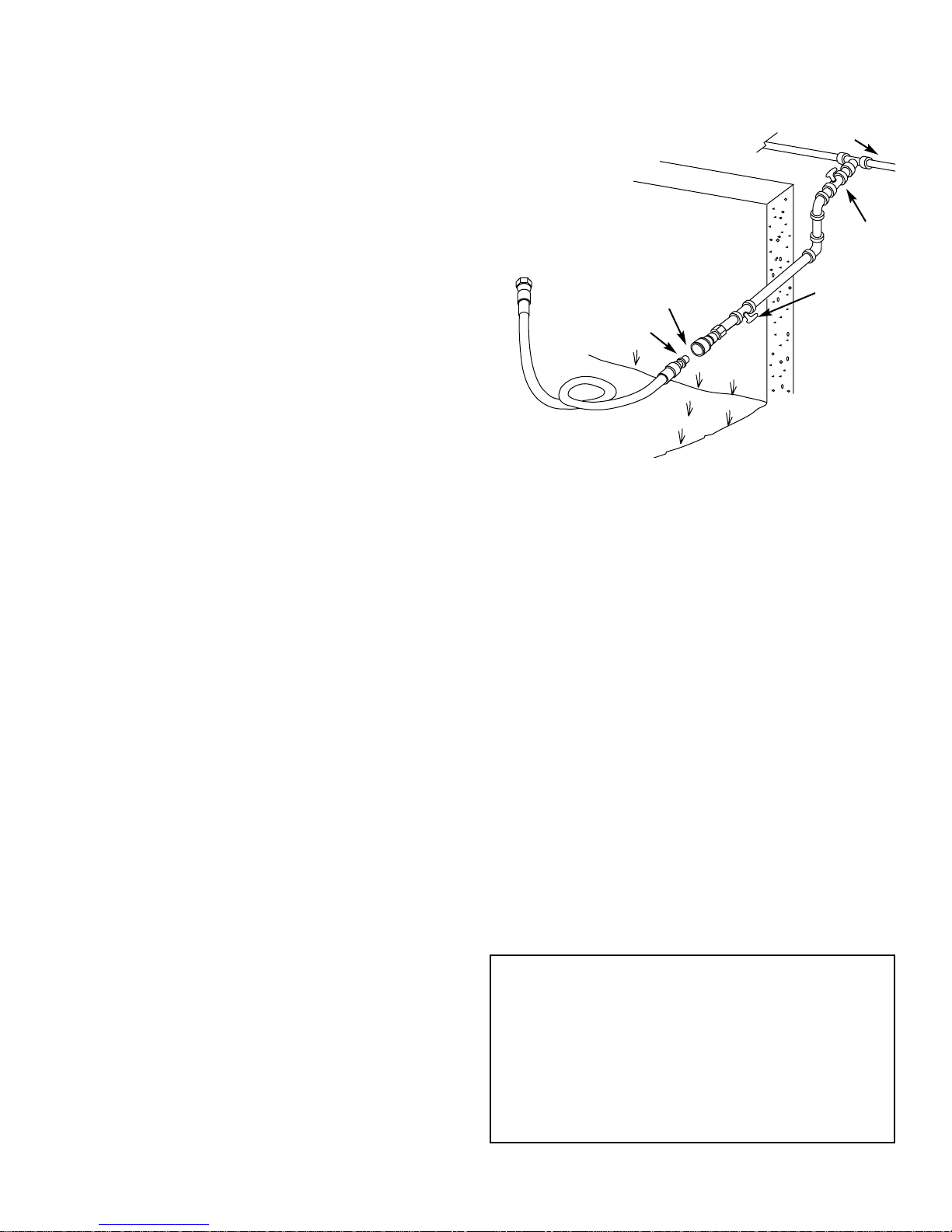

INSTALL GAS SUPPLY (CART INSTALLATIONS ONLY)

Typical natural gas supply installation. Figure 1.

Figure 1

The quick disconnect is

installed above ground

Gas supply

Shut off

Locking

shut off

Quick Disconnect

Male fitting

To barbecue

Outside wall

Inside wall

DANGER

Do not use an open flame to check for gas

leaks. Be sure there are no sparks or open

flames in the area while you check for gas

leaks. This will result in a fire or explosion

which can cause serious bodily injury or

death, and damage to property.

General Specifications for Piping

Note - Contact your local municipality for building

codes regulating outdoor gas barbecue installations.

In absence of Local Codes, you must conform to the

latest edition of ANSI Z223.1. WE RECOMMEND THAT

THIS INSTALLATION BE DONE BY A PROFESSIONAL.

Some of the following are general requirements taken

from ANSI Z223.1, for gas supply installations. Refer to

ANSI Z223.1 latest edition for complete specifications.

■ This barbecue is designed to operate at 4.5 inches

of water column pressure (.1625 psi). Use only the

regulator with the cooking module.

■ A manual shut-off valve must be installed outdoors,

immediately ahead of the quick disconnect.

■ An additional manual shut-off valve indoors should

be installed in the branch fuel line in an accessible

location near the supply line.

■ The quick disconnect connects to a 3/8 inch NPT

thread from the gas source. The quick disconnect

fitting is a hand-operated device that automatically

shuts OFF the flow of gas from the source when the

barbecue is disconnected.

■ The quick disconnect fitting can be installed

horizontally, or pointing downward. Installing the

fitting with the open end pointing upward can result

in collecting water and debris.

■ The dust covers (supplied plastic plugs) help keep the

open ends of the quick disconnect fitting clean while

disconnected.

■ Pipe compound should be used which is resistant to

the action of natural gas when connections are made.

■ The outdoor connector must be firmly attached to

rigid, permanent construction.

WARNING: Do not route the 12 foot hose under a

deck. The hose must be visible.

2

Gas line piping

■ If the length of line required does not exceed 50 feet,

use a 5/8" O.D. tube. One size larger should be used

for lengths greater than 50 feet.

■ Gas piping may be copper tubing, type K or L;

polyethylene plastic tube, with a minimum wall

thickness of .062 inch; or standard weight (schedule

40) steel or wrought iron pipe.

■ Copper tubing must be tin-lined if the gas contains

more than 0.3 grams of hydrogen sulfide per 100

cubic feet of gas.

■ Plastic tubing is suitable only for outdoor,

underground use.

■ Gas piping in contact with earth, or any other material

which may corrode the piping, must be protected

against corrosion in an approved manner.

■ Underground piping must have a minimum of 18" cover.

Test connections

All connections and joints must be thoroughly tested for

leaks in accordance with local codes and all listed

procedures in the latest edition of ANSI Z223.1.

Page 3

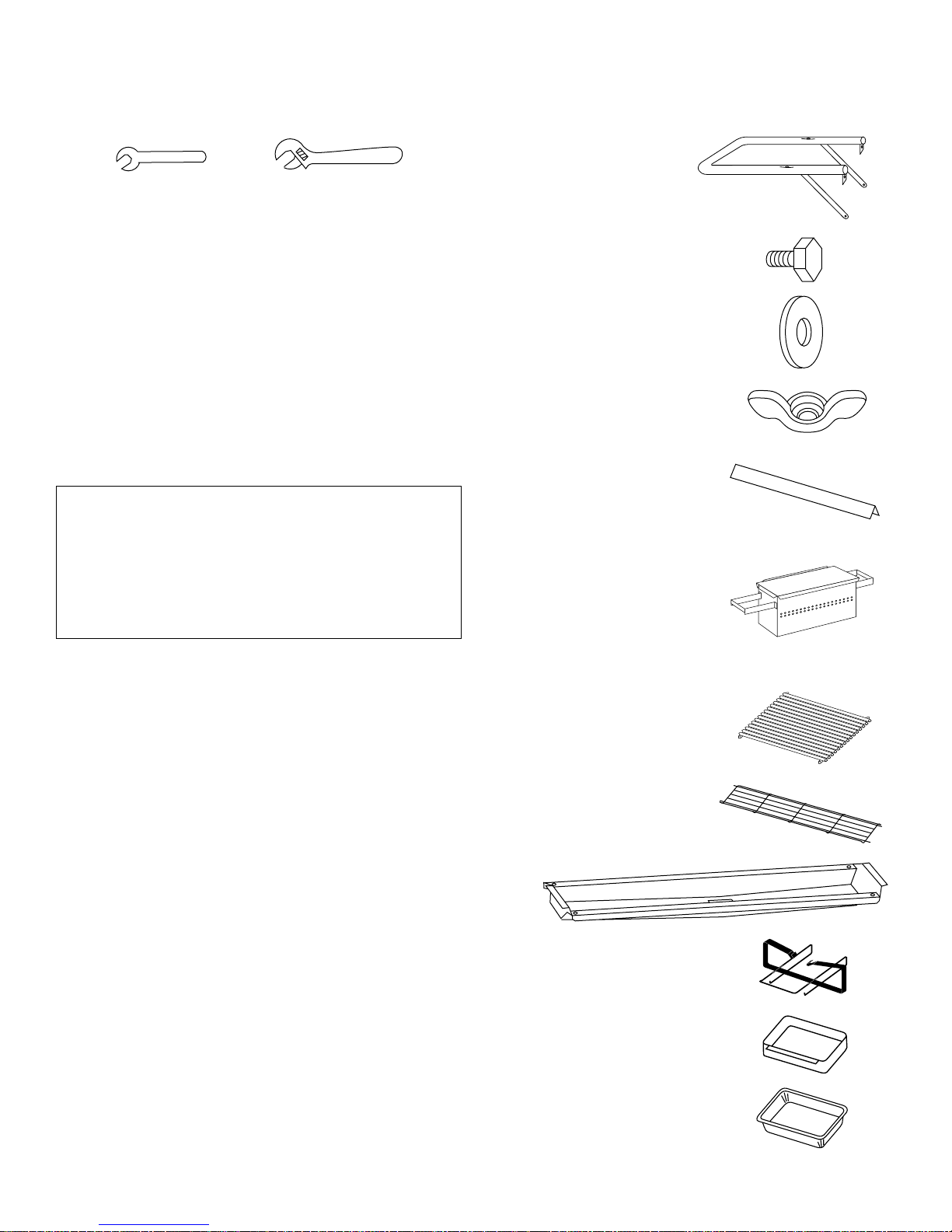

3

CONTINUE TO REMOVE

PACKAGED CONTENTS

TOOLS NEEDED

SUPPLIES NEEDED

7/16 and 3/4 inch open end or an adjustable wrench

Your LP tank is shipped empty for safety. After setting the

LP fuel scale you will need to fill it. (See Step "Fill LP tank.")

You will need a soap and water solution to check for gas

leaks. (See Step "Check for gas leaks.")

Note - The hardware size of nuts, bolts and screws is

given. For example "1/4-20 x 2 inch bolt" means a bolt

1/4 inch in diameter with 20 threads to the inch, 2 inches

long. On a small screw for example, "6-32 x 1/2 inch

screw" means a number 6 screw, with 32 threads to the

inch, 1/2 inch long.

While we give much attention to our products,

unfortunately an occasional error may occur. If a part is

missing, do not go back to the store. Call the Weber

Customer Service Center toll free 1-888-33-SUMMIT

(1-888-337-8664) to receive immediate assistance.

Have your owner’s manual and serial number of the

barbecue available for reference.

Cooking grate

(2) (Summit 425 or 450)

(3) (Summit 625 or 650)

Flavorizer bar

(7) (Summit 425 or 450)

(11) (Summit 625 or 650)

Bottom tray

1/4-20 x 1/2 inch bolt (8)

Nylon washer (8)

Steam-N-Chips smoker

Note: If you use the Steam-NChips Smoker, you will be

removing one of the Flavorizer

bars. You have a full set of

Flavorizer bars to use when not

using the Steam-N-Chips smoker.

Warm-up rack

“U” rails (2)

1/4-20 wing nuts (4)

Drip pan

Catch pan

Catch pan holder

Note: Remove all

packaging materials

from the barbecue,

the front, back sides,

inside the barbecue

cart, and the bottom

shipping platform.

Once the packaging

material is removed,

carefully roll the

barbecue off the

shipping platform

and lock the casters.

Page 4

4

Stainless steel work surface (2)

Condiment holder (2)

Tool holder (4)

Hose

REMOVE PACKAGED

CONTENTS (CONTINUED)

Wire bottom rack

(For Summit 450 and 650)

Stainless steel bottom shelves

(For Summit 425 and 625)

Thermometer

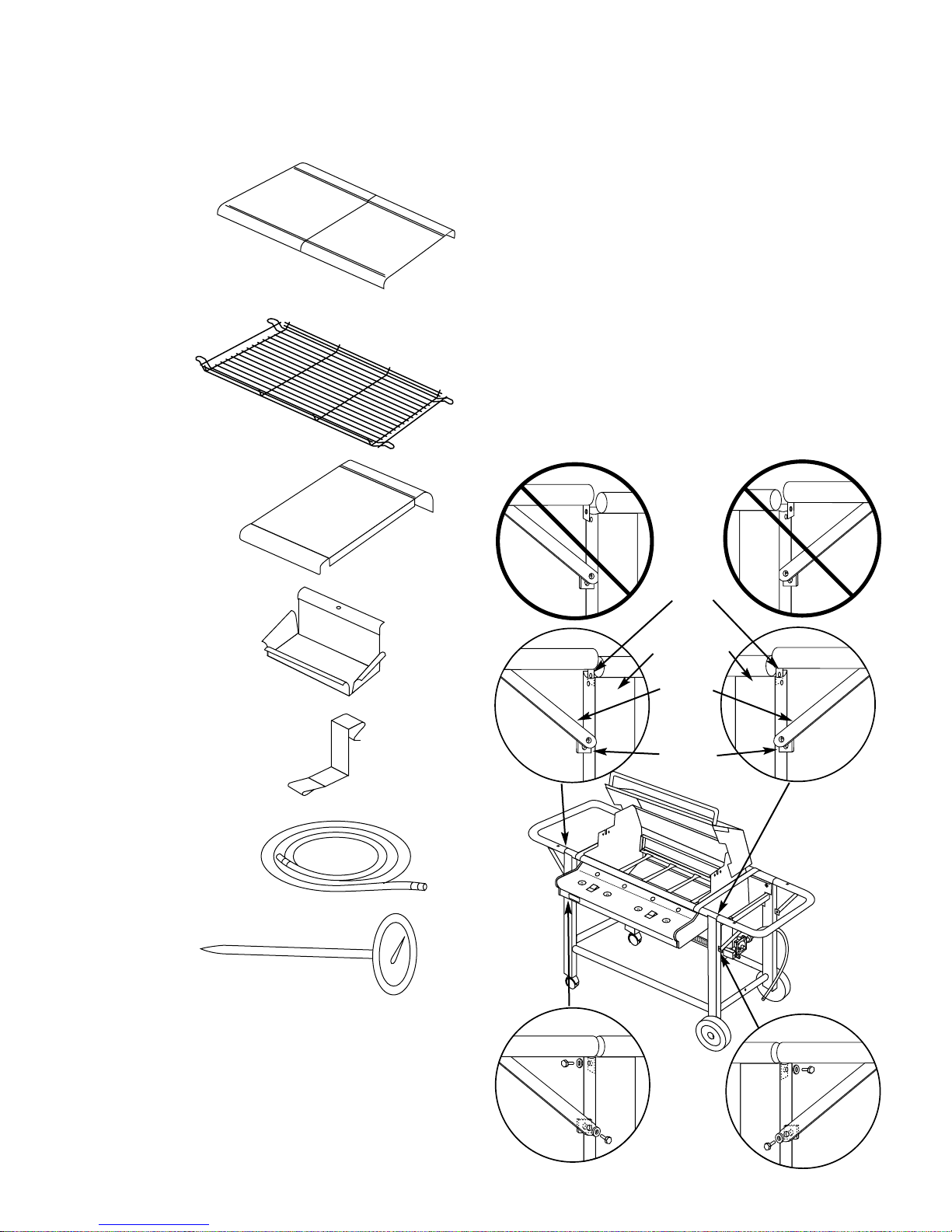

INSTALL “U” RAILS

a)

b)

Figure 2

“U” rail

support

mounts

Tabs

Frame rails

“U” rail

supports

Note: lock the casters before starting assembly.

You will need: two “U” rails, eight 1/4-20 x 1/2 inch bolts,

eight nylon washers, and a 7/16 inch or adjustable wrench.

Insert the tabs of the “U” rail into the frame rails. Make sure

both tabs are inside the frame rails. Figure 2(a) and that the

“U” rail supports are outside of the “U” rail support mounts.

Figure 2(a).

Push the “U” rail down into place on top of the frame rail.

Add a nylon washer to a bolt and start the bolt through the

hole of the frame rail into the tab of the “U” rail. Only start the

two bolts. Figure 2(b).

Align the holes of the “U” rail support with the holes in the

“U” rail support mount. Add a washer to a bolt and start the

bolt through the “U” rail support and into the “U” rail support

mount. Figure 2(b). Only start the two bolts.

Once you have started the four bolts per side, use the

7/16 inch or adjustable wrench to tighten the four bolts on

each side of the barbecue.

Page 5

5

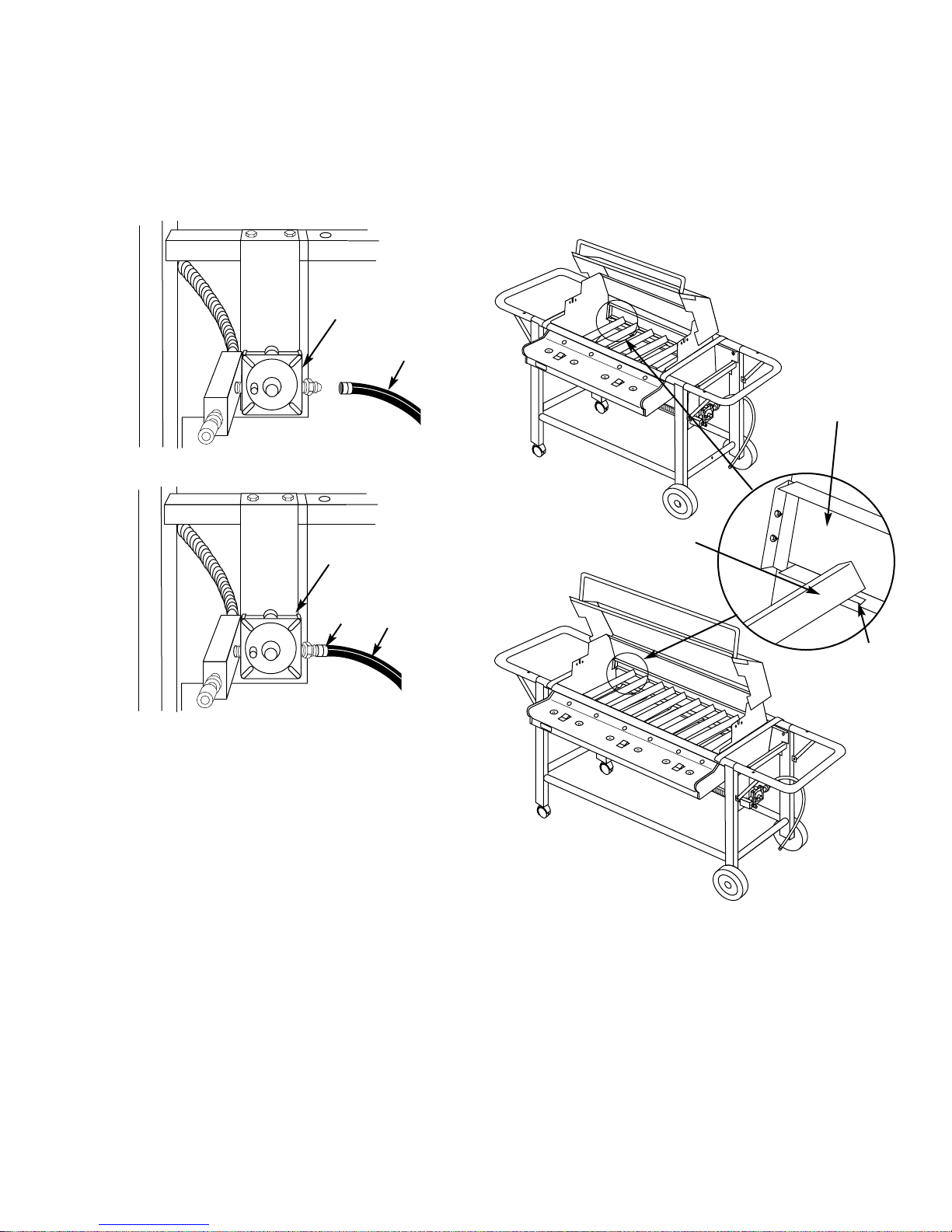

CONNECT FLEXIBLE

HOSE TO REGULATOR

You will need: the 12 foot natural gas supply hose and a

3/4 inch or adjustable wrench.

Thread fitting end of hose onto regulator. Figure 3.

Tighten with wrench.

Figure 3

a)

b)

Regulator

Gas supply

hose

Regulator

Gas supply

hose

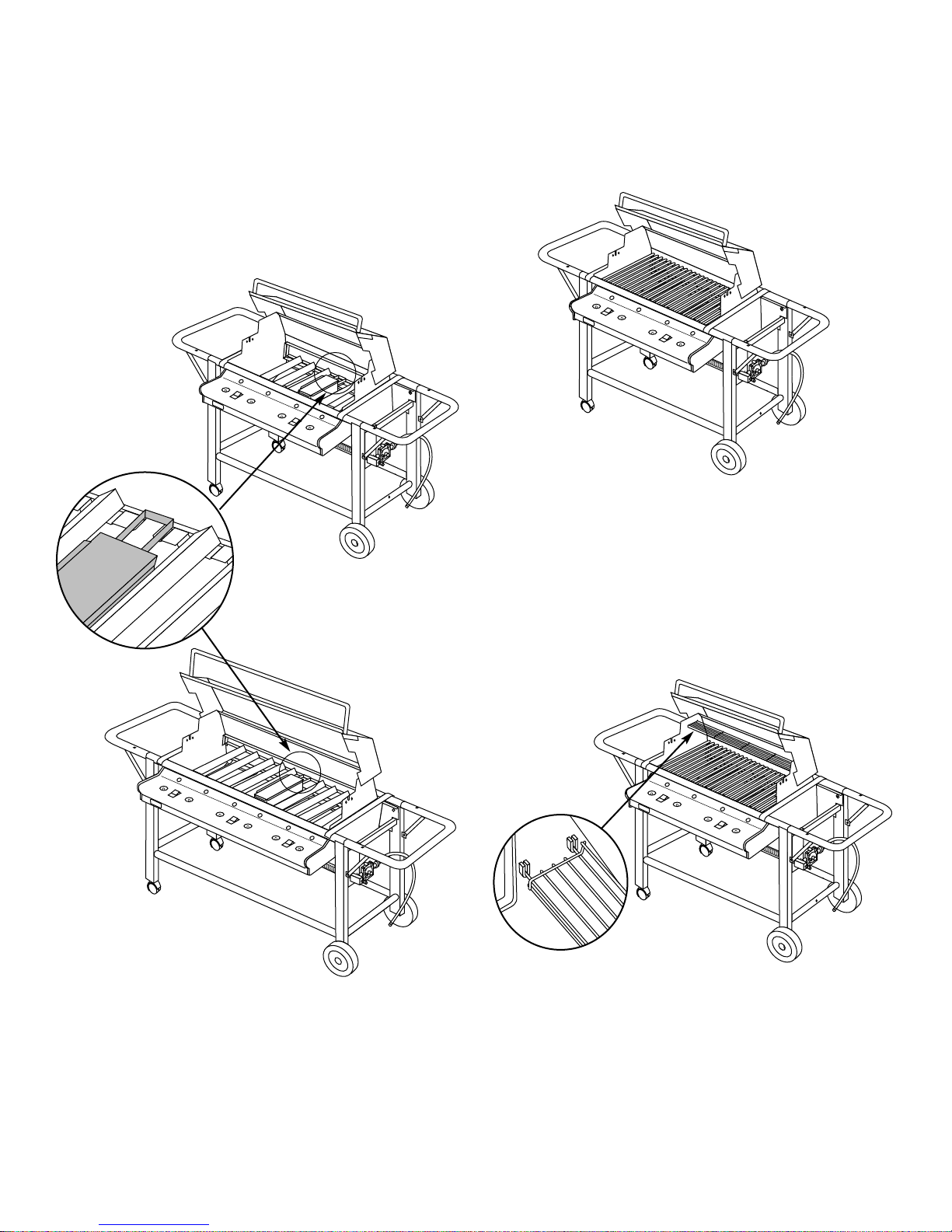

INSTALL FLAVORIZER

BARS

You will need: seven (Summit 425 or 450) or eleven

(Summit 625 or 650) flavorizer bars

Set the Flavorizer bars front to back over the burners in

the slots of the Flavorizer Bar/cooking grill support.

Figure 4 (a).

Figure 4

Flavorizer Bar/

cooking grill support

Flavorizer Bar

Slot

Summit 425 or

Summit 450

Summit 625 or

Summit 650

Page 6

6

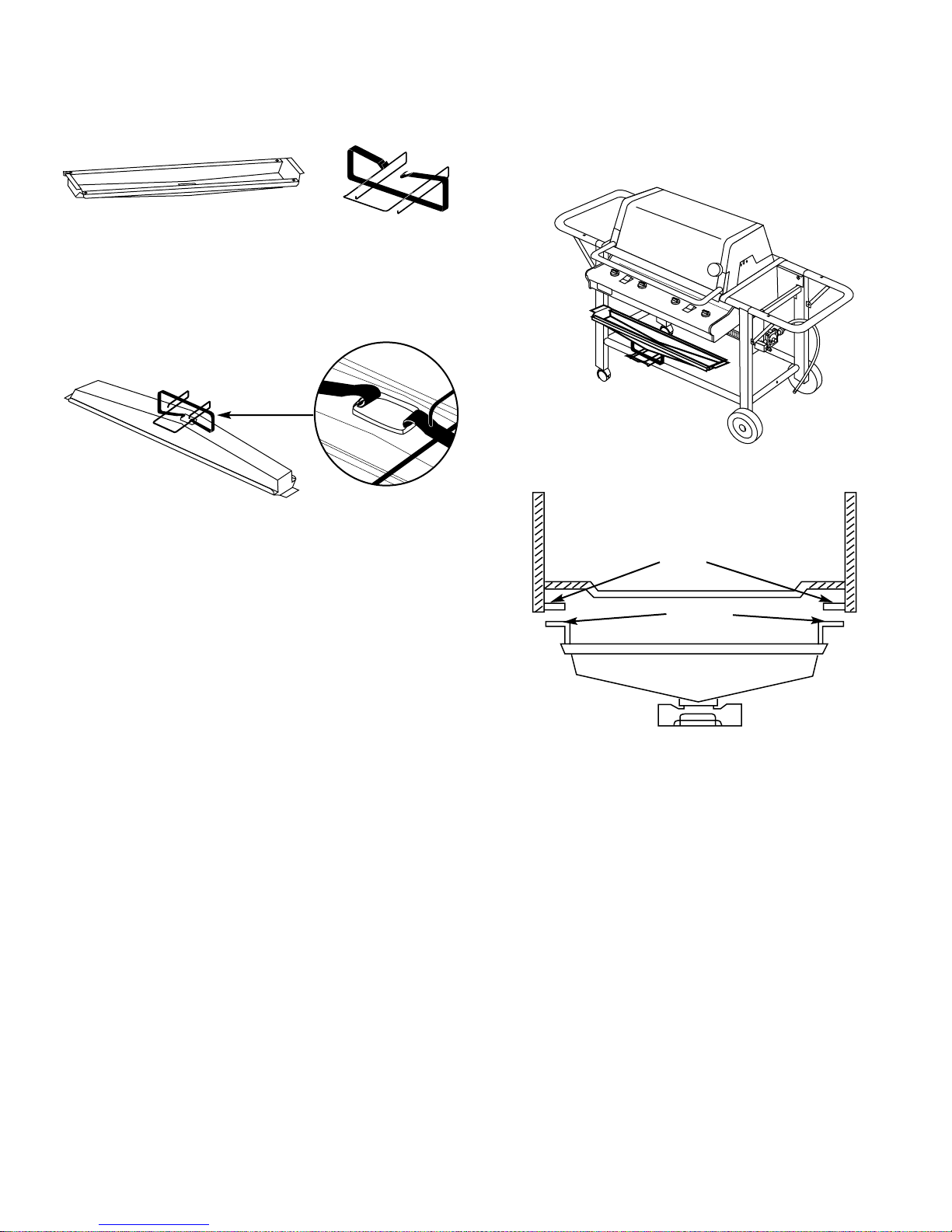

INSTALL STEAM-N-CHIPS

SMOKER

You will need: Steam-N-Chips smoker.

Remove the center Flavorizer bar (the one that is not over

a burner). Set the handles of the Steam-N-Chips smoker

on the Flavorizer bar holder. Figure 5 (a).

Note: For directions on how to use the Steam-N-Chips

smoker, see the Operating Guide.

Figure 5

ADD COOKING GRATES

Figure 6

You will need: two (Summit 425 or 450) or three

(Summit 625 or 650) cooking grates.

The cross-wire of the cooking grate goes down. Set the

cooking grates in place next to each other. Figure 6.

a)

Summit 425 or Summit 450

Summit 625 or Summit 650

INSTALL WARM-UP RACK

Figure 7

You will need: warm-up rack.

Install one end of the warm-up rack into the hole on the

right end of the lid and the other end into the slot in the

left end of the lid. Figure 7 (a).

a)

Page 7

7

Figure 11

Put the foil drip pan into the catch pan.

Mounting

slots

View from front of the Cooking Box

Tabs of

bottom tray

INSTALL BOTTOM TRAY

You will need: Bottom tray, catch pan holder, catch pan,

and one drip pan.

Figure 8

Figure 9

Note: It may be easier to install the catch pan holder by

removing the catch pan from the holder.

Hook the ends of the catch pan holder into the hole in the

bottom tray. Figure 9.

Figure 10

Slide the bottom tray into the mounting slots under the

bottom of the cooking box with the finger grip of the catch

pan toward you. Figure 15.

CAUTION: Do not line the bottom tray with aluminum

foil. It can cause grease fires by trapping the grease

and not allowing grease to flow into the catch pan.

Page 8

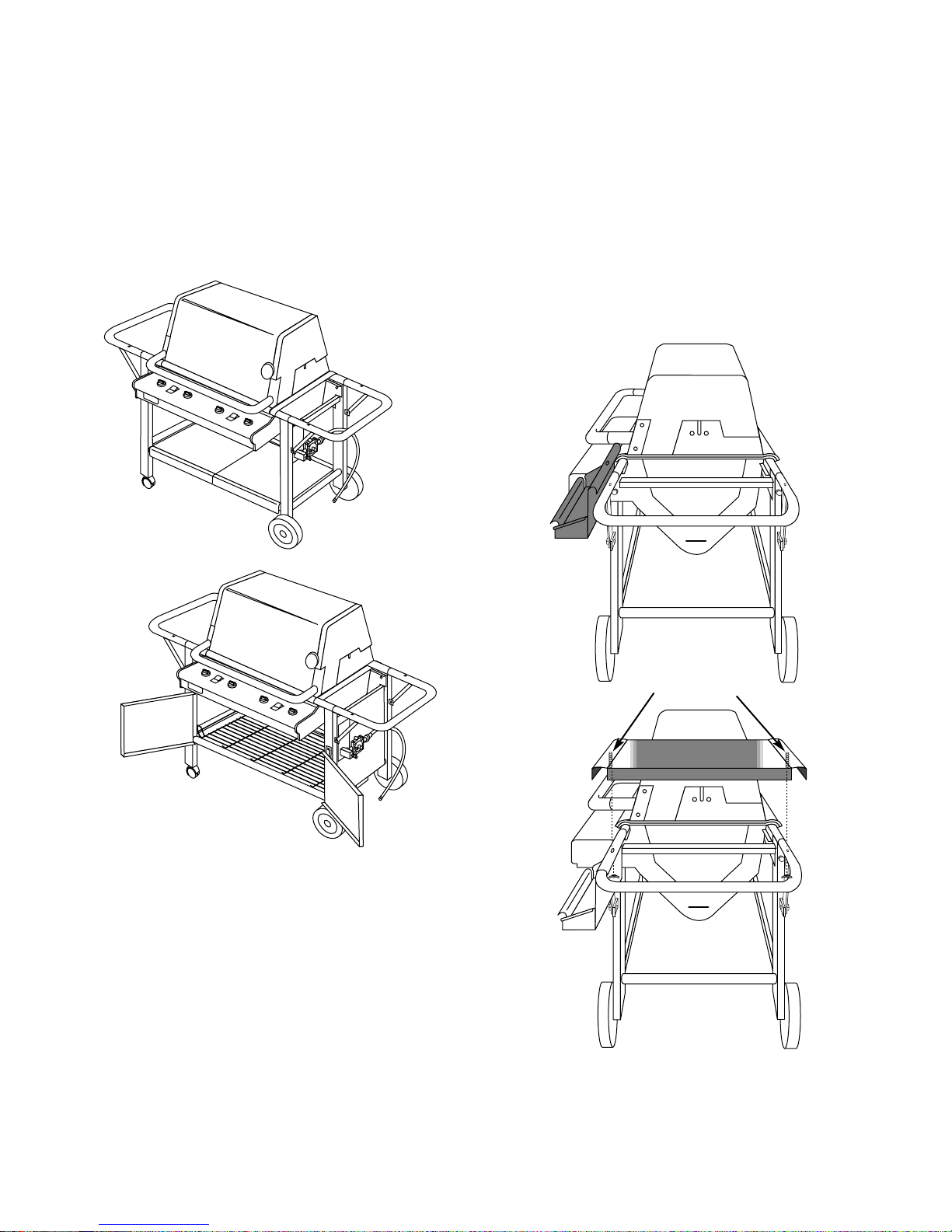

8

INSTALL BOTTOM

SHELVES

Figure 12

For the Summit 425 or 625, place the stainless steel

bottom shelves between the frame supports.

For the Summit 450 and 650, place the bottom rack under

the cart between the frame supports. Lift up one end of

the rack so it clears the crosspiece. Continue to lift until

the opposite end clears the opposite crosspiece. Set the

rack in place on both crosspieces.

Summit 425 or 625

Summit 450 or 650

INSTALL CONDIMENT

HOLDERS AND WORK

SURFACES

You will need: two condiment holders, two stainless steel

work surfaces, and four wing nuts.

Place the condiment holders on the left and right side of

the frame. Figure 13(a). Set the work surfaces over the

condiment holders on both sides of the barbecue. The

studs of the work surface go through the holes in the

top of the condiment holder and through the frame rail.

Thread on the wing nuts on the front and back and

tighten. Figure 13(b).

Figure 13

a)

b)

Studs

underneath

work surface

Page 9

9

Remove burner control knobs, control panel

and front panel

Remove the burner control knobs. The control panel is

separate from the front panel. The control panel needs to

be removed before the front panel can be removed.

Figure 14.

Figure 14

Control

panel

Front

panel

CHECK FOR GAS LEAKS

WARNING

The gas connections of your Weber Gas

Barbecue have been factory tested. We do

however recommend that you leak check

all gas connections before operating your

Weber Gas Barbecue.

Front edge of the

control panel

Put your fingers under the front edge of the control panel,

lift up, and pull evenly toward you. Figure 15 (a).

Figure 15

(a)

Front Panel

Control Panel

Pull the front panel up and out of the cooking box

assembly. Figure 16.

Figure 16

Front panel

Page 10

10

WARNING:You should check for gas leaks every

time you disconnect and reconnect a gas fitting.

You will need: a soap and water solution and a rag or

brush to apply it.

Note: Since some leak test solutions, including soap and

water, may be slightly corrosive, all connections should be

rinsed with water after checking for leaks.

WARNING: Make sure all burner control knobs are

in the OFF position, including the side burner, if the

barbecue has a side burner.

Turn on gas supply.

Check for leaks by wetting the connections with the soap

and water solution and watching for bubbles. If bubbles

form or if a bubble grows there is a leak.

WARNING: Do

not ignite

burners when leak checking.

DANGER

Do not use an open flame to check for gas

leaks. Be sure there are no sparks or open

flames in the area while you check for

leaks. This will result in a fire or explosion

which can cause serious bodily injury or

death and damage to property.

CHECK FOR GAS LEAKS

(CONTINUED)

Manifold

Manifold

Summit 425 or

Summit 450

Figure 17

a)

d)

c)

Manifold

a)

c)

b)

d)

Manifold

Figure 17

Summit 625 or

Summit 650

Check:

a) Left valves to manifold connection. Figure 17 (a).

b) Center valves to manifold connection. Figure 17 (b).

(For Summit 625 or 650 only.)

c) Right valves to manifold connection. Figure 17 (c).

d) Gas line to manifold connection. Figure 17 (d)

WARNING: If there is a leak at connection 17 (d),

turn OFF the gas and retighten the fitting with a

wrench and recheck for leaks with soap and water

solution.

If a leak persists after retightening the fitting, turn

OFF the gas. DO

NOT OPERATE THE BARBECUE.

Contact your dealer.

Page 11

11

Figure 18

b)

Summit 425 or

Summit 450

Summit 625 or

Summit 650

a) Hose to regulator connection. Figure 18 (b).

b) Hose to quick disconnect connection. Figure 18 (a).

WARNING: If there is a leak at connections

17 (a), 17 (b), 17 (c) 18 (a), or 18 (b) turn OFF the gas.

Do not operate the barbecue. Contact your dealer.

When leak checks are complete, turn gas supply OFF at

the source and rinse connections with water.

a)

CHECK FOR GAS LEAKS

(CONTINUED)

REINSTALL FRONT

PANEL

You will need: front panel.

With the Weber logo to the left, slide front panel down

into place. Figure 19.

Figure 19

Page 12

12

INSTALL TOOL HOLDERS

Figure 20

a)

You will need: four tool holders.

Place the tool holder under the control panel and over the

front panel. Figure 20 (a). Set the tool holder on top of the

front panel and slide it to the left.

Control panel

Front panel

REINSTALL CONTROL

PANEL

You will need: control panel.

Pull igniter buttons up until they stay in the up position.

Place the control panel into the grooves on either side of

the front of the cooking box. Push the control panel into

place, using even pressure while pushing. Figure 20 (a).

Use your fingers to lift the front edge of the control panel

slightly and set it into the recess on both sides of the

cooking box. Figure 21.

Figure 21

(a)

Front Panel

Control Panel

Page 13

13

REFER TO OPERATING

GUIDE BEFORE LIGHTING

BARBECUE

REINSTALL BURNER

CONTROL KNOBS

Figure 22

You will need: four (Summit 425 or 450) or six

(Summit 625 or 650) burner control knobs.

Push on the burner control knobs. Figure 22.

Page 14

14

EXPLODED VIEWS FOR SUMMIT 425 NG

W

E

B

E

R

W

E

B

E

R

1

3

4

5

6

7

8

9

10

11

12-16

17

18

19

20

22

21

23

25

26

27

28

29

32

31

30

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

56

57

58

55

54

59

24

36

33

34

35

2

Page 15

15

REPLACEMENT PARTS LIST FOR SUMMIT 425 NG

W

E

B

E

R

W

E

B

E

R

WARNING: Use only Weber factory

authorized parts. The use of any part that is

not factory authorized can be dangerous.

This will also void your warranty.

All items are single quantities unless otherwise specified.

Parts can be ordered directly from Weber-Stephen

Products Company by phone or mail.

Note - Do not return parts to Weber-Stephen Products Co.

without first contacting the Customer Service Center by

phone or mail. Returning the part may not be necessary.

While we give much attention to our products,

unfortunately an occasional error may occur. If a part is

missing, do not go back to the store. Call the Weber

Customer Service Center toll free 1-888-33-SUMMIT

(1-888-337-8664) to receive immediate assistance. Have

your owner’s manual and serial number of the barbecue

available for reference.

Weber-Stephen Products Company

Customer Service Center

250 South Hicks Road

Palatine, IL 60067-6241

(888) 33-SUMMIT

(888-337-8664)

1 Left pivoting endcap

2 Shroud assembly

3 Stainless steel handle

4 Steam-N-Chips smoker

5 Stainless steel work surface (2)

6 Condiment holder (2)

7 Left fixed endcap

8 Crossover tube (2)

9 Left burner (2)

10 Right burner (2)

11 Burner control knobs (4)

12 Igniter (2)

13 Igniter lock nut (2)

14 Igniter wire (white) (2)

15 Igniter wire (black) (2)

16 Gas catcher ignition chamber (2)

17 Manifold assembly

18 Manifold mounting clips (2)

19 Control panel

20 Igniter button (2)

21 Front panel

22 Tool holder (4)

23 Caster frame

24 Frame support (4)

25 1/4-20 x 3 1/2 inch bolt (4)

26 Match holder and chain

27 Bottom tray

28 Catch pan holder

29 Catch pan kit

30 Caster (2)

31 Bottom connector (2)

32 Stainless steel bottom shelf (2)

33 Thermometer mount assembly

34 Thermometer

35 Right pivoting endcap

36 Warm-up rack

37 Cooking grates (2)

38 Flavorizer bar / cooking grate holder (2)

39 Flavorizer bar (7)

40 Hair pin cotter (2)

41 Clevis pin (2)

42 Rear shroud

43 Burner tube rest

44 Right fixed endcap

45 Cookbox assembly

46 Corrugated gas line

47 Regulator assembly

48 Straight frame rail (2)

49 “U” rail (2)

50 1/4-20 wing nuts (4)

51 Back panel

52 Nylon washer (18)

53 1/4-20 x 1/2 inch bolt (14)

54 Wheel frame

55 Wheel hubcap (2)

56 Wheel (2)

57 Hose

58 1/4-20 keps nut (6)

59 Regulator mounting bracket

Page 16

16

EXPLODED VIEWS FOR SUMMIT 450 NG

W

E

B

E

R

W

E

B

E

R

1

2

3

4

5

6

7

8

9

10

11-15

16

17

18

19

20

21

22

23

24

25

26

27

32

31

30

29

28

37

33

34

35

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

54

56

55

57

64

63

61

62

60

59

65

66

58

53

36

Page 17

17

REPLACEMENT PARTS LIST FOR SUMMIT 450 NG

1 Left pivoting endcap

2 Shroud assembly

3 Stainless steel handle

4 Flavorizer bar / cooking grate holder (2)

5 Flavorizer bar (7)

6 Left fixed endcap

7 Crossover tube (2)

8 Left burner (2)

9 Right burner (2)

10 Burner control knob (4)

11 Igniter (2)

12 Igniter lock nut (2)

13 Igniter wire (black) (2)

14 Igniter wire (white) (2)

15 Gas catcher ignition chamber (2)

16 Manifold assembly

17 Manifold mounting clips (2)

18 Control panel

19 Igniter button (2)

20 Front panel

21 1/4-20 wing nut (4)

22 Left panel

23 Match holder and chain

24 Caster frame

25 Tool holder (4)

26 1/4-20 x 3 1/2 inch bolt (6)

27 Caster (2)

28 Bottom tray

29 Catch pan holder

30 Catch pan kit

31 Left front door

32 Door knob (2)

33 Thermometer mount assembly

34 Thermometer

35 Right pivoting endcap

36 Cooking grates (2)

37 Warm-up rack

38 Steam-N-Chips smoker

39 Hair pin cotter (2)

40 Clevis pin (2)

41 Rear shroud

42 Burner tube rest

43 Cookbox assembly

44 Right fixed endcap

45 Stainless steel work surface (2)

46 Condiment holder (2)

47 Corrugated gas line

48 Regulator assembly

49 Frame rail (2)

50 “U” rail (2)

51 Back panel

52 Nylon washer (20)

53 1/4-20 x 1/2 inch bolts (14)

54 Back panel

55 Wheel hubcap (2)

56 Wheel (2)

57 Wheel frame

58 Regulator mounting bracket

59 Plastic button (4)

60 Right panel

61 Frame support (4)

W

E

B

E

R

W

E

B

E

R

WARNING: Use only Weber factory

authorized parts. The use of any part that is

not factory authorized can be dangerous.

This will also void your warranty.

All items are single quantities unless otherwise specified.

Parts can be ordered directly from Weber-Stephen

Products Company by phone or mail.

Note - Do not return parts to Weber-Stephen Products Co.

without first contacting the Customer Service Center by

phone or mail. Returning the part may not be necessary.

While we give much attention to our products,

unfortunately an occasional error may occur. If a part is

missing, do not go back to the store. Call the Weber

Customer Service Center toll free 1-888-33-SUMMIT

(1-888-337-8664) to receive immediate assistance. Have

your owner’s manual and serial number of the barbecue

available for reference.

Weber-Stephen Products Company

Customer Service Center

250 South Hicks Road

Palatine, IL 60067-6241

(888) 33-SUMMIT

(888-337-8664)

62 Bottom connector

63 Hose

64 Bottom connector with bushing (2)

65 Accessory rack

66 Right front door

Page 18

18

EXPLODED VIEWS FOR SUMMIT 625 NG

W

E

B

E

R

W

E

B

E

R

1

4

2

3

5

6

8

9

10

11

12

13

14-18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

35

34

33

7

39

38

36

37

40

41

42

43

44

45

46

47

48

49

50

51

58

56

57

55

54

53

52

Page 19

19

REPLACEMENT PARTS LIST FOR SUMMIT 625 NG

1 Left pivoting endcap

2 Shroud assembly

3 Stainless steel handle

4 Cooking grates (3)

5 Flavorizer bar / cooking grate holder (2)

6 Flavorizer bar (11)

7 Stainless steel work surface (2)

8 Condiment holder (2)

9 Left fixed endcap

10 Crossover tube (3)

11 Left burner (3)

12 Right burner (3)

13 Burner control knob (6)

14 Igniter (3)

15 Igniter lock nut (3)

16 Igniter wire (black) (3)

17 Igniter wire (white) (3)

18 Gas catcher ignition chamber (3)

19 Manifold assembly

20 Manifold mounting clips (2)

21 Control panel

22 Igniter button (3)

23 Front panel

24 “U” rail (2)

25 Frame rail (2)

26 Caster frame

27 Match holder and chain

28 Tool holder (4)

29 1/4-20 x 3 1/2 inch bolt (4)

30 Bottom connector (2)

31 Caster (2)

32 Stainless steel bottom shelf (2)

33 Bottom tray

34 Catch pan holder

35 Catch pan kit

36 Thermometer mount assembly

37 Thermometer

38 Right pivoting endcap

39 Warm-up rack

40 Steam-N-Chips smoker

41 Rear shroud

42 Hair pin cotter (2)

43 Burner tube rest

44 Clevis pin (2)

45 Cookbox assembly

46 Right fixed endcap

47 Corrugated gas line

48 Regulator

49 Back panel

50 Nylon washer (18)

51 1/4-20 x 1/2 inch bolt (14)

52 1/4-20 wing nut (4)

53 Wheel frame

54 Wheel hubcap (2)

55 Wheel (2)

56 Frame support (4)

57 Hose

58 Regulator mounting bracket

W

E

B

E

R

W

E

B

E

R

WARNING: Use only Weber factory

authorized parts. The use of any part that is

not factory authorized can be dangerous.

This will also void your warranty.

All items are single quantities unless otherwise specified.

Parts can be ordered directly from Weber-Stephen

Products Company by phone or mail.

Note - Do not return parts to Weber-Stephen Products Co.

without first contacting the Customer Service Center by

phone or mail. Returning the part may not be necessary.

While we give much attention to our products,

unfortunately an occasional error may occur. If a part is

missing, do not go back to the store. Call the Weber

Customer Service Center toll free 1-888-33-SUMMIT

(1-888-337-8664) to receive immediate assistance. Have

your owner’s manual and serial number of the barbecue

available for reference.

Weber-Stephen Products Company

Customer Service Center

250 South Hicks Road

Palatine, IL 60067-6241

(888) 33-SUMMIT

(888-337-8664)

Page 20

20

EXPLODED VIEWS FOR SUMMIT 650 NG

W

E

B

E

R

W

E

B

E

R

1

2

3

4

5

6

7

8

9

10

11

12

13

14-18

19

20

21

22

23

24

25

26

27

28

29

30

31

35

36

33

34

32

39

38

37

40

41

42

43

44

46

45

47

48

49

50

51

52

53

55

56

54

59

65

66

64

63

62

61

60

58

57

Page 21

21

REPLACEMENT PARTS LIST FOR SUMMIT 650 NG

1 Left pivoting endcap

2 Shroud assembly

3 Stainless steel handle

4 Cooking grates (3)

5 Flavorizer bar / cooking grate holder (2)

6 Flavorizer bar (11)

7 Left fixed endcap

8 Stainless steel work surface (2)

9 Condiment holder (2)

10 Crossover tube (3)

11 Left burner (3)

12 Right burner (3)

13 Burner control knob (6)

14 Igniter (3)

15 Igniter lock nut (3)

16 Igniter wire (black) (3)

17 Igniter wire (white) (3)

18 Gas catcher ignition chamber (3)

19 Manifold mounting clips (2)

20 Manifold assembly

21 Control panel

22 Igniter button (3)

23 Front panel

24 “U” rail (2)

25 Frame rail (2)

26 Left panel

27 Caster frame

28 Match holder and chain

29 Tool holder (4)

30 Bottom connector with bushing (2)

31 1/4-20 x 3 1/2 inch bolt (6)

32 Caster (2)

33 Left front door

34 Door knob (2)

35 Accessory rack

36 Right front door

37 Thermometer mount assembly

38 Thermometer

39 Right pivoting endcap

40 Warm-up rack

41 Steam-N-Chips smoker

42 Rear shroud

43 Hair pin cotter (2)

44 Clevis pin (2)

45 Burner tube rest

46 Cookbox assembly

47 Right fixed endcap

48 Regulator assembly

49 Corrugated gas line

50 Rear panel

51 Back panel

52 Nylon washer (20)

53 1/4-20 x 1/2 inch bolt (14)

54 1/4-20 wing nut (4)

55 Wheel frame

56 Hose

57 Regulator mounting bracket

58 Plastic button (4)

59 Right panel

60 Frame support (4)

61 Bottom connector

W

E

B

E

R

W

E

B

E

R

WARNING: Use only Weber factory

authorized parts. The use of any part that is

not factory authorized can be dangerous.

This will also void your warranty.

All items are single quantities unless otherwise specified.

Parts can be ordered directly from Weber-Stephen

Products Company by phone or mail.

Note - Do not return parts to Weber-Stephen Products Co.

without first contacting the Customer Service Center by

phone or mail. Returning the part may not be necessary.

While we give much attention to our products,

unfortunately an occasional error may occur. If a part is

missing, do not go back to the store. Call the Weber

Customer Service Center toll free 1-888-33-SUMMIT

(1-888-337-8664) to receive immediate assistance. Have

your owner’s manual and serial number of the barbecue

available for reference.

Weber-Stephen Products Company

Customer Service Center

250 South Hicks Road

Palatine, IL 60067-6241

(888) 33-SUMMIT

(888-337-8664)

62 Bottom tray

63 Catch pan holder

64 Catch pan kit

65 Wheel (2)

66 Wheel hubcap (2)

Page 22

Page 23

Page 24

Loading...

Loading...