Page 1

®®

55159 10/18/01

NOTICE TO INSTALLER: These

instructions must be left with the owner

and the owner should keep them for

future use.

WARNING: Follow all leak-check

procedures carefully in this manual prior

to barbecue operation. Do this even if

barbecue was dealer-assembled.

WARNING: Do not try to light this

appliance without reading "Lighting"

instructions section of this manual.

THIS GAS APPLIANCE IS DESIGNED

FOR OUTDOOR USE ONLY.

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your

gas supplier or your fire department.

Leaking gas may cause a fire or

explosion which can cause serious

bodily injury or death, or damage to

property.

Owners Guide

Natural Gas

Y

OU MUST READ THIS OWNERS GUIDE

BEFORE OPERATING YOUR GAS GRILL

WARNING

Do not store or use gasoline or other

flammable liquids or vapors within 25

feet (8m) of this appliance.

Page 2

2

DANGER

Failure to follow the Dangers, Warnings and Cautions contained in this Owner’s

Manual may result in serious bodily injury or death, or in a fire or an explosion

causing damage to property.

WARNINGS

Do not store a spare or disconnected LP tank under or near this barbecue.

Improper assembly may be dangerous. Please carefully follow the assembly instructions in this

manual.

After a period of storage, and/or nonuse, the Weber Gas Barbecue should be checked for gas

leaks and burner obstructions before using. See instructions in this manual for correct

procedures.

Do not operate the Weber Gas Barbecue if there is a gas leak present.

Do not use a flame to check for gas leaks.

Combustible materials should never be within 24 inches of the top, bottom, back or sides of

your Weber Gas Barbecue.

Do not put a barbecue cover or anything flammable on or in the storage area under the

barbecue.

Your Weber Gas Barbecue should never be used by children. Accessible parts of the barbecue

may be very hot. Keep young children away while it is in use.

You should exercise reasonable care when operating your Weber Gas Barbecue. It will be hot

during cooking or cleaning, and should never be left unattended, or moved while in operation.

Should the burners go out while in operation, turn all gas valves off. Open the lid and wait five

minutes before attempting to relight, using the lighting instructions.

Do not use charcoal or lava rock in your Weber Gas Barbecue.

Never lean over open grill or place hands or fingers on the front edge of the cooking box.

Should a grease fire occur, turn off all burners and leave lid closed until fire is out.

Do not enlarge valve orifices or burner ports when cleaning the valves or burners.

The Weber Gas Barbecue should be thoroughly cleaned on a regular basis.

Liquid Propane gas is not natural gas. The conversion or attempted use of natural gas in an

liquid propane unit or liquid propane gas in a natural gas unit is dangerous and will void your

warranty.

Do not attempt to disconnect any gas fitting while your barbecue is in operation.

Use heat-resistant barbecue mitts or gloves when operating barbecue.

Combustion byproducts produced when using this product contain chemicals known to the

state of California to cause cancer, birth defects, or other reproductive harm.

Page 3

3

Weber-Stephen Products Co. (Weber) hereby

warrants to the ORIGINAL PURCHASER of this

Weber Gas Grill that it will be free of defects in

material and workmanship from the date of purchase

as follows:

Aluminum Castings, lifetime, 1 year paint

Porcelain Hood Section, 25 years

Burners, 10 years

Igniter, 3 years

Cooking Grates, 3 years no rust through

Flavorizer Bars, 1 year no rust through

Thermoplastic/

Thermoset Parts, 10 years excluding fading

All Remaining Parts, 5 years,

when assembled and operated in accordance with the

printed instructions accompanying it.

Weber may require reasonable proof of your date of

purchase. THEREFORE, YOU SHOULD RETAIN

YOUR SALES SLIP OR INVOICE.

This Limited Warranty shall be limited to the repair or

replacement of parts that prove defective under

normal use and service and which on examination

shall indicate, to Weber's satisfaction, they are

defective. Before returning any parts, contact the

Customer Service representative in your region using

the contact infromation sheet provided with your

manual. If Weber confirms the defect and approves

the claim, Weber will elect to replace such parts

without charge. If you are required to return defective

parts, transportation charges must be prepaid. Weber

will return parts to the purchaser, freight or postage

prepaid.

This Limited Warranty does not cover any failures or

operating difficulties due to accident, abuse, misuse,

alteration, misapplication, vandalism, improper

installation or improper maintenance or service, or

failure to perform normal and routine maintenance,

including but not limited to damage caused by insects

within the burner tubes, as set in this owner's manual.

Deterioration or damage due to severe weather

conditions such as hail, hurricanes, earthquakes or

tornadoes, discoloration due to exposure to chemicals

either directly or in the atmosphere, is not covered by

this Limited Warranty.

There are no other express warrants except as set

forth herein and any applicable implied warranties of

merchantability and fitness are limited in duration to

the period of coverage of this express written Limited

Warranty. Some states do not allow limitation on how

long an implied warranty lasts, so this limitation may

not apply to you.

Weber is not liable for any special, indirect or

consequential damages. Some regions do not allow

the exclusion or limitation of incidental or

consequential damages, so this limitation or exclusion

may not apply to you.

Weber does not authorize any person or company to

assume for it any other obligation or liability in

connection with the sale, installation, use, removal,

return, or replacement of its equipment; and no such

representations are binding on Weber.

This Warranty applies only to products sold at retail.

WEBER-STEPHEN PRODUCTS CO.

Customer Service Center

1890 Roselle Road, Suite 308

Schaumburg, IL 60195

USA

WARRANTY

Page 4

4

CONTENTS

Danger & Warnings . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Instructions . . . . . . . . . . . . . . . . . . . .5

Exploded View . . . . . . . . . . . . . . . . . . . . . . . .6

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General Specifications for Piping . . . . . . . . .11

Assembly Instructions . . . . . . . . . . . . . . . . . .14

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Manual Lighting . . . . . . . . . . . . . . . . . . . . . . .29

Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

After a Period of Nonuse . . . . . . . . . . . . . . . .30

Periodic Cleaning . . . . . . . . . . . . . . . . . . . . .30

Annual Maintenance . . . . . . . . . . . . . . . . . . .31

General Maintenance . . . . . . . . . . . . . . . . . .32

Replacing Main Burners . . . . . . . . . . . . . . . .32

Crossover Ignition System Operations . . . . .34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . .35

Page 5

55

General Instructions

Your Weber Gas Barbecue is a stationary outdoor

cooking appliance. With the Weber Gas Barbecue you

can grill, barbecue, roast and bake with results that are

difficult to duplicate with indoor kitchen appliances. The

closed lid and Flavorizer Bars produce that "outdoor"

flavor in the food.

The natural gas supply is easy to use and gives you

more cooking control than charcoal fuel.

• These instructions will give you the minimum

requirements for assembling your Weber Gas

Barbecue. Please read the instructions carefully

before using your Weber Gas Barbecue. Improper

assembly can be dangerous.

• Not for use by children.

• If there are local codes that apply to gas grills, you

will have to conform to them. If there are no local

codes, you must conform to the latest edition of

the National Fuel Gas Code: ANSI Z 223.1.

• This Weber Gas Barbecue is designed for natural

(piped in city) gas only. Do not use Liquid Propane

(LP) bottled gas. The valves and orifices are for

natural gas only.

• Do not use with charcoal fuel.

• Check that the area under the control panel and

the bottom tray are free from debris that might

obstruct the flow of combustion or ventilation air.

For Installation in Canada

These instructions, while generally accecptable, do not

necessarily comply with the Canadian Installation

codes, particularly with piping above and below ground.

In Canada the installation of this appliance must comply

with local codes and/or Standards CAN/ CGA-B149.1

(Installation Code for Natural Gas Burning Appliances

and Equipment).

Storage

• The gas must be turned OFF at the natural gas

supply when the Weber Gas Barbecue is not in

use.

Operating area

WARNING: Only use this barbecue outdoors in a

well ventilated area. Do not use in a garage,

building, breezeway or any other enclosed area.

WARNING: Never use your Weber Gas Barbecue

under an unprotected combustible roof or

overhang.

WARNING: Your Weber Gas Barbecue is not

intended to be installed in or on recreational

vehicles and/or boats.

WARNING: Do not use combustible materials

within 24 inches of the top, bottom, back or sides

of the grill.

WARNING: The entire cooking box gets hot

when in use. Do not leave unattended.

WARNING: Keep any electrical supply cord away

from any heated surface.

WARNING: Keep the cooking area clear of

flammable vapors and liquids, such as gasoline,

alcohol, etc., and combustible materials.

Gas supply testing

• Disconnect your Weber Gas Barbecue when the

gas supply is being tested at high pressures. This

appliance and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5 kPa).

• Turn off your Weber Gas Barbecue when the gas

supply is being tested at low pressures. This

appliance must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at the pressure equal to

or less than 1/2 psig (3.5 kPa).

Page 6

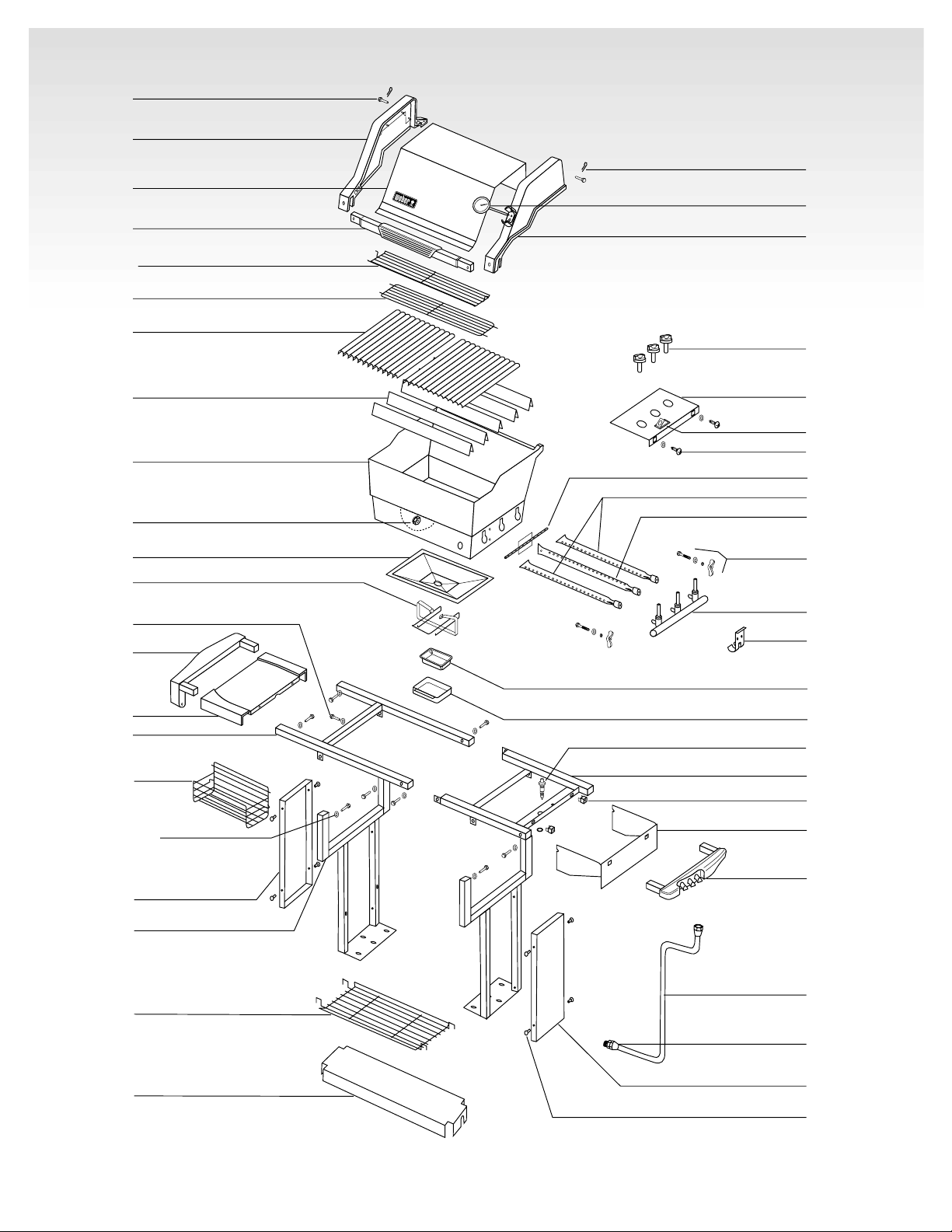

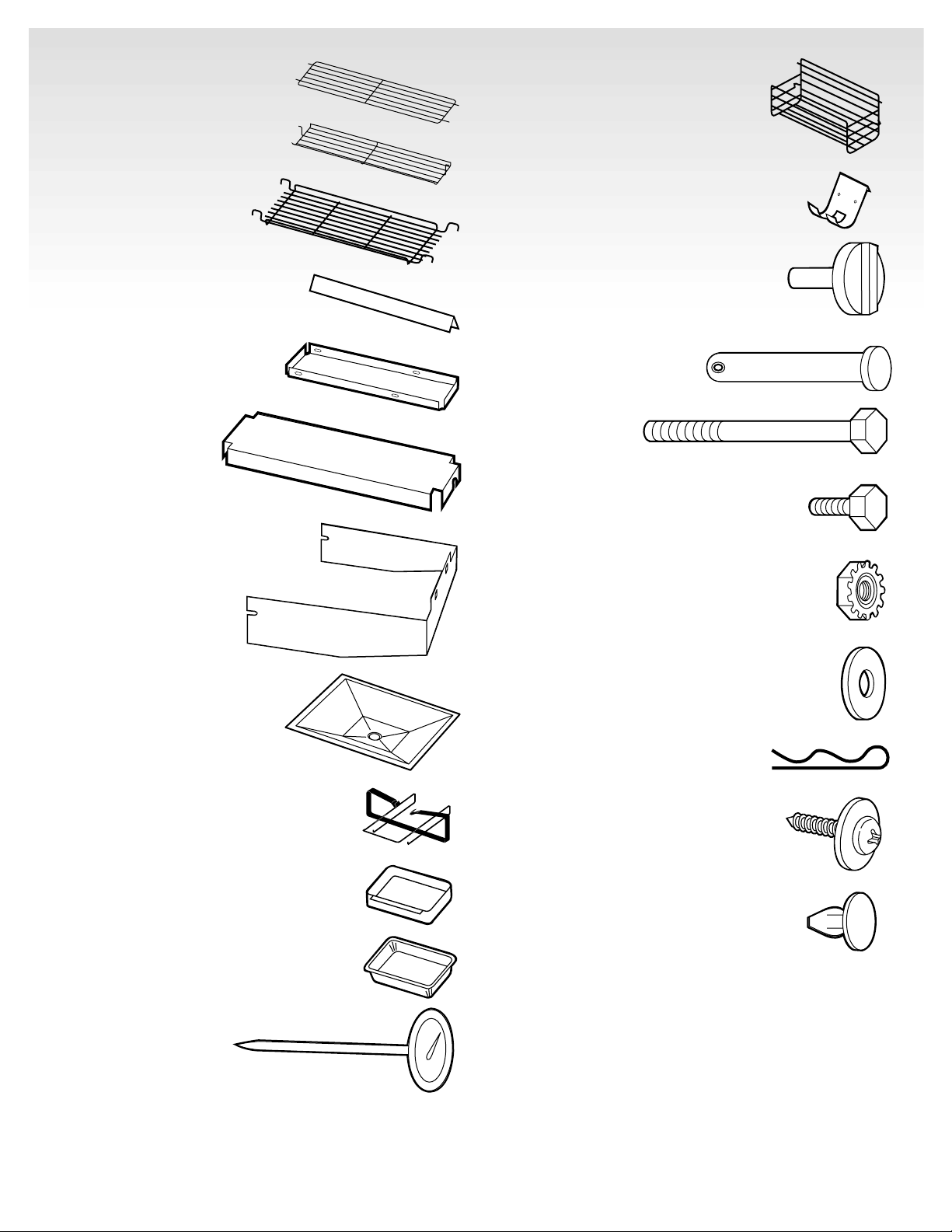

6

Genesis Silver-B Permamount NG 051701

1

2

3

4

6

7

8

9

10

11

12

14

13

15

16

17

18, 19

20

21

22

23

42

43

44

20

41

30

40

39

37

38

36

35

34

33

32

31

30

29

28

27

26

25

24

5

45

Page 7

7

1 Hinge pin

2 Left endcap

3 Shroud

4 Handle

5 Warm-Up basket

6 Warming rack

7 Cooking grate

8 Flavorizer bar

9 Cooking box

10 1/4-20 keps nut

11 Slide out bottom tray

12 Catch pan holder

13 1/4-20 x 2 inch bolt

14 Left trim piece

15 Work surface

16 Left frame

17 Condiment basket

18 1/4-20 x 1/2 inch bolt

19 1/4 inch nylon washer

20 Side panel

21 Side frame

22 Accessory rack

23 Base panel

24 Hair pin cotter

25 Thermometer

26 Right endcap

27 Burner control knob

28 Control panel

29 Igniter button

30 Control panel hardware

31 Crossover tube

32 Front and back burners

33 Center burner

34 Manifold hardware

35 Manifold

36 Manifold support bracket

37 Disposable drip pan

38 Catch pan

39 Igniter

40 Right frame

41 Control panel trim piece

42 Right trim piece

43 Gas supply line

44 Flare fitting

45 Plastic button

Page 8

8

© 2001 Weber-Stephen Products Co., Weber, the silhouette, and the kettle configuration are registered

trademarks of Weber-Stephen Products Co., 200 East Daniels Road, Palatine, IL, 60067-6266, U.S.A. This

product is covered by one or more United States patents and patents in other nations globally. Printed in the

U.S.A.

®

Page 9

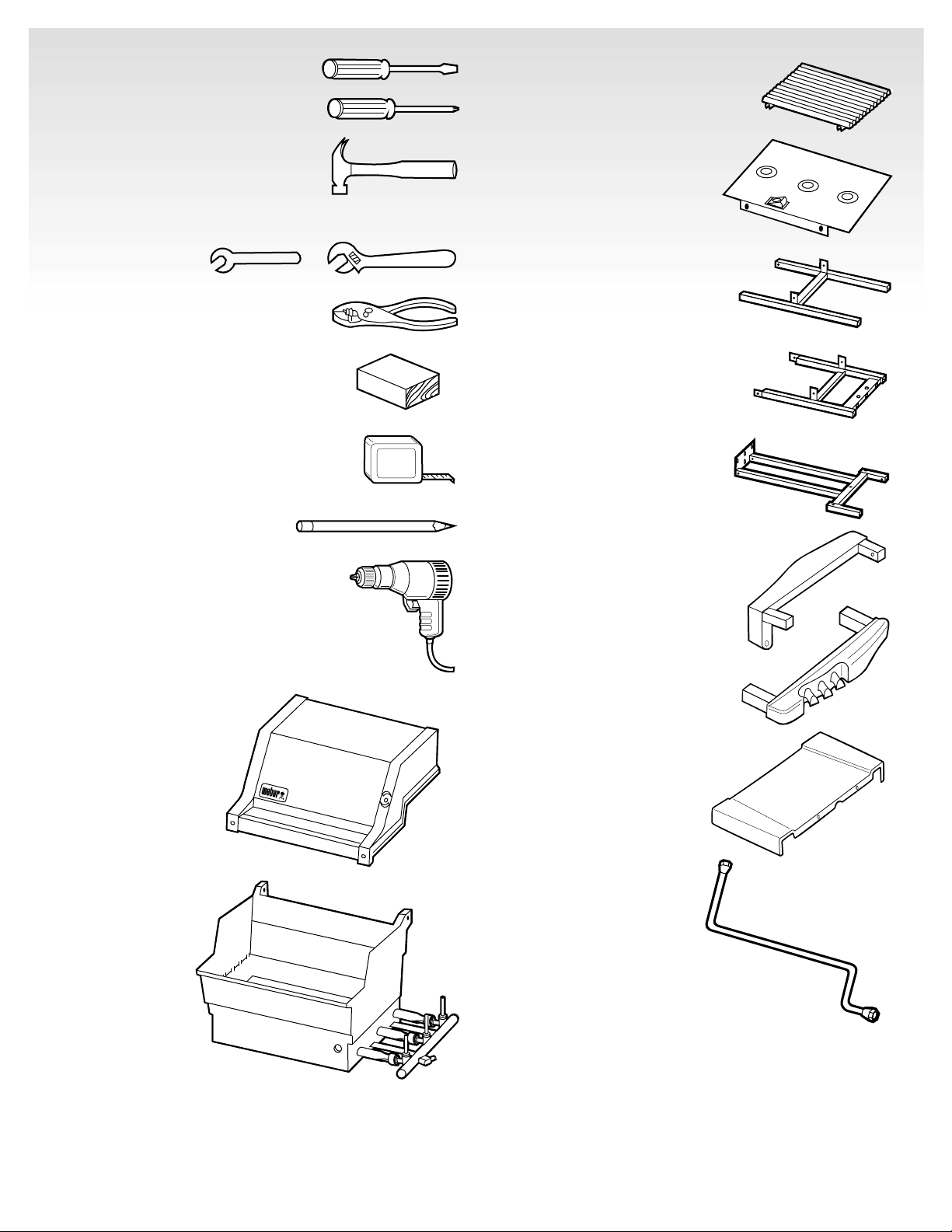

9

Screwdriver

Phillips screwdriver

Hammer

7/16 open-end wrench or adjustable wrench

Pliers

Block of wood

Tape Measure

Pencil

Electric Drill

Lid - 1

Cooking Box - 1

Cooking grates - 2

Control panel - 1

Left frame - 1

Right frame - 1

Side frame - 2

Left trim piece - 1

Right trim piece - 1

Work surface - 1

Gas supply line

(with the flare fitting

loosely attached

for shipping purposes)

®

®®®®

Page 10

Warming rack - 1

Warm-up basket - 1

Accessory rack - 1

Flavorizer bars - 5

Side panel - 2

Base panel - 1

Wrap-around trim piece - 1

Bottom tray - 1

Catch pan holder - 1

Catch pan - 1

Disposable drip pans - 2

Thermometer - 1

10

Condiment basket - 1

Manifold support bracket - 1

Burner control knobs - 3

Hinge pins (1/4-20 x 1 1/2 inch clevis pin) - 2

2 inch bolts (1/4-20 x 2 inch bolts) - 1

1/2 inch bolts (1/4-20 x 1/2 inch bolts) - 8

Keps nut (1/4-20 keps nut) - 1

1/4 inch nylon washers - 15

Cotter pin - 2

Control panel hardware

(phillips screws/washers) - 2

Plastic button - 8

Page 11

1111

General Specifications for

Piping

American National Standards Institute (ANSI)

Recommendations for gas supply installations:

Connections:

■ This barbecue is designed to operate at 7 inches

of water column pressure (.2526 psi).

■ A manual shut-off valve must be installed

outdoors, immediately ahead of any connections

or change in pipe material.

■ An additional manual shut-off valve indoors should

be installed in the branch fuel line in an accessible

location near the supply line.

■ The point of tie into the branch line should be

carefully selected to avoid a drip leg or be

downstream of a valve controlling another

appliance.

■ Pipe compound should be used which is resistant

to action of natural gas when connections are

made.

■ The outdoor connector must be firmly attached to

rigid, permanent construction.

Gas line piping

■ If the length of line required does not exceed 50

feet, use a 5/8" O.D. tube. One size larger should

be used for lengths greater than 50 feet.

■ Indoor and above ground piping can be steel or

copper.

Steel

New standard weight (Schedule 40) steel pipe with

malleable iron fittings.

Copper

New copper tubing type K or L.

Copper tubing must meet requirements of ASTM B88

latest edition.

Use flared fittings. Metallic ball sleeve compression

fittings must not be used.

Copper tube joints may be soldered or brazed with

material having a melting point in excess of 1,000°F.

Outside underground piping

Outside underground piping may be copper tubing,

type K or L (ASTM B88) or polyethylene plastic tube

PE3306 (Minimum wall thickness .062") meeting

ASTM 2513, latest specifications.

Steel pipe is not recommended for underground use

unless it is protected with an approved coating,

insulated from hose piping and cathodically protected.

It is recommended that copper tubing be corrosion

protected with a satisfactory material such as TC

Mastic.

All buried fittings should be corrosion protected with a

satisfactory material such as TC Mastic.

Underground piping must have a minimum of 10"

cover.

Plastic tubing

Plastic tubing is suitable only for outside underground

use.

■ The transition from metallic pipe to plastic pipe

should be made outside and at least 10"

underground.

■ When compression or crimp type mechanical

joints are used with plastic pipe, it is advisable to

use an internal rigid stiffener in conjunction with

the fitting.

■ The stiffener should be assembled flush with the

end of the tube and extend at least to the outside

edge of the compression fitting.

Testing connections

You will need a soap and water solution and a rag or

brush to apply it.

All connections and joints must be thoroughly tested

for leaks after gas has been turned into the line.

Notice Before Installation

Contact your local municipality for any building codes regulating outdoor barbecue installations. In

absence of local codes, you must conform to the latest edition of ANSI Z223.1.

WE RECOMMEND THAT THIS INSTALLATION BE DONE BY A PROFESSIONAL.

DANGER

Do not use an open flame to check for

gas leaks. Be sure there are no sparks

or open flames in the area while you

check for gas leaks. This will result in

a fire or explosion which can cause

serious bodily injury or death, and

damage to property.

Wet the fitting with a soap and water solution. Any

bubbles that form or grow indicate a leak. If bubbles

occur shut off gas, tighten the fitting, and retest.

WARNING: If a leak persists after tightening the

fitting, turn gas off at the supply. DO NOT

OPERATE YOUR BARBECUE. Contact WeberStephen Customer Service.

Page 12

1212

Typical natural gas supply installation to a

concrete patio or pad

Figure 1

CAUTION: Follow "General Specifications for

Piping" in this manual.

We recommend that this installation be done by a

professional.

CAUTION: Combustible materials should never

be within 24 inches of the top, bottom, back or

sides of the barbecue. Do not locate under

overhead combustible construction.

Typical natural gas supply installation to a

wood deck

Figure 2

CAUTION: Follow "General Specifications for

Piping" in this manual.

We recommend that this installation be done by a

professional.

CAUTION: Combustible materials should never

be within 24 inches of the top, bottom, back or

sides of the barbecue. Do not locate under

overhead combustible construction.

Figure 3

Typical natural gas supply installation

over an existing post

WARNING: Turn off the natural gas supply at the

source before working on the post.

Prepare the post so that it will be approximately 2

inches above the pad or ground. Inspect the gas

supply line at the post for any sign of deterioration or

corrosion.

CAUTION: If you are in doubt as to the condition

of an existing natural gas supply line, you should

contact a professional or your local gas utility

before attempting any assembly.

CAUTION: Combustible materials should never

be within 24 inches of the top, bottom, back or

sides of the barbecue. Do not locate under

overhead combustible construction.

View from behind barbecue

Outside

Inside

Gas supply

Indoor shut off

Accessible

locking shut off

Outside

Inside

Gas supply

Indoor shut off

Accessible

locking shut off

Outside

Inside

Gas supply

Indoor shut off

Accessible

locking shut off

Page 13

1313

Recommended concrete pad requirements

We recommend a pad a minimum of 40 inches left

to right, 20 inches front to back and 4 inches deep

(1.85 cubic feet). Figure 4.

Note - Cubic feet is determined by multiplying length

times width times depth and dividing by 1728.

20”

4”

40”

Figure 4

If you use a concrete bag mix, use the mix for

maximum strength. An average 80 pound bag of

concrete mix will make approximately 2/3 of a cubic

foot of concrete.

Note - Follow the concrete bag mix, manufacturers

recommendations concerning pad preparation,

gravel, sand, etc. Figure 5.

Figure 5

CAUTION: Allow fresh concrete to cure

completely before attempting to anchor the

barbecue to the concrete.

Crushed stone,

sand or gravel

Earth

Concrete pad

Page 14

14

Step 2

Assemble the frame

You will need: left frame, right frame, two nylon

washers, two 1/4-20 x 1/2 inch bolts and a 7/16 inch

wrench.

Note - Work on carpeted area (on grass, or on one of

the boxes) to protect the finish during frame

assembly.

Put the frame pieces so the leg tabs are up. Put the

right frame to your right and left frame to your left.

Figure 1.

Slip the two frame halves together with the tabs

inside, until the tabs of the right frame are inside the

left frame and the holes align. Figure 1 (a).

Slip washers over bolts; insert and tighten bolts. (If

you try to insert a bolt and there are no holes, you

have the left frame turned the wrong way. Turn the left

frame around.) Figure 1 (b).

Step 3

Continue frame assembly

You will need: frame assembly, two side frames,

four 1/4-20 x 1/2 inch bolts, four nylon washers

and a 7/16 inch wrench.

Assemble one side frame onto the leg tabs of the

right frame, and the second side frame onto the leg

tabs of the left frame. Make sure the anchoring base

plates are facing in toward each other. The tabs must

be on the inside

of the frames when the joints are

closed.

Add washers, then bolts. Do not full

y tighten these

bolts. You will tighten them once the base is

anchored. Figure 2 (a).

Turn frame assembly right side up.

Figure 1

Figure 2

(a)

(a)

(b)

Do not fully tighten

these bolts

Anchoring base

plates are facing in

Page 15

15

(1)

(2)

Step 4

Add Wrap-around Frame Panel

You will need: wrap around frame panel and a

wrench.

Place wrap-around frame panel in place:

1) The cut-out tabs should fit between the washer

and the frame, as shown.

2) The square cut-out holes fit around the white

plugs in the frame as shown.

Tighten Bolts with wrench.

Turn the frame over and continue with assembly.

Figure 2.1

Figure 2.2

Fully tighten the 1/4-20 bolts in the frame assembly,

that you only started in Step “Continue Frame

Assembly” Figure 2.2.

Page 16

16

Figure 3

Figure 5

Figure 4

25

5/8

1

2

3

4

Step 5

Measure and drill holes

You will need: Completed frame assembly, base

panel, tape measure, and pencil.

CAUTION: Combustible materials should never

be within 24 inches of the top, bottom, back or

sides of the barbecue. Do not locate under

overhead combustible construction.

Note - With the lid open the depth of the barbecue

is 28 inches, front to back.

Set the completed frame assembly in position on your

deck, concrete pad, or patio for anchoring. Measure the

distance from the outside of the base plate to the

outside of the other base plate. It should be 26 5/8”

across. Figure 3.

Note: If the measurement is not 26 5/8” across

adjust the legs as necessary so that the

measurement is 26 5/8”.

Place the base panel in between the legs to insure fit.

Figure 4. Once the fit is established, remove the base

panel and mark the holes.

CAUTION: A minimum of 2 bolts are required on

each side.

You are now ready to anchor the base.

Step 6

Typical installation of the base for an existing

concrete patio, new pad or wood deck

CAUTION: Combustible materials should never

be within 24 inches of the top, bottom, back or

sides of the barbecue. Do not locate under

overhead combustible construction.

Note - With the lid open the depth of the barbecue

is 28 inches, front to back.

For anchoring, we recommend use of one of the

following methods:

WARNING:Whichever method used, the base

must be bolted down (anchored) at a minimum of

four anchoring points (two per side) prior to

barbecue assembly. One anchor in each corner of

the base plate. Figure 5.

Page 17

17

3/8-16 x 1 1/2 machine screw

3/8 inch flat washer

Mount plate

3/8 inch screw anchor

Drilled hole

Figure 8

Concrete lag bolt

3/8 inch flat washer

Mount plate

Lag shield

Drilled hole

Figure 7

Strike anchor

3/8 inch nut

3/8 inch flat washer

Mount plate

Drilled hole

Figure 6

Method 3 - Concrete

A 3/8 inch machine screw anchor, using a 3/8-16 x

1 1/2 inch machine screw and a flat washer. Figure 8.

Note - Use a 3/4 inch diameter concrete drill bit for

drilling the hole for the screw base. The machine screw

anchor requires a setting tool.

Typical installation of the base for an existing

concrete patio, new pad or wood deck

(continued)

Method 1 - Concrete

A strike anchor, a minimum size of 3/8 inch x 3 1/2

inches long with a 3/8 inch flat washer and 3/8 inch

nut. Figure 6.

Note - Use a 3/8 inch diameter concrete drill bit for

drilling the hole for the strike anchor.

Method 2 - Concrete

A concrete lag bolt, a minimum of 3/8 inch x 2 1/2

inches long with a 3/8 inch diameter long lag shield

and a 3/8 inch flat washer. Figure 7.

Note - Use a 5/8 inch concrete drill bit for drilling the

hole for the lag shield.

Page 18

18

Figure 10

3/8 inch x 1 1/2 inch lag bolt

3/8 inch flat washer

Mount plate

Drilled hole

Figure 9

1

2

3

4

Typical installation of the base for an existing

concrete patio, new pad or wood deck

(continued)

Method 4 - Wood deck

After assembling the base according to the assembly

instructions, position the base assembly on your deck

for anchoring.

CAUTION: Combustible materials should never

be within 24 inches of the top, bottom, back or

sides of the barbecue. Do not locate under

overhead combustible construction.

CAUTION: For a deck installation, it is

recommended to anchor one screw into a joist.

Note - With the lid open, the depth of the barbecue

is 28 inches, front to back.

Anchor the base to the deck. We recommend using a

minimum of a 3/8 inch x 1 1/2 inch lag bolt with a 3/8

inch flat washer. Figure 9.

Note - Use a 3/16 inch drill bit for drilling a pilot hole

for a 3/8 inch lag bolt.

WARNING: Whichever method used, the base

must be bolted down (anchored) at a minimum of

four anchoring points (two per side) prior to

barbecue assembly. One anchor in each corner of

the base plate. Figure 10.

Page 19

19

Guide screw

(a)

(b)

Wing nuts

View from

behind

cooking

box

Figure 13

Figure 11

Burner tubes

Frame brace

Slide the cooking box to the left within the frame. Put

nylon washer on bolt. Insert the bolt through the frame

and cooking box with the head of the bolt outside the

frame. Figure 12. Add the keps nut. Tighten by holding

the bolt with pliers while you tighten the nut with the

7/16 inch wrench.

Figure 12

Step 7

Add cooking box

You will need: frame assembly, cooking box assembly,

spacer bracket, 1/4-20 x 2 inch bolt, nylon washer,

1/4-20 keps nut, pliers and a 7/16 inch wrench.

Set the cooking box in the frame so the burner tubes

are under the frame brace. Figure 11.

Note: Be careful when sliding the burner tubes

through the side frame.

Your Weber Gas Barbecue burner assembly has been

factory assembled, pressure and flame tested. As a

safety precaution we recommend you check the burner

alignment:

a) Are the ends of the burners under the washers at

the left rear and left front of the cooking box? The

screws are only guides. Do not tighten. Figure 13 (a).

b) Are the wing nuts under the burner assembly hand

tight? Do not tighten with pliers. Figure 13 (b).

If you answered YES to a and b, the burners are

correctly aligned. If you answered NO, the burners are

misaligned. Contact Weber-Stephen Customer

Service. Do not use barbecue.

Page 20

Step 8

Connect barbecue gas supply line to the

natural gas supply

Note - We recommend that the connection

between the barbecue gas supply line and the

natural gas supply be flare to flare. A 3/8-inch flare

fitting has been included with the barbecue gas

supply line of your gas barbecue. The fitting is

loosely connected for shipping and should be

removed before installation.

You will need: barbecue gas supply line, 3/8 inch flare

fitting, 3/4 inch and 11/16 inch wrenches.

WARNING: This barbecue is NO

T portable. It

must be bolted down at all times when it is

connected to a natural gas supply.

Unscrew the 3/8 inch flare fitting from the barbecue

gas supply line. Apply pipe sealant to the threads

of the pipe fitting. Screw the pipe fitting end of the

3/8 inch flare fitting into the natural gas supply pipe.

Tighten with an 11/16 inch wrench. Figure 14 (a).

Attach the flare nut on the barbecue gas supply line

to the flare fitting end of the 3/8 inch flare fitting.

Tighten with a 3/4 inch wrench. Figure 14 (a).

Attach the flare nut at the other end of the barbecue

gas supply line to the manifold fitting. Tighten with a 3/4

inch wrench. Figure 14 (b).

20

Figure 14

(a)

(b)

Natural Gas

Supply Pipe

Pipe fitting end

of 3/8-inch

Flare Fitting

Flare fitting end of

3/8-inch Flare Fitting

Barbecue gas

supply line

Apply pipe

sealant here

Figure 15

View from below

cooking box

Frame brace

Manifold bracket

Figure 16

(a)

Step 9

Check all valves are off

You will need: one burner control knob.

(Valves are shipped in the OFF position, but you

should check to be sure.) Put the knob on each valve.

Check by pushing down and turning clockwise. If they

do not turn they are off. Proceed to the next step.

Figure 15.

Step 10

Install manifold bracket

You will need: manifold bracket.

Hook the bracket onto the manifold at the center burner

valve. Figure 16. Place your hand underneath the

bracket. Lift the bracket, manifold and cooking

box slightly as a unit and hook onto the frame brace.

Figure 16 (a).

Page 21

21

Figure 17

Igniter lock nut

Keyhole in

frame brace

Small part of keyhole

in frame brace

Frame brace

Frame brace

(a)

(b)

(c)

Figure 18

Step 11

Install igniter

Note - The igniter wires are already attached to the

Gas Catcher Ignition Chamber and the igniter. This

was done to factory test the ignition system.

The igniter lock nut is on the igniter.

Insert the top of the igniter up through the large part of

the keyhole in the frame brace. Figure 17 (b). Loosen

the igniter lock nut and slide the igniter into the small

part of the keyhole. Figure 17 (c). Tighten the igniter

lock nut. Figure 17.

Note - If the igniter works loose, carefully tighten the

igniter lock nut with an adjustable wrench or pliers.

Step 12

Purge air from gas lines

You will need: one burner control knob.

DANGER

Be sure there are no sparks or open

flames in the area while purging. This

can cause fire, explosion or serious

bodily injury.

It is necessary to bleed the air out of newly installed

gas lines. Turn gas supply ON at the source. Put on the

front burner control knob. Push the front burner control

knob down and turn to HI. When you start

to smell gas, turn front burner control knob to OFF.

Figure 18.

Page 22

22

Figure 20

Figure 19

(a)

Gas supply shut

off at the house

(c)

(b)

Step 13

Check for gas leaks

DANGER

Do not use an open flame to check for

gas leaks. Be sure there are no sparks

or open flames in the area while you

check for leaks.This will result in a fire

or explosion which can cause serious

bodily injury or death and damage to

property.

WARNING:You should check for gas leaks

every time you disconnect and reconnect a gas

fitting.

Note - All factory made connections have been

thoroughly checked for gas leaks. The burners have

been flame tested. As a safety precaution you should

recheck all fittings for leaks before using your Weber

Gas Barbecue. Shipping and handling may have

loosened or damaged a gas fitting.

WARNING: Perform these leak checks even if

your barbecue was dealer or store assembled.

You will need: soap and water solution and a rag or

brush to apply it.

To perform leak checks: Turn ON gas supply at the

source. Figure 19.

WARNING: Do

not ignite burners while leak

checking.

Check for leaks by wetting the connections with the

soap and water solution and watching for bubbles. If

bubbles form or if a bubble grows there is a leak.

Note - Since some leak test solutions, including soap

and water, may be slightly corrosive, all connections

should be rinsed with water after checking for leaks.

Check:

a) Gas supply line to manifold connection.

Figure 20 (a).

WARNING: If there is a leak at connection a,

retighten the fitting with a wrench and recheck for

leaks with soap and water solution.

If a leak persists after retightening the fitting, turn

OFF the gas. DO NO

T OPERATE THE BARBECUE.

Contact Weber-Stephen Customer Service.

b) Valves to manifold connections. Figure 20 (b).

c) Barbecue gas supply line to natural gas supply

connection. Figure 20 (c).

WARNING: If there is a leak at connections b or

c, turn OFF the gas. DO NO

T OPERA

TE THE

BARBECUE.

Contact Weber-Stephen Customer

Service.

When leak checks are complete, turn gas supply OFF

and rinse connections with water.

Page 23

23

Figure 21

Figure 22

(a)

Base panel

Left side

panel

top

bottom

Right side

panel

Step 14

Add base panel

You will need: Base panel.

Put the right side in and down, tilt and set the left side

in place. Figure 21.

Step 15

Install side panels

You will need: two side panels, and eight plastic

buttons.

From the inside of the frame assembly, set the left

side panel in place between the side frame legs.

Notice that there are two sets of holes in each side

panel. Align the holes in the side panel to match the

holes in the left side frame legs. Push in the four

plastic buttons. Figure 22 (a).

Repeat with the right side panel.

Page 24

24

Figure 26

Figure 25

Figure 27

Bottom tray

Finger grip on front

edge of bottom tray

Finger grip

Front side of catch

pan holder

Figure 23

Figure 24

Step 16

Install Flavorizer Bars and Cooking Grates

You will need: five long Flavorizer Bars and two

cooking grates.

Set the long Flavorizer Bars side to side in position.

Figure 23.

The open "U" of the cooking grates goes down. Set

the cooking grates onto the ledges in the cooking box.

Figure 24.

Step 17

Install the bottom tray

You will need: bottom tray, catch pan holder, catch pan

and one drip pan.

Hook the ends of the catch pan holder into the hole in

the bottom tray. Figure 26. The front of the catch pan

holder must be on the same side as the finger grip

of the bottom tray.

Slide the bottom tray onto the mounting rails under the

cooking box with finger grip toward you. Figure 27.

CAUTION: Do not line bottom tray with aluminum

foil. It can cause grease fires by trapping the

grease and not allowing grease to flow into the

catch pan.

Put the foil drip pan into the catch pan.

Slide the catch pan into the catch pan holder with its

finger grip towards you.

Page 25

25

Hair pin cotter

Hinge pin

Figure 28

Figure 29

Tool holders

Control panel

push-in buttons

(a)

(b)

Step 18

Install Lid

You will need: lid, two hinge pins and two hair pin

cotters.

Set the lid in place. Align the hinges at the rear of the

barbecue. Insert hinge pins from the outside. Insert hair

pin cotters into the small holes in the hinge pins. Figure

28.

Step 19

Add tool holders, control panel and burner

control knobs

You will need: three tool holders, control panel, two

Phillips screws/washers, a Phillips screwdriver, and

three burner control knobs.

Hook the tool holders over the frame rail and snap

down into place. Figure 29.

Set the control panel in place over both frame braces.

(Hold the Crossover Ignition button up while setting the

control panel in place.) Line up the holes in the control

panel with the holes in the inserts in the frame brace.

Insert screws and tighten with a Phillips screwdriver

until snug. Do not overtighten. Figure 29 (a).

Push on the burner control knobs. Figure 29 (b).

Crossover

Ignition Button

Insert in

frame brace

Page 26

26

Slot in frame

(view from

below)

Figure 30

Wire end

(a)

Step 20

Install the condiment basket

You will need: condiment basket, left end trim piece,

two 1/4-20 x 1/2 inch bolts, and two nylon washers.

Insert one wire end of the condiment basket into the

hole in the side frame. Figure 30 (a).

Push the trim piece into the frame. Check to see that

the lower tab of the bracket is hooked in the slot in

the frame. Figure 31.

Add a washer to the bolt and insert it through the hole

in the frame and the hole in the trim piece. Tighten

with a wrench. Figure 32.

Figure 31

Figure 32

Start the left end trim piece into the frame as shown.

Figure 30 (b). Do not push the trim piece all the

way and do not add bolts yet. While holding the

condiment basket in position, insert the other wire end

of the condiment basket into the left end trim piece.

WARNING: If the left end trim piece is in any

way cracked or damaged, do

not use the

condiment basket. Call our Customer Service

Center to order a new part.

(view from below)

(b)

Page 27

27

Figure 34

Figure 33

(b)

(a)

Right side

frame

Left side

frame slots

Left hooks

Step 21

Install the accessory rack

You will need: accessory rack.

Rest the left end of the accessory rack on the base

panel. Figure 33 (a).

Insert the right hooks into the right side frame slots.

Figure 33 (b).

Raise the left end up and slide left hooks into the left

side frame slots. Figure 33.

Step 22

Complete accessory installation

You will need: Warm-Up Basket, warming rack, work

surface, thermometer, right trim piece with tool holder,

and a hammer.

Insert one end of the Weber Warm-Up Basket into the

hole in the right end of the lid and the other end into

the slot in the left end of the lid. Figure 34 (a).

Set the warming rack into the slots at the rear of the

cooking box. Figure 34 (b).

Set the work surface onto the left side rails. Figure

34 (c). Make sure that the tabs on the side of the

table are to the right, next to the cooking box.

Insert the thermometer into its holder. Figure 34 (d).

Push the right trim piece into the frame as shown

34 (e), making sure that the tabs on the underside

of the trim piece are snapped into the slots in the

frame 34 (f).

(a)

(b)

(d)

(c)

(e)(f)

Page 28

2828

Figure 1

Crossover Ignition System

OPERATING INSTRUCTIONS

Lighting

Summary lighting instructions are on the control panel.

1) Open the lid. Figure 1.

2) Make sure all burner control knobs are turned OFF.

(Push each burner control knob down and turn

clockwise.)

3) Turn gas supply valve on.

WARNING: Do not lean over open barbecue.

Keep your face and body at least one foot away

from the matchlight hole when lighting the

barbecue.

4) Push Front burner control knob down and turn to

START / HI.

5) Push the Crossover Ignition Button several times,

so it clicks each time.

6) Check that the burner is lit by looking through the

matchlight hole on the front of the cooking box.

WARNING: If the burner does not light, turn the

Front burner control knob to OFF and wait 5

minutes to let the gas clear before you try again or

try to light with a match.

7) After the FRONT burner is lit you can turn on the

other burners.

Note - Always light the FRONT burner first. The other

burners ignite from the FRONT burner.

To Extinguish

Turn gas supply OFF at the source, then push

down and turn each burner control knob

clockwise to OFF.

DANGER

Failure to open lid while igniting the

barbecue, or not waiting 5 minutes to

allow the gas to clear if the barbecue

does not light, may result in an

explosive flame-up which can cause

serious bodily injury or death.

Crossover Ignition System

Note - The Crossover Ignition System ignites the Front

burner with a spark from the igniter electrode inside the

Gas Catcher Ignition Chamber. You generate the

energy for the spark by pushing the Crossover Ignition

Button until it clicks.

WARNING: Check gas supply line before each

use of barbecue for nicks or cracking. If the gas

supply line is found to be damaged in any way, do

not use the barbecue. Replace using only Weber

authorized replacement gas supply line. Order

from Weber-Stephen Products Co., Customer

Service Center.

1

2

7

6

5

4

Page 29

29

Figure 2

Manual Lighting

WARNING: If the burner does not light, turn the

Front burner control knob to OFF and wait 5

minutes to let the gas clear before you try again or

try to light with a match.

7) After the FRONT burner is lit you can turn on the

other burners.

Note - Always light the FRONT burner first. The other

burners ignite from the FRONT burner.

To Extinguish

Turn gas supply OFF at the source, then push

down and turn each burner control knob

clockwise to OFF.

DANGER

Failure to open lid while igniting the

barbecue, or not waiting 5 minutes to

allow the gas to clear if the barbecue

does not light, may result in an

explosive flame-up which can cause

serious bodily injury or death.

1) Open the lid. Figure 2.

2) Make sure all burner control knobs are turned OFF.

(Push each burner control knob down and turn

clockwise.)

3) Turn gas supply valve on.

4) Strike a match and put the flame into the matchlight

hole in the front of the cooking box.

Manual Lighting

WARNING: Do not lean over open barbecue.

Keep your face and body at least one foot away

from the matchlight hole when lighting the

barbecue.

5) Push Front burner control knob down and turn to

START / HI.

6) Check that the burner is lit by looking through the

matchlight hole on the front of the cooking box.

1

2

7

4,6

5

Page 30

30

Cooking

You can adjust the FRONT, CENTER and BACK

burners as desired. The control settings High (H),

Medium (M), Low (L), or Off (O) are described in your

Weber cookbook. The cookbook uses these notations

to describe the settings of the FRONT, CENTER, and

BACK burners. For example, to sear steaks you would

use (HHH) (all burners at high). Then to complete

cooking you would use (MOM) (FRONT at medium,

CENTER off, and BACK at medium). See your Weber

cookbook for detailed cooking instructions.

Note: The temperatures inside your cooking box, for

the first few uses, while surfaces are still very

reflective, may be hotter than those shown in your

cookbook. Cooking conditions may require the

adjustment of the burner controls to attain the correct

cooking temperatures.

CAUTION: Replace thermometer in lid when not

in use. Do not leave thermometer in food while

cooking.

If burners go out during cooking, open lid, turn off

all burners and wait 5 minutes before relighting.

Preheating

Your Weber Gas Barbecue is an energy efficient

appliance. It operates at a low B.T.U. rate for economy.

To preheat, after lighting, close lid and turn all burners

to high (HHH). Preheating to between 500° and 550° F

(260° and 290° C) will take 10 to 15 minutes depending

on conditions such as air temperature and wind.

Drippings and grease

The Flavorizer Bars are designed to "smoke" the right

amount of drippings for flavorful cooking. Excess

drippings and grease accumulate in the catch pan under

the bottom tray. Disposable foil liners are available that fit

the catch pan.

CAUTION: Check the bottom tray for grease

build-up before each use. Remove excess grease

to avoid a grease fire in the bottom tray.

Periodic Cleaning

CAUTION: Turn your Weber Gas Barbecue OFF

and wait for it to cool before cleaning.

CAUTION: Do not clean your Flavorizer Bars or

cooking grates in a self-cleaning oven.

Replacement cooking grates and Flavorizer Bars

are available through your retailer or the WeberStephen Customer Service Center.

Outside surfaces - Use a warm soapy water solution.

CAUTION: Do not use oven cleaner, abrasive

cleansers (kitchen cleansers) cleaners that contain

citrus products or abrasive cleaning pads on

barbecue or cart surfaces.

Bottom tray - Remove excess grease and then wash

with warm soapy water.

Flavorizer Bars and Cooking Grates - Clean with a

suitable brass bristle brush. As needed, remove from

grill and wash with warm soapy water.

Catch pan - Disposable foil trays are available, or you

can line the catch pan with aluminum foil. To clean the

catch pan, wash with warm soapy water.

Thermometer - Wipe with warm soapy water, clean

with plastic scrub ball. Do not put in dishwasher or

submerge in water.

Inside cooking box - Brush any debris off of burners

tubes. DO NOT ENLARGE BURNER PORTS

(OPENINGS). Wash inside of cooking box with warm

soapy water.

Inside Lid - While lid is warm, wipe inside with paper

towel to prevent flaking due to grease build-up.

Work tables and accessory trays - Use any

household cleaners on these surfaces except those that

contain acid, mineral spirits or Xylene. Rinse well after

cleaning.

Plastic work surfaces are not to be used as cutting

boards.

After a Period of Nonuse

■ The Weber Gas Barbecue should be checked for

gas leaks and any obstructions in the burner tubes

before using. (See Sections General and Annual

Maintenance.)

■ Check that the areas under the control panel and

the bottom tray are free from debris that might

obstruct the flow of combustion or ventilation air.

■ The Spider Stopper Guards should also be

checked for any obstructions. (See Section "Annual

Maintenance.")

■ Keep the appliance area clear and free from

combustible materials, gasoline and other

flammable vapors and liquids.

Page 31

31

(a)

(c)

(b)

Figure 3

Annual Maintenance

After a period of nonuse we recommend that you

perform the following maintenance procedures f

or

your safety.

WARNING: Check gas supply line before each

use of barbecue for nicks or cracking. If the gas

supply line is found to be damaged in any way, do

not use the barbecue. Replace using only Weber

authorized replacement gas supply line. Order

from Weber-Stephen Products Co., Customer

Service Center.

CAUTION: If the barbecue gas supply line is

damaged in any way or leaking, do not use the

barbecue.

■ Inspect the burners for correct flame pattern.

Clean if necessary, following the procedures

outlined in the "General Maintenance" section of

this manual.

■ Check all gas fittings for leaks.

DANGER

Do not use an open flame to check for

gas leaks. Be sure there are no sparks

or open flames in the area while you

check for leaks. This will result in a fire

or explosion which can cause serious

bodily injury or death, and damage to

property.

WARNING: You should check for gas leaks

every time you disconnect and reconnect a gas

fitting.

You will need: a soap and water solution and a rag or

brush to apply it.

To perform leak checks: Make sure all burners are in

the OFF position. Turn on gas supply.

Refer to the steps “Add side panels” and “Add base

panel” to remove the panels to expose the gas supply

line for leak checking.

WARNING: Do not ignite burners while leak

checking.

Check for leaks by wetting the connections with the

soap and water solution and watching for bubbles. If

bubbles form or if a bubble grows there is a leak.

Note - Since some leak test solutions, including soap

and water, may be slightly corrosive, all connections

should be rinsed with water after checking for leaks.

Check:

a) Gas supply line to manifold connection. Figure 3 (a).

WARNING: If there is a leak at connection (a),

retighten the fitting with a wrench and recheck for

leaks with soap and water solution.

If a leak persists after retightening the fitting, turn

OFF the gas. DO NOT OPERATE THE BARBECUE.

Contact Weber-Stephen Customer Service.

b) Valves to manifold connections. Figure 3 (b).

c) Barbecue gas supply line to natural gas supply

connection. Figure 3 (c).

WARNING: If there is a leak at connections (b)

or (c), turn OFF the gas. DO NO

T OPERATE THE

BARBECUE.

Contact Weber-Stephen Customer

Service.

When leak checks are complete, see steps “Add side

panels” and “Add base panel” to reinstall. Turn gas

supply OFF at the source and rinse connections

with water.

Inspection and cleaning of the Spider/Insect

screens

To inspect the spider/insect screens, remove the

control panel. If there is dust or dirt on the screens,

remove the burners for cleaning the screens. Refer to

Maintenance, Replacing Main Burners. Brush the

spider/inspect screens, lightly, with a soft bristle brush

(i.e. an old toothbrush).

Caution: Do not clean the spider/insect screens

with hard or sharp tools. Do not dislodge the

spider/insect screens or enlarge the screen

openings.

Lightly tap the burner to get debris and dirt out of the

burner tube. Once the spider/insect screens and

burners are clean replace the burners.

If the spider/insect screen becomes damaged or

cannot be cleaned, call Weber-Stephen Products

Customer Service for replacement parts.

Page 32

32

General Maintenance

Weber Spider/Insect Screen

Your Weber Gas Barbecue, as well as any outdoor

gas appliance, is a target for spiders and other

insects. They can nest in the venturi section of the

burner tubes. This blocks the normal gas flow, and

can cause the gas to flow back out of the air shutter.

This could result in a fire in and around the air

shutters, under the control panel, causing serious

damage to your barbecue.

The burner tube air shutter is fitted with a stainless steel

screen(1) to prevent spiders and other insects access

to the burner tubes through the air shutter openings.

We recommend that you inspect the Spider/Insect

Screens at least once a year. (See section “Annual

Maintenance”.) Also inspect and clean the

Spider/Insect Screens if any of the following

symptoms should ever occur.

1. The smell of gas in conjunction with the burner

flames appearing yellow and lazy.

2. Barbecue does not reach temperature.

3. Barbecue heats unevenly.

4. One or more of the burners do not ignite.

DANGER

Failure to correct the above mentioned

symptoms may result in a fire, which

may cause serious bodily injury or

death, and cause damage to property.

Main Burner Flame Pattern

The Weber Gas Barbecue burners have been factory

set for the correct air and gas mixture. The correct

flame pattern is shown.

1) Burner Tube

2) Tips occasionally flicker yellow

3) Light Blue

4) Dark Blue

If the flames do not appear to be uniform the length of

the burner tube, follow the burner cleaning procedures.

Main Burner Cleaning Procedure

Turn off the gas supply. Remove the manifold.

Look inside each burner with a flashlight.

Clean the inside of the burners with a wire (a

straightened out coat hanger will work). Check and

clean the air shutter opening at the ends of the

burners. Check and clean the valve orifices at the

base of the valves. Use a brass bristle brush to clean

outside of burners. This is to make sure all the burner

ports are fully open.

CAUTION: Do not enlarge the burner ports when

cleaning.

Replacing Main Burners

1) Your Weber Gas Barbecue must be OFF and cool.

2) Turn gas OFF at source.

3) Remove control panel: take off the burner control

knobs. Remove the screws holding the control

panel in place. Lift off the control panel.

(1)

(1)

(2)

(3)

(4)

(1)

Page 33

33

(1)

(1)

4) Disconnect gas supply line.

5) Unhook the manifold bracket and unscrew the two

wing nuts(1) that hold the manifold to the cooking

box. Pull the manifold and valve assembly out of

the burners and carefully set it down.

6) Slide the burner assembly out from under the

guide screw and washer(1) in the corners of the

cooking box.

7) Lift and twist the burner assembly slightly, to

separate the crossover tube(1) from the burners.

Remove the burners from the cooking box.

7) To reinstall the burners, reverse steps 3) through 7).

CAUTION: The burner openings(1) must be

positioned properly over the valve orifices(2).

Check proper assembly before fastening manifold in

place.

WARNING: After reinstalling the gas lines, they

should be leak checked with a soap and water

solution before using the barbecue. (See

Step:”Checking for Gas Leaks.”

(1)

(2)

(1)

Page 34

34

Crossover®Ignition System Operations

If the Crossover Ignition System fails to ignite the

Front burner, light the Front burner with a match. If the

Front burner lights with a match, then check the

Crossover Ignition System.

■ Check that both the white(1) and black(2) ignition

wires are attached properly.

■ Check that the Crossover Ignition button pushes

the igniter (button) down, and returns to the up

position.

■ Check to see if the igniter is loose in the frame.

Tighten if necessary; see Step “Install igniter” for

correct procedure.

If the Crossover Ignition System still fails to light,

Contact the Customer Service Representative in your

region using the contact information sheet provided

with your manual.

(1) (2)

Page 35

35

Problem

Burners burn with a yellow or orange

flame, in conjunction with the smell of gas.

Burner does not light, or flame is low in

HIGH position.

Experiencing flare-ups:

CAUTION: Do not line the bottom tray

with aluminum foil.

Burner flame pattern is erratic. Flame is low

when burner is on HIGH. Flames do not run

the whole length of the burner tube.

Inside of lid appears to be “peeling.”

(Resembles paint peeling.)

Check

Inspect Spider/Insect Screens for

possible obstructions. (Blockage of

holes.)

Is natural gas supply on ?

Does the Front burner light with a

match?

Were natural gas lines purged?

(Air removed)

Are you preheating barbecue in the

prescribed manner?

Are the cooking grates and

Flavorizer Bars heavily coated with

burned-on grease?

Is the bottom tray "dirty" and not

allowing grease to flow into catch

pan?

Are burners clean?

The lid is porcelain-on-steel, not

paint. It cannot “peel.” What you are

seeing is baked on grease that has

turned to carbon and is flaking off.

THIS IS NOT A DEFECT.

Cure

Clean Spider/Insect

Screens. (See Section

"Annual Maintenance".)

Turn on natural gas supply.

If you can light the Front

burner with a match, then

check the Crossover

Ignition System.

Purge the natural gas lines.

See Step “Purge air from

gas lines.”

All burners on high for 10

to 15 minutes for

preheating.

Clean thoroughly. (See

Section "Periodic

Cleaning".)

Clean bottom tray.

Clean burners. (See

Section "General

Maintenance".)

Clean thoroughly. (See

Section "Periodic

Cleaning".)

TROUBLESHOOTING

If problems cannot be corrected by using these methods, please contact Weber-Stephen Customer

Service.

Loading...

Loading...