Page 1

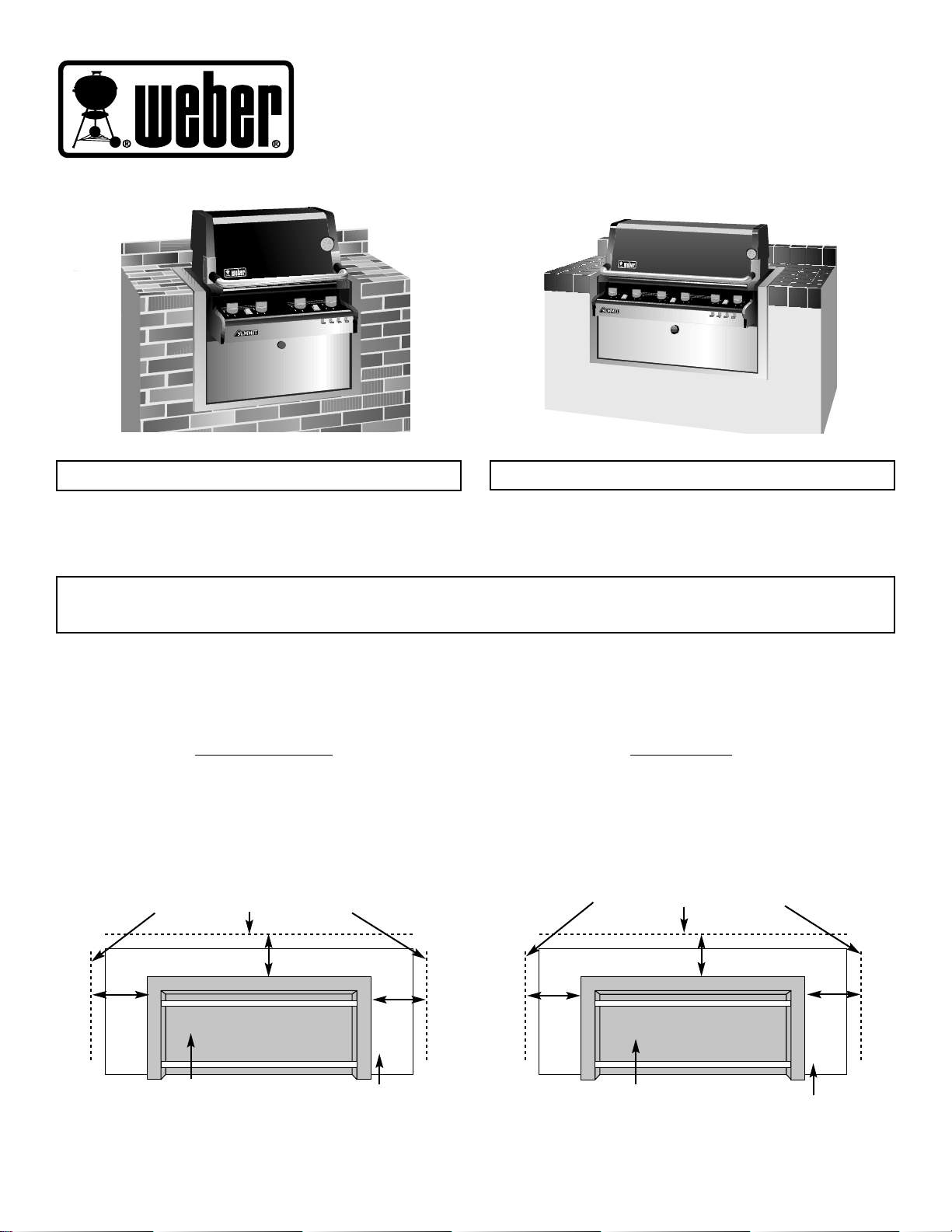

SUMMIT 475 & 675

Natural Gas Barbecues

Summit 475 NG

Summit 675 NG

THIS GAS APPLIANCE IS DESIGNED FOR OUTDOOR USE ONLY.

GENERAL INFORMATION

BUILT-IN CONSTRUCTION GENERAL INFORMATION

WARNING

A Weber-Stephen Products Co. insulated sleeve must be used for any built-in installation.

CLEARANCE FROM COMBUSTIBLE SURFACES OR

STRUCTURES

Warning: Clearance from the outside walls of the sides and

back of the insulated sleeve must be a minimum of 24

inches from a combustible surface. Measure from the

outside wall of the insulated surface to the combustible

surface. Figure 2. Refer to “Install Gas Supply” on page 2

before starting installation.

Figure 2

Figure 1

CLEARANCE FROM NON-COMBUSTIBLE SURFACES OR

STRUCTURES

Warning: Clearance from the outside walls of the sides and

back of the insulated sleeve must be a minimum of 6 inches

from a non-combustible surface. Measure from the outside

wall of the insulated surface to the non-combustible

surface. Figure 1. Refer to “Install Gas Supply” on page 2

before starting installation.

COMBUSTIBLE SURFACE

24 inches

24 inches

24 inches

NON- COMBUSTIBLE SURFACE

6 inches

6 inches

6 inches

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

Countertop

Countertop

Insulated sleeve

Insulated sleeve

LOCA TING YOUR BARBECUE

When determining a suitable location for your barbecue installation, give attention to concerns such as exposure to wind, proximity to

traffic paths, and keeping any gas supply lines as short as possible. Never locate the Weber Gas Barbecue in a garage, breezeway,

shed, under an unprotected overhang, or other enclosed area. Locate the barbecue and structure so there is enough room to safely

evacuate the area in case of a fire.

THIS GAS APPLIANCE IS DESIGNED FOR OUTDOOR USE ONLY.

98251 3/99

Page 2

2

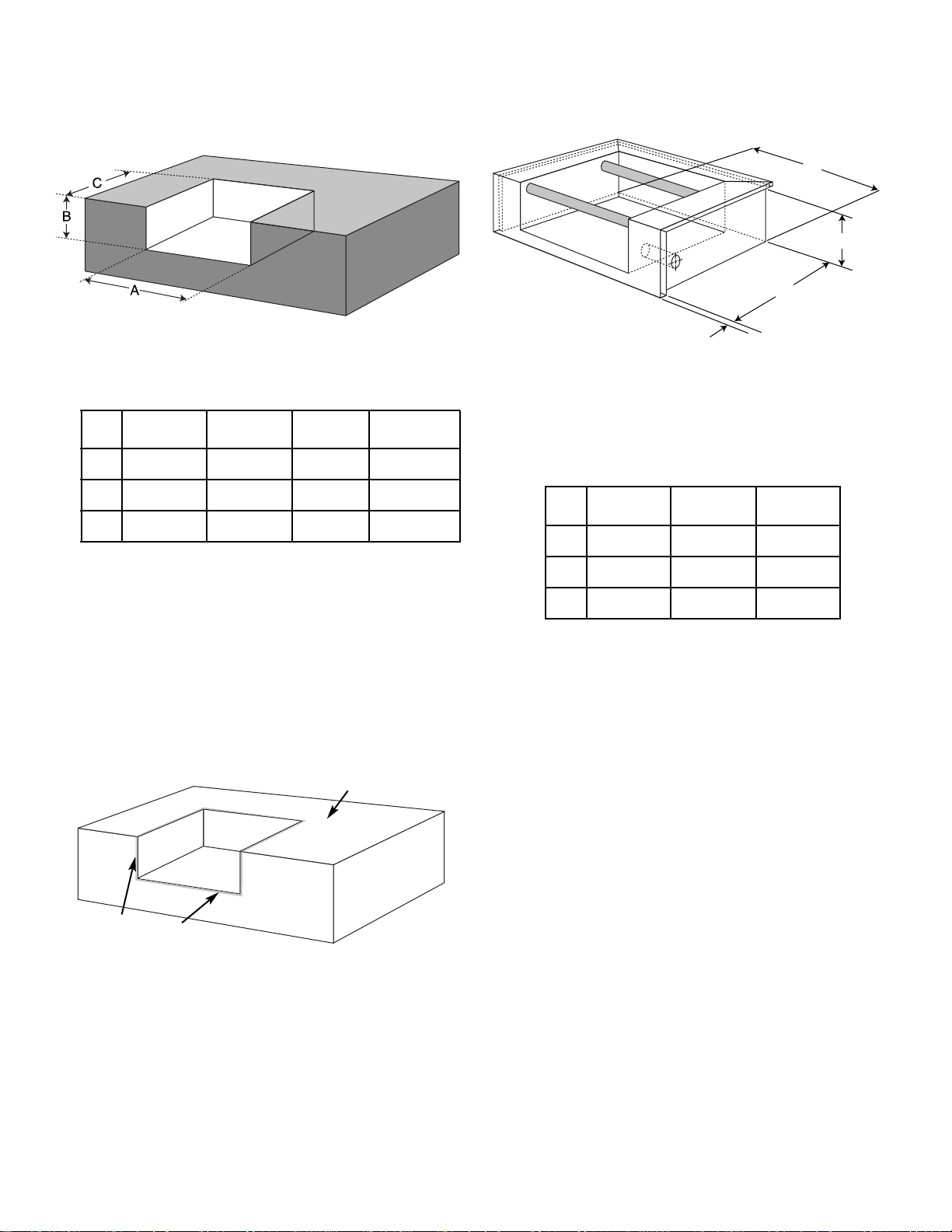

BUILT-IN STRUCTURE

CUTOUT DIMENSIONS

Side

475 675 Burner Tolerances

A31

5

⁄8”43

5

⁄8”10

3

⁄4”

B21

1

⁄8”21

1

⁄8”4

1

⁄2”

C 25” 25” 24”

WT 240 285 40

DIMENSIONS

+ 3⁄16”

- 0

+ 3⁄32”

- 0

+ 3⁄16”

-0

BUILT-IN CUTOUT DIMENSIONS

BUILT-IN STRUCTURE

SLEEVE DIMENSIONS

A

B

C

.625

TYP. TRIM

OVERHANG

DEPTH

HEIGHT

WIDTH

475 675 Tolerances

A31

1

⁄2”43

1

⁄2”

B21

1

⁄16”21

1

⁄16”

C2415⁄16”24

15

⁄16”

WT 240 285

DIMENSIONS

+ 1⁄4”

- 0

+ 3⁄16”

- 0

+ 3⁄16”

-0

BUILT-IN INSULATED SLEEVE

DIMENSIONS

Weight (expressed in pounds) represents the total weight

of the insulated sleeve and the cooking unit and does not

include the permanent structure housing the sleeve.

Specified insulated sleeve dimensions “A through C”

reflect the dimension to the mounting surface of the trim

excluding the .625 trim overhang.

If the supporting structure is going to have an

electrical outlet for a rotisserie, it should be on the

left side of the structure.

WARNING: Air holes must be provided in the

structure at the top and bottom to provide ventilation

in the event of a gas leak.

Air holes can be located in a low visibility area and should

be protected by screening material to prevent rodents and

insects from entering the structure. Air holes will also help

dry moisture.

Before installing the sleeve, lay a bead of silicon sealant

around the top perimeter and front sides of the structure

in the areas that the flanges of the sleeve will rest. This

will prevent moisture seepage. The sealant you use must

have a temperature rating above 120°F. If necessary,

caulk between the flange of the sleeve and finished

countertop surface.

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

Countertop

Silicon sealant

Figure 3

Figure 4

Figure 5

Weight (expressed in pounds) represents the total weight

of the insulated sleeve and the cooking unit and does not

include the permanent structure housing the sleeve.

The sleeve must be supported from the bottom.

Recommended cutout dimensions “A through C” include a

nominal clearance dimension to facilitate installation. Any

additional clearance must be within tolerances shown or

fit-up of sleeve and built-in structure may be adversely

affected.

All dimensions are to finished surfaces.

All dimensions are to finished surfaces.

Page 3

3

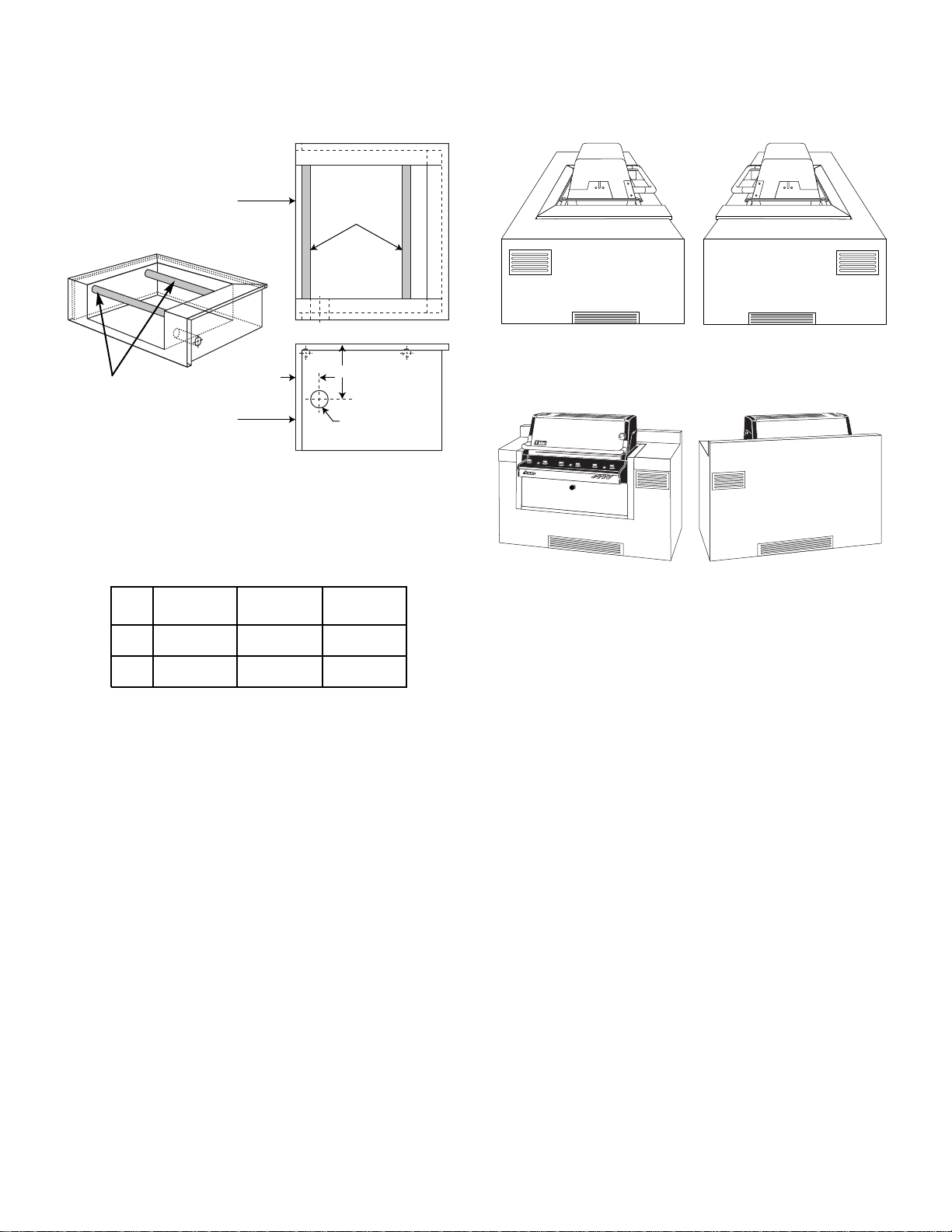

BUILT-IN SLEEVE GAS

LINE LOCATIONS

A

B

C

Support tubes

Front of sleeve

Front of sleeve

Plan view

Right side view

475 675 Tolerances

A 5.0” 5.0”

B 10.1” 10.1”

C 2.5” 2.5”

DIMENSIONS

+ 1⁄16

- 1⁄16

+ 1⁄16

- 1⁄16

+ 1⁄32

- 1⁄32

BUILT-IN SLEEVE GAS LINE

LOCATIONS

The dimensions shown indicate the location of the gas

line inlet flange in the insulated sleeve. The support

members of the built-in structure must not impede

passage of the gas lines.

Area should be kept clear of sharp, jagged, or extremely

abrasive surfaces to avoid possible damage to gas supply

lines. Exercise caution when pulling gas lines through

built-in structure.

Note: Leave an access in the structure for gas supply

and regulator service.

Figure 6

Support tubes

■ Cross ventilation must be incorporated in the

supporting structure. We recommend a minimum of

100 square inches of venting per side.

■ Vents should be on two sides of the structure.

Figures 5 and 6 are references only.

■ Location of the vents should be from the center,

outward.

■ Locate the vents at both the bottom of the structure

and at the top of the structure.

■ The bottom vents should be as close to ground level

as possible. Make sure the vent area is not blocked

by interior supports of the structure.

■ We recommend vents with screens.

■ Access doors to the structure are not considered vents.

■ Clean the vents periodically.

DANGER: Failure to follow recommended minimum

venting instructions can cause gas to collect in the

structure in the event of a gas leak.This may result in

a fire or an explosion which can cause serious bodily

injury or death, and damage to property.

Note:These drawings are only a reference.

VENTILATION

View of left side View of right side

View of front side View of back side

Figure 7

Figure 8

Page 4

4

TYPICAL GAS SUPPLY

INSTALLATION

Gas line piping

■ If the length of line required does not exceed 50 feet,

use a 5/8" O.D. tube. One size larger should be used

for lengths greater than 50 feet.

■ Gas piping may be copper tubing, type K or L;

polyethylene plastic tube, with a minimum wall

thickness of .062 inch; or standard weight (schedule

40) steel or wrought iron pipe.

■ Copper tubing must be tin-lined if the gas contains

more than 0.3 grams of hydrogen sulfide per 100 cubic

feet of gas.

■ Plastic tubing is suitable only for outdoor,

underground use.

■ Gas piping in contact with earth, or any other material

which may corrode the piping, must be protected

against corrosion in an approved manner.

■ Underground piping must have a minimum of 18" cover.

Test connections

All connections and joints must be thoroughly tested for

leaks in accordance with local codes and all listed

procedures in the latest edition of ANSI Z223.1.

DANGER

Do not use an open flame to check for gas

leaks. Be sure there are no sparks or open

flames in the area while you check for gas

leaks. This will result in a fire or explosion

which can cause serious bodily injury or death,

and damage to property.

WE RECOMMEND THAT THIS INSTALLATION BE

DONE BY A LICENSED PROFESSIONAL.

General Specifications for Piping

Note - Contact your local municipality for building

codes regulating outdoor gas barbecue installations.

In absence of Local Codes, you must conform to the

latest edition of ANSI Z223.1.

■ This barbecue is designed to operate at 4.5 inches of

water column pressure. Use only the regulator

supplied with the cooking module.

■ A manual shut-off valve must be installed outdoors,

and be accessible, not in the “built-in” structure. An

additional manual shut-off valve indoors should be

installed in the branch fuel line in an accessible

location near the supply line.

CAUTION: If young children are in the area, a locking

valve should be considered.

■ Pipe compound should be used which is resistant to the

action of natural gas when gas connections are made.

■ The gas connections must be firmly attached to rigid,

permanent construction.

The information provided in this manual is general for

typical installations.We cannot cover all possible

installation ideas.We recommend prior to installation

that you contact your municipality for local building

codes and your local fire department for installation

verification.You can also call Weber-Stephen

Products Co. at 1-888-33SUMMIT (1-888-337-8664) and

we will try and answer any questions you may have.

If you have any questions, contact the Weber-Stephen

Customer Service Center at 1-888-33-SUMMIT

(1-888-337-8664).

Page 5

5

BUILT-IN SIDE BURNER

For Summit Natural

Gas Cooking Modules

THIS ACCESSORY MAY BE PURCHASED SEPERATELY.

GENERAL INFORMATION

BUILT-IN CONSTRUCTION GENERAL INFORMATION

WARNING

A Weber-Stephen Products Co. insulated sleeve must be used for any built-in installation.

CLEARANCE FROM COMBUSTIBLE SURFACES OR

STRUCTURES

Warning: Clearance from the outside walls of the sides and

back of the sleeve must be a minimum of 24 inches from a

combustible surface. Measure from the outside wall of the

sleeve to the combustible surface. Figure 2. Refer to “Install

Gas Supply” on page 2 before starting installation.

Figure 2

Figure 1

CLEARANCE FROM NON-COMBUSTIBLE SURFACES OR

STRUCTURES

Warning: Clearance from the outside walls of the sides and

back of the sleeve must be a minimum of 6 inches from a

non-combustible surface. Measure from the outside wall of

the sleeve to the non-combustible surface. Figure 1. Refer to

“Install Gas Supply” on page 2 before starting installation.

COMBUSTIBLE SURFACE

24 inches

24 inches

24 inches

NON- COMBUSTIBLE SURFACE

6 inches

6 inches

6 inches

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

Countertop

Countertop

Insulated sleeve

Insulated sleeve

LOCA TING YOUR SIDE BURNER

When determining a suitable location for your side burner installation, give attention to concerns such as exposure to wind, proximity

to traffic paths, and keeping any gas supply lines as short as possible. Never locate the Weber Gas Side Burner in a garage,

breezeway, shed, under an unprotected overhang, or other enclosed area. Locate the side burner and structure so there is enough

room to safely evacuate the area in case of a fire.

THIS GAS APPLIANCE IS DESIGNED

FOR OUTDOOR USE ONLY.

Page 6

6

BUILT-IN STRUCTURE

CUTOUT DIMENSIONS

Side Burner Tolerances

A10

3

⁄

4”

B4

1

⁄

2”

C 24”

WT 40

DIMENSIONS

+ 3⁄16”

- 0

+ 3⁄32”

- 0

+ 3⁄16”

-0

BUILT-IN CUTOUT DIMENSIONS

BUILT-IN STRUCTURE

SLEEVE DIMENSIONS

Side burner Tolerances

A1019⁄32”

B4

9

⁄64”

C2325⁄32”

WT 40

DIMENSIONS

+ 1⁄4”

- 0

+ 1⁄8”

- 0

+ 1⁄4”

-0

BUILT-IN INSULATED SLEEVE

DIMENSIONS

Weight (expressed in pounds) represents the total weight

of the sleeve and the cooking unit and does not include

the permanent structure housing the sleeve.

Specified sleeve dimensions “A through C” reflect the

dimension to the mounting surface of the trim excluding

the overhang.

WARNING:Air holes must be provided in the structure

at the top and bottom to provide ventilation in the event

of a gas leak.

Air holes can be located in a low visibility area and should

be protected by screening material to prevent rodents and

insects from entering the structure. Air holes will also help

dry moisture.

If you are going to use a rotisserie with the cooking module,

make sure you space the side burner far enough away to

facilitate its use.

Before installing the sleeve, lay a bead of silicon sealant

around the top perimeter and front sides of the structure

in the areas that the flanges of the sleeve will rest. This

will prevent moisture seepage. The sealant you use must

have a temperature rating above 120°F. If necessary,

caulk between the flange of the sleeve and finished

countertop surface.

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

Countertop

Silicon sealant

Figure 3

Figure 4

Figure 5

Weight (expressed in pounds) represents the total weight

of the sleeve and the cooking unit and does not include

the permanent structure housing the sleeve.

The sleeve must be supported from the bottom.

Recommended cutout dimensions “A through C” include a

nominal clearance dimension to facilitate installation. Any

additional clearance must be within tolerances shown or fitup of sleeve and built-in structure may be adversely affected.

A

B

C

DEPTH

HEIGHT

WIDTH

All dimensions are to finished surfaces.

Page 7

7

BUILT-IN CONSTRUCTION GENERAL INFORMATION

WARNING

A Weber-Stephen Products Co. factory

installed sleeve must be used for any

built-in installation.

CLEARANCE FROM COMBUSTIBLE SURFACES OR

STRUCTURES

Warning: Clearance from the outside walls of the

sides and back of the sleeve must be a minimum of

24 inches from a combustible surface. Measure from

the outside wall of the sleeve to the combustible

surface. Figure 2. Refer to “Install Gas Supply”on

page 2 before starting installation.

Figure 2

Figure 1

LOCA TING Y OUR SIDE BURNER

When determining a suitable location for your side burner

installation, give attention to concerns such as exposure

to wind, proximity to traffic paths, and keeping any gas

supply lines as short as possible. Never locate the Weber

Gas Side Burner in a garage, breezeway, shed, under an

unprotected overhang, or other enclosed area. Locate the

side burner and structure so there is enough room to

safely evacuate the area in case of a fire.

CLEARANCE FROM NON-COMB

USTIBLE SURFACES

OR STRUCTURES

Warning: Clearance from the outside walls of the

sides and back of the sleeve must be a minimum of 6

inches from a non-combustible surface. Measure from

the outside wall of the sleeve to the non-combustible

surface. Figure 1. Refer to “Install Gas Supply”on

page 2 before starting installation.

COMBUSTIBLE SURFACE

24 inches

24 inches

24 inches

NON- COMBUSTIBLE SURFACE

6 inches

6 inches

6 inches

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

WARNING: All countertop finished surfaces must be

constructed of a noncombustible material.

Countertop

Countertop

Sleeve

Sleeve

Page 8

8

TYPICAL GAS SUPPLY

INSTALLATION

■ A manual shut-off valve must be installed outdoors,

and be accessible, not in the “built-in” structure. An

additional manual shut-off valve indoors should be

installed in the branch fuel line in an accessible

location near the supply line.

CAUTION: If young children are in the area, a locking

valve should be considered.

■ Pipe compound should be used which is resistant to the

action of natural gas when gas connections are made.

■ The gas connections must be firmly attached to rigid,

permanent construction.

The information provided in this manual is general

for typical installations.We cannot cover all possible

installation ideas.We recommend prior to installation

that you contact your municipality for local building

codes and your local fire department for installation

verification.You can also call Weber-Stephen Products

Co. at 1-888-33SUMMIT (1-888-337-8664) and we will try

and answer any questions you may have.

Gas line piping

■ If the length of line required does not exceed 50 feet,

use a 5/8" O.D. tube. One size larger should be used

for lengths greater than 50 feet.

■ Gas piping may be copper tubing, type K or L;

polyethylene plastic tube, with a minimum wall

thickness of .062 inch; or standard weight

(schedule 40) steel or wrought iron pipe.

■ Copper tubing must be tin-lined if the gas contains

more than 0.3 grams of hydrogen sulfide per 100 cubic

feet of gas.

■ Plastic tubing is suitable only for outdoor,

underground use.

■ Gas piping in contact with earth, or any other material

which may corrode the piping, must be protected

against corrosion in an approved manner.

■ Underground piping must have a minimum of 18" cover.

Test connections

All connections and joints must be thoroughly tested for

leaks in accordance with local codes and all listed

procedures in the latest edition of ANSI Z223.1.

DANGER

Do not use an open flame to check for gas

leaks. Be sure there are no sparks or open

flames in the area while you check for gas

leaks. This will result in a fire or explosion

which can cause serious bodily injury or death,

and damage to property.

WE RECOMMEND THAT THIS INSTALLATION BE

DONE BY A LICENSED PROFESSIONAL.

General Specifications for Piping

Note - Contact your local municipality for building

codes regulating outdoor gas barbecue installations.

In absence of Local Codes, you must conform to the

latest edition of ANSI Z223.1.

■ This barbecue is designed to operate at 4.5 inches of

water column pressure. Use only the regulator

supplied with the cooking module.

If you have any questions, contact the Weber-Stephen

Customer Service Center at 1-888-33-SUMMIT

(1-888-337-8664).

BUILT-IN SLEEVE GAS

LINE LOCATIONS

Side Burner Tolerances

A1

19

⁄32”

B8”

DIMENSIONS

+ 1⁄16

- 1⁄16

+ 1⁄16

- 1⁄16

BUILT-IN SLEEVE GAS LINE

LOCATIONS

The dimensions shown indicate the location of the gas line

inlet flange in the sleeve. The support members of the builtin structure must not impede passage of the gas lines.

Area should be kept clear of sharp, jagged, or extremely

abrasive surfaces to avoid possible damage to gas supply

lines. Exercise caution when pulling gas lines through

built-in structure.

Note: Leave an access in the structure for gas supply

and regulator service.

Figure 6

B

A

Loading...

Loading...