Page 1

WeatherHawk

Temperature Inversion System

Site Installation Manual

Page 2

Page 3

Table of Contents

1. Overview................................................................................1

1.1. Power Sources .........................................................................................1

1.2. Site Selection............................................................................................1

1.3. Communications Considerations ..............................................................2

1.3.1 Direct Communications....................................................................................... 2

1.3.1.1 Cable Lengths..................................................................................... 2

1.3.1.2 Grounding Issues................................................................................ 2

1.3.2. Wireless Communications.................................................................................. 2

1.3.2.1. Transmission Ranges ........................................................................ 3

1.3.2.2. Line-of-Sight....................................................................................... 3

1.3.2.3. Testing Radio Transmissions............................................................. 4

2. Installation Procedures.........................................................4

2.1. Inversion System on Pre-Installed 30-foot Tower/Pole .............................4

2.1.1 Mounting Sensors and Enclosure....................................................................... 5

2.1.2 Cable Connections.............................................................................................. 6

2.1.3. Grounding the System ....................................................................................... 7

2.2. Installing CM375 Mast with the Inversion System.....................................8

2.2.1. Assembling CM375 Mast Sections .................................................................... 9

2.2.2. Mounting Top Temperature Sensor and Wind Set Sensor.............................. 14

2.2.3. Lightning Rod Assembly .................................................................................. 15

2.2.4. Guy-Anchor Kit Installation............................................................................... 16

2.2.5. Raise, Plumb Mast ........................................................................................... 19

2.2.6. Mounting Equipment to Lower Part of Mast..................................................... 20

2.2.7. Cable Connections........................................................................................... 21

2.2.8. Grounding Rod Installation............................................................................... 22

3. Maintenance.......................................................................23

Appendix A. Separately Purchased Equipment ......................26

A.1. Communications Options .......................................................................26

A.1.1 USB-AD Serial-to-USB Adapter........................................................................ 26

A.1.2. RS485-KT Communications Module Kit.......................................................... 26

A.2. Power Supply Options............................................................................27

A.2.1. SP2-KT Solar Panel Kit ................................................................................... 27

A.2.2. ACP1 AC Converter......................................................................................... 27

A.3. Instrument Mounts and Mounting Hardware...........................................27

A.3.1 Grounding Kit (pn. 21660) ................................................................................ 27

A.3.2. CM375 10-Meter Mast..................................................................................... 28

A.3.3. Heavy-Duty Duckbill Anchor Kit (pn. 25699) ................................................... 28

A.3.4. Standard Anchor Kit (pn. 19282)..................................................................... 28

A.3.5. Guy Tensioning Kit (pn. 22071)....................................................................... 29

Page 4

Site Installation Guide

The WeatherHawk Temperature Inversion System is a meteorological platform designed for detecting the presence of

a surface temperature inversion. A temperature inversion occurs when temperature increases with height within the

lowest layer of the atmosphere (troposphere). This is called an inversion because normally within the troposphere,

temperature decreases with height. Temperature inversions can effect human-environment interaction in different

ways including agriculture, air quality, prescribed burns, and many others.

This guide includes procedures for installing your WeatherHawk Inversion system on a 30 foot tower for permanent

or portable installations. For permanent installations, use the WeatherHawk CM375 Mast with the Heavy Duty

Anchor Kit ( pn. 25699), UT30 Permanent Tower, or preinstalled user-supplied tower. For temporary installations,

use the WeatherHawk CM375 mast with the Standard Anchor Kit (pn. 19282) or a user-supplied temporary mast.

Before installing your WeatherHawk Inversion system read over the sections on power sources, site selection, and

communications considerations. Equipment that is purchased separately is described in Appendix A.

1. Overview

1.1. Power Sources

WeatherHawk Inversion systems are provided with an internal sealed rechargeable lead acid battery that must be

recharged to assure continued system function. To recharge the battery, WeatherHawk offers solar panels or an

AC/DC power converter. If no power supply has been ordered, you must provide an external DC power source with

an output of 18 V @ 1.2 A.

Connecting an incompatible power source to your WeatherHawk voids your Warranty. Please

check with WeatherHawk Customer Service before connecting a third party power source.

1.2. Site Selection

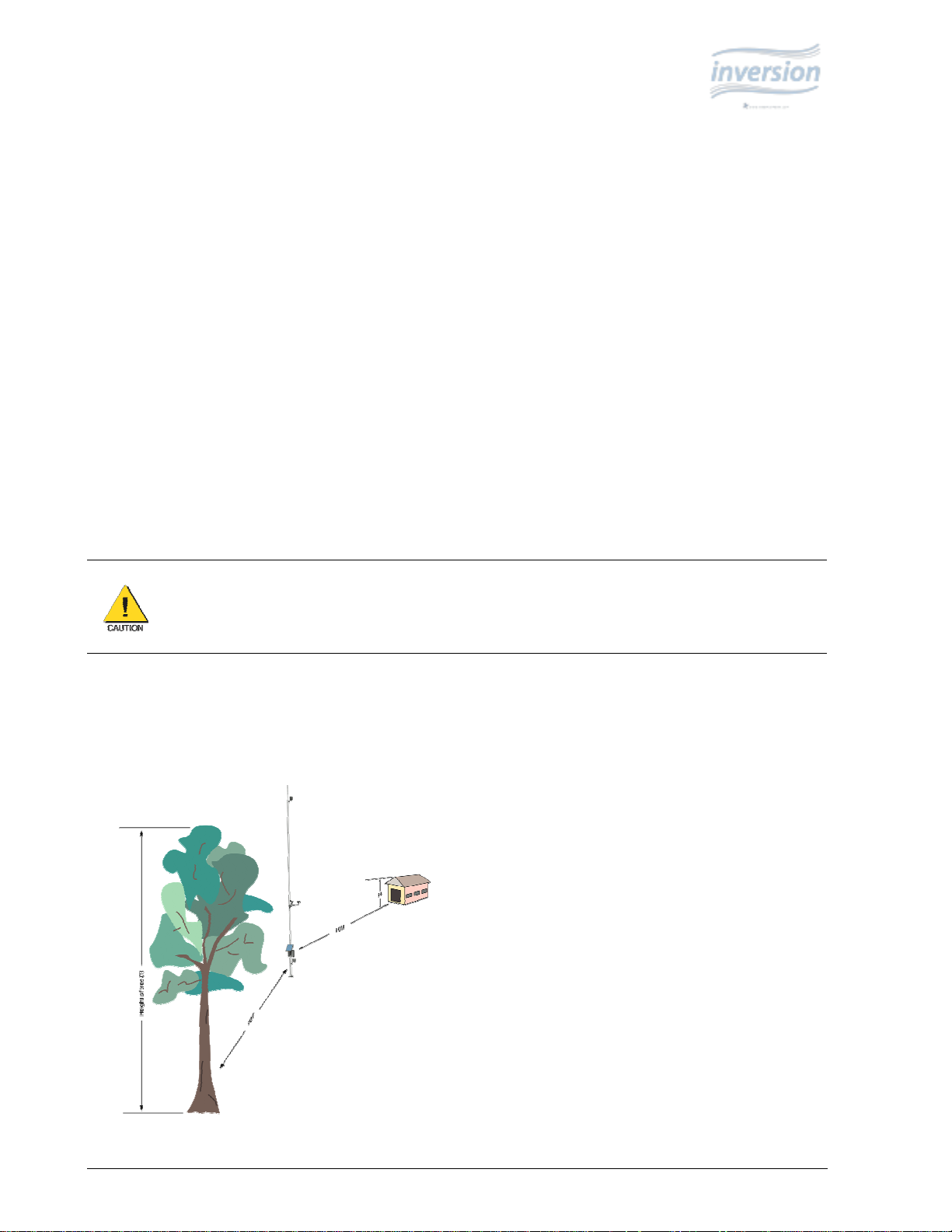

WeatherHawk Inversion systems are designed for installations on a 30-foot mast or tower. The ideal WeatherHawk

Inversion installation site is level and well away from obstructions such as buildings, trees and steep slopes. If

obstructions do exist, use the “Ten Times the Height Rule”, which is illustrated in Figure 1.

WeatherHawk ® 1

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Figure 1: Ten Times the Height Rule. n example, if the height of the

tree, T, is 37 feet and the height of the shed, H, is 24 feet then the

WeatherHawk station should be placed at least 370 feet from the tree

(i.e., 10T = 10 x 37 = 370 ft) and 240 feet away from the shed (i.e.,

10H = 10 x 24 = 240 ft).

Page 5

If your WeatherHawk station will be inside a fence to discourage vandalism, the fence top

edge must be lower than the wind sensors even if the fence is chain-link. .

1.3. Communications Considerations

WeatherHawk offers a variety of communication options for use with the WeatherHawk Temperature Inversion

System. The best communication option to use is dependent on the end user’s application and location resources.

The most common options used are direct RS232 or wireless, spread spectrum radio. Other communication options

are available for the Temperature Inversion System. For information on other communications options, contact

WeatherHawk Customer Service.

1.3.1. Direct Communications

Direct communications simply use an RS232 cable connected directly to the WeatherHawk and a host computer. If

direct communications are used, an optical isolation kit is recommended to help protect the host computer in case of a

lightning strike.

1.3.1.1. Cable Lengths

The maximum length for an RS232 cable is 75 feet. For cable lengths longer than 75 feet, use an MD485-KT

Communications Module Kit and a user-supplied CAT 5 cable, or a StrikeGuard fiber optic modem kit.

1.3.1.2. Grounding Issues

The tower or mast must be properly grounded to protect the WeatherHawk Inversion system and/or any connected

Host device or computer from electrical surges caused by lightning or other environmental sources. The Grounding

Kit (pn. 21660) includes the equipment required to properly ground the system. This kit consists of a lightning rod,

lightning rod bracket, U-bolt with matching nuts, grounding rod, ground wire, ground wire clamp, and locking nut.

The Grounding Kit is included with the CM375 mast and can also be purchased separately.

1.3.2. Wireless Communications

Wireless communications use a spread spectrum radio to transmit data between the WeatherHawk Inversion System

and a host computer over short distances. In order for the wireless communications to work properly, line-of-site

between the WeatherHawk and the radio receiver attached to the host computer must be present.

To minimize the possibility of equipment damage or personal hazard, we strongly recommend a

qualified electrician install the grounding and data isolation components of a directly wired

installation.

WeatherHawk ® 2

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 6

The ranges assume no obstructions are in the line

-of-

sight. Line

-of-

sight is defined and described below.

1.3.2.1. Transmission Ranges

Site your WeatherHawk within the spread spectrum radio transmission range. Typical line-of-sight (LOS)

transmission ranges are listed below:

• Standard WeatherHawk Antennas: up to ½ mile (0.8 km)

• Optional Higher Gain Antennas on Both the Weatherhawk Station and the Base Station: Up to 7

miles

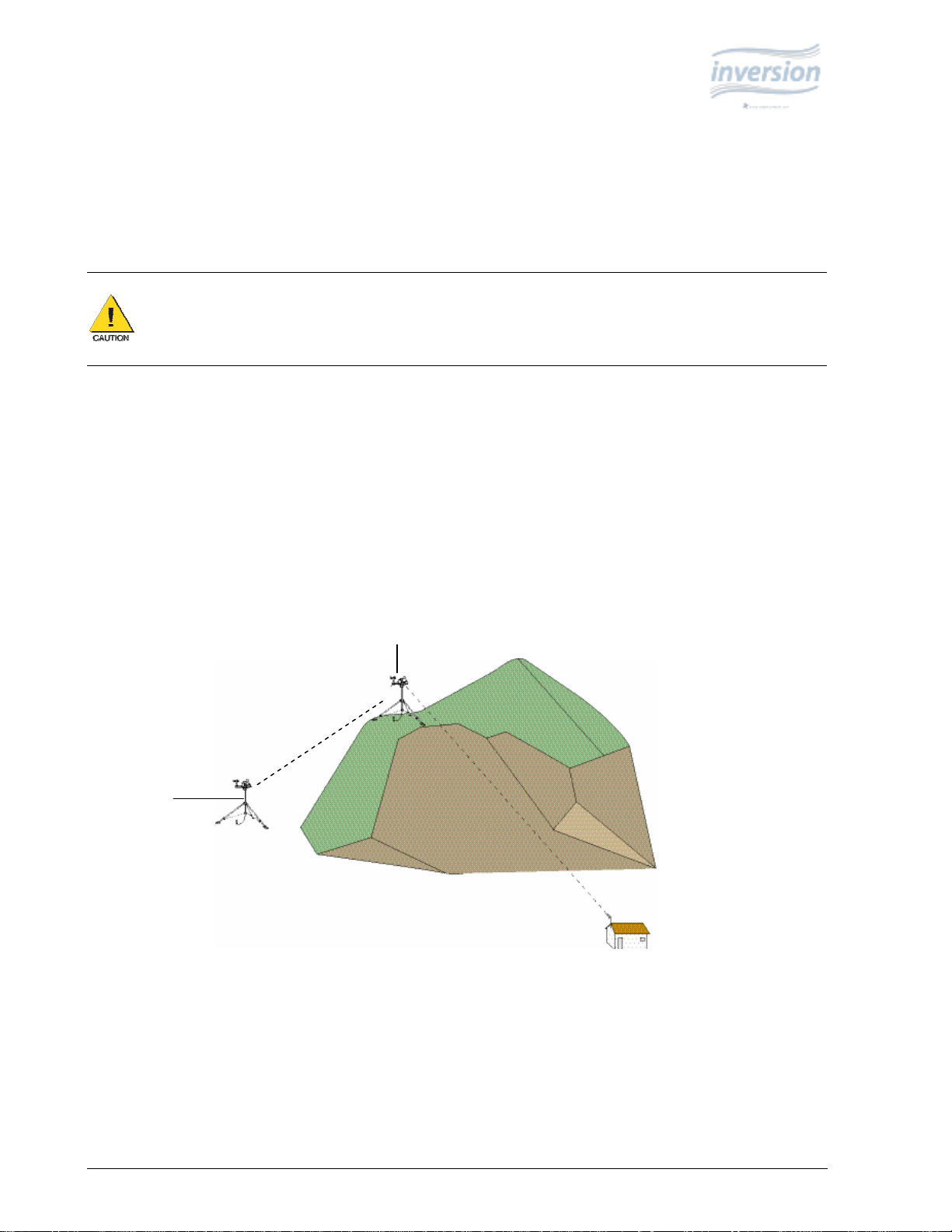

1.3.2.2. Line-of-Sight

Line-of-sight is defined as a straight path between a transmitting and receiving antenna that is unobstructed by

intermediate topography or obstructions (see Figure 2). A clear line-of-sight is required to achieve the optimum

transmission range.

The affect of obstructions on the transmission range can vary. Generally, trees, foliage, metal siding, and metal

roofing absorb or reflect radio frequency—reducing the direct transmission range of a WeatherHawk wireless system.

Wood frame and brick buildings affect the radio frequency less significantly. Sometimes, radio frequencies find an

indirect path by reflecting from the weather station to the base location. However, over-the-horizon sites must use

repeaters or antennas mounted high on a tall mast to get a clear line-of-sight.

Station 2

Station 1

Figure 2: Line-of-sight examples. As the dotted line indicates, Station 1 has a clear line-of-sight with the Computer

Site. The mountain obstructs Station 2's line-of-sight and would attenuate the RF signal or prevent the

communications completely. Station 1 can be used as a repeater for Station 2.

If obstructions lie within the line-of-sight, you should test radio transmission range before permanently installing your

WeatherHawk station (see Testing Radio Transmissions below).

WeatherHawk ® 3

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 7

1.3.2.3. Testing Radio Transmissions

Test the radio transmission of your WeatherHawk Inversion system by doing the following:

1. Connect your WeatherHawk Inversion System to the Host computer using the RS-232 cable or the RS-232

cable/USB adapter combination.

2. Initiate communications using WeatherHawk Inversion software. If the Inversion system is not properly

communicating with the computer, check the settings and connections. You can also contact WeatherHawk

Customer Service for help.

3. After establishing communications with the computer via the hard-wired connection, disconnect the cable from

the WeatherHawk and the host computer.

4. Initiate wireless communications between with the WeatherHawk and the host computer. If the Inversion system

is not properly communicating with the computer, check the settings and connections. You can also contact

WeatherHawk Customer Service for help.

5. After successfully establishing wireless communications in the office, move the WeatherHawk station to the field

site.

6. Initiate wireless communications with the WeatherHawk station using the Host computer. If the station is not

properly communicating with the computer, obstructions in the line-of-sight may be preventing communications.

If obstructions in the line of sight are preventing the WeatherHawk from communicating, try the following:

• Relocate your WeatherHawk away from obstructions.

• Remove the obstructions.

• Mount the computer base station antenna outside of the building by running the antenna cable through a

window or cable run.

• Use a higher gain antenna at the computer site.

• Install a higher gain antenna on the roof of the computer site’s building and align it above the obstructions.

If you experience problems with RF communications, you can contact WeatherHawk Customer

Service. To allow us to effectively help you, please be prepared to describe, in detail, your

installation and site conditions.

2. Installation Procedures

This document provides installation procedures for two standard configurations. Other configurations for the

WeatherHawk are possible. For questions about configurations not described in this document, contact

WeatherHawk Customer Service.

2.1. Inversion System on Pre-Installed Tower/Pole at Least

30-feet Tall

This procedure is for customers who are using a pre-existing tower or pole that is at least 30 feet tall. If the

tower/pole is not collapsible or foldable to ground level, a lift bucket will be required to mount the equipment at the

30 feet level. The user will need a cross-arm with which to mount the wind sensor on. The cross-arm should mount

perpendicular to the tower/pole, extend at least 3 feet away from the tower, and have a diameter of 1 inch. The user

will also need a grounding rod and cable with which to ground the system. A compass should be used to ensure

proper alignment of instrumentation. These items are available for purchase from WeatherHawk if needed.

WeatherHawk ® 4

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 8

If you are installing the CM375 mast at the same time as the Inversion System, go to Section 2.2.

The following tables list the equipment that is included with an inversion system for mounting on a pre-existing

tower/pole. It is advisable to inventory the system for completeness before beginning installation. Power supply

options are listed in Appendix A.

Inversion System Common Components

Equipment Description Part Number Quantity

Temperature Probe, Top 21414 1

Temperature/RH Probe, Bottom 21415 1

6-Plate Gill Solar Radiation Shield 4020 2

Lead Acid Battery, 12 Volt, 2.9 AHr 18860 1

Wind Sensor Set w/Mounting Hardware 21413 1

Cable Tie, Black, UV Resistant 17592 12

Direct Connect System Specific Components

Equipment Description Part # Qty

Enclosure Assembly – 232 21379 1

RS – 232 Optical Isolator, 9 – pin 21429 1

RS – 232 Optical Isolator Power

Supply

RS – 232 Data Cable 10873 1

21435 1

Wireless System Specific Components

Equipment Description Part # Qty

Enclosure Assembly – 916 21380 1

900MHz Spread Spectrum

Radio

900MHz Dipole Antenna 15970 1

Radio Power Adapter 15966 1

18102 1

The top temperature probe and the bottom temperature/RH probe should already be mounted inside the solar radiation

shields. The following table lists the hand tools necessary to install a WeatherHawk Temperature Inversion System.

½ inch wrench Compass

#2 Phillips Screwdriver Post Level

Small Wire Cutters Tape Measure

Hand Tools List

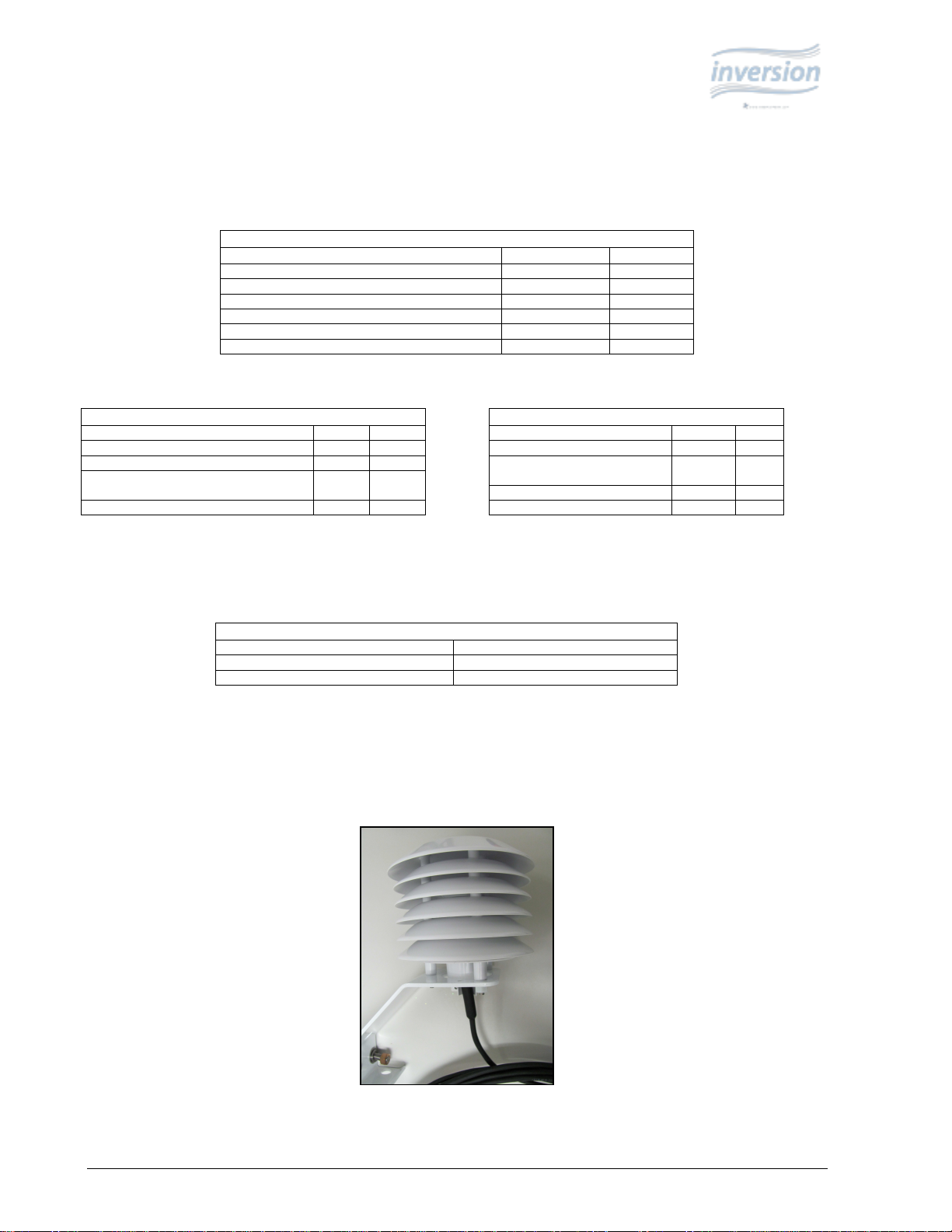

2.1.1. Mounting Sensors and Enclosure

1. Mount the top Temperature Sensor (pn. 21414) at a height of 30 feet on the south side of the tower/pole. Place the

provided U-bolt in the side holes of the radiation shield (see Figure 5) and tighten the nuts.

Figure 5: Temperature

radiation shield

(pn 21414).

WeatherHawk ® 5

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 9

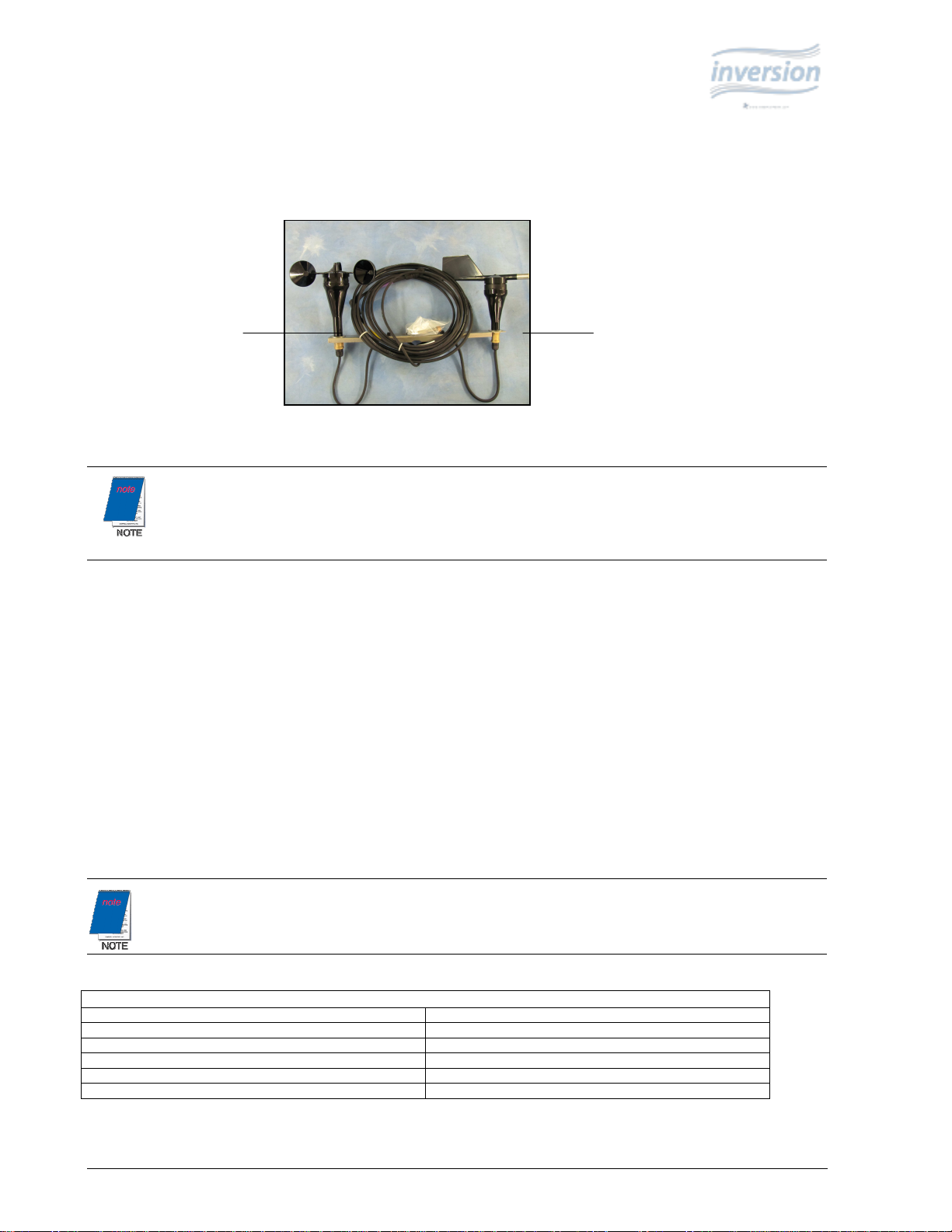

2. Mount the wind speed and direction sensors onto the crossarm using the provided U-bolts (see Figure 6). The

cross-arm should be mounted to the tower such that the wind sensors are at a height of 11 feet, on the south side

of the tower with the direction sensor to the west and the speed sensor to the east. There is a reference mark on

the wind direction sensor that should face north when mounted correctly.

Wind Speed Sensor

Wind Direction Sensor

Figure 6: Wind speed and direction sensors.

A compass is included in the Tensioning Kit (pn. 22071) to help you properly align the sensors. The

tensioning kit is purchased separately from WeatherHawk.

3. Secure the sensor cables to the mast using UV-tolerant plastic cable ties (supplied).

4. At a height of 3 feet , use the supplied U-bolt to mount the Temperature/RH sensor (pn. 21415), on the south side

of the tower/pole . The U-bolt is placed in the side holes of the radiation shield and then the nuts tightened.

5. Open the enclosure and retrieve the mounting U-bolts from the battery mounting bracket (wrapped in bubble

wrap). At a height of 4 feet, mount the enclosure to the tower/pole so that it’s facing NORTH.

6. If applicable, mount the solar panel to the mast using the provided U-bolts. The solar panel should be mounted 1

foot above the enclosure and facing SOUTH.

2.1.2. Cable Connections

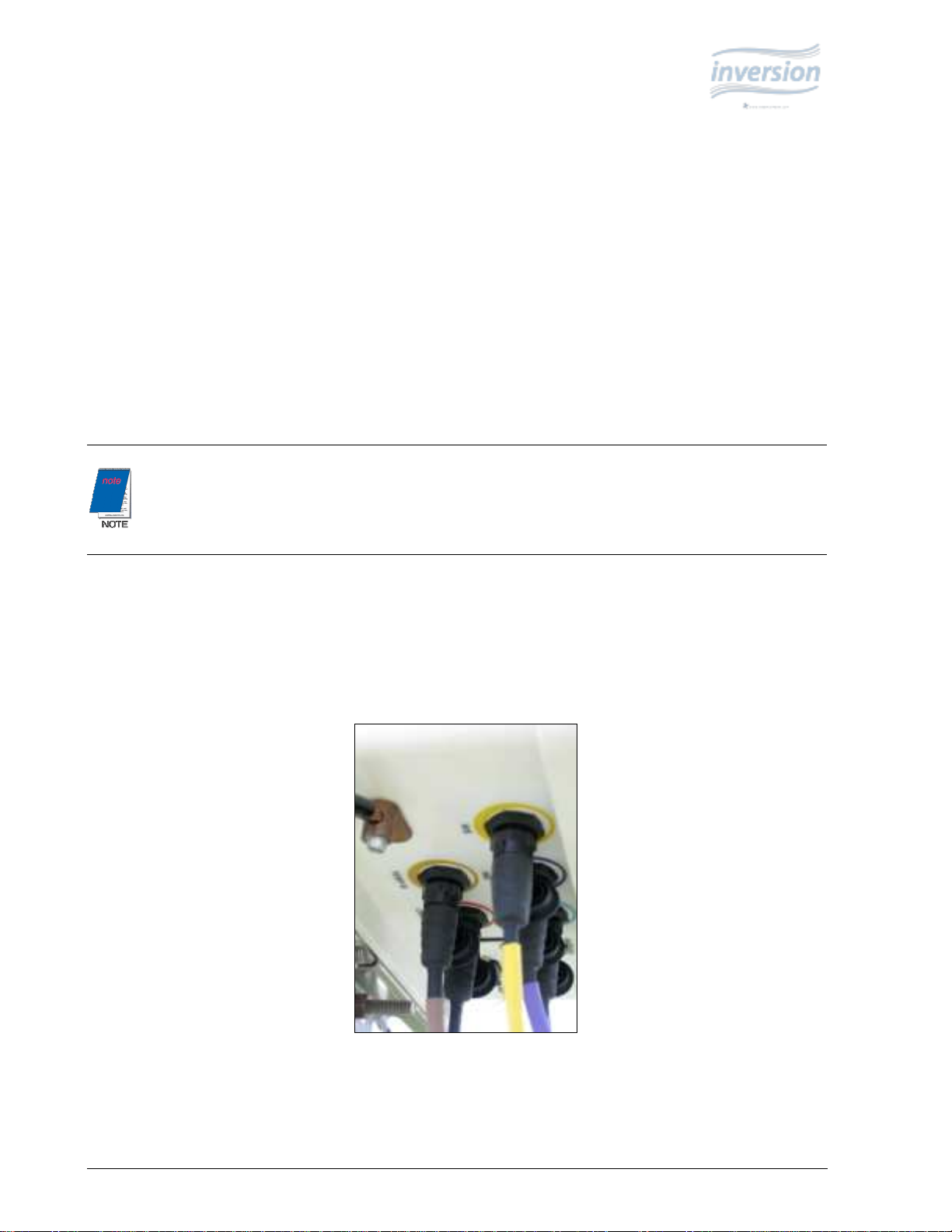

1. Connect the sensor cables to the underside of the enclosure (see Table 1).

WeatherHawk Inversion sensor cables and enclosure connectors are color coded to assist with correct

installation (see Table 1).

Table 1. Connections

Sensor/Device Color

21414 Top Temperature Sensor Blue

Lower Temperature/RH sensor Brown

Wind Direction Sensor Purple

Wind Speed Sensor Yellow

Power/Charge Red

WeatherHawk ® 6

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 10

2. Secure the sensor cables to the mast with the provided cable ties.

3. If your system is direct communications, attach the serial cable connector to the WeatherHawk 9-pin RS232

connector.

4. If your system is wireless, attach the antenna to the enclosure connector labeled ANTENNA (antenna is taped to

the inside of enclosure).

5. Open the enclosure and install battery on battery mounting bracket using strap to secure battery to bracket.

Remove plastic protective caps from battery posts and attach battery cables making sure to connect the red cable

to the red battery post and the black cable to the black battery post.

6. Attach the AC power converter or solar panel cable to the enclosure connector labeled CHARGE (Red).

7. Open the enclosure and turn the system power switch to the ON position, making sure the green light is

illuminated.

a. If using a serial connection, ensure that the serial port on host computer is not already assigned to

an open program.

b. Connection to a computer’s USB port is possible via the USB-AD serial-to-USB converter cable.

The USB-AD (pn. 16878) can be purchased separately from WeatherHawk.

2.1.3. Grounding the System

If not already present, drive ground rod into ground within 1 foot of tower and attach ground cable to rod.

1. Insert the grounding cable into the ground lug on the bottom of the system enclosure, and tighten the lug (see

Figure 8).

Figure 8: Ground Cable

connected to enclosure

ground lug (upper left).

WeatherHawk ® 7

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 11

2.2. Installing the CM375 Mast with the Inversion System

This procedure is for customers who are installing the CM375 30-foot mast at the same time as their inversion system.

Use Procedure 1 (instead of this procedure) if your CM375 mast has already been installed. The table below is a list of

hand tools necessary for installing the CM375 mast with the inversion system.

½ inch Wrench Compass

#2 Phillips Screwdriver Rubber Mallet

Small Wire Cutters Guy-wire Tension Tool

Tape Measure (25 ft) Post Level

Hand Tool List

The compass, guy-wire tension tool, and post level are included in the Tensioning Kit which can be purchased

separately from WeatherHawk.

The following tables list the equipment that is included with the WeatherHawk Inversion System. To ensure that all

equipment is present, and inventory should be conducted before beginning installation.

Inversion System Common Components

Equipment Description Part Number Quantity

Temperature Probe, Top 21414 1

Temperature/RH Probe, Bottom 21415 1

6-Plate Gill Solar Radiation Shield 4020 2

Lead Acid Battery, 12 Volt, 2.9 AHr 18860 1

Wind Sensor Set w/Mounting Hardware 21413 1

Cable Tie, Black, UV Resistant 17592 12

Direct Connect System Specific Components

Equipment Description Part # Qty

Enclosure Assembly – 232 21379 1

RS – 232 Optical Isolator, 9 – pin 21429 1

RS – 232 Optical Isolator

Power Supply

RS – 232 Data Cable 10873 1

21435 1

Description Qty Description Qty

Baseplate Assembly 1 Grounding cable w/hardware 1

Baseplate Stakes 4 Duckbilled anchor driver 1

Mast Extensions 5 Duckbilled anchor w/cables 3

Mast Extension Couplers 3 Guy wire set, short 1

Mast Hardware 8 sets Guy wire set, long 1

Lightning Rod with bracket 1 Turnbuckles 6

Cross-arm w/mounting hardware 1 Ground Rod 1

CM375 Mast Assembly

The top temperature probe and bottom temperature/RH probe should already be housed in the 6-plate solar radiation

shield. The mast extension couplers should already be installed on the proper mast extensions.

Wireless System Specific Components

Equipment Description Part # Qty

Enclosure Assembly – 916 21380 1

900MHz Spread Spectrum

Radio

900MHz Dipole Antenna 15970 1

Radio Power Adapter 15966 1

18102 1

WeatherHawk ® 8

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 12

2.2.1. Assembling CM375 Mast Sections

1. Remove mast sections and other bundled hardware from the tote (see Figure 9).

The crossarm-to-pole

mounting kit (pn. 21669)

contains the lightning rod,

copper grounding rod, and

duckbill anchor drive rod.

2. Place Mast Section 1 at the site location with the base oriented as shown in Figure 11, and with the mast aligned

NORTH/SOUTH.

Sections are numbered for sequential assembly (see Figure 10).

Base

Figure 11: Mast Section 1

Oriented on Base

Figure 9: CM375 Tote (pn. 21720)

Figure 10: Mast Sections and Base

WeatherHawk ® 9

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 13

3. Use the provided spikes (three each) to secure the base to the ground (see Figure 12).

A compass is included in the Tensioning Kit (pn. 22071) to help you properly align the sensors. The

tensioning kit is purchased separately from WeatherHawk.

Figure 12: Spikes Installation

4. Insert the coupler from Mast Section 2 into the top of Mast Section 1 (see Figure 13).

Figure 13: Coupler Installed in Top of Mast Section 1

WeatherHawk ® 10

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 14

5. Secure the coupler joint using two flat washers, two lock washers and two bolts from the hardware bag (see

Figure 14)

Figure 14: Bag

Containing Hardware

6. Place Mast Section 3 near the top of Mast Section 2 (see Figure 15).

The BLACK tape around Mast Section 2 is a reference indicator (11 foot level) for wind set sensor mounts.

7. Remove the collars from Mast Section 3 and place them next to the mounting holes in Mast Section 2 (see

Figures 15 and 16).

Figure 15: Mast Section 2 and Mast Section 3

Figure 16: Guy Ring, Mast Section 2, and Mast Section 3

WeatherHawk ® 11

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 15

8. Remove the guy ring from the bottom guy kit (pn. 21663); see Figures 16 and 17.

9. Insert the ball end of each guy cable into its slot in the guy ring, and place the coupler of Mast Section 3 into the

guy ring (see Figure 18).

10. Slide the coupler into Mast Section 2, and assemble the collars as shown in Figure 19.

Only one of three cables is shown.

Figure 19: Mast Section 3 and Guy Ring/Collar Assembly

Figure 17: Bottom Guy Kit (pn. 21663)

Figure 18: Guy Cables Inserted into Guy Ring

WeatherHawk ® 12

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 16

11. Slide the coupler end of Mast Section 4 into the top of Mast Section 3, and fasten with the remaining components

from hardware bag (see Figure 20).

Figure 20: Mast Section 4 Ready to Be Installed in Mast Section 3

12. Remove the collars from Mast Section 5 (see Figure 21).

Figure 21: Mast Section 5

13. Slide mast into Section 4 and assemble the collars as shown in Figure 22.

Figure 22: Mast Section 5 Installed in Mast Section 4

WeatherHawk ® 13

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 17

14. Remove the guy collar from the top guy kit (pn. 21661); see Figure 23.

15. Insert the ball ends of the guy cable into the guy ring, and then slide the ring down the mast to the collar (see

Figure 24).

Figure 23: 21661 Guy Kit

Figure 24: Mast Section 5 and Guy Ring/Collar Assembly

2.2.2. Mounting Top Temperature Sensor and Wind Set Sensor

1. Mount the top Temperature Sensor (pn. 21414) 10 inches from the top of Mast Section 5. Place the provided Ubolt in the side holes of the radiation shield and tighten the nuts.

WeatherHawk ® 14

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 18

2. Mount the wind speed and direction sensors onto the crossarm using the provided U-bolt (see Figure 25).

3. Use the supplied U-bolts and mounting hardware to attach the crossarm to the mast. The cross-arm should be

mounted such that the cross-arm is perpendicular to the mast at a height of 11 feet on the mast. The wind sensors

should be oriented such that they are on the south side of the mast when upright, and the directions sensor

reference mark is facing due north. Black masking tape on Mast Section 2 indicate the proper location for the

crossarm.

Figure 25: Wind speed and direction sensors.

Be sure to run guy wires under the crossarm.

4. Secure the cables to the mast using UV-tolerant plastic tie wraps (supplied).

2.2.3. Lightning Rod Assembly

1. Retrieve the lightning rod clamp, lightning rod, U-bolt, and nuts from the Grounding Kit (pn. 21660);

see Figure 26.

Figure 26: Lightning Rod Assembly

WeatherHawk ® 15

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 19

2. Mount the lightning rod clamp onto the top of Mast Section 5 using the U-bolt and nuts (see Figure 27).

3. Insert the lightning rod into the clamp and tighten the screws (see Figure 27).

Figure27: Installed Lightning Rod

2.2.4. Guy-Anchor Kit Installation

A choice of duckbill anchor kits is offered for the CM375. The Duckbill Standard Anchor Kit (pn. 19282) is for

standard soils, and the Duckbill Heavy Duty Anchor Kit (pn. 25699) is for aggressive soils. Aggressive soils have:

• Resistivity of less than 3000 ohm-cm

• pH of less than 5

• Chloride of greater than 1000 ppm

• Sulfate of greater than 500 ppm

• Poor aeration

Both anchor kits have one drive rod. The Standard Duckbill Anchor Kit has three duckbill anchors with a cable

attached to each of them. At the end of the cable is a loop for connecting the guy wires. The Heavy-Duty Duckbill

Anchor Kit has a threaded rod attached to each of the three duckbill anchors instead of the cable. At the end of the

threaded rod is a metal ring for connecting the guy wires.

1. For the SOUTH anchor, place the tape measure in the base slot centering the tape in the notch on the edge of the

base. Locate a point 20 feet from the mast base (see Figure 28).

Figure 28: Tape Measure in Slot for South Anchor

WeatherHawk ® 16

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 20

NE

Drive Bar

2. At 20 feet, install the duckbill anchor with the supplied drive rod. The anchor needs to be driven into the ground

at a 45° angle (see Figure 29). Drive the anchor into the soil until the loop or metal ring is approximately 4

inches above the ground.

3. With a rod through the loop or metal ring, pull up on the cable or threaded rod until the anchor rotates and locks

(see Figure 30).

Duckbill Anchor

o

60

UTDUK

Figure 29: Anchor Driven into Ground at 45° Angle.

(towers)

Figure 30: Locking Anchor

4. Fill-in the hole around the cable or threaded rod with loose dirt and tap firm.

5. Repeat process for the northeast (see Figure 31) and northwest anchors.

Figure 31: Tape Measure in slot

for North East Anchor

WeatherHawk ® 17

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 21

6. Attach guy wires to anchors by first opening the turnbuckle to the widest setting. Attach turnbuckle to wedge

end of the guy cable, and then attach the other end of the turnbuckle to an anchor (see Figure 32).

Guy Cable Wedge

7. If using a rope ratchet to assist assembly, set to 7 feet and attach to tension clamp on cable and to anchor end. Do

this for both NE and NW anchors and top bottom guy cables.

8. Course adjustments to cable length are made by loosening screw clamp and then releasing wedge with a flatbladed screwdriver. This allows the cable to be adjusted through the wedge clamp (see Figure 33).

Do not connect the SOUTH cables at this time.

Figure 32: Turnbuckle Fastened to Guy Cable and Anchor.

Open turnbuckle to widest setting Anchor

Retighten screw when adjustment is complete.

Figure 33: Adjusting Cable through Wedge Clamp

WeatherHawk ® 18

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 22

2.2.5. Raise and Plumb the Mast

1. With NW and NE cables attached to anchors, have one person lift the mast, while another person pulls on the

SOUTH cables to bring the mast to an upright position (see Figure 34). If using rope ratchets, adjust them to

allow further steps.

2. Attach the SOUTH cables to the anchor. While one person holds onto the mast and uses the post level, the

second person can adjust each of the bottom guy cable wedge clamps—maintaining level in all directions (see

Figure 35). The rope ratchet can be used to temporarily remove the load from the wedge assembly during wedge

adjustments.

Figure 35: Pole

Level Ensures

Vertical Mast.

3. Repeat the process with the top guy cables to establish a straight mast.

4. Apply fine tensioning adjustments using the turnbuckles (see Figure 36).

Figure 36: Adjusting

Turnbuckles.

Figure 34: Raising the Mast.

WeatherHawk ® 19

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 23

5. Adjust each cable turnbuckle to maintain plumb and increase cable tension. A deflection of 3 inches (when using

a 4.4 pound (2N) perpendicular force 68 inches from the duckbill anchor loop) equates to 100 pounds of tension

in the cables (see Figure 37).

Figure 37: Guy Cables with 100 lbs of Tension.

6. After tensioning the top guy cables, recheck the bottom guy cables. Adjust as necessary.

2.2.6. Mounting Equipment to Lower Part of Mast

1. Use the U-bolt to mount the Temperature/RH sensor (pn. 21415) onto Mast Section 1. Mount the sensor so that

it’s facing SOUTH at a height of 3 feet (see Figure 38).

2. Open the system enclosure and remove the mounting U-bolts (wrapped in bubble wrap) from the battery

mounting bracket. Mount the enclosure to Mast Section 1, so that it’s facing NORTH at a height of 4 feet

(see Figure 38).

Figure 38: Temperature

and RH sensor and

enclosure mounted to

CM375 Mast.

WeatherHawk ® 20

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 24

3. Open the enclosure and install battery on battery mounting bracket using strap to secure battery to bracket.

Remove plastic protective caps from battery posts and attach battery cables making sure to connect the red cable

to the red battery post and the black cable to the black battery post.

4. If applicable, mount the solar panel to Mast Section 1 using the provided U-bolts. The solar panel should be

mounted 1 foot above the enclosure and facing SOUTH.

2.2.7. Cable Connections

1. Connect the sensor cables to the underside of the enclosure (see Table 2).

2. Secure the cables to Mast Section 1 with the provided cable ties.

3. If your system is direct connect, attach the serial cable connector to the WeatherHawk 9-pin RS232 connector.

4. If your system is wireless, attach the antenna to the enclosure connector labeled ANTENNA.

5. Attach the AC Power Converter or solar panel cable to the enclosure connector labeled CHARGE (Red).

6. Open the enclosure and turn the system power switch to the ON position, making sure the green light is

illuminated.

WeatherHawk Inversion sensor cables and enclosure connectors are color coded to assist with correct

installation (see Table 2).

Sensor/Device Color

Table 2. Connections

21414 Top Temperature Sensor Blue

Lower Temperature/RH sensor Brown

Wind Direction Sensor Purple

Wind Speed Sensor Yellow

Power/Charge Red

a. If using a serial connection, ensure that the serial port is not already assigned to an open

program.

b. Connection to a computer’s USB port is possible via the USB-AD serial-to-USB converter cable.

The USB-AD (pn. 16878) can be purchased separately from WeatherHawk.

WeatherHawk ® 21

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 25

2.2.8. Grounding Rod Installation

1. Retrieve the grounding rod, ground wire, ground wire clamp, and locking nut from the grounding kit.

2. Within 1 foot of the base, drive the copper grounding rod into the ground (see Figure 39).

3. Fasten the grounding cable to the grounding rod using with the locking nut (see Figure 39).

4. Insert the grounding cable to the ground lug on the underside of the enclosure, and tighten the lug

Leave approximately 5 inches of the rod above the ground.

Figure 39: Grounding Rod Driven into Ground

with Grounding Cable Secured

(see Figure 40).

Figure 40: Grounding

cable fastened to the

ground lug (top left).

WeatherHawk ® 22

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 26

3. Maintenance

In order to ensure continued optimal operation, routine maintenance should be performed by the user on the

WeatherHawk Inveriosn System.

The following tasks should be performed on a monthly basis for permanently installed stations.

1. Inspect the mast base

• Check base for damage, cracks, corrosion, etc.

o If the base is damaged in any way, repair or replace the base immediately

• Ensure base is securely attached to ground

o The stakes holding the base to the ground may become loose for a number of reasons including:

freezing and thawing of the ground, heavy rains, strong winds, etc. If the base is not securely

attached to the ground, secure it immediately

2. Inspect mast assembly

• Check mast assembly for damage, corrosion, etc.

• Ensure mast is plumb

o Use a post level to ensure that the mast is plumb

• Check security/tightness of mast section couplers

o Check each individual bolt holding mast sections together for tightness and tighten all loose bolts

3. Inspect guy wires

• Ensure anchors are secure

o Tighten any loose components

• Inspect guy wires, turnbuckles, and wedge ends for damage, corrosion, etc.

o Repair or replace any damaged components

• Check tension of guy wires

o Tighten/loosen any guy wires not within specifications

4. Inspect vegetation around station

• Ensure vegetation is not growing into system sensors or enclosure

o Cut vegetation as necessary

The following tasks should be performed on a quarterly basis for permanently installed stations

1. Inspect lightning rod

• Check lightning rod for damage and corrosion

o Replace any damaged components

• Ensure lightning rod is securely fastened to top of mast

o Tighten any loose connections

WeatherHawk ® 23

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 27

2. Inspect top temperature sensor and radiation shield

• Remove temperature sensor from radiation shield and inspect sensor for visible damage

o Replace any damaged sensors

• Inspect radiation shield for damage, debris, insects, and spider nests

o Replace any damaged shields. Remove any foreign objects from shield and clean shield

• Once radiation shield is clean, replace top temperature sensor

• Ensure radiation shield is securely mounted to mast

3. Inspect wind sensors

• Check wind speed sensor for damage

• Check wind direction sensor for damage

• Ensure sensors are securely mounted to crossarm

• Ensure crossarm is securely mounted to mast

• Ensure crossarm is level

4. Inspect bottom temperature/RH sensor and radiation shield

• Remove temperature/RH sensor from radiation shield and inspect sensor for visible damage

• Inspect radiation shield for damage, debris, insects, and spider nests

• Once radiation shield is clean, replace temperature/RH sensor

• Ensure radiation shield is securely mounted to mast

Do not spray insect/spider killer inside radiation shield while temperature sensor is housed inside

shield. Contact with these chemicals could damage temperature sensor.

o Check wind speed sensor for smooth turning operation

o Listen for any grinding noise while speed sensor is turning

o Check wind direction sensor for 360° of smooth operation

o Ensure reference mark is facing north

o Replace any damaged sensors

o Replace any damaged shields. Remove any foreign objects from shield and clean shield

Do not spray insect/spider killer inside radiation shield while temperature/RH sensor is housed inside

shield. Contact with these chemicals could damage temperature/RH sensor.

WeatherHawk ® 24

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 28

5. Inspect system enclosure

• Check outside of system enclosure for damage and corrosion

o Clean outside of enclosure

• Open system enclosure and check for insects and spiders

o Remove any insects or spiders

• Visually inspect wires/cables inside enclosure for frays and breaks

• Ensure battery is secured to mounting bracket with strap

o Tighten battery strap if loose

• Ensure enclosure is securely mounted to mast

o Tighten any loose nuts/bolts

6. Inspect solar panel (if equipped)

• Inspect solar panel for damage, corrosion, and cleanliness

7. Inspect all sensor, power, and communication cables

• Inspect all system cables for breaks and frays

• Ensure all cables are secured to mast using cable ties

For systems that are used for temporary installations, all maintenance procedures should be performed between

deployments or according to the above schedule if deployment time is greater than one month.

Do not spray insect/spider killer inside enclosure. Contact with these chemicals will damage

electronic components inside system enclosure.

o Replace any damaged panels

o Clean panels if necessary

o Repair or replace any damaged cables

o Secure any loose cables to mast using cable ties

WeatherHawk ® 25

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 29

Appendix A. Separately Purchased Equipment

The following equipment can be used with the WeatherHawk Inversion System, but is purchased separately. This

equipment can be ordered on-line at www.weatherhawk.com. Contact WeatherHawk Customer Service for questions

concerning the equipment.

A.1. Communications Options

A.1.1 USB-AD Serial-to-USB Adapter (pn. 16878)

The USB-AD Serial-to-USB Adapter allows the WeatherHawk station to be connected to the USB port on a

computer. It is required for newer laptops or PCs that do not have a 9-pin RS-232 port. The USB-AD supports data

rates up to 230 kbps.

The USB-AD includes:

• Universal Serial Bus (USB) Converter with a 1 m cable

•

Driver Software from the manufacturer (FTDI Chip): The driver software runs on Windows

98/98SE/ME/2000/XP and Linux operating systems. The WeatherHawk Inversion XP/X software CD

includes this software. It is also available from: www.ftdichip.com

A.1.2. RS485-KT Communications Module Kit (pn. 16685-5)

The RS485-KT is a wired communication option that allows the distance between the WeatherHawk Inversion 232

weather station and a host computer (PC) to be up to 4,000 feet (1300 m). A user-supplied CAT5 cable is required to

connect the WeatherHawk to the host computer. Each end of the CAT5 cable must terminate in RJ-11 connectors.

The RS485-KT includes:

•

•

• RS485 interface module for the WeatherHawk weather station

This product is commercially produced and may not always be available in this specific configuration.

WeatherHawk may substitute a part of equal or greater value if this device is discontinued by the

manufacturer.

Opto-isolated RS485 interface module for the Host PC

Power supply for the RS485 module located at the Host PC

The RS485 module for the WeatherHawk is not weatherproof and must be housed in a non-condensing

environment within 50 feet of the WeatherHawk station, or in a weatherproof enclosure at the

WeatherHawk station.

WeatherHawk ® 26

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 30

A.2. Power Supply Options

A.2.1. SP2-KT Solar Panel Kit (pn. 16851)

The SP2-KT is a solar panel kit for recharging the internal battery. It has a 72 inch2 surface area and produces 5 W of

power at a peak of 17.1 V. The SP2-KT includes:

•

5 W solar panel

•

Mounting hardware

A.2.2. ACP1 AC Converter (pn. 18863)

The ACP1 recharges the WeatherHawk battery by converting 110-220 VAC, 50/60 Hz power to 18 VDC. It must be

housed in a non-condensing environment or a weatherproof enclosure. The ACP1 includes:

• UL-approved, AC/DC converter with US Standard plug prongs 20 feet (6.2 m)

•

UV resistant waterproof cable with an environmental connector for connecting to the WeatherHawk station.

A.3. Instrument Mounts and Mounting Hardware

A.3.1. Grounding Kit (pn. 21660)

The Grounding Kit provides the equipment required to properly ground the system. It is included with the CM375

mast, but can also be purchased separately for preinstalled towers or masts. This kit consists of:

• Lightning rod

• Lightning rod bracket

• U-bolt with matching nuts

• Copper grounding rod

• Ground wire

• Ground wire clamp

• Locking nut

WeatherHawk ® 27

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 31

A.3.2. CM375 10-Meter Mast (pn. 21722)

The CM375 10-meter Mast can be used for either permanent or temporary installations. It comes with five 6-foot

galvanized pipes, a stainless-steel base, guy cables, a 1 m crossarm, and a mounting bracket. A duck-bill anchor kit

(required) and the guy-wire tensioning kit (recommended) are ordered separately; see below. An 80-inch-long bag is

included with the CM375; all of the CM375's components fit inside the bag allowing the CM375 to be carried from

site to site.

A.3.3. Heavy-Duty Duckbill Anchor Kit (pn. 25699)

The Heavy-Duty Duckbill Anchor Kit is one of the two kits offered by WeatherHawk; an anchor kit is required when

using the CM375. The heavy-duty anchor kit is used for permanent installations and is also recommended for areas

with aggressive soils. It consists of:

• Three duckbill anchors

• Three threaded rods (attached to each duckbill anchor)

• One driver rod (used to drive the duckbill anchors into the soil)

A.3.4. Standard Duckbill Anchor Kit (pn. 19282)

The Standard Duckbill Anchor Kit is one of the two kits offered by WeatherHawk; an anchor kit is required when

using the CM375. The standard anchor kit is used for temporary installations located in areas with standard soils. It

consists of:

• Three duckbill anchors

• Three cables (attached to each duckbill anchor)

• One driver rod (used to drive the duckbill anchors into the soil)

Anchor Cable

Figure 41: The drive rod (right) is included

with both the standard and heavy duty

anchor kits. A duckbill anchor and anchor

cable from the Standard Anchor Kit is

shown at left. The heavy duty anchor kit

includes a threaded rod instead of the cable.

Anchor

WeatherHawk ® 28

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Page 32

A.3.5. Guy Tensioning Kit (pn. 22071)

The Guy Tensioning Kit provides equipment that helps you install the WeatherHawk to the correct three-axis vertical

orientation and to align the station to the magnetic North. Using this kit to properly orient the weather station helps

assure accurate measurements. The tension Kit consists of:

• One TP1-TK Tripod Installation Kit (includes multi-axis bubble level, compass, and rubber band for attaching

the bubble level to the mast)

• Three Ratchet Tie Downs

• One Guy Cable Tensiometer

WeatherHawk ® 29

815 W. 1800 N. Logan, Utah 84321-1784, Email: service@weatherhawk.com Copyright © 2004, 2010

Toll free in USA: 866-670-5982, International: 435-750-1802, FAX: 435-750-1749 Printed November 2010

Loading...

Loading...