Page 1

WINDLOAD RATED

DS-350 COMMERCIAL ROLL-UP DOORS

INSTALLATION INSTRUCTIONS

IMPORTANT NOTICE!!

Read the enclosed instructions carefully before attempting to install this door. Pay close

attention to all warnings and important safety notices.

This manual MUST be attached to the wall in close proximity of the door.

©Copyright 2002 Wayne-Dalton Corp.

P/N 291341, DOC #101-0093-1 REV 02

Page 2

CAUTION

CAUTION

IMPORTANT!

HINT:

NOTE:

IMPORTANT SAFETY NOTICES

Read the enclosed instructions carefully before attempting installation. If there are any

questions about any of the procedures, do not perform the work. Instead, have a qualified

door agency do the installation or repairs.

1. Operate the door ONLY when it is properly adjusted and free of all obstructions.

2. The door is constantly under EXTREME SPRING TENSION. Repairs, adjustments, installation and

removal, ESPECIALLY of SPRINGS AND RELATED PARTS, are dangerous so that such work should

be performed ONLY by qualified door service people.

3. DO NOT PERMIT children to play with the door. Children could get caught between the door and the

floor causing severe injury or death.

4. Avoid standing in the open doorway or walking through the doorway while the door is moving. One could

get caught between the door and the floor causing severe injury or death.

5. Should the door become hard to operate or completely inoperative, it is recommended that a qualified door

agency correct the problem to prevent possible injuries or door damage.

6. Avoid installing the door on windy days. The door could fall causing door damage or injury.

7. To prevent injuries due to loose components, at least monthly check all bolted connections to make sure they

are secure.

8. To prevent injuries, never place hands or fingers between the curtain and the guides while the door is being

operated.

9. This manual is not intended to provide "take-down" instructions for existing doors. Consult your local door

agency if this is required, before new doors are to be installed.

10. Thoroughly familiarize yourself with the construction codes in your region before initiating work.

11. Wear the proper protective safety gear at all times when installing, adjusting, and/or repairing doors.

12. Consider using a 2-person (or larger) crew for installing, adjusting and/or repairing larger doors.

13. To prevent injury or death due to falling, use scaffolding or mechanical lifts, rather than ladders, when

installing, adjusting, and/or repairing larger doors.

14. Definitions of key words used in this manual are as follows:

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

WARNING indicates a potential hazardous situation which, if

WARNING

NOTE: indicates information assuring proper installation of the door.

HINT: indicates a suggested step to simplify installation based on experience.

not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

IMPORTANT! indicates a required step for safe and proper

door operation.

2

Page 3

INTRODUCTION

This manual's main function is to assist the installer in correctly mounting doors with due regard for safety,

operation, and sound construction practices. Reference must be made to construction codes in your area.

All Wayne-Dalton DS-350 Windload Rated Commercial Roll-Up Doors follow the general instructions contained

herein. Additional installation information for the specific door shipped is found with the packing slip and on

supplementary drawings. There are also bolt and small sealed parts bags with accessory lists, describing proper

application.

PREPARATION

Read the installation instructions thoroughly to become familiar with the names of the various components and their

relation to each other. It is necessary for the installer to determine the following:

Method of operation (push-up, hand chain, or motor operated).

Type of jamb (masonry or steel) on which the door mounting angles mount and the fasteners required.

The dimensions for the opening width, opening height, headroom, and side room.

MATERIAL

Inspect your door for possible damage or shortage of parts. Report any shortages to your door supplier immediately,

or transit related damage claims to your freight carrier.

CLEARANCES

Check the door opening dimensions and available clearances versus the dimensions listed on the packing slip. Be

sure that the dimensions are correct for the opening you are working on, taking special note of the opening width

and height. Be sure that the required clearances listed on the Dimension Tables in this manual are available prior to

installation.

TOOLS

The tools recommended for proper installation of each door will vary, but commonly used tools are:

Electric drill with 3/8" or 1/2" chuck with nut driver bits

Masonry drill or impact hammer and bits.

Chain hoist and sling for raising barrel and curtain assembly.

Scaffolding, Mechanical Lift, and/or Ladders (ladders not recommended for larger doors).

Hammer.

Channel Lock Pliers

Center punch.

Screwdrivers.

Drills.

Wrenches, vise grips, C-clamps, torque wrench, and a large pipe wrench.

Plumb line, tape measure, chalk line, and a water level.

3

Page 4

STEP 1 UNPACKING DOORS

NOTE:

IMPORTANT!

Doors shipped by common carrier arrive at the job site packed in cardboard. Before removing the door from the

packaging, inspect the door and packaging for visible signs of damage. If damage is noted, file a freight claim with

the freight company immediately. Remove the door from the packaging.

Do not cut tape that holds door in a roll. You will be told in

step #7 when to cut tape.

No guarantee will be given by Wayne-Dalton Corp. if the door is not erected as instructed. For best operation, follow

the instructions step by step. Please review all instructions thoroughly before starting installation.

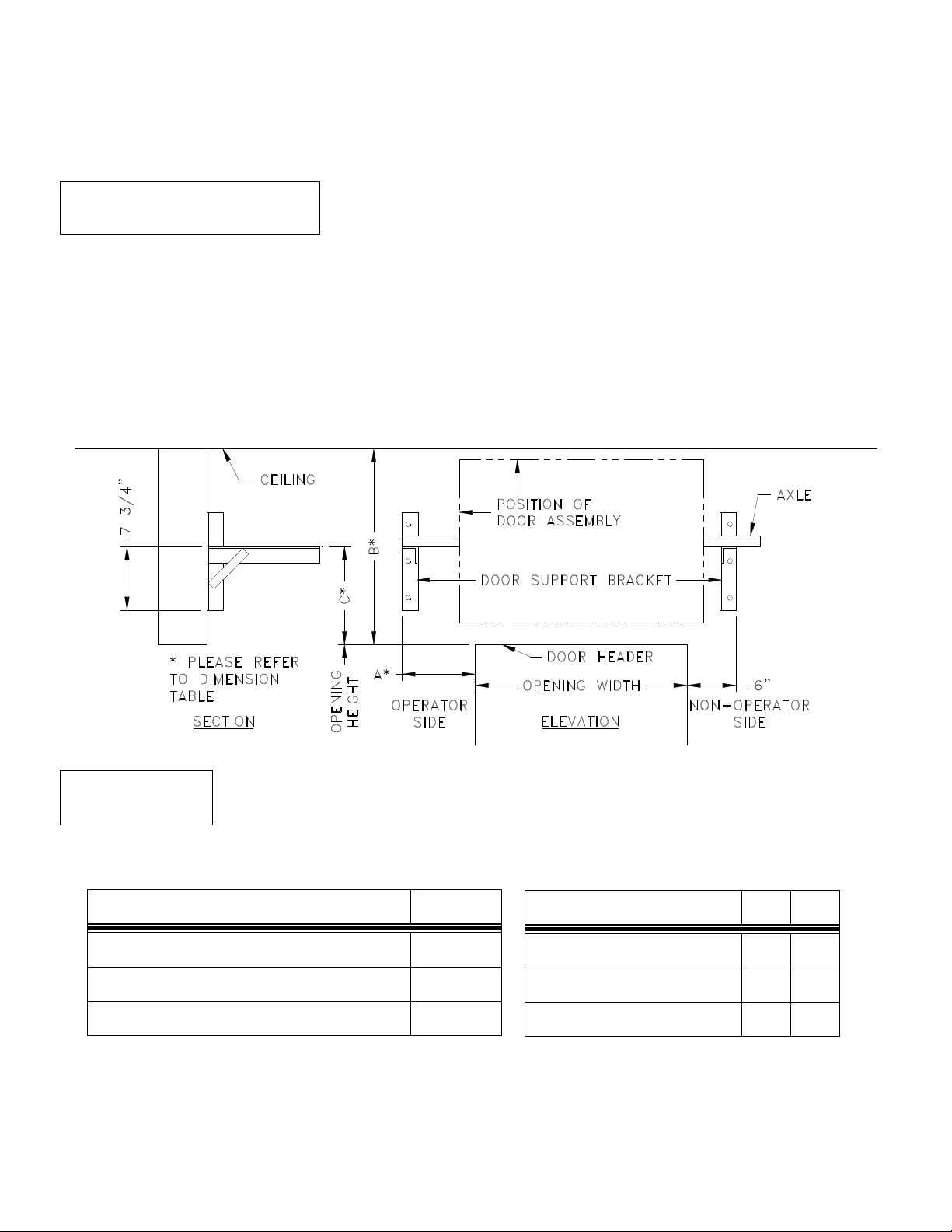

STEP 2 CHECK THE DOOR OPENING

Verify the opening measurements with the door packing slip. Consult the factory if the actual opening width varies

from that shown on the packing slip by more than 2 inches. Check door jambs, header, and floor for plumb/level

condition. Check that there is sufficient clearance at jambs and head (see Dimension Tables below).

Left hand operated door shown above. Right hand is opposite.

OPERATION A

PUSH-UP 6”

DIRECT DRIVE CHAIN/MOTOR 9”

REDUCED DRIVE CHAIN 8”

DIMENSION TABLES - MINIMUM OVERHEAD CLEARANCE (B) INDICATED

4

OPENING HEIGHT B C

UP TO 8’ HIGH 20” 10”

FROM 8’ TO 10’ HIGH 22” 11”

OVER 10’ HIGH 24” 12”

Page 5

STEP 3 INSTALLING MOUNTING ANGLES AND GUIDES

IMPORTANT!

IMPORTANT!

IMPORTANT!

Obtain the appropriate Bolt Line (BL) measurement from the chart below. Use Opening Width listed on packing

slip. Any variation between the actual opening width and the width listed on the packing slip is to be ignored.

Using the BL measurement, loosely

clamp the right hand wall angle to the

right hand jamb. Position the wall angle

such that the BL measurement falls near

the center of the slots. Adjust the wall

angle so that it is level and tighten the

clamp. Install wall angle fasteners in the

centers of the top and bottom slots only

and tighten.

Select the appropriate Angle Face to

Angle Face equation from the chart

above. Add the opening width listed on

the packing slip to obtain the Angle

Face to Angle Face measurement. Use

this measurement to locate the left hand

wall angle on the left hand jamb and clamp in place. Install the top and bottom bolts in the wall angle. Verify that

both wall angles are level and double check the angle to angle measurement at the top, middle, and bottom to ensure

that the wall angles are properly located. Using a string and a level, ensure that the mounting angles are parallel to

each other, shimming if necessary, to achieve both vertical and horizontal leveling. Now install the remaining bolts

in both wall angles.

Align the guide slots with the slots in the wall angles and fasten guides with the interior

windlock return towards the door jamb using the 5/16-18 x 5/8” truss head bolts,

washers, and flange nuts. Slide guides to set the “H” dimension as shown above at 1-3/4”

prior to tightening the guide fasteners.

OPENING WIDTH BL

(STEEL)

UP TO 10’ WIDE 1-9/16” 4-15/16” OPENING WIDTH + 6-11/16”

OVER 10’ WIDE 1-7/16” 4-7/8” OPENING WIDTH + 6-7/16”

Use BL measurement to locate wall mounting angle for one

jamb only. Second angle will be located using Angle Face to

Angle Face measurement.

Angle Face to Angle Face measurement

must be held to ensure proper door

operation and resistance to windload.

Use of any other fasteners than those

provided must be approved by

manufacturer or building authority and

cannot be of lesser diameter or grade.

BL

(MASONRY)

ANGLE FACE TO ANGLE FACE

5

Page 6

Trim the top of each wear strip at a 45° angle as shown and clip onto the appropriate

IMPORTANT!

leg of each guide. Be sure that trimmed edges of the wear strips end just below the

flare of the guides. Install the bottom bar stops with the same 5/16-18 x 5/8” truss

head bolts and flange nuts used to assemble the guides (no washer). Leave the

fasteners loose to allow the bottom bar stops to pivot out of the way of the bottom bar

angle when the curtain will be pulled into the guides. You will be instructed to

tighten the bottom bar stop fasteners in step #7.

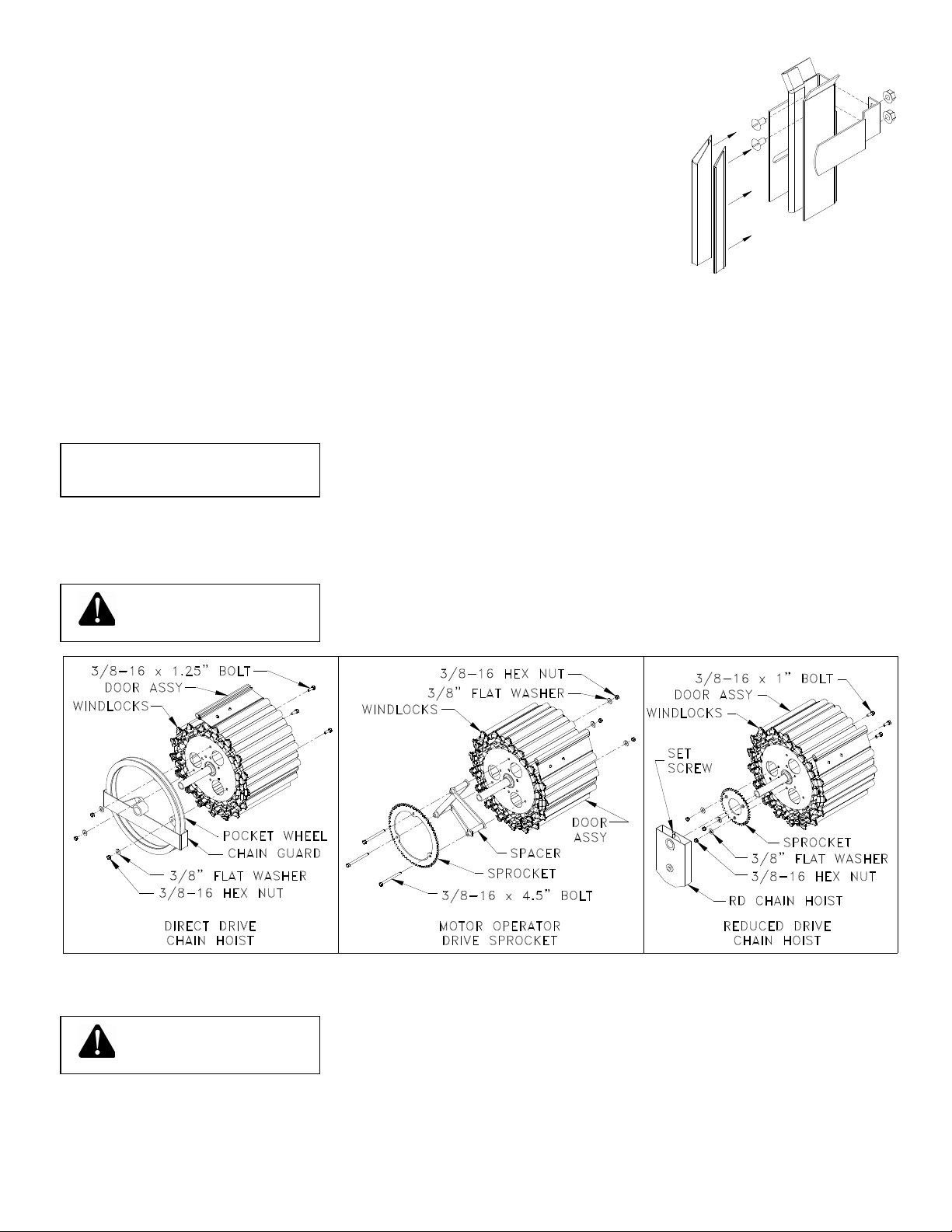

STEP 4 INSTALL BRACKETS AND DRIVE COMPONENTS

From the Dimension Tables on page 4, mark the width location of each bracket by using dimension A for the

operator side and 6” for the non-operator side. If the actual opening width varies from the packing slip width, adjust

these dimensions by adding or subtracting ½ of the difference to each dimension. Subtract if the opening is larger

and add if smaller. Mark the height location of the brackets by using dimension C. Verify the ceiling clearance

minimum from dimension B. Use a string and a level to verify that the brackets are level with each other. Adjust

bracket height as needed to level. Drill anchor holes and fasten the brackets with the anchors provided.

Brackets must be level to each other with respect to height.

Failure to level bracket heights will prevent door from

operating properly.

If the door is to be chain hoist or motor operated, install the components shown below to the operator side of the

curtain at this time using the fasteners provided. Do not tighten set screws at this time, you will be instructed to

tighten these in step #9.

Keep loose clothing, fingers, hands and arms away from all

WARNING

moving mechanisms, or serious injury or death could result.

STEP 5 LIFTING THE DOOR ASSEMBLY

WARNING

Lift door assembly up to door support brackets. Care should be taken to avoid any damage to the curtain. Make sure

that the door assembly is centered between the guides and that clearance between the windlocks and the guides is the

same on both sides. Adjust door assembly location as needed. Place the axle saddle castings under the axle on each

6

Door assembly is extremely heavy. Do not allow door

assembly to fall from lifting mechanism, or serious injury or

death could result.

Page 7

side and position the door as close as possible to the door header. Be sure that the door is able to revolve without

HINT:

scraping against door header or guides. Rotate door assembly so that bottom bar angle is at bottom of curtain roll.

To avoid serious injury or death, never walk, stand, or work

WARNING

below door assembly before it is secured to support brackets.

STEP 6 SECURE AXLE SADDLE CASTINGS

Making sure that the bottom bar angle is at the bottom of the

curtain roll; place the axle saddle castings around the axle on each

side, with the flat keeper plate on top. Install the 3/8-24 x 3-1/2”

bolts, flat and lock washers, and 3/8-24 nuts as shown. Be certain

to tighten both nuts to a torque of 40 foot-pounds. Spring tension

will be lost if both axle saddles are not tightly secured.

Axle saddles hold extreme spring tension. Loose axle saddles

WARNING

could result in loss of spring tension, causing door to fall,

possibly producing serious injury or death.

STEP 7 PRE-TENSION THE DOOR SPRINGS

Starting with the bottom bar angle at the bottom of the curtain roll, apply two complete

turns of pretension to the springs by rotating the curtain roll in the direction shown. The

amount of tension required may vary slightly. Final adjustment, if necessary, will be made

in Step #10.

Spring tension can cause curtain roll to rotate rapidly.

WARNING

WARNING

WARNING

Cut the tape that holds the door in a roll and gently pull the curtain down into the

guides on both sides until the bottom bar is below the bottom bar stops. Do not pry on

the bottom bar stops to get bottom bar past, loosen fasteners until bottom bar angle

easily clears stops. If the door has a tendency to close, secure in position using clamps.

If the door has a tendency to rise, secure in position using a wood prop as shown.

While the door is secured from moving, tighten the bottom bar stop fasteners on both

guide assemblies.

Tighten bottom bar stop fasteners with impact gun

to prevent bolts from spinning.

Securely hold curtain roll from rotating while applying

pretension or serious injury or death could result.

Securely hold door curtain until bottom bar stop fasteners

have been tightened. If not securely held, door may raise or

drop, possibly causing injury or death.

Do not apply pretension to larger

doors using ladders. Ladders may fall

causing serious injury or death.

7

Page 8

STEP 8 INSTALL SLIDE BOLT LOCKS

IMPORTANT!

HINT:

Install slide bolt locks, if provided,

as shown.

Install the lift handle to bottom bar

angle at this time.

STEP 9 LUBRICATE AND ADJUST THE GUIDES

Lubricate the insides of the guides and wearstrips with weather resistant lubricating spray. Be sure to spray lubricant

over the flares at the tops of the guides. Move the door up and down to check for proper operation. Adjust the guides

and mounting angles if necessary to allow for proper clearance and operation.

If door is difficult to move up and/or down due to spring imbalance,

continue on to step #10 and return to step #9 once springs are properly

adjusted.

STEP 10 CHECK AND ADJUST SPRING BALANCE

WARNING

If the door lowers easily and raises hard, more spring tension is required. If the door lowers hard and raises easily,

less spring tension is required. Before adjusting the spring tension, be sure that the door is in the full up position.

Secure the door in the full up position to prevent the door from falling if the adjustment wrench slips. Use one of

these methods:

• Tie a rope around the door roll and bottom bar angle.

• Place a clamp on guides holding the door securely at the stops.

WARNING

It is strongly recommended that two or more installers perform

this next step.

Never remove bottom bar stops when adjusting tension,

otherwise, door can spin uncontrollably resulting in serious

injury or death.

Always stand to one side of wrench when adjusting tension.

Never adjust tension with wrench in front of/above you. This

will help avoid serious injury if you lose control of wrench.

8

Page 9

Place a large pipe wrench in position on the door axle as shown and slightly

NO

TE:

loosen both axle saddle castings. Pull down on the wrench for more spring

tension and let up on the wrench for less spring tension.

As saddle castings are

WARNING

cause serious injury if not controlled properly.

Tighten both axle saddle castings per Step #6 while holding the pipe wrench

firmly to maintain desired adjustment. Let off the pipe wrench tension only

after the nuts on both axle saddle castings are tightened back to 40 foot-pounds.

WARNING

Test the door as in Step #9 above. Repeat the above procedure if further adjustments are required. Once all

adjustments have been made and the door is operating properly, recheck all fasteners and bolted connections to

ensure that they are in place and properly tightened. Tighten all set screws in the components installed in step #4.

loosened, hold wrench securely.

Springs are very strong and can

When removing pipe wrench from axle, slowly reduce applied

tension until wrench is free from axle. This will help avoid

serious injury in event that saddle castings have not been

tightened sufficiently.

STEP 11 INSTALLATION OF TOP DRAFT STOP

Close the door and secure it in the down

position. Use a pencil to mark the door panel

corrugation that is parallel with the bottom of

the header/lintel from the outside of the

opening. If this corrugation protrudes below the

header, mark the one just above. Open the door

until the marked corrugation is accessible.

Stretch the top draft stop across the door and

attach it to the curtain on the marked

corrugation with the #8 x ½” self-drilling

screws provided, locating the screws every 12"

on center. Trim the Top Draft Stop to clear the

guides if required. When the door is closed, the

draft-stop should seal on the header.

Top Draft Stop may not seal on header if not installed on a corrugation as

shown.

9

Page 10

REDUCED DRIVE CHAIN HOIST INSTALLATION INSTRUCTIONS (if applicable)

STEP 12 ALIGN THE SPROCKETS

Feed the hand chain through the pocket wheel assembly (installed in step #4),

around the cast iron hand chain wheel, and connect the two end links.

Align the chain hoist so that the 41B9 sprocket on the pocket wheel assembly is

in line with the 41A40 sprocket bolted to the barrel. Next, tighten the hoistlocking bolts to lock the pocket wheel assembly to the shaft to prevent it from

shifting or rocking.

Hoist locking bolts must be tight to ensure hoist cannot shift

WARNING

Next, connect the #41 roller chain between the pocket wheel assembly sprocket and the barrel sprocket. Now run the

door up and down several times to ensure that the roller chain does not come off. If it does, go back and check the

alignment of the sprockets.

WARNING

and permit roller chain to come off, thereby allowing door to

drop possibly causing severe injury or death.

Keep loose clothing, fingers, hands, and arms away from all

moving mechanisms and places where chain meets either

sprocket, or serious injury or death could result.

STEP 13 INSTALL THE CHAIN KEEPER

Now install the hand chain keeper to the wall

approximately four feet above the finished floor with the

hardware provided. Refer to the figure in step #7 of this

manual for an additional view.

10

Page 11

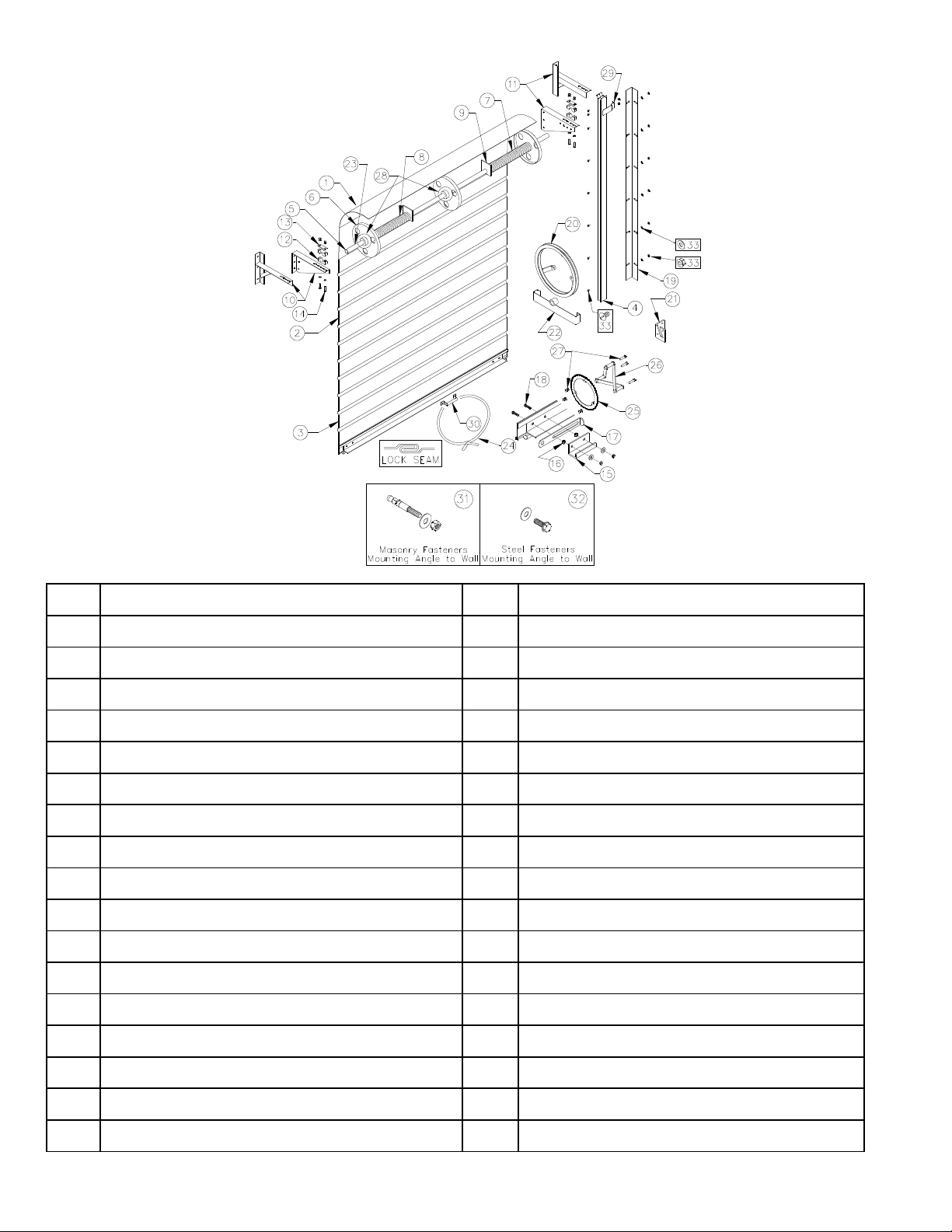

Item Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Top Sheets - Give Length

Intermediate Sheets - Give Length

Bottom Sheet Assembly - Give Length

Guide, Left Hand or Right Hand (Right Hand Shown)

Axle - Give Length

Drum Assembly

Spring - Right - Give Length & Wire Diameter

Spring - Left - Give Length & Wire Diameter

Spring Clip

Left Mounting Bracket – Based on Door Size - Give Type

Right Mounting Bracket – Based on Door Size – Give Type 28

Axle Saddle

Keeper Plate

3/8-24 x 3½” Axle Bolt + Washer, Lock Washer, & 3/8” Nut 31

Lift Clip - Edge Mounted

Spacer Nut

Slide Bolt Lock

Item Description

18

19

20

21

22

23

24

25

26

27

29

30

32

33

1/4-20 x 1” Slotted Screw, Washer & Nylon Nut

Mounting Angle, Give Mounting Condition, Give Length

Direct Drive Chain Wheel

Chain Retainer Clip

Direct Drive Chain Guide

1/2" Collar (Not Shown)

5/16” Polypropylene Rope

Electric Operator Sprocket

Electric Operator Mounting Bracket

Electric Operator 3/8” x 3” Bolt & Tube

Drum Bearing

Bottom Bar Stop, 5/16-18 x 5/8” THMS & Flange Nuts

Lift Handle (center mounted)

3/8” x 5” Wedge Anchor

5/16-12 x 1” Self-Drilling Screw and Washer

Guide Fasteners, 5/16-18 x 5/8” THMS, Washers & Nuts

11

Page 12

Roll-Up Sheet Door

LIMITED WARRANTY

Wayne-Dalton Corp

P.O. Box 67- Mt. Hope, Ohio 44660

The Manufacturer warrants the ROLL-UP SHEET DOOR and hardware fittings for a period of ONE YEAR from the time of

delivery against any defects in workmanship or material. Manufacturer shall, upon notification, correct such nonconformity at its option, by

repairing or replacing any defective part or parts.

NO EMPLOYEE, DISTRIBUTOR, OR REPRESENTATIVE IS AUTHORIZED TO CHANGE THE FOREGOING

WARRANTIES IN ANY WAY OR GRANT ANY OTHER WARRANTY ON BEHALF OF MANUFACTURER.

The Manufacturer shall not be responsible for any damage resulting to or caused by its products by reason of installation, improper

storage, unauthorized service, alteration of products, neglect or abuse, or attempt to use the products for other than the customary usage or

for their intended purposes. The ROLL-UP SHEET DOOR warranty becomes null and void if other than Manufacturer’s specified holes are

drilled. The above warranty does not cover wear or any damage beyond Manufacturer’s control or replacement labor.

THIS WARRANTY COVERS A COMMERCIAL PRODUCT, THE FOREGOING WARRANTIES ARE IN LIEU OF ALL

OTHER WARRANTIES AND NO REPRESENTATIONS, GUARANTEES, OR WARRANTIES, EXPRESSED OR IMPLIED,

(INCLUDING, BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE), ARE MADE BY MANUFACTURER IN CONNECTION WITH MANUFACTURE OR SALE OF ITS PRODUCTS.

Claims for defects in material and workmanship covered by this warranty shall be made in writing to the dealer from whom the

product was purchased within the warranty period. Manufacturer may either send a service representative or have the product returned to the

Manufacturer at Buyer’s expense for inspection. If judged by Manufacturer to be defective in material or workmanship, the product will be

replaced or repaired at the option of Manufacturer, free from all charges except authorized transportation and replacement labor.

THE REMEDIES OF BUYER SET FORTH HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER REMEDIES.

THE LIABILITY OF MANUFACTURER, WHETHER IN CONTRACT, TORT, UNDER ANY WARRANTY, OR OTHERWISE,

SHALL NOT EXTEND BEYOND ITS OBLIGATION TO REPAIR OR REPLACE, AT ITS OPTION, ANY PRODUCT OR PART

FOUND BY MANUFACTURER TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP. MANUFACTURER SHALL NOT BE

LIABLE FOR COST OF REMOVAL OR INSTALLATION OR SHALL NOT BE RESPONSIBLE FOR ANY DIRECT, INDIRECT,

SPECIAL, OR CONSEQUENTIAL DAMAGES OF ANY NATURE.

This warranty gives you specific legal rights which may vary from state to state. However, some states do not allow limitations on

how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations or

exclusions may not apply to you.

Wayne-Dalton Corporation

Door & Systems Division

2589 County Road 168

Dundee, OH 44624

1-800-795-5095

12

Loading...

Loading...