Page 1

1

WavetekWavetek

WavetekWavetek

Wavetek

CATV Division

5808 Churchman Bypass

Indianapolis, IN 46203-6109

(800)851-1198

(317)788-5960

Fax: (317)782-4607

E-Mail: catvsupport@wavetek.com

Internet: http://www.wavetek.com

3/96

Manual Part No.

6510-00-0283

This document contains information proprietary to

Wavetek. The information in this document

is not to be used or duplicated in any manner without

the prior approval, in writing, of Wavetek.

OPERATION MANUAL

MODEL MS1300

SCANNING/LOGGING

SIGNAL LEVEL METER

Page 2

2

WARRANTY

Wavetek warrants that all Products manufactured or procured by Wavetek conform to

Wavetek’s published specifications and are free from defects in materials and workmanship

for a period of one (1) year from the date of delivery to the original Buyer, when used under

normal operating conditions and within the service conditions for which they were designed.

This warranty is not transferrable and does not apply to used or demonstration products.

The obligation of Wavetek arising from a Warranty claim shall be limited to repairing, or at

its option, replacing without charge, any assembly or component (except batteries) which in

Wavetek’s sole opinion proves to be defective within the scope of the Warranty. In the event

Wavetek is not able to modify, repair or replace nonconforming defective parts or components

to a condition as warranted within a reasonable time after receipt thereof, Buyers shall receive

credit in the amount of the original invoiced price of the product.

Wavetek must be notified in writing of the defect or nonconformity within the Warranty

period and the affected Product returned to Wavetek’s factory, designated Service Provider,

or Authorized Service Center within thirty (30) days after discovery of such defect or

nonconformity. Buyer shall prepay shipping charges and insurance for Products returned to

Wavetek or its designated Service Provider for warranty service. Wavetek or its designated

Service Provider shall pay costs for return of Products to Buyer.

Wavetek shall have no responsibility for any defect or damage caused by improper storage,

improper installation, unauthorized modification, misuse, neglect, inadequate maintenance,

accident or for any Product which has been repaired or altered by anyone other than Wavetek

or its authorized representative or not in accordance with instructions furnished by Wavetek.

The Warranty described above is Buyer’s sole and exclusive remedy and no other warranty,

whether written or oral, expressed or implied by statute or course of dealing shall apply.

Wavetek specifically disclaims the implied warranties of merchantability and fitness for a

particular purpose. No statement, representation, agreement, or understanding, oral or

written, made by an agent, distributor, or employee of Wavetek, which is not contained in the

foregoing Warranty will be binding upon Wavetek, unless made in writing and executed by

an authorized representative of Wavetek. Under no circumstances shall Wavetek be liable for

any direct, indirect, special, incidental, or consequential damages, expenses, or losses,

including loss of profits, based on contract, tort, or any other legal theory.

Extended Warranty Programs

Extended warranties and service contracts are available for new and currently owned

equipment for an additional cost. Contact the Customer Service Department (800 851-

1198) for details pertaining to extended warranties and service contracts.

Return Authorization Procedure

The customer MUST obtain a RETURN AUTHORIZATION NUMBER from the

Customer Service Department (800 851-1198) prior to returning any equipment for

warranty or non-warranty repair. Wavetek accepts no liability for any instrument or

subassembly returned to the factory without this number. Any correspondence regarding

returned instruments or subassemblies should be referenced to that number.

Page 3

3

Contents

Introducing microStealth ................................................................ 7

Introduction................................................................................ 7

Measurement Logging .............................................................. 8

Auto Tests .................................................................................. 8

Multiple Channel Plans ............................................................ 10

Getting Acquinted with the Keypad ....................................... 10

Getting Acquinted with the Screen ......................................... 12

The Navigator............................................................................ 15

Configuring microStealth.......................................................... 16

Global Configuration ................................................................. 17

Measurements Configuration ................................................... 20

Channel Plan Configuration ..................................................... 23

Using microStealth ........................................................................... 31

Introduction................................................................................ 31

Installation.................................................................................. 31

Selecting Channel Packages ............................................. 32

Selecting the Test Point .................................................... 32

Installation Results Summary ........................................... 33

The Channel List ............................................................... 34

The Pass/Fail Indicator ..................................................... 34

Channel Measurement ...................................................... 35

Printing an Installation Report ......................................... 36

Storing Installation Results ............................................... 36

Level........................................................................................... 36

Adjusting the Reference Level ......................................... 37

Tuning by Channel ............................................................ 37

Tuning by Frequency ........................................................ 37

Measurement Hold ............................................................ 38

Printing the Screen ............................................................ 38

Warning Indicators ............................................................. 39

Full Scan..................................................................................... 39

Moving the Marker ............................................................ 40

Adjusting the Reference Level ......................................... 40

Adjusting the Scale ............................................................ 40

Zooming In and Out .......................................................... 41

Checking Limits ................................................................. 41

Page 4

4

Checking Limits on an Individual Channel .................... 42

Measurement Hold ............................................................ 43

Printing the Screen ............................................................ 43

Storing a Scan File ............................................................. 43

Warning Indicators ............................................................. 44

Tilt .............................................................................................. 44

Moving the Marker ............................................................ 45

Selecting the Low and High Carriers ............................... 45

Adjusting the Reference Level ......................................... 45

Adjusting the Scale ............................................................ 45

Measurement Hold ............................................................ 46

Printing the Screen ............................................................ 46

Storing a Tilt File............................................................... 46

Scan ............................................................................................. 46

Moving the Marker ............................................................ 47

Adjusting the Reference Level ......................................... 47

Adjusting the Scale ............................................................ 47

Checking Limits ................................................................. 47

Measurement Hold ............................................................ 48

Printing the Screen ............................................................ 48

Storing a Scan File ............................................................. 49

Auto Test.................................................................................... 49

Configuring an Auto Test .................................................. 49

Performing an Auto Test ................................................... 52

Canceling an Auto Test ..................................................... 53

View ............................................................................................ 53

The File Directory ............................................................. 54

Viewing Installation Files.................................................. 55

Viewing Scan Files ............................................................. 56

Viewing Auto Test Files.................................................... 57

Reference........................................................................................... 61

Using the Reference Section .................................................... 61

Help ............................................................................................ 61

Information................................................................................. 62

Technical Support ..................................................................... 63

Page 5

5

Appendices

Appendix A: Specifications....................................................... 65

Appendix B: Power Management and Battery ....................... 67

Battery Pack Location and Installation ............................ 67

Charging the Battery Pack ................................................ 67

Battery Tips ........................................................................ 67

Appendix C: Interface Port ...................................................... 69

Connector ............................................................................ 69

Cable Specifications ........................................................... 70

Page 6

6

Page 7

7

MODEL MS1300

1

Introducing

microSTEALTH

INTRODUCTION

The MS1300 Signal Level Meter is a high performance instrument

designed for cable television technicians. The durable, water

resistant MS1300 makes innovative use of a graphics LCD to

simplify operation. The LCD backlight makes measurements

easier in crawl spaces and behind TVs. The display is easy to see

in bright sunlight.

A scan mode allows you to see the levels of all carriers in a spectral

display. You can also view level measurements at a single frequency or for a specific channel. When tuned to a channel, the

display indicates the levels of the video and audio carriers, and the

difference between the carrier levels.

When performing an installation, you can press the Installation

Check key to quickly verify that all channels are within limits that

you have defined. You can use this feature to determine whether

or not a subscriber connection meets FCC or other government

requirements.

A special channel plan building mode automatically determines

which channels are active on your cable system. Once you have

defined a channel plan, you can copy it to any MicroStealth unit

having a built-in serial port. You can also create channel plans

using StealthWare, the Windows™ based data management

package for Stealth products.

Page 8

8

For documentation purposes, you can print any measurement

screen to a serial printer (Wavetek P-Stealth Printer). Following an

installation check, you can print an installation report that can be

filed with the work order. You can also print a report that lists all

configuration settings including the channel plan.

The MS1300 tunes from 45 to 550 MHz with an option to extend

the range to 5 to 890 MHz.

MEASUREMENT LOGGING

With the MS1300, you can store installation checks that you have

performed throughout the day. You can also store scan and tilt

measurements. Each file is time and date stamped and can be

recalled later for viewing on the LCD screen.

When viewing a file, you can adjust the screen settings the same as

when you are viewing a “live” measurement. Using the built-in

serial port, you can print files and even upload them to StealthWare

for further analysis and archiving.

AUTO TESTS

Automated tests are easy with the MS1300 and provide a convenient way of acquiring proof-of-performance compliance data.

Tests can be executed immediately or scheduled over a period of

time. To conserve battery life, MicroStealth shuts itself off

between scheduled intervals. When configuring an Auto Test, you

can record information about the location at which the test is being

performed. Files can be created for commonly tested locations so

you need only enter the information once.

Auto Tests results are time, date, and temperature stamped and

can be viewed on the LCD screen. Limits are applied to the

measurement data with out-of-tolerance conditions concisely

indicated. You can print a test report for each interval or a comprehensive 24 hour report that summarizes data collected from up to

four intervals. Auto Test result files can be uploaded to

StealthWare.

Page 9

9

1

2

5

3

6

4

7

7

Page 10

10

MULTIPLE CHANNEL PLANS

The MS1300 stores channel plans that you have built and edited.

This is convenient if you use your MicroStealth for more than one

plant. You can quickly select the correct channel plan for the plant

at which you are working.

GETTING ACQUAINTED WITH THE KEYPAD

The keypad consists of the following:

• three Soft keys

• a Power key

• four Mode Selection keys

• an Enter key

• eleven Alphanumeric keys

• a Shift key

1. SOFT KEYS

There are three horizontally oriented soft keys located below the

display. The function of each soft key changes depending on the

particular operation being performed and is represented by an

icon immediately above the key.

2. POWER KEY - ON/OFF

Turns your microStealth on and off.

3. MODE SELECTION KEYS

INSTALLATION MODE

Easily check the channels that you have installed and

verify that they are within limits.

LEVEL MODE

Measure the signal level at a specific channel or frequency.

Page 11

11

FULL SCAN MODE

View a spectrum graph of all carrier levels in your channel

plan.

NAVIGATOR

Instantly "travel" to any mode using the NAVIGATOR.

4. ENTER KEY

Press this key to terminate your entry or selection.

5. ALPHANUMERIC KEYS

You use the alphanumeric keys to enter data while operating your

microStealth. Notice that these keys have a numeral and up to

three alphabetic characters labeled on them. You can only access

the characters when alphanumeric entry is allowed. In the alphanumeric entry mode, you sequence through each character and

the numeral by repeatedly pressing the key. You can also access a

set of special characters that do not appear on the keypad by using

the up and down arrows. Once the desired character is displayed,

move the cursor to the next position using the right arrow. Be sure

to terminate your entry by pressing the key.

6. SHIFT KEY

Some keys perform more than one function. The secondary

function of a key is represented by an icon printed next to it.

Notice that the icons are color coded with the SHIFT key. You

access the secondary function by first pressing the SHIFT key and

then the icon representing the desired function.

7. SECONDARY FUNCTIONS

CONFIGURE MODE

Configure your microStealth for your own specific needs.

AUTO REFERENCE

Let microStealth automatically set the reference level for

you.

Page 12

12

SNAP SHOT

Hold the measurement. The measurement is retained even

if the cable is disconnected from the input.

CLEAR

Clear-out your entry and start over again.

BACKLIGHT ON/OFF

Quickly turn the backlight on when it is too dark to see the

display.

POSITIVE/NEGATIVE

Enter positive and negative values (when allowed).

HELP

View a description of each icon found in the current soft

key menu.

PRINT

Print a measurement screen, installation report, auto test

report, or configuration report to a serial printer.

STORE FILE

Store an Installation, Scan, or Tilt screen for later viewing,

printing or uploading to StealthWare.

GETTING ACQUAINTED WITH THE SCREEN

There are certain elements of the screen that will become familiar

to you as you use your microStealth.

The Title Bar

Notice the title bar at the very top of the screen. It presents the title

and icon for the current mode you are using.

Page 13

13

Title Bar Indicators

You may see indicators appear above the title bar from time to time.

This is what they represent:

This indicator appears in the top right-hand corner of

the screen when you press the SHIFT key. This means

that microStealth interprets the next key that you press

to be a secondary function.

This indicator is displayed to warn you that the battery is

low. When you see this, recharge the battery or change to a

fresh one as soon as possible.

This indicates that the RF synthesizer has become

unlocked. If this condition persists, the unit may need

repair.

The Status Bar

Look for the status bar in the lower portion of the screen. It

displays the current date and time. A bar meter indicates the charge

remaining in your MicroStealth’s battery. When the battery meter

reads low, you should switch to a freshly charged battery soon.

Note

When viewing an Installation or Scan file, the status bar shows the

date and time that the file was stored instead of the current date and

time.

Soft Key Icons

There are three soft keys located immediately below the display.

The function of a soft key is represented by the icon directly above

it.

Page 14

14

Note

If the soft key function is not currently available, the icon appears

"grayed" or "dimmed".

Lists

Lists present several items for viewing and/or selecting. Notice that

the currently chosen item is highlighted. You can scroll through the

list using the up and down arrows.

A list can be either "active" or "inactive". You can tell by looking at

the border. If the border is solid, the list is active and any keys that

you press are directed toward it. If the border is dim, the list is

inactive and is not affected by key presses. Usually you can make a

list become active by pressing the key.

When there are more items in the list than can be displayed at one

time, a scroll bar appears along the right-hand edge of the list. You

can use this to get an idea of where you are. When you have

reached the first or last item, an arrow appears inside the scroll box

pointing to the direction you can go.

The Edit Box

The edit box appears in the lower portion of the screen when it is

necessary to enter values into your microStealth.

Page 15

15

An edit box can be either “active” or “inactive”. You can tell by

looking at the border. If the border is solid, the edit box is active

and any keys that you press are directed toward it. If the border is

dim, the edit box is inactive and is not be affected by key presses.

Usually, you can make the edit box become active by pressing the

key. Be sure to press the again when you have finished

making you entry.

THE NAVIGATOR

You can easily travel to any mode using the NAVIGATOR. To

access the NAVIGATOR, press the key.

An icon appears on the screen for each available mode. Use the up,

down, left, and right arrows to highlight the icon that represents the

mode you want to use. Notice that the name of the mode appears

on the lower portion of the screen beneath the status bar. To get a

description of the highlighted mode, press the SHIFT + key. To

travel to the mode you have highlighted, press any one of the soft

keys or the key.

Tip

You can also use the numeric keys, 1 through 9 to highlight the

desired icon in the NAVIGATOR screen. Each key corresponds to

an icon in the 3 by 3 matrix.

Page 16

16

CONFIGURING microSTEALTH

Before using your microStealth, you may want to configure it for

your specific needs. The CONFIGURE mode allows you to select

global and measurement related preferences and to build and edit a

channel plan that matches your cable plant.

To configure your microStealth, press the SHIFT + keys or

choose the icon from the NAVIGATOR. The following screen

appears:

Configuration settings are divided into three categories; GLOBAL,

MEASUREMENTS, and CHANNEL PLAN. Use the up and

down arrows to highlight the category you want and then press the

key.

Tip

You can also use the left-hand and right-hand soft keys to scroll

through the CONFIGURE categories and then press the middle

soft key to select the highlighted category.

PRINTING A CONFIGURATION REPORT

In most configuration screens, you can print a comprehensive

configuration report by pressing the SHIFT + keys. A bar graph

appears indicating the status of the printout. The report lists all of

the configurable settings including the active channel plan.

Page 17

17

Global Configuration

OPERATOR NAME

You can personalize your microStealth by entering your name here.

Your name will then appear on report printouts.

CONTRAST LEVEL

Adjusts the contrast level of the LCD for optimum viewing.

SHUTOFF TIME-OUT

Sets the amount of inactive time allowed before your microStealth

turns off automatically. This feature is useful for conserving battery

life by preventing the microStealth from being left on accidentally

when it is not in use. You can set the time-out period to 1, 3, or 5

minutes. There is also an "always on" setting that defeats the

automatic shutoff feature if desired.

Note

You can manually turn off your microStealth at any time by pressing

the button.

BACKLIGHT TIME-OUT

Sets the amount of inactive time allowed before the backlight turns

off automatically. The backlight consumes significant power. This

feature conserves battery life by minimizing the amount of time

that the backlight is on. You can set the time-out period to; 5 or 10

seconds. There is an always off setting for when the backlight is not

needed at all. There is also an always on setting that defeats the

backlight time-out feature.

You can manually turn the backlight on or off at any time by

pressing the SHIFT + keys. When manually activated, the

backlight remains on continuously until the unit shuts off.

Page 18

18

Tip

You can tell when the backlight is on even in bright sunlight by

looking for the backlight indicator at the left-hand edge of the Title

Bar. The indicator means that the backlight is currently on and

will turn off automatically. The indicator means that the backlight is on and will remain on continuously. If you see no indicator,

the backlight is off.

TIME

Sets the time for the internal real-time clock. The time is set,

displayed and printed in 24 hour format only (HH:MM:SS).

DATE FORMAT

You can specify the format in which the date is displayed and

printed. Select between the following formats:

MM/DD/YY

DD.MM.YY

YY.MM.DD

DATE

Sets the date for the internal real-time clock. You can specify the

format in which the date is set, displayed and printed (see DATE

FORMAT).

PRINTER

Select the manufacturer of the printer that you will be using. A

printer with a serial interface is required. Set your printer configuration as follows:

Baud Rate: same as your microStealth

Date Bits: 8

Stop Bits: 1

Parity: NONE

Flow Control: Xon/Xoff

Important

The baud rate of both your microStealth and your printer must

match (see BAUD RATE).

Page 19

19

Tip

A serial to parallel converter (such as the on manufactured by Black

Box Corp.) can be used for printing to a parallel printer.

LINES/PAGE

For text reports, you can specify the number of lines that will be

printed on each page before a form feed command is sent. Enter 0

if you do not want any form feeds to be sent.

BAUD RATE

This is the baud rate that is used when your microStealth communicates with another device through the serial port. Generally, you

will want to use the highest rate supported. Be sure that the baud

rate setting of your microStealth matches that of the device that it is

connected to.

CLONE

You can easily transfer the entire configuration from one

microStealth unit to another. This saves you time when configuring

multiple units. First, connect a cable between the two microStealth

units. Select CLONE only on the unit that you want to copy the

configuration to. Press the soft key to begin the transfer.

Important

Be sure that the baud rate setting of your microStealth matches that

of the device that it is connected to (see BAUD RATE).

DIAGNOSTICS

Performs hardware diagnostics and defaults stored preferences to

factory presets. Press the key to access the diagnostics options.

Factory Default

Sets all stored preferences to factory presets. Press the

key to initiate the default operation.

Important

All stored settings are lost when you perform this operation.

Page 20

20

Test Display

Exercises all pixels on the LCD for test purposes. Repeated pressing of the key sequences the display

between all pixels "on", all pixels "off", and the display test

screen.

Measurements Configuration

TEMPERATURE UNITS

Selects the units that will be used for the ambient temperature

during Auto tests. You can select between; °C and °F.

SIGNAL LEVEL UNITS

Selects the units that will be used for all signal level measurements.

You can select between; dBmV, dBµV and dBm.

PROBE COMPENSATION

This can be used to compensate for losses associated with probe

points found on certain amplifiers. You can enter a value between

-99.9 and +99.9 dB. Probe compensation is added directly to signal

level measurements. The compensation value is indicated in the

upper left-hand corner of the measurement screens. There is no

indication, however, if the compensation value is zero.

Important

The PROBE COMPENSATION value does not affect INSTALLATION or CHANNEL PLAN BUILD mode. Level measurements

made while checking an installation are uncompensated.

FREQUENCY TUNING STEP SIZE

This setting affects the increment/decrement step size when you

are tuning the frequency using the left and right arrows. You can

select a value between 25kHz and 100MHz in steps of 25kHz.

SCAN AUDIO CARRIERS

Select YES if you want to see the audio carriers in the full scan

screen. You can achieve a faster scan by omitting the audio carriers.

Page 21

21

SCAN SCRAMBLED CHANNELS

Scrambled channels require more time to measure. You can achieve

a faster scan by omitting scrambled channels. Select YES if you

want to see scrambled channels in the full scan screen.

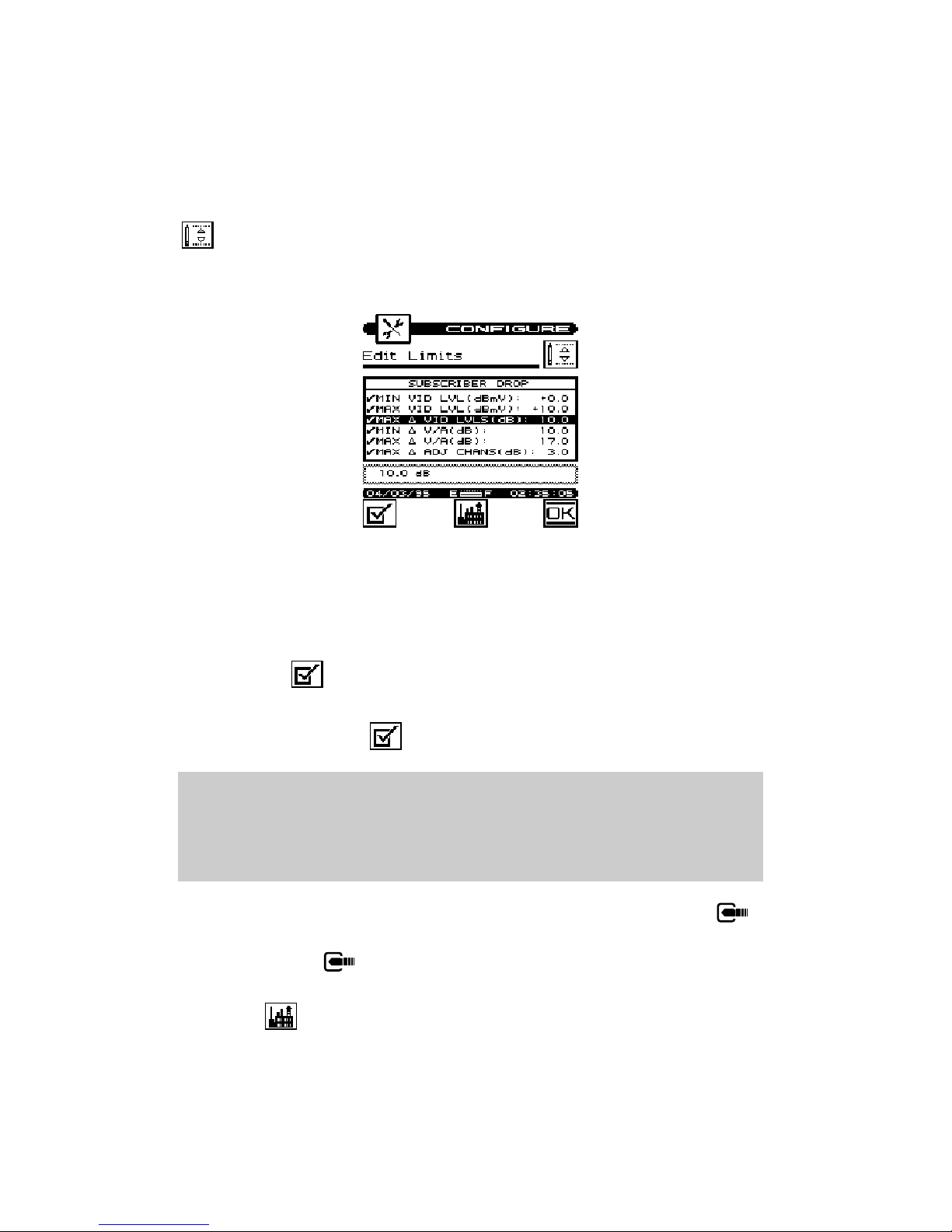

EDIT TEST POINTS

Your microStealth is capable of performing tests at various locations

including; SUBSCRIBER DROP, GROUND BLOCK, TAP, and

USER DEFINED (or CUSTOM). Each test point has its own set

of limits that you can edit. Press the key to edit the test points.

A list of available test points appears.

You can enable or disable each test point in the list. When a test

point is disabled, you cannot use it when performing tests. Use the

up or down arrow to highlight the desired test point. If the high-

lighted test point is disabled, you can enable it by pressing the

soft key. A check mark appears in the left-hand column to indicate

when a test point is enabled. If the test point is already enabled,

pressing the soft key disables it.

Tip

You can change the name of the USER DEFINED (CUSTOM)

test point. Notice that the edit box appears when this test point is

highlighted. When you press the key, the edit box becomes

active and you can enter any name up to fifteen characters long. Be

sure to press the key when finished to terminate your entry.

Page 22

22

You can edit the limits for the highlighted test point by pressing the

soft key. The limits appear on the screen.

You can selectively enable or disable each individual limit. When a

limit is disabled, your microStealth excludes it when checking

limits. If the highlighted limit is disabled, you can enable it by

pressing the soft key. A check mark appears in the left-hand

column to indicate when a limit is enabled. If the limit is already

enabled, pressing the soft key disables it.

Note

If you disable all of the limits within a test point, the test point

becomes disabled. You cannot enable a test point that has no

enabled limits.

You can edit the value of the highlighted limit by pressing the

key. When the edit box becomes active, enter the desired value. Be

sure to press the key when finished to terminate your entry.

Press the soft key to return all limits in the test point to their

factory preset values.

Page 23

23

Channel Plan Configuration

SELECT CHANNEL PLAN

Channel plans are stored automatically when they are created. Use

this option to select from a list of available plans.

A small arrow appears in the list to the left of the name of the

currently active plan. To load a different plan, use the up and down

arrows to highlight the desired plan and then press the . Press

the soft key to delete the highlighted plan.

Note

The currently active plan cannot be deleted. To delete this plan,

you must first load a different plan.

Tip

You can rename the plan highlighted in the directory by pressing

the SHIFT + keys. A screen will appear asking you to enter a

new name.

VIDEO SIGNAL TYPE

Your microStealth is capable of measuring signal levels on NTSC or

PAL video signals. You should make sure that the correct video

type is selected.

Page 24

24

CHANNEL SEQUENCE

You can specify whether channels are listed in numeric or frequency order. This setting also affects the sequence in which

channels are tuned in the LEVEL screen when using the left and

right arrows.

Note

The SCAN screen always displays channels in order of frequency

regardless of the CHANNEL SEQUENCE setting.

BUILD CHANNEL PLAN

Your microStealth is capable of identifying which channels are on

your cable plant. This allows you to quickly and easily generate a

customized channel plan. Press the key and let microStealth

learn your system.

Important

Ensure that your microStealth is connected to the cable system

before initiating this procedure.

Step 1

You are asked to enter a name for the channel plan. Using

the edit box, you can enter any name up to fifteen characters long. Be sure to terminate your entry with the key.

Press the soft key to continue with the next step.

Step 2

There are several standard channel plans to use as a

foundation for building your plan. Use the up or down

arrows to highlight the one that is appropriate for your

system. Press the soft key to continue with the next

step.

Page 25

25

Step 3

You can tell microStealth what frequency to stop searching

for channels. This will save time when building the plan.

The frequency you enter should be just above the highest

channel on your system. If you are not sure what the

frequency of your highest channel is, just use the default

value that appears in the edit box. If you have entered a

value, be sure to terminate your entry with the key.

Press the soft key to begin building the plan.

Upon pressing the soft key, microStealth begins searching your

system for active channels. A bar graph indicates the percentage of

the channels searched. After the plan has been built, press the

soft key to return to the Channel Plan Configuration screen.

EDIT CHANNEL PLAN

You can edit various parameters for each channel. Press the

key to edit the channels. A list of all the channels in the plan

appears.

A check mark appears in the left-hand column when the channel is

enabled. When you built the channel plan, MicroStealth automatically enabled all the channels it found to be active on your system.

You may want to verify that all your channels have been correctly

enabled. Use the soft key to enable/disable the channel

highlighted in the list.

Page 26

26

Important

You must enable a channel in order to perform measurements on it.

There are several parameters that you can specify for each channel.

To do this, highlight the desired channel using the up or down

arrow and press the soft key or the key. The parameters

for that channel appear.

Use the up or down arrow to highlight the desired parameter. Press

the key to edit the selected parameter. After completing your

entry, be sure to press the key again.

Enabled

As mentioned earlier, a channel must be enabled in order

for it to be measured. This is another place where you can

enable or disable the channel.

Type

There are three channel types from which to choose:

TV -the standard video and audio carriers

DUAL -a video carrier with two independent

audio carriers (a European format)

SNGL -a single carrier

Frequency

This is the frequency of the video carrier in MHz.

Page 27

27

Channel Number

The channel number can range from 1 to 999.

Label

You can enter a label up to four characters in length for

each channel. This label appears next to the channel

number on most screens to help you to remember what

programming is on that channel.

Package

You can organize channels into packages. In the edit box,

you can select any package that is enabled (see the section

on CHANNEL PACKAGES). When you are checking an

installation, you can specify which packages the subscriber

has ordered and your microStealth will verify that the

channels are correctly installed.

Scrambled

If the channel is scrambled, select YES here so that accurate measurements can be made.

Important

microStealth supports several scrambling formats including

the following:

Horizontal Sync Suppression

Audio Offset (TV and DUAL type only)

This is the offset between the video and audio carriers in

MHz.

Audio Offset 2 (DUAL type only)

This is the offset between the video and second audio

carriers in MHz.

When you are finished editing the channel, press the soft key

to return to the channel list.

Page 28

28

Tip

Notice that the selected channel number is displayed in the upper

right-hand corner of the parameter list. When the list is active, you

can use the left or right arrows to select the previous or next channel in the plan. You can also use the numeric keys to directly enter

a specific channel number.

SELECT TILT CHANNELS

Press the key to specify which carriers to measure on the

TILT screen. A list of all enabled channels in the current plan

appears.

Up to six channels can be selected. To select a channel, use the up

or down arrow to highlight the desired channel in the list, then press

the soft key. A check mark appears in the left-hand column of

the list indicating that this is now a TILT channel. Also, the

channel number appears in one of the six boxes above the list.

Press the a second time to deselect the TILT channel.

Note

The TILT channel numbers are displayed above the list in order of

increasing frequency — not in the order in which they were selected.

When you have finished, press the soft key.

Page 29

29

CHANNEL PACKAGES

Channel packages allow you to organize channels into groups or

tiers. You can specify which channels you have installed for a

subscriber when checking an installation. Your microStealth can

then determine if the channels are installed properly.

Press the key to display a list of channel packages.

These are the packages that will be available to you when you edit

a channel. You will be able to select from one of these packages for

each channel in the plan.

To enable a package, press the soft key. A check mark appears

in the left-hand column to indicate that the package is enabled. If

the package is already enabled, pressing the soft key disables it.

You will be asked to verify your intention to disable the package.

Important

The number in the right-hand column of the package list indicates

how many channels are currently using the package. When you

disable a package, all channels using that package default to NONE

(no package).

To edit the name of a package, use the up or down arrow to highlight the desired package and then press the key. You can then

use the edit box to change the name. Be sure to press the key

when you are finished to terminate the entry.

Page 30

30

Tip

There is no minimum on the number of channels that a package

can contain. If you want, you can create a package for only one

channel.

COPY REMOTE PLAN

You can easily copy a channel plan from one microStealth unit to

another. This saves you time when configuring multiple units.

First, connect a cable between the two microStealth units. Select

COPY REMOTE PLAN only on the unit that you want to copy the

channel plan to. A list of all available channel plans found on the

remote unit appears. Use the up or down arrow to highlight the

plan that you want to copy. Press the soft key to begin copying

the plan.

Important

Be sure that the baud rate setting of your microStealth matches that

of the device that it is connected to (see BAUD RATE).

Page 31

31

MODEL MS1300

INTRODUCTION

The best way to learn about microStealth is to use it. Section 2

discusses the individual measurements available with the MS1300.

Each measurement mode discussion includes detailed descriptions

on how to perform the measurement as well as operating controls

and indicators.

INSTALLATION

The INSTALLATION mode allows you to easily check the

channels that you have just installed and verify that they are within

limits. If you have configured channel packages, you can tell your

microStealth which packages the subscriber has ordered and it will

display only those channels.

Press the key to select the INSTALLATION mode or choose

the icon from the NAVIGATOR. Your microStealth will begin

measuring all the enabled channels in the plan. A bar graph

indicates the percentage of channels measured. When microStealth

has finished, you can view the results and verify that all channels

are within limits.

2

Using

microSTEALTH

Page 32

32

SELECTING CHANNEL PACKAGES

If you have configured channel packages, a list of available packages will appear. From this list, you can select the packages that

the subscriber has ordered. The number to the right of the package

name tells you how many channels are included in each package.

Use the up or down arrows to highlight a package and then press the

soft key to select it. A check mark appears in the left-hand

column of the list indicating that the package is selected. If the

highlighted package is already selected, pressing the soft key

deselects it.

Tip

Select “ALL CHANNELS” if you want to include all the enabled

channels in the plan.

Press the soft key or when you have finished. Now your

microStealth will only evaluate the channels from the packages that

you have selected.

Tip

You can return to this screen at any time to change your package

selection by pressing the soft key.

SELECTING THE TEST POINT

The next thing you should do is tell microStealth at which test

point you are located. This determines which set of limits are used.

Press the soft key to sequence through the available test points.

The test point that you have selected is represented in the upper

portion of the screen by one of the following icons:

Subscriber Drop

Ground Block

Tap

User Defined

Page 33

33

Note

Be sure that you have enabled all of the test points that you are

interested in using. The soft key is only available if there is

more than one enabled test point. (see EDIT TEST POINTS).

Important

Only the limits that are enabled in the selected test point are

checked (see EDIT TEST POINTS).

INSTALLATION RESULTS SUMMARY

This is the overall limit check summary for all channels in the

packages that you have selected.

To quickly determine the status of the overall limit check, look at

the PASS/FAIL indicator located in the upper portion of the screen.

This indicates FAIL if any channel is not within the required limits.

For each limit, the worst case actual value is displayed along with a

pass/fail status.

Note

Only the limits that are enabled in the selected test point appear on

this screen. If there are no enabled test points, this screen will not

be available. You can however, view the CHANNEL LIST and

CHANNEL MEASUREMENT screens described below.

Page 34

34

THE CHANNEL LIST

Press the soft key or to sequence to the channel list

screen.

Tip

In addition to using the and keys, you can also use the

left and right arrows to sequence through the results screens.

The channel list provides essential information about each channel.

In the list you will find the channel number in the first column

followed by the label. The level of the video carrier is in the next

column. The package in which the channel is contained is displayed in the fourth column. Finally, the overall limits pass/fail

result for the channel is found in the last column.

THE PASS/FAIL INDICATOR

Use the PASS/FAIL indicator located directly above the channel

list to quickly determine whether the highlighted channel has

passed the limits check. If the channel failed, you can identify the

reason(s) for the failure by looking at the symbols that appear in this

indicator.

Page 35

35

Adjacent Channel Failures

lower adjacent channel level

upper adjacent channel level

both upper and lower adjacent channel

levels

Video Level Failures

video level too high

video level too low

DVA Failures

DVA too high

DVA too low

CHANNEL MEASUREMENT

Press the soft key or to sequence to the channel measurement screen.

This screen displays video and audio carrier level measurements

along with the DVA for the selected channel. Use the up or down

arrows to select the previous or next channel in the list.

Page 36

36

PRINTING AN INSTALLATION REPORT

Press the SHIFT + keys to print a comprehensive report of the

installation results. A bar graph appears indicating the status of the

printout. The report lists level measurements for all the channels

that you installed and indicates out-of-limit conditions with an

overall PASS/FAIL conclusion. Space is provided for you to fill in

subscriber information. You can attach the report to your work

order or file it for future reference.

STORING INSTALLATION RESULTS

Press the SHIFT + keys to store the results of the installation

check into a file. A screen will appear asking you to enter a name

for the file. See the section on VIEW mode to find out how to

access files that you have stored.

Tip

The results from the most recent installation check are stored

automatically. If you have selected another mode and wish to

return to viewing the installation results you can do so without

having to repeat the measurement process. Simply press the

SHIFT + keys and the results of the most recent installation

check will appear.

LEVEL

Press the key to select LEVEL mode or choose the icon

from the NAVIGATOR. Here you can measure the signal level of a

specific channel or frequency. The level is indicated both numerically and on an analog meter.

Page 37

37

ADJUSTING THE REFERENCE LEVEL

You can adjust the reference level setting of the analog bar meter

using the up and down arrows. When you press the SHIFT +

keys, your microStealth automatically sets the optimum reference

level for you.

TUNING BY CHANNEL

When you are tuned to a channel, both the video and audio carriers

of the channel are measured and displayed simultaneously. The

difference between the video and audio carriers (DVA) is also

shown. The channel number, type and label for the channel that

you are currently tuned to appear in the upper right-hand portion of

the screen. You can use the left or right arrows to tune to the

previous or next enabled channel in the plan. You can also use the

numeric entry keys to tune directly to the desired channel. Press

the soft key to tune by frequency.

TUNING BY FREQUENCY

The soft key toggles between frequency and channel tuning.

When you choose frequency tuning, microStealth tunes to the video

carrier frequency of the previously selected channel.

Page 38

38

Use the left and right arrows to tune your microStealth. The

frequency increments or decrements by the step size that you have

specified in the Measurement configuration (see FREQUENCY

TUNING STEP SIZE). You can also use the numeric entry keys to

tune directly to the frequency desired.

MEASUREMENT HOLD

You can freeze the level measurement at any time by pressing the

SHIFT + keys. The measurement is retained even if the cable

is disconnected from the input port. Notice that the mode icon in

the upper left-hand portion of the screen flashes when the measurement is on hold. Press the SHIFT + keys again to release the

hold. The hold is also released when you tune to a different

channel or frequency. The measurement is not retained when

another mode is selected or the microStealth is shut off.

PRINTING THE SCREEN

You can print the entire screen at any time by pressing the SHIFT

+ keys. A bar graph appears indicating the status of the printout.

Tip

If you are using your microStealth at a location where it is not

convenient to connect to a printer (such as on a pole), you can put

the measurement on hold until you are able to access the printer.

Page 39

39

WARNING INDICATORS

If the current measurement is inaccurate due to an out-of-range

condition or hardware failure, microStealth warns you by dimming

the numeric measurement value and displaying one of the following

warning indicators.

Over-range

The signal level is above the measurement range of the

instrument.

Under-range

The signal level is below the measurement range of the

instrument.

Error

A hardware problem exists. If this condition persists, the

unit may need repair.

FULL SCAN

Press the key to select the FULL SCAN mode or choose the

icon from the NAVIGATOR. A spectral graph of all the

carriers in the channel plan appears.

Page 40

40

MOVING THE MARKER

A vertical marker appears over the currently selected channel. The

channel number, type and label appear in the upper right-hand

portion of the screen. The frequency and level of the video and

audio carriers for the selected channel can be seen directly beneath

the graph. You can use the left or right arrows to select the previous

or next channel. You can also use the numeric entry keys to tune

directly to the desired channel.

ADJUSTING THE REFERENCE LEVEL

The reference level setting is displayed above the graph. This is

the level at the very top line. You can adjust the reference level

using the up and down arrows. When you press the SHIFT +

keys, your microStealth automatically sets the optimum reference

level for you.

ADJUSTING THE SCALE

The scale setting is displayed above the graph. You can adjust the

scale to provide the best view of the carrier levels by pressing the

soft key. A new set of soft keys appear. Use the and

soft keys to increment and decrement the scale value. Press the

soft key when you have finished.

Page 41

41

ZOOMING IN AND OUT

To zoom in on or out from the channel selected by the marker,

press the soft key. A new set of soft keys appear. Use the

soft key to zoom in and the soft key zoom out. The magnification factor is displayed above the graph. Press the soft key

when you have finished.

CHECKING LIMITS

You can verify that the carrier levels are within limits. First, you

need to tell microStealth which test point you are at. This determines which set of limits are used.

Press the soft key to access the limits submenu. A new set of

soft keys appear.

Press the soft key to sequence through the available test points.

The test point that you have selected is represented in the upper

portion of the screen by one of the following icons:

Subscriber Drop

Ground Block

Tap

User Defined

Page 42

42

Note

Be sure that you have enabled all of the test points that you are

interested in using. The soft key is only available if there is

more than one enabled test point. (see EDIT TEST POINTS).

When you have selected the limits submenu, the marker information below the graph is replaced by the overall limit check summary

for channels currently being displayed on the graph. For each

limit, the worst case actual value is displayed along with a pass/fail

status. The results are updated upon the completion of each scan.

Important

The limit check results apply only to the channels currently being

displayed on the graph — not the entire channel plan.

Note

Only the limits that are enabled in the selected test point appear on

this screen.

Your microStealth can indicate the minimum and maximum carrier

level limits on the graph. The out-of-limit portions appears as

diagonal “hash” areas. You can toggle the hash lines on and off by

pressing the key.

Note

The limit check results are updated with each scan. They are also

update immediately when you press the or soft keys.

When you are finished viewing the overall limit results, press the

soft key to return to the main menu.

CHECKING LIMITS ON AN INDIVIDUAL CHANNEL

Indicators appear in the marker information area when a channel is

outside the limits of the currently selected test point.

Page 43

43

Up or down arrows to the left of the video level and DVA numeric

measurement tell you when the limits have been exceeded.

measurement too high

measurement too low

When an adjacent channel error occurs, one of the following

indicators will appear in the lower left-hand area of the marker

information area:

lower adjacent channel level

upper adjacent channel level

both upper and lower adjacent channel levels

MEASUREMENT HOLD

You can freeze the scan measurement at any time by pressing the

SHIFT + keys. The measurement is retained even if the cable

is disconnected from the input port. Notice that the mode icon in

the upper left-hand portion of the screen flashes when the measurement is on hold. Press the SHIFT + keys again to release the

hold. The measurement is not retained when another mode is

selected or the microStealth is shut off.

PRINTING THE SCREEN

You can print the entire screen at any time by pressing the SHIFT

+ keys. A bar graph appears indicating the status of the printout.

STORING A SCAN FILE

Press the SHIFT + keys to store the current scan measurement

into a file. A screen will appear asking you to enter a name for the

file. Once stored, you will be able to recall the file at a later time

and view it on the Scan screen. You will be able to adjust the screen

settings the same as when you are viewing a “live” measurement.

See the section on VIEW mode to find out how to access files that

you have stored.

Page 44

44

WARNING INDICATORS

If the current measurement is inaccurate due to an out-of-range

condition or a hardware failure, MicroStealth warns you by displaying one of the following warning indicators to the left of the numeric level measurement in the marker information area:

Over-range

The signal level is above the measurement range of the

instrument.

Under-range

The signal level is below the measurement range of the

instrument.

Error

A hardware problem exists. If this condition persists, the

unit may need repair.

TILT

TILT mode simplifies the process of balancing an amplifier. TILT

mode can only be accessed by choosing the icon from the

NAVIGATOR. A spectral graph of the TILT carriers appears.

Page 45

45

Important

You can choose which carriers appear on this screen when you

configure your channel plan (see SELECT TILT CHANNELS).

MOVING THE MARKER

You can view up to six carriers. A vertical marker appears over the

currently selected carrier. The channel number, type and label

appear in the upper right-hand portion of the screen. The frequency and level of the selected carrier can be seen directly beneath the graph. You can use the left or right arrows to select the

previous or next carrier.

SELECTING THE LOW AND HIGH CARRIERS

Notice that the bars representing the low and high pilots are solid

and all others are dim. You can select which carriers are used for

the tilt measurement. To select the low pilot carrier, move the

cursor to the desired carrier and press the soft key. To select

the high pilot carrier, move the cursor to the desired carrier and

press the soft key. The tilt measurement is calculated from

the low and high pilot carriers that you have selected.

ADJUSTING THE REFERENCE LEVEL

The reference level setting is displayed above the graph. This is

the level at the very top line. You can adjust the reference level

using the up and down arrows. When you press the SHIFT +

keys, your microStealth automatically sets the optimum reference

level for you.

ADJUSTING THE SCALE

The scale setting is displayed above the graph. You can adjust the

scale to provide the best view of the carrier levels by pressing the

soft key. A new set of soft keys appears. Use the and

soft keys to increment and decrement the scale value. Press the

soft key when you have finished.

Page 46

46

MEASUREMENT HOLD

You can freeze the tilt measurement at any time by pressing the

SHIFT + keys. The measurement is retained even if the cable

is disconnected from the input port. Notice that the mode icon in

the upper left-hand portion of the screen flashes when the measurement is on hold. Press the SHIFT + keys again to release the

hold. The measurement is not retained when another mode is

selected or the microStealth is shut off.

PRINTING THE SCREEN

You can print the entire screen at any time by pressing the SHIFT

+ keys. A bar graph appears indicating the status of the printout.

STORING A TILT FILE

Press the SHIFT + keys to store the current tilt measurement

into a file. A screen will appear asking you to enter a name for the

file. Once stored, you will be able to recall the file at a later time

and view it on the Tilt screen. You will be able to adjust the screen

settings the same as when you are viewing a “live” measurement.

See the section on VIEW mode to find out how to access files that

you have stored.

SCAN

The MS1300 includes an additional SCAN mode that can display

up to six video carriers. You can access this mode by choosing the

icon from the NAVIGATOR.

Page 47

47

Note

The channels that appear on this screen are the same ones that you

selected when you configured your tilt channels. (see SELECT

TILT CHANNELS).

MOVING THE MARKER

A vertical marker appears over the currently selected carrier. The

channel number, type and label appear in the upper right-hand

portion of the screen. The frequency and level of the selected

carrier can be seen directly beneath the graph. You can use the left

or right arrows to select the previous or next carrier.

ADJUSTING THE REFERENCE LEVEL

The reference level setting is displayed above the graph. This is

the level at the very top line. You can adjust the reference level

using the up and down arrows. When you press the SHIFT +

keys, your microStealth automatically sets the optimum reference

level for you.

ADJUSTING THE SCALE

The scale setting is displayed above the graph. You can adjust the

scale to provide the best view of the carrier levels by pressing the

soft key. A new set of soft keys appears. Use the and

soft keys to increment and decrement the scale value. Press the

soft key when you have finished.

CHECKING LIMITS

You can verify that the carrier levels are within limits. First, you

need to tell microStealth which test point you are at. This deter-

mines which set of limits are used. Press the soft key to

sequence through the available test points. The test point that you

have selected is represented in the upper portion of the screen by

one of the following icons:

Subscriber Drop

Ground Block

Tap

User Defined

Page 48

48

Note

Be sure that you have enabled all of the test points that you are

interested in using. The soft key is only available if there is

more than one enabled test point. (see EDIT TEST POINTS).

When you have selected the proper test point, microStealth shows

the minimum and maximum carrier level limits for that test point

on the graph. The out-of-limit portions appears as diagonal “hash”

areas. You can toggle the hash lines on and off by pressing the

key.

You can quickly check to see if all SCAN carriers are within limits

by looking at the PASS/FAIL indicator above the graph.

MEASUREMENT HOLD

You can freeze the scan measurement at any time by pressing the

SHIFT + keys. The measurement is retained even if the cable

is disconnected from the input port. Notice that the mode icon in

the upper left-hand portion of the screen flashes when the measurement is on hold. Press the SHIFT + keys again to release the

hold. The measurement is not retained when another mode is

selected or the microStealth is shut off.

PRINTING THE SCREEN

You can print the entire screen at any time by pressing the SHIFT

+ keys. A bar graph appears indicating the status of the printout.

Page 49

49

STORING A SCAN FILE

Press the SHIFT + keys to store the current scan measurement

into a file. A screen will appear asking you to enter a name for the

file. Once stored, you will be able to recall the file at a later time

and view it on the Scan screen. You will be able to adjust the screen

settings the same as when you are viewing a “live” measurement.

See the section on VIEW mode to find out how to access files that

you have stored.

AUTO TEST

Your MicroStealth is capable of performing unattended, automated

level measurement sequences. The sequences can be programmed

to repeat over a period of time. Measurement data is stored into a

file that can be viewed, printed or uploaded to StealthWare. See the

section on VIEW mode to find out how to access files from Auto

Tests that you have performed.

Important

When performing an Auto Test, only the channels enabled in the

currently selected channel plan are measured.

CONFIGURING AN AUTO TEST

Choose the icon from the NAVIGATOR to configure an

automated test sequence. Your MicroStealth will guide you step by

step.

Choose Location

If desired, you can log information about the location at

which you are performing the test. The information will be

stored in the Auto Test file along with the measurement

data. It will be available when viewing and printing the

Auto Test results. This first screen presents you with a list

of available locations. To create a new location, press the

soft key. Press to delete the location highlighted

in the list. Press to select the highlighted location and

continue to the next step.

Page 50

50

Tip

If you are not interested in logging the information, select

NONE from the list. Your MicroStealth will present you

with only the steps required to configure the test.

Tip

You can rename the location highlighted in the directory by

pressing the SHIFT + keys. A screen will appear asking

you to enter a new name.

New/Edit Location

This screen is where you enter the information for a new or

existing location. Use the up and down arrows to select the

item to be edited. The items that appear in the list depend

on the type of location you have selected. If you regularly

perform tests at this location, you can save it for future use

so that you only need to enter the information once. To do

this, press the soft key and enter a name for the

location. When you are done editing, press to continue

configuring the Auto Test.

Note

Your MicroStealth will remind you when you have not

stored the location. You should only do this, however, if

you think you will return for another test.

Choose Probe Point

Some location types have multiple points at which you can

make test measurements. If you have selected such a type,

this screen will appear. Use the up and down arrows to

choose the appropriate probe point from the list and then

press the soft key.

Measure Voltage

You can log voltage measurements that you make using

your multimeter. These will appear when viewing or

printing the results of the Auto Test. When you have

finished entering the measurements, press the soft key.

Page 51

51

Compensation

Compensation is added directly to the signal level measurements. You can use this to compensate for losses associated

with probe points found on certain amplifiers. The default

is the Probe Compensation value specified in Configure.

Enter a different value if necessary. Press the soft key

to continue.

Results File Name

Enter the name you want to use for the results file that is

created. Your MicroStealth will let you know if there is

already a results file with the name that you enter. If

desired, you can overwrite an existing file of the same

name. When you are ready for the next step, press the

soft key.

Type of Test

Tests can be executed immediately or scheduled over a

period of time. Use the up and down arrows to select the

type of test you want and then press the soft key.

Set Schedule

This screen will appear only if you have selected a scheduled test. The default schedule will perform four intervals

over a twenty-four hour period beginning at the present

time and date. If you require a different schedule, use the

up and down arrows to edit the schedule and then press the

soft key.

Temperature

The ambient temperature at which the test is performed is

recorded. Your MicroStealth contains an internal temperature sensor for this purpose. If you prefer to use your own

thermometer, you can manually enter the temperature

here.

Page 52

52

Important

For scheduled tests, the manual temperature entry is used

for the first interval only. Subsequent intervals will record

the temperature as measured by the internal sensor. For

accurate measurements, MicroStealth reads the internal

temperature sensor immediately upon power-up.

When you are ready to begin the test, press the soft

key.

PERFORMING AN AUTO TEST

The following screen appears when MicroStealth is performing

Auto Test measurements:

The number, type and carrier frequency of the channel currently

being measured is displayed. The bar graph indicates the percentage of channels measured.

If you are performing a scheduled test, the time remaining until the

next interval will appear upon completion of the measurements.

Page 53

53

Important

To conserve battery life, your MicroStealth will automatically shut

itself off between scheduled intervals.

When the auto test is complete, MicroStealth will display a list of

Auto Test files that are available for viewing and printing.

Note

See the section on VIEW mode to find out how to access files from

Auto Tests that you have performed.

CANCELING AN AUTO TEST

While performing an Auto Test, you will not be able to select other

modes without first canceling the test in progress. Doing this will

result in an incomplete test — you will not be able to resume the

previously configured test.

Press the soft key to cancel the Auto Test. MicroStealth will

display a warning message and ask you to confirm your request.

VIEW

To access measurement files that you have stored in your

MicroStealth, choose the icon from the NAVIGATOR. Files

are categorized into Installations, Scans (including Tilt measurements), and Auto Tests.

Page 54

54

Use the up and down arrows to select the type of file that you want

to view from the main menu and then press the key.

THE FILE DIRECTORY

Upon selecting the file category from the VIEW main menu, you

are presented with a directory of existing files. For example, below

is the directory of Scan files:

To view a file, use the up and down arrows to highlight the name of

the file that you want to view and then press either the soft

key or the key.

Page 55

55

To delete the highlighted file, press the soft key. You can

delete more than one file at a time by selecting multiple files using

the soft key. Each press of this soft key alternately selects and

deselects the file that you have highlighted. An indicator appears in

the left-hand column to show that you have selected the file. Select

all the files that you want to delete before pressing the soft

key.

Tip

You can print Installation and Auto Test files from the directory.

To print an Installation or Auto Test file, use the up and down

arrows to highlight the name of the file that you want to print and

then press SHIFT + . If a scheduled type Auto Test is highlighted, all intervals contained in the file will be printed. You must

view Scan files in order to print them.

Tip

You can rename the file highlighted in the directory by pressing the

SHIFT + keys. A screen will appear asking you to enter a new

name.

VIEWING INSTALLATION FILES

You view Installation files using the Installation results screens

described earlier in this manual. When viewing a file, you can print

a comprehensive report of the installation results by pressing the

SHIFT + keys.

Note

When viewing an Installation file, the date and time that the file

was stored appears in the status bar and the file name appears at the

top of the screen above the title bar.

Tip

You can resave an Installation file by pressing the SHIFT + keys.

This allows you to change the name of the file.

Page 56

56

VIEWING SCAN FILES

There are three types of scans that you can store and view — full

scans, six-channel scans and tilt measurements. The type of scan

depends on which screen you are in when you store the file. Once

the scan is stored, you cannot change its type.

Tip

You can tell what type of scan you have selected in the directory

without having to view it. Just look at the icon in the upper righthand portion of the screen directly below the title bar:

FULL SCAN

SIX-CHANNEL SCAN

TILT MEASUREMENT

You view Scan files using the same screen in which the file was

stored. For example, the following screen is used to view full scan

files:

Important

When viewing a Scan file, you can adjust the screen settings the

same as when you are viewing a “live” measurement. These

settings are described earlier in this manual.

Page 57

57

Note

You can print the entire screen at any time by pressing the SHIFT

+ keys. A bar graph appears indicating the status of the printout.

Note

When viewing a Scan file, the date and time that the file was stored

appears in the status bar and the file name appears at the top of the

screen above the title bar.

Tip

You can resave a Scan file by pressing the SHIFT + keys. This

allows you to change the name of the file and/or save any changes

you have made to the screen settings.

VIEWING AUTO TEST FILES

Upon selecting the desired Auto Test file, you are presented with a

list of intervals that are contained within the file. The list includes

the interval number, date, time and temperature when the interval

was recorded.

Note

Immediate type Auto Tests consist of only a single interval.

Press the soft key to view information about the Auto Test file.

This displays the information that was logged when you configured

the test. The items presented depend upon the location type that

you selected.

Page 58

58

Note

To print a 24-hour format report, use the up and down arrows to

highlight the first interval that you want included in the report and

then press SHIFT + . The report will include the highlighted

interval plus the following three for a total of (up to) four intervals.

To view the measurement data from an interval, use the up and

down arrows to highlight the desired interval then press either the

soft key or the key. There are three screens in which the

data is presented:

The first screen that will appear is a tabular list that includes the

video and audio carrier levels along with the delta V/A for each

channel. Use the up and down arrows to scroll through the list.

Page 59

59

Indicators appear within the list to flag out-of-limit conditions. The

following table relates each indicator with its meaning:

* adjacent channel limit violation

↑ over limit violation

↓ under limit violation

> over range measurement error

< under range measurement error

E unlocked measurement error

To view the data for the channel highlighted in the list press the

soft key or the key. Use the PASS/FAIL indicator to

quickly determine whether the channel has passed the limits check.

If the channel failed, you can identify the reason(s) for the failure

by looking at the symbols that appear in this indicator.

Press the soft key or the key again to scroll to the limit

check summary. To quickly determine the status of the overall

limit check, look at the PASS/FAIL indicator located in the upper

portion of the screen. This indicates FAIL if any channel is not

within the required limits. For each limit, the worst case value is

displayed along with a pass/fail status.

Press the soft key to sequence through the available test points.

The test point that you have selected is represented in the upper

portion of the screen by one of the following icons:

Subscriber Drop

Ground Block

Tap

User Defined

Note

Be sure that you have enabled all of the test points that you are

interested in using. The soft key is only available if there is

more than one enabled test point. (see EDIT TEST POINTS).

Page 60

60

Only the limits that are enabled in the selected test point will be

checked.

Note

When viewing the data from an interval, you can print a comprehensive report by pressing SHIFT + .

Page 61

61

MODEL MS1300

USING THE REFERENCE SECTION

This section provides additional information concerning the use of

the MS1300. Items to be discussed include; Help, Information, and

Technical Support.

HELP

The HELP mode provides on-line user assistance by means of

context-sensitive help screens. During normal operations, soft key

icons appear at the bottom of the display. Each help screen describes the condition of the soft key icons at the time HELP was

pressed.

Press the SHIFT + key to select the HELP mode.

3

Reference

Page 62

62

Next to the icon is a brief description of the function that the soft

key performs. If an icon is currently inactive "feature not available"

is displayed.

INFORMATION

Choose the icon from the NAVIGATOR. Here you can view

information concerning your MS1300. The type of information

includes; model, frequency range, serial #, firmware version,

calibration date, and channel plan.

Page 63

63

TECHNICAL SUPPORT

We've worked hard to make the MS1300 as easy-to-use as possible.

However, if you have a problem using your unit you can contact

Wavetek's Technical Support for help. You can reach Wavetek's

Technical Support, Monday through Friday between 8 am and 5 pm

at (317) 788-5960. Wavetek also maintains a support forum on the

Internet. You can leave messages and a Technical Support Specialist will get back to you at Internet address:

CATVSUPPORT@wavetek.com.

If you received your unit and found it to be damaged or incomplete

in any way, phone Wavetek immediately. Save the shipping carton

and packing material in the event that you have to return it.

FOR CUSTOMER SERVICE call: WAVETEK (800) 851-1198,

International Customers, contact your local Wavetek Representative.