Page 1

Watts TK-99E

Backflow Preventer Test Kit

IS-TK-99E

Designed for operator convenience and rugged

reliability in a compact package. The Watts TK-99E

offers the latest in gauge technology in a durable

custom-fitted case with room for tools.

Features:

• Lightweight body for durability & chemical resistance.

• Color-coded valves and hoses for ease

of use.

• Large anti-parallax dial which indicates

descending measurement, accurate to ±

1 percent of full scale.

• Replaceable hose lter and valve stem

seals for eld reliability.

• Top mounted drain/purge valves and

conveniently located line pressure gauge.

• Complete kit contains gauge with colorcoded valves and hoses, hose adapter,

shock cord for easy mounting and purge

hose encased in a durable case with

room for tools.

• Forward needle valve positions for easy

access.

Bleed Valve B

Bleed Valve A

Connections

Caution: To avoid freeze damage to the test

kit it should be stored in a dry warm area when

not in use.

Specifications:

• Maximum working pressure - 200 psig

• Maximum working temperature - 200°F

• Gauge - 4.5" diameter face, dual scale

0-15 psid and 0-1 kg/cm2, ± 1% accuracy full scale

• Test valves - Three needle valves

• Pressure gauge - 0-200psi system

gauge

C

A

C

A

B

B

Needle Valves

• Hoses - Three 6 foot color-coded hoses

with female threaded swivel couplings.

• Adapter - Three 3⁄4" x 1⁄4" bushings

Three 1⁄2" x 1⁄4" bushings

Three 3⁄8" x 1⁄4" bushings

Three 1⁄4" Flared ttings

• One shock cord.

• One moisture resistant instruction guide

• One lightweight durable carrying case

Page 2

Test Procedure for Spill Resistant Vacuum Breaker

Note: For both of the following tests the test kit must be held at the same level as assembly being tested.

A. Before starting test, all needle valves and bleed valves on test kit must be closed. B. Flush test cocks before test.

Bleed Valve A

Bleed Valve B

Test No. 1 and 2

008QT shown

Test No. 1 - Differential Test

Requirement: Differential pressure across check must be 1.0

psid or above

Step 1: Remove two screws on top of hood then remove hood.

Step 2: Install hose between test cock and connection “A”

high side (red) of test kit.

Step 3: Open test cock then open bleed valve “A” on top of

test kit. Bleed air from hose then close bleed valve

“A” on top of test kit.

Step 4: Open needle valve “A” on high side (red) of test kit.

Step 5: Close shutoff valve No. 2 then shut off valve No. 1 on

test assembly.

Step 6: Slowly unscrew bleed screw on spill resistant vacuum

breaker body to relieve pressure down stream of

check (about 3 turns).

Step 7: When dripping from bleed screw stops and psid nee-

dle on gauge stabilizes, record the differential pressure.

Test No. 2 - Air Inlet - Vent Opening

Requirement: Air inlet must start to open when supply pressure is 1.0psi or above. Air inlet must be fully open when supply pressure is atmospheric.

Step 8: Slowly open needle valve “C” bypass (yellow) until

psid gauge reads 1.0psid then close needle valve “C”

bypass (yellow) holding pressure at 1.0psid.

Step 9: Visually inspect that the vent on top is slightly open,

about 1⁄32" or more, to pass test.

Step 10: Open needle valve “C” bypass (yellow) fully until

dripping from connection “C” stops.

Step 11: Visually inspect that the vent is fully open to pass

test.

Step 12: Replace hood and two screws on top of assembly.

Step 13: Restore valve to original working condition.

Note: After test, all valves on test kit must be fully open and

hose removed to prevent damage to test kit.

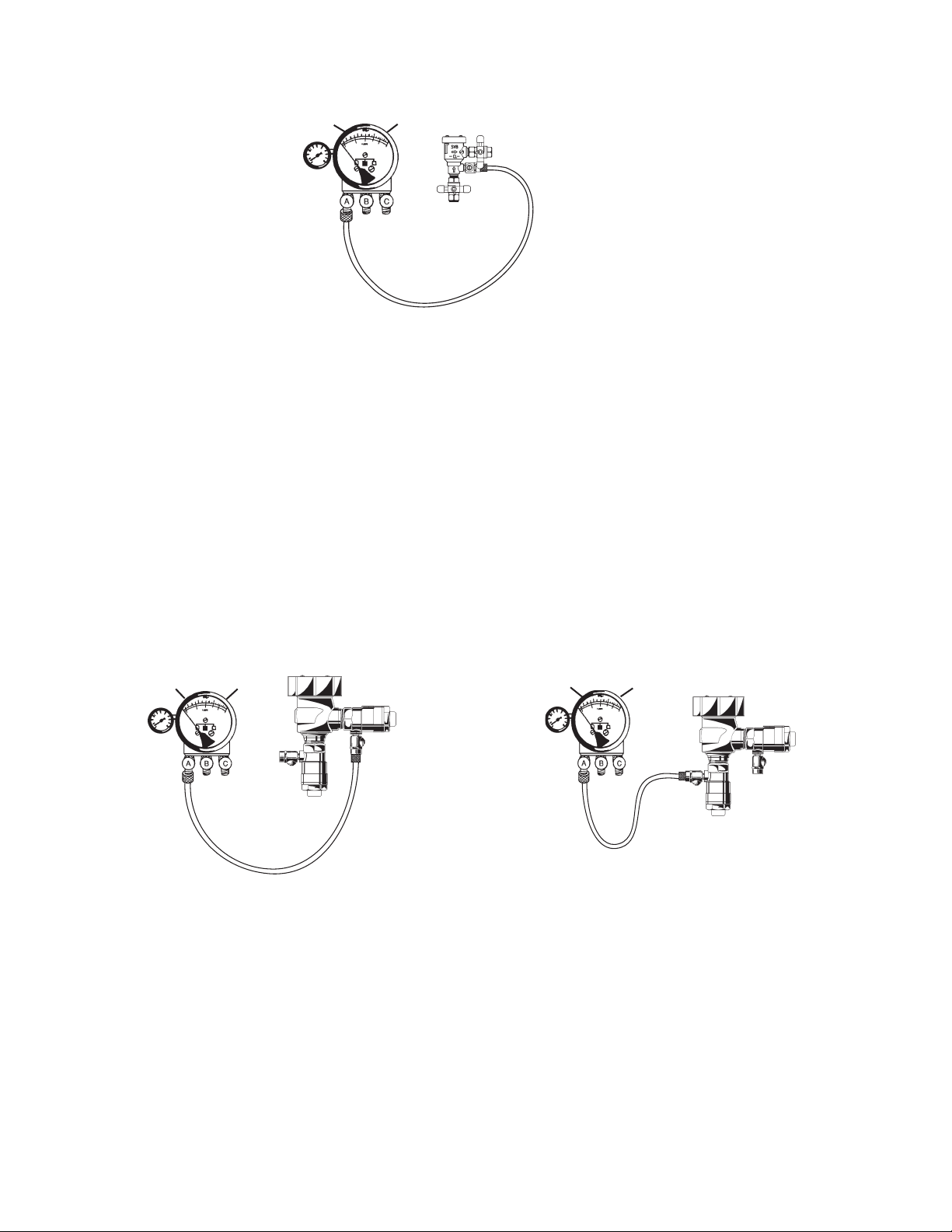

Test Procedure for Pressure Type Vacuum Breaker

NOTE: For both of the following tests the test kit must be held at the same level as assembly being tested.

A. Before starting test all needle valves and bleed valves must be closed. B. Flush test cock #2 and #1.

Bleed Valve A

Bleed Valve B

Test Cock No. 2

Bleed Valve BBleed Valve A

Test Cock

No. 1

Test No. 1

800M4-QT shown

Test No. 1 - Air Inlet

Requirement: Air inlet must start to open when down stream

pressure is 1.0psi or above.

Step 1: Remove two screws on top of hood and remove hood.

Step 2: Install hose between test cock No. 2 and connection

“A” on high side (red) on test kit.

Step 3: Open test cock No. 2 and needle valve “A” high side

(red) on test kit.

Step 4: Open bleed valve “A” on top of test kit. Bleed air from

hose. Then close bleed valve “A” on top of test kit.

Step 5: Close shutoff valve No. 2 then shutoff valve No. 1.

Step 6: Slowly open needle valve “C” bypass (yellow) just as air

inlet opens. Record differential pressure.

Step 7: Close test cock No. 2 and remove hose.

Step 8: Close needle valve “C” bypass (yellow).

Step 9: Open shutoff valve No. 1.

2

Test Cock

No. 1

Test Cock No. 2

Test No. 2

800M4-QT shown

Test No. 2 - Test Check Valve Pressure Drop

Requirement: Supply pressure drop must be 1.0psid or

above when water ow stops from test cock No. 2.

Step 10: Install hose between test cock No. 1 and connec-

tion “A” high side (red) on test kit.

Step 11: Open test cock No. 1 and bleed valve “A” on top of

test kit. Open bleed valve “A” on top of test kit and

bleed air from hose. Shutoff bleed valve “A” on top

of test kit.

Step 12: Close shutoff valve #1.

Step 13: Open test cock No. 2. When ow of water out of

test cock No. 2 stops, the differential reading is the

pressure drop record.

Step 14: Close test cock No. 1 and test cock No. 2.

Step 15: Replace hood and two screws on top of hood.

Open shutoff valves Nos. 1 then 2.

Page 3

Test Procedure for Reduced Pressure Assembly

A. All needle valves must be closed on test kit.

B. Open test cock No. 4 and ush test cocks Nos. 1, 2 and 3 on reduced pressure assembly then close test cock No. 4.

C. Attach hoses as shown. Bleed air from kit, close No. 2 shutoff.

Bleed Valve A

High

(red)

Low

(Blue)

Bleed Valve B

Bypass

(yellow)

Test No. 1 - Check Valve No. 2

Purpose: To test check valve No. 2 for tightness against

reverse ow.

Requirements: Valve must be tight against reverse ow under

all pressure differentials.

Step 1: Slowly open the needle valve “A” high side (red) and

“C” bypass (yellow). Keep the “B” low (blue) closed.

Step 2: Open test cock No. 4. Open test cock No. 2 and test

cock No. 3 after opening test cock No. 4.

Step 3: Indicated pressure differential will decrease slightly.

If pressure differential continues to decrease (until

the vent opens) the No. 2 check valve is reported as

“leaking”.

Test No. 2 - Shutoff Valve No. 2

Purpose: To test shutoff valve No. 2 for tightness.

Step 1: After passing Test No. 1, continue to test No. 2 by

closing test cock No. 2.

Step 2: The indicated pressure differential will decrease

slightly. If pressure differential continues to decrease

(approaching “zero”) the No. 2 shutoff valve is reported to be “leaking”. Note: A leaking No. 2 shutoff

will give a false reading in tests No. 3 and 4.

No. 2

Shutoff

909 shown

Test No. 4 - Pressure Differential Relief Valve

Purpose: To test operation of pressure differential relief valve.

Requirements: The pressure differential relief valve must

operate to maintain the “zone” between the two check valves

at least 2 PSI less than the supply pressure.

Step 1: Close needle valve “C” bypass (yellow).

Step 2: Open needle valve “A” high side (red).

Step 3: Open needle valve “B” low (blue) very slowly until the

differential gauge needle starts to drop.

Step 4: Hold the valve at this position and observe the gauge

reading at the moment the rst discharge is noted

from the relief valve. Record this as the opening differential pressure of the relief valve. Note: it is important

that the differential gauge needle drops slowly.

Step 5: Close test cocks Nos. 2 and 3. Remove hose from

test cocks Nos. 2 and 3.

Step 6: Use bypass hose (yellow) to relieve pressure from

test kit by opening needle valve “A”, “B” and “C” and

bleed valves “A” and “B”.

Step 7: Remove all test equipment and open No. 2 shutoff

valve of the device.

Test No. 3 - To test No. 1 Check Valve

Purpose: To test check valve No. 1 for tightness.

Requirements: Valve must be tight against reverse ow under

all pressure differentials.

Step 1: Close needle valve “A” high side (red) and open test

cock No. 2.

Step 2: Close test cock No. 4. Disconnect bypass hose (yel-

low) at test cock No. 4.

Step 3: Open needle valve “B” low (blue) and “C” bypass

(yellow), bleeding to atmosphere, then closing needle

valve “B” (blue) restores the system to a normal static

condition.

Step 4: Observe the pressure differential gauge. If there is a

decrease in the indicated value, the No. 1 check valve

is reported as “leaking”.

3

Page 4

Test Procedure for Double Check Valve Assembly

A. Before starting test, all needle valves and bleed valves on test kit must be closed.

B. Flush test cocks before test.

NOTE: Supply pressure gauge reading will decrease when performing this test procedure.

Bleed Valve A

Bleed Valve B

High

(red)

Low

(blue)

Bypass

(yellow)

007 shown

Test No. 1 - Check Valve No. 1

NOTE: Close all needle valve “A”, “B” and “C” and bleed

valve “A” and “B” on test kit.

Step 1: Insure shutoff No. 1 is open, shutoff No. 2 is closed.

Step 2: Install high side hose between connection “A” high

side and test cock No. 3, low side hose between

“B” low side and test cock No. 2 and open both test

cock No. 2 and 3.

Step 3: Open bleed valve “A” to bleed air from the high side.

Close “A” then open bleed valve “B” to bleed low

side. Close “B”.

Step 4: Connect bypass hose between connection “C”

bypass and loosely to test cock No. 1. Open needle

valves “A” high side and “C” bypass to vent air from

bypass hose. Tighten bypass hose at test cock No.

1, open test cock No. 1.

Step 5: Close shutoff No. 1. Slowly open bleed “B” until dif-

ferential gauge rises to 2psi and close. If the differential reading does not decrease, record check valve

as “tight”.

Step 6: Close all test cocks and open bleed valves “A” and “B”.

Then close needle valves “A”, “B” and “C” and bleed

valves “A” and “B”. Remove hoses from test cocks.

Step 9: Connect bypass hose loosely to test cock No. 1.

Open needle valves “A” high side and “C” bypass to

vent air from the bypass hose. Tighten bypass hose at

test cock No. 1, open test cock No. 1.

Step 10: Close shutoff No. 1, then slowly open bleed “B” until

differential gauge rises to 2psi and close. If the differential reading does not decrease, record check as

tight. Close all test cocks and remove hoses. Open

bleed valves “A” and “B”. Restore valve to original

working condition.

NOTE: The assembly will fail both the rst and second check

valve tests above, if shutoff No. 2 leaks excessively. To test for

a leaky No. 2 shutoff, use the following procedure.

Test for Leaky No. 2 Shutoff

Step 11: Connect the high side hose to test cock No. 1, low

side hose to test cock No. 4. Open test cocks No. 1

and 4. Close shutoffs No. 1 and 2.

Step 12: Close needle valve “C” bypass. Open needle valve

“A” high side, then open needle valve “B” low side

one turn, loosen hose at test cock No. 4 to remove

air. Retighten hose.

Step 13: If the differential gauge rises above 0 there is exces-

sive leakage at shutoff No. 2 and it must be replaced

to test the assembly.

Test No. 2 - Check Valve No. 2

Step 7: Move the high side hose to test cock No. 4, low side

hose to test cock No. 3 and open both test cock No.

3 and 4. Remove bypass hose from test cock No. 1,

open shutoff valve No. 1.

Step 8: Open bleed valve “A” to bleed air from the high side.

Close bleed “A” then open bleed “B” to bleed low

side. Close bleed “B”.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

IS-TK-99E 0829 EDP# 1915122 © 2009 Watts

Loading...

Loading...