Page 1

For Balancing and Flow Measurement Applications

ES-TDV

Job Name

–––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

–––––––––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Engineer

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

––––––––––––––––––––––––––––––––––––––––

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Series TDV

Triple Duty Valves

Sizes: 21⁄2" – 12" (65 – 300mm)

Series TDV Triple Duty Valves are designed for use on single, double,

and vertical in-line pump applications. The TDV combines the functions of a positive hand-tight shutoff valve, check valve, and flow control valve into one versatile package, and eliminates the need to utilize

three separate valves on the pump system. By using the series TDV,

fewer components and fewer connections are required. Therefore,

installation time is reduced, less space is needed, and the potential

for leaks is reduced: adding up to significant cost savings.

The field-convertible design allows the TDV to be changed from

the factory-standard, straight pattern to an optional angle pattern by using standard tools, and no additional parts. This allows

the TDV to be used as a replacement for angles and elbows,

and generates even greater savings on space and connections.

The TDV is designed for easy field serviceability with bonnet O-rings

that can be replaced under pressure by backseating the valve, and

seats that can be changed without the use of special tools.

Features

• Reduced field installation and material cost

• Eliminates requirement of three valves on pump discharge

• Soft seat to ensure tight shutoff

• Spring closure design, non-slam silent check valve feature

•Valve Cv designed to ASHRAE flow recommendations for

quiet system operation

•Grooved end connections with optional flange adaptors

Specifications

A Triple Duty Valve shall be installed on the discharge side of each

pump as indicated on the plans. The valve body shall be ductile iron

with grooved ends and anti-rotation lugs on the inlet and outlet of

the body. The valve shall have two

1

⁄4" (6mm) NPT connections on

each side of the valve seat. Two connections to have brass pressure

metering ports with check valve and gasketted caps. Two other connections to be supplied with brass drain plugs. Metering ports are to

be inter-changeable with brass drain plugs. The valve disc shall be

bronze plug type with engineered resin seat 2

1

/2" – 6" and EPDM

for 8" – 12". Valve stem shall be stainless steel with wrench flats.

Flange adaptors, where necessary, shall be class 125 ductile iron

flanges with anti-rotation lugs and EPDM gaskets. Valve shall be a

Watts Regulator Company Series TDV.

Materials of Construction

Body Ductile Iron ASTM A536 GR65-45-12

Disc Bronze ASTM B584 C-84400

Seat 2

1

⁄2" – 6" Engineered Resin,

8" – 12" EPDM

Stem Stainless Steel ASTM S582 Type 416

Spring Stainless Steel ASTM S302

O-rings Buna-N

Metering Ports Brass NPT Brass Body with Cap

Drain Tappings (2)

1

/4

" with Brass plug

Optional equipment

Flange Adapters Ductile iron ASTM S536 GR 65045-12

Flange Gaskets EPDM

Insulation Fiberglass

TDV

Angle Pattern

Straight Pattern

Flange Adapter Details

VALVE SIZE 125psi/150psi DUCTILE IRON

Bolt Bolt Diameter

No. Size

in. mm in. mm in. mm

21⁄

2

64 4

5

⁄

8 16 5

1

⁄

2 140

37645⁄

8 16 6 152

4 102 8

5

⁄

8 16 7

1

⁄

2 191

5 127 8

3

⁄

4 19 8

1

⁄

2 216

6 152 8

3

⁄

4 19 9

1

⁄

2 214

Page 2

ES-TDV 0341 © Watts Regulator Company, 1997 Printed in U.S.A.

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

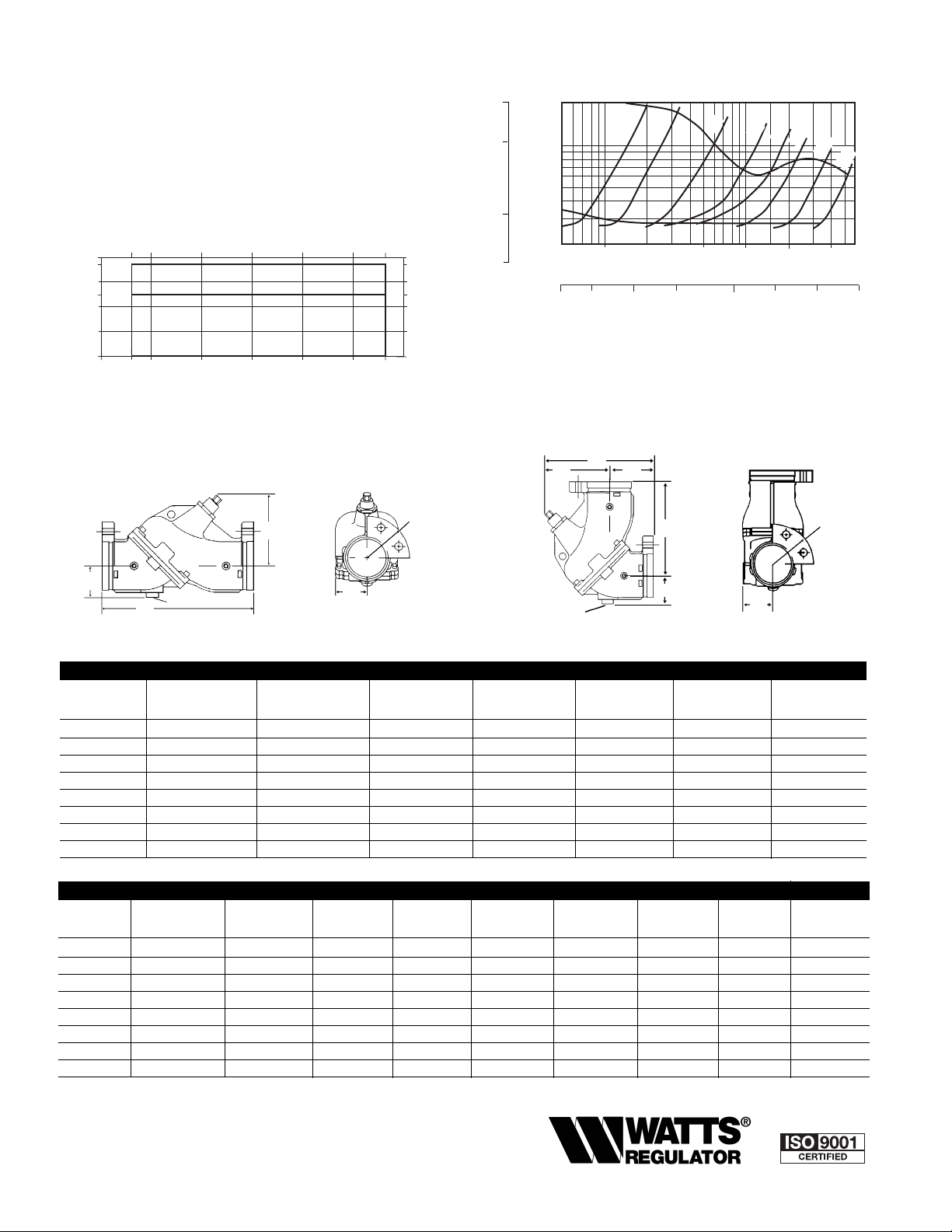

Dimensions-Weights

A

C

D

F

F

2

E

A

C

D

F1

Flange

Dia.

Flange

Dia.

Spacer

Spacer

Pressure-Temperature

Grooved Ends Only

Maximum Working Pressure: 375psi (26.25 bars)

Maximum Temperature: 230°F (110°C)

Flange

Maximum Working Pressure: 175psi (12 bars)

Maximum Temperature: 230°F (110°C)

Angle Pattern (Convertible)

Straight Pattern (Standard)

Straight Pattern

SIZE (DN) DIMENSIONS FLANGE DIA. SPACER WEIGHT

ACDF125#

in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs kgs

21⁄

2

65 12 305 7 178 23⁄

4

70 29⁄

16

65 7 178 1 25 19 8.6

380 12305 713⁄

16

198 2

7

⁄

16

613767

1

⁄

2

191 1 25 24 10.9

4 100 14 356 8 203 3 76 37⁄

16

87 91⁄

4

235 11⁄

4

32 42 19.0

5 125 171⁄

2

445 101⁄

8

257 35⁄

8

92 415⁄

16

125 10 254 11⁄

4

32 81 36.7

6 150 2011⁄

16

526 103⁄

8

264 47⁄

16

113 57⁄

8

149 11 279 2 51 120 54.4

8 200 283⁄

16

716 2213⁄

16

579 511⁄

16

144 77⁄

8

200 131⁄

2

343 21⁄

4

57 310 140.6

10 250 30 762 285⁄

8

727 69⁄

16

167 915⁄

32

240 16 406 21⁄

4

57 460 208.6

12 300 381⁄

16

967 325/

8

829 75⁄

8

194 125⁄

8

321 19 483 21⁄

4

57 870 394.6

Angle Pattern (Field Convertible*)

SIZE (DN) DIMENSIONS FLANGE DIA. SPACER WEIGHT

ACDEF

1

F

2

125#

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs kgs

21⁄265 115⁄8295 73⁄8187 23⁄470 45⁄8117 29⁄1664 7 178 7 178 1 25 19 8.6

3801111⁄

16

297 8

3

⁄

8

213 2

7

⁄

16

61 3

7

⁄

8

983767

13

⁄

16

199 7

1

⁄

2

191 1 25 24 10.9

4 100 123⁄8314 95⁄8245 3 76 43⁄8111 37⁄1687 8 200 91⁄4235 11⁄432 42 19.0

5 125 155⁄8397 12 305 35⁄892 51⁄2140 415⁄16124 101⁄8253 10 254 11⁄432 81 36.7

6 150 17 432 141⁄

8

359 4

7

⁄

16

111 6

5

⁄

8

168 5

7

⁄

8

149 10

3

⁄

8

264 11 279 2 50 120 54.4

8 200 32 813 1815⁄16481 511⁄16145 93⁄16234 77⁄8200 2213⁄16580 131⁄2343 21⁄457 310 140.6

10 250 387⁄8975 205⁄16516 69⁄16161 93⁄4248 915⁄32240 285⁄8727 16 406 21⁄457 460 208.6

12 300 465⁄

8

1184 24

1

⁄

16

612 7

5

⁄

8

194 14 356 12

5

⁄

8

321 32

5

/

8

825 19 483 2

1

⁄

4

57 870 394.6

*Note: Series TDV valves are shipped as straight pattern from factory. To convert to angle pattern refer to instruction sheet shipped with valve.

B

A

Temperature ˚C

Temperature ˚F

Note: For temperatures between 230˚F and 300˚F

(110˚C and 149˚C), specify Viton Elastomers

Pressure psi

Pressure kPa

-46˚ -29˚-18˚ 10˚ 38˚ 66˚ 93˚ 110˚

-50˚ -20˚ 0˚ 50˚ 100˚ 150˚ 200˚ 230˚

400

375

300

250

200

100

0

2760

2585

2070

1724

1380

690

250

Legend

A Ductile iron flange adapters for ANSI 150# flanges

B Grooved end with 375psi rated pipe coupling

Pressure Drop ft (WG)

Pressure Drop (mH

2O)

Flow Rate (USgpm)

Flow Rate (l/sec)

20

10

5

2

20

10

5

2

5

3

1

.5

50 100 500 1000 2000 4000 6000

3.0 5.0 10 20 50 100 200 400

Performance Curve with valve in Open Position

2

1

/

2

"

3"

4"

5"

6"

8"

10"

12"

Loading...

Loading...