Page 1

Instructions for Installing TD-300

Elevator Channel Drain

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

!

WARNING

Local building or plumbing codes may require modifications to the information provided. You are required to

consult the local building and plumbing codes prior

to installation. If the information provided here is not

consistent with local building or plumbing codes, the

local codes should be followed. This product must be

installed by a licensed contractor in accordance with

local codes and ordinances.

IS-WD-TD-300-CAN

NOTICE

Follow the guidelines listed here for proper installation,

operation, and maintenance.

Installation Guidelines

General Note: Please consult all local plumbing codes before installing

Watts channel drains.

Introduction

Watts TD-300 Elevator Channel Drain is designed with safety and aesthetics in

mind. Our channel drain is engineered to withstand heavy foot traffic, as well as

heavy loads without compromising style and design. The stainless steel surface area

provides durability and safe integration in outdoor to indoor transitions and in elevator

and building thresholds. The TD-300 is heel proof, wheelchair accessible and ADA

compliant. It complies with 2013 California Building Code 403.6.1, 403.6.2, 3007.4,

3008.4, and SFFC Section 511.1.4 for a flow rate of 100 GPM.

Benefits Of Elevator & Threshold Drains

Low profile offers a smooth integration between outdoor and indoor areas

Available in lengths from 36" min. to 96" max.

12 ga. 304 stainless steel is engineered for both durability and style

Removable grating allows for low maintenance and easy installation

TD-300 offers superior flow rates while maintaining a shallow depth

Page 2

Note: The TD-300 offers a 6"(152) no hub outlet. The product ships standard with center

outlet. End outlets are available by special request. Please make sure that you have specified

the correct area before installation begins.

Note: Minimum dimensional requirements must be met to satisfy 100 gpm flow rate

specification.

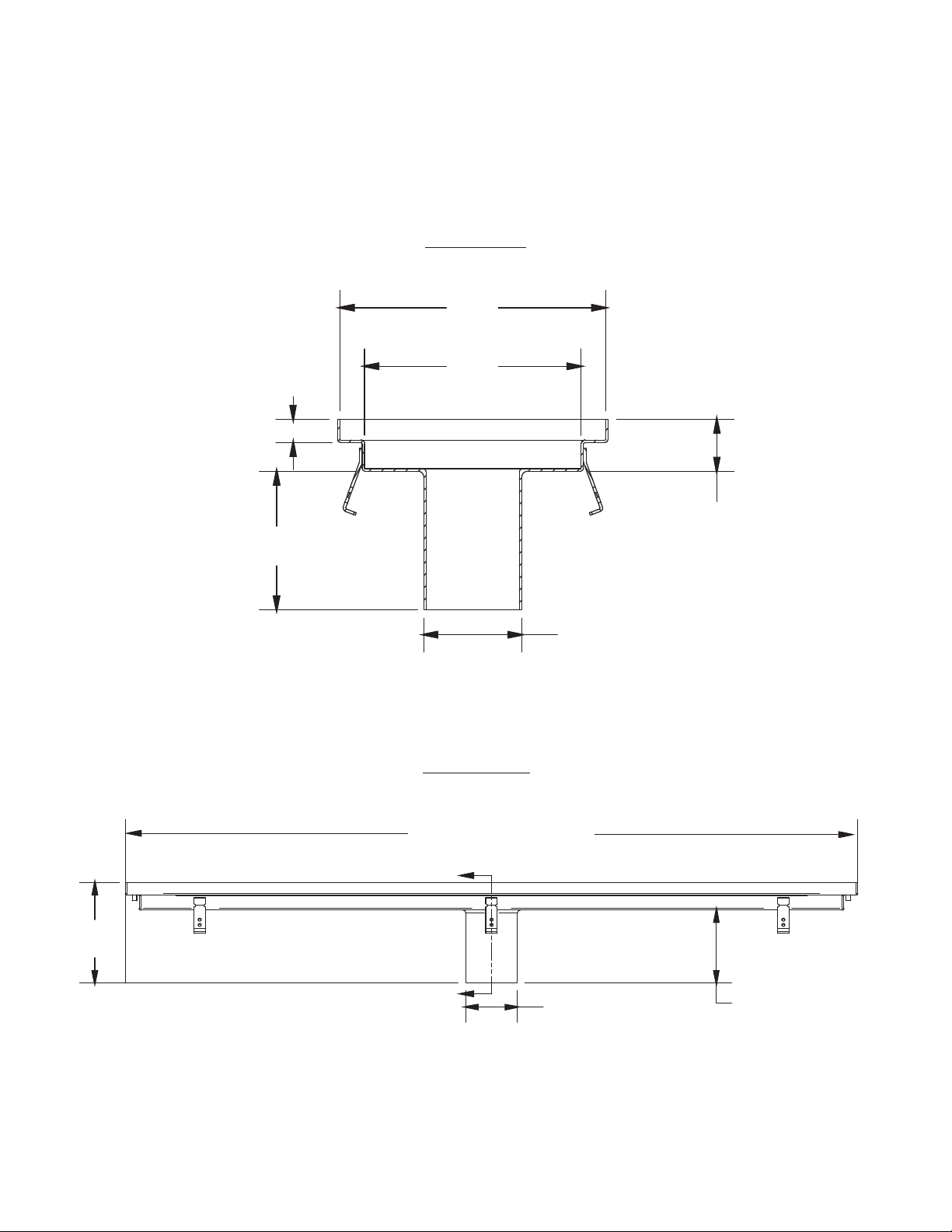

End View

11 1/2"

(292)

(25)

6"

(152)

1"

9 3/8"

(238)

2 1/4"

(57)

4 1/4"

(108)

Side View

8 1/4"

(210)

2

Specify (36" Min. / 96" Max.)

A

A

4 1/4"

(108)

6"

(152)

Page 3

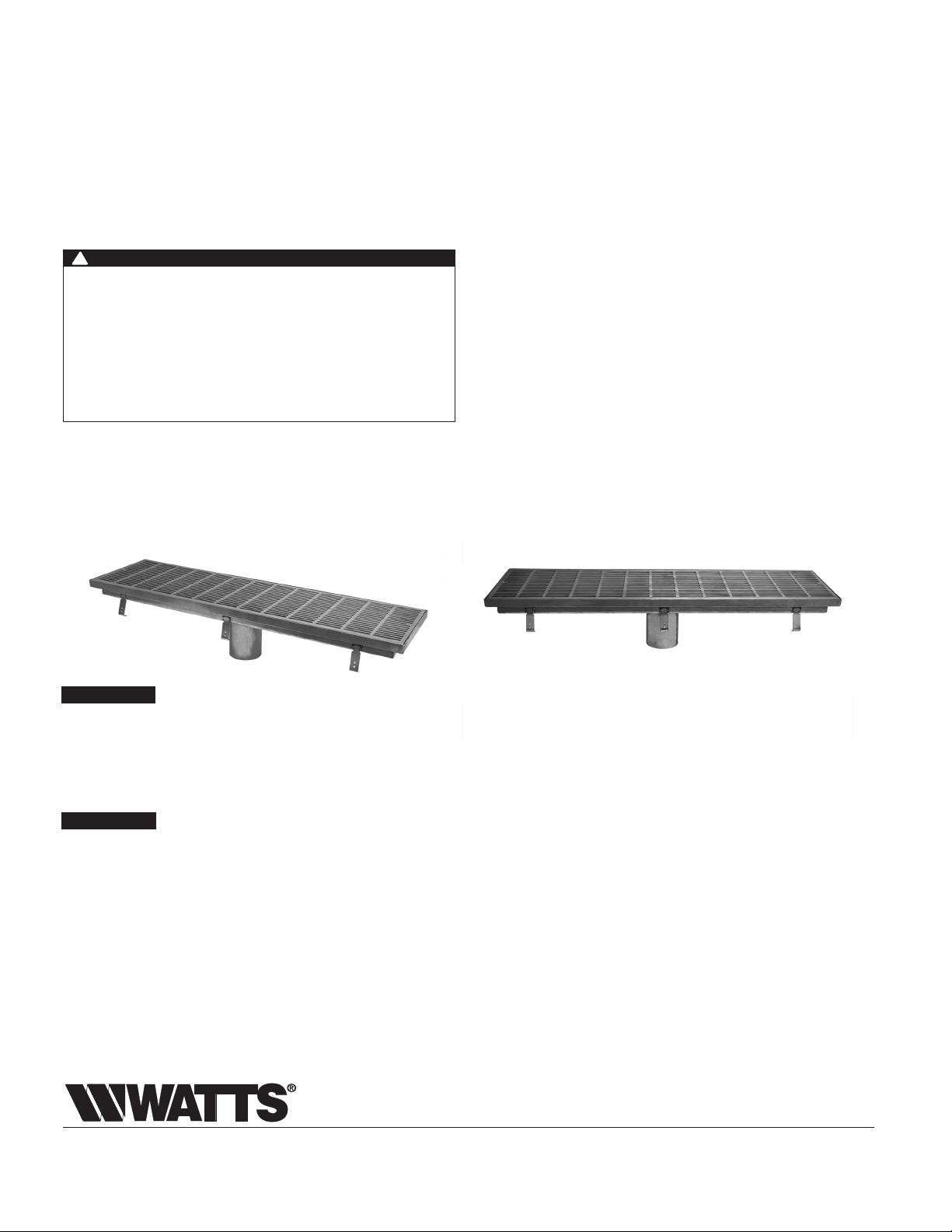

Anchor Strap

Top View

Watts TD-300 installs during new construction or in existing floors

Elevator/Threshold channels should sit slightly below flooring to ensure a smooth

transition from one area to another when the grate is installed. The grate should

match up flush with the floors and create a safe level transition.

Installing the channel

Leader drain pipes must be installed to connect with the center or end drain outlet

in order to divert and filter excess water.

Leader drain pipes are used to connect the drain to the intended drain lines. These

pipes should be in place and designed to connect to the drain outlet whether it is

located in the center or in the ends of the channel.

The drain is designed to fit into "boxed-out" areas in both new construction and in

existing floors.

Wood is used to create a form or boxed-out area to hold the channel.

Create a solid level base for the channel. This may be done with concrete or other

materials. Use a level to ensure that the channel is level and will properly meet

floor level when grate is installed.

Form the approach to the entrance by laying the required sub-base up to the

channel, leaving sufficient space for the surface finish. Any final adjustments

should be made at this time.

Anchor straps may be screwed into existing concrete or flooring, or screwed into

wood forms to hold the channel steady during a concrete pour.

Concrete may be poured around the channel.

3

Page 4

Installing the grate

The TD-300 is equipped with type 304 stainless steel grating. The stainless steel is

both durable and allows for an aesthetically attractive entrance.

The grate is rated for Class A top load classification and complies with both ADA

and heel-proof requirements.

Lower the grate onto the top of the channel and lock down to the channel with

two vandal-proof flathead machine screws, one on each end.

!

WARNING

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes,

but at least once per year or more as service conditions

warrant. All products must be retested once maintenance

has been performed. Corrosive water conditions and/or

unauthorized adjustments or repair could render the product

ineffective for the service intended. Regular checking and

cleaning of the product’s internal and external components

helps assure maximum life and proper product function.

Maintenance

The stainless steel grating offers easy-to-remove grating that provides accessible

cleaning and maintenance. The grating can be removed by removing both screws

and lifting the grate out for cleaning the channel of debris.

NOTICE

The information contained herein is not intended to replace the

full product installation and safety information available or the

experience of a trained product installer. You are required to

thoroughly read all installation instructions and product safety

information before beginning the installation of this product.

NOTICE

Inquire with governing authorities for local installation

requirements

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

USA: Tel: (800) 338-2581 • Fax: (828) 248-3929 • Watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • Watts.ca

Latin America: Tel: (52) 81-1001-8600 • Watts.com

IS-WD-TD-300-CAN 1916 EDP# 1915422 © 2019 Watts

Page 5

IS-WD-TD-300-CAN

Instructions pour l’installation de TD-300

Drain de canalisation pour ascenseur

!

AVERTISSEMENT

Lisez ce manuel AVANT d’utiliser cet équipement.

Le non-respect de toutes les instructions de sécurité

et d’utilisation de ce produit peut endommager ce

LA SÉCURITÉ

AVANT

TOUT

!

AVERTISSEMENT

Les codes locaux du bâtiment ou de la plomberie peuvent

nécessiter des modifications aux renseignements

donnés. Vous êtes tenus de consulter des codes locaux

du bâtiment ou de la plomberie avant de commencer

l’installation. Si les renseignements donnés ci-dessous ne

sont pas cohérents avec les codes locaux du bâtiment ou

de la plomberie, les codes locaux doivent être respectés.

Ce produit doit être installé par un entrepreneur licencié

conformément aux codes et règlements locaux.

produit ou entraîner d’autres dommages matériels, des

blessures graves ou la mort.

Conservez ce manuel pour référence ultérieure.

AVIS

Suivez les consignes ci-dessous pour une installation, une

utilisation et une maintenance adéquates.

Directives d’installation

Remarque générale: veuillez consulter tous les codes locaux de plomberie

avant l’installation des drains de canalisation de Watts.

Introduction

Le drain de canalisation pour ascenseur TD-300 est conçu avec la sécurité et l’esthétique à

l’esprit. Notre drain de canalisation est spécialement conçu pour résister à une forte circulation

piétonnière, ainsi que des charges lourdes, sans compromettre le style et la conception. La

surface en acier inoxydable procure la durabilité et l’intégration sécuritaire des transitions de

l’extérieur à l’intérieur, et dans les seuils d’ascenseur et de bâtiment. Le TD-300 est résistant

aux talons, accessible pour les fauteuils roulants et conforme à l’ADA. Il respecte le California

Building Code de2013 403.6.1, 403.6.2, 3007.4, 3008.4, et la section511.1.4 du SFFC pour

le débit de 100gallons par minute (378L par minute).

Avantages des drains d’ascenseur et de seuil

Le profil bas offre une intégration lisse entre les zones extérieures et intérieures.

Offert en longueurs de 36po min./96po max. (914mmmin./2438mmmax.).

L’acier inoxydable304 de calibre12 est spécialement conçu pour la durabilité et le style.

Le retrait des grilles permet un faible entretien et une installation facile.

TD-300 offre des débits supérieurs, tout en conservant une faible profondeur.

Page 6

Remarque: le TD-300 offre une sortie de 6po (152mm) sans moyeu. Le produit est expédié

standard avec une sortie centrale. Les sorties d’extrémité sont disponibles par demande

spéciale. Assurez-vous d’avoir précisé la zone appropriée avant de préparer l’installation.

Remarque: les exigences minimales de dimensions doivent être respectées pour répondre à

un débit de 100gallons par minute (378L par minute) qui est précisé.

Vue de l’extrémité

11 1/2 po

(292 mm)

1 po

(25 mm)

6 po

(152 mm)

9 3/8"po

(238 mm)

2 1/4 po

(57 mm)

4 1/4 po

(108 mm)

Vue de côté

8 1/4 po

(210 mm)

2

Préciser (36 po min./96 po max. [914 mm min./2 438 mm max.])

A

A

4 1/4 po

(108 mm)

6 po

(152 mm)

Page 7

Sangle d’ancrage

Anchor Strap

Vue de dessus

Top View

Le TD-300 de Watts s’installe lors d’une nouvelle construction ou dans des

planchers existants

Les canalisations d’ascenseur/de seuil devraient être placées légèrement sous le couvre

plancher afin d’assurer une transition lisse d’une zone à l’autre lorsque la grille est

installée. La grille devrait être au ras avec les planchers et créer une transition sécuritaire

des niveaux.

Installation de la canalisation

Les tuyaux principaux des drains devraient être installés pour raccorder avec la sortie du

centre ou de l’extrémité, afin de détourner et filtrer l’excès d’eau.

Les tuyaux principaux des drains sont utilisés pour raccorder le drain aux tuyaux prévus

de drainage. Ces tuyaux devraient être en place et conçu pour se raccorder à la sortie du

drain, qu’elle soit située au centre ou à l’extrémité de la canalisation.

Le drain est conçu pour être logé dans des zones «encastrées», dans les constructions

neuves et les planchers existants.

Le bois est utilisé pour créer une forme ou une zone encastrée pour tenir la canalisation.

Créer une base de niveau solide pour la canalisation. Cela peut se faire en béton ou

d’autres matériaux. Utiliser un niveau afin d’assurer que la canalisation est de niveau et

arrivera de façon appropriée au niveau du plancher lorsque la grille est installée.

Former l’approche à l’entrée en posant la sous-base nécessaire jusqu’à la canalisation,

laissant suffisamment de place pour la finition de la surface. Tout ajustement final devrait

être effectué à ce moment.

Des sangles d’ancrage peuvent être vissées dans le béton ou le couvre-plancher existant,

ou vissées dans des formes en bois pour tenir la canalisation en place lorsque le béton

est coulé.

Le béton peut être coulé autour de la canalisation.

3

Page 8

Installation de la grille

Le TD-300 est muni d’une grille en acier inoxydable de type304. L’acier inoxydable

est à la fois durable et permet une entrée d’allure esthétique.

La grille est cotée pour une classification de charge supérieure de classeA et

respecte les exigences de l’ADA et de résistance aux talons.

Abaisser la grille sur le dessus de la canalisation et la fixer à la canalisation à l’aide

des deux vis mécaniques à tête plate à l’épreuve du vandalisme.

!

AVERTISSEMENT

Nécessité d'inspection périodique/maintenance : Ce produit

doit être testé périodiquement en conformité avec les codes locaux,

mais au moins une fois par an ou plus, comme les conditions de

service le justifient. Tous les produits doivent être testés une fois

que les opérations d'entretien ont été effectuées. Des conditions

d'admission corrosives et/ou des réglages ou des réparations

non autorisés peuvent rendre le produit inefficace pour le service

prévu. La vérification et le nettoyage réguliers des composants

internes et externes du produit contribuent à assurer une durée de

vie maximale et un fonctionnement correct du produit.

Entretien

La grille en acier inoxydable est une grille facile à retirer qui offre l’accessibilité pour

le nettoyage et l’entretien. La grille peut être retirée en retirant les deux vis, pour

ensuite la lever et nettoyer tout débris de la canalisation.

AVIS

Les présentes informations ne sont pas destinées à remplacer

les informations d’installation et de sécurité complètes du produit

ou l’expérience d’un installateur professionnel. Vous êtes tenu de

lire attentivement toutes les instructions d’installation et toutes

les informations de sécurité du produit avant de commencer

l’installation de ce produit.

AVIS

Renseignez-vous auprès des autorités de réglementation pour

les exigences d’installation locales.

Garantie limitée: Watts Regulator Co. (la «Société») garantit que chacun de ses produits est exempt de vice de matériau et de fabrication dans des conditions normales d’utilisation pour une période

d’un an à compter de la date d’expédition d’origine. Si une telle défaillance devait se produire au cours de la période sous garantie, la Société aura à sa discrétion l’alternative suivante: le remplacement

ou bien la remise en état du produit, sans frais pour le demandeur.

LA PRÉSENTE GARANTIE EXPRESSE EST LA SEULE ET UNIQUE GARANTIE, RELATIVE AU PRODUIT, FOURNIE PAR LA SOCIÉTÉ. LA SOCIÉTÉ NE FORMULE AUCUNE AUTRE GARANTIE, EXPRESSE

OU IMPLICITE. LA SOCIÉTÉ REJETTE AUSSI FORMELLEMENT PAR LA PRÉSENTE TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, Y COMPRIS (SANS S’Y LIMITER) LES GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE PARTICULIER.

Le dédommagement précisé dans le premier paragraphe de cette garantie constitue la seule et unique alternative en cas de service demandé sous cette garantie. La Société ne pourra être tenue

responsable de dommages spéciaux ou indirects, incluant, sans s’y limiter: pertes de profit, coûts de réparation ou de remplacement des autres biens ayant été endommagés si ce produit ne fonctionne

pas correctement, autres coûts afférents aux frais de main-d’œuvre, de retards, de vandalisme, de négligence, d’engorgement causés par des corps étrangers, dommages causés par des propriétés

de l’eau défavorables, des produits chimiques, ou toute autre circonstance indépendante de la volonté de la Société. La présente garantie est déclarée nulle et non avenue en cas d’usage abusif ou

incorrect, d’application, d’installation ou d’entretien incorrects ou de modification du produit.

Certains États n’autorisent pas les limitations de durée d’une garantie tacite ou l’exclusion ou la limitation des dommages accessoires ou indirects. En conséquence, ces limitations pourraient ne pas

s’appliquer à votre cas. Cette garantie limitée vous confère des droits spécifiques, reconnus par la loi; vous pourriez également avoir d’autres droits, lesquels varient selon la loi en vigueur. Vous devez

donc prendre connaissance des lois applicables pour votre cas particulier. LA DURÉE DE TOUTE GARANTIE IMPLICITE PRÉVUE PAR LA LOI EN APPLICATION ET DEVANT DONC ÊTRE ASSUMÉE,

Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE PARTICULIER, SERA LIMITÉE À UN AN À PARTIR DE LA DATE DE L’EXPÉDITION D’ORIGINE.

É.-U.: Tél.: (800) 338-2581 • Téléc.: (828) 248-3929 • Watts.com

Canada: Tél.: (905) 332-4090 • Téléc.: (905)332-7068 • Watts.ca

Amérique latine: Tél.: (52)81-1001-8600 • Watts.com

IS-WD-TD-300-CAN 1916 EDP n°1915422 © 2019 Watts

Loading...

Loading...