Page 1

For Health Hazard Applications

ES-SS009

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

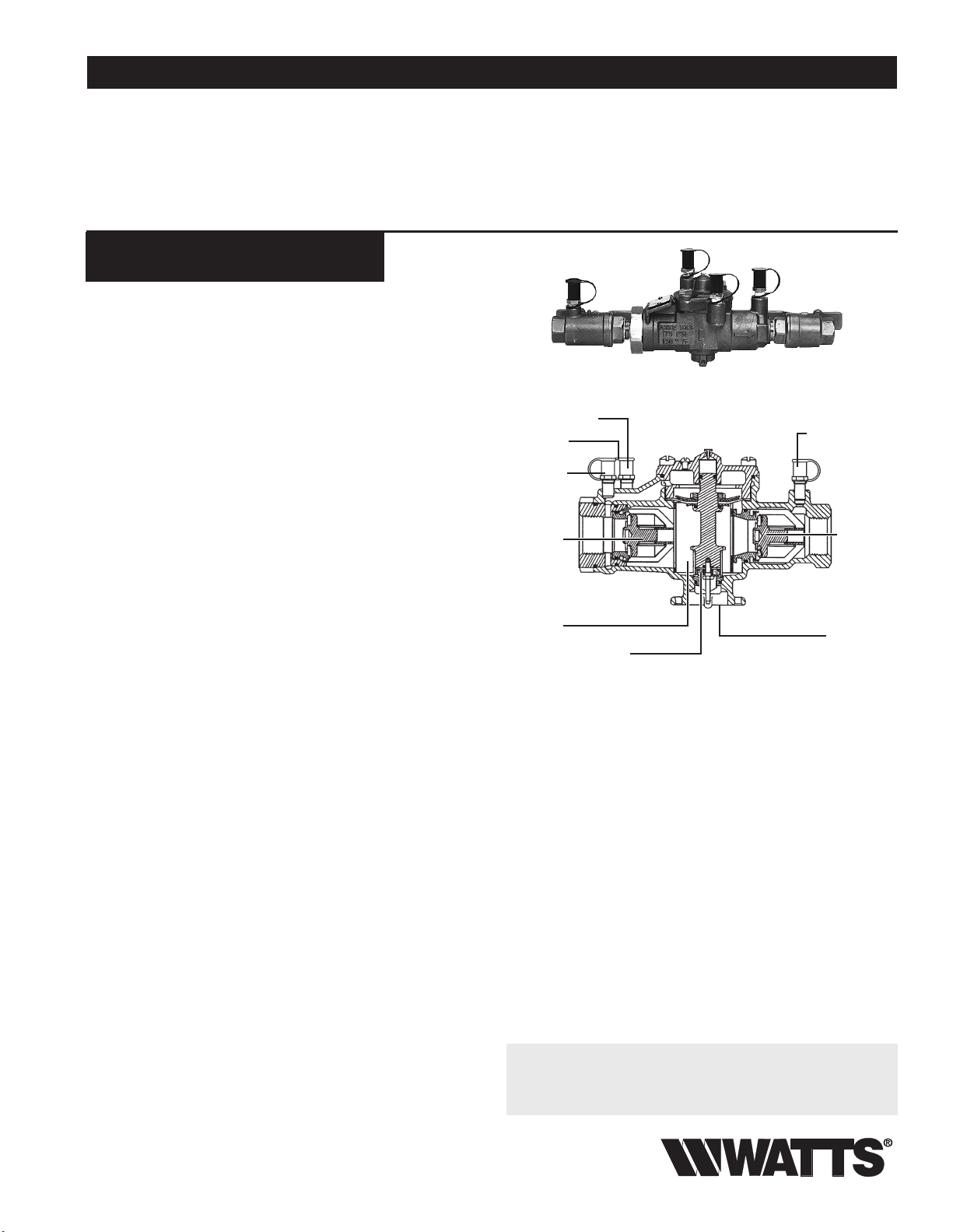

Series SS009

Stainless Steel Reduced Pressure

Zone Assemblies

Sizes: 1⁄4" – 1" (8 – 25mm)

Series SS009QT Stainless Steel Reduced Pressure Zone

Assemblies provide protection of the potable water supply in accordance with national plumbing codes and water authority requirements. Series SS009 can be used in a variety of health hazard

installations whenever the downstream liquid is of a composition

which may damage bronze material or it is desirable to eliminate

trace elements of lead and copper. Typical applications are:

Industrial or plant use, medical/diagnostic equipment, reverse

osmosis systems, carbonated beverage machines, breweries/distillers, paper and pulp industry, chemical plants and aggressive

atmospheres. The SS009 series features two in-line independent

check valves, captured springs, replaceable check seats, corrosion

resistant internal parts and a hydraulically operated differential pressure relief valve. All sizes are constructed with NPT body connections and are standardly furnished with vandal resistant EZ-TC Test

Cocks. Series SS009QT's are furnished with 316 Stainless Steel,

full port, investment cast, quarter turn ball valve shutoffs with 304

Stainless Steel tee handles.

Features

• Investment Cast 316 Stainless Steel Assembly

for corrosion resistance

• All wetted valve components — test cocks, ball valve

shutoffs, pipe nipples, body and cover, check modules and relief

valve assembly are made from "Lead Free" Stainless Steel or

Plastic construction

• Bolted on, top entry single access cover for ease

of maintenance

• Modular check construction featuring nonreversible checks with

captured springs for simplified servicing

• Top mounted vandal resistant EZ-TC test cocks provide easy

access for testing

• Stainless Steel EZ-TC test cocks include dust covers to protect

the threads from dirt, dust and insects

• EZ-TC Test cocks eliminate the need for tools and test fittings

• True line sized check modules open further allowing dirt and debris to

pass freely through the valve reducing fouling problems

• Check and Relief Valve Seats are replaceable without the use of

special tools

• Internal relief valve for right and left hand installations

*The wetted surface of this product contacted by consumable water

contains less than one quarter of one percent (0.25%) of lead by weight.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

SS009QT

Test Cock No. 3

EZ-TC-SS

Test Cocks

Test Cock

No. 2

First Check

Module

Assembly

R.P. Zone

Relief Valve Assembly

Test Cock No. 4

Second

Check

Module

Assembly

Water Outlet

Specifications

A reduced pressure zone assembly shall be installed at each noted

potential health hazard location to prevent backflow due to backsiphonage and/or backpressure. The assembly shall consist of an

internal pressure differential relief valve located in a zone between

two independently operating positive seating check modules with

captured springs and silicone seat discs. Seats and seat discs shall

be replaceable in both check modules and the relief valve, without

the use of special tools. There shall be no threads or screws, in the

waterway, exposed to line fluids. Service of all internal components

shall be through a single access cover secured with stainless steel

bolts. The assembly shall include two resilient seated isolation

valves, four top mounted vandal resistant test cocks with dust covers, a protective stainless steel wye strainer with a 20 mesh screen

and an air gap fitting. The assembly shall consist of an investment

cast 316 Stainless Steel body and cover with Series 300 Stainless

Steel test cocks, 316 Stainless Steel Ball Valve Shutoffs with PTFE

Seat blowout proof 304 Stainless Steel Stems, and 304 Stainless

Steel Tee Handles. The assembly shall meet the requirements of

ASSE Standard 1013, AWWA Standard C511. Assembly shall be a

Watts Regulator Company Series SS009QT.

Now Available

WattsBox Insulated Enclosures.

For more information, send for literature ES-WB.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

Available Models

Suffix:

QT – quarter-turn ball valves

S – stainless steel strainer

Note: The installation of a drain line is recommended. When

installing a drain line, an air gap is necessary (see ES-AG/EL/TC).

Materials

Body: 316 stainless steel

Disc and Relief Valve: Silicone rubber

Check Seats: Replaceable polymer

Relief Valve Seat: Stainless steel

Cover Bolts: Stainless steel

Pressure — Temperature

Temperature Range: 33°F – 180°F (0.5°C – 82°C) continuous

Maximum Working Pressure: 175psi (12.1 bar)

Standards

USC Manual 9th Edition

AWWA C511-92

1013

B64.4

61

Approvals

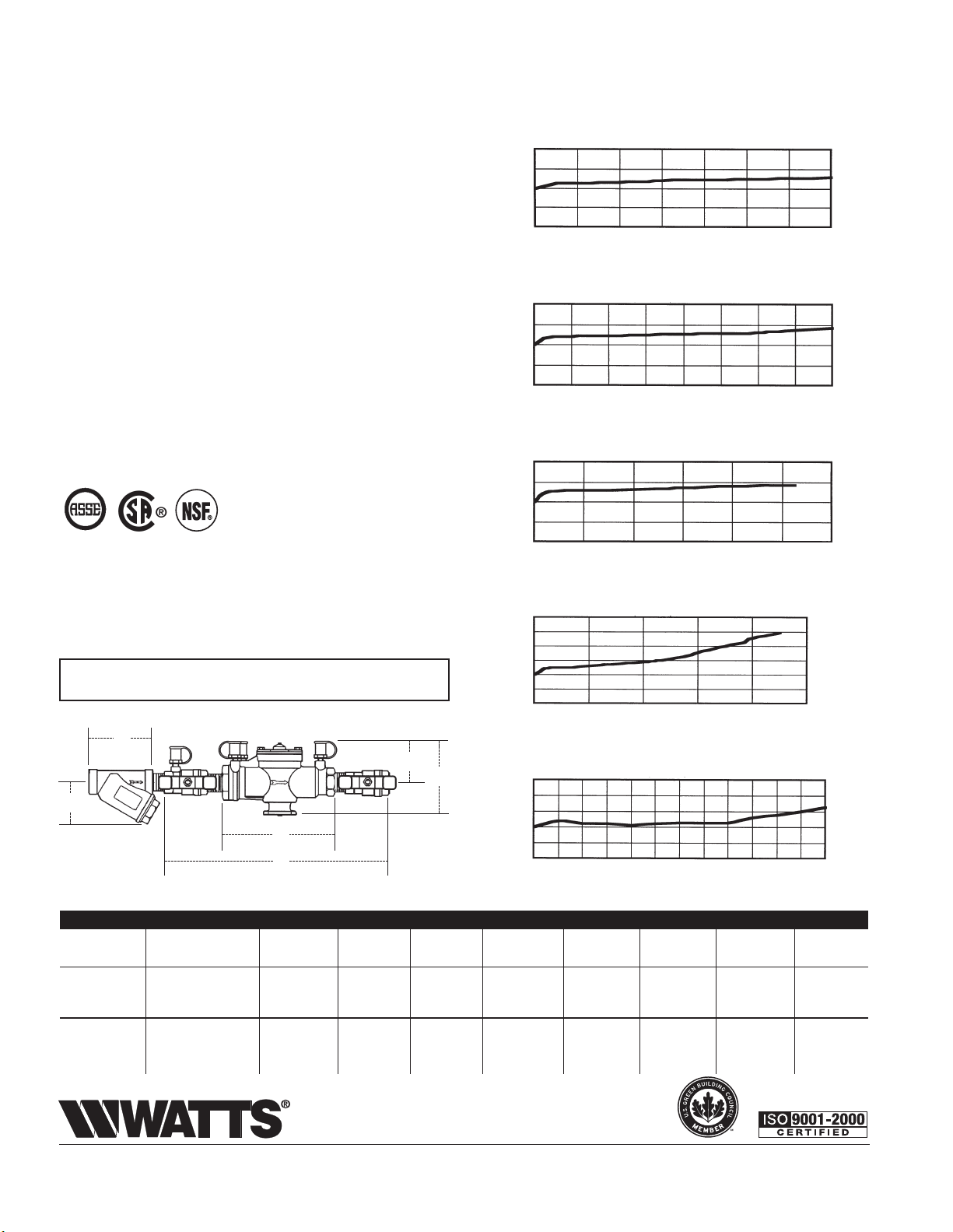

Capacity

Performance as established by an independent testing laboratory.

*Typical maximum system flow rate (7.5 feet/sec.)

kPa psi

138 20

103 15

69 10

34 5

00

0 0.2 0.4 0.6 0.8 1 1.2 1.4 gpm

0 .76 1.5 2.3 3 3.8 4.6 5.3 lpm

kPa psi

138 20

103 15

69 10

34 5

00

0 0.5 1 1.5 2 2.5 3 3.5 4 gpm

0 1.9 3.8 5.7 7.6 9.5 11.4 13.3 15.2 lpm

kPa psi

138 20

103 15

69 10

34 5

00

0 2 4 6 8 10 12 gpm

0 7.6 15 23 30 38 46 lpm

1

⁄4" (8mm)

3

⁄8" (10mm)

1

⁄2" (15mm)

ASSE, AWWA, USC

1

CSA –

Dimensions — Weight

⁄2" and 3⁄4" horizontal

IMPORTANT: INQUIRE WITH GOVERNING AUTHORITIES

FOR LOCAL INSTALLATION REQUIREMENTS

M

C

B

N

L

A

MODEL SIZE (DN) DIMENSIONS (approx.) WEIGHT

A B C L M N Width

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

kPa psi

207 30

172 25

138 20

103 15

69 10

34 5

00

0 1020 3040 50gpm

0 38 75 114 152 190 lpm

kPa psi

172 25

138 20

103 15

69 10

34 5

00

0 5 10 15 20 25 30 35 40 45 50 55 60 gpm

0 1938577695

3

⁄4" (20mm)

1" (25mm)

114 133 152 171 190 209 228

lpm

SS009M3QT1⁄4,3⁄8,1⁄2 8,10,15 10 250 45⁄8 117 33⁄8 86 51⁄2 140––––51274.50 2.0

SS009M3QT

SS009QT 1 25 16

3

⁄4 20 103⁄4 273 5 127 31⁄2 89 63⁄4 171––––61⁄4 159 5.75 2.6

3

⁄4 425 51⁄2 140 3 76 91⁄2 241––––81⁄4 210 12.25 5.6

SS009M3QT-S1⁄4,3⁄8,1⁄2 8,10,15 10 250 6 150 33⁄8 86 51⁄2 140 313⁄16 97 25⁄8 67 5 127 7.25 3.3

SS009M3QT-S

SS009QT-S 1 25 16

3

⁄4 20 103⁄4 273 61⁄4 159 31⁄2 89 63⁄4 171 43⁄8 111 33⁄16 81 61⁄4 159 9.25 4.2

3

⁄4 425 73⁄4 197 3 76 91⁄2 241 53⁄16 132 33⁄4 95 81⁄4 210 17.00 7.7

A Watts Water Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

ES-SS009 0940 © 2009 Watts

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...