Watlow EZ-ZONE Operating Manual

ISO 9001

EZ-ZONE® RUI/Gateway

User’s Guide

EZ-ZONE RM

EZ-ZONE ST

RUI/Gateway

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

TOTAL

CUSTOMER

SATISFACTION

3 Year Warranty

Registered Company

Winona, Minnesota USA

0600-0060-0000 Rev. C Made in the U.S.A.

March 2012

Safety Information

We use note, caution and warning symbols throughout

this book to draw your attention to important operational and safety information.

A “NOTE” marks a short message to alert you to an

important detail.

A “CAUTION” safety alert appears with information

that is important for protecting your equipment and

performance. Be especially careful to read and follow

all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you, others and

equipment from damage. Pay very close attention to

all warnings that apply to your application.

The electrical hazard symbol, Ó (a lightning bolt

in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Unit is compliant with European

Union directives. See Declaration

of Conformity for further details

on Directives and Standards used

for Compliance.

Unit has been reviewed and approved by CSA International for

use as Temperature IndicatingRegulating Equipment per CSA

C22.2 No. 24 or C22.2 #14. See:

www.csa-international.org

Unit has been reviewed and approved by ODVA for compliance

with DeviceNet communications

protocol. See: www.odva.org

Unit has been reviewed and approved by ODVA for compliance

with Ethernet/IP communications

protocol. See: www.odva.org

Symbol Explanation

CAUTION – Warning or Hazard

that needs further explanation

than label on unit can provide.

Consult User's Guide for further

information.

ESD Sensitive product, use proper

grounding and handling techniques when installing or servicing product.

Unit protected by double/reinforced insulation for shock hazard

prevention.

Do not throw in trash, use proper

recycling techniques or consult

manufacturer for proper disposal.

Enclosure made of Polycarbonate

material. Use proper recycling

techniques or consult manufacturer for proper disposal.

Unit can be powered with either

alternating current (ac) voltage or

direct current (dc) voltage.

Unit is a Listed device per Underwriters Laboratories®. It has

been evaluated to United States

and Canadian requirements for

Process Control Equipment. UL

61010 and CSA C22.2 No. 61010.

File E185611 QUYX, QUYX7.

See: www.ul.com

Unit is a Listed device per Underwriters Laboratories®. It has

been evaluated to United States

and Canadian requirements for

industrial control equipment UL

508 CSA C22.2 #14 File E102269

NKCR, NKCR7.

See: www.ul.com

Warranty

The EZ-ZONE® RUI/Gateway is manufactured by ISO

9001-registered processes and is backed by a three-year

warranty to the first purchaser for use, providing that

the units have not been misapplied. Since Watlow has no

control over their use, and sometimes misuse, we cannot

guarantee against failure. Watlow’s obligations hereunder, at Watlow’s option, are limited to replacement, repair

or refund of purchase price, and parts which upon examination prove to be defective within the warranty period

specified. This warranty does not apply to damage resulting from transportation, alteration, misuse or abuse. The

purchaser must use Watlow parts to maintain all listed

ratings.

Technical Assistance

If you encounter a problem with your Watlow controller, review your configuration information to verify

that your selections are consistent with your application: inputs, outputs, alarms, limits, etc. If the problem persists, you can get technical assistance from

your local Watlow representative (see back cover), by

e-mailing your questions to wintechsupport@watlow.

com or by dialing +1 (507) 494-5656 between 7 a.m.

and 5 p.m., Central Standard Time (CST). Ask for for

an Applications Engineer. Please have the following

information available when calling:

• Complete model number

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300,

for a Return Material Authorization (RMA) number before returning any item for repair. If you

do not know why the product failed, contact an

Application Engineer or Product Manager. All

RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the

product.

2. Prior approval and an RMA number from the

Customer Service Department is required when

returning any product for credit, repair or evaluation. Make sure the RMA number is on the outside

of the carton and on all paperwork returned. Ship

on a Freight Prepaid basis.

3. After we receive your return, we will examine it and

try to verify the reason for returning it.

4. In cases of manufacturing defect, we will enter a

repair order, replacement order or issue credit for

material returned. In cases of customer mis-use,

we will provide repair costs and request a purchase

order to proceed with the repair work.

5. To return products that are not defective, goods

must be be in new condition, in the original boxes

and they must be returned within 120 days of

receipt. A 20 percent restocking charge is applied

for all returned stock controls and accessories.

6. If the unit is not repairable, you will receive a letter

of explanation and be given the option to have the

unit returned to you at your expense or to have us

scrap the unit.

7. Watlow reserves the right to charge for no trouble

found (NTF) returns.

The EZ-ZONE® Remote User's Interface User's Guide

is copyrighted by Watlow Winona, Inc., © March 2012

with all rights reserved.

TC

Table of Contents

Chapter 1: Overview .....................................3

Features and Benefits ....................................... 3

RUI/GTW Panel Cutout Dimensions ............................4

Chapter 2: Install, Wire and Set Address .......................4

Mounting the Remote User Interface (RUI) ......................5

Standard Bus EIA-485 Communications ........................6

EIA-232/485 Modbus RTU Communications .....................6

EtherNet/IP™ and Modbus TCP Communications .................7

DeviceNet™ Communications ................................. 7

Profibus DP Communications ................................ 7

Wiring a Serial EIA-485 Network ..............................8

Responding to a Displayed Message .......................... 10

Chapter 3: Keys and Displays .............................10

Programming the EZ Key Using an RUI ........................13

Using the RUI with PM Family Controllers ...................... 13

Using the RUI with RM Family Controllers ...................... 13

Using the RUI with ST Family Controllers ......................13

Default Home Pages ....................................... 15

EZ-ZONE PM Express Home Page ............................ 16

EZ-ZONE ST Home Page ...................................17

EZ-ZONE PM Home Page ...................................18

EZ-ZONE RMC (Controller) Home Page ........................19

EZ-ZONE RME (Expansion) Home Page ........................19

EZ-ZONE RMS (Scanner) Home Page ......................... 19

EZ-ZONE RMH (High Density) Home Page ...................... 19

EZ-ZONE RMH (High Density) Home Page (cont.) ................ 20

EZ-ZONE RML (Limit) Home Page ............................20

Chapter 4: RUI Page ....................................21

Communications Menu ..................................... 22

Global Menu ............................................. 25

Gateway Menu ...........................................25

Security Setting Menu .....................................26

Unlock Security Setting Menu ...............................27

Diagnostics Menu ......................................... 27

Watlow EZ-ZONE® RUI/Gateway • 1 • Table of Contents

TC

Table of Contents (cont.)

Chapter 5: Using an RUI/Gateway ...........................29

Conceptual View of the RUI/GTW ............................. 29

Using RUI Lockout and Password Security .....................29

Using Lockout Method 1 (Read and Set Lock) ................. 29

Using Lockout Method 2 (Password Enable) .................. 30

Using Modbus RTU .......................................31

CIP - Communications Capabilities ...........................32

Using DeviceNet™ ......................................33

DeviceNet RUI/GTW LED Indicators .........................34

Using EtherNet/IP™ ..................................... 35

Using Modbus TCP .......................................36

Ethernet RUI/GTW LED Indicators ..........................36

Using Profibus DP ........................................37

Profibus DP RUI/GTW LED Indicators .......................38

Software Configuration ..................................... 39

Saving Settings to Non-volatile Memory ....................... 42

Chapter 6: Appendix ....................................43

Troubleshooting ..........................................43

Modbus - Programmable Memory Blocks ...................... 44

PM Modbus Assembly Definition ...........................44

RM Modbus Assembly Definition ..........................46

CIP Implicit Assemblies ....................................49

ST CIP Implicit Assemblies ................................49

PM CIP Implicit Assemblies ...............................50

RME CIP Implicit Assemblies ..............................51

RMC CIP Implicit Assemblies ..............................52

RMH, RMS and RML CIP Implicit Assemblies ................. 54

Specifications ............................................56

Ordering Information ......................................57

How to Reach Us .........................................59

Watlow EZ-ZONE® RUI/Gateway • 2 • Table of Contents

1

RUI/Gateway

Chapter 1: Overview

Features and Benefits

Remote User Interface/Gateway (RUI/GTW)

• Uses one RUI for multiple zones

• The RUI without a gateway card utilizes minimal

panel depth allowing it to fit in small spaces

• Eliminates the costs and complexity of having to

bring all controller related wires to the front

panel

• Enables the use of multiple RUIs to improve the

system’s usability and flexibility

Agency approvals: UL Listed, cULus, CSA, CE,

RoHS,

• Assures prompt product acceptance

• Reduces end product documentation costs

Short Case

• CSA C22.2 #14 Approved File 158031

• cULus UL 508 Listed approval File E102269

• UL® 50 Type 4X, NEMA 4X indoor locations, IP65

front panel seal (indoor use only)

Long Case

• UL® Listed to UL 61010-1 File E185611

®

• UL

• UL® 50 Type 4X, NEMA 4X indoor locations, IP66

• ODVA-EtherNet/IP™ and DeviceNet Compliance

• CSA C22.2 No. 24 File 158031 Class 4813-02

• Profibus DP

P3T Armor Sealing System

• NEMA 4X and IP65, indoor use only

• Offers water and dust resistance, can be cleaned

Three-year warranty

• Demonstrates Watlow’s reliability and product sup-

Reviewed to CSA C22.2 No.61010-1-04

front panel seal (indoor use only)

and washed down

port

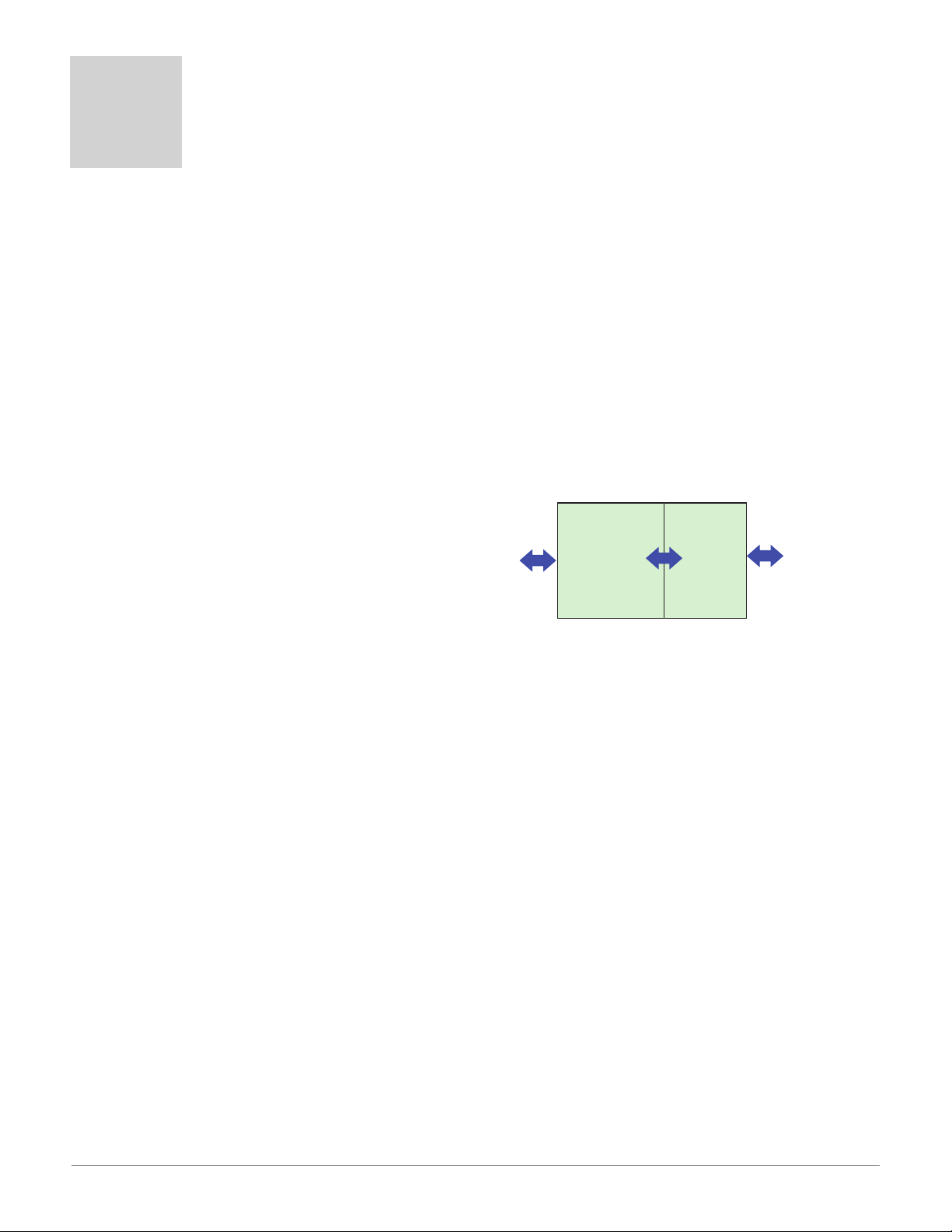

Using the RUI/GTW as a Gateway

The addition of a gateway card allows information to

be passed from the Standard Bus side of the gateway

(EZ-ZONE®-family controllers) to one or more of the

following popular field bus networks:

• EtherNet/IP™

• DeviceNet™

• Modbus TCP

• Modbus RTU

• Profibus DP

The networks see the gateway and RUI as separate

devices. Both sides (1 port on each side) of the gateway will require unique addresses based on the protocol specifications.

Fieldbus

Network Protocol

PLCs

or PCs

Note:

Excessive writes through the gateway to other EZZONE® family controllers may cause premature

EE-PROM failure. For more detail see the section

entitled “Saving Settings to Nonvolatile Memory.”

Note:

A Standard Bus network can communicate with a

maximum of eight RUIs with up to four of those

being gateways. Valid Standard Bus addresses for

RUIs equipped with the gateway option are 1, 2, 3

or 4. As is always the case each RUI must have a

unique Standard Bus address.

- EtherNet/IP

- DeviceNet

- Modbus TCP

- Modbus RTU

- Profibus DP

Watlow

Standard

Bus

Network

EZ-ZONE-family

Controllers or RUIs

EZ-Key

• Programmable EZ-Key enables simple one-touch

operation of repetitive user activities

Watlow EZ-ZONE® RUI/Gateway • 3 • Chapter 1 Overview

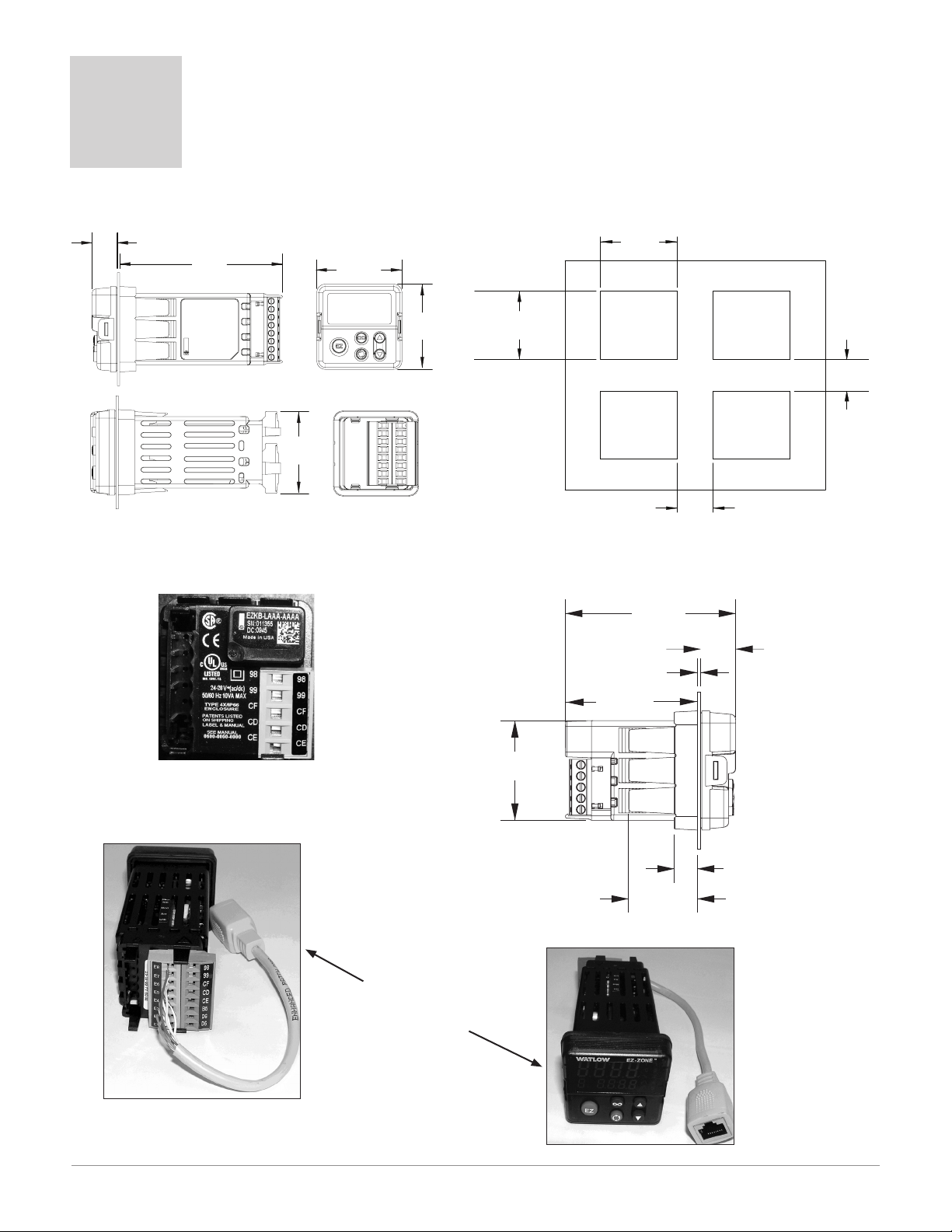

Chapter 2: Install, Wire and

44.96 to 45.47 mm

2

Set Address

RUI/GTW Panel Cutout Dimensions

15.8 mm

(0.62 in)

101.6 mm

(4.00 in)

Side Front

Top

Top View

long case

(EZK_-_(2, 3, 5 or 6)_ _-_ _ _ _)

51.2 mm

(2.02 in)

53.3 mm

(2.10 in)

E8

E7

E6

E5

E4

E3

E2

E1

Back

53.3 mm

(2.10 in)

98

99

CF

CD

CE

44.96 to 45.47 mm

(1.77 to 1.79 inches)

(1.77 to 1.79 inches)

panel thickness 1. 53 to 9.52 mm

(0.060 to 0.375)

21.6 mm

(0.85 in)

Minimum

76.25 mm

(3.00 in)

1.40 mm

(0.06 in)

59.10 mm

(2.33 in)

15.75 mm

(0.62 in)

21.6 mm

(0.85 in)

Minimum

44.70 mm

Back View

(1.76 in)

short case

Side View

short case

(EZK _ - _ A _ _ - _ _ _ _)

30.73 mm

(1.21 in)

10.16 mm

(4.00 in)

EtherNet/IP™ and Modbus

TCP gateway in slot B. Shown

with supplied cable.

Watlow EZ-ZONE® RUI/Gateway • 4 • Chapter 2 Install and Wire

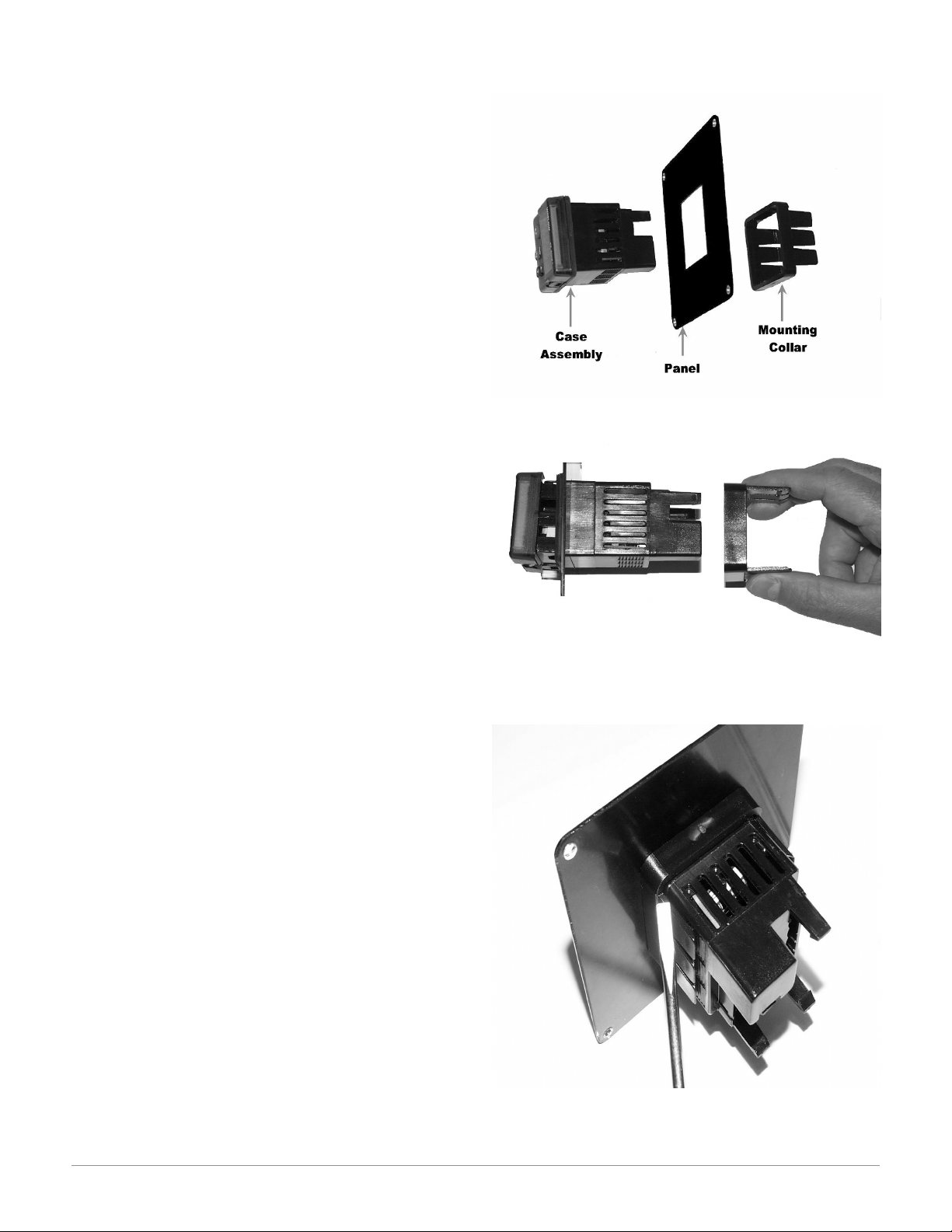

Mounting the Remote User Interface (RUI)

1. Make the panel cutout using the mounting template dimensions in this chapter. Insert the case assembly into

the panel cutout.

2. While pressing the case assembly firmly against the panel,

slide the mounting collar over the back of the RUI. If

the installation does not require an IP66/NEMA 4X seal,

slide the mounting collar up to the back of the panel tight

enough to eliminate the spacing between the gasket and

the panel.

3. For an IP66/NEMA 4X seal, place the blade of a screwdriver in the notch of the mounting collar assembly an

push to ward the panel while applying pressure to the

face of the RUI. Don't be afraid to apply enough pressure

to properly install the RUI. If you can move the case assembly back and forth in the cutout, you do not have a

proper seal. The tabs on each side of the bracket have

teeth that latch into the ridges. Each tooth is staggered

at a different depth from the front so that only one of

the tabs one each side is locked onto the ridges at a time.

The seal is good if the distance from the panel and the

top half of the assembly is 16 mm (0.630 in.) or less, and

the distance bottom half and the panel is 13.3 mm (0.525

in.) or less

Watlow EZ-ZONE® RUI/Gateway • 5 • Chapter 2 Install and Wire

Ó

Slot C

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Power

Slot C

long case

98

99

CF

CD

CE

B5

D6

D5

power

power

fuse

Slot C

short case

98

99

CF

CD

CE

power

power

• Minimum/Maximum Ratings

• 85 to 264VÅ (ac)

• 20.4 to 26.4 Vı (ac/dc)

fuse

• 47 to 63Hz

• 6VA maximum

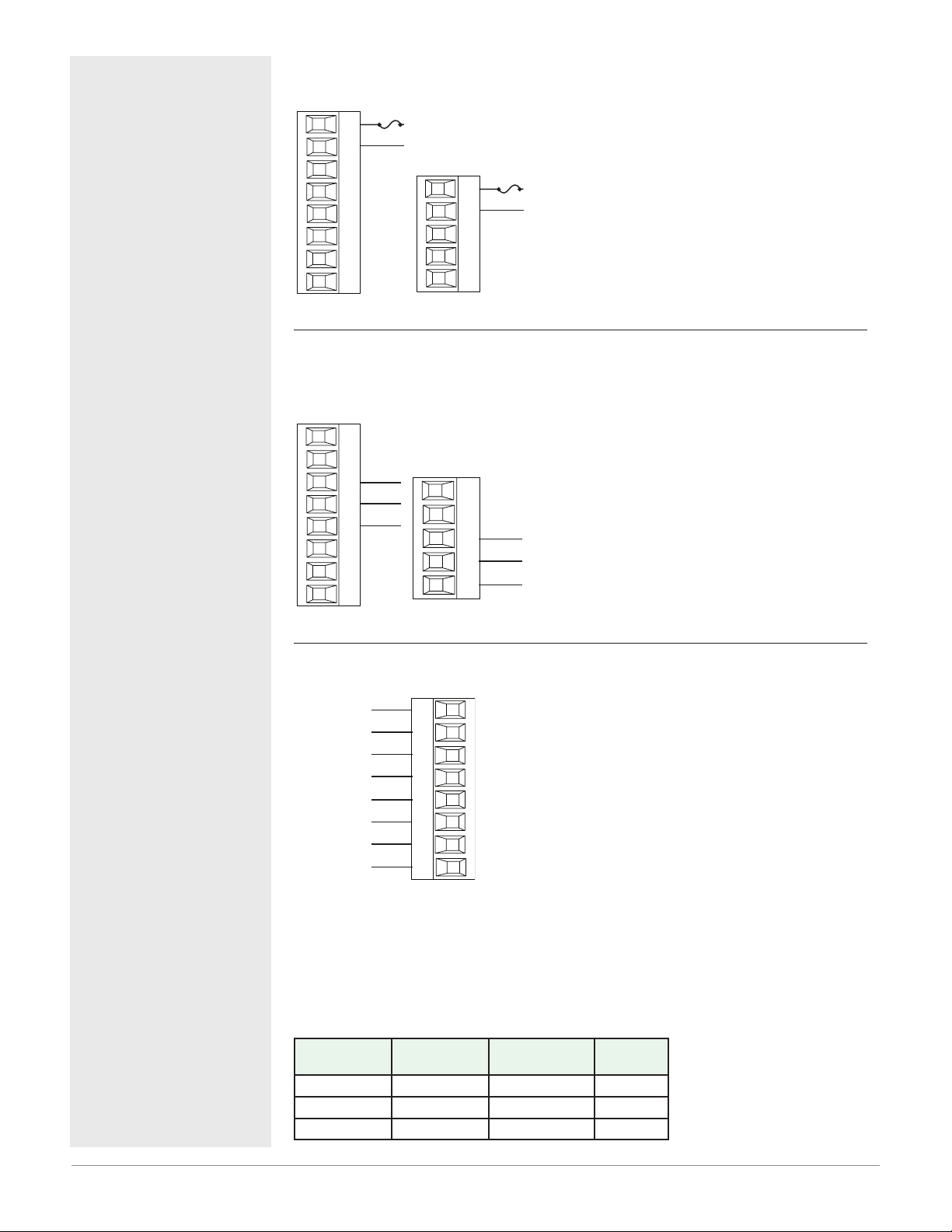

Standard Bus EIA-485 Communications

• WireT-/R-totheAterminaloftheEIA-485port.

Slot C

long case

98

99

CF

CD

CE

B5

D6

D5

common

T-/R-

T+/R+

short case

98

99

CF

CD

CE

common

T-/R-

T+/R+

• WireT+/R+totheBterminaloftheEIA-485port.

• WirecommontothecommonterminaloftheEIA-485

port.

• Donotroutenetworkwireswithpowerwires.Connect

network wires in daisy-chain fashion when connecting

multiple devices in a network.

• Donotconnectmorethan16controllersonanetwork.

• maximumnetworklength:1,200meters(4,000feet)

• 1/8thunitloadonEIA-485bus

Note:

Disconnect any USB to EIA-485 converter when not

connected to a PC (without power). Failure to do so

may cause communications errors.

EIA-232/485 Modbus RTU Communications

485 T+/R+

485 T-/R-

485 common

485 T+/R+

485 T-/R-

232 common

232 (TX) to DB9 pin 2 (RD)

232 (RD) to DB9 pin 3 (TX)

Modbus-IDA

Terminal

DO A CA or CD T-/R-

D1 B CB or CE T+/R+

common common CC or CF common

Slot B

CB

CA

CC

CB

CA

C5

C3

C2

EIA/TIA-485

Name

•WireT-/R-totheAterminal

of the EIA-485 port.

• WireT+/R+totheBterminal of the EIA-485 port.

• Wirecommontothecommon terminal of the EIA485 port.

• Donotroutenetworkwires

with power wires. Connect

network wires in daisychain fashion when connecting multiple devices in a

network.

• Aterminationresistormay

be required. Place a 120 Ω

resistoracrossT+/R+and

T-/R- of last controller on

network.

• DonotwiretoboththeEIA-

485 and the EIA-232 pins at

Note:

Disconnect any USB to EIA-485 converter when not connected to a PC

(without power). Failure to do so may cause communications errors.

Watlow Termi-

nal Label

Function

the same time.

• TwoEIA-485terminalsof

T/R are provided to assist in

daisy-chain wiring.

• Donotconnectmorethan

one EZ-ZONE

EIA-232 network.

• MaximumnumberofEZ-

ZONE

RTU EIA-485 network: 247

• MaximumEIA-232network

length: 15 meters (50 feet)

• MaximumEIA-485network

length: 1,200 meters (4,000

feet)

• 1/8thunitloadonEIA-485

bus.

EZK _-_ 2 _ _-A _ A A

®

RUI on a

®

RUI on a Modbus®

Watlow EZ-ZONE® RUI/Gateway • 6 • Chapter 2 Install and Wire

Ó

Slot B

Warning:

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices when

wiring and connecting

this controller to a power

source and to electrical

sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

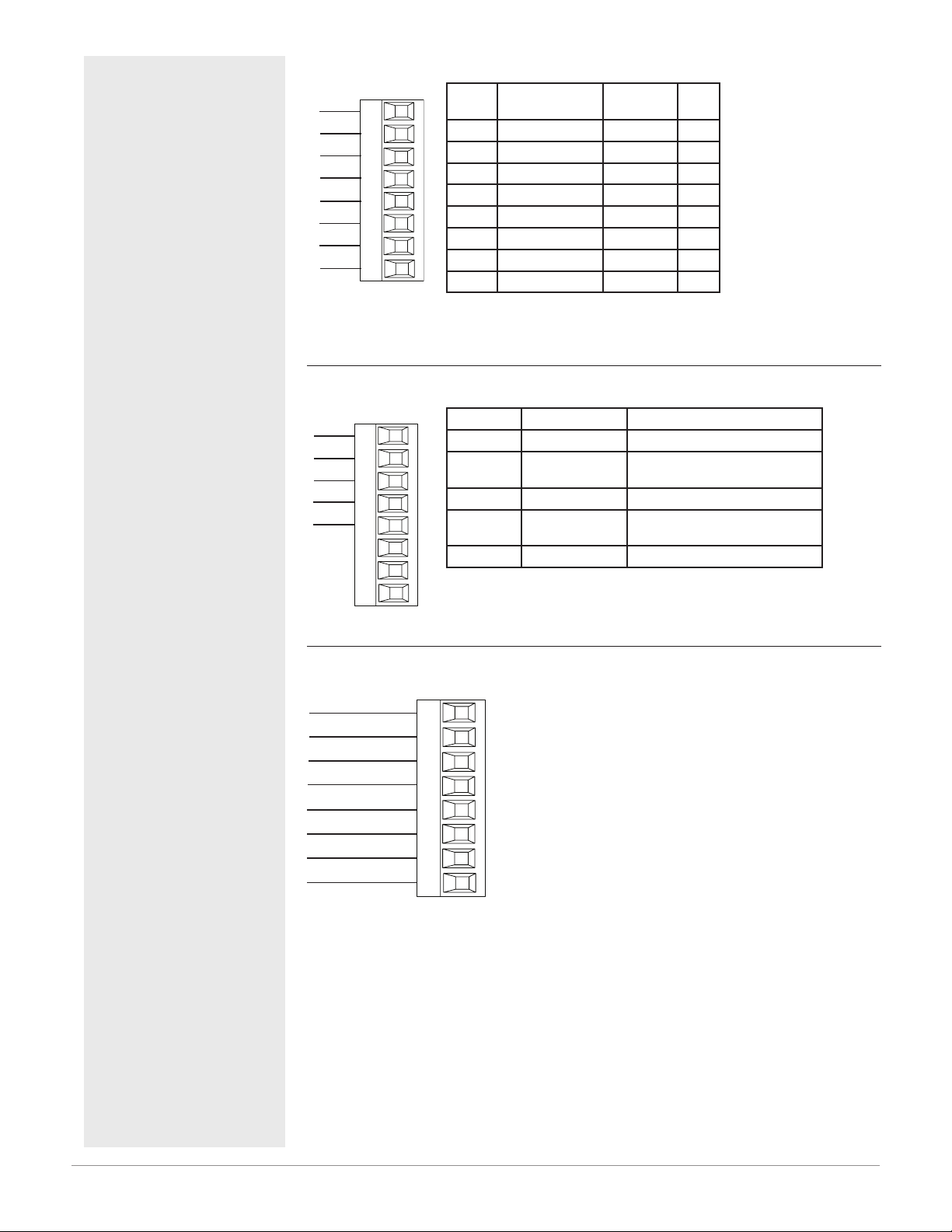

EtherNet/IP™ and Modbus TCP Communications

unused

unused

receive -

unused

unused

receive +

transmit -

transmit +

Note:

When changing the fixed IP address on the RUI cycle module power for new address to take effect.

Slot B

E8

E7

E6

E5

E4

E3

E2

E1

RJ-45

pin

8 brown unused E8

7 brown & white unused E7

6 green receive - E6

5 white & blue unused E5

4 blue unused E4

3 white & green receive+ E3

2 orange transmit - E2

1 white & orange transmit+ E1

T568B wire

color

Signal Slot

• Donotroutenetwork

B

wires with power wires.

• ConnectoneEthernet

cable per device to a

10/100 mbps Ethernet

switch. Both Modbus

TCP and EtherNet/IP™

are available on the

network.

DeviceNet™ Communications

®

CAN_H

shield

CAN_L

Slot B

V+

V+

CH

SH

CL

V-

V-

T2

Terminal Signal Function

V+ V+ DeviceNet™ power

CH CAN_H positive side of DeviceNet™

SH shield shield interconnect

CL CAN_L negative side of DeviceNet™

V- V- DeviceNet™ power return

S2

R2

Profibus DP Communications

+5Vdc Voltage Potential

485 T+/R+

485 T-/R-

Digital ground

Te rmination resistor B

485 T+/R+

485 T-/R-

Te rmination resistor A

VP

B

A

DG

trB

B

A

trA

• Wire T-/R- to the A

terminal of the EIA485 port.

• WireT+/R+totheB

terminal of the EIA485 port.

• Wire Digital Ground

to the common terminal of the EIA-485

port.

• Do not route network

wires with power

wires. Connect network wires in daisychain fashion when

connecting multiple

devices in a network.

• A termination resistor

should be used if this

controller is the last

one on the network.

• If using a 150 Ω cable

Watlow provides internal termination. Place

bus

bus

a jumper across pins

trB and B and trA and

A.

• If external termination is to be used with

a 150 Ω cable place a

390 Ω resistor across

pins VP and B, a 220

Ω resistor across pins

B and A, and lastly,

place a 390 Ω resistor

across pins DG and A.

• Do not connect more

than 32 EZ-ZONE

devices on any given

segment.

• Maximum EIA-485

network length: 1,200

meters (4,000 feet)

• 1/8th unit load on

EIA-485 bus.

Watlow EZ-ZONE® RUI/Gateway • 7 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric (NEC)

or other country-specific

standard wiring and safety

practices when wiring and

connecting this controller to

a power source and to electrical sensors or peripheral

devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

Note:

Excessive writes through the

gateway to other EZ-ZONE

family controllers may cause

premature EEPROM failure.

For more detail see the section entitled “Saving Settings

to Non-volatile Memory.”

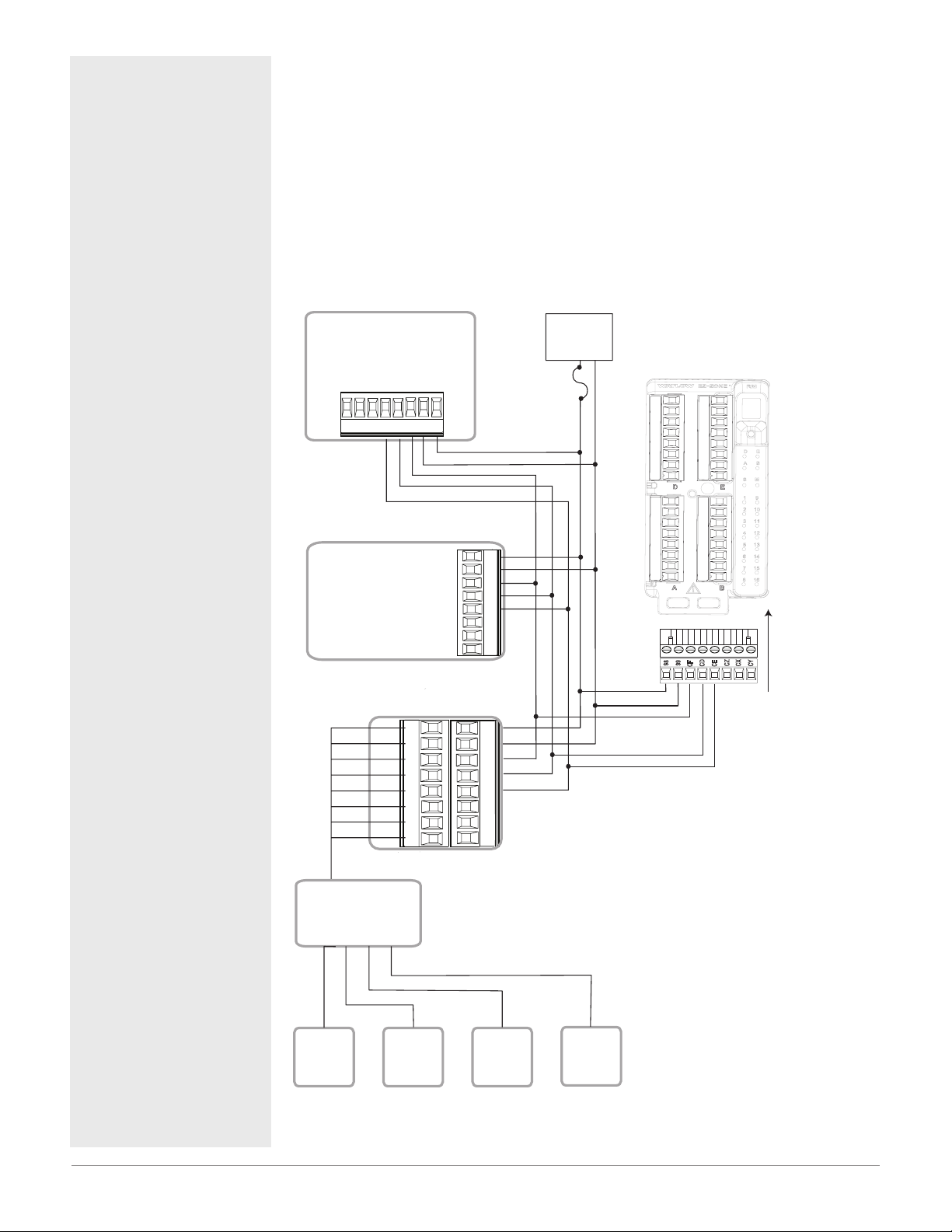

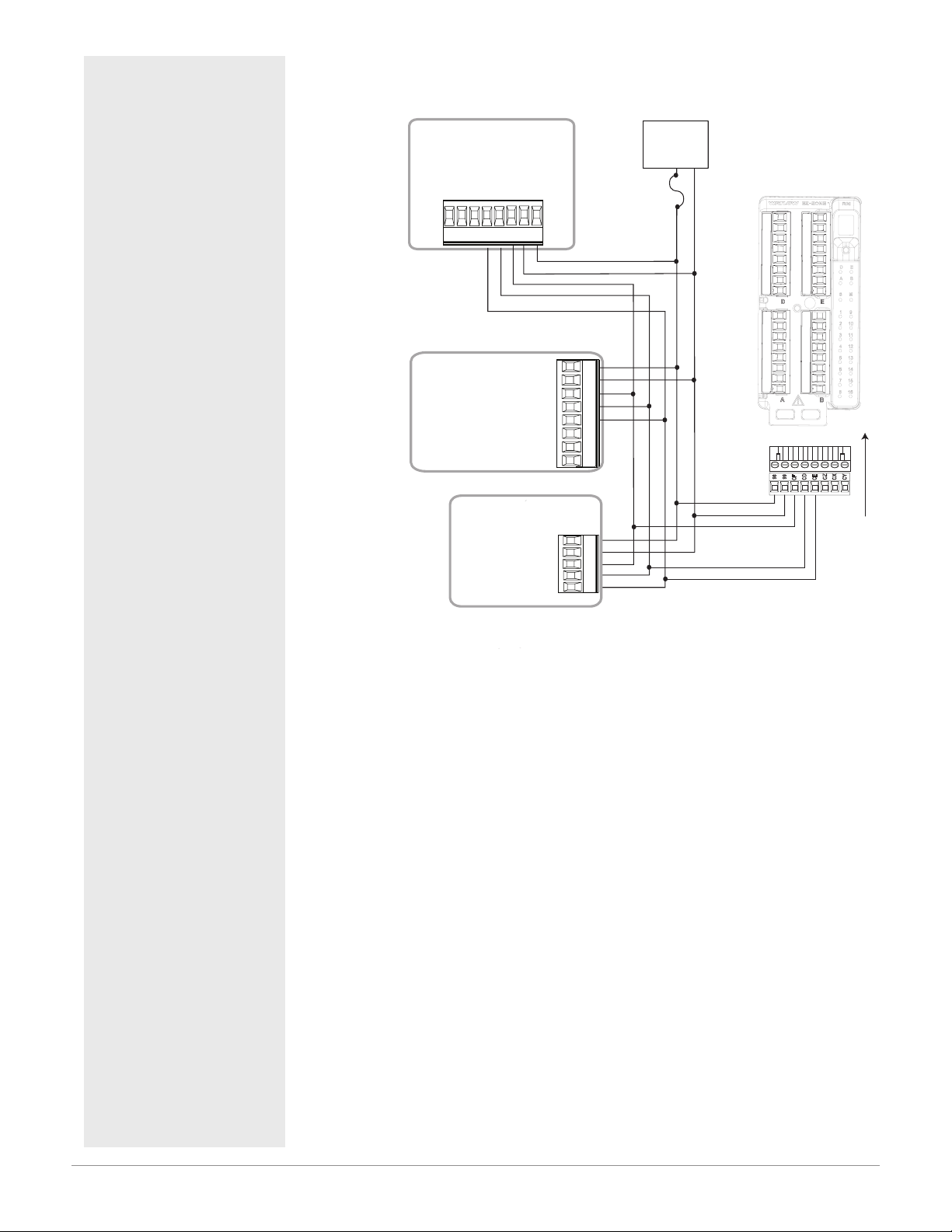

Wiring a Serial EIA-485 Network

Do not route network wires with power wires. Connect network wires in

daisy-chain fashion when connecting

multiple devices in a network.

A termination resistor may be re-

quired. Place a 120 Ω resistor across

T+/R+andT-/R-ofthelastcontroller

Note:

The RUI without a gateway installed, can communicate using

Watlows' Standard Bus only.

Note:

Do not route network wires with

power wires.

on a network.

An RUI/Gateway allows for connectivity between dissimilar networks. In this case, Ethernet on one side and Standard Bus on the

other.

EZ-ZONE ST

ST_ _ - _ _ A _ -_ _ _ _

CD

CE

D6

D5

CF

B5

T+/R+

T-/R-

98

99

power

common

power

Standard Bus

Network

Power

Supply

fuse

EZ-ZONE RMC

RMC _ _ _ _ _ _ _ _ _ A _ _

EZ-ZONE PM

PM _ _ _ _ _ - A _ _ _ _ _ _

EZ-ZONE RUI/GTW

EZK _ - _ 3 _ _ - _ _ _ _

E8

E7

E6

E5

E4

E3

E2

E1

Ethernet

Switch

EtherNet IP and/or Modbus TCP

Network

98

99

CF

CD

CE

power

98

power

99

com

CF

T-/R-

CD

T+/R+

CE

B5

D6

D5

power

power

power

power

common

T-/R-

T+/R+

Standard Bus

Network

common

t

C

l

o

S

98

99

T-/R-

CF

T+/R+

CZ

CX

CD

CY

CE

PC HMI

PLC

PLC

Watlow EZ-ZONE® RUI/Gateway • 8 • Chapter 2 Install and Wire

Ó

Warning:

Use National Electric

(NEC) or other countryspecic standard wiring

and safety practices when

wiring and connecting

this controller to a power

source and to electrical

sensors or peripheral devices. Failure to do so may

result in damage to equipment and property, and/or

injury or loss of life.

A network using Watlow's Standard Bus and an RUI

EZ-ZONE ST

ST_ _ - _ _ A _ -_ _ _ _

CD

CE

D6

D5

EZ-ZONE PM

PM _ _ _ _ _ - A _ _ _ _ _ _

CF

B5

EZ-ZONE RUI

T- / R-

T+ / R+

98

99

common

power

EZK _ - _ A _ _ - _ _ _ _

CF

CD

CE

D6

D5

98

99

CF

CD

CE

98

99

B5

power

com

T- / RT+ / R+

power

common

T- / RT+ / R+

Power

Supply

fuse

EZ-ZONE RMC

RMC _ _ _ _ _ _ _ _ _ A _ _

t

C

l

o

S

98

99

CZ

CX

CY

CD

CE

CF

power

common

T- / R-

T+ / R+

Watlow EZ-ZONE® RUI/Gateway • 9 • Chapter 2 Install and Wire

‰

3

‰

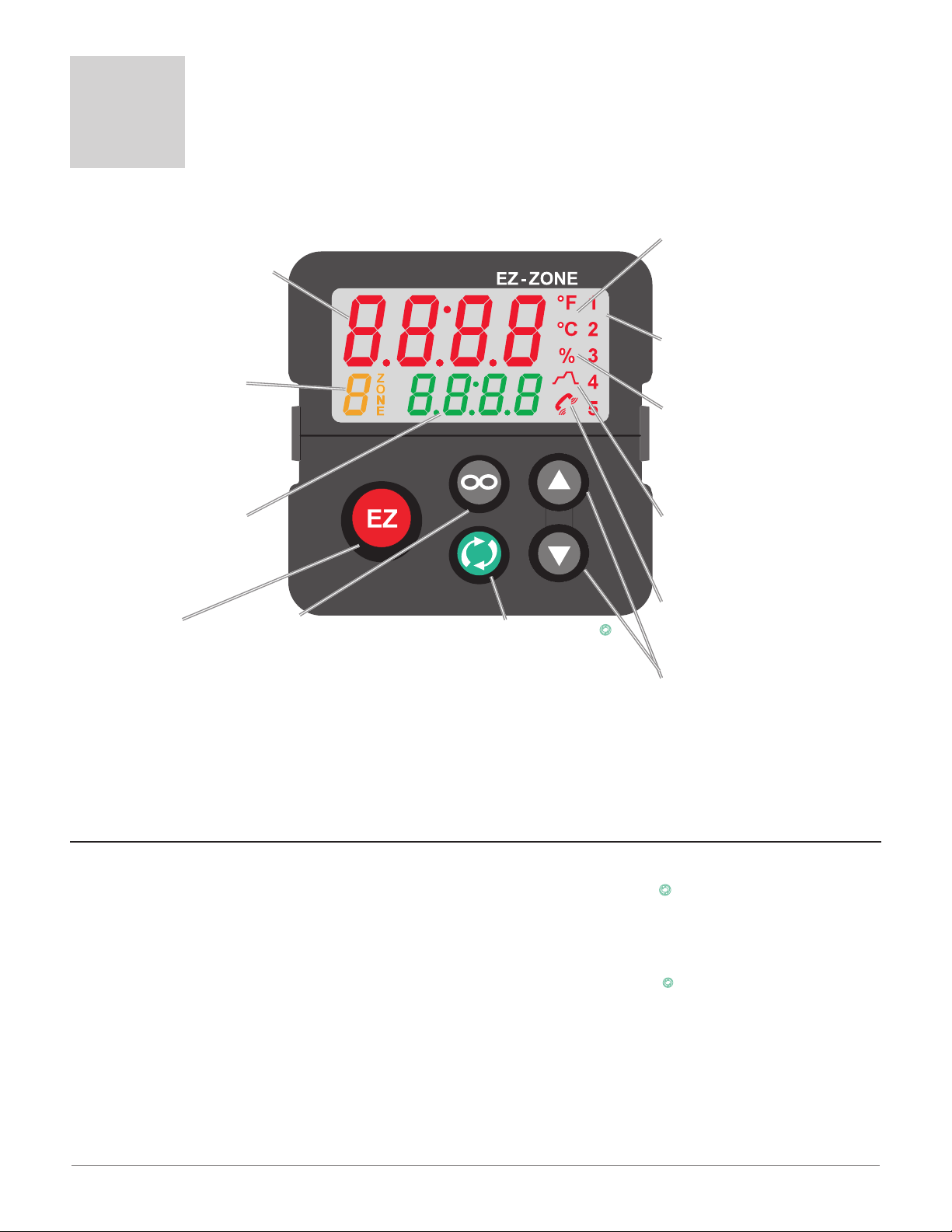

Chapter 3: Keys and Displays

Upper Display:

In the Home Page, displays

the parameter specified by

Custom 1 in the factory page,

otherwise displays the value

of the parameter in the lower

display.

Zone Display:

Indicates the controller zone

that the RUI is currently

communicating with.

A = zone 10 E = zone 14

b = zone 11 F = zone 15

C = zone 12 h = zone 16

d = zone 13 J = zone 17

Lower Display:

Indicates the set point or

output power value during

operation, or the parameter

whose value appears in the

upper display.

EZ Key:

This key can be programmed

to do various tasks, such as

starting a profile.

Note:

Upon power up, the upper or left display will

briefly indicate the firmware revision and the

lower or right display will

show RUI.

Infinity Key ˆ

In the Home Page, press

to scroll through the network zones, clears alarms

and errors if clearable.

On other pages, press

to back up one level, or

press and hold for two

seconds to return to the

Home Page.

®

Advance Key

Advances through parameter prompts.

Temperature Units:

Indicates whether the temperature is displayed in Fahrenheit or Celsius.

Output Activity:

Number LEDs indicate activity of outputs. A flashing light

indicates output activity.

Percent Units:

Lights when the controller is

displaying values as a percentage or when the open-loop set

point is displayed.

Profile Activity;

Lights when a profile is running. Flashes when a profile is

paused.

Communications Activity

Flashes when another device is

communicating with the RUI.

Up and Down Keys ¿ ¯

In the Home Page, the parameter specified by Custom 1 in

the factory page. In other pages, changes the upper display

to a higher or lower value, or

changes a parameter selection.

Responding to a Displayed Message

Attention Codes

An active message will cause the display to toggle between the normal settings and the active message in

the upper display and Attention [Attn] in the lower

display.

Your response will depend on the message and the

controller settings. Some messages, such as Ramping and Tuning, indicate that a process is underway.

If the message was generated by a latched alarm or

limit condition, the message can be cleared when the

condition no longer exists by simply pushing the Infinity ˆ key or alternatively, by following the steps

below. If an alarm has silencing enabled, it can also

be silenced.

Watlow EZ-ZONE® RUI/Gateway • 10 • Chapter 3 Keys and Displays

Push the Advance Key

in the upper display and the message source, such

as Limit High [Li;h1] in the lower display. Use the

Up ¿ and Down ¯ keys to scroll through possible

responses, such as Clear [`CLr] or Silence [`SiL],

then push the Advance ‰ or Infinity ˆ key to execute the action. See the table below for further information on the Attention Codes.

to display Ignore [ignr]

Display Parameter Name

[Attn]

[P;St1]

Attention

An active message will cause the

display to toggle between the normal settings and the active message instance in the upper display,

[Attn] in the lower display, and the

Zone will flash reflecting the Zone

which generated the message.

Your response will depend on the

message and the controller settings.

Some messages, such as Ramping

and Tuning, indicate that a process

is underway. If the message was

generated by a latched alarm or

limit condition, the message can be

cleared when the condition no longer exists. If an alarm has silencing

enabled, it can be silenced.

Push the Advance Key ‰ to display

[ignr] in the upper display and the

message source (such as [Li;h1]) in

the lower display.

Use the Up ¿ and Down ¯ keys

to scroll through possible responses,

such as Clear [`CLr] or Silence

[`SiL]. Then push the Advance ‰

or Infinity ˆ key to execute the

action.

Profile Start

Select a profile or step number that

will be affected by Profile Action.

Description

Setting Range Default Appears If

Note:

Due to the fact that the RUI/GTW can

be used with all EZ-ZONE controllers, the

prompts and the number of instances

shown below reflect features and the

maximum values that could be available

across the family of controllers at the time

this manual was written. The maximum

values shown are subject to change in

the future. To determine the features and

the maximum number of instances avail able for your controller please reference

the associated product user manual.

[AL;L1] to [AL;L8] Alarm Low 1 to 24

[AL;h1] to [AL;h8] Alarm High 1 to 24

[AL;E1] to [AL;E8] Alarm Error 1 to 24

[Er;i1] to [Er;16] Error Input 1 to 16

[Li;L1] to [Li;L4] Limit Low 1 to 16

[Li;h1] to [Li;h4] Limit High 1 to 16

[Li;E1] to [Li;E4] Limit Error 1 to 16

[tUn1] to [tUn9] Tuning 1 to 9

[tU10] to [tU16] Tuning 10 to 16

[`rP1] to [rP16] Ramping 1 to 16

[LP;o1] to [LP;16] Loop Open Error 1 to 16

[LP;r1] to [LP;16] Loop Reversed Error 1

to 16

[C;Er1] to [C;Er4] Current Error

[h;Er1] to [h;Er4 Heater Error

an alarm or error

message is active.

[uAL;h] Value too large to be displayed (≥ 10000.0)

[uAL;L] Value too small to be displayed (≤ -2000.0)

Note:

Due to the fact that the RUI/GTW can

be used with all EZ-ZONE controllers, the

prompts and the number of instances

shown below reflect features and the

maximum values that could be available

across the family of controllers at the time

this manual was written. The maximum

values shown are subject to change in

the future. To determine the features and

the maximum number of instances avail able for your controller please reference

the associated product user manual.

0 the controller in-

cludes profiling.

0 to 250

[P;AC1]

Profile Action Request

Select the action to apply to the profile or step selected in Profile Start.

[nonE] No Action

[ProF} Start a Profile

[PAUS] Pause

[rESU] Resume

[`End] End

None the controller in-

cludes profiling

No Device Connected

If there is no device connected to the RUI/GTW or the controller on the selected zone is disconnected, [``no]

will appear in the upper display and [`deu] will appear in the lower display. Press the Infinity Key ˆ to move

to the next zone.

If a zone disappears, ensure that its Standard Bus address was not intentionally changed. Also, check all network wiring and ensure that communications wiring is routed seperately from power wiring.

Watlow EZ-ZONE® RUI/Gateway • 11 • Chapter 3 Keys and Displays

Changing the Position of a Controllers Operations Page and or Profiling Page in the

Lockout Menu

To change the position of the Operations Page or Profiling Page in the Lockout Menu, you must go to the

Lock Operations Page parameter [LoC;O] or Lock Profiling Page parameter [LoC;P] in the Lockout Menu in

the Factory Page.

• To go to the Factory Page from the Home Page,

press both the Advance ‰ and Infinity ˆ keys

for six seconds. [CUSt] will appear in the Upper

Display and [FCty] will appear in the Lower

Display.

• Press the Up ¿ or Down ¯ key to move to the

Lockout Menu [`LoC].

• Press the Advance Key ‰ to select a parameter.

• Press the Up ¿ or Down ¯ key to change the

parameter value. The value you select (1, 2 or

3) will determine the position of the Operations

Page or Profiling Pages in the Lockout Menu in

the RUI Page.

• Press the Infinity Key ˆ to move backwards

through the levels: parameter to menu; menu to

Home Page.

• Press and hold the Infinity Key ˆ for two seconds

to return to the Home Page.

Example 3

The operator wants to read the Operations Page,

Setup Page. Profiling Page, Diagnostics Menu, Lock

Menu, Calibration Menu and Custom Menus. The operator also wants to read and write to the Home Page.

In the RUI Page, Lockout Menu, set Read Lock

[rLoC] to 1 and Set Lock [SLoC] to 5.

In the Factory Page, Lockout Menu, set Lock Operations Page [LoC;O] to 2 and Lock Profiling Page

[LoC;P] to 3.

Note:

[rLoC] and [SLoC] settings of the RUI will always

take precedence over any other individual controller

settings. In other words, if an RUI is on a network

with multiple PM controllers where all of the PM

controllers have [SLoC] set to 0 (not writable) and

the RUI has [SLoC] set to 5, all writable parameters in all PM controllers can be written to via the

RUI. Conversely, if all PM controllers have [SLoC]

set to 5 and the RUI has it set to 0 all of the PM

controllers will be write protected. If it is required

that protection for any given controller not be overridden by the RUI turn to the Features section of

the controller user manual and find the section entitled "Using Password Security".

Example 1

The operator wants to read all the menus and not allow any parameters to be changed.

In the RUI Page, Lockout Menu, set Read Lock

[rLoC] to 5 and Set Lock [SLoC] to 0.

Example 2

The operator wants to read and write to the Home

Page and Profiling Page, and lock all other pages and

menus.

In the RUI Page, Lockout Menu, set Read Lock

[rLoC] to 2 and Set Lock [SLoC] to 2.

In the Factory Page, Lockout Menu, set Lock Operations Page [LoC;O] to 3 and Lock Profiling Page

[LoC;P] to 2.

Watlow EZ-ZONE® RUI/Gateway • 12 • Chapter 3 Keys and Displays

Programming the EZ Key Using an RUI

The following examples show how to program the EZ

Key to start and stop a profile using PM, RM and ST

family controllers.

Note:

This functionality is embedded in the configuration

of the control, therefore, any "EZ" Function Key

from any RUI pointing to the programmed control

will assume the programmed function.

Using the RUI with PM Family Controllers

Note:

The steps shown below were created using PM

firmware version 11.00. Slight differences may exist if your controller has a different version. The

firmware version can be found by cycling power

to the controller (first numerical value displayed

in the upper display) or by navigating to the revision [`reu] prompt found in the Diagnostic Menu

[diag] in the Factory Page

1. Go to the Setup Page from the Home Page, press

both the Up ¿ and Down ¯ keys for six seconds.

[``Ai] will appear in the upper display and [`Set]

will appear in the lower display.

2. Press the Up ¿ or Down ¯ key until [`FUn] appears in the upper display and [`SEt] will appear in

the lower display.

3. Press the Advance Key ‰ once. [high] will appear

in the upper display and [`LEu] (high or low) will

appear in the lower display. Select whether a high

state or a low state will start the profile.

3. Press the Up ¿ or Down ¯ key to scroll through

the functions that can be assigned to the EZ Key.

When [P;StS] (Profile Start/Stop) appears in the upper display and [``Fn] appears in the lower display,

press the Infinity Key once to select that function

and move to the [``F;i] (Function Instance equals

Profile 1, 2, 3 or 4) parameter.

4. Press the Up ¿ or Down ¯ key to select the profile

of choice.

5. Press the Infinity Key ˆ once to return to the submenu, twice to return to the Home Page.

Using the RUI with RM Family Controllers

Note:

The steps shown below were created using RM

firmware version 6.00. Slight differences may exist

if your controller has a different version. The firmware version can be found by navigating to the revision [`reu] prompt found in the Diagnostic Menu

[diag] in the Factory Page.

1. Go to the Setup Page from the Home Page, press

both the Up ¿ and Down ¯ keys for six seconds.

[``Ai] will appear in the upper display and [`Set]

will appear in the lower display.

2. Press the Up ¿ or Down ¯ key until the Action

prompt [`ACt] appears in the upper display and

[`SEt] will appear in the lower display.

3. Press the Advance Key ‰ once and select the Action

instance (1-8) using the Up ¿ or Down ¯ key. Upon

entry, the upper display will show [```1] and the

lower display will show [`ACt].

4. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key to select Profile Start/Stop

[p;sts] as the Function [``Fn].

5. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key select the Function Instance

[``F;i] (Function Instance equals Profile 1, 2, 3...25).

6. Press the Advance Key ‰ once to define the source

of this Action by using the Up ¿ or Down ¯ key to

select the Function Key [`Fun] as the Source Function [SFn;a].

7. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key select the Source Instance

[`Si;a] (Source Instance in this case equals EZ-Key

1 or 2.

8. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key select the Source Zone [`S2;a]

(Source Zone equals 0 -16).

Note:

Zone 0 represents the current module being configured while in this example, this selection represents

the module in which the profile will run.

9. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key select the Level [`Leu]

desired to trigger the Action, high [high] or low

[low].

10. Press the Infinity Key ˆ three times to return to

the Home Page.

Using the RUI with ST Family Controllers

Note:

The steps shown below were created using PM

firmware version 8.00. Slight differences may exist if your controller has a different version. The

firmware version can be found by cycling power

to the controller (first numerical value displayed

in the upper display) or by navigating to the revision [`reu] prompt found in the Diagnostic Menu

[diag] in the Factory Page

1. Go to the Setup Page from the Home Page, press

both the Up ¿ and Down ¯ keys for six seconds.

[``Ai] will appear in the upper display and [`Set]

will appear in the lower display.

2. Press the Up ¿ or Down ¯ key until [`FUn] appears in the upper display and [`SEt] will appear in

the lower display.

3. Press the Advance Key ‰ once. [```1] will appear

in the upper display and [`FUn] will appear in the

lower display. At this time select instance 1.

Watlow EZ-ZONE® RUI/Gateway • 13 • Chapter 3 Keys and Displays

Note:

As of this firmware revision (8.0), two instances appear to be available and selectable. However, instance

2 is provided for future firmware enhancements only.

4. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key to select Profile Start/Stop

[p;sts] as the Function [``Fn].

5. Press the Advance Key ‰ once and then using the

Up ¿ or Down ¯ key select the Function Instance

[``F;i] (Function Instance equals Profile 1, 2, 3 or

4).

5. Press the Infinity Key ˆ twice to return to the sub-

menu, three times to return to the Home Page.

Watlow EZ-ZONE® RUI/Gateway • 14 • Chapter 3 Keys and Displays

Default Home Pages

‰

Watlow’s patented user-defined menu system improves operational efficiency. The user-defined Home

Page provides you with a shortcut to monitor or

change the parameter values that you use most often. The default Home Pages for the EZ-ZONE PM

Express, ST, Panel Mount (PM) and Rail Mount (RM)

controllers are shown on the following pages. When a

parameter normally located in the Setup Page or Operations Page is placed in the Home Page, it is accessible through both. If you change a parameter in the

Home Page, it is automatically changed in its original

page. If you change a parameter in its original page it

is automatically changed in the Home Page.

Use the Advance Key‰to step through the Home

Page parameters. When not in pairs the parameter

prompt will appear in the lower display, and the parameter value will appear in the upper display. You

can use the Up ¿ and Down ¯ keys to change the

value of writable parameters, just as you would in

any other menu.

If Control Mode is set to Auto, the Process Value

is in the upper display and the Closed Loop Set Point

(read-write) is in the lower display.

If a profile is running, the process value is in the

upper display and the Target Set Point (read only) is

in the lower display. If Control Mode is set to Manual,

the Process Value is in the upper display and the output power level (read-write) is in the lower display.

If Control Mode is set to Off, the Process Value is

in the upper display and [`oFF] (read only) is in the

lower display.

If a sensor failure has occurred, the upper display

will show four dashes [----] and the output power

level (read-write) is in the lower display.

As stated above, the user can define pairs of

prompts to appear on the display every time the Advance

pair will always be as defined in the Custom Menu

and as stated will default (factory settings) to the Active Process Value loop 1 [aC;pu], and the Active Set

Point loop 1 [aC;sp]. For the Limit, it would be the

Active Process Value [aC;pu],and Limit Status, either

Safe [safe] or Fail [fail]. When configuring the

Custom Menu to your liking it should be noted that

if 2 changeable (writable) prompts are displayed in a

Pair, i.e., Control Mode on top and Idle Set Point on

the bottom, only the lower display (Idle Set Point) can

be changed.

On some controllers the display can also be configured to scroll automatically through multiple channels and then through all configured display pairs.

Go to the Setup Page under the Global Menu and

change the Display Time [`d;ti] prompt to something

greater than 0. If set to 2, the display will scroll every

2 seconds from channel 1 to 2 (if present) and then

through all of the custom pairs that are configured.

key is pushed. For each controller the first

Changing the Set Point

You can change the set point by using the Up ¿ or

Down ¯ keys when a profile is not running.

Modifying the Home Page

To modify the Home Page proceed to the Factory

Menu by pushing and holding the Advance ‰ key

and the Infinity ˆ key for approximately six seconds.

Upon entering the Factory Page the first menu will

be the Custom Menu [Cust]. Once there push the

Advance

[Cust] and the upper display will show [1]. Again,

push the Advance

Process Value [aC;pu] will be displayed on the top and

Parameter [`par] on the bottom. Using the Up ¿ or

Down ¯ arrow keys will allow for a customized selection of choice. There are twenty positions available

that can be customized.

key where the lower display will show

button where the prompt for the

Modifying the Display Pairs

The Home Page, being a customized list of as many

as 20 parameters can be configured in pairs of up to

10 via the Display Pairs [d;prs] prompt found in the

Global Menu [glbl] (Setup Page).

Watlow EZ-ZONE® RUI/Gateway • 15 • Chapter 3 Keys and Displays

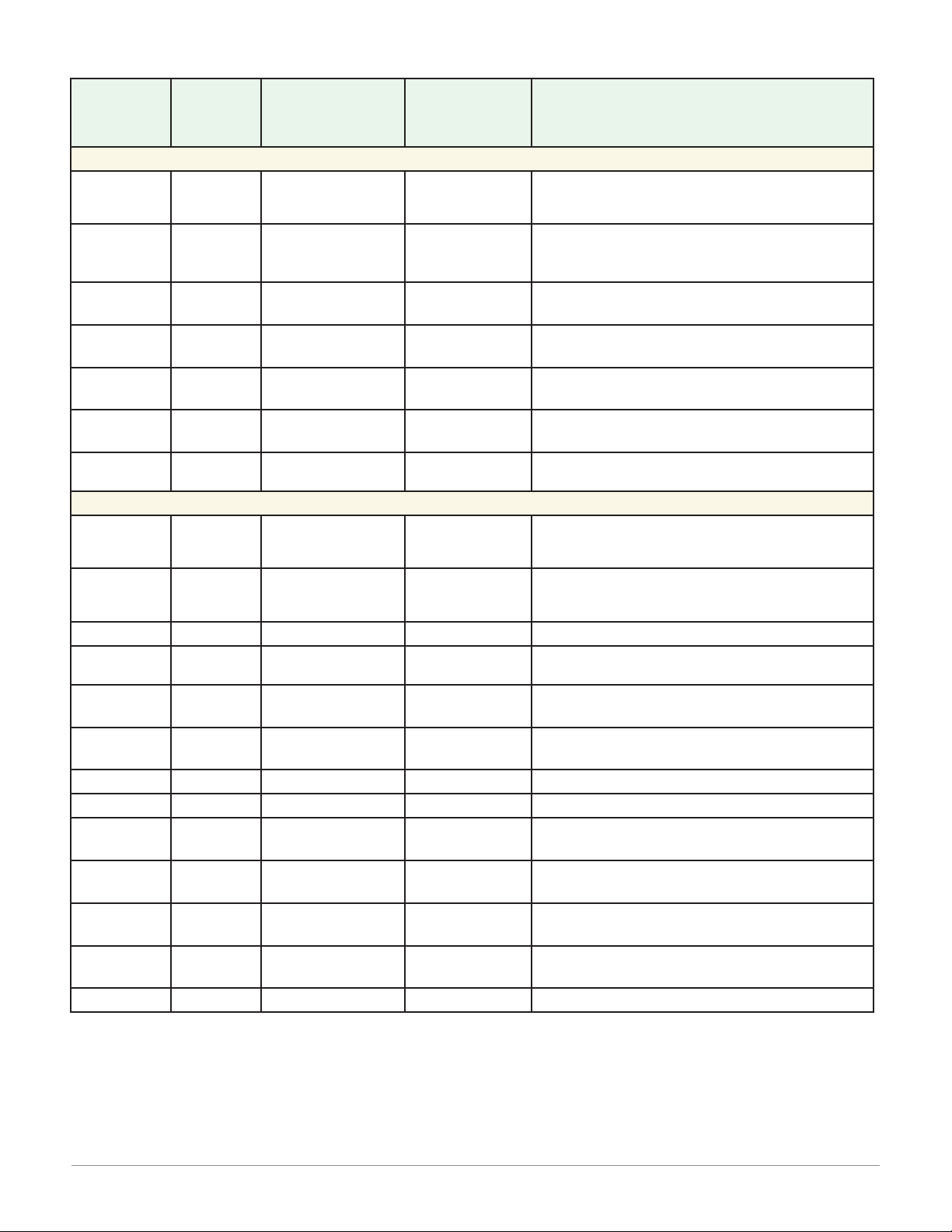

EZ-ZONE PM Express Home Page

Custom

Menu

Number

IF 4th digit of PN is equal to: PM _ [L] _ _ _ - _ _ _ _ B _ _ (Limit Controller)

1 Upper or

left display

2 Lower or

right display

- - - - (value

- - - - (value

- - - - (value

- - - - (value

- - - - (value

IF 4th digit of PN is equal to: PM _ [C] _ _ _ - _ _ _ _ B _ _ (PID Controller)

1 Upper or

left display

2 Lower or

right display

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

Home

Page

Display

(defaults)

(value

only)

[safe]

or

[fail[

only)

only)

only)

only)

only)

(value

only)

(value

only)

[AUt1]

[C;m1]

[h;pb1]

[C;pb1]

[`ti1]

[`td1]

[o;tb1]

[o;tb2]

[a;lo1]

[a;hi1]

[i;Ca1]

Parameter

Name

Active Process

Value

Limit State

Limit Low Set

Point

Limit High Set

Point

Alarm Low Set

Point

Alarm high Set

Point

Calibration Offset

Active Process

Value

Active Set Point

Autotune

User Control

Mode

Heat Proportional

Band

Cool Proportional

Band

Time Integral

Time Derivative

Time Base Out-

put 1

Time Base Out-

put 2

Alarm Low Set

Point

Alarm High Set

Point

Calibration Offset

Custom Menu

Display

(defaults)

[AC;Pu]

[`l;st]

[`ll;s]

[`lh;s]

[`a;lo]

[`a;hi]

[`i;Ca]

[AC;Pu]

[AC;SP]

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

Parameter Page and Menu

Home Page

Home Page

Operations Page

Operations Page

Operations Page

Operations Page

Operations Page

Home Page

Home Page

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Operations Menu

Watlow EZ-ZONE® RUI/Gateway • 16 • Chapter 3 Keys and Displays

Loading...

Loading...