Watlow EZ-ZONE Specifications

EZ-ZONE

™

ST

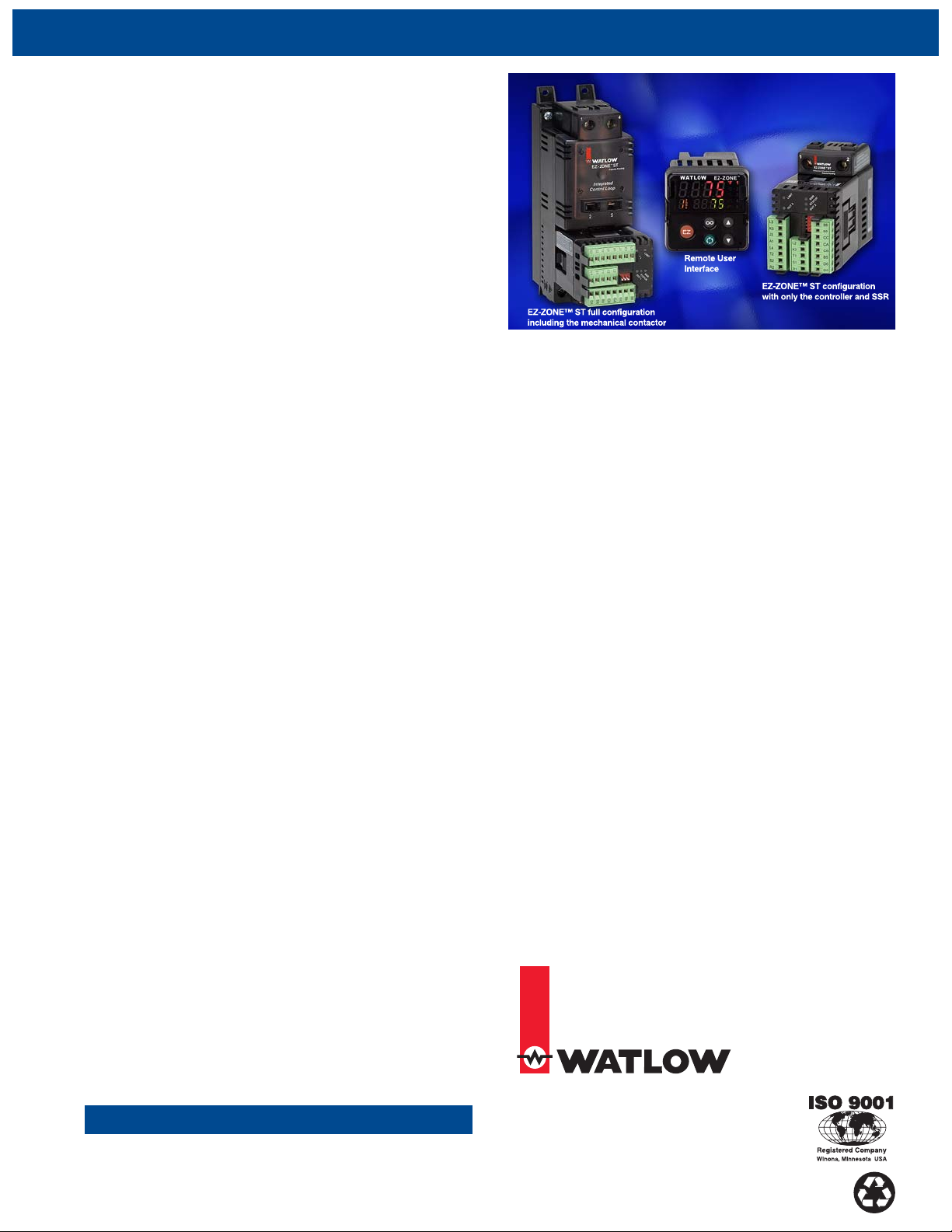

Watlow’s new EZ-ZONE™ ST integrated control loop solid

state controller offers complete thermal system control in a

single package solution. You get a PID temperature controller

already connected to a high amperage solid state relay with

the option of adding a properly sized heat sink, an over/under

temperature limit, a shut-down power contactor, digital

communications and a remote user interface in one complete

and professionally engineered product. Your life just became

a whole lot easier when it comes to solving the thermal

requirements of your system.

Because the system is modular and scalable you only pay

for what you need.You can stack the EZ-ZONE ST integrated

thermal loop into multiple configurations giving you the

flexibility to standardize on the product’s platform to solve your

wide range of application needs.

EZ-ZONE™ST Integrated

Control Loop Makes

Solving the Thermal

Requirements of Your

System Easy

Features and Benefits

Back panel or DIN-rail mount

• Provides several mounting options

Compact package

• Reduces panel size

Touch-safe package

• Complies to IP2X which increases safety for user

±0.1 percent temperature accuracy

• Provides efficient and accurate temperature control

Agency approvals: UL

®

, CSA, CE, RoHS, W.E.E.E.

• Meets applications requiring agency approvals

EZ-ZONE ST P3T Armor Sealing System Remote User

Interface (RUI)

• Complies to NEMA 4X, IP65 RUI

• Offers water and dust resistance, can be cleaned and

washed down

Three-year warranty

• Demonstrates Watlow’s reliability and product support

Off-the-shelf designed system solution

• Improves system reliability and termination reduction

• Reduces installation cost

• Eliminates compatibility headaches often encountered with

using many different components and brands

Advanced controllability algorithms

• Offers TRU-TUNE™+ for meeting demanding controllability

requirements

Profile capability

• Includes ramp and soak with four files and 40 total steps

© 2006 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste

1241 Bundy Boulevard

Winona, Minnesota 55987-5580 USA

Phone: +1 (507) 454-5300

Fax: +1 (507) 452-4507

Internet: www.watlow.com

E-mail: info@watlow.com

WIN-EZST-0306

Features and Benefits (con’t)

Solid state relay output

• Allows faster cycling, more precise control, increased

heater life and energy efficiency

PID temperature control

• Provides accurate temperature control

• Allows single input/dual output

• Allows standard PID or advanced PID tuning algorithms

Optional 485 Modbus™ RTU communication

• Allows network connectivity to PC or PLC

Optional temperature limit

• Increases safety in under/overtemperature condition

Optional definite purpose mechanical contactor

• Enables circuit safety shut down driven by limit control or

PID alarm output signal

Optional current monitoring feature

• Detects heater current flow and alarm indication of failed

Solid State Relay (SSR) or heater zone

Optional Remote User Interface (RUI)

• Use one RUI for multiple zone solutions to save costs

• Fits in small places due to shallow panel depth

• Eliminates costs and complexity of having to bring all

controller related wires to front panel area

• Enables use of multiple remote user interfaces to improve

usability of system

Optional SSR heat sink

• Sized and engineered for specific applications

• Factory supplied heat sink provides UL

®

listed benefits

System diagnostics

• Provides continuous self-monitoring alerts when there

is any system trouble to reduce maintenance and

service costs

PC Software—EZ-ZONE ST configurator

• Wizard style configuration of controller settings

• On-line or off-line recipe editing

UL®is a registered trademark of Underwriter’s Laboratories Inc.

Modbus™ is a trademark of Schneider Automation Incorporated.

Multiple U.S. and international patents pending.

Specifications

Line Voltage/Power

• 100 to 240VÅ(ac), +10/-15 percent; (85-264V~[ac]),

50/60Hz, ±5 percent

• 24Vı(ac/dc), +10/-15 percent; 50/60Hz, ±5 percent

• 12VA maximum power consumption without mechanical

contactor in system

• 50VA maximum power consumption with mechanical

contactor used in system, 140VA if using external contactor

• Data retention upon power failure via nonvolatile memory

Environment

• -18 to 70°C (0 to 149°F) operating temperature

• -40 to 85°C (-40 to 185°F) storage temperature

• 0 to 90 percent RH, non-condensing

Accuracy

• Calibration accuracy and sensor conformity: ±0.1 percent

of span, ±1°C @ the calibrated ambient temperature and

rated line voltage

• Types R, S, B; 0.2 percent

• Type T below -50°C; 0.2 percent

• Calibration ambient temperature @ 25°C ±3°C (77°F ±5°F)

• Accuracy span: 540°C (1000°F) minimum

• Temperature stability: ±0.1°C/°C (±0.1°F/°F) rise in ambient

maximum

Agency Approvals

• UL

®

, CSA, CE, IP65/NEMA 4X indoor use RUI, RoHS,

W.E.E.E.

• Limit version features FM approval

Controller

• Microprocessor based user-selectable control modes

• PID module: Single universal input, 2 outputs

• Limit module: Single universal input, 2 outputs

• Two total additional digital input/outputs shared between

PID and limit functions

• Control sampling rates: input = 10Hz, outputs = 10Hz

• Isolated EIA 485 Modbus™ RTU serial communications

Wiring Termination—Touch Safe Terminals

• Input, power and controller output terminals touch safe

removable 12 to 22 AWG

• Power load terminals 6 to 12 AWG

• Tightening torque: 30 in.-lbs

Universal Input

• Thermocouple, grounded or ungrounded sensors

• >20MΩ input impedance

• Maximum of 20Ω source resistance

• RTD 2- or 3-wire, platinum, 100Ω and 1000Ω @ 0°C

calibration to DIN curve (0.00385 Ω/Ω/°C)

• Process, 0-20mA @ 100Ω, or 0-10VÎ(dc) @ 20kΩ input

impedance; scalable, 0-50mV

• Inverse scaling

Digital Input

• Update rate 1Hz

• Dry contact or dc voltage

DC voltage

• Maximum input 36V at 3mA

• Minimum high state 3V at 0.25mA

• Maximum low state 2V

Dry contact

• Maximum short circuit 13mA

• Minimum open resistance 500Ω

• Maximum closed resistance 100Ω

Current Measurement

• Accuracy ±15 percent of displayed value

• Accuracy range 5 to 50A

• Operating range 2 to 50A

Digital Output

• Update rate 1Hz

• Output voltage 24V, current limit 10mA

Allowable Operating Range

Type J: 0 to 815°C or 32 to 1500°F

Type K: -200 to 1370°C or -328 to 2500°F

Type T: -200 to 400°C or -328 to 750°F

Type N: 0 to 1300°C or 32 to 2372°F

Type E: -200 to 800°C or -328 to 1470°F

Type C: 0 to 2315°C or 32 to 4200°F

Type D: 0 to 2315°C or 32 to 4200°F

Type F: 0 to 1395°C or 32 to 2543°F

Type R: 0 to 1760°C or 32 to 3200°F

Type S: 0 to 1760°C or 32 to 3200°F

Type B: 0 to 1816°C or 32 to 3300°F

RTD (DIN): -200 to 800°C or -328 to 1472°F

Process: -1999 to 9999 units

Output Hardware

• User selectable for heat/cool as on-off, P, PI, PD, PID, or

alarm action. Not valid for limit controls

• Electromechanical relay. Form A, rated 2A

• SSR drive 20-28VÎ(dc) low side open collector switch

• SSR, Form A, 0.5A @ 24VÅ(ac)

minimum, 264VÅ(ac) maximum, opto-isolated, without

contact suppression

• Electromechanical relay, Form A, rated 5A, auxiliary output

on PID module, output 2

• Electromechanical relay, Form C, rated 5A, auxiliary output

on limit module, output 3

Specifications for Basic Remote User

Interface (RUI)

Operator Interface

• Dual 4 digit, 7 segment LED displays

• Forward, backward, up and down keys plus a customer

programmable function key

• Typical display update rate 1Hz

• Agency approved to IP65/NEMA 4X

Line Voltage/Power

• 100 to 240VÅ(ac), +10/-15 percent; (85-264V~[ac])

50/60Hz, ±5 percent

• 24Vı(ac/dc), +10/-15 percent; 50/60Hz, ±5 percent

Specifications for Mechanical Contactor

• Insulation class: UL®class B 130°C (266°F)

• Minimum load of 100 watts

• Duty cycle: continuous

40 2 240/277 240 50 120 2

480 200 50 240 3

600 160 50

Full Load Number Line Locked Resistive Amp Maximum Horsepower

Amps of Poles Voltage Rotor Amps Rating Voltage Single Phase

Contact Ratings

Loading...

Loading...