Page 1

CPC400 Series

User’s Guide

Watlow Controls

1241 Bundy Blvd.

Winona, MN 55987

Repairs and Returns:

334 Westridge Drive

Watsonville, CA 95076

Customer Service:

Phone.....1-800-414-4299

Fax.........1-800-445-8992

Technical Support:

Phone.....(507) 494-5656

Fax.........(507) 452-4507

Email ......wintechsupport@watlow.com

Part No. 0600-2900-2000 Rev. 2.2

August 2005

Page 2

Copyright © 2005, Watlow Anafaze, Incorporated

Information in this manual is subject to change without notice. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form

without written permission from Watlow Anafaze.

Anafaze is a registered trademark, and LogicPro is a trademark, of Watlow Electric

Manufacturing Company. Modbus is a trademark of Schneider Automation Incorporated. Windows is a registered trademark of Microsoft Corporation in the United

States and/or other countries. UL is a registered trademark of Underwriters Laboratories, Inc. All other trademarks are the property of their respective owners.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be free from defects in material and workmanship for a period of three years

from the date of shipment. The Customer shall provide notice of any defect to Watlow

Anafaze, Incorporated within one week after the Customer's discovery of such defect.

The sole obligation and liability of Watlow Anafaze, Incorporated under this warranty

shall be to repair or replace, at its option and without cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be

defective shall immediately be returned at the Customer's expense to Watlow Anafaze,

Incorporated. Replaced or repaired products or parts will be shipped to the Customer

at the expense of Watlow Anafaze, Incorporated.

There shall be no warranty or liability for any products or parts that have been subject to misuse, accident, negligence, failure of electric power or modification by the

Customer without the written approval of Watlow Anafaze, Incorporated. Final determination of warranty eligibility shall be made by Watlow Anafaze, Incorporated. If a

warranty claim is considered invalid for any reason, the Customer will be charged for

services performed and expenses incurred by Watlow Anafaze, Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty

period, the warranty period for the replacement or repaired part shall terminate with

the termination of the warranty period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated

and the Customer's sole remedy with respect to the products. It is in lieu of all other

warranties, liabilities, and remedies. Except as thus provided, Watlow Anafaze, Inc.

disclaims all warranties, express or implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note: External safety devices must be used with this equipment.

Page 3

List of Figures v

List of Tables ix

1 System Overview 1

Manual Contents 1

Getting Started 2

Product Features 2

CPC400 Parts List 4

Technical Description 6

Safety 9

2 Installation 11

Typical Installation 12

Mounting Controller Components 13

System Wiring 20

Power Connections 23

Testing the System 26

Sensor Wiring 27

Wiring Control and Digital I/O 32

Analog Outputs 39

Serial Communications 41

Table of Contents

3 Operation and Setup 47

General Navigation Map 48

Keypad 49

Displays 50

Changing the Set Point 54

Changing the Control Mode and Output Power 55

Accessing and Navigating the Setup Menus 56

Setting Up Closed-Loop Control 57

Setting Up a Process or Pulse Input 58

Autotuning 62

Setting Up Alarms 63

Setting Up Process Variable Retransmit 67

Setting Up Cascade Control 69

Setting Up Ratio Control 73

Setting Up Differential Control 75

Doc. 0600-2900-2000 Watlow Anafaze i

Page 4

Table of Contents CPC400 Series User’s Guide

Setting Up Remote Analog Set Point 76

Setting Parameters Through Serial Communications or a LogicPro Program 78

4 Tuning and Control 81

Control Algorithms 81

Manually Tuning PID Loops 85

Control Outputs 88

5 Menu and Parameter Reference 91

Operator Parameters 92

Overview of the Setup Menus 94

Global Setup Menu

Input Menu 104

Channel Menu 109

Control Menu 111

Output Menu 116

Alarms Menu 121

Process Variable Retransmit Menu 125

Cascade Menu 127

Ratio Menu 128

Soft Integers Menu 130

Soft Booleans Menu 131

I/O Tests Menu 131

Additional Parameters for Serial Communications and LogicPro Programs 132

96

6 Troubleshooting and Reconfiguring 139

When There is a Problem 139

Troubleshooting the Controller 140

Corrective and Diagnostic Procedures 145

Additional Troubleshooting for Computer Supervised Systems 152

Clearing the RAM 153

Replacing the Flash Memory Chip 154

Changing the Hardware Communications Protocol 157

Installing Scaling Resistors 157

Configuring Serial DAC Outputs 162

Configuring Dual DAC Outputs 163

7 Specifications 165

CPC400 System Specifications 165

CPC400 Power Supply 176

Dual DAC Specifications 178

Serial DAC Specifications 180

Appendix A: Modbus Protocol 183

Master-Slave Model 183

Modbus ASCII and RTU Modes 185

Message Framing 185

Error Checking Methods 188

Function Codes 190

Examples 193

ii Watlow Anafaze Doc. 0600-2900-2000

Page 5

CPC400 Series User’s Guide Table of Contents

Glossary 195

Index 201

Parameter Address Reference 209

Declaration of Conformity 215

Menu Structure 216

Doc. 0600-2900-2000 Watlow Anafaze iii

Page 6

Table of Contents CPC400 Series User’s Guide

iv Watlow Anafaze Doc. 0600-2900-2000

Page 7

List of Figures

1 System Overview 1

Figure 1.1—CPC400 Standard Parts List 5

Figure 1.2—CPC400 Special Inputs Parts List 6

Figure 1.3—CPC400 Rear Views 6

Figure 1.4—CPC400 Front Panel 7

Figure 1.5—TB50 8

2 Installation 11

Figure 2.1—CPC400 System Components 12

Figure 2.2—Clearance with Straight SCSI Cable (L) and Right-Angle SCSI Cable (R) 14

Figure 2.3—Wiring Clearances 14

Figure 2.4—Mounting Bracket 15

Figure 2.5—Mounting the TB50 16

Figure 2.6—TB50 Mounted on a DIN Rail (Front) 16

Figure 2.7—TB50 Mounted on DIN Rail (Side) 17

Figure 2.8—Mounting a TB50 with Standoffs 17

Figure 2.9—CPC400 Power Supply Mounting Bracket 18

Figure 2.10—Dual DAC and Serial DAC Dimensions 19

Figure 2.11—CPC400 Series Controller with TB18 23

Figure 2.12—CPC400 Series Controller with TB50 23

Figure 2.13—Power Connections with the CPC400 Power Supply 25

Figure 2.14—CPC400 Connector Locations 28

Figure 2.15—Thermocouple Connections 29

Figure 2.16—RTD Connections 29

Figure 2.17—Voltage Signal Connections 30

Figure 2.18—Current Signal Connections 30

Figure 2.19—Encoder with 5V

Figure 2.20—Encoder Input with Voltage Divider 31

Figure 2.21—Digital Output Wiring 33

Figure 2.22—Sample Heat, Cool and Alarm Output Connections 35

Figure 2.23—Output Connections Using External Power Supply 35

Figure 2.24—TB50 Watchdog Timer Output 35

Figure 2.25—TB18 Watchdog Timer Output 35

Figure 2.26—Wiring Digital Inputs 36

Figure 2.27—Dual DAC with Current Output 39

Figure 2.28—Dual DAC with Voltage Output 40

Figure 2.29—Single/Multiple Serial DACs 41

Î

(dc) TTL Signal 31

Doc. 0600-2900-2000 Watlow Anafaze v

Page 8

List of Figures CPC400 Series User’s Guide

Figure 2.30—Connecting One CPC400 to a Computer Using EIA/TIA-232 42

Figure 2.31—Four-Wire EIA/TIA-485 Wiring 43

Figure 2.32—Two-Wire EIA/TIA-485 Wiring 43

Figure 2.33—Recommended System Connections 44

3 Operation and Setup 47

Figure 3.1—General Navigation Map 48

Figure 3.2—Keypad Navigation 49

Figure 3.3—Loop Display 50

Figure 3.4—Loop Display with Alarm Code 51

Figure 3.5—Display for Failed Sensor Alarm 51

Figure 3.6—Input Scaling 59

Figure 3.7—Activation and Deactivation of Process Alarms 66

Figure 3.8—Application Using Process Variable Retransmit 68

Figure 3.9—Secondary Set Point When Primary Loop Has Heat and Cool Outputs 70

Figure 3.10—Secondary Set Point When Primary Loop Has Heat Output Only 70

Figure 3.11—Example Application Using Cascade Control 72

Figure 3.12—Relationship of Secondary Loop Set Point to Primary Loop Process

Variable in Cascade Example 73

Figure 3.13—Relationship Between the Process Variable on the Master Loop and the

Set Point of the Ratio Loop 74

Figure 3.14—Application Using Ratio Control 75

4 Tuning and Control 81

Figure 4.1—On/Off Control 82

Figure 4.2—Proportional Control 83

Figure 4.3—Proportional and Integral Control 83

Figure 4.4—Proportional, Integral and Derivative Control 84

Figure 4.5—Time Proportioning and Distributed Zero Crossing Waveforms 88

5 Menu and Parameter Reference 91

Figure 5.1—Operator Parameter Navigation 92

Figure 5.2—Setup Menus and Parameters 95

Figure 5.3—The Effect of Tune Gain on Recovery from a Load Change 115

Figure 5.4—Linear and Nonlinear Outputs 121

6 Troubleshooting and Reconfiguring 139

Figure 6.1—Removal of Electronics Assembly from Case 155

Figure 6.2—Screw Locations on PC Board 155

Figure 6.3—Location of Flash Memory Chip 156

Figure 6.4—Removal of Flash Memory Chip 156

Figure 6.5—Jumper Configurations 157

Figure 6.6—Input Circuit 158

Figure 6.7—Serial DAC Voltage and Current Jumper Positions 162

Figure 6.8—Dual DAC 163

vi Watlow Anafaze Doc. 0600-2900-2000

Page 9

CPC400 Series User’s Guide List of Figures

7 Specifications 165

Figure 7.1—CPC400 Module Dimensions 166

Figure 7.2—CPC400 Clearances with Straight SCSI Cable 167

Figure 7.3—CPC400 Clearances with Right-Angle SCSI Cable 167

Figure 7.4—TB50 Dimensions 169

Figure 7.5—TB50 Dimensions with Straight SCSI Cable 170

Figure 7.6—TB50 Dimensions with Right-Angle SCSI Cable 171

Figure 7.7—Power Supply Dimensions (Bottom View) 177

Figure 7.8—Dual DAC Dimensions 179

Figure 7.9—Serial DAC Dimensions 181

Appendix A: Modbus Protocol 183

Figure A.1—Query - Response Cycle 184

Figure A.2—Example Message Frame 186

Doc. 0600-2900-2000 Watlow Anafaze vii

Page 10

List of Figures CPC400 Series User’s Guide

viii Watlow Anafaze Doc. 0600-2900-2000

Page 11

2 Installation 11

Table 2.1—Cable Recommendations 21

Table 2.2—Power Connections 24

Table 2.3—Digital Output States and Values Stored in the Controller 33

Table 2.4—Digital Input States and Values Stored in the Controller 36

Table 2.5—TB18 Connections 37

Table 2.6—TB50 Connections 38

Table 2.7—EIA/TIA-232 Connections 42

Table 2.8—RTS/CTS and DSR/DTR Pins in DB-9 and DB-25 Connectors 42

List of Tables

3 Operation and Setup 47

Table 3.1—Control Modes on the Loop Display 50

Table 3.2—Alarm Codes and Messages for Process and Failed Sensor Alarms 52

Table 3.3—System Alarm Messages 53

Table 3.4—Input Readings 60

Table 3.5—Scaling Values 60

Table 3.6—Input Readings and Calculations 61

Table 3.7—Scaling Values 61

Table 3.8—Scaling Values 62

Table 3.9—Parameters Settings for Process Variable Retransmit Example 69

Table 3.10—Parameter Settings for the Primary Loop in the Cascade Example 72

Table 3.11—Parameter Settings for the Secondary Loop in the Cascade Example 72

Table 3.12—Ratio Control Settings for the Ratio Loop (Loop 2) in the Example 75

Table 3.13—Parameter Settings for the Ratio Loop (Loop 2) for the Example 76

Table 3.14—Parameters Settings for the Master Loop (Loop 1) in the Example 77

Table 3.15—Parameter Settings for the Ratio Loop (Loop 2) in the Example 78

Table 3.16—Number of Decimal Places for Numeric Values via Modbus or Logic 80

4 Tuning and Control 81

Table 4.1—Proportional Band Settings 85

Table 4.2—Integral Term and Reset Settings 86

Table 4.3—Derivative Term Versus Rate 86

Table 4.4—General PID Constants 87

Doc.0600-2900-2000 Watlow Anafaze ix

Page 12

List of Tables CPC400 Series User’s Guide

5 Menu and Parameter Reference 91

Table 5.1—Control Mode Menu Options 93

Table 5.2—CPC400 Setup Menus 94

Table 5.3—

Table 5.4—Digital Input States Required to Load Each Job 98

Table 5.5—Power Up Loop Modes 100

Table 5.6—Digital Output Alarm Polarity 103

Table 5.7—Input Types and Ranges 104

Table 5.8—Calibration Offset Ranges 106

Table 5.9—Display Formats 107

Table 5.10—Characters for the Loop Name and Input Units Parameters 110

Table 5.11—PV Source Options 110

Table 5.12—Proportional Band Values 111

Table 5.13—Values for the Control Hysteresis and Deviation Alarm Parameters 113

Table 5.14— Control Types 115

Table 5.15—Heat and Cool Output Types 116

Table 5.16—Alarm Functions 122

Table 5.17—Values for Alarm Hysteresis 125

Table 5.18—Bit Positions for Alarm Enable and Alarm Function 133

Table 5.19—Bit Positions for Alarm Status and Alarm Acknowledge 134

Table 5.20—System Status Bits 137

Values for BCD Job Load

97

6 Troubleshooting and Reconfiguring 139

Table 6.1—Operator Response to Process Alarms 142

Table 6.2—Other Symptoms 143

Table 6.3—Resistor Values for Current Inputs 159

Table 6.4—Resistor Locations for Current Inputs 159

Table 6.5—Resistor Values for Voltage Inputs 160

Table 6.6—Resistor Locations for Voltage Inputs 160

Table 6.7—Resistor Locations for RTD Inputs 161

Table 6.8—Dual DAC Jumper Settings 163

7 Specifications 165

Table 7.1—Agency Approvals / Compliance 165

Table 7.2—Environmental Specifications 165

Table 7.3—Physical Dimensions 166

Table 7.4—CPC400 with Straight SCSI 166

Table 7.5—CPC400 with Right Angle SCSI 167

Table 7.6—CPC400 Connections 168

Table 7.7—TB50 Physical Dimensions 168

Table 7.8—TB50 Connections 169

Table 7.9—TB50 with Straight SCSI 169

Table 7.10—TB50 with Right Angle SCSI 170

Table 7.11—Analog Inputs 172

Table 7.12—Pulse Inputs 172

Table 7.13—Programmable Logic 173

Table 7.14—Thermocouple Range and Resolution 173

x Watlow Anafaze Doc. 0600-2900-2000

Page 13

CPC400 Series User’s Guide List of Tables

Table 7.15—RTD Range and Resolution 173

Table 7.16—Input Resistance for Voltage Inputs 174

Table 7.17—Digital Inputs 174

Table 7.18—Digital Outputs Control / Alarm 175

Table 7.19—CPU Watchdog Output 175

Table 7.20—5V

Î

(dc) Output (Power to Operate Solid-State Relays) 175

Table 7.21—CPC400 Serial Interface 176

Table 7.22—CPC400 Power 176

Table 7.23—Power Supply Environmental Specifications 176

Table 7.24—Power Supply Agency Approvals / Compliance 176

Table 7.25—Power Supply Physical Specifications 177

Table 7.26—Power Supply with Mounting Bracket 177

Table 7.27—Power Supply Inputs and Outputs 178

Table 7.28—Dual DAC Physical Specifications 178

Table 7.29—Dual DAC Power Requirements 179

Table 7.30—Dual DAC Specifications by Output Range 180

Table 7.31—Serial DAC Environmental Specifications 180

Table 7.32—Serial DAC Physical Specifications 180

Table 7.33—Serial DAC Agency Approvals / Compliance 181

Table 7.34—Serial DAC Inputs 181

Table 7.35—Serial DAC Power Requirements 182

Table 7.36—Serial DAC Analog Output

Specifications 182

Appendix A: Modbus Protocol 183

Table A.1—Function Codes 190

Table A.2—Diagnostics Subfunctions 191

Table A.3—Sample Packet for Host Query 193

Table A.4—Sample Packet for Slave Response 193

Table A.5—Sample Packet for Host Query 194

Table A.6—Sample Packet for Slave Response 194

Table A.7—Sample Packet for Host Query 194

Table A.8—Sample Packet for Slave Response 194

Doc. 0600-2900-2000 Watlow Anafaze xi

Page 14

List of Tables CPC400 Series User’s Guide

xii Watlow Anafaze Doc. 0600-2900-2000

Page 15

1

System Overview

Manual Contents

This manual describes how to install, set up, and operate a

CPC400 series controller. Each chapter covers a different aspect of your control system and may apply to different users:

• Chapter 1: System Overview provides a component

list and summary of features for the CPC400 series

controllers.

• Chapter 2: Installation provides detailed instructions on installing the CPC400 series controller and its

peripherals.

• Chapter 3: Operation and Setup provides instructions about operating and setting up the CPC400.

• Chapter 4: Tuning and Control describes available

control algorithms and suggestions for applications.

• Chapter 5: Menu and Parameter Reference provides detailed descriptions of all menus and parameters for controller setup and for accessing parameter

and I/O values with a LogicPro program or via the serial communications interface.

• Chapter 6: Troubleshooting and Reconfiguring

includes troubleshooting, upgrading and reconfiguring procedures for technical personnel.

• Chapter 7: Specifications lists detailed specifications of the controller and optional components.

• Appendix: Modbus Reference describes the Modbus RTU communications protocol, which is used to

read and set parameter values through the serial communications interface. This information is intended

for programmers writing software to communicate

with the CPC400.

• Parameter Address Reference provides a way to

quickly locate parameter addresses.

Doc. 0600-2900-2000 Watlow Anafaze 1

Page 16

Chapter 1: System Overview CPC400 Series User’s Guide

Getting Started

Safety Symbols

These symbols are used throughout this manual:

Initial Inspection

WARNING!

CAUTION!

NOTE!

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury or property damage.

Indicates pertinent information or an item that

may be useful to document or label for later reference.

Accessories may or may not be shipped in the same container as the CPC400, depending upon their size. Check

the shipping invoice against the contents received in all

boxes.

Product Features

CPC400 series controllers offer high-performance closedloop control and user-programmable logic to manipulate

process control algorithms and sequential logic.

The CPC400 provides four or eight independent control

loops with analog inputs—thermocouples, RTDs and process. An additional 2 kHz pulse loop is also provided.

When used as a stand-alone controller, you may operate

the CPC400 via the two-line 16-character display and

touch keypad. You can also use it as the key element in a

computer-supervised data acquisition and control system.

The CPC400 can be locally or remotely controlled via an

EIA/TIA-232 or EIA/TIA-485 serial communications interface.

CPC400 features include:

2 Watlow Anafaze Doc. 0600-2900-2000

Page 17

•

Ω

CPC400 Series User’s Guide Chapter 1: System Overview

TRU-TUNE+™Adaptive Control : Enable adaptive

control using the unique TRU-TUNE+™ adaptive algorithm and optimize even difficult-to-control or dynamic processes. TRU-TUNE+™ monitors the process

variable and adjusts the control parameters automatically to keep your process at set point and optimize for

set point and load changes.

• User-Programmable Logic : Customize the controller to run custom closed-loop control algorithms or processes. All closed-loop control parameters and system

I/O are available for user programs. Program and

closed-loop control variables can be shared or independent. Use LogicPro software to write, monitor and debug logic programs.

• Direct Connection of Mixed Thermocouple Sen-

sors: Connect most thermocouples to the controller

with no hardware modifications. Thermocouple inputs

feature reference junction compensation, linearization, offset calibration to correct for sensor inaccuracies, detection of open, shorted or reversed

thermocouples, and a choice of Fahrenheit or Celsius

display.

• Accepts Resistive Temperature Detectors

(RTDs): Use three-wire, 100

, platinum, 0.00385-

curve sensors. Special inputs must be installed.

• Automatic Scaling for Process Analog Inputs:

The CPC400 series automatically scales process inputs used with industrial process sensors. Enter two

points, and all input values are automatically scaled.

Special inputs must be installed.

• Dual Outputs: The CPC400 series includes both heat

and cool control outputs for each loop. Independent

control parameters are provided for each output.

• Independently Selectable Control and Output

Modes: Set each control output to on/off, time propor-

tioning, Serial DAC (digital-to-analog converter) or

distributed zero crossing mode. Set up to two outputs

per loop for on/off, P, PI or PID control with reverse or

direct action.

• Boost Output Function: Set digital outputs to function as boost on/off control in association with any

alarm.

• Flexible Alarms: Independently set high and low

alarms and high and low deviation alarms for each

loop. Alarms can activate a digital output by themselves, or they can be grouped with other alarms to activate an output.

• Global Alarm Output: Any alarm event activates

the global alarm output.

• CPU Watchdog: The CPU watchdog timer output notifies you of system failure.

Doc. 0600-2900-2000 Watlow Anafaze 3

Page 18

•

Chapter 1: System Overview CPC400 Series User’s Guide

Keypad or Computer Operation: Set up and run

the controller from the keypad or from a local or remote computer. Use WATVIEW HMI software to set

up the controller, manage jobs (recipes), log data or

monitor system performance.

• Modbus RTU Protocol, EIA/TIA-232 and 485

Communications: Connect operator interface termi-

nals and third-party software packages using the

widely supported Modbus RTU protocol.

• Multiple Job Storage: Store up to eight jobs in the

controller’s battery-backed memory. Load a job

through the keypad, digital inputs or software. Each

job is a set of operating conditions, including set points

and alarm limits.

• Nonlinear Output Curves: Select either of two nonlinear output curves for each control output.

• Pulse Input: Use the pulse input for precise control of

motor or belt speed.

• Low Power Shutdown: The controller shuts down

and turns off all outputs when it detects the input voltage drop below the minimum safe operating level.

• Process Variable Retransmit: Scale a temperature

or process and convert it to an analog output for external devices such as chart recorders.

• Two-Zone Cascade Control: Control thermal systems with long lag times, which cannot be accurately

controlled with a single loop.

• Ratio or Offset Control: Control one process as a ratio or offset of another process.

• Remote Analog Set Point: Scale an external voltage

or current source to provide a set point for a loop.

CPC400 Parts List

You may have received one or more of the following components. See Figure 2.1 on page 12 for CPC400 configuration

information.

• CPC400 series controller

• Controller mounting kit

• TB50 with 50-pin SCSI cable

• EIA/TIA-232 or EIA/TIA-485 communications cable

• Power supply with mounting bracket and screws

• Serial DAC (digital-to-analog converter)

• Special input resistors (installed in CPC400)

• User’s guide

4 Watlow Anafaze Doc. 0600-2900-2000

Page 19

CPC400 Series User’s Guide Chapter 1: System Overview

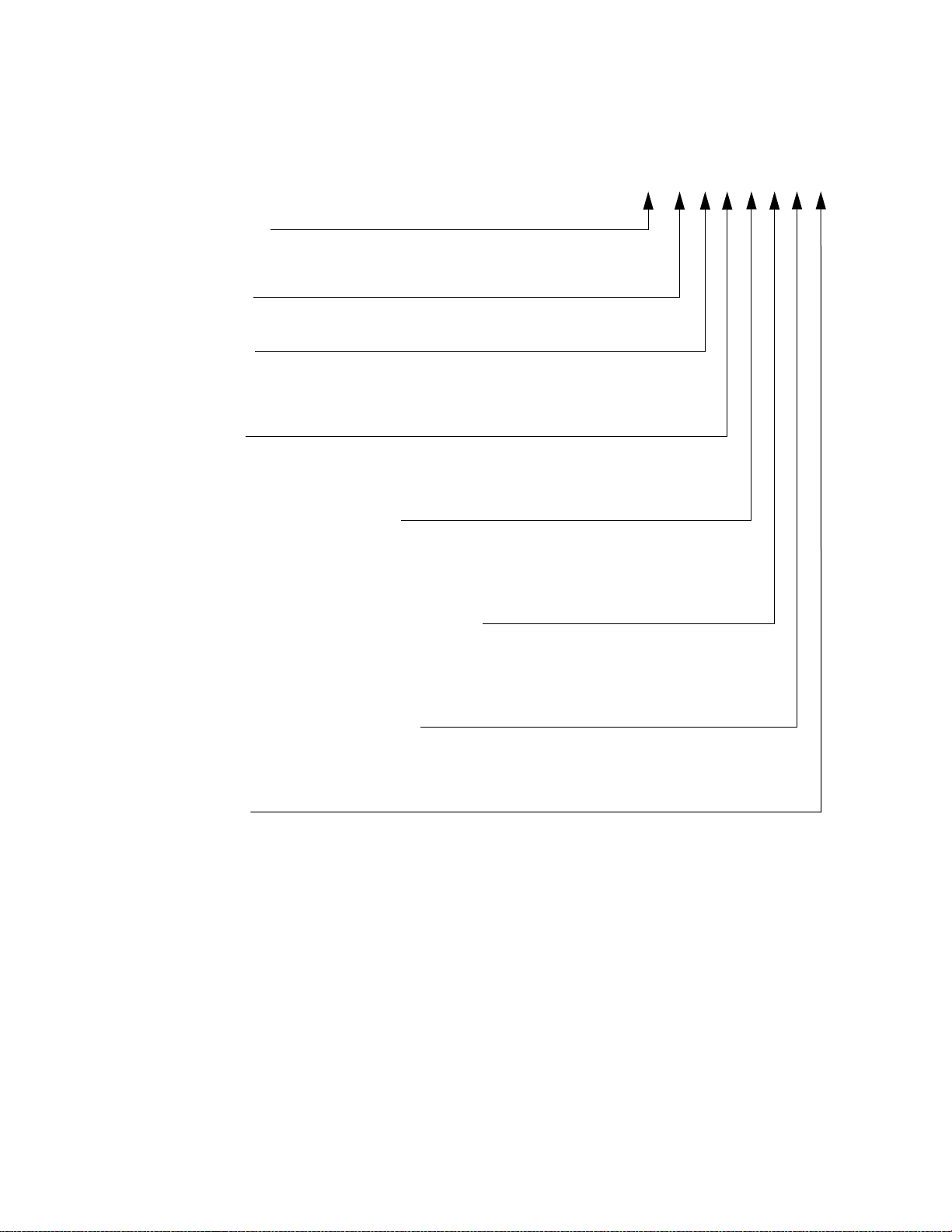

40 _ -1 _ _ _ _ _ _

Number of Loops

4 = 4 loops

8 = 8 loops

Controller T ype

1 = Standard firmware

Terminal Block

0 = No terminal block accessory

1 = 18-terminal block

2 = 50-terminal block, includes 3-foot (0.9 m) 50-pin SCSI cable (TB50-SCSI)

Power Supply

0 = No power supply

2 = 120/240V

(5V

Å (ac), 50/60 Hz power supply adapter

Î [dc] @ 4 A, 15VÎ [dc] @ 1.2 A), CE approved

SCSI Cables (for use with TB50-SCSI)

0 = No special SCSI cable (3-foot [0.9 m] cable is included with 50-terminal block)

1 = 6-foot (1.8 m) SCSI cable (CA-SCSI-6)

2 = 3-foot (0.9 m) right-angle SCSI cable (CA-SCSI-RT-3)

3 = 6-foot (1.8 m) right-angle SCSI cable (CA-SCSI-RT-6)

Serial Cables (for communications with computer)

0 = No serial communications cable

1 = 10-foot (3.0 m) serial cable, DB-9 female/bare wire (CA-COMM-010)

2 = 25-foot (7.6 m) serial cable, DB-9 female/bare wire (CA-COMM-025)

3 = 50-foot (15.2 m) serial cable, DB-9 female/bare wire (CA-COMM-050)

Serial Communications Jumper Settings

0 = EIA/TIA-232

1 = EIA/TIA-485

2 = EIA/TIA-485 terminated

Special Inputs

Standard unit is configured for thermocouples and -10 to +60mV process inputs.

For other sensors, special inputs are required.

0 = Thermocouples and -10 to +60mV inputs only

X = Number of current and voltage inputs.

Figure 1.1 CPC400 Standard Parts List

Doc. 0600-2900-2000 Watlow Anafaze 5

Page 20

Chapter 1: System Overview CPC400 Series User’s Guide

CPCSI _ _ - _ _ - _ _

Special/Process Input Type

(Not required for thermocouple sensor inputs)

23 = RTD

43 = 0 to 10 mA

44 = 0 to 20 mA

50 = 0 to 100 mV

52 = 0 to 500 mV

53 = 0 to 1 V

55 = 0 to 5 V

56 = 0 to 10 V

57 = 0 to 12 V

Start Loop

XX = Loop number XX

Î (dc)

Î (dc) or 4 to 20 mAÎ (dc)

Î (dc)

Î (dc)

Î (dc)

Î (dc)

Î (dc)

Î (dc)

End Loop

XX = Loop number XX

Technical Description

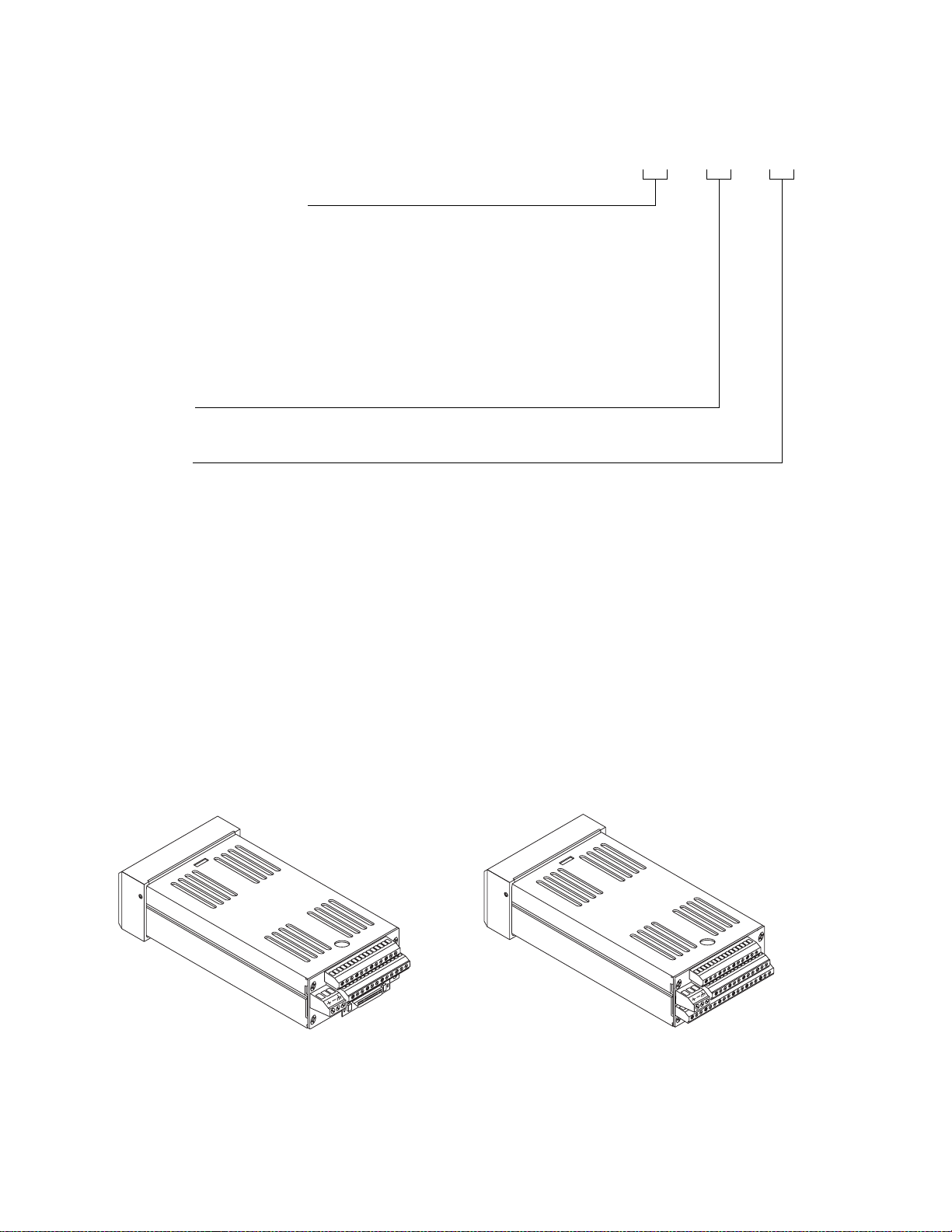

CPC400

Figure 1.2 CPC400 Special Inputs Parts List

This section contains a technical description of each component of the CPC400 series controller.

The CPC400 is housed in a 1/8-DIN panel mount package.

It contains the central processing unit (CPU), random access memory (RAM) with a built-in battery, flash memory,

serial communications, digital I/O, analog inputs, display

and touch keypad.

CPC400 Series

with SCSI Connector

CPC400 Series

with TB18 Connector

Figure 1.3 CPC400 Rear Views

6 Watlow Anafaze Doc. 0600-2900-2000

Page 21

CPC400 Series User’s Guide Chapter 1: System Overview

The CPC400 has the following features:

• Keypad and two-line, 16-character display.

• Screw terminals for the power and analog inputs and

communications.

• Input power of 12 to 24 VÎ (dc) at 1 Amp.

• 50-pin SCSI cable to connect the digital inputs and

outputs to the 50-terminal block (TB50). The CPC400

is available with an 18-terminal block (TB18) in place

of the SCSI connector, as shown in Figure 1.3 on page

6.

• Nonvolatile flash memory for storage of firmware and

programmable logic.

• Battery-backed storage of operating parameters. If a

power loss occurs, the operating parameters are stored

in memory. The battery has a ten-year shelf life, and

it is not used when the controller is on.

• Microprocessor control of all calculations for input signal linearization, PID control, alarms, and communications.

Front Panel Description

The display and keypad provide an intelligent way to operate the controller. The display has 16 alphanumeric or

graphic characters per line. The eight-key keypad allows

you to change the operating parameters, controller functions and displays.

The displays show process variables, set points and output

levels for each loop. A single-loop display, scanning display

and alarm display offer a real-time view of process conditions.

For useful tips, help and menu information, press i from

any screen.

Figure 1.4 CPC400 Front Panel

Doc. 0600-2900-2000 Watlow Anafaze 7

Page 22

Chapter 1: System Overview CPC400 Series User’s Guide

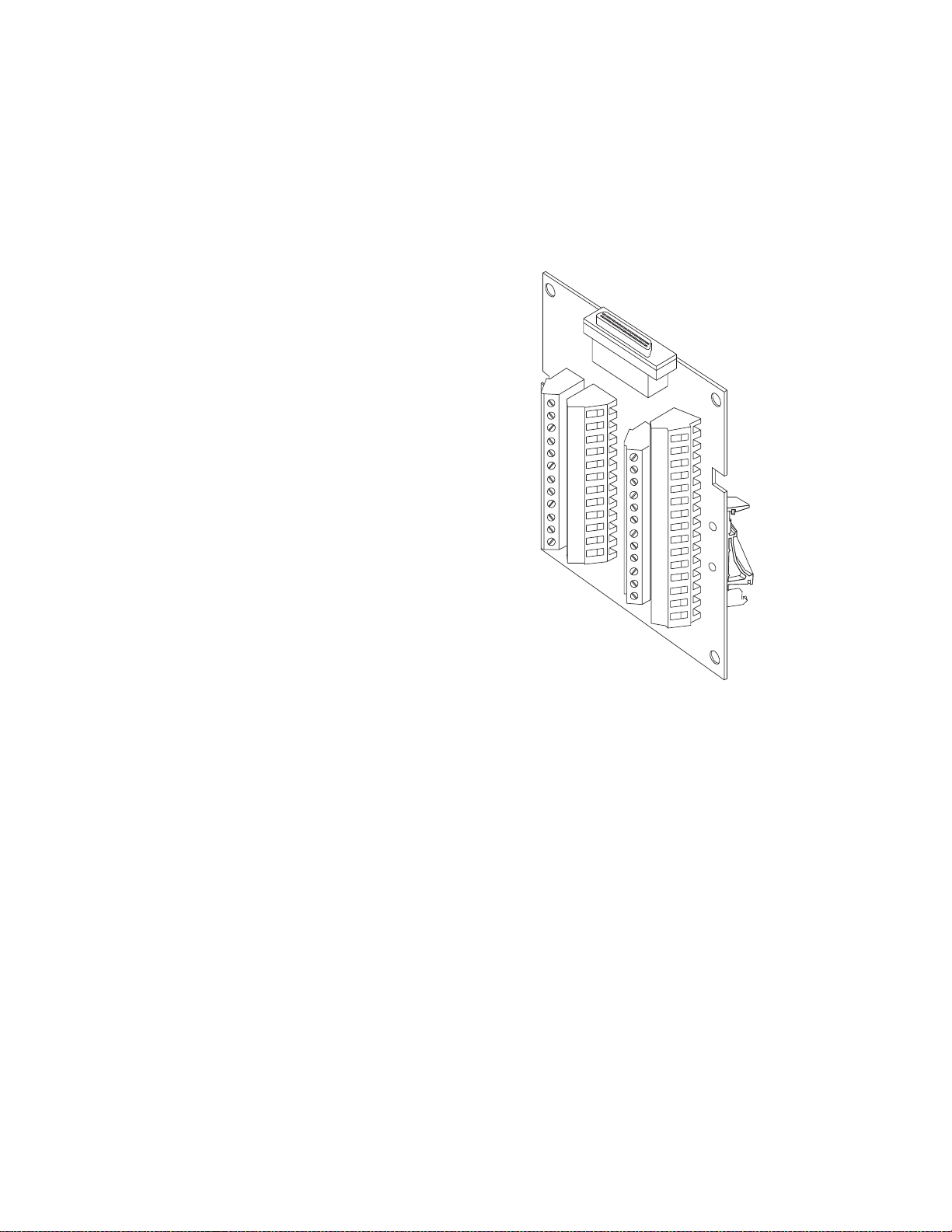

TB50

The TB50 is a screw-terminal interface for control wiring.

It allows you to connect relays, encoders and discrete I/O

devices to the CPC400. The screw terminal blocks accept

wires as large as 18 AWG (0.75 mm2). A 50-pin SCSI cable

connects the TB50 to the CPC400.

CPC400 Cabling

Figure 1.5 TB50

Watlow Anafaze provides cables required to install the

CPC400. A 50-pin SCSI cable connects the TB50 to the

CPC400.

The optional cable used to connect the CPC400 to a computer using EIA/TIA-232 communications has a DB-9 or DB25 connector for the computer and bare wires for connecting to the CPC400.

8 Watlow Anafaze Doc. 0600-2900-2000

Page 23

CPC400 Series User’s Guide Chapter 1: System Overview

Safety

Watlow Anafaze has made every effort to ensure the reliability and safety of this product. In addition, we have provided recommendations that will allow you to safely install

and maintain this controller.

External Safety Devices

The CPC400 controller may fail full-on (100 percent output

power) or full-off (0 percent output power), or may remain

full-on if an undetected sensor failure occurs.

Design your system to be safe even if the controller sends a

0 percent or 100 percent output power signal at any time.

Install independent, external safety devices such as the

Watlow Anafaze TLM-8 that will shut down the system if a

failure occurs.

Typically, a shutdown device consists of an agency-approved high/low process limit controller that operates a

shutdown device such as an mechanical contactor. The limit controller monitors for a hazardous condition such as an

under-temperature or over-temperature fault. If a hazardous condition is detected, the limit controller sends a signal

to open the contactor.

The safety shutdown device (limit controller and contactor)

must be independent from the process control equipment.

WARNING!

The controller may fail in a 0 percent or 100 percent output power state. To prevent death, personal injury, equipment damage or property

damage, install external safety shutdown devices

that operate independently from the process control equipment.

With proper approval and installation, thermal fuses may

be used in some processes.

Doc. 0600-2900-2000 Watlow Anafaze 9

Page 24

Chapter 1: System Overview CPC400 Series User’s Guide

Power-Fail Protection

In the occurrence of a sudden loss of power, the CPC400

controller can be programmed to reset the control outputs

to off (this is the default). The controller can also be configured to restart to data stored in memory.

A memory-based restart might create an unsafe process

condition for some installations. Use a memory-based restart only if you are certain your system will safely restart.

See Power Up Loop Mode on page 100.

When using a computer or host device, you can program the

software to automatically reload desired operating constants or process values on powerup. These convenience

features do not eliminate the need for independent safety

devices.

Contact Watlow Anafaze immediately if you have any questions about system safety or system operation.

10 Watlow Anafaze Doc. 0600-2900-2000

Page 25

2

Installation

This chapter describes how to install the CPC400 series

controller and its peripherals. Installation of the controller

involves the following procedures:

• Determining the best location for the controller

• Mounting the controller and TB50

• Power connection

• Input wiring

• Communications wiring (EIA/TIA-232 or EIA/TIA-

485)

• Output wiring

WARNING!

WARNING!

Doc.0600-2900-2000 Watlow Anafaze 11

Risk of electric shock. Shut off power to your entire process before you begin installation of the

controller.

The controller may fail in a 0 percent or 100 percent power output state. To prevent death, personal injury, equipment damage or property

damage, install external safety shutdown devices

that operate independently from the process control equipment.

Page 26

Chapter 2: Installation CPC400 Series User’s Guide

Typical Installation

Figure 2.1 shows typical installations of the controller with

the TB50 and the TB18 terminal blocks. The type of terminal block you use greatly impacts the layout and wiring of

your installation site. See Figure 2.2 to Figure 2.10 to determine potential space requirements.

We recommend that you read this entire chapter before beginning the installation procedure. This will help you to

carefully plan and assess the installation.

CPC400 with TB50

Signal Inputs

CPC400 with TB18

Signal Inputs

3 Digital Inputs

Pulse Input

11 Digital Outputs (Control, Alarm, Logic)

SCSI Cable

8 Digital Inputs

Pulse Input

35 Digital Outputs

(Control, Alarm, Logic)

CPC400

Power Supply

CPC400

Power Supply

Figure 2.1 CPC400 System Components

12 Watlow Anafaze Doc. 0600-2900-2000

Page 27

CPC400 Series User’s Guide Chapter 2: Installation

Mounting Controller Components

Install the controller in a location free from excessive heat

(>50º C), dust and unauthorized handling. Electromagnetic

and radio frequency interference can induce noise on sensor wiring. Choose locations for the CPC400 and TB50 such

that wiring can be routed clear of sources of interference

such as high voltage wires, power switching devices and

motors.

NOTE!

WARNING!

Recommended Tools

For indoor use only.

To reduce the risk of fire or electric shock, install

the CPC400 in a controlled environment, relatively free of contaminants.

Use any of the following tools to cut a hole of the appropriate size in the panel.

• Jigsaw and metal file, for stainless steel and heavyweight panel doors.

• Greenlee 1/8-DIN rectangular punch (Greenlee part

number 600-68), for most panel materials and thicknesses.

• Nibbler and metal file, for aluminum and lightweight

panel doors.

You will also need these tools:

• Phillips head screwdriver

• 1/8-inch (3 mm) flathead screwdriver for wiring

• Multimeter

Mounting the Controller

Mount the controller before you mount the terminal block

or do any wiring. The controller’s placement affects placement and wiring considerations for the other components

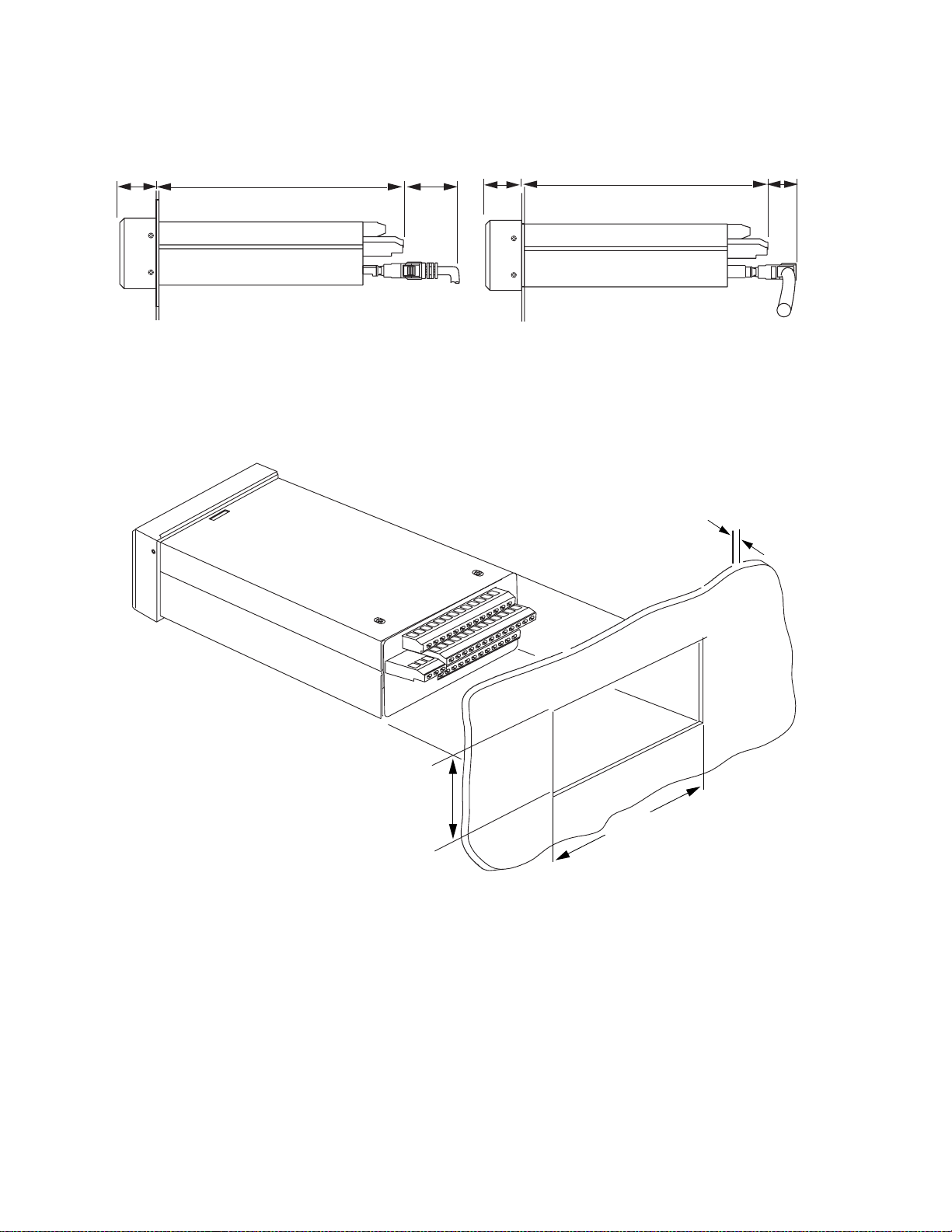

of your system.

Ensure that there is enough clearance for mounting brackets, terminal blocks, and cable and wire connections. The

controller extends up to 7.0 inches (178 mm) behind the

panel face and the screw brackets extend 0.5 inch (13 mm)

above and below it. If using a straight SCSI cable, allow for

an additional 1.6 inches (41 mm) beyond the terminal

block. If using a right-angle SCSI cable, allow an additional

0.6 inch (15 mm). Refer to Figure 2.2.

Doc. 0600-2900-2000 Watlow Anafaze 13

Page 28

Chapter 2: Installation CPC400 Series User’s Guide

1.0 in.

(25 mm)

7.0 in.

(178 mm)

1.6 in.

(41 mm)

1.0 in.

(25 mm)

7.0 in.

(178 mm)

0.6 in.

(15 mm)

Figure 2.2 Clearance with Straight SCSI Cable (L) and Right-Angle SCSI Cable (R)

Maximum Panel Thickness

0.2 in. (5 mm)

1.80 ± 0.020 in.

(45.7 ± 0.5 mm)

3.63 ± 0.020 in.

(92.2 ± 0.5 mm)

Figure 2.3 Wiring Clearances

We recommend you mount the controller in a panel not

more than 0.2 in. (5 mm) thick.

1. Choose a panel location free from excessive heat (more

than 50° C [122° F]), dust, and unauthorized handling.

(Make sure there is adequate clearance for the mounting hardware, terminal blocks, and cables. The controller extends 7.0 in. (178 mm) behind the panel.

14 Watlow Anafaze Doc. 0600-2900-2000

Page 29

CPC400 Series User’s Guide Chapter 2: Installation

Allow for an additional 0.60 to 1.60 in. (15 to 41 mm)

beyond the connectors.)

2. Temporarily cover any slots in the metal housing so

that dirt, metal filings, and pieces of wire do not enter

the housing and lodge in the electronics.

3. Cut a hole in the panel 1.80 in. (46 mm) by 3.63 in. (92

mm) as shown below. Use caution; the dimensions given here have 0.02 in. (0.5 mm) tolerances.

4. Remove the brackets and collar from the processor

module, if they are already in place.

5. Slide the processor module into the panel cutout.

6. Slide the mounting collar over the back of the processor module, making sure the mounting screw indentations face toward the back of the processor module.

.

Bracket (top and bottom)

25

23

21

19

17

15

13

11

9

7

5

3

1

+

26

24

22

20

18

16

14

12

10

8

6

4

2

Bezel

Panel

Mounting Collar

Figure 2.4 Mounting Bracket

7. Loosen the mounting bracket screws enough to allow

for the mounting collar and panel thickness. Place

each mounting bracket into the mounting slots (head

of the screw facing the back of the processor module).

Push each bracket backward then to the side to secure

it to the processor module case.

8. Make sure the case is seated properly. Tighten the installation screws firmly against the mounting collar to

secure the unit. Ensure that the end of the mounting

screws fit into the indentations on the mounting collar.

Doc. 0600-2900-2000 Watlow Anafaze 15

Page 30

Chapter 2: Installation CPC400 Series User’s Guide

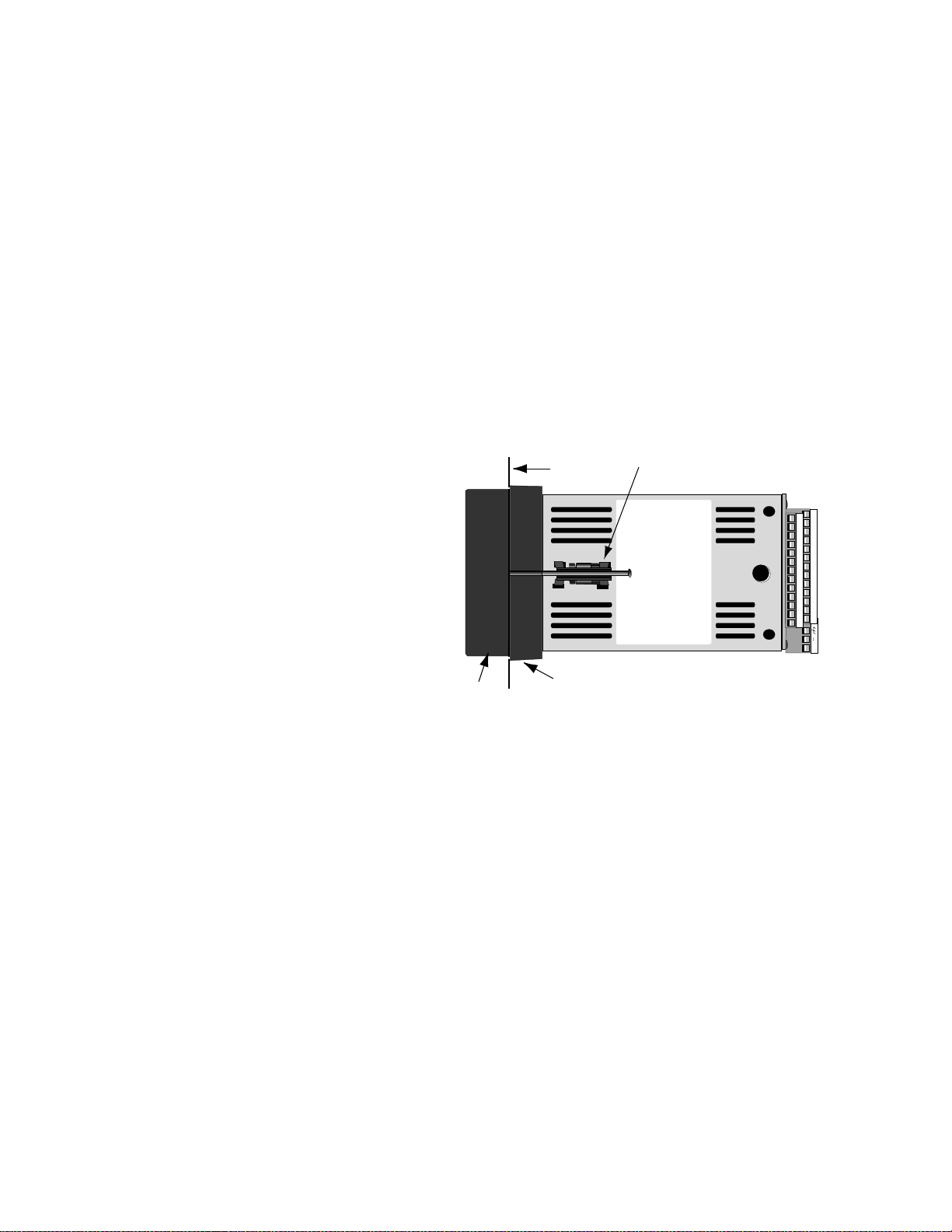

Mounting the TB50

There are two ways to mount the TB50: Use the pre-installed DIN rail mounting brackets or use the plastic

standoffs.

TB50

Mounted

with Standoffs

TB50

Mounted to

DIN Rail

Figure 2.5 Mounting the TB50

DIN Rail Mounting

Snap the TB50 on to the DIN rail by placing the hook side

on the rail first, then pushing the snap latch side in place.

See Figure 2.6.

Figure 2.6 TB50 Mounted on a DIN Rail (Front)

16 Watlow Anafaze Doc. 0600-2900-2000

Page 31

CPC400 Series User’s Guide Chapter 2: Installation

To remove the TB50 from the rail, use a flathead screw

driver to unsnap the bracket from the rail. See Figure 2.7.

Removal

Catch for

Screwdriver

DIN Rail

Snap Latch

Hook Side

Figure 2.7 TB50 Mounted on DIN Rail (Side)

Mounting with Standoffs

1. Remove the DIN rail mounting brackets from the

TB50.

2. Choose a location with enough clearance to remove the

TB50, its SCSI cable and the controller itself.

3. Mark the four mounting holes.

4. Drill and tap four mounting holes for #6 (3.5 mm)

screws or bolts.

5. Mount the TB50 with four screws or bolts.

There are four smaller holes on the terminal board. Use

these holes to secure wiring to the terminal block with tie

wraps.

0.7 in

(18 mm)

4 Holes for

#6 (3.5 mm)

Bolts or Screws

0.2 in

(5 mm)

3.4 in

(86 mm)

0.2 in

(5 mm)

0.2 in

(5 mm)

2.6 in

(66 mm)

SCSI Connector

3.6 in

(91 mm)

Figure 2.8 Mounting a TB50 with Standoffs

Doc. 0600-2900-2000 Watlow Anafaze 17

Page 32

Chapter 2: Installation CPC400 Series User’s Guide

Mounting the Power Supply

If you use your own power supply for the CPC400, refer to

the power supply manufacturer’s instructions for mounting

information. Choose a Class 2 power supply that supplies

an isolated, regulated 12 to 24VÎ (dc) at 1 A.

Mounting Environment

Leave enough clearance around the power supply so that it

can be removed.

2 Holes for #10 (4.5 mm)

Bolts or Screws

1.4 inch

(36 mm)

Mounting Steps

CAUTION!

0.3 inch

(8 mm)

7.5 inches

(191 mm)

8.1 inches

(206 mm)

0.7 inch

(18 mm)

Figure 2.9 CPC400 Power Supply Mounting

Bracket

When attaching the bracket to the power supply,

use screws that are no longer than 1/4-inch (6

mm) long. Longer screws may extend too far into

the power supply and short to components, damaging the power supply.

1. Attach the bracket to the power supply using the two

center holes in the bracket.

2. Choose a location with enough clearance to remove the

power supply and bracket.

3. Mark the bracket’s two outer holes for mounting.

4. Drill and tap the two mounting holes. The bracket

holes accept up to #10 (4.5 mm) screws.

5. Mount the power supply on the panel.

6. Tighten the screws.

18 Watlow Anafaze Doc. 0600-2900-2000

Page 33

CPC400 Series User’s Guide Chapter 2: Installation

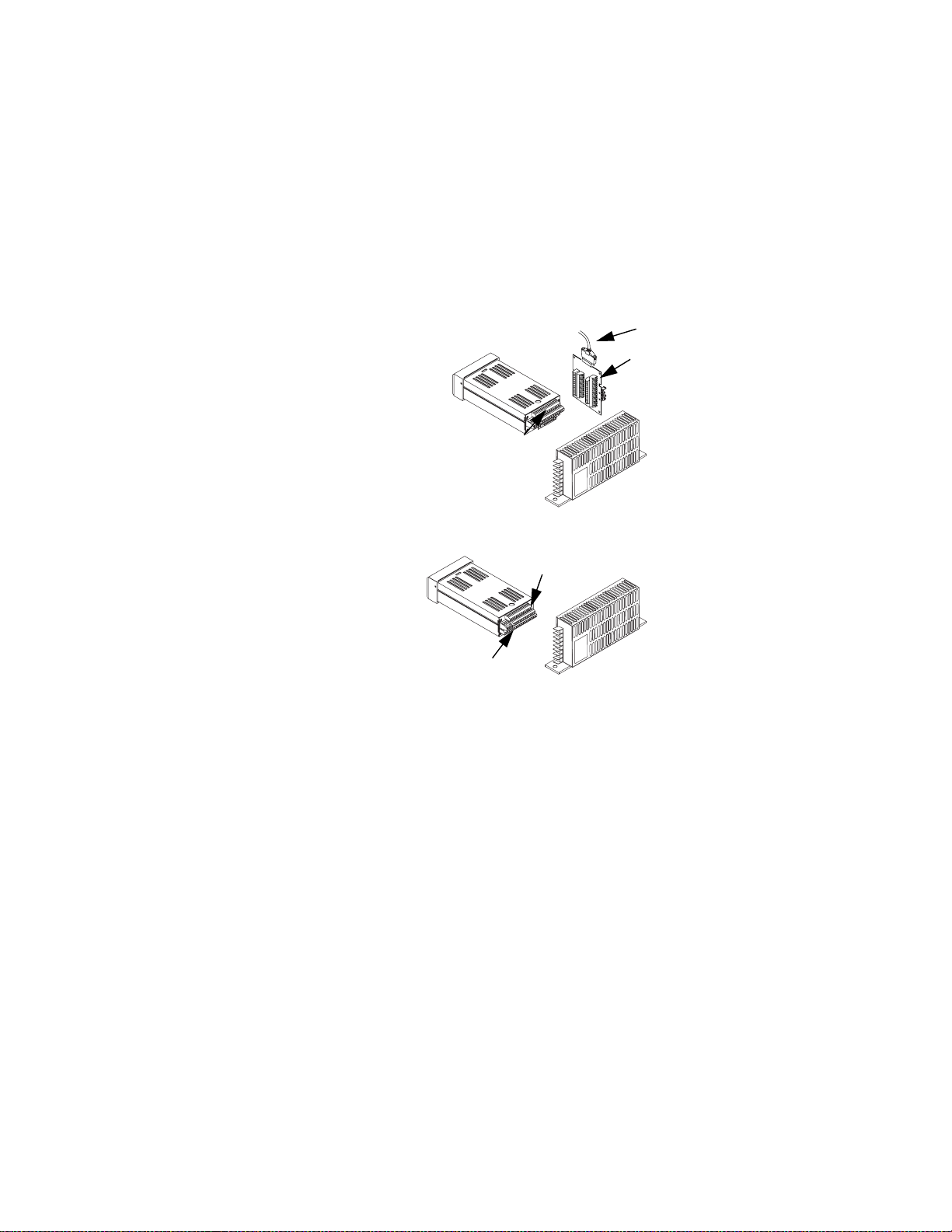

Mounting the Dual DAC or Serial DAC Module

This section describes how to mount the optional Dual DAC

and Serial DAC digital-to-analog converters.

Mounting of the Dual DAC and Serial DAC is essentially

the same, except that the dimensions differ.

Jumpers

The output signal range of the Dual DAC and Serial DAC

modules is configured with jumpers. See Configuring Dual

DAC Outputs on page 163 and Configuring Serial DAC

Outputs on page 162 for information about setting these

jumpers.

Mounting

1. Choose a location. The unit is designed for wall mounting. Install it as close to the controller as possible.

2. Mark and drill four holes for screw mounting. Holes

accommodate #8 (3.5 mm) screws. See Figure 2.10 for

screw locations. Install the unit with the four screws.

Dual DAC

4 Holes for #8 (3.5 mm)

Screws or Bolts

3.62 in

(91 mm)

Electrical

Connectors

Electrical

Connectors

3.7 in

(94 mm)

4.40 in

(112 mm)

0.3 in

(8 mm)

3.00 in

(76 mm)

(17 mm)

1.75 in

(44 mm)

0.37 in

(9 mm)

0.65 in

4 Holes for #8 (3.5 mm)

Screws or Bolts

3.62 in

(91 mm)

Electrical

Connectors

Serial DAC

Electrical

Connectors

4.7 in

(119 mm)

5.40 in

(137 mm)

0.3 in

(8 mm)

3.00 in

(76 mm)

0.37 in

(9 mm)

0.65 in

(17 mm)

1.75 in

(44 mm)

Figure 2.10 Dual DAC and Serial DAC Dimen-

sions

Doc. 0600-2900-2000 Watlow Anafaze 19

Page 34

Chapter 2: Installation CPC400 Series User’s Guide

System Wiring

Successful installation and operation of the control system

can depend on placement of the components and on selection of the proper cables, sensors and peripheral components.

Routing and shielding of sensor wires and proper grounding of components can insure a robust control system. This

section includes wiring recommendations, instructions for

proper grounding and noise suppression, and considerations for avoiding ground loops.

WARNING!

CAUTION!

Wiring Recommendations

To reduce the risk of electrical shock, fire, and

equipment damage, follow all local and national

electrical codes. Correct wire sizes, fuses and

thermal breakers are essential for safe operation

of this equipment.

Do not wire bundles of low-voltage signal and

control circuits next to bundles of high-voltage ac

wiring. High voltage may be inductively coupled

onto the low-voltage circuits, which may damage

the controller or induce noise and cause poor

control.

Physically separate high-voltage circuits from

low-voltage circuits and from CPC400 hardware.

If possible, install high-voltage ac power circuits

in a separate panel.

Follow these guidelines for selecting wires and cables:

• Use stranded wire. (Solid wire can be used for fixed

service; it makes intermittent connections when you

move it for maintenance.)

• Use 20 AWG (0.5 mm2) thermocouple extension wire.

Larger or smaller sizes may be difficult to install, may

break easily or may cause intermittent connections.

• Use shielded wire. The electrical shield protects the

signals and the CPC400 from electrical noise. Connect

one end of the input and output wiring shield to earth

ground.

• Use copper wire for all connections other than thermocouple sensor inputs.

20 Watlow Anafaze Doc. 0600-2900-2000

Page 35

CPC400 Series User’s Guide Chapter 2: Installation

Table 2.1 Cable Recommendations

Function Mfr. P/N

Analog Inputs

RTD Inputs

Thermocouple Inputs T/C Ext. Wire 2 20 0.5 —

Control Outputs and

Digital I/O

Analog Outputs

Computer Communication: EIA/TIA-232,

422 or 485, or 20 mA

Belden 9154

Belden 8451

Belden 8772

Belden 9770

Belden 9539

Belden 9542

Ribbon Cable

Belden 9154

Belden 8451

Belden 9729

Belden 9730

Belden 9842

Belden 9843

Belden 9184

No. of

Wires

2

2

3

3

9

20

50

2

2

4

6

4

6

4

AWG

20

22

20

22

24

24

22 to 14

20

22

24

24

24

24

22

2

mm

0.5

0.5

0.5

0.5

0.2

0.2

0.5 to 2.5

0.5

0.5

0.2

0.2

0.2

0.2

0.5

Maximum

Length

4000 ft. (1219 m)

4000 ft. (1219 m)

6000 ft. (1829 m)

Noise Suppression

—

—

—

—

Symptoms of Noise

The CPC400 outputs are typically used to drive solid-state

relays. These relays may in turn operate more inductive

types of loads such as electromechanical relays, alarm

horns and motor starters. Such devices may generate electromagnetic interference (EMI, or noise). If the controller is

placed close to sources of EMI, it may not function correctly. Below are some tips on how to recognize and avoid problems with EMI.

For earth ground wire, use a large gauge and keep the

length as short as possible. Additional shielding may be

achieved by connecting a chassis ground strap from the

panel to CPC400 case.

If your controller displays the following symptoms, suspect

noise:

• The display screen blanks out and then reenergizes as

if power had been turned off for a moment.

• The process variable value is incorrect on the controller display.

Noise may also damage the digital output circuit such that

the digital outputs will not turn on. If the digital output circuit is damaged, return the controller to Watlow Anafaze

for repair.

Doc. 0600-2900-2000 Watlow Anafaze 21

Page 36

Chapter 2: Installation CPC400 Series User’s Guide

Avoiding Noise

To avoid or eliminate most RFI/EMI noise problems:

• Connect the CPC400 case to earth ground. The

CPC400 system includes noise suppression circuitry.

This circuitry requires proper grounding.

• Separate the 120VÅ (ac) and higher power leads from

the low-level input and output leads connected to the

CPC400 series controller. Do not run the digital I/O or

control output leads in bundles with ac wires.

• Where possible, use solid-state relays (SSRs) instead

of electromechanical relays. If you must use electromechanical relays, avoid mounting them in the same

panel as the CPC400 series equipment.

• If you must use electromechanical relays and you

must place them in a panel with CPC400 series equipment, use a 0.01 microfarad capacitor rated at 1000V

(ac) (or higher) in series with a 47 Ω, 0.5 watt resistor

across the normally-open contacts of the relay load.

This is known as a snubber network and can reduce

the amount of electrical noise.

• You can use other voltage suppression devices, but

they are not usually required. For instance, you can

place a metal oxide varistor (MOV) rated at 130VÅ (ac)

for 120VÅ (ac) control circuits across the load, which

limits the peak ac voltage to about 180VÅ (ac) (Watlow

Anafaze part number 26-130210-00). You can also

place a transorb (back-to-back zener diodes) across the

digital output, which limits the digital output voltage.

Å

Additional Recommendations for a Noise Immune System

We strongly recommended the following:

• Isolate outputs through solid-state relays, where possible.

• Isolate digital inputs from ground through solid-state

relays. If this is not possible, then make sure the digital input is the only connection to earth ground other

than the chassis ground.

22 Watlow Anafaze Doc. 0600-2900-2000

Page 37

CPC400 Series User’s Guide Chapter 2: Installation

Ground Loops

Ground loops occur when current passes from the process

through the controller to ground. This can cause instrument errors or malfunctions.

The best way to avoid ground loops is to minimize unnecessary connections to ground. Do not connect any of the following terminals to each other or to earth ground:

• Power supply dc common

• TB1 terminals 5, 6, 11, 12 (analog common)

• TB1 terminal 17 (reference voltage common)

• TB1 terminals 23, 24 (communications common)

• TB2 terminal 2 (dc power common)

Power Connections

This section explains how to make power connections to the

CPC400 and the TB50.

TB2

(to power

supply)

TB2

(to power

supply)

TB1

(to signal

inputs

TB18

(to digital

outputs)

Figure 2.11 CPC400 Series Controller with

TB18

TB1

(to signal

inputs

SCSI-2

(to TB50)

Figure 2.12 CPC400 Series Controller with

TB50

Doc. 0600-2900-2000 Watlow Anafaze 23

Page 38

Chapter 2: Installation CPC400 Series User’s Guide

Wiring the Power Supply

WARNING!

Use a power supply with a Class 2 rating only. UL

approval requires a Class 2 power supply.

Connect power to the controller before any other connections, This allows you to ensure that the controller is working before any time is taken installing inputs and outputs.

Table 2.2 Power Connections

Function Power Supply CPC400 TB2

DC Power

(Controller)

DC Common

Earth Ground Ground

1. Connect the dc common terminal on the power supply

to the dc common (-) terminal on CPC400 TB2.

2. Connect the positive terminal on the power supply to

the dc positive (+) terminal on CPC400 TB2.

3. If using an isolated dc output or another power supply

to power the loads, connect the dc common of the supply powering the loads to the dc common of the supply

powering the controller.

4. Use the ground connector on TB2 for chassis ground.

This terminal is connected to the CPC400 chassis and

must be connected to earth ground.

5. Connect 120/240VÅ (ac) power to the power supply.

+12 to 24VÎ (dc) +

12 to 24VÎ (dc)

Common

-

NOTE!

NOTE!

24 Watlow Anafaze Doc. 0600-2900-2000

Connect the dc common of the power supply

used for loads to the dc common of the supply

powering the controller. If the supplies are not referenced to one another, the controller’s outputs

will not be able to switch the loads.

When making screw terminal connections, tighten to 4.5 to 5.4 in.-lb. (0.5 to 0.6 Nm).

Page 39

CPC400 Series User’s Guide Chapter 2: Installation

CAUTION!

CAUTION!

NOTE!

Without proper grounding, the CPC400 may not

operate properly or may be damaged.

To prevent damage from incorrect connections,

do not turn on the ac power before testing the

connections as explained in Testing the System

on page 26.

Do not connect the controller’s dc common

(COM) to earth ground . Doing so will defeat the

noise protection circuitry, making measurements

less stable.

Power Supply

+V1 (5V)

0 (5V COM)

+V2 (+15V)

Add jumper *

solid-state relay

C

G

OMV

N

+

D

CPC400

**

solid-state relay

COM (15V COM)

-V2 (-15V)

(Ground)

ACL (AC Line)

ACN (AC Neutral)

white

120/240

VÅ (ac)

Supply

** Connect terminals to ac panel ground.

N

black

H

green

G

**

* If using 5VÎ (dc) for outputs, jumper 5V common to 15V common.

1 2 3 4

+

5

solid-state relay

Serial DAC

C

O

M

solid-state relay

Figure 2.13 Power Connections with the

CPC400 Power Supply

Doc. 0600-2900-2000 Watlow Anafaze 25

Page 40

Chapter 2: Installation CPC400 Series User’s Guide

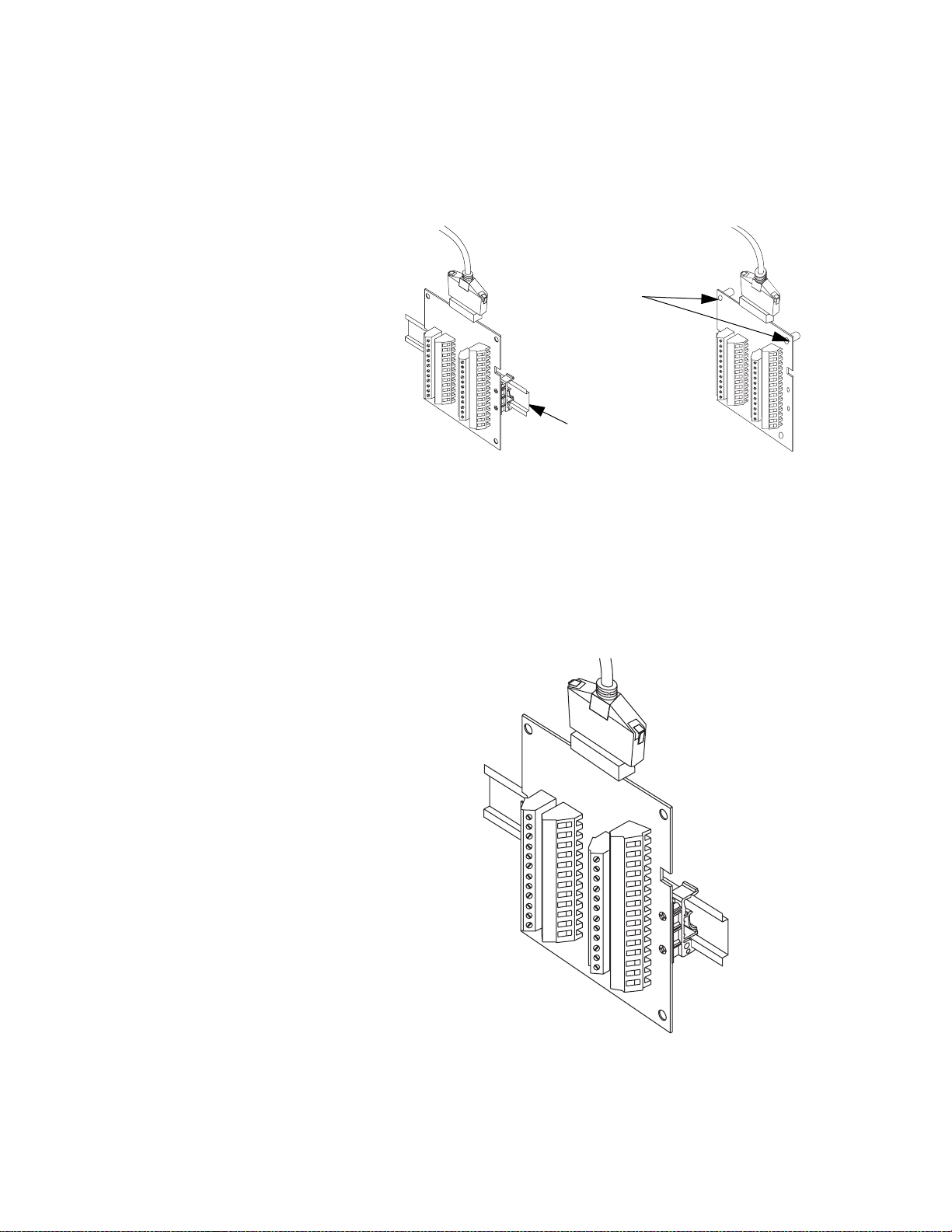

Connecting the TB50 to the CPC400

1. Connect the SCSI cable to the controller.

2. Connect the SCSI cable to the TB50.

Testing the System

This section explains how to test the controller after installation and prior to making field wiring connections.

TB50 or TB18 Test

Use this procedure to verify that the TB50 or TB18 is properly connected and supplied with power:

1. Turn on power to the CPC400. The display should first

show Calculating checksum, and then show the singleloop display. If you do not see these displays, disconnect power and check wiring and power supply output.

2. Measure the +5VÎ dc supply at the TB50 or TB18:

a) Connect the voltmeter’s common lead to TB50 ter-

minal 3 or TB18 terminal 2.

b) Connect the voltmeter’s positive lead to TB50 or

TB18 terminal 1. The voltage should be +4.75 to

+5.25VÎ dc.

Digital Output Test

NOTE!

Use this procedure to test the controller outputs before

loads are connected. If using it at another time for troubleshooting, disconnect loads from outputs before testing.

1. Connect a 500 Ω to 100 kΩ resistor between TB50 or

TB18 terminal 1 and a digital output terminal. See

Table 2.5 on page 37 for TB18 connections or Table 2.6

on page 38 for TB50 connections.

2. Connect the voltmeter’s positive lead to terminal 1 on

the TB50 or TB18.

3. Connect the voltmeter’s common lead to the digital

output terminal.

4. Use the digital output test in the

the digital output on and off (see Test Digital Output 1 to

35 on page 132). When the output is on, the output voltage should be less than 1 V. When the output is off, the

output voltage should be between 4.75 and 5.25 V.

By default, heat outputs are enabled. Only disabled

outputs may be turned on using the manual I/O test.

To test heat outputs, set the corresponding loop to

manual mode 100 percent output. See Changing the

Control Mode and Output Power on page 55.

I/O tests

menu to turn

26 Watlow Anafaze Doc. 0600-2900-2000

Page 41

CPC400 Series User’s Guide Chapter 2: Installation

Digital Input Test

Use the following procedure to test digital inputs before

connecting to field devices:

1. Disconnect any system wiring from the input to be

tested.

2. Go to the Digital inputs test in the I/O tests menu.

This test shows whether the digital inputs are off

(open) or on (closed).

3. Attach a wire to the terminal of the digital input you

want to test. See Table 2.5 on page 37 for TB 18 con-

nections or Table 2.6 on page 38 for TB50 connections.

a) When the wire is connected only to the digital in-

put terminal, the digital input test should show

that the input is off (open).

b) When you connect the other end of the wire to the

controller common (TB50 terminal 3 or TB18 terminal 2), the digital input test should show that

the input is on (closed).

Sensor Wiring

CAUTION!

This section describes how to properly connect thermocouples, RTDs, current and voltage inputs to the controller.

The controller can accept any mix of available input types.

Some input types require that special scaling resistors be

installed (generally done by Watlow Anafaze before the

controller is delivered).

All inputs are installed at the “CH” input connectors (TB1)

at the back of the controller. The illustrations below show

the connector locations for all CPC400 series controllers.

Never run input leads in bundles with high power

wires or near other sources of EMI. This could inductively couple voltage onto the input leads and

damage the controller, or could induce noise and

cause poor measurement and control.

Doc. 0600-2900-2000 Watlow Anafaze 27

Page 42

Chapter 2: Installation CPC400 Series User’s Guide

Figure 2.14 CPC400 Connector Locations

Input Wiring Recommendations

Use multicolored stranded shielded cable for analog inputs.

Watlow Anafaze recommends that you use 20 AWG wire

(0.5 mm2). If the sensor manufacturer requires it, you can

also use 24 or 22 AWG wiring (0.2 mm2). Most inputs use a

shielded twisted pair; some require a three-wire input.

The controller accepts the following inputs without any

special scaling resistors:

• J, K, T, S, R, B and E thermocouples.

• Process inputs with ranges between -10 and +60 mV.

To avoid thermocouple open alarms on unused inputs, ei-

ther set the Input type parameter to skip or jumper the input.

Thermocouple Connections

Connect the positive lead of the thermocouple to the IN+

terminal for one of the loops, and connect the negative lead

to the corresponding IN- terminal.

28 Watlow Anafaze Doc. 0600-2900-2000

Page 43

CPC400 Series User’s Guide Chapter 2: Installation

Use 18 or 20 AWG (0.5 or 0.75 mm2) for all thermocouple

inputs. Most thermocouple wire is solid, unshielded wire.

When using shielded wire, ground one end only.

CAUTION!

CH IN+

CH IN-

White

Red

Shield (if present)

Earth Ground

at Process End

Type J

Thermocouple

Figure 2.15 Thermocouple Connections

Connect the earth ground terminal on TB2 to a

good earth ground, but do not connect the analog

common to earth ground. The CPC400 uses a

floating analog common for sensor measurements. The noise protection circuits on the sensor inputs function correctly only if the controller

is correctly installed. See Ground Loops on page

23.

RTD Input Connections

RTD input requires scaling resistors. Watlow Anafaze recommends that you use a 100 Ω, three-wire platinum RTD

to prevent reading errors due to cable resistance. If you use

a two-wire RTD, jumper the negative input to common. If

you must use a four-wire RTD, leave the fourth wire uncon-

nected.

IN +

CH

100 Ω RTD

IN -

CH

Com

Figure 2.16 RTD Connections

Doc. 0600-2900-2000 Watlow Anafaze 29

Page 44

Chapter 2: Installation CPC400 Series User’s Guide

Reference Voltage Terminals

The +5V Ref and Ref Com terminals are provided to power

external bridge circuits for special sensors. Do not connect

any other type of device to these terminals.

Voltage Input Connections

Voltage input requires scaling resistors. Special input resistors installed at Watlow Anafaze divide analog input

voltages such that the controller sees a -10 to 60 mV signal

on the loop.

Current Input Connections

CH IN+

CH IN-

Device with

Voltage

Output

Figure 2.17 Voltage Signal Connections

Current input requires scaling resistors. Special input resistors installed at Watlow Anafaze for analog current signals are such that the controller sees a -10 to 60 mV signal

across its inputs for the loop.

CH IN+

CH IN-

Device with

Current

Output

Figure 2.18 Current Signal Connections

30 Watlow Anafaze Doc. 0600-2900-2000

Page 45

CPC400 Series User’s Guide Chapter 2: Installation

Pulse Input Connections

The CPC400 can accept a pulse input up to 2000 Hz from a

device such as an encoder. The frequency of this input is

scaled with user-configured parameters; see Setting Up a

Process or Pulse Input on page 58. This scaled value is the

process variable for loop 5 on a CPC404, or loop 9 on a

CPC408.

The CPC400 can accommodate encoder signals up to 24VÎ

(dc) using a voltage divider or can power encoders with the

5VÎ (dc) from the TB50 or TB18. The following figures

show how to connect encoders. A pull-up resistor in the

CPC400 allows open collector inputs to be used.

NOTE!

If the signal on the pulse input exceeds 10kHz the

controller’s operation may be disrupted. Do not

connect the pulse input to a signal source that

may exceed 10kHz.

CPC400 and TB50 or TB18

+5VÎ (dc)

10 kΩ

Figure 2.19 Encoder with 5V

CPC400 and TB50 or TB18

+5VÎ (dc)

10 kΩ

Pulse Input

Com

Pulse Input

Com

R2

Encoder

ÎÎ

ÎÎ

(dc) TTL Signal

R1

Encoder

Figure 2.20 Encoder Input with Voltage Divider

For encoders with signals greater than 5VÎ (dc), use a voltage divider to drop the voltage to 5 volts at the input. Use

appropriate values for R1 and R2 depending on the encoder

excitation voltage. Do not exceed the specific current load

on the encoder.

Doc. 0600-2900-2000 Watlow Anafaze 31

Page 46

Chapter 2: Installation CPC400 Series User’s Guide

Wiring Control and Digital I/O

This section describes how to wire and configure the control

outputs for the CPC400 series controller. The CPC400 provides dual control outputs for each loop. These outputs can

be enabled or disabled, and are connected through a TB50

or TB18.

NOTE!

Control outputs are connected to controller common when the control output is on. If you connect

external devices that may have a low side at a

voltage other than controller ground, you may

create ground loops. To prevent ground loops,

use isolated solid-state relays and isolate the

control device inputs.

Output Wiring Recommendations

When wiring output devices, use multicolored, stranded,

shielded cable for analog outputs and digital outputs connected to panel-mounted solid-state relays.

• Analog outputs usually use a twisted pair.

• Digital outputs usually have 9 to 20 conductors, depending on wiring technique.

Cable Tie Wraps

After you wire outputs to the TB50, install the cable tie

wraps to reduce strain on the connectors. Each row of terminals has a cable tie wrap hole at one end. Thread the cable tie wrap through the cable tie wrap hole. Then, wrap

the cable tie wrap around the wires attached to that terminal block.

Digital Outputs

The CPC400 provides dual control outputs for up to eight

loops. By default, heat outputs are enabled and cool outputs are disabled. If the heat or cool output is disabled for

a loop, then the output is available for alarms or programmable logic. The CPU watchdog timer output can be used

to monitor the state of the controller; see CPU Watchdog

Timer on page 35.

32 Watlow Anafaze Doc. 0600-2900-2000

Page 47

CPC400 Series User’s Guide Chapter 2: Installation

Table 2.3 Digital Output States and Values

Stored in the Controller

State

Off 0 Open circuit

On 1 Sinking current to controller common

1

Read and write these values through serial communications and Log-

icPro programs.

All digital outputs sink current to controller common when

on. The load may powered by the 5VÎ (dc) supplied by the

controller at the TB50, or by an external power supply.

When using an external power supply, bear in mind:

• The CPC400 power supply available from Watlow

Anafaze includes a 5VÎ (dc) supply. When using it to

supply output loads, connect the 5VÎ (dc) common to

the 15VÎ (dc) common at the power supply.

• Do not exceed +24 volts.

• If you connect the external load to earth ground, or if

you cannot connect it as shown in Figure 2.21, then

use a solid-state relay.

The outputs conduct current when they are on. The maximum current sink capability is 60 mA at 24VÎ (dc). The

outputs cannot “source” current to a load.

Value

1

Description

Using Internal Power Supply

TB50 or TB18

+5VÎ dc

Digital Output 1

Digital Output 2

Figure 2.21 Digital Output Wiring

Loads

Using External Power Supply

External

Power

Supply

to earth ground or

equipment ground

TB50 or TB18

Control Common

Digital Output 1

Digital Output 2

+

-

Do not connect

Loads

Doc. 0600-2900-2000 Watlow Anafaze 33

Page 48

Chapter 2: Installation CPC400 Series User’s Guide

Configuring Outputs

As you choose outputs for control and alarms, bear in mind

the following points:

• You can enable or disable the control outputs. By default, heat outputs are enabled and cool outputs are

disabled.

• You can program each control output individually for

on/off, time proportioning, distributed zero-crossing or

Serial DAC control.

• You can individually program each control output for

direct or reverse action.

• Alarm outputs other than the global alarm are nonlatching. See Global Alarm on page 67.

• Alarms can be suppressed during process start up and

for preprogrammed durations. See Power Up Alarm

Delay on page 100.

• Alarm outputs can be configured, as a group, to sink to

output during an alarm or stop current flow during an

alarm. See Digital Output Alarm Polarity on page 103.

Control and Alarm Output Connections

Typically control and alarm outputs use external opticallyisolated solid-state relays (SSRs). SSRs accept a 3 to 32VÎ

(dc) input for control, and some can switch up to 100 Amps

at 480VÅ (ac). For larger currents, use silicon control rectifier (SCR) power controllers up to 1000 Amps at 120 to

600VÅ (ac). You can also use SCRs and a Serial DAC for

phase-angle fired control.

The 34 control and alarm outputs are open collector outputs referenced in the CPC400’s common. Each output

sinks up to 60 mAdc to the controller common when on.

NOTE!

Control outputs are sink outputs. They sink current when the output is on. Connect them to the

negative side of solid-state relays.

Figure 2.22 shows sample heat, cool and alarm output connections.

34 Watlow Anafaze Doc. 0600-2900-2000

Page 49

CPC400 Series User’s Guide Chapter 2: Installation

CPU Watchdog Timer

Solid-State

Relay

TB50 or TB18

Solid-State

Relay

+-

Solid-State

Relay

+-

Heat Output

Cool Output

Alarm Output

+5VÅ (ac)

Figure 2.22 Sample Heat, Cool and Alarm Out-

put Connections

TB50 or TB18

Heat Output

Cool Output

Alarm Output

Common

Solid-State

Relay

+-

- PS +

Solid-State

Relay

+-

Solid-State

Relay

Figure 2.23 Output Connections Using Exter-

nal Power Supply

The CPU watchdog timer constantly monitors the microprocessor. It is a sink output located on TB50 terminal 6 or

TB18 terminal 3. The output can be connected to an external circuit or device to monitor whether the controller is

powered and operational. Do not exceed the 5VÎ (dc), 10

mAdc rating for the watchdog output. The output is on

(low) when the microprocessor is operating; when it stops

operating, the output goes off (high).

Figure 2.24 and Figure 2.25 show the recommended circuit

for the watchdog timer output for the TB50 and the TB18.

+-

+-

TB50

+ 5VÎ (dc)

(Terminal 1)

Watchdog Timer

(Terminal 6)

+

Solid-State Relay

-

Figure 2.24 TB50 Watchdog Timer Output

TB18

+ 5VÎ (dc)

(Terminal 1)

Watchdog Timer

(Terminal 3)

+

Solid-State Relay

-

Figure 2.25 TB18 Watchdog Timer Output

Doc. 0600-2900-2000 Watlow Anafaze 35

Page 50

Chapter 2: Installation CPC400 Series User’s Guide

Digital Inputs

All digital inputs are transistor-transistor logic (TTL) level

inputs referenced to controller common and the internal

+5V power supply of the CPC400.

When an input is connected to the controller common, the

input is considered on. Otherwise, the input is considered

off. Most features that use the digital inputs can be userconfigured to activate when an input is either on or off.

In the off state, internal 10 kΩ resistors pull the digital inputs high to 5VÎ (dc) with respect to the controller common.

Table 2.4 Digital Input States and Values

Stored in the Controller

External Switching Device

State

Off 0 Open circuit

On 1

1

Read these values through serial communications and LogicPro pro-

grams.

To ensure that the inputs are reliably switched, use a

switching device with the appropriate impedances in the on

and off states and do not connect the inputs to external

power sources.

When off, the switching device must provide an impedance

of at least 11 kΩ to ensure that the voltage will rise to

greater than 3.7VÎ (dc). When on, the switch must provide

not more than 1 kΩ impedance to ensure the voltage drops

below 1.3VÎ (dc).

To install a switch as a digital input, connect one lead to the

common terminal on the TB50 (terminals 3 and 4) or TB18

(terminal 2). Connect the other lead to the desired digital

input terminal on the TB50 (terminals 43 to 50) or TB18

(terminals 16 to 18).

Value

1

Digital input connected to controller

common

Description

TB50

Input

Control Com

External

Switching

Device

Figure 2.26 Wiring Digital Inputs

36 Watlow Anafaze Doc. 0600-2900-2000

Page 51

CPC400 Series User’s Guide Chapter 2: Installation

Functions Activated by Digital Inputs

Use digital inputs to activate the following functions:

• Load a job that is stored in controller memory. See

BCD Job Load on page 97.

• Change all loops to manual mode at specified output

levels. See Mode Override on page 99.

• Enable thermocouple short detection. See Thermocou-

ple Short Alarm on page 101.

• Restore automatic control after a failed sensor has been

repaired. See Restore Automatic Mode on page 114.

TB18 Connections

Table 2.5 TB18 Connections

Control Output

1

Terminal Function CPC404 CPC408

1 +5VÎ (dc)

2 CTRL COM

3 Watchdog timer

4 Global alarm

5 Output 1 Loop 1 heat Loop 1 heat

6 Output 2 Loop 2 heat Loop 2 heat

7 Output 3 Loop 3 heat Loop 3 heat

8 Output 4 Loop 4 heat Loop 4 heat

9 Output 5 Pulse loop heat Loop 5 heat

10 Output 6 Loop 1 cool Loop 6 heat

11 Output 7 Loop 2 cool Loop 7 heat

12 Output 8 Loop 3 cool Loop 8 heat

13 Output 9 Loop 4 cool Pulse loop heat

14 Output 10 Pulse loop cool Loop 1 cool

15

Output 34

2

Serial DAC clock Serial DAC clock

16 Input 1

17 Input 2

18 Input 3/Pulse input

1

The indicated outputs are dedicated for control when enabled in the

loop setup. If one or both of the outputs are disabled for a loop, then the

corresponding digital outputs become available for alarms or programmable logic.

2

If you install a Watlow Anafaze Serial DAC, the CPC400 series controller uses digital output 34 for a clock line. You cannot use output 34 for

anything else if a Serial DAC is installed.

Doc. 0600-2900-2000 Watlow Anafaze 37

Page 52

Chapter 2: Installation CPC400 Series User’s Guide

TB50 Connections

Table 2.6 TB50 Connections

Control Output

Ter-

minal

1

3 CTRL COM 4 CTRL COM

5 Not Used 6 Watchdog

7 Pulse Input 8 Global Alarm

9 Output 1 Loop 1 heat Loop 1 heat 10

11 Output 2 Loop 2 heat Loop 2 heat 12 Output 33

13 Output 3 Loop 3 heat Loop 3 heat 14 Output 32

15 Output 4 Loop 4 heat Loop 4 heat 16 Output 31

17 Output 5 Loop 5 heat Pulse loop

19 Output 6 Loop 6 heat Loop 1 cool 20 Output 29

21 Output 7 Loop 7 heat Loop 2 cool 22 Output 28

23 Output 8 Loop 8 heat Loop 3 cool 24 Output 27

25 Output 9 Pulse loop

27 Output 10 Loop 1 cool Pulse loop

29 Output 11 Loop 2 cool 30 Output 24

31 Output 12 Loop 3 cool 32 Output 23

33 Output 13 Loop 4 cool 34 Output 22

35 Output 14 Loop 5 cool 36 Output 21

37 Output 15 Loop 6 cool 38 Output 20

39 Output 16 Loop 7 cool 40 Output 19

41 Output 17 Loop 8 cool 42 Output 18 Pulse loop

43 Input 1 44 Input 2

45 Input 3 46 Input 4

47 Input 5 48 Input 6

49 Input 7 50 Input 8

Function CPC408 CPC404

+5VÎ (dc)

heat

1

Ter-

minal

2

18 Output 30

heat

Loop 4 cool 26 Output 26

28 Output 25

cool

1

The indicated outputs are dedicated for control when enabled in the

loop setup. If one or both of a loop’s outputs are disabled, the corresponding digital outputs become available for alarms or programmable

logic.

2

If you install a Watlow Anafaze Serial DAC, the CPC400 uses digital

output 34 (terminal 10) for a clock line. You cannot use output 34 for

anything else if a Serial DAC is installed.

Function CPC408 CPC404

+5VÎ (dc)

Timer

Output 34

2

Control Output

cool

1

38 Watlow Anafaze Doc. 0600-2900-2000

Page 53

CPC400 Series User’s Guide Chapter 2: Installation

Analog Outputs

Analog outputs can be provided by using a Dual DAC or Serial DAC module to convert the open collector outputs from

the controller. Use multicolored stranded shielded cable for

analog outputs. Analog outputs generally use a twisted

pair wiring. The following sections describe how to connect

the Dual DAC and Serial DAC modules to power the controller outputs and the load.

Wiring the Dual DAC

A Dual DAC module includes two identical circuits. Each

can convert a distributed zero cross (DZC) signal from the

controller to a voltage or current signal. Watlow Anafaze

strongly recommends using a power supply separate from

the controller supply to power the Dual DAC. Using a separate power supply isolates the controller’s digital logic circuits and analog measurement circuits from the frequently

noisy devices that take the analog signal from the Dual

DAC.

Several Dual DAC modules may be powered by one power

supply. Consult the Specifications chapter for the Dual

DAC’s power requirements. Also note in the specifications

that the Dual DAC does not carry the same industry approvals as the Serial DAC.

TB50 or TB18