Page 1

300A to 700A Power Controller

ISO 9001

User’s Guide

1663-1873 Rev D

April 2019

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507

http://www.watlow.com

Registered Company

Winona, Minnesota USA

Page 2

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to important operational

and safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and performance. Be especially careful to read and follow all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for protecting you, others and equipment

from damage. Pay very close attention to all warnings that apply to your application.

The safety alert symbol, (an exclamation point in a triangle) precedes a general CAUTION or WARNING

statement.

The electrical hazard symbol, (a lightning bolt in a triangle) precedes an electric shock hazard CAUTION or

WARNING safety statement. Further explanations follow:

Symbol Explanation

CAUTION – Warning or Hazard that needs further explanation than the label on unit can provide.

Consult User's Guide for further information.

Electrical Shock Hazard - Symbol (a lightning bolt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

ESD Sensitive product, use proper grounding and handling techniques when installing or servicing

product.

Do not throw in trash, use proper recycling techniques or consult manufacturer for proper disposal.

Unit is a Listed device per Underwriters Laboratories. It has been investigated to ANSI/UL® 508

standards for Industrial Control Switches and equivalent to CSA C22.2 #14. For more detail search

for File E73741 on www.ul.com.

Unit is compliant with European Union directives. See Declaration of Conformity for further details on Directives and Standards used for Compliance.

WARNING! To avoid damage to property and equipment, injury and loss of life, adhere to applicable electrical codes and standard wiring practices when installing and operating this product. Failure to do so could result

in damage, injury and death.

WARNING! All service including inspection, installation, wiring, maintenance, troubleshooting, fuse or other

user-serviceable component replacement must be performed only by properly qualied personnel. Service personnel must read this manual before proceeding with work. While service is being performed other, unqualied

personnel should not work on the unit or be allowed in the immediate vicinity.

WARNING! When in use the power controller is connected to dangerous voltages. Do not remove the protec-

tive covers without rst disconnecting and preventing power from being restored while servicing the unit.

WARNING! Do not use in aerospace or nuclear applications.

Watlow - ASPYRE 300A to 700A Power Controller • 2 •

Page 3

WARNING! The power controller’s protection rating is IP20 with all covers installed and closed. It must be

installed in an enclosure that provides all the necessary additional protections appropriate for the environment

and application.

WARNING! Ground the power controller via the provided protective earth grounding terminal. Verify ground

is within impedance specications. This should be veried periodically.

WARNING! Electric Shock Hazard: when the power controller has been energized, after shutting off the power, wait at least one minute for internal capacitors to discharge before commencing work that brings you in to

contact with power connections or internal components.

WARNING! The installation must be protected by electromagnetic circuit breakers or by fuses. The semicon-

ductor fuses located inside the power controller are classied for UL® as supplementary protection for semicon-

ductor devices. They are not approved for branch circuit protection.

WARNING! When making live voltage or current measurements, use proper personal protective equipment

for the voltages and arc-ash potentials involved.

WARNING! Verify the voltage and current ratings of the power controller are correct for the application.

CAUTION: To avoid compromising the insulation, do not bend wire or other components beyond their bend

radius specications.

CAUTION: Protect the power controller from high temperature, humidity and vibrations.

CAUTION: The power controller warranty is void if the tested and approved fuses are not used.

CAUTION: Only trained and authorized personnel should access and handle the internal electronics and they

must follow proper electro-static prevention procedures.

CAUTION: Install an appropriately sized RC lter across contactor coils, relays and other inductive loads.

NOTE! Provide a local disconnect to isolate the power controller for servicing.

NOTE! The nominal current is specied for ambient temperatures at or below 40° C. Ensure the application

design allows for adequate cooling of each power controller. The power controller must be mounted vertically.

The cooling design must prevent air heated by one power controller from causing power controllers mounted

above to exceed the ambient operating temperature limit. When power controllers are mounted side by side

allow a minimum spacing of 15mm between them.

NOTE! Use only copper cables and wires rated for use at 75°C or greater.

AVERTISSEMENT! Tous les services, y compris l’inspection, l’installation, le câblage, l’entretien, le dépan-

nage, le remplacement de fusibles ou d’autres composants pouvant être réparés par l’utilisateur, doivent être

effectués uniquement par un personnel dûment qualié. Le personnel de service doit lire ce manuel avant d’effectuer tout travail. Pendant que l’entretien est exécuté, tout personnel non qualié ne doit effectuer de travail

sur l’appareil ni se trouver à proximité.

Watlow - ASPYRE 300A to 700A Power Controller • 3 •

Page 4

AVERTISSEMENT! Pour éviter d’endommager la propriété et l’équipement, les blessures et la perte de vie,

respecter les codes électriques en vigueur et les pratiques de câblage standard au moment de l’installation et

de l’utilisation de ce produit. Dans le cas contraire, cela peut entraîner la mort, des blessures graves ou des

dommages.

AVERTISSEMENT! Au moment de l’utilisation, le régulateur de puissance est connecté à des tensions dangereuses. Ne retirer aucun couvercle de protection sans d’abord débrancher l’appareil et ainsi empêcher l’alimentation d’être rétablie pendant l’entretien.

AVERTISSEMENT! Ne pas utiliser pour les applications aérospatiales ou nucléaires.

AVERTISSEMENT! L’indice de protection du régulateur de puissance est de IP20 lorsque les couvercles sont

installés et fermés. L’appareil doit être installé dans une enceinte qui assure toute la protection supplémentaire

nécessaire pour l’environnement et l’application.

AVERTISSEMENT! Mise à la terre du régulateur de puissance par le biais de la borne de prise de terre de

protection fournie. Vérier que la prise de terre est conforme aux spécications de l’impédance. Cela doit être

vérié périodiquement.

AVERTISSEMENT! Risque de décharges électriques : lorsque le régulateur de puissance est mis sous tension,

après avoir été éteint, attendre au moins une minute pour que les condensateurs internes se déchargent avant

de commencer tout travail incluant le contact avec les connexions électriques ou les composants internes.

AVERTISSEMENT! L’installation doit être protégée par des disjoncteurs électromagnétiques ou des fusibles.

Les fusibles pour semi-conducteurs situés à l’intérieur du régulateur de puissance sont classés UL® comme protection supplémentaire pour les dispositifs pour semi-conducteurs. Ils ne sont pas approuvés pour la protection

des circuits de dérivation.

AVERTISSEMENT! Au moment de relever des mesures de tension ou de courant en direct, utiliser un équipement de protection individuelle approprié pour les tensions et les potentiels d’arc électrique concernés.

AVERTISSEMENT! Vérier que les valeurs de tension et de courant du régulateur de puissance sont correctes

pour l’application.

ATTENTION : Pour éviter de compromettre l’isolation, ne pas plier le l ou tout autre composant au-delà de

ses spécications en matière de rayon de courbure.

ATTENTION : Protéger le régulateur de puissance contre les températures élevées, l’humidité et les vibrations.

ATTENTION : La garantie du régulateur de puissance est nulle si aucun fusible testé et approuvé n’est utilisé.

ATTENTION : Seul le personnel formé et autorisé peut accéder aux composants électroniques internes et les

gérer, et il doit se conformer à des procédures de prévention électrostatique appropriées.

ATTENTION : Installer un ltre RC de dimensions appropriées sur les bobines du contacteur, les relais et

autres charges par induction.

Watlow - ASPYRE 300A to 700A Power Controller • 4 •

Page 5

REMARQUE : Fournir une déconnexion locale an d’isoler le régulateur de puissance pour l’entretien.

REMARQUE : Le courant nominal est précisé pour des températures ambiantes égales ou inférieures à 40°C.

S’assurer que la conception de l’application permette le refroidissement adéquat de chaque régulateur de

puissance. Le régulateur de puissance doit être monté verticalement. La conception de refroidissement doit

empêcher l’air chauffé par le régulateur de puissance de dépasser la limite de température de fonctionnement

ambiante de la part des régulateurs de puissance montés au-dessus. Lorsque les régulateurs de puissance sont

montés côte à côte, il faut conserver un espacement minimal de 15 mm entre les deux.

REMARQUE : N’utiliser que des câbles et des ls en cuivre pour l’utilisation à 75°C ou plus.

Technical Assistance

If you encounter a problem with your Watlow® controller, review your conguration information to verify that

your selections are consistent with your application: inputs, outputs, alarms, limits, etc. If the problem persists,

you can get technical assistance from your local Watlow representative (see back cover), by e-mailing your questions to wintechsupport@watlow.com or by dialing +1 (507) 494-5656 between 7 a.m. and 5 p.m. Central Time

USA & Canada. Ask for for an Applications Engineer. Please have the complete model number available when

calling.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a Return Material Authorization (RMA) number before

returning any failed product to Watlow. If you do not know why the product failed, contact an Application

Engineer. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the product

2. Prior approval and an RMA number from the customer service department is required when returning any

product. Make sure the RMA number is on the outside of the carton and on all paperwork returned. Ship on

a freight prepaid basis.

3. After we receive your return, we will examine it to verify the reason for the product failure. Unless otherwise agreed to in writing, Watlow’s standard warranty provisions, which can be located at, www.watlow.

com/terms, will apply to any failed product.

4. In the event that the product is not subject to an applicable warranty, we will quote repair costs to you

and request a purchase order from you prior to proceeding with the repair work.

5. Watlow reserves the right to charge for no trouble found (NTF) returns.

Warranty

The ASPYRE® power controller is warranted by Watlow for a period of 36 months in accordance with the terms

and conditions set forth on Watlow’s website, which may be accessed at www.watlow.com/terms.

Watlow - ASPYRE 300A to 700A Power Controller • 5 •

Page 6

Document Number: 10-05823 Rev D

©2019 Watlow Electric Manufacturing Company, all rights reserved.

Watlow® and ASPYRE® are registered trademarks of Watlow Electric and Manufacturing Company.

Cooper Bussman® is a registered trademark of Cooper Industries Inc.

EtherNet/IP™ is a trademark of Open DeviceNet Vendors Association.

Kanthal® is a registered trademark of Bulten-Kanthal Aktiebolag Joint Stock Company

Windows® is a registered trademark of Microsoft Corporation.

Modbus® is a registered trademark of Schneider Automation Incorporated.

Siemens® is a registered trademark of Siemens Aktiengesellschaft Corporation.

UL® is a registered trademarks of Underwriter’s Laboratories, Inc.

Watlow - ASPYRE 300A to 700A Power Controller • 6 •

Page 7

TC

Contents

Safety Information ......................................................2

Technical Assistance ....................................................5

Return Material Authorization (RMA) .......................................5

Warranty ..............................................................5

Overview ...........................................11

Recognizing Product Features ............................................11

Identifying the Product ..................................................11

Product Selection ......................................................12

Features and Benefits ...................................................14

Product Block Diagram .................................................15

Installation ..........................................17

Installing the ASPYRE Power Controller ....................................17

Environmental Conditions ...............................................17

Cooling Requirements ..................................................18

Mounting Dimensions ..................................................19

Wiring .............................................21

Wiring the ASPYRE Power Controller ......................................21

Good Wiring Practices ..................................................21

Wiring Overview Diagrams ...............................................22

Wire Selection, Prep and Torque ..........................................23

Removing the Covers ...................................................24

Connecting Control Signals ..............................................25

Powering the Cooling Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Auxiliary Power ...........................................29

Wiring the Line Power and Load ..........................................30

Initial Setup .........................................31

Using the ASPYRE Configurator Software ...................................31

Configuring the ASPYRE Power Controller ..................................31

Operation ...........................................35

Control Panel .........................................................35

Menu Navigation ......................................................36

Indicators (LEDs) ......................................................37

Alarms and Messages ..................................................38

Using ASPYRE Configurator ..............................39

Overview ............................................................39

How To ..............................................................39

Reference ............................................................44

Parameter Reference ...................................53

Alarm Function ........................................................53

Watlow - ASPYRE 300A to 700A Power Controller • 7 •

Page 8

Analog In 1 [Signal Type] ................................................53

Analog In 1 [Value] ....................................................54

Analog In 2 [Signal Type] ................................................54

Analog In 2 [Value] ....................................................54

Analog In 2 Function ...................................................54

Aux Voltage ..........................................................54

Bakeout Current (Models with Current Limit) ................................54

Bakeout Off Time (Models with Current Limit) ................................55

Bakeout Ramp Time (Models with Current Limit) .............................55

Command Bits ........................................................55

Cycle Time ...........................................................56

Delay ...............................................................56

Digital In 1 ...........................................................56

Digital In 1 Function ....................................................56

Digital In 2 ...........................................................57

Digital In 2 Function ....................................................57

Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Ethernet Address ......................................................57

Ethernet Subnet .......................................................58

Ethernet Gateway ......................................................58

Feedback ............................................................58

Firing ...............................................................58

Frequency ...........................................................59

Half Cycles to Delay ....................................................59

Heater Bakeout (Models with Current Limit) .................................59

HH:MM:SS ...........................................................59

Host Name ...........................................................59

Htr Break Delay .......................................................59

Htr Break Sensitivity ....................................................59

I Limit (Models with Current Limit) ........................................60

I Limit Local / Remote (Models with Current Limit) ............................60

I Output .............................................................60

Integral Current (Models with Current Limit) .................................60

Integral Power ........................................................60

kVA Real Time ........................................................60

kW Real Time .........................................................60

kW Total .............................................................61

Leg 1 I Output (DT2 and DT3 Models) ......................................61

Leg 2 I Output (DT2 and DT3 Models) ......................................61

Leg 3 I Output (DT2 and DT3 Models) ......................................61

Limit Peak Current (Models with Current Limit) ..............................61

Load Ω ..............................................................61

Logging .............................................................61

Logging Interval .......................................................62

Max Current .........................................................62

Max Voltage ..........................................................62

Min Cycles ...........................................................62

MM/DD/YY ...........................................................62

Watlow - ASPYRE 300A to 700A Power Controller • 8 •

Page 9

Neutral Connected (DT2 and DT3 Models) ...................................62

Nominal I ............................................................62

Nominal V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Out Scale ............................................................63

Port 1 Address ........................................................63

Port 1 Baud ..........................................................63

Port 2 ...............................................................63

Port 2 Access .........................................................64

Port 2 Address ........................................................64

Port 2 Baud ..........................................................64

Power ..............................................................64

Power Factor .........................................................64

Prop Band Current (Models with Current Limit) ..............................64

Prop Band Power ......................................................65

Release ..............................................................65

Remote SP ...........................................................65

Retransmit (Models with Retransmit) ......................................65

Retransmit Scale (Models with Retransmit) ..................................66

Retransmit Type (Models with Retransmit) ..................................66

Safety Ramp Duration ..................................................66

Safety Ramp Off Time ..................................................66

SCR Temperature ......................................................67

Serial Number ........................................................67

Set Point ............................................................67

Set Point Source ......................................................67

Soft Start ............................................................67

Start Ramp ...........................................................67

Startup Display ........................................................68

Status Bits ...........................................................68

Thermal Alarm Counter .................................................68

Unit Type ............................................................68

User Access Level .....................................................69

V Input .............................................................69

V Output .............................................................69

Version ..............................................................69

Watchdog ............................................................69

Watchdog Reset Time ..................................................69

Wi-Fi ................................................................70

Wi-Fi Address .........................................................70

Features ...........................................71

Closed Loop Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Feedback ............................................................72

Current Limit .........................................................74

Configurable Inputs and Outputs ..........................................74

Firing Types ..........................................................76

Soft Start ............................................................82

Start Ramp (DT1 and DT3 Models) ........................................82

Watlow - ASPYRE 300A to 700A Power Controller • 9 •

Page 10

Safety Ramp (DT1 and DT3 Models) .......................................83

Heater Bakeout Function (Models with Current Limit) ..........................83

Totalizer .............................................................83

Data Logging .........................................................84

Maintenance & Troubleshooting ...........................85

Routine Maintenance ...................................................85

Alarms and Indicators ..................................................85

Removing the Covers ...................................................87

Replacement Fuses ....................................................88

Replacing the Battery ...................................................89

Calibration Procedures ..................................................89

Updating the Firmware ..................................................91

Troubleshooting .......................................................92

Troubleshooting Schematics .............................................93

Communication .......................................97

Overview ............................................................97

Enabling the Secondary Port .............................................98

Ethernet Network Setup .................................................98

Modbus® TCP .........................................................99

EtherNet/IP™ Setup ....................................................99

Profinet IO Setup .....................................................102

Profibus DP Setup ....................................................107

Holding Registers .....................................................113

Input Registers .......................................................114

Modbus® RTU .......................................................116

Modbus® RTU Holding Registers .........................................117

Specifications .......................................121

Declaration of Conformity ..............................................127

Watlow - ASPYRE 300A to 700A Power Controller • 10 •

Page 11

1

Overview

This chapter describes how to locate the model number of the ASPYRE® power controller, explains how to deter-

mine which ordering options are present, identies its physical features, lists its main functional features and

benets and provides a functional overview in the form of a block diagram.

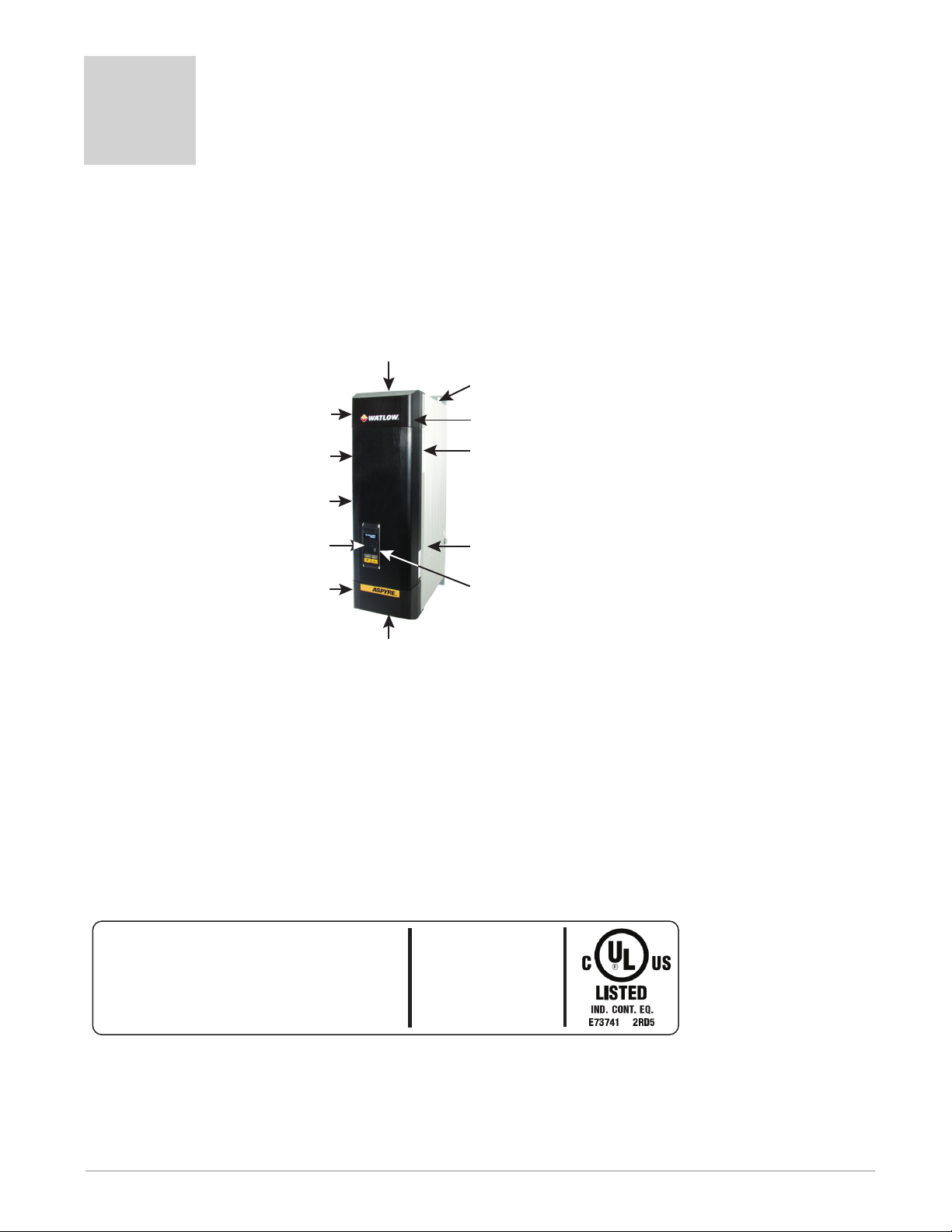

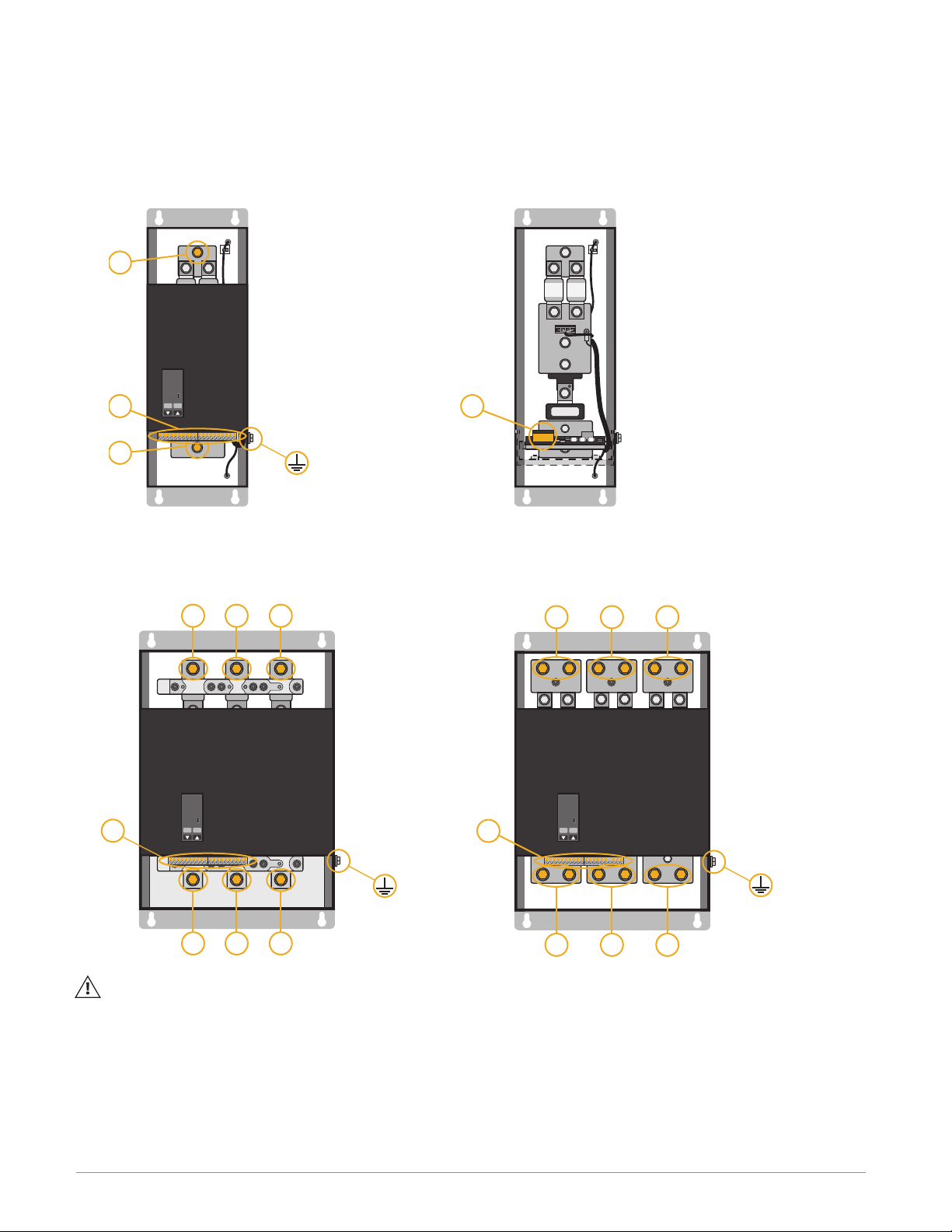

Recognizing Product Features

This illustration indicates the physical features of the product as referenced in this manual.

Line power connection

Mounting slots (top and bottom)

Part number label

Product identification label

Center cover

Control panel

Bottom cover

Load power connection

Top cover

Part number label

Earth ground connection

USB connector

Identifying the Product

To identify the power controller, locate the part number on the product identication label, see the illustration.

With the part number and the part number table you can determine important characteristics of the power controller.

Product Identification Label

The product identication label includes not only the part number but also the voltage and current ratings and

auxiliary and fan voltage requirements.

Sample Label

Max. Load Current

Max. Load Voltage

Auxiliary Voltage

Fan Voltage

Second Port

Watlow - ASPYRE 300A to 700A Power Controller • 11 • Chapter 1 Overview

: 300A

: 600Vac ~ 50/60Hz

: 540-660Vac ~ 50/60Hz 6VA

: 120 VAC

: Modbus TCP

1 Phase 1 Leg Control

Use Wire rated 75°C,

Max Ambient 40°C

For use in Pollution

Degree 2 Environment

User Manual:

1663-1873

Page 12

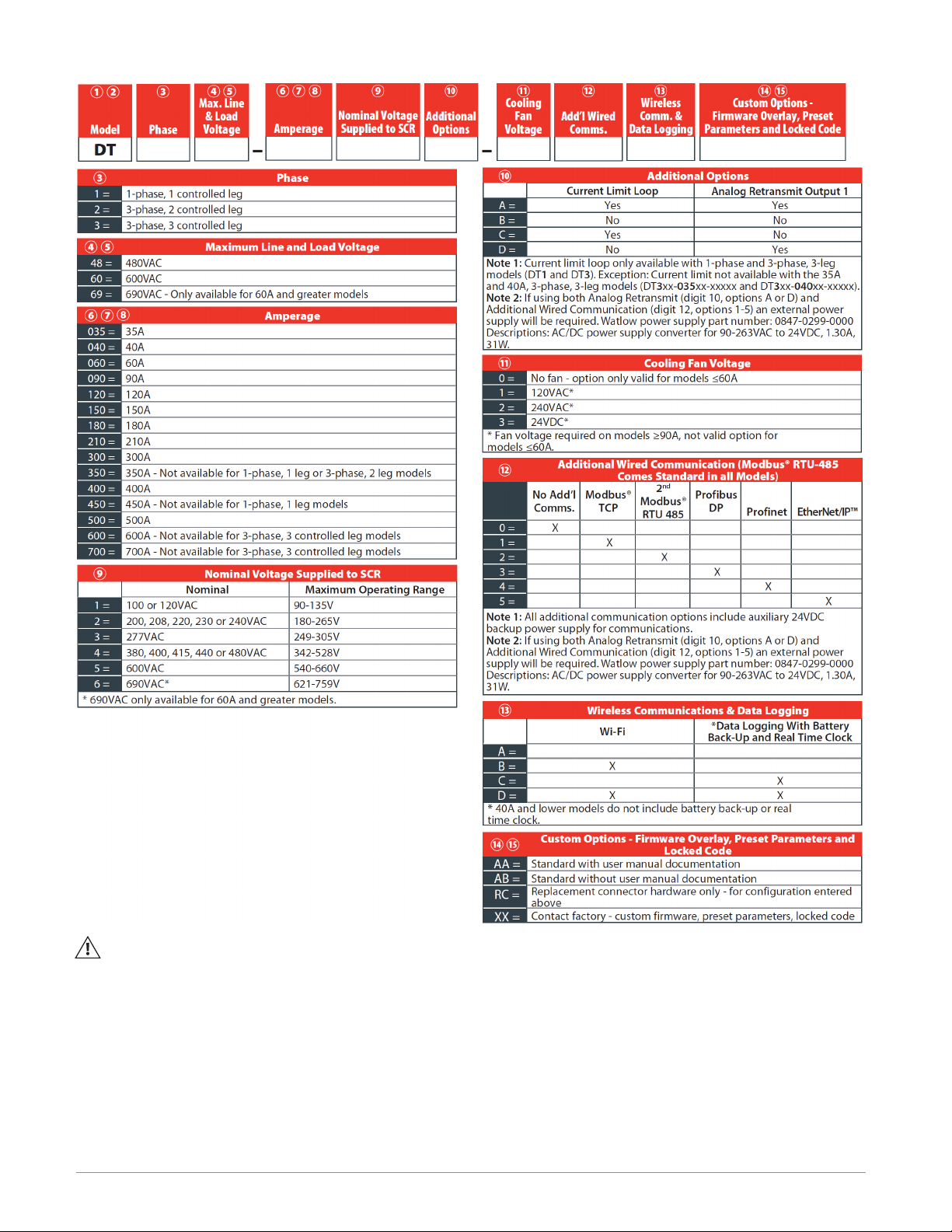

Part Number

NOTE! No UL® on 690V models.

Product Selection

This section describes how to choose the appropriate ordering options.

Digit 3, Phase

Choose the number of switched legs. Ungrounded-wye and delta loads are most economically controlled with

two-leg switching. Grounded-wye and open-delta loads require three-leg switching.

Watlow - ASPYRE 300A to 700A Power Controller • 12 • Chapter 1 Overview

Page 13

Digits 4 and 5, Maximum Line and Load Voltage

V

V

V

V

V

V

V

Choose the lowest voltage range that is equal to or greater than the nominal voltage supplied to the ASPYRE

power controller. The actual voltage is specied with digit 9.

Digits 6, 7 and 8, Amperage

These digits indicate the maximum current that can be switched. Choose a power controller with adequate current capacity for your load. Use one of the formulas below to determine the nominal load current based on the

load conguration, the line voltage and the load power or resistance.

In the formulas below:

• I is the nominal load current calculated according to the formula

• P is the total power of the load

• R is the resistance of each heating element

• V is the nominal voltage supplied to the ASPYRE power controller (see the 9

th

digit in the part number)

Single Phase Resistive Load

I

P

V

1.73V

=

I

V

=

R

P

1.73V

1.73V

=

R

P

=

V

1.73R

=

I

R

2-Leg, 3-Phase Resistive Load in Delta Conguration

I

=

R

R

3-Leg, 3-Phase Resistive Load in Grounded Wye Cong.

R R R

I

R

I

2-Leg, 3-Phase Resistive Load in Wye Conguration

I

P

=

I

R R R

3-Leg, 3-Phase Resistive Load in Wye Conguration

R R R

3-Leg, 3-Phase Resistive Load in Delta Conguration

R

R

1.73V

I

I

I

=

I

=

1.73V

P

1.73V

P

=

=

=

V

1.73R

V

1.73R

1.73V

R

R

3-Leg, 3-Phase Resistive Load in Open Delta Cong.

I

R

Watlow - ASPYRE 300A to 700A Power Controller • 13 • Chapter 1 Overview

R

R

P

=

I

3V

V

=

R

Page 14

Digit 9, Nominal Voltage Supplied to SCR

Choose the voltage the will be used to power the load. This is also the voltage for the auxiliary power supply

input. The voltage chosen here must be less than or equal to the Maximum Line and Load Voltage chosen with

digits 4 and 5.

Digit 10, Current Limit Loop and Analog Retransmit Output 1*

Choose if the power controller limits current and/or can retransmit load voltage, current, power or measured

input. The current limit option is available only with single phase and three-phase, three-leg models.

Digit 11, Cooling Fan Voltage

For power controllers that switch 90A or more, choose the voltage you will supply to power the fans in the ASPYRE power controller. Models that switch less than 90A do not require or include cooling fans.

Digit 12, Additional Wired Communication Option*

If desired, choose an optional communication port in addition to the EIA-485, Modbus® RTU port that comes standard on all models.

Digit 13, Wireless Communication and Data Logging Option

Choose the desired combination of Wi-Fi and data logging options.

Characters 14 and 15, Custom Options

Choose the desired options or use a factory supplied two-character option.

*If using both analog retransmit (digit 10, options A or D) and additional wired communication (digit 12, options 1

to 5) an external power supply is required.

Features and Benefits

This section provides a high-level overview of the features and benets of the ASPYRE power controller.

Heater bakeout

• Protects heater upon start up

• Eliminates labor and time associated with checking for wet heaters

Integrated semiconductor fusing, current transformer and user interface

• Saves installation time and eases setup and commissioning

• Delivers a user-friendly, intuitive interface

Industry-leading design and serviceability

• Offers a robust SCR design to meet a rugged industrial environment’s high quality and reliability needs

• Provides quick and easy access to maintain and service fuses and individual legs in minimal time

• Enables fast troubleshooting by providing helpful thermal system diagnostics

Comprehensive power controller range

• Provides wide range of options from simple single phase to complex three-phase loads to 690V

100KA short circuit current rating (SCCR)

• Enables greater protection in the event of a short circuit

c-UL® 508 Listed

• Shortens project schedules, agency testing and expenses

Control modes: contactor, voltage, current or power

• Satises a wide range of demanding thermal applications

Watlow - ASPYRE 300A to 700A Power Controller • 14 • Chapter 1 Overview

Page 15

Load firing modes: zero-cross, burst fire, phase angle, soft start, half-cycle, single-cycle, delayed trig-

Voltage

Sensing

Analog

Input

USB Device

• Configuration

Software Connection

• Data Log File Transfer

Analog

Retransmit

• User-Selectable

Retransmit Parameter

DC Power

Supply

• Dry Contact

Switches

• Potentiometers

WiFi

• Configuration

• Monitor Operation

2 Analog Inputs

• Set Point

• Feedback

• Current Limit*

2 Digital Inputs

• Enable

• Select Feedback

• Local/Remote

• Set Firing Type

Auxiliary Power

• Controller

Electronics

• Voltage Sensing

• Zero-Cross Sensing

Mechanical

Relay Output

• Alarm Annunciation

Fan Power

• 120VAC

• 240VAC

• 24VDC

Out to LoadIndustrial Communications

• Modbus

®

TCP

• EtherNet/IP™

• 2nd Modbus

®

RTU (485)

Analog

Input

Data

Logging

RS-485

Interface

NCNO

Analog

Retransmit

Current

Sensing

Power

Demand

Loop

(Optional)

(Optional)

(Optional)

•

Profibus DP

• Profinet

(Optional)

(Optional)

+10 VDC

Output

Current

Limit

Loop*

Fan Power

Input

Auxiliary

Power

Supplemental

Power

• Retransmit

• Communications

+24 VDC

Input

* Single-phase and three-phase, three-leg models only

Power Switching

• 1, 2 or 3 Legs

• Back-to-Back SCR Switching

• Replaceable Semiconductor Fuses

(Optional)

(Optional)

(Optional)

gering

• Handles a wide range of load types including nichrome, medium and long waveform infrared lamps, moly,

transformers, silicon carbide, UV lamps and tungsten

• Protects and extends the life of connected loads

Wide range of communication protocols

• Enable factory and process automation with connectivity to process and equipment data via Modbus® RTU,

Modbus® TCP, EtherNet/IP™ , Wi-Fi, Probus, Pronet, USB device (conguration and data le transfers)

Open heater and shorted SCR indication

• Minimizes production downtime with easy to understand, intelligent, troubleshooting diagnostics

Integrated USB and user interface for configuration

• Easily and safely program conguration settings as the user interface can be powered through USB connection

• Eliminates need to work in a high voltage hazard environment. High voltage to the power controller and

system panel can be shut off and locked out for safety while conguring controller.

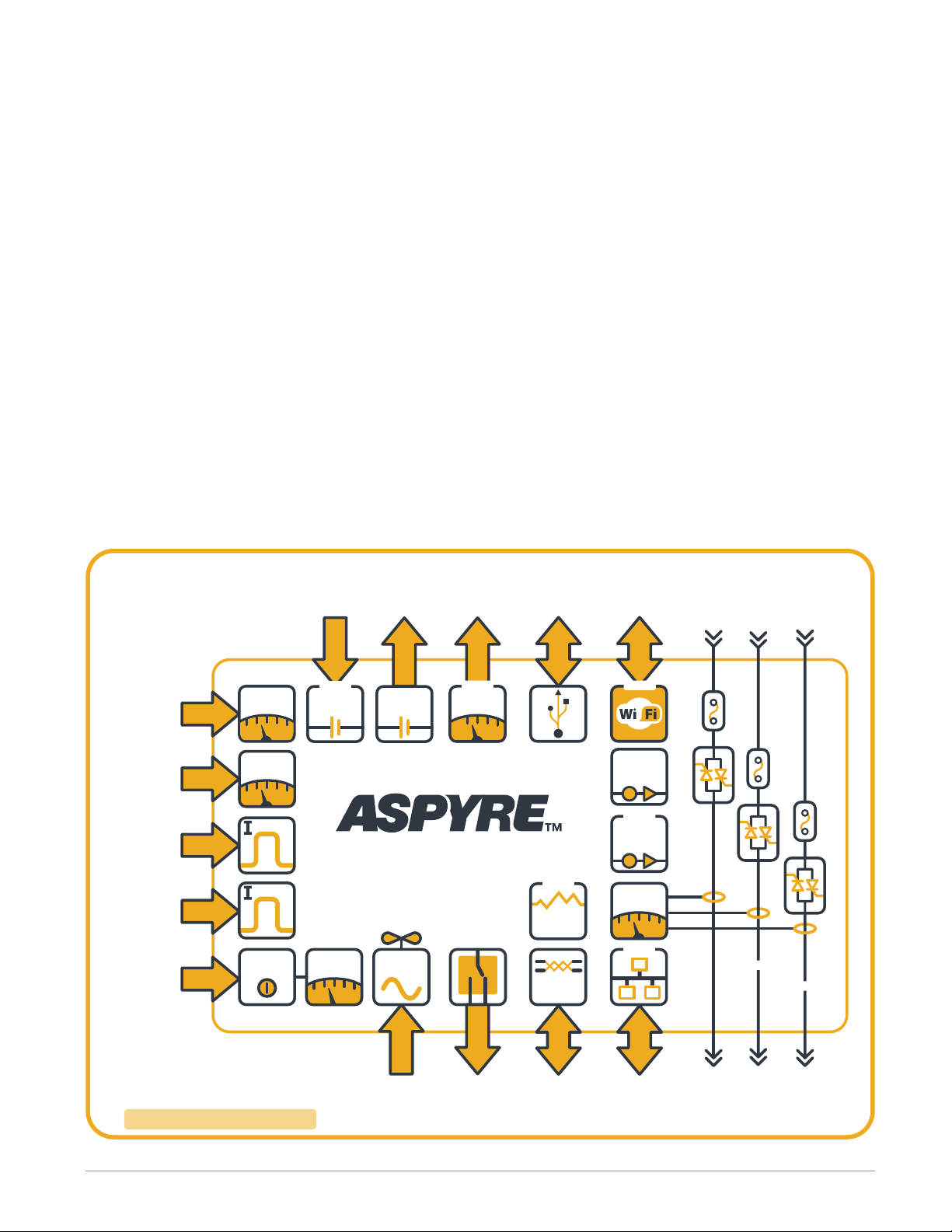

Product Block Diagram

This diagram represents the features and functions of the ASPYRE power controller in a graphical format showing

the relationships between various functions. Optional features are indicated.

Product Block Diagram for 300A to 700A Models

Watlow - ASPYRE 300A to 700A Power Controller • 15 • Chapter 1 Overview

Page 16

Wi-Fi Transmitter Module

Models DT_ _ _-_ _ _ _-_ _ _[B or D]_ _ contain a Wi-Fi transmitter module. See the label on the module to

determine which of the following modules is installed. The transmitter module is mounted on the top of the

microprocessor board visible when the center cover is tipped forward.

Module FCC ID: 2ADUIESP-12-F WiFi module 802.11b/g/n 2412-2462 MHz

Output power:

• 802.11b: 15.58 dBm (Max.)

• 802.11g: 13.72 dBm (Max.)

• 802.11n: 12.53 dBm (Max.)

Antenna gain: 1.0 dBi PCB antenna 11 channels.

Module FCC ID: 2AL3B-ESP-F 802.11b/g/n 2412-2462 MHz

Output power:

• 802.11b: 14.0 dBm (Max.)

• 802.11g: 12.8 dBm (Max.)

• 802.11n: 13.6 dBm (Max.)

Antenna gain: 1.0 dBi PCB antenna 11 channels.

Unit is assembled from tested components, complete system not tested.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Watlow - ASPYRE 300A to 700A Power Controller • 16 • Chapter 1 Overview

Page 17

2

Installation

WARNING: To avoid damage to property and equipment, injury and loss of life, adhere to applicable electrical codes and standard wiring practices when installing and operating this product. Failure to do so could result

in damage, injury and death.

AVERTISSEMENT! Pour éviter d’endommager la propriété et l’équipement, les blessures et la perte de vie,

respecter les codes électriques en vigueur et les pratiques de câblage standard au moment de l’installation et

de l’utilisation de ce produit. Dans le cas contraire, cela peut entraîner la mort, des blessures graves ou des

dommages.

Installing the ASPYRE Power Controller

This chapter provides the information necessary to select and prepare a location and to mount one or more

ASPYRE power controllers.

Consider the spacing required for power, load, and control signal wiring before mounting the power controller.

Take in to account the controller dimensions, wire bending radius, and cooling requirements. Use good wiring

practices to minimize electrical noise problems.

Peripheral Components

Allow room for fuses and fuse holders for the auxiliary input power and fans (if present).

Mounting Orientation

Mount power controllers vertically.

Bend Radius

Allow adequate space to route cables without requiring bending more than permitted for the type of cable.

Environmental Conditions

Mount ASPYRE power controllers in a suitable electrical enclosure. Allow adequate wire bending space and cool-

ing. The maximum ambient temperature in the enclosure must not exceed 104°F (40°C).

Ambient Temperature

Storage Temperature

Installation Location

Altitude

Humidity

Pollution degree

32° to 104°F (0° to 40°C)

-13° to 158°F (-25°to 70°C)

Install away from direct sun light, conductive dust, corrosive gas, vibration,

water and corrosive salts.

Up to 6560 feet (2000m) above sea level

At altitudes above 3280 feet (1000m) reduce the nominal current by 2% for

each 328 feet (100m).

From 5 to 95% relative humidity, non-condensing and without ice

Installation Category III, Pollution degree 2

Watlow - ASPYRE 300A to 700A Power Controller • 17 • Chapter 2 Installation

Page 18

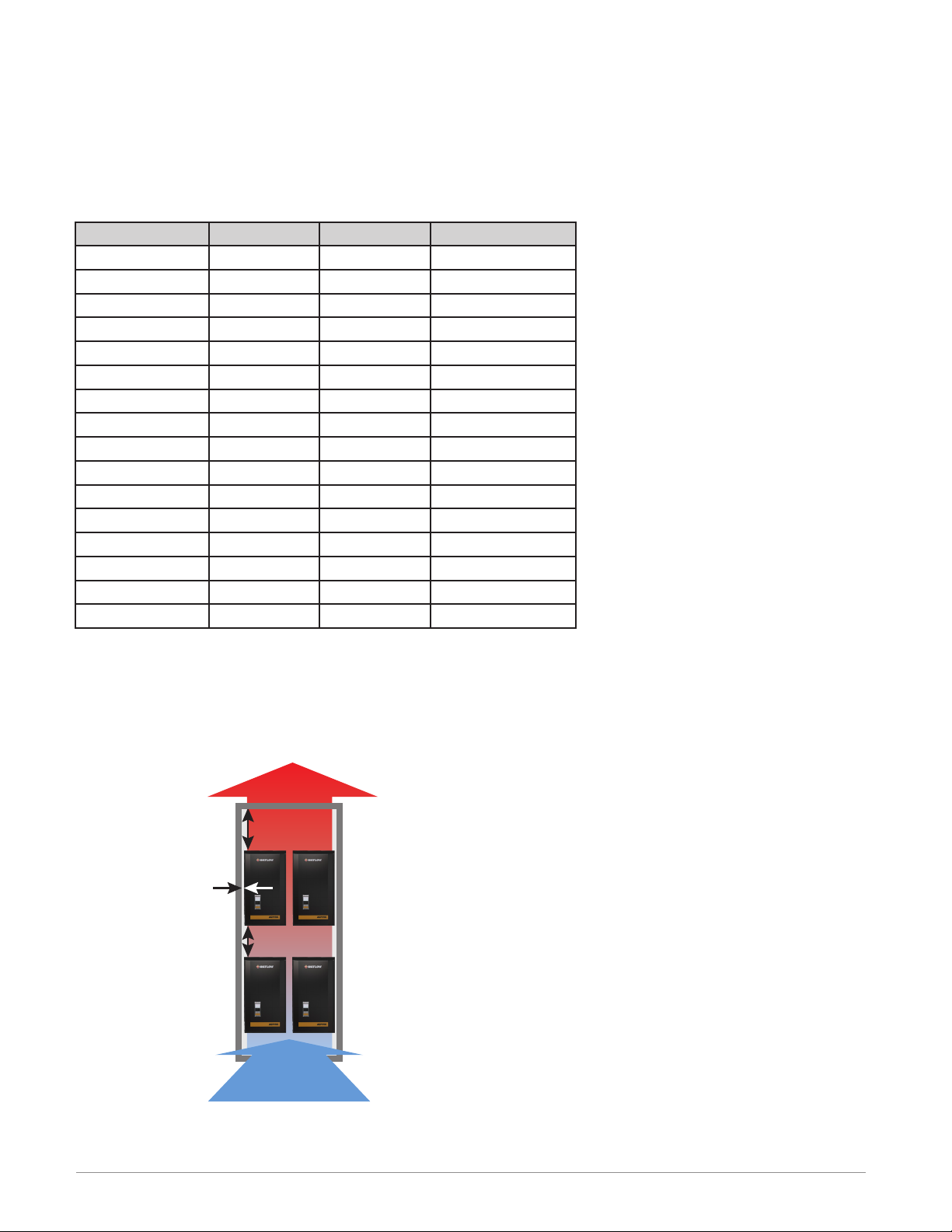

Cooling Requirements

To maintain the ambient temperature in the enclosure in which the power controller, circuit breakers, fuses and

other components are installed, there must be adequate cooling to remove the heat generated by all the devices. The power controllers are designed to be cooled by drawing cool air in from the bottom and expelling heated

air at the top. Typically cabinets are designed with one or more fans on the front door or on the top of the enclosure. The designer will need to know the heat generated by the power controller. See the table below.

Total Heat Generated by ASPYRE Power Controller

Model Current (A) Switched Legs Generated Heat (W)

DT1_ _-300... 300 1 443

DT1_ _-400... 400 1 547

DT1_ _-500... 500 1 591

DT1_ _-600... 600 1 832

DT1_ _-700... 700 1 945

DT2_ _-300... 300 2 903

DT3_ _-300... 300 3 1324

DT3_ _-350... 350 3 1439

DT2_ _-400... 400 2 1092

DT3_ _-400... 400 3 1641

DT2_ _-450... 450 2 1259

DT3_ _-450... 450 3 2096

DT2_ _-500... 500 2 1407

DT3_ _-500... 500 3 2096

DT2_ _-600... 600 2 1528

DT2_ _-700... 700 2 1753

Spacing for Multiple Power Controllers

Maintain the minimum distances as shown in the diagram. When multiple power controllers are mounted side-byside they may be placed as close together as is practical for installation and service.

Power Controller Spacing

Hot Air

30 cm (11.8 in.)

2 cm (0.8 in.)

20 cm (7.9 in.)

Outlet

Cool Air

Intake

Watlow - ASPYRE 300A to 700A Power Controller • 18 • Chapter 2 Installation

Page 19

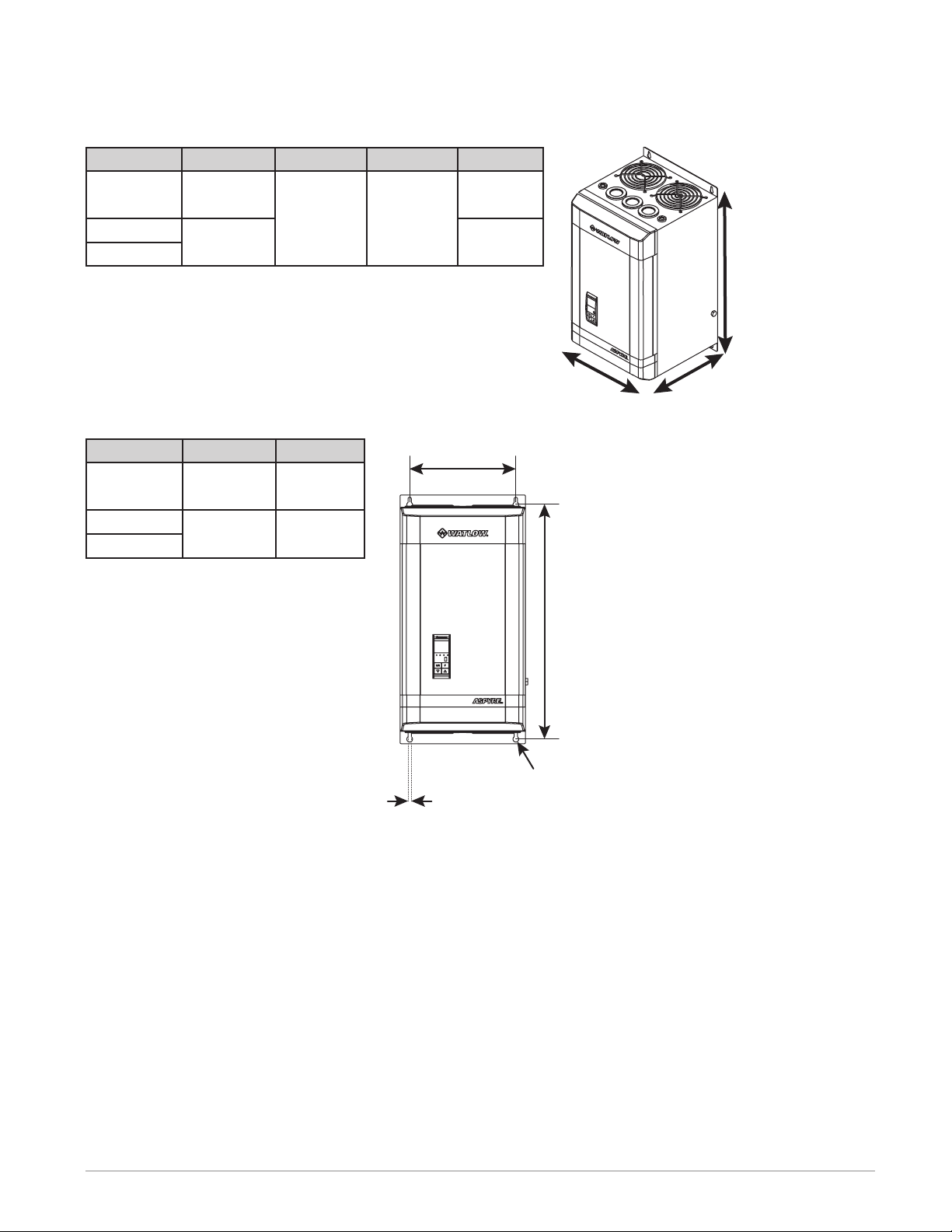

Mounting Dimensions

See the tables for the product dimensions, weight and keyhole mounting slot locations and size.

Power Controller Dimensions and Weight

Model W H D Weight

DT1...

DT2...

DT3...

Mounting Slot Locations

Model A B

DT1...

DT2...

DT3...

5.39 in.

137 mm

10.32 in.

262 mm

3.82 in.

97 mm

8.74 in.

222 mm

20.47 in.

520 mm

19.29 in.

490 mm

19.29 in.

490 mm

10.63 in.

270 mm

Slot Locations

33.1 lb.

15 kg

49.6 lb.

22.5 kg

A

Dimensions

W

H

D

B

0.47 in. (12 mm) diameter typical

0.28 in. (7 mm) typical

Watlow - ASPYRE 300A to 700A Power Controller • 19 • Chapter 2 Installation

Page 20

Watlow - ASPYRE 300A to 700A Power Controller • 20 • Chapter 2 Installation

Page 21

3

Wiring

WARNING: To avoid damage to property and equipment, injury and loss of life, adhere to applicable electrical codes and standard wiring practices when installing and operating this product. Failure to do so could result

in damage, injury and death.

AVERTISSEMENT! Pour éviter d’endommager la propriété et l’équipement, les blessures et la perte de vie,

respecter les codes électriques en vigueur et les pratiques de câblage standard au moment de l’installation et

de l’utilisation de ce produit. Dans le cas contraire, cela peut entraîner la mort, des blessures graves ou des

dommages.

WARNING: The installation must be protected by electromagnetic circuit breakers or by fuses. The semicon-

ductor fuses located inside the power controller are classied for UL® as supplementary protection for semicon-

ductor devices. They are not approved for branch circuit protection.

AVERTISSEMENT! L’installation doit être protégée par des disjoncteurs électromagnétiques ou des fusibles.

Les fusibles pour semi-conducteurs situés à l’intérieur du régulateur de puissance sont classés UL® comme protection supplémentaire pour les dispositifs pour semi-conducteurs. Ils ne sont pas approuvés pour la protection

des circuits de dérivation.

Wiring the ASPYRE Power Controller

This chapter describes how to select, prepare and attach power and signal wires to the power controller.

Good Wiring Practices

Follow good wiring practices to minimize the effects of interference from nearby equipment and the line power

on the operation of the power controller:

• Install an appropriately sized RC lter across contactor coils, relays and other inductive loads

• Use shielded twisted-pair cables for input, output and communication signals

• Route control and signal cables away from motors and other sources of electromagnetic interference and

not parallel to power cables

• Follow all local regulations applicable to electrical installations

NOTE: Use only copper cables and wires rated for use at 75°C or greater.

REMARQUE : N’utiliser que des câbles et des ls en cuivre pour l’utilisation à 75 °C ou plus.

Watlow - ASPYRE 300A to 700A Power Controller • 21 • Chapter 3 Wiring

Page 22

Wiring Overview Diagrams

The diagrams in this section indicate the locations of the line power, load, earth ground and control signal connections on the power controller.

Connection Locations on Single Phase

Top and Bottom Covers O

L1

Center Cover Tipped Forward

M1

T1

L/R F

M2

Connection Locations on Three-Phase Models

Models with 30mm Bus Bar

Top and Bottom Covers O

L1 L2 L3

M1

L/R F

Models with 60mm Bus Bar

Top and Bottom Covers O

M1

L1 L2 L3

L/R F

T1 T2 T3

T1 T2 T3

NOTE! See the tabel below for the bus bar width and number of bolts for your model.

Watlow - ASPYRE 300A to 700A Power Controller • 22 • Chapter 3 Wiring

Page 23

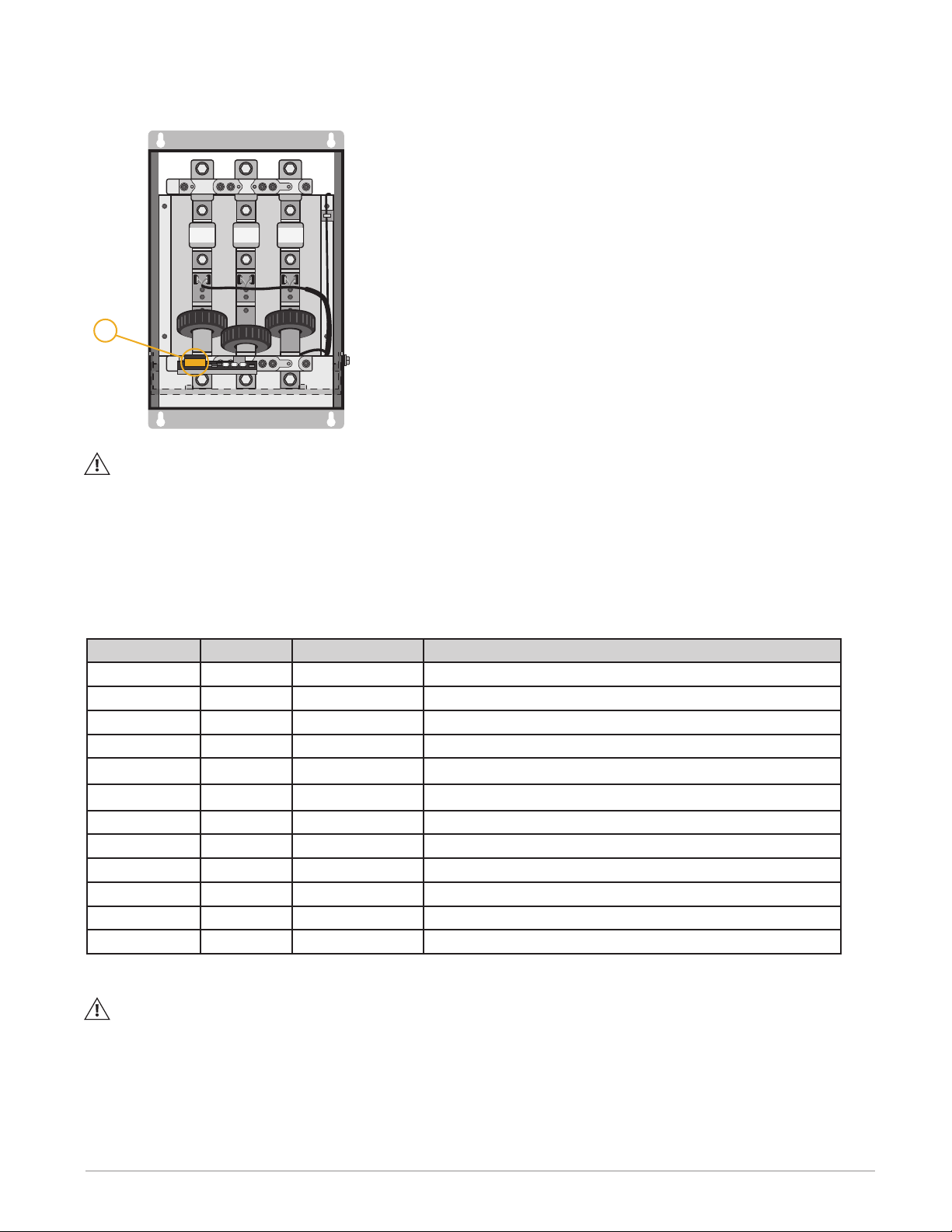

M2 Location on Three-Phase Models

Top and Bottom Covers O and

Center Cover Tipped Forward

M2

NOTE! Three-leg, 400A model shown. The number of fuses and their placement depends on the model. In all

cases the M2 connector is found as indicated.

Wire Selection, Prep and Torque

This section lists the recommended cable and bus bar sizes for line power, load, earth ground and control signal

connections. There are also recommendations for insulation stripping and termination torque.

Line Power and Load Cable and Bus Bar Size

Model Bolt(s) Bus Bar Cable Size*

DT_ _ _-300... 1 ea. M10 1 ea. 30 x 6 mm 2 ea. 1/0 AWG (70 mm2) or 1 ea. 350 kcmil (185 mm2)

DT3_ _-350... 1 ea. M10 1 ea. 30 x 6 mm 2 ea. 2/0 AWG (70 mm2) or 1 ea. 500 kcmil (300 mm2)

DT_ _ _-400... 1 ea. M10 1 ea. 30 x 6 mm 2 ea. 3/0 AWG (95 mm2) or 1 ea. 600 kcmil (400 mm2)

DT2_ _-450... 1 ea. M10 1 ea. 30 x 6 mm 2 ea. 4/0 AWG (120 mm2) or 1 ea. 700 kcmil (400 mm2)

DT3_ _-450... 2 ea. M10 1 ea. 60 x 4 mm 2 ea. 4/0 AWG (120 mm2) or 1 ea. 700 kcmil (400 mm2)

DT1_ _-500... 2 ea. M10 1 ea. 60 x 4 mm 2 ea. 250 kcmil (150 mm2) or 1 ea. 900 kcmil (400 mm2)

DT2_ _-500... 1 ea. M10 2 ea. 30 x 6 mm 2 ea. 250 kcmil (150 mm2) or 1 ea. 900 kcmil (400 mm2)

DT3_ _-500... 2 ea. M10 1 ea. 60 x 4 mm 2 ea. 250 kcmil (150 mm2) or 1 ea. 900 kcmil (400 mm2)

DT1_ _-600... 2 ea. M10 1 ea. 60 x 5 mm 2 ea. 350 kcmil (185 mm2) or 1 ea. 1500 kcmil (800 mm2)

DT2_ _-600... 2 ea. M10 1 ea. 60 x 5 mm 2 ea. 350 kcmil (185 mm2) or 1 ea. 1500 kcmil (800 mm2)

DT1_ _-700... 2 ea. M10 1 ea. 60 x 6 mm 2 ea. 500 kcmil (300 mm2)

DT2_ _-700... 2 ea. M10 1 ea. 60 x 6 mm 2 ea. 500 kcmil (300 mm2)

*With UL® Listed (ZMVV) Copper Tube Crimp Lug

NOTE! The line power and load wires for the lower amperage units should enter and exit the package

through the provided grommets. The grommets are not pre-cut. Use a knife to cut an appropriately sized slash in

the center of each grommet.

Watlow - ASPYRE 300A to 700A Power Controller • 23 • Chapter 3 Wiring

Page 24

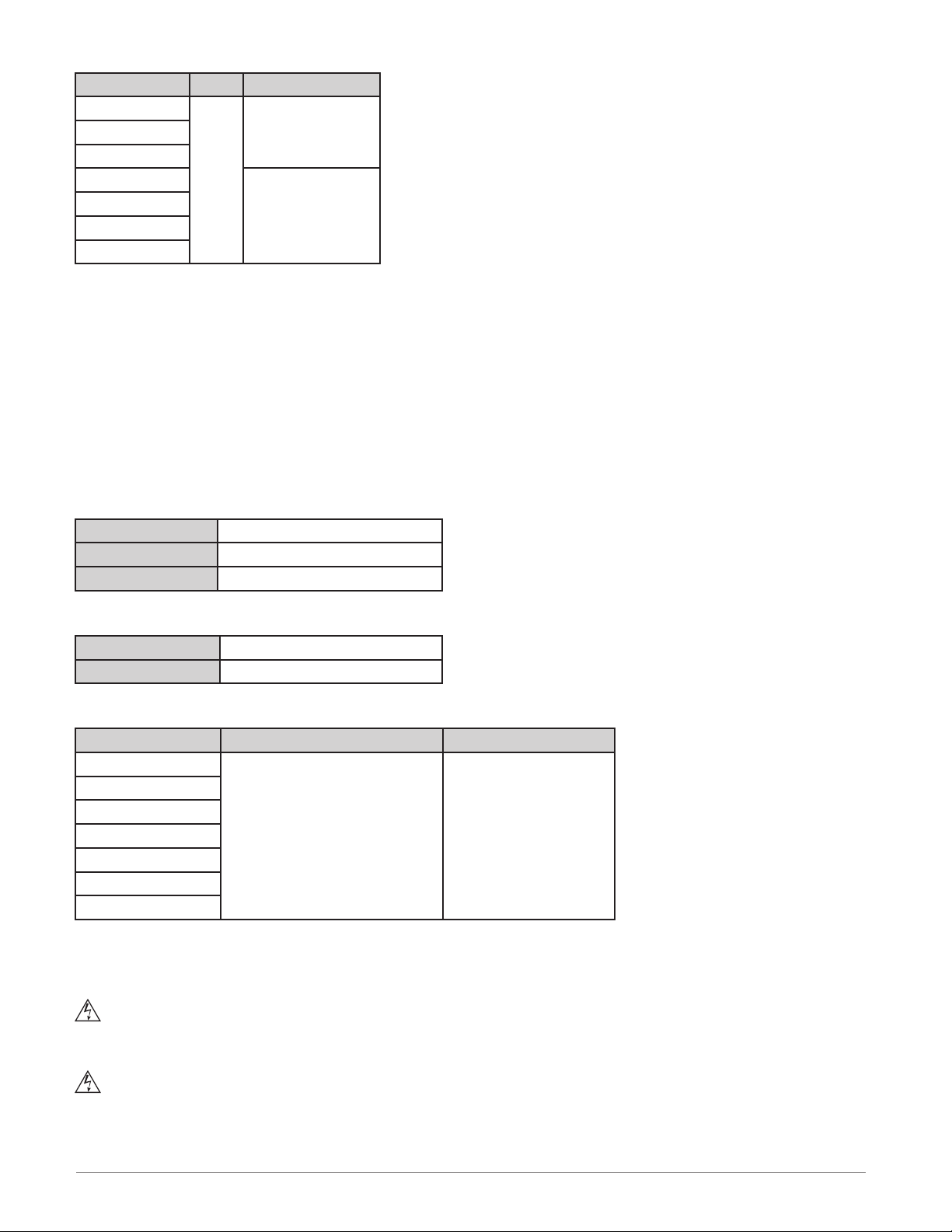

Ground Cable Size

Model Bolt Wire Size

DT_ _ _300...

1 AWG (50mm2)DT_ _ _350...

DT_ _ _400...

DT_ _ _450...

DT_ _ _500...

DT_ _ _600...

DT_ _ _700...

M8

1/0 AWG

(70mm2)

Control and Signal Cable Size

Range: 22 to 14 AWG (0.50 to 1.5mm2)

Recommended: 18 AWG (0.75mm2)

Insulation Stripping and Torque

To insure proper connections, but minimize hazardous exposure of conductors, strip the correct amount of insulation from each cable.

Insulation Stripping

Load & Line Power

Ground

Control and Signal

Per crimp lug requirements

Per crimp lug requirements

0.24 in. (6mm)

Control Signal and Ground Torque

Control & Signal

Ground

Line Power and Load Torque

Model Wire Termination Proper Torque

DT_ _ _-300...

DT_ _ _-350...

DT_ _ _-400...

DT_ _ _-450...

DT_ _ _-500...

DT_ _ _-600...

DT_ _ _-700...

4 in.-lb. (0.11 Nm)

221 in.-lb. (25.0 Nm)

UL® Listed (ZMVV) Copper

Tube Crimp Lug or bus bar

505 in.-lb. (57 Nm)

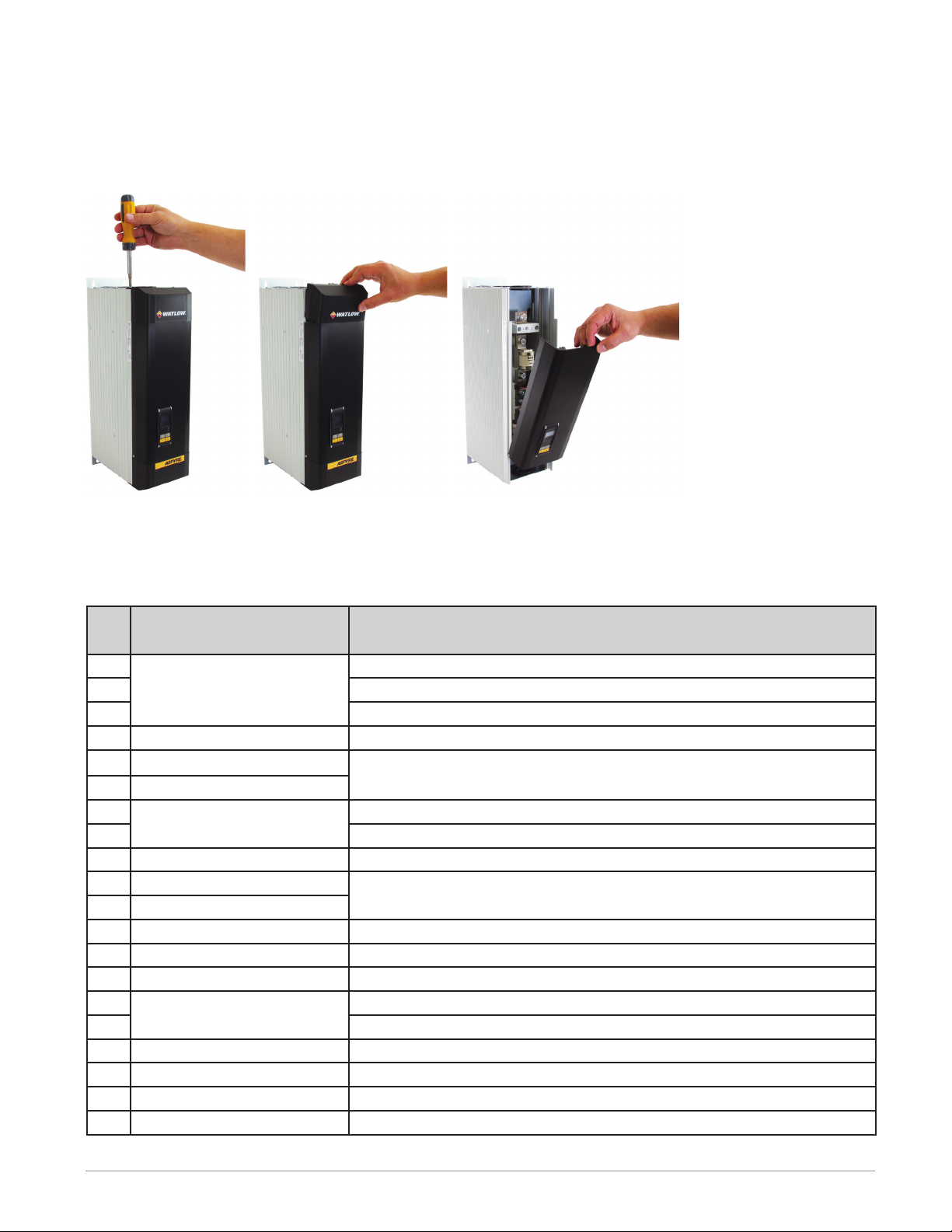

Removing the Covers

WARNING: To prevent injury and loss of life, shut off power and ensure it cannot be restored while perform-

ing work with the covers open or removed.

AVERTISSEMENT : Pour éviter les blessures et les pertes de vie, couper l’alimentation électrique et s’assurer

qu’elle ne peut être restaurée pendant l’exécution du travail avec les couvercles ouverts ou enlevés.

Watlow - ASPYRE 300A to 700A Power Controller • 24 • Chapter 3 Wiring

Page 25

To remove the top cover (line power) or bottom cover (load connections):

1. Loosen and remove the fasteners (1 ea. single-phase, 2 ea. three-phase).

2. Tilt the cover toward you and remove it.

To access the M2 connector:

• After removing the top and bottom covers, tilt the center cover forward.

Connecting Control Signals

This section shows how to connect control signals to the M1 and M2 terminal strips.

M1 Terminal Connections

M1 Function Description

1

Alarm output

2 C (common)

3 NC (normally closed contact)

4 Analog input 2+ Alternate set point, external feedback or current limit (DT1 and DT3)

5 Digital input 2

6 Digital input 1

7

Port 1 Modbus® RTU RS-485*

8 Connect to A- on USB-to-485 adapter

9 +10VDC power supply For dry contact digital inputs or potentiometers for analog inputs

10 Analog common 10 and 24V

11 Analog common 10 and 24V

12 Analog input 1+ Set point signal input

13 Digital input common Reference to analog common, if necessary

14 Not Used

15

Power input for fan

16 - For DC fans, line or neutral for AC fans

17 Not used

18 Auxiliary power input Line 1

19 Not used

20 Auxiliary power input Line 2 or neutral on single phase units

NO (normally open contact)

See “Congurable Digital Inputs (Digital Input 1 and Digital Input 2)” on

page 27

Connect to B+ on USB-to-485 adapter

For analog inputs, retransmit and RS-485 common

+ For DC fans, line or neutral for AC fans

Watlow - ASPYRE 300A to 700A Power Controller • 25 • Chapter 3 Wiring

Page 26

M2 Terminal Connections

M2 Function

+24VDC supplemental power for applications that use both analog retransmit and the sec-

1

ond communication port (other than Modbus® RTU)

2 Unused

3 Retransmit output+

4 Analog common 10 and 24V for 24VDC input, retransmit output and RS-485 common

Secondary Modbus® RTU Terminal Connections*

Function Description

A+

Port 2 Modbus® RTU RS-485

B- Connect to A- on USB-to-485 adapter

*Connect 485 signal here only on units with second Modbus® RTU 485 communications port option. Connecting

signal here on units with other wired communications options will interfere with the operation of that option.

Connect to B+ on USB-to-485 adapter

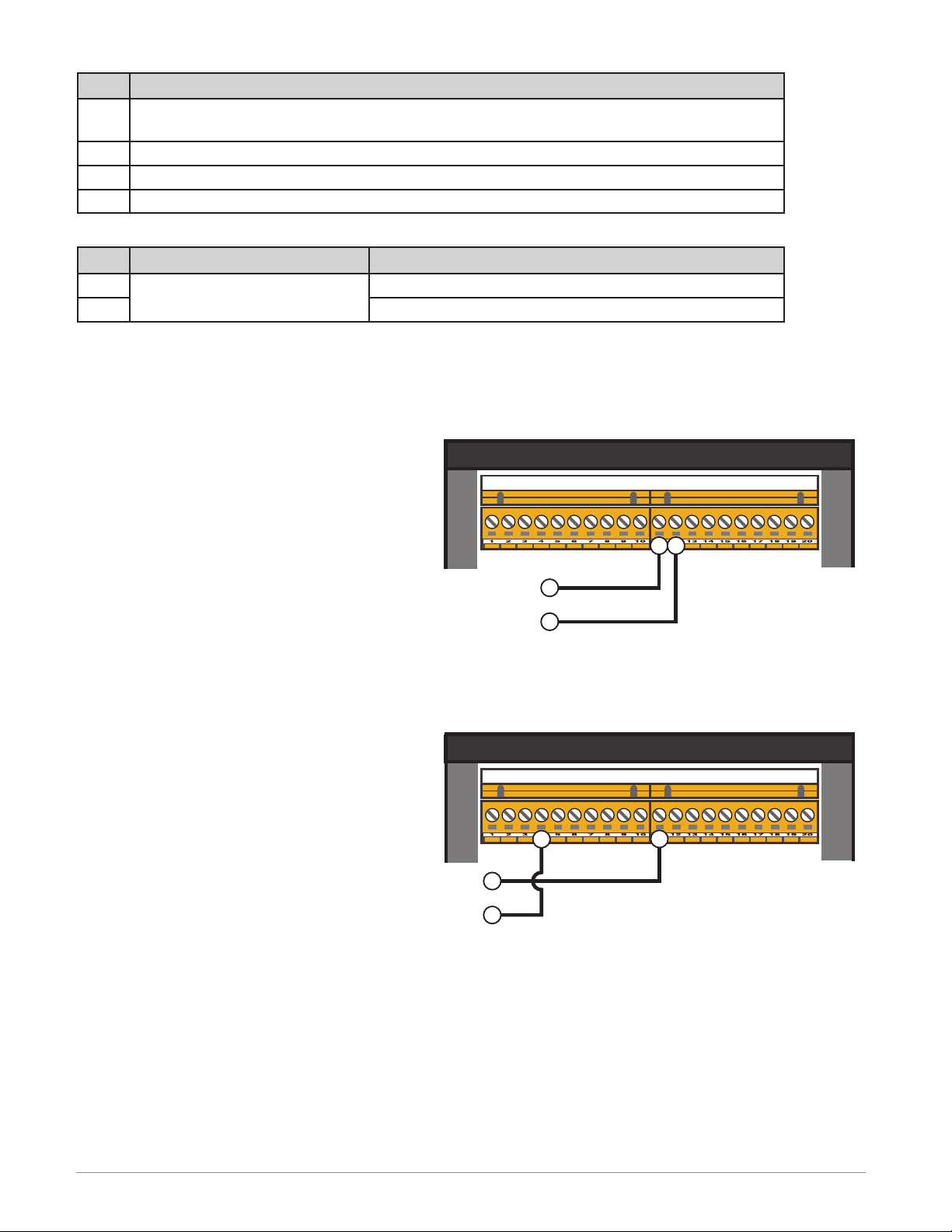

Set Point (Analog Input 1)

To control the power to the load with a device

such as a temperature controller, connect the control signal to analog input 1.

This input accepts current (0 to 20mADC, 4 to

20mADC), voltage (0 to 10VDC) and potentiometer (0 to 10,000Ω) signals. Congure the power

controller to recognize the signal on the hardware

menu; see “Analog In 1 [Signal Type]” on page

53.

Analog Input 1 Wiring on M1 Terminals

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

11 12

–

Analog Input 1

+

Set Point, Feedback or Current

Limit (Analog Input 2)

What this input does is user-congurable.

Connect an analog signal that indicates:

• An alternate set point signal

• Measured power, voltage or current

for use as feedback

• In models with the current limit

option: the maximum current to the

load (current limit set point)

This input accepts current (0 to 20mADC,

4 to 20mADC), voltage (0 to 10VDC) and

potentiometer (0 to 10,000Ω) signals.

Congure the power controller to recognize the signal and how the power controller uses it on the hardware menu; see

“Analog In 2 [Signal Type]” on page 54

and “Analog In 2 Function” on page 54.

Analog Input 2 Wiring on M1 Terminals

Analog Input 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

4

11

–

+

Watlow - ASPYRE 300A to 700A Power Controller • 26 • Chapter 3 Wiring

Page 27

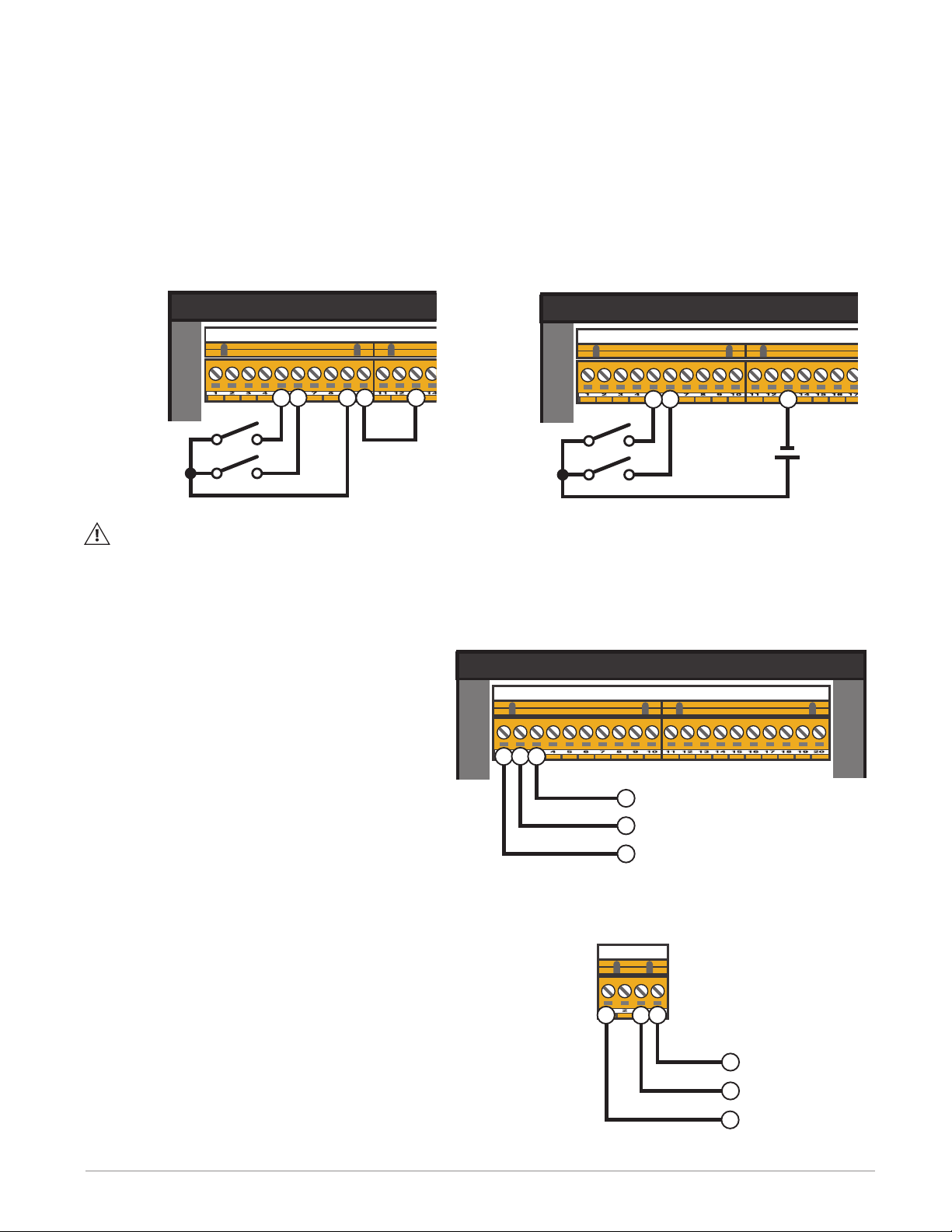

Configurable Digital Inputs (Digital Input 1 and Digital Input 2)

14 15 16 17 18 19 20

17 18 19 20

What these inputs do is user-congurable. Connect digital signals to:

• Enable the power controller to output power to the load

• Change the feedback to voltage

• Change whether the local or remote set point is used

• Change the ring type to phase angle

Congure how the power controller uses these signals on the hardware menu; see “Digital In 1 Function” on page

56 and “Digital In 2 Function” on page 57.

Digital Input Wiring on M1 Terminals

1 2 3 4 5 6 7 8 9 10 11 12 13

5

10 1396

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

5

136

–

Digital Input 2

Digital Input 1

Digital Input 2

Digital Input 1

External DC

Power Supply

+

NOTE! If you use the +10VDC power supply to provide the input signal, connect the 10VDC common (M1 ter-

minal 10) to the digital input common (M1 terminal 13).

Alarm Outputs

Connect to the relay contacts so that alarms in the

power controller can be detected or enunciated by

external devices. Congure which alarms cause the

relay to energize with the hardware menu; see

“Alarm Function” on page 53.

Alarm Wiring on M1 Terminals

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

2

3

1

Alarm Output

NC

Normally Closed Contact

C

Common

NO

Normally Open Contact

Retransmit Option

Connect the analog output to an external device so it can monitor or

record set point, current, voltage, or actual power.

Which data is retransmitted and the scaling of the output are user-congurable on the hardware menu; see “Retransmit (Models with Retransmit)” on page 65, “Retransmit Type (Models with Retransmit)” on

page 66 and “Retransmit Scale (Models with Retransmit)” on page

66.

If using the retransmit feature and any of the Ethernet protocols or

Probus, connect an external power to the supplemental 24VDC input.

Watlow - ASPYRE 300A to 700A Power Controller • 27 • Chapter 3 Wiring

Retransmit Wiring on M2 Terminals

1 2 3 4

1

4

3

Retransmit Output

C

Common

Retransmit

+

+24VDC Input

+

Page 28

Communication Connections

All models include at least one RS-485 communication port. Some models include a second communication port. Connect these ports to allow

other equipment to monitor, operate or congure

the power controller. The communication protocols have adjustable software settings on the

Communication menu see the “Menu Listing” on

page 37. Connect RS-485 communication common to any analog common terminal.

Accessing the Optional Second Communication Port

The second communication port, if present is located on a daughter card mounted on the back of the main electronics board. Tip the center cover forward and down to access the port.

Communication Options

Model Communication Option Connector Location on Daughter Card

DT_ _ _-_ _ _ _ _-_0_ _ _ No additional port N/A

DT_ _ _-_ _ _ _ _-_1_ _ _ Modbus® TCP (Ethernet) RJ-45 on right side

DT_ _ _-_ _ _ _ _-_2_ _ _ Modbus® RTU (2nd RS485 port) 2-pin connector on left side*

DT_ _ _-_ _ _ _ _-_3_ _ _ Probus DP DB9 connector on right side

DT_ _ _-_ _ _ _ _-_4_ _ _ Pronet RJ-45 on right side

DT_ _ _-_ _ _ _ _-_5_ _ _ EtherNet/IP™ RJ-45

RS-485, Modbus® RTU Wiring on M1 Terminals

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

8

7

10

A-

B+

Common

RS-485

*Connect 485 signal here only on units with second Modbus® RTU 485 communications port option. Connecting

signal here on units with other wired communication options will interfere with the operation of that option.

Connect RS-485 communication common to any analog common terminal.

RS-485

RJ-45

or DB9

Watlow - ASPYRE 300A to 700A Power Controller • 28 • Chapter 3 Wiring

Page 29

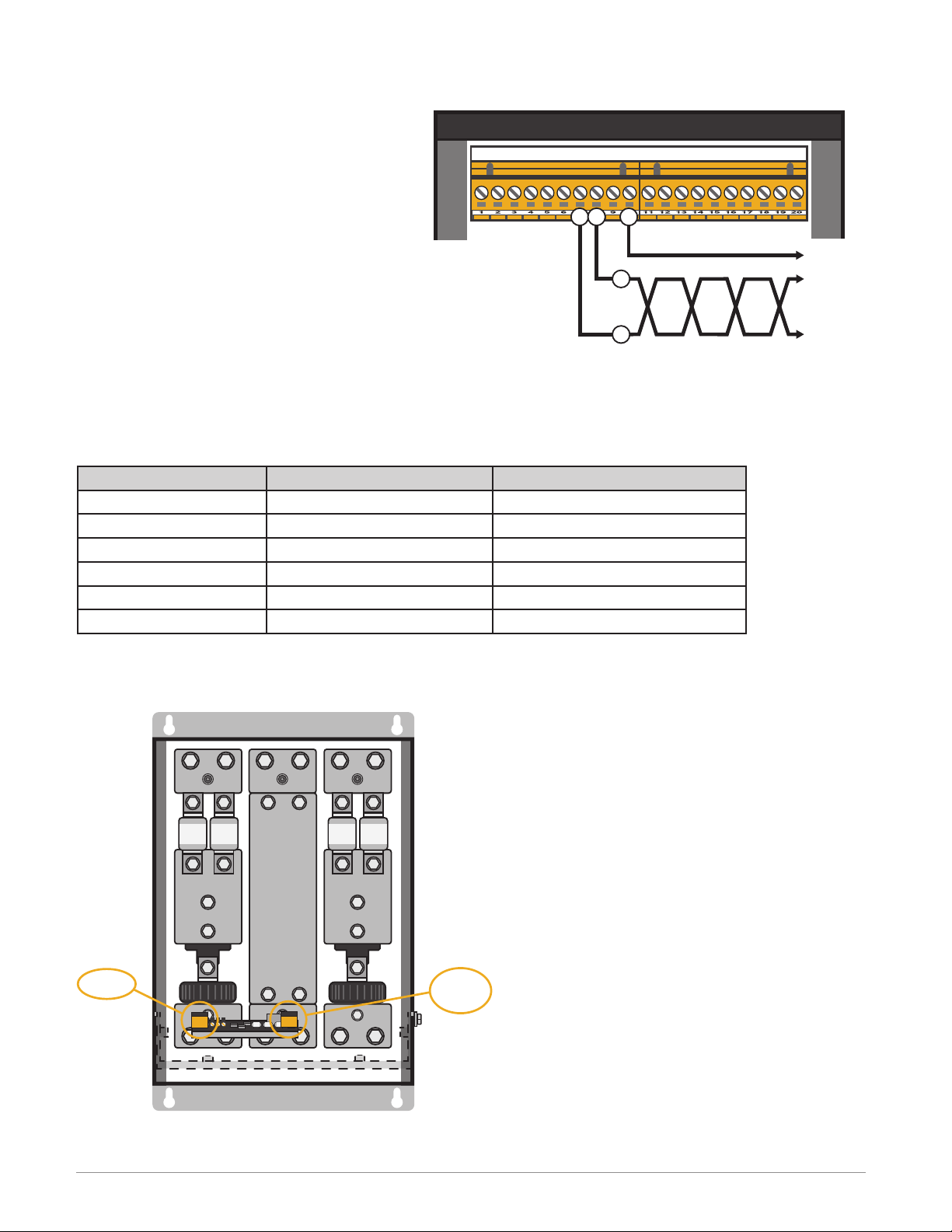

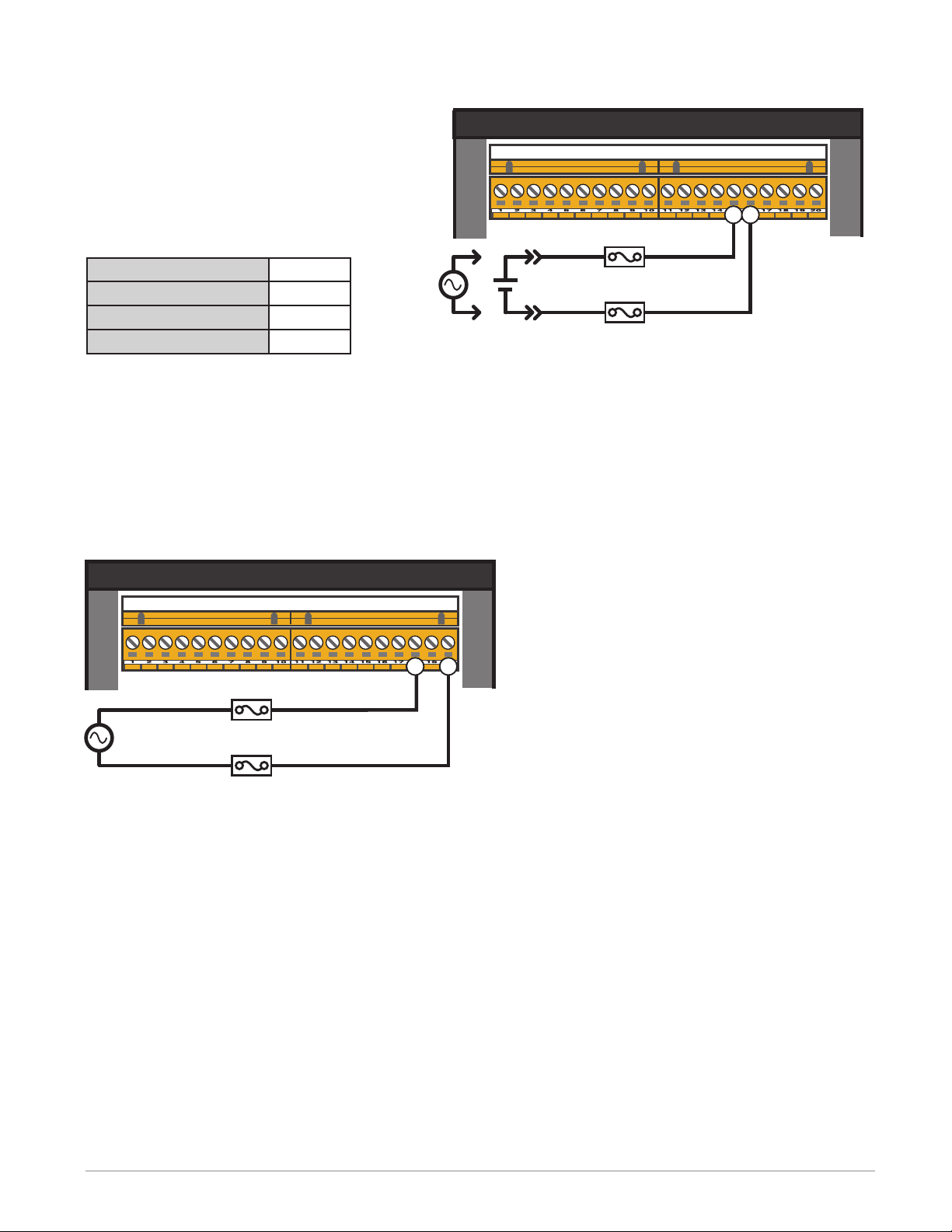

Powering the Cooling Fans

Connect power of the appropriate voltage for

the cooling fans. Install fuses on each hot leg

(not required for single-phase neutral). Use 2A

class CC fuses rated for 600VAC similar to Cooper

Bussman® LP-CC Series. Supply power for fans:

34W (single-phase models), 68W (three-phase

models).

Fan Power Wiring on M1 Terminals

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

15 16

Cooling Fan Voltage

DT_ _ _-_ _ _ _ _-0_ _ _ _

DT_ _ _-_ _ _ _ _-1_ _ _ _

DT_ _ _-_ _ _ _ _-2_ _ _ _

DT_ _ _-_ _ _ _ _-3_ _ _ _

No Fan

120VAC

240VAC

24VDC

Fan Power

+

–

Fuses (for AC fans)

Connecting the Auxiliary Power

The auxiliary power input supplies the controller’s electronics. The voltage supplied at M1 terminal 18 must be

synchronized with the phase that is connected to the L1 line power terminal. The auxiliary voltage is indicated

on the product identication label and encoded in the part number as the nominal voltage (character 9).

Install fuses on each hot leg (not required for single-phase neutral). Use 2A class CC fuses rated for 600VAC similar to Cooper Bussman® LP-CC Series.

Auxiliary Power Input on M1 Terminals

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

18 20

Line 1

Line 2 /Neutral

Fuses

Watlow - ASPYRE 300A to 700A Power Controller • 29 • Chapter 3 Wiring

Page 30

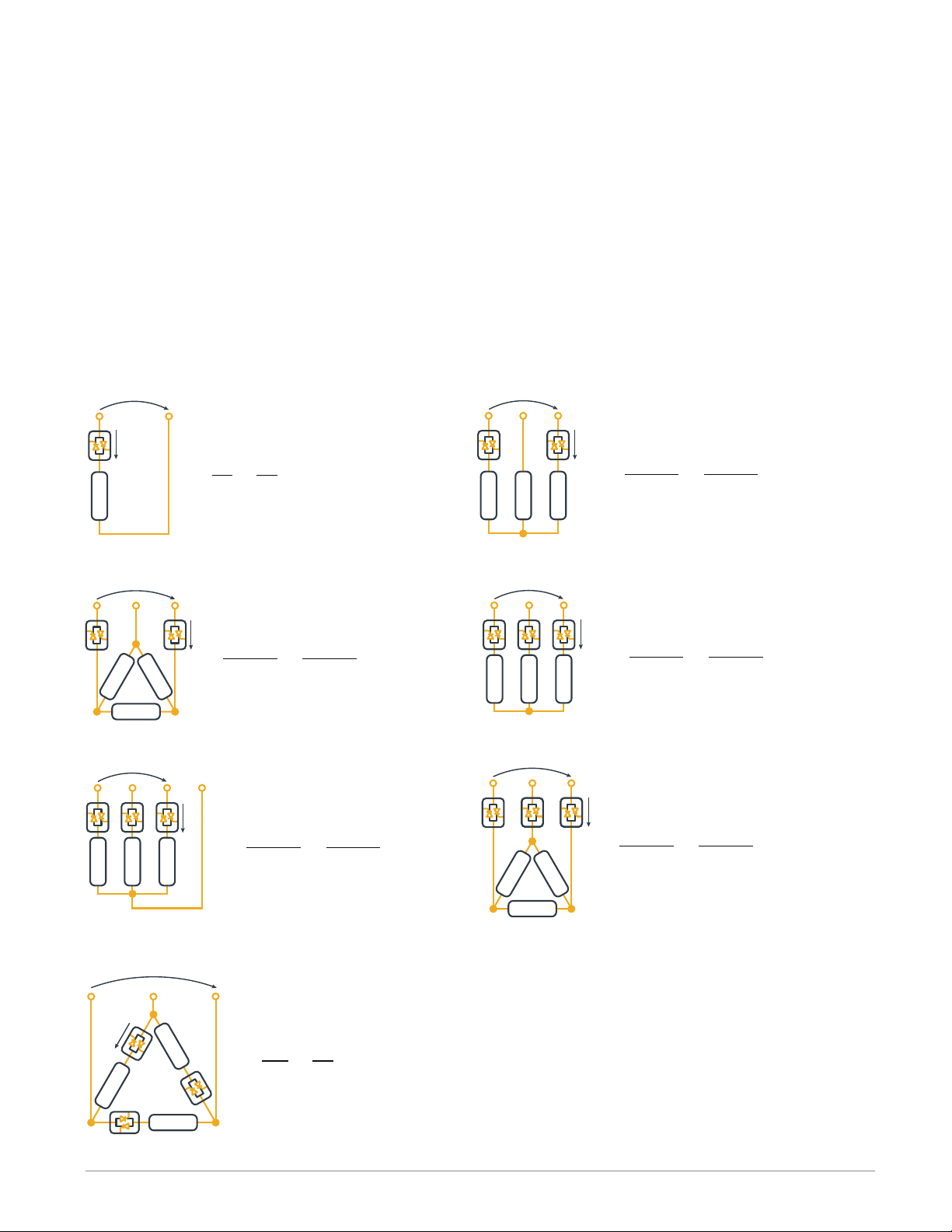

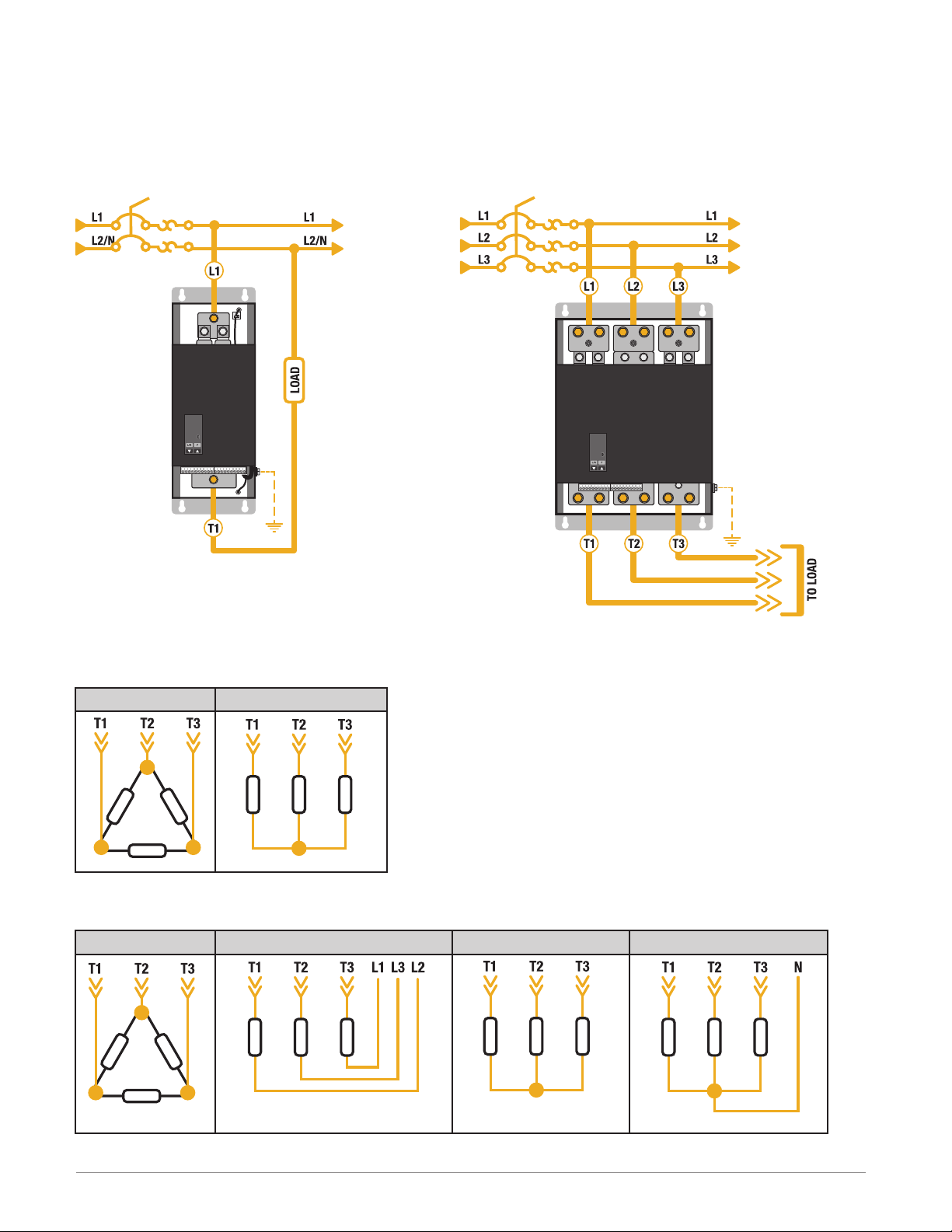

Wiring the Line Power and Load

Line Power Connection Locations

The following illustrations indicate how to connect line power and loads.

Single-Phase Line Power and Load Wiring

Three-Phase Line Power and Load Wiring

Three-Phase, Two-Leg Load Wiring Congurations

Delta Wye

Three-Phase, Three-Leg Load Wiring Congurations

Delta Open Delta Wye Grounded Wye

Watlow - ASPYRE 300A to 700A Power Controller • 30 • Chapter 3 Wiring

Page 31

4

Initial Setup

This chapter provides the information necessary to begin using your ASPYRE power controller.

The procedures below call for setting and verifying parameter settings. These parameters can be set via the

control panel or using the ASPYRE Congurator software. To learn more about how to use the control panel to

access and set parameters on the menus; see “Menu Navigation” on page 36.

Using the ASPYRE Configurator Software

The power controller can be set up and monitored via the menus using the on-board keypad and display or using

a computer running the ASPYRE Congurator software. The ASPYRE Congurator software is available on the

Watlow website.

To use the software:

1. Download and run the ASPYRE Congurator software installa-

tion le and follow the on-screen instructions.

2. Connect a USB cable (Watlow p/n 0219-0480-0000) between

a USB host port on the computer and the micro USB port on

the front of the ASPYRE power controller.

3. Wait for the communications port installation to complete.

4. Launch the ASPYRE Congurator software

5. From the Setting menu, choose Serial Port.

6. Choose the communications port and click OK.

7. For a single-phase model select ASPYRE or for a 2-leg or

3-leg model, select ASPYRE 3PH.

8. Click Upload from unit.

9. Click Read.

10. In the Selection list under power controller click the menu to access.

ASPYRE Congurator Software

Configuring the ASPYRE Power Controller

The ASPYRE power controller includes many advanced features. You can learn more about these in the Features

chapter of the manual. In order to get the optimum performance in your application, be sure to verify or adjust

these settings before beginning operation.

Initial setup:

1. Nominal current and voltage

2. Firing type

3. Feedback type

4. Input for power request / set point

5. Enable input, if used

6. Current limit (DT1 and DT3 models), if used

Watlow - ASPYRE 300A to 700A Power Controller • 31 • Chapter 4 Initial Setup

Page 32

Set Nominal Current and Voltage

In order for the power controller to function correctly, set the nominal line voltage and load current. To calculate the nominal load current see “Digits 6, 7 and 8, Amperage” on page 13. Otherwise it can be determined

empirically after completing the installation and other setup steps by applying 100% power and measuring the

resulting current.

On this menu... set this parameter... to the...

Setup Nominal V nominal line voltage (RMS)

1

Setup Nominal I nominal current (RMS) in each leg of the load at 100% power

2

Set the Firing Type

Choose the ring type in order to optimize the performance of the load.

On this menu... set this parameter... to the...

Adv Setup Firing type of power switching appropriate for your load

Also on the Adv Setup menu set the parameters that adjust the behavior of the ring type you chose.

For... set this parameter... to the...

Phase Angle Soft Start Soft Start amount of time for the output to ramp to the set point

Burst Fire Start Ramp Start Ramp number of half cycles over which each burst should ramp

Burst Fire

Burst Fire Start Ramp

Burst Fire Delay Trigger

BF Strt Rmp Delay Trigger

Burst Fire Delay Trigger

BF Strt Rmp Delay Trigger

Zero Crossing Cycle Time duration of each on-off cycle

Half Cycle Safety Ramp

Min Cycles fewest number of cycles the output should be on or off

Delay ring delay from zero cross in degrees

Half Cycles to Delay number of half-cycles to which to apply the delayed ring

Safety Ramp Duration

Safety Ramp Off

Time

amount of time for the output to ramp to the set point

minimum amount of off-time before ramping is needed

Set the Feedback

Choose the variable to use for feedback to optimize the performance of the application.

On this menu... set this parameter... to the...

Adv Setup Feedback type of measured feedback appropriate for your application

Configure the Input for Power Demand / Set Point

The signal to analog input 1 indicates the desired percent of full output the power control should deliver to the

load.

Congure the power request / set point signal:

On this menu... set this parameter... to the type of signal and range...

0-10 V / 10k pot (0 to 10 VDC or potentiometer)

Hardware Analog In 1

NOTE! This procedure assumes the analog input signal wiring, if used has been connected and that the signal

can be set to various values as needed to perform the procedure. See “Set Point” on page 67.

Watlow - ASPYRE 300A to 700A Power Controller • 32 • Chapter 4 Initial Setup

4-20mA (4 to 20 mADC)

0-20mA (0 to 20 mADC)

Page 33

Configure the Enable Input

By default digital input 1 is used to enable the power controller.

To verify that digital input 1 is congured to enable the power controller:

• On the Hardware menu verify that Digital In 1 Function is set to Enable.

NOTE! If the power controller is used to switch power on and off simply following an on-off or time propor-

tioned signal, that signal can be connected to the enable input and the set point can be set to 100%.

Configure the Current Limit

For models with this option the current limit feature prevents the current from exceeding the user-set current

limit. As the current approaches the limit, the power controller decreases its output to avoid exceeding the current limit. The current limit set point can be set with the I Limit parameter or by an analog input.

CAUTION: This procedure must be performed only by qualied persons.

CAUTION: This procedure requires turning on full power to the load. This should only be performed once the

installation is complete and when it is safe to provide full power.

NOTE! this procedure assumes the analog input signal wiring, if used has been connected and that the signal

can be set to various values as needed to perform the procedure. See “Set Point, Feedback or Current Limit

(Analog Input 2)” on page 26.

ATTENTION : Cette procédure ne doit être effectuée que par le personnel qualié.

ATTENTION : Cette procédure nécessite la mise sous tension totale de la charge. Cela ne doit être effectué

qu’une fois l’installation terminée et lorsque la puissance maximale peut être fournie en toute sécurité.

To limit the current using the parameter setting:

1. On the Hardware menu set I Limit Local / Remote to Local.

2. On the Operator menu set I Limit to 0%.

3. Enable the power controller and set the power demand set point to 100%.

4. Gradually increase the current limit set point until the RMS current is at the maximum desired value.

5. Disable the power controller.

To limit the current using the signal to analog input 2:

1. On the Hardware menu set Analog In 2 for the type of signal and range:

0 to 10 VDC or 10k potentiometer

4 to 20 mADC

0 to 20 mADC

2. On the Hardware menu set the Analog In 2 Function to I Limit.

3. On the Hardware menu set the I Limit Local / Remote to Analog In 2.

4. Set the signal to the analog input to the minimum value (typically 0 V).

5. Enable the power controller and set the power demand / set point to 100%.

6. Gradually increase the signal to the analog input until the RMS current is at the maximum desired value.

7. Disable the power controller.

0-10 V / 10k

4-20mA

0-20mA

Watlow - ASPYRE 300A to 700A Power Controller • 33 • Chapter 4 Initial Setup

Page 34

Page 35

5

Operation

This chapter describes how to operate the controller using its control panel interface, how to access and navigate the menus and how to interpret the indicators and alarm messages.

Control Panel

The control panel is located on the front of the power controller. The display indicates the alarms, input and

output signals, and by navigating the menus with the keypad, provides access to the conguration parameters.

Iout0.0A

SP 100%

Output Current RMS Output Voltage (RMS)

On the home page the keys are used as follows:

Press... to...

Function Scroll through the parameters on the home page

Local / Remote Switch between local and remote set point for power demand

Up Increment power demand set point when set to local

Down Decrement power demand set point when set to local

Vout0.0V

SP 100%

Pout0%

SP 100%

Output Power

(Average)

Aux High

ALARM

Alarms

+

To view the status parameters:

• Press function once to advance from one parameter to the next

To set the set point locally:

1. Press local / remote (Note: indicator 1 ashes steadily when set point is set locally.)

2. Use down and/or up to set the local set point.

Watlow - ASPYRE 300A to 700A Power Controller • 35 • Chapter 5 Operation

Press and hold for about two seconds to access the menus

Page 36

Menu Navigation

The menus are accessible using the control panel keypad and display.

Home

Page

Choose

Menu

Enter Password Choose Parameter Edit Parameter

+

(~2 sec.)

(wrong password)

(~2 sec.)

+

To access a menu and edit a setting:

1. Press and hold local / remote and function together + until the upper display ashes Menu.

2. Press up to choose the menu. (Press down if you overshoot the menu you want.)

3. Press function to advance to the password prompt.

4. Use up and/or down to set the password (see the table).

5. Press function to enter the password and advance to the rst parameter on the menu.

6. Press up to advance to the next parameter and repeat to reach the desired parameter.

7. Press function to start editing the parameter. The parameter name ashes in the upper display.

8. Use up and/or down to change the parameter setting.

9. Press function to stop editing the parameter. The parameter name stops ashing.

10. Press and hold local / remote and function together + for about two seconds to exit the menus.

Menu Password Parameters Used To...

Operator 0 View measured values and basic settings including current, voltage and set point

Setup 2 Congure the power controller for the load

Adv Setup 10

Hardware 5

Comm 3 Congure communication parameters

Monitor 0

Congure power switching, closed-loop control of power and adjustable settings for

data logging and heater bakeout

Congure the functions of the analog and digital inputs and outputs, and the re-

transmission parameters

View the states of digital inputs, values of analog inputs and information about the

power controller such as serial number and software version

Watlow - ASPYRE 300A to 700A Power Controller • 36 • Chapter 5 Operation

Page 37

Menu Listing

Aux High

ALARM

The table below lists the parameters found on each menu. See “Parameter Reference” starting on page 53 for

descriptions and the other details of each parameter.

Operator Setup Advanced Setup Hardware Communication Monitor

Set Point Out Scale Firing Analog In 1 Port 1 Baud Digital In 1

V Output I Limit

I Output Nominal V Soft Start Analog In 2 Function Port 2 Baud Enable

Leg 1 I Output1Nominal I Safety Ramp Off Time Digital In 1 Function Port 2 Access Set Point Source

Leg 2 I Output1Soft Start Safety Ramp Duration Digital In 2 Function Watchdog Analog In 1

Leg 3 I Output1Remote SP Start Ramp Alarm Function Watchdog Reset Time Analog In 2

Power Half Cycles to Delay2I Limit Local / Remote2Wi-Fi Address

V Input Delay Retransmit

Frequency Cycle Time Retransmit Scale

Power Factor Feedback Retransmit Type

Load Ω Prop Band Power Startup Display Host Name Max Current

2

I Limit

Out Scale Prop Band Current

Nominal V Integral Current

Nominal I Htr Break Sensitivity MM/DD/YY

Shaded items are read only.

1

DT2 and DT3 models

2

DT1 and DT3 models with the current limit option

3

Models with corresponding options (retransmit, Ethernet, Wi-Fi and/or real-time clock)

2

Min Cycles Analog In 2 Port 1 Address Digital In 2

3

3

3

3

Integral Power Port 2 Address Aux Voltage

2

2

Htr Break Delay HH:MM:SS

Logging kW Real Time

Logging Interval kW Total

Heater Bakeout

Bakeout Ramp Time

Bakeout Current

Bakeout Off Time

Neutral Connected

2

2

2

2

1

Ethernet Address

Ethernet Subnet

Ethernet Gateway

Port 2 Serial Number

3

Wi-Fi

3

3

3

Version

Release

Unit Type

Max Voltage

SCR Temperature

3

3

kVA Real Time

Thermal Alarm Counter

Indicators (LEDs)

The four indicators on the control panel show the general state of the power controller.

Flashing Power output set locally or via communications

Local/Remote

1

Off Power output set remotely (via analog input)

On Output enabled

Enable

2

Off Output disabled

Communication Flashing Active communications

3

On Active alarm

Alarm

4

Off No alarm

Watlow - ASPYRE 300A to 700A Power Controller • 37 • Chapter 5 Operation

Page 38

Alarms and Messages

The power controller display indicates certain modes of operation and alarms by ashing a message on the top

display.

Alarm or Message DT1 DT2 DT3 Description

Aux High X X X Aux voltage too high

Aux Line Loss X X X Auxiliary power is not detected

Aux Low X X X Aux voltage too low

Bakeout X X Heater bakeout function is active

Heater Break X X X Heater break alarm

I Limit X X Output reduced by current limit feature

PH Loss X X One or more phases of the line power are disconnected

SD Card Error X X X SD card error

SCR Short X X X Shorted SCR causing output to be on continuously

SCR Over Temp X X X Thermal switch over temperature

Unbalance Load X X One or more legs of the load are open

Watchdog X X X Communication watchdog error

Watlow - ASPYRE 300A to 700A Power Controller • 38 • Chapter 5 Operation

Page 39

6

Using ASPYRE Configurator

This chapter explains how to use the ASPYRE Congurator software as an alternative to using the power controller’s keypad and display for viewing and setting parameters as well as the advanced features not available via

the power controller’s onboard user interface.

Overview

This section describes the scope and intent of the ASPYRE Congurator software.

Typical Uses

The software may be used during commissioning to set and make a record of settings that determine how the

power controller operates and performs; to copy or clone the setup or one power controller to another; on a

day-to-day basis to monitor operation and power usage; if necessary, to examine performance in more detail to

determine if any corrective actions are needed; or to restore the setup of the power controller.

Communicating with Power Controllers

ASPYRE Congurator software can communicate with ASPYRE power controllers via USB or RS-485. When initially

commissioning the power controller it is convenient to connect a computer to the power controller via the USB

port located below the control panel’s display. The power controller’s electronics are powered by the computer

via the USB connection when the auxiliary line power is turned off. This makes it possible to examine and congure the power controller’s settings prior to applying power to the panel.

USB is designed to connect consumer electronics and peripheral devices such as cameras and keyboards to computers in home and ofce environments; it is not an industrial communications protocol. To continue communicating once the panel door is closed and line power is on, connect the computer to the power controller via the

RS-485 communications port. See “Communication Connections” on page 28.

Recipes

A recipe is a computer le which contains a setting for each user adjustable parameter in a power controller. A

recipe can be used to congure a power controller for a particular application or job. A recipe can be used to

copy the settings of one power controller to another. A recipe can be created by uploading the settings from a

power controller to the ASPYRE Congurator software and saving it as a le on the computer. A power controller

can be congured by downloading a saved recipe from the ASPYRE Congurator software to the power controller.

How To

This section provides step-by-step procedures for common tasks.

Communicate For the First Time

These procedures are for installing the software and establishing communications for the rst time.

To install ASPYRE Congurator:

1. Locate the installer:

• On www.watlow.com linked to the ASPYRE power controller product page. Download the installer to your

computer

• On the Controls Tools DVD ROM disk.

Watlow - ASPYRE 300A to 700A Power Controller • 39 • Chapter 6 Using ASPYRE Configurator

Page 40

2. Double-click the installer program.