Page 1

ANAFAZE 12LS

Installation And Operation Manual

Revision 3

August 1, 1991

Copyright (c) 1990

Watlow Anafaze, Incorporated

334 Westridge Dr

Watsonville, CA 95076

Phone: 831-724-3800

Facsimile: 831-724-0320

All RIGHTS RESERVED: No part of this publication may be reproduced, stored in a retrieval

system or transmitted in any form by any means; electronic, mechanical, photo copying,

recording, or otherwise, without the prior written permission of ANAFAZE, Inc.

Printed in U.S.A.

Page 2

STATEMENT OF WARRANTY

ANAFAZE, Incorporated warrants that the Products furnished under this Agreement will be free

from material defects in material and workmanship for a period of one year from the date of

shipment. The customer shall provide notice to ANAFAZE, Incorporated of any defect within

one week after the Customer's discovery of such defect. The sole obligation and liability of

ANAFAZE, Incorporated under this warranty shall be to repair or replace, at its option, without

cost to the Customer, the product or part which is so defective and as to which such notice is

given.

Upon request by ANAFAZE, Incorporated, the product or part claimed to be defective shall

immediately be returned at the Customer's expense to ANAFAZE, Inc. Replaced or repaired

products or parts will be shipped to the Customer at the expense of ANAFAZE, Incorporated

There shall be no warranty or liability for any products or parts which have been subject to

misuse, accident, negligence, failure of electric power or modification by the Customer without

ANAFAZE, Incorporated's written approval. Final determination of warranty eligibility shall be

made by ANAFAZE, Incorporated. If a warranty claim is considered invalid for any reason, the

Customer will be charged for services performed and expenses incurred by ANAFAZE,

Incorporated in handling and shipping the returned unit.

As to replacement parts supplied or repairs made during the original warranty period, the

warranty period of the replacement or repaired part shall terminate with the termination of the

warranty period with respect to the original product or part.

THE FOREGOING WARRANTY CONSTITUTES THE SOLE LIABILITY OF

ANAFAZE INCORPORATED AND THE CUSTOMER'S SOLE REMEDY WITH

RESPECT TO THE PRODUCTS AND IS IN LIEU OF ALL OTHER WARRANTIES,

LIABILITIES AND REMEDIES. EXCEPT AS THUS PROVIDED, ANAFAZE, INC.

DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

PLEASE NOTE EXTERNAL SAFETY DEVICES MUST BE USED WITH THIS

EQUIPMENT SEE WARNING ON NEXT PAGE.

PLEASE -- See last page to register your name and address with ANAFAZE for technical

updates.

ii

Page 3

WARNING

ANAFAZE HAS MADE EFFORTS TO ENSURE THE RELIABILITY AND SAFETY OF

THE 12LS AND PROVIDE RECOMMENDATIONS FOR ITS SAFE USE IN SYSTEMS

APPLICATIONS. PLEASE NOTE THAT IN ANY APPLICATION, FAILURES CAN

OCCUR THAT WILL RESULT IN FULL CONTROL OUTPUTS OR OTHER

OUTPUTS THAT MAY CAUSE DAMAGE OR UNSAFE CONDITIONS IN THE

EQUIPMENT OR PROCESS CONNECTED TO THE ANAFAZE 12LS.

GOOD ENGINEERING PRACTICES, ELECTRICAL CODES, AND INSURANCE

REGULATIONS REQUIRE INDEPENDENT, EXTERNAL, SAFETY DEVICES BE

USED TO PREVENT POTENTIALLY DANGEROUS OR UNSAFE CONDITIONS

ASSUMING THAT THE ANAFAZE 12LS CAN FAIL WITH OUTPUTS FULL ON, OR

OUTPUTS FULL OFF, OR OTHER CONDITIONS THAT WOULD BE UNEXPECTED.

THE 12LS INCLUDES A RESET CIRCUIT THAT WILL SET THE CONTROL

OUTPUTS OFF OR TO THE DATA STORED IN MEMORY IF THE

MICROPROCESSOR RESETS -- NORMALLY THE RESULT OF A POWER FAILURE

AND POWER RETURN. IF THERE IS ANY POSSIBILITY THAT A RESTART

BASED ON MEMORY WILL BE UNSAFE, THE 12LS MUST BE PROGRAMMED TO

START WITH OUTPUTS OFF. FOR ADDITIONAL SAFETY, THE COMPUTER OR

OTHER HOST DEVICE SHOULD BE PROGRAMMED TO AUTOMATICALLY

RELOAD THE DESIRED OPERATING CONSTANTS, OR SAFE VALUES FOR THE

PROCESS, UPON RETURN OF SYSTEM POWER. IN ANY EVENT, THESE SAFETY

FEATURES DO NOT ELIMINATE THE NEED TO PROVIDE EXTERNAL,

INDEPENDENT SAFETY DEVICES IN POTENTIALLY DANGEROUS OR UNSAFE

CONDITIONS.

ANAFAZE ALSO OFFERS ANASOFT, AN OPTIONAL SOFTWARE PROGRAM FOR

IBM PC COMPATIBLE COMPUTERS THAT WILL RELOAD THE 12LS WITH THE

CURRENT VALUES IN THE COMPUTER MEMORY UPON A RESET. THE USER

MUST INSURE THAT THIS WILL BE SAFE FOR THE PROCESS. AGAIN, USING

THIS FEATURE STILL DOES NOT ELIMINATE THE NEED FOR APPROPRIATE

EXTERNAL, INDEPENDENT SAFETY DEVICES.

PLEASE CONTACT ANAFAZE IMMEDIATELY IF THERE ARE ANY QUESTIONS

ABOUT SYSTEM SAFETY

iii

Page 4

ANAFAZE 12LS

TABLE OF CONTENTS

1.0 INTRODUCTION..................................................................................................................1-1

2.0 SPECIFICATIONS ................................................................................................................2-1

2.1 Analog Inputs......................................................................................................................2-1

2.2 Control Capability...............................................................................................................2-2

2.3 Digital Outputs....................................................................................................................2-2

2.4 Digital Inputs.......................................................................................................................2-2

2.5 Serial Interface ....................................................................................................................2-2

2.6 Power Supply......................................................................................................................2-2

3.0 INSTALLATION ...................................................................................................................3-1

3.1 PHYSICAL CONSIDERATIONS.....................................................................................3-1

3.1.1 MOUNTING...............................................................................................................3-2

3.1.2 EXTERNAL WIRING .................................................................................................3-3

3.1.3 GENERAL WIRING REQUIREMENTS ....................................................................3-4

3.1.4 RECOMMENDED CABLES P/N ...............................................................................3-6

3.1.5 NOISE SUPPRESSION FOR DIGITAL OUTPUTS...................................................3-6

3.2 TERMINAL BLOCK AND CONNECTOR LAYOUT .....................................................3-7

3.3 ANALOG INPUTS...........................................................................................................3-10

3.3.1COMMON MODE VOLTAGE ..................................................................................3-10

3.3.2NORMAL MODE VOLTAGE ...................................................................................3-10

3.3.3GROUNDING .............................................................................................................3-10

3.3.4 SOURCE IMPEDANCE ...........................................................................................3-10

3.3.5 INPUT SCALING ......................................................................................................3-11

3.3.6 VOLTAGE INPUTS ..................................................................................................3-12

3.3.7MILLIAMP INPUTS...................................................................................................3-12

3.3.8THERMOCOUPLE INPUTS......................................................................................3-12

3.3.9RTD INPUTS ..............................................................................................................3-13

3.3.10 INFRARED NON-CONTACT TEMPERATURE SENSORS................................3-13

3.3.11 SCALING AND CALIBRATION............................................................................3-14

3.3.12 DIAGRAMS OF TYPICAL INPUTS ......................................................................3-14

3.4 CONTROL OUTPUTS.....................................................................................................3-14

3.4.1 PID CONTROL AND ALARM OUTPUTS CONNECTIONS.................................3-15

3.4.2 PID OUTPUT LIMITING ..........................................................................................3-15

3.5 COMPUTER SERIAL COMMUNICATIONS................................................................3-16

3.5.1 RS-232 CONNECTIONS...........................................................................................3-16

3.5.2 OTHER RS-232 LINES .............................................................................................3-16

3.5.3 RS-485 DESCRIPTION.............................................................................................3-17

4.0 FRONT PANEL OPERATION AND DISPLAYS................................................................4-1

4.1 FRONT PANEL KEYS ......................................................................................................4-3

4.2 DISPLAYS..........................................................................................................................4-4

4.2.1 BAR GRAPH DISPLAY..............................................................................................4-4

4.2.2 SINGLE LOOP DISPLAY...........................................................................................4-5

4.2.3 SCANNING DISPLAY................................................................................................4-6

4.2.4 ALARM DISPLAY ......................................................................................................4-7

4.3 GENERAL PROGRAMMING AND EDITING................................................................4-8

iv

Page 5

4.4 OPERATIONAL MENUS..................................................................................................4-9

4.4.1 CHANGE SETPOINT..................................................................................................4-9

4.4.2 SET LOOP TO MANUAL/AUTO.............................................................................4-10

4.4.3 ADJUSTING OUTPUT LEVELS MANUALLY......................................................4-10

4.5 SETUP MENUS ...............................................................................................................4-11

4.5.1 SETUP GLOBAL PARAMETERS?..........................................................................4-13

4.5.2 SETUP LOOP INPUT................................................................................................4-19

4.5.3 SETUP LOOP CONTROL PARAMETERS .............................................................4-23

4.5.4 SETUP LOOP OUTPUTS..........................................................................................4-25

4.5.5 SETUP ALARMS ......................................................................................................4-28

4.5.6 MANUAL I/O TEST..................................................................................................4-32

4.6 RAMP AND SOAK OPTION ..........................................................................................4-34

4.6.1 DESCRIPTION ..........................................................................................................4-35

4.6.2 RAMP/SOAK FRONT PANEL DISPLAY ...............................................................4-37

4.6.3 PROFILE STATUS DISPLAY ..................................................................................4-38

4.6.4 PROFILE SELECTION MENU.................................................................................4-38

4.6.5 PROFILE TIME DISPLAY........................................................................................4-39

4.6.6 CYCLE COUNT DISPLAY.......................................................................................4-40

4.6.7 PROFILE OPERATION MENU................................................................................4-40

4.6.8 RESET PROFILE.......................................................................................................4-41

4.7 SETUP RAMP/SOAK PROFILE.....................................................................................4-45

4.7.1 SELECT A PROFILE FOR EDITING.......................................................................4-45

4.7.2 COPY ANOTHER PROFILE ....................................................................................4-47

4.7.3 EDIT TOLERANCE ALARM TIME ........................................................................4-47

4.7.4 EDIT READY SETPOINT.........................................................................................4-48

4.7.5 EDIT READY EVENT STATES...............................................................................4-49

4.7.6 EDIT EXTERNAL RESET........................................................................................4-50

4.7.7 EDIT SEGMENT NUMBER .....................................................................................4-50

4.7.8 EDIT SEGMENT TIME.............................................................................................4-51

4.7.9 EDIT SEGMENT SETPOINT ...................................................................................4-51

4.7.10 EDIT SEGMENT EVENTS.....................................................................................4-52

4.7.11 EDIT EVENT OUTPUT NUMBER ........................................................................4-52

4.7.12 EDIT EVENT OUTPUT STATE.............................................................................4-53

4.7.13 EDIT SEGMENT TRIGGERS.................................................................................4-54

5.0 PID CONTROL......................................................................................................................5-1

5.1 CONTROL MODES..........................................................................................................5-1

5.1.1 REVERSE-DIRECT ACTION....................................................................................5-1

5.1.2 HEAT/COOL DUAL OUTPUTS................................................................................5-1

5.1.3 CONTROL OUTPUTS ...............................................................................................5-1

5.1.4 DIGITAL OUTPUT ....................................................................................................5-1

5.1.5 DISTRIBUTED ZERO CROSSING...........................................................................5-2

5.2 TUNING PID LOOPS .......................................................................................................5-2

5.2.1 PROPORTIONAL CONTROL:..................................................................................5-2

5.2.2 PROPORTIONAL WITH INTEGRAL CONTROL:..................................................5-3

5.2.3 PROPORTIONAL W/ INTEGRAL W/ DERIVATIVE CONTROL: .........................5-3

5.2.4 OUTPUT DIGITAL FILTER: .....................................................................................5-3

5.2.5 PID TUNING CONSTANTS......................................................................................5-5

5.2.6 GENERAL PID CONSTANTS BY APPLICATION ..................................................5-6

v

Page 6

6.0 SOFTWARE ..........................................................................................................................6-1

6.1 ANASOFT .........................................................................................................................6-1

6.2 CUSTOM APPLICATION PROGRAMS.........................................................................6-1

7.0 TROUBLE SHOOTING INFORMATION ...........................................................................7-1

7.1 Stand Alone Systems ..........................................................................................................7-1

7.1.1 Checking Control Outputs............................................................................................7-1

7.1.2 Checking Digital I/O.....................................................................................................7-1

7.2 Computer Supervised Systems............................................................................................7-1

7.2.1 Computer Problems ......................................................................................................7-2

7.2.2 Computer Software.......................................................................................................7-2

7.2.3 User Written Software ..................................................................................................7-2

7.2.4 ANASOFT....................................................................................................................7-2

7.2.5 Communications Problems...........................................................................................7-3

7.2.6 Serial Interface..............................................................................................................7-3

8.0 SOFTWARE COMMAND STRUCTURE............................................................................8-1

9.0 GLOSSARY OF TERMS ......................................................................................................9-1

vi

Page 7

vii

Page 8

1.0 INTRODUCTION

The ANAFAZE 12LS is a powerful 1/8th DIN controller that delivers 12 fully independent loops

of PID control. It functions as both a stand alone controller and as the key element in computer

supervised data acquisition and control systems. An LCD front panel display and a touch keypad

are available for local entry of control and other operating parameters. The ANAFAZE 12LS

can also be supervised by a computer or programmable controller through the standard serial

interface.

The ANAFAZE 12LS delivers critical flexibility needed for multiple loop industrial and other

control applications:

Direct Connection of Mixed Sensors: Versatile analog inputs allow direct connection of

most industrial sensors. Thermocouple inputs include reference junction compensation,

linearization, upscale break detection, and a choice of °F or °C display.

Automatic Scaling: All sensors can be automatically scaled by entering any two

measurement points. For example, to scale a pressure sensor, enter two points such as 28%

is 80 PSI, and 82% is 260 PSI. All subsequent readings, and entries such as setpoint and

alarms will be in PSI.

Selectable Control Outputs: Each digital control output can be selected as: on/off, time

proportioning, or distributed zero crossing. Each loop can be independently set for on/off,

P, PI, or PID control with reverse acting [heat] or direct acting [cool] output.

Alarms -- Complete Process Monitoring: For process monitoring a unique alarm

capability is included. A deviation band alarm, and high and low process [fixed] alarms

can be independently set for each loop. In addition to global annunciator digital output,

each alarm can include a single or grouped digital output. For example, the digital output

from all the high process alarms can be directed to a single output for automatic process

shutdown.

Front Panel or Computer Operation: Controller operation and setup is possible from

the front panel or from a local or remote computer. ANAFAZE offers ANASOFT, an IBM

PC or compatible, menu driven program to set the ANAFAZE 12LS parameters. In

addition, ANASOFT features graphic trend plotting, process overviews, printouts, and data

archiving in LOTUS compatible files.

Multiple Job Storage: Up to 8 jobs can be stored in protected memory and selected with

a single entry. Each job is a set of operating conditions, including setpoints and alarms.

Thus if a single oven is producing multiple products, entry of the job number will setup all

the loops. Dual Output Standard: The ANAFAZE 12LS includes dual control outputs

for each loop with a second set of control constants for heat/cool applications.

Optional Ramp and Soak: The ANAFAZE 12LS is also available with a built in

powerful ramp and soak programmer for batch processing.

Intelligent Front Panel Delivers Convenient Operation

1-1

Page 9

The ANAFAZE 12LS front panel provides an intelligent method for both viewing the process

conditions and operating the controller. Displays show information in increasing detail: bar graph

summary, single loop displays, and detailed guided setup menus. For operating security, all front

panel entries can be password protected with two levels. With the panel "unlocked" common

operator changes, such as setpoint or manual/auto, are made easier with single dedicated keys.

Detailed setup requires a password, and entries are made on guided menus. The result is a

controller that is both easy and logical to use.

The front panel features a two line alphanumeric LCD display. Different process displays are

quickly selected with the front panel push-buttons:

Bar Graph Display: Provides a system overview by displaying a deviation bar graph for

each loop. Loop status including acknowledged alarms, manual or auto are also displayed.

Single Loop Display: Highlights the detailed status for any selected loop including the

process variable, engineering units, the setpoint, any alarms, and the control output

percentage.

Scanning Display: The scanning display sequentially shows the single loop display for all

the loops.

Alarm Display: If an alarm occurs, the front panel switches to the alarm display which is

the single loop display with the alarm condition flashing. Pressing ALARM ACK stops

the flashing and allows the display to be switched to any function.

1-2

Page 10

Guided Menus Simplify Setup

The ANAFAZE 12LS directs operator and supervisor changes with guided menus. Two levels are

provided: one for operator changes and one for supervisor controller setup.

Operator Changes: Single dedicated keys are used to make process changes from the

single loop display. The setpoint can be changed, the loop can be set to auto or manual,

and ramp and soak loops can be started, held, or stopped. If the loop is set to manual, the

percent output can be changed. These changes can be locked out from the supervisor

menus if desired.

Supervisor Setup: Detailed editing is done by pressing a special sequence of keys to enter

the setup menus. The supervisor is guided through a list of functions to change:

Global? This is used to save and restore jobs, define action on power up,

communications address and baud rate, communications error checking, panel lock,

and alarm delay.

Inputs? Input sensor type, engineering units, scaling, and sample time for pulse

inputs.

Control? The loop control constants including: Proportional gain [P], Integral or

reset [I], and derivative or rate [D], and a digital output filter. For the dual outputs,

a second gain, reset, rate, filter and spread can be entered for the second output.

Output? Selects the control output including: analog, on/off, cycle time

proportioning, distributed zero crossing, and reverse [heat] or direct [cool] action.

The heat output can be directed to the terminals or ribbon connector.

Alarms? Independent deviation alarm band, high process, and low process alarms

can be set for each loop. Each alarm can be set to activate any of the digital outputs

on alarm. A deadband can be entered for each loop.

Ramp/Soak? If this option is installed up to eight, 20 segment ramp and soak

profiles can be defined.

I/O Test? This is used to check the state of the digital inputs and outputs.

1-3

Page 11

Digital Inputs and Outputs Expand Versatility

Digital inputs and outputs are provided to further enhance the ANAFAZE 12LS flexibility. Digital

outputs are provided for global alarms, systems status, individual high and low alarms, and ramp

and soak events. Digital inputs are available to control the ANAFAZE 12LS in response to

external conditions.

Annunciator Alarm Output: One of the digital outputs is setup as a global output for

connection to an annunciator. This output is turned on when any alarm occurs. The output

will be turned off when the operator acknowledges the alarm from the computer or the

front panel. New alarms will cause the output to be turned on again.

Digital Outputs: 9 digital outputs can be assigned through the front panel or the computer

as alarms or as ramp and soak events. The same output can be used by more than one

alarm or event. This allows alarms to be grouped as needed. For example output 1 could

be set to respond to a high alarm on loops 2, 4, 7, and 8 or any other combination.

Digital Inputs: 8 digital inputs can be assigned as triggers for controller functions. These

would be used to change setpoint in response to an external event or as hold/continue

inputs for ramp and soak profiles.

Ramp, Soak, and Batch Control

The ANAFAZE 12LS ramp and soak version delivers powerful batch control. Independent ramp

and soak profiles can be assigned to any or all loops. Up to 12 profiles, one for each loop, can be

stored in non-volatile memory. Each profile can have up to 20 segments with digital inputs for

triggers, digital outputs for events, assured soak limits, and unlimited repeats. The profiles can be

started, stopped, held or continued from the front panel, the computer, or through the digital

inputs. Up to 9 digital outputs can be used as events and included in any profile.

1-4

Page 12

2.0 SPECIFICATIONS

2.1 Analog Inputs

Analog Inputs 12, Solid state, common ground.

Isolation: Between inputs and ground: 10volts peak.

A/D Converter: Integrating voltage to frequency.

Range: -10 to 60mv, can be changed with scaling resistors to any range

from 0 up to 25v.

Resolution: 0.02%, greater than 12 bits.

Accuracy: 0.1% at 25°C

Calibration: Automatic zero and full scale.

Temperature Coef: Less than 100ppm/°C, 0.01%/°C.

Normal Mode Rejection: 60db at 60Hz, full scale range maximum.

Loop Update Time: 1 time per second, every input.

Thermocouple Inputs: J, K, T, B, S, and R. Measurement Ranges:

J -350 to 1500 B 150 to 3200

K -450 to 2700 S 0 to 3200

T -300 to 800 R 0 to 3210

T/C Break: Pulse type for up scale break.

Milliamp Inputs: 4-20ma, 10-50ma, 0-50ma, etc. with scaling resistors.

Infrared Inputs: Power supply included, withscaling resistors.

Source Impedance: Measurements are within specification with up to 500 ohms source

resistance.

2-1

Page 13

2.2 Control Capability

Number of Loops: 12, Dual Output.

Control Outputs: Cycle Time Proportioning, Distributed Zero Crossing, or On/Off;

all independently selectable for each loop.

Control Action: Reverse [heat] or Direct [cool], independently selectable for each

loop.

Digital Control Outputs: Nominal 5vdc at 10ma to driveoptically- isolated solid-state relays.

Cycle Time: Programmable foreach loop, 1-255 secs.

Output Resolution: 16 bits.

2.3 Digital Outputs

Number: 11

Configuration: 1 Global Alarm

9 for alarms or events.

1 not used standard PROM

2.4 Digital Inputs

Number: 9

Configuration: 8 for triggers

1 not used standard PROM

2.5 Serial Interface

Type: RS-232 or RS-485 4 wire, factory select

Isolation: RS-232: None.

RS-485: To RS-485 Specification.

Baud Rate: 2400 or 9600, menu selectable.

Protocol: Form of ANSI X3.28-1976, Compatible with Allen-Bradley PLC,

Half Duplex.

Error Check: BCC or CRC, menu selectable.

Number of Controllers: Each communications line: 32 with RS- 485, 1 with RS-232.

2.6 Power Supply

2-2

Page 14

Power input: 10 to 30VDC, 3 Watts typical, 110VAC adapter provided.

2-3

Page 15

3.0 INSTALLATION

There are some precautions that must be observed when installing ANAFAZE 12LS.

WARNING! -- ELECTRICAL SHOCK DANGER

It is very important that all system power including

the power input be disconnected before servicing the

ANAFAZE 12LS. HIGH VOLTAGE MAY BE PRESENT EVEN WHEN

POWER IS TURNED OFF! To reduce the danger of elec trical shock always mount the 12LS in an enclosure

that prevents personal contact.

Although the ANAFAZE 12LS makes measurements of input signals that are referenced to

ground, the 12LS ground and other signal lines can inadvertently have power line or other high

voltage present even if the input power is turned off. This is possible, for example, if a

thermocouple was shorted to the AC power line.

WARNING!

USE CORRECT INSULATION TRIM LENGTH AND WIRE GAUGE

The correct insulation trim length is 1/4" or 5 mm.

Care must be taken to prevent contact between wires

and the case, which is grounded. The terminal

manufacturer has UL approval for #14 to #30 (AWG).

ANAFAZE recommends using #18 or #20 AWG.

To effectively use the terminals, the wire insulation should be trimmed so that the wire fits inside

the terminal with no bare wire exposed. Stranded wire should be tinned.

WARNING! -- SUPPORT CABLES

Power, input and output cables should be supported

to reduce strain on the terminals and to prevent

wires from being pulled out.

WARNING! -- PROVIDE CLEARANCE FOR VENTILATION

Always install the 12LS such that the slots in the

housing will have unrestricted air flow. Do not

block the slots with other equipment. If temporary

covers are placed over the 12LS during wiring ensure

they are removed prior to operation.

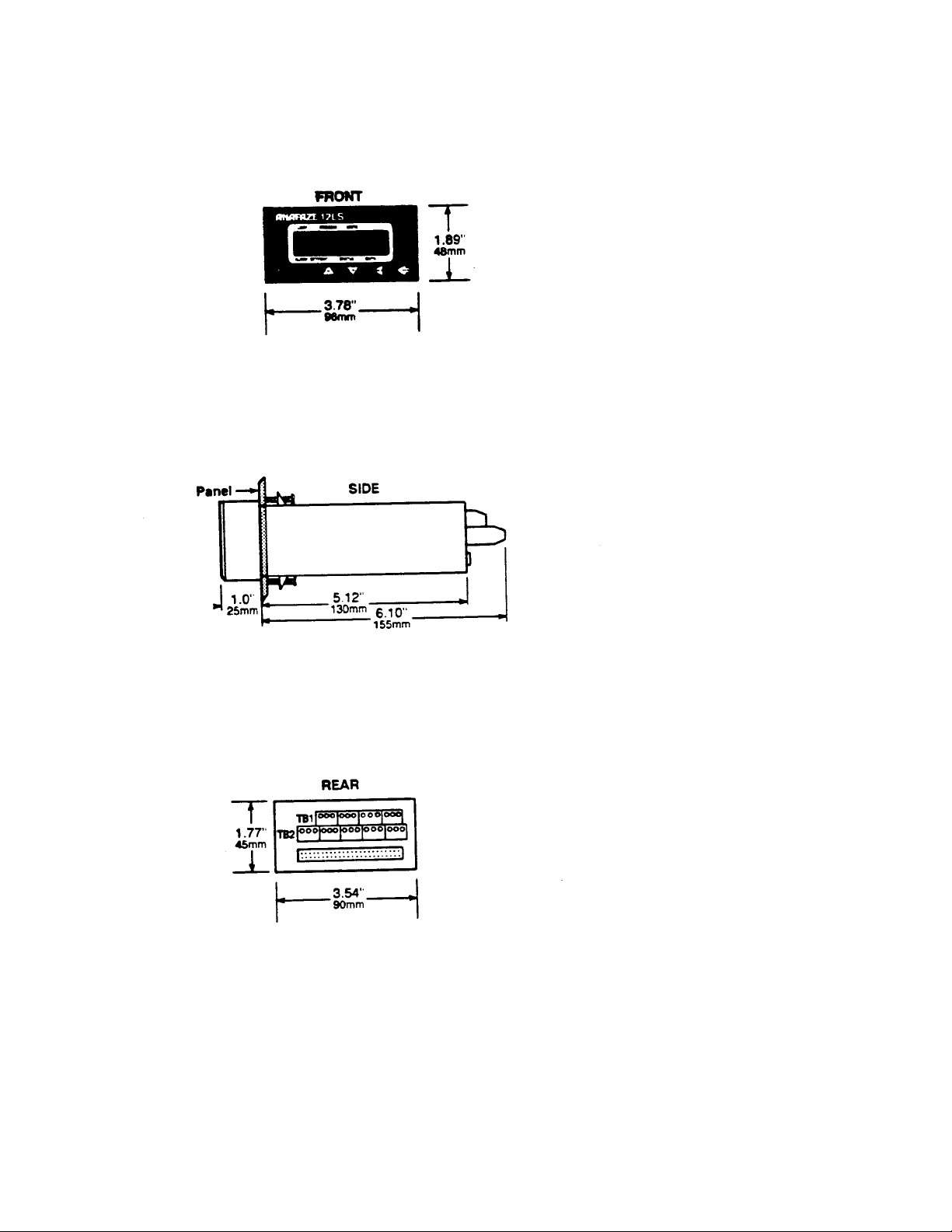

3.1 PHYSICAL CONSIDERATIONS

The ANAFAZE 12LS consists of a 1/8th DIN housing with a front plug in electronics module.

3-1

Page 16

3.1.1 MOUNTING

For optimum performance when directly connecting thermocouple inputs the unit should be

protected from thermal shocks whenever possible. This will minimize any temperature gradients

across the terminal strips and ensure the highest accuracy.

The required panel cutout is a rectangular hole 46mm x 92mm [1.81in x 3.63in]. This should be

carefully cut since the 1/8th DIN specification only allows a front panel of 48mm x 96mm [3.78in

x 3.78in] -- so there is not a lot of room for error.

After the hole is cut the ANAFAZE 12LS is inserted through the front of the panel and the top and

bottom clamps are screwed into place. If excessive vibration is anticipated a rear support may be

required both for the 12LS and the interconnecting cables.

Mounting Hole Dimensions

|-----------------------3.63+.05"----------------------------¦

----- |---------------------------------------------------------------|

¦ ¦ ¦

¦ | ¦

1.81+.05" ¦ ¦

¦ ¦ ¦

¦ ¦ ¦

¦ ¦ ¦

----- |---------------------------------------------------------------|

Dimensions are in inches.

3-2

Page 17

1/8th DIN HOUSING

3-3

Page 18

3.1.2 EXTERNAL WIRING

During wiring, it is recommended that the 12LS electronics be removed or temporary covers be put over the housing

slots to ensure pieces of wire do not enter the housing and lodge in the electronics. Always ensure that the housing is

clean when the electronics is plugged in.

The successful installation of the ANAFAZE 12LS control system will be the result of selecting the proper equipment

and the use of correct installation techniques with appropriate material. One area of concern is the wiring type and

placement of the wiring.

The wiring is selected as to the function of the wire, the installation requirements, and the possible

mechanicalelectrical problems that may occur.

The function of the wire is divided into two basic categories: INPUTS and OUTPUTS. The process control

requirements will dictate the TYPE of INPUTS and the TYPE of OUTPUTS along with the mechanical electrical

requirements of the individual installation.

As defined by ANAFAZE, the term AC power is applied to the 120 VAC control supply. High power is applied to 240

VAC or higher, primarily used for control loads.

3.1.3 GENERAL WIRING REQUIREMENTS

1. Use stranded wire. Solid wire is recommended for fixed service and tend to make intermittent connections when

moving the field wiring around for maintenance.

2. Use 18 or 20 ga. size wire. The use of 16,18,20,22, or 24 ga.is permissible also. The power requirement is not a

factor in the wire size. Only the mechanical strength and the ohmage of the wire may be factors to consider.

Smaller or larger sizes are not easily installed, may be easily broken and/or cause intermittent connections.

3. Use shielded wire. The electrical shield is used primarily to protect from unwanted electrical noise.

Normal use of the INPUT WIRING SHIELD is to connect one end only to the 120 VAC panel ground at the 12LS

panel location.

Normal use of the OUTPUT WIRING SHIELD would be to connect one end only to the 120 VAC panel

ground in the panel that the 12LS is mounted in. Actual use of the shields will be determined by the

installation requirement.

For additional noise suppression measures see NOISE SUPPRESSION FOR Digital Outputs.

3-4

Page 19

4.

Use Thermocouple Extension Wire for all thermocouple (T/C) inputs.

unshielded. When using such, the shield function cannot be utilized and only 16, 18, or 20 ga should be

used.

Install all T/C wiring in its own conduit away from AC Power and High Power wiring.

Depending on type and wire size up to 400-500 feet in length may be used to be within stated accuracy and

source impedance.

5.

Use multiconductor stranded shielded cable for analog inputs.

Most inputs will use a shielded twisted pair, but some may require a 3 wire input.

its own conduit away from AC Power and High Power wiring.

Wire sizes of 20, 22, or 24 ga. may be used.

Most T/C Ext. Wire is solid wire

Run all analog input wiring in

6.

Use multiconductor stranded shielded cable for analog outputs and PID digital outputs

mount SSR's. The analog output will normally use a twisted pair while the digital outputs will be up to 9 or 20

conductors depending on wiring techniques. All cables will be shielded. The wiring size will normally be 24

ga.

The maximum length for the digital outputs should not exceed 25 feet. The maximum length for the

analog outputs should not exceed 400 feet. All wiring must be in a separate conduit away from AC

Power and High Power wiring.

When using the 50 conductor flat ribbon cable for the I/O, use of the 50-pin connector is recommended for both ends

of the cable. The wire is too small to withstand much flexing when connected to a screw terminal.

length should not exceed 15 feet.

7. When installing communications wiring, by pulling in an extra pair, a sound power phone system could be utilized

for communications between the ANAFAZE controllers and the computer. This could be used for

maintenance, checking calibration and many other functions. A David Clark #H5030 sound powered system

has been used successfully in systems requiring this function.

8.

When installing any I/O wiring to the ANAFAZE controllers inside a panel, it should never be run in the

same bundle as AC power wiring.

Also wiring bundles of low power ANAFAZE circuits next to bundles of high power AC wiring should never

be done.

prime importance. In fact most AC voltage high power circuits are installed in a separate panel.

The physical separation of the high power circuits from the ANAFAZE controllers should be of

connected to panel

The cable

3-5

Page 20

3.1.4 RECOMMENDED CABLES P/N

Use these cables or equivalent.

|--------------------------------------------------------------|

¦ FUNCTION ¦ MFR P/N ¦ # of WIRE ¦

|--------------------------------------------------------------¦

¦ Analog Inputs ¦ Belden #9154 ¦ 2-20ga ¦

¦ ¦ Belden #8451 ¦ 2-22ga ¦

¦ ¦ ¦ ¦

¦ RTD Inputs ¦ Belden #8772 ¦ 3-20ga ¦

¦ ¦ Belden #9770 ¦ 3-22ga ¦

¦ ¦ ¦ ¦

¦ T/C Inputs ¦ T/C EXT.WIRE ¦ 2-wire ¦

¦ ¦ ¦ ¦

¦ Carbon Probe Input ¦ Belden #88760 ¦ 2-18ga ¦

¦ ¦ ¦ ¦

¦ ¦ ¦ ¦

¦ Digital PID Outputs ¦ Belden #9539 ¦ 9-24ga ¦

¦ and Digital I/O ¦ Belden #9542 ¦ 20-24ga ¦

¦ ¦ Ribbon Cable ¦ 50-wire ¦

¦ ¦ ¦ ¦

¦ Analog Outputs ¦ Belden #9154 ¦ 2-20ga ¦

¦ ¦ Belden #8451 ¦ 2-22ga ¦

¦ ¦ ¦ ¦

¦ Computer Communication ¦ Belden #9729 ¦ 4-24ga ¦

¦ --RS232,RS422,RS485, ¦ Belden #9730 ¦ 6-24ga ¦

¦ or 20ma-- ¦ Belden #9842 ¦ 4-24ga ¦

¦ ¦ Belden #9843 ¦ 6-24ga ¦

|--------------------------------------------------------------|

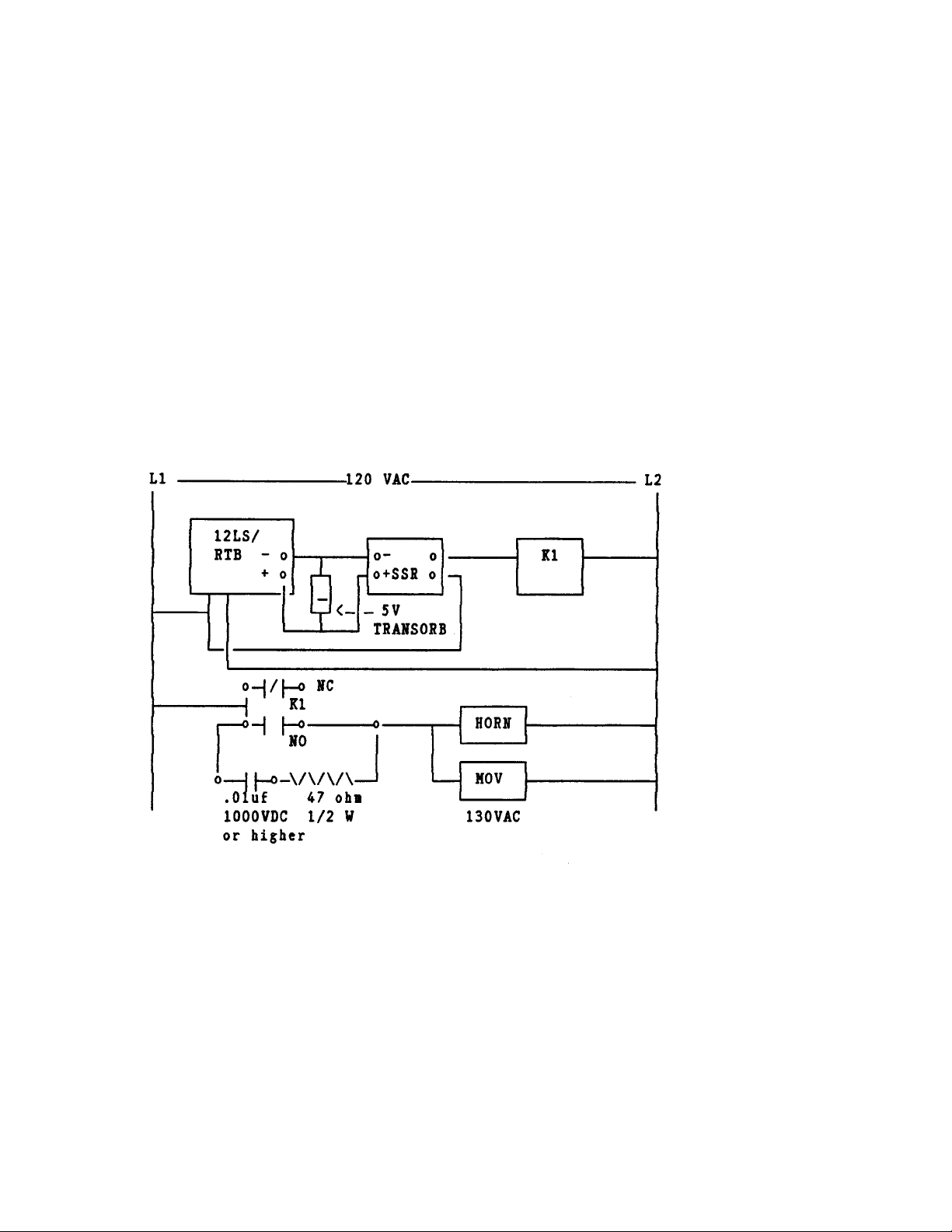

3.1.5 NOISE SUPPRESSION FOR DIGITAL OUTPUTS

When using the digital outputs from ANAFAZE multiloop controllers to energize dry contact electrical- mechanical

relays with inductive loads, generation of RFI may become a problem.

This problem may cause the display on the 8LS to blank out and then re-energize as if power had been momentary

turned off. It may also cause the CPU in the equipment to reset, thus losing the PID output levels. It may also damage

the digital output IC circuit, thus not being to energize the digital outputs. If, the IC circuit is damaged, factory repair

will be required.

The type of loads that may cause a problem are motor starters, alarm horns, etc. The RFI is generated upon opening of

the metallic relay contacts.

To correct the problem of RFI noise problems:

1. Use Solid State Relays (SSR) wherever possible in place of electrical-mechanical relays (E-M relays).

2. When using E-M relays, if possible do not mount them in the same panel as the ANAFAZE equipment.

3-6

Page 21

3. Separate the 120 vac power leads from the low level input and outputs leads from the ANAFAZE. Do not run the

digital outputs or PID control outputs leads in the same wire bundle as any 120 vac wires. Inputs leads should never be

run in the same bundle with any high power leads. See 3.3.3.

4. If, E-M relays are required and must be in the same panel as the ANAFAZE equipment, use a .01 uF at 1000 vdc or

higher vdc disk capacitor in series with a 47 ohm 1/2 W resistor across the NO contacts of the relay load contacts. This

is the most important step in suppressing RFI from relay contacts. This network is known as arc suppresser or snubber

networks.

5. Use of other voltage suppressing devices may also be used, but are not normally required. A device known as a

MOV rated at 130 vac for 120 vac control circuits may be placed across the load. This will limit the peak ac voltage to

about 180 vac. A device known as a transorb (back to back zeners) may be used across the digital output. The rating of

5 vdc should be used. This will limit the dc voltage to 5 vdc on the digital output loop.

See diagrams for proper placement of the above devices. The parts for RFI suppression are available from ANAFAZE.

The above steps should eliminate any noise problems that might be present with using E-M relays. If, problems

persists and/or any questions about the above steps arises, please call ANAFAZE.

DIAGRAM OF TYPICAL DIGITAL OUTPUTS WITH RFI SUPPRESSION

3-7

Page 22

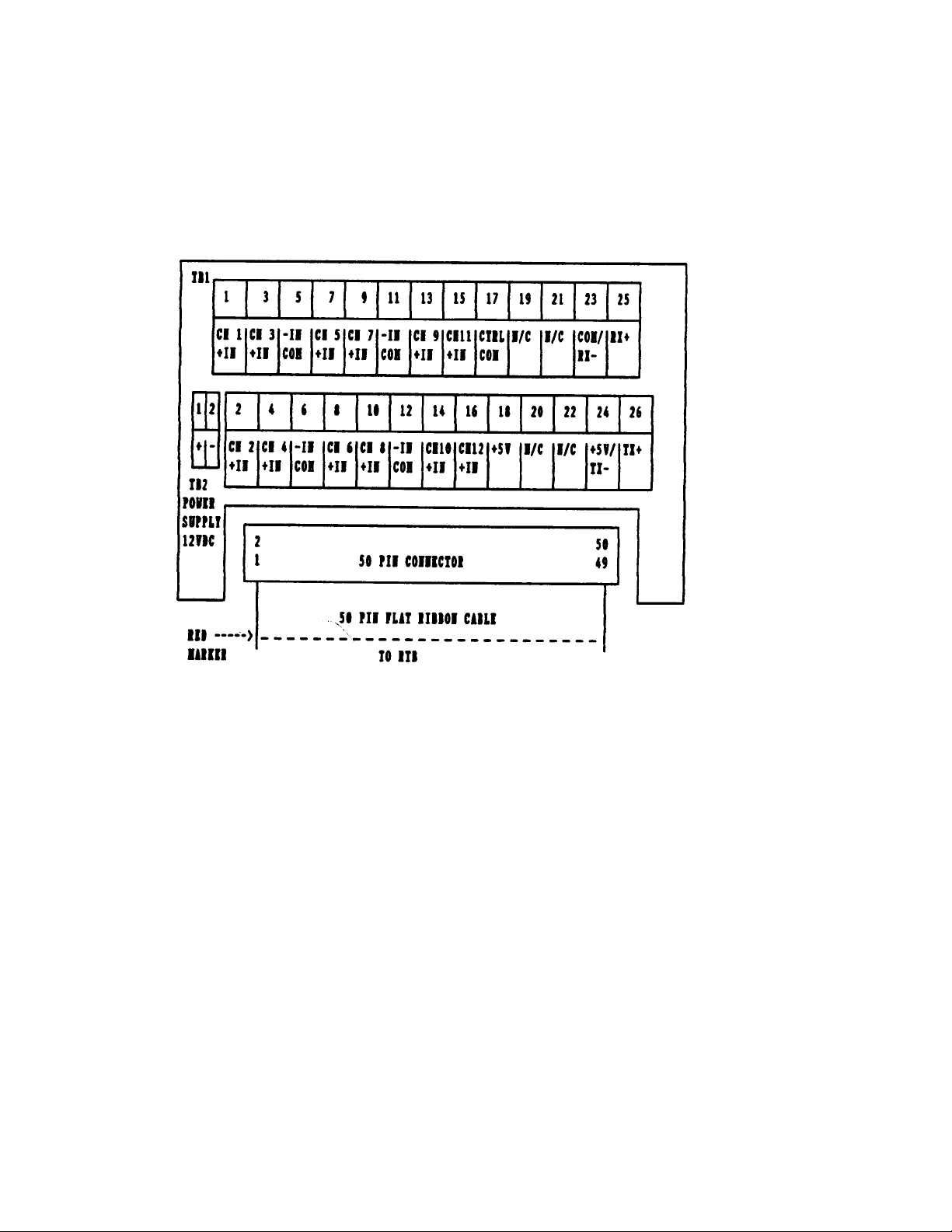

3.2 TERMINAL BLOCK AND CONNECTOR LAYOUT

The ANAFAZE 12LS terminal blocks and connectors are assigned according to the following two pages. Subsequent

sections provide detailed connection descriptions.

12LS REAR PANEL

NOTES:

1. THE CH (LOOP NUMBER) +IN IS THE ANALOG POSITIVE OF THE INPUT SIGNAL FOR THAT LOOP.

2. -IN COM IS THE ANALOG COMMON NEGATIVE OF THE INPUT SIGNAL.

3. CTRL COM IS THE COMMON FOR THE DIGITAL I/O CIRCUITS, SERIAL COMMUNICATIONS, AND IS

CONNECTED TO THE NEGATIVE OF THE POWER SUPPLY.

4. THE COMMUNICATIONS SELECTION OF RS-232 OR RS-485 WILL DETERMINE THE FUNCTION OF

TERMINALS #23 AND #24. SEE SECTION 3.5.1 RS-232 CONNECTIONS AND SECTION 3.5.3.3 RS-485

CONNECTIONS.

5. TERMINAL #24 WILL SUPPLY +5VDC FOR THE SOURCE TO OPERATE THE GLOBAL ALARM AND

DIGITAL OUTPUTS WHEN USED WITH RS-232 COMMUNICATIONS.

6. DIGITAL OUTPUTS #8 AND #9 ARE DUPLICATED ON TERMINAL #19 AND #20 RESPECTIVELY AS

WELL AS THE RTB TERMINALS OF #14 AND #12.

3-8

Page 23

The remote terminal block (RTB) provides the control outputs and additional digital inputs and outputs as follows:

|------------------------------------------------------------|

¦ FUNCTION ¦ TERMINAL ¦ FUNCTION ¦

|------------------------------------------------------------¦

¦ +5VDC ¦ 1 ¦ 2 ¦ +5VDC ¦

¦ CTRL COM ¦ 3 ¦ 4 ¦ CTRL COM ¦

¦SPARE ¦ 5 ¦ 6 ¦ SPARE ¦

¦SPARE ¦ 7 ¦ 8 | BOX SELECTED ¦

¦ PIDHEAT 1 ¦ 9 ¦ 10 ¦ GLOBAL ALARM ¦

¦ PIDHEAT 2 ¦ 11 ¦ 12 ¦ DIG OUTPUT 9 ¦

¦ PIDHEAT 3 ¦ 13 ¦ 14 ¦ DIG OUTPUT 8 ¦

¦ PIDHEAT 4 ¦ 15 ¦ 16 ¦ DIG OUTPUT 7 ¦

¦ PIDHEAT 5 ¦ 17 ¦ 18 ¦ DIG OUTPUT 6 ¦

¦ PIDHEAT 6 ¦ 19 ¦ 20 ¦ DIG OUTPUT 5 ¦

¦ PID HEAT 7 ¦ 21 ¦ 22 ¦ DIG OUTPUT 4 ¦

¦ PIDHEAT 8 ¦ 23 ¦ 24 ¦ DIG OUTPUT 3 ¦

¦ PIDHEAT 9 ¦ 25 ¦ 26 ¦ DIG OUTPUT 2 ¦

¦ PIDHEAT 10 ¦ 27 ¦ 28 ¦ DIG OUTPUT 1 ¦

¦ PIDHEAT 11 ¦ 29 ¦ 30 ¦ PID COOL 12 ¦

¦ PIDHEAT 12 ¦ 31 ¦ 32 ¦ PID COOL 11 ¦

¦ PIDCOOL 1 ¦ 33 ¦ 34 ¦ PID COOL 10 ¦

¦ PIDCOOL 2 ¦ 35 ¦ 36 ¦ PID COOL 9 ¦

¦ PIDCOOL 3 ¦ 37 ¦ 38 ¦ PID COOL 8 ¦

¦ PIDCOOL 4 ¦ 39 ¦ 40 ¦ PID COOL 7 ¦

¦ PID COOL 5 ¦ 41 ¦ 42 ¦ PID COOL 6 ¦

¦ DIG INPUT 1 ¦ 43 ¦ 44 ¦ DIG INPUT 2 ¦

¦ DIG INPUT 3 ¦ 45 ¦ 46 ¦ DIG INPUT 4 ¦

¦ DIG INPUT 5 ¦ 47 ¦ 48 ¦ DIG INPUT 6 ¦

¦ DIG INPUT 7 ¦ 49 ¦ 50 ¦ DIG INPUT 8 ¦

|------------------------------------------------------------|

REMOTE TERMINAL BLOCK CONNECTIONS

All digital outputs and PID outputs on this flat ribbon connection are SINK OUTPUTS. They are in reference

to the 5Vdc supply. The outputs will be low when they are ON.

All digital inputs are TTL level inputs and may be selected from software if they will be high/false or low/true

inputs. The inputs are in reference to CTRL COM.

NOTE! WHEN USING THE RTB, PROPER POLARITY OF THE FLAT RIBBON CABLE IS

NECESSARY FOR CORRECT PIN TERMINATIONS. INSTALL THE RED MARKER INDICATING

PIN #1 TO THE LEFT WHEN TERMINAL #1 OF THE RTB IS TO THE LEFT. THE FLAT RIBBON

CABLE SHOULD HAVE THE RED MARKER TO THE LEFT WHEN IT IS INSTALLED ON THE

REAR OF THE 12LS. TO CONFIRM PROPER POLARITY, CHECK THAT PIN #1 IS +5VDC WITH

RESPECT TO PIN #3.

WARNING

3-9

Page 24

3.3 ANALOG INPUTS

Connecting analog signals to the ANAFAZE 12LS is normally straightforward. Most thermocouples can be directly

connected and mixed in any order. Other types of analog signals such as mAdc or Vdc require scaling resistors

installed on the 12LS inputs. However, some problems may occur that could reduce accuracy and possibly damage the

unit. Sections 3.1 through 3.4 indicate some of the potential areas for concern. [See typical input DIAGRAM in

section 3.13].

3.3.1COMMON MODE VOLTAGE

Common mode voltage is the voltage between the ground at the sensor and the ground at the ANAFAZE 12LS. It can

be an AC or DC voltage and appears equally at the high and low input terminals. Frequently it is caused by large

currents flowing in the ground path between the 12LS and the sensors. The effects are minimized by using isolated

sensors or ungrounded thermocouples. Since the 12LS uses common ground inputs, if grounded sensors are used, any

common mode voltage will cause current flow in the sensor leads and reading errors.

3.3.2NORMAL MODE VOLTAGE

Normal mode voltage appears across the terminals of the input and is the signal from the sensor plus any undesirable

noise. The major cause of this noise is AC power line pick-up. The effects are reduced by the ANAFAZE 12LS

capacity to integrate the signal over a multiple of the power line frequency. Further reduction can be achieved by

locating the 12LS near the sensors and by using twisted and shielded sensor wires. To ensure accurate readings, the

maximum of normal mode plus signal should not exceed -10mv to +60mv.

3.3.3GROUNDING

For best accuracy, observe the grounding recommendations for connecting each input and output signal. The analog

signal grounds should be connected to the analog ground terminals. The communication and control outputs should

be connected to their respective grounds. Do not mix the grounds or connect them together. If possible, route the

analog signal cables separately from the communication, control and power cables.

3.3.4 SOURCE IMPEDANCE

Each sensor has a certain output impedance which is effectively connected across the ANAFAZE 12LS input amplifier

when a measurement is made. To reach the rated accuracy, the maximum source impedance should not exceed 500

ohms. Consult ANAFAZE for operation with higher source impedance.

3-10

Page 25

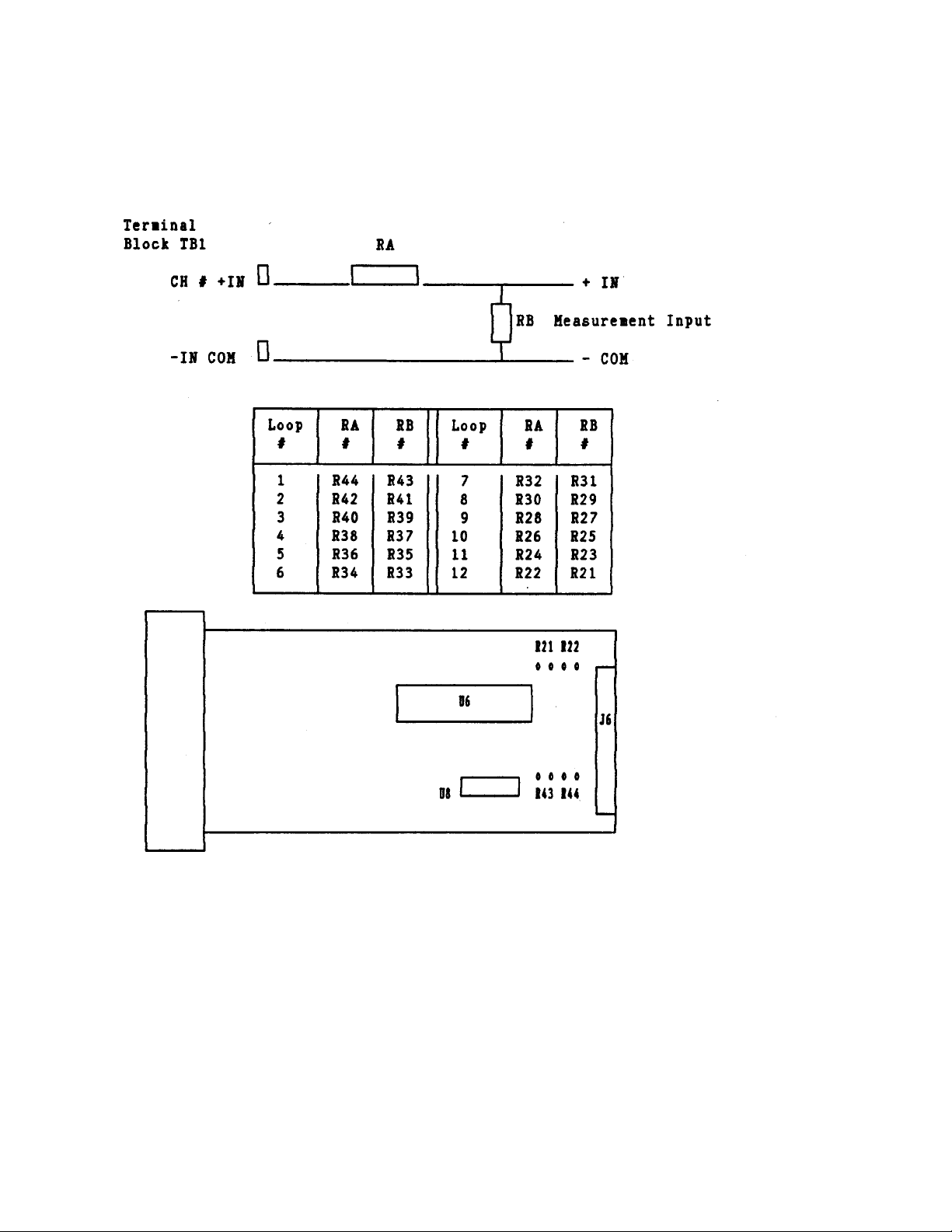

3.3.5 INPUT SCALING

The ANAFAZE 12LS contains an area that can be used to install resistors to scale input voltages and convert milliamp

inputs to match the -10 to 60mv (-16.7% to 100%) input range. The input circuit is designed to enable connection of

current inputs (such as 4 to 20ma), and voltage inputs. ANAFAZE will supply input scaling as needed -- order option

12LS-SI-XX. The input circuit is shown below:

The location of RA and RB for each input is shown on the following table:

RA

is shorted by a jumper on the PC board, remove this jumper to install RA.

Resistors should be 0.1% metal film, 1/4 watt. Note that the resistors must be stood on end due to the compact size of

the unit. Other components such as capacitors can be installed for signal conditioning. Please consult ANAFAZE.

The PC board silk screen shows the resistor locations.

3-11

Page 26

3.3.6 VOLTAGE INPUTS

DC Voltage inputs should be connected with the positive side to the CH +IN terminal and the negative side to one of

the -IN COM terminal. The input range is -10 to +60 mv. Signals greater than 60 mv must be scaled with resistors to

match the input full scale to 60 mv. The scaling resistor RA is selected as the voltage dropping and/or current limiting

resistor. RB is selected for the 60 mv full scale dropping resistor. It should normally be less then 500 _ and should

never be greater then 1000 _. Any value above 1000 _ for RB will cause error due to the upscale burnout circuit.

|------------------------------------------------------------------|

¦ TABLE 3-1. TYPICAL STANDARD VALUE SCALING RESISTOR ¦

|------------------------------------------------------------------¦

¦ Output Voltage Range ¦ RA ¦ RB ¦ Accuracy ¦

+------------------------¦----------¦----------¦-------------------¦

¦ 0 - 100 mV ¦ 499 Ω ¦ 750 Ω ¦ + .1 % ¦

¦ 0 - 500 mV ¦5.49 KΩ ¦ 750 Ω ¦ + .1 % ¦

¦ 0 - 1 V ¦6.91 KΩ ¦ 442 Ω ¦ + .2 % ¦

¦ 0 - 5 V ¦39.2 KΩ ¦ 475 Ω ¦ - .2 % ¦

¦ 0 - 10 V ¦49.9 KΩ ¦ 301 Ω ¦ - .1 % ¦

|------------------------------------------------------------------|+

The above values are standard metal film values and will give an accuracy of +0.25% when using .1% tolerance

resistors. Any possible error due to resistor tolerance may be corrected by using the built in linear scaling.

3.3.7MILLIAMP INPUTS

Current inputs from transmitters are accommodated by placing resistors in the input section to convert the current input

into a voltage. The input connections are the same as the voltage inputs. Different current input ranges are

accommodated by selecting the proper resistor values.

A single 0.1% resistor is used as follows:

4 to 20 ma 0 to 10 ma

RB = 3.000 Ω RB = 6.000

Ω

3.3.8THERMOCOUPLE INPUTS

All thermocouple types may be directly connected to the ANAFAZE 12LS. Types J,K,T,R, S and B linearization

and cold junction compensation are provided standard in the ANAFAZE 12LS. For other thermocouple types, optional

input ranges are required. Thermocouples should be connected with the positive lead to the CH +IN terminal and the

negative lead to one of the -IN COM analog grounds.

Use 20 gage or smaller T/C Extension wire as there are only four terminals for the common negative input lead for 12

loops.

3-12

Page 27

Use of the grounded T/C, meaning that the T/C junction is at the same potential of the metal protection sheath of the

T/C assembly, may cause calibration shifts and/or erratic temperature readings of the input. The use of a grounded T/C

in a process using electrical energy for heating, may also cause damage to the 12LS.

The ungrounded T/C, meaning that the T/C junction is electrically isolated from the metal sheath of the T/C assembly

is recommended by ANAFAZE for use as the type of T/C to be use with the 12LS.

When updating an existing temperature control system with the ANAFAZE 12LS, it is highly recommended that all

grounded T/C in use with the old system be changed to ungrounded types of T/C.

WARNING

3.3.9RTD INPUTS

RTD's should have external signal conditioning with an isolated 4-20ma output or the equivalent for connection to the

12LS. Please consult ANAFAZE for additional information.

3.3.10 INFRARED NON-CONTACT TEMPERATURE SENSORS

The ANAFAZE IRSM (infrared sensing module) is ideally suited for many infrared non-contact temperature

applications. It can be supplied by ANAFAZE as a fully integrated system with the 12LS configured to provide

power for up to four IRSM modules and for direct connection of the IRSM output. The following connections are

required if the IRSM internal ambient sensor is not used:

+--------------------------------------------------------------+

¦ TABLE 3-2. IRSM CONNECTIONS ¦

+--------------------------------------------------------------¦

¦ 12LS ¦ IRSM Wires ¦

¦ TB1 +------------------------------------------------¦

¦ TERMINALS ¦ Pin Nr. ¦ Color ¦ Function ¦

+-------------¦----------¦---------¦---------------------------¦

¦ CH # +IN ¦ A ¦ Orange ¦ Signal Out (0-10 madc) ¦

¦ -IN COM ¦ B ¦ White ¦ Signal Ground ¦

¦ -IN COM ¦ K ¦ ¦ Shield ¦

¦ +5VDC ¦ E ¦ Red ¦ +5 VDC Supply ¦

¦ CTRL COM ¦ C ¦ Black ¦ Power Ground ¦

¦ CTRL COM ¦ J ¦ Brown ¦ No Peak Hold ¦

¦ N/C ¦ D ¦ Green ¦ +15 VDC Supply ¦

¦ N/C ¦ F ¦ Blue ¦ Ambient Sensor ¦

¦ N/C ¦ H ¦ Yellow ¦ Track and Hold ¦

+--------------------------------------------------------------+

The range of the standard ANAFAZE IRSM is 0-1000o F with an output of 0-10mAdc. The input of the ANAFAZE

12LS must be configured for a 0-10madc input. See section 3.3.7

To use more than four IRSM's with the 12LS, use an external power supply of 8-15vdc.

3-13

Page 28

If desired, a second input may be used to monitor the internal IRSM ambient temperature. Consult ANAFAZE for

more information.

3.3.11 SCALING AND CALIBRATION

The ANAFAZE 12LS includes a scaling provision to convert analog inputs into engineering units. Section 4.5.2.3

describes how to set the automatic scaling.

3.3.12 DIAGRAMS OF TYPICAL INPUTS

CH # +IN O--- White -------------------------- Type J T/C

-IN COM O--- Red --------------------------- UNGROUNDED

Earth GND O-- T/C Wire Shield if used------

CH # +IN O--- Yellow -------------------------

-IN COM O--- Red --------------------------- Type K T/C

Earth GND O-- T/C Wire Shield if used------ UNGROUNDED

CH # +IN O------------------------------------ 4-20mAdc/

-IN COM O------------------------------------ Voltage

Earth GND O-- Shielded wiring recommended-----

3.4 CONTROL OUTPUTS

+-----------------------------------------------------+

¦ WARNING! -- GROUND LOOP POTENTIAL ¦

+-----------------------------------------------------¦

¦ The ground of every control output is connected to ¦

¦the ANAFAZE 12LS logic ground. Use caution when ¦

¦connecting external devices that may have their low ¦

¦ side at voltage other than controller ground, since ¦

¦ potential ground loops can be created. Use isolated ¦

¦ relays or the isolated control device inputs if ¦

¦ possible grounding problems are expected. ¦

+-----------------------------------------------------+

The ANAFAZE 12LS includes two sets of control outputs for each loop. These are provided on the 50 pin ribbon

cable connector and are set for heat/cool whether or not they will be used for each application.

1. Each output may be individually programmed as a different type (on/off, CTP, or DZC.).

2. Each output can be individually programmed to be direct or reverse acting [both outputs can be the same].

3. There may be a deadband programmed for heat/cool, and within that deadband both outputs will be off.

3-14

Page 29

3.4.1 PID CONTROL AND ALARM OUTPUTS CONNECTIONS

Typical digital control outputs utilize external optically- isolated solid-state relays. These relays use a 3 to 32vdc input

for control and can be sized to switch up to 100 amps at 480vac. For larger currents these relays can be used to drive

contactors.

|-----------------------------------------------------|

¦ NOTE: Control outputs are SINK OUTPUTS. They will be¦

¦low when the output is ON. They should be connected ¦

¦to the minus (-) side of SSRs. ¦

|-----------------------------------------------------|

Example of Heat/Cool And Alarm Outputs Connections:

SSR 1 SSR 2 SSR 3

|------| |------| |------|

RTB TERMINALS PIN ¦ - + ¦ ¦ - + ¦ ¦ - + ¦

|------| |------| |------|

PID HEAT 1 9 ||-------| ¦ ¦ ¦ ¦ ¦

¦ ¦ ¦ ¦ ¦

PID COOL 1 33 ||----------¦---------| ¦ ¦ ¦

¦ ¦ ¦ ¦

+5VDC 1 ||----------|------------|---------¦--|

¦

DIG OUTPUT 1 28 ||---------------------------------|

3.4.2 PID OUTPUT LIMITING

The output from each loop's dual heat/cool output may be limited to a value less than 100%. This level may not be

exceeded by the PID control action. This limit on the control output may be limited by a period of time and than

returned to full 100% output or it may be a continuous limit until changed by the programming keys.

The limit time delay is restarted whenever:

a) A new time period is entered.

b) A loop is switched from MANUAL to AUTO mode.

c) The controller is restarted(powered up).

The time period is adjustable from 1 to 999 seconds for a maximum period of time of over 16 minutes. A time of 0

seconds will be displayed as C, the same as for Continuous.

The Output Limiting is disabled by setting the value to 100%. The control mode of ON/OFF has no output limiting

available.

The output limiting may be used for "Soft Start" type of requirements of different processes. May also be used to

restrict the energy into a process, thus tailoring the controller output to the process requirements.

3-15

Page 30

3.5 COMPUTER SERIAL COMMUNICATIONS

The ANAFAZE 12LS offers two types of serial communications: RS- 232 and RS-485. The RS-232 is used primarily

for local communications of up to the recommended RS-232 distance of 50 feet. It can only be used with one

ANAFAZE 12LS. More than one unit requires RS-485

The RS-485 is a voltage balanced, 4-wire, long distance, multi- point transmission interface. Up to 32 addresses can be

set in the 12LS for one communication line.

Units must be ordered for the RS-485 communications, otherwise the factory standard of RS-232 will be supplied with

the ANAFAZE 12LS.

3.5.1 RS-232 CONNECTIONS

The optically-isolated RS-232 interface is connected using the Communications terminal block 1. See

connections.

|--------------------------------------------------------------|

¦ TABLE 3-3. RS-232 CONNECTIONS ¦

|--------------------------------------------------------------¦

¦ Computer Connector ¦ 12 LS ¦

|------------------------------¦ TB 1 Pin Nr. ¦

¦ DB 25 ¦ DB 9 ¦ ¦

|--------------¦---------------¦-------------------------------¦

¦ RX Pin 3 ¦ RX Pin 2 ¦ TX Pin 26 ¦

¦ TX Pin 2 ¦ TX Pin 3 ¦ RX Pin 25 ¦

¦ GND Pin 7 ¦ GND Pin 5 ¦ GND Pin 23 ¦

|--------------------------------------------------------------|

The computer pins are for the normal 25 pin RS-232 connector [DB25] and the normal 9 pin connector [DB9]. On

some computers transmit TX and receive RX may be reversed. Please check your computer manual for details.

Table 3-3

for

3.5.2 OTHER RS-232 LINES

Some host computers or other RS-232 devices use additional communication lines that are not required by the 12LS.

These include:

RTS - Ready to Send DSR - Data Set Ready

CTS - Clear To Send DTR - Data Terminal Ready

If the host computer uses RTS and CTS or DSR and DTR, these lines should be connected together in pairs [or as

shown in the computer manual]. Normally this is done in the RS-232 connector hood at the host computer.

Alternately, the effect of these lines can be eliminated in software. The ANAFAZE 12LS is ready to receive data;

therefore these lines are not required.

3-16

Page 31

3.5.3 RS-485 DESCRIPTION

The EIA Standard RS-485 specifies only the electrical characteristics of generators (transmitters) and receivers for use

in digital multi-point systems. The specification of transmission lines, signaling rates, protocols, etc. is left entirely up

to the user. The transmitters and receivers selected by ANAFAZE also meet the requirements of RS-422.

The following information is intended to make recommendations for the application of the RS-485 interface to

ANAFAZE equipment.

The maximum signaling rate used by the ANAFAZE 12LS and associated equipment is 9600 baud. Since this is far

below the maximum signaling rate covered by the specification, satisfactory performance may be expected without

strict adherence to all of the design rules. ANAFAZE has presented conservative recommendations to insure reliable

operation. If deviations are necessary, please contact ANAFAZE.

3.5.3.1 CABLE RECOMMENDATIONS

ANAFAZE recommends twisted shielded pairs for the RS-485 cables. The transmitters and receivers specified in RS485 are very tolerant of cable characteristics, and some leeway is possible unless distances and signaling rates push the

specification limits.

One requirement is very important, as it impacts performance even down to low frequency operation. The loop

resistance of the transmission line [wire only -- not terminating resistor] must not exceed 200 _ for a properly

terminated line with a reasonable margin for noise. Thus the following recommendations for distance and wire gauge

should be observed:

|------------------------------------------------------|

¦ Distance ¦ Wire Gauge ¦ Recommended Cable ¦

|------------------------------------------------------¦

¦ 4000 ft. ¦ 24 AWG ¦ Belden 9729/9842 ¦

¦ 6000 ft. ¦ 22 AWG ¦ Belden 9184 ¦

|------------------------------------------------------|

See 3.1.3 para. 7 and 3.1.4 for further recommendations.

The use of a shield depends on the noise environment and grounding considerations. The above cables are shielded.

3-17

Page 32

3.5.3.2 RS-485 CONNECTIONS

Connection of ANAFAZE controllers to a system computer requires an interface at the computer to convert RS-232

levels to RS-485. Anafaze recommends Black Box Model LD485A for this purpose. The LD485A should be

configured for DCE operation, with the RTS/CTS delay jumper in the "on" position. ANAFAZE can supply this

converter configured and checked out with the system on request.

Normal Operation LD485A installation setup:

1. DCE operation (Dip shunt in XW1A socket)

2. Normal operation (Front panel switch out)

3. Full Duplex operation (Jumper W8 on Full)

4. RTS/CTS Delay set to ON (Jumper W9 to ON)

5. Unterminated operation (Switch S2 to Unterm)

6. No jumper at position W7

The RS-485 specification is for "balanced line" operation, and is not true differential. Thus a common connection is

required between all stations on the communication line. This can be accomplished by either a 5th wire (which could

be shield) or a common ground connection.

The ANAFAZE system more conveniently supports the common ground connection, although 5th wire can be

supported if required due to common mode voltages generated in a given installation. The 3rd wire connection would

be required only if the "common mode" voltage between stations exceeds the RS-485 specification of 7 volts peak.

To make sure the communication system works, the controller chassis must be electrically tied to Earth ground, and

the host computer communication must be tied to Earth ground. If the host computer RS-232 communication is not

referenced to Earth ground, install the 100 _ resistor in W7 as recommended by Black Box.

The following diagram shows the recommended system hookup. The transmitter from the host computer connects in

parallel to the controller receivers, and the host computer receiver connects in parallel to the controller transmitters. A

single "daisy chain" is recommended. Octopus connections or "spurs" are discouraged. A termination resistor is

required at each end of the transmission line. This is accomplished by applying a 200 _ resistor across the line at the

farthest point from the computer transmitter. Check with ANAFAZE for setting the Black Box SW2 to the "term"

position to terminate the computer receive line.

3-18

Page 33

ANAFAZE 12LS connections for a single unit are as follows:

Black Box 12LS

LD485A TB 1

TXA ---------------------------------------- RX+ #25 ---||

¦¦ 200 Ω-

TXB ---------------------------------------- RX- #23 ---||

RXA ---------------------------------------- TX+ #26

RXB ---------------------------------------- TX- #24

Shield ----- Earth Ground ------- Shield Do not Ground

|-----------------------------------------------------|

¦ NOTE: Connect the shields to EARTH ground only at ¦

¦the computer or other 485 interface. No shield ¦

¦connection is required at the 12LS. Connect a 200_ ¦

¦ terminating resistor between RX- and RX+ at the 12LS¦

|-----------------------------------------------------|

For multiple units connect the system in parallel as follows:

Black Box 12LS 12LS

LD485A [1] [n]

TXA --------------- RX+ #25 ------------------ RX+ #25 ---||

¦¦ 200Ω

TXB --------------- RX- #23 ------------------ RX- #23 ---||

RXA --------------- TX+ #26 ------------------ TX+ #26

RXB --------------- TX- #24 ------------------ TX- #24

Ground -----------O---------O---------------- Do not Ground

3-19

Page 34

4.0 FRONT PANEL OPERATION AND DISPLAYS

The 12LS front panel provides the operator interface for the controller. The 12LS may be fully

programmed and operated by using the eight keys on the front panel.

The 32 character display shows process information and setup displays. The 12LS will power up

with the BAR GRAPH display being shown. Press the BACK key to get to the SINGLE LOOP

display. Refer to section 4.2 for more detailed information on these and other system displays.

|-----------------------------------------------------|

¦ WARNING! - BATTERY CHECK ¦

|-----------------------------------------------------¦

¦ On power-up the 12LS checks its memory for valid ¦

¦data. If an error is detected the message BATTERY ¦

¦ DEAD is displayed and default values are assumed. ¦

¦ Press ANY key to clear the message. Be sure to enter¦

¦ valid system data before continuing. Consult ANAFAZE¦

¦ about battery replacement. ¦

|-----------------------------------------------------¦

¦ This message may also appear if the internal PROM ¦

¦ has been changed or the unit has been disassembled. ¦

|-----------------------------------------------------|

PROM CHANGE OR BATTERY DEAD:

It is recommended that upon changing the PROM, that the RAM memory be cleared.

To clear the battery backed RAM and to re-initialize the factory default values into the RAM,

PRESS THE NO KEY while turning on the power to the 12LS. Never press the NO key upon

power up unless it is necessary to clear the RAM memory as this will replace all customer entered

values with the factory default values.

The RAMP SOAK key is used only if the optional RAMP/SOAK package is included in the

controller. Information pertaining to programming and operation of ramp and soak profiles is

included in Chapter 7 - RAMP AND SOAK OPTION.

The ANAFAZE 12LS displays operate in a sequence that is shown on the following flow chart,

Figure 4-1. Main menu headings are shown in outlined boxes while the sub-menus under each

main heading are listed below it.

4-1

Page 35

|- - - - - - - - - - - - - -|

Back

|------------------| ¦ ¦ ¦

¦|----------| |----------| |----------| Any Display |----------| |--------------|

¦¦ Bar |<-->¦ Single |---->¦ Scan ¦ >------------¦ Alarm ¦ ¦ | - -¦ SETUP || ¦

¦¦ Graph ¦BACK¦ Loop ¦Enter¦ Loops ¦ On Alarm ¦ Display ¦ ¦ RAMP AND SOAK¦

¦|----------| |----------|Enter|----------| |----------| ¦ ¦ |--------------|¦ ¦

¦ ¦|--------| ¦|--------| ¦

¦ |¦ CHNG ¦ |¦ ALARM ¦ ¦ ¦ |-Profile # ¦ ¦

¦ ¦¦ SP ¦ ¦ ACK ¦ |-Copy Prof.

¦ ¦|--------| |--------| ¦ ¦ |-Tol. Time ¦ ¦

¦ ¦|--------| | Return |-Ready Sp

¦ |¦ MAN |-Set % Output ¦ ¦ |-Ready Events ¦ ¦

Pass ¦¦ AUTO ¦ |-Segment #

Key ¦|--------| ¦ ¦ |-Time ¦ ¦

Sequence |- -¦- - - - - - - - - - - - - - - - - - --| |-Setpoint

¦ ¦ ¦|--------| ¦ ¦ ¦ |-Events ¦ ¦

ENTER |¦ RAMP |-Select Profile |-Triggers

ALARM ACK ¦ ¦ SOAK |-Run, Hold, Continue, Reset ¦ ¦ ¦ |-Tolerance ¦ ¦

CHNG SP |--------| |-Last Segment

¦ ¦ |----View Profile Status ¦ ¦ ¦ |-Cycles ¦ ¦

¦ |----View Time Remaining

¦ ¦ |----View Cycle Counter ¦ ¦ ¦ (optional) ¦ ¦

¦ (optional) |- - - --- - - - - - - - -|

¦ |- - - - - - - - - - - - - - - - - - - - --| ¦ ¦

¦ Back Back Back Back Back Back

¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦ ¦

|--------------| |--------------| |--------------| |--------------| |--------------| |--------------|

¦SETUP GLOBAL ¦ ¦SETUP LOOP XX |-¦SETUP LOOP XX |--¦SETUP LOOP XX |--¦SETUP LOOP XX |--¦ MANUAL I/O ¦

¦PARAMETERS ¦ ¦INPUT ¦ ¦CONTROL PARAMS¦ ¦OUTPUTS ¦ ¦ALARMS ¦ ¦ TEST ¦

|--------------| |--------------| |--------------| |--------------| |--------------| |--------------|

¦ ¦ ¦ ¦ ¦ ¦

|-Save To Job# |-Type |-PB-Heat |-Type-Heat |-Hi Process |-Digital Inputs

|-Load From Job# | Units |-TI-Heat ¦|CycleTime-Heat |-HP On/Off |-Digital Outputs

|-Alarm Delay |-Units |-TD-Heat |-Rev/Dir-Heat |-HP Out #

|-R/S Time |-Scaling |-FIL-Heat |-Output Limit |-Deviation

|-Panel Lock |-PB-Cool |-Limit Time |-Dev On/Off

|-Power Up State |-TI-Cool |-Type-Cool |-HD Out #

|-Ctlr Address |-TD-Cool ¦|CycleTime-Cool |-LD Out #

|-Comm Err Chk |-FIL-Cool |-Rev/Dir-Cool |-Low Process

|-Baud Rate |-Heat/Cool |-Output Limit |-LP On/Off

|-AC Frequency Spread |-Limit Time |-LP Out #

|-PROM Version |-Deadband

Figure 4-1. DISPLAY FLOWCHART

4-2

Page 36

4.1 FRONT PANEL KEYS

The four main function keys on the front panel are used to perform specific operations :

|-----| o Adjust the setpoint on displayed loop.

¦CHNG ¦

¦ SP ¦

|-----|

|-----| o Toggle loop status between MANUAL and AUTO.

¦ MAN ¦ o Adjust output power level of loops in MANUAL

¦AUTO ¦ mode.

|-----|

|-----| o No function if OPTION not installed.

¦RAMP ¦ o Assign a ramp/soak profile to selected loop.

¦SOAK ¦ o Perform operations on profile already assigned.

|-----|

|-----| o Acknowledge an alarm condition, reset global

¦ALARM¦ alarm digital output.

¦ ACK ¦

|-----|

A panel lock feature within the password-protected global menu can lock out these keys.

The four cursor keys are used to select menus, select data for editing, increment or decrement numerical data and step

through choices within menus.

|-----| o Select a menu when prompt is blinking.

¦ / \ ¦ o Answer YES to YES/NO prompts.

¦/YES\¦ o Increment a number or choice being edited.

|-----|

|-----| o Skip a menu when prompt is blinking.

¦\ NO/¦ o Answer NO to YES/NO prompts.

¦ \ / ¦ o Decrement a number or choice being edited.

|-----|

|-----| o Abort editing.

¦ ¦ o Return to previous menu.

¦BACK ¦

|-----|

|-----| o Store data or menu choice after editing.

¦ ¦ o Proceed to the next menu.

¦ENTER¦

|-----|

Changes such as input types, tuning, and control output types are made from DETAILED MENUS after a pass key

sequence is pressed.

4-3

Page 37

4.2 DISPLAYS

On power-up the controller defaults to the BAR GRAPH display which shows the status of all 12 loops.

From there the user may switch to the SINGLE LOOP display which provides more detailed information about any

selected channel. The channel displayed in the SINGLE LOOP display may be changed by using the UP and DOWN

ARROW keys.

A SCANNING display is also available which automatically increments the channel to be displayed in the SINGLE

LOOP fashion continually looping through all active channels of the 12 available, showing each for a short period of

time.

If an alarm occurs the ALARM display is shown.

4.2.1 BAR GRAPH DISPLAY

This is the default display on power up.

The upper display shows the BAR GRAPH for each loop. The highest and lowest level of the BAR GRAPH display

are the upper and lower deviation alarms. If deviation alarms are OFF the display range is +5% of setpoint. The

intermediate levels are linearly spaced between the upper and lower limits.

|-------------------------------------------------|

¦ ¦

¦ Bar Graphs | ¦

¦ ¦ ¦

¦ Channel -| ¦ |- Channel ¦

¦ 1 |----------------| 12 ¦

¦ ¦-___ -__ _-____-¦ ¦

¦ ¦ MMAH CCHH MAAM ¦ ¦

¦ |----------------| ¦

¦ ¦ ¦

¦ ¦ ¦

¦ |- Loop Status Symbols ¦

¦ ¦

|-------------------------------------------------|

Figure 4-2. BAR GRAPH DISPLAY

Refer to

If an acknowledged alarm exists, the BAR GRAPH is replaced by an alarm symbol. Refer to

description of alarm symbols used.

Table 4-2

for descriptions of loop status symbols used.

4-4

TABLE 4-2

for a

Page 38

4.2.2 SINGLE LOOP DISPLAY

The SINGLE LOOP Display shows the detailed information for one loop at a time. The UP/DOWN arrows select the

loop number. Press the BACK key to return to the BAR GRAPH display.

FIGURE 4-3

|-------------------------------------------------|

¦ Process ¦

¦ Loop Variable Engineering ¦

¦ Number -| ¦ |- Units ¦

¦ ¦ ¦ ¦ ¦

¦ |----------------| ¦

¦ ¦08 200 °F ¦ ¦

¦ ¦ 305HEAT 98¦ ¦

¦ |----------------| ¦

¦ ¦ ¦ ¦ Output Power ¦

¦ ¦ ¦ |- Percentage ¦

¦ Setpoint -| ¦ ¦

¦ |- Loop Status ¦

¦ ¦

|-------------------------------------------------|

Figure 4-3. SINGLE LOOP DISPLAY

The SINGLE LOOP display shows:

LOOP NUMBER 01 to 12

PROCESS VARIABLE -999 to 9999

A decimal point may be used where

possible if selected by the user.

ENGINEERING UNITS Up to three alpha characters.

identifies the data shown on the SINGLE LOOP Display.

SETPOINT Same format as process variable.

LOOP STATUS Refer to TABLE 4-1 for definitionsof the various loop

status displays.

PERCENT OUTPUT Heat or cool output power percentage,

0 to 100%.

4-5

Page 39

|--------------------------------------------------------------|

¦ Table 4-1. LOOP STATUS DEFINITIONS ¦

|--------------------------------------------------------------¦

¦ Loop Status Symbol ¦ ¦

|---------------------¦ Description ¦

¦Bar Graph¦Single Loop¦ ¦

¦ Display ¦ Display ¦ ¦

|---------¦-----------¦----------------------------------------¦

¦ A ¦ AUTO ¦ Single output loop is in automatic ¦

¦ ¦ ¦ control mode. The output power percent-¦

¦ ¦ ¦ age displayed is for the heat output. ¦

¦ ¦ ¦ ¦

¦ H ¦ HEAT ¦ Dual output loop is in automatic ¦

¦ T ¦ ¦ control and the heat output is active. ¦

¦ ¦ ¦ The output power percentage displayed ¦

¦ ¦ ¦ is for the heat output. ¦

¦ ¦ ¦ ¦

¦ C ¦ COOL ¦ Dual output loop is in automatic ¦

¦ L ¦ ¦ control and the cool output is active. ¦

¦ ¦ ¦ The output power percentage displayed ¦

¦ ¦ ¦ is for the cool output. ¦

¦ ¦ ¦ ¦

¦ M ¦ MAN ¦ Loop is in manual control mode. Output ¦

¦ ¦ ¦ power percentage displayed is for the ¦

¦ ¦ ¦ heat output. ¦

|--------------------------------------------------------------|

4.2.3 SCANNING DISPLAY

Press the ENTER key twice from the SINGLE LOOP display to enter the SCANNING display.

In this mode the controller will automatically step through the channels, showing the SINGLE LOOP display for each

for about a second before advancing.

Press any of the cursor keys (YES, NO, BACK or ENTER) to return to the SINGLE LOOP display.

4-6

Page 40

4.2.4 ALARM DISPLAY

The ALARM display interrupts any system display. If more than one alarm is present the first alarm is shown.

|-------------------------------------------------|

¦ Process ¦

¦ Loop Variable Engineering ¦

¦ Number -| ¦ |- Units ¦

¦ ¦ ¦ ¦ ¦

¦ |----------------| ¦

¦ ¦08 200 °F ¦ ¦

¦ ¦LP 305HEAT 98¦ ¦

¦ |----------------| ¦

¦ Alarm ¦ ¦ ¦ ¦ Output Power ¦

¦ Status -| ¦ ¦ |- Percentage ¦

¦ Flashing ¦ ¦ ¦

¦ ¦ |- Loop Status ¦

¦ Setpoint -| ¦

|-------------------------------------------------|

Figure 4-4. ALARM DISPLAY

The ALARM display is the same as the SINGLE LOOP display except the alarm status is flashing. Refer to

for a list of the various alarm indicator symbols.

4-2

|--------------------------------------------------------------|

¦ Table 4-2. ALARM SYMBOLS ¦

|--------------------------------------------------------------¦

¦ Alarm ¦ Symbol Displayed ¦

¦ Condition ¦----------------------------------------¦

¦ ¦ Bar Graph Display ¦ Single Loop Display¦

|---------------------|-------------------¦--------------------¦

¦ High Process ¦ HP ¦ > ¦

¦ High Deviation ¦ HD ¦ > ¦

¦ Low Deviation ¦ LD ¦ < ¦

¦ Low Process ¦ LP ¦ < ¦

¦ Tolerance Error ¦ T ¦ T ¦

¦ (Ramp/Soak Only) ¦ ¦ ¦

|--------------------------------------------------------------|

When the ALARM ACK key is pressed the flashing stops but the alarm indicator remains as long as the alarm

condition exists. Pressing ALARM ACK acknowledges ALL alarms on thedisplayed loop.

If another alarm is present on another loop the display switches the ALARM display to that loop. In general multiple

alarms are displayed from the lowest loop to the highest loop.

Multiple alarms on a SINGLE LOOP are acknowledged in the sequence they occurred.

When all alarms are acknowledged the global annunciator digital output is cleared.

TABLE

4-7

Page 41

4.3 GENERAL PROGRAMMING AND EDITING

In general, the 12LS menu structure consists of several main menus each having a group of sub-menus beneath them.

The user selects a main heading and then steps through the sub-menus until the desired menu is reached.

Most menus will appear with a prompt denoting the parameter to be edited followed by a blinking question mark (?)

and the current value or setting of the parameter.