Page 1

Watlow Series 101 User’s Manual ■1

(2060)

Control Mode

• On-Off

• Nominal switching hysteresis:

Type J thermocouple; 1.7°C (3°F);

Type K thermocouple; 2.2°C (4°F)

Operator Interface

• 76 mm (3 in.) dial scale calibrated to compensate for sensor

non-linearities

• Dual °C and °F scales

• D-shaft pot and adjustable ratchet knob

Input

• Thermocouple with automatic cold junction compensation

• Sensor may be isolated or grounded

• Sensor break protection de-energizes output

Output

• Electromechanical relay with contact suppression, 3A, SPST: 3A

@ 230V~ 3A @ 30VÎ (dc), 125VA pilot duty @ 120 or 230V~

• Solid-state relay, Form A, 0.5A @ 24V~ min., 230V~ max.,

opto-isolated burst fire switched, without contact suppression.

Off state output impedance is 31MΩ.

• Switched dc signal provides a non-isolated minimum turn on

voltage of 3VÎ (dc) into a minimum 500W load maximum on

voltage not greater than 28VÎ (dc) into an infinite load.

Accuracy

• Calibration accuracy and sensor conformity: ±1% of span, at 25°C

± 3°C (77°F ±5°F) ambient and rated line voltage ±1%

• Set point accuracy: ±2% of dial scale

• Accuracy span: 540°C (1000°F) minimum

• Temperature stability: 9µV/°C (5µV/°F) ambient, maximum

referred to the input

• Voltage stability: ±0.01% of span per % of rated line voltage

Agency Approvals

• CE approved:

89/336/EEC Electromagnetic Compatibility Directive

EN 55011: 1991 Emissions class B

EN 50082-1: 1992 Immunity

73/23/EEC Low Voltage Directive

EN 61010-1: 1993 Safety

• 873, File #E43684

• to C22.2 No. 24, File #E43684

• ANSI Z21.23. Gas Appliance Thermostats

Classification

• Installation category II, Pollution category II

Terminals

• Quick connects, 1/4 in. (6 mm) appliance

Power

• 115V~, ±10%, 50/60 Hz

• 230V~, ±10%, 50/60 Hz

• 24V~, ±10%, 50/60 Hz

• 4VApower consumption

Operating Environment

• 0 to 70°C (30 to 158°F)

• 0 to 90% RH, non-condensing

Dimensions

• See page 2.

Weight

• 0.3kg (0.7 lb)

and are registered trademarks of Underwriter’s

Laboratories, Inc.

Note: Specifications subject to change without notice.

Specifications

Series 101

User ’s Manual

Temperature Controller

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507, Internet: http://www.watlow.com

The Watlow Series 101 is an on-off temperature

controller that comes in three common temperature

ranges or can be custom ordered to meet your requirements. The input sensor can be either Type J or K

thermocouple. The setpot is integral and has both degree

Celsius and Fahrenheit scales.

General Description

$5.00

Made in the U.S.A.

Printed on Recycled Paper

10% Postconsumer Waste

0600-0036-0001 Rev D

January 2001

Supersedes:

0600-0036-0001 Rev C

TOT AL

CUSTO M ER

SA TISFACTI O N

3 Y ear Warranty

Page 2

Watlow Series 101 User’s Manual ■2

(1576) 101 _ - _ _ _ _ - 0000

Output

A = Electromechanical relay,

Form A, 3A, with contact

suppression

B = Solid-state relay, 0.5A, Form A,

without contact suppression

C = Switched dc, non-isolated

Line Voltage

1 = 120VÅ

2 = 230VÅ

3 = 24VÅ

Input and Range

Type J 601 = -20 to 260°C (0 to 500°F)

602 = -20 to 540°C (0 to 1000°F)

608 = -20 to 120°C (0 to 250°F)

Type K 603 = -20 to 1100°C (0 to 2000°F)

Note: User documentation may be available in French, German, Spanish,

Italian, and Dutch, as well as English. Check Watlow’s website

(www.watlow.com/) for availability. Specify language at time of order.

ç

A Caution symbol (an exclamation point in a triangle) appears with

information that is important to protect equipment and performance. Read and follow all cautions that apply to your application.

The equipment is protected throughout by double or reinforced

insulation. Use only to Watlow specifications. If the Series 101 is

used in a manner not specified by Watlow, the protection provided by the equipment may be impaired.

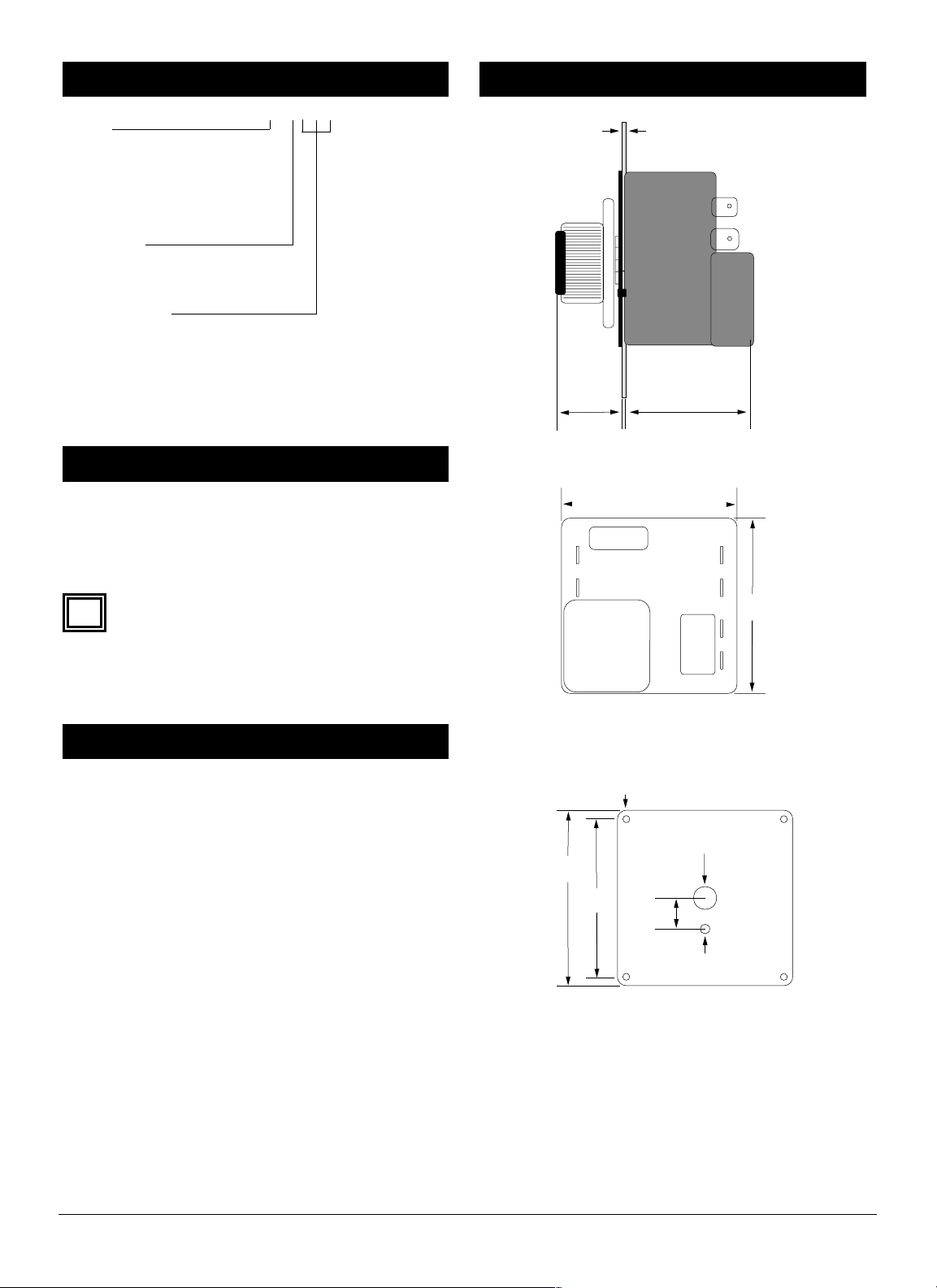

1.Remove the setpot knob and the dial scale from the

Series 101 control. See the side view in Figure 2a.

2.Using the dial scale as a location/drilling template,

locate and center punch the setpot locating tab, setpot

shaft and four mounting holes at the desired location.

See Figure 2c.

3.Drill one 4 mm (0.156 in.) setpot locating tab hole, one

10.3 mm (0.406 in.) setpot shaft hole and four 3.2 mm

(0.128 in.) diameter mounting holes.

4.Insert the setpot shaft of the controller through the 10.3

mm (0.4064 in.) diameter hole. Replace the dial scale

and align the mounting holes, then tighten the pot

shaft nut.

5.Insert #4 thread-forming screws in mounting holes and

tighten in place.

6.Wire the control following the wiring diagrams. See

next page.

NOTE: The Series 101 has a 2.3 mm (0.090 in.) diameter by 13

mm (0.500 in.) deep screw hole cavity. Design is based on using

Textron Camcar Division “Plastite” or “Pushtite” thread forming

hardware or equivalent. Screw length is 9.5 to 12.7 mm (0.375 to

0.500 in.) maximum.

Figure 2a — Series 101 side dimensions.

Figure 2b — Series 101 dimensions.

Figure 2c — Series 101 mounting.

Dimensions

Installation

Safety

Ordering Information

2.3 mm (0.09 in.) maximum

panel thickness

27.9 mm

(1.10 in.)

54.1 mm

(2.13 in.)

75.2 mm

(3.00 in.)

Mounting hole, (4) 3.1 mm (0.120 in.)

diameter for #4 thread-forming screws.

NOTE: Screw length ranges from 9.5 mm

(0.375 in.) to 12.7 mm (0.500 in.) maximum.

setpot shaft hole,

75.2 mm

(3.00 in.)

56.6 mm

(2.70 in.)

9.9 mm (0.39 in.) diameter

13.5 mm

(0.53 in.)

Setpot locating tab hole,

3.6 mm (0.140 in.) diameter

75.2 mm

(3.00 in.)

Page 3

Watlow Series 101 User’s Manual ■3

• Use the correct thermocouple type matching the model

number on the unit sticker. See the underside of the

unit.

• Use the proper thermocouple polarity. Red is negative.

• Insulate the thermocouple mounting from the mounting

surface to prevent heat migration input errors.

• Thermocouple leads should be twisted pair wire and

routed separately from any other lines.

• In electrically noisy environments (heavy switching of

contactor, motors, solenoids, etc.) use shielded thermocouple lead wire with the shield connected at the sensor

end only.

• All wiring and fusing must conform to the National

Electric Code (NEC) NFPA70 and any other locally

applicable codes.

• Fuse the independent load voltage on the L1 (hot) side

and connect it to the common (COM) side of the relay.

120VÅ 101 _ - 1 _ _ _ - 0000

230VÅ 101 _ - 2 _ _ _ - 0000

24VÅ 101 _ - 3 _ _ _ - 0000

NOTE: The line voltage is specified by your model number.

Figure 3a — Power wiring.

Ó

WARNING: To avoid potential electric shock, use National

Electrical Code safety practices when wiring and connecting this

unit to a power source and to electrical sensors or peripheral

devices.

All wiring and fusing must conform to the National Electric Code

and to any locally applicable codes.

Ó

WARNING: Applying incorrect voltage may result in irreversible

damage to the control.

NOTE: We strongly recommend that all control loops use an

approved temperature limit control for over or under temperature

limit protection. Failure to install temperature limit control protection where a potential hazard exists could result in damage to

equipment and property and injury to personnel.

Figure 3b — Thermocouple wiring.

NOTE: When an external device with a non-isolated circuit common is connected to the dc output, you must use an isolated or

ungrounded thermocouple.

Electromechanical Relay, Form C with suppression 3A

101A - _ _ _ _ - 0000

Solid State Relay, Form A, 0.5A without suppression

101B - _ _ _ _ - 0000

Figure 3c — Mechanical and solid-state relay wiring.

Switched DC

10 1C - _ _ _ _ - 0000

Figure 3d — Switched dc wiring.

Output Wiring

Input Wiring

Power Wiring

Wiring Guidelines

+

tc

-

tc

L1

L2

Fuse

L1

L2

Fuse

External

Device

L2

L1

dc+

dc-

dc-

External

Device

dc+

Internal Circuitry

18V Î (dc)+

dc-

Page 4

Watlow Series 101 User’s Manual ■4

Check sensor element location for proper

temperature response.

Calibrate the unit following the field

calibration procedure above.

Sensor is not measuring actual tempera-

ture.

Unit is out of calibration.

Controller is out of calibra-

tion.

Check for open sensor element or open

sensor lead wires.

Check sensor wiring. See wiring page.

Sensor is not wired correctly.Relay will not energize, ac

voltage is present, and the

controller is wired correctly.

Check wiring. See wiring page.

Check fuses or circuit breakers.

Check power sources.

Voltage is not present at ac input or load

output.

Control will not operate.

ActionProbable CauseProblem

Troubleshooting

Required Equipment

• A calibration quality portable temperature indicator.

• A sensor for the portable indicator.

Setup

1.With the Series 101 installed in your system, set the

controller to your desired set point.

2.Apply power to your system and allow it to stabilize.

Procedure

1.Measure temperature at the point you wish to control

(near the Series 101 sensor) with a portable temperature indicator.

2.Adjust the Series 101 until the portable indicator reads

the average of the system temperature variations as the

Series 101 switches on and off.

3.Carefully pull the Series 101 knob straight off the Dshaft.

4.Slightly loosen the two screws on the back of the knob.

5.Carefully replace the knob on the D-shaft without

moving the shaft.

6.Read the portable indicator. Then hold the black part of

the knob in place while turning the clear plastic skirt to

match the portable indicator reading. Simply put the

white line on the clear skirt over the dial scale position

which is the average of the portable indicator readings.

7.Carefully remove the knob from the D-shaft again and

tighten the screws.

8.Replace the knob on the shaft and check the portable

indicator for agreement. Repeat as required.

The Series 101 is warranted to be free of defects in

material and workmanship for 36 months after delivery to

the first purchaser for use, providing that the unit has not

been misapplied. Since Watlow has no control over its use

or misuse, we cannot guarantee against failure. Watlow’s

obligations hereunder, at Watlow’s option, are limited to

replacement or refund of purchase price of a unit which

upon examination proves to be defective within the warranty period. This warranty does not apply to damage

resulting from transportation, alteration, misuse or abuse.

• Call or fax Customer Service for a Return Material

Authorization (RMA) number before returning a product.

• Put the RMA number on the shipping label, and also a

description of the problem.

• A 20% of net price restocking charge applies to all

standard units returned to stock.

Contact:

• Phone: +1 (507) 454-5300

• Fax: +1 (507) 452-4507

If you encounter a problem with your Watlow controller, verify that your wiring is correct for your specific

model number. If the problem persists, an Application

Engineer can discuss your application with you.

Before calling, please have the complete model number and user’s manual available. You can get technical

support by dialing +1 (507) 454-5300, 7 a.m. to 7 p.m.

Central Standard Time.

The Series 101 User’s Manual is copyrighted by

Watlow Winona, Inc., © 2001, with all rights reserved.

(2059)

Technical Support

Returns

WarrantyField Calibration

Page 5

Declaration of Conformity

Series 101

Watlow

1241 Bundy Boulevard

Winona, Minnesota USA 55987

Declares that the following product: English

Designation: Series 101

Model Number(s): 101 (A, B or C) (1 or 2) (Any three numbers) -

(Any four letters or numbers)

Classification: Controller, Installation Category II, Pollution

Degree II

Rated Voltage: 120V~ (ac) or 230V~ (ac)

Rated Frequency: 50/60 Hz

Rated Power

Consumption: 4VA

Meets the essential requirements of the following European Union

Directive(s) using the relevant section(s) of the normalized standards and

related documents shown:

89/336/EEC Electromagnetic Compatibility Directive

EN 50082-1: 1992 EMC Generic immunity standard, Part 1:

Residential, commercial and light industry

environment

EN 61000-4-2: 1995 Electrostatic discharge

EN 61000-4-4: 1995 Electrical fast transients

EN 60801-2: 1994 Electrostatic discharge requirements

IEC 801-3: 1994 Radiated electromagnetic field requirements

IEC 801-4: 1988 Electrical fast transient/burst requirements

EN 55011: 1991 Limits and methods of measurement of radio

disturbance characteristics of industrial,

scientific and medical radio-frequency

equipment (Class B)

EN 61000-3-2: 1995 Limits for harmonic current emissions

EN 61000-3-3: 1995 Limitations of voltage fluctuations and flicker

73/23/EEC Low-Voltage Directive

EN 61010-1 1993 Safety requirements for electrical equipment

for measurement, control, and laboratory use,

Part 1: General requirements

Déclare que le produit suivant : Français

Désignation : Série 101

Numéro(s) de

modèle(s) : 101 (A, B ou C) (1 ou 2) (Trois lettres

quelconques) (quatre lettres ou chiffres

quelconques)

Classification : Commande, installation catégorie II, degré de

pollution II

Tension nominale : 120V~ (ac) ou 230V~ (ac)

Fréquence nominale : 50/60 Hz

Consommation

d’alimentation nominale : 4VA

Conforme aux exigences de la (ou des) directive(s) suivante(s) de l’Union

Européenne figurant aux sections correspondantes des normes et

documents associés ci-dessous :

89/336/EEC Directive de compatibilité électromagnétique

EN 50082-1 : 1992 Norme générique sur l’immunité, Partie 1 :

Environnement résidentiel, commercial et

industrielléger

EN 61000-4-2 : 1995 Décharge électrostatique

EN 61000-4-4 : 1995 Transitoires rapides électriques

EN 60801-2: 1994 Exigences concernant les décharges

électrostatiques

IEC 801-3: 1994 Insensibilité à l’énergie rayonnée

IEC 801-4: 1988 Exigences concernant les courants électriques

transitoires rapides et les suramplifications

brusques

EN 55011 : 1991 Limites et méthodes de mesure des

caractéristiques des perturbations

radioélectriques des appareils industriels,

scientifiques et médicaux (Classe B)

EN 61000-3-2: 1995 Limites d’émission d’harmoniques

EN 61000-3-3: 1995 Limitations d’écarts de tensions et de

papillotement

73/23EEC Directive sur les basses tensions

EN 61010-1 1993 Exigences de sécurité pour le matériel

électrique de mesure, commande et de

laboratoire, Partie 1: Exigences générales

(2061)

Erklärt, daß das folgende Produkt: Deutsch

Beschreibung: Serie 101

Modellnummer(n): 101 (A, B oder C) (1 oder 2) (3 beliebige

Ziffern) - (4 beliebige Buchstaben oder Ziffern)

Klassifikation: Regelsystem, Installationskategorie II,

Emissionsgrad II

Nennspannung: 120V~ (ac) oder 230V~ (ac)

Nennfrequenz: 50/60 Hz

Nominaler Strom

verbrauch: 4VA

Erfüllt die wichtigsten Normen der folgenden Anweisung(en) der

Europäischen Union unter Verwendung des wichtigsten Abschnitts bzw.

der wichtigsten Abschnitte der normalisierten Spezifikationen und der

untenstehenden einschlägigen Dokumente:

89/336/EEC EWG Elektromagnetische Verträglichkeit

EN 50082-2: 1992 EMC-Rahmennorm für Störsicherheit, Teil 1:

Wohngegenden, Handelsverkehr und

Leichtindustrie

EN 61000-4-2: 1995 Elektrostatische Entladung

EN 61000-4-4: 1995 Elektrische schnelle Stöße

EN 60801-2: 1994 Elektrostatische Entladung (Anforderungen)

IEC 801-3: 1994 Strahlungsimmunität

IEC 801-4: 1988 Elektrische schnelle Stöße/Burst (Anforderungen)

EN 55011: 1991 Beschränkungen und Methoden der Messung

von Funkstörungsmerkmalen industrieller, wis

senschaftlicher und medizinischer

Hochfrequenzgeräte (Klasse B)

EN 61000-3-2: 1995 Grenzen der Oberwellenstromemission

EN 61000-3-3: 1995 Grenzen der Spannungsschwankungen und

Flimmern

72/23/EEC EWG Niederspannungsrichtlinie

EN 61010-1 1993 Sicherheitsrichtlinien für Elektrogeräte zur

Messung, zur Steuerung und im Labor, Teil 1:

Allgemeine Richtlinien

Declara que el producto siguiente: Español

Designación: Serie 101

Números de modelo: 101 (A, B ór C) (1ór 2) (Cualquier

combinación de tres números) - (Cualquier

combinación de cuatro números y letras)

Clasificación: Control, categoría de instalación II, grado de

contaminación ambiental II

Tensión nominal: 120V~ (ac) ór 230V~ (ac)

Frecuencia nominal: 50/60 Hz

Consumo nomina

de energía: 4VA

Cumple con los requisitos esenciales de las siguientes Directivas de la

Unión Europea, usando las secciones pertinentes de las reglas

normalizadas y los documentos relacionados que se muestran:

89/336/EEC - Directiva de Compatibilidad

Electromagnética

EN 50082-1: 1992 Norma de inmunidad genérica del EMC, Parte

1: Ambiente residencial, comercial e industria

ligera

EN 61000-4-2: 1995 Descarga electrostática

EN 61000-4-4: 1995 Perturbaciones transitorias eléctricas rápidas

EN 60801-2: 1994 Requerimientos de descargas electrostáticas

IEC 801-3: 1994 Inmunidad radiada

IEC 801-4: 1988 Requerimientos de perturbaciones transitorias

eléctricas rápidas

EN 55011: 1991 Límites y métodos de medición de

características de perturbaciones de radio

correspondientes a equipos de

radiofrecuencia industriales, científicos y

médicos (Clase B)

EN 61000-3-2: 1995 Límites para emisiones de corriente armónica

EN 61000-3-3: 1995 Limitaciones de oscilaciones y fluctuaciones

de voltaje

73/23/EEC Directiva de Baja Tensión

EN 61010-1 1993 Requerimientos de seguridad para equipos

eléctricos de medición, control y uso en

laboratorios, Parte 1: Requerimientos

generales

Signature of Authorized Representative

Erwin D. Lowell

Name of Authorized

Representative

General Manager

Title of Authorized

Representative

Winona, Minnesota USA

Place of Issue

November, 1998

Date of Issue

Page 6

Watlow Series 101 User’s Manual

Watlow, 1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 Internet: http://www.watlow.com

For other product information: Watlow FAX REPLY: +1 (732) 885-6344, outside the U.S.; or +1 (800) 367-0430, inside the U.S.

Loading...

Loading...