WaterFurnace NSKW06, NSKW08, NSKW12, NSKW17 Installation Information

NSKW

Geothermal Hydronic Heat Pump

Installation Information

Water Piping Connections

Electrical Data

Startup Procedures

Preventive Maintenance

Versatec Ultra NSKW Installation Manual

IM2566WN 07/16

Table of Contents

Model Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Water Quality

Field Connected Water Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Potable Water Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Hydronic Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Accessories and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-19

External Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Converting to a Dedicated Cooling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unit Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

The Aurora Base Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-25

Reference Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Legend and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Thermistor Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Antifreeze Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Troubleshooting Guideline for Refrigerant Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

HR Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-32

HE Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35

DHW HE Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Heating and Cooling Cycle Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Troubleshooting Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Technical Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42-45

Revision Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

VERSATEC ULTRA NSKW INSTALLATION MANUAL

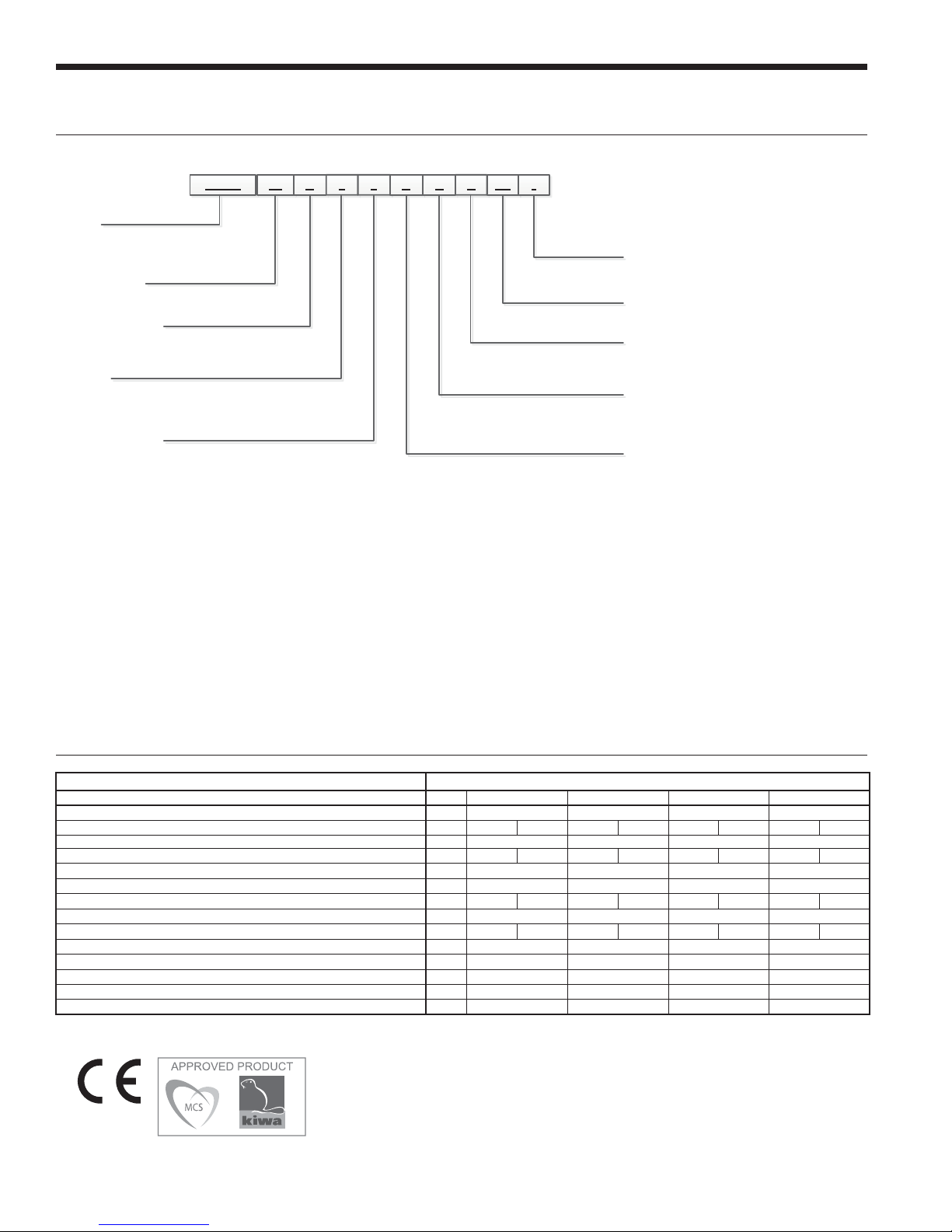

Model Nomenclature

1-4

NSKW 08 H 6 0 A C

Model

NSKW – Versatec Hydronic

Heat Pump

Unit Capacity

06, 08, 12, 17

Reversible Option

H- Heating Only

R- Reversible

Voltage

6 – 220-240/50/1

7 – 380-420/50/3

Hot Water Option

0 – No Hot Water Generation, No IntelliStart

2 – Hot Water Generation, No IntelliStart

3 – No Hot Water Generation, IntelliStart

5 – Hot Water Generation, IntelliStart

1

5-6 7 8 9 10 11

12

C

13-14

SS *

15

Vintage

* – Factory Use Only

Future Option

SS – Standard Option

Load Coax

C – Copper

N - Cupronickel

Source Coax

C – Copper

N – Cupronickel

Controls Option

A – Aurora™ Base Controls (ABC)

Rev.: 15 June 2016

2

NOTES: 1 – Available on 08, 12, 17 only. Hot water generator requires field installed external pump kit.

2 – NSKW06 heating only models are available only with copper double wall vented load coax for potable water,

and are not designed to be converted to dedicated cooling units.

Energy Labelling

Supplier WaterFurnace International, Inc.

Model NSKW06 NSKW08 NSKW12 NSKW17

Model hot water heater - - - Temperature application °C 35 55 35 55 35 55 35 55

Declared load profile for water heating - - - Seasonal space heating energy efficiency class, average climate A++ A++ A++ A++ A++ A++ A++ A++

Water heating energy efficiency class, average climate - - - Rated heat output (Pdesignh), average climate kW 6 8 12 17

Annual energy consumption space heating, average climate kWh 2,860 3,432 3,689 4,543 4,920 6,343 7,985 9,656

Annual energy consumption water heating, average climate kWh - - - Seasonal space heating energy efficiency, average climate % 160 119 178 132 187 137 164 126

Water heating energy efficiency, average climate % - - - Sound power level LWA indoors dB 57 57 61 63

Rated heat output (Pdesignh), cold climate kW 6 8 12 17

Rated heat output (Pdesignh), warm climate kW 6 8 12 17

Sound power level LWA outdoors dB dB - - - -

3/18/2016

All Versatec Ultra NSKW product is safety tested to CE standards and

performance tested in accordance with standard BS EN 14511-2.

4

General Installation Information

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Safety Considerations

Installing and servicing air conditioning and heating

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service heating and air

conditioning equipment. When working on heating and

air conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available for all brazing operations.

NOTE: Before installing, check voltage of unit(s) to ensure

proper voltage.

WARNING: Before performing service or

maintenance operations on the system, turn off

main power switches to the unit. Electrical shock

could cause serious personal injury.

Process Water Applications

For process water applications, it is recommended that

a secondary load heat exchanger be installed to prevent

corrosion to the unit’s primary coaxial coil. In situations

where scaling could be heavy or where biological growth

such as iron bacteria will be present, a closed loop system is

recommended. Over a period of time, ground water unit heat

exchanger coils may lose heat exchange capability due to a

buildup of mineral deposits. These can be cleaned only by

a qualified service mechanic as special pumping equipment

and solutions are required. Never use flexible hoses with a

smaller inside diameter than that of water connections.

WARNING: To avoid equipment damage, do not

leave the system filled in a building without heat

during cold weather, unless adequate freeze

protection levels of antifreeze are used. Heat

exchangers do not fully drain and will freeze

unless protected, causing permanent damage.

Unit Location

Provide sufficient room to make water and electrical

connections. If the unit is located in a confined space,

provisions must be made for unit servicing. Locate the

unit in an indoor area that allows easy removal of the

access panels and has enough space for service personnel

to perform maintenance or repair. These units are not

approved for outdoor installation and, therefore, must be

installed inside the structure being conditioned. Do not

locate units in areas subject to freezing conditions.

WARNING: Do not store or install units in

corrosive environments or in locations subject

to temperature or humidity extremes (e.g. attics,

garages, rooftops, etc.). Corrosive conditions and

high temperature or humidity can significantly

reduce performance, reliability, and service life.

Mounting Units

Prior to setting the unit in place, remove and discard the

compressor hold down shipping bolt located at the front of

the compressor mounting bracket.

Units should be mounted level on a vibration absorbing pad

slightly larger than the base to provide isolation between

the unit and the floor. It is not necessary to anchor the unit

to the floor. Allow access to the front, back, and side access

panels for servicing.

Moving and Storage

Move units in the normal “Up” orientation as indicated by

the labels on the unit packaging. When the equipment

is received, all items should be carefully checked against

the bill of lading to ensure that all crates and cartons

have been received in good condition. Examine units for

shipping damage, removing unit packaging if necessary

to properly inspect unit. Units in question should also

be internally inspected. If any damage is observed, the

carrier should make the proper notation on delivery receipt

acknowledging the damage. Units are to be stored in a

location that provides adequate protection from dirt, debris

and moisture.

Vibration Pad Mounting

5

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Water Quality

General

Water-to-water heat pumps may be successfully applied

in a wide range of residential and light commercial

applications. It is the responsibility of the system designer

and installing contractor to ensure that acceptable water

quality is present and that all applicable codes have been

met in these installations. Failure to adhere to the guidelines

in the water quality table could result in loss of warranty.

Application

These heat pumps are not intended for direct coupling

to swimming pools and spas. If used for this type of

application, a secondary heat exchanger must be used.

Failure to supply a secondary heat exchanger for this

application will result in warranty exclusion for primary heat

exchanger corrosion or failure.

Water Treatment

Do not use untreated or improperly treated water.

Equipment damage may occur. The use of improperly

treated or untreated water in this equipment may result in

scaling, erosion, corrosion, algae or slime. The services of a

qualified water treatment specialist should be engaged to

determine what treatment, if any, is required. The product

warranty specifically excludes liability for corrosion,

erosion or deterioration of equipment.

The heat exchangers and water lines in the units are copper

or cupronickel tube. There may be other materials in the

building’s piping system that the designer may need to take

into consideration when deciding the parameters of the

water quality.

If an antifreeze or water treatment solution is to be used,

the designer should confirm it does not have a detrimental

effect on the materials in the system.

Contaminated Water

In applications where the water quality cannot be held to

prescribed limits, the use of a secondary or intermediate

heat exchanger is recommended to separate the unit from

the contaminated water.

The following table outlines the water quality guidelines

for unit heat exchangers. If these conditions are exceeded,

a secondary heat exchanger is required. Failure to supply

a secondary heat exchanger where needed will result in a

warranty exclusion for primary heat exchanger corrosion

or failure.

WARNING: Must have intermediate heat

exchanger when used in pool and spa

applications.

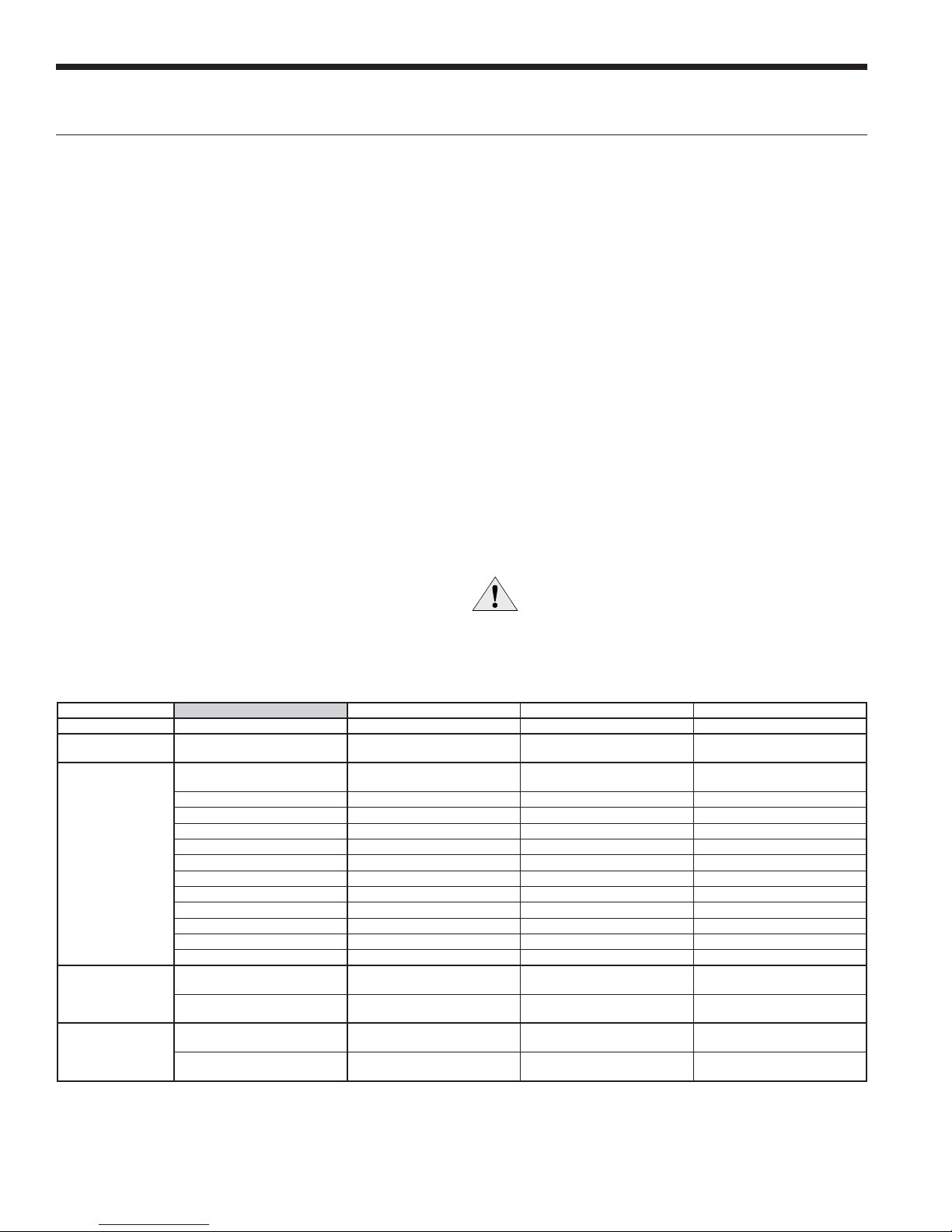

Water Quality Guidelines

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity

Scaling

Corrosion

Iron Fouling

(Biological Growth)

Erosion

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

Calcium and

Magnesium Carbonate

Hydrogen Sulfide

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron, FE

Bacterial Iron Potential

Iron Oxide

Suspended Solids

Threshold Velocity

(Fresh Water)

Less than 0.5 ppm (rotten egg

smell appears at 0.5 ppm)

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

2

+ (Ferrous)

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

7 - 9 7 - 9 7 - 9

(Total Hardness)

less than 350 ppm

< 0.2 ppm < 0.2 ppm < 0.2 ppm

< 1.8 m/sec < 1.8 m/sec < 1.8 m/sec

(Total Hardness)

less than 350 ppm

10 - 50 ppm Less than 1 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

(Total Hardness)

less than 350 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

2/22/12

6

Field Connected Water Piping

VERSATEC ULTRA NSKW INSTALLATION MANUAL

General

Each unit is equipped with captive FPT water connections

to eliminate ‘egg-shaping’ from use of a backup wrench.

For making the water connections to the unit, a Teflon tape

thread sealant is recommended to minimize internal fouling

of the piping. Do not over tighten connections. All supply and

return water piping should be insulated to prevent excess

condensation from forming on the water lines.

NOTES: 1) WaterFurnace recommends a male national pipe

thread (NPT) to British standard pipe fitting (BSPF) to

adapt to NSKW water connections. 2) Units are factory runtested using propylene glycol. Prior to connecting piping

to unit, thoroughly flush heat exchangers.

The piping installation should provide service personnel with

the ability to measure water temperatures and pressures.

The water lines should be routed so as not to interfere with

access to the unit. The use of a short length of high pressure

hose with a swivel type fitting may simplify the connections

and prevent vibration. Optional stainless steel hose kits are

available as an accessory item.

Before final connection to the unit, the supply and return

hose kits must be connected, and the system flushed

to remove dirt, piping chips and other foreign material.

Normally, a combination balancing and close-off (ball) valve

is installed at the return, and a rated gate or ball valve is

installed at the supply. The return valve can be adjusted to

obtain the proper water flow. The valves allow the unit to be

removed for servicing.

The proper water flow must be delivered to each unit

whenever the unit heats or cools. To assure proper flow,

the use of pressure/temperature ports is recommended

to determine the flow rate. These ports should be located

adjacent to the supply and return connections on the unit.

The proper flow rate cannot be accurately set without

measuring the water pressure drop through the refrigerantto-water heat exchanger (See Pressure Drop Table for water

flow and pressure drop information). Normally about 0.054

L/s flow rate per kw of cooling capacity (0.040 L/s per kw

minimum) is needed. Both source as well as load fluid piping

must be at least as large as the unit connections on the heat

pump (larger on long runs).

Never use flexible hoses of a smaller inside diameter than

that of the water connection on the unit and limit hose length

to 3.05m per connection. Check carefully for water leaks.

CAUTION: Water piping exposed to outside

temperature may be subject to freezing.

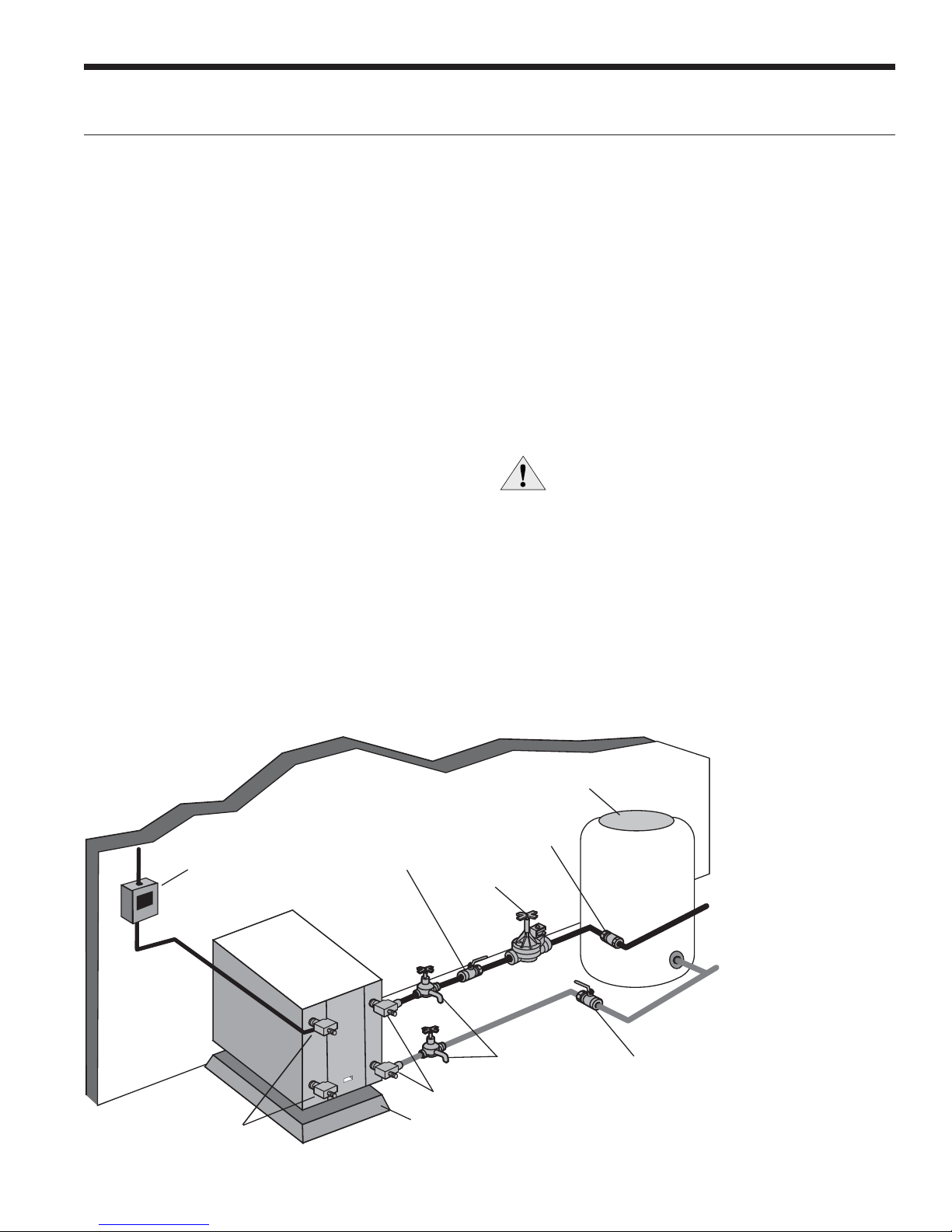

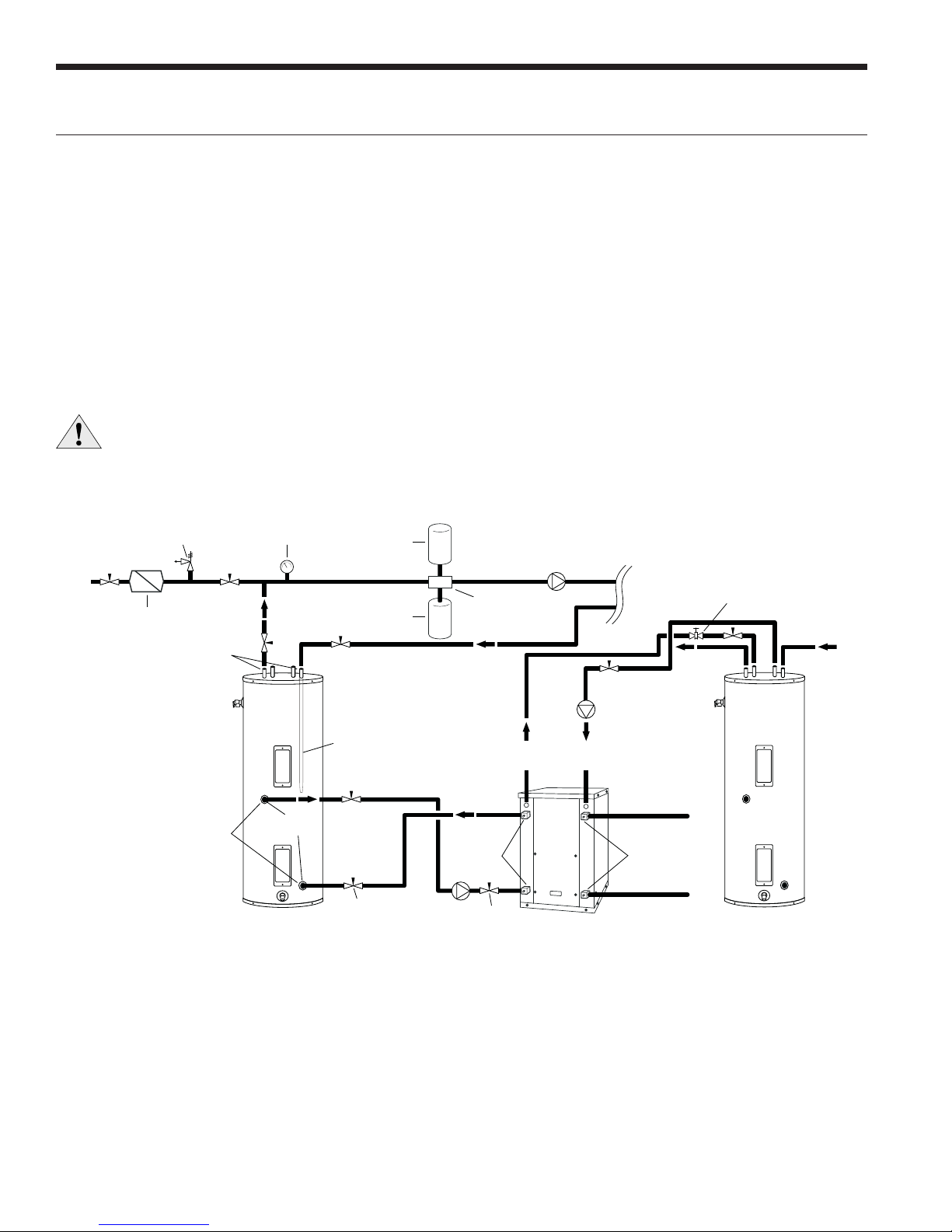

Typical Open Loop Installation

Line Voltage

Disconnect

Load Liquid

Connections

Shut-off Valve

(to isolate solenoid

valve while acid

flushing)

Rubber Bladder

Expansion Tank

Flow Regulator Valve

Solenoid

Valve

Boiler Drains for

HX Flushing

P/T Plugs

Vibration Absorbing

Mesh or Air Pad

Water Out

Water In

Shut-off

Valve

NOTE: Valves and boiler drains must be installed

so the heat exchanger can be acid flushed.

7

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Field Connected Water Piping cont.

Open Loop Well Water Systems

Always maintain water pressure in the heat exchanger by

placing water control valves at the outlet of the unit. Use

a closed bladder type expansion tank to minimize mineral

deposits. Ensure proper water flow through the unit by

checking pressure drop across the heat exchanger and

comparing it to the figures in the pressure drop table.

Normally, about 0.038 L/s per kW flow rate of cooling

capacity is needed in open loop systems, 0.029 L/s per kW

minimum if entering source temperature is above 10°C.

Some water control valves draw their power directly from

the unit’s 24V transformer and can overload and possibly

burn out the transformer. Check total VA draw of the water

valve(s) and ensure it is under 40 VA.

Discharge water from a heat pump can be disposed of in

various ways depending on local building codes (i.e. recharge

well, storm sewer, drain field, adjacent stream or pond,

etc.). Most local codes restrict the use of sanitary sewer for

disposal. Consult your local building and zoning departments

to ensure compliance in your area.

Figure 9a: Open Loop Solenoid Valve Connection Option

Typical quick operating external 24V water solenoid valve

(type PPV100 or BPV100) wiring.

C

P1

R

SV

Solenoid

Acc Com

Acc NC

Acc NO

ABC Board

1

2

P2

3

Valve

NOTE: SW2-4 and SW2-5 should be “OFF” to cycle with

the compressor.

Figure 9b: Open Loop Solenoid Valve Connection Option

Typical slow operating external 24V water solenoid valve

(type V100FPT) wiring.

C

R

C

W/Y

Acc Com

ACC NC

Acc NO

V Valve ABC Board

NOTE: SW2-4 should be “ON” and SW2-5 should be “OFF”

when using a slow opening (V100FPT) water valve.

8

Field Connected Water Piping cont.

VERSATEC ULTRA NSKW INSTALLATION MANUAL

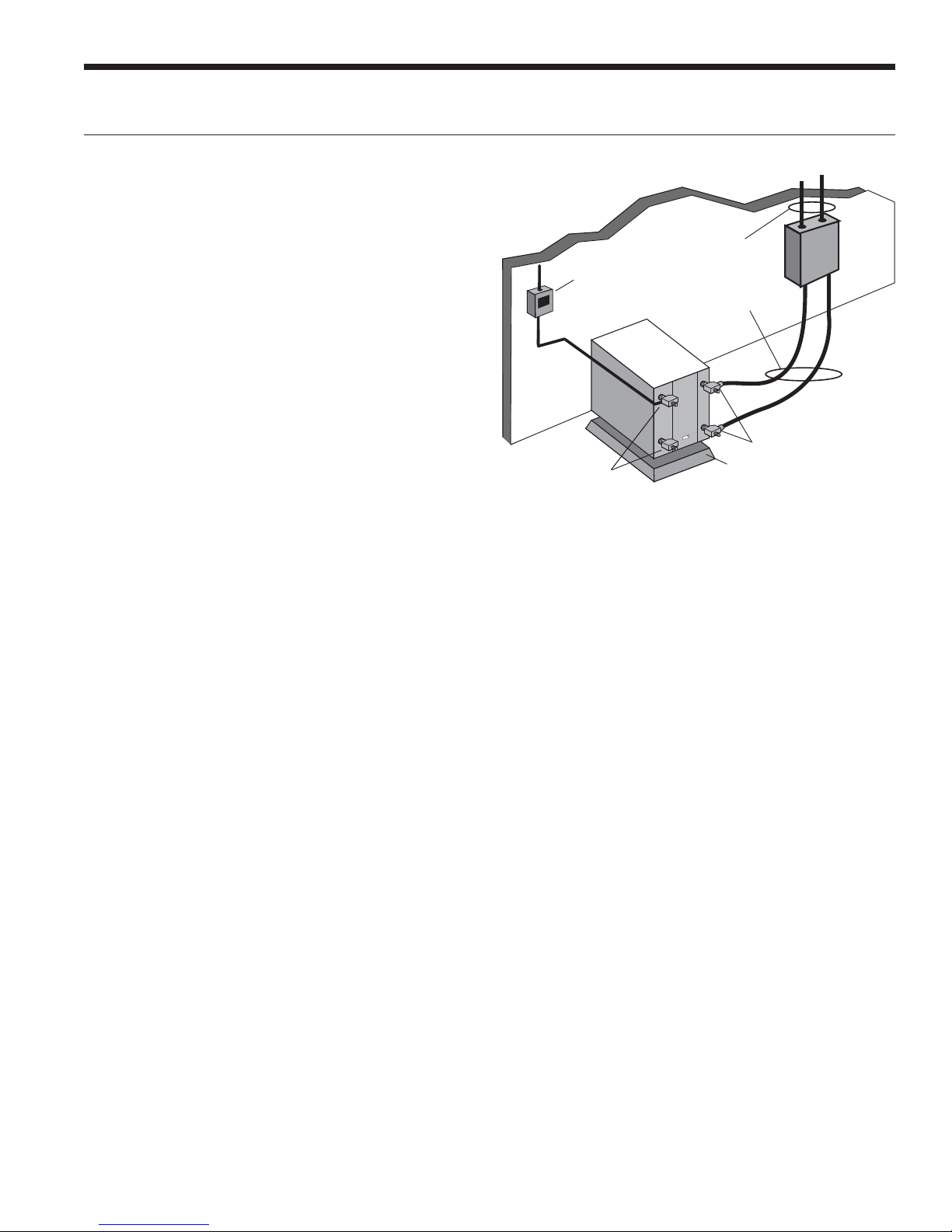

Earth Coupled Systems with Flow Center

nce piping is completed between the unit, flow center and

the earth loop, final purging and charging of the loop is

needed. A pump capable of 14 m

3

/hr @ 25 meters of head

is needed to achieve adequate flow velocity in the loop to

purge air and dirt particles from the loop itself. Antifreeze

solution is used in most areas to prevent freezing. Maintain

the pH in the 7.6-8.2 range for final charging.

Flush the system adequately to remove as much air as

possible. Then, pressurize the loop to a static pressure of

345-517 kPa. This is normally adequate for good system

operation. Ensure that the flow center provides adequate

flow through the unit by checking pressure drop across the

heat exchanger and by comparing it to the figures shown

in the Pressure Drop tables. Usually, 0.054 L/s per kW or

minimum 0.040 L/s per kW of cooling capacity is needed in

closed loop earth-coupled applications.

Ground Loop Design and Installation

This instruction manual does not cover the design and

installation of the ground loop system. WaterFurnace

recommends that all ground loops are designed using

GeoLink

software package. Installers shall follow the guidelines

detailed in Microgeneration Certification Scheme (MCS)

Installation Standard MIS 3005 for designing ground loop

collectors. Additional guidance on ground collectors is

provided by International Ground-Source Heat Pump

Association (IGSHPA).

TM

Design Studio (GDS) or another commercial

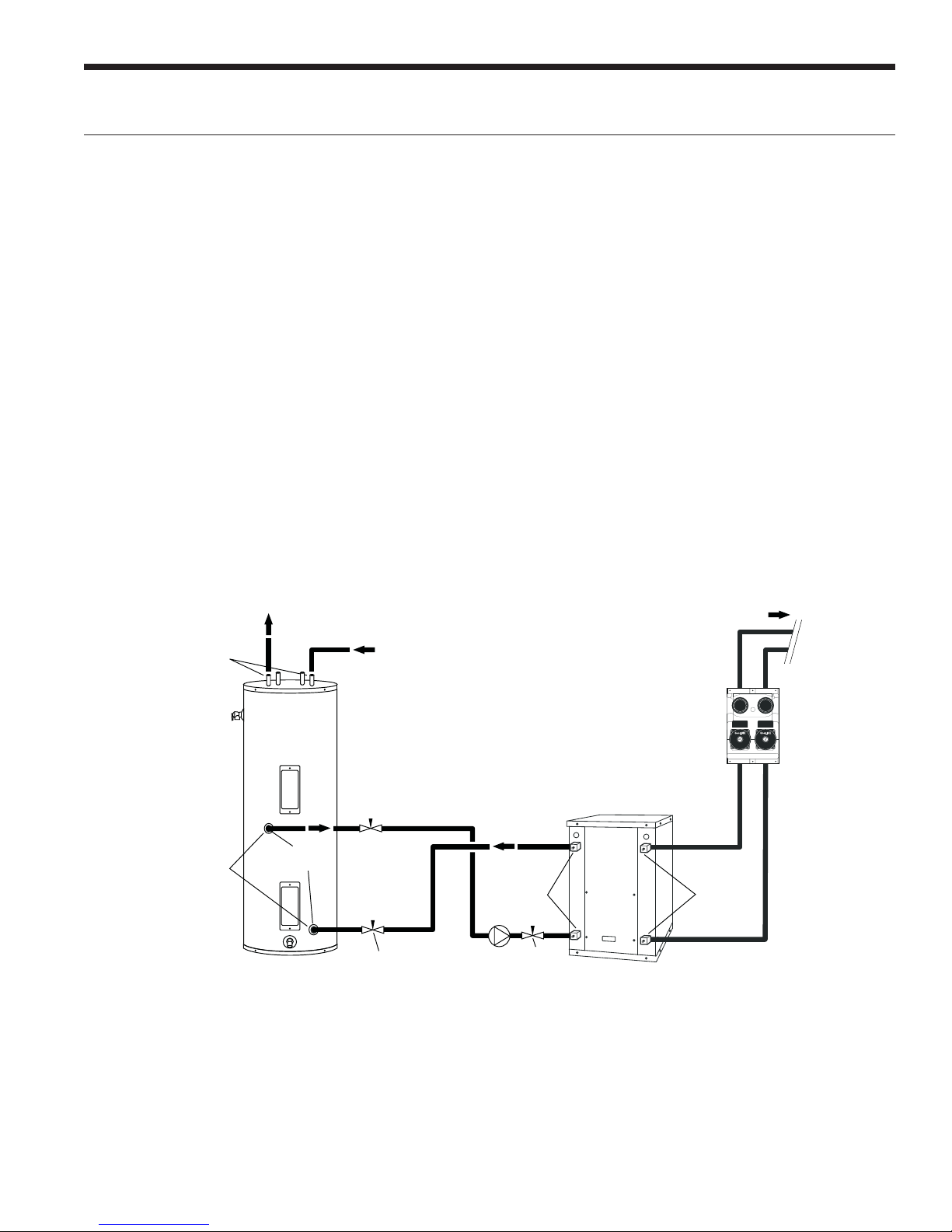

Typical Closed Loop Earth Coupled Installation

Earth Coupled Loop

Piping with Insulation

Line Voltage

Disconnect

Unit Connector Kits

with Insulation

P/T Plugs

Load Liquid

Connections

Vibration Absorbing

Mesh or Air Pad

9

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Potable Water Systems

TNSKW06 kW heat pumps can be equipped with a double-

wall vented coaxial heat exchanger capable of hot water

generation (HWG). An optional factory-installed hot water

generator coil may be provided with NSKW08-17. The

temperature of the hot water produced by the heat pump

cannot be adjusted and will vary with the inlet temperature.

WaterFurnace recommends the use of a properly sized

buffer tank equipped with supplemental electric immersion

heaters in conjunction with all NSKW models used in an

HWG application. Immersion heaters must be capable

of heating the water to 60°C at a regular time interval

to prevent the build-up of bacteria such as Legionella.

Installations must meet minimum requirements outlined in

UK Domestic Heating Compliance Guide.

CAUTION: Hot water in excess of 60°C can cause

scalding.

Suggested Domestic Water Heater Hookup

207 kPa

RELIEF VALVE

Back Flow Preventer /

Pressure Relief Valve

Dielectric

Unions

Dielectric

Unions

NOTES:

* A 207 kPa pressure relief valve (Part No: SRV30) should be used in

hydronic applications.

** Vent valve or P/T port at highest point in return line prior to ball valve.

Pressure

Gauge

GEO

STORAGE

TANK

1-1/2 in.

FPT

Dip Tube

Expansion

Tank

Ball Valve

Air

Vent

Air

Separator

Ball Valve

LOAD PUMP

FROM

HWG

Versatec Ultra

5 Series

TO

HWG

HYDRONIC

PUMP

Source OUT

P/T PortsP/T Ports

Source IN

LOAD

HOT

(Piped in

series to

an electric

water heater)

Vent Valve/

P/T Port**

DOMESTIC

COLD

10

Potable Water Systems cont.

Hot Water Generator Connections

The heat reclaiming hot water generator coil is vented double-

wall copper construction and is suitable for potable water. To

maximize the benefits of the hot water generator a minimum

50-gallon water heater is recommended. For higher demand

applications, use an 80-gallon water heater as shown below or

two 50-gallon water heaters connected in a series. A geo storage

tank should not be used in this application unless it is plumbed

in a series with an electric water heater. The geo storage tank is

equipped with a single 4500 Watt element and will not be able

to provide adequate water heating if used as a standalone water

heater. Electric water heaters are recommended. Make sure all

local electrical and plumbing codes are met for installing a hot

water generator. The Versatec Ultra NSKW is not supplied with

an internal circulator.

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Alternate Hot Water Installation with

Direct Coupling to a Double Wall Unit

Dielectric

Unions

Dielectric

Unions

HOT

COLD

1-1/2˝

FPT

WaterFurnace

GEOTANK

Ball Valve

LOOP FIELD

FLOW CENTER

P/T PortsP/T Ports

Ball Valve

5 Series

NSW018 or NSW025 (Heating Only)

Versatec Ultra

06 (Heating Only)

with Double Wall Load Coax

NOTES:

1) Unions and valves must be installed so that acid flushing

of the heat exchanger is possible.

2)

Make sure there is not a check valve in the diptube of

the tank.

11

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Hydronic Section

General guidelines are shown below for component

selection and design/installation criteria for the piping

system. Local codes supersede any recommendations in

this manual.

Shut Off/Flow Regulation Valves

Use full port ball valves or gate valves for component

isolation. If valves are going to be used frequently, ball

valves are recommended. Globe valves are designed for flow

regulation. Always install globe valves in the correct direction

(fluid should enter through the lower body chamber).

Check valves

Swing check valves must be installed in the horizontal

position with the bonnet of the valve upright. Spring check

valves can be mounted in any position. A flow check valve

is required to prevent thermo-siphoning (or gravity flow)

when the circulator pump is off or when there are two

circulators on the same system.

Storage (Buffer) Tank

A buffer tank is required for all hydronic heating systems

using Versatec Ultra heat pumps. The tank should be sized

to provide 7.6 L of storage capacity for every 300 W of

nominal heat pump capacity.

Pressure Reducing Valves or Feed Water Valves

This valve lowers the pressure from the make-up water line

to the system. Most are adjustable and directional. A “fast

fill” valve is required for initial filling of the system. Some

have screens, which must be cleaned after the initial filling.

If there is a restriction in the screen, the system could go to

0 kPa, potentially causing pumps(s) failure. A valve should

be installed on each side of the pressure reducing valve for

servicing. Both valves should have tags reading “Do not

shut this valve under normal operation – service valve only.”

Expansion Tanks

Expansion tanks are required on hydronic systems to help

absorb the pressure swings as the temperature in the

system fluctuates.

Elbows/Tees

Long radius elbows or two 45° elbows will lower pressure

drop. Standard tees have a greater restriction on the “T”

portion than tees designed with angled outlet ports.

Antifreeze

Antifreeze is required if any of the piping system is located

in areas subject to freezing.

Pressure Relief Valve

Most codes require the use of a pressure relief valve if a

closed loop heat source can be isolated by valves. Even

if local code does not require this device, WaterFurnace

recommends its installation. If the pressure relief valve in

the buffer tank is not already rated at 207 kPa maximum

pressure, one must be installed. The pressure relief valve

should be tested at start up for operation. Note that the

waste pipe must be at least the same diameter as the valve

outlet (never reduce), and valves may not be added to this

pipe. The bottom of the pipe must terminate at least 15 cm

above the floor. If the piping is connected to a drain, there

must be an air gap.

Backflow Prevention Check Valves

Most codes require backflow prevention check valves.

Note that a single check valve is not equal to a backflow

prevention check valve. Even if local code does not require

this device, WaterFurnace recommends its installation. This

is particularly important if the system will use antifreeze.

Dielectric Unions

Dielectric unions are recommended whenever connecting

two dissimilar metals to one and other to prevent electrogalvanic corrosion.

When using the various types of hydronic heat distribution

systems, the temperature limits of the geothermal system

must be a major consideration. In new construction, the

distribution system can easily be designed with the

temperature limits in mind. In retrofits, care must be

taken to address the operating temperature limits of the

existing distribution system. The maximum storage tank

temperature for the Versatec Ultra NSKW is 54.4°C. Typical

in floor radiant systems require much lower temperatures,

typically 37.8°-46.1°C, which is ideal for the Versatec Ultra

NSKW.

12

Hydronic Section cont.

VERSATEC ULTRA NSKW INSTALLATION MANUAL

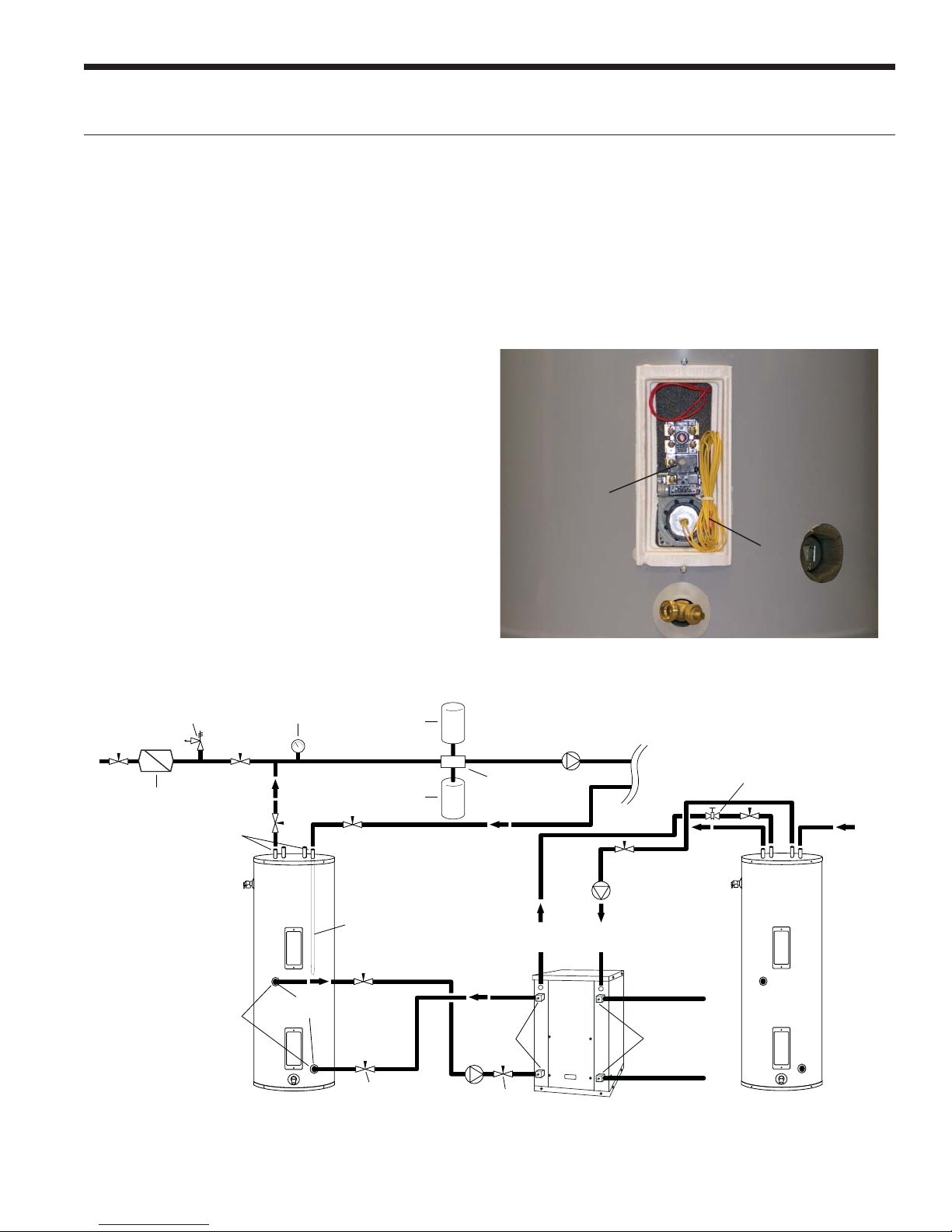

If using a Geothermal Storage tank there will be two red

wires exiting out of the top of the tank. These red wries

extend internally down to the thermistor/tank thermostat

section of the tank. Remove the bottom tank cover to expose

the red wires as well as the yellow tank thermistor wires.

HydroZone

If using HydroZone control, connect the two red wires to

the two yellow wires using wire nuts. Next, connect the two

red wires from the top of the Geothermal Storage tank to

“TS” and “GND” on the HydroZone. The “OAT” and “GND”

terminals on the HydroZone are used for an outdoor air

sensor.

HydroStat

If using HydroStat control, connect the two red wires to the

yellow wires using wire nuts. Next, connect the two red wires

from the top of the Geothermal Storage tank to “TS” and

“GND” on the HydroStat. The “OAT” and “GND” terminals

on the HydroStat are used to connect the controller to the

ELWT (Entering Load Water Temperature) well point sensor.

This sensor is located on the load side entering water line

inside the unit.

For other field installed controllers, these two red wires

will need wired to the appropriate sensor input terminals.

Another option for connection is to connect the thermostat

on the Geothermal Storage tank directly to “R” and “Y1” on

the ABC board.

Adequate rate of flow (L/s) is very important to system

performance and long term reliability. Follow the guidelines

for recommended flow in the recommendations table.

Geothermal Storage Tank Thermostat and Thermistor

Combination

Unit

Water To

Wat er

Thermistor Wires Connected to TS and GND on

HydroZone Controller.

207 kPa

RELIEF VALVE

Back Flow Preventer /

Pressure Relief Valve

Dielectric

Unions

Dielectric

Unions

NOTES:

* A 207 kPa pressure relief valve (Part No: SRV30) should be used in

hydronic applications.

** Vent valve or P/T port at highest point in return line prior to ball valve.

Pressure

Gauge

GEO

STORAGE

TANK

1-1/2 in.

FPT

Dip Tube

Ball Valve

Expansion

Tank

Air

Vent

Air

Separator

Ball Valve

LOAD PUMP

FROM

HWG

Versatec Ultra

5 Series

TO

HWG

HYDRONIC

PUMP

Source OUT

P/T PortsP/T Ports

Source IN

LOAD

HOT

(Piped in

series to

an electric

water heater)

Vent Valve/

P/T Port**

DOMESTIC

COLD

13

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Accessories and Options

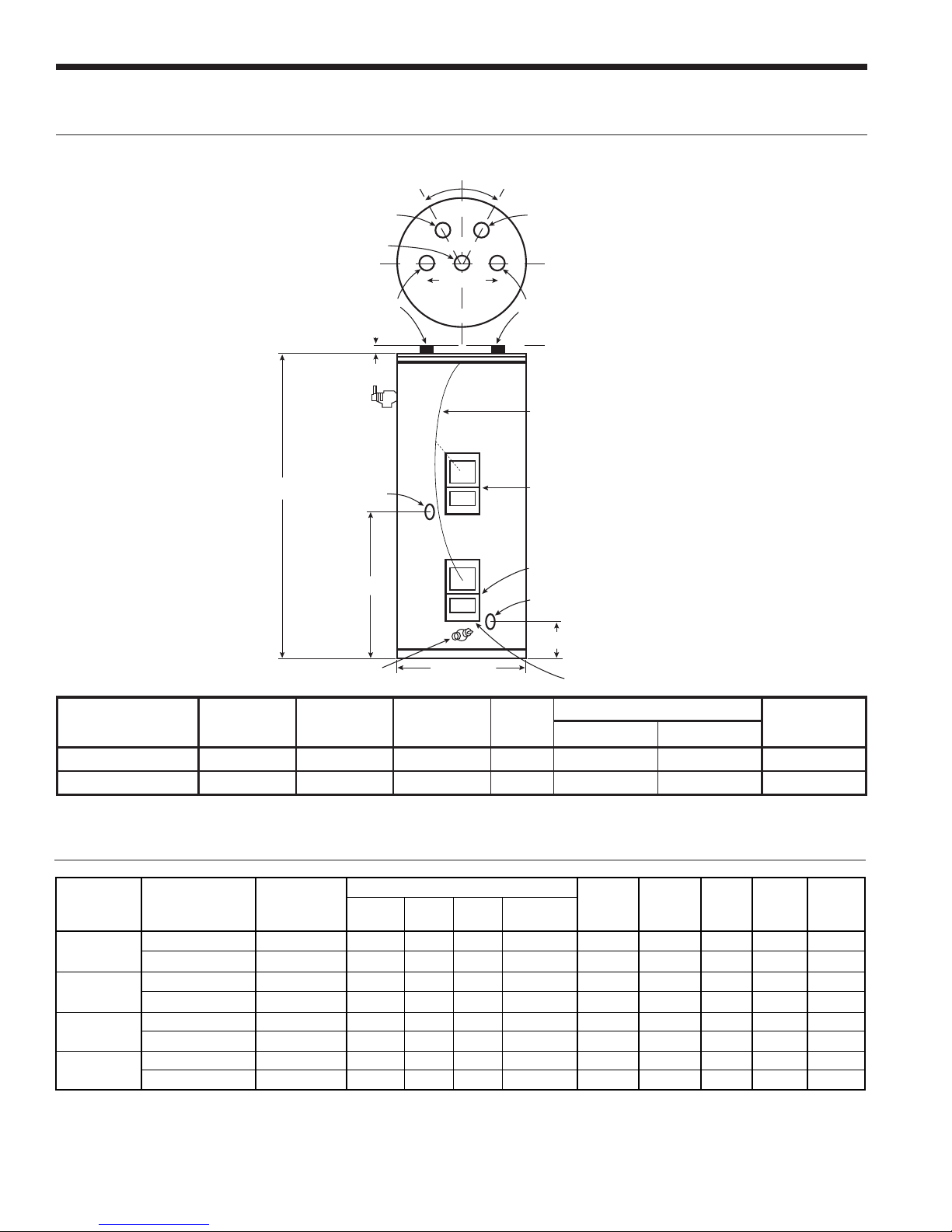

Geo Storage Tank Dimensions

°

3

0

0

3

°

From Geo

PRIMARY ANODE

99 cm - 80 Gallon

106.7 cm - 119 Gallon

HOT OUTLET

w/35.6 cm SECONDARY ANODE

Approx. 2.54 cm

T & P

VALVE

HEIGHT

90.8 cm

To Geo 150 cm Dip Tube

20.3 cm

COLD INLET

132.0 cm DIP TUBE

Yellow Wire attached

to Thermistor or Thermostat

for Top Exit

Element Location

Lower Sensor Thermistor (12P541-01)

to be used by Water to Water Units

Optional “From Geo” Connection

13.3 cm

DRAIN VALVE

Model

Number

GEO-STORAGE-80

GEO-STORAGE-120

Gallon [Liter]

Capacity

80 [303] 4500 1 16 160.6 61.0 92.5

119 [450] 4500 1 16 160.6 71.1 141.1

Element

Wattage

(240 Volt)

Electrical Data

Model

06

08

12

17

Rated

Voltage

220-240/50/1 198/264 17.5 11.2 60.0 24.0 1.5 4.5 17.2 20.0 30

380-420/50/3 342/462 6.5 4.2 28.0 16.8 - - 4.2 5.3 6

220-240/50/1 198/264 27.0 17.3 97.0 34.0 1.5 4.5 23.3 27.6 40

380-420/50/3 342/462 10.0 6.4 45.0 27.0 - - 6.4 8.0 10

220-240/50/1 198/264 31.5 20.2 126.0 44.0 1.5 4.5 26.2 31.2 50

380-420/50/3 342/462 12.1 7.8 51.5 31.0 - - 7.8 9.8 15

220-240/50/1 198/264 45.0 29.0 130.0 46.0 1.5 4.5 35.0 42.3 70

380-420/50/3 342/462 19.0 12.2 87.0 52.0 - - 12.2 15.3 25

Notes:

* - With optional IntelliStart, Type D MCB recommended

Voltage

Min/Max

MCC RLA LRA LRA*

DIAMETER

Number

of

Elements

Compressor

R

Value

Lower Thermostat

Dimensions in cm

Height Diameter

Load

Pump

FLA

Source

Pump

FLA

Total

Unit

FLA

Approx Shipping

Weight kg

Min

Circ

Amp

Max

Fuse/

HACR

1/15/15

14

Electrical Data cont.

Control Box

Circuit Breakers

VERSATEC ULTRA NSKW INSTALLATION MANUAL

Run Capacitor

Load Pump Relay

Transformer

Ground Lug

Compressor Contactor

Aurora Base Control

Board (ABC)

Accessory Relay

A set of “dry” contacts has been provided to control

accessory devices, such as water solenoid valves on open

loop installations, electronic air cleaners, humidifiers, etc.

This relay contact should be used only with 24 volt signals

and not line voltage power. The relay has both normally

open and normally closed contacts and can operate with

either the fan or the compressor. Use DIP switch SW2-4

and 5 to cycle the relay with blower, compressor, or control

a slow opening water valve. The relay contacts are available

on terminals #1 and #3 for normally closed, and #2 and #3

for normally open on P2.

When powering high VA draw components, or V type open

loop water valves, R should be taken ‘pre-fuse’ from the ‘R’

quick connect on the ABC board and not the ‘post-fuse’ ‘R’

terminal on the thermostat connection. If not, blown ABC

fuses might result.

Optional IntelliStart

Load Pump Power Block

Source Pump Power Block

Control Box Relocation

The control box can be installed on the rear of the unit. To

relocate the control box, follow the procedures below.

1. Remove all power sources to the unit.

2. Remove the unit’s top panel.

3. Cut all plastic wire ties to the following:

a) High pressure switch (black wires)

b) Low pressure switch (blue wires)

c) Freeze sensing and Thermistors

d) Compressor wires

4. Remove the four screws from the control box.

5. Relocate the control box to opposite end of the unit.

6. Using the screws removed in step 4 above, reattach the

control box.

7. Move the RS485 Keystone Coupler to the opening on the

back side of the unit.

8. Secure all wires so they do not come in contact with

refrigerant lines.

9. Replace the top of the unit.

10. Replace both access panels.

11. Reapply power sources.

15

Loading...

Loading...