WaterFurnace Envision User Manual

Installation Information

Water Piping Connections

Electrical Connections

Startup Procedures

Preventive Maintenance

IM1021ANA 01/15

Envision 7-25 Tons Installation Manual

Water Source/Geothermal Heat Pump

7 to 25 Tons

ENVISION 7-25 TONS INSTALLATION MANUAL

Table of Contents

Model Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vertical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Horizontal Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing Horizontal Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Installating Vertical Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

System Cleaning and Flushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Blower Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-25

Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

Optional FX10 Microprocessor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-37

Blower Drive Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Unit Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operating Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pressure Drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Startup/Troubleshooting Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

ENVISION 7-25 TONS INSTALLATION MANUAL

4

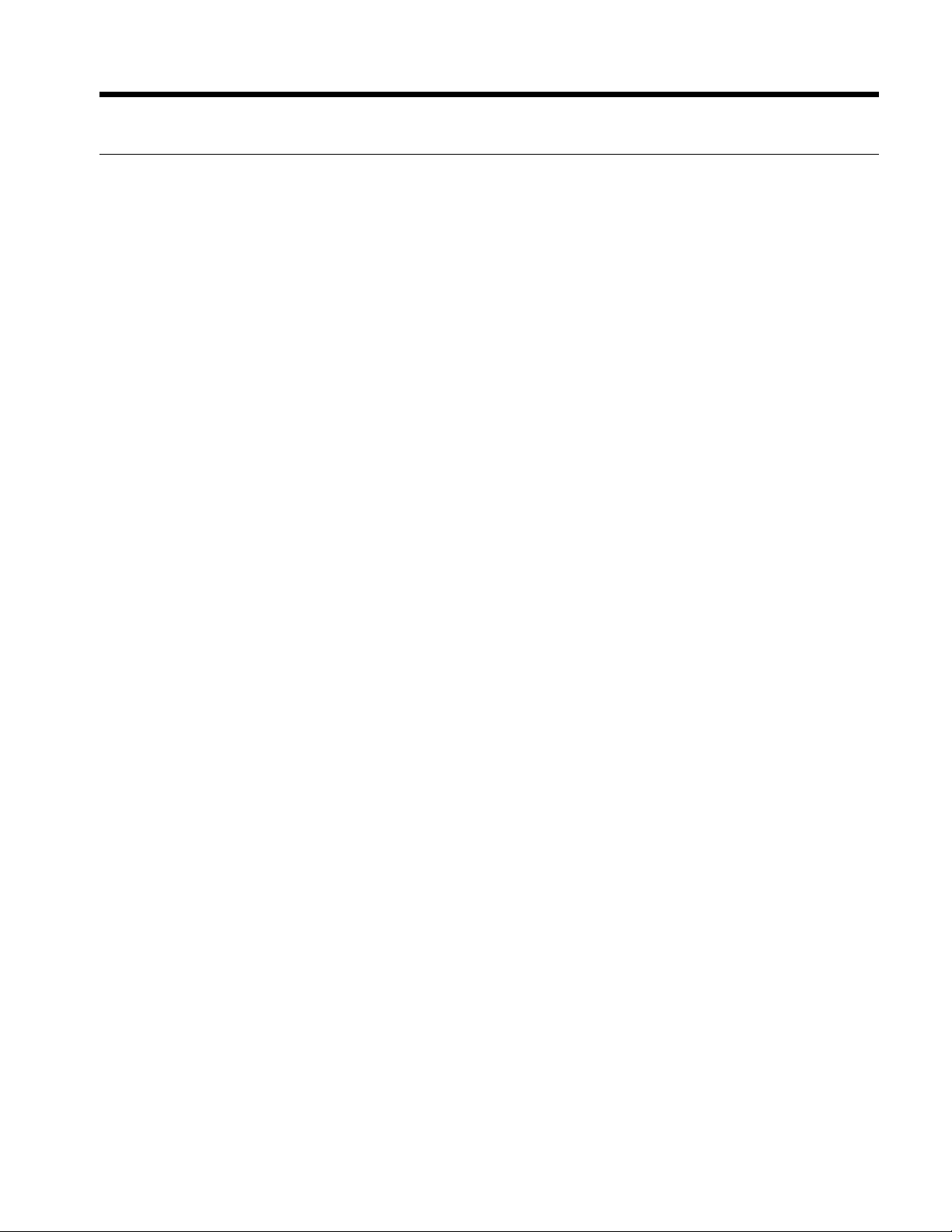

Model Nomenclature

NL

1-2 3-5 6 7 8

Model Type

NL – Envision Series

(Low Temp)

NX – Envision Series

(Extended Range)

Unit Capacity (MBTUH)

080, 095, 120, 160

180, 240, 300

Discharge Configuration

T – Top Upflow (Vertical)

E – End Discharge (Horizontal)

S – Discharge Side (Horizontal)

Return Air Configuration

L – Left

R – Right

Voltage

3 – 208-230/60/3

4 – 460/60/3

5 – 575/60/3

Future Option

0 – Future

Blower Options

A – Standard Static, Standard Motor

B – Low Static, Standard Motor

1

C – High Static, Standard Motor

2

D – Standard Static, Large Motor

2,3

E – High Static, Large Motor

3

Water Coil Option

C – Copper

N – CuproNickel

Vintage

* - Factory Use Only

Non-Standard Options

SS – Standard

QP – 2" MERV 13 Filter

SF – Stainless Steel Drain Pan

4

SG – 2" MERV 13 Filter, Stainless Steel Drain Pan

4

Air Coil/Insulation Option

3 – Uncoated

4 – AlumiSeal

TM

Control Option

4 – FX10 Standard without Communication

5 – FX10 with Open N2 Communication

6 – FX10 with Lonworks Communication

7 – FX10 with BacNet Communication

8 – FX10 Standard with User Interface

9 – FX10 with Open N2 & User Interface

0 – FX10 with Lonworks & User Interface

3 – FX10 with BacNet & User Interface

Water Control Option

N – None

V – Two-Way Valve

Hot Gas Bypass/Reheat Option

N – None

G – Hot Gas Bypass

R – Hot Gas Reheat

B – Hot Gas Bypass w/Hot Gas Reheat

Sound Kit Option

A – None

B – Sound Kit

Rev.: 14 November 2014D

91011 13

120 T L 3 0 A C A N

12

N

14

4

15

1

16

SS

17-18

*

19

Notes:

1 – Not available on vertical NL/NX095, 180, horizontal NL/NX080

2 – Not available on vertical NL/NX080, 160

3 – Not available on horizontal NL/NX120, vertical NL/NX300

4 – Not available on vertical NL/NX160-300. Stainless steel is standard on vertical NL/NX160-300

COMMERCIAL

ENVISION 7-25 TONS INSTALLATION MANUAL

5

WARNING: Before performing service or maintenance operations on a system, turn off main power switches to

the indoor unit. If applicable, turn off the accessory heater power switch. Electrical shock could cause personal

injury.

Installing and servicing heating and air conditioning equipment can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel should install, repair or service heating and air conditioning

equipment. Untrained personnel can perform the basic maintenance functions of cleaning coils and cleaning and

replacing filters. All other operations should be performed by trained service personnel. When working on heating and

air conditioning equipment, observe precautions in the literature, tags and labels attached to the unit and other safety

precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use a quenching cloth for brazing operations and have a fire

extinguisher available.

Moving and Storage

Move units in the normal “up” orientation. Horizontal units may be moved and stored per the information on the packaging.

Do not stack more than three units in total height. Vertical units may be stored one upon another to a maximum height

of two units. Do not attempt to move units while stacked. When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and cartons have been received. Examine units for shipping damage,

removing the units from the packaging if necessary. Units in question should also be internally inspected. If any damage is

noted, the carrier should make the proper notation on the delivery receipt, acknowledging the damage.

Unit Location

Locate the unit in an indoor area that allows for easy removal of the filter and access panels. Location should have enough

space for service personnel to perform maintenance or repair. Provide sufficient room to make water, electrical and duct

connection(s). If the unit is located in a confined space, such as a closet, provisions must be made for return air to freely

enter the space by means of a louvered door, etc. Any access panel screws that would be difficult to remove after the

unit is installed should be removed prior to setting the unit. On horizontal units, allow adequate room below the unit for

a condensate drain trap and do not locate the unit above supply piping. Care should be taken when units are located

in unconditioned spaces to prevent damage from frozen water lines and excessive heat that could damage electrical

components.

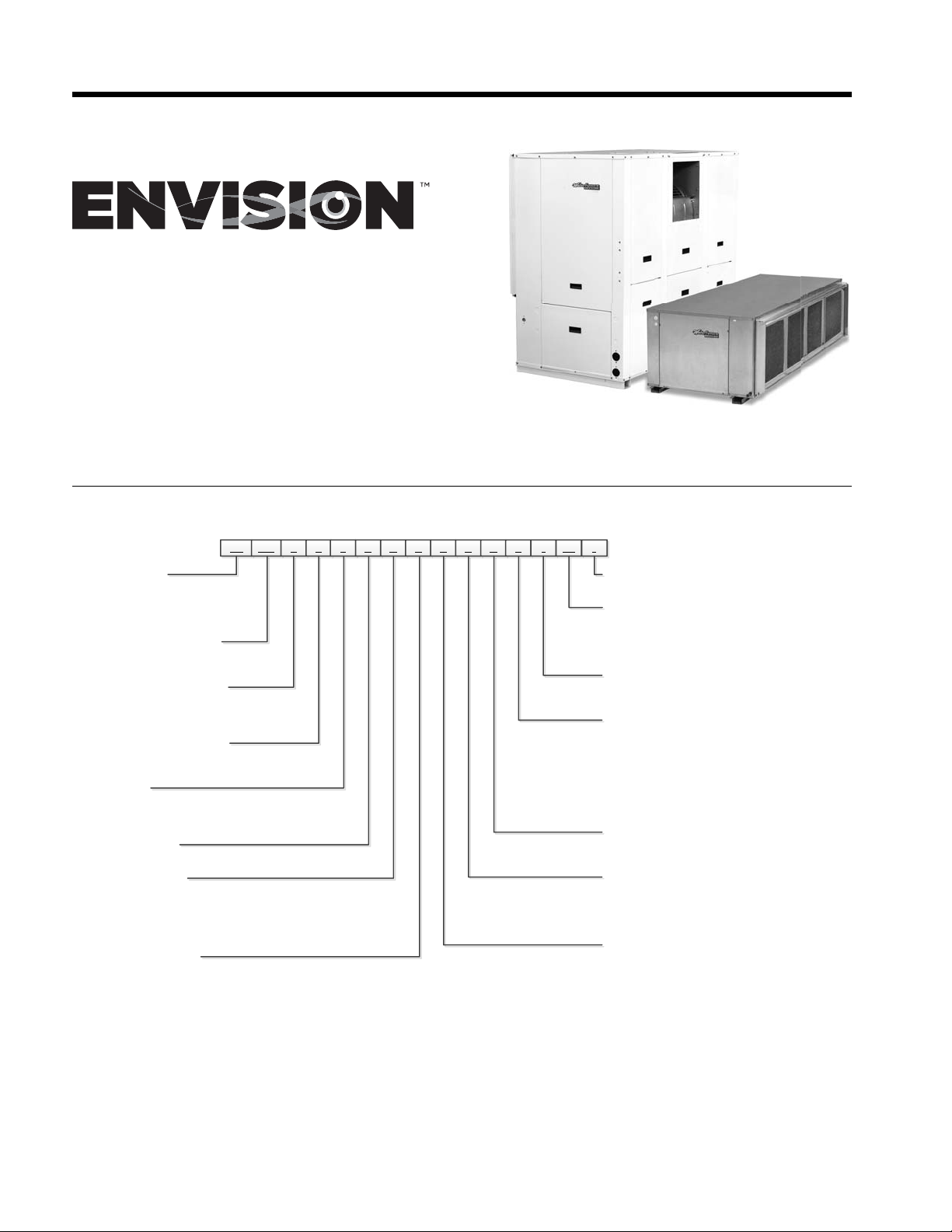

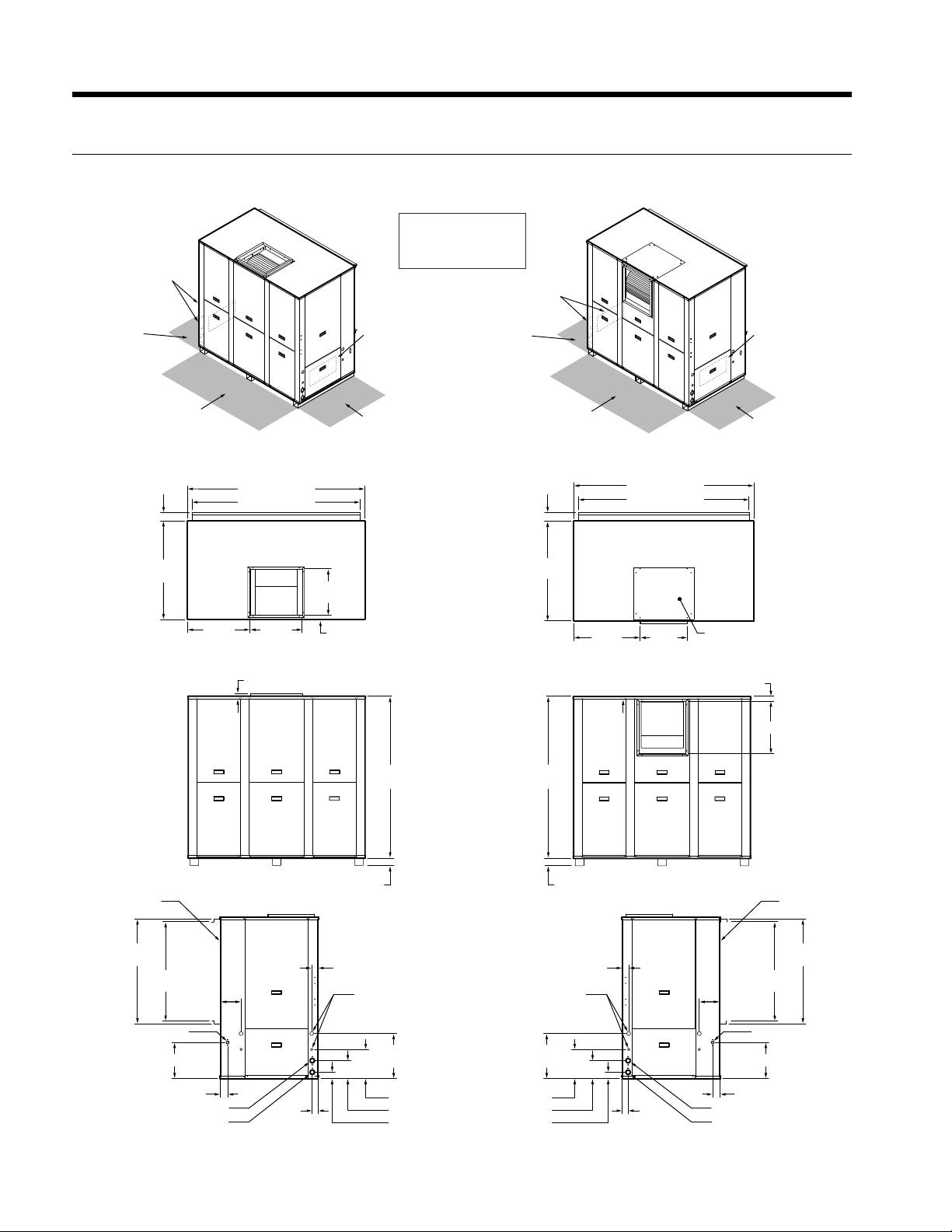

Installing Vertical Units

Prior to setting the unit in place, remove and discard the compressor hold down

shipping bolt located at the front of the compressor mounting bracket.

Vertical units are available in left or right air return configurations. Top flow vertical

units should be mounted level on a vibration absorbing pad slightly larger than the

base to provide isolation between the unit and the floor. It is not necessary to anchor

the unit to the floor (see right).

Safety Considerations

General Installation Information

Figure 1: Vertical Unit Mounting

(NXV/NLV 080-300)

ENVISION 7-25 TONS INSTALLATION MANUAL

6

CONTROL BOX

RIGHT RETURN

CONTROL BOX AND WATER

LEFT RETURN

2’ PRIMARY

SERVICE ACCESS

FOR LEFT RETURN

2’ PRIMARY

CONTROL BOX

RIGHT RETURN

SERVICE ACCESS

FOR RIGHT RETURN

2’ SECONDARY

SERVICE ACCESS

CONTROL BOX

AND WATER

LEFT RETURN

TOP DISCHARGE

2’ PRIMARY

SERVICE ACCESS

FOR LEFT RETURN

2’ PRIMARY

SERVICE ACCESS

FOR RIGHT RETURN

2’ SECONDARY

SERVICE ACCESS

SIDE DISCHARGE

56 in

[142.2 cm]

2 in [5.1 cm]

1 in [2.5 cm]

2 in [5.1 cm]

18.1 in [46 cm]

1.8 in [4.6 cm]

56 in

[142.2 cm]

22.6 in

[57.4 cm]

TOP PANEL

COVER

58.1 in [147.6 cm]

61.3 in [155.7 cm]

34.1 in

[86.6 cm]

2.9 in

[7.4 cm]

16.1 in

[40.9 cm]

TOP VIEW

Left or Right Return

SIDE VIEW

Left or Right Return

34.1 in

[86.6 cm]

58.1 in [147.6 cm]

61.3 in [155.8 cm]

21.6 in

[54.9 cm]

18.1 in

[46.0 cm]

1.42 in

[3.6 cm]

16.1 in

[40.9 cm]

2.9 in

[7.4 cm]

15.6 in

[39.6 cm]

12.5 in [31.8 cm]

36.3 in

[92.2 cm]

2.6 in [6.6 cm]

DRAIN CONNECTION

WATER OUT

WATER IN

ELECTRICAL

CONNECTIONS

ELECTRICAL

CONNECTIONS

AIR COILS

34.4 in

[87.4 cm]

4.0 in [10.2 cm]

2.2 in [5.6 cm]

10.1 in [25.7 cm]

2.0 in

[5.1 cm]

2.2 in

[5.6 cm]

7.2 in

[18.3 cm]

LEFT RETURN RIGHT RETURN

15.6 in

[39.6 cm]

4.0 in [10.2 cm]

2.2 in [5.6 cm]

10.1 in [25.7 cm]

2.2 in

[5.6 cm]

12.5 in [31.8 cm]

36.3 in

[92.2 cm]

2.6 in [6.6 cm]

DRAIN CONNECTIO

N

WATER OUT

WATER IN

AIR COILS

34.4 in

[87.4 cm]

7.2 in

[18.3 cm]

2.0 in

[5.1 cm]

TOP OR SIDE DISCHARGE

Legend

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

AP

CMP

AP

CMP

CPCP

CP CP

REV 2/11/0

8

Vertical Dimensions

7-10 Tons

ENVISION 7-25 TONS INSTALLATION MANUAL

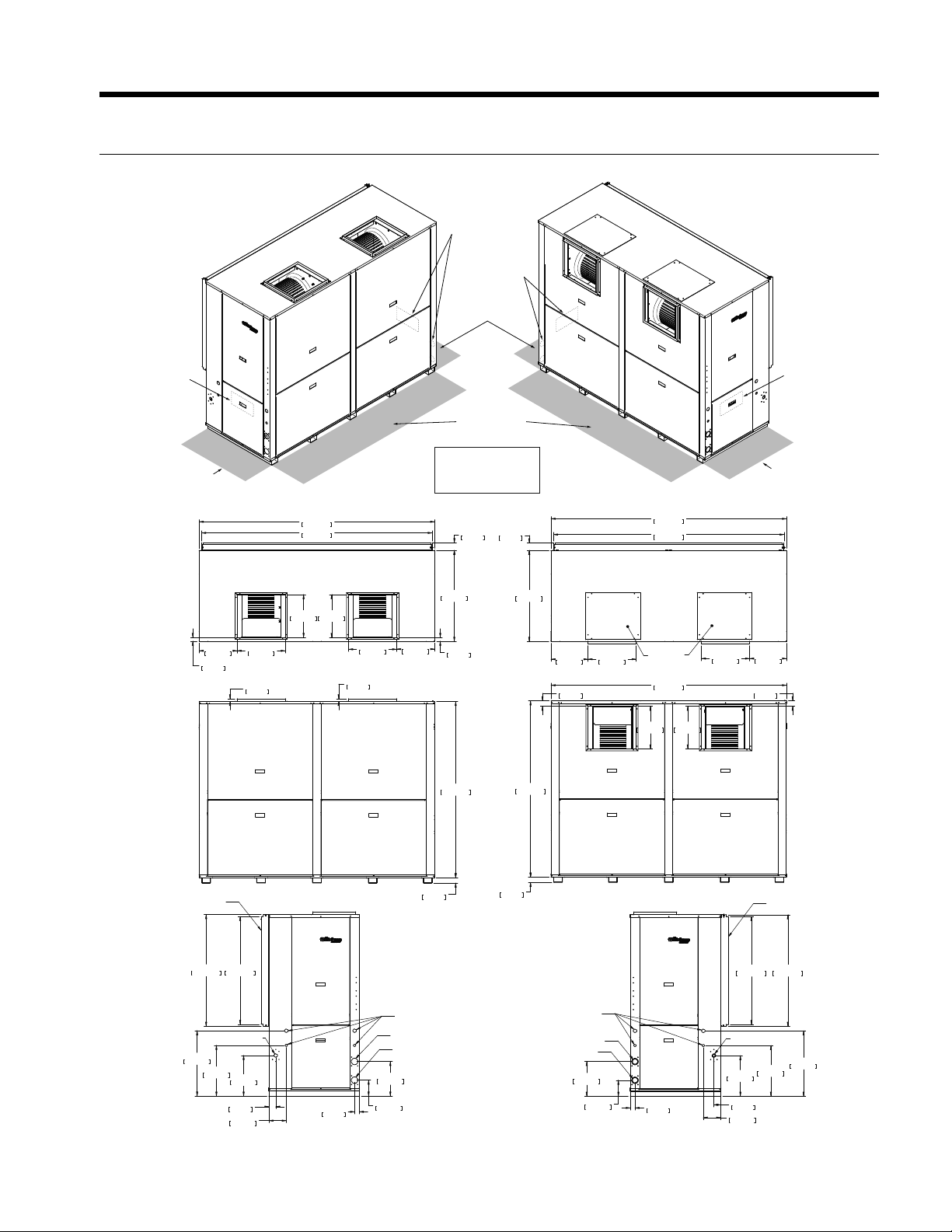

7

LEFT RETURN

6.0 in

15.2 cm

13.0 in

33.0 cm

15.2 in

38.7 cm

19.0 in

48.2 cm

24.5 in

62.2 cm

18.0 in

45.7 cm

18.0 in

45.7 cm

16.0 in

40.6 cm

16.0 in

40.6 cm

16.0 in

40.6 cm

16.0 in

40.6 cm

1.5 in

3.7 cm

1.5 in

3.7 cm

2.0 in

5.1 cm

2.0 in

5.1 cm

34.0 in

86.4 cm

14.2 in

36.1 cm

14.2 in

36.1 cm

2.6 in

6.5 cm

6.5 in

16.5 cm

88.1 in

223.8 cm

RIGHT RETURN

TOP DISCHARGE

SIDE DISCHARGE

88.1 in

223.8 cm

86.3 in

219.1 cm

1.0 in

2.5 cm

66.0 in

167.5 cm

2.0 in

5.1 cm

1.0 in

2.5 cm

34.0 in

86.4 cm

2.9 in

7.3 cm

86.3 in

219.1 cm

88.1 in

223.8 cm

18.0 in

45.8 cm

13.8 in

35.1 cm

18.0 in

45.8 cm

13.8 in

35.1 cm

TOP PANEL

COVER

2.9 in

7.3 cm

66.0 in

167.5 cm

2.0 in

5.1 cm

DRAIN CONNECTION

ELECTRICAL

CONNECTIONS

40.4 in

102.6 cm

41.8 in

106.2 cm

AIR COILS

AIR COILS

41.8 in

106.2 cm

40.4 in

102.6 cm

15.2 in

38.7 cm

19.0 in

48.2 cm

24.5 in

62.2 cm

2.6 in

6.5 cm

6.5 in

16.5 cm

6.0 in

15.2 cm

13.0 in

33.0 cm

1.7 in

4.4 cm

1.7 in

4.4 cm

DRAIN CONNECTION

WATER OUT

WATER IN

WATER OUT

WATER IN

ELECTRICAL

CONNECTIONS

2’ PRIMARY

SERVICE ACCESS

2’ SECONDARY

SERVICE ACCESS

2’ PRIMARY

SERVICE ACCESS

2’ PRIMARY

SERVICE ACCESS

Legend

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

CONTROL BOX

AND WATER

RIGHT RETURN

CONTROL BOX

AND WATER

LEFT RETURN

CONTROL BOX

LEFT RETURN

AP

CMP

AP

CMP

CP CP

CPCP

CONTROL BOX

RIGHT RETURN

TOP VIEW

L or R Return

SIDE VIEW

L or R Return

TOP OR SIDE DISCHARGE

REV 8/16/07

Vertical Dimensions cont.

13-25 Tons

ENVISION 7-25 TONS INSTALLATION MANUAL

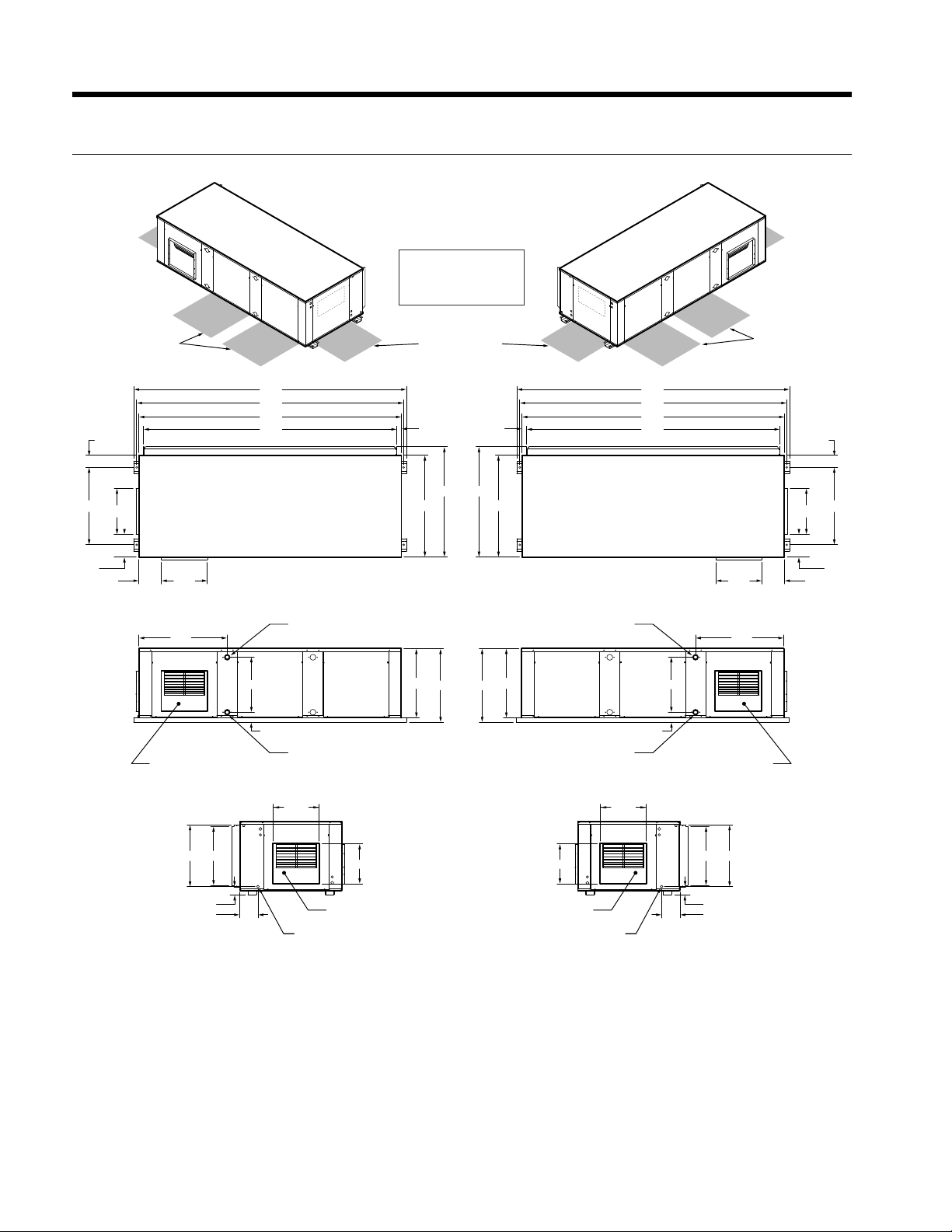

8

RIGHT RETURN

LEFT RETURN

26.2

4.1

15.6

89.0

34.5

90.0

37.3

92.5

7.6

7.615.6

85.91.6

TOP VIEW

26.2

4.1

15.6

89.0

34.5

90.0

37.3

92.5

7.6

7.6 15.6

85.9 1.6

DRAIN CONNECTION

END DISCHARGE

OPTION

15.62

13.5

2.9

6.1

20.1

21.0

END VIEW

DRAIN CONNECTION

END DISCHARGE

OPTION

15.62

2.9

6.1

20.1

21.0

SIDE DISCHARGE

WATER IN

WATER OUT

OPTION

SIDE VIEW

18.6

3.4

29.929.9

24.5

23.5

SIDE DISCHARGE

WATER IN

WATER OUT

OPTION

18.6

3.4

29.929.9

24.5

23.5

13.5

Legend

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

CMP

CMP

CMP

CMP

CPCP

BP BP

2’ PRIMARY

SERVICE ACCESS

2’ SECONDARY

SERVICE ACCESS

2’ SECONDARY

SERVICE ACCESS

REV 4/28/08

Horizontal Dimensions

7-10 Tons

ENVISION 7-25 TONS INSTALLATION MANUAL

9

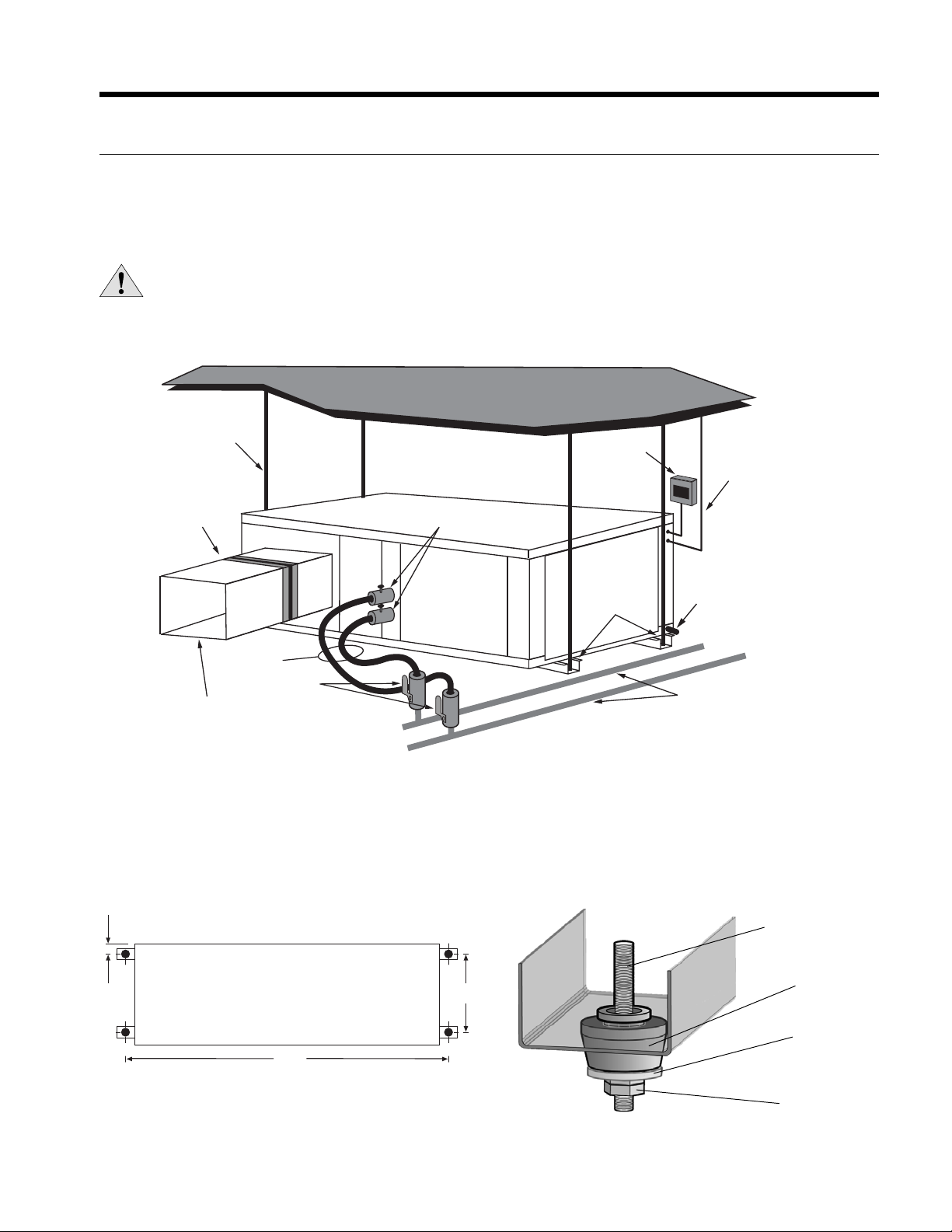

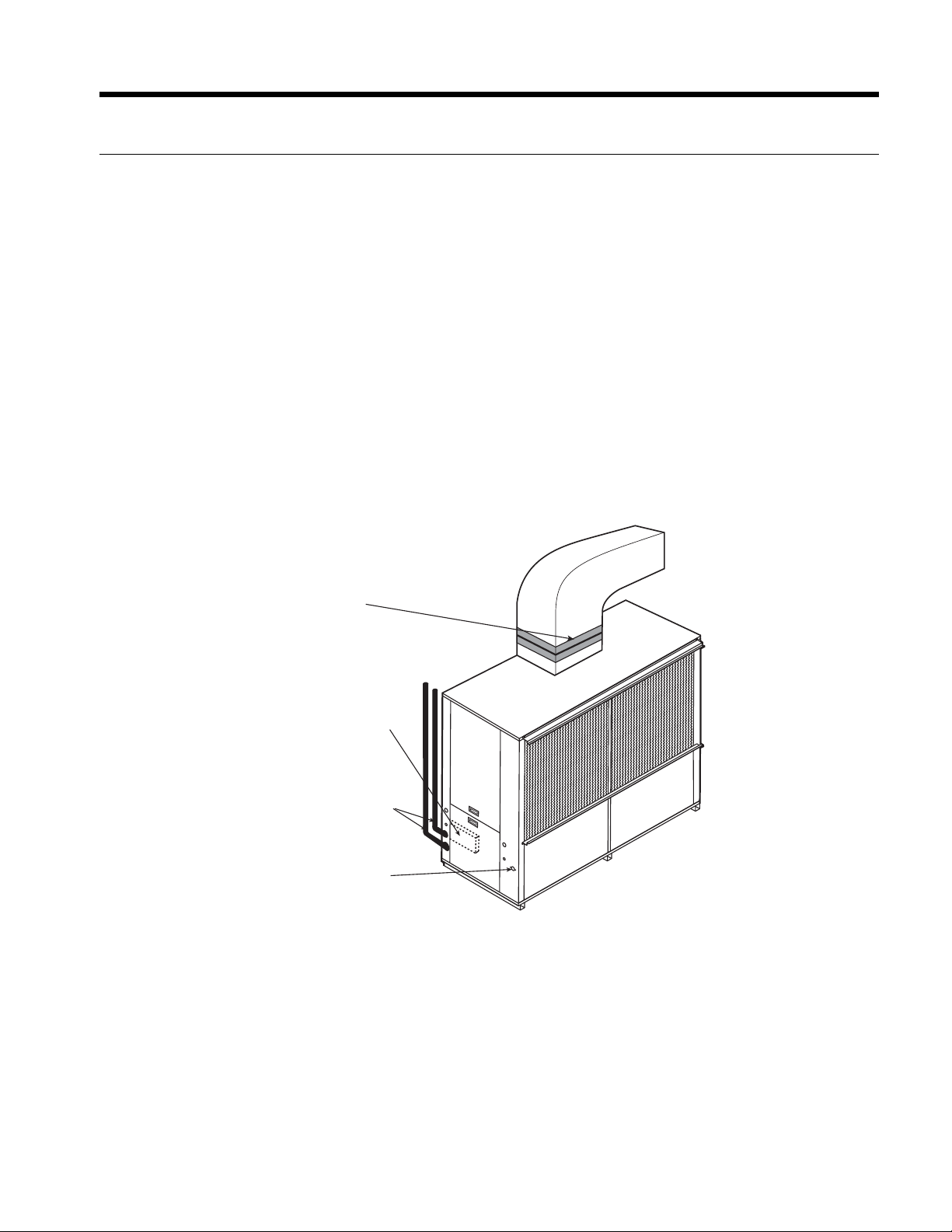

Installing Horizontal Units

Mounting Horizontal Units

Units are available with side or end discharge in left-hand or right-hand return air configurations. Horizontal units are

normally suspended from a ceiling by four 1/2 in. diameter threaded rods. The rods are usually attached to the unit corners

by the bottom panel mounting channel and the mounting grommets furnished with each unit.

CAUTION: Do not use rods smaller than 1/2 in. diameter since they may not be strong enough to support the

unit. The rods must be securely anchored to the ceiling (the units are approximately 800 lbs.).

To p V i e w

90.5

26.244.13

Figure 3: Mounting HardwareFigure 2: Mounting Rod Layout

Ball Valves

Water Loop

Flexible Duct

Collar

1/2”

Threaded Rods

(4)

P/T Plugs

Hose Kits

Insulate supply

plenum and use at

least a 90° elbow

to reduce noise

Condensate

Drain

Connection

Power

Disconnect

Low

Voltage

Isolation

Grommets

(Included)

Figure 1: Typical Horizontal Application

Layout the threaded rods per the dimensions in Figure 2. Assemble the hangers to the unit as shown in Figure 3. Securely

tighten the brackets to the unit. When attaching the hanger rods to the bracket, a double nut is recommended since

vibration could loosen a single nut. The unit should be pitched approximately 1/2 in. towards the drain in both directions, to

facilitate condensate removal.

1/2 in. Threaded Rod

(not included)

Vibration

Isolator

Washer

(not included)

Hex Nuts

(not included)

ENVISION 7-25 TONS INSTALLATION MANUAL

10

1/2'' Pitch

Figure 5: Unit Pitch for DrainFigure 4: Suggested Layout of Condensate

Installing Horizontal Units cont.

ABCD

Front Front Back Back

Model Return / Discharge Left Right Right Left

Left / Side or End 30% 26% 22% 22%

Right / Side or End 26% 30% 22% 22%

Approximate

080 - 120

A

B

C

D

Controls

Horizontal Unit Corner Weight Distribution

Duct System

An air outlet collar is provided on vertical top flow units and all horizontal units to facilitate a duct connection. A flexible

connector is recommended for discharge and return air duct connections on metal duct systems. Uninsulated duct should

be insulated with a minimum of 1-inch duct insulation. Application of the unit to uninsulated ductwork in an unconditioned

space is not recommended as the unit’s performance will be adversely affected.

If the unit is connected to existing ductwork, check the duct system to ensure that it has the capacity to accommodate the

air required for the unit application. If the duct is too small, as in the replacement of heating only systems, larger ductwork

should be installed. All existing ductwork should be checked for leaks and repaired if necessary.

The duct system should be sized to handle the design airflow quietly and efficiently. To maximize sound attenuation of the

unit blower, the supply and return plenums should include an internal duct liner of fiberglass or constructed of ductboard

for the first few feet. On systems employing a sheet metal duct system, canvas connectors should be used between the unit

and the ductwork. If air noise or excessive airflow is a problem, the blower speed can be changed.

Water Piping

The proper water flow must be provided to each unit whenever the unit operates. To assure proper flow, use pressure/tem-

perature ports to determine the flow rate. These ports should be located at the supply and return water connections on the

unit. The proper flow rate cannot be accurately set without measuring the water pressure drop through the refrigerant-to-

water heat exchanger.

All source water connections on commercial units are fittings that accept a male pipe thread (MPT). Insert the connectors

by hand, then tighten the fitting with a wrench to provide a leakproof joint. When connecting to an open loop (groundwa-

ter) system, thread any copper MPT fitting into the connector and tighten in the same manner as described above.

1.5 in.

1.5 in.

3/4 in. PVC tube stub

3/4 in. PVC

Coupling

Vent (if needed)

3/4 in. PVC

1/8 in. per foot

ENVISION 7-25 TONS INSTALLATION MANUAL

11

Control Box

Condensate

Drain

Water Supply

and Return

Connections

Flexible duct

Collar

ACCESS

PAN EL

ACCESS

PANEL

P

A

N

E

L

A

C

C

E

S

S

Figure 6: Typical Vertical Application

Installing Vertical Units

Mounting Vertical Units

Units are available with top/side discharge, left-hand or right-hand return air configurations. Vertical units are assembled on

rails which facilitate moving and placement of the units. It is not necessary to anchor the unit to the floor.

Duct System

A supply air duct flange is provided for field installation to facilitate the secure duct connection at the job site. A flexible

connector is recommended for discharge and return air duct connections on metal duct systems to prevent vibration

transmission. It is recommended that all ductwork be insulated with a minimum of 1/2-inch coated insulation. Installation of

the units with uninsulated ductwork in an unconditioned space is not recommended, as the system’s performance will be

adversely affected.

Condensate Drain

In vertical units, the internal condensate drain assembly consists of a flexible drain tube which is attached to the drain pan

and a 3/4-inch (7-10 tons) and 1-inch (13-25 tons) female pipe thread. An external water trap is not required as the drain

tube serves as a trapping loop. The field-installed piping and unit connection must be properly installed and sealed to

prevent water leakage.

ENVISION 7-25 TONS INSTALLATION MANUAL

12

Water Connections

All supply and return water connections are female pipe thread of size specified in physical dimensions. Never use flexible

hoses smaller than separate water connections on the unit and limit hose length to 10 ft. per connection. Check carefully for

water leaks.

Interior Piping

All units are recommended to be connected to supply and return piping in a two-pipe reverse return configuration. A

reverse return system is inherently self-balancing and requires only trim balancing when multiple quantities of units with

different flow and pressure drop characteristics are connected to the same loop. A direct return system may also be made

to work acceptably, but proper water flow balance is more difficult to achieve and maintain.

Supply and return runouts are usually connected to the unit by short lengths of high pressure flexible hose which are sound

attenuators for both unit operating noise and hydraulic pumping noise. One end of the hose should have a swivel fitting to

facilitate removal for service. Hard piping can also be connected directly to the unit although it is not recommended since

no vibration or noise attenuation can be accomplished. The hard piping must have unions to facilitate unit removal (see

figure 1 & 6) for typical application).

Some flexible hose threaded fittings are supplied with sealant compound. If not, apply Teflon tape to assure a tight seal.

Supply and return shutoff valves are required at each unit. The return shutoff valve can be used for balancing and should be

adjusted for proper flow required, or a manual or automatic flow control device should be on the leaving water hose assembly.

No unit should be connected to the supply and return piping until the water system has been cleaned and flushed

completely. After the cleaning and flushing has taken place, the initial connection should have all valves wide open in

preparation for water system filling.

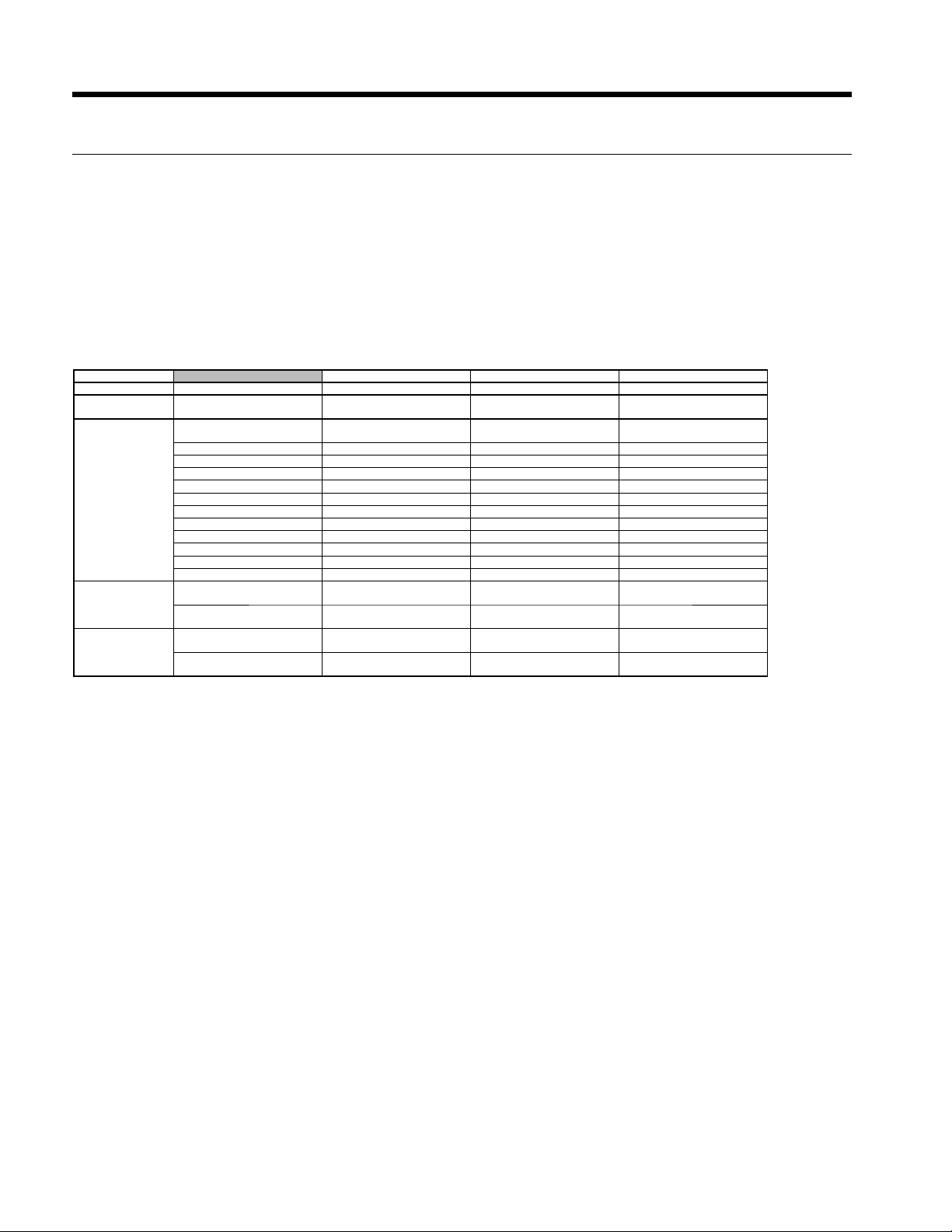

Water Quality Guidelines

In ground water situations where scaling could be heavy or where biological growth such as iron bacteria will be present,

a closed loop system is recommended. The heat exchanger coils in ground water systems may, over a period of time, lose

heat exchange capabilities due to a buildup of mineral deposits inside. These can be cleaned, but only by a qualified service

mechanic, as special solutions and pumping equipment are required. Hot water generator coils can likewise become scaled

and possibly plugged. In areas with extremely hard water, the owner should be informed that the heat exchanger may

require occasional flushing.

Units with cupronickel heat exchangers are recommended for open loop applications due to the increased resistance to

build-up and corrosion, along with reduced wear caused by acid cleaning.

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity

7 - 9 7 - 9 7 - 9

Scaling

Calcium and

Magnesium Carbonate

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

Corrosion

Hydrogen Sulfide

Less than 0.5 ppm (rotten egg

smell appears at 0.5 ppm)

10 - 50 ppm Less than 1 ppm

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron Fouling

(Biological Growth)

Iron, FE

2

+ (Ferrous)

Bacterial Iron Potential

< 0.2 ppm < 0.2 ppm < 0.2 ppm

Iron Oxide

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Erosion

Suspended Solids

Less than 10 ppm and filtered

for max. of 600 mic

ron size

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Threshold Velocity

(Fresh Water)

< 6 ft/sec < 6 ft/sec < 6 ft/sec

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

2/22/12

Water Quality

ENVISION 7-25 TONS INSTALLATION MANUAL

13

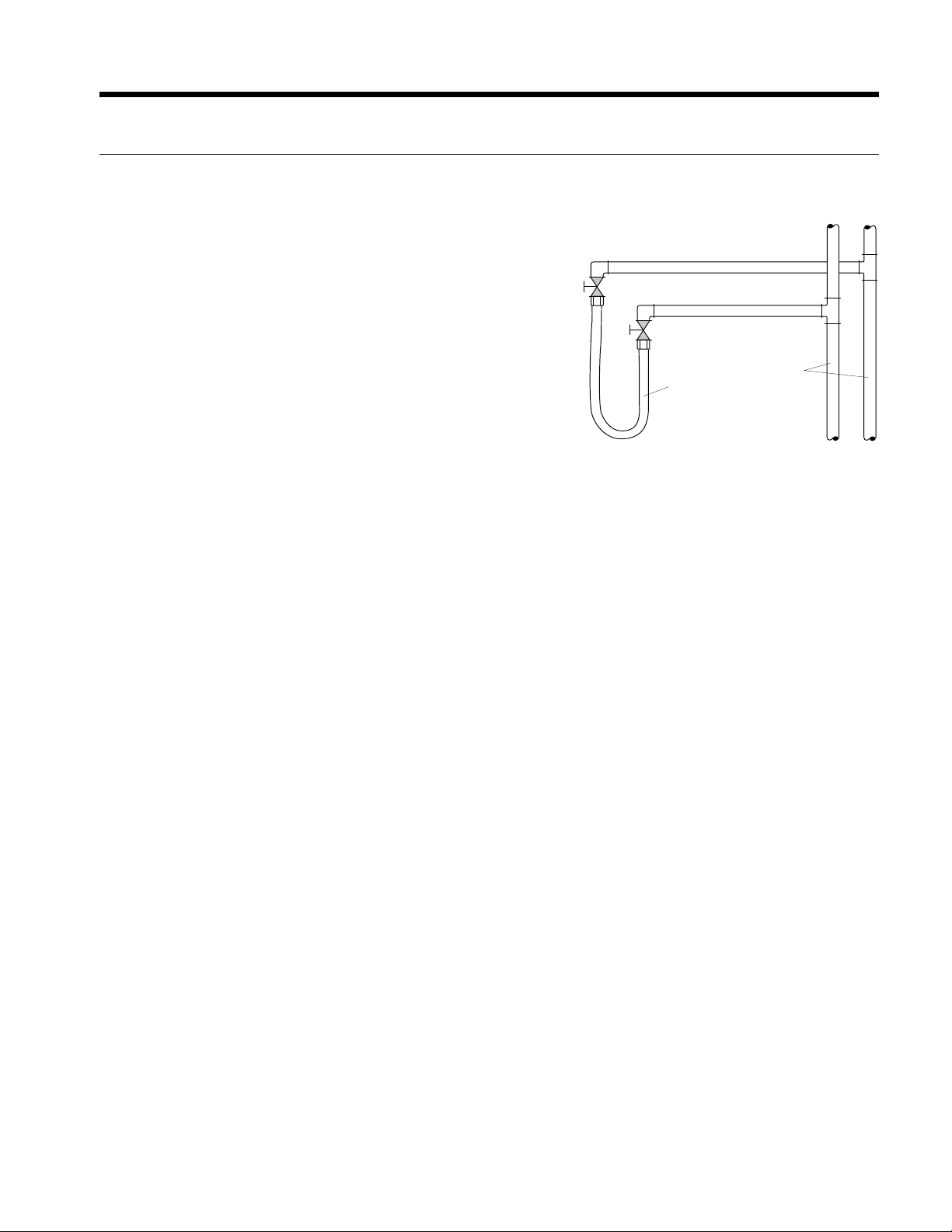

System Cleaning and Flushing

Cleaning and Flushing

Prior to start up of any heat pump, the water circulating system must be

cleaned and flushed of all dirt and debris.

If the system is equipped with water shutoff valves, the supply and

return runouts must be connected together at each unit location (This

will prevent the introduction of dirt into the unit, see Figure 7). The

system should be filled at the water make-up connection with all air

vents open. After filling, vents should be closed.

The contractor should start the main circulator with the pressure

reducing valve makeup open. Vents should be checked in sequence

to bleed off any trapped air and to verify circulation through all

components of the system.

As water circulates through the system, the contractor should check

and repair any leaks found in the piping system. Drain(s) at the lowest

point(s) in the system should be opened for initial flush and blowdown, making sure water fill valves are set at the same

rate. Check the pressure gauge at the pump suction and manually adjust the make-up water valve to hold the same

positive pressure both before and after opening the drain valves. Flushing should continue for at least two hours, or longer

if required, until drain water is clean and clear.

The supplemental heater and/or circulator pump, if used, should be shut off. All drains and vents should be opened to

completely drain the system. Short-circuited supply and return runouts should now be connected to the unit supply and

return connections.

Refill the system with clean water. Test the system water for acidity and treat as required to leave the water slightly alkaline

(pH 7.5 to 8.5). The specified percentage of antifreeze may also be added at this time. Use commercial grade antifreeze

designed for HVAC systems only. Environol™ brand antifreeze is recommended..

Once the system has been filled with clean water and antifreeze (if used), precautions should be taken to protect the

system from dirty water conditions. Dirty water will result in system-wide degradation of performance, and solids may clog

valves, strainers, flow regulators, etc. Additionally, the heat exchanger may become clogged which reduces compressor

service life and can cause premature unit failure.

In boiler/tower application, set the loop control panel set points to desired temperatures. Supply power to all motors

and start the circulating pumps. After full flow has been established through all components including the heat rejector

(regardless of season), air vented and loop temperatures stabilized, each of the units will be ready for check, test and start

up and for air and water balancing.

Ground Source Loop System Checkout

Once piping is completed between the unit pumping system and ground loop, final purging and charging of the loop is

needed. A high pressure pump is needed to achieve adequate flow velocity in the loop to purge air and dirt particles from

the loop itself. Antifreeze solution is used in most areas to prevent freezing. Flush the system adequately to remove as

much air as possible; then pressurize the loop to a static pressure of 40-50 PSI (summer) or 50-75 PSI (winter). This is

normally adequate for good system operation. Loop static pressure may decrease soon after initial installation, due to pipe

expansion and loop temperature change. Running the unit for at least 30 minutes after the system has been completely

purged of air will allow for the “break-in” period. It may be necessary to adjust static loop pressure (by adding water) after

the unit has run for the first time. Loop static pressure will also fluctuate with the seasons. Pressures will be higher in the

winter months than during the cooling season. This fluctuation is normal and should be considered when charging the

system initially.

Ensure the pump provides adequate flow through the unit by checking pressure drop across the heat exchanger.

Usually 2.25-3.0 GPM of flow per ton of cooling capacity is recommended in earth loop applications.

Return Runout

Supply Runout

Mains

Rubber Hose

Runouts Initially

Connected Together

Figure 7: Flushing with Water

Shutoff Valve Equipped Systems

ENVISION 7-25 TONS INSTALLATION MANUAL

14

Electrical Connections

General

Be sure the available power is the same voltage and phase as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the National Electric Code.

Unit Power Connection

Line voltage connection is made by connecting the incoming line voltage wires to the terminal block as shown on the unit’s

wiring diagram attached to the inside front panel. Consult the Unit Electrical Data below for correct fuse size.

208 Volt Operation

NOTE: All 208-230 volt units are factory wired for 230 volt operation. For 208 volt operation, the red and the blue

transformer wires must be switched between terminal strip PS and contactor RB.

Loading...

Loading...