WaterFurnace IntelliZone2 Installation Manual

Comfort Zoning System

Four Zone Capability

Designed for Use with Typical 24VAC Heat Pump Controllers

Installation Information

Damper Installation

Thermostat Installation

Electrical

Startup Procedures

IntelliZone2 ● 24V Installation Manual

Wiring Schematic

IM1678EW 12/16

Table of Contents

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Damper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Thermostat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

IntelliZone2 ● 24V Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

System Startup and Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wiring Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

IntelliZone2 ● 24V Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Revision Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

INTELLIZONE2 ● 24V INSTALLATION MANUAL

INTELLIZONE2 ● 24V INSTALLATION MANUAL

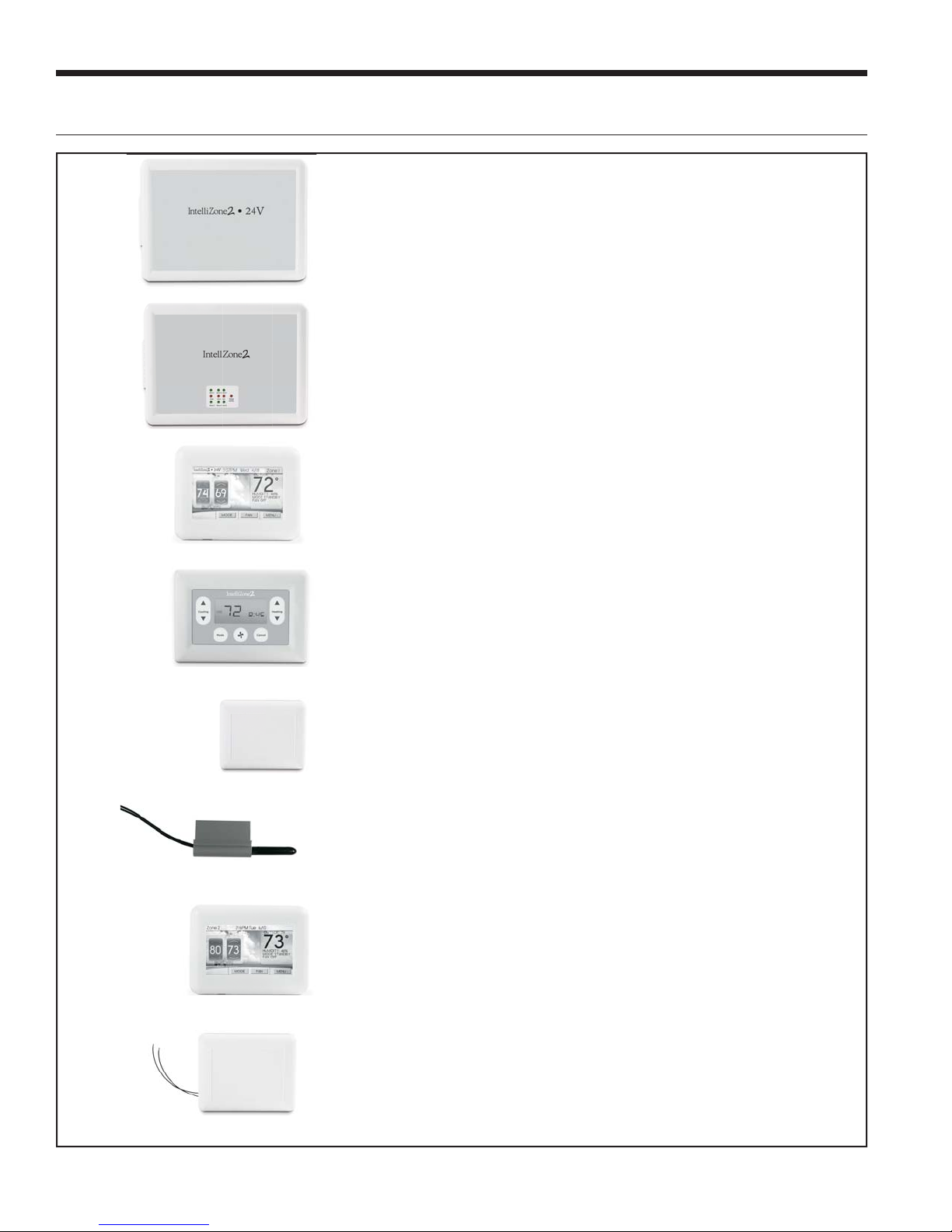

IntelliZone2 ● 24V Components

IntelliZone2 ● 24V Conversion Board

The IntelliZone2 ● 24V conversion board communicates via Modbus with

the IntelliZone2 relay board and converts the Modbus communication into

typical 24VAC signals to be sent to the ABC or Premier heat pump control.

This zoning system is designed for use with non-communicating heat pump

controls.

IntelliZone2 Relay Board (Firmware Version 2.01 or Later)

The IntelliZone2 relay board provides basic relay logic for the damper

operation and serves as a common connection point for all IntelliZone2

thermostats and the heat pump.

IntelliZone2 MasterStat

The IntelliZone2 MasterStat is the master control for the system and has all

of the programming for operation. It is a 4.3 in. communicating color touch

screen device that also functions as a zone thermostat for Zone 1. Optional

remote sensor capability is also available.

IntelliZone2 ZoneStat

The IntelliZone2 ZoneStat is a zone thermostat option for any of Zones 2

through 4. It has full setback capability and communicates to the

IntelliZone2 system.

IntelliZone2 SensorStat

The IntelliZone2 SensorStat is a zone thermostat option for any of Zones 2

through 4. It has full setback capability (through the MasterStat interface

only) and communicates to the IntelliZone2 system.

IntelliZone2 Outdoor Sensor

The IntelliZone2 Outdoor Sensor measures the outdoor temperature and

communicates to the IntelliZone2 system. This temperature is displayed on

the MasterStat, and also used to balance response as well as auxiliary electric

heat use. The Outdoor Sensor is included in every kit.

TPCC32U01 (Optional) (Firmware Version 3.01 or Later)

The TPCC32U01 is a 4.3 in. communicating color touch screen device that

can be used as a zone thermostat for zones 2 through 6. It has full set back

capability and communicates to the IntelliZone2 System.

SensorStat-Remote-Kit (Optional)

The SensorStat-Remote-Kit is an option for an invisible thermostat installation

and communicates with the IntelliZone2 relay panel. The kit will include

the SensorStat Remote, TSU03 (mud in sensor) and wire nuts. This kit will

monitor the zone temperature in zones 2 through 6. All set point adjustments

are made at the MasterStat.

4

General Installation Information

D

INTELLIZONE2 ● 24V INSTALLATION MANUAL

Safety Considerations

Installing and servicing heating and air conditioning

equipment can be hazardous due to system electrical

components. Only trained and qualifi ed service personnel

should install, repair or service heating and air conditioning

equipment. When working on equipment, observe

precautions in the literature, tags and labels attached to the

unit, and other safety precautions that may apply. Follow all

safety codes. Wear safety glasses and work gloves.

WARNING: Before performing service or

maintenance operations on the system, turn

off main power switches to the indoor unit.

Turn off accessory heater power switch if

applicable. Electrical shock could cause

serious personal injury.

Delivery Information

When the equipment is received, all items should be

carefully checked against the bill of lading to be sure

all crates and cartons have been received. Examine the

contents for shipping damage, removing them from the

cartons if necessary. If any damage is noted, the carrier

should make the proper notation on the delivery receipt,

acknowledging the damage.

General rules to follow when installing a

zone system:

CAUTION: When installing the IntelliZone2 ● 24V

in a structure with fossil fuel (oil, gas, propane)

appliances, it is important that both supply and

return dampers are used in each zone to avoid

potential back-drafting of fossil-fueled appliances.

• Up to four zones with dual capacity units (two with

single-speed units).

• All dampers should be located as close to the main

trunk as possible to limit the amount of pressurized

trunk line and thus limit air leakage.

• No less than three branch runs in a zone to prevent

a single branch obstruction (curtains or clothes etc.)

from affecting unit airfl ow.

• Insulate and seal around rectangular dampers to

prevent leakage.

• All dampers must be wired with 18-gauge wire.

NOTE: Crimp connections should never be used on

solid conductor wire.

• Ensure that the transformer can handle the power

requirements of the system.

• No more than three dampers per zone.

• Ductboard-mounted dampers should be supported

within six inches of the damper due to the weight and

stress on the ductboard.

Installation and Design Steps

1. Decide which areas of a home or offi ce will comprise

each of the individual zones. A maximum of four

individual zones with dual capacity (two with singlespeed equipment) can be chosen.

2. Calculate loads using software or other

recognized methodology.

3. Use software to determine the equipment size and

performance based on the total heating and cooling

demands of the building, not the sum of the individual

zone demands.

4. Find the peak heating and cooling demands and the

peak cfm required for each of the zones.

5. Determine zone design air fl ow and zone size settings

using IntelliZone2 Design software.

6. Lay out and size the supply air ductwork and dampers.

Care should be taken to avoid under sizing either the

supply air systems, return air systems, or diffusers.

7. Decide where to locate the thermostats.

8. Install the unit and the IntelliZone2 ● 24V Comfort

Zoning system.

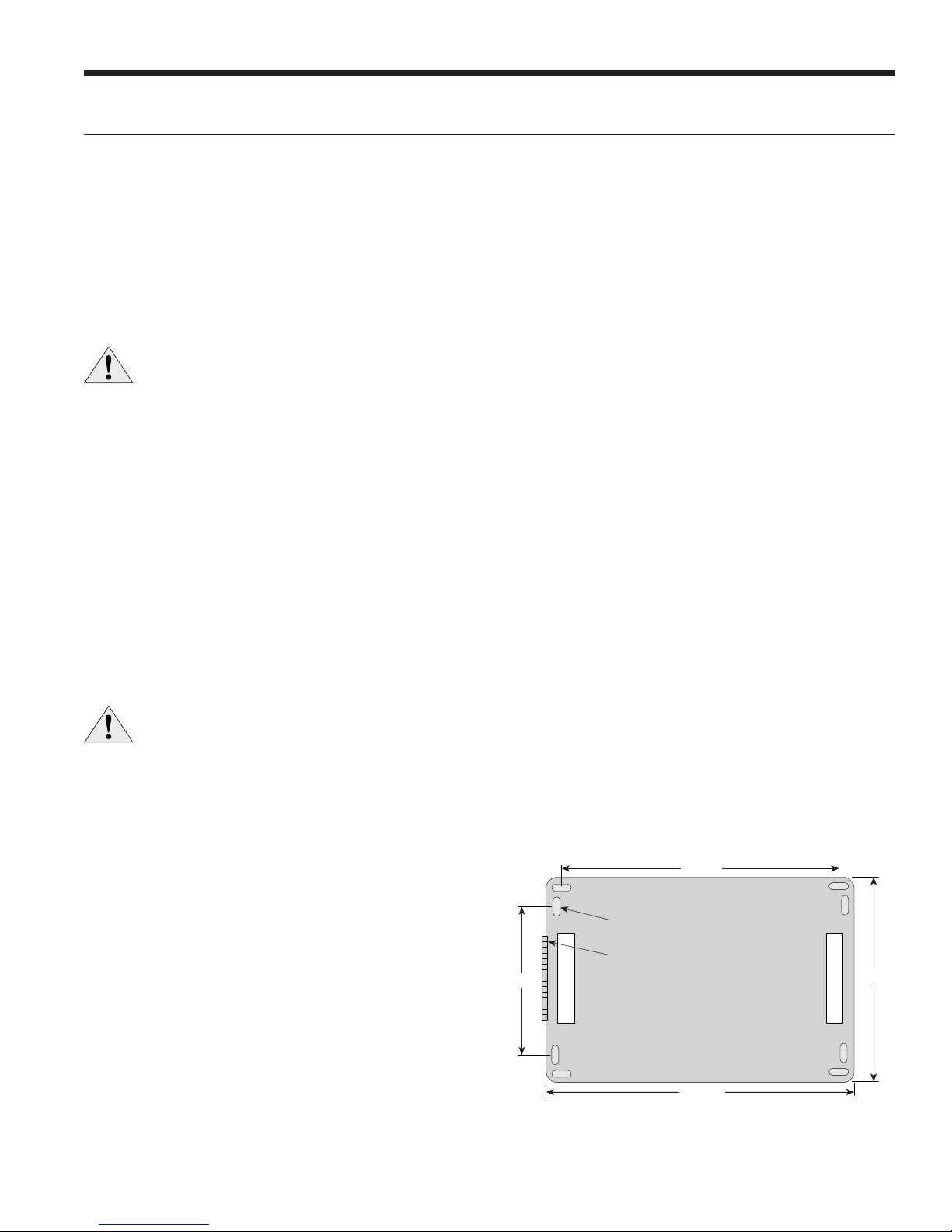

Zone Control Panels

Locate the IntelliZone2 and IntelliZone2 ● 24V panels in an

indoor area that has enough space for service personnel

to perform maintenance or repair. Provide sufficient room

to make electrical connection(s). The IntelliZone2 and

IntelliZone2 ● 24V is not approved for outdoor installation

and, therefore, must be installed inside the structure being

conditioned. Do not locate the control panels in areas

where ambient conditions are not maintained within 45°F

to 95°F and are greater than 75% relative humidity. The

IntelliZone2 and IntelliZone2 ● 24V control panels should

be mounted on or as close to the unit as possible by using

the mounting hardware provided. See Figure 1 for mounting

hole locations.

Figure 1: IntelliZone2 ● 24V and IntelliZone2 Relay Panel

9.25 in.

Mounting Slots

Hinge Side

6.00 in.

Wire Access

epth = 2.00 in. Deep with cover

10.35 in.

NOTE: Use longer screws (not provided) to penetrate

through drywall into stud.

Wire Access

7.75 in.

5

INTELLIZONE2 ● 24V INSTALLATION MANUAL

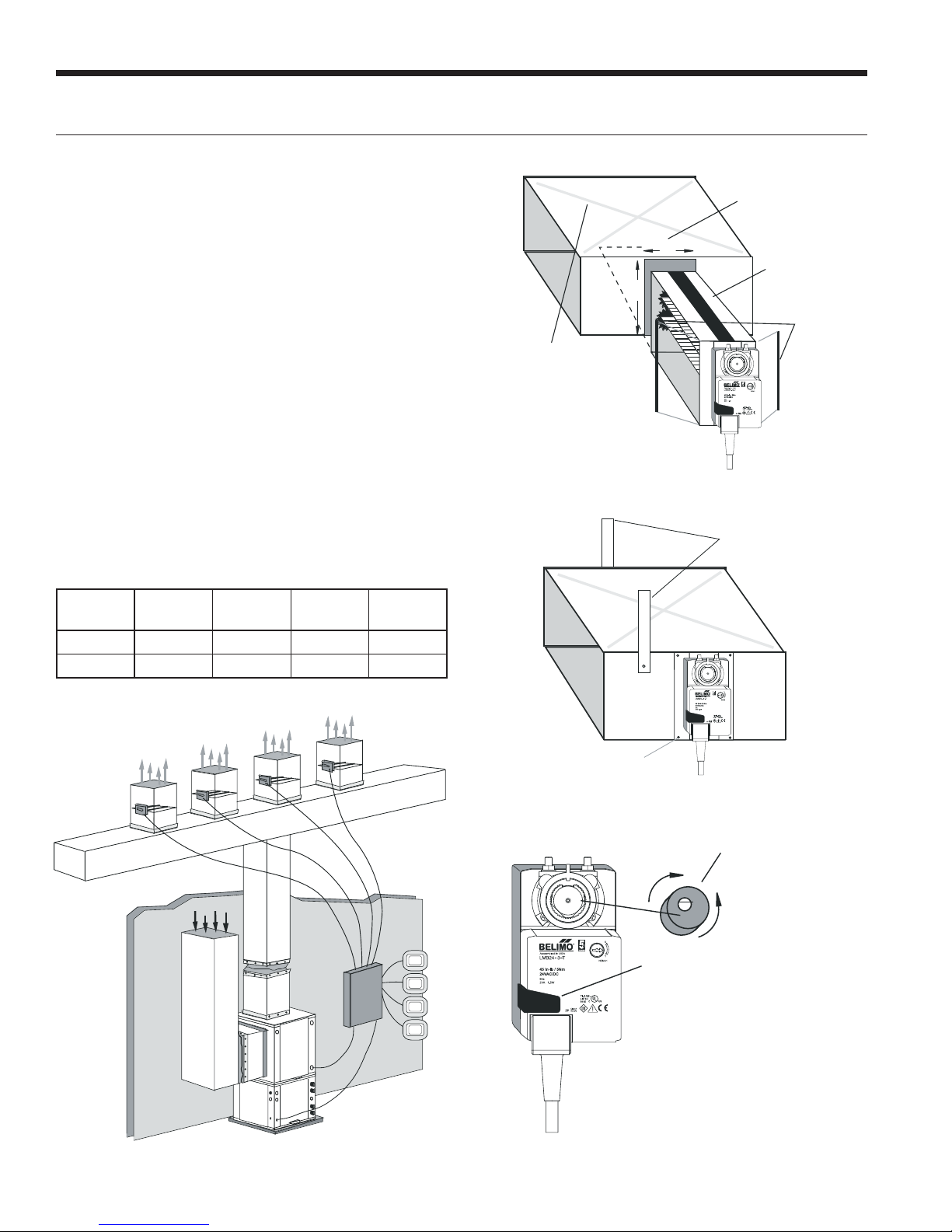

Damper Installation

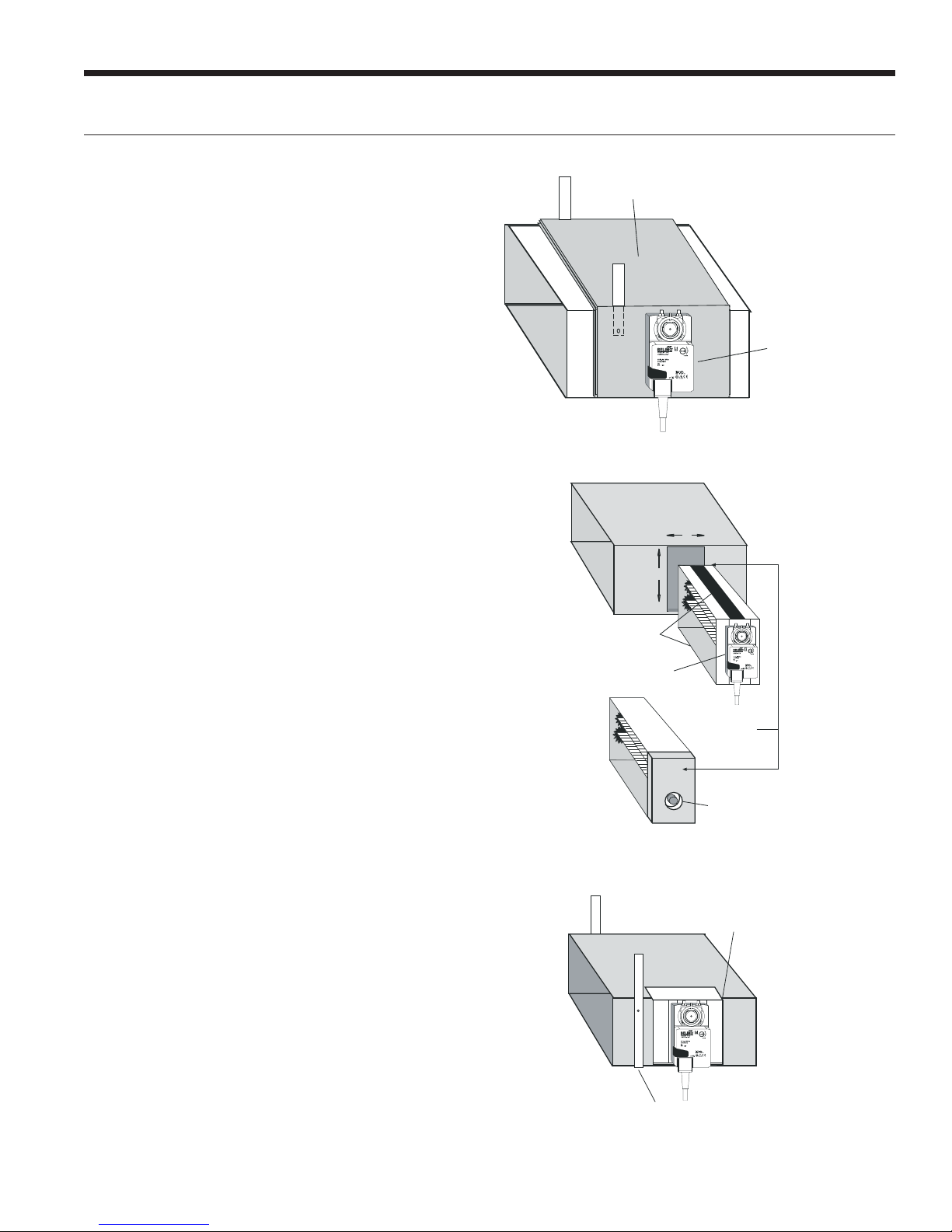

Installing Rectangular Dampers in

Metal Ductwork

1. Cut out dimensions A and B as shown in Figure 2 by

using sheet metal snips. NOTE: Dimensions A and B are

listed in the Dimensional Examples table.

2. Use foam insulation tape on the top and bottom of

the zone damper to prevent excessive air bypass. Also

check the cross emboss for excessive air bypass (see

Figure 2).

3. Slide the zone damper into the ductwork making

sure no obstructions will interfere with damper blade

operation.

4. Use the screws provided to mount the damper flange

to the ductwork. Four to six mounting holes are

provided as shown in Figure 3.

5. Use drive cleats or regular duct mounting brackets to

attach ductwork to joist within six inches on both sides

of the damper (see Figure 3).

6. Check damper blade operation for obstructions by

holding the manual release button and rotating the

damper shaft CCW (Open) and CW (Closed) 3 Wire

only as shown in Figure 4.

Dimensional Examples

Damper

Model

ZDR1024 10 in. 24 in. 10 in. 3.75 in.

ZDR0812 8 in. 12 in. 8 in. 3.75 in.

HWA B

Figure 2: Foam Taping Zone Damper

B

A

Cross emboss for

duct stiffness may

cause excessive

air bypass

Figure 3: Mounting Damper

Attach duct/damper

to joist within 6" on

3.75”

Foam Tape

(top and bottom)

Foam Seal

both sides

Four Zone System Representational Layout

Premier2

Mounting Screws

(4 places)

Figure 4: Checking Damper Blade for Obstructions

CCW

Open

72

72

72

72

Rotate by hand

CW

Closed

Manual release

6

Damper Installation cont.

INTELLIZONE2 ● 24V INSTALLATION MANUAL

Insulating Rectangular Dampers in

Metal Ductwork

Insulate ductwork as shown in Figure 5. All metal must

be covered. Care must be taken not to obstruct the shaft

from rotating when insulating. Do not insulate the zone

damper actuator.

Installing Rectangular Dampers

in Ductboard

1. Cut out dimensions A and B by using a ductboard

knife. NOTE: Dimensions A and B are listed in the

Dimensional Examples table.

2. A ductboard spacer should be installed on the end

of the damper frame as shown in Figure 6 to prevent

excessive air bypass. For example: A one-inch-thick,

8 in. x 20 in. ductboard and a 8 in. x 20 in. zone

damper would have a one-inch gap at the end of the

frame once it is installed without a ductboard spacer.

Use the piece cut out for installation.

3. Foam insulation tape should be used on the top and

bottom of the zone damper to prevent excessive air

bypass as shown in Figure 6.

4. Slide the zone damper into the ductboard making

sure no obstructions will interfere with damper

blade operation.

5. Tape the damper face flange to the ductboard using

foil tape making sure the damper is secure and air tight

as shown in Figure 7.

6. Support the full length of the ductboard underside

within six inches and on both sides of the damper as

shown in Figure 7.

7. Check the damper blade operation for obstructions

by holding the manual release button and rotating the

damper shaft CCW and CW (see Figure 4).

Figure 5: Insulating Rectangular Metal Ductwork

Duct wrap insulation

Do not insulate zone

damper actuator

Figure 6: Taping Zone Damper with Foam Tape

B

A

Foam tape

(top and bottom)

Insulate between

actuator and damper

Duct board

spacer

Keep spacer clear

of end bushing

Figure 7: Taping Damper Flange to Ductboard

Foil tape damper face

to ductboard

Support the full length of ductboard

underside within 6” of damper

7

INTELLIZONE2 ● 24V INSTALLATION MANUAL

Support with wide

steel strap

1-1/2’’ or 2’’ if in unconditioned space

Do not insulate

damper actuator

Flexible duct

Clamp with duct strap. Install screw no farther

than 1” from either end of damper

Slide duct 2-3’’ past

damper end rib

Air Flow

Damper Installation cont.

Insulating Rectangular Ductboard/

Metal Sleeve

Care must be taken not to obstruct the shaft from rotating

when insulating. Do not insulate the zone damper actuator.

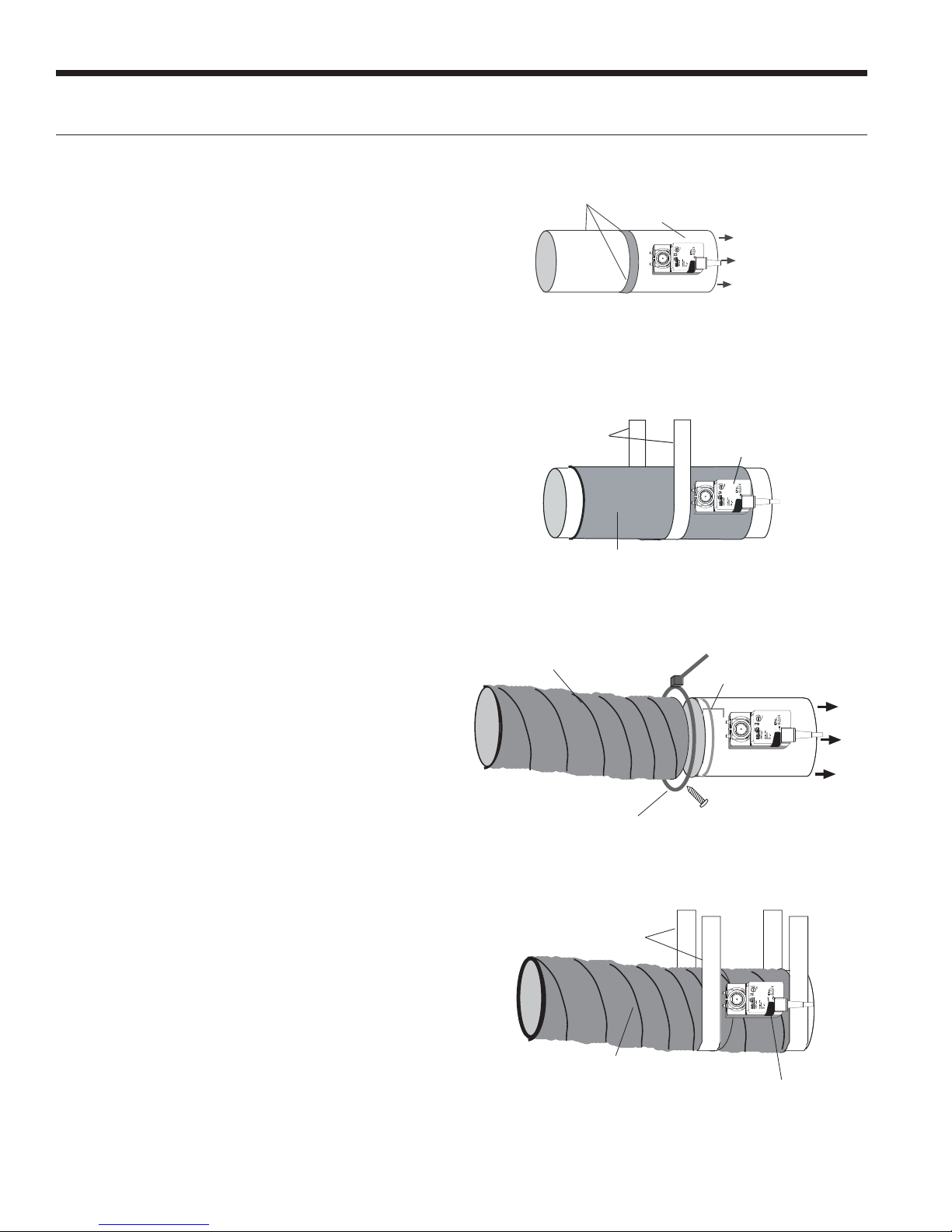

Installing Circular Dampers in Round

Metal Duct

1. Crimp the end of the duct that is the supply air to

damper. Insert into circular damper no more than

1.5 inches.

2. Fasten the duct to the damper with three screws.

Screws installed more than one inch from either end

may obstruct damper blade rotation.

3. Seal completely around the duct with metal duct tape

or mastic to prevent air leakage as shown in Figure 8.

4. Check the damper blade operation for obstructions by

holding the manual release button and rotating damper

shaft CCW and CW (3 wire only). See Figure 4.

5. Support the duct to joist within six inches of the

damper as shown in Figure 9.

Insulating Circular Dampers in Round

Metal Duct

Insulate ductwork as shown in Figure 9. All metal must be

covered to prevent condensation. Care must be taken not

to obstruct the shaft from rotating when insulating. Do not

insulate the zone damper actuator.

Figure 8: Taping Round Duct to Circular Damper

Three screws sealed

with duct tape or mastic

Manual release button

Air Flow

Figure 9: Supporting and Insulating Circular Damper

Support with

wide steel strap

1-1/2" or 2" if in unconditioned space

Figure 10: Attaching Flexible Duct to Damper

Do not insulate

damper actuator

Installing Circular Dampers in

Flexible Duct

1. Slide flexible duct two to three inches over the damper

pipe past the damper rib as shown in Figure 10.

2. Fasten duct to damper with a nylon duct strap,

screwing the strap to the pipe to prevent the duct from

slipping off. Screws installed more than one inch from

either end may obstruct damper rotation.

3. Seal completely around the duct with metal duct tape

or mastic to prevent any air leakage.

4. Check the damper blade operation for obstructions by

holding the manual release button and rotating damper

shaft CCW (Open) and CW (Closed) - 3 wire only. See

Figure 4.

5. Support the damper to joist within six inches on both

sides of the damper as shown in Figure 11.

Insulating Damper Actuators

Insulate the damper as shown in Figure 11. All metal must

be covered to prevent condensation. When insulating, care

must be taken not to obstruct the shaft from rotating. Do

not insulate the zone damper actuator.

Figure 11: Supporting and Insulating Circular Damper

8

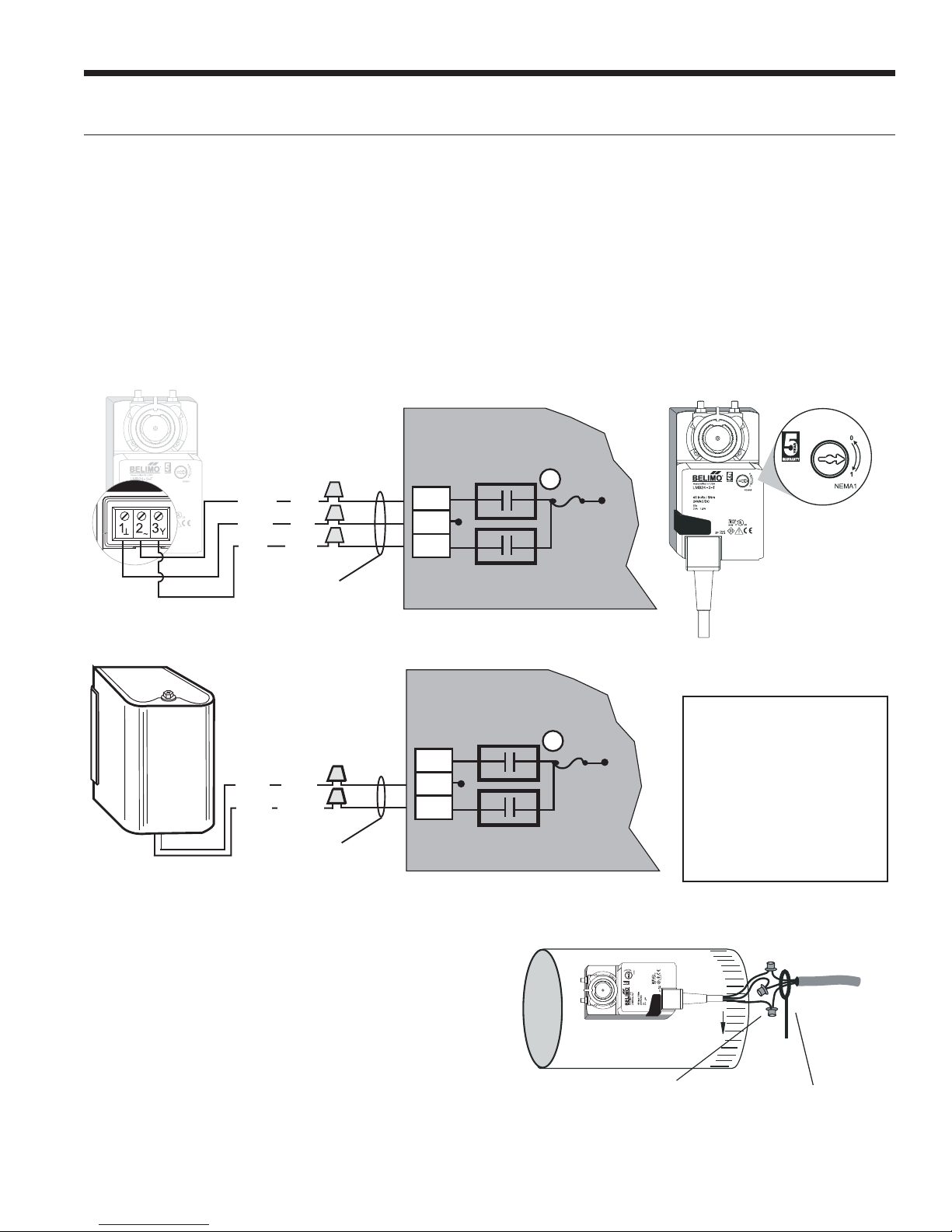

Electrical Wiring

Wire Nuts Strain Relief

3-Wire Damper

Zone 4

Com

Open

Close

G

Minimum

18-gauge wire

(Indicated rotation direction

is valid for switch position ‘0’ )

BlkCOM

Grn

CCW

Red

CW

IntelliZone2 PCB

2-Wire Damper

Minimum

18-gauge wire

Zone 4

IntelliZone2 PCB

Com

Open

Close

G

COM

Gray

CCW

Yellow

Wiring Damper Actuators

All wiring must comply with local and state codes.

Disconnect the power supply before beginning to wire to

prevent electrical shock or equipment damage. All wiring

should be run back to the control panel. Keep wires a

minimum of 12 inches from any high voltage lines. Follow

the damper wiring schematic as shown in Figure 12. Verify

that damper rotation direction is correct. The 3-wire

damper rotation direction is reversible with switch on front

cover.

Figure 12: Damper Actuator Wiring

INTELLIZONE2 ● 24V INSTALLATION MANUAL

Damper Actuator Wiring Notes

1. Minimum of 18-gauge thermostat wire is recommended.

2. Use wire nuts to connect the thermostat wire to the

actuator wire (solid wire to stranded wire) as shown in

Figure 13.

3. The actuator wiring should be secured using a wire tie to

prevent the wires from being separated (see Figure 13).

Figure 13: Actuator Wiring

9

Damper Switch

Reverse Rotation

Note:

Note:

1. Each zone must have

1. Each zone must have

dampers that match by

dampers that match by

manufacturer and type.

manufacturer and type.

2. Each IntelliZone

2. Each IntelliZone2•24V

System must have

System must have

dampers that match,

dampers that match

either 2-wire or 3-wire.

either 2-wire or 3-wire.

Loading...

Loading...