Page 1

Geothermal Hydronic Heat Pump

Commercial 1.5 to 6 Tons

Installation Information

Water Piping Connections

Electrical Data

Startup Procedures

Preventive Maintenance

NSW Installation Manual

IM1056WN 03/13

Page 2

Page 3

Table of Contents

Model Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

NSW INSTALLATION MANUAL

Water Quality

Field Connected Water Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Potable Water Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Hydronic Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Accessories and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-23

External Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-25

Converting to a Dedicated Cooling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Unit Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Standard Board - Control Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29

Standard Control - Panel Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-31

Optional Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32-36

Reference Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Legend and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AHRI/ISO 13256-2 Performance Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Thermistor and Compressor Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Antifreeze Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Troubleshooting Guideline for Refrigerant Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Heating and Cooling Cycle Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Troubleshooting Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46-47

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49-50

Revision Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 4

NSW INSTALLATION MANUAL

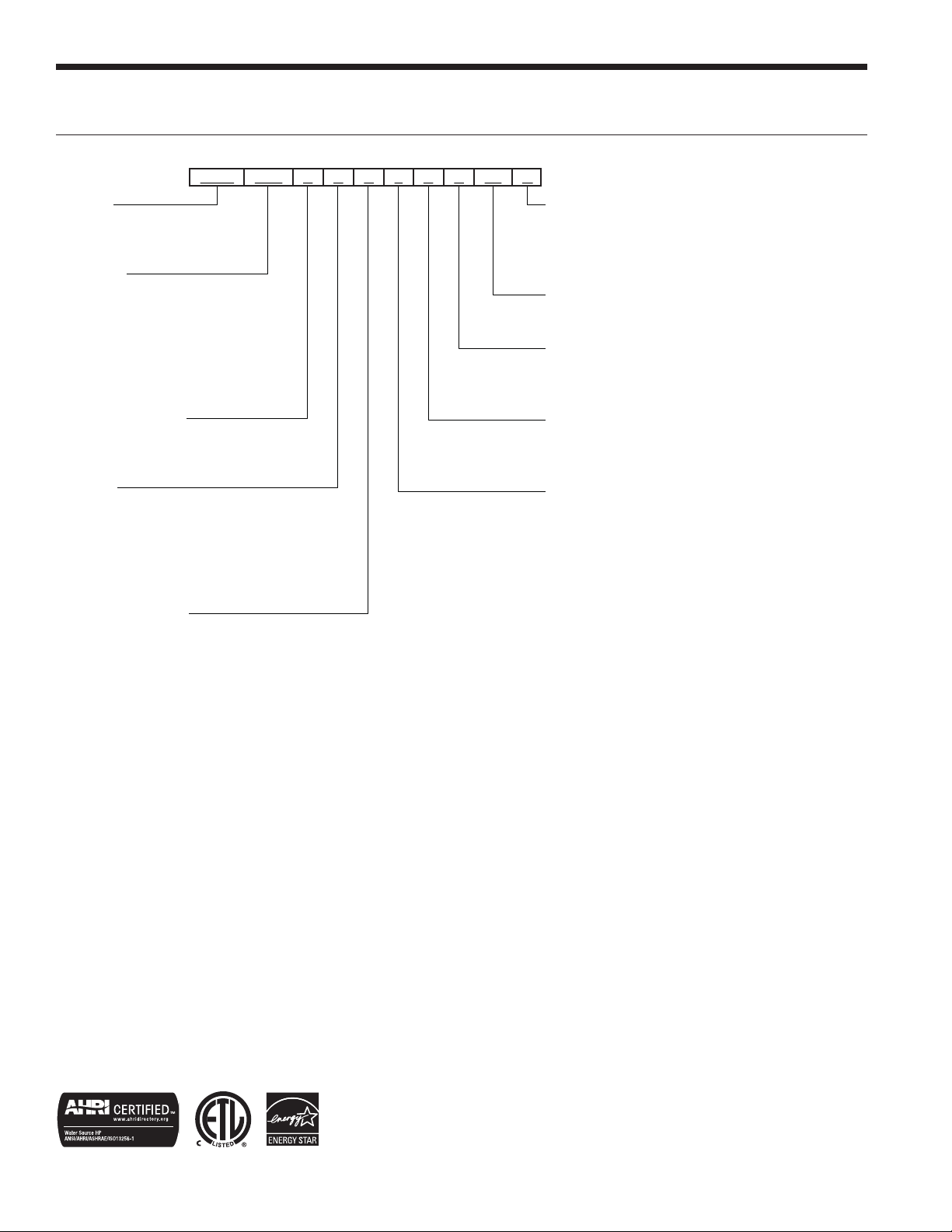

Model Nomenclature

1-3

NSW

4-6

050

7R809010211C12 15

Model

NSW = Envision Series

Hydronic Heat Pump

Capacity

018 MBTUH

025 MBTUH

040 MBTUH

050 MBTUH

060 MBTUH

075 MBTUH

Reversible Option

H = Heating Only

R = Reversible

Voltage

0 = 208-230/60/1 (Commercial)

2 = 265/60/1 (025 & 050 only)

3 = 208-230/60/3 (040 - 075 only)

4 = 460/60/3 (025 - 075 only)

5 = 575/60/3 (040 - 075 only)

Hot Water Option

0 = No Hot Water Generation, No IntelliStart

2 = Hot Water Generation (requires accessory

pump kit), No IntelliStart

3 = No Hot Water Generation, IntelliStart

5 = Hot Water Generation (requires accessory

pump kit), IntelliStart

2

1

1, 2

13-14

SS

A

C

Vintage

A = NSW040 - NSW075

B = NSW025

C = NSW018

Future Option

SS = Standard Option

Load Coax

3

C = Copper

N = Cupronickel

Source Coax

C = Copper

N = Cupronickel

Controls Option

2 = Standard Board

4 = FX10 without interface

5 = FX10 with N2 card without interface

6 = FX10 with LonWorks card without interface

7 = FX10 with BACnet card without interface

8 = FX10 with MUI

9 = FX10 with N2 card and MUI

0 = FX10 with Lonworks card and MUI

3 = FX10 with BACnet card and MUI

Rev.: 26 March 2013D

NOTES: 1 IntelliStart is only available on 208-230/60/1 voltage

2

Available on 040, 050, 060, and 075 only. HWG requires field installed external pump kit.

3

NSW018 and NSW025 heating only models are available only with copper double wall vented load coax

for potable water.

All Envision Series product is safety listed under UL1995 thru ETL and performance

listed with AHRI in accordance with standard 13256-1. The Envision Series is also

ENERGY STAR

®

rated.

4

Page 5

General Installation Information

NSW INSTALLATION MANUAL

Safety Considerations

Installing and servicing air conditioning and heating

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service heating and air

conditioning equipment. When working on heating and

air conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available for all brazing operations.

NOTE: Before installing, check voltage of unit(s) to ensure

proper voltage.

WARNING: Before performing service or

maintenance operations on the system, turn off

main power switches to the unit. Electrical shock

could cause serious personal injury.

Process Water Applications

For process water applications, it is recommended that

a secondary load heat exchanger be installed to prevent

corrosion to the unit’s primary coaxial coil. In situations

where scaling could be heavy or where biological growth

such as iron bacteria will be present, a closed loop system is

recommended. Over a period of time, ground water unit heat

exchanger coils may lose heat exchange capability due to a

buildup of mineral deposits. These can be cleaned only by

a qualified service mechanic as special pumping equipment

and solutions are required. Never use flexible hoses with a

smaller inside diameter than that of water connections.

WARNING: To avoid equipment damage, do not

leave the system filled in a building without heat

during cold weather, unless adequate freeze

protection levels of antifreeze are used. Heat

exchangers do not fully drain and will freeze

unless protected, causing permanent damage.

Unit Location

Provide sufficient room to make water and electrical

connections. If the unit is located in a confined space,

provisions must be made for unit servicing. Locate the

unit in an indoor area that allows easy removal of the

access panels and has enough space for service personnel

to perform maintenance or repair. These units are not

approved for outdoor installation and, therefore, must be

installed inside the structure being conditioned. Do not

locate units in areas subject to freezing conditions.

WARNING: Do not store or install units in

corrosive environments or in locations subject

to temperature or humidity extremes (e.g. attics,

garages, rooftops, etc.). Corrosive conditions and

high temperature or humidity can significantly

reduce performance, reliability, and service life.

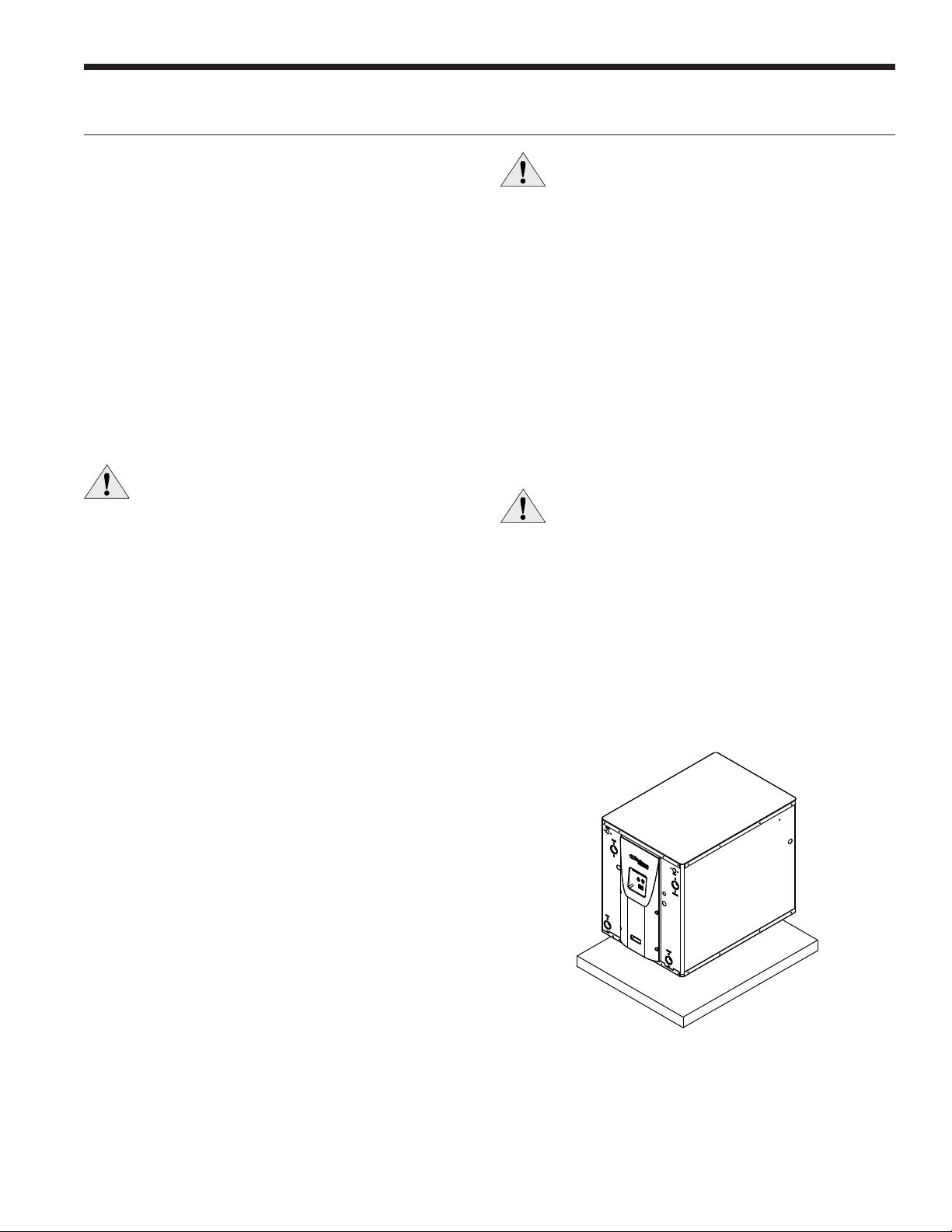

Mounting Units

Units should be mounted level on a vibration absorbing pad

slightly larger than the base to provide isolation between

the unit and the floor. It is not necessary to anchor the unit

to the floor. Allow access to the front, back, and side access

panels for servicing.

Moving and Storage

Move units in the normal “Up” orientation as indicated by

the labels on the unit packaging. When the equipment

is received, all items should be carefully checked against

the bill of lading to ensure that all crates and cartons

have been received in good condition. Examine units for

shipping damage, removing unit packaging if necessary

to properly inspect unit. Units in question should also

be internally inspected. If any damage is observed, the

carrier should make the proper notation on delivery receipt

acknowledging the damage. Units are to be stored in a

location that provides adequate protection from dirt, debris

and moisture.

DWP`ObW]\>OR;]c\bW\U

5

Page 6

NSW INSTALLATION MANUAL

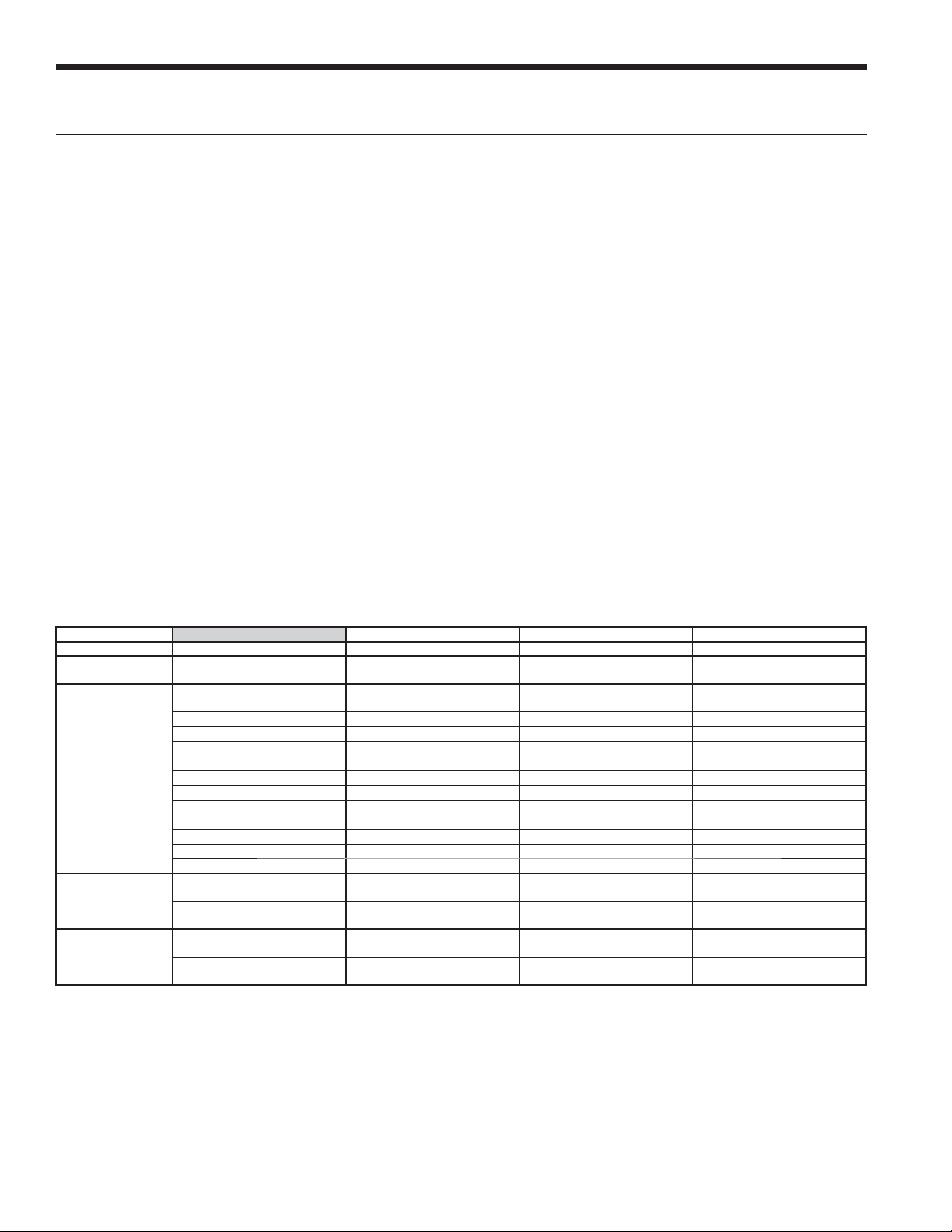

Water Quality

General

NSW water-to-water heat pumps may be successfully

applied in a wide range of residential and light commercial

applications. It is the responsibility of the system designer

and installing contractor to ensure that acceptable water

quality is present and that all applicable codes have been

met in these installations. Failure to adhere to the guidelines

in the water quality table could result in loss of warranty.

Water Treatment

Do not use untreated or improperly treated water.

Equipment damage may occur. The use of improperly

treated or untreated water in this equipment may result in

scaling, erosion, corrosion, algae or slime. The services of a

qualified water treatment specialist should be engaged to

determine what treatment, if any, is required. The product

warranty specifically excludes liability for corrosion,

erosion or deterioration of equipment.

The heat exchangers and water lines in the units are copper

or cupronickel tube. There may be other materials in the

Water Quality Guidelines

building’s piping system that the designer may need to take

into consideration when deciding the parameters of the

water quality.

If an antifreeze or water treatment solution is to be used,

the designer should confirm it does not have a detrimental

effect on the materials in the system.

Contaminated Water

In applications where the water quality cannot be held to

prescribed limits, the use of a secondary or intermediate

heat exchanger is recommended to separate the unit from

the contaminated water.

The following table outlines the water quality guidelines

for unit heat exchangers. If these conditions are exceeded,

a secondary heat exchanger is required. Failure to supply

a secondary heat exchanger where needed will result in a

warranty exclusion for primary heat exchanger corrosion

or failure.

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity

Scaling

Corrosion

Iron Fouling

(Biological Growth)

Erosion

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

Calcium and

Magnesium Carbonate

Hydrogen Sulfide

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron, FE

Bacterial Iron Potential

Iron Oxide

Suspended Solids

Threshold Velocity

(Fresh Water)

Less than 0.5 ppm (rotten egg

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

2

+ (Ferrous)

smell appears at 0.5 ppm)

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

7 - 9 7 - 9 7 - 9

(Total Hardness)

less than 350 ppm

< 0.2 ppm < 0.2 ppm < 0.2 ppm

< 6 ft/sec < 6 ft/sec < 6 ft/sec

(Total Hardness)

less than 350 ppm

10 - 50 ppm Less than 1 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

(Total Hardness)

less than 350 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

2/22/12

6

Page 7

Field Connected Water Piping

NSW INSTALLATION MANUAL

General

Each unit is equipped with captive FPT water connections

to eliminate ‘egg-shaping’ from use of a backup wrench.

For making the water connections to the unit, a Teflon tape

thread sealant is recommended to minimize internal fouling

of the piping. Do not over tighten connections. All supply and

return water piping should be insulated to prevent excess

condensation from forming on the water lines.

NOTE: Units are factory run-tested using propylene

glycol. Prior to connecting piping to unit, thoroughly flush

heat exchangers.

The piping installation should provide service personnel with

the ability to measure water temperatures and pressures.

The water lines should be routed so as not to interfere with

access to the unit. The use of a short length of high pressure

hose with a swivel type fitting may simplify the connections

and prevent vibration. Optional stainless steel hose kits are

available as an accessory item.

Before final connection to the unit, the supply and return

hose kits must be connected, and the system flushed

to remove dirt, piping chips and other foreign material.

Normally, a combination balancing and close-off (ball) valve

is installed at the return, and a rated gate or ball valve is

installed at the supply. The return valve can be adjusted to

obtain the proper water flow. The valves allow the unit to be

removed for servicing.

to-water heat exchanger (See Pressure Drop Table for water

flow and pressure drop information). Normally about 3 GPM

flow rate per ton of cooling capacity (2.25 GPM per ton

minimum) is needed. Both source as well as load fluid piping

must be at least as large as the unit connections on the heat

pump (larger on long runs).

Never use flexible hoses of a smaller inside diameter than

that of the water connection on the unit and limit hose length

to 10 ft. per connection. Check carefully for water leaks.

CAUTION: Water piping exposed to outside

temperature may be subject to freezing.

Open Loop Well Water Systems

Always maintain water pressure in the heat exchanger by

placing water control valves at the outlet of the unit. Use

a closed bladder type expansion tank to minimize mineral

deposits. Ensure proper water flow through the unit by

checking pressure drop across the heat exchanger and

comparing it to the figures in the pressure drop table.

Normally, about 2 GPM flow rate per ton of cooling capacity

is needed in open loop systems, (1.5 GPM per ton minimum if

entering source temperature is above 50°F [10°C].

Some water control valves draw their power directly from

the unit’s 24V transformer and can overload and possibly

burn out the transformer. Check total VA draw of the water

valve(s) and ensure it is under 40 VA.

The proper water flow must be delivered to each unit

whenever the unit heats or cools. To assure proper flow,

the use of pressure/temperature ports is recommended

to determine the flow rate. These ports should be located

adjacent to the supply and return connections on the unit.

The proper flow rate cannot be accurately set without

measuring the water pressure drop through the refrigerant-

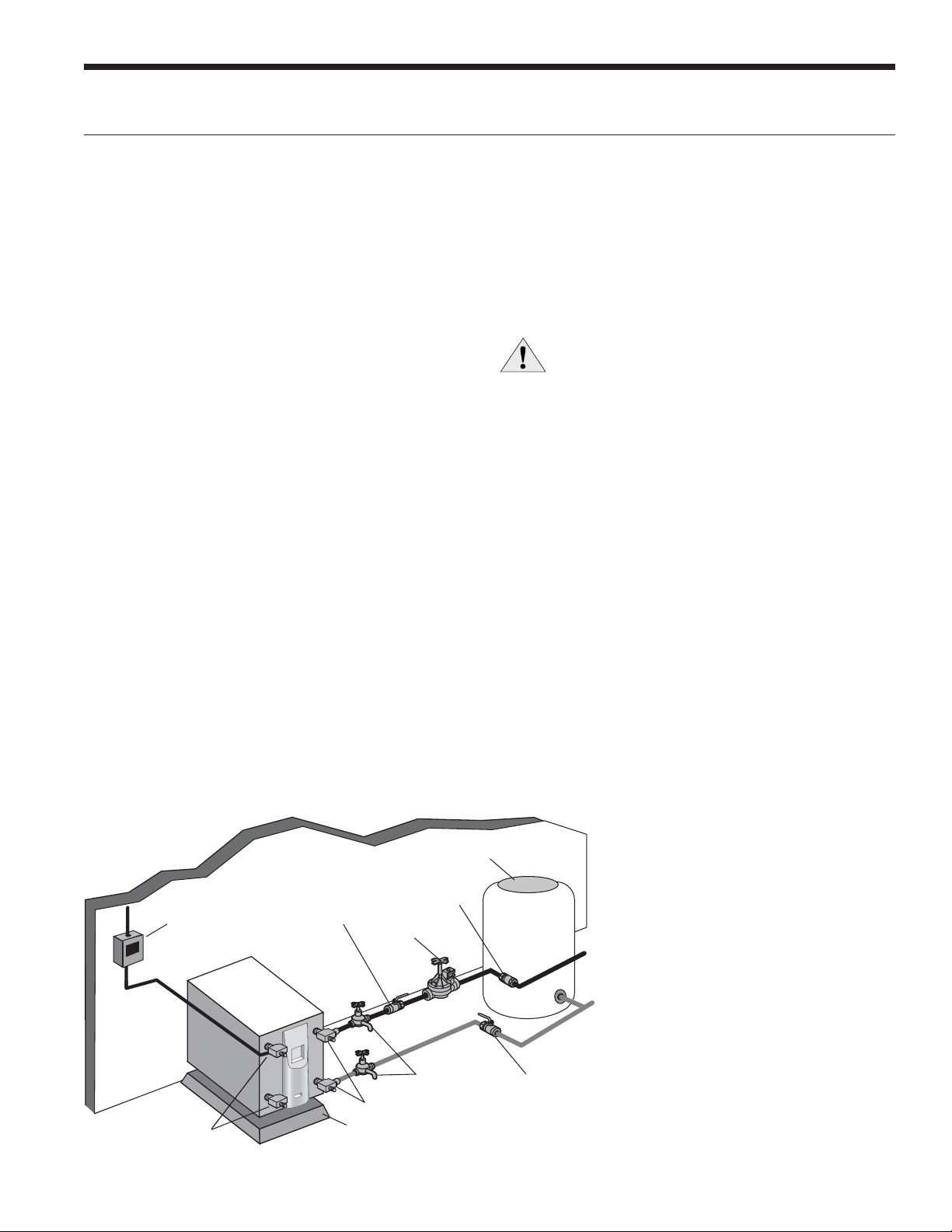

Typical Open Loop Installation

Rubber Bladder

Expansion Tank

Flow Regulator Valve

Line Voltage

Disconnect

Load Liquid

Connections

Shut-off Valve

(to isolate solenoid

valve while acid

flushing)

Solenoid

Valve

Boiler Drains for

HX Flushing

P/T Plugs

Vibration Absorbing

Mesh or Air Pad

Discharge water from a heat pump can be disposed of in

various ways depending on local building codes (i.e. recharge

well, storm sewer, drain field, adjacent stream or pond,

etc.). Most local codes restrict the use of sanitary sewer for

disposal. Consult your local building and zoning departments

to ensure compliance in your area.

Water Out

Water In

Shut-off

Valve

NOTE: Valves and boiler drains must be installed

so the heat exchanger can be acid flushed.

7

Page 8

NSW INSTALLATION MANUAL

Field Connected Water Piping cont.

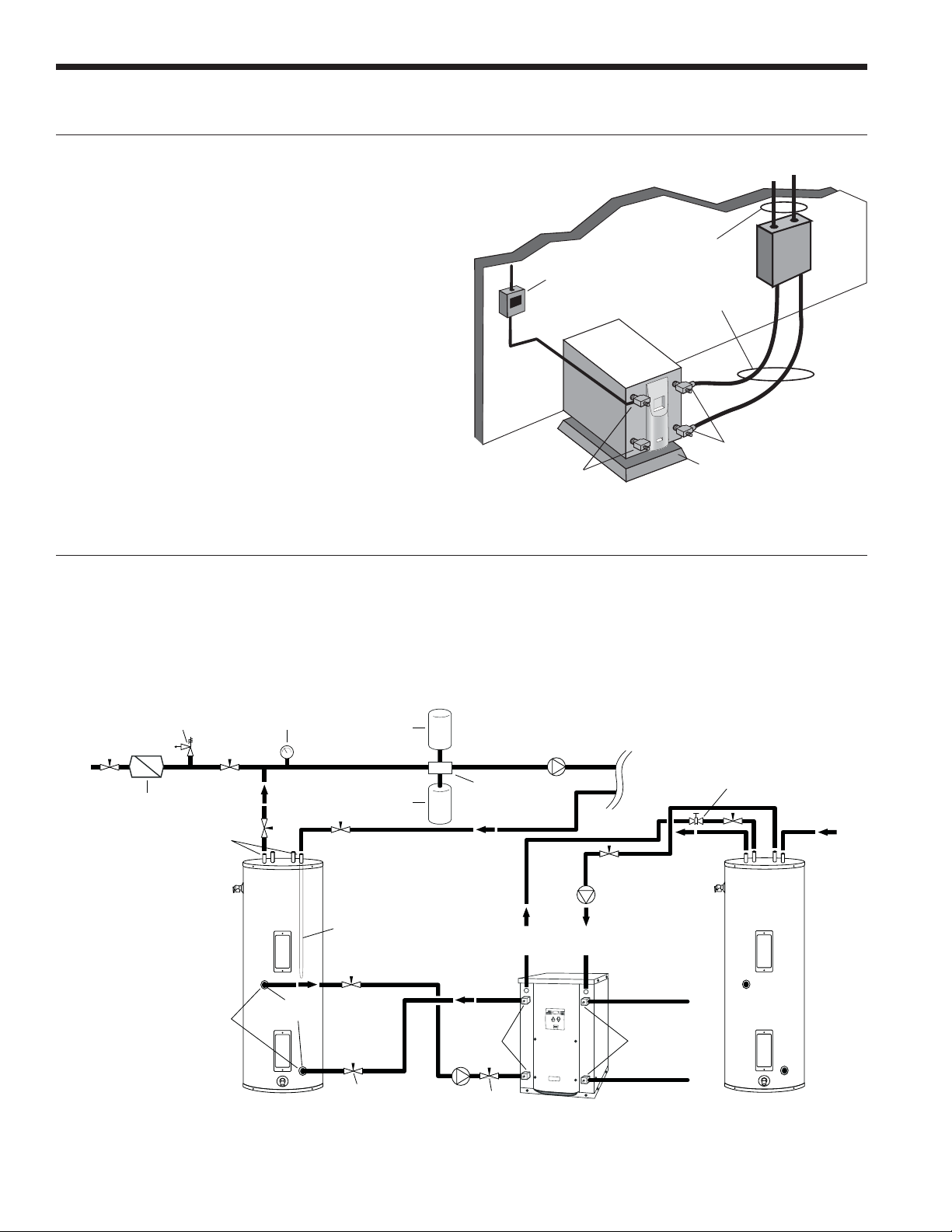

Earth Coupled Systems with Flow Center

Once piping is completed between the unit, flow center

and the earth loop, final purging and charging of the loop

is needed. A flush cart (at least a 1.5 HP or 1.12 kW pump)

is needed to achieve adequate flow velocity in the loop to

purge air and dirt particles from the loop itself. Antifreeze

solution is used in most areas to prevent freezing. Maintain

the pH in the 7.6-8.2 range for final charging.

Flush the system adequately to remove as much air as

possible. Then, pressurize the loop to a static pressure of

50-75 psi [345-517 kPa]. This is normally adequate for good

system operation. Ensure that the flow center provides

adequate flow through the unit by checking pressure drop

across the heat exchanger and by comparing it to the

figures shown in the Pressure Drop tables. Usually, 3 GPM/

ton [0.054 L/s/kW] L/s/kW or minimum 2.25 GPM/ton

[0.04 L/s/kW] of cooling capacity is needed in closed loop

earth-coupled applications

Potable Water Systems

The NSW018 and NSW025 models can be equipped to

provide domestic hot water generation. An optional

factory-installed hot water generator coil may be provided

with the NSW040, NSW050, NSW060, and NSW075 to

assist with this process.

Typical Closed Loop Earth Coupled Installation

Earth Coupled Loop

Piping with Insulation

Line Voltage

Disconnect

Unit Connector Kits

with Insulation

P/T Plugs

Load Liquid

Connections

Vibration Absorbing

Mesh or Air Pad

Suggested Domestic Water Heater Hookup

30 psi

RELIEF VALVE

Back Flow Preventer /

Pressure Relief Valve

Dielectric

Unions

Dielectric

Unions

NOTES:

* A 30 psi pressure relief valve (Part No: SRV30) should be used in

hydronic applications.

** Vent valve or P/T port at highest point in return line prior to ball valve.

Pressure

Gauge

GEO

STORAGE

TANK

1-1/2 in.

FPT

Dip Tube

Expansion

Tank

Ball Valve

Air

Vent

Air

Separator

Ball Valve

LOAD PUMP

FROM

HWG

HWG

WaterFurnace

NSW Series

TO

HYDRONIC

PUMP

Source OUT

P/T PortsP/T Ports

Source IN

LOAD

HOT

(Piped in

series to

an electric

water heater)

Vent Valve/

P/T Port**

DOMESTIC

COLD

8

Page 9

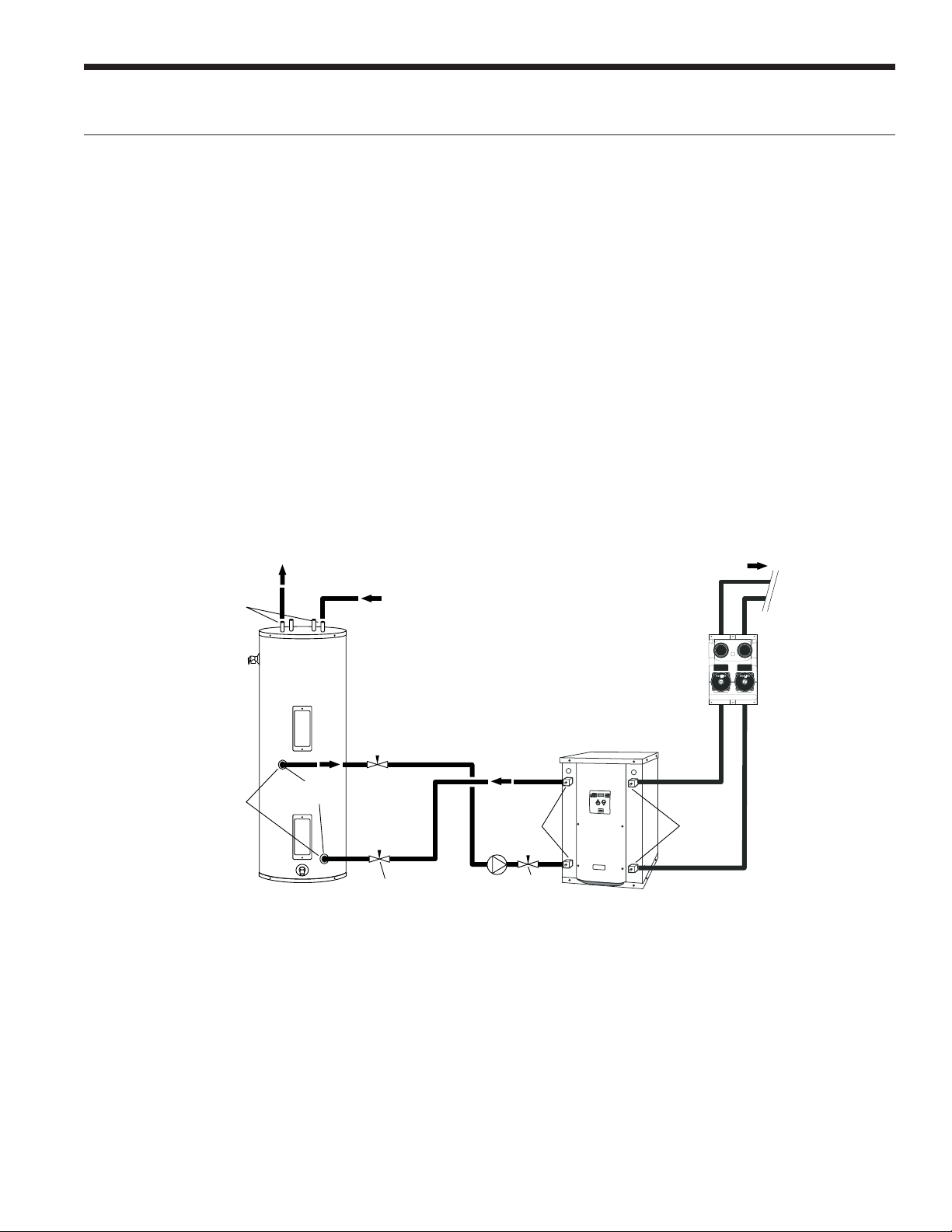

Potable Water Systems cont.

NSW INSTALLATION MANUAL

NOTES:

1) Unions and valves must be installed so that acid flushing

of the heat exchanger is possible.

2) Route thermistor wires to NSW. Remove yellow

thermistor wires on TB 3 and 4 from control box and

connect thermistor wires from geothermal storage tank.

Set the pump sampling (PS) in the set up of the control

board to continuously (C) sampling (reference Note 5 in

the Wiring Schematic).

Alternate Hot Water Installation with

Direct Coupling to a Double Wall Unit

2WSZSQb`WQ

C\W]\a

6=B

1=:2

Hot Water Generator Connections

The heat reclaiming hot water generator coil is vented double-

wall copper construction and is suitable for potable water. To

maximize the benefits of the hot water generator a minimum

50-gallon water heater is recommended. For higher demand

applications, use an 80-gallon water heater as shown below or

two 50-gallon water heaters connected in a series. A geo storage

tank should not be used in this application unless it is plumbed

in a series with an electric water heater. The geo storage tank

is equipped with a single 4500 Watt element and will not be

able to provide adequate water heating if used as a standalone

water heater. Electric water heaters are recommended. Make

sure all local electrical and plumbing codes are met for installing

a hot water generator. The Envision NSW is not supplied with

an internal circulator. A DPK5 kit will need to be purchased to

connect to the hot water generator. The DPK5 kit is supplied with

installation instructions, circulator, tank adaptor and temperature

limit switch. Be sure to burp (vent) the pump. Open the screw

2 turns only in the end of the pump motor (if Grundfos

are used) to allow trapped air to be discharged and to ensure the

motor housing has been flooded.

:==>473:2

®

pumps

Þ

2WSZSQb`WQ

C\W]\a

4>B

0OZZDOZdS

EObS`4c`\OQS

53=B/<9

NOTES:

1) Unions and valves must be installed so that acid flushing

of the heat exchanger is possible.

2)

Make sure there is not a check valve in the diptube of

the tank.

3) Route thermistor wires to NSW. Remove yellow

thermistor wires on TB 3 and 4 from control box and

connect thermistor wires from geothermal storage tank.

Set the pump sampling (PS) in the set up of the control

board to continuously (C) sampling (reference Note 5 in

the Wiring Schematic).

4:=E13<B3@

>B>]`ba>B>]`ba

0OZZDOZdS

EObS`4c`\OQS

<AE&]`<AE #6SObW\U=\Zg

eWbV2]cPZSEOZZ:]OR1]Of

9

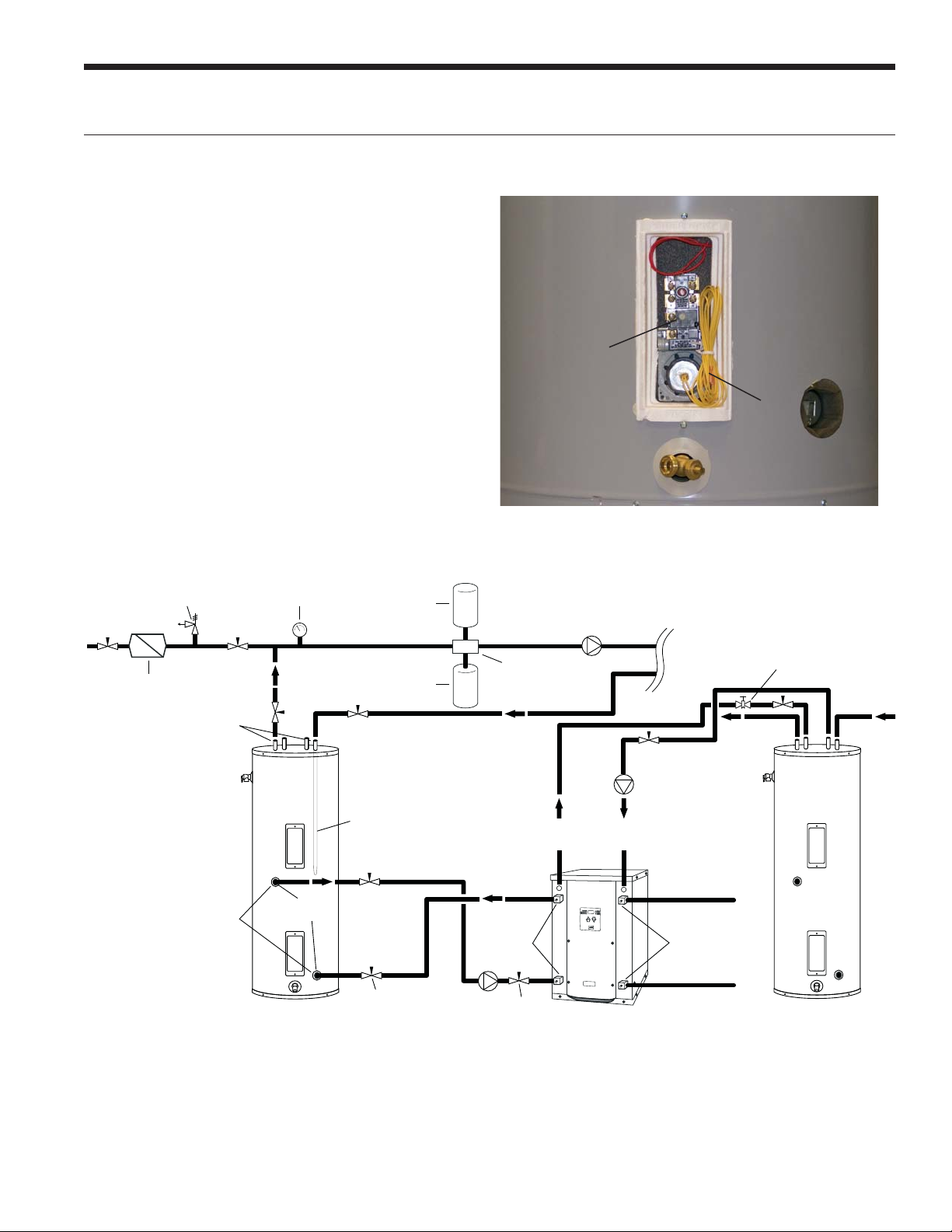

Page 10

NSW INSTALLATION MANUAL

Hydronic Section

General guidelines are shown below for component

selection and design/installation criteria for the piping

system. Local codes supersede any recommendations in

this manual.

Shut Off/Flow Regulation Valves

Use full port ball valves or gate valves for component

isolation. If valves are going to be used frequently, ball

valves are recommended. Globe valves are designed for flow

regulation. Always install globe valves in the correct direction

(fluid should enter through the lower body chamber).

Check valves

Swing check valves must be installed in the horizontal

position with the bonnet of the valve upright. Spring check

valves can be mounted in any position. A flow check valve

is required to prevent thermo-siphoning (or gravity flow)

when the circulator pump is off or when there are two

circulators on the same system.

Storage (Buffer) Tank

A buffer tank is required for all hydronic heating systems

using Envision NSW heat pumps. The tank should be sized

to provide 2 gallons of storage capacity for every one

thousand Btuh’s of nominal heat pump capacity.

Pressure Relief Valve

Most codes require the use of a pressure relief valve if a

closed loop heat source can be isolated by valves. Even

if local code does not require this device, WaterFurnace

recommends its installation. If the pressure relief valve in

the buffer tank is not already rated at 30 psi (207 kPa)

maximum pressure, one must be installed. The pressure

relief valve should be tested at start up for operation. Note

that the waste pipe must be at least the same diameter

as the valve outlet (never reduce), and valves may not be

added to this pipe. The bottom of the pipe must terminate

at least 6” (15 cm) above the floor. If the piping is connected

to a drain, there must be an air gap.

0 psi (0 kPa), potentially causing pumps(s) failure. A valve

should be installed on each side of the pressure reducing

valve for servicing. Both valves should have tags reading

“Do not shut this valve under normal operation – service

valve only.”

Expansion Tanks

Expansion tanks are required on hydronic systems to help

absorb the pressure swings as the temperature in the

system fluctuates.

Elbows/Tees

Long radius elbows or two 45° elbows will lower pressure

drop. Standard tees have a greater restriction on the “T”

portion than tees designed with angled outlet ports.

Antifreeze

Antifreeze is required if any of the piping system is located

in areas subject to freezing.

Dielectric Unions

Dielectric unions are recommended whenever connecting

two dissimilar metals to one and other to prevent electrogalvanic corrosion.

When using the various types of hydronic heat distribution

systems, the temperature limits of the geothermal system

must be a major consideration. In new construction, the

distribution system can easily be designed with the

temperature limits in mind. In retrofits, care must be

taken to address the operating temperature limits of the

existing distribution system. The maximum storage tank

temperature for the Envision NSW is 130°F (54.4°C). Typical

in floor radiant systems require much lower temperatures,

typically 100°-115°F, which is ideal for the Envision NSW.

Backflow Prevention Check Valves

Most codes require backflow prevention check valves.

Note that a single check valve is not equal to a backflow

prevention check valve. Even if local code does not require

this device, WaterFurnace recommends its installation. This

is particularly important if the system will use antifreeze.

Pressure Reducing Valves or Feed Water Valves

This valve lowers the pressure from the make-up water line

to the system. Most are adjustable and directional. A “fast

fill” valve is required for initial filling of the system. Some

have screens, which must be cleaned after the initial filling.

If there is a restriction in the screen, the system could go to

10

Page 11

Hydronic Section cont.

NSW INSTALLATION MANUAL

Open the screw 2 turns only in the end of the pump motor

(if Grundfos

®

pumps are used) to allow trapped air to be

discharged and to ensure the motor housing has been flooded.

Route thermistor wires to NSW. Remove yellow thermistor

wires on TB 3 and 4 from control box and connect thermistor

wires from geothermal storage tank. Set the pump sampling

(PS) in the set up of the control board to continuously (C)

sampling (reference Note 5 in the Wiring Schematic).

Adequate rate of flow (GPM) is very important to system

performance and long term reliability. Follow the guidelines

for recommended flow and pipe sizing in the NSW

recommendations table.

30 psi

RELIEF VALVE

Back Flow Preventer /

Pressure Relief Valve

Pressure

Gauge

Air

Vent

Expansion

Tank

WaterFurnace Geothermal Storage Tank Thermostat

and Thermistor

Synergy3D

Thermostat

NSW

Yellow Thermistor Wires Connected to TB (3 and 4) on

NSW Control Board

LOAD PUMP

HYDRONIC

Air

Separator

LOAD

Vent Valve/

P/T Port**

Dielectric

Unions

GEO

STORAGE

TANK

Dip Tube

1-1/2 in.

Dielectric

Unions

NOTES:

* A 30 psi pressure relief valve (Part No: SRV30) should be used in

hydronic applications.

** Vent valve or P/T port at highest point in return line prior to ball valve.

FPT

Ball Valve

Ball Valve

11

FROM

HWG

HWG

WaterFurnace

NSW Series

TO

PUMP

Source OUT

P/T PortsP/T Ports

Source IN

HOT

(Piped in

series to

an electric

water heater)

COLD

DOMESTIC

Page 12

NSW INSTALLATION MANUAL

Accessories and Options

Water Connection Kits (Field Installed)

Water connection kits have been designed to facilitate load-

side and loop-side water connections.

Earth Loop Pump Kit (Field Installed)

A specially designed one or two-pump module provides all

liquid flow, fill and connection requirements for independent

single unit systems (230/60/1 only). The one-pump module

is capable of 20 feet of head at 16.0 GPM, while the twopump module is capable of 40 feet of head at 16.0 GPM.

Hot Water Generator (Factory Installed, NSW040,

NSW050, NSW060, and NSW075 Only)

An optional heat reclaiming hot water generator coil

constructed of vented double-wall copper construction

suitable for potable water is available. The coil is factory

mounted inside the unit. A DPK5 pump kit is required (field

installed), which includes a DHW tank connection and a

temperature limit pump shutoff.

Load-side Pump Kit (Field Installed)

Four (4) load pump kits are available to provide all liquid

flow requirements for independent single unit systems

(230/60/1 only). WaterFurnace part number 24P501A04

(Grundfos UP15-42B7) and EWPK2 (Grundfos UP26-64BF)

are bronze body pumps. Bronze body pumps should be

used when water conditions exist that are not compatible

with cast iron or for applications such as domestic water

heating. WaterFurnace part number EWPK1 and EWPK3

come with a cast iron body pump (Grundfos UP26-99F)

that can be used for hydronic heating applications.

Calculate the system pressure drop then refer to the

pump curves to select the proper pump. All four of the

WaterFurnace pump kits can be used for hydronic heating

applications as long as they meet the flow requirements. If the

flow requirements are outside the pump curve, an alternate

pump will need to be obtained to maintain the necessary flow.

IntelliStart

®

The optional IntelliStart single phase soft starter will reduce

the normal start current (LRA) by 60-70%. This allows the

heat pump to go off-grid. Using IntelliStart also provides a

substantial reduction in light flicker, reduces start-up noise,

and improves the compressor’s start behavior. IntelliStart is

available in a field retrofit kit (WaterFurnace part number

IS60RKL or IS60RKS) or as a factory installed option for all

Envision and Synergy3D units.

Water Connection Kits (Field Installed)

Water connection kits are available to facilitate loop side and

load side water connections.

• MA4FPT - Forged brass 1” MPT x 1” FPT square street elbow

with P/T plug for NSW018-NSW040 water side connections

• MA5FPT - Forged brass 1.25” MPT x 1.25” FPT square

street elbow with P/T plug for NSW050-NSW075 water

side connections

• HKC8S - 1 inch x 24 inch stainless steel braided hose kit

• HKC10S - 1

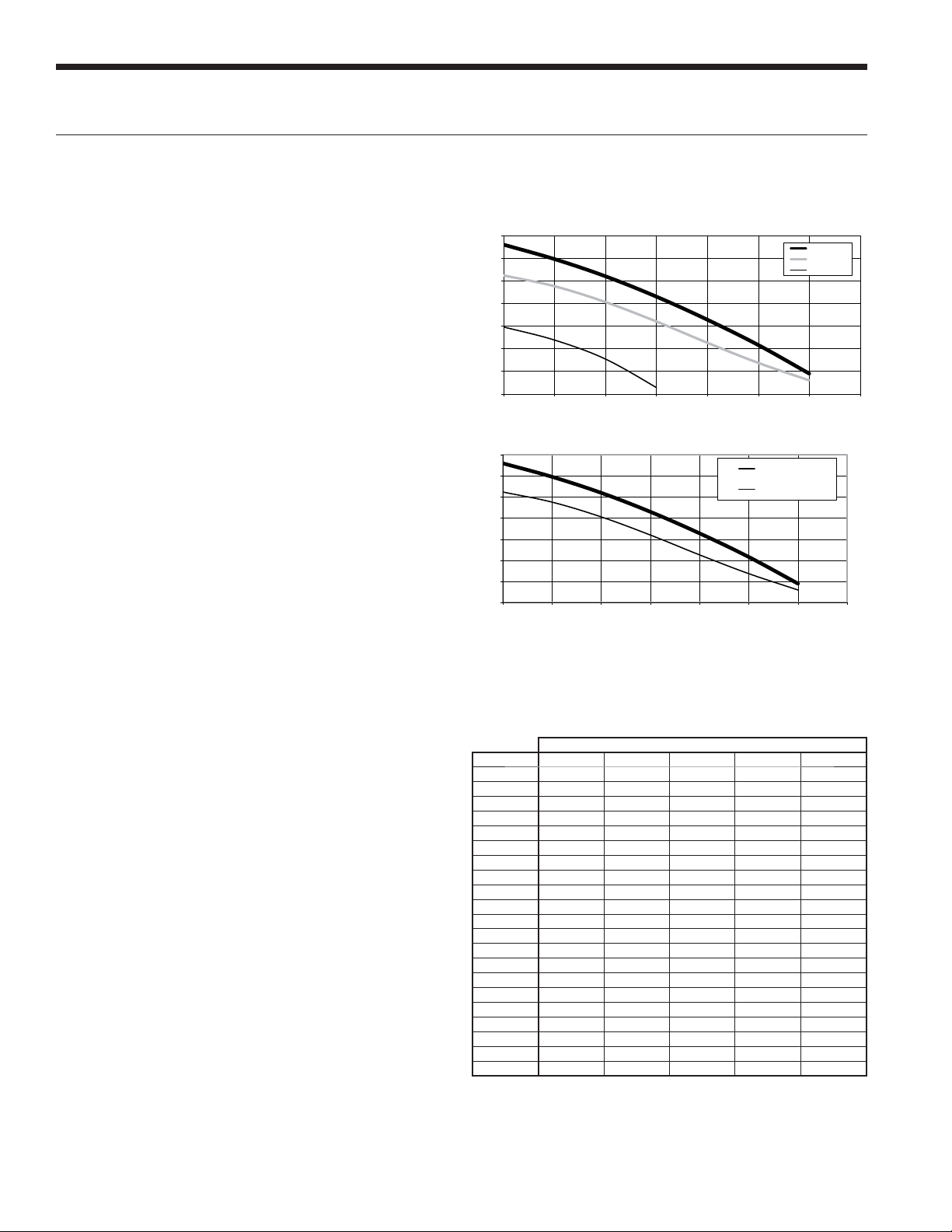

Single Pump Curve: UP15-42B7, UP26-64BF, and UP26-99F

35

30

25

20

15

Feet of Head

10

5

0

0 5 10 15 20 25 30 35

70

60

50

40

30

Feet of Head

20

10

0

0 5 10 15 20 25 30 35

1

⁄4 inch x 24 inch stainless steel braided hose kit

GPM

Two Pump Curve: UP26-64BF and UP26-99F

UP26-99F (2 pumps)

UP26-64BF (2pumps)

GPM

UP26-99F

UP26-64BF

UP15-42B7

NOTE: Never use piping smaller than 1 inch. Limit length of

pipe to 50 feet or less.

Type L Copper Pressure Loss

Ft of Hd per 100 ft

GPM 3/4 1 1-1/4 1-1/2 2

2

3

4

5

6

7

8

9

10

12

14

16

18

20

22

25

30

35

40

45

50

1.5

3.2

5.5 1.4

8.5 2.1

Type L Copper Tube

2.9 1.1

3.9 1.4

5.0 1.8

6.1 2.3 0.9

7.5 2.8 1.1

3.9 1.6

5.2 2.1

6.6 2.7

8.2 3.4

10.0 4.1 1.1

5.0 1.3

6.3 1.6

2.2

2.9

3.8

4.7

5.7

NOTE: Standard piping practice limits pressure drop to 4

feet of hd per 100 feet in 2 inch and larger pipe.

12

Page 13

Accessories and Options cont.

NSW INSTALLATION MANUAL

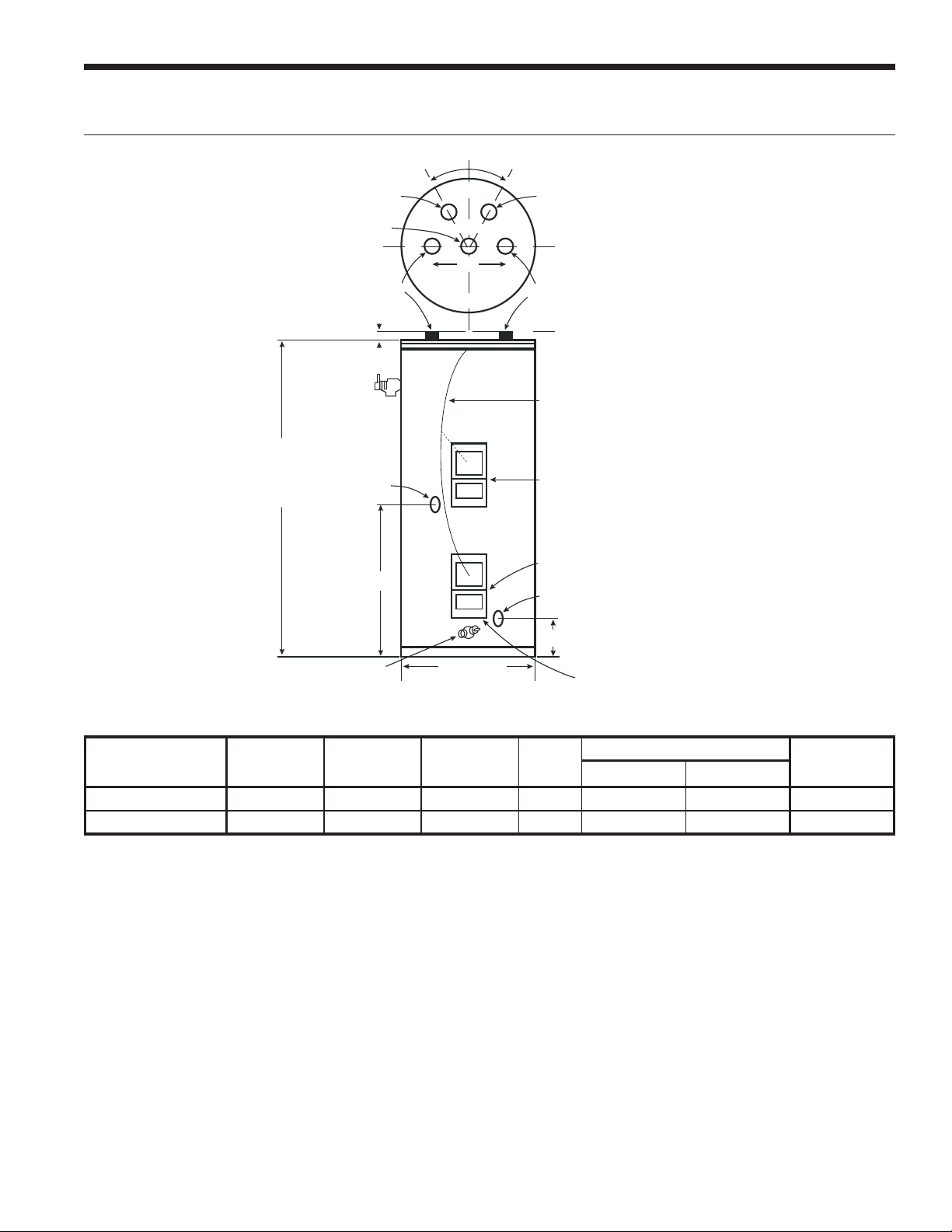

Geo Storage Tank Dimensions

>@7;/@G/<=23

!"Þ6=B=CB:3B

e"ÞA31=<2/@G/<=23

63756B

=^bW]\OZµB]5S]¶

1]\\SQbW]\AVW^^SReWbV

Þ>W^S>ZcU7\abOZZSR

4`][5S]

Þf!Þ<W^^ZS

!'Þ&5OZZ]\

" Þ'5OZZ]\

/^^`]fÞ

B>

D/:D3

!#!"Þ

!

!

&Þ

B]5S]#'Þ2W^BcPS

eÞf!Þ<W^^ZS

1=:27<:3B

!"Þ

# Þ27>BC03

GSZZ]eEW`SObbOQVSR

b]BVS`[Wab]`]`BVS`[]abOb

T]`B]^3fWb

3ZS[S\b:]QObW]\

:]eS`AS\a]`BVS`[Wab]` >#"

b]PScaSRPgEObS`b]EObS`C\Wba

=^bW]\OZµ4`][5S]¶1]\\SQbW]\

AVW^^SReWbV Þ>W^S>ZcU7\abOZZSR

MODEL

NUMBER

GEO-STORAGE-80

GEO-STORAGE-120

#"Þ

2@/7<D/:D3

GALLON

CAPACITY

80 4500 1 16 63-1/4 24 204

119 4500 1 16 63-1/4 28 311

ELEMENT

WATTAGE

(240 VOLT)

27/;3B3@

NUMBER

OF

ELEMENTS

R

VALUE

:]eS`BVS`[]abObb]PScaSR

eWbVAg\S`Ugc\Wba

DIMENSIONS IN INCHES APPROX.

HEIGHT DIAMETER

SHIPPING

WEIGHT (lbs.)

13

Page 14

NSW INSTALLATION MANUAL

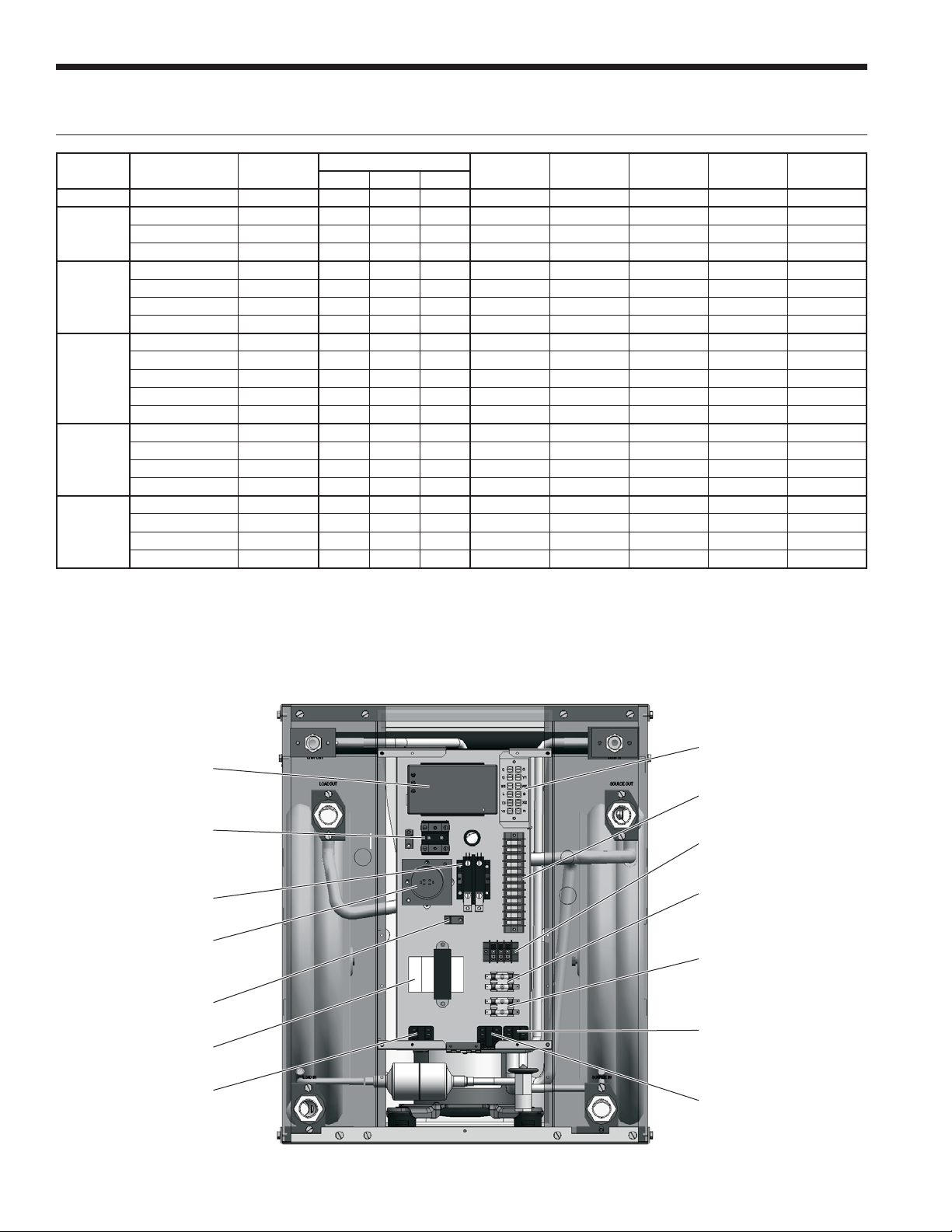

Electrical Data

Model

018

025

040

050

060

075

NOTES: All fuses type “D” time delay (or HACR circuit breaker in USA).

Source pump amps shown are for up to a 1/2 HP pump.

Load pumps amps shown are for small circulators.

*LRA with optional IntelliStart installed (208-230/60/1).

Rated

Voltage

208-230/60/1 197/254 9.0 48.0 17.0 1.8 5.4 16.2 18.5 30

208-230/60/1 197/254 13.5 61.0 21.4 1.8 5.4 20.7 24.1 35

265/60/1 239/292 10.9 58.0 - - - 10.9 13.6 20

460/60/3 414/506 4.5 27.0 - - - 4.5 5.6 10

208-230/60/1 197/254 20.0 115.0 40.3 1.8 5.4 27.2 32.2 50

208-230/60/3 197/254 12.8 95.0 - - - 12.8 16.0 25

460/60/3 414/506 6.4 45.0 - - - 6.4 8.0 10

575/60/3 518/632 5.4 38.0 - - - 5.4 6.8 10

208-230/60/1 197/254 26.4 134.0 46.9 1.8 5.4 33.6 40.2 60

265/60/1 239/292 19.9 130.0 - - - 19.9 24.9 40

208-230/60/3 197/254 16.0 110.0 - - - 16.0 20.0 35

460/60/3 414/506 7.8 52.0 - - - 7.8 9.8 15

575/60/3 518/632 5.7 38.9 - - - 5.7 7.1 10

208-230/60/1 197/254 30.1 145.0 50.8 1.8 5.4 37.3 44.8 70

208-230/60/3 197/254 17.3 120.0 - - - 17.3 21.6 35

460/60/3 414/506 9.6 70.0 - - - 9.6 12.0 20

575/60/3 518/632 8.0 53.0 - - - 8.0 10.0 15

208-230/60/1 197/254 26.9 145.0 50.8 1.8 5.4 34.1 40.8 60

208-230/60/3 197/254 22.4 190.0 - - - 22.4 28.0 50

460/60/3 414/506 12.2 87.0 - - - 12.2 15.3 25

575/60/3 518/632 9.6 62.0 - - - 9.6 12.0 20

Voltage

Min/Max

Compressor

RLA LRA LRA*

Load

Pump

Source

Pump

Total Unit

FLA

Min Ckt

Amp

Maximum

Fuse/HACR

03/26/13

NSW Control Box

Optional IntelliStart

Power Block

IntelliStart Only

Compressor Contactor

Run Capacitor

(Single Phase Only)

Ground Lug

Transformer

Load Pump Relay

Terminal Board

Terminal Power Strip

Power Block

Load Pump Fuse Block

(Single Phase Only)

Source Pump Fuse Block

(Single Phase Only)

Reversing Valve Relay

(Reversible Units Only)

Source Pump Relay

14

Page 15

Electrical Data cont.

NSW INSTALLATION MANUAL

208 Volt Operation

All 208-230 volt units are factory wired for 230 volt

operation. To convert the unit from a 230V unit to a 208V

unit follow these steps:

1. Remove the blue transformer wire from terminal L2 on

the compressor contactor and secure the wire taking

care to insulate the end with electrical tape.

2. Locate the red transformer wire and connect it to the L2

terminal of the compressor contactor.

Electrical

Be sure the available power is the same voltage and phase

as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable. Refer to

the Electrical Data table for wire and fuse or circuit breaker

sizing information.

Flow Center Pump Connection (208-230/60/1)

Two fuse internal terminal block connections with 1/4-inch

spade connectors are provided; one for the load pump

and one for the source pump. The source pump directly

connects to the fuse terminal block for the source pump.

The load pump directly connects to the fuse terminal block

for the load pump.

NSW Control Box Relocation

The NSW control box can be installed on the rear of the unit.

To relocate the control box, follow the procedures below.

1. Remove all power sources to the unit.

2. Remove the unit’s top panel.

3. Cut all plastic wire ties to the following:

a) High pressure switch (black wires)

b) Low pressure switch (blue wires)

c) Freeze sensing (yellow wires)

d) Load temperature sensor (black wires)

e) Compressor wires

4. Remove the four screws from the control box.

5. Relocate the control box to opposite end of the unit.

6. Using the screws removed in step 4 above, reattach the

control box.

7. Secure all wires so they do not come in contact with

refrigerant lines.

8. Replace the top of the unit.

9. Replace both access panels.

10. Reapply power sources.

NOTE: If geothermal storage tank is used, connect yellow

thermistor wires from the bottom access panel of the tank

to spade connectors 3 and 4 on the terminal block.

15

Page 16

NSW INSTALLATION MANUAL

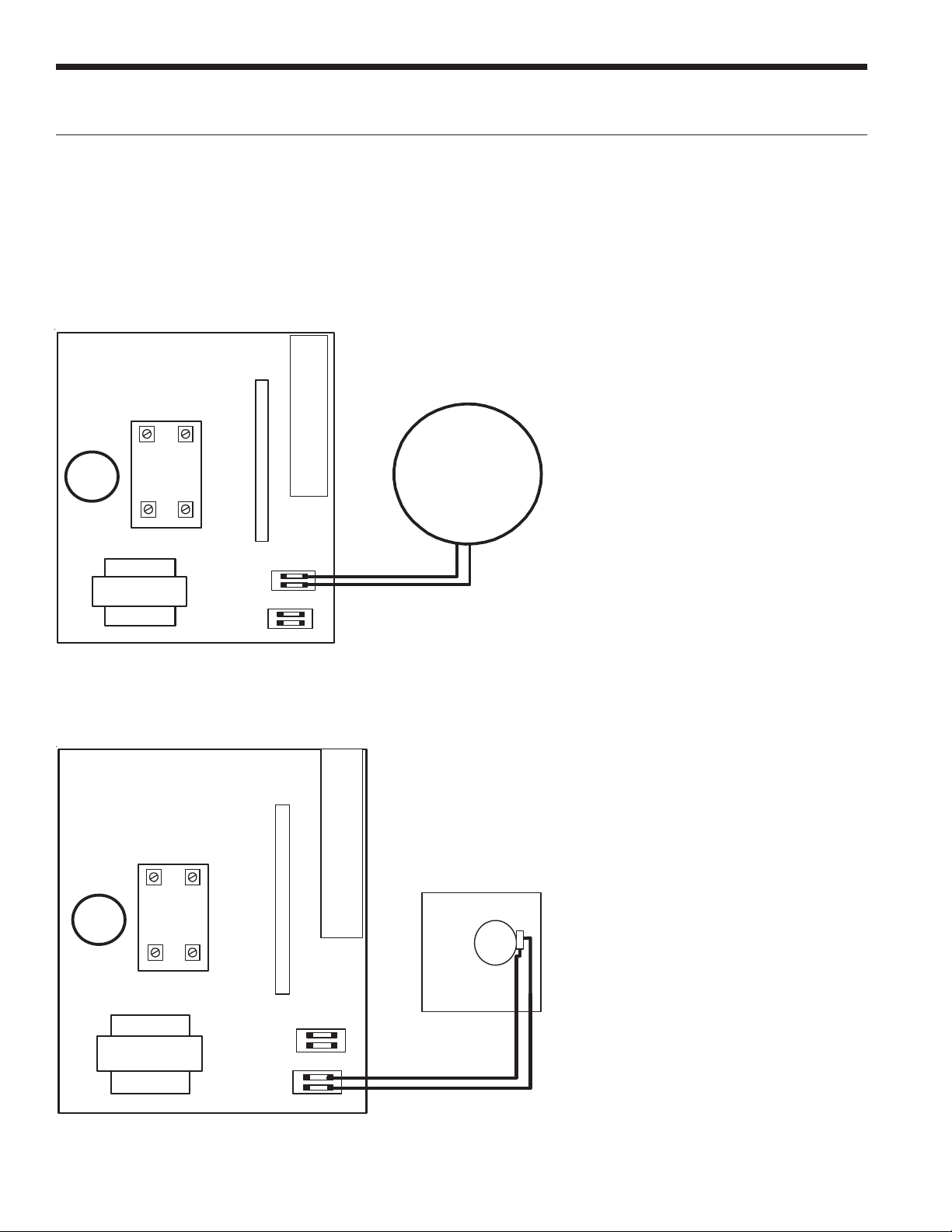

Wiring Schematics

For all NSW 208/230 volt single-phase units, the circulator

wiring is as shown in the illustrations below. The internal

relay and fusing allow for external pumps no larger than .5

horsepower. The external loop pump connections mentioned

in this manual include a dedicated flow center for each unit

as well as an NSW unit connected to an Envision; “P” or an

“E” series unit containing a microprocessor.

Load Circulator Wiring

CONNECTIONS

LOW VO LTAGE

THERMOSTAT

T2

T1

CAPACITOR

COMPRESSOR

CONTACTOR

L1 L2

CIRCULATOR

LOW VOLTAGE

TERMINAL STR IP

LOAD

PUMP

TRANSFORMER

CONT RO L B O X

Dedicated Flow Center Wiring

T2

T1

CAPACITOR

COMPRESSOR

CONTACTOR

L1 L2

FUSE

BLOCKS

TERMINAL STRIP

CONNECTIONS

LOW VOLTAGE

THERMOSTAT

LOW VOLTAGE

FLOW CENTER

TRANSFORMER

CONTROL BOX

FUSE

BLOCKS

16

Page 17

Wiring Schematics cont.

Multiple Units on a Single Flow Center Wiring

P1

R

C

Y1

Y2

W

O

G

LO

P2

SHUT

DOWN

C

C

SL1 IN

SL1 OUT

Not

Used

NSW INSTALLATION MANUAL

CONTROL

BOX

CAPACITOR

TRANSFORMER

T2

T1

COMPRESSOR

CONTACTOR

L1 L2

CONTROL BOX

CONNECTIONS

TERMINAL STRIP

LOW VOLTAGE

FUSE

BLOCKS

THERMOSTAT

LOW VOLTAGE

13P003B RELAY

(FIELD SUPPLIED)

17

Page 18

NSW INSTALLATION MANUAL

Wiring Schematics - Residential

NSW Heating Only - 208-230/60/1

External

G

Load

Pump

NOTE 2

Orange

LFB

L2 L2L1L1

Brown/Blk

LPR

BCD

Red

Black

Black/Gry

SI

T1T1 T2T2

Green/Yellow

PS1

SFB

Black/Wht

External

Source

Pump

Brown/Wht

Red

208V

SI

Blue/Wht

Brown

Compressor

C

S

Blue

G

R

BlackRed

Cap

Tan

T1

T2

CC

L2

L1

Unit

Power Supply

208-230/60/1

G

Blue

Blue

Black

230V

Com

NOTE 1

Transformer

24V

Note 3

Black/

White

Green/Yellow

Orange

Blk/Wht

Violet

Black

Black

White/Blue

White/Blue

Red

Black

Black

Yellow

Yellow

Violet

Violet

Orange

Orange

Gray

Gray

P1

1

Not Used

Microprocessor Control

HP HP CC CG HI LO CLP LPR

HP HP CC CG HI LO CLP LPR

P2

T

T

R

R

1

T

T

R

R

T

T

L

L

E

E

T

T

L

L

E

E

1

1

X

X

1

X1

X

2

Not Used

X

X2

Not Used

X2

X2

3

3

X

X

Not Used

3

X

X3

Not Used

TEST

PIN

RV RVG

P3

MODE

Interface Panel

Yellow

24 V

LPR

CC

HP

LP

TB

1

RT

T

2

3

ELT

T

4

5

6

7

8

9

10

11

12

Factory low voltage wiring

Factory line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

Quick connect terminal

Screw terminal - field connection

Fuse

RCY1OX1

Violet

CC -

Compressor contactor

-

RV Reversing Valve output

ELT-Entering Load Side Water Temperature

-

HP

High pressure switch

-

LP

Low pressure switch

-

LPR

Load Pump Relay

RT-Refrigerant Liquid line Temperature

SI-Slave Input relay

RC-Reversing Valve Coil

-

Load Pump Fuse Block

LFB

SFB-

Source Pump Fuse Block

04/02/09

Legend

T

Switch -High pressure

Switch -Low pressure

Relay coil

Capacitor

Thermistor

Field wire lug

L1

Ground

Relay Contacts -

N.O., N.C.

132

P

Polarized connector

18

Notes:

1. Taped and wire tied off

2. 3AG 10 Amp fuse

3. For cycle load pump with a geo storage

tank. Remove the orange wire from the LPR

relay coil and install a jumper between the

LPR relay coil and the comp contactor coil

as shown in the schematic above.

Page 19

Wiring Schematics - Residential cont.

NSW INSTALLATION MANUAL

NSW Reversible with IntelliStart - 208-230/60/1

Orange

Red

Black

Black/Gry

SI

External

Load

Pump

Black/Org

G

NOTE 2

Green/Yellow

PS1

BCD

RVR

T1T1 T2T2

LFB

L2 L2L1L1

Brown/Blk

LPR

NOTE 4

RVR

Violet

RVR

External

Source

Pump

SFB

Blue/Wht

Brown/Wht

Blue

Red

208 V

Black/Wht

RT

Blue Blue

T

RT

Black Black

T

ELT

T

SIR

Org/Grn

G

Brown

Org/Gry

Yellow

Yellow

NOTE 1

LPR

CC

HP

LP

Blue

Yellow

24 V

TB

1

2

3

4

5

6

7

8

9

10

11

12

Compressor

C

S

R

Cap

Blue

230V

Black

T1

CC

L1

Black

Com

Unit

Power Supply

208-230/60/1

G

Tan

T2

L2

Black

Black

Blue

PB

2

1

Pink

Run Winding

RedRed

Active

IntelliStart

Start

Common

Transformer

24V

Black/

White

NOTE 3

Note 5

Orange

Green/Yellow

Orange

Blk/Wht

Violet

Black

Black

White/Blue

White/Blue

Black

Black

Yellow

Yellow

Violet

Violet

Orange

Orange

Gray

Gray

P1

1

Not Used

CC CG HI LO CLP LPR

HP HP CC CG HI LO CLP LPR

HP HP

Red

P2

T

T

R

R

T

T

R

R

T

T

L

L

E

E

T

T

L

E

EL

X1

X1

1

X

X1

2

X

X2

2

X2

X

3

3

X

X

3

3

X

X

TEST

PIN

P3

Microprocessor Control

1

Not Used

Not Used

RV RVG

MODE

Interface Panel

Org/Brn

Org/Wht

Org/Blk

RC

RCY1OX1

Factory low voltage wiring

Factory line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

Quick connect terminal

Screw terminal - field connection

Fuse

-

Compressor Contactor

CC

-

RV

Reversing Valve Output

-

ELT

Entering Load Side Water Temperature

-

High Pressure Switch

HP

-

Low Pressure Switch

LP

-

Load Pump Relay Contacts

LPR

-

Refrigerant Liquid Line Temperature

RT

-

Slave Input Relay

SIR

-

Reversing Valve Coil

RC

-

Load Pump Fuse Block

LFB

-

Source Pump Fuse Block

SFB

RVR -Reversing Valve Relay

04/02/09

Legend

T

Switch -High pressure

Switch -Low pressure

Relay coil

Capacitor

Thermistor

Field wire lug

L1

Ground

Relay Contacts -

N.O., N.C.

132

P

Polarized connector

19

Notes:

1. Taped and wire tied off

2. 3AG 10 Amp fuse

3. Move jumper wire to 5 and 6 for reversible

secondary unit.

4. Black Thermistor - Source Coax Blue

Thermistor - Load Coax

5. For cycle load pump with a geo storage tank.

Remove the orange wire from the LPR relay coil

and install a jumper between the LPR relay coil

and the comp contactor coil as shown in the

schematic above.

Page 20

NSW INSTALLATION MANUAL

Wiring Schematics - Commercial

NSW Heating Only - 208-230/60/3

Green/Yellow (67)

J8

5VDC

23

24

LST

LFP

SFP

EST

LLT

ELT

NOTE 7

1

NOTE 2

2

3

PB2

NOTE 3

Blue (66)

Brown (42)

Whit e ( 43)

T

Wht/Blu (44)

Black (4 5)

T

Blk/Red (46)

Gray (47)

T

Gray/Wht (48)

Blue (49 )

T

Blue/Wht (50)

Orange (51)

T

Org/ Wht (52)

Black (53)NOTE 6

Black (26)

Black (5 5 )

Black (5 6 )

Black (5 7 )

Black (5 8 )

Black (5 9 )

Red (60)

LP

Gray (61)

Blue (62 )

Black (6 3 )

Black (64)

Black (6 5 )

Brown (41)

T

25

26

27

28

29

30

31

32

33

34

35

36

37

38

J2

39

40

41

J10

42

43

44

45

46

47

48

J9

49

50

51

52

53

54

55

56

-

AI3

+

-

AI5

+

-

AI4

+

AI6

+

-

AI2

+

5VDC

-

AI1

+

LED

5VDC

PWM2

PWM2 C om

PWM1

24VAC Com

DI12

DI11

DI10

DI9

DI8

DI7

DI 3/4/5/6/ Com

DI6

DI5

DI4

DI3

DI2

9VDC

DI1

GROUND

24VAC

24VAC Com

A1 4

A24

A34

A25 A22

A21A12

A23

A13

A33

A32

A31A35

A11

A15

Johnson

FX-10

J

7

Compressor

T1

T3

T2

Blue Black

Red

T2

Black (20)

Black (19)

Black (1 8)

Black (1 7)

Black (1 6)

Black (1 5 )

Black (1 2 )

Black (1 0 )

Black (6 )

Black (5)

Black (1 4 )

Black (1 3 )

Black (1 1 )

Black (9 )

Black (8)

Black (7 )

Black (2 )

Black (1 )

T3

L3

Unit

Power Supply

208-230/60/3

G

20

19

D09

18

D08

17

16

D07

15

14

13

D06

12

11

D05

D04

10

9

8

7

D03

6

5

D02

4

Black (4 )

3

Black (3 )

2

D01

1

L2

Blk/ W ht (6 9)

CC

L1

Yellow (68)

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

T1

Black (3 7 )

Black (22)

Black (4 0 )

Black (38)

Black (35)

Black (33)

Yellow (34)

Black (31)

Black (3 0 )

Black (28)

Black (2 7 )

Black (2 5 )

Viol et (2 4)

Factory low voltage wiring

Factory line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

Field Zone Sensor Wiring

L1

T

Internal junction

Field wire lug

Ground

Relay Contacts-

N.O., N.C.

Thermistor

Relay coil

Black (53)

Black (55)

Black (5 6 )

Black (57)

Black (58)

Black (6 3 )

Black (64)

Black (65)

Black (26)

97P799-05

Yellow (21)

4/02/09

Legend

Switch - High pressure

Switch - Low pressure

Open Jumper

Closed Jumper

1 2 3

P

Polarized connector

Compressor contactorCC CP - Compressor Proving

ELT - Entering Load Water Temp

ES - Emergency Shutdown

EST -Entering Source Water Temp

HP - High pressure switch

LFP - Load Freeze Protection

LFS - Load Flow Proving Switch

LLT - Leaving Load Water Temp

LP - Low pressure switch

LST - Leaving Source Water Temp

RV - Reversing Valve coil

Source Freeze ProtectionSFP SFS - Source Flow Proving Switch

TB - Terminal Board

20

Notes:

1 - Switch Blue and Red wires for 208V operation

2 - Disconnect for 15 degree load side freeze detection

3 - Disconnect for 15 degree source side freeze detection

4 - Acc 1 and ACC 2 outputs are cycled with the compressor.

5 - R, C, Y1, and O inputs are for use with an aqua stat.

6 - If no flow proving switch is being used on the load side, the

LF terminal on the terminal board must be jumpered to the R

terminal for the unit to operate.

7 - If no flow proving switch is being used on the source side, the

SF terminal on the terminal board must be jumpered to the R

terminal for the unit to operate.

8 - A closed contact will enable the emergency shutdown input

(ES) and the compressor proving input (CP).

9 - Primary over-ride input (POI) on a primary unit must be wired

to R through a normally open contact. If the POI input is on a

secondary unit connect the Primary Over-ride output (PO) from

the primary unit to the POI terminal on the secondary unit.

10 - Apply 24VAC to the O terminal for cooling.

Page 21

Wiring Schematics - Commercial cont.

NSW Heating Only - 208-230/60/3

Red 208V

NOTE 1

Transformer

Black

Blue230V

HP

Violet (70 )

Black (54)

CC

Green/Yellow (72)

PB1

3

2

1

Blk/Wht

Yellow

Yellow (21)

Yellow (29)

Black (40)

Black (3 8 )

Black (3 5 )

Black (33)

Black (31)

Black (30)

Black (2 8 )

Black (2 7 )

NOTE 6 Bla ck (53)

Black (5 5 )

Black (56)

Black (57)

NOTE 7

Black (58)

Black (36)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Black (R )

Black (L V)

Black (X2)

Black (X1)

Black (L )

Black (PO)

Black (SE)

Black (SN)

Black (SHC)

Black (C)

Black (LF)

Black (PO I)

Black (O )

Black (SF )

Black (Y1)

Black (ES)

Black (9DC)

Black (C P)

R 24VAC

Load Valve

LV

Output

X2 Acc 2

X1 Acc 1

Alarm

L

Primar y Load

PO

Over-ride Out put

Secondary Unit

SE

Enable

Secondary

SN

24VAC I nput

Secondary Unit

SHC

Heat/Cool

C

24V COM

Load Flow

LF

Proving S wit c h

Primar y Load

POI

Over-ride I nput

O Rev Valve

Source Flow

SF

Proving S wit c h

Comp 1

Y1

Emergency

ES

Shutdown

9 VDC -Use

9DC

for CP and E S

Compressor

CP

Proving S wit c h

To Primary Load Over-ride Input

(POI) of secondary unit.

To Y1 input of secondary unit.

To R from secondary unit.

To O input of secondary unit.

NSW INSTALLATION MANUAL

TB

Field Connection Diagram

(For units using Set Point control mode

with or without a secondary unit.)

NOTE 7

NOTE 6

R 24VAC

LV Load Valve Output

X2 Acc 2

Acc 1

X1

Alarm

L

Primary Load

PO

Over-ride Output

Secondary Unit

SE

Enable

Secondary

SN

24VAC Input

Secondary Unit

SHC

Heat/ Cool

TB

Field Connection Diagram

(For units using aqua stat control

mode.)

24VAC

R

LV Load Valve Output

X2 Acc 2

Acc 1

X1

Alarm

L

Primary Load

PO

Over -ride Output

Secondary Unit

SE

Enable

Secondary

SN

24VAC Input

Secondary Unit

SHC

Heat /Cool

C

24V COM

Load Flow

LF

Proving Switch

Primary Load

POI

Over-ride Input

ORev Valve

Source Flow

SF

Proving Switch

Y1Comp 1

Emergency

ES

Shutdown

9 VDC - Use

9DC

for CP and ES

Compressor

CP

Proving Switch

C

24V COM

Load Flow

LF

Proving Switch

Primary Load

POI

Over-ride Input

Rev Valve

O

Source Flow

SF

Proving Switch

Y1Comp 1

Emergency

ES

Shutdown

9 VDC - Use

9DC

for CP and ES

Compressor

CP

Proving Switch

97P799-05

NOTE 6

NOTE 7

NOTE 9

NOTE 8

NOTE 9

NOTE 10

Aqua St at Y1

NOTE 8

4/02/09

21

Page 22

NSW INSTALLATION MANUAL

Wiring Schematics - Commercial cont.

NSW Reversible - 575/460/3

LST

LFP

SFP

EST

LLT

ELT

NOTE 6

1

NOTE 1

Blue (66)

NOTE 2

LP

2

3

PB2

T

T

T

T

T

T

Brown (41 )

Brown (42 )

Whit e ( 43)

Wht/Blu (44)

Black (45)

Blk/Red (46)

Gray (47)

Gray/Wht (48)

Blue (49 )

Blue/Wht (50)

Orange (51)

Org/ Wht (52)

Black (53)NOTE 5

Black (26)

Black (5 5 )

Black (5 6 )

Black (5 7 )

Black (5 8 )

Black (5 9 )

Red (60)

Gray (61)

Blue (62)

Black (63 )

Black (64)

Black (65 )

J8

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

J2

39

40

41

J10

42

43

44

45

46

47

48

J9

49

50

51

52

53

54

55

56

5VDC

-

AI3

+

-

AI5

+

-

AI4

+

AI6

+

-

AI2

+

5VDC

-

AI1

+

A21A12

LED

5VDC

PWM2

PWM2 C om

PWM1

24VAC Com

DI12

DI11

DI10

DI9

DI8

DI7

DI 3/4/5/6/ Com

DI6

DI5

DI4

DI3

DI2

9VDC

DI1

A23

A1 4

24VAC

A24

A25 A22

A13

A11

J

7

Green/Yellow (67)

GROUND

24VAC Com

A34

A32

A15

A33

A31A35

Johnson

FX-10

Compressor

T1

T3

T2

Blue Black

Red

Unit

Power Supply

460/60/3

575/60/3

G

20

19

D09

18

D08

17

16

D07

15

14

13

D06

12

11

D05

10

D04

9

8

7

D03

6

5

D02

4

3

2

D01

1

Black (4 )

Black (3 )

Black (20)

Black (19)

Black (1 8)

Black (1 7)

Black (1 6)

Black (1 5 )

Black (1 2 )

Black (1 0 )

Black (6)

Black (5)

Black (14)

Black (13 )

Black (11)

Black (9 )

Black (8 )

Black (7 )

Black (2 )

Black (1 )

T2

T3

L3

L2

Blk/Wht (69)

CC

L1

Yellow (68)

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

T1

Black (3 7 )

Black (22)

Black (4 0 )

Black (38)

Black (35)

Black (33)

Yellow (34)

Black (31)

Black (3 0 )

Black (28)

Black (2 7 )

Black (2 5 )

Viol et (2 4)

Orange (23)

Black

Blue

Factory low voltage wiring

Factory line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

Field Zone Sensor Wiring

L1

T

Internal junction

Field wire lug

Ground

Relay Contacts-

N.O., N.C.

Thermistor

Relay coil

Black (53)

Black (55)

Black (5 6 )

Black (57)

Black (58)

Black (6 3 )

Black (64)

Black (65)

Black (26)

97P799-08

Yellow (21)

4/02/09

Legend

Switch - High pressure

Switch - Low pressure

Open Jumper

Closed Jumper

1 2 3

P

Polarized connector

Compressor contactorCC CP - Compressor Proving

ELT - Entering Load Water Temp

ES - Emergency Shutdown

EST -Entering Source Water Temp

HP - High pressure switch

LFP - Load Freeze Protection

LFS - Load Flow Proving Switch

LLT - Leaving Load Water Temp

LP - Low pressure switch

LST - Leaving Source Water Temp

RV - Reversing Valve coil

Source Freeze ProtectionSFP SFS - Source Flow Proving Switch

TB - Terminal Board

22

Notes:

1 - Disconnect for 15 degree load side freeze detection

2 - Disconnect for 15 degree source side freeze detection

3 - Acc 1 and ACC 2 outputs are cycled with the compressor.

4 - R, C, Y1, and O inputs are for use with an aqua stat.

5 - If no flow proving switch is being used on the load side, the

LF terminal on the terminal board must be jumpered to the R

terminal for the unit to operate.

6 - If no flow proving switch is being used on the source side, the

SF terminal on the terminal board must be jumpered to the R

terminal for the unit to operate.

7 - A closed contact will enable the emergency shutdown input (ES)

and the compressor proving input (CP).

8 - Primary over-ride input (POI) on a primary unit must be wired to

R through a normally open contact. If the POI input is on a

secondary unit connect the Primary Over-ride output (PO) from

the primary unit to the POI terminal on the secondary unit.

9 - Apply 24VAC to the O terminal for cooling.

Page 23

Wiring Schematics - Commercial cont.

NSW INSTALLATION MANUAL

NSW Reversible - 575/460/3

Transf ormer

HP

PB1

Violet (70 )

Black (54)

CC

Green/Yellow (72)

Orange (39)

RV

3

2

1

Blk/Wht

Yellow

Yell ow (2 1)

Yellow (29)

Black (40)

Black (3 8 )

Black (3 5 )

Black (33)

Black (31)

Black (30)

Black (2 8 )

Black (27 )

NOTE 5 Black (53)

NOTE 6

Black (55)

Black (56)

Black (57)

Black (58)

Black (36)

TB

Field Connection Diagram

(For units using Set Point control mode

with or without a secondary unit.)

NOTE 6

NOTE 5

R 24VAC

LV Load Valve Output

X2 Acc 2

X1

To Primary Load Over-ride Input

(POI) of secondary unit.

To Y1 input of secondary unit.

To R from secondary unit.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Black (R )

Black (L V)

Black (X2)

Black (X1)

Black (L )

Black (PO)

Black (SE)

Black (SN)

Black (SHC)

Black (C)

Black (LF)

Black (PO I)

Black (O )

Black (SF )

Black (Y1)

Black (ES)

Black (9DC)

Black (C P)

R 24VAC

Load Valve

LV

Output

X2 Acc 2

NOTE 3

X1 Acc 1

Alarm

L

Primar y Load

PO

Over-ride Out put

Secondary Unit

SE

Enable

Secondary

SN

24VAC I nput

Secondary Unit

SHC

Heat/Cool

C

24V COM

Load Flow

LF

Proving S wit c h

Primar y Load

POI

Over-ride I nput

O Rev Valve

Source Flow

SF

Proving S wit c h

Comp 1

Y1

Emergency

ES

Shutdown

9 VDC - Use

9DC

for CP and E S

Compressor

CP

Proving S wit c h

To O input of secondary unit.

L

PO

SE

SN

SHC

Field Connection Diagram

(For units using aqua stat control

R

LV Load Valve Output

X2 Acc 2

X1

L

PO

SE

SN

SHC

Acc 1

Alarm

Primary Load

Over- ride Output

Secondary Unit

Enable

Secondary

24VAC Input

Secondary Unit

Heat /Cool

24VAC

Acc 1

Alarm

Primary Load

Over-ride Output

Secondary Unit

Enable

Secondary

24VAC Input

Secondary Unit

Heat /Cool

24V COM

Load Flow

Proving Switch

Primary Load

Over-ride Input

Source Flow

Proving Switch

Emergency

Shutdown

9 VDC - Use

for CP and ES

Compressor

Proving Switch

TB

mode.)

24V COM

Load Flow

Proving Switch

Primary Load

Over-ride Input

Rev Valve

Source Flow

Proving Switch

Emergency

Shutdown

9 VDC - Use

for CP and ES

Compressor

Proving Switch

97P799-08

C

LF

POI

ORev Valve

SF

Y1Comp 1

ES

9DC

CP

NOTE 6

NOTE 5

C

LF

POI

O

SF

Y1Comp 1

ES

9DC

CP

NOTE 8

NOTE 7

NOTE 8

NOTE 9

Aqua St at Y1

NOTE 7

4/02/09

23

Page 24

NSW INSTALLATION MANUAL

External Control

Primary Mode

In dedicated heating or cooling units, the unit is controlled

by the internal controller. Compressor output is determined

by the entering load-side water temperature.

The secondary output will be energized if two

conditions occur:

1. The initial temperature is greater than IC away from the

set point.

2. The change in temperature in a given period of time P is

less than d.

In a reversible unit, the unit is controlled by the internal

controller. Compressor output is determined by the

entering load-side water temperature. For reversible units,

the jumper wire must be positioned across terminals 6 and

7, (factory default set to this position). Reversible units do

not have a secondary output.

NOTES: SL in the configuration menu must be set to 0,

(factory default). All parameters should be checked for each

application on primary unit, (refer to the parameter table).

WARNING: Reversible units cannot be

staged.

Secondary Mode

In dedicated heating or cooling units, secondary mode

allows the unit to be controlled by an external source.

Compressor output is determined by the Y1 input only.

The secondary output will be energized after the following

condition occurs:

1. The change in temperature in a given period of time P is

less than d.

In reversible units, secondary mode allows the unit to

be controlled by an external source. Compressor output

is determined by the Y1 input and the reversing valve

is determined by the O input. In reversible units, the

jumper wire must be positioned across terminals 5 and 6.

Reversible units do not have a secondary input.

NOTES: SL in the configuration menu must be set to 1. P

and d must be setup for each secondary unit.

Wiring an Aquastat - Reversible Unit

• To create a secondary unit, set SL to 1 in the

configuration menu.

• Position the jumper wire in the control box across

terminals 5 and 6.

Aquastat Wiring for Dedicated Heating or Cooling Unit

Secondary Unit

(SL=1)

Typical Aquastat

C

G

W1

L

Y1 = Compressor call

R = 24VAC

Control Box

X1

Y2

Y1

W2

X2

Aquastat Wiring for Reversible Unit

Typical Aquastat

O

S

R

Secondary Unit

(SL=1)

1

2

3

Jumper

Wire

4

5

6

7

8

9

10

11

12

C

G

W1

X1

Y2

O

Y1

W2

S

L

X2

R

Y1 = Compressor call

O = Reversing valve call

R = 24VAC

Note: Jumper wire must be

moved to terminals 5 & 6.

Control Box

24

Page 25

()

External Control cont.

NSW INSTALLATION MANUAL

Staging with Primary/Secondary Mode

Staging is only possible with dedicated heating or cooling

units. Reversible units cannot be staged. Staging can be

accomplished with primary/secondary modes or by using

an aquastat.

WARNING: Do not stage more than 6 units.

The first stage must be setup as a primary unit. All other

units must be setup as secondary units. The set point is

stored in the primary unit. Once the set point in the primary

unit has been satisfied, all units will immediately shutdown.

Staging with Aquastat

When staging units using an Aquastat, all units must be

setup as secondary units.

WARNING: Do not stage more than 6 units.

Wiring for Primary/Secondary Unit Staging

C

O

G

Y1

W1

W2

S

L

X1

X2

R

Y2

O

C

Y1

G

W2

W1

S

L

X1

X2

R

Y2

First Stage Second Stage Third Stage

NOTES: X1 = Secondary output

Y1 = Compressor call

Wiring for Dedicated Heating or Cooling Units

with Aquastat

Typical Aquastat

O

C

Y1

G

W2

W1

S

L

X1

X2

Y2

R

O

C

Y1

G

W2

W1

S

L

X1

X2

R

Y2

O

C

Y1

G

W2

W1

S

L

X1

X2

R

Y2

First Stage Second Stage

NOTES: X1 = Secondary output

Y1 = Compressor call

R = 24 VAC

25

Page 26

NSW INSTALLATION MANUAL

Converting to a Dedicated Cooling Unit

Procedure to Convert a Heating Only Unit to a

Cooling Only Unit

All non-reversible NSW units are built at the factory as

dedicated heating units. Follow the procedures below to

make the unit a dedicated cooling unit.

1. Shut off all power to the unit.

2. Remove the top and access panel.

3. Remove the brass in-well thermistor from the load

water-in line.

4. Remove the brass plug from the source water-in line.

5. Place new Teflon

well thermistor.

6. Thread the brass in-well thermistor into the source

water-in line.

7. Make sure the thermistor wires do not touch the

discharge line.

8. Place new Teflon

9. Thread the brass plug into the load water-in line.

10. Refer to the labels on the unit for the location of ports

and lines.

11. Connect the “Source Water-In” line to the port marked

“Load Water-In.” Then, connect the “Source Water-Out”

line to the port marked “Load Water-Out.”

12. Connect the “Load Water-In” line to the port marked

“Source Water-In.” Then, connect the “Load Water-Out”

line to the port marked “Source Water-Out.”

®

tape on the threads of the brass in-

®

tape on the threads of the brass plug.

13. Open the control box.

14. Find the connection marked “P4” as shown in the

Control Board with Jumper illustration.

15. Move the “P4” jumper from across 1 and 2 to across 2

and 3.

16. Close the control box and secure the screws.

17. Replace the top and access panel.

18. Make sure all screws have been re-installed.

19. Turn on the power.

20. Using the touch-pad, press the UP arrow.

21. The displays should blink “44” to show set point. Now,

the unit should operate as a cooling only unit.

Jumper Pin Location

The location of the jumper pin determines the controller’s

mode of operation. Move the jumper pins to the correct

location for dedicated heating, dedicated cooling or

reversible settings as indicated below.

Dedicated heating - 1 & 2 *

Dedicated cooling - 2 & 3

Reversible - 3 & 4 *

* Indicates factory setting.

NOTE: A reversible unit can not be configured to heating only.

Control Board with Jumper

P4

P5 Key Pad

(Interface)

P9

Not Used

P2

P1

26

Page 27

Unit Startup

NSW INSTALLATION MANUAL

Before Powering Unit

Check the following:

• High voltage wiring is correct and matches the nameplate.

• Fuses, breakers and wire size are correct.

• Piping is completed and water system has been cleaned

and flushed.

• Air is purged from the closed loop system.

• Isolation valves are open and loop water control valves or

loop pumps are wired.

• Service/access panels are in place.

Primary Unit Startup

1. Apply power to the unit. Upon power up, the unit will

display the current operation mode.

• H for dedicated heating.

• C for dedicated cooling.

• U for reversible units.

2. Press the mode button. The LED screen will display the

current entering water temperature. The load pump will

activate after a 5 minute delay.

3. Once the load pump has been active for 3 minutes, the

controller will sample the temperature of the water

system. In heating mode, when the temperature of the

water shown on the display is lower than the set point

the compressor will activate.

4. By using a pressure gauge and the P/T ports, check the

pressure drop through both the load and source coaxes.

Compare this to the capacity tables in the specification

catalog to verify the proper flow rate through the unit.

5. Verify that the compressor, load side and source side

pumps are operating.

6. After determining the flow rates, use a thermometer and

the PT ports to determine the change in temperature on

both the load and source side coaxes.

7.

Compute the formula GPM flow rate X Change in

temperature X 500 (485 on source side if antifreeze/brine

is used in the loop) = Heat of Extraction on the source

side in heating, Heat of Rejection on the source side in

cooling. To ensure proper operation, compare these

values to the capacity tables in the specification catalog.

8. Press the down arrow on the keypad to reduce the

set point below the incoming load temperature.

Compressor should shut off and the load pump should

shut off 30 seconds after the compressor.

9. Wait 7 minutes. The load pump should start to sample

load temperature.

10. Compressor and source side circulator should not start.

11. Press the up arrow on the keypad to increase the

set point to 5 degrees above the water temperature

displayed on the LED screen.