Page 1

COMPACT

Water Source/Geothermal Heat Pump

• R-410A Refrigerant

• Commercial 0.75-6 Ton

Installation Information

Water Piping Connections

Hot Water Connections

Electrical

Startup Procedures

Troubleshooting

Preventive Maintenance

Compact Installation Manual

2

Envision

IM1022ANA 05/14

Page 2

Page 3

Table of Contents

Model Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensional Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing Horizontal Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hanger Bracket Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Duct System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Cleaning and Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Open Loop Ground Water Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ENVISION2 COMPACT INSTALLATION MANUAL

Hot Water Generator Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Freeze Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Blower Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Unit Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Operating Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Operating Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Reference Calculations and Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Refrigerant Circuit Guideline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Compressor and Thermistor Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Heat of Extraction/Rejection Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Preventive Maintenance and Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Revision Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Page 4

ENVISION2 COMPACT INSTALLATION MANUAL

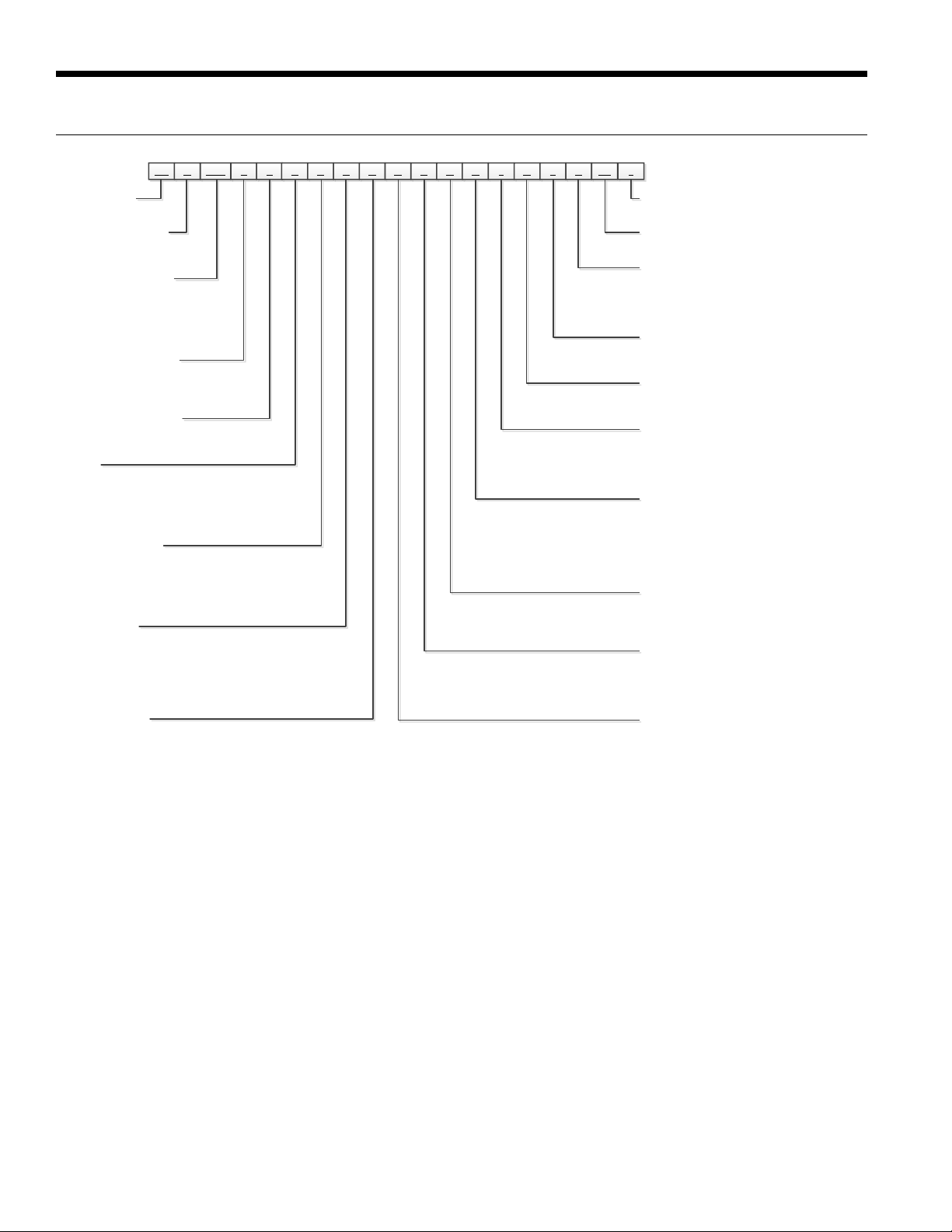

1-2 3 4-6 7 8 9

10 11 12 14

NB V 048 T L 0 0 0 C A N13A15N16117A18319020SS

21-22*23

Model Nomenclature

Model Type

NB – Envision

Cabinet Configuration

V – Vertical

H - Horizontal

Unit Capacity (MBTUH)

Single Speed

009, 012, 015, 018, 024, 030

036, 042, 048, 060, 070

Dual-Capacity

026, 038, 049, 064, 072

Discharge Configuration

T – Top (Vertical)

E – End (Horizontal)

S – Side (Horizontal)

Return Air Configuration

L – Left

R – Right

Voltage

0 – 208-230/60/1

2 – 265-277/60/1 (009-038)

3 – 208-230/60/3 (024-072)

4 – 460/60/3 (024-072)

5 – 575/60/3 (PSC Only 042-070)

Refrigeration Option

0 – None

2 – HWG Only w/o Pump (Vertical 018-072)

G – Hot Gas Bypass (015-072)

R – Hot Gas Reheat (015-072)

B – Hot Gas Bypass w/Hot Gas Reheat (015-072)

Blower Options

0 – PSC Blower (Single Speed Only)

1 – Variable Speed ECM Blower (015-072)

2 – High Static Variable Speed ECM Blower

(036, 038, 042, 048, 049)

3 – High Static PSC Blower (024-048)

4 – 5-Speed ECM Blower (015-072)

Water Coil Option

C – Copper

D – Insulated Copper

N – CuproNickel

P – Insulated CuproNickel

Note:

1 - Phase Guard Only Available on 208-230/60/3, 460/60/3, and 575/60/3

2

Compact

Vintage

* - Factory Use Only

Non-Standard Options

SS – Standard

Drain Pan Option

0 – Composite, No Secondary Connection

1 – Composite, Secondary Connection

2 – Stainless Steel, No Secondary Connection

3 – Stainless Steel, Secondary Connection

Air Coil Option

3 – All-Aluminum, Uncoated

4 – All-Aluminum, AlumiSeal

Filter Option

A – MERV 4

B – MERV 13

Cabinet Option

0 – Unpainted Cabinet, Filter Rail

1 – Painted Cabinet, Filter Rail

2 – Unpainted Cabinet, 4-Sided Filter Rack

3 – Painted Cabinet, 4-Sided Filter Rack

Electrical Option

N – None

A – IntelliStart

E – IntelliStart and Disconnect

P – Phase Guard, No Disconnect

B – Phase Guard, Disconnect

D – No Phase Guard, Disconnect

Control Option

A – Aurora

E – Aurora UPC DDC Controller

F – Aurora UPC DDC Controller with LON

Water Control Option

N – None

R – Water Flow Regulator

V – 2-Way Valve

B – 2-Way Valve w/ Water Flow Regulator

Sound Kit Option

A – None

B – Sound Kit

Rev.: 24 April 2014D

1

®

Only

TM

Base Control (ABC)

TM

4

Page 5

General Installation Information

ENVISION2 COMPACT INSTALLATION MANUAL

Safety Considerations

WARNING: Before performing service or

maintenance operations on a system, turn off main

power switches to the indoor unit. If applicable,

turn off the accessory heater power switch.

Electrical shock could cause personal injury.

Installing and servicing heating and air conditioning

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service heating and air

conditioning equipment. Untrained personnel can perform

the basic maintenance functions of cleaning coils and

cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working on heating and air conditioning equipment, observe

precautions in the literature, tags and labels attached to the

unit and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use a quenching cloth for brazing operations and

have a fire extinguisher available.

Moving and Storage

Move units in the normal “up” orientation. Horizontal units

may be moved and stored per the information on the

packaging. Do not stack more than three units in total

height. Vertical units may be stored one upon another to

a maximum height of two units. Do not attempt to move

units while stacked. When the equipment is received, all

items should be carefully checked against the bill of lading

to be sure all crates and cartons have been received.

Examine units for shipping damage, removing the units

from the packaging if necessary. Units in question should

also be internally inspected. If any damage is noted, the

carrier should make the proper notation on the delivery

receipt, acknowledging the damage.

Unit Location

Locate the unit in an indoor area that allows for easy

removal of the filter and access panels. Location should

have enough space for service personnel to perform

maintenance or repair. Provide sufficient room to make

water, electrical and duct connection(s). If the unit is

located in a confined space, such as a closet, provisions

must be made for return air to freely enter the space

by means of a louvered door, etc. Any access panel

screws that would be difficult to remove after the unit

is installed should be removed prior to setting the unit.

On horizontal units, allow adequate room below the unit

for a condensate drain trap and do not locate the unit

above supply piping. Care should be taken when units are

located in unconditioned spaces to prevent damage from

frozen water lines and excessive heat that could damage

electrical components.

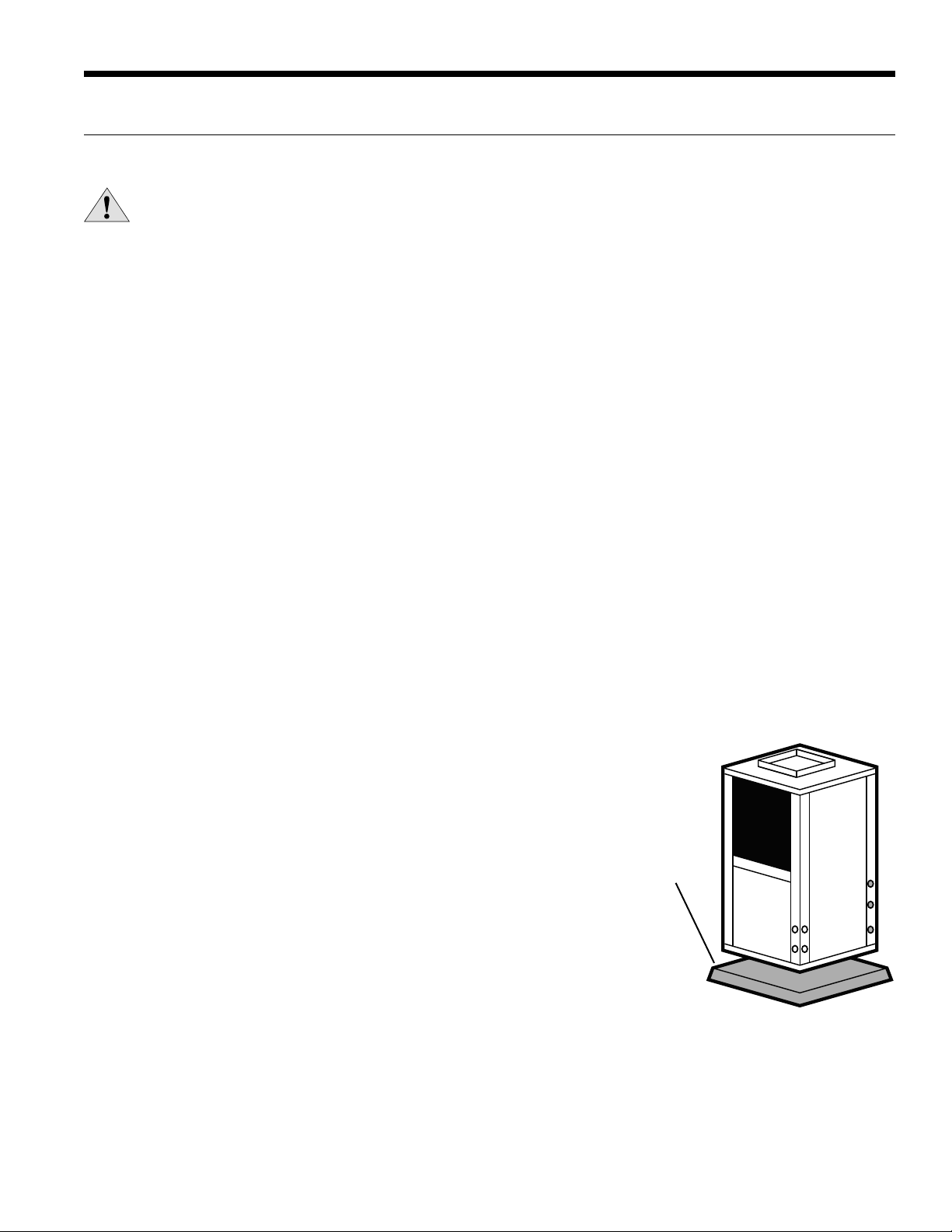

Installing Vertical Units

Prior to setting the unit in place, remove and discard the

compressor hold down shipping bolt located at the front of

the compressor mounting bracket.

Vertical units are available in left or right air return

configurations. Top flow vertical units should be mounted

level on a vibration absorbing pad slightly larger than the

base to provide isolation between the unit and the floor.

It is not necessary to anchor the unit to the floor (see

figure below).

Vertical Unit Mounting

2 in. PEX Foam

5

Page 6

ENVISION2 COMPACT INSTALLATION MANUAL

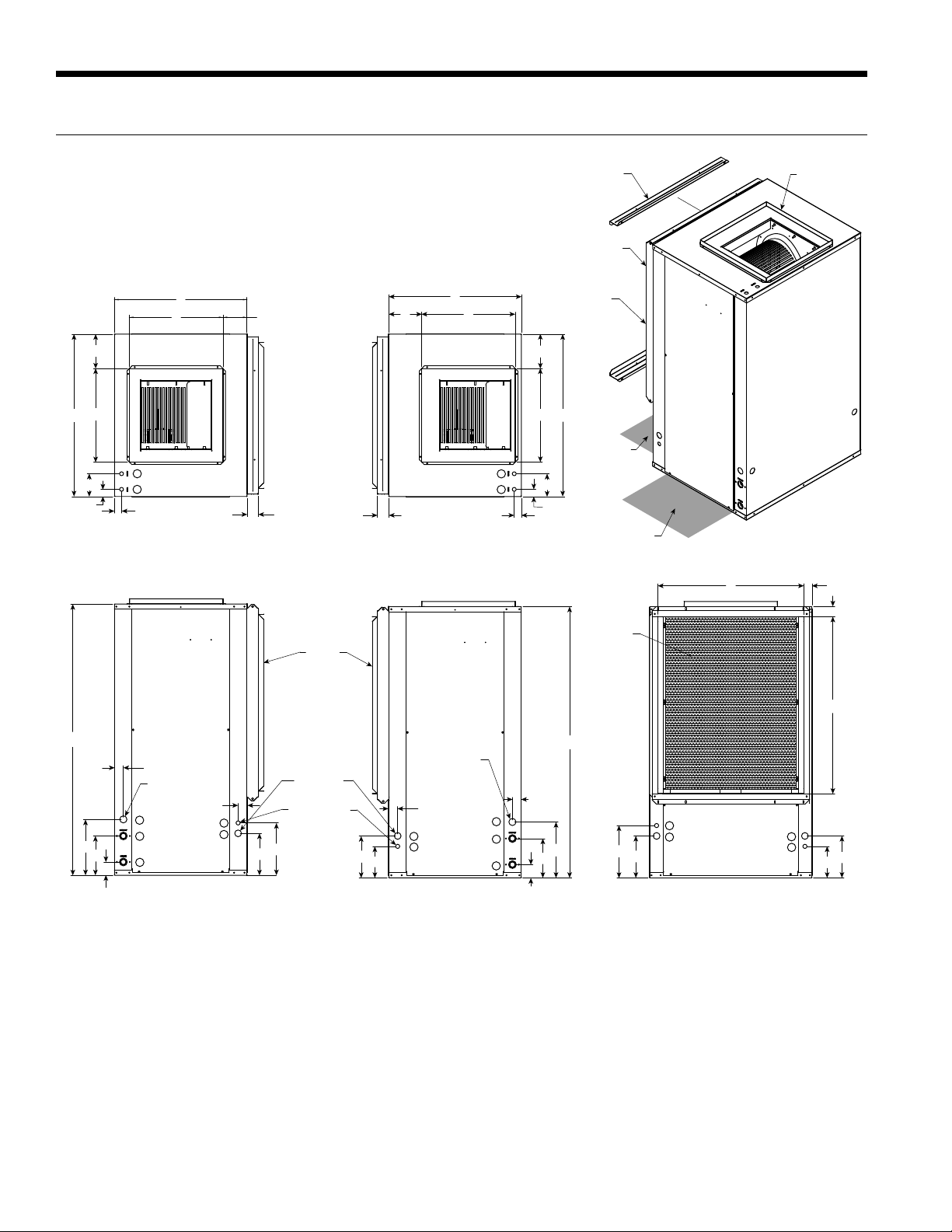

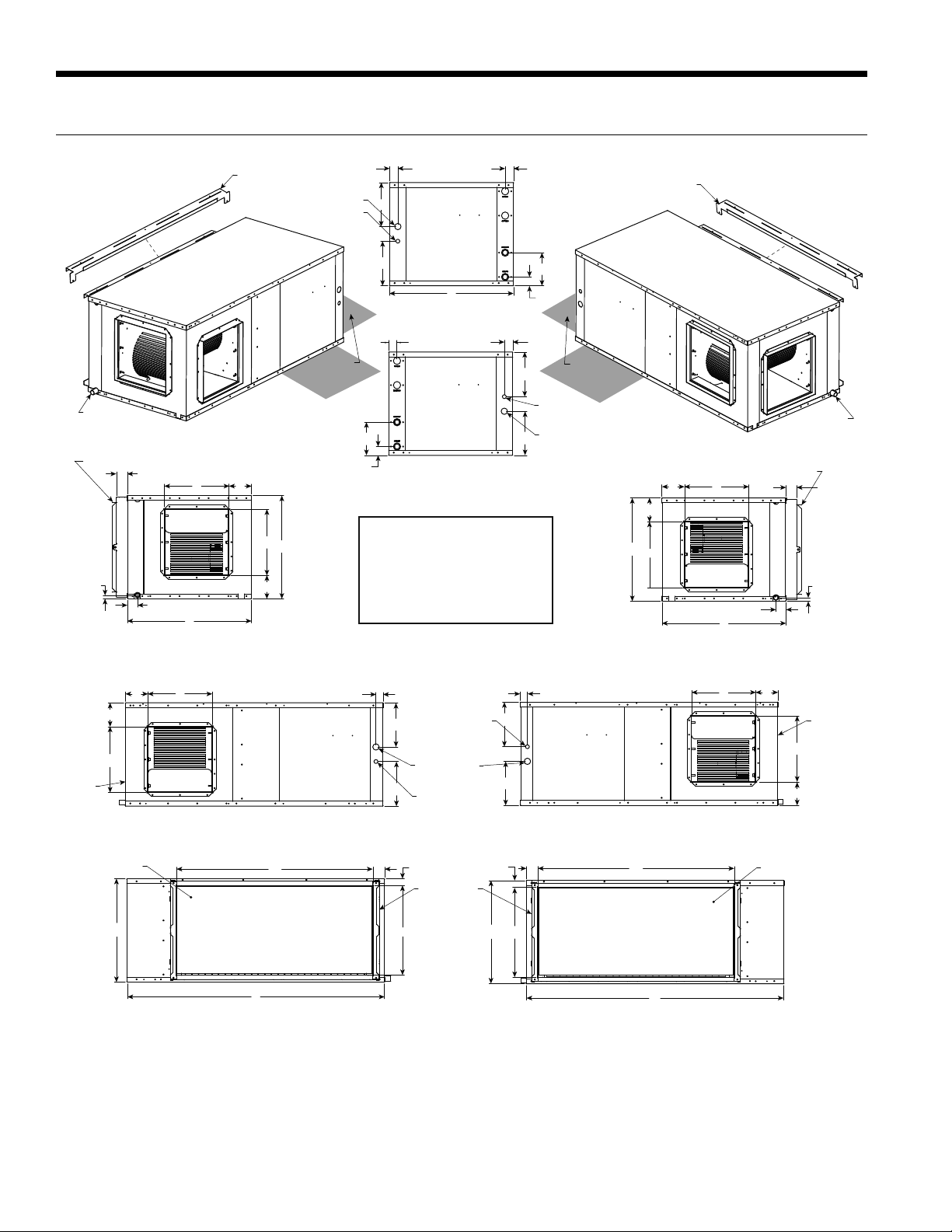

Vertical Dimensional Data

Standard filter rails for

open return applications

Field installed

duct flange

Deluxe filter rack for

ductable return applications

A

RN

S

Q

AIR COIL SIDE

P

B

AIR COIL SIDE

F

4

3

FRONT

1.4 in (3.5 cm)

M

M

G

Top View - Right Return Top View - Left Return

A

N

FRONT

1.4 in (3.5 cm)

Air coil

Q

P

B

2' (61 cm)

G

Alternate

Service Access

4

3

F

Service Access Left Return

2' (61 cm)

ACCESS

PANEL

Isometric View - Left Return

(Right Return opposite side)

U

T

W

Air coil

Air coil

ACCESS

PANEL

C

1.6 in (4.1 cm)

Condensate 3/4 in

PVC glue socket

1.6 in (4.1 cm)

5

H

2

E

1

D

6

8

1 in (25.4 mm)

1/2" (12.7 mm)

J

L

Power supply

knockout

Low voltage

knockout

L

K

Front View - Right Return

ACCESS

PANEL

Condensate

3/4 in PVC

glue socket

1.6 in (4.1 cm)

8

7

5

2

1

Front View - Left Return

1.6 in

(4.1 cm)

H

E

D

V

C

6

ACCESS

J

8

L

PANEL

8

7

L

K

Right View - Right Return

Left View - Left Return

6

Page 7

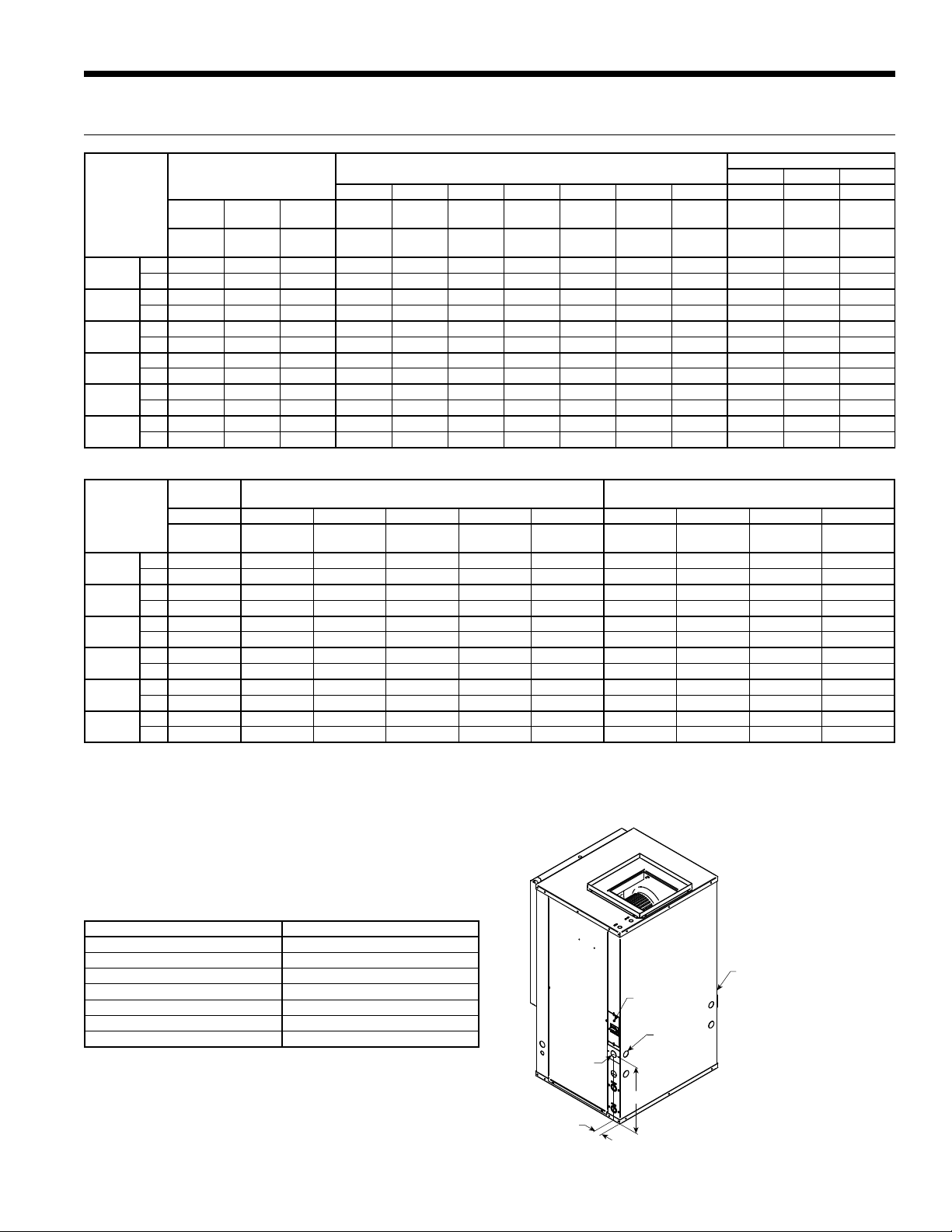

Vertical Dimensional Data cont.

ENVISION2 COMPACT INSTALLATION MANUAL

Overall Cabinet

Vertical

Models

009-012

015-018

024-030

036-038

042-049

060-072

009-012

015-018

024-030

036-038

042-049

060-072

Condensate is 3/4 in. PVC female glue socket and is switchable from side to front.

*Discharge fl ange is fi eld installed and extends 1 in. (25.4 mm) from top of cabinet.

**Vertical units shipped with standard 2 in. (fi eld adjustable to 1 in.) open application fi lter rack extending 2.2 in. from

unit and is not suitable for duct connection, for ductable return connection applications, order the deluxe 2 in. (fi eld

adjustable to 1 in.) duct collar/fi lter rack which extends 3.25 in. from the unit and is suitable for duct connections.

cm. 57.2 56.4 76.7 6.6 19.3 N/A N/A 27.4 12.7 mm N/A 23.9 13.7 18.8

cm. 57.2 66.5 102.1 6.6 19.3 3.6 11.2 27.4 19.1 mm 22.2 mm 25.7 15.5 20.6

cm. 57.2 66.5 112.3 6.6 19.3 3.6 11.2 27.4 19.1 mm 22.2 mm 25.7 15.5 20.6

cm. 64.8 79.2 112.3 6.6 19.3 3.6 11.2 27.4 25.4 mm 22.2 mm 25.7 15.5 20.6

cm. 64.8 79.2 122.4 6.6 19.3 3.6 11.2 27.4 25.4 mm 22.2 mm 25.7 15.5 20.6

cm. 64.8 79.2 132.6 6.6 19.3 3.6 11.2 27.4 25.4 mm 22.2 mm 25.7 15.5 20.6

Vertical

Models

cm. 5.6 25.4 25.4 15.5 13.5 24.9 5.1 46.0 35.6 5.1

cm. 5.6 35.6 35.6 15.5 11.4 19.6 5.1 56.1 55.9 4.8

cm. 5.6 35.6 35.6 15.5 11.4 19.6 5.1 56.1 66.3 4.6

cm. 5.6 45.7 45.7 16.8 11.7 16.0 4.1 71.4 66.3 5.1

cm. 5.6 45.7 45.7 16.8 11.7 16.0 4.1 71.4 76.2 5.1

cm. 5.6 45.7 45.7 16.8 12.7 16.3 4.1 71.4 86.4 5.1

A B C D E F G H Loop Knockout

Width Depth Height* In Out HWG In HWG Out

in. 22.5 22.2 30.2 2.6 7.6 N/A N/A 10.8 1/2 in. N/A 9.4 5.4 7.4

in. 22.5 26.2 40.2 2.6 7.6 1.4 4.4 10.8 3/4 in. 0.875 10.1 6.1 8.1

in. 22.5 26.2 44.2 2.6 7.6 1.4 4.4 10.8 3/4 in. 0.875 10.1 6.1 8.1

in. 25.5 31.2 44.2 2.6 7.6 1.4 4.4 10.8 1 in. 0.875 10.1 6.1 8.1

in. 25.5 31.2 48.2 2.6 7.6 1.4 4.4 10.8 1 in. 0.875 10.1 6.1 8.1

in. 25.5 31.2 52.2 2.6 7.6 1.4 4.4 10.8 1 in. 0.875 10.1 6.1 8.1

MNPQR S T U VW

Filter Rack

Width

in. 2.2 10.0 10.0 6.1 5.3 9.8 2.0 18.1 14.0 2.0

in. 2.2 14.0 14.0 6.1 4.5 7.7 2.0 22.1 22.0 1.9

in. 2.2 14.0 14.0 6.1 4.5 7.7 2.0 22.1 26.1 1.8

in. 2.2 18.0 18.0 6.6 4.6 6.3 1.6 28.1 26.1 2.0

in. 2.2 18.0 18.0 6.6 4.6 6.3 1.6 28.1 30.0 2.0

in. 2.2 18.0 18.0 6.6 5.0 6.4 1.6 28.1 34.0 2.0

Supply

Width

12345 JKL

Discharge Connection

duct fl ange installed (±0.10 in)

Supply

Depth

Water Connections

Cond-

ensate

Water

FPT

HWG

Provisions

**Return Connection

using deluxe fi lter rack (±0.10 in)

Return

Depth

Electrical Knockouts

678

1/2 in.

cond

Low

Voltage

1/2 in.

Voltage

Return

Height

cond

Low

1 in. cond

Power

Supply

3/16/12

3/16/12

Vertical Disconnect

When using disconnect, do not use dimension L from

the standard vertical dimensional data. Use dimension

LL from the vertical disconnect dimensional data.

Vertical Models LL

009-012

015-018

024-030

036-038

042-049

060-064

070-072

Dimensions in inches [cm] 3/16/12

17.8 [45.2]

14.3 [36.3]

15.3 [38.9]

14.3 [36.3]

14.3 [36.3]

14.3 [36.3]

External

Disconnect Located on this

Side for a Right Return

Disconnect

Location

Alternative

Power

Power

Location

Supply

LL

1.8 in.

[4.6 cm]

Vertical Shown in

Left Return Configuration

7

Page 8

ENVISION2 COMPACT INSTALLATION MANUAL

Horizontal Dimensional Data

Right Return

Condensate

"X" PVC size

End Discharge

Deluxe filter rack option shown

H

2.3 in. [5.8 cm]

FILTER RACK

AIR COIL SIDE

2.1 in. [5.3 cm]

Right Return

End Discharge

N

BLOWER

OUTLET

A

Standard filter rails

1 in. [2.5 cm] knockout

0.5 in. [1.3 cm] knockout

Side Discharge

P

M

C

L

Front

AP

CMP

Service Access

2' (61 cm)

1.7 in.

[5.3 cm]

K

J

E

D

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

CP

AP

A

RR Front View

1.7

CP

AP

LR Front View

Legend

1.7

1.7 in.

[5.3 cm]

E

D

J

0.5 in. [1.3 cm]

knockout

1 in. [2.5 cm]

K

knockout

Standard filter rails

Front

AP

CMP

2' (61 cm)

Service Access

Side Discharge

Deluxe filter rack option shown

P

N

L

C

M

BLOWER

OUTLET

2.1 in. [5.3 cm]

Left Return

End Discharge

A

Left Return

Condensate

"X" PVC size

End Discharge

2.3 in.

[5.8 cm]

AIR COIL SIDE

FILTER RACK

H

BP

Front

P

N

L

M

Air Coil

BLOWER

OUTLET

Right Return Side Discharge

C

Right Return Side View

J

K

T

R

1.5 in. [3.8 cm]

AP

CMP

S

Left Return Side Discharge

Q

B

Left Return Side View

1.5 in. [3.8 cm]

0.5 in. [1.3 cm]

K

AP

CMP

FILTER RACK CONNECTION FILTER RACK CONNECTION

B

J

SQ

R

Front

1 in. [2.5 cm]

knockout

0.5 in. [1.3 cm]

knockout

T

Deluxe filter

rack option

(shown)

knockout

Front

C

N

BLOWER

OUTLET

P

BP

M

L

Air Coil

Front

8

Page 9

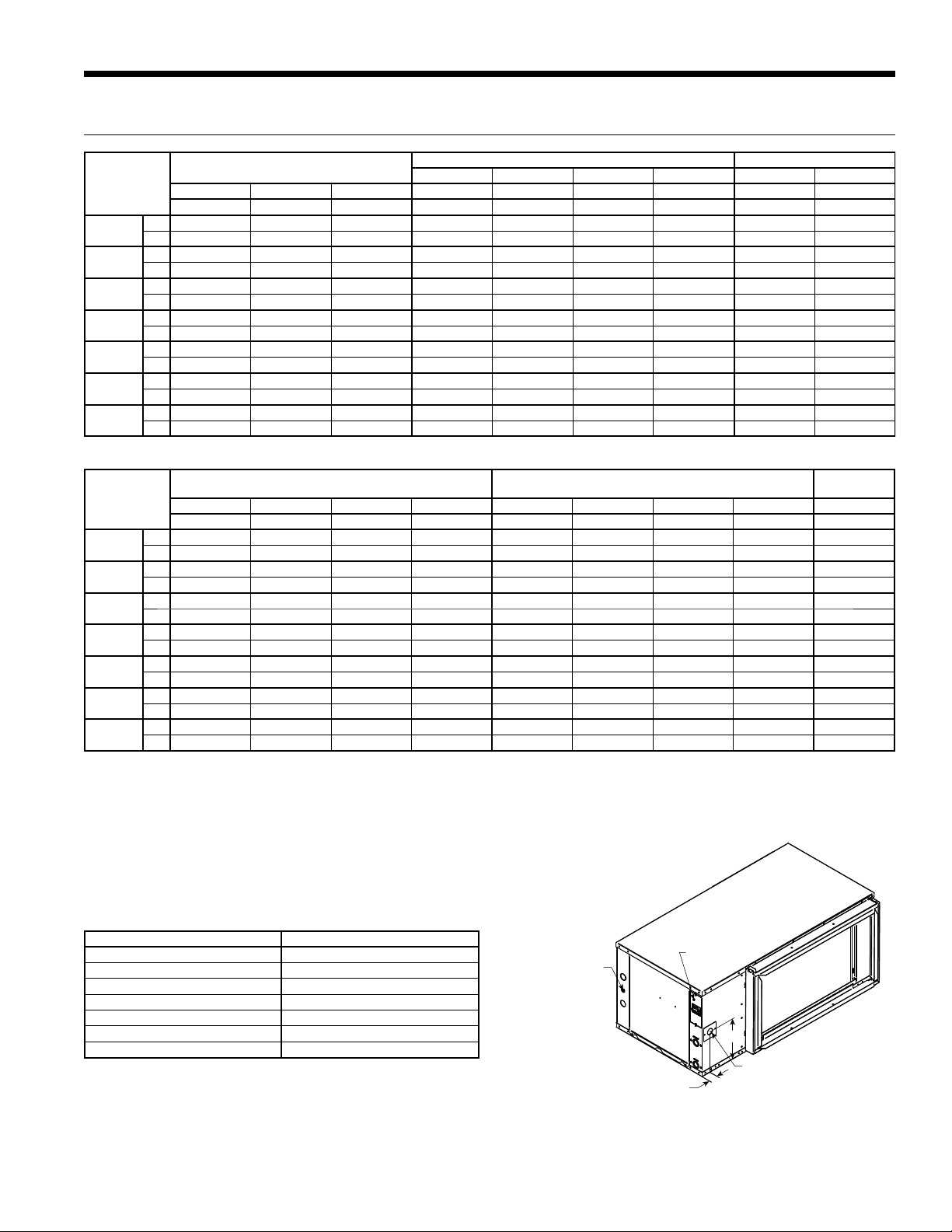

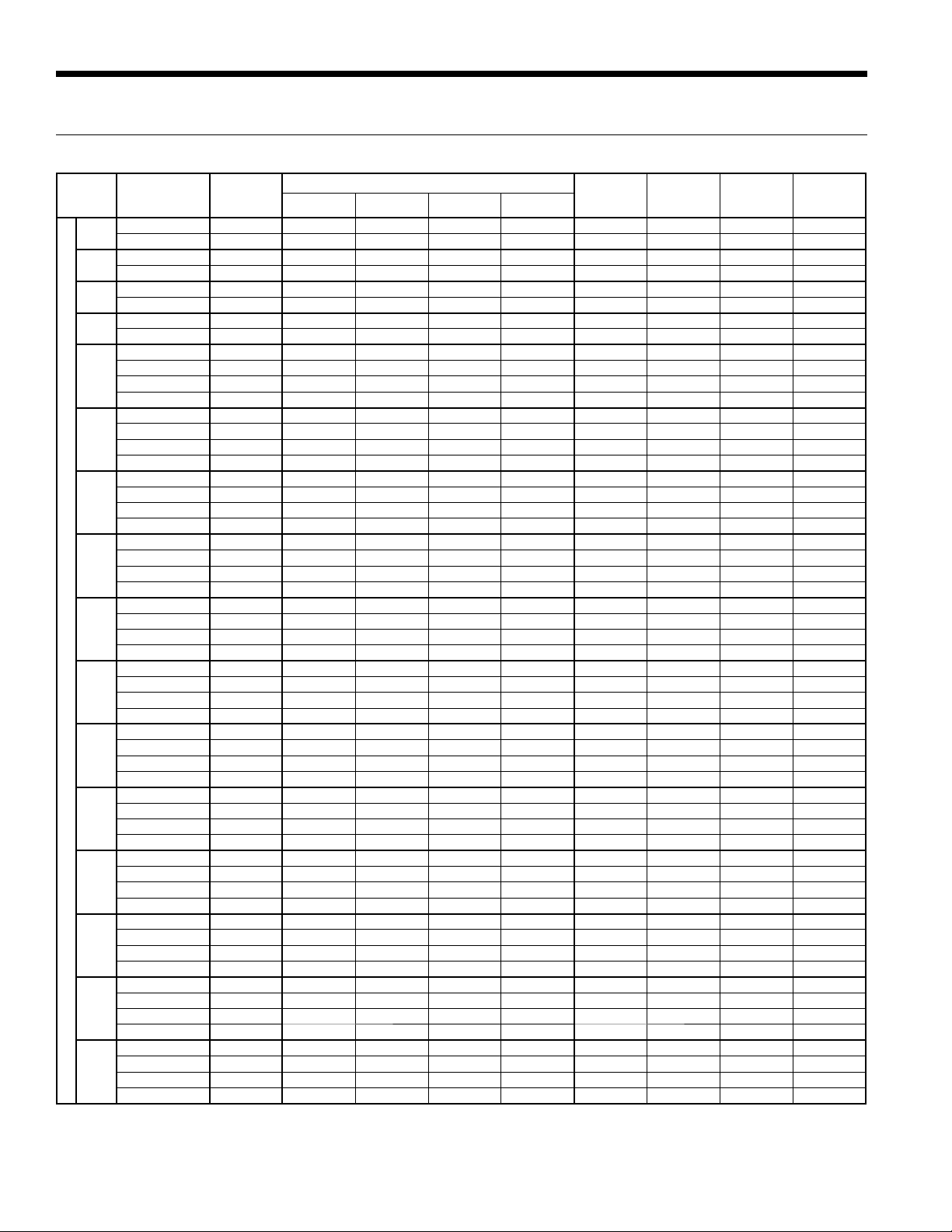

Horizontal Dimensional Data cont.

ENVISION2 COMPACT INSTALLATION MANUAL

Horizontal

Models

Width Depth Height* In Out Condensate Water FPT Low Voltage Power Supply

009-012

015-018

024-030

036-038

042-049

060-064

070-072

Horizontal

009-012

015-018

024-030

036-038

042-049

060-064

070-072

Horizontal units shipped with standard 2 in. (fi eld adjustable to 1 in.) open application fi lter rack extending 2.2 in. from unit and is

not suitable for duct connection, for ductable return connection applications, order the deluxe 2 in. (fi eld adjustable to 1 in.) fi lter

rail/fi lter rack which extends 3.25 in. from the unit and is suitable for duct connections.

in. 22.5 35.0 17.2 1.8 6.8 0.8 1/2 in. 7.1 7.1

cm. 57.2 88.9 43.7 4.6 17.3 2.0 12.7 mm 18.0 18.0

in. 22.5 42.0 19.2 1.8 6.8 0.8 3/4 in. 9.1 7.1

cm. 57.2 106.7 48.8 4.6 17.3 2.0 19.05 mm 23.1 18.0

in. 22.5 45.0 19.2 1.8 6.8 0.8 3/4 in. 9.2 7.1

cm. 57.2 114.3 48.8 4.6 17.3 2.0 19.05 mm 23.4 18.0

in. 25.5 48.0 21.2 1.8 6.8 0.8 1 in. 9.2 9.1

cm. 64.8 121.9 53.8 4.6 17.3 2.0 25.4 mm 23.4 23.1

in. 25.5 53.0 21.2 1.8 6.8 0.8 1 in. 9.2 9.1

cm. 64.8 134.6 53.8 4.6 17.3 2.0 25.4 mm 23.4 23.1

in. 25.5 61.0 21.2 1.8 6.8 0.8 1 in. 9.2 9.1

cm. 64.8 154.9 53.8 4.6 17.3 2.0 25.4 mm 23.4 23.1

in. 25.5 68.0 21.2 1.8 6.8 0.8 1 in. 9.2 9.1

cm. 64.8 172.7 53.8 4.6 17.3 2.0 25.4 mm 23.4 23.1

Models

in. 5.9 7.2 9.5 6.0 16.4 14.5 2.0 1.4 3/4”

cm. 15.0 18.3 24.1 15.2 41.7 36.8 5.1 3.6 1.9

in. 6.7 10.5 9.4 4.9 27.4 16.6 2.0 1.4 3/4”

cm. 17.0 26.7 23.9 12.4 69.6 42.2 5.1 3.6 1.9

in. 6.7 10.5 9.4 4.9 30.4 16.6 2.0 1.5 3/4”

cm. 17.0 26.7 23.9 12.4 77.2 42.2 5.1 3.8 1.9

in. 4.9 13.6 13.2 4.6 35.4 18.6 2.3 1.4 3/4”

cm. 12.4 34.5 33.5 11.7 89.9 47.2 5.8 3.6 1.9

in. 4.9 13.6 13.2 4.6 40.4 18.6 2.3 1.4 3/4”

cm. 12.4 34.5 33.5 11.7 102.6 47.2 5.8 3.6 1.9

in. 4.9 13.6 13.2 4.6 45.4 18.6 2.3 1.4 3/4”

cm. 12.4 34.5 33.5 11.7 115.3 47.2 5.8 3.6 1.9

in. 4.9 13.6 13.2 4.6 45.4 18.6 2.3 1.4 3/4”

cm. 12.4 34.5 33.5 11.7 115.3 47.2 5.8 3.6 1.9

Overall Cabinet

A B C D E H Loop 1/2 in. cond 1 in. cond

Discharge Connection

duct fl ange installed (±0.10 in.)

LMNPQRS TX

Supply Width Supply Depth Return Depth Return Height

123 JK

Water Connections Electrical Knockouts

Return Connection

using deluxe fi lter rack option (±0.10 in.)

3/16/12

PVC Size

3/16/12

Horizontal Disconnect

When using disconnect, do not use dimension K from the

standard horizontal dimensional data. Use dimension KK from

the horizontal disconnect dimensional data.

Horizontal Models KK

009-012

015-018

024-030

036-038

042-049

060-064

070-072

Dimensions in inches [cm] 3/16/12

8.2 [20.8]

9.2 [23.4]

9.2 [23.4]

11.2 [28.4]

10.2 [25.9]

11.2 [28.4]

10.2 [25.9]

Disconnect Located

on this Side for a

Left Return

9

2.1 in.

[5.3 cm]

Disconnect

Location

KK

Power Supply

Horizontal Shown in

Right Return Configuration

Page 10

ENVISION2 COMPACT INSTALLATION MANUAL

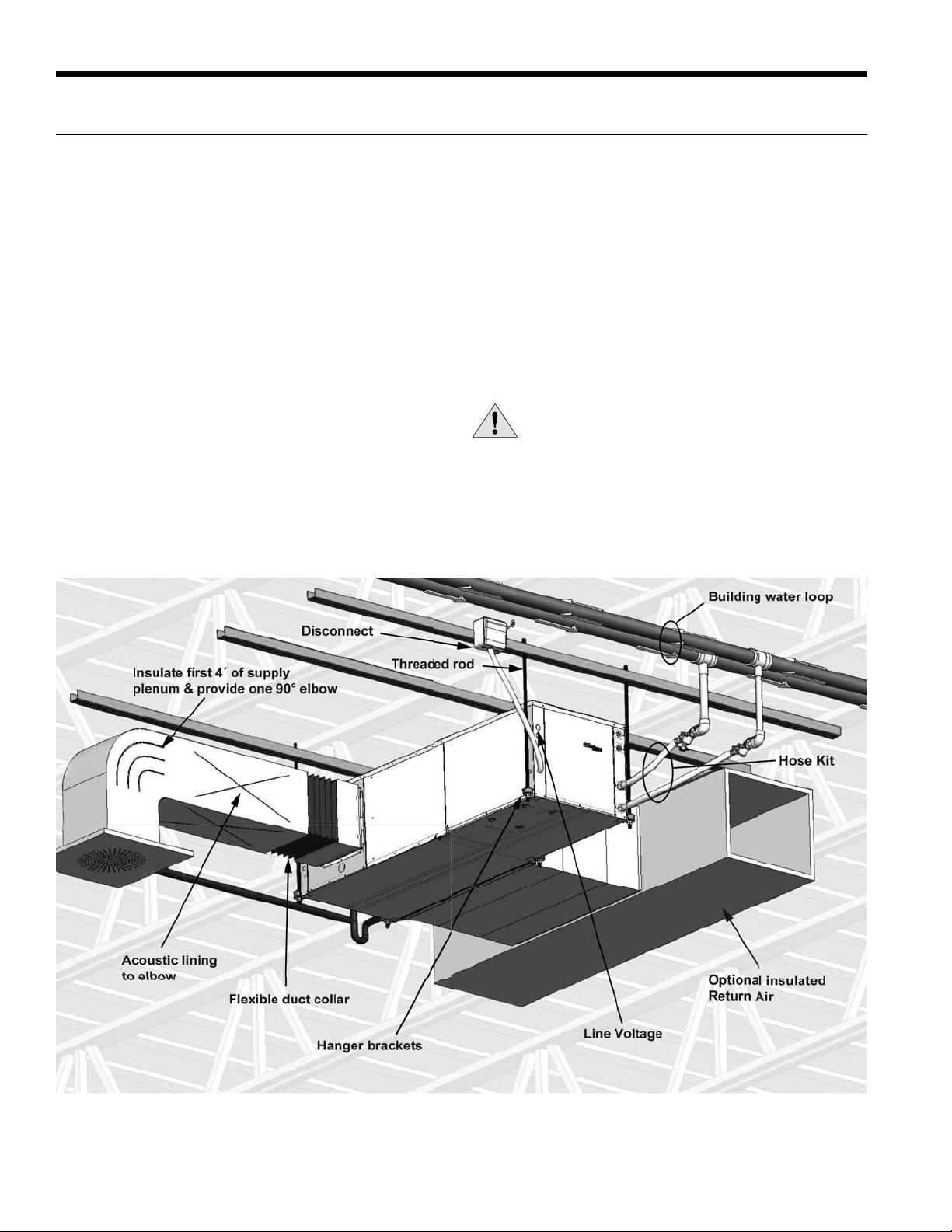

Installing Horizontal Units

Installing Horizontal Units

Remove and discard the compressor hold down shipping

bolt located at the front of the compressor mounting

bracket prior to setting the unit in place. Horizontal units

are available with side or end discharge.

NOTE: Horizontal units are normally suspended from a

ceiling by four (009-060 models) or five (070-072 models)

3/8 in. diameter threaded rods. The rods are usually

attached to the unit by hanger bracket kits furnished with

each unit.

Lay out the threaded rods per the Hanger Bracket

Dimensions table. Assemble the hangers to the unit as

shown. Securely tighten the brackets to the unit using the

weld nuts located on the underside of the bottom panel.

When attaching the hanger rods to the bracket, a double

nut is required since vibration could loosen a single nut.

To allow filter access, install hanger brackets as illustrated

in the Hanger Bracket Locations section. The unit should

be pitched approximately 1/4 in. towards the drain in both

directions to facilitate the removal of condensate. Use only

the bolts provided in the kit to attach hanger brackets. The

use of longer bolts could damage internal parts.

Some applications require the installation of horizontal

units on an attic floor. In this case, the unit should be set

in a full size secondary drain pan on top of a vibration

absorbing pad. The secondary drain pan prevents possible

condensate overflow or water leakage damage to the

ceiling. The secondary drain pan is usually placed on a

plywood base isolated from the ceiling joists by additional

layers of vibration absorbing material.

CAUTION: Do not use rods smaller than 3/8 in.

diameter since they may not be strong enough

to support the unit. The rods must be securely

anchored to the ceiling.

10

Page 11

Hanger Bracket Locations

ENVISION2 COMPACT INSTALLATION MANUAL

H

D

Compressor

Section

B

E

NOTE: Model sizes 070-072 will be shipped with six (6) hanger brackets. Only five (5) hanger brackets will be used on the unit.

See the above illustration for the fifth hanger bracket location. All other models will use four (4) hanger brackets.

Hanger Bracket Dimensions

Model

009-012

015-018

024-030

036

042-048

Single Speed

060

070

026

038

049

064

Dual Capacity

072

Hanger Kit

Part Number

in.

99S500A04

cm. 90.7 63.8 54.4 n/a

in.

99S500A04

cm. 108.7 63.8 54.4 n/a

in.

99S500A04

cm. 116.3 63.8 54.4 n/a

in.

99S500A04

cm. 124.0 71.4 62.0 n/a

in.

99S500A04

cm. 136.7 71.4 62.0 n/a

in.

99S500A04

cm. 157.0 71.4 62.0 n/a

in.

99S500A03

cm. 174.8 71.4 62.0 74.4

in.

99S500A04

cm. 116.3 63.8 54.4 n/a

in.

99S500A03

cm. 124.0 71.4 62.0 n/a

in.

99S500A04

cm. 136.7 71.4 62.0 n/a

in.

99S500A04

cm. 157.0 71.4 62.0 n/a

in.

99S500A03

cm. 174.8 71.4 62.0 74.4

Right

F

C

Air Handler

Section

G

A

3/8”

Threaded Rod

(not supplied)

Bolt and

Lockwasher

Unit Hanger Dimensions

ABCH

35.7 25.1 21.4 n/a

42.8 25.1 21.4 n/a

45.8 25.1 21.4 n/a

48.8 28.1 24.4 n/a

53.8 28.1 24.4 n/a

61.8 28.1 24.4 n/a

68.8 28.1 24.4 34.0

45.8 25.1 21.4 n/a

48.8 28.1 24.4 n/a

53.8 28.1 24.4 n/a

61.8 28.1 24.4 n/a

68.8 28.1 24.4 34.0

3/16/12

E

Compressor

Section

D

H

Vibration Isolator

Washer

Hex Nuts

(not supplied)

Weight Distribution

009

012

015

018

024

030

036

042

048

060

070

026

038

049

064

072

Vertical

Weight

[202] [206] [61] [54] [45] [39]

[202] [206] [61] [54] [45] [39]

Model

Single Speed

Dual Capacity

Weights are listed in lbs. [kg]. 3/16/12

Horizontal

Weight

171 176 32 67 32 45

[78] [80] [15] [30] [15] [20]

171 176 32 67 32 45

[78] [80] [15] [30] [15] [20]

210 220 65 40 70 35

[95] [100] [29] [18] [32] [16]

210 220 65 40 70 35

[95] [100] [29] [18] [32] [16]

280 295 75 70 75 20

[127] [134] [34] [31] [34] [13]

285 295 75 70 75 30

[129] [134] [34] [31] [34] [13]

300 305 85 80 85 40

[136] [138] [39] [36] [39] [18]

365 375 115 95 75 60

[166] [170] [52] [43] [34] [27]

370 380 120 100 80 65

[168] [172] [54] [45] [36] [29]

410 420 120 110 95 80

[186] [191] [54] [50] [43] [36]

445 455 135 120 100 85

280 295 75 70 75 50

[127] [134] [34] [31] [34] [13]

360 375 115 95 75 60

[163] [170] [52] [43] [34] [27]

370 380 120 100 80 65

[168] [172] [54] [45] [36] [29]

410 420 120 110 95 80

[186] [191] [54] [50] [43] [36]

445 455 135 120 100 85

Left

G

Air Handler

Section

F

Horizontal Weight Distribution

Front Back

DEFG

11

Page 12

ENVISION2 COMPACT INSTALLATION MANUAL

Duct System

An air outlet collar is provided on vertical top flow units

and all horizontal units to facilitate a duct connection.

A flexible connector is recommended for discharge

and return air duct connections on metal duct systems.

Uninsulated duct should be insulated with a minimum of

1-inch duct insulation. Application of the unit to uninsulated

ductwork in an unconditioned space is not recommended

as the unit’s performance will be adversely affected.

If the unit is connected to existing ductwork, check the duct

system to ensure that it has the capacity to accommodate

the air required for the unit application. If the duct is too

small, as in the replacement of heating only systems, larger

ductwork should be installed. All existing ductwork should

be checked for leaks and repaired if necessary.

Water Piping

The proper water flow must be provided to each unit

whenever the unit operates. To assure proper flow, use

pressure/temperature ports to determine the flow rate.

These ports should be located at the supply and return

water connections on the unit. The proper flow rate cannot

be accurately set without measuring the water pressure

drop through the refrigerant-to-water heat exchanger.

The duct system should be sized to handle the design

airflow quietly and efficiently. To maximize sound

attenuation of the unit blower, the supply and return

plenums should include an internal duct liner of fiberglass

or constructed of ductboard for the first few feet. On

systems employing a sheet metal duct system, canvas

connectors should be used between the unit and the

ductwork. If air noise or excessive airflow is a problem, the

blower speed can be changed.

All source water connections on commercial units are

fittings that accept a male pipe thread (MPT). Insert the

connectors by hand, then tighten the fitting with a wrench

to provide a leakproof joint. When connecting to an open

loop (groundwater) system, thread any copper MPT fitting

into the connector and tighten in the same manner as

described above.

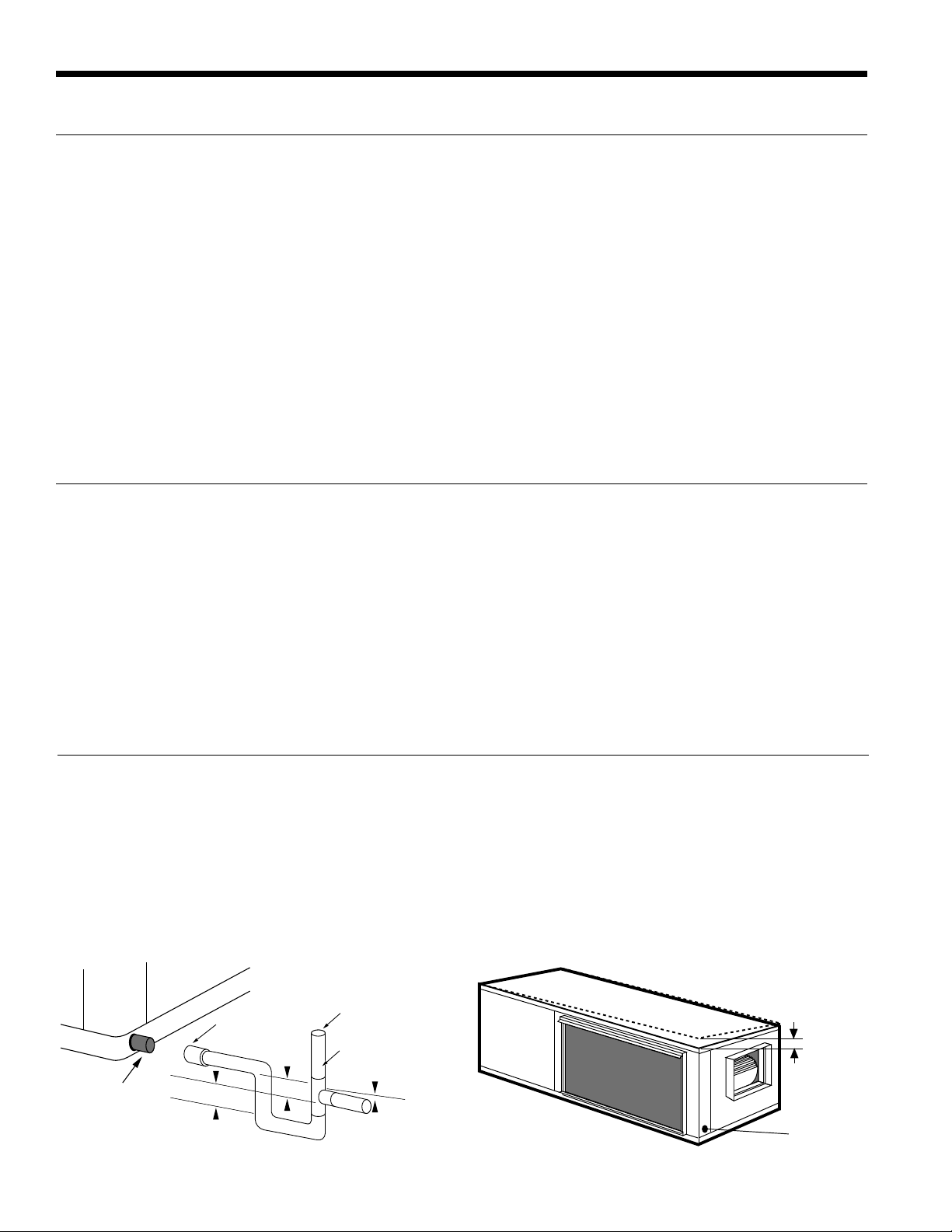

Condensate Drain

On vertical units, the internal condensate drain assembly

consists of a drain tube which is connected to the drain

pan, a 3/4 in. PVC female adapter and a flexible connecting

hose. The female adapter may exit either the front or the

side of the cabinet. The adapter should be glued to the

field-installed PVC condensate piping. On vertical units, a

condensate hose is inside all cabinets as a trapping loop;

therefore, an external trap is not necessary.

Vent (if needed)

PVC tube stub

1/8 in. per foot

PVC tube stub

PVC coupling

1.5 in.

1.5 in.

On horizontal units, a PVC stub or stainless steel tube

is provided for condensate drain piping connection. An

external trap is required (see below). If a vent is necessary,

an open stand pipe may be applied to a tee in the fieldinstalled condensate piping.

Unit Pitch for DrainHorizontal Drain Connection (Composite Drain Pan)

1/2'' Pitch

Drain

12

Page 13

Water Quality

ENVISION2 COMPACT INSTALLATION MANUAL

In ground water situations where scaling could be heavy

or where biological growth such as iron bacteria will be

present, a closed loop system is recommended. The heat

exchanger coils in ground water systems may, over a period

with extremely hard water, the owner should be informed

that the heat exchanger may require occasional flushing.

Failure to adhere to the guidelines in the water quality table

could result in loss of warranty.

of time, lose heat exchange capabilities due to a buildup

of mineral deposits inside. These can be cleaned, but only

by a qualified service mechanic, as special solutions and

pumping equipment are required. Hot water generator coils

can likewise become scaled and possibly plugged. In areas

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity

Scaling

Corrosion

Iron Fouling

(Biological Growth)

Erosion

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

Calcium and

Magnesium Carbonate

Hydrogen Sulfide

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron, FE

Bacterial Iron Potential

Iron Oxide

Suspended Solids

Threshold Velocity

(Fresh Water)

Less than 0.5 ppm (rotten egg

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

2

+ (Ferrous)

smell appears at 0.5 ppm)

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 mic

7 - 9 7 - 9 7 - 9

(Total Hardness)

less than 350 ppm

< 0.2 ppm < 0.2 ppm < 0.2 ppm

< 6 ft/sec < 6 ft/sec < 6 ft/sec

Units with cupronickel heat exchangers are recommended

for open loop applications due to the increased resistance

to build-up and corrosion, along with reduced wear caused

by acid cleaning.

ron size

(Total Hardness)

less than 350 ppm

10 - 50 ppm Less than 1 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

(Total Hardness)

less than 350 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

2/22/12

System Cleaning and Flushing

Cleaning and Flushing

Prior to start up of any heat pump, the water circulating

system must be cleaned and flushed of all dirt and debris.

If the system is equipped with water shutoff valves, the

supply and return runouts must be connected together

at each unit location (This will prevent the introduction of

dirt into the unit, see Flushing with Water Shutoff Valve

Equipped Systems illustration). The system should be filled

at the water make-up connection with all air vents open.

After filling, vents should be closed.

The contractor should start the main circulator with the

pressure reducing valve makeup open. Vents should be

checked in sequence to bleed off any trapped air and to

verify circulation through all components of the system.

As water circulates through the system, the contractor

should check and repair any leaks found in the piping

system. Drain(s) at the lowest point(s) in the system should

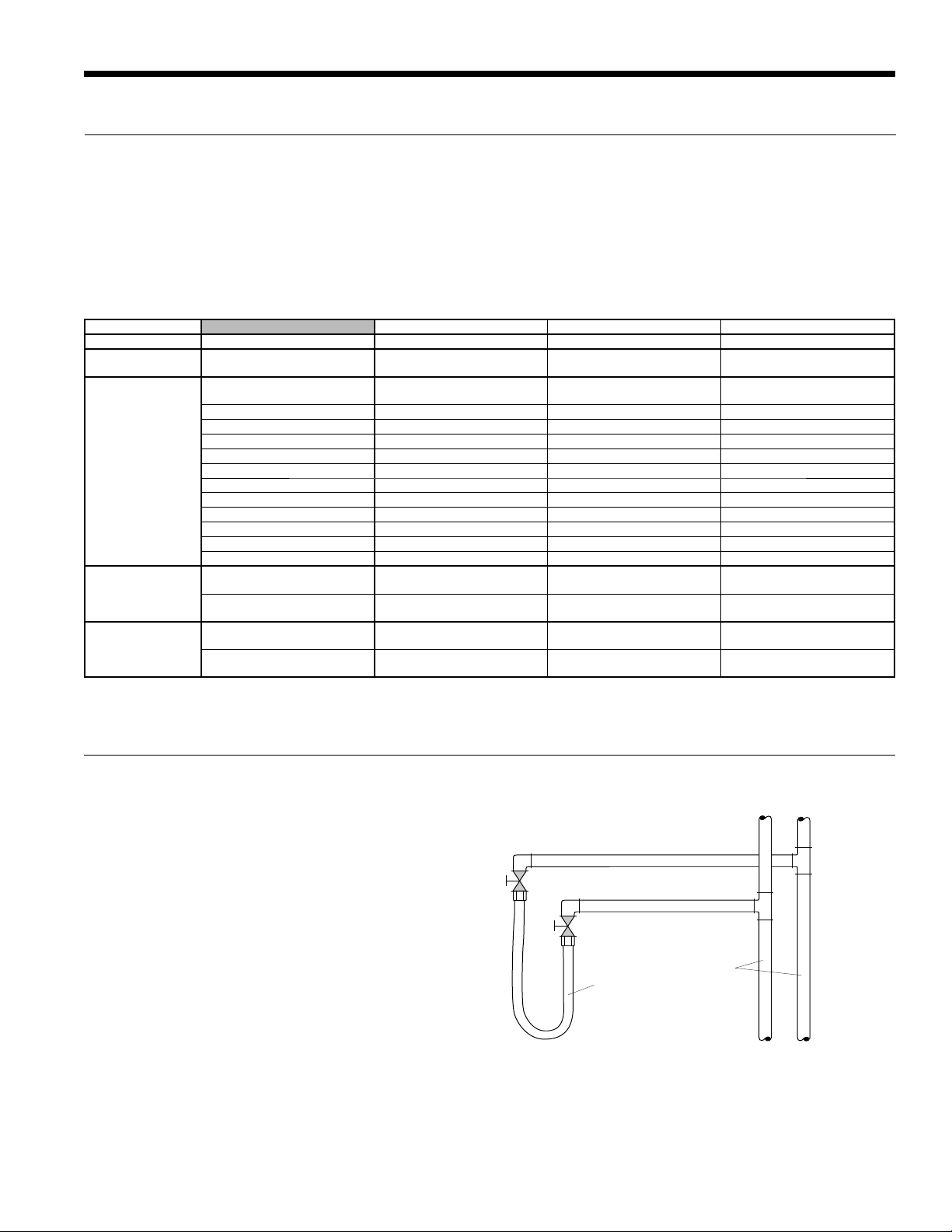

Flushing with Water Shutoff Valve Equipped Systems

Return Runout

Supply Runout

Mains

Rubber Hose

Runouts Initially

Connected Together

13

Page 14

ENVISION2 COMPACT INSTALLATION MANUAL

System Cleaning and Flushing cont.

be opened for initial flush and blowdown, making sure

water fill valves are set at the same rate. Check the pressure

gauge at the pump suction and manually adjust the makeup water valve to hold the same positive pressure both

before and after opening the drain valves. Flushing should

continue for at least two hours, or longer if required, until

drain water is clean and clear.

The supplemental heater and/or circulator pump, if used,

should be shut off. All drains and vents should be opened

to completely drain the system. Short-circuited supply and

return runouts should now be connected to the unit supply

and return connections.

Refill the system with clean water. Test the system water

for acidity and treat as required to leave the water slightly

alkaline (pH 7.5 to 8.5). The specified percentage of

antifreeze may also be added at this time. Use commercial

grade antifreeze designed for HVAC systems only.

Environol™ brand antifreeze is recommended.

Once the system has been filled with clean water and

antifreeze (if used), precautions should be taken to protect

the system from dirty water conditions. Dirty water will

result in system-wide degradation of performance, and

solids may clog valves, strainers, flow regulators, etc.

Additionally, the heat exchanger may become clogged

which reduces compressor service life and can cause

premature unit failure.

In boiler/tower application, set the loop control panel

set points to desired temperatures. Supply power to all

motors and start the circulating pumps. After full flow has

been established through all components including the

heat rejector (regardless of season), air vented and loop

temperatures stabilized, each of the units will be ready for

check, test and start up and for air and water balancing.

Ground Source Loop System Checkout

Once piping is completed between the unit pumping

system and ground loop, final purging and charging of

the loop is needed. A high pressure pump is needed to

achieve adequate flow velocity in the loop to purge air

and dirt particles from the loop itself. Antifreeze solution

is used in most areas to prevent freezing. Flush the

system adequately to remove as much air as possible;

then pressurize the loop to a static pressure of 40-50

PSI (summer) or 50-75 PSI (winter). This is normally

adequate for good system operation. Loop static pressure

may decrease soon after initial installation, due to pipe

expansion and loop temperature change. Running the

unit for at least 30 minutes after the system has been

completely purged of air will allow for the “break-in”

period. It may be necessary to adjust static loop pressure

(by adding water) after the unit has run for the first time.

Loop static pressure will also fluctuate with the seasons.

Pressures will be higher in the winter months than during

the cooling season. This fluctuation is normal and should be

considered when charging the system initially.

Ensure the pump provides adequate flow through the unit

by checking pressure drop across the heat exchanger.

Usually 2.25-3.0 gpm of flow per ton of cooling capacity is

recommended in earth loop applications.

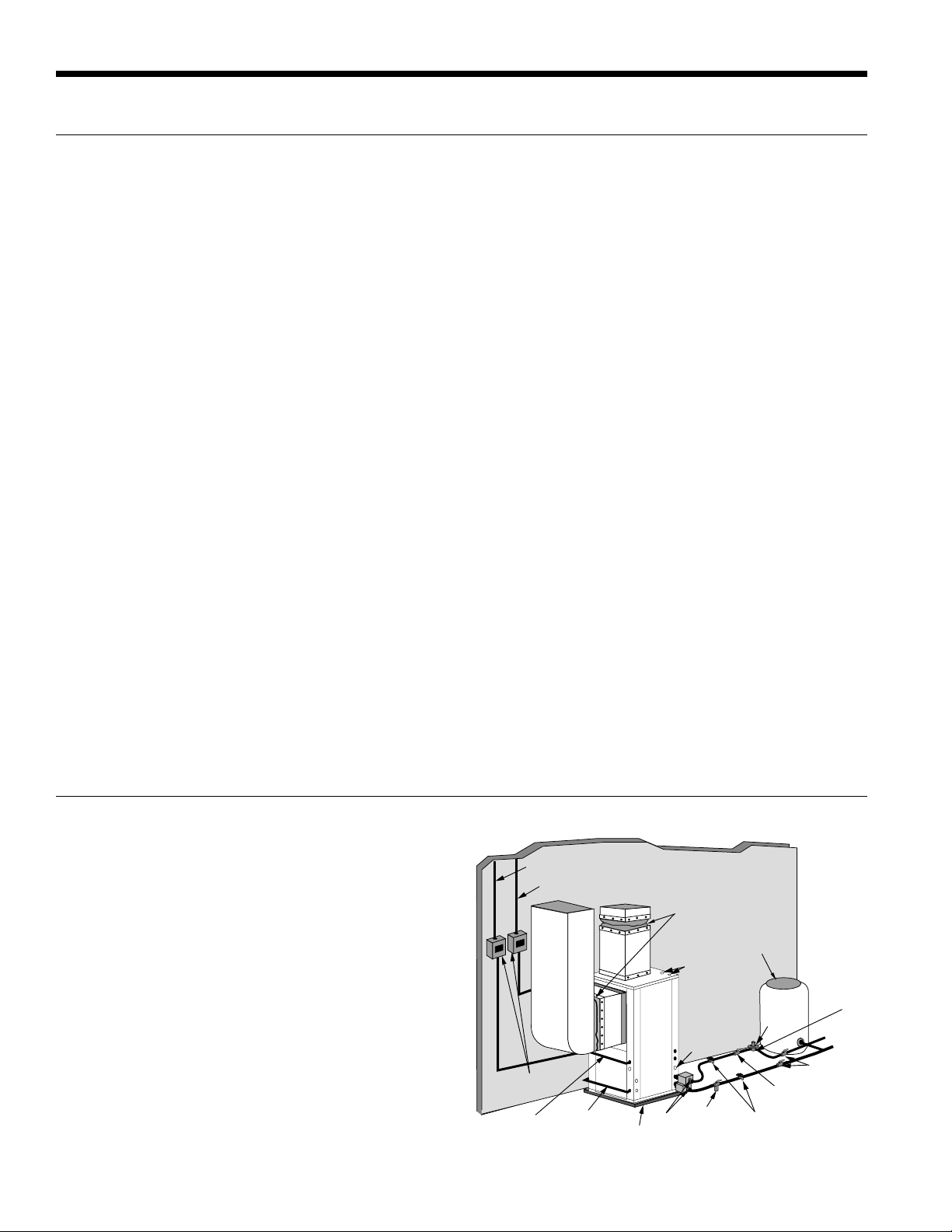

Open Loop Ground Water Systems

Typical open loop piping is shown below. Always maintain

water pressure in the heat exchanger by placing water

control valves at the outlet of the unit to prevent mineral

precipitation. Use a closed, bladder-type expansion tank

to minimize mineral formation due to air exposure. Insure

proper water flow through the unit by checking pressure

drop across the heat exchanger and comparing it to the

figures in unit capacity data tables in the specification

catalog. 1.5-2 gpm of flow per ton of cooling capacity is

recommended in open loop applications. Due to only minor

differences in flow rate from low to high, only one solenoid

valve should be used. The valve should be sized for full flow.

Discharge water from the unit is not contaminated in any

manner and can be disposed of in various ways, depending

on local codes, i.e. recharge well, storm sewer, drain field,

adjacent stream or pond, etc. Most local codes forbid the use

of sanitary sewer for disposal. Consult your local building and

zoning departments to assure compliance in your area.

Open System - Groundwater Application

14

Unit Supply

Disconnects

(IfApplicable)

Compressor

Line Voltage

Aux. Heat Supply

Low Voltage

to Thermostat

and Valve

P/T Plugs

Vibration

Absorbing Pad

Flexible

Duct Collar

Hot Water Generator

Connections

Drain

Strainer

Rubber Bladder

Expansion Tank

Solenoid

Valve

valve while acid flushing)

Boiler Drains

For HX Flushing

Flow Control

(on outlet of

Solenoid Valve)

Water Out

Shut Off Valves

Shut Off Valves

(to isolate solenoid

Valve

Water In

Page 15

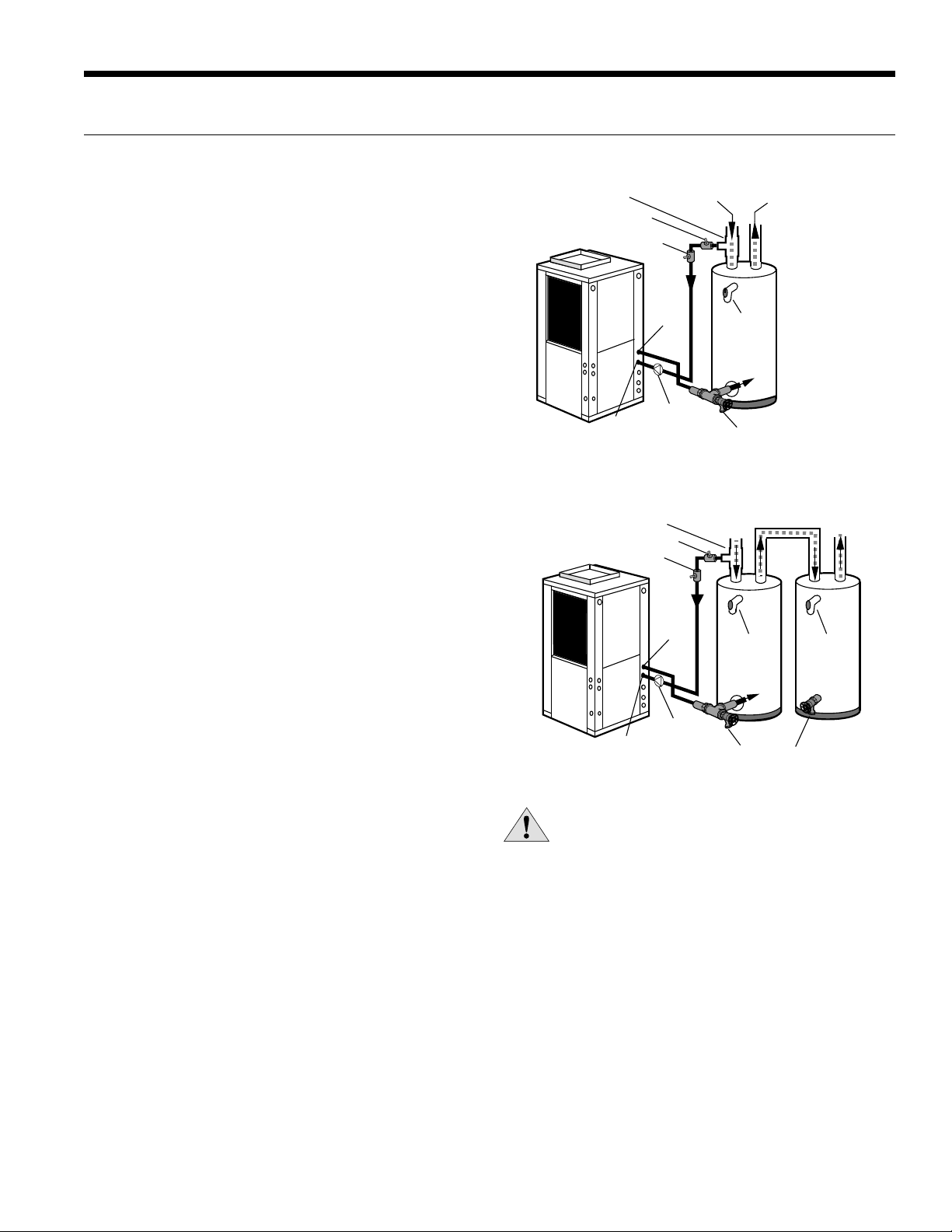

Hot Water Generator Connections

ENVISION2 COMPACT INSTALLATION MANUAL

The heat reclaiming hot water generator coil is of vented

double-wall copper construction and is suitable for

potable water.

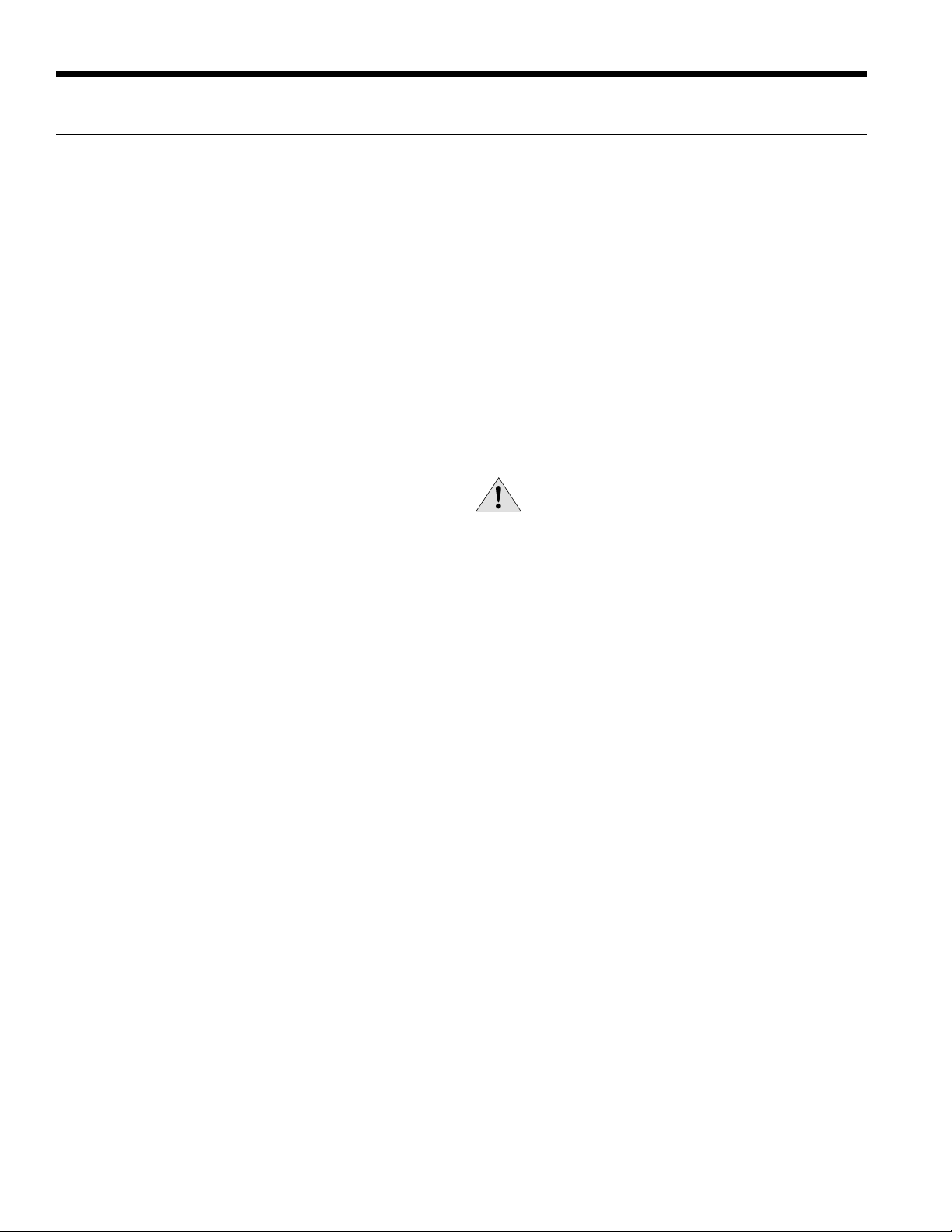

To maximize the benefits of the hot water generator a

minimum 50-gallon water heater is recommended. For

higher demand applications, use an 80-gallon water heater

or two 50-gallon water heaters connected in a series as

shown below. Electric water heaters are recommended.

Make sure all local electrical and plumbing codes are met

for installing a hot water generator. A water softener is

recommended with hard water (greater than 10 grains or

170 total hardness).

Water Tank Preparation

To install a unit with a hot water generator, follow these

installation guidelines.

1. Turn off the power to the water heater.

2. Attach a water hose to the water tank drain connection and

run the other end of the hose to an open drain or outdoors.

3. Close the cold water inlet valve to the water heater tank.

4. Drain the tank by opening the valve on the bottom of the

tank, then open the pressure relief valve or hot water faucet.

5. Flush the tank by opening the cold water inlet valve to

the water heater to free the tank of sediments. Close

when draining water is clear.

6. Disconnect the garden hose and remove the drain valve

from the water heater.

7. Refer to Plumbing Installation and Hot Water

Generator Startup.

Typical Hot Water Generator Installation

3/4 in. x 3/4 in. x 1/2 in. Tee

Ball Valve

Vent

HWG

Water Out

Field Installed

HWG Pump

HWG

Water In

Cold

Water In

Drain Valve

P/T Relief

Valve

Water Out

In

Hot

Hot Water Generator Installation In Preheat Tank

Cold

3/4 in. x 3/4 in. x 1/2 in. Tee

Ball Valve

Vent

Water Out

Field Installed

HWG

Water In

HWG

HWG Pump

Water In

P/T Relief

Valve

In

Drain Valve

NOTE: This configuration maximizes hot water

generator capability.

Hot

Water Out

P/T Relief

Valve

Plumbing Installation

1. Inspect the dip tube in the water heater cold inlet

for a check valve. If a check valve is present it must

be removed or damage to the hot water generator

circulator will occur.

2. Remove drain valve and fitting.

3. Thread the 3/4-inch NPT x 3-1/2-inch brass nipple into

the water heater drain port.

4. Attach the center port of the 3/4-inch FPT tee to the

opposite end of the brass nipple.

5. Attach the 1/2-inch copper to 3/4-inch NPT adaptor to

the side of the tee closest to the unit.

6. Install the drain valve on the tee opposite the adaptor.

7. Run interconnecting tubing from the tee to HWG

water out.

CAUTION: Elements will burn out if energized dry.

8. Cut the cold water “IN” line going to the water heater.

9. Insert the reducing solder tee in line with cold water

“IN” line as shown.

10. Run interconnecting copper tubing between the unit

DHW water “IN” and the tee (1/2-inch nominal). The

recommended maximum distance is 50 feet.

11.

To prevent air entrapment in the system, install a vent

coupling at the highest point of the interconnecting lines.

12. Insulate all exposed surfaces of both connecting water

lines with 3/8-inch wall closed cell insulation.

NOTE: All plumbing and piping connections must comply

with local plumbing codes.

15

Page 16

ENVISION2 COMPACT INSTALLATION MANUAL

Hot Water Generator Connections cont.

Hot Water Generator Startup

1. Make sure the power is off to the heat pump. Connect

the wire from the hot water generator pump to T1 on

the contactor.

2. Close the drain valve to the water heater.

3. Open the cold water supply to the tank.

4. Open a hot water faucet in the building to bleed air

from the system. Close when full.

5. Open the pressure relief valve to bleed any remaining

air from the tank, then close.

6. If so equipped, turn the venting (burping) screw in the

center of the pump two (2) turns open (water will drip out),

wait until all air is purged from the pump, then tighten the

plug. Use vent couplings to bleed air from the lines.

7. Carefully inspect all plumbing for water leaks and

correct as required.

8. Before restoring electrical supply to the water heater,

adjust the temperature setting on the tank.

• On tanks with both upper and lower elements,

the lower element should be turned down to

the lowest setting, approximately 100°F. The

upper element should be adjusted to 120°F to

130°F. Depending upon the specific needs of

the customer, you may want to adjust the upper

element differently.

• On tanks with a single element, lower the

thermostat setting to 120°F.

9. After the thermostat(s) is adjusted, replace the access

cover and restore electrical supply to the water heater.

10. Make sure that any valves in the hot water generator

circuit are open.

11. Turn on the unit to heating.

12. The HWG pump should be running. When the pump

is first started, turn the venting (burping) screw (if

equipped) in the center of the pump two (2) turns open

until water dribbles out, then replace. Allow the pump

to run for at least five minutes to ensure that water has

filled the circulator properly.

13. The temperature difference between the water entering

and leaving the hot water generator should be 5°F to

15°F. The water flow should be approximately 0.4 gpm

per ton of nominal cooling.

14. Allow the unit to heat water for 15 to 20 minutes to be

sure operation is normal.

CAUTION: Never operate the HWG circulating

pump while dry. If the unit is placed in operation

before the hot water generator piping is

connected, be sure that the pump wires are

disconnected from the contactor.

16

Page 17

Freeze Detection

For Aurora Base Control, set SW2-1, FP1, on the printed

circuit board for applications using a closed loop antifreeze

solution to 15°F [-9.4°C]. On applications using an open

loop/ground water system (or closed loop no antifreeze), set

this dip switch to 30°F [-1.1°C], the factory default setting.

(Refer to the Dip Switch Field Selection table).

Electrical Connections

ENVISION2 COMPACT INSTALLATION MANUAL

General

Be sure the available power is the same voltage and phase

as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable.

Power Connection

Connect the incoming line voltage wires to L1 and L2 of the

contactor for single-phase unit. Consult the Electrical Data

tables for correct fuse sizes.

Aurora Base Control Box

208 Volt Operation

All 208/230 units are factory wired for 230 volt operation.

For 208 volt operation, the red and blue transformer wires

must be switched on terminal strip PS.

CAUTION: When installing a unit with a variable

speed ECM blower motor in 460/60/3 voltage,

a neutral wire is required to allow proper unit

operation.

17

Page 18

ENVISION2 COMPACT INSTALLATION MANUAL

Electrical Data

PSC Motor

Model

009

012

015

018

024

024*

030

030*

036

036*

Single Speed

042

042*

048

048*

060

070

HACR circuit breaker in USA only

*With optional High-static PSC motor

**With optional IntelliStart

Rated

Voltage

208-230/60/1 187/253 6.4 4.1 21.0 n/a 0.6 4.7 5.7 10/15

265/60/1 238/292 6.7 4.3 22.0 n/a 0.6 4.9 6.0 10/15

208-230/60/1 187/253 7.7 4.9 25.0 n/a 0.6 5.5 6.7 10/15

265/60/1 238/292 7.0 4.5 22.0 n/a 0.6 5.1 6.2 10/15

208-230/60/1 187/253 9.7 6.2 29.0 n/a 1.1 7.3 8.9 15

265/60/1 238/292 7.8 5.0 28.0 n/a 1.0 6.0 7.3 10/15

208-230/60/1 187/253 13.1 8.4 33.5 13.4 1.1 9.5 11.6 20

265/60/1 238/292 8.7 5.6 28.0 n/a 1.0 6.6 8.0 10/15

208-230/60/1 187/253 21.0 13.5 58.3 23.3 1.2 14.7 18.1 25

265/60/1 238/292 14.0 9.0 54.0 n/a 1.1 10.1 12.4 20

208-230/60/3 187/253 11.0 7.1 55.4 33.2 1.2 8.3 10.1 15

460/60/3 414/506 5.5 3.5 28.0 16.8 0.6 4.1 5.0 10/15

208-230/60/1 187/253 21.0 13.5 58.3 23.3 1.5 15.0 18.4 30

265/60/1 238/292 14.0 9.0 54.0 n/a 1.5 10.5 12.8 20

208-230/60/3 187/253 11.0 7.1 55.4 33.2 1.5 8.6 10.4 15

460/60/3 414/506 5.5 3.5 28.0 16.8 1.0 4.5 5.4 10/15

208-230/60/1 187/253 20.0 12.8 58.0 23.2 1.5 14.3 17.5 30

265/60/1 238/292 15.0 9.6 54.0 n/a 1.5 11.1 13.5 20

208-230/60/3 187/253 12.0 7.7 55.4 33.2 1.5 9.2 11.1 15

460/60/3 414/506 5.6 3.6 28.0 16.8 1.0 4.6 5.5 10/15

208-230/60/1 187/253 20.0 12.8 58.0 23.2 2.8 15.6 18.8 30

265/60/1 238/292 15.0 9.6 54.0 n/a 2.0 11.6 14.0 20

208-230/60/3 187/253 12.0 7.7 55.4 33.2 2.2 9.9 11.8 15

460/60/3 414/506 5.6 3.6 28.0 16.8 1.1 4.7 5.6 10/15

208-230/60/1 187/253 22.0 14.1 73.0 29.2 2.8 16.9 20.4 30

265/60/1 238/292 17.5 11.2 60.0 n/a 2.0 13.2 16.0 25

208-230/60/3 187/253 13.9 8.9 58.0 34.8 2.8 11.7 13.9 20

460/60/3 414/506 6.5 4.2 28.0 16.8 1.4 5.6 6.7 10/15

208-230/60/1 187/253 22.0 14.1 73.0 29.2 3.5 17.6 21.1 35

265/60/1 238/292 17.5 11.2 60.0 n/a 3.5 14.7 17.5 25

208-230/60/3 187/253 13.9 8.9 58.0 34.8 1.8 10.7 12.9 20

460/60/3 414/506 6.5 4.2 28.0 16.8 1.8 5.6 6.7 10/15

208-230/60/1 187/253 26.0 16.7 79.0 31.6 3.5 20.2 24.4 40

208-230/60/3 187/253 16.3 10.4 73.0 43.8 3.5 13.9 16.5 25

460/60/3 414/506 9.0 5.8 38.0 22.8 1.8 7.6 9.0 10/15

575/60/3 517/633 5.9 3.8 36.5 n/a 1.4 5.2 6.1 10/15

208-230/60/1 187/253 26.0 16.7 79.0 31.6 4.6 21.3 25.5 40

208-230/60/3 187/253 16.3 10.4 73.0 43.8 4.6 15.0 17.6 25

460/60/3 414/506 9.0 5.8 38.0 22.8 2.3 8.1 9.5 15

575/60/3 517/633 5.9 3.8 36.5 n/a 1.9 5.7 6.6 10/15

208-230/60/1 187/253 31.0 19.9 109.0 43.6 3.5 23.4 28.4 45

208-230/60/3 187/253 21.2 13.6 83.1 49.9 3.5 17.1 20.5 30

460/60/3 414/506 9.5 6.1 41.0 24.6 1.8 7.9 9.4 15

575/60/3 517/633 6.5 4.2 33.0 n/a 1.4 5.6 6.7 10/15

208-230/60/1 187/253 31.0 19.9 109.0 43.6 4.6 24.5 29.5 45

208-230/60/3 187/253 21.2 13.6 83.1 49.9 4.6 18.2 21.6 35

460/60/3 414/506 9.5 6.1 41.0 24.6 2.3 8.4 9.9 15

575/60/3 517/633 6.5 4.2 33.0 n/a 1.9 6.1 7.2 10/15

208-230/60/1 187/253 41.2 26.4 134.0 53.6 5.9 32.3 38.9 60

208-230/60/3 187/253 24.9 16.0 110.0 66.0 5.9 21.9 25.9 40

460/60/3 414/506 12.1 7.8 52.0 31.2 3.0 10.8 12.8 20

575/60/3 517/633 8.9 5.7 38.9 n/a 1.9 7.6 9.0 10/15

208-230/60/1 187/253 44.2 28.3 178.0 71.2 5.9 34.2 41.3 70

208-230/60/3 187/253 30.0 19.2 136.0 81.6 5.9 25.1 29.9 45

460/60/3 414/506 13.6 8.7 66.1 39.7 3.0 11.7 13.9 20

575/60/3 517/633 10.7 6.9 55.3 n/a 1.9 8.8 10.5 15

Voltage

Min/Max

MCC RLA LRA LRA**

Compressor

Blower

Motor

FLA

Total

Unit

FLA

Min

Circ

Amp

Max Fuse/

HACR

Breaker

8/06/13

18

Page 19

Electrical Data cont.

5-Speed ECM Motor

Model

015

018

024

030

036

Single Speed

042

048

060

070

026

038

049

Dual Capacity

064

072

HACR circuit breaker in USA only

**With optional IntelliStart

Rated

Voltage

208-230/60/1 187/253 9.7 6.2 29.0 n/a 4.1 10.3 11.9 15

265/60/1 238/292 7.8 5.0 28.0 n/a 3.6 8.6 9.9 10/15

208-230/60/1 187/253 13.1 8.4 33.5 13.4 4.1 12.5 14.6 20

265/60/1 238/292 8.7 5.6 28.0 n/a 3.6 9.2 10.6 15

208-230/60/1 187/253 21.0 13.5 58.3 23.3 4.1 17.6 21.0 30

265/60/1 238/292 14.0 9.0 54.0 n/a 3.6 12.6 14.9 20

208-230/60/3 187/253 11.0 7.1 55.4 33.2 4.1 11.2 13.0 20

460/60/3 414/506 5.5 3.5 28.0 16.8 2.1 5.6 6.5 10/15

208-230/60/1 187/253 20.0 12.8 58.0 23.2 4.1 16.9 20.1 30

265/60/1 238/292 15.0 9.6 54.0 n/a 3.6 13.2 15.6 25

208-230/60/3 187/253 12.0 7.7 55.4 33.2 4.1 11.8 13.7 20

460/60/3 414/506 5.6 3.6 28.0 16.8 2.1 5.7 6.6 10/15

208-230/60/1 187/253 22.0 14.1 73.0 29.2 4.1 18.2 21.7 35

265/60/1 238/292 17.5 11.2 60.0 n/a 3.6 14.8 17.6 25

208-230/60/3 187/253 13.9 8.9 58.0 34.8 4.1 13.0 15.2 20

460/60/3 414/506 6.5 4.2 28.0 16.8 2.1 6.3 7.4 10/15

208-230/60/1 187/253 26.0 16.7 79.0 31.6 7.6 24.3 28.5 45

208-230/60/3 187/253 16.3 10.4 73.0 43.8 7.6 18.0 20.6 30

460/60/3 414/506 9.0 5.8 38.0 22.8 4.0 9.8 11.2 15

208-230/60/1 187/253 31.0 19.9 109.0 43.6 7.6 27.5 32.5 50

208-230/60/3 187/253 21.2 13.6 83.1 49.9 7.6 21.2 24.6 35

460/60/3 414/506 9.5 6.1 41.0 24.6 4.0 10.1 11.6 15

208-230/60/1 187/253 41.2 26.4 134.0 53.6 7.6 34.0 40.6 60

208-230/60/3 187/253 24.9 16.0 110.0 66.0 7.6 23.6 27.6 40

460/60/3 414/506 12.1 7.8 52.0 31.2 4.0 11.8 13.8 20

208-230/60/1 187/253 44.2 28.3 178.0 71.2 7.6 35.9 43.0 70

208-230/60/3 187/253 30.0 19.2 136.0 81.6 7.6 26.8 31.6 50

460/60/3 414/506 13.6 8.7 66.1 39.7 4.0 12.7 14.9 20

208-230/60/1 187/253 18.2 11.7 58.3 23.3 4.1 15.8 18.7 30

265/60/1 238/292 14.2 9.1 54.0 n/a 3.6 12.7 15.0 20

208-230/60/3 187/253 10.1 6.5 55.4 33.2 4.1 10.6 12.2 15

460/60/3 414/506 5.4 3.5 28.0 16.8 2.1 5.6 6.4 10/15

208-230/60/1 187/253 23.8 15.3 83.0 33.2 4.1 19.4 23.2 35

265/60/1 238/292 20.3 13.0 72.0 n/a 3.6 16.6 19.9 30

208-230/60/3 187/253 18.1 11.6 73.0 43.8 4.1 15.7 18.6 30

460/60/3 414/506 8.9 5.7 38.0 22.8 2.1 7.8 9.2 10/15

208-230/60/1 187/253 33.0 21.1 104.0 41.6 7.6 28.7 34.0 50

208-230/60/3 187/253 21.9 14.0 83.1 49.9 7.6 21.6 25.1 35

460/60/3 414/506 10.0 6.4 41.0 24.6 4.0 10.4 12.0 15

208-230/60/1 187/253 42.3 27.1 152.9 61.2 7.6 34.7 41.5 60

208-230/60/3 187/253 25.8 16.5 110.0 66.0 7.6 24.1 28.2 40

460/60/3 414/506 11.3 7.2 52.0 31.2 4.0 11.2 13.0 20

208-230/60/1 187/253 46.3 29.7 179.2 71.7 7.6 37.3 44.7 70

208-230/60/3 187/253 27.4 17.6 136.0 81.6 7.6 25.2 29.6 45

460/60/3 414/506 13.2 8.5 66.1 39.7 4.0 12.5 14.6 20

Voltage

Min/Max

ENVISION2 COMPACT INSTALLATION MANUAL

Compressor

MCC RLA LRA LRA**

Blower

Motor

FLA

Total

Unit

FLA

Min

Circ

Amp

Max Fuse/

HACR

Breaker

5/21/13

19

Page 20

ENVISION2 COMPACT INSTALLATION MANUAL

Electrical Data cont.

Variable Speed ECM Motor

Model

015

018

024

030

036

036*

Single Speed

042

042*

048

048*

060

070

026

038

038*

049

Dual Capacity

049*

064

072

HACR circuit breaker in USA only

*With optional 1 HP variable speed ECM motor

**With optional IntelliStart

Rated

Voltage

208-230/60/1 187/253 9.7 6.2 29.0 n/a 4.0 10.2 11.8 15

265/60/1 238/292 7.8 5.0 28.0 n/a 4.1 9.1 10.4 15

208-230/60/1 187/253 13.1 8.4 33.5 13.4 4.0 12.4 14.5 20

265/60/1 238/292 8.7 5.6 28.0 n/a 4.1 9.7 11.1 15

208-230/60/1 187/253 21.0 13.5 58.3 23.3 4.0 17.5 20.9 30

265/60/1 238/292 14.0 9.0 54.0 n/a 4.1 13.1 15.4 20

208-230/60/3 187/253 11.0 7.1 55.4 33.2 4.0 11.1 12.9 20

460/60/3 414/506 5.5 3.5 28.0 16.8 4.1 7.6 8.5 10/15

208-230/60/1 187/253 20.0 12.8 58.0 23.2 4.0 16.8 20.0 30

265/60/1 238/292 15.0 9.6 54.0 n/a 4.1 13.7 16.1 25

208-230/60/3 187/253 12.0 7.7 55.4 33.2 4.0 11.7 13.6 20

460/60/3 414/506 5.6 3.6 28.0 16.8 4.1 7.7 8.6 10/15

208-230/60/1 187/253 22.0 14.1 73.0 29.2 4.0 18.1 21.6 35

265/60/1 238/292 17.5 11.2 60.0 n/a 4.1 15.3 18.1 25

208-230/60/3 187/253 13.9 8.9 58.0 34.8 4.0 12.9 15.1 20

460/60/3 414/506 6.5 4.2 28.0 16.8 4.1 8.3 9.4 10/15

208-230/60/1 187/253 22.0 14.1 73.0 29.2 7.0 21.1 24.6 35

265/60/1 238/292 17.5 11.2 60.0 n/a 6.9 18.1 20.9 30

208-230/60/3 187/253 13.9 8.9 58.0 34.8 7.0 15.9 18.1 25

460/60/3 414/506 6.5 4.2 28.0 16.8 6.9 11.1 12.2 15

208-230/60/1 187/253 26.0 16.7 79.0 31.6 4.0 20.7 24.9 40

208-230/60/3 187/253 16.3 10.4 73.0 43.8 4.0 14.4 17.0 25

460/60/3 414/506 9.0 5.8 38.0 22.8 4.1 9.9 11.3 15

208-230/60/1 187/253 26.0 16.6 79.0 31.6 7.0 23.6 27.8 40

208-230/60/3 187/253 16.3 10.4 73.0 43.8 7.0 17.4 20.0 30

460/60/3 414/506 9.0 5.8 38.0 22.8 6.9 12.7 14.1 15

208-230/60/1 187/253 31.0 19.9 109.0 43.6 4.0 23.9 28.9 45

208-230/60/3 187/253 21.2 13.6 83.1 49.9 4.0 17.6 21.0 30

460/60/3 414/506 9.5 6.1 41.0 24.6 4.1 10.2 11.7 15

208-230/60/1 187/253 31.0 19.9 109.0 43.6 7.0 26.9 31.9 50

208-230/60/3 187/253 21.2 13.6 83.1 49.9 7.0 20.6 24.0 35

460/60/3 414/506 9.5 6.1 41.0 24.6 6.9 13.0 14.5 20

208-230/60/1 187/253 41.2 26.4 134.0 53.6 7.0 33.4 40.0 60

208-230/60/3 187/253 24.9 16.0 110.0 66.0 7.0 23.0 27.0 40

460/60/3 414/506 12.1 7.8 52.0 31.2 6.9 14.7 16.7 20

208-230/60/1 187/253 44.2 28.3 178.0 71.2 7.0 35.3 42.4 70

208-230/60/3 187/253 30.0 19.2 136.0 81.6 7.0 26.2 31.0 50

460/60/3 414/506 13.6 8.7 66.1 39.7 6.9 15.6 17.8 25

208-230/60/1 187/253 18.2 11.7 58.3 23.3 4.0 15.7 18.6 30

265/60/1 238/292 14.2 9.1 54.0 n/a 4.1 13.2 15.5 20

208-230/60/3 187/253 10.1 6.5 55.4 33.2 4.0 10.5 12.1 15

460/60/3 414/506 5.4 3.5 28.0 16.8 4.1 7.6 8.4 10/15

208-230/60/1 187/253 23.8 15.3 83.0 33.2 4.0 19.3 23.1 35

265/60/1 238/292 20.3 13.0 72.0 n/a 4.1 17.1 20.4 30

208-230/60/3 187/253 18.1 11.6 73.0 43.8 4.0 15.6 18.5 30

460/60/3 414/506 8.9 5.7 38.0 22.8 4.1 9.8 11.2 15

208-230/60/1 187/253 23.8 15.3 83.0 33.2 7.0 22.3 26.1 40

265/60/1 238/292 20.3 13.0 72.0 n/a 7.0 20.0 23.3 35

208-230/60/3 187/253 18.1 11.6 73.0 43.8 7.0 18.6 21.5 30

460/60/3 414/506 8.9 5.7 38.0 22.8 6.9 12.6 14.0 15

208-230/60/1 187/253 33.0 21.1 104.0 41.6 4.0 25.1 30.4 50

208-230/60/3 187/253 21.9 14.0 83.1 49.9 4.0 18.0 21.5 35

460/60/3 414/506 10.0 6.4 41.0 24.6 4.1 10.5 12.1 15

208-230/60/1 187/253 33.0 21.1 104.0 41.6 7.0 28.1 33.4 50

208-230/60/3 187/253 21.9 14.0 83.1 49.9 7.0 21.0 24.5 35

460/60/3 414/506 10.0 6.4 41.0 24.6 6.9 13.3 14.9 20

208-230/60/1 187/253 42.3 27.1 152.9 61.2 7.0 34.1 40.9 60

208-230/60/3 187/253 25.8 16.5 110.0 66.0 7.0 23.5 27.6 40

460/60/3 414/506 11.3 7.2 52.0 31.2 6.9 14.1 15.9 20

208-230/60/1 187/253 46.3 29.7 179.2 71.7 7.0 36.7 44.1 70

208-230/60/3 187/253 27.4 17.6 136.0 81.6 7.0 24.6 29.0 45

460/60/3 414/506 13.2 8.5 66.1 39.7 6.9 15.4 17.5 25

Voltage

Min/Max

MCC RLA LRA LRA**

Compressor

Blower

Motor

FLA

Total

Unit

FLA

Min

Circ

Amp

Max Fuse/

HACR

Breaker

5/21/13

CAUTION: When installing a unit with a variable speed ECM blower motor in 460/60/3 voltage, a neutral wire is required to

allow proper unit operation.

20

Page 21

ENVISION2 COMPACT INSTALLATION MANUAL

Blower Performance Data

Standard PSC Motor

Blower

Blower

Model

009

012

015

018

024

030

036

042

048

060

070

Spd

H

MH

ML* 395370360340330310290280270250240-----

L 325310300280270250240230220210200-----

H

MH* 440410400380370350330310300280270-----

ML 395370360340330310290280270250240-----

L 325310300280270250240230220210200----H

M 735730725715705700690675660630600485----

L

H

M

L 620615610605600590580565550520490----H

M

L 845830815795775750725702.5680650625505---H

M

L 910 905 900 895 885 875 865 850 835 810 780 710 560 - - H

M

L 1130 1115 1100 1090 1075 1035 995 965 930 895 860 795 730 - - H

M

L 1220 1215 1210 1295 1200 1180 1160 1130 1100 1060 1020 930 ---H

M

L 1220 1215 1210 1295 1200 1180 1160 1130 1100 1060 1020 930 ---H

M

L 2075 2050 2020 1995 1965 1940 1915 1885 1850 1820 1785 1720 1610 1505 1335 1175

H

M 2265 2235 2205 2175 2145 2110 2070 2035 2000 1960 1915 1825 1730 1605 1440 1260

L 2075 2050 2020 1995 1965 1940 1915 1885 1850 1820 1785 1720 1610 1505 1335 1175

Motor

Size

HP

6 x 8 1/10

6 x 8 1/10

9 x 7 1/6

9 x 7 1/6

9 x 7 1/5

9 x 7 1/3

10 x 10 1/2

10 x 10 1/2

10 x 10 1/2

11 x 10 1

11 x 10 1

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

480450440420410380360340330310300-----

440410400380370350330310300280270-----

480450440420410380360340330310300-----

845835825815800790775755735710680565----

620615610605600590580565550520490----845835825815800790775755735710680565---735730725715705700690675660630600485----

1085 1055 1030 1005 980 950 925 895 870 830 795 735 555 - - -

915 895 875 855 835 815 795 765 735 705 675 590 520 - - -

1290 1270 1245 1220 1190 1160 1125 1090 1055 1020 985 880 760 - - 1100 1090 1075 1060 1045 1020 995 970 940 910 875 785 625 - - -

1665 1640 1610 1580 1550 1515 1480 1450 1415 1315 1215 1090 980 - - 1465 1445 1425 1400 1375 1350 1325 1260 1190 1140 1090 990 890 - - -

2010 1975 1940 1905 1870 1825 1780 1735 1690 1640 1590 1470 1210 - - 1670 1650 1630 1610 1590 1560 1530 1495 1460 1425 1390 1190 1080 - - -

2010 1975 1940 1905 1870 1825 1780 1735 1690 1640 1590 1470 1210 - - 1670 1650 1630 1610 1590 1560 1530 1495 1460 1425 1390 1190 1080 - - -

2430 2400 2365 2330 2290 2255 2215 2180 2140 2095 2045 1945 1835 1715 1510 1330

2265 2235 2205 2175 2145 2110 2070 2035 2000 1960 1915 1825 1730 1605 1440 1260

2430 2400 2365 2330 2290 2255 2215 2180 2140 2095 2045 1945 1835 1715 1510 1330

Optional High Static PSC Motor

Blower

Blower

Model

Factory settings are in Bold

Air fl ow values are with dry coil and 1 in. MERV 4.

For wet coil performance fi rst calculate the face velocity of the air coil (Face Velocity [fpm] = Airfl ow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, 400 fpm by 0.12in. wg. and 500

fpm by 0.16 in. wg.

* Denotes setting for 265 V operation.

024

030

036

042

048

Spd

H

M

L 910 905 900 895 885 875 865 850 835 810 780 710 560 - - H

M

L 880 880 880 880 875 870 860 840 820 800 775 730 480 - - H

M

L 1230 1230 1225 1215 1200 1165 1130 1095 1060 1035 1005 935 795 675 - H

M

L 1860 1835 1805 1780 1750 1715 1675 1635 1590 1540 1490 1260 1115 980 - H

M

L 1860 1835 1805 1780 1750 1715 1675 1635 1590 1540 1490 1260 1115 980 - -

Motor

Size

HP

9 x 7 1/3

9 x 7 1/2

10 x 10 1/2

10 x 10 3/4

10 x 10 3/4

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

1290 1270 1245 1220 1190 1160 1125 1090 1055 1020 985 880 760 - - -

1100 1090 1075 1060 1045 1020 995 970 940 910 875 785 625 - - -

1365 1340 1325 1305 1280 1250 1215 1180 1140 1100 1055 960 850 - - -

1040 1040 1035 1030 1020 1005 990 970 945 915 885 810 735 - - -

1930 1905 1875 1840 1805 1765 1725 1680 1635 1530 1425 1270 1150 1025 - -

1635 1620 1600 1580 1555 1530 1505 1465 1425 1335 1240 1135 1035 775 - -

2115 2075 2035 1980 1920 1900 1880 1840 1795 1730 1660 1390 1225 1070 - -

2005 1980 1950 1910 1865 1815 1765 1725 1685 1585 1485 1315 1140 1025 - -

2115 2075 2035 1980 1920 1900 1880 1840 1795 1730 1660 1390 1225 1070 - -

2005 1980 1950 1910 1865 1815 1765 1725 1685 1585 1485 1315 1140 1025 - -

Airfl ow (cfm) at External Static Pressure (in. wg)

Airfl ow (cfm) at External Static Pressure (in. wg)

3/16/12

3/16/12

Setting Blower Speed - PSC

CAUTION: Disconnect all power before

performing this operation.

21

E

R

I

W

D

E

E

P

S

R

E

W

O

L

B

HIGH

PSC BLOWER MOTOR BODY

LOWMEDIUM

Page 22

ENVISION2 COMPACT INSTALLATION MANUAL

Blower Performance Data cont.

5-Speed ECM - Single Speed

Motor

Motor

T’Stat

Blower

Model

Factory settings are in Bold

Air fl ow values are with dry coil and standard 1 in. fi lter

Spd

Tap

Cnct.

High 5

Med High 4 W 809 787 765 754 743 725 707 688 669 654 639 606 536 - - -

Med 3 727 715 703 682 661 638 616 601 587 561 536 485----

015

Med Low 2 Y1 699 675 652 631 611 594 577 551 525 490 455 -----

Low 1 G 656 604 552 530 508 493 479 436 394 350 - -----

High 5

Med High 4 W 809 787 765 754 743 725 707 688 669 654 639 606 536 - - -

018

Med 3 727 715 703 682 661 638 616 601 587 561 536 485----

Med Low 2 Y1 699 675 652 631 611 594 577 551 525 490 455 -----

Low 1 G 656 604 552 530 508 493 479 436 394 350 - -----

High 5 W

Med High 4 Y1 935 915 895 880 875 855 840 825 815 800 785 755 720 580 - -

024

Med 3 865 855 845 825 810 795 780 765 750 735 720 675 610 570 - -

Med Low 2 G 810 790 770 755 740 725 710 695 680 660 640 560 530 - - -

Low 1 695 645 595 575 550 520 495 455 420 400 - -----

High 5

Med High 4 W 1146 1134 1122 1111 1099 1085 1071 1062 1052 1042 1031 966 ----

030

Med 3 Y1 102310121001985969959949937925913901-----

Med Low 2 978 962 946 934 922 907 891 882 872 858 843 -----

Low 1 G 795777759748737718698686673650626-----

High 5 W

Med High 4 Y1 1413 1388 1363 1342 1321 1303 1285 1263 1240 1226 1212 1173 1016 946 - -

036

Med 3 1355 1325 1294 1276 1258 1235 1212 1188 1164 1144 1123 982 909 883 - -

Med Low 2 1336 1299 1261 1242 1222 1202 1181 1157 1132 1111 1090 937 874 830 - -

Low 1 G 1243 1182 1121 1061 1000 964 928 856 784 744 703 647 592 - - -

High 5

Med High 4 W 1799 1783 1767 1744 1720 1693 1666 1649 1631 1617 1603 1560 1530 1492 - -

042

Med 3 1694 1680 1666 1642 1617 1592 1567 1552 1537 1519 1500 1453 1421 1372 - -

Med Low 2 Y1 1575 1560 1540 1520 1502 1487 1471 1448 1424 1409 1393 1351 1308 1266 - -

Low 1 G 1454 1406 1358 1333 1308 1285 1261 1239 1217 1198 1179 1072 1002 988 - -

High 5

Med High 4 W 1799 1783 1767 1744 1720 1693 1666 1649 1631 1617 1603 1560 1530 1492 - -

048

Med 3 Y1 1694 1680 1666 1642 1617 1592 1567 1552 1537 1519 1500 1453 1421 1372 - -

Med Low 2 1575 1560 1540 1520 1502 1487 1471 1448 1424 1409 1393 1351 1308 1266 - -

Low 1 G 1454 1406 1358 1333 1308 1285 1261 1239 1217 1198 1179 1072 1002 988 - -

High 5 W

Med High 4 Y1 2081 2065 2048 2032 2015 1998 1980 1963 1946 1928 1910 1880 1849 1806 1767 1728

060

Med 3 1951 1931 1910 1889 1868 1850 1831 1812 1793 1774 1755 1722 1688 1654 1612 1562

Med Low 2 1812 1790 1767 1748 1728 1708 1688 1671 1654 1640 1626 1584 1547 1510 1472 1417

Low 1 G 1668 1651 1633 1612 1591 1566 1540 1525 1510 1491 1472 1433 1400 1351 1299 1208

High 5 W

Med High 4 Y1 2271 2248 2225 2205 2184 2166 2147 2129 2110 2094 2078 2039 2011 1977 1930 1846

070

Med 3 2133 2115 2096 2072 2047 2030 2013 1996 1979 1965 1950 1909 1873 1837 1793 1748

Med Low 2 2008 1985 1962 1939 1915 1898 1880 1862 1843 1828 1812 1774 1742 1703 1669 1635

Low 1 G 1806 1784 1761 1742 1722 1696 1669 1656 1642 1625 1607 1564 1527 1490 1443 1404

Motor

Size

HP

9 x 7 1/2

9 x 7 1/2

9 x 7 1/2

9 x 7 1/2

11 x 10 1/2

11 x 10 1

11 x 10 1

11 x 10 1

11 x 10 1

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

916 898 881 866 851 679 813 804 795 774 754

916 898 881 866 851 679 813 804 795 774 754 731 695 643 - -

1015 1003 990 975 955 945 935 920 905 890 880 850 825 745 - -

1407 1381 1354 1327 1300 1267 1233 1201 1168 1131 1094 1009 ----

1530 1503 1476 1453 1429 1413 1397 1376 1355 1342 1329 1276 1231 1173 - -

1934 1910 1886 1871 1855 1827 1799 1780 1760 1747 1734 1700 1659 1617 - -

1934 1910 1886 1871 1855 1827 1799 1780 1760 1747 1734 1700 1659 1617 - -

2230 2212 2193 2173 2152 2139 2125 2109 2092 2076 2059 2026 1992 1951 1892 1806

2472 2454 2435 2414 2393 2371 2349 2328 2306 2289 2271 2236 2189 2121 2033 1936

Airfl ow (cfm) at External Static Pressure (in. wg)

731 695 643 - -

11/20/12

About 5-Speed ECM Constant

Torque Motors

The 5-speed ECM is a ‘Constant Torque’ ECM motor and delivers

air fl ow similar to a PSC but operates as effi ciently as a variable

speed ECM motor. Because it is an ECM motor, the 5-speed

ECM can ramp slowly up or down like the variable speed ECM

motor. There are 5 possible speed taps available on the 5-speed

ECM motor with #1 being the lowest airfl ow and #5 being the

highest airfl ow. These speed selections are preset at the time of

manufacture and are easily changed in the fi eld if necessary.

If more than one tap are energized at the same time, built in

logic gives precedence to the highest tap number and allows

air fl ow to change with G, Y1, Y2 and W signals. Each of those

5 speeds has a specifi c ‘Torque’ value programmed into the

motor for each speed selection. As static pressure increases,

airfl ow decreases resulting in less torque on the rotor. The

motor responds only to changes in torque and adjusts its

speed accordingly.

The 5-speed ECM motor is powered by line voltage but the

motor speed is energized by 24VAC.

5-Speed ECM Benefi ts:

- High effi ciency

- Soft start

- 5 speeds with up to 4 speeds on-line

- Built in logic allows air fl ow to change with G, Y1, Y2 and

W signals

- Super effi cient low airfl ow continuous blower setting (G)

22

Page 23

ENVISION2 COMPACT INSTALLATION MANUAL

L

5

Blower Performance Data cont.

5-Speed ECM - Dual Capacity

Motor

Motor

T’stat

Blower

Model

Speed

Med High 4

026

Med Low 2

Med High 4

038

Med Low 2 1336 1299 1261 1242 1222 1202 1181 1157 1132 1111 1090 937 874 830 - -

Med High 4 1799 1783 1767 1744 1720 1693 1666 1649 1631 1617 1603 1560 1530 1492 - -

049

Med Low 2

Med High 4

064

Med Low 2

Med High 4

072

Med Low 2

Factory speed settings are in Bold

Air fl ow values are with dry coil and standard fi lter

For wet coil performance fi rst calculate the face velocity of the air coil (Face Velocity [fpm] = Airfl ow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, 400 fpm by 0.12in. wg., and 500 fpm by 0.16 in. wg.

Highest setting is for auxiliary heat (W) and lowest setting is for constant blower (G). The “Y1” and “Y2” settings must be between the “G” and “W” settings.

Tap

High 5

Med 3 917 906 895 884 872 854 836 824 812 792 772 754 719 - - -

Low 1

High 5

Med 3

Low 1

High 5

Med 3

Low 1

High 5

Med 3 1951 1931 1910 1889 1868 1850 1831 1812 1793 1774 1755 1722 1688 1654 1612 1562

Low 1

High 5

Med 3 2133 2115 2096 2072 2047 2030 2013 1996 1979 1965 1950 1909 1873 1837 1793 1748

Low 1

Cnct.

W

Y2 1020 1006 991 980 968 950 932 922 911 894 876 849 812 - - -

Y1 836 824 812 794 776 765 754 735 715 703 691 653 631 - - G 735 721 707 687 666 653 640 622 603 589 574 533 - - - W

Y2 1413 1388 1363 1342 1321 1303 1285 1263 1240 1226 1212 1173 1016 946 - -

Y1 1355 1325 1294 1276 1258 1235 1212 1188 1164 1144 1123 982 909 883 - -

G 1243 1182 1121 1061 1000 964 928 856 784 744 703 647 592 - W

Y2 1694 1680 1666 1642 1617 1592 1567 1552 1537 1519 1500 1453 1421 1372 - -

Y1 1575 1560 1540 1520 1502 1487 1471 1448 1424 1409 1393 1351 1308 1266 - G 1454 1406 1358 1333 1308 1285 1261 1239 1217 1198 1179 1072 1002 988 - W

Y2 2092 2073 2054 2035 2015 1995 1975 1958 1940 1922 1904 1880 1843 1806 1767 1728

Y1 1812 1796 1780 1761 1741 1718 1695 1682 1668 1651 1633 1591 1555 1518 1480 1433

G 1682 1661 1640 1616 1591 1573 1555 1533 1510 1495 1480 1441 1400 1351 1316 1263

W

Y2 2271 2248 2225 2205 2184 2166 2147 2129 2110 2094 2078 2039 2011 1977 1930 1846

Y1 2008 1985 1962 1939 1915 1898 1880 1862 1843 1828 1812 1774 1742 1703 1669 1635

G 1806 1784 1761 1742 1722 1696 1669 1656 1642 1625 1607 1564 1527 1490 1443 1404

Motor

Size

HP

9 x 7 1/2

11 x 10 1/2

11 x 10 1

11 x 10 1

11 x 10 1

0 0.05 0.10 0.15 0.20 0.25 0.30 0. 35 0. 40 0.45 0.50 0.60 0.70 0.80 0. 90 1.00

1120 1109 1097 1082 1066 1055 1044 1028 1011 1001 991 932 839 - - -

1530 1503 1476 1453 1429 1413 1397 1376 1355 1342 1329 1276 1231 1173 - -

1934 1910 1886 1871 1855 1827 1799 1780 1760 1747 1734 1700 1659 1617 - -

2245 2360 2214 2315 2173 2290 2136 2275 2103 2250 2070 2032 1998 1957 1910 1825

2472 2360 2435 2315 2393 2290 2349 2275 2306 2250 2271 2236 2189 2121 2033 1936

Airfl ow (cfm) at External Static Pressure (in. wg)

3/16/12

Setting Blower Speed - 5-Speed ECM

5-speed ECM blower motors have fi ve (5) speeds of which

three (3) are selectable on single speed and four (4) are

selectable on dual capacity.

CAUTION: Disconnect all power before

performing this operation.

-Speed ECM Motor Connections - Single Speed 5-Speed ECM Motor Connections - Dual Capacity

High Voltage

C - Black

L - Orange

G - Green

G - Blue

Y1 - Red

Connections

3/16 in.

C

GN

L

12

345

Low Voltage

Connections 1/4 in.

N - Brown

AUX - Gray

C - Black

L - Orange

G - Green

G - Blue

Y1 - Red

High Voltage

Connections

3/16 in.

C

GN

345

12

Low Voltage

Connections 1/4 in.

N - Brown

AUX - Gray

Y2 - Tan

23

Page 24

ENVISION2 COMPACT INSTALLATION MANUAL

Blower Performance Data cont.

Variable Speed ECM Motor

Single Speed

Max

Model

015

018

024

030

036

036

w/1hp*

042

042

w/1hp*

048

048

w/1hp*

060

070

Blower

ESP

0.50 9 x 7 1/2

0.50 9 x 7 1/2

0.50 9 x 7 1/2

0.50 9 x 7 1/2

0.50 11 x 10 1/2

0.75 11 x 10 1

0.50 11 x 10 1/2

0.75 11 x 10 1

0.50 11 x 10 1/2

0.75 11 x 10 1

0.75 11 x 10 1

0.75 11 x 10 1

Dual Capacity

Max

Model

026

038

038

w/1hp*

049

049

w/1hp*

064

072

Factory settings are at recommended L-M-H DIP switch locations

M-H settings MUST be located within boldface cfm range

Lowest and Highest DIP switch settings are assumed to be L and H respectively

cfm is controlled within ±5% up to the maximum ESP

Max ESP includes allowance for wet coil and 1 in. MERV 4

Blower

ESP

0.50 9 x 7 1/2

0.50 11 x 10 1/2

0.75 11 x 10 1

0.50 11 x 10 1/2

0.75 11 x 10 1

0.75 11 x 10 1

0.75 11 x 10 1

Size

Size

Motor

hp

Motor

hp

123456789101112

300 400

300 400

400 500

400 500 600

650 750 850 1000

800 1000

650 800 900 1050

800 900 1000

650 800 900 1050 1150

800 900 1000 1200

800 950 1100 1300

800 950 1100 1300

123456789101112

400 500 600

650 750 850 1000

800 1000

L

650 800 900 1050 1150

800 900 1000 1200

L

800 950 1100 1300

800 950 1100 1300

500 600 700

L

500 600 700 800

L

L

L

L

1100 1300 1500 1600

L

L

L

L

L

MH

L

L

L

L

L

1100 1300 1500 1600

MH

L