Page 1

Water Source/Geothermal Heat Pump

7 to 25 Tons

Installation Information

Water Piping Connections

Electrical Connections

Startup Procedures

Preventive Maintenance

Envision 7-25 Tons Installation Manual

IM1021ANA 01/15

Page 2

Table of Contents

Model Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vertical Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Horizontal Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing Horizontal Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Installating Vertical Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

System Cleaning and Flushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Blower Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-25

ENVISION 7-25 TONS INSTALLATION MANUAL

Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

Optional FX10 Microprocessor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-37

Blower Drive Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Unit Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operating Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pressure Drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Startup/Troubleshooting Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Page 3

ENVISION 7-25 TONS INSTALLATION MANUAL

COMMERCIAL

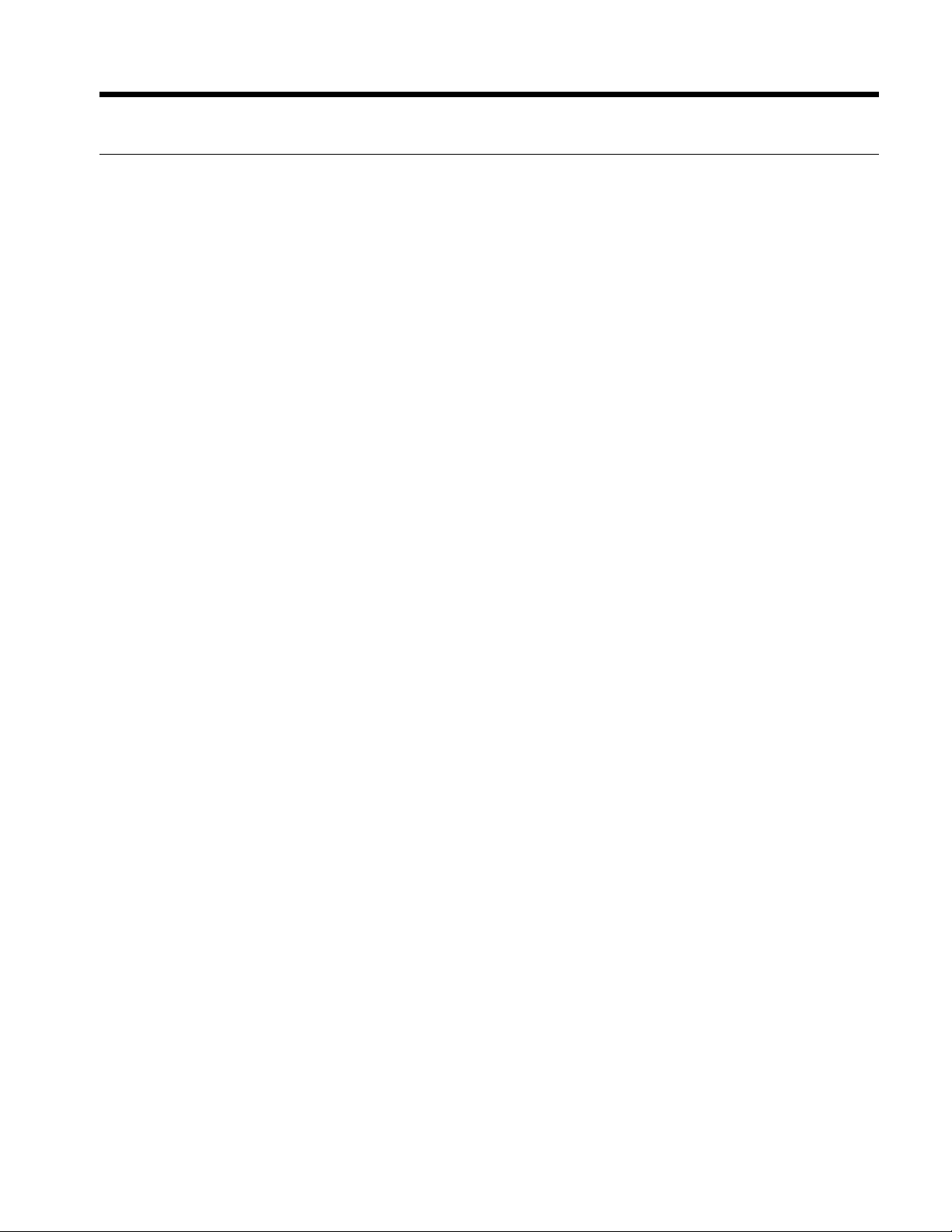

Model Nomenclature

1-2 3-5 6 7 8

NL

120 T L 3 0 A C A N12N14415116SS

Model Type

NL – Envision Series

(Low Temp)

NX – Envision Series

(Extended Range)

Unit Capacity (MBTUH)

080, 095, 120, 160

180, 240, 300

Discharge Configuration

T – Top Upflow (Vertical)

E – End Discharge (Horizontal)

S – Discharge Side (Horizontal)

Return Air Configuration

L – Left

R – Right

Voltage

3 – 208-230/60/3

4 – 460/60/3

5 – 575/60/3

Future Option

0 – Future

Blower Options

A – Standard Static, Standard Motor

B – Low Static, Standard Motor

C – High Static, Standard Motor

D – Standard Static, Large Motor

E – High Static, Large Motor

Water Coil Option

C – Copper

N – CuproNickel

1

2

2,3

3

91011 13

17-18*19

Vintage

* - Factory Use Only

Non-Standard Options

SS – Standard

QP – 2" MERV 13 Filter

SF – Stainless Steel Drain Pan

SG – 2" MERV 13 Filter, Stainless Steel Drain Pan

Air Coil/Insulation Option

3 – Uncoated

4 – AlumiSeal

Control Option

4 – FX10 Standard without Communication

5 – FX10 with Open N2 Communication

6 – FX10 with Lonworks Communication

7 – FX10 with BacNet Communication

8 – FX10 Standard with User Interface

9 – FX10 with Open N2 & User Interface

0 – FX10 with Lonworks & User Interface

3 – FX10 with BacNet & User Interface

Water Control Option

N – None

V – Two-Way Valve

Hot Gas Bypass/Reheat Option

N – None

G – Hot Gas Bypass

R – Hot Gas Reheat

B – Hot Gas Bypass w/Hot Gas Reheat

Sound Kit Option

A – None

B – Sound Kit

TM

4

4

Notes:

1 – Not available on vertical NL/NX095, 180, horizontal NL/NX080

2 – Not available on vertical NL/NX080, 160

3 – Not available on horizontal NL/NX120, vertical NL/NX300

4 – Not available on vertical NL/NX160-300. Stainless steel is standard on vertical NL/NX160-300

4

Rev.: 14 November 2014D

Page 4

ENVISION 7-25 TONS INSTALLATION MANUAL

General Installation Information

Safety Considerations

WARNING: Before performing service or maintenance operations on a system, turn off main power switches to

the indoor unit. If applicable, turn off the accessory heater power switch. Electrical shock could cause personal

injury.

Installing and servicing heating and air conditioning equipment can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel should install, repair or service heating and air conditioning

equipment. Untrained personnel can perform the basic maintenance functions of cleaning coils and cleaning and

replacing filters. All other operations should be performed by trained service personnel. When working on heating and

air conditioning equipment, observe precautions in the literature, tags and labels attached to the unit and other safety

precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use a quenching cloth for brazing operations and have a fire

extinguisher available.

Moving and Storage

Move units in the normal “up” orientation. Horizontal units may be moved and stored per the information on the packaging.

Do not stack more than three units in total height. Vertical units may be stored one upon another to a maximum height

of two units. Do not attempt to move units while stacked. When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and cartons have been received. Examine units for shipping damage,

removing the units from the packaging if necessary. Units in question should also be internally inspected. If any damage is

noted, the carrier should make the proper notation on the delivery receipt, acknowledging the damage.

Unit Location

Locate the unit in an indoor area that allows for easy removal of the filter and access panels. Location should have enough

space for service personnel to perform maintenance or repair. Provide sufficient room to make water, electrical and duct

connection(s). If the unit is located in a confined space, such as a closet, provisions must be made for return air to freely

enter the space by means of a louvered door, etc. Any access panel screws that would be difficult to remove after the

unit is installed should be removed prior to setting the unit. On horizontal units, allow adequate room below the unit for

a condensate drain trap and do not locate the unit above supply piping. Care should be taken when units are located

in unconditioned spaces to prevent damage from frozen water lines and excessive heat that could damage electrical

components.

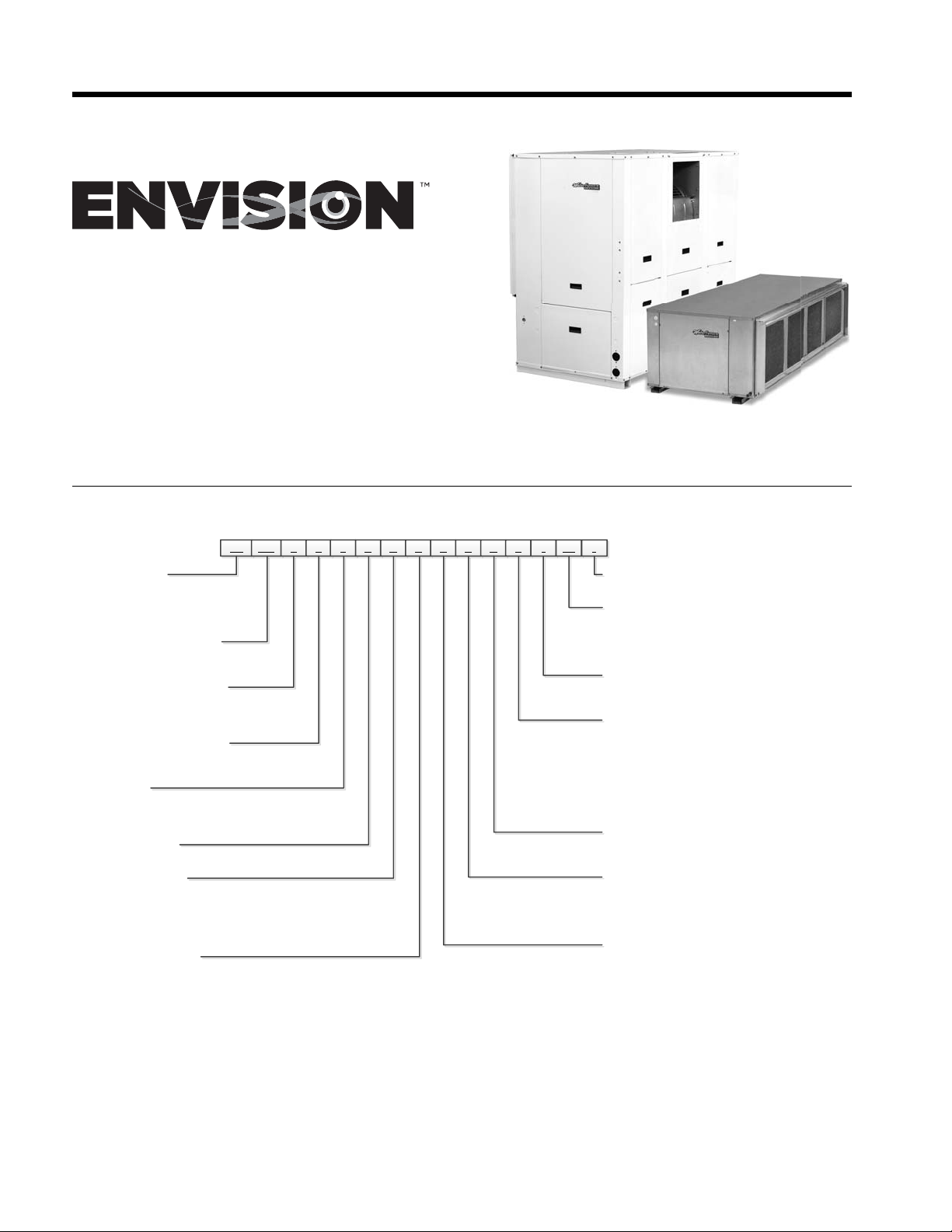

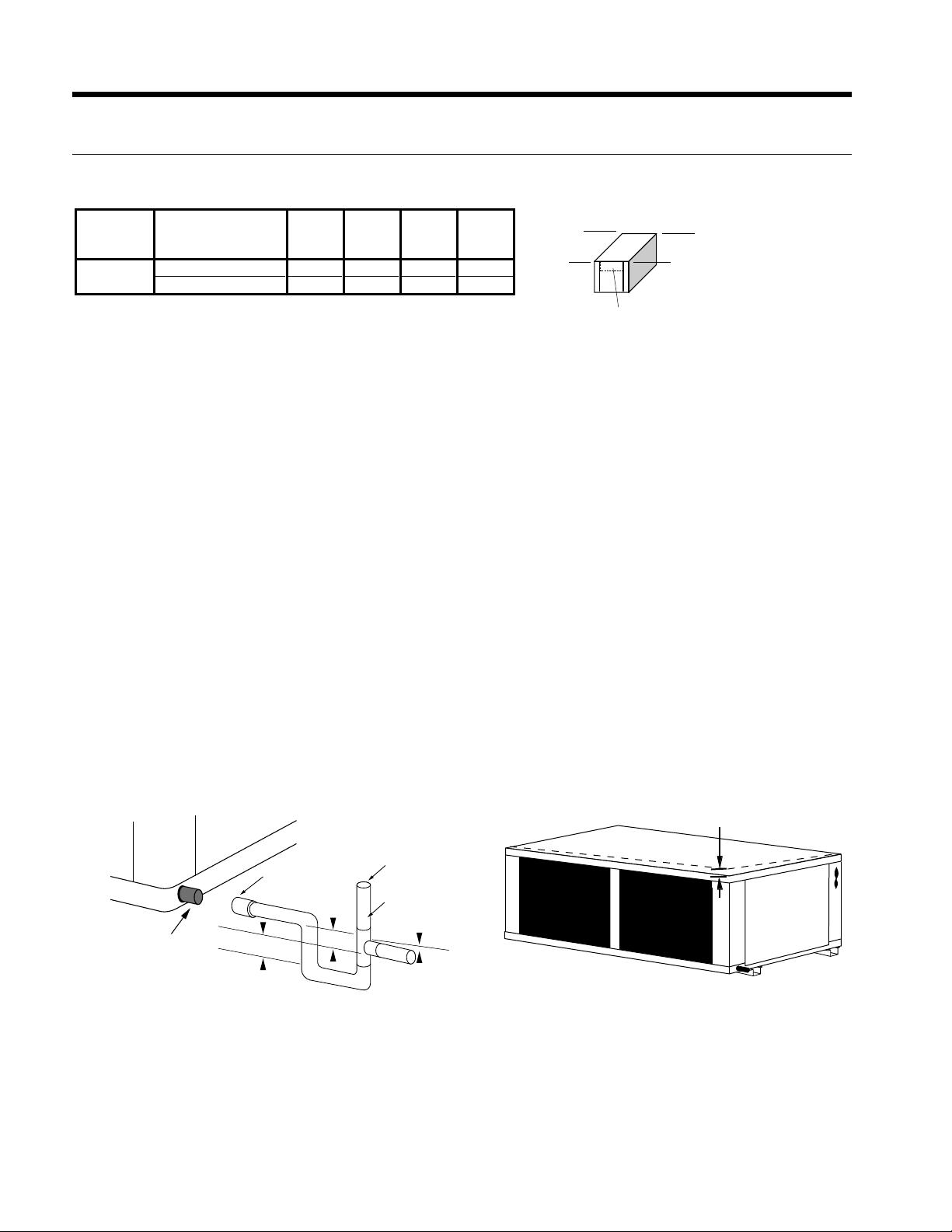

Installing Vertical Units

Prior to setting the unit in place, remove and discard the compressor hold down

shipping bolt located at the front of the compressor mounting bracket.

Vertical units are available in left or right air return configurations. Top flow vertical

units should be mounted level on a vibration absorbing pad slightly larger than the

base to provide isolation between the unit and the floor. It is not necessary to anchor

the unit to the floor (see right).

Figure 1: Vertical Unit Mounting

(NXV/NLV 080-300)

5

Page 5

ENVISION 7-25 TONS INSTALLATION MANUAL

N

8

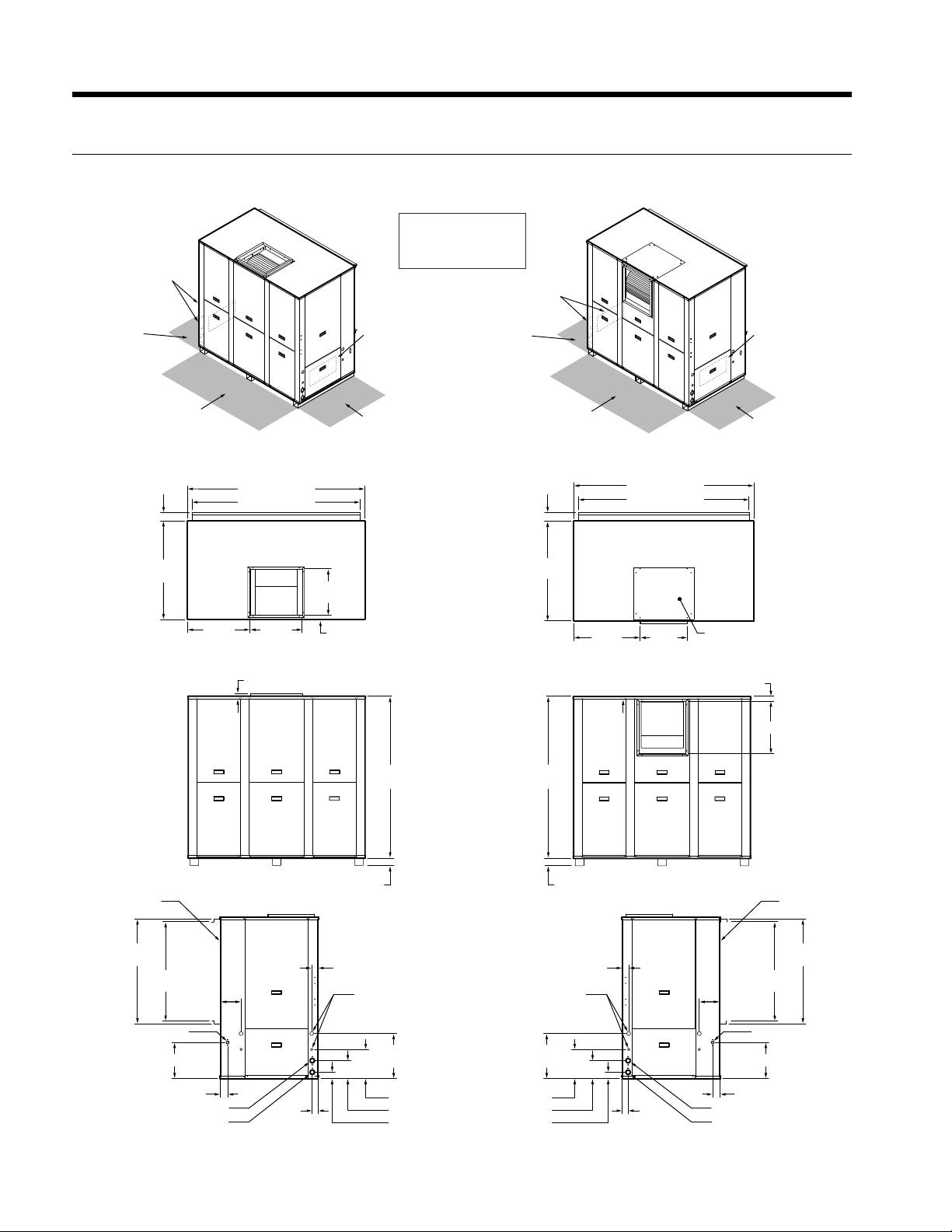

Vertical Dimensions

7-10 Tons

CONTROL BOX

AND WATER

LEFT RETURN

2’ PRIMARY

SERVICE ACCESS

FOR LEFT RETURN

2’ SECONDARY

SERVICE ACCESS

TOP DISCHARGE

Legend

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

CONTROL BOX AND WATER

LEFT RETURN

CP CP

AP

CMP

2.9 in

[7.4 cm]

61.3 in [155.8 cm]

58.1 in [147.6 cm]

CONTROL BOX

RIGHT RETURN

2’ PRIMARY

SERVICE ACCESS

FOR RIGHT RETURN

2’ PRIMARY

SERVICE ACCESS

FOR LEFT RETURN

TOP VIEW

34.1 in

[86.6 cm]

16.1 in

[40.9 cm]

Left or Right Return

AP

CMP

2’ SECONDARY

SERVICE ACCESS

2.9 in

[7.4 cm]

34.1 in

[86.6 cm]

SIDE DISCHARGE

61.3 in [155.7 cm]

58.1 in [147.6 cm]

CONTROL BOX

RIGHT RETURN

CPCP

2’ PRIMARY

SERVICE ACCESS

FOR RIGHT RETURN

AIR COILS

36.3 in

[92.2 cm]

34.4 in

[87.4 cm]

DRAIN CONNECTION

12.5 in [31.8 cm]

[54.9 cm]

7.2 in

[18.3 cm]

21.6 in

18.1 in

[46.0 cm]

1 in [2.5 cm]

1.42 in

[3.6 cm]

SIDE VIEW

Left or Right Return

2 in [5.1 cm]

56 in

[142.2 cm]

56 in

[142.2 cm]

LEFT RETURN RIGHT RETURN

2.2 in

[5.6 cm]

TOP OR SIDE DISCHARGE

ELECTRICAL

CONNECTIONS

15.6 in

[39.6 cm]

ELECTRICAL

CONNECTIONS

15.6 in

[39.6 cm]

22.6 in

[57.4 cm]

2 in [5.1 cm]

2.2 in

[5.6 cm]

16.1 in

[40.9 cm]

TOP PANEL

COVER

1.8 in [4.6 cm]

7.2 in

[18.3 cm]

12.5 in [31.8 cm]

18.1 in [46 cm]

AIR COILS

36.3 in

[92.2 cm]

34.4 in

[87.4 cm]

DRAIN CONNECTIO

2.6 in [6.6 cm]

WATER OUT

WATER IN

2.0 in

[5.1 cm]

10.1 in [25.7 cm]

4.0 in [10.2 cm]

2.2 in [5.6 cm]

10.1 in [25.7 cm]

4.0 in [10.2 cm]

2.2 in [5.6 cm]

6

2.0 in

[5.1 cm]

2.6 in [6.6 cm]

WATER OUT

WATER IN

REV 2/11/0

Page 6

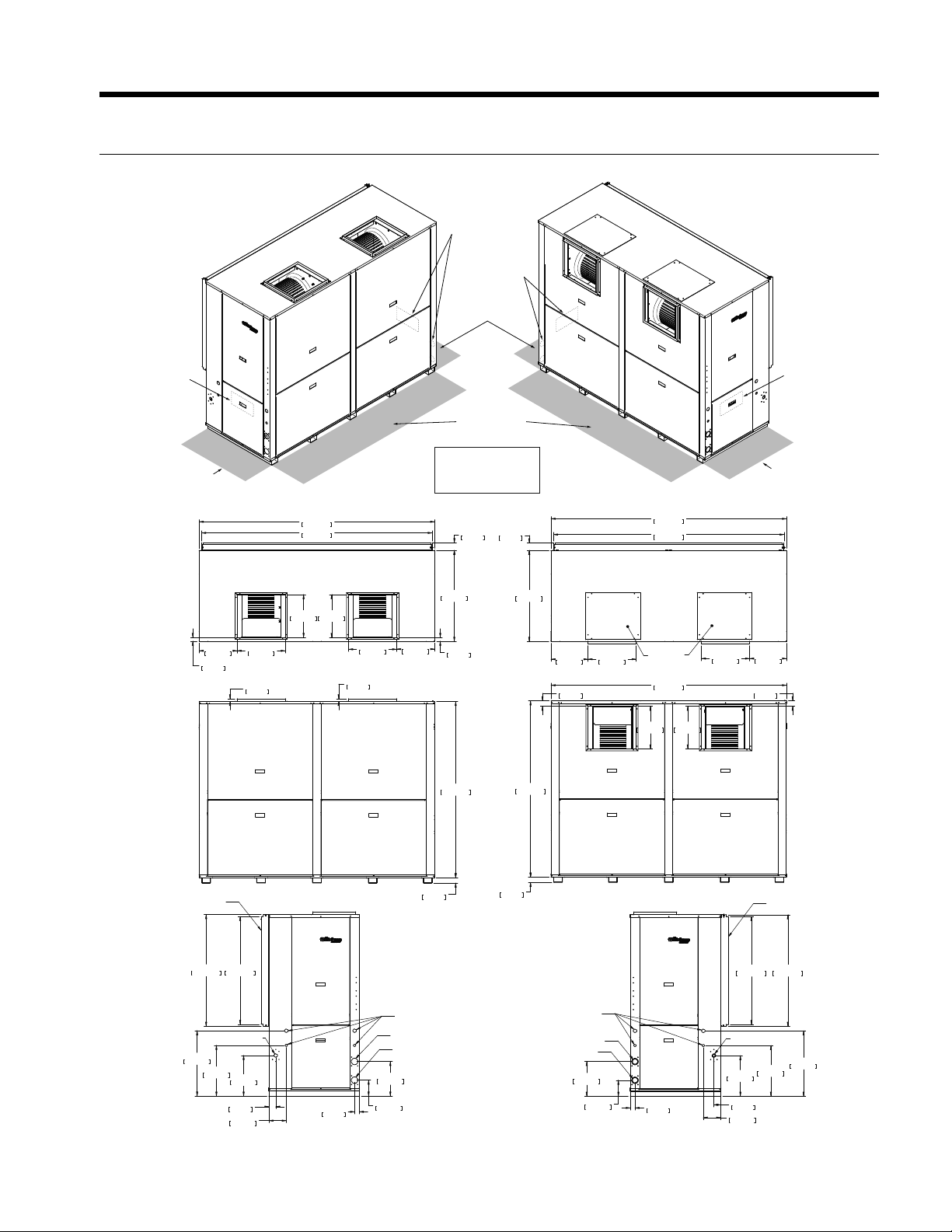

Vertical Dimensions cont.

13-25 Tons

TOP DISCHARGE

CONTROL BOX

AND WATER

RIGHT RETURN

CONTROL BOX

AND WATER

LEFT RETURN

2’ PRIMARY

SERVICE ACCESS

ENVISION 7-25 TONS INSTALLATION MANUAL

SIDE DISCHARGE

CONTROL BOX

LEFT RETURN

2’ PRIMARY

SERVICE ACCESS

CPCP

2’ SECONDARY

AP

16.0 in

40.6 cm

CMP

1.0 in

2.5 cm

18.0 in

45.7 cm

14.2 in

36.1 cm

CP CP

88.1 in

223.8 cm

86.3 in

219.1 cm

16.0 in

40.6 cm

18.0 in

14.2 in

45.7 cm

36.1 cm

1.5 in

3.7 cm

1.0 in

2.5 cm

SERVICE ACCESS

Legend

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

2.9 in

2.9 in

7.3 cm

7.3 cm

TOP VIEW

L or R Return

34.0 in

86.4 cm

1.5 in

3.7 cm

SIDE VIEW

L or R Return

66.0 in

167.5 cm

34.0 in

86.4 cm

66.0 in

167.5 cm

13.8 in

35.1 cm

2.0 in

5.1 cm

18.0 in

45.8 cm

AP

CMP

TOP PANEL

COVER

16.0 in

40.6 cm

88.1 in

223.8 cm

86.3 in

219.1 cm

88.1 in

223.8 cm

16.0 in

40.6 cm

18.0 in

45.8 cm

CONTROL BOX

RIGHT RETURN

2’ PRIMARY

SERVICE ACCESS

13.8 in

35.1 cm

2.0 in

5.1 cm

AIR COILS

41.8 in

106.2 cm

DRAIN CONNECTION

24.5 in

62.2 cm

19.0 in

48.2 cm

40.4 in

102.6 cm

15.2 in

38.7 cm

2.6 in

6.5 cm

6.5 in

16.5 cm

1.7 in

4.4 cm

2.0 in

5.1 cm

LEFT RETURN

TOP OR SIDE DISCHARGE

ELECTRICAL

CONNECTIONS

WATER OUT

WATER IN

13.0 in

33.0 cm

6.0 in

15.2 cm

2.0 in

5.1 cm

RIGHT RETURN

7

ELECTRICAL

CONNECTIONS

WATER OUT

WATER IN

13.0 in

33.0 cm

6.0 in

15.2 cm

1.7 in

4.4 cm

AIR COILS

40.4 in

41.8 in

102.6 cm

106.2 cm

DRAIN CONNECTION

19.0 in

15.2 in

48.2 cm

38.7 cm

2.6 in

6.5 cm

6.5 in

16.5 cm

24.5 in

62.2 cm

REV 8/16/07

Page 7

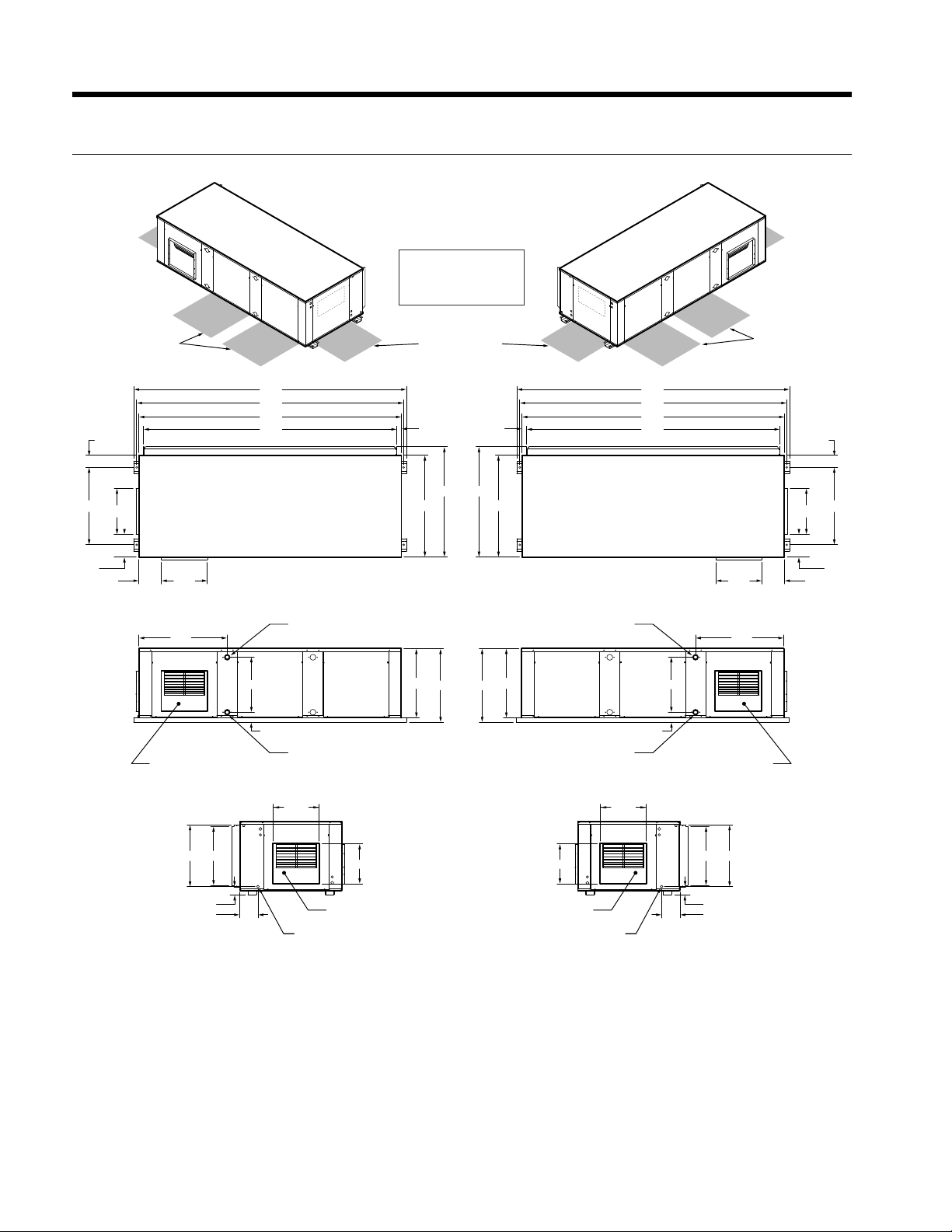

ENVISION 7-25 TONS INSTALLATION MANUAL

Horizontal Dimensions

7-10 Tons

2’ SECONDARY

SERVICE ACCESS

4.1

26.2

15.6

7.6

7.6 15.6

RIGHT RETURN

BP BP

Legend

AP = Alternate Service Panel

BP = Blower Service Panel

CP = Control Access Panel

CMP = Compressor Service Panel

CMP

2’ PRIMARY

SERVICE ACCESS

TOP VIEW

37.3

37.3

34.5

SIDE VIEW

29.929.9

CMP

92.5

90.0

89.0

85.9 1.6

WATER OUT

LEFT RETURN

34.5

CPCP

WATER OUT

92.5

90.0

89.0

85.91.6

CMP

CMP

2’ SECONDARY

SERVICE ACCESS

29.929.9

15.6

4.1

26.2

7.6

7.615.6

SIDE DISCHARGE

OPTION

21.0

20.1

2.9

6.1

18.6

3.4

WATER IN

15.62

DRAIN CONNECTION

13.5

END DISCHARGE

OPTION

23.5

24.5

END VIEW

24.5

23.5

END DISCHARGE

OPTION

DRAIN CONNECTION

13.5

WATER IN

15.62

18.6

3.4

SIDE DISCHARGE

OPTION

21.0

20.1

2.9

6.1

REV 4/28/08

8

Page 8

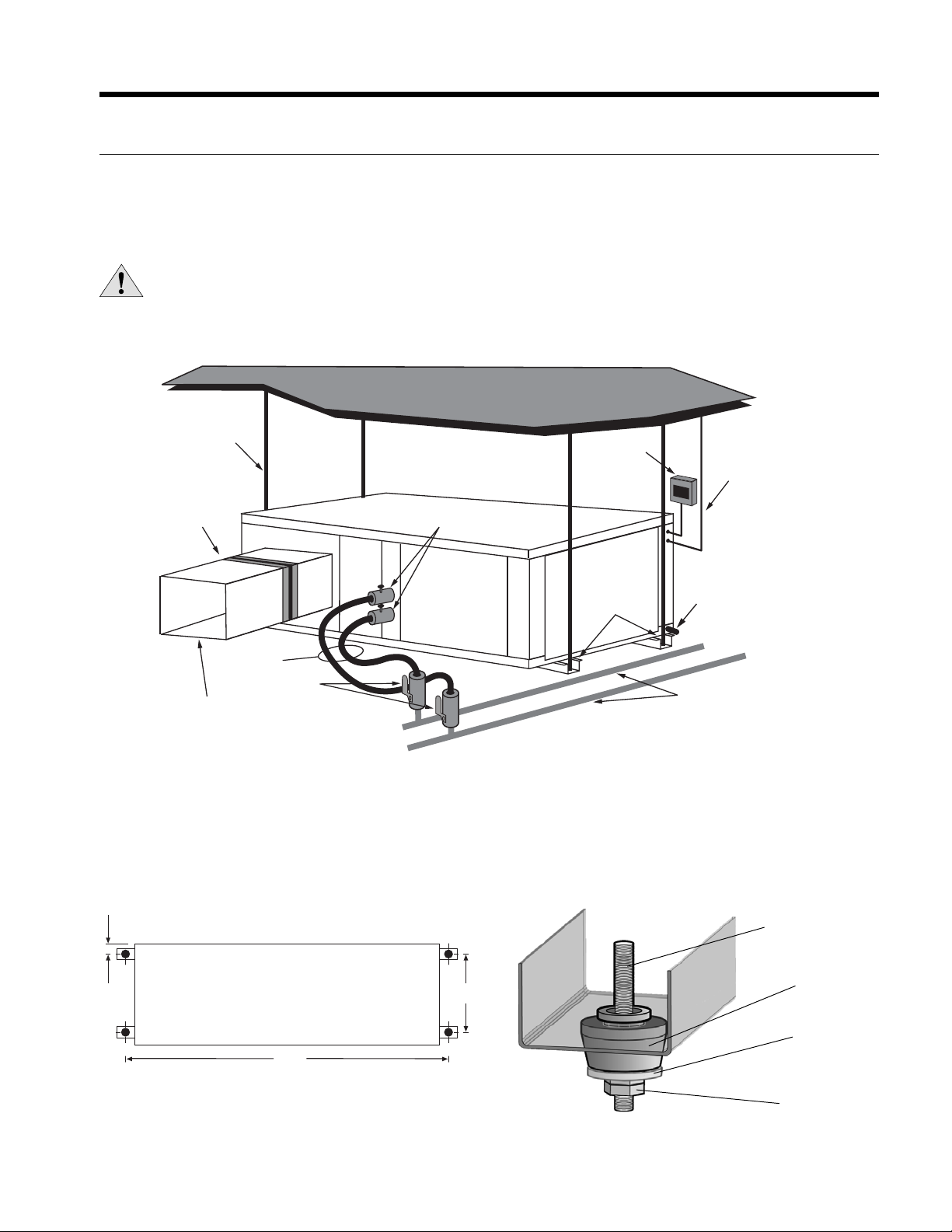

ENVISION 7-25 TONS INSTALLATION MANUAL

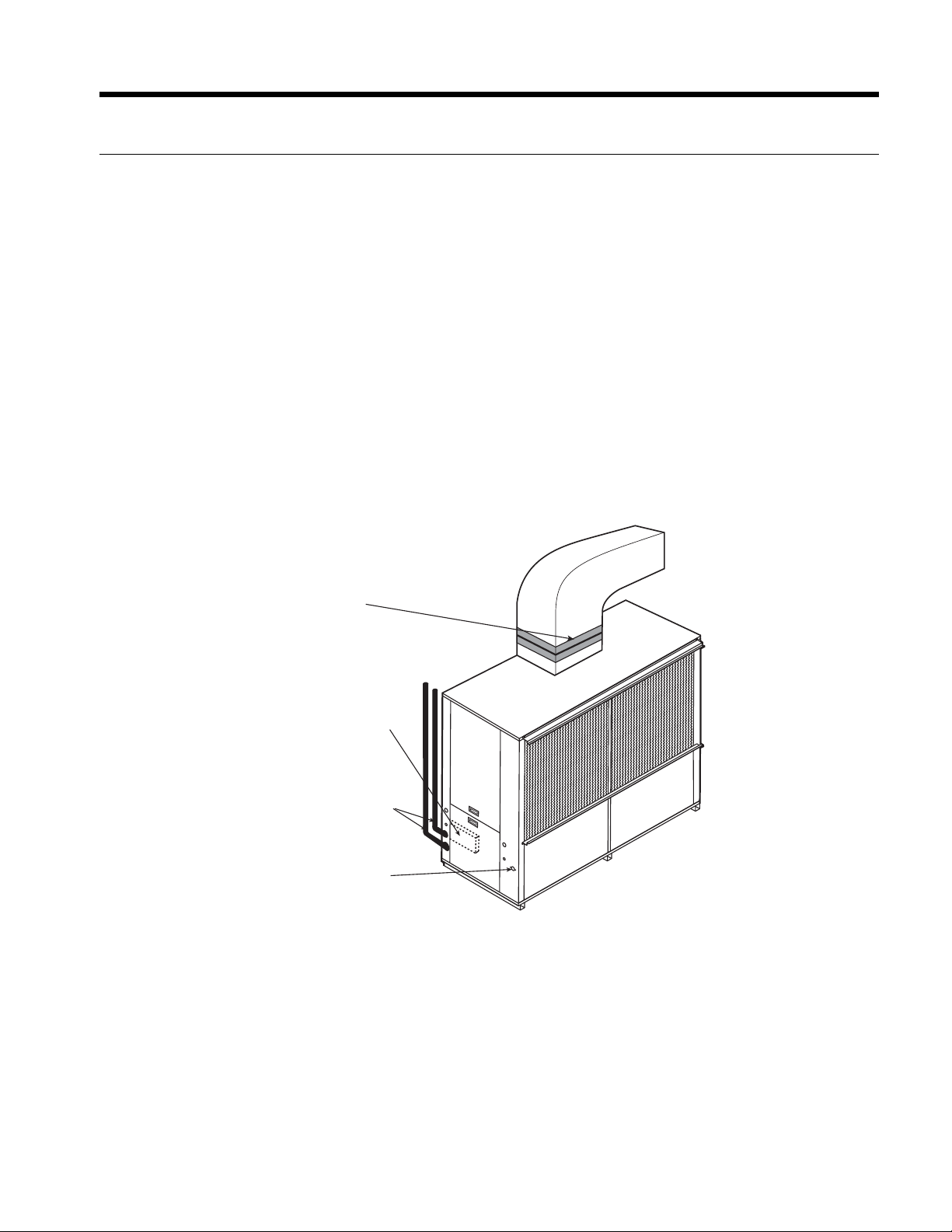

Installing Horizontal Units

Mounting Horizontal Units

Units are available with side or end discharge in left-hand or right-hand return air configurations. Horizontal units are

normally suspended from a ceiling by four 1/2 in. diameter threaded rods. The rods are usually attached to the unit corners

by the bottom panel mounting channel and the mounting grommets furnished with each unit.

CAUTION: Do not use rods smaller than 1/2 in. diameter since they may not be strong enough to support the

unit. The rods must be securely anchored to the ceiling (the units are approximately 800 lbs.).

Figure 1: Typical Horizontal Application

1/2”

Threaded Rods

(4)

Power

Disconnect

Low

Voltage

Flexible Duct

Collar

Hose Kits

Ball Valves

Insulate supply

plenum and use at

least a 90° elbow

to reduce noise

P/T Plugs

Isolation

Grommets

(Included)

Condensate

Drain

Connection

Water Loop

Layout the threaded rods per the dimensions in Figure 2. Assemble the hangers to the unit as shown in Figure 3. Securely

tighten the brackets to the unit. When attaching the hanger rods to the bracket, a double nut is recommended since

vibration could loosen a single nut. The unit should be pitched approximately 1/2 in. towards the drain in both directions, to

facilitate condensate removal.

Figure 3: Mounting HardwareFigure 2: Mounting Rod Layout

1/2 in. Threaded Rod

To p V i e w

(not included)

90.5

26.244.13

Isolator

Washer

(not included)

Hex Nuts

(not included)

9

Vibration

Page 9

ENVISION 7-25 TONS INSTALLATION MANUAL

Installing Horizontal Units cont.

Horizontal Unit Corner Weight Distribution

ABCD

Front Front Back Back

Model Return / Discharge Left Right Right Left

080 - 120

Approximate

Left / Side or End 30% 26% 22% 22%

Right / Side or End 26% 30% 22% 22%

D

A

Controls

C

B

Duct System

An air outlet collar is provided on vertical top flow units and all horizontal units to facilitate a duct connection. A flexible

connector is recommended for discharge and return air duct connections on metal duct systems. Uninsulated duct should

be insulated with a minimum of 1-inch duct insulation. Application of the unit to uninsulated ductwork in an unconditioned

space is not recommended as the unit’s performance will be adversely affected.

If the unit is connected to existing ductwork, check the duct system to ensure that it has the capacity to accommodate the

air required for the unit application. If the duct is too small, as in the replacement of heating only systems, larger ductwork

should be installed. All existing ductwork should be checked for leaks and repaired if necessary.

The duct system should be sized to handle the design airflow quietly and efficiently. To maximize sound attenuation of the

unit blower, the supply and return plenums should include an internal duct liner of fiberglass or constructed of ductboard

for the first few feet. On systems employing a sheet metal duct system, canvas connectors should be used between the unit

and the ductwork. If air noise or excessive airflow is a problem, the blower speed can be changed.

Water Piping

The proper water flow must be provided to each unit whenever the unit operates. To assure proper flow, use pressure/temperature ports to determine the flow rate. These ports should be located at the supply and return water connections on the

unit. The proper flow rate cannot be accurately set without measuring the water pressure drop through the refrigerant-towater heat exchanger.

All source water connections on commercial units are fittings that accept a male pipe thread (MPT). Insert the connectors

by hand, then tighten the fitting with a wrench to provide a leakproof joint. When connecting to an open loop (groundwater) system, thread any copper MPT fitting into the connector and tighten in the same manner as described above.

Figure 5: Unit Pitch for DrainFigure 4: Suggested Layout of Condensate

1/2'' Pitch

Vent (if needed)

3/4 in. PVC

1/8 in. per foot

3/4 in. PVC tube stub

3/4 in. PVC

Coupling

1.5 in.

1.5 in.

10

Page 10

ENVISION 7-25 TONS INSTALLATION MANUAL

Installing Vertical Units

Mounting Vertical Units

Units are available with top/side discharge, left-hand or right-hand return air configurations. Vertical units are assembled on

rails which facilitate moving and placement of the units. It is not necessary to anchor the unit to the floor.

Duct System

A supply air duct flange is provided for field installation to facilitate the secure duct connection at the job site. A flexible

connector is recommended for discharge and return air duct connections on metal duct systems to prevent vibration

transmission. It is recommended that all ductwork be insulated with a minimum of 1/2-inch coated insulation. Installation of

the units with uninsulated ductwork in an unconditioned space is not recommended, as the system’s performance will be

adversely affected.

Condensate Drain

In vertical units, the internal condensate drain assembly consists of a flexible drain tube which is attached to the drain pan

and a 3/4-inch (7-10 tons) and 1-inch (13-25 tons) female pipe thread. An external water trap is not required as the drain

tube serves as a trapping loop. The field-installed piping and unit connection must be properly installed and sealed to

prevent water leakage.

Figure 6: Typical Vertical Application

Flexible duct

Collar

Control Box

Water Supply

and Return

Connections

Condensate

Drain

A

C

C

E

S

P

S

A

N

E

L

ACCESS

PAN EL

ACCESS

PANEL

11

Page 11

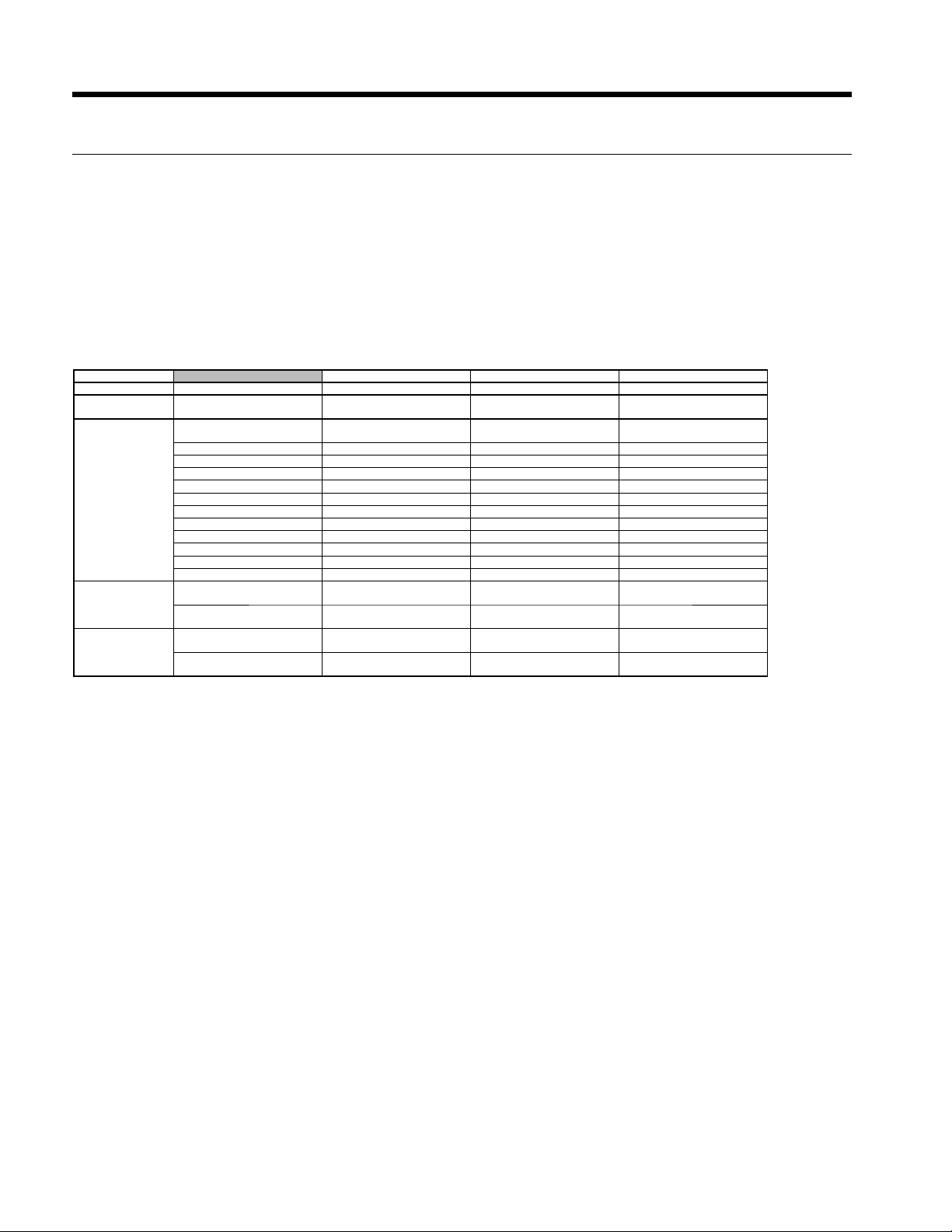

ENVISION 7-25 TONS INSTALLATION MANUAL

Water Quality

Water Quality Guidelines

In ground water situations where scaling could be heavy or where biological growth such as iron bacteria will be present,

a closed loop system is recommended. The heat exchanger coils in ground water systems may, over a period of time, lose

heat exchange capabilities due to a buildup of mineral deposits inside. These can be cleaned, but only by a qualified service

mechanic, as special solutions and pumping equipment are required. Hot water generator coils can likewise become scaled

and possibly plugged. In areas with extremely hard water, the owner should be informed that the heat exchanger may

require occasional flushing.

Units with cupronickel heat exchangers are recommended for open loop applications due to the increased resistance to

build-up and corrosion, along with reduced wear caused by acid cleaning.

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity

Scaling

Corrosion

Iron Fouling

(Biological Growth)

Erosion

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

Calcium and

Magnesium Carbonate

Hydrogen Sulfide

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron, FE

Bacterial Iron Potential

Iron Oxide

Suspended Solids

Threshold Velocity

(Fresh Water)

Less than 0.5 ppm (rotten egg

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

2

+ (Ferrous)

smell appears at 0.5 ppm)

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 mic

7 - 9 7 - 9 7 - 9

(Total Hardness)

less than 350 ppm

< 0.2 ppm < 0.2 ppm < 0.2 ppm

ron size

< 6 ft/sec < 6 ft/sec < 6 ft/sec

(Total Hardness)

less than 350 ppm

10 - 50 ppm Less than 1 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

(Total Hardness)

less than 350 ppm

2/22/12

Water Connections

All supply and return water connections are female pipe thread of size specified in physical dimensions. Never use flexible

hoses smaller than separate water connections on the unit and limit hose length to 10 ft. per connection. Check carefully for

water leaks.

Interior Piping

All units are recommended to be connected to supply and return piping in a two-pipe reverse return configuration. A

reverse return system is inherently self-balancing and requires only trim balancing when multiple quantities of units with

different flow and pressure drop characteristics are connected to the same loop. A direct return system may also be made

to work acceptably, but proper water flow balance is more difficult to achieve and maintain.

Supply and return runouts are usually connected to the unit by short lengths of high pressure flexible hose which are sound

attenuators for both unit operating noise and hydraulic pumping noise. One end of the hose should have a swivel fitting to

facilitate removal for service. Hard piping can also be connected directly to the unit although it is not recommended since

no vibration or noise attenuation can be accomplished. The hard piping must have unions to facilitate unit removal (see

figure 1 & 6) for typical application).

Some flexible hose threaded fittings are supplied with sealant compound. If not, apply Teflon tape to assure a tight seal.

Supply and return shutoff valves are required at each unit. The return shutoff valve can be used for balancing and should be

adjusted for proper flow required, or a manual or automatic flow control device should be on the leaving water hose assembly.

No unit should be connected to the supply and return piping until the water system has been cleaned and flushed

completely. After the cleaning and flushing has taken place, the initial connection should have all valves wide open in

preparation for water system filling.

12

Page 12

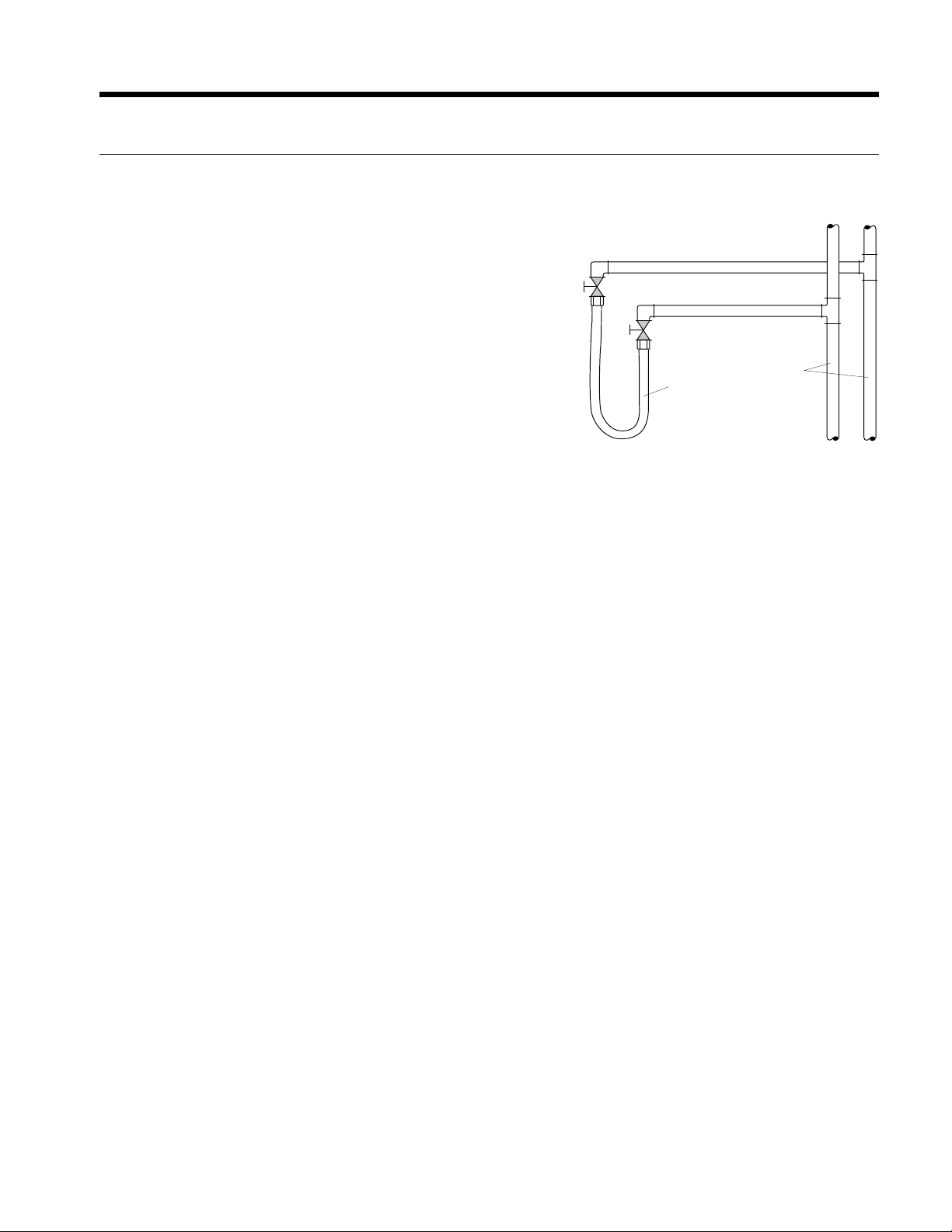

System Cleaning and Flushing

ENVISION 7-25 TONS INSTALLATION MANUAL

Cleaning and Flushing

Prior to start up of any heat pump, the water circulating system must be

cleaned and flushed of all dirt and debris.

If the system is equipped with water shutoff valves, the supply and

return runouts must be connected together at each unit location (This

will prevent the introduction of dirt into the unit, see Figure 7). The

system should be filled at the water make-up connection with all air

vents open. After filling, vents should be closed.

The contractor should start the main circulator with the pressure

reducing valve makeup open. Vents should be checked in sequence

to bleed off any trapped air and to verify circulation through all

components of the system.

As water circulates through the system, the contractor should check

and repair any leaks found in the piping system. Drain(s) at the lowest

point(s) in the system should be opened for initial flush and blowdown, making sure water fill valves are set at the same

rate. Check the pressure gauge at the pump suction and manually adjust the make-up water valve to hold the same

positive pressure both before and after opening the drain valves. Flushing should continue for at least two hours, or longer

if required, until drain water is clean and clear.

The supplemental heater and/or circulator pump, if used, should be shut off. All drains and vents should be opened to

completely drain the system. Short-circuited supply and return runouts should now be connected to the unit supply and

return connections.

Figure 7: Flushing with Water

Shutoff Valve Equipped Systems

Return Runout

Supply Runout

Mains

Rubber Hose

Runouts Initially

Connected Together

Refill the system with clean water. Test the system water for acidity and treat as required to leave the water slightly alkaline

(pH 7.5 to 8.5). The specified percentage of antifreeze may also be added at this time. Use commercial grade antifreeze

designed for HVAC systems only. Environol™ brand antifreeze is recommended..

Once the system has been filled with clean water and antifreeze (if used), precautions should be taken to protect the

system from dirty water conditions. Dirty water will result in system-wide degradation of performance, and solids may clog

valves, strainers, flow regulators, etc. Additionally, the heat exchanger may become clogged which reduces compressor

service life and can cause premature unit failure.

In boiler/tower application, set the loop control panel set points to desired temperatures. Supply power to all motors

and start the circulating pumps. After full flow has been established through all components including the heat rejector

(regardless of season), air vented and loop temperatures stabilized, each of the units will be ready for check, test and start

up and for air and water balancing.

Ground Source Loop System Checkout

Once piping is completed between the unit pumping system and ground loop, final purging and charging of the loop is

needed. A high pressure pump is needed to achieve adequate flow velocity in the loop to purge air and dirt particles from

the loop itself. Antifreeze solution is used in most areas to prevent freezing. Flush the system adequately to remove as

much air as possible; then pressurize the loop to a static pressure of 40-50 PSI (summer) or 50-75 PSI (winter). This is

normally adequate for good system operation. Loop static pressure may decrease soon after initial installation, due to pipe

expansion and loop temperature change. Running the unit for at least 30 minutes after the system has been completely

purged of air will allow for the “break-in” period. It may be necessary to adjust static loop pressure (by adding water) after

the unit has run for the first time. Loop static pressure will also fluctuate with the seasons. Pressures will be higher in the

winter months than during the cooling season. This fluctuation is normal and should be considered when charging the

system initially.

Ensure the pump provides adequate flow through the unit by checking pressure drop across the heat exchanger.

Usually 2.25-3.0 GPM of flow per ton of cooling capacity is recommended in earth loop applications.

13

Page 13

ENVISION 7-25 TONS INSTALLATION MANUAL

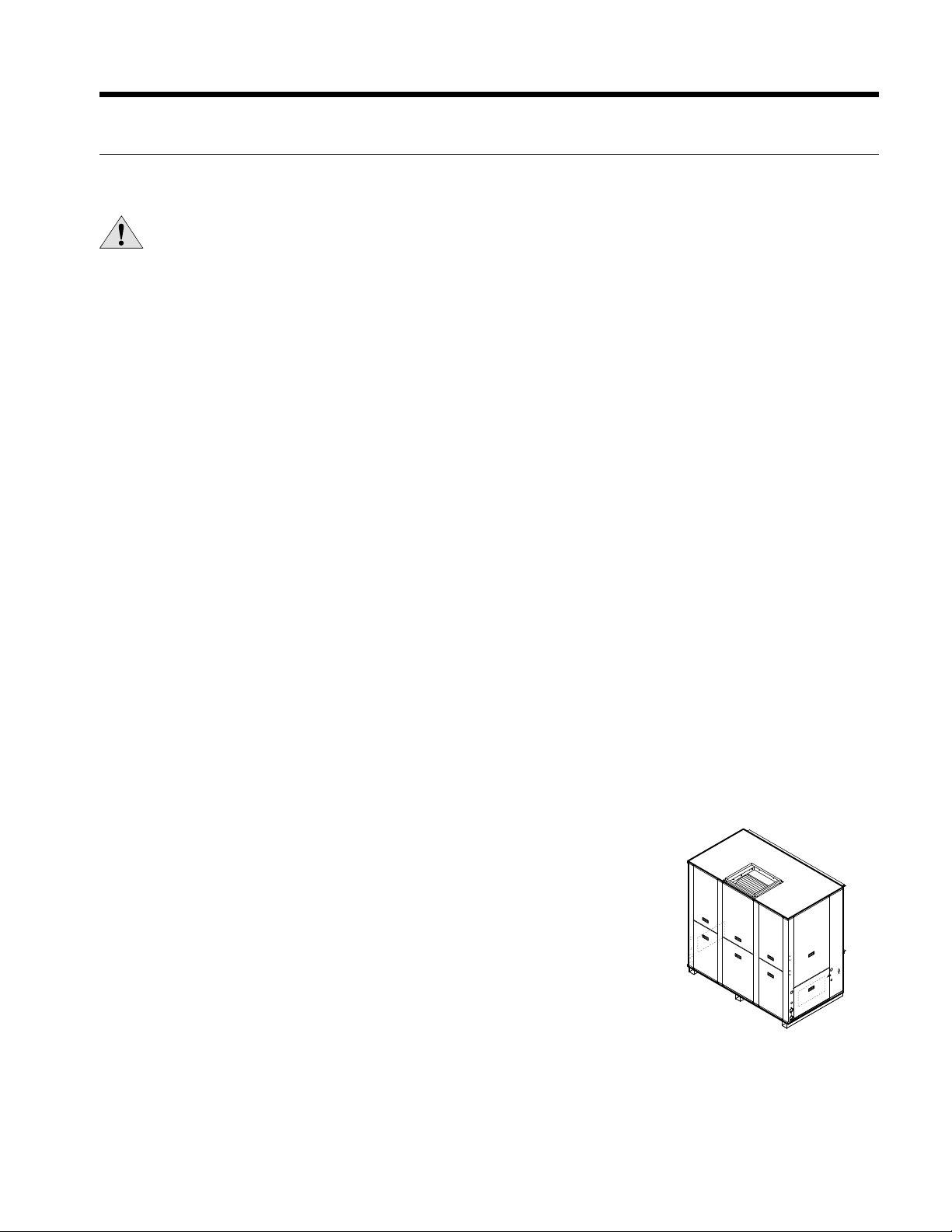

Electrical Connections

General

Be sure the available power is the same voltage and phase as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the National Electric Code.

Unit Power Connection

Line voltage connection is made by connecting the incoming line voltage wires to the terminal block as shown on the unit’s

wiring diagram attached to the inside front panel. Consult the Unit Electrical Data below for correct fuse size.

208 Volt Operation

NOTE: All 208-230 volt units are factory wired for 230 volt operation. For 208 volt operation, the red and the blue

transformer wires must be switched between terminal strip PS and contactor RB.

14

Page 14

Electrical Data

ENVISION 7-25 TONS INSTALLATION MANUAL

Model

Horizontal

080 460/60/3 414/506 9.0 5.8 38.0 2.4 1.5 13.9 15.4 20.0

080** 460/60/3 414/506 9.0 5.8 38.0 3.1 2.0 14.6 16.1 20.0

095 460/60/3 414/506 9.5 6.1 41.0 3.1 2.0 15.3 16.8 20.0

095** 460/60/3 414/506 9.5 6.1 41.0 4.3 3.0 16.5 18.0 20.0

120 460/60/3 414/506 12.1 7.7 52.0 4.3 3.0 19.8 21.7 25.0

Vertical

080 460/60/3 414/506 9.0 5.8 38.0 1.8 1.0 13.3 14.8 20.0

080** 460/60/3 414/506 9.0 5.8 38.0 2.4 1.5 13.9 15.4 20.0

095 460/60/3 414/506 9.5 6.1 41.0 2.4 1.5 14.6 16.1 20.0

095** 460/60/3 414/506 9.5 6.1 41.0 3.1 2.0 15.3 16.8 20.0

120 460/60/3 414/506 12.1 7.7 52.0 3.1 2.0 18.6 20.5 25.0

120** 460/60/3 414/506 12.1 7.7 52.0 4.3 3.0 19.8 21.7 25.0

160 460/60/3 414/506 16.5 10.6 75.0 1.8 1.0 24.8 54.0 35.0

160** 460/60/3 414/506 16.5 10.6 75.0 2.4 1.5 26.0 28.7 35.0

180 460/60/3 414/506 17.5 11.2 75.0 2.4 1.5 27.2 30.0 40.0

180** 460/60/3 414/506 17.5 11.2 75.0 3.1 2.0 28.6 31.4 40.0

240 460/60/3 414/506 26.0 16.6 114.0 3.1 2.0 39.5 43.6 60.0

240** 460/60/3 414/506 26.0 16.6 114.0 4.3 3.0 41.9 46.0 60.0

300 460/60/3 414/506 28.0 17.9 125.0 4.3 3.0 44.4 48.9 60.0

*Ratings per each compressor - unit supplied with two 9/10/07

**With optional motor

***Ratings per each blower motor - Vertical models 160-300 supplied with two.

Rated Voltage

Voltage Min/Max

208-230/60/3 187/253 16.3 10.4 88.0 4.8 1.5 25.7 28.3 35.0

575/60/3 518/632 5.9 3.8 36.5 1.9 1.5 9.5 10.4 10.0

208-230/60/3 187/253 16.3 10.4 88.0 6.2 2.0 27.1 29.7 40.0

575/60/3 518/632 5.9 3.8 36.5 2.5 2.0 10.1 11.0 10.0

208-230/60/3 187/253 21.2 13.6 83.1 6.2 2.0 33.3 36.7 50.0

575/60/3 518/632 7.8 5.0 34.0 2.5 2.0 12.5 13.7 15.0

208-230/60/3 187/253 21.2 13.6 83.1 9.2 3.0 36.3 39.7 50.0

575/60/3 518/632 7.8 5.0 34.0 3.4 3.0 13.4 14.6 15.0

208-230/60/3 187/253 24.9 15.9 110.0 9.2 3.0 41.1 45.1 60.0

575/60/3 518/632 8.9 5.7 38.9 3.4 3.0 14.8 16.2 20.0

208-230/60/3 187/253 16.3 10.4 88.0 3.6 1.0 24.5 27.1 35.0

575/60/3 518/632 5.9 3.8 36.5 1.5 1.0 9.0 9.9 10.0

208-230/60/3 187/253 16.3 10.4 88.0 4.8 1.5 25.7 28.3 35.0

575/60/3 518/632 5.9 3.8 36.5 1.9 1.5 9.5 10.4 10.0

208-230/60/3 187/253 21.2 13.6 83.1 4.8 1.5 31.9 35.3 45.0

575/60/3 518/632 7.8 5.0 34.0 1.9 1.5 11.9 13.1 15.0

208-230/60/3 187/253 21.2 13.6 83.1 6.2 2.0 33.3 36.7 50.0

575/60/3 518/632 7.8 5.0 34.0 2.5 2.0 12.5 13.7 15.0

208-230/60/3 187/253 24.9 15.9 110.0 6.2 2.0 38.1 42.1 50.0

575/60/3 518/632 8.9 5.7 38.9 2.5 2.0 13.9 15.3 20.0

208-230/60/3 187/253 24.9 15.9 110.0 9.2 3.0 41.1 45.1 60.0

575/60/3 518/632 8.9 5.7 38.9 3.4 3.0 14.8 16.2 20.0

208-230/60/3 187/253 35.0 22.4 149.0 3.6 1.0 52.0 57.6 80.0

575/60/3 518/632 12.0 7.7 54.0 1.5 1.0 18.4 20.3 25.0

208-230/60/3 187/253 35.0 22.4

575/60/3 518/632 12.0 7.7 54.0 1.9 1.5 19.2 21.1 25.0

208-230/60/3 187/253 36.2 23.2 164.0 4.8 1.5 56.0 61.8 80.0

575/60/3 518/632 12.3 7.9 54.0 1.9 1.5 19.6 21.6 25.0

208-230/60/3 187/253 36.2 23.2 164.0 6.2 2.0 58.8 64.6 80.0

575/60/3 518/632 12.3 7.9 54.0 2.5 2.0 20.8 22.8 30.0

208-230/60/3 187/253 47.0 30.1 225.0 6.2 2.0 72.6 80.1 110.0

575/60/3 518/632 19.0 12.2 80.0 2.5 2.0 29.3 32.4 40.0

208-230/60/3 187/253 47.0 30.1 225.0 9.2 3.0 78.6 86.1 110.0

575/60/3 518/632 19.0 12.2 80.0 3.4 3.0 31.1 34.2 45.0

208-230/60/3 187/253 52.0 33.3 239.0 9.2 3.0 85.0 93.3 125.0

575/60/3 518/632 20.0 12.8 80.0 3.4 3.0 32.4 35.6 45.0

Compressor*

MCC RLA LRA FLA*** *** FLA Amp HACR

149.0 4.8 1.5 54.4 60.0 80.0

Blower Blower Total Min Max

Motor HP Unit Circ Fuse/

HACR circuit breaker in USA only

All fuses Class RK-5

15

Page 15

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV080 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0

BHP 0.29 0.33 0.38 0.37 0.45 0.47 0.50 0.54 0.58 0.64 0.69 0.71 0.73 0.84 0.95 1.05

2200

RPM 437 478 518 539 586 617 647 677 707 736 765 775 809 843 876 909

TURNS OPEN 4.0 3.0 2.0 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.38 0.44 0.43 0.52 0.56 0.59 0.63 0.68 0.73 0.78 0.81 0.83 0.94 1.05 1.13 1.20

2400

RPM 477 517 538 585 615 645 675 704 734 763 774 807 841 874 907 940

TURNS OPEN 3.0 2.0 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.49 0.50 0.59 0.63 0.67 0.72 0.77 0.83 0.89 0.91 0.94 1.05 1.17 1.24 1.32

2600

RPM 516 537 584 614 643 673 702 732 761 772 806 839 871 905 938

TURNS OPEN 2.0 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.05.05.05.05.05.0

BHP 0.56 0.66 0.71 0.75 0.81 0.86 0.92 0.99 1.02 1.05 1.17 1.29 1.37 1.44

2800

RPM 536 582 612 642 671 700 729 758 770 804 837 869 903 936

TURNS OPEN 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.72 0.78 0.83 0.89 0.95 1.02 1.09 1.12 1.16 1.29 1.41 1.49 1.57

3000

RPM 581 611 640 669 698 727 756 768 802 835 867 900 933

TURNS OPEN 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.83 0.90 0.97 1.03 1.11 1.18 1.14 1.27 1.40 1.53 1.61 1.70

3200

RPM 610 639 668 697 726 754 767 800 833 865 898 930

TURNS OPEN 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.97

3400

RPM 637 666 695 725 731 765 798 830 862 895 927

TURNS OPEN 4.0 3.5 3.0 2.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0

Bold Face Requires 1.5 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 3 turns open (2600 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 3 turns open (2600 cfm @ 0.6 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12in. wg.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

B

1.04 1.11 1.19 1.23 1.30 1.37 1.51 1.64 1.73 1.82

External Static Pressure (in. w.g.)

A

E

07/25/07

16

Page 16

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV095 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

External Static Pressure (in. w.g.)

Rated CFM

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0

BHP 0.61 0.64 0.66 0.68 0.76 0.81 0.87 0.89 0.94 1.05

2600

RPM 581 601 621 663 703 739 774 784 827 867

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.0 2.0 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0

BHP 0.65 0.66 0.68 0.75 0.86 0.87 0.88 1.02 1.05 1.14 1.23

2800

RPM 580 600 621 662 701 722 742 782 805 855 905

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.0 2.5 1.5 0.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 0.72 0.73 0.74 0.84 0.96 0.98 0.99 1.13 1.14 1.17 1.23 1.36 1.48 1.59 1.69

3000

RPM 579 600 620 660 700 721 741 780 797 813 845 890 940 960 991

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.0 3.0 2.5 2.0 1.0 0.0 3.0 2.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0

BHP 0.79 0.80 0.82 0.93 1.06 1.08 1.10 1.25 1.26 1.31 1.36 1.49 1.62 1.67 1.85 2.03

3200

RPM 578 599 619 659 699 719 739 778 795 819 843 890 937 942 967 991

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.0 3.0 2.5 2.0 1.0 0.0 3.0 2.5 2.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0

BHP 0.84 0.89 1.01 1.15 1.17 1.20 1.35 1.36 1.42 1.48 1.52 1.61 1.82 1.90 1.99 2.03

3400

RPM 597 619 658 697 718 738 776 794 818 841 857 888 940 963 986 1034

TURNS OPEN 4.5 4.0 3.0 2.0 1.5 1.0 0.0 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0 5.0

BHP 0.97 1.09 1.23 1.26 1.29 1.45 1.47 1.53 1.60 1.67 1.74 1.95 2.05 2.14 2.19 2.41

3600

RPM 618 657 696 716 736 775 792 815 838 862 885 937 960 983 1031 1077

TURNS OPEN 4.0 3.0 2.0 1.5 1.0 0.0 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.0 0.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0 5.0

BHP 1.17 1.32 1.35 1.38 1.55

3800

RPM 656 695 715 735 773 790 814 837 860 883 935 958 981 1029 1074

TURNS OPEN 3.0 2.0 1.5 1.0 0.0 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.0 0.0

Bold Face Requires Larger 2 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 2 turns open (2800 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 1 turns open (2800 cfm @ 0.7 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12in. wg.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

D

A

C

E

1.57 1.64 1.71 1.78 1.86 2.09 2.18 2.28 2.34 2.57

7/25/07

17

Page 17

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV120 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 0.50 0.51 0.59 0.68 0.68 0.79 0.92 0.92 0.92 1.08 1.16 1.30 1.31 1.41 1.59

3200

RPM 418 438 480 521 541 582 623 644 665 705 732 787 826 867 932

TURNS OPEN 4.5 4.0 3.0 2.0 1.0 5.0 4.0 3.5 3.0 2.0 1.5 0.5 2.0 1.0 0.0

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 0.58 0.67 0.77 0.78 0.90 1.04 1.05 1.07 1.16 1.26 1.28 1.37 1.47 1.65

3400

RPM 438 480 520 541 582 622 643 664 694 724 746 795 843 888

TURNS OPEN 4.0 3.0 2.0 1.0 5.0 4.0 3.5 3.0 2.5 1.5 1.0 3.0 1.5 0.5

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 0.74 0.86 0.88 1.00 1.02 1.17 1.20 1.22 1.24 1.44 1.47 1.52 1.82 1.90

3600

RPM 479 519 540 581 602 643 663 684 704 745 765 806 866 906

TURNS OPEN 3.0 2.0 1.0 5.0 4.5 3.5 3.0 2.5 2.0 1.0 3.5 2.5 1.0 0.0

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 0.94 0.96 1.10 1.15 1.24 1.32 1.35 1.38 1.41 1.62 1.66 1.91 2.06

3800

RPM 519 539 581 622 642 662 683 704 723 764 784 823 884

TURNS OPEN 2.0 1.0 5.0 4.0 3.5 3.0 2.5 2.0 1.5 3.5 3.0 2.0 0.5

MTR/SHEAVE 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0

BHP 1.04 1.20 1.26 1.35 1.44 1.47 1.51 1.55 1.58 1.81 1.86 1.96 2.17 2.25 2.39 2.66

4000

RPM 539 580 621 641 661 682 703 724 744 783 803 843 893 933 970 1017

TURNS OPEN 1.0 5.0 4.0 3.5 3.0 2.5 2.0 1.5 1.0 3.0 2.5 1.5 0.0 3.5 2.5 1.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 4.0 5.0 5.0 5.0

BHP 1.28 1.36 1.45 1.54 1.59 1.63 1.67 1.72 1.95 2.01 2.06 2.19 2.31 2.48 2.75 3.03

4200

RPM 580 620 641 661 682 702 722 742 782 802 822 863 902 944 991 1037

TURNS OPEN 5.0 4.0 3.5 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.0 0.0 3.0 2.0 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0

BHP 1.46 1.55 1.65 1.70 1.75 1.80 1.85 2.09 2.15 2.21 2.28 2.41 2.54 2.80 3.08

4400

RPM 620 640 660 681 701 722 742 781 801 821 841 881 919 965 1012

TURNS OPEN 4.0 3.5 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.5 0.5 3.5 2.5 1.5

Bold Face Requires Larger 3 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 3 turns open (3600 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 1 turns open (3600 cfm @ 0.9 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12 in. wg.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

B

External Static Pressure (in. w.g.)

A

C

E

1.0 1.0 4.0 4.0 4.0 4.0 4.0 5.0 5.0 5.0

D

07/25/07

18

Page 18

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV160 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0

BHP 0.29 0.33 0.38 0.37 0.45 0.47 0.50 0.54 0.58 0.64 0.69 0.71 0.73 0.84 0.95 1.05

4400

RPM 437 478 518 539 586 617 647 677 707 736 765 775 809 843 876 909

TURNS OPEN 4.0 3.0 2.0 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0

BHP 0.33 0.38 0.41 0.44 0.50 0.53 0.57 0.61 0.66 0.71 0.75 0.77 0.84 0.95 1.04 1.13

4600

RPM 457 498 528 562 601 631 661 691 720 750 770 791 825 858 892 925

TURNS OPEN 3.5 2.5 1.5 0.5 4.5 4.0 3.5 3.0 2.5 2.0 1.0 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.38 0.44 0.43 0.52 0.56 0.59 0.63 0.68 0.73 0.78 0.81 0.83 0.94 1.05 1.13 1.20

4800

RPM 477 517 538 585 615 645 675 704 734 763 774 807 841 874 907 940

TURNS OPEN 3.0 2.0 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.44 0.47 0.51 0.58 0.62 0.66 0.70 0.75 0.81 0.85 0.87 0.94 1.05 1.15 1.22 0.60

5000

RPM 497 527 561 599 629 659 688 718 747 768 790 823 856 889 923 470

TURNS OPEN 2.5 1.5 1.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 3.0 2.5 2.0 1.5 1.0 0.5

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.49 0.50 0.59 0.63 0.67 0.72 0.77 0.83 0.89 0.91 0.94 1.05 1.17 1.24 1.32

5200

RPM 516 537 584 614 643 673 702 732 761 772 806 839 871 905 938

TURNS OPEN 2.0 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.53 0.58 0.65 0.69 0.74 0.79 0.85 0.91 0.95 0.98 1.05 1.17 1.27 1.34 0.66

5400

RPM 526 560 598 628 657 686 716 745 766 788 821 854 887

TURNS OPEN 1.5 1.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 3.0 2.5 2.0 1.5 1.0 0.5

MTR/SHEAVE 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 5.0 5.0 5.0 5.0 5.0 5.0

BHP 0.56 0.66 0.71 0.75 0.81 0.86 0.92 0.99 1.02 1.05 1.17 1.29 1.37 1.44

5600

RPM 536 582 612 642 671 700 729 758 770 804 837 869 903 936

TURNS OPEN 1.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 3.5 3.0 2.5 2.0 1.5 1.0

Bold Face Requires Larger 1.5 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 3 turns open (5000 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 2.0 turns open (5000 cfm @ 0.7 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12 in. wg.

BHP is given for each blower. Multiply BHP x 2 for unit BHP.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

B

External Static Pressure (in. w.g.)

A

E

920 469

7/25/07

19

Page 19

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV180 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0

BHP 0.61 0.64 0.66 0.68 0.76 0.81 0.87 0.89 0.94 1.05

5200

RPM 581 601 621 663 703 739 774 784 827 867

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.5 2.0 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0

BHP 0.64 0.66 0.71 0.77 0.82 0.85 0.94 0.97 1.04 1.14

5400

RPM 591 611 642 682 712 740 778 795 841 886

TURNS OPEN 4.5 4.0 3.5 2.5 1.5 1.0 0.5 0.0 1.5 0.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0

BHP 0.65 0.66 0.68 0.75 0.86 0.87 0.88 1.02 1.05 1.14 1.23

5600

RPM 580 600 621 662 701 722 742 782 805 855 905

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.0 2.5 1.5 0.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 0.69 0.70 0.76 0.86 0.92 0.93 1.01 1.08 1.11 1.19 1.30 0.74 0.80 0.85

5800

RPM 590 610 641 681 711 731 761 790 809 850 898 470 480 496

TURNS OPEN 4.5 4.0 3.5 2.5 1.5 1.0 0.5 0.0 3.0 2.5 2.0 1.0 3.0 2.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 0.72 0.73 0.74 0.84 0.96 0.98 0.99 1.13 1.14 1.17 1.23 1.36 1.48 1.59 1.69

6000

RPM 579 600 620 660 700 721 741 780 797 813 845 890 940 960 991

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5 1.0 0.0 3.0 2.5 2.0 1.0 0.0 3.0 2.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0

BHP 0.76 0.77 0.84 0.95 1.02 1.04 1.12 1.20 1.23 1.27 1.36 1.49 1.58 1.72 1.86

6200

RPM 589 609 640 680 710 730 760 788 808 828 868 914 941 963 991

TURNS OPEN 4.5 4.0 3.5 2.5 1.5 1.0 0.5 0.0 2.5 2.0 1.5 0.5 3.5 2.5 2.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0

BHP 0.79 0.80 0.82 0.93 1.06 1.08 1.10 1.25 1.26 1.31 1.36 1.49 1.62 1.67 1.85 2.03

6400

RPM 578 599 619 659 699 719 739 778 795 819 843 890 937 942 967 991

TURNS OPEN 5.0 4.5 4.0 3.0 2.0 1.5

Bold Face Requires Larger 2.0 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 3 turns open (5600 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 1.5 turns open (5600 cfm @ 0.7 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12 in. wg.

BHP is given for each blower. Multiply BHP x 2 for unit BHP.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

External Static Pressure (in. w.g.)

A

D

C

1.0 0.0 3.0 2.5 2.0 1.0 0.0 3.0 2.5 2.0

E

7/25/07

20

Page 20

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV240 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 0.50 0.51 0.59 0.68 0.68 0.79 0.92 0.92 0.92 1.08 1.16 1.30 1.31 1.41 1.59

6400

RPM 418 438 480 521 541 582 623 644 665 705 732 787 826 867 932

TURNS OPEN 4.5 4.0 3.0 2.0 1.0 5.0 4.0 3.5 3.0 2.0 1.5 0.5 2.0 1.0 0.0

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 0.58 0.67 0.77 0.78 0.90 1.04 1.05 1.07 1.16 1.26 1.28 1.37 1.47 1.65

6800

RPM 438 480 520 541 582 622 643 664 694 724 746 795 843 888

TURNS OPEN 4.0 3.0 2.0 1.0 5.0 4.0 3.5 3.0 2.5 1.5 1.0 3.0 1.5 0.5

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 0.74 0.86 0.88 1.00 1.02 1.17 1.20 1.22 1.24 1.44 1.47 1.52 1.82 1.90

7200

RPM 479 519 540 581 602 643 663 684 704 745 765 806 866 906

TURNS OPEN 3.0 2.0 1.0 5.0 4.5 3.5 3.0 2.5 2.0 1.0 3.5 2.5 1.0 0.0

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 0.94 0.96 1.10 1.15 1.24 1.32 1.35 1.38 1.41 1.62 1.66 1.91 2.06

7600

RPM 519 539 581 622 642 662 683 704 723 764 784 823 884

TURNS OPEN 2.0 1.0 5.0 4.0 3.5 3.0 2.5 2.0 1.5 3.5 3.0 2.0 0.5

MTR/SHEAVE 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0

BHP 1.04 1.20 1.26 1.35 1.44 1.47 1.51 1.55 1.58 1.81 1.86 1.96 2.17 2.25 2.39 2.66

8000

RPM 539 580 621 641 661 682 703 724 744 783 803 843 893 933 970 1017

TURNS OPEN 1.0 5.0 4.0 3.5 3.0 2.5 2.0 1.5 1.0 3.0 2.5 1.5 0.0 3.5 2.5 1.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 4.0 5.0 5.0 5.0

BHP 1.28 1.36 1.45 1.54 1.59 1.63 1.67 1.72 1.95 2.01 2.06 2.19 2.31 2.48 2.75 3.03

8400

RPM 580 620 641 661 682 702 722 742 782 802 822 863 902 944 991 1037

TURNS OPEN 5.0 4.0 3.5 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.0 0.0 3.0 2.0 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0

BHP 1.46 1.55 1.65 1.70 1.75 1.80 1.85 2.09 2.15 2.21 2.28 2.41 2.54 2.80 3.08

8800

RPM 620 640 660 681 701 722 742 781 801 821 841 881 919 965 1012

TURNS OPEN 4.0 3.5 3.0 2.5 2.0 1.5 1.0 3.0 2.5 2.0 1.5 0.5 3.5 2.5 1.5

Bold Face Requires Larger 3.0 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 2.5 turns open (7600 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 2 turns open (7600 cfm @ 0.7 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12 in. wg.

BHP is given for each blower. Multiply BHP x 2 for unit BHP.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

B

External Static Pressure (in. w.g.)

A

C

E

1.0 1.0 4.0 4.0 4.0 4.0 4.0 5.0 5.0 5.0

D

7/25/07

21

Page 21

ENVISION 7-25 TONS INSTALLATION MANUAL

NLV300 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0

BHP 1.46 1.49 1.77 1.94 2.11 2.29 2.32 2.39 2.65 2.72 2.80 2.36

8400

RPM 677 696 745 778 810 841 858 878 912 932 951 994

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 4.0 3.5 3.0 2.0 1.5 1.0 4.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0

BHP 1.55 1.70 1.86 2.03 2.21 2.39 2.42 2.50 2.75 2.83 2.91 2.63 2.61

8800

RPM 674 708 742 774 806 837 853 873 907 926 945 981 1010

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 4.0 3.5 3.0 2.0 1.5 1.0 4.5 4.0

MTR/SHEAVE 2.0 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 1.63 1.79 1.96 2.13 2.31 2.49 2.52 2.60 2.85 2.93 3.01 2.87 2.87 2.86

9200

RPM 671 705 738 771 802 833 849 869 903 922 940 969 997 1025

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 4.0 3.5 3.0 2.0 1.5 1.0 4.5 4.0 3.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 1.72 1.88 2.04 2.22 2.40 2.58 2.62 2.70 2.95 3.03 3.11 3.09 3.10 3.11

9600

RPM 668 702 735 767 799 829 845 864 898 917 935 959 985 1012

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 4.0 3.5 3.0 2.0 1.5 1.0 4.5 4.0 3.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 1.96 2.13 2.31 2.49 2.68 2.71 2.79 3.05 3.13 3.21 3.29 3.31 3.33

10000

RPM 699 732 764 795 825 841 860 894 912 931 949 975 1001

TURNS OPEN 4.0 3.0 2.0 1.0 4.0 3.5 3.0 2.0 1.5 1.0 4.5 4.0 3.5

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 2.21 2.39 2.58 2.77 2.81 2.89 3.13 3.22 3.31 3.39 3.51 3.54 3.56

10400

RPM 729 761 792 821 837 856 890 908 926 944 965 990 1016

TURNS OPEN 3.0 2.0 1.0 4.0 3.5 3.0 2.0 1.5 1.0 4.5 4.0 3.5 3.0

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 2.48 2.66 2.85 2.90 2.98 3.23 3.32 3.40 3.48 3.61 3.73 3.76

10800

RPM 758 788 818 833 852 885 904 922 939 960 980 1005

TURNS OPEN 2.0 1.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

4.0 3.5 3.0 2.0 1.5 1.0 4.5 4.0 3.5 3.0

External Static Pressure (in. w.g.)

AB

C

7/25/07

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 3.0 turns open (9500 cfm @ 0.7 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 3.0 turns open (9500 cfm @ 0.7 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12 in. wg.

BHP is given for each blower. Multiply BHP x 2 for unit BHP.

22

Page 22

ENVISION 7-25 TONS INSTALLATION MANUAL

NLH080 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 5.0 5.0 5.0 5.0

BHP 0.37 0.40 0.43 0.47 0.52 0.59 0.65 0.71 0.75 0.78 0.81 0.86 0.90

2200

RPM 583 624 665 706 747 770 791 821 865 911 957 986 1015

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 3.0 2.0 1.0 0.0 3.5 3.0 2.5 2.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 5.0 5.0 5.0 5.0 5.0

BHP 0.45 0.49 0.53 0.59 0.62 0.67 0.70 0.74 0.79 0.85 0.88 0.91 0.95 1.08

2400

RPM 582 623 664 705 746 765 790 820 861 906 938 970 1004 1030

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 3.0 2.0 1.0 0.0 4.0 3.0 2.5 2.0 1.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0 5.0

BHP 0.51 0.56 0.62 0.66 0.69 0.73 0.76 0.84 0.90 0.93 0.96 1.04 1.12 1.17

2600

RPM 602 643 684 726 760 783 805 853 877 916 954 988 1021 1051

TURNS OPEN 4.5 3.5 2.5 1.5 4.0 3.5 2.5 2.0 1.5 3.5 3.0 2.5 1.5 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0

BHP 0.53 0.58 0.64 0.69 0.76 0.79 0.80 0.94 0.99 1.03 1.15 1.16 1.17 1.27

2800

RPM 581 622 663 704 744 776 802 851 876 900 951 976 1001 1033

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 3.5 3.0 2.0 1.5 1.0 3.0 2.5 2.0 1.5

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.05.05.05.0 5.0

BHP 0.59 0.66 0.73 0.80 0.87 0.90 0.92 1.07 1.08 1.10 1.30 1.33 1.35 1.40 1.44

3000

RPM 580 621 662 702 743 775 801 848 873 898 949 973 997 1022 1046

TURNS OPEN 5.0 4.0 3.0 2.0 1.0 3.5 3.0 2.0 1.5 1.0 3.0 2.5 2.0 1.5 1.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0 5.0

BHP 0.72 0.81 0.90 0.98 1.02 1.04 1.19 1.21 1.23 1.44 1.47 1.51 1.54 1.57

3200

RPM 620 661 701 741 773 799 846 871 895 946 970 994 1019 1043

TURNS OPEN 4.0 3.0 2.0 1.0 3.5 3.0 2.0 1.5 1.0 3.02.52.01.51.0

MTR/SHEAVE 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0 5.0 5.0 5.0

BHP 0.87 0.98 1.08 1.12 1.16 1.31 1.34 1.36 1.58 1.62 1.65 1.69 1.73

3400

RPM 660 700 740 772 797 844 869 893 944 968 992 1016 1040

TURNS OPEN 3.0 2.0 1.0 3.5 3.0 2.0 1.5 1.0 3.0 2.5 2.0 1.5 1.0

Bold Face Requires Larger 2 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 2.5 turns open (2600 cfm @ 0.4 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 1.5 turns open (2600 cfm @ 0.5 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12in. wg.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

A

External Static Pressure (in. w.g.)

D

C E

07/25/07

23

Page 23

ENVISION 7-25 TONS INSTALLATION MANUAL

NLH095 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 5.0

BHP 0.44 0.47 0.52 0.57 0.66 0.78 0.79 0.80 0.92 0.97 1.08 1.18 1.37 1.56

2600

RPM 584 625 667 708 757 806 831 856 905 960 1021 1082 1142 1202

TURNS OPEN 5.0 4.0 3.0 2.0 4.0 3.0 2.5 2.0 1.0 3.0 2.0 1.0 0.0 3.0

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 5.0 5.0

BHP 0.51 0.56 0.61 0.67 0.77 0.89 0.90 0.91 1.06 1.11 1.14 1.38 1.44 1.59 1.73

2800

RPM 583 625 665 707 756 804 829 854 902 933 982 1055 1100 1156 1212

TURNS OPEN 5.0 4.0 3.0 2.0 4.0 3.0 2.5 2.0 1.0 3.5 2.5 1.5 0.5 3.5 2.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 4.0 4.0 4.0 4.0 4.0 5.0 5.0

BHP 0.57 0.64 0.70 0.76 0.87 1.00 1.01 1.03 1.19 1.25 1.28 1.33 1.59 1.64 1.68 1.91

3000

RPM 582 624 665 705 754 802 827 852 900 930 955 1005 1078 1110 1169 1228

TURNS OPEN 5.0 4.0 3.0 2.0 4.0 3.0 2.5 2.0 1.0 3.5 3.0 2.0 0.5 0.0 3.0 2.0

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 0.70 0.78 0.86 0.97 1.11 1.13 1.15 1.31 1.31 1.38 1.44 1.61 1.69 1.80 2.02

3200

RPM 623 664 704 753 801 826 851 899 919 949 978 1036 1086 1137 1196

TURNS OPEN 4.0 3.0 2.0 4.0 3.0 2.5 2.0 1.0 4.0 3.5 3.0 2.5 1.5 3.5 2.5

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 0.85 0.94 1.07 1.21 1.24 1.26 1.42 1.43 1.50 1.57 1.65 1.71 1.76 2.10 2.35

3400

RPM 663 703 752 800 825 849 896 917 947 976 1020 1057 1094 1164 1223

TURNS OPEN 3.0 2.0 4.0 3.0 2.5 2.0 1.0 4.0 3.5 3.0 2.5 1.8 1.0 3.0 2.0

MTR/SHEAVE 2.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 1.01 1.16 1.31 1.34 1.37 1.54 1.55 1.63 1.70 1.78 1.87 2.06 2.15 2.40

3600

RPM 702 751 798 823 848 894 915 945 974 1003 1031 1088 1133 1191

TURNS OPEN 2.0 4.0 3.0 2.5 2.0 1.0 4.0 3.5 3.0

MTR/SHEAVE 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 3.0 5.0 5.0

BHP 1.23 1.40 1.44 1.48 1.66 1.67 1.75 1.83 1.91 2.00 2.10 2.19 2.44

3800

RPM 750 797 821 845 893 913 942 971 1000 1029 1086 1102 1160

TURNS OPEN 4.0 3.0 2.5 2.0 1.0 4.0 3.5 3.0 2.5 2.0 1.5 4.0 3.0

Bold Face Requires Larger 2 HP Motor

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 2 turns open (3200 cfm @ 0.6 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 2 turns open (3200 cfm @ 0.6 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12in. wg.

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

B

External Static Pressure (in. w.g.)

A

C

2.5 2.0 1.5 3.5 2.5

D

E

07/25/07

24

Page 24

ENVISION 7-25 TONS INSTALLATION MANUAL

NLH120 - Blower Performance Data

Belt Drive

Airflow in CFM with dry coil and clean air filter.

Rated CFM

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0

BHP 0.80 0.88 0.96 1.07 1.09 1.11 1.13 1.28 1.36 1.48 1.67 1.86

3000

RPM 707 748 789 830 857 882 907 931 956 1032 1115 1198

TURNS OPEN 5.0 4.0 3.0 2.0 5.0 4.5 4.0 3.5 2.5 1.0 4.5 3.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0

BHP 0.90 0.99 1.09 1.16 1.22 1.25 1.27 1.34 1.49 1.63 1.77 1.98 2.08

3200

RPM 707 747 788 830 855 880 905 930 955 1031 1107 1166 1210

TURNS OPEN 5.0 4.0 3.0 2.0 5.0 4.5 4.0 3.5 2.5 1.0 4.0 3.0 2.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 0.99 1.09 1.20 1.19 1.35 1.38 1.41 1.44 1.47 1.55 1.76 2.06 2.15 2.24

3400

RPM 706 747 787 829 854 879 904 929 954 1004 1070 1137 1180 1224

TURNS OPEN 5.0 4.0 3.0 2.0 5.0 4.5 4.0 3.5 3.0 2.0 4.5 3.5 2.5 2.0

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0

BHP 1.05 1.18 1.30 1.32 1.47 1.51 1.54 1.58 1.61 1.85 1.90 2.12 2.22 2.32 2.51

3600

RPM 706 746 787 828 853 878 903 928 953 1001 1044 1103 1134 1184 1233

TURNS OPEN 5.0 4.0 3.0 2.0 5.0 4.5 4.0 3.5 3.0 2.0 5.0 4.0 3.5 2.5 1.5

MTR/SHEAVE 2.0 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0

BHP 1.11 1.25 1.39 1.53 1.59 1.63 1.67 1.71 1.75 1.99 2.08 2.16 2.27 2.37 2.64 2.75

3800

RPM 705 756 786 827 853 878 902 927 951 999 1037 1075 1118 1161 1219 1255

TURNS OPEN 5.0 4.0 3.0 2.0 5.0 4.5 4.0 3.5 3.0 2.0 1.0 4.5 3.5 3.0 2.0 1.5

MTR/SHEAVE 2.0 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0 3.0 3.0

BHP 1.31 1.46 1.61 1.68 1.74 1.79 1.84 1.89 2.13 2.17 2.20 2.43 2.68 2.76 2.84 2.94

4000

RPM 745 786 826 852 877 901 926 950 998 1023 1047 1100 1157 1188 1231 1275

TURNS OPEN 4.0 3.0 2.0 5.0 4.5 4.0 3.5 3.0 2.0 1.0 5.0 4.0 3.0 2.5 1.5 1.0

MTR/SHEAVE 2.0 2.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 3.0 3.0 3.0 3.0

BHP 1.52 1.69 1.85 1.88 1.90 1.96 2.02 2.26 2.30 2.34 2.57 2.84 2.91 2.97 3.28

4200

RPM 785 825 851 876 900 925 949 997 1018 1039 1098 1155 1184 1214 1270

TURNS OPEN 3.0 2.0 5.0 4.5 4.0 3.5 3.0 2.0 1.0 5.0 4.5 3.5 2.5 2.0 1.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 1.8 2.0

B

External Static Pressure (in. w.g.)

A

C

3.0 3.0

07/23/07

A=Std Static/Std Mtr;B=Low Static/Std. Mtr;C=High Static/Std. Mtr;D=Std Static/Large Mtr;E=High Static/Large Mtr

Units factory shipped with standard static sheave and drive at 3.0 turns open (3600 cfm @ 0.9 in. ESP). Other speeds require field selection.

ISO/AHRI rating point with standard static sheave and drive at 2.0 turns open (3600 cfm @ 1.0 in. ESP). Other speeds require field selection.

For applications requiring higher static pressures, contact your local representative.

Performance data does not include drive losses and is based on sea level conditions.

Do not operate in gray region. "na" = information not available at time of printing.

All airflow is rated at lowest Voltage if unit is dual Voltage rated, i.e. 208V for 208-230V units.

For wet coil performance first calculate the face velocity of the air coil (Face Velocity [fpm] = Airflow [cfm] / Face Area [sq ft]).

Then for velocities of 200 fpm reduce the static capability by 0.03 in. wg, 300 fpm by 0.08 in. wg, and 400 fpm by 0.12in. wg.

25

Page 25

ENVISION 7-25 TONS INSTALLATION MANUAL

Wiring Schematic - FX10 Control

208-230/60/3

Note 1

TB

24VAC

R

24V COM

C

Comp 1

Y1

Rev Valve

O

Fan

G

Alarm

Acc 2

Acc 1

Comp 2

Setpoint Shift

AI Com

Room Sens or

Sensor Com

Temp Oc c

Brown (13 )

L

X2

X1

Y2

SS

AIC

RS

Black (6 0 )

SC

TO

PB2

1

2

3

Yellow (18)

Viol et (1 5)

Black (61)

NOTE 4

NOTE 3

Unit Power Supply

480/60/3 or 575/60/3

Viol et (5 9)

AP

ES

OS

NOTE 2

Blue (58 )

CO

FP1

DA

FP2

Orange (35)

Org /Wht (36)

LP2

LP1

L3L1 L2

Brown (24 )

Brown (25)

White (26)

T

White/Blue (27)

Black (2 8 )

T

Black/Red (29)

Gray (30 )

T

Gry/Wht (31)

Blue/Wht (33)

Pink (5 )

Viol et (1 )

Green (45)

Orange (46)

Blue (47)

Yellow (48)

Viol et (5 0)

Blk/ W ht (5 5)

Orange (56)

G

Black (49 )

Red (51)

Gray (52)

Blue (53)

Pink (5 4)

11K

Red (69)

Yellow ( 70)

Black (71)

J8

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

J2

39

40

41

J10

42

43

44

45

46

47

48

J9

49

50

51

52

53

54

55

56

Compressor 1

5VDC

AI3

+

AI5

+

AI4

+

AI6

+

AI2

+

5VDC

AI1

+

LED

5VDC

PWM2

PWM2 Com

PWM1

24VAC Com

DI12

DI11

DI10

DI9

DI8

DI7

DI 3/4/5/6/ Com

DI6

DI5

DI4

DI3

DI2

9VDC

DI1

Compresso r 2

Viol et (1 5)

D09

D08

D07

D06

D05

D04

D03

D02

D01

Yellow

T2

L2

T2

CC2

Brown (13)

T1T3

T1

L1

Black (44 )

BlackRed

Yellow ( 63)

Brown (64)

Gray (65)

Red (43)

20

19

Yellow

(172)

18

17

16

15

Yellow

(126)

14

13

12

Yellow

(912)

11

10

Orange (10)

9

8

7

Gray (7)

6

Black/Wh i te (6 )

5

Pink (5 )

4

White/Red (4)

3

White (3)

2

Black (2 )

1

T1T3

T2

BlackRed

Yello w

CC1

T3

T2

T1

L3

A21A12

A23

L1

L2

Yellow (40)

24VAC

24VAC Com

GROUND

A14

A13

A34

A24

A25

A22

A11

A33

A35

A32

A31

A15

Red (66)

Yellow (67)

Black (6 8 )

Blk/ W ht (4 1)

T3

L3

Yellow ( 18)

Johnson FX-10

J7

Violet (1)

Pink (5)

Green

Yellow (78)

Yellow (20)

RV1

HP2

HP1

Org (37)

Org (38)

Belt Drive

Blower

Motor

Brown (79)

L2 L1L3

Grn/Y e l ( 62)

Orange (32)

RV2

RB

Gray/Wht (39)

CC2

Blk /W ht (3 4)

CC1

Gray (80)

PB1

Blk/ W ht (2 2)

Black (21 )

RBT2 T1T3

Transformer Switch

Black

(75)

1

2

Yellow (57)

3

2

Blk/WhtGrn/Yel (42)

Blk /W ht (2 3)

1

Red

3

Black

208V

Blue

230V

Transformer

Yellow

L1

Factory low voltage wiring

Factory line voltage wiring

Field low voltage wiring

Field line voltage wiring

Optional block

Internal junction

Quick connect terminal

Wire nut

Field wire lug

Ground

Relay Contacts-

N.O., N.C.

Thermistor - Johnson Control

T

Relay coil

Legend

AP - Air Proving

Compressor contactor 1CC1 -

Switch - High pressure

Switch - Low pressure

Polarized connector

132

P

Condensate Overflow

CC2 - Compressor contactor 2

Condensate overflowCO CPM1 - Compressor Protection Module 1

CPM2 - Compressor Protection Module 2

Discharge Air TemperatureDA -

ES - Emergency Shutdown

Freeze protection sensor 1FP1 -

Freeze protection sensor 2FP2 -

Notes:

1 - R, C, Y1, Y2, O, and G are for use with a wall mounted thermostat

2 - Disconnect for 15 degree freeze protection

3 - Acc 1 output is cycled with the compressor

4 - Acc 2 output is cycled with the fan

26

HP1 - Stage 1 High Pressure

HP2 - Stage 2 High Pressure

LP1 - Stage 1 Low Pressure

LP2 - Stage 2 Low Pressure

OS - Occupied Switch

RB - Blower power relay

RV1 - Reversing Valve coil 1

RV2 - Reversing Valve coil 2

97P699-01 5/17/06

Page 26

Wiring Schematic - FX10 Control cont.

ENVISION 7-25 TONS INSTALLATION MANUAL

460/60/3 and 575/60/3

Unit Power Supply

480/60/3 or 575/60/3

L3L1 L2

Note 1

TB

24VAC

R

24V COM

C

Comp 1

Y1

Rev Valve

Fan

Alarm

Acc 2

Acc 1

Comp 2

Setpoint Shif t

AI Com

Room Sens or

Sensor Com

Temp Oc c

O

G

Brown (13)

L

X2

X1

Y2

SS

AIC

RS

Black (60)

SC

TO

PB2

1

2

3

Yellow (18)

Violet (15)

Black (61)

NOTE 4

NOTE 3

Violet (59)

AP

ES

OS

NOTE 2

Blue (58 )

CO

FP1

DA

FP2

Orange (35)

Org /Wht (36)

LP2

LP1

Brown (24)

Brown (25)

White (26)

T

White/Blue (27)

Black (28)

T

Black/Red (29)

Gray (30 )

T

Gry/Wht (31)

Blue/Wht (33)

Pink (5 )

Violet (1)

Green (45)

Orange (46)

Blue (47 )

Yellow (48)

Violet (50)

Blk/Wht (55)

Orange (56)

G

Black (49)

Red (51)

Gray (52)

Blue (53)

Pink (54)

11K

Red (69)

Yellow (70)

Black (71 )

J8

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

J2

39

40

41

J10

42

43

44

45