Water Furnace 500A11 5 Series, 500A11 Installation Manual

500A11

mation

s

nntion

s

en

ce

Geothermal Heat Pump

• R-410A Refrigerant

• 1, 1.5, 2, 2.5, 3, 3.5, 4, 5, 6 Ton Single Speed

• 2, 3, 4, 5, 6 Ton Dual Capacity

Installation Information

Water Piping Connections

Hot Water Generator Connections

Electrical

Startup Procedures

Troubleshooting

Preventive Maintenance

nnection

ures

5 Series 500A11 Installation Manual

CUS

IM2500AN 02/13

Table of Contents

Model Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Closed Loop Ground Source Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Open Loop Ground Water Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Hot Water Generator Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electronic Thermostat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Auxiliary Heat Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Auxiliary Heat Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 SERIES 500A11 INSTALLATION MANUAL

Blower Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

The Aurora™ Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Reference Calculations and Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Unit Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Compressor and Thermistor Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Refrigerant Circuit Guideline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Heat of Extraction/Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Service Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

5 SERIES 500A11 INSTALLATION MANUAL

Model Nomenclature

1N2D3V4-6

0497G819110111C12T13L14015A16N

Model Type

N = 5 Series Water-to-Air

Compressor Type

D = Dual Capacity

S = Single Speed

Cabinet Configuration

V = Vertical

H = Horizontal

Unit Capacity

012, 018, 022, 026, 030, 036, 038,

042, 048, 049, 060, 064, 070, 072

Vintage

G = Current

Voltage

1 = 208-230/60/1

Hot Water Generation

0 = No Hot Water Generation

1 = Hot Water Generation with factory

installed pump (018-072)

Blower Options

0 = PSC

1 = Variable Speed ECM (018-072)

2 = High Static Variable Speed ECM (036-049)

3 = High Static PSC (022, 030, 036, 042, 048)

4 = 5-Speed ECM (022-072)

IntelliStart Options

N = None

A = IntelliStart (022-072)

Controls Options

TM

A = Aurora

Base Control (ABC)

B = Aurora Advanced Control

(ABC and AXB)

C = Aurora Performance Package

(018-072)

2

D = Aurora Performance and

Refrigeration Package (018-072)

Filter Option

0 = 2 in. MERV 11 Filter

1 = AlpinePure 411 (022-072)

1

Return Air Configuration

L = Left

R = Right

Discharge Air Configuration

T = Top (vertical)

S = Side (horizontal)

E = End (horizontal)

B = Bottom (vertical 022-072)

R = Rear (vertical 042-072)

Water Coil Options

C = Copper

N = Cupronickel

2

NOTES: All models include sound kits as standard equipment.

1

Available on vertical configurations only (not available on horizontal models).

2

Control option not available with PSC motor.

4

General Installation Information

5 SERIES 500A11 INSTALLATION MANUAL

Safety Considerations

WARNING: Before performing service or

maintenance operations on a system, turn off main

power switches to the indoor unit. If applicable,

turn off the accessory heater power switch.

Electrical shock could cause personal injury.

Installing and servicing heating and air conditioning

equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service

personnel should install, repair or service heating and air

conditioning equipment. Untrained personnel can perform

the basic maintenance functions of cleaning coils and

cleaning and replacing filters. All other operations should

be performed by trained service personnel. When working

on heating and air conditioning equipment, observe

precautions in the literature, tags and labels attached to the

unit and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use a quenching cloth for brazing operations and

have a fire extinguisher available.

Moving and Storage

Move units in the normal “up” orientation. Horizontal units

may be moved and stored per the information on the

packaging. Do not stack more than three units in total

height. Vertical units may be stored one upon another to

a maximum height of two units. Do not attempt to move

units while stacked. When the equipment is received, all

items should be carefully checked against the bill of lading

to be sure all crates and cartons have been received.

Examine units for shipping damage, removing the units

from the packaging if necessary. Units in question should

also be internally inspected. If any damage is noted, the

carrier should make the proper notation on the delivery

receipt, acknowledging the damage.

Filter Rack Conversion

A 2 in. MERV 11 filter is shipped with the heat pump. To

field convert the filter rack to use 1 in. filters, simply insert

the provided plastic push pins into the holes located in the

filter rack. There are holes on the top and bottom of the

rack, underneath the instruction labels, for field conversion

to 1 in. filters.

Installing Vertical Units

Prior to setting the unit in place, remove and discard the

compressor hold down shipping bolt located at the front of

the compressor mounting bracket.

Vertical units are available in left or right air return

configurations. Top and rear air discharge vertical units

should be mounted level on a vibration absorbing pad

slightly larger than the base to provide isolation between

the unit and the floor. It is not necessary to anchor the unit

to the floor (see below).

Bottomflow units should be mounted level and sealed well

to floor to prevent air leakage. Bottomflow units require

the supply air opening to be cut at least 1/2 in. larger than

the unit’s air outlet. Protect the edges of combustible

flooring with sheet metal over-wrap or other noncombustible material.

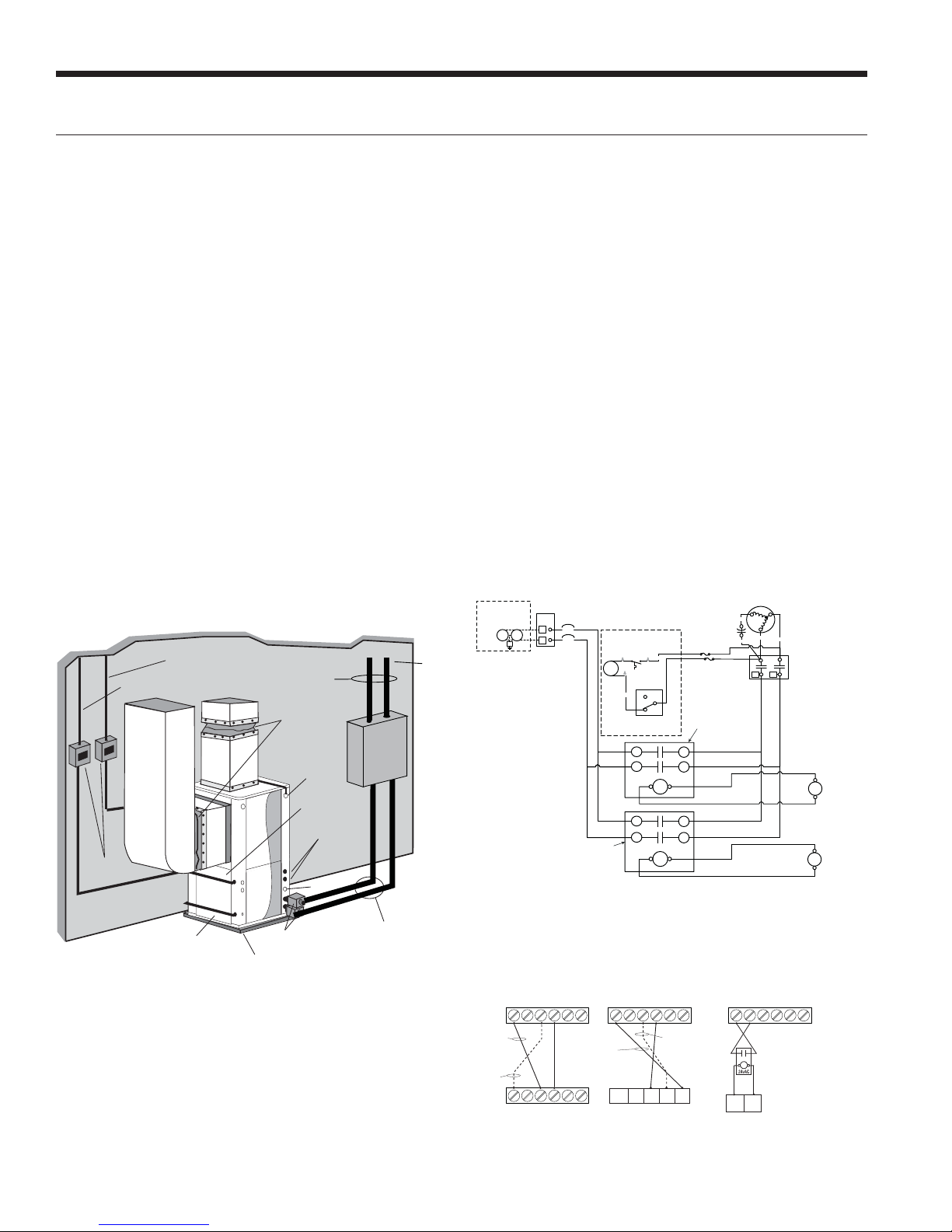

Figure 1: Vertical Unit Mounting

Unit Location

Locate the unit in an indoor area that allows for easy removal

of the filter and access panels. Location should have enough

space for service personnel to perform maintenance or

repair. Provide sufficient room to make water, electrical and

duct connection(s). If the unit is located in a confined space,

such as a closet, provisions must be made for return air to

freely enter the space by means of a louvered door, etc. Any

access panel screws that would be difficult to remove after

the unit is installed should be removed prior to setting the

unit. On horizontal units, allow adequate room below the

unit for a condensate drain trap and do not locate the unit

above supply piping. Care should be taken when units are

located in unconditioned spaces to prevent damage from

frozen water lines and excessive heat that could damage

electrical components.

2 in. Extruded

Polystyrene

5

5 SERIES 500A11 INSTALLATION MANUAL

General Installation Information cont.

Installing Horizontal Units

Remove and discard the compressor hold down shipping

bolt located at the front of the compressor mounting

bracket prior to setting the unit in place. Horizontal units

are available with side or end discharge. Horizontal units

are normally suspended from a ceiling by four or six 3/8 in.

diameter threaded rods. The rods are usually attached to

the unit by hanger bracket kits furnished with each unit.

Lay out the threaded rods per the dimensions in Figure

3. Assemble the hangers to the unit as shown. Securely

tighten the brackets to the unit using the weld nuts located

on the underside of the bottom panel. When attaching the

hanger rods to the bracket, a double nut is required since

vibration could loosen a single nut. To allow filter access,

one bracket on the filter side should be installed 180° from

Figure 2: Horizontal Unit Mounting

O

Threaded Rods

To Line

Power

To

Thermostat

Hanging

Brackets

(Included)

Hose

Kits

Flexible Duct

Collar

Insulate supply

plenum and use

at least one 90

elbow to

reduce noise

the position shown in Figure 3. The unit should be pitched

approximately 1/4-inch towards the drain in both directions

to facilitate the removal of condensate. Use only the bolts

provided in the kit to attach hanger brackets. The use of

longer bolts could damage internal parts.

Some residential applications require the installation of

horizontal units on an attic floor. In this case, the unit

should be set in a full size secondary drain pan on top of a

vibration absorbing pad. The secondary drain pan prevents

possible condensate overflow or water leakage damage to

the ceiling. The secondary drain pan is usually placed on a

plywood base isolated from the ceiling joists by additional

layers of vibration absorbing material.

CAUTION: Do not use rods smaller than 3/8-inch

diameter since they may not be strong enough

to support the unit. The rods must be securely

anchored to the ceiling.

Electrical

Disconnect

Line Voltage

Building Water Loop

Ball Valves

6

General Installation Information cont.

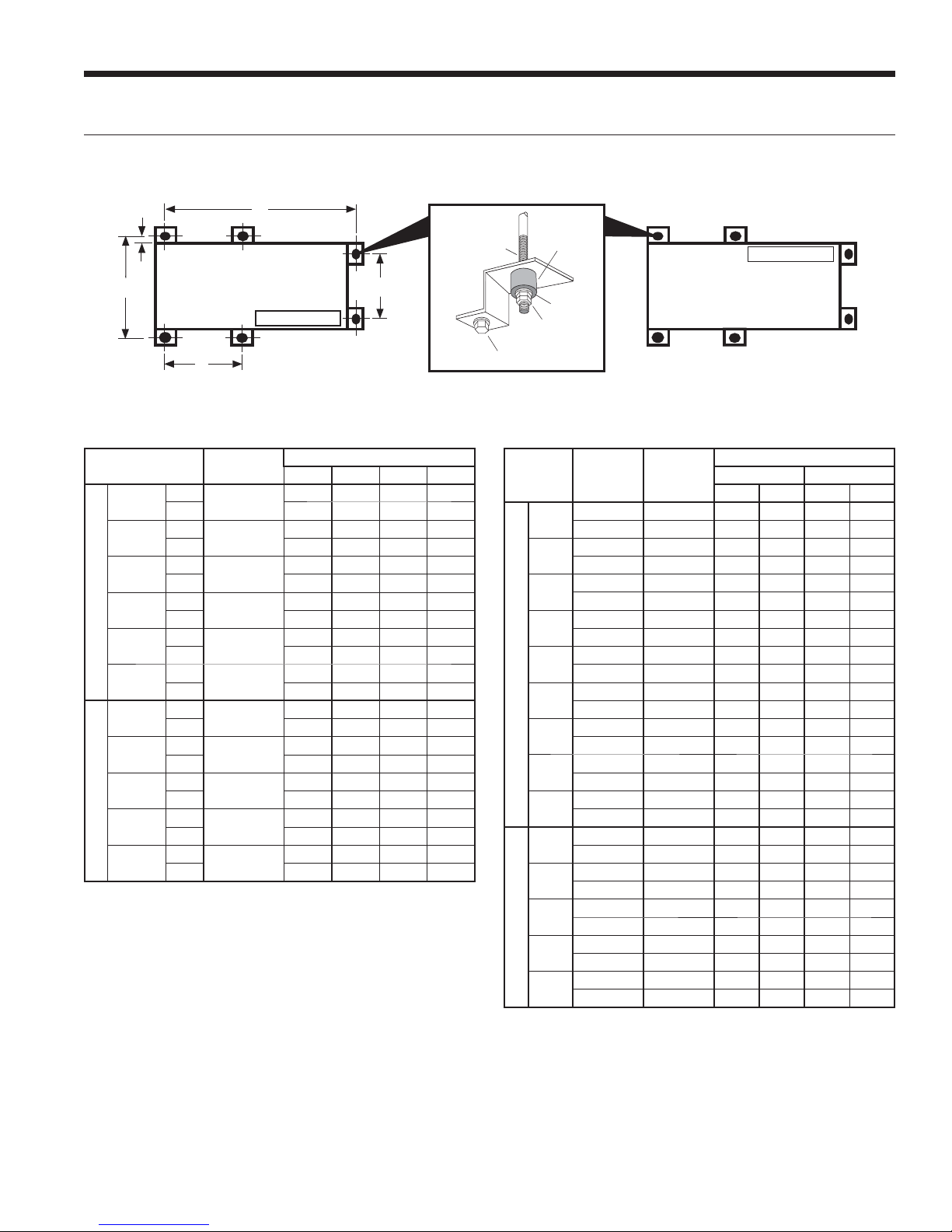

Figure 3: Hanger Location and Assembly

4

/

5 SERIES 500A11 INSTALLATION MANUAL

:STb@WUVb

0

2

Hanger Dimensions

Model

012

018

022-030

036

Single Speed

042-048

060-070

026

038

049

Dual Capacity

064

072

in.

cm. 113.5 63.8 54.4 n/a

in.

cm. 136.4 63.8 54.4 n/a

in.

cm. 161.0 63.0 53.6 n/a

in.

cm. 183.9 70.6 61.2 74.4

in.

cm. 196.6 70.6 61.2 74.4

in.

cm. 209.3 70.6 61.2 74.4

in.

cm. 161.0 63.0 53.6 n/a

in.

cm. 183.9 70.6 61.2 74.4

in.

cm. 196.6 70.6 61.2 74.4

in.

cm. 209.3 70.6 61.2 74.4

in.

cm. 209.3 70.6 61.2 74.4

Hanger Kit

Part Number

99S500A04

99S500A04

99S500A04

99S500A03

99S500A03

99S500A03

99S500A04

99S500A03

99S500A03

99S500A03

99S500A03

!

1

"

/W`1]WZ

Unit Hanger Dimensions

ABCD

44.7 25.1 21.4 n/a

53.7 25.1 21.4 n/a

63.4 24.8 21.1 n/a

72.4 27.8 24.1 29.3

77.4 27.8 24.1 29.3

82.4 27.8 24.1 29.3

63.4 24.8 21.1 n/a

72.4 27.8 24.1 29.3

77.4 27.8 24.1 29.3

82.4 27.8 24.1 29.3

82.4 27.8 24.1 29.3

!&BV`SORSR

@]RPg]bVS`a

2/8/12

6Sf<cba

Pg]bVS`a

0]ZbO\R

:]QYEOaVS`

DWP`ObW]\

7a]ZOb]`

EOaVS`

/W`1]WZ

"

!

Weight Distribution

Horizontal Weight Distribution

Front Back

1234

012

018

Vertical

Weight

185 185 70 45 45 25

[84] [84] [32] [20] [20] [11]

220 220 84 44 59 33

[100] [100] [38] [20] [27] [15]

313 320 122 64 86 48

[142] [145] [55] [29] [39] [22]

328 335 130 42 105 59

[149] [152] [59] [19] [47] [27]

373 388 147 94 94 52

[169] [176] [67] [43] [43] [24]

388 423 161 56 130 76

[176] [192] [73] [25] [59] [35]

428 438 136 114 123 66

[194] [199] [62] [52] [56] [30]

463 473 147 123 132 71

[210] [214] [67] [56] [60] [32]

488 498 154 129 139 75

[221] [226] [70] [59] [63] [34]

313 320 121 78 78 43

[142] [145] [55] [35] [35] [20]

378 388 147 94 94 52

[171] [176] [67] [43] [43] [24]

428 438 136 114 123 66

[194] [199] [62] [52] [56] [30]

473 483 150 126 135 72

[214] [219] [68] [57] [61] [33]

488 500 155 130 140 75

[221] [226] [70] [59] [64] [34]

Model

022

030

036

Single Speed

042

048

060

070

026

038

049

Dual Capacity

064

072

Weights are listed in lbs. [kg] 2/29/12

Horizontal

Weight

7

5 SERIES 500A11 INSTALLATION MANUAL

General Installation Information cont.

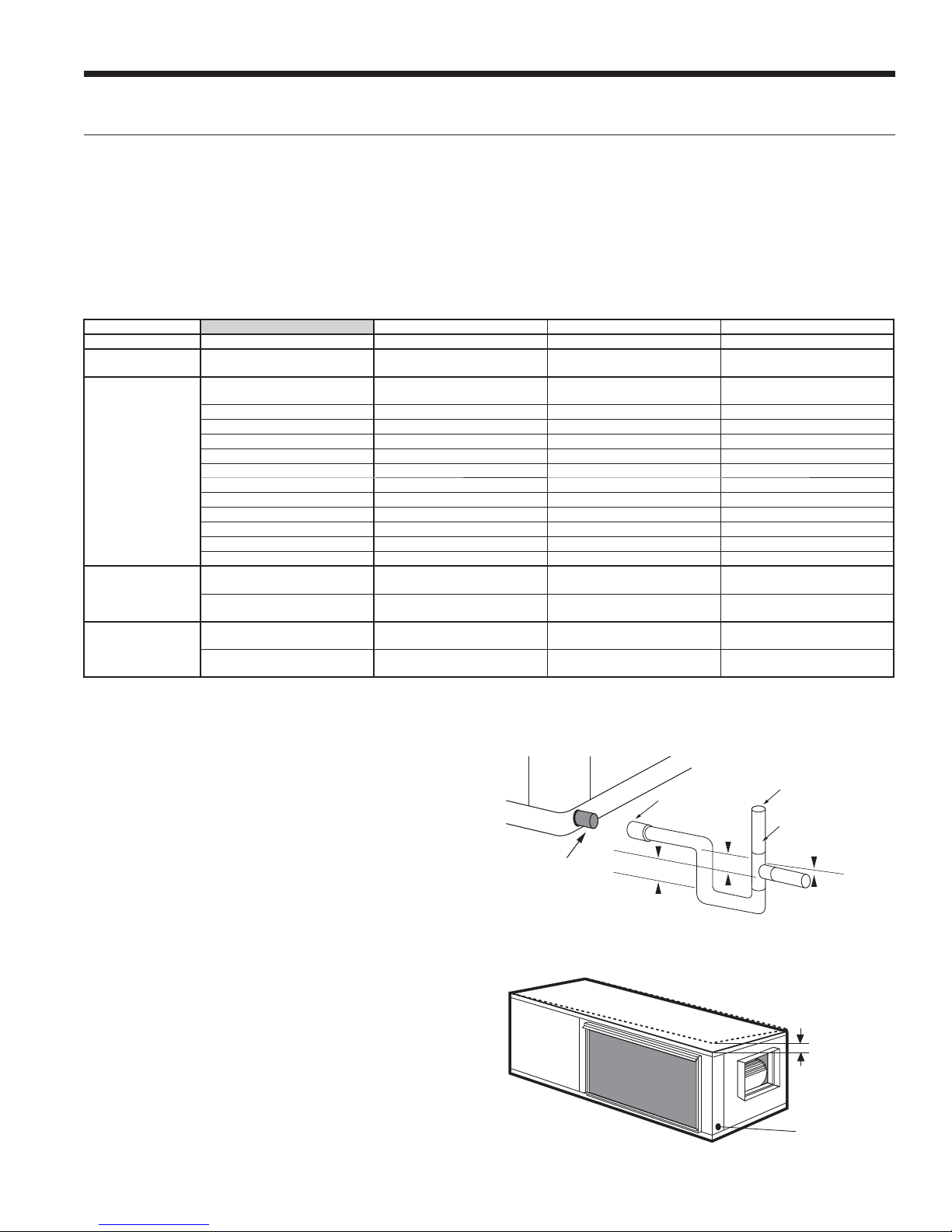

Duct System

An air outlet collar is provided on vertical top and rear

air discharge units and all horizontal units to facilitate

a duct connection (vertical bottomflow units have no

collar). A flexible connector is recommended for discharge

and return air duct connections on metal duct systems.

Uninsulated duct should be insulated with a minimum of

1-inch duct insulation. Application of the unit to uninsulated

ductwork in an unconditioned space is not recommended

as the unit’s performance will be adversely affected.

If the unit is connected to existing ductwork, check the duct

system to ensure that it has the capacity to accommodate

the air required for the unit application. If the duct is too

small, as in the replacement of heating only systems, larger

ductwork should be installed. All existing ductwork should

be checked for leaks and repaired if necessary.

The duct system should be sized to handle the design

airflow quietly and efficiently. To maximize sound

attenuation of the unit blower, the supply and return

plenums should include an internal duct liner of fiberglass

or constructed of ductboard for the first few feet. On

systems employing a sheet metal duct system, canvas

connectors should be used between the unit and the

ductwork. If air noise or excessive airflow is a problem, the

blower speed can be changed.

CAUTION: When attaching ductwork or

accessories to the cabinet, make sure the

fasteners do not come into contact with the

air coil.

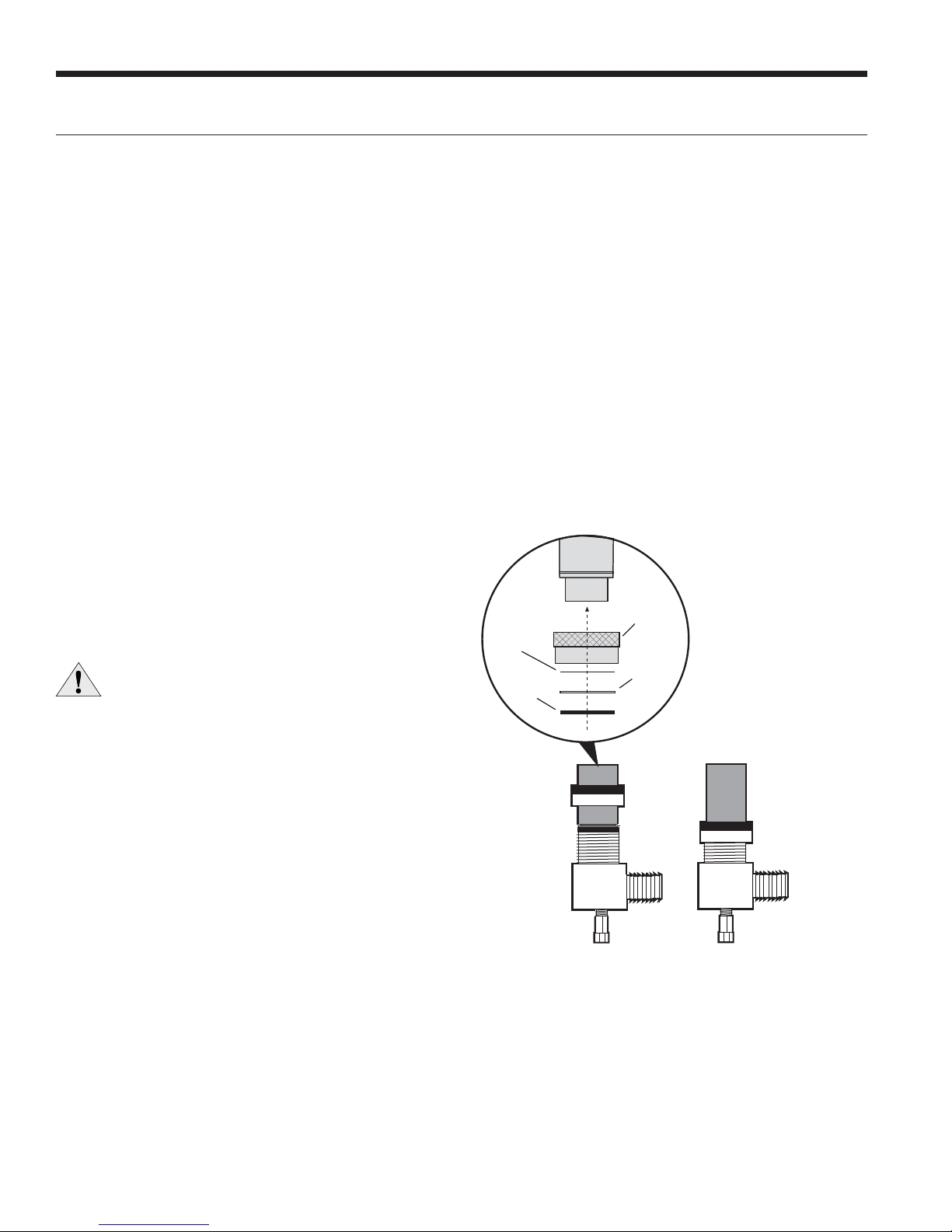

the swivel connector prior to attempting any connection.

The rubber seals are shipped attached to the waterline.

To make the connection to a ground loop system, mate

the brass connector (supplied in CK4LI connector kit)

against the rubber gasket in the swivel connector and

thread the female locking ring onto the pipe threads, while

maintaining the brass connector in the desired direction.

Tighten the connectors by hand, then gently snug the

fitting with pliers to provide a leak-proof joint. When

connecting to an open loop (ground water) system, thread

any 1-inch MPT fitting (SCH80 PVC or copper) into the

swivel connector and tighten in the same manner as noted

above. The open and closed loop piping system should

include pressure/temperature taps for serviceability.

Never use flexible hoses smaller than 1-inch inside diameter

on the unit. Limit hose length to 10 feet per connection.

Check carefully for water leaks.

Figure 4: Swivel Connections

Stainless

Steel

Snap Ring

Gasket

Material

Locking

Ring

Gasket

Support

Sleeve

Water Piping

The proper water flow must be provided to each unit

whenever the unit operates. To assure proper flow, use

pressure/temperature ports to determine the flow rate.

These ports should be located at the supply and return

water connections on the unit. The proper flow rate cannot

be accurately set without measuring the water pressure

drop through the refrigerant-to-water heat exchanger.

All source water connections on residential units are swivel

piping fittings (see Figure 4) that accept a 1-inch male pipe

thread (MPT). The swivel connector has a rubber gasket

seal similar to a rubber hose gasket, which when mated

to the flush end of any 1-inch threaded pipe provides a

leak-free seal without the need for thread sealing tape

or compound. Check to ensure that the rubber seal is in

8

General Installation Information cont.

5 SERIES 500A11 INSTALLATION MANUAL

Water Quality

In ground water situations where scaling could be heavy

or where biological growth such as iron bacteria will be

present, a closed loop system is recommended. The heat

exchanger coils in ground water systems may, over a period

of time, lose heat exchange capabilities due to a buildup

of mineral deposits inside. These can be cleaned, but only

by a qualified service mechanic, as special solutions and

pumping equipment are required. Hot water generator coils

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity

Scaling

Corrosion

Iron Fouling

(Biological Growth)

Erosion

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

Calcium and

Magnesium Carbonate

Hydrogen Sulfide

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron, FE

Bacterial Iron Potential

Iron Oxide

Suspended Solids

Threshold Velocity

(Fresh Water)

Less than 0.5 ppm (rotten egg

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

2

+ (Ferrous)

smell appears at 0.5 ppm)

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

7 - 9 7 - 9 7 - 9

(Total Hardness)

less than 350 ppm

< 0.2 ppm < 0.2 ppm < 0.2 ppm

< 6 ft/sec < 6 ft/sec < 6 ft/sec

can likewise become scaled and possibly plugged. In areas

with extremely hard water, the owner should be informed

that the heat exchanger may require occasional flushing.

Units with cupronickel heat exchangers are recommended

for open loop applications due to the increased resistance

to build-up and corrosion, along with reduced wear caused

by acid cleaning. Failure to adhere to the guidelines in the

water quality table could result in the loss of warranty.

(Total Hardness)

less than 350 ppm

10 - 50 ppm Less than 1 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

(Total Hardness)

less than 350 ppm

Less than 1 ppm, above this

level deposition will occur

Less than 10 ppm and filtered

for max. of 600 micron size

2/22/12

Low Water Coil Limit

Set the freeze sensing switch SW2-1 on the Aurora Base

Control (ABC) printed circuit board for applications using

a closed loop antifreeze solution to “LOOP” (15°F). On

applications using an open loop/ground water system (or

closed loop no antifreeze), set this dip switch to “WELL”

(30°F), the factory default setting. (Refer to the DIP Switch

Settings table in the Aurora Control section.)

Condensate Drain

On vertical units, the internal condensate drain assembly

consists of a drain tube which is connected to the

drain pan, a 3/4-inch PVC female adapter and a flexible

connecting hose. The female adapter may exit either the

front or the side of the cabinet. The adapter should be

glued to the field-installed PVC condensate piping. On

vertical units, a condensate hose is inside all cabinets as a

trapping loop; therefore, an external trap is not necessary.

On horizontal units, a PVC stub is provided for condensate

drain piping connection. An external trap is required (see

below). If a vent is necessary, an open stand pipe may be

applied to a tee in the field-installed condensate piping.

Figure 5: Horizontal Drain Connection

PVC coupling

PVC tube stub

NOTE: Check dimensional data for actual PVC sizes.

1.5 in.

1.5 in.

Figure 6: Unit Pitch for Drain

9

Vent (if needed)

PVC tube stub

1/8 in. per foot

1/2'' Pitch

Drain

5 SERIES 500A11 INSTALLATION MANUAL

Closed Loop Ground Source Systems

NOTE: For closed loop systems with antifreeze protection,

set SW2-1 to the “LOOP” (15°F) position. (Refer to the DIP

Switch Settings table in the Aurora Control section.)

Once piping is completed between the unit, pumps and the

ground loop (see figure below), final purging and charging

of the loop is required. A flush cart (or a 1.5 HP pump

minimum) is needed to achieve adequate flow velocity

in the loop to purge air and dirt particles from the loop

itself. Antifreeze solution is used in most areas to prevent

freezing. Flush the system adequately to remove as much

air as possible then pressurize the loop to a static pressure

of 40-50 psi (summer) or 50-75 psi (winter). This is

normally adequate for good system operation. Loop static

pressure will fluctuate with the seasons. Pressures will be

higher in the winter months than during the cooling season.

This fluctuation is normal and should be considered when

initially charging the system.

After pressurization, be sure to turn the venting (burping)

screw in the center of the pump two (2) turns open (water

will drip out), wait until all air is purged from the pump,

then tighten the plug. Ensure that the loop pumps provide

adequate flow through the unit(s) by checking the pressure

drop across the heat exchanger and comparing it to the unit

capacity data in this catalog. 2.5 to 3 gpm of flow per ton of

cooling capacity is recommended in earth loop applications.

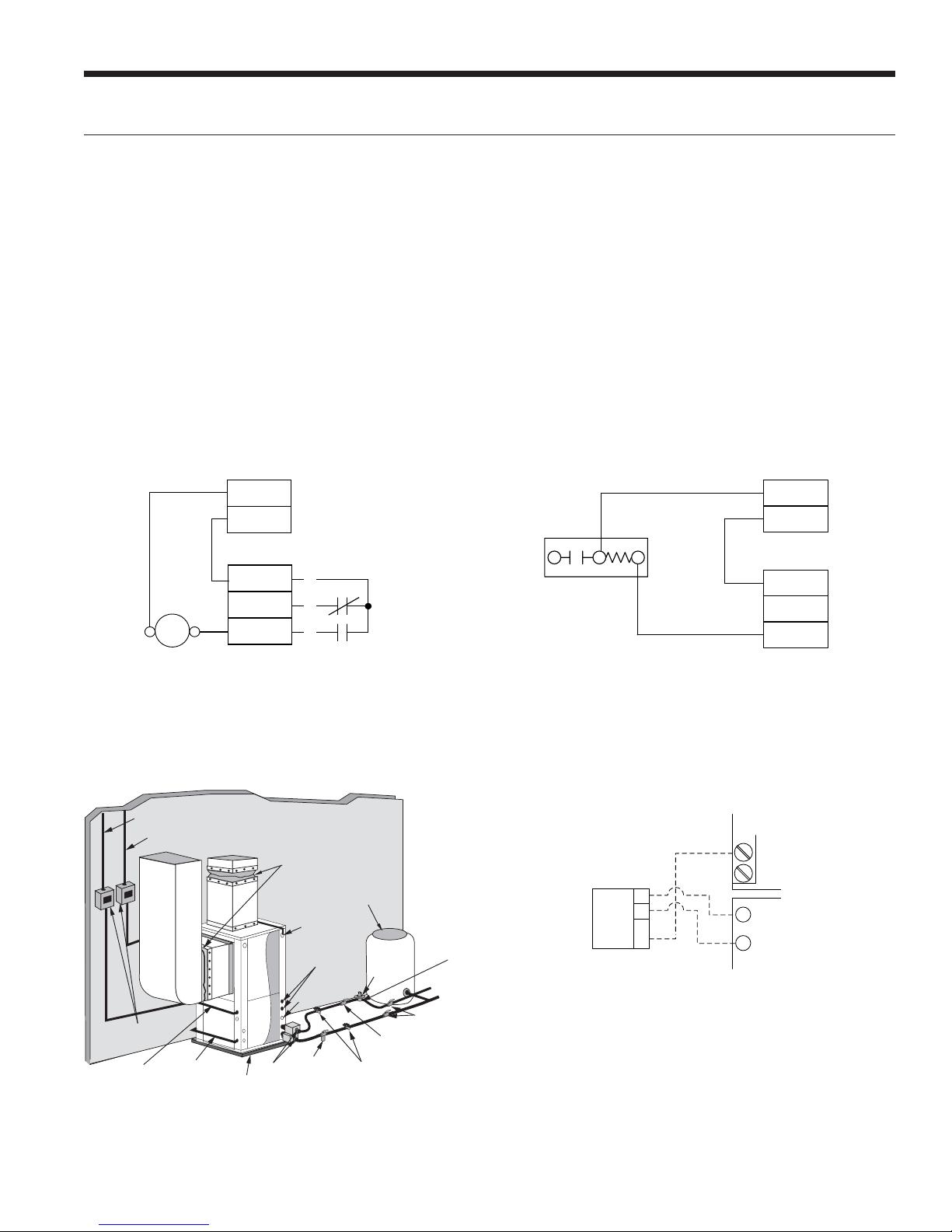

Figure 7: Closed Loop Ground Source Application

Disconnects

(If Applicable)

Unit Supply

Auxiliary Heat

Supply

Low

Voltage to

Thermostat

P/T Plugs

Vibration Absorbing Pad

®

GeoLink

Polyethylene w/

®

Armaflex

Insulation

Flexible Duct

Collar

Auxiliary

Heater

Knockout

Unit Power

Hot Water Generator

Connections

Drain

P/T

®

GeoLink

low

F

enter

C

Insulated piping

or hose kit

TO

LOOP

NOTE: Additional information can be found in Flow

Center installation manual and Flush Cart manual.

Multiple Units on One Flow Center

NOTE: This feature is only available in the Aurora Advanced

Control package (AXB board), NOT the Aurora Base

Control (ABC).

When two units are connected to one loop pumping system,

pump control is automatically achieved by connecting the

SL terminals on connector P2 in both units with 2-wire

thermostat wire. These terminals are polarity dependant (see

Figure 8b). The loop pump(s) may be powered from either

unit, whichever is more convenient. If either unit calls, the loop

pump(s) will automatically start. The use of two units on one

flow center is generally limited to a total of 20 gpm capacity.

NOTE: To achieve this same feature when heat pumps have

only the Aurora Base Control, follow Figure 8a. Installer will

be required to supply fuses, two relays, and wiring.

Variable Speed Pump Setup

When using a variable speed pump flow center (FCV1-GL or

FCV2-GL) the use of an AID Tool will be necessary to adjust

minimum and maximum flow rates. The factory default is:

minimum=75% and maximum=100% speed levels.

Figure 8a: Primary/Secondary Wiring with Aurora Base

Control (no AXB Board)

Ext Pump

1/2 hp Total

208-230/60/1

Pump

G

Pump

Circuit

Breaker

PB1

1

1

1

2

2

Circuit

Breaker

Field Supplied

Relay for Heat

5A

5A

Pump 2

Hot Water

Limit Switch

130°F

HWG

Pump

Cabinet

HW Switch

Blue

Optional Internal

HWG Pump

Cap

Field Supplied

Fuses 5A

Purple

3

2

1

Field Supplied

Relay for Heat

Pump 1

Figure 8b: Primary/Secondary Hook-up

5 Series to

Envision Units

5 Series Unit #1

with AXB Board

With pump

wired to

Unit 1

Shut

Down

Envision Unit #2

OUTIN C C

CC

VSSLOSLI

With pump

wired to

Unit 2

SL1InSL1

Out

Electromechanical Units

To Electromechanical Unit

With pump

wired to Unit 1

With pump

wired to

Unit 2

5 Series to

5 Series Units

5 Series Unit #1

with AXB Board

OUTIN C C

OUTIN C C

5 Series Unit #2

with AXB Board

VSSLOSLI

VSSLOSLI

Compressor

Blue

CRS

Red

Black

Tan(6)

T1

T2

CC

L2

L1

5 Series to

5 Series Unit #1

with AXB Board

OUTIN C C

C

S

Heat Pump 1

Contactor Coil

Heat Pump 2

Contactor Coil

VSSLOSLI

10

Open Loop Ground Water Systems

5 SERIES 500A11 INSTALLATION MANUAL

Typical open loop piping is shown below. Always maintain

water pressure in the heat exchanger by placing water

control valves at the outlet of the unit to prevent mineral

precipitation. Use a closed, bladder-type expansion tank

to minimize mineral formation due to air exposure. Ensure

proper water flow through the unit by checking pressure

drop across the heat exchanger and comparing it to the

figures in unit capacity data tables in the specification

catalog. 1.5-2 gpm of flow per ton of cooling capacity is

recommended in open loop applications.

Discharge water from the unit is not contaminated in any

manner and can be disposed of in various ways, depending

Figure 9a: Open Loop Solenoid Valve Connection Option

Typical quick operating external 24V water solenoid valve

(type PPV100 or BPV100) wiring.

C

P1

R

SV

Acc Com

Acc NC

Acc NO

1

2

P2

3

Solenoid

Valve

on local codes, i.e. recharge well, storm sewer, drain field,

adjacent stream or pond, etc. Most local codes forbid

the use of sanitary sewer for disposal. Consult your local

building and zoning departments to assure compliance in

your area.

NOTE: For open loop/groundwater systems or systems

that do not contain an antifreeze solution, set SW2-Switch

#1 to the “WELL” (30°F) position. (Refer to the DIP Switch

Settings table in the Aurora Control section.) Slow opening/

closing solenoid valves (type VM) are recommended to

eliminate water hammer.

Figure 9b: Open Loop Solenoid Valve Connection Option

Typical slow operating external 24V water solenoid valve

(type VM) wiring and one (1) quick operating valve.

C

R

VM Valve

Acc Com

ACC NC

Acc NO

NOTE: SW2-4 and SW2-5 should be “OFF” to cycle with

the compressor.

Figure 10: Open System - Groundwater Application

Unit Supply

Aux. Heat Supply

Flexible

Duct Collar

Rubber Bladder

Expansion Tank

Auxiliary

Disconnects

(IfApplicable)

Compressor

Line Voltage

Low Voltage

to Thermostat

and Valve

P/T Plugs

Vibration

Absorbing Pad

Heater

Knockout

Hot Water Generator

Connections

Drain

Strainer

Boiler Drains

For HX Flushing

Solenoid

Valve

valve while acid flushing)

Flow Control

(on outlet of

Solenoid Valve)

Water Out

Shut Off Valves

Shut Off Valves

(to isolate solenoid

Valve

Water In

NOTE: SW2-4 should be “ON” and SW2-5 should be “OFF”

when using a slow opening (VM) water valve.

Figure 9c: Modulating Water Valve Connection Option

Typical 0-10VDC modulating water valve.

AXB BOARD

2 1

GND

24 VAC

0-10DC

1

2

3

VS PUMP

C

R

ABC BOARD

11

5 SERIES 500A11 INSTALLATION MANUAL

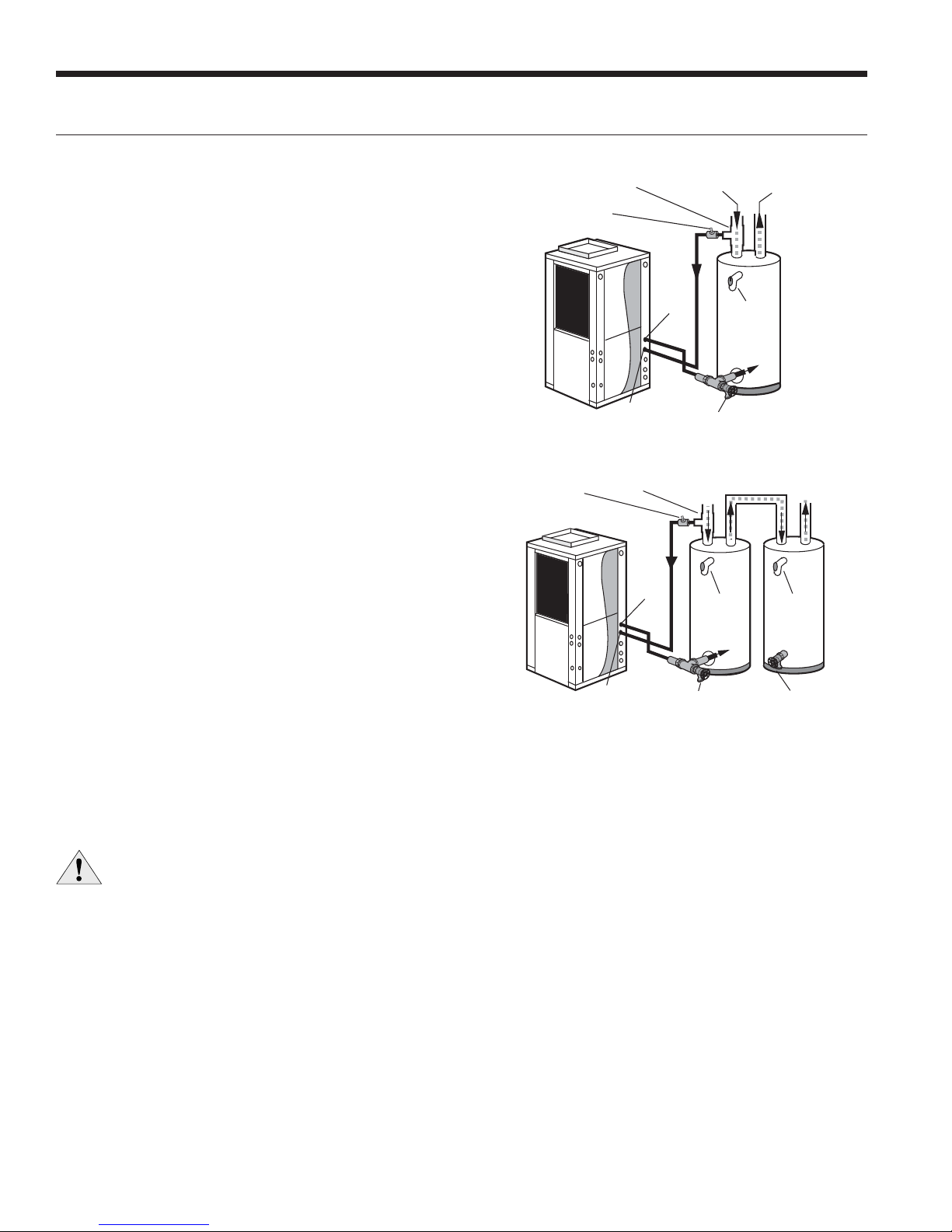

Hot Water Generator Connections

To maximize the benefits of the hot water generator a

minimum 50-gallon water heater is recommended For

higher demand applications, use an 80-gallon water

heater or two 50-gallon water heaters connected in a

series as shown below. Two tanks plumbed in a series

is recommended to maximize the hot water generator

capability. Electric water heaters are recommended. Make

sure all local electrical and plumbing codes are met for

installing a hot water generator. Residential units with hot

water generators contain an internal circulator and fittings.

A water softener is recommended with hard water (greater

than 10 grains or 170 total hardness).

NOTES: 1) Using a preheat tank, as shown in Figure 12, will

maximize hot water generator capabilities. 2) The hot water

generator coil is constructed of vented double wall copper

suitable for potable water.

Water Tank Preparation

To install a unit with a hot water generator, follow these

installation guidelines.

1. Turn off the power to the water heater.

2. Attach a water hose to the water tank drain

connection and run the other end of the hose to an

open drain or outdoors.

3. Close the cold water inlet valve to the water heater tank.

4. Drain the tank by opening the valve on the bottom

of the tank, then open the pressure relief valve or hot

water faucet.

5. Flush the tank by opening the cold water inlet valve to

the water heater to free the tank of sediments. Close

when draining water is clear.

6. Disconnect the garden hose and remove the drain valve

from the water heater.

7. Refer to Plumbing Installation and Hot Water

Generator Startup.

Figure 11: Typical Hot Water Generator Installation

3/4” x 3/4” x 1/2” tee

Venting Waste

Valve or Vent

Coupling

HWG

Water In

HWG

Water Out

Cold

Water In

P/T Relief

Drain Valve

Valve

Hot

Water Out

In

Figure 12: Hot Water Generator Installation In Preheat Tank

Venting Waste Valve

or Vent Coupling

Water In

3/4" x 3/4"

x 1/2" tee

HWG

HWG

Water Out

Cold

Water In

P/T Relief

Valve

Storage

Tank

Water Out

P/T Relief

In

Drain ValveDrain Valve

Electric Powered

Water Heater

Hot

Valve

NOTE: This configuration maximizes hot water

generator capability.

CAUTION: Elements will burn out if energized dry.

12

Hot Water Generator Connections cont.

5 SERIES 500A11 INSTALLATION MANUAL

Plumbing Installation

1. Inspect the dip tube in the water heater cold inlet

for a check valve. If a check valve is present it must

be removed or damage to the hot water generator

circulator will occur.

2. Remove drain valve and fitting.

3. Thread the 3/4-inch NPT x 3-1/2-inch brass nipple into

the water heater drain port.

4. Attach the center port of the 3/4-inch FPT tee to the

opposite end of the brass nipple.

5. Attach the 1/2-inch copper to 3/4-inch NPT adaptor to

the side of the tee closest to the unit.

6. Install the drain valve on the tee opposite the adaptor.

7. Run interconnecting tubing from the tee to hot water

generator water out.

8. Cut the cold water “IN” line going to the water heater.

9. Insert the reducing solder tee in line with cold water

“IN” line as shown.

10.

Run interconnecting copper tubing between the unit hot

water generator water “IN” and the tee (1/2-inch nominal).

The recommended maximum distance is 50 feet.

11.

To prevent air entrapment in the system, install a vent

coupling at the highest point of the interconnecting lines.

12. Insulate all exposed surfaces of both connecting water

lines with 3/8-inch wall closed cell insulation.

NOTE: All plumbing and piping connections must comply

with local plumbing codes.

Hot Water Generator Switch

The hot water generator switch is taped in the disabled

position at the factory.

Hot Water Generator Startup

1. Turn the hot water generator switch to the “ON”

position. The hot water generator switch will allow the

hot water generator pump to be enabled or disabled by

the service technician or homeowner.

2. Close the drain valve to the water heater.

3. Open the cold water supply to the tank.

4. Open a hot water faucet in the building to bleed air from

the system. Close when full.

5. Open the pressure relief valve to bleed any remaining air

from the tank, then close.

6. If so equipped, turn the venting (burping) screw in the

center of the pump two (2) turns open (water will drip

out), wait until all air is purged from the pump, then

tighten the plug. Use vent couplings to bleed air from

the lines.

7. Carefully inspect all plumbing for water leaks and

correct as required.

8. Before restoring electrical supply to the water heater,

adjust the temperature setting on the tank.

• On tanks with both upper and lower elements,

the lower element should be turned down to

the lowest setting, approximately 100°F. The

upper element should be adjusted to 120°F to

130°F. Depending upon the specific needs of

the customer, you may want to adjust the upper

element differently.

• On tanks with a single element, lower the

thermostat setting to 120°F.

9. After the thermostat(s) is adjusted, replace the access

cover and restore electrical supply to the water heater.

10. Make sure that any valves in the hot water generator

water circulating circuit are open.

11. Turn on the unit to first stage heating.

12. Use an AID Tool to enable HWG and select the desired

water heating set point. Selectable set points are 100°F

– 140°F in 5°F increments (default 130°F). From the Main

Menu of the AID Tool select Setup, then AXB Setup.

13. The hot water generator pump should be running. When

the pump is first started, turn the venting (burping)

screw (if equipped) in the center of the pump two (2)

turns open until water dribbles out, then replace. Allow

the pump to run for at least five minutes to ensure that

water has filled the circulator properly. Be sure the

switch for the hot water generator pump switch is “ON”.

14. The temperature difference between the water entering

and leaving the hot water generator should be 5°F to

15°F. The water flow should be approximately 0.4 gpm

per ton of nominal cooling.

15. Allow the unit to heat water for 15 to 20 minutes to be

sure operation is normal.

CAUTION: Never operate the HWG circulating

pump while dry. If the unit is placed in operation

before the hot water generator piping is

connected, be sure that the pump switch is set

to the OFF position.

13

5 SERIES 500A11 INSTALLATION MANUAL

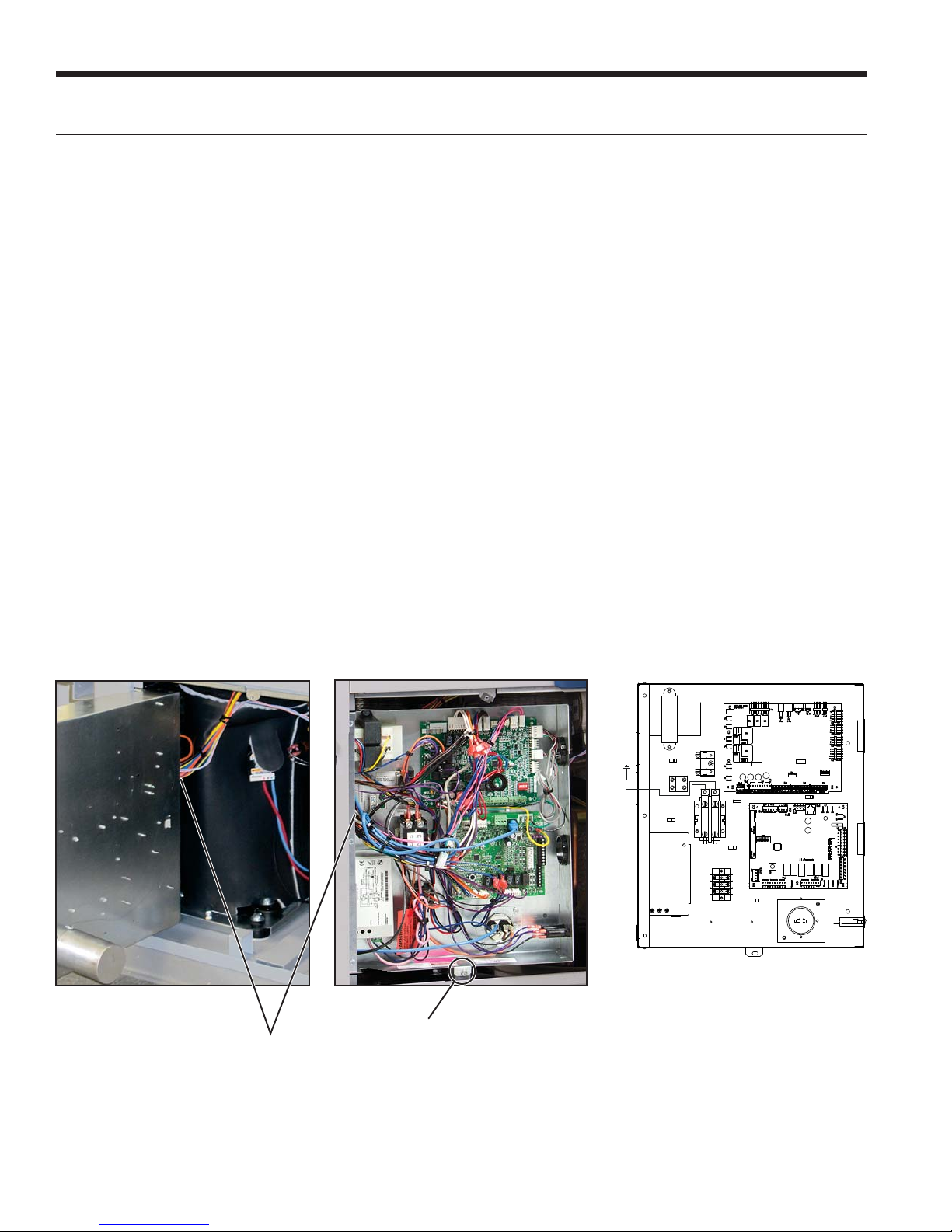

Electrical Connections

General

Be sure the available power is the same voltage and phase

as that shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable.

Unit Power Connection

Connect the incoming line voltage wires to L1 and L2 of

the contactor as shown in Figure 13C for single-phase unit.

Consult the Unit Electrical Data in this manual for correct

fuse sizes.

Open lower front access panel. Remove ground fastener

from bottom of control box (Figure 13B). Swing open

control box (Figure 13A). Insert power wires through

knockouts on lower left side of cabinet. Route wires

through left side of control box and connect to contactor

and ground (Figure 13C). Close control box and replace

grounding fastener before unit start-up.

Accessory Relay

A set of “dry” contacts has been provided to control

accessory devices, such as water solenoid valves on open

loop installations, electronic air cleaners, humidifiers, etc.

This relay contact should be used only with 24 volt signals

and not line voltage power. The relay has both normally

open and normally closed contacts and can operate with

either the fan or the compressor. Use DIP switch SW2-4

and 5 to cycle the relay with blower, compressor, or control

a slow opening water valve. The relay contacts are available

on terminals #2 and #3 of P2.

A second configurable accessory relay is provided on the

AXB board, if installed. When powering high VA draw

components such as electronic air cleaners or VM type

open loop water valves, R should be taken ‘pre-fuse’ from

the ‘R’ quick connect on the ABC board and not the ‘postfuse’ ‘R’ terminal on the thermostat connection. If not,

blown ABC fuses might result.

208 Volt Operation

All 208/230 units are factory wired for 230 volt operation.

For 208 volt operation, the red and blue transformer wires

must be switched on terminal strip PB2.

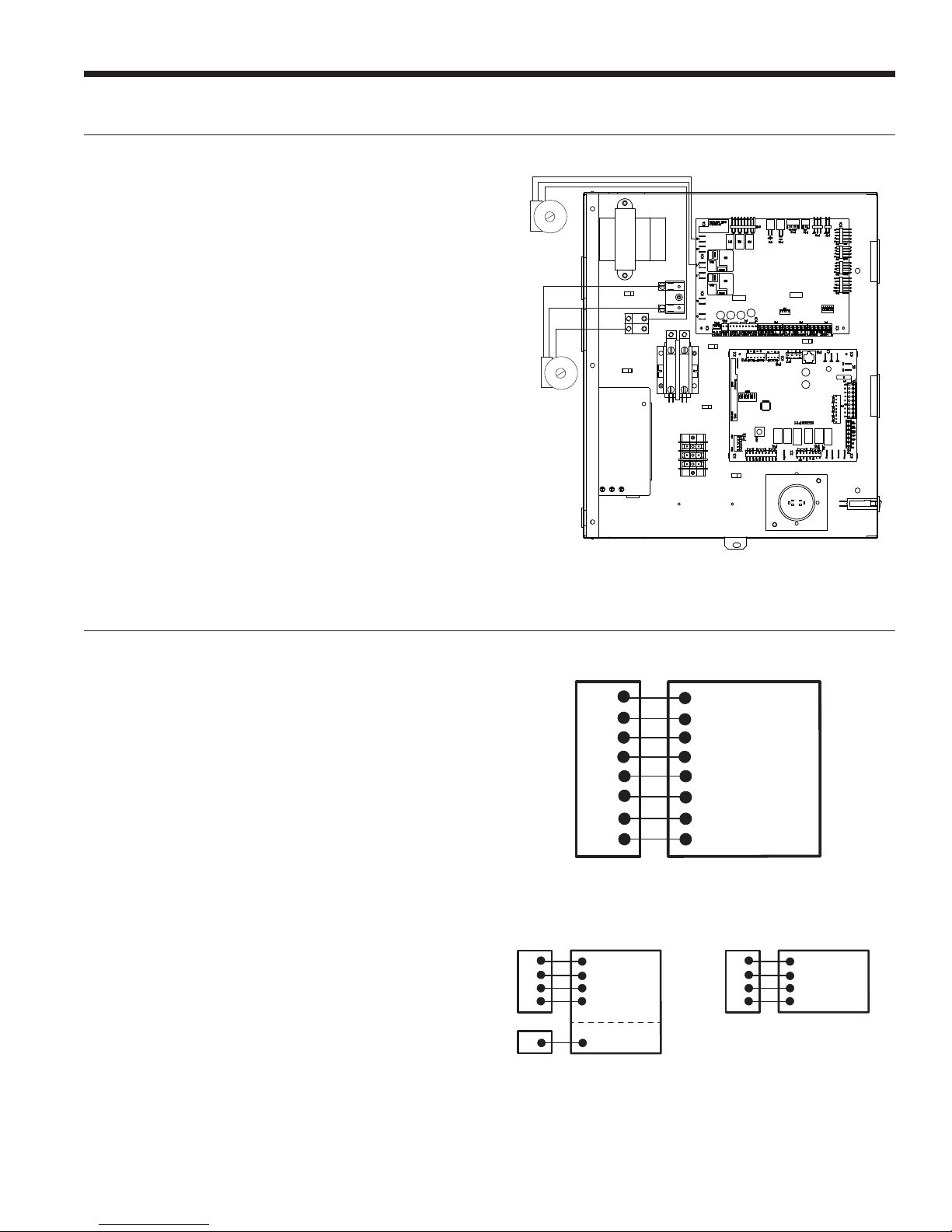

Figure 13A:

Wire access (control box open)

Wire Insert

Location

Figure 13B:

Wire access (control box closed)

Ground Fastener

must be installed for

proper unit ground

Figure 13C:

Line Voltage 208-230/60/1 control box

1

PB1

2

L2

L1

T1T2

1

2

3

PS

14

Electrical Connections cont.

5 SERIES 500A11 INSTALLATION MANUAL

Pump Power Wiring

See Figure 14 for electrical connections from control box

to pumps.

FC1/FC2 style flow centers with fixed speed pumps

connect to PB1 in the control box. If using a variable speed

pump it should be connected to L1 and L2 on the AXB.

Figure 14: Pump Wiring 208-230/60/1

Optional External

Variable Speed Loop

Pump (ex. Magna Geo)

208-230/60/1

PB1

External

Loop Pump(s)

208-230/60/1

1/2 hp Max

CB

Electronic Thermostat Installation

Position the thermostat subbase against the wall so that

it is level and the thermostat wires protrude through

the middle of the subbase. Mark the position of the

subbase mounting holes and drill holes with a 3/16-inch

bit. Install supplied anchors and secure base to the wall.

Thermostat wire must be 8-conductor (4 or 5 counductor

for communicating thermostats), 20-AWG (minimum)

wire. Strip the wires back 1/4-inch (longer strip lengths

may cause shorts) and insert the thermostat wires into

the connector as shown. Tighten the screws to ensure

secure connections. The thermostat has the same type

connectors, requiring the same wiring. See instructions

enclosed in the thermostat for detailed installation and

operation information. The W1 terminal on TPCM32U03

and TPCM32U04 communicating thermostats may be

hard wired to provide aux/emergency heat in the event

communication is lost between the thermostat and the

ABC microprocessor.

NOTE: Aurora Base Control (ABC) DIP switch SW2-7 is

required to be in the “OFF” position for the control to

operate with FaultFlash or ComforTalk thermostats. SW2-7

in the “ON” position configures the control to operate with

typical thermostats (continuous lockout signal). There

must be a wire connecting Y2 on the Aurora controller

to 2nd stage compressor on the thermostat for proper

operation. SW2-7 DIP switch position is not relevant with

communicating thermostats.

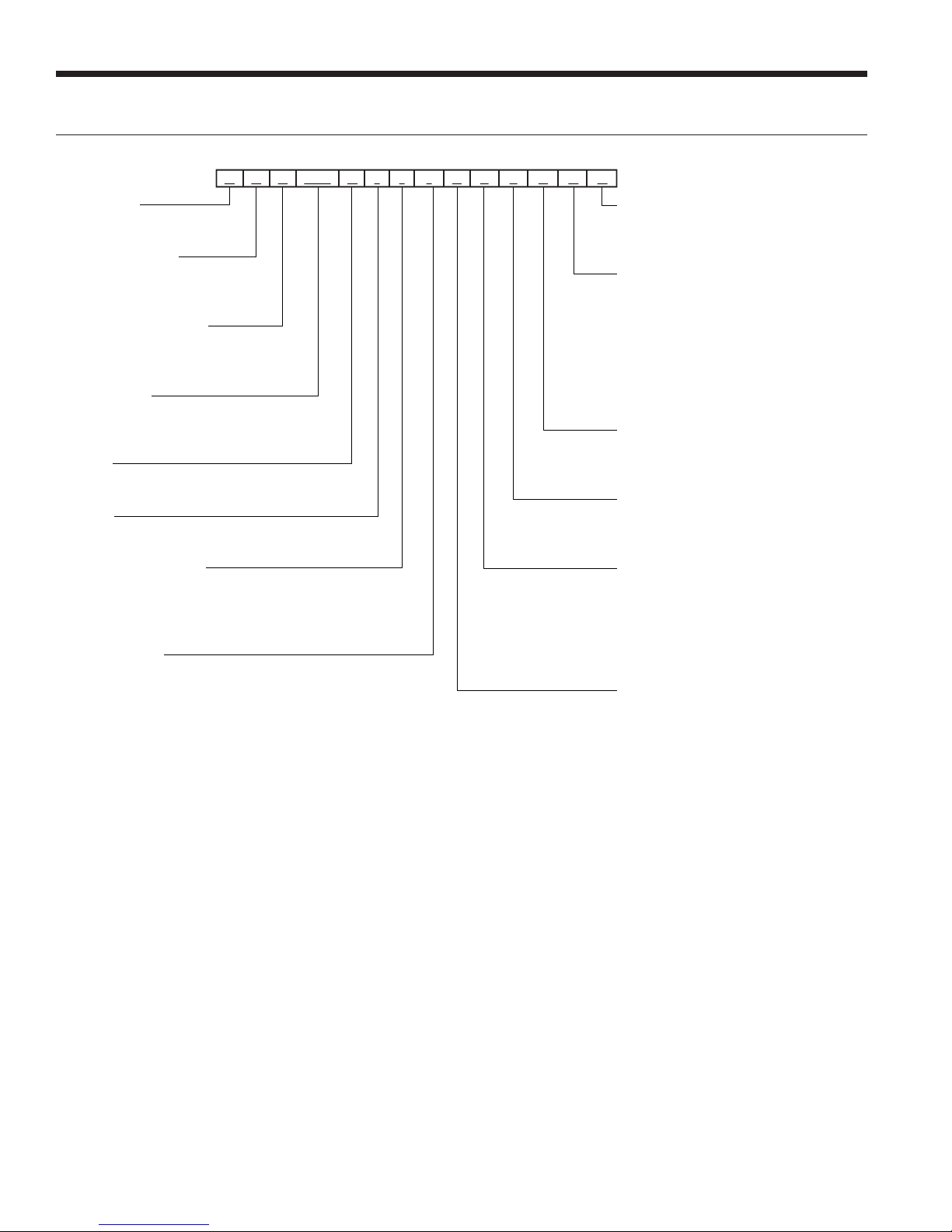

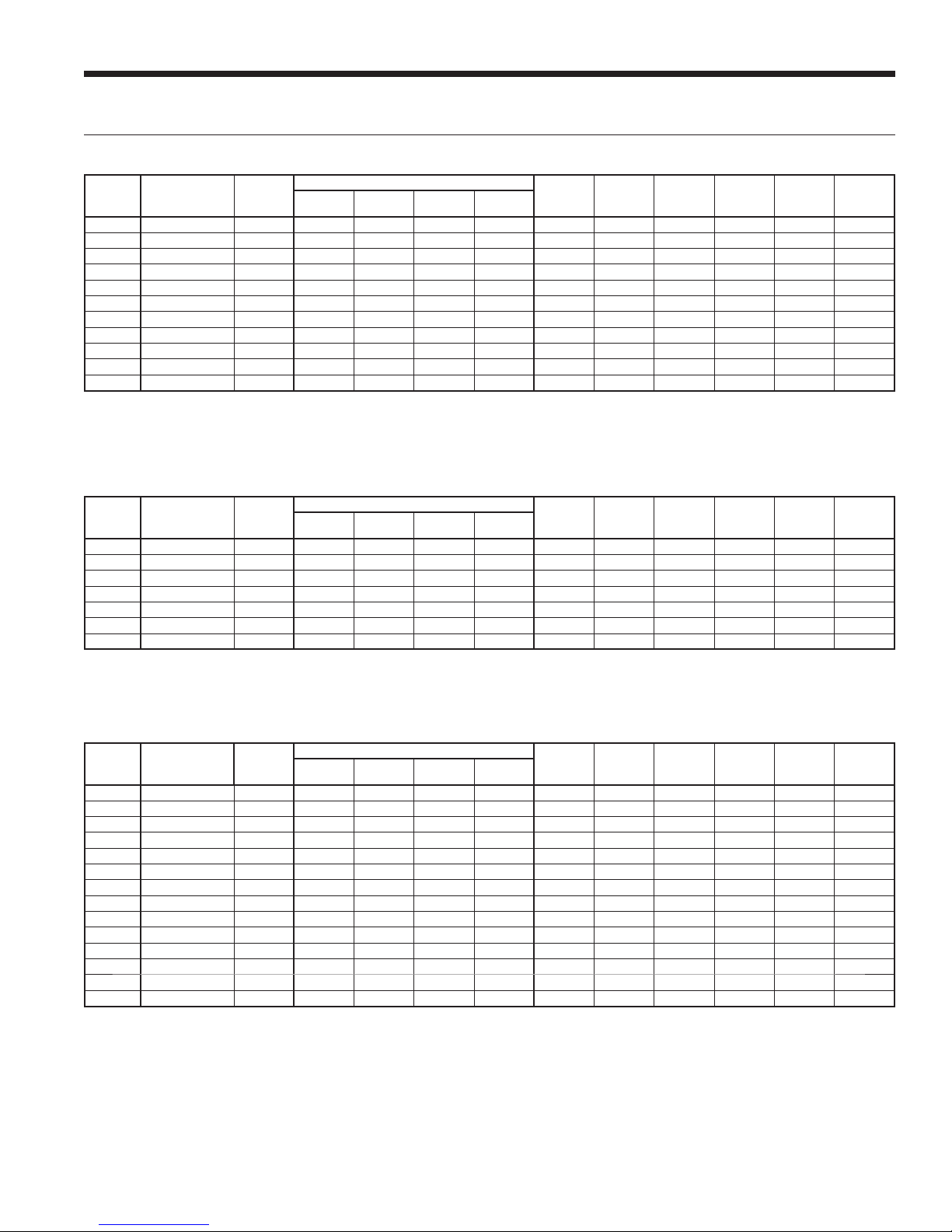

Figure 15a: Thermostat Wiring (Y1 Style Signals)

R

C

Y1

Y2

W

O

G

L

Microprocessor Controller

24VAC (Hot)

24VAC (Common)

Compressor (1st Stage)

Compressor (2nd Stage)

Aux. Heat

Reversing Valve

Blower Relay

System Monitor

Thermostat Connection

Figure 15b: Thermostat Wiring (Communicating Style Signals)

P7

Microprocessor Controller

C

R

–

+

P1

W

C 24VAC (Common)

R 24VAC (Hot)

B- Communication

A+ Communication

W1 (Optional)

TPCM32U03/TPCM32U04

Monochrome Thermostats

Thermostat Connection

P7

Microprocessor

Controller

C

R

–

+

C 24VAC (Common)

R 24VAC (Hot)

DX- Communication

DX+ Communication

TPCC32U01

Color Touchscreen

Thermostat

Connection

Thermostat

15

5 SERIES 500A11 INSTALLATION MANUAL

Auxiliary Heat Ratings

Model

EAS(H)4 2.9 3.8 1 9,700 12,900 250

EAM(H)5 3.6 4.8 1 12,300 16,300 450

EAM(H)8 5.7 7.6 2 19,400 25,900 550

EAM(H)10 7.2 9.6 2 24,600 32,700 650

EAL(H)10 7.2 9.6 2 24,600 32,700 1100

EAL(H)15 10.8 14.4 3 36,900 49,100 1250

EAL(H)20 14.4 19.2 4 49,200 65,500 1500

Order the “H” part number when installed on horizontal and vertical rear discharge units

Air flow level for auxiliary heat (Aux) must be above the minimum cfm in this table

kW

208V 230V 208V 230V 012 018 022 026 - 030 036 - 042 048 - 072

Stages

Btu/h

Min cfm

Auxiliary Heat Electrical Data

Model

EAS(H)4

EAM(H)5

EAM(H)8

EAM(H)10

EAL(H)10

EAL(H)15

EAL(H)20

All heaters rated single phase 60 cycle and include unit blower load

All fuses type “D” time delay (or HACR circuit breaker in USA)

Supply wire size to be determined by local codes

Supply

Circuit

Single 13.7 15.8 17.9 20.5 20 20 20 20 20 20

Single 17.3 20.0 26.7 30.0 30 30 30 30 30 30

Single 27.5 31.7 39.3 44.6 40 45 40 45 40 45

Single 34.7 40.0 48.3 55.0 50 60 50 60 50 60

Single 34.7 40.0 53.3 60.0 60 60 60 60 60 60

Single 52.0 60.0 75.0 85.0 80 90 80 90 70 100

L1/L2 34.7 40.0 53.3 60.0 60 60 60 60 60 60

L3/L4 17.3 20.0 21.7 25.0 25 25 25 25 20 30

Single 69.3 80.0 96.7 110.0 100 110 100 110 100 100

L1/L2 34.7 40.0 53.3 60.0 60 60 60 60 60 60

L3/L4 34.7 40.0 43.3 50.0 45 50 45 50 40 50

Heater Amps Min Circuit Amp Fuse (USA) Fuse (CAN) CKT BRK

208 V 240 V 208 V 240 V 208 V 240 V 208 V 240 V 208 V 240 V

Model Size Compatibility

•

•••

•••

•

••

••

•

5/8/12

2/11/12

16

Electrical Data

Single Speed Unit with Variable Speed ECM Motor

Model Rated Voltage

018

208-230/60/1 197/253 10.4 6.7 33.5 n/a 0.4 5.4 4.0 16.5 18.1 20

022

030

036

036*

042

042*

048

048*

060

070

* With optional 1 hp ECM motor

** With optional IntelliStart

Rated voltage of 208/230/60/1

All fuses Class RK-5

HACR circuit breaker in USA only

208-230/60/1 197/253 14.0 9.0 48.0 17.0 0.4 5.4 4.0 18.8 21.0 30

208-230/60/1 197/253 20.0 12.8 58.3 21.0 0.4 5.4 4.0 22.6 25.8 35

208-230/60/1 197/253 22.0 14.1 73.0 26.0 0.4 5.4 4.0 23.9 27.4 40

208-230/60/1 197/253 22.0 14.1 73.0 26.0 0.4 5.4 7.0 26.9 30.4 40

208-230/60/1 197/253 26.0 16.6 79.0 28.0 0.4 5.4 4.0 26.4 30.6 45

208-230/60/1 197/253 26.0 16.6 79.0 28.0 0.4 5.4 7.0 29.4 33.6 50

208-230/60/1 197/253 31.0 19.8 109.0 38.0 0.4 5.4 4.0 29.6 34.6 50

208-230/60/1 197/253 31.0 19.8 109.0 38.0 0.4 5.4 7.0 32.6 37.6 50

208-230/60/1 197/253 41.2 26.4 134.0 47.0 0.4 5.4 7.0 39.2 45.8 70

208-230/60/1 197/253 44.2 28.3 178.0 63.0 0.4 5.4 7.0 41.1 48.2 70

Voltage

Min/Max

®

MCC RLA LRA LRA**

Single Speed Unit with 5-Speed ECM Motor

Model

022

030

036

042

048

060

070

** With optional IntelliStart

Rated voltage of 208/230/60/1

All fuses Class RK-5

HACR circuit breaker in USA only

Rated

Voltage

208-230/60/1 197/253 14.0 9.0 48.0 17.0 0.4 5.4 4.1 18.9 21.1 30

208-230/60/1 197/253 20.0 12.8 58.3 21.0 0.4 5.4 4.1 22.7 25.9 35

208-230/60/1 197/253 22.0 14.1 73.0 26.0 0.4 5.4 4.1 24.0 27.5 40

208-230/60/1 197/253 26.0 16.6 79.0 28.0 0.4 5.4 7.6 30.0 34.2 50

208-230/60/1 197/253 31.0 19.8 109.0 38.0 0.4 5.4 7.6 33.2 38.2 50

208-230/60/1 197/253 41.2 26.4 134.0 47.0 0.4 5.4 7.6 39.8 46.4 70

208-230/60/1 197/253 44.2 28.3 178.0 63.0 0.4 5.4 7.6 41.7 48.8 70

Voltage

Min/Max

®

MCC RLA LRA LRA**

Compressor HWG

Compressor HWG

Pump

FLA

Pump

FLA

5 SERIES 500A11 INSTALLATION MANUAL

Ext

Loop

FLA

Ext

Loop

FLA

Blower

Motor

FLA

Blower

Motor

FLA

Total

Unit

FLA

Total

Unit

FLA

Min

Circ

Amp

Min

Circ

Amp

Max

Fuse/

HACR

4/6/12

Max

Fuse/

HACR

4/6/12

Single Speed Unit with PSC Motor

Model Rated Voltage

012

208-230/60/1 197/253 7.7 4.9 25.0 n/a - 5.4 0.6 10.9 12.2 15

018

022

022*

030

030*

036

036*

042

042*

048

048*

060

070

* With optional high static motor

** With optional IntelliStart

Rated voltage of 208/230/60/1

All fuses Class RK-5

HACR circuit breaker in USA only

208-230/60/1 197/253 10.4 6.7 33.5 n/a 0.4 5.4 1.1 13.6 15.2 20

208-230/60/1 197/253 14.0 9.0 48.0 17.0 0.4 5.4 1.2 16.0 18.2 25

208-230/60/1 197/253 14.0 9.0 48.0 17.0 0.4 5.4 1.5 16.3 18.5 25

208-230/60/1 197/253 20.0 12.8 58.3 21.0 0.4 5.4 1.5 20.1 23.3 35

208-230/60/1 197/253 20.0 12.8 58.3 21.0 0.4 5.4 2.8 21.4 24.6 35

208-230/60/1 197/253 22.0 14.1 73.0 26.0 0.4 5.4 2.8 22.7 26.2 40

208-230/60/1 197/253 22.0 14.1 73.0 26.0 0.4 5.4 3.5 23.4 26.9 40

208-230/60/1 197/253 26.0 16.6 79.0 28.0 0.4 5.4 3.5 25.9 30.1 45

208-230/60/1 197/253 26.0 16.6 79.0 28.0 0.4 5.4 4.6 27.0 31.2 45

208-230/60/1 197/253 31.0 19.8 109.0 38.0 0.4 5.4 3.5 29.1 34.1 50

208-230/60/1 197/253 31.0 19.8 109.0 38.0 0.4 5.4 4.6 30.2 35.2 50

208-230/60/1 197/253 41.2 26.4 134.0 47.0 0.4 5.4 5.9 38.1 44.7 70

208-230/60/1 197/253 44.2 28.3 158.0 63.0 0.4 5.4 5.9 41.8 49.3 70

Voltage

Min/Max

®

MCC RLA LRA LRA**

Compressor HWG

17

Pump

FLA

Ext

Loop

FLA

Blower

Motor

FLA

Total

Unit

FLA

Min

Circ

Amp

Max

Fuse/

HACR

4/6/12

5 SERIES 500A11 INSTALLATION MANUAL

Electrical Data cont.

Dual Capacity Unit with Variable Speed ECM Motor

Model

026

038

038*

049

049*

064

072

* With optional 1 hp ECM motor

** With optional IntelliStart

Rated voltage of 208/230/60/1

All fuses Class RK-5

HACR circuit breaker in USA only

Rated

Voltage

208-230/60/1 197/253 18.2 11.6 58.3 21.0 0.4 5.4 4.0 21.4 24.4 35

208-230/60/1 197/253 23.8 15.2 83.0 30.0 0.4 5.4 4.0 25.0 28.8 40

208-230/60/1 197/253 23.8 15.2 83.0 30.0 0.4 5.4 7.0 28.0 31.8 50

208-230/60/1 197/253 33.0 21.1 104.0 37.0 0.4 5.4 4.0 30.9 36.2 50

208-230/60/1 197/253 33.0 21.1 104.0 37.0 0.4 5.4 7.0 33.9 39.2 60

208-230/60/1 197/253 42.3 27.1 152.9 54.0 0.4 5.4 7.0 39.9 46.6 70

208-230/60/1 197/253 46.3 29.6 179.2 63.0 0.4 5.4 7.0 42.4 49.8 70

Voltage

Min/Max

®

MCC RLA LRA LRA**

Dual Capacity Unit with 5-Speed ECM Motor

Model

026

038

049

064

072

** With optional IntelliStart

Rated voltage of 208/230/60/1

All fuses Class RK-5

HACR circuit breaker in USA only

Rated

Voltage

208-230/60/1 197/253 18.2 11.6 58.3 21.0 0.4 5.4 4.1 21.5 24.5 35

208-230/60/1 197/253 23.8 15.2 83.0 30.0 0.4 5.4 4.1 25.1 28.9 40

208-230/60/1 197/253 33.0 21.1 104.0 37.0 0.4 5.4 7.6 34.5 39.8 60

208-230/60/1 197/253 42.3 27.1 152.9 54.0 0.4 5.4 7.6 40.5 47.2 70

208-230/60/1 197/253 46.3 29.6 179.2 63.0 0.4 5.4 7.6 43.0 50.4 80

Voltage

Min/Max

®

MCC RLA LRA LRA**

Compressor HWG

Pump

Compressor HWG

Pump

FLA

FLA

Ext

Loop

FLA

Ext

Loop

FLA

Blower

Motor

FLA

Blower

Motor

FLA

Total

Unit

FLA

Total

Unit

FLA

Min

Circ

Amp

Min

Circ

Amp

Max

Fuse/

HACR

4/6/12

Max

Fuse/

HACR

4/6/12

18

5 SERIES 500A11 INSTALLATION MANUAL

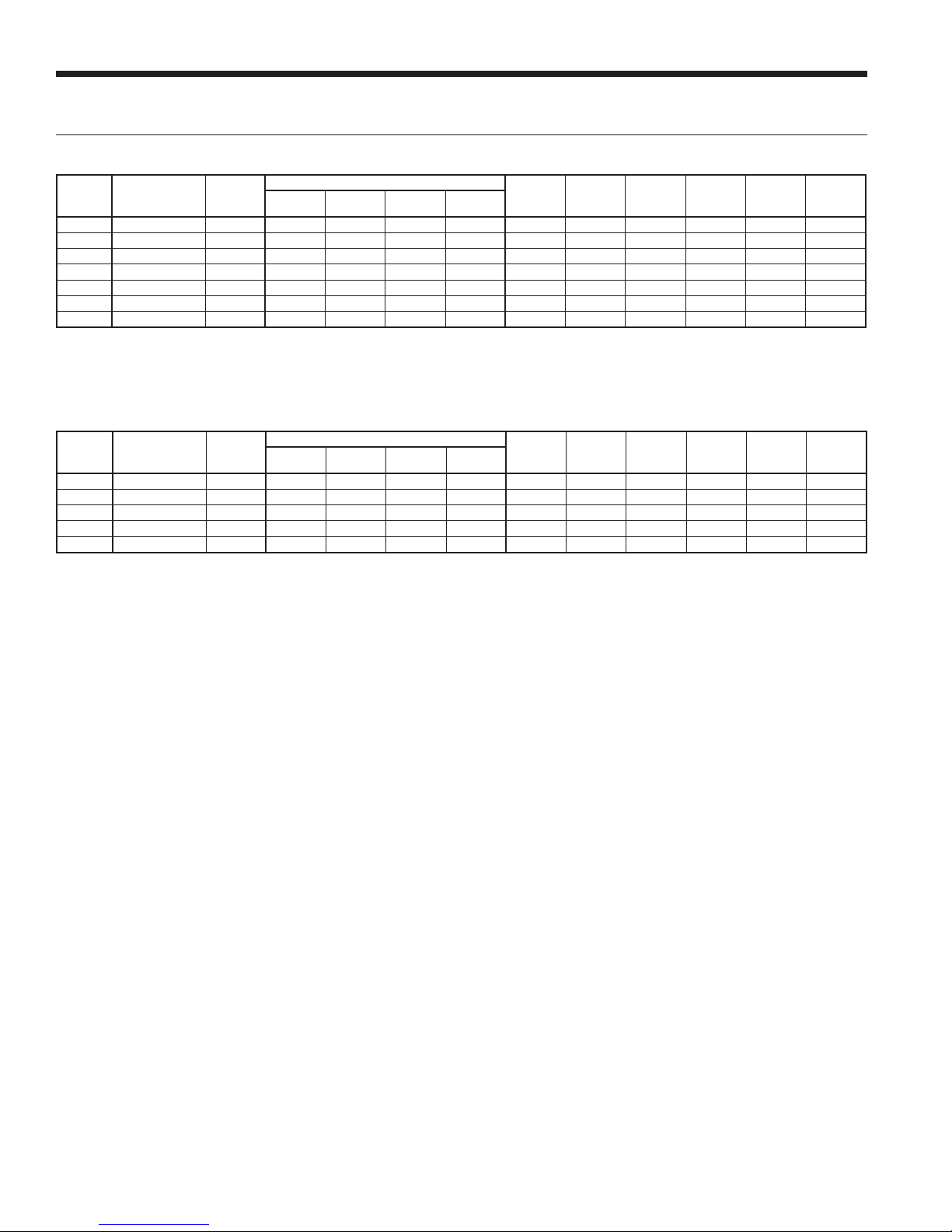

Blower Performance Data

Single Speed Unit with Variable Speed ECM Motor

Model

018

022

030

036

036

w/1hp*

042

042

w/1hp*

048

048

w/1hp*

060

070

Factory settings are at recommended G-L-H-Aux speed settings

L-H settings MUST be located within boldface cfm range

“Aux” is factory setting for auxiliary heat and must be equal to or above the “H” setting as well as at least the minimum required for the auxiliary heat package

“G” may be located anywhere within the airflow table

Cfm is controlled within ±5% up to the maximum ESP

Max ESP includes allowance for wet coil and standard filter

Max

ESP

0.50

0.50

0.50

0.50

0.75

0.50

0.75

0.50

0.75

0.75

0.75

123456789101112

300 400

G

400 500

400 500 600

650 750 850 1000

800 1000

G

650 800 900 1050

800 900 1000

G

650 800 900 1050 1150

800 900 1000 1200

800 950 1100 1300

800 950 1100 1300

500 600 700 800

LH

600 700 800 900

G

G

G

1100 1300 1500 1600

LH

G

G

G

G

LH

1200 1400 1600 1700 1850

LH

G

Airflow Speed Settings

875 950 1025 1125

1000 1100 1200

700 800 900 1000 1100

LH

1100 1200 1300 1400 1500

LH

1800 1950 2100 2200

1150 1250 1350 1450 1550

LH

2000 2200 2300 2400

1250 1350 1450 1550

LH

1400 1600 1700 1850

LH

1500 1750 1950 2100 2300

LH

1500 1750 1950 2100 2300

LH

2000 2200 2300 2400

Aux

Aux

1200

Aux

1550

Aux

Aux

1600

Aux

Aux

1600

Aux

Aux

2325

Aux

2325

Aux

6/8/12

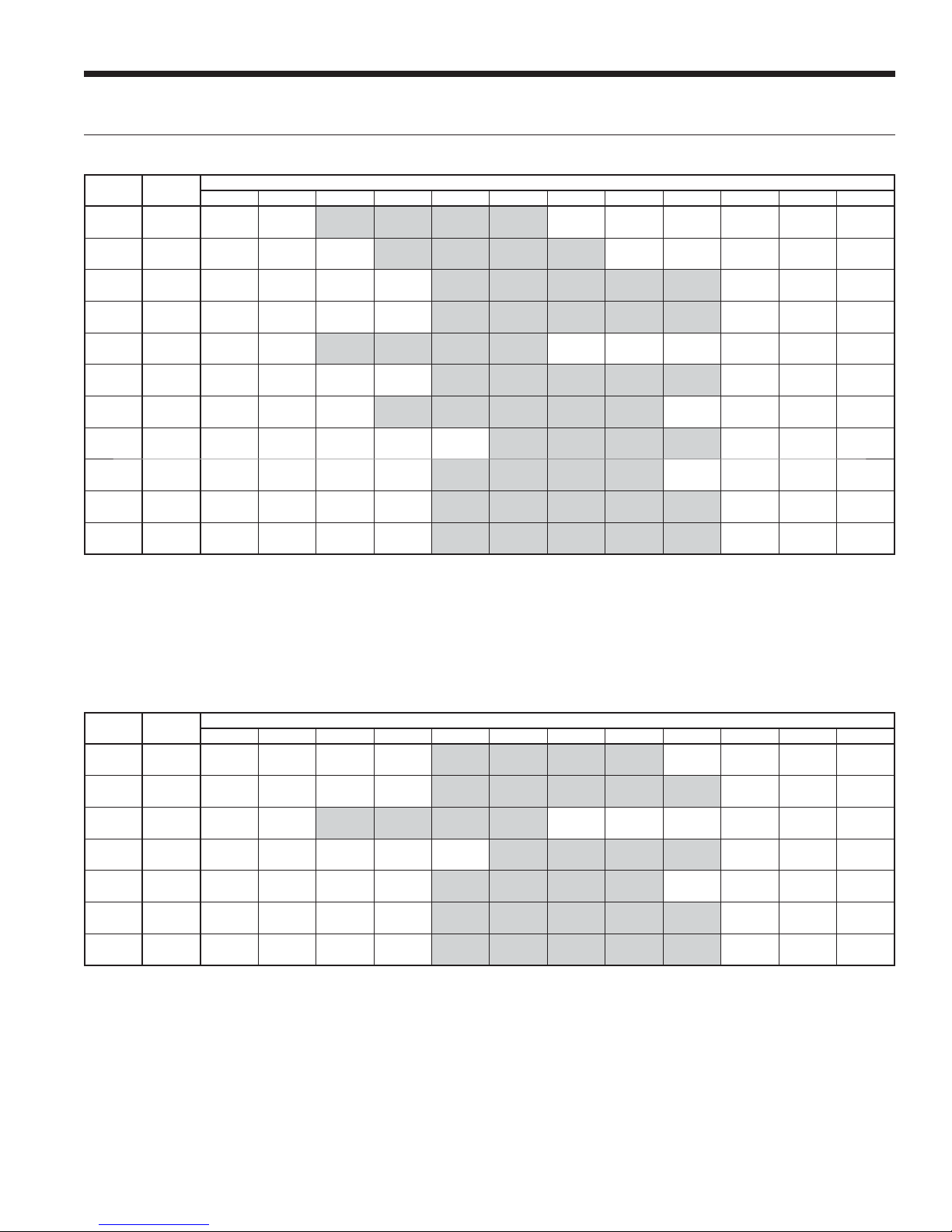

Dual Capacity Unit with Variable Speed ECM Motor

Model Max ESP

026

038

038

w/1hp*

049

049

w/1hp*

064

072

Factory settings are at recommended G-L-H-Aux speed settings

L-H settings MUST be located within boldface cfm range

“Aux” is factory setting for auxiliary heat and must be equal to or above the “H” setting as well as at least the minimum required

for the auxiliary heat package

“G” may be located anywhere within the airflow table

Cfm is controlled within ±5% up to the maximum ESP

Max ESP includes allowance for wet coil and standard filter

0.50

0.50

0.75

0.50

0.75

0.75

0.75

123456789101112

400 500 600

G

650 750 850 1000

G

800 1000

G

650 800 900 1050 1150

G

800 900 1000 1200

G

800 950 1100 1300

G

800 950 1100 1300

1100 1300 1500 1600

LH

G

Airflow Switch Settings

700 800 900 1000

LH

1100 1200 1300 1400 1500

LH

1800 1875 1925 2000

1250 1350 1450 1550

LH

1400 1600 1700 1850

LH

1500 1750 1950 2100 2300

LH

1500 1750 1950 2100 2300

LH

1100 1200

2000 2200 2300 2400

Aux

1550

Aux

Aux

1575

Aux

Aux

2325

Aux

2325

Aux

6/8/12

19

5 SERIES 500A11 INSTALLATION MANUAL

Blower Performance Data cont.

Setting Blower Speed - ECM

The ABC board’s Yellow Config LED will flash the current

ECM blower speed selections for “G”, low, and high

continuously with a short pause in between. The speeds

can also be confirmed with the AID Tool under the Setup/

ECM Setup screen. The Aux will not be flashed but can be

viewed in the AID Tool. The ECM blower motor speeds can

be field adjusted with or without using an AID Tool.

ECM Setup without an AID Tool

The blower speeds for “G”, Low (Y1), High (Y2), and Aux

can be adjusted directly at the Aurora ABC board which

utilizes the push button (SW1) on the ABC board. This

procedure is outlined in the ECM Configuration Mode

portion of the Aurora ‘Base’ Control System section. The

Aux cannot be set manually without an AID Tool.

ECM Setup with an AID Tool

A much easier method utilizes the AID Tool to change

the airflow using the procedure below. First navigate to

the Setup screen and then select ECM Setup. This screen

displays the current ECM settings. It allows the technician

to enter the setup screens to change the ECM settings.

Change the highlighted item using the ◀ and ▶ buttons and

then press the ◙ button to select the item.

ECM Speed Info

Blower Only Speed 3

Lo Compressor 6

Hi Compressor 9

Aux Heat 10

Selecting YES will enter ECM

speed setup, while selecting NO

will return to the previous screen.

ECM Speed Setup - These screens allow the technician to

select the “G”, low, high, and auxiliary heat blower speed for

the ECM blower motor. Change the highlighted item using

the ▲ and ▼ buttons. Press the ◙ button to select the speed.

ECM Speed Info

1

▶

2 ◀ G

3

4

5

6

7

8

9

10

11

12

Option ◀▶ Enter ◙

ECM Speed Info

1

2 G

3 ◀ Lo

▶

4

5

6

7

8

9

10

11

12

Option ◀▶ Enter ◙

ECM Speed Info

1

2 G

3 Lo

4

5

▶

6 ◀ Hi

7

8

9

10

11

12

Option ◀▶ Enter ◙

ECM Speed Info

1

2 G

3 Lo

4

5

6 Hi

7

8

9

▶10

◀ Aux

11

12

Option ◀▶ Enter ◙

After the auxiliary heat speed setting is selected the AID

Tool will automatically transfer back to the ECM Setup screen.

Cooling Airflow Setup - These screens allow the technician

to select -15%, -10%, -5%, None or +5%. Change the

adjustment percentage using the ▲ and ▼ buttons. Press

the ◙ button to save the change.

Cooling Airflow Setup

--- ECM Only ---

The airflow will be

adjusted by the chosen

amount in cooling mode.

Adjustment:

-15%

Want To Change?

Yes

Option ◀▶No Enter ◙

Cooling Airflow Setup

--- ECM Only ---

The airflow will be

adjusted by the chosen

amount in cooling mode.

Adjustment:

-15%

Change ▼▲ Enter ◙

Want To Change?

Yes

Option ◀▶NoEnter ◙

20

Loading...

Loading...