Wascomat WS3 230-340-470-670 H, WSB3 230-340-470-670 H, WS3 230 H, WS3 340 H, WS3 470 H Instruction Handbook Manual

...

08100226gb

WASHER-EXTRACTORS

WS3 230-340-470-670 H

WSB3 230-340-470-670 H

INSTRUCTION HANDBOOK

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

General instructions

General..................................................... 1/1

Precautions for use...................................1/2

Environmental information........................ 1/3

Preliminary instructions ............................ 1/4

Locking and tagging procedure ................ 1/5

Handling/Weight

Handling ................................................... 1/6

Packing - Weight ...................................... 1/7

Technical characteristics

Technical characteristics .......................... 1/8

Sound level.............................................. 17/8

Label of energetic performances ............. 17/8

Installation/Putting into service

Installation ................................................ 1/9

Working place lighting .............................. 2/9

Supplies.................................................... 2/9

Mechanical installation ............................. 3/9

Fitting of the safety flanges....................... 4/9

Fitting of the filling angles ......................... 5/9

Assembling of the partition for

barrier machine.........................................6/9

Water connections.................................... 7/9

Steam connection..................................... 8/9

Drain connection......................................10/9

Air vent connection .................................. 11/9

Installation of the gas exchanger............. 11/9

Connection of the evacuation pipe of

the gas exchanger ................................... 13/9

Gas connection........................................15/9

Liquid detergents connection...................22/9

Electrical connection................................24/9

Remove of the transport locks fitted ........ 29/9

Operating inspection

Manual operation..................................... 1/10

Automatic operation.................................2/10

Machine operation

Auxiliary control ....................................... 1/11

Automatic operation.................................3/11

Detergent dispenser ................................ 5/11

To run a wash program ........................... 6/11

The "move back" key............................... 6/11

To start the wash program.......................6/11

To start a wash program from the

program library .......................................10/11

To change parameters in the current

program step ..........................................13/11

Rapid advance........................................14/11

Pages/Chapters

The manufacturer reserves the right to modify construction and equipment characteristics.

Table of contents

0401

0

0

Pages/Chapters

Show weight ...........................................15/11

Pause .....................................................17/11

Manual operation during a program .......18/11

Text.........................................................24/11

To change the wash program after

program operation has commenced.......25/11

To change temperature scale °C/ °F ......26/11

Auto restart .............................................27/11

Manual operation

To select a manual operation .................28/11

Motor/door ..............................................29/11

Water/drain.............................................30/11

Heating ...................................................31/11

Detergent signals and water flushing .....32/11

At the end of the wash............................34/11

Statistics

To select "statistics"................................35/11

Resetting statistic registers.....................37/11

Automatic weighing

Scale adjustments ..................................42/11

ON/OFF and pause

On/off and pause by exterior signals ......53/11

Memory card

General introduction ...............................54/11

To select the "Memory card" function.....55/11

To run a wash program straight from

a memory card........................................58/11

To copy a program from a memory card

to the machine's program control unit.....59/11

To copy a program from the program

control unit to a memory card .................61/11

To delete a program on a

memory card...........................................63/11

To delete all programs on a

memory card...........................................64/11

Weighing equipment.................................65/11

HACCP option ...........................................76/11

Safety

Safety ...................................................... 1/12

Maintenance

Operating incidents.................................. 1/13

Preventive maintenance .......................... 1/14

Electric diagrams

Electric diagrams ..................................... 1/15

Appendices

Convertion measurement units................ 1/16

Washing symbols .................................... 2/16

Gas exchanger (25 kW)........................... 3/16

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0300 1

1

1. General

Identification

plate

General instructions

The machines described in this handbook have a washing capacity of 229, 338, 467 or 668

litres according to their type.

They are washer-extractors designed to meet the most severe requirements.

They are designed to be installed in hotels, laundries, hospitals or collectivities.

The suspension device mounted with springs and shock absorbers limits to the maximum

ground vibrations.

A important G factor guarantees the highest extraction quality for your linen.

These machines also exist in barrier version allowing the respect of linen's hygiene rules.

D0630/434

Adjustment label

GAS EXCHANGER

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1199 2

1

1. General

1

2

3

45

6

7

89

0

During a wash : "Pause" key.

Before and after a wash, and during programming : "Move

back key".

By pressing this key repeatedly you can move backwards

through the menus you have navigated through. This will

always bring you back to the menu shown on the display in

this illustration.

Function keys.

The functions of these keys change, depending on

which menu or part of a menu you are using. Their

current functions at any time are shown on the

display immediately above each key.

Card reader for

memory cards

Display screen

Numeric keyboard

This washer extractor is controlled by a microprocessor-based program control unit placed on

the loading side. There are many advantages to this equipment, including :

•Timing, levels and temperatures are controlled with great precision and flexibility.

• The large display screen means that detailed information on wash programs, machine status

and operations, wash times and temperatures can be accessed in plain language

• It is possible for the user to create new wash programs, and to adapt programs with great

precision, on the basis of experience and to suit various types of textile, degrees of soiling

etc.

• a very high level of machine safety through continuous monitoring and built-in safety

interlocks.

• The program control unit has a reader for "smart cards". These are cards the size of a credit

card which contain a memory chip. Smart cards allow the user to :

- transfer wash programs between a PC and the washer extractor, or from one washer

extractor to another

- run programs straight from a card

• Great flexibility during program operation :

- rapid advance both forwards and backwards in the program

- the user can change temperatures, program module lengths and extraction speeds

directly, during program operation

- change to running a different wash program, at any time during program operation of the

washer extractor.

4221 3651

RUN A W ASH PROGR AM

GO TO THE MENU

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1298 3

1

1. General

A very high working safety level of the machine is achieved thanks to a continuous monitoring

and built-in safety devices.

Even the compound textile fabrics can be washed at a high temperature with no crumpling risk

thanks to a special cooling process before the rinsing cycle.

In order to avoid an excessive mechanical fatigue during the hydro-extraction process, the

machine is equipped with an unbalance detector. If the latter detects the least unbalance of the

load, the hydro-extraction cycle is interrupted and the machine fills with water to make a new

distribution of the linen possible.

The machine then resumes the distribution speed and another hydro-extraction cycle begins.

The machine can also be controlled sequence by sequence and is equipped with a keyboard

for the manual control of certain functions.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0700 1

2

2. Precautions for use

Precautions for use

. The machine should not be used by children.

. The machine is designed for "water washing" of textile only.

. This machine is for professional use and must be used exclusively by qualified personnel.

. It is forbidden to wash textiles soaked with solvents.

. In case of a gas heated machine, do not assemble the machine on premises containing a

dry cleaning machines or other similar machines.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0401 1

3

3. Environmental

information

Environmental information

Concerned by providing the end user with useful and necessary environmental information, we

wish to precise :

. Data about energetic consumptions, wastes (atmospheric and liquid) and sound level are

indicated in the paragraph "Technical characteristics".

. The running of this machine requires the use of detergents which draining in the nature can

have a significant environmental impact. So, we do recommend to only use, with agreement

of the manufacturers, the quantities of detergents strictly necessary.

. This machine is fully dismantle.

. This machine is free from any asbestos.

. Our machine packing complies with the provisions of rule 98-639 dated July 20th 1998

regarding environmental demands.

For additional information, do not hesitate to consult our environmental department.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

A flash of lightning with an arrow at its

end displayed inside an equilateral triangle, warns the user about the presence of uninsulated "dangerous current" sufficient in intensity to cause

electrocution.

An exclamation mark inside an equilateral triangle offers the user important advice about usage, servicing and

hazardous conditions.

This symbol warns the user that there

are mechanisms inside the machine

which can be dangerous. The protective housing must be in place during

use.

This symbol warns the user of the presence of high temperatures which could

cause severe burns. Some surfaces

can reach close to 200 °C (392 °F).

Explanation of graphic symbols

0401 1

4

4. Preliminary

instructions

Preliminary instructions

Before any use, it is compulsory to read the instruction handbook.

Users must have learnt how the machine operates.

The identification plate is placed on the left hand side of the machine.

In order to prevent any risk of fire or explosion, flammable products should never be used to

clean the machine.

Any repair or maintenance intervention should be carried out by qualified personnel only.

Detergents used in laundry are particularly agressive. No stainless steel is able to resist their

corrosive actions. Detergent dispenser must consequently be considered as wearing parts

likely to be replaced.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1199 2

4

4. Preliminary

instructions

SAFETY

The mechanical and electrical installation

of the machine should only be done by

qualified personnel.

CAUTION

Do not use the machine unless it is plugged

into a correctly earthed power socket complying with standards in force.

CAUTION

For your personal safety, never use the

machine without the protective housings.

CAUTION

Disconnect the machine electrical power

supply before doing any repair or servicing work.

SAFETY

This machine should be installed in conformance to the health and safety regulations, and only used in a sufficiently aerated area.

Check the instructions before installing or

using the machine.

Disconnect all the sources of energy before any intervention on the machine.

Never try to open the drum door before the complete stop of the cage.

The safety devices of the drum door(s) should in no case be made inoperative.

The machines comply with the European Directive EMC (Electromagnetic Compatibility). They

have been tested in laboratory and approved as such. It is so prohibited to add wires or non

shielded electric cables in the cabinets, strands or cables' troughs.

Considering that the volume of the cage is superior to 150 liters, the standard kept for the

electric part is the IN 60204.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1101 3

4

4. Preliminary

instructions

The use and handling of chemical products such as detergent, chlorine, acids, antiliming agents etc... may create hazards for health

and environment ; the following precautions should be taken.

- Do not breathe the dusts or steam.

- Avoid contact with skin or eyes (may cause burns).

- In case of important spillage, wear a protecting mask, gloves, and

eye protectors.

- Handle with care.

- Consult the use and first aid advice on the packings.

- Do not dispose pure products in the environment.

The machine can work without the protective casing when the electric supply is not cut off.

Interlock the main isolating switch with a padlock.

Close the steam or gas inlet valves.

Ensure that the machine is not loaded beyond its nominal capacity

(see "Specific load" in the instruction booklet’s technical characteristics).

An excessive load has consequences for the lifetime of the machine’s organs, as follows:

· Rapid destruction of the suspension elements (springs, shock

absorbers);

· Excessive fatigue of motorisation elements (engine, belt);

· Rapid reduction of lifetime of drum bearings (rolling bearings);

· Opening and destruction of drum doors and tank doors during

oil dehydration.

This is particularly important for your safety and that of others.

The consequence is an immediate cancellation of the warranty.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1298 4

4

4. Preliminary

instructions

Distributor Letter

Chemical System Responsibility

Disclaimer

The following policy should be considered and understood as a warranty/disclaimer to customers

operating textile care installations where liquid supply (chemical) systems use or may use peristaltic

pumps to inject supplies into equipment.

To Whom it May Concern :

We, the undersigned, accept no responsibility for loss or damage when, during periods of non-use,

concentrated chemicals leak, spray or "dribble" onto any part of our machines or their contents.

It is well known that many pumped liquid chemical systems tend to permit concentrated chemicals to

dribble out of the injection tubes when the system has not been used for relatively long periods of

time – as after working hours and during weekends. This puts highly concentrated corrosive chemicals in direct contact with dry stainless steel surfaces and often directly on any textiles left in the

machine. Chemical deterioration (rusting) of the stainless steel and damage to the textiles is the

inevitable result.

It is absolutely useless to flush the affected sites after each injection because the harmful dribble

always occurs later – after the machine is no longer in use. One seemingly foolproof solution for

"dribbling chemicals" (which we highly recommend but obviously cannot guarantee) is to locate the

chemical tanks and pumps well below the injection point on the machine (so the contents of the

injection tube(s) cannot siphon into the machine) and to completely purge the just-used chemical

injection tube(s), or manifold, with fresh water after every injection so that only fresh water (which

cannot cause a problem) can dribble out. Naturally, this – or any other solution – is the sole responsibility of the pump and/or chemical supplier (not the machine manufacturer).

Additionally, external chemical leakage is dangerous to personal health and safety, and will also

cause severe damage to machines and/or their surroundings. The installer and/or user of the chemical injection system must make sure there are no external chemical leaks and that excessive pressure can never build up in any chemical delivery tube, because excessive pressure can burst the

tube, or disconnect it from the machine, and spray dangerous concentrated chemicals about the

premises.

The machinery manufacturer is not, and cannot be, responsible for compliance with the

above.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1298 1

5

5. Locking and

tagging procedure

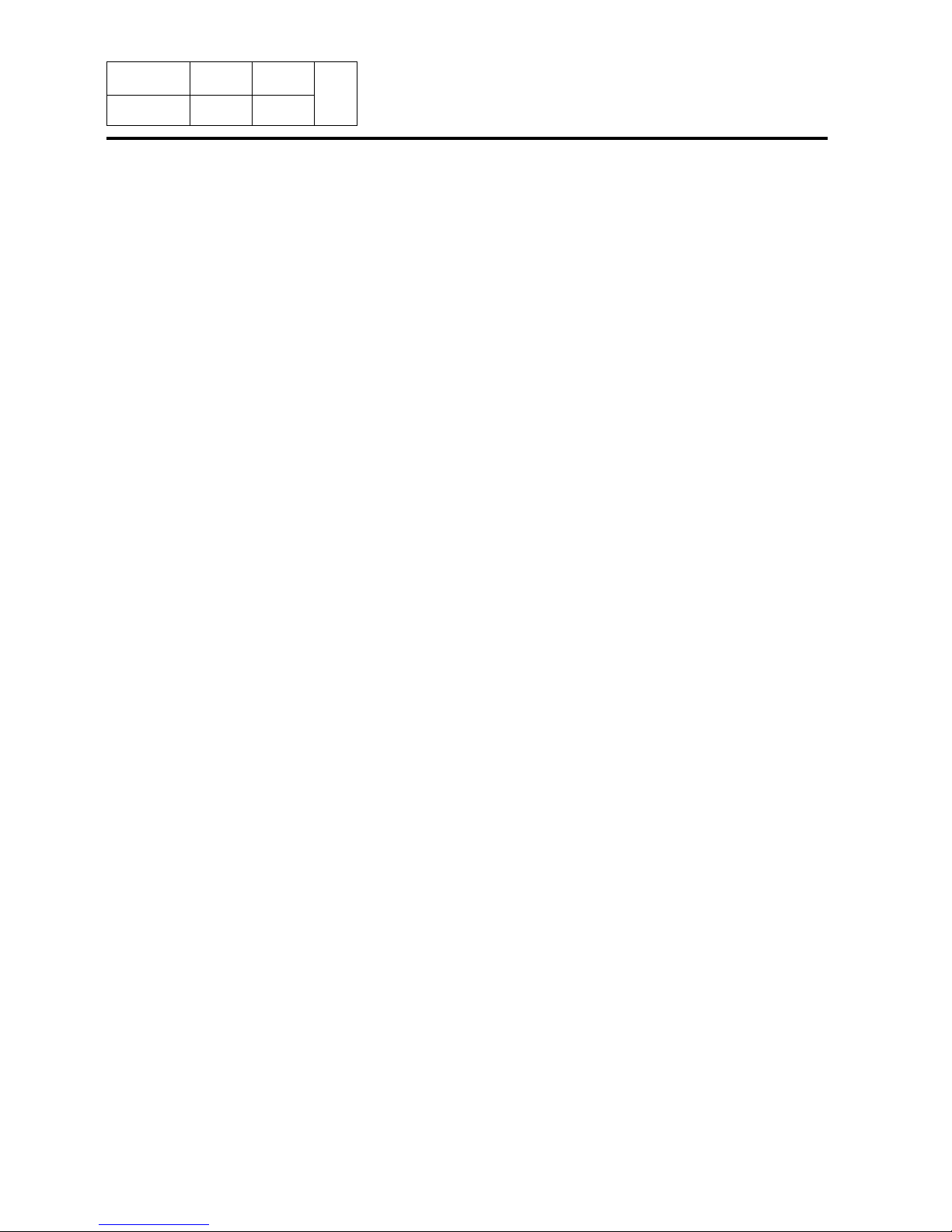

Locking and tagging procedure

1

2

3

4

A red insert at the beginning of this instruction handbook schematically shows the locking and

tagging procedure described below. If you wish, you can detach this insert and display it close

to the machine to remind maintenance personnel of the safety instructions.

Put the main switch

to Off and lock the

handle with a padlock

in one of the three

holes provided for

this purpose.

Always respect items

2, 3 and 4 carefully

before doing any repair or maintenance

work on the machine.

Open the fixed

protectors (casings,

doors) with the key

provided or a special

tool.

Close and carefully

lock the fixed

protectors.

Unlock the stop

valves and the

main switch.

Do the maintenance.

Close the stop valves for

the other supplies

(steam, gas, thermal

fluid, compressed air)

to stop and lock their

handle with a padlock.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1298 1

6

6. Handling

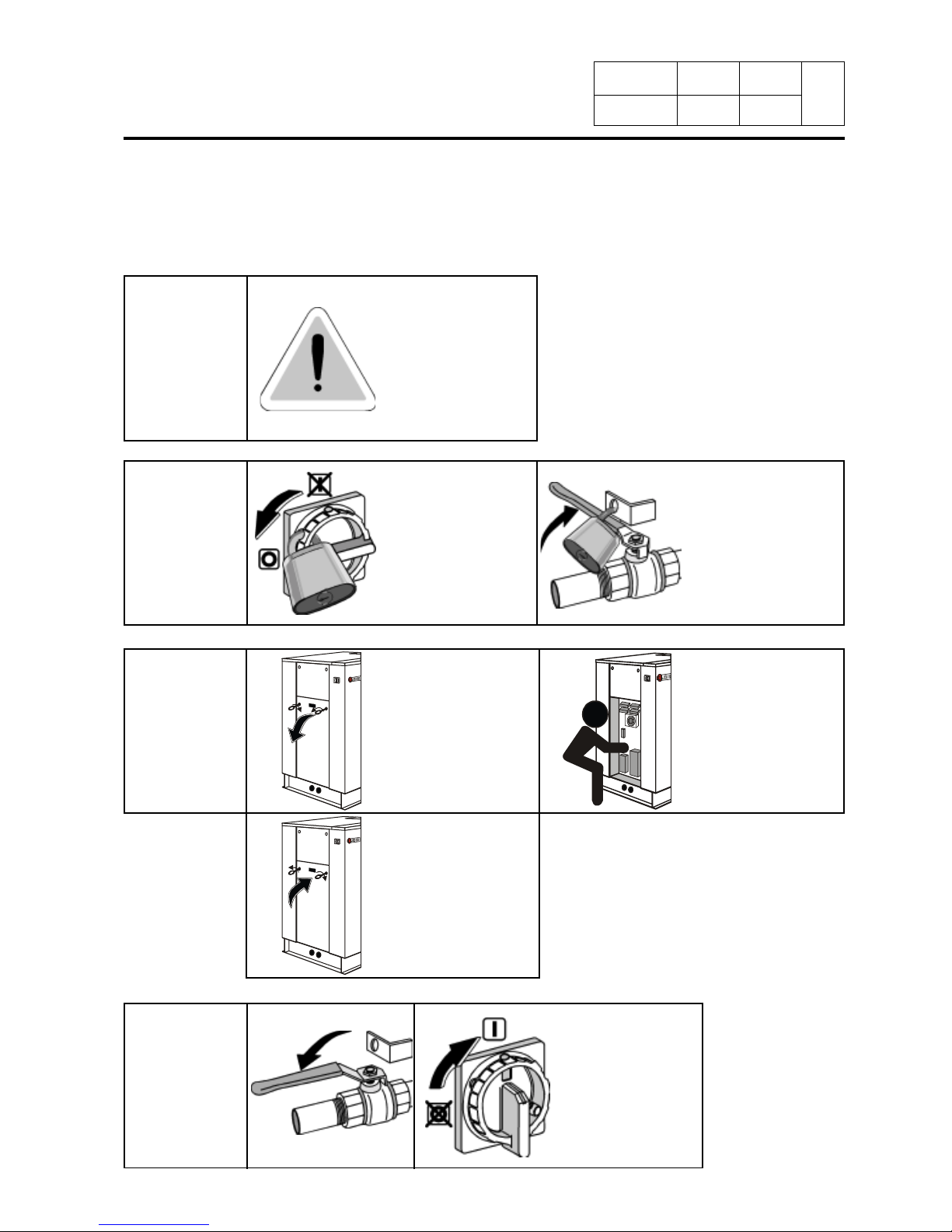

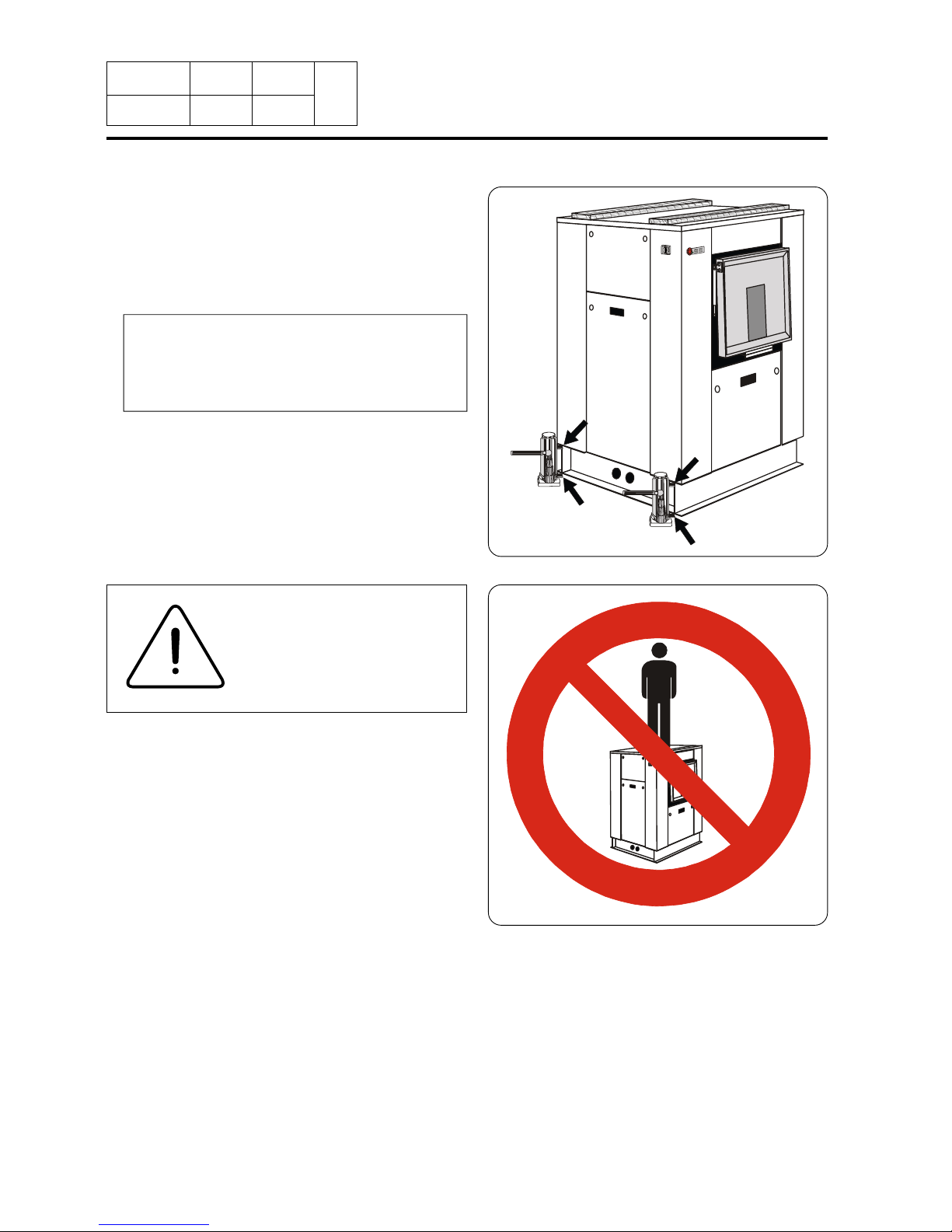

1/ Lifting with handling straps

Lifting in that case can only be done with

handling straps (minimum capacity 1000

daN) which bear weight of the machine.

Nota : in order to avoid bending of the

machine's casings, make sure to place

the lifting straps at each end of the

wooden planks.

Handling

D0604

1000 daN

1000 daN

Before any handling, check that the four

transport locks fitted are still in place and

well-tightened.

To do so, remove the front and rear casings

and check presence of four locks (B).

D0650

SAFETY

It is obligatory that all

these operations are

undertaken by handling

specialists.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1298 2

6

D0603

2/ Lifting with a fork-lift truck

This can be carried out from the front or

back, at the centre of the machine.

CAUTION

You should never handle the machine in

its longitudinal side (any other than shown

on the drawing below) with a fork-lift truck.

Important risk of parts deterioration for

those fixed under the machine.

OK

3/ Ground moving

The machine frame is made up of two parallel parts, making ground moving possible by

means of rollers.

D0659

6. Handling

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

1298 3

6

6. Handling

7

4

0

3

2

1

4

6

CAUTION

In order to avoid any bending of casings, you should

never climb and stand on

top of the machine.

4/ Lifting with a jack

Lifting in this case can only be done with a

jack (minimum capacity 500 daN) which can

bear the machine's weight.

Nota : in order to avoid the bending of

the sole, make sure to place the lifting

jack at each corner of the machine at

point A or B.

D0671

A

B

B

A

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0102 1

7

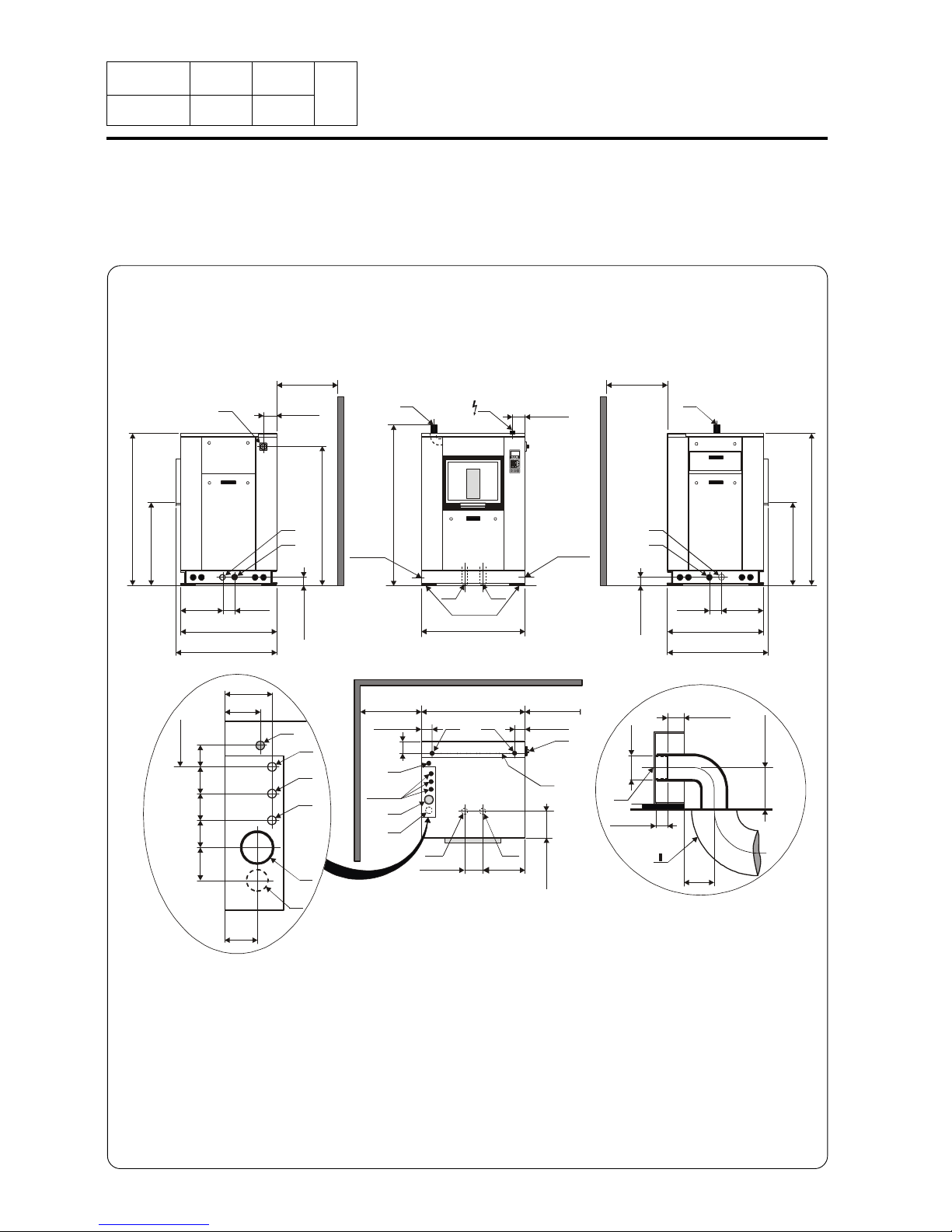

7. Packing - Weight

Packing

Packing dimensions in mm/inch Size A Size B Size C

Washer extractor Type 230 standard 1180/46.5 1230/48.4 1840/72.4

Washer extractor Type 230 barrier 1180/46.4 1230/48.4 1840/72.4

Washer extractor Type 340 standard 1180/46.4 1450/57 1840/72.4

Washer extractor Type 340 barrier 1180/46.4 1450/57 1840/72.4

Washer extractor Type 470 standard 1180/46.4 1760/69.3 1840/72.4

Washer extractor Type 470 barrier 1180/46.4 1760/69.3 1840/72.4

Washer extractor Type 670 standard 1180/46.4 2180/85.8 1840/72.4

Washer extractor Type 670 barrier 1180/46.4 2180/85.8 1840/72.4

Weight

Weight in kg/lb (machine + crate) Gas Electric Steam/T.F

Washer extractor Type 230 standard 775/1709 775/1709 775/1709

Washer extractor Type 230 barrier 775/1709 775/1709 775/1709

Washer extractor Type 340 standard 890/1963 890/1963 890/1963

Washer extractor Type 340 barrier 890/1963 890/1963 890/1963

Washer extractor Type 470 standard 1090/2404 1090/2404 1090/2404

Washer extractor Type 470 barrier 1090/2404 1090/2404 1090/2404

Washer extractor Type 670 standard 1195/2636 1195/2636 1195/2636

Washer extractor Type 670 barrier 1195/2636 1195/2636 1195/2636

Identification plate

(for gas machine only)

A

B

C

D0660/776

Adjustment label

GAS

EXCHANGER

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

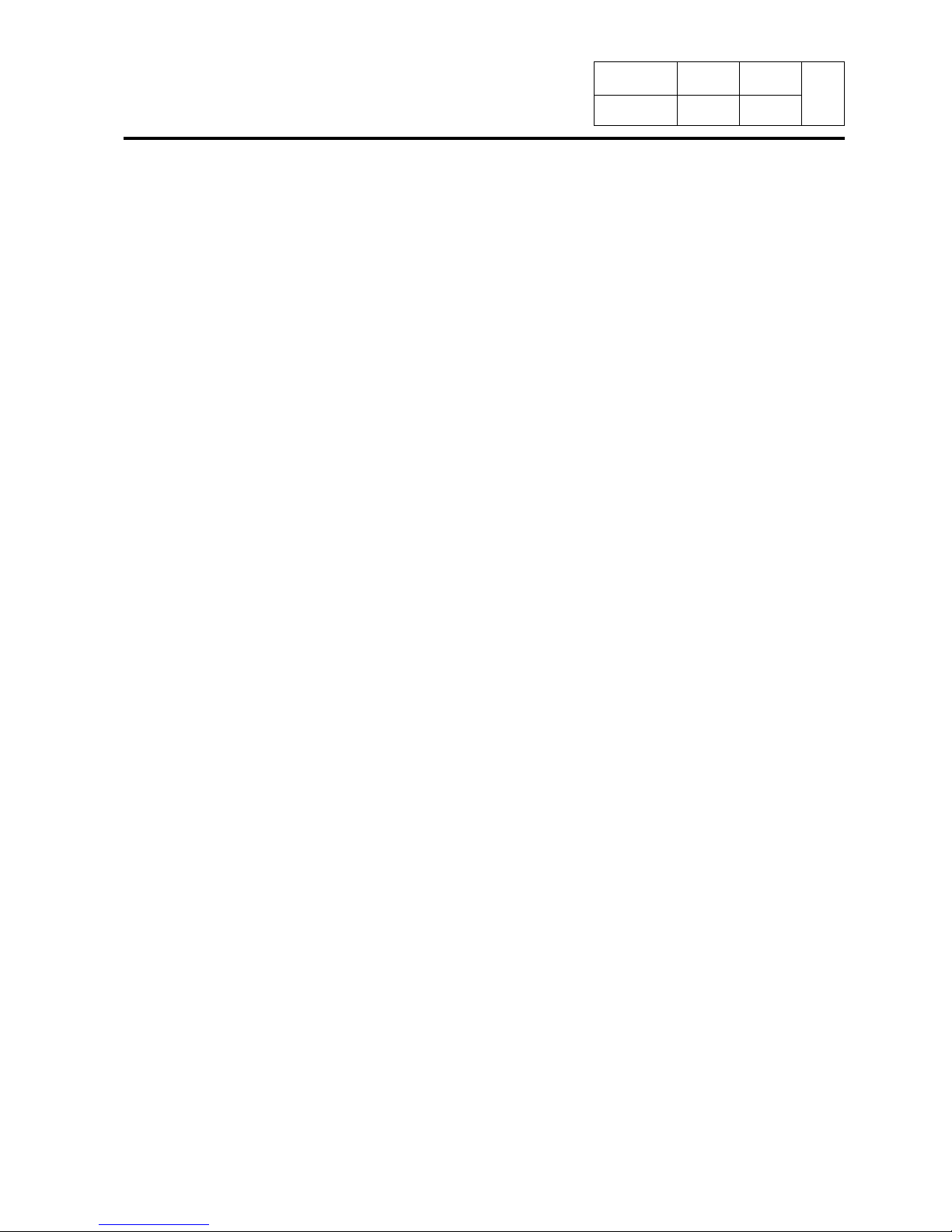

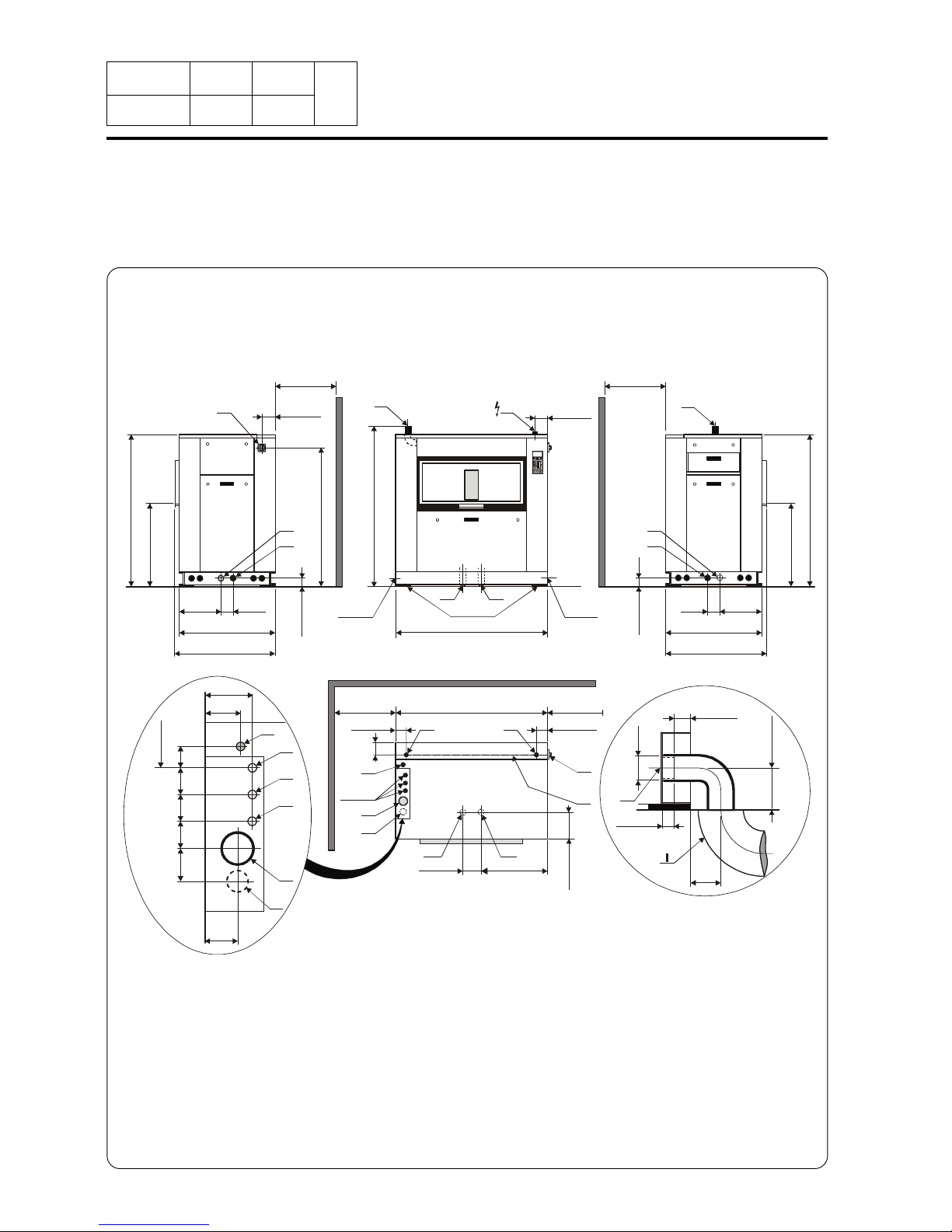

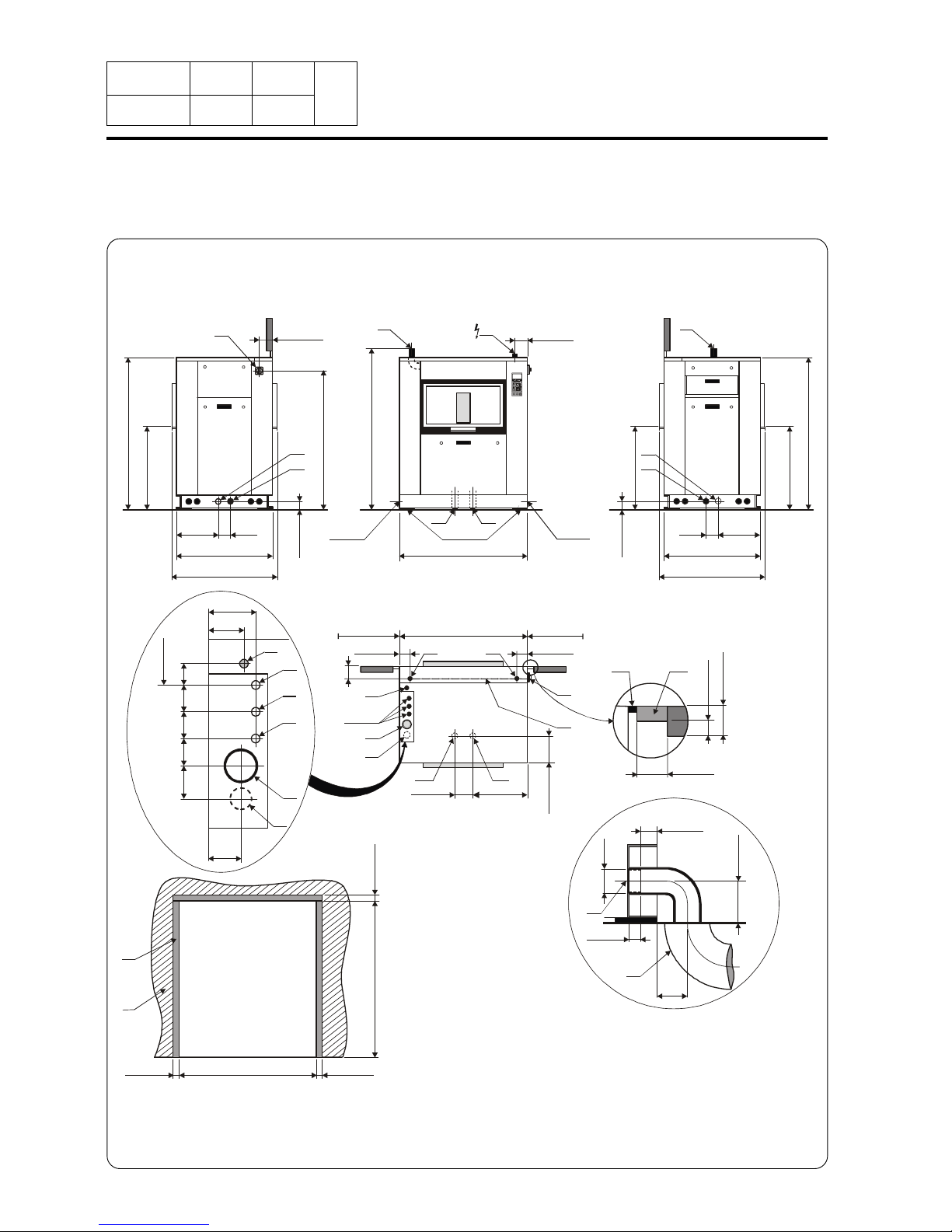

Front view

Top view

Right view Left view

Example of

drain connection

0999 1

8

8.Technical

characteristics

07100081

Washer extractor type 230 standard

8

7

0

/

3

4

.

2

5

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

1

6

1

0

/

6

3

.

3

8

”

> 1 m/40” > 1 m/40”

> 1 m/40”> 1 m/40”

430/17”

430/17”

110/

4.33”

110/

4.33”

1

0

0

/

3

.

9

3

”

1

0

0

/

3

.

9

3

”

160/6.3”

150/5.9”

150/5.9”

1045/41.14”

980/38.58” 980/38.58”

1015/39.96” 1015/39.96”

1045/41.14”

NN'

M

L

L

H3 H1

H4 H2

1

4

4

0

/

5

6

.

6

9

”

H3-H4

F-D-E

J

K

G

1

7

1

0

/

6

7

.

3

2

”

J

H1-H2

J

150/5.9”

N

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

H1

120/

4.72”

E

J

K

F

D

G

2

7

0

/

1

0

.

6

”

100/

3.93”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

“Gripsol”

H6

H5

H6 H5

170/6.7”

440

17.3”

2

7

5

/

1

0

.

8

”

7

5

/

3

”

1

3

0

/

5

.

1

”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0102 2

8

Washer extractor type 230 standard Diagram no. 07100081

8.Technical

characteristics

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------------- 770 mm (30.31")--------------------

Cage length --------------------------- 520 mm (20.47")-------------------Cage volume ----------------------- 229 dm³ (229 l) -------------------Specific load 1/11 ----------------------------- 21 kg (46 lb)----------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) ----------------- 450 x 400 mm (17.71x15.74")-----------Opening drum door (L x H) ------------------ 466 x 525 mm (18.34x20.67") ------------

Floor area --------------------------- 1 m² (10.76 sq. ft) ------------------

Net weight --------------------------- 670 daN (1478 lb)-----------------

Weight loaded (high level) --------------------------- 834 daN (1840 lb)-----------------

Water volume, washing, low level xx l xx l xx l xx l

Water volume, washing, high level xx l xx l xx l xx l

Dynamic stress --------------------- F = 101 daN (222 lb)-------------------

Transmitted floor laod ----------------------- 814 daN (1795 lb)-------------------

Spin efficiency ---------------------------------- 350 G ------------------------

Max. unbalance --------------------------- 3.6 kg (7.94 lb)--------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x6 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 3.7 kW 21.7 kW 3.7 kW 3.7 kW

Installed heating power 40 kW 18 kW - -

Electric consumption for a normal cycle* 0.8 kWh/h 6 kWh/h 0.6 kWh/h 0.6 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP)

- Maximum supply pressure 600 kPa (87 psi)

- Steam intantaneous flow rate at 600 kPa x kg/h

- Seam consumption for a normal cycle* 12 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure --------------------------- 50 kPa (7.25 psi)------------------

Water supply maximum pressure --------------------------- 300 kPa (43.5 psi)----------------

Water consumption for a normal cycle* 360 l 340 l 340 l 340 l

Water consumption for an ECO cycle** 282 l 260 l 260 l 260 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection --------------------------- Ø 75 mm (3")----------------------

(H2 or H4 or H6) Double drain connection --------------------------- Ø 75 mm (3")----------------------

Maximum flow rate ------------------------------- xx l/min -------------------------

(I) Waste water collector ------------------------ DN 150 mm (6" BSP)----------------

(3 cm/m ( 3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36 ") -------------------

(N') Thermic fluid inlet DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid exchanger xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0999 3

8

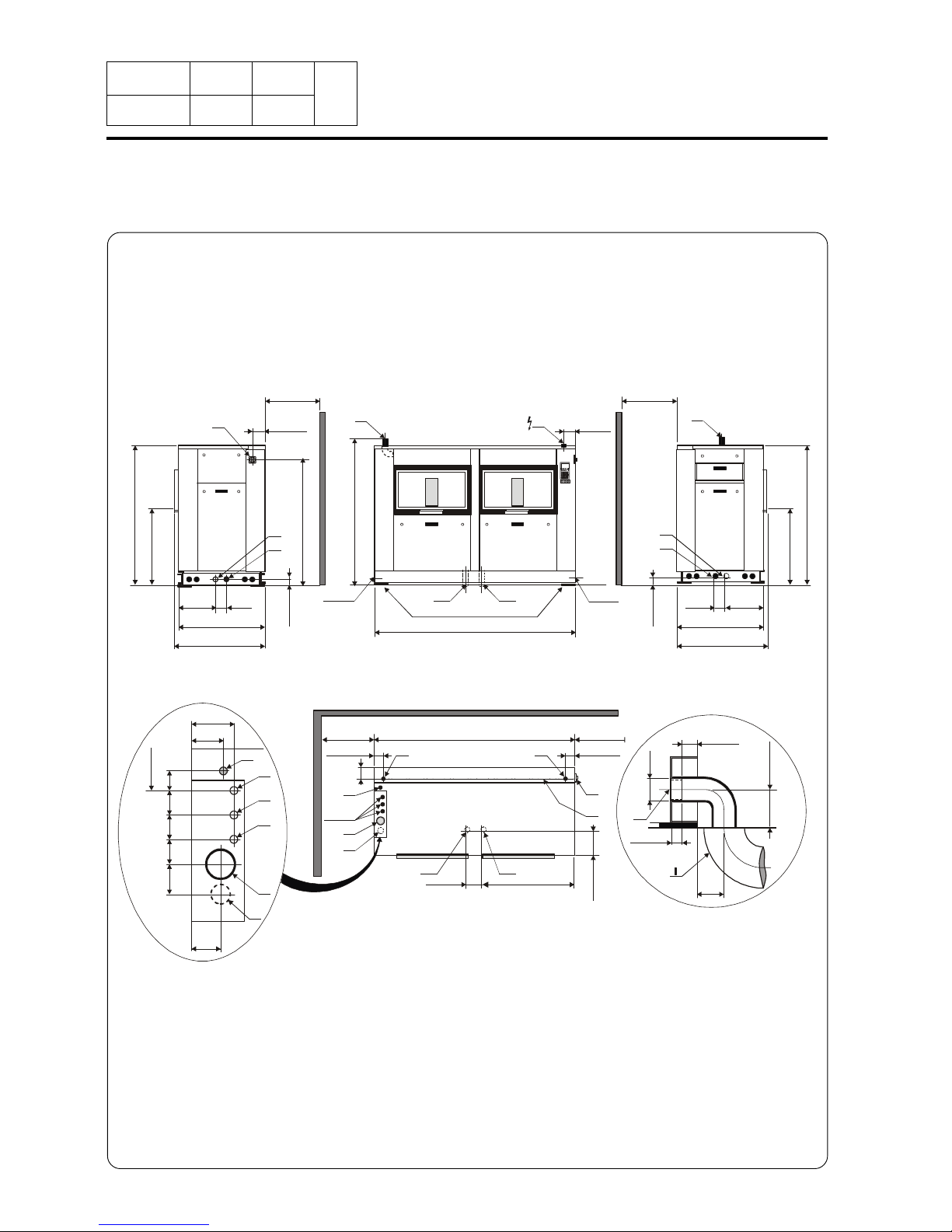

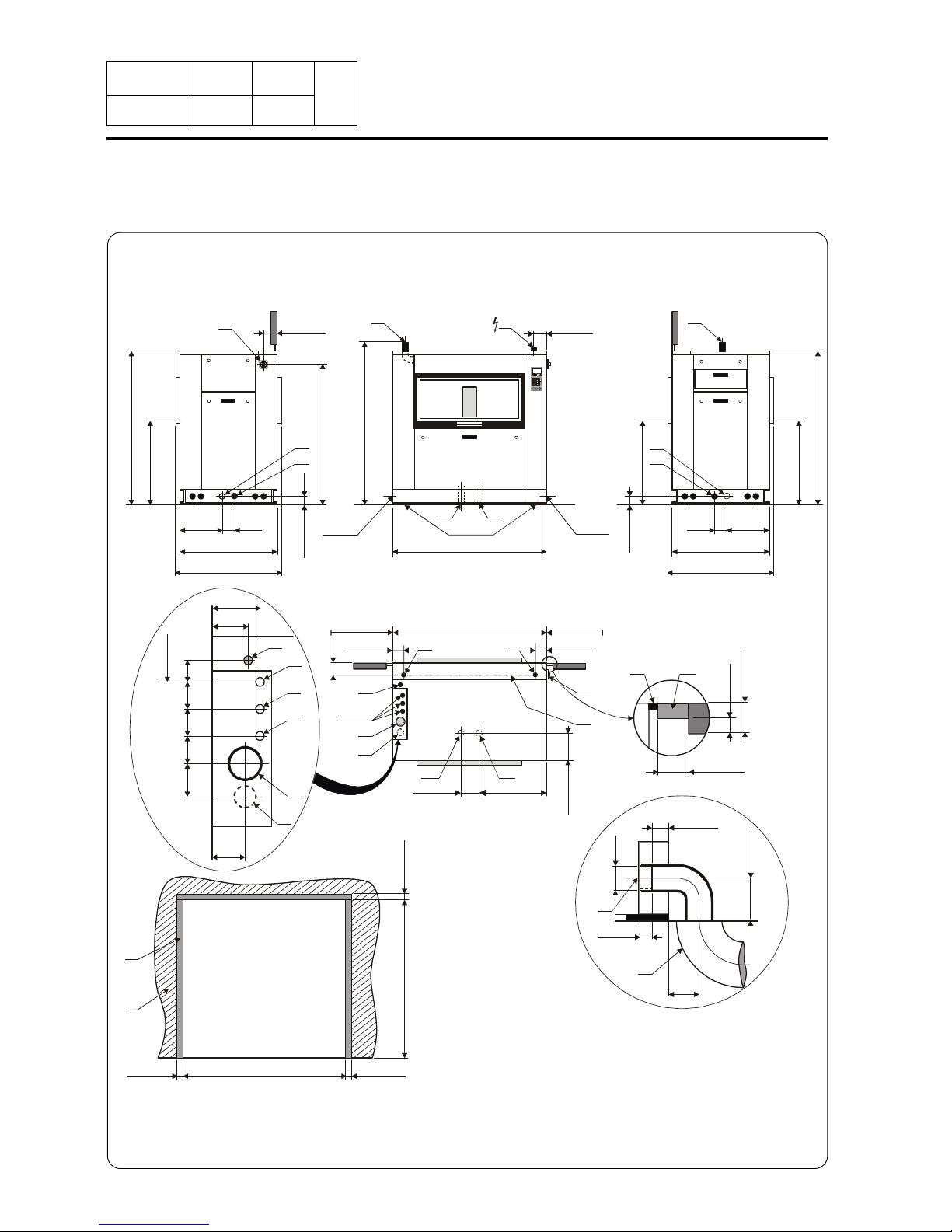

07100083

Washer extractor type 340 standard

Top view

Example of

drain connection

Front viewRight view Left view

8.Technical

characteristics

J

8

7

0

/

3

4

.

2

5

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

1

6

1

0

/

6

3

.

3

8

”

> 1 m/40”

> 1 m/40”

> 1 m/40”> 1 m/40”

430/17”

430/17”

110/

4.33”

110/

4.33”

1

0

0

/

3

.

9

3

”

1

0

0

/

3

.

9

3

”

150/5.9”

150/5.9”

980/38.58”

980/38.58”

1015/39.96” 1015/39.96”

1285/50.59”

1285/50.59”

H1-H2

NN'

M

L

H3

H1

H4 H2

H3-H4

F-D-E

J

K

G

1

7

1

0

/

6

7

.

3

2

”

1

4

4

0

/

5

6

.

6

9

”

J

150/5.9”

N

E

J

K

F

D

G

7

5

/

3

”

1

3

0

/

5

.

1

”

160/6.3”

L

“Gripsol”

H6

H5

H6 H5

560

22”

2

7

5

/

1

0

.

8

”

2

7

0

/

1

0

.

6

”

100/

3.93”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

170/6.7”

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

H1

120/

4.72”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

Washer extractor type 340 standard Diagram n°. 07100083

0201 4

8

8.Technical

characteristics

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------------- 770 mm (30.31")--------------------

Cage length ----------------------------- 760 mm (30")---------------------Cage voume ----------------------- 338 dm³ (338 l) -------------------Specific load 1/11 ----------------------------- 31 kg (68 lb)----------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) ----------------- 600 x 400 mm (23.62x15.74")-----------Opening drum door (L x H) ------------------ 616 x 525 mm (24.25x20.67") ------------

Floor area ------------------------ 1.25 m² (13.45 sq. ft) ----------------

Net weight --------------------------- 760 daN (1676 lb)-----------------

Weight loaded (high level) -------------------------- 1008 daN (2223 lb)-----------------

Water, washing, low level xx l xx l xx l xx l

Water, washing, high level xx l xx l xx l xx l

Dynamic stress --------------------- F = 155 daN (342 lb)-------------------

Transmitted floor load ----------------------- 800 daN (1765 lb)-------------------

Spin efficiency ---------------------------------- 350 G ------------------------

Max. unbalance --------------------------- 4.8 kg (10.58 lb)--------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x16 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 4.8 kW 32 kW 4.8 kW 4.8 kW

Installed heating power 40 kW 27 kW - -

Electrical consumption for a normal cycle* 1.2 kWh/h 9.2 kWh/h 1 kWh/h 1 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP)

- Maximum supply pressure 600 kPa (87 psi)

- Steam instantaneous flow rate at 600 kPa x kg/h

- Steam consumption for a normal cycle* 18 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure --------------------------- 50 kPa (7.25 psi)------------------

Water supply maximum pressure --------------------------- 300 kPa (43.5 psi)----------------

Water consumption for a normal cycle* 495 l 470 l 470 l 470 l

Water consumption for a ECO cycle** 415 l 395 l 395 l 395 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection --------------------------- Ø 75 mm (3")----------------------

(H2 or H4 or H6) Double drain connection --------------------------- Ø 75 mm (3")----------------------

Maximum drain flow rate xx l/min xx l/min xx l/min xx l/min

(I) Waste water collector ------------------------ DN 150 mm (6" BSP)----------------

(3 cm/m (3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36 ") ---------------------

(N') Thermic fluid inlet DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure. xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0999 5

8

07100085

Washer extractor type 470 standard

Top view

Example of

drain connection

Front viewRight view Left view

8.Technical

characteristics

J

1565/61.61”

1565/61.61”

H1-H2

NN'

H3 H1

H4 H2

H3-H4

F-D-E

J

K

G

1

7

1

0

/

6

7

.

3

2

”

J

150/5.9”

N

E

J

K

F

D

G

L

M

L

H6 H5

700/27.56”

“Gripsol”

H6 H5

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

> 1 m/40” > 1 m/40”

> 1 m/40”

> 1 m/40”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

160/6.3”

980/38.58”

1015/39.96”

1

4

4

0

/

5

6

.

6

9

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

980/38.58”

1015/39.96”

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

H1

120/

4.72”

150/5.9”

150/5.9”

170/6.7”

2

7

5

/

1

0

.

8

”

1

3

0

/

5

.

1

”

2

7

0

/

1

0

.

6

”

100/

3.93”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

7

5

/

3

”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

Washer extractor type 470 standard Diagram no. 07100085

0102 6

8

8.Technical

characteristics

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------------- 770 mm (30.31")--------------------

Cage length ----------------------------- 1040 mm (41") ------------------Cage volume ----------------------- 467 dm³ (467 l) -------------------Specific load 1/11 --------------------------- 42.5 kg (94 lb)----------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) ---------------- 2x450 x 400 mm (17.71x15.74")----------Opening drum door (L x H) ------------------ 935 x 527 mm (36.81x20.74") ------------

Floor area ------------------------ 1.52 m² (16.36 sq. ft) ----------------

Net weight --------------------------- 870 daN (1919 lb)-----------------

Weight loaded (high level) --------------------------- 1272 daN (2805 lb)----------------

Water, washing, low level xx l xx l xx l xx l

Water, washing, high level xx l xx l xx l xx l

Dynamic stress --------------------- F = 275 daN (606 lb)-------------------

Transmitted floor load ----------------------- 830 daN (1830 lb)--------------------

Spin efficiency ---------------------------------- 350 G ------------------------

Max. unbalance --------------------------- 5.5 kg (12.13 lb)--------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x25 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 5.8 kW 42 kW 5.8 kW 5.8 kW

Installed heating power 40 kW 36 kW - -

Electrical consumption for a normal cycle* 1.5 kWh/h 11 kWh/h 1.2 kWh/h 1.2 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP)

- Maximum supply pressure 600 kPa (87 psi)

- Steam instantaneous flow rate at 600 kPa x kg/h

- Steam consumption for a normal cycle* 24.5 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure --------------------------- 50 kPa (7.25 psi)------------------

Water supply maximum pressure --------------------------- 300 kPa (43.5 psi)----------------

Water consumption for a normal cycle* 638 l 610 l 610 l 610 l

Water consumption for an ECO cycle** 558 l 530 l 530 l 530 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection --------------------------- Ø 75 mm (3")----------------------

(H2 or H4 or H6) Double drain connection --------------------------- Ø 75 mm (3")----------------------

Maximum drain flow rate xx l/min xx l/min xx l/min xx l/min

(I) Waste water collector ------------------------ DN 150 mm (6" BSP)----------------

(3 cm/m (3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36 ") ---------------------

(N') Thermic fluid inlet DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0999 7

8

8.Technical

characteristics

07100087

Washer extractor type 670 standard

Front viewRight view Left view

Top view

Example of

drain connection

J

200078.74”

200078.74”

H1-H2 H6

H6

H5

H5

H3 H1

H4 H2

H3-H4

1

7

1

0

/

6

7

.

3

2

”

J

150/5.9”

N

915/36”

NN'

M

L

F-D-E

J

K

G

E

J

K

F

D

G

L

“Gripsol”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

> 1 m/40”

> 1 m/40”

> 1 m/40”

> 1 m/40”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

160/6.3”

980/38.58”

1015/39.96”

1

4

4

0

/

5

6

.

6

9

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

980/38.58”

1015/39.96”

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

H1

120/

4.72”

150/5.9”

150/5.9”

170/6.7”

2

7

5

/

1

0

.

8

”

1

3

0

/

5

.

1

”

2

7

0

/

1

0

.

6

”

100/

3.93”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

7

5

/

3

”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0102 8

8

8.Technical

characteristics

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------------- 770 mm (30.31")--------------------

Cage length ----------------------------- 1500 mm (59") ------------------Cage volume ----------------------- 668 dm³ (668 l) -------------------Specific load 1/11 --------------------------- 61 kg (134 lb)----------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) ---------------- 2x600 x 400 mm (23.62x15.74")----------Opening drum door (L x H) --------------- 2x616 x 525 mm (24.25x20.66") -----------

Floor area ------------------------ 2 m² (21.53 sq. ft) --------------------

Net weight --------------------------- 940 daN (2073 lb)-----------------

Weight loaded (high level) ---------------------------1589 daN (3504 lb)-----------------

Water, washing, low level xx l xx l xx l xx l

Water, washing, high level xx l xx l xx l xx l

Dynamic stress --------------------- F = 466 daN (1028 lb)-------------------

Transmitted floor load ------------------------ 811 daN (1789 lb)------------------

Spin efficiency ---------------------------------- 350 G ------------------------

Max. unbalance --------------------------- 8 kg (17.65 lb)--------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x35 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 7.8 kW 61.5 kW 7.8 kW 7.8 kW

Installed heating power 40 kW 54 kW - -

Electrical consumption for a normal cycle* 2 kWh/h 23 kWh/h 2 kWh/h 2 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP)

- Maximum supply pressure 600 kPa (87 psi)

- Steam instantaneous flow rate at 600 kPa x kg/h

- Steam consumption for a normal cycle* 24.5 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure --------------------------- 50 kPa (7.25 psi)------------------

Water supply maximum pressure --------------------------- 300 kPa (43.5 psi)----------------

Water consumption for a normal cycle* 977 l 977 l 977 l 977 l

Water consumption for an ECO cycle** 782 l 782 l 782 l 782 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection --------------------------- Ø 75 mm (3")----------------------

(H2 or H4 or H6) Double drain connection --------------------------- Ø 75 mm (3")----------------------

Maximum drain flow rate xx l/min xx l/min xx l/min xx l/min

(I) Waste water collector ------------------------ DN 150 mm (6" BSP)----------------

(3 cm/m (3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36 ") ---------------------

(N') Thermic fluid inlet DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

Washer extractor type 670 standard Diagram no. 07100087

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0999 9

8

07100082

Washer extractor type 230 barrier

Top view

Example of

drain connection

Front viewRight view Left view

8.Technical

characteristics

1

7

1

0

/

6

7

.

3

2

”

> 1 m/40”

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

150/5.9”

> 1 m/40”

1055/41.53”

1045/41.14”

1045/41.14”

N

JJ

F-D-E

J

K

E

J

K

F

D

G

G

H1-H2

H3-H4

NN'

M

L

H3 H1

H4 H2

H1

I

100/

3.93”

120/

4.72”

100/3.93”

5

0

/

1

.

9

7

”

1

0

0

/

3

.

9

3

”

R

P

O

P

100/3.93”

100/3.93”

1

0

0

/

3

.

9

3

”

1075/42.32”

1

6

2

5

/

6

3

.

9

7

”

L

H6 H5

170/6.7”

440/

17.3”

2

7

5

/

1

0

.

8

”

“Gripsol”

H6

H5

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

160/6.3”

980/38.58”

1

4

4

0

/

5

6

.

6

9

”

1055/41.53”

8

7

0

/

3

4

.

2

5

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

980/38.58”

2

7

0

/

1

0

.

6

”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

7

5

/

3

”

150/5.9”

150/5.9”

1

3

0

/

5

.

1

”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

Washer extractor type 230 barrier Diagram no. 07100082

0102 10

8

8.Technical

characteristics

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------- 770 mm (30.31") -------------------

Cage length --------------------- 520 mm (20.47") ------------------Cage volume ---------------------- 229 dm³ (229 l) --------------------Specific load 1/11 -------------------- 21 kg (46 lb) ------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) ----------- 450 x 400 mm (17.71x15.74") ------------Opening drum door (L x H) ----------- 466 x 525 mm (18.34x20.67") -------------

Floor area ------------------- 1 m² (10.76 sq. ft) -------------------

Net weight --------------------- 670 daN (1478 lb) -------------------

Weight loaded (high level) --------------------- 934 daN (1840 lb) -------------------

Water, washing, low level xx l xx l xx l xx l

Water, washing, high level xx l xx l xx l xx l

Dynamic stress ---------------------- F = 101 daN (222 lb) --------------------

Transmitted floor load ----------------------- 814 daN (1795 lb) ----------------------

Spin efficiency ------------------------------- 350 G -------------------------------

Max. unbalance ----------------------------- 3.6 kg (7.94 lb) ---------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x6 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 3.7 kW 21.70 kW 3.7 kW 3.7 kW

Installed heating power 40 kW 18 kW - -

Electrical consumption for a normal cycle* 0.8 kWh/h 5.3 kWh/h 0.6 kWh/h 0.6 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP) (87 psi)

- Maximum supply pressure 600 kPa

- Steam instantaneous flow rate at 600 kPa x kg/h

- Steam consumption for a a normal cycle* 12 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure ---------------------- 50 kPa (7.25 psi) -------------------

Water supply maximum pressure ---------------------- 300 kPa (43.5 psi) ------------------

Water consumption for a normal cycle* 360 l 340 l 340 l 340 l

Water consumption for an ECO cycle** 282 l 260 l 260 l 260 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection ------------------------- Ø 75 mm (3") ---------------------

(H2 or H4 or H6) Double drain connection ------------------------- Ø 75 mm (3") ---------------------

Maximum drain flow rate xx l/min xx l/min xx l/min xx l/min

(I) Waste water collector --------------------- DN 150 mm (6" BSP) --------------

(3 cm/m (3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36") ------------------

(N') Thermic fluid inlet

DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

(O) Barrier partition (provided by customer)

(P) Frame 50x100 mm (provided by customer)

(R) Foam joint

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0999 11

8

07100084

Washer extractor type 340 barrier

Top view

Example of

drain connection

Front viewRight view Left view

8.Technical

characteristics

> 1 m/40”

> 1 m/40”

1285/50.59”

1285/50.59”

H1-H2

H3-H4

N

M

H3 H1

H4 H2

R

P

O

P

1315/51.77”

F-D-E

J

K

G

1

7

1

0

/

6

7

.

3

2

”

J J

150/5.9”

N

H1

I

N'

E

J

K

F

D

G

L

L

H6 H5

560/22”

2

7

5

/

1

0

.

8

”

“Gripsol”

H6

H5

1055/41.53”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

160/6.3”

980/38.58”

1

4

4

0

/

5

6

.

6

9

”

100/

3.93”

100/3.93” 100/3.93”

1

0

0

/

3

.

9

3

”

1

6

2

5

/

6

3

.

9

7

”

2

7

0

/

1

0

.

6

”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

7

5

/

3

”

1

3

0

/

5

.

1

”

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

120/

4.72”

100/3.93”

5

0

/

1

.

9

7

”

1

0

0

/

3

.

9

3

”

1055/41.53”

8

7

0

/

3

4

.

2

5

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

980/38.58”

170/6.7”

150/5.9”

150/5.9”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

Washer extractor type 340 barrier Diagram no. 07100084

0102 12

8

8.Technical

characteristics

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------- 770 mm (30.31") -------------------

Cage lenght ----------------------- 760 mm (30") ------------------Cage volume ---------------------- 338 dm³ (338 l) --------------------Specific load 1/11 ------------------------ 31 kg (68 lb) ---------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) -------------- 600 x 400 mm (23.62x15.74") ------------Opening drum door (L x H) --------------- 616 x 525 mm (24.25x20.67") -------------

Floor area ------------------ 1.25 m² (13.45 sq. ft) ------------------

Net weight --------------------- 760 daN (1676 lb) -------------------

Weight loaded (high level) -------------------- 1008 daN (2223 lb) ------------------

Water, washing, low level xx l xx l xx l xx l

Water, washing, high level xx l xx l xx l xx l

Dynamic stress -------------------- F = 155 daN (342 lb) ----------------

Transmitted floor load ---------------------- 800 daN (1765 lb) ------------------

Spin efficiency ----------------------------- 350 G ---------------------------

Max. unbalance ------------------------ 4.8 kg (10.58 lb) ------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x16 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 4.8 kW 32 kW 4.8 kW 4.8 kW

Installed heating power 40 kW 27 kW - -

Electrical consumption for a normal cycle* 1.2 kWh/h 9.2 kWh/h 1 kWh/h 1 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP) (87 psi)

- Maximum supply pressure 600 kPa

- Steam instantaneous flow rate at 600 kPa x kg/h

- Steam consumption for a normal cycle* 18 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure ---------------------- 50 kPa (7.25 psi) -------------------

Water supply maximum pressure --------------------- 300 kPa (43.5 psi) ------------------

Water consumption for a normal cycle* 495 l 470 l 470 l 470 l

Water consumption for an ECO cycle** 315 l 395 l 395 l 395 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection ------------------------- Ø 75 mm (3") ---------------------

(H2 or H4 or H6) Double drain connection ------------------------- Ø 75 mm (3") ---------------------

Maximum drain flow rate xx l/min xx l/min xx l/min xx l/min

(I) Waste water collector --------------------- DN 150 mm (6" BSP) --------------

(3 cm/m (3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36") ------------------

(N') Thermic fluid inlet DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

(O) Barrier partition (provided by customer)

(P) Frame 50x100 mm (provided by customer)

(R) Foam joint

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

0999 13

8

07100086

Washer extractor type 470 barrier

Top view

Example of

drain connection

Front viewRight view Left view

8.Technical

characteristics

1565/61.61”

1565/61.61”

H1-H2

H3-H4

N

H3 H1

H4 H2

O

P

1595/62.79”

F-D-E

J

K

G

1

7

1

0

/

6

7

.

3

2

”

J

J

150/5.9”

N

N'

E

J

K

F

D

G

L

M

L

“Gripsol”

H6

H5

H6 H5

700/27.56”

1055/41.53”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

160/6.3”

980/38.58”

1

4

4

0

/

5

6

.

6

9

”

100/

3.93”

100/3.93”

100/3.93”

1

0

0

/

3

.

9

3

”

1

6

2

5

/

6

3

.

9

7

”

2

7

0

/

1

0

.

6

”

1

0

0

/

3

.

9

3

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

8

0

/

3

.

1

5

”

135/5.3”

160/6.3”

7

5

/

3

”

1

3

0

/

5

.

1

”

55/2.16”

40/1.57”

1

0

0

/

3

.

9

3

”

Ø

7

5

/

3

”

H1

I

120/

4.72”

100/3.93”

5

0

/

1

.

9

7

”

1

0

0

/

3

.

9

3

”

R

P

1055/41.53”

8

7

0

/

3

4

.

2

5

”

8

7

0

/

3

4

.

2

5

”

1

6

1

0

/

6

3

.

3

8

”

430/17”

110/

4.33”

1

0

0

/

3

.

9

3

”

980/38.58”

> 1 m/40”

> 1 m/40”

170/6.7”

2

7

5

/

1

0

.

8

”

150/5.9”

150/5.9”

Notice

Date Page

01201055

INSTRUCTION

HANDBOOK

Washer extractor type 470 barrier Diagram no. 07100086

0102 14

8

8. Characteristics

techniques

Heating Gas Electric Steam Thermic fluid

Characteristics Ø cage --------------------- 770 mm (30.31") -------------------

Cage length ----------------------- 1040 mm (41") ------------------Cage volume ---------------------- 467 dm³ (467 l) --------------------Specific load 1/11 ----------------------- 42.5 kg (94 lb) --------------------(dry linen, ISO 9398-4)

Opening cage doors (L x H) -------------- 2x450 x 400 mm (17.71x15.74") ------------Opening drum door (L x H) ----------------- 935 x 527 mm (36.81x20.74") -------------

Floor area ------------------ 1.52 m² (16.36 sq. ft) ------------------

Net weight -------------------- 870 daN (1919 lb) -------------------

Weight loaded (high level) -------------------- 1272 daN (2805 lb) ------------------

Water, washing, low level xx l xx l xx l xx l

Water, washing, high level xx l xx l xx l xx l

Dynamic stress -------------------- F = 275 daN (606 lb) ----------------

Transmitted floor load ---------------------- 830 daN (1830 lb) ------------------

Spin efficiency ----------------------------- 350 G ---------------------------

Max. unbalance ------------------------ 5.5 kg (12.13 lb) ------------------

(L) Main switch to connect main cable

(M) Electric cable (section) 4x2.5 mm² 4x25 mm² 4x2.5 mm² 4x2.5 mm²

(N) or (N') Stuffing box for main cable

Supply voltage -------------------------380 / 415 V 3+E ~ 50/60 Hz------------

Installed electric power 5.8 kW 42 kW 5.8 kW 5.8 kW

Installed heating power 40 kW 36 kW - -

Electrical consumption for a normal cycle* 1.5 kWh/h 11 kWh/h 1.2 kWh/h 1.2 kWh/h

Heat loss -------------------3 % of installed heating power--------------

(G) Steam inlet DN 20 (3/4" BSP)

- Maximum supply pressure 600 kPa (87 psi)

- Steam instantaneous flow rate at 600 kPa x kg/h

- Steam consumption for a normal cycle* 24.5 kg/h at 600 kPa (87 psi)

(D) Hot water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(E) Cold hard water connection / flow DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

(F) Cold soft water connection / flow (option) DN 20 (3/4" BSP) - 70 l/min at 250 kPA (36 psi)

Water supply minimum pressure ---------------------- 50 kPa (7.25 psi) -------------------

Water supply maximum pressure --------------------- 300 kPa (43.5 psi) ------------------

Water consumption for a normal cycle* 638 l 610 l 610 l 610 l

Water consumption for an ECO cycle** 558 l 530 l 530 l 530 l

(K) Liquid detergents inlet

(H1 or H3 or H5) Drain connection ------------------------- Ø 75 mm (3") ---------------------

(H2 or H4 or H6) Double drain connection ------------------------- Ø 75 mm (3") ---------------------

Maximum drain flow rate xx l/min xx l/min xx l/min xx l/min

(I) Waste water collector --------------------- DN 150 mm (6" BSP) --------------

(3 cm/m (3 %) minimum slope)

(J) Air vent hole ------------------------ Ø 60 mm (2.36") ------------------

(N') Thermic fluid inlet DN 15 (1/2" BSP)

(G) Thermic fluid return DN 15 (1/2" BSP)

- Maximum supply pressure xxx kPa

- Installed calorific power xxx kcal

- Average calorific consumption xxx kcal/h

- Inner volume thermic fluid xx l

Gas inlet DN 20 (3/4" BSP)

Combustion products evacuation Ø 125 mm (5")

(O) Barrier partition (provided by customer)

(P) Frame 50x100 mm (provided by customer)

(R) Foam joint

* normal cycle : prewash 3 min at 35 °C, drain. 2 min, main wash 4 min at 65 °C, drain 2 min, rinse 2 min, extract. 2 min, rinse 2 min,

extract 2 min, rinse 2 min, extrac. 10 min (cold water supply at 15 °C).

** ECO cycle : normal cycle with rinse 5 l/kg instead of 6 l/kg dry linen.

Loading...

Loading...