Wascomat W620 Classic, W630 Classic, W640 Classic, W655 Classic, W675 Classic Service Manual

Page 1

DOC. NO. 438.9205-85/07 EDITION 49.2004

W620, W630, W640,

W655, W675

Classic

SERVICE MANUAL

Page 2

Page 3

NOTICE TO SERVICE PERSONNEL

INSTALLATION

Improper installation of Wascomat laundry and wet cleaning equipment can result in

personal injury and severe damage to the machine.

REFER INSTALLATION TO QUALIFIED PERSONNEL!

RISK OF ELECTRIC SHOCK

The equipment utilizes high Voltages. Disconnect electric power before servicing.

The use of proper service tools and techniques, and the use of proper repair procedures,

is essential to the safety of service personnel and equipment users.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

RISK OF PERSONAL INJURY

This equipment contains moving parts, and some components that may have sharp edges.

Improper or careless service procedures may result in serious injury to service personnel.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

ABOUT THIS MANUAL

This manual is intended to provide service guidance to qualified service personnel.

Wascomat and its authorized dealers make no determination regarding the qualification of

individuals requesting this service manual. The service provider assumes all risks inherent

to the servicing of this equipment and any risks that arise as result of the lack of

knowledge or ability of any person servicing this equipment.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL!

NOTE:

Improper installation or servicing of Wascomat equipment will void the

manufacturer's warranty!

Page 4

Intentionally blank

Page 5

Service Manual

W620, W630, W640, W655, W675

Classic

WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE NEXT

PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF

YOUR WASCOMAT MACHINE.

PLEASE ENTER THE FOLLOWING INFORMATION AS IT APPEARS ON THE MACHINE(S)

DATA PLATE(S).

MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE

REFERENCE.

MACHINE TYPE OR MODEL

MACHINE SERIAL NUMBER(S)

ELECTRICAL CHARACTERISTICS:________ VOLTS, _______ PHASE,_______ HZ.

Page 6

Intentionally blank

Page 7

SAFETY AND WARNINGS SIGNS

Replace If Missing Or Illegible

One or more of these signs must be affixed on each machine as indicated, when not included as part of the front instruction panel.

LOCATED ON THE OPERATING INSTRUCTION SIGN OF THE MACHINE:

CAUTION

1. Do not attempt to open door unitl "Door unlocked" indicator

is lit.

2. Machine must not be used by children.

3. Do not use flammable liquids in this machine.

MACHINE MUST NOT BE USED BY CHILDREN

PRECAUCION

1. No intente abrir la puerta hasta que la luz indicadora este

encendida.

2. La maquina no debe ser operado por ninos.

3. No use liquidos inflamable en la lavadora.

LAS MÁQUINAS NO DEBEN SER USADAS POR NIÑOS

Page 8

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANTES MESURES DE SECURITE

WARNING -

To reduce the risk of fire, electric chock, or injury to persons when using your appliance:

AVERTISSEMENT -

Pour réduire les risques d´incendie, de choc électrique ou de blessure quand, I´appareil est utilisé:

1. Read all instructions before using the appliance.

Lire toutes les instructions avant d’utiliser l’appareil.

2. This machine must be securely bolted to the floor according to the installation instructions.

Ce machine doit être visseé sur le plancher selon les instructions d’installation.

3. This machine MUST be serviced and operated in compliance with manufacturers instructions. CHECK DOOR

LOCKS EVERY DAY FOR PROPER OPERATION TO PREVENT INJURY OR DAMAGE. IF THE DOOR LOCK

FAILS TO OPERATE PROPERLY, PLACE THE MACHINE OUT OF ORDER UNTIL THE PROBLEM IS

CORRECTED.

IL FAUT QUE cette appareil soit entretenue et actionnée conformement aux instructions du fabriquant. CONTROLEZ LA

SERRURE DE PORTE TOUS LES JOURS AFIN DE EVITER DES DOMMAGES OU DES RISQUES PERSONNELLES. SI LA

SERRURE DE PORTE NE FONCTIONNE PAS, IL FAUT METTRE LA MACHINE HORS SERVICE JUSQU’Á LE

PROBLEME SOIT CORRIGÉ.

4. Do not wash articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline,

drycleaning solvents, or other flammable or explosive substances, as they give off vapors that could ignite or

explode.

Ne pas laver des articles qui ont été nettoyés ou lavés avec de l’essence, des solvants pour nettoyage à sec ou d’autres

substances inflammables ou explosives, ou que l’on a fait tremper dans ces produits. Ces substances dégagent des vapeurs qui

peuvent s’enflammer ou exploser.

5. Do not add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the wash water. These

substances giveoff vapours that could ignite or explode.

Ne pas ajouter d’essence, de solvants pour nettoyage à sec ou d’autres substances inflammables ou explosives à l’eau de

lavage. Ces substances dégagent des vapeurs qui peuvent s’enflammer ou exploser.

6. Under certain conditions, hydrogen gas may be produced in a hot-water system that has not been used for 2 weeks

or more. HYDROGEN GAS IS EXPLOSIVE. If the hot-water system has not been used for such a period, before

using a washing machine, turn on all hot-water faucets and let the water flow from each for several minutes. This

will release any accumulated hydrogen gas. As the gas is flammable, do not smoke or use an open flame during

this time.

De l’hydrogène peut être produit dans un système à eau chaude qui n’a pas été utilisé depuis deux semaines ou plus.

L’HYDROGÈNE EST EXPLOSIF. Si le système à eau chaude n’a pas été utilisé depuis un certain temps, ouvrir tous les

robinets d’eau chaude et laisser l’eau couler pendant plusieurs minutes avant d’utiliser une laveuse, l’hydrogène accumulé, le

cas échéant, s’échappera. L’hydrogène étant inflammable, ne pas fumer ou utiliser un appareil à flamme nue pendant que l’eau

coule.

7. Do not allow children to play on or in the appliance. Close supervision of children is necessary when the appliance

is used near children.

Ne pas permettre aux enfants de jouer sur ou dans l’appareil. Surveiller ètriotement les enfants lorsqu’ils se trou vent près de

l’appareil qui fonctionne.

8. Before the appliance is removed from service or discarded, remove the door.

Avant de mettre l’appareil hors service ou de jeter, retirer la porte.

9. Do not reach into the appliance if the tube is moving.

Ne pas mettre la main dans l’appareil lorsque la cuve bougent.

10. Do not install or store this appliance where it will be exposed to the weather.

Ne pas installer ou placer cet appareil dans un endroit où il sera exposé aux intempéries.

11. Do not tamper with controls.

Ne pas trafiquer les commandes.

12. Do not repair or replace any part of the appleance or attempt any servicing unless specifically recommanded in the

user-maintenance instructions or in published user-repair instructions that you understand and have the skills to

carry out.

Ne pas réparer ou remplacer les pièces de l’appareil ou procéder à l’entretien de celui-ci sauf si les instructions visant

l’entretien et les réparations qui doivent être effectués par l’utilisateur le spécifient, si vous comprenez bien ces instructions et

si vous possédez les

connaissances nécessaires.

MANUFACTURED BY WASCATOR

DISTRIBUTED BY WASCOMAT INWOOD, NEW YORK, USA

Page 9

NOTICE TO: OWNERS, OPERATORS AND DEALERS OF WASCOMAT MACHINES

II

IMPROPER INSTALLATION AND INADEQUATE MAINTENANCE, POOR HOUSEKEEPING AND WILLFUL

NEGLECT OR BYPASSING OF SAFETY DEVICES MAY RESULT IN SERIOUS ACCIDENTS OR INJURY.

TO ASSURE THE SAFETY OF CUSTOMERS AND/OR OPERATORS OF YOUR MACHINE, THE FOLLOWING MAINTENANCE CHECKS MUST BE PERFORMED ON A DAILY BASIS.

NOTICE À L’ATTENTION DES PROPRIÉTAIRES, UTILISATEURS ET REVENDEURS

DE MACHINES WASCOMAT

UNE INSTALLATION INCORRECTE ET UN ENTRETIEN INADÉQUAT, DE MÊME QUE LA NÉGLIGENCE

OU LA NEUTRALISATION DÉLIBÉRÉES DES DISPOSITIFS DE SÉCURITÉ, PEUVENT ÊTRE CAUSES

DE BLESSURES OU D’ACCIDENTS SÉRIEUX. POUR ASSURER LA SÉCURITÉ DES CLIENTS ET/OU

DES UTILISATEURS DE VOTRE MACHINE, IL EST INDISPENSABLE DE PROCÉDER CHAQUE JOUR

AUX CONTRÔLES DE ROUTINE CI-APRÈS.

1. Prior to operation of the machine, check to make certain that all operating instructions and

warning signs are affixed to the machine and legible. (See the following page of this manual

for description and location of the signs.) Missing or illegible ones must be replaced immediately. Be sure you have spare signs and labels available at all times. These can be obtained from your dealer or Wascomat.

2. Check the door safety interlock, as follows:

(a) OPEN THE DOOR of the machine and attempt to start in the normal manner:

For coin-operated models, insert the proper coins to start the machine.

For manually operated models, place the ON-OFF switch in the ON position and

press the Start switch.

THE MACHINE(S) MUST NOT START !

(b) CLOSE THE DOOR to start machine operation and, while it is operating, attempt to

open the door without exerting extreme force on the door handle. The door should

remain locked!

If the machine can start with the door open, or can continue to operate with the door

unlocked, the door interlock is no longer operating properly. The machine must be

placed out of order and the interlock immediately replaced.

(See the door interlock section of the manual.)

3. DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO BYPASS OR REWIRE ANY OF

THE MACHINE SAFETY DEVICES AS THIS CAN RESULT IN SERIOUS ACCIDENTS.

4. Be sure to keep the machine(s) in proper working order: Follow all maintenance and

safety procedures. Further information regarding machine safety, service and parts can be

obtained from your dealer or from Wascomat through its Teletech Service Hotline - 516/371-

0700.

All requests for assistance must include the model, serial number and electrical characteristics as

they appear on the machine identification plate. Insert this information in the space provided on the

previous page of this manual.

5. WARNING: DO NOT OPERATE MACHINE(S) WITH SAFETY DEVICES BYPASSED, REWIRED OR

INOPERATIVE! DO NOT OPEN MACHINE DOOR UNTIL DRUM HAS STOPPED ROTATING!

AVERTISSEMENT: NE PAS FAIRE FONCTIONNER LA (LES) MACHINE(S) AVEC UN DISPOSITIF

DE SÉCURITÉ NEUTRALISÉ, RECÂBLÉ OU NON OPÉRATIONNEL! NE PAS OUVRIR LA

MACHINE TANT QUE LE TAMBOUR NE S’EST PAS IMMOBILISÉ!

Page 10

Intentionally blank

Page 11

Safety precautions

Technical data

Machine presentation

Regular matintenace

Control unit

Level control

Thermostat

Door and door lock

Motor

Drain valve

Detergent compartment

Heating

Coin-meter

Instruction for pulley and replacing bearings

1

2

3

4

5

11

12

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Overview

Service

instructions

Machine

components

and parts

Page 12

Intentionally blank

Page 13

1

1

1. Safety precautions

Service

Manual

Contents

Safety precautions ....................................................................................3

Page 14

Intentionally blank

Page 15

3

1

1. Safety precautions

Service

Manual

Safety Precautions

• The machine is only intended for washing with water.

•Do not allow minors to operate the machine.

• Installation and maintenance work should only be done by authorized

persons.

•Do not bypass the door lock of the machine.

•Any leaks, e.g. a worn-out door seal, should be repaired immediately.

•Prior to repairs or maintenance, be sure to read the corresponding

handbooks and service manuals.

•Do not flush the machine with water.

Page 16

Intentionally blank

Page 17

2. Technical data

Contents

Technical data...........................................................................................3

Connections .........................................................................................3

Page 18

Intentionally blank

Page 19

3

2

2. Technical data

Service

Manual

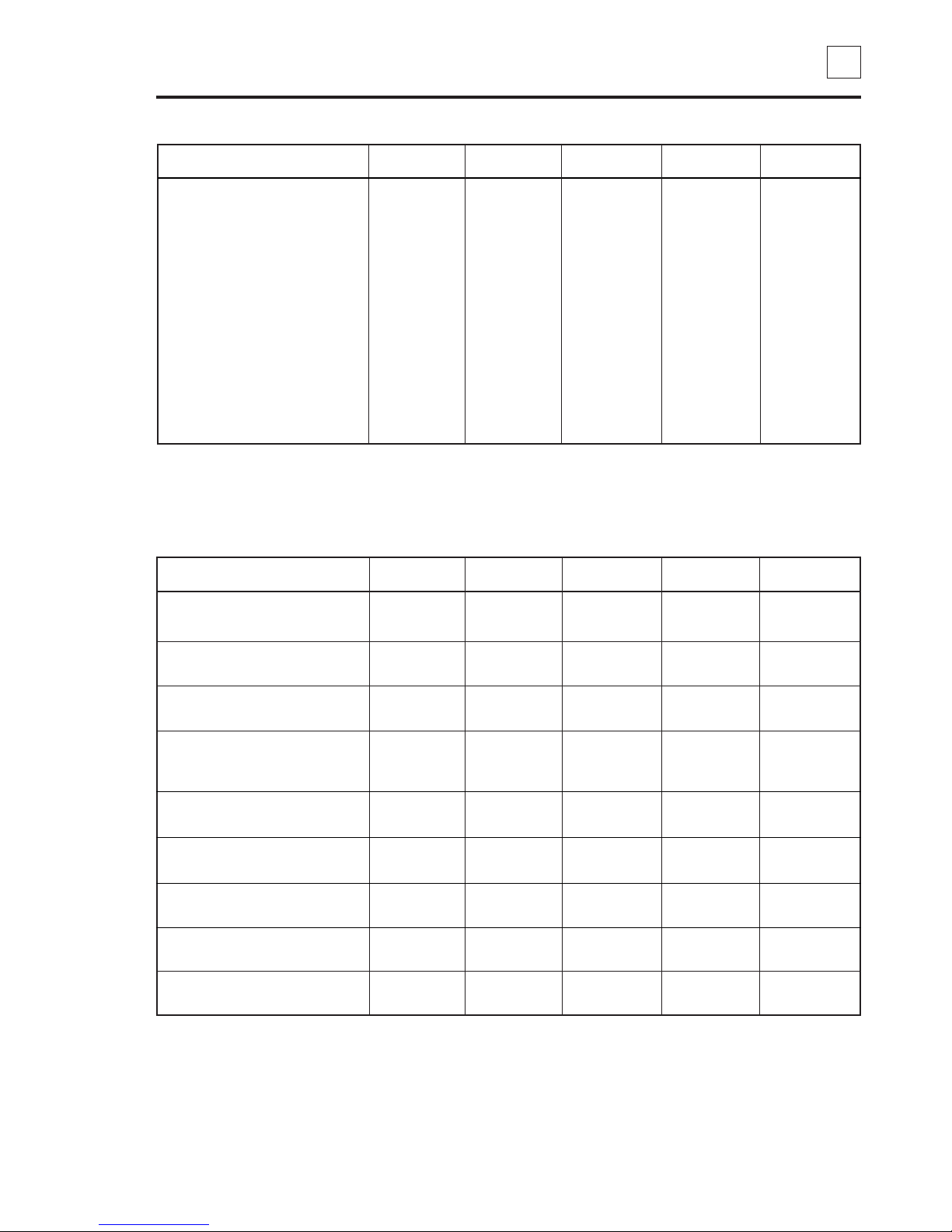

W620 W630 W640 W655 W675

85/3.0 130/4.6 180/6.4 250/8.8 330/11.7

520/20 1/2 595/23 7/16 650/25 9/16 725/28 9/16 795/31 5/16

52 49 44 44 42

528 494 471 446 427

5.4/7.5 7.5/10 13 10.7/18 11/23

xx x x x

xx x x x

81 81 81 81 81

136/300 175/386 228/503 287/633 330/727

W620 W630 W640 W655 W675

DN20 DN20 DN20 DN20 DN20

3/4" 3/4" 3/4" 3/4" 3/4"

30-90 30-90 30-90 30-90 30-90

200-600 200-600 200-600 200-600 200-600

8-145 8-145 8-145 8-145 8-145

50-1000 50-1000 50-1000 50-1000 50-1000

55 51515

20 20 20 60 60

33 3 33

75 75 75 75 75

45 45 45 45 45

170 170 170 170 170

DN15 DN15 DN15 DN15 DN15

1/2" 1/2" 1/2" 1/2" 1/2"

45-90 45-90 45-90 45-90 45-90

300-600 300-600 300-600 300-600 300-600

8-115 8-115 8-115 8-115 8-115

50-800 50-800 50-800 50-800 50-800

Water valves

connection

Rec. water pressure psi

kPa

Functioning limits psi

for water valve kPa

Capacity at 45 psi

(300 kPa) gallon/min

l/min

Drain valve inch

outer Ø mm

Draining gallon/min

capacity l/min

Steam valve

connection

Rec. steam pressure psi

kPa

Functioning limits for psi

steam valve kPa

Connections

Technical data

Innerdrum

volume litres/ft

3

diameter mm/inch

Drum speed

wash rpm

extraction rpm

Heating

electricity kW

steam

hot water

G-factor

Weight, net kg/lbs

Page 20

2

2. Technical data

4

Service

Manual

in mm A B C D E F G H I K L M N O P R

W620 660 730 1115 355 765 825 45 1030 215 1010 130 830 385 – 100 210

W630 720 790 1200 365 825 910 45 1115 215 1095 130 910 420 – 100 235

W640 750 880 1325 435 915 1035 45 1245 130 1225 210 1040 325 295 100 225

W655 830 955 1410 495 990 1120 45 1330 160 1290 245 1125 325 325 100 265

W675 910 1040 1445 500 1075 1155 45 1365 160 1325 245 1155 280 325 100 210

1 Electrical connection

2 Cold water

3 Hot water

4 Steam connection

5 Drain

6 Liquid detergent supply

7 Control panel

8 Soap box

9 Water reuse

10 Door opening, W620: ø 310 mm/12 3/16", W630: ø 395 mm/15 9/16", W640, W655, W675:

ø 435 mm/17 1/8"

A

D

C

8

10

7

B

E

N

P

R

F

L

G

I

1

2

3

9

4

5

6

5281

5282 5283

K

M

H

5

W620-630

5459

N

G

3

L

O

I

2

P

6

9

K

M

H

R

F

1

4

5

Rear side

Right sideFront Rear side

W640-675

Page 21

5

2

2. Technical data

Service

Manual

in inch A B C D E F G H I K

W620 26 28 3/4 43 7/8 14 30 1/8 32 1/2 1 3/4 40 9/16 8 7/16 39 3/4

W630 28 3/8 31 1/8 47 1/4 14 3/8 32 1/2 35 13/16 1 3/4 40 7/8 8 7/16 43 1/8

W640 29 1/2 34 5/8 52 3/16 17 1/8 36 40 3/4 1 3/4 49 5 1/8 48 1/4

W655 32 11/16 37 5/8 55 1/2 19 1/2 39 44 1/8 1 3/4 52 3/8 6 5/16 50 13/16

W675 35 13/16 40 15/16 56 7/8 19 11/16 42 5/16 45 1/2 1 3/4 53 3/4 6 5/16 52 3/16

in inch L M N O P R

W620 5 1/8 32 11/16 15 3/16 – 3 15/16 8 1/4

W630 5 1/8 35 13/16 16 9/16 – 3 15/16 9 1/4

W640 8 1/4 40 15/1612 13/16 11 5/8 3 15/16 8 7/8

W655 9 5/8 44 5/16 12 13/16 12 13/16 3 15/16 10 7/16

W675 9 5/8 45 1/2 11 12 13/16 3 15/16 8 1/4

A

D

C

8

10

7

B

E

N

P

R

F

L

G

I

1

2

3

9

4

5

6

5281

5282 5283

K

M

H

5

W620-630

5459

N

G

3

L

O

I

2

P

6

9

K

M

H

R

F

1

4

5

Rear side

Right sideFront Rear side

W640-675

Page 22

2

2. Technical data

6

Service

Manual

Frequency of the

dynamic force Hz

Max floor load lbs force

at extraction kN

9.3 8.7 7.9 8.3 7.5

289±747 410±988 675±1277 530±1133 916±2265

1.2±3.1 1.7±4.1 2.8±5.3 2.2±4.7 3.8±6.0

W620 W630 W640 W655 W675

Page 23

7

2

2. Technical data

Service

Manual

E/W620

120 V 1 AC 0.65 16

200 V 3 AC 0.95 10

230-240 V 1 AC 0.75 10

240 V 3 AC 0.95 10

220 V 3 AC 6.6 20

230 V 1 AC 7.2 35

230 V 3 AC 7.2 25

240 V 1 AC 7.8 35

240 V 3 AC 7.8 25

Heating Voltage Total Fuse

alternative alternative kW A

No heating

or Steam

heating

El heating

Page 24

2

2. Technical data

8

Service

Manual

E/W630

200 V 3 AC 1.3 10

220 V 1 AC 0.95 10

230 V 1 AC 0.95 10

240 V 3 AC 1.3 10

440-480 V 3 AC 1.3 10

200 V 3 AC 7.3 25

230 V 3 AC 3.2 16

230 V 3 AC 6.9 25

230 V 3 AC 7.3 25

230 V 3 AC 9.6 35

240 V 3 AC 3.4 16

240 V 3 AC 7.9 25

240 V 3 AC 10.4 35

380 V 3N AC 2.9 10

380 V 3N AC 6.3 16

380 V 3N AC 6.7 16

380 V 3N AC 8.8 16

400 V 3/3N AC 3.2 10

400 V 3/3N AC 6.9 16

400 V 3/3N AC 7.3 16

400 V 3/3N AC 9.7 16

415 V 3N AC 3.4 10

415 V 3N AC 7.9 16

415 V 3N AC 10.4 16

440 V 3 AC 10.4 16

Heating Voltage Total Fuse

alternative alternative kW A

No heating

or Steam

heating

El heating

Page 25

9

2

2. Technical data

Service

Manual

E/W640

200 V 3 AC 2.0 10

240 V 1 AC 1.7 16

240 V 3 AC 1.5 10

415 V 3/3N AC 1.5 10

200 V 3 AC 9.5 35

230 V 1 AC 4.9 25

240 V 1 AC 5.3 25

230 V 3 AC 12.4 50

230 V 3 AC 4.9 20

230 V 3 AC 9.8 35

240 V 3 AC 5.3 20

240 V 3 AC 13.5 50

380 V 3N AC 4.5 10

380 V 3N AC 8.9 16

380 V 3N AC 11.3 20

400 V 3/3N AC 4.9 10

400 V 3/3N AC 9.9 20

400 V 3/3N AC 12.5 25

415 V 3N AC 5.3 10

415 V 3N 13.4 25

440-480 V 13.5 20

Heating Voltage Total Fuse

alternative alternative kW A

No heating

or Steam

heating

El heating

Page 26

2

2. Technical data

10

Service

Manual

E/W655

200 V 3 AC 2.3 10

230 V 3 AC 2.3 10

240 V 1 AC 2.1 16

240 V 3 AC 2.3 10

230 V 3 AC 17.2 50

240 V 3 AC 18.7 50

380 V 3/3N AC 15.7 35

400 V 3/3N AC 17.3 35

415 V 3/3N AC 18.6 35

440-480 V 3 AC 18.7 35

Heating Voltage Total Fuse

alternative alternative kW A

No heating

or Steam

heating

El heating

Page 27

11

2

2. Technical data

Service

Manual

E/W675

200 V 3 AC 1.4 10

230-240 V 3 AC 1.6 10

400 V 3/3N AC 1.4 10

230 V 3 AC 22 63

240 V 3 AC 23.9 63

380 V 3N AC 20.1 35

400 V 3/3N AC 22.2 35

415 V 3/3N AC 23.8 35

440-480 V 3 AC 23.9 35

Heating Voltage Total Fuse

alternative alternative kW A

No heating

or Steam

heating

El heating

Page 28

Intentionally blank

Page 29

3. Machine presentation

Contents

Description................................................................................................3

General ................................................................................................3

Function ....................................................................................................4

General ................................................................................................4

Programme unit....................................................................................5

Door lock ..............................................................................................6

Heating.................................................................................................7

Water connections ...............................................................................7

Rear control unit...................................................................................7

Detergent compartment .......................................................................8

Drain valve ...........................................................................................8

Page 30

Intentionally blank

Page 31

3. Machine presentation

3

3

Service

Manual

5203 A

Fig.

1

1

Description

General

The machines covered in this manual include the

following models:

Drum volume Model name

(litres) (ft3)

85 3 W620

130 4.6 W630

180 6.4 W640

250 8.8 W655

330 11.7 W675

The machines feature an electromechanical

programme unit with fixed washing programmes.

The machines are supplied to customer

specifications with e.g. electric or steam heating

or no heating.

The machines are designed for installation in

hotels, laundries (such as apartment buildings

and coin laundries), factories, hospitals, various

institutions, etc.

Page 32

3

3. Machine presentation

4

Service

Manual

5916

Fig.

2

2

Function

General

This section presents a general overview of the functions of the machine.

Most functions are then presented in detailed in separate chapters in this

service manual.

Detergent compartment

Programme unit

Control panel

Door

Door lock

Heating elements

Drain valve

Frame

Outer drum

Motor relays

Rear control unit

Motor

Water inlet valves

Page 33

3. Machine presentation

3

5

Service

Manual

5916

5190

Fig.

3

Fig.

4

3

4

Programme unit

The control panel has a rotary switch for

selection of fixed machine programmes and a

combined start/pause button with rapid advance.

The programme unit controls the water valves,

drain valve and heating via the communication

card in the rear control unit. This unit can also be

connected to send control signals to external

units for detergent pumps.

The programme unit of the machine is described

in detail in section 23. Programme unit.

Programme unit

Heating

element

Voltage

supply

K21

Programme unit

A1

Communication card A21

Water

valves

Drain

valve

Drain, water, detergent

Page 34

3

3. Machine presentation

6

Service

Manual

Fig.

5

Fig.

6

Door lock

The door lock is an electro-mechanical type with

double safety switches. The lock is bi-stable, i.e.,

it needs to receive an active pulse from the

control in order both to lock and unlock the door.

A separate printed circuit board, called door lock

control, can be fitted onto the programme unit.

This board controls locking and unlocking. The

card has separate checks for empty drum and

stopped drum. Together with the checks built into

the programme unit, this guarantees that the

door cannot be opened by a mistake.

The door lock on the machine is described in

detail in section 29. Door and door lock.

6

5191

Door lock

control

A31

Level

guard

B2

M1

Door lock

A41

Programme unit

A1

Motor

module A107

Rotation sensor B3

5

6108

Door lock control

Door lock

Page 35

3. Machine presentation

3

7

Service

Manual

7

Fig.

7

Fig.

7

Fig.

7

Heating

When using electric heating, the water for

washing is heated by three heating elements

accessible from the front of the machine.

The machine can also be fitted with steam

heating using a steam valve fitted on the rear of

the machine.

The heating system of the machine is described

in detail in section 40. Heating.

Water connections

Depending on the machine size and customer

specifications, the machine has one, two, three

or four inlet valves.

This unit also holds eight connectors for external

detergent supply.

Rear control unit

This box contains the main power switch or a

connection block for the input voltage, heating

contactor and a communication card with outputs

that control the water and drain valves of the

machine as well as the heating. There are also

connection blocks for connection to e.g., an

external detergent supply.

The rear electric box of the machines is

described in detail in section 21. Control unit.

5182, 5916

Water connections

Rear control unit

Heating elements

T1

T2

T3L1N

N

L2

L3

Main power switch

Contactor K21 (heating)

Communication

card

Supply voltage

connection

Page 36

3

3. Machine presentation

8

Service

Manual

8

Fig.

8

Fig.

8

Detergent compartment

The compartment is divided into four for prewash, main wash, rinse and bleaching-agent/

liquid detergent.

The detergent compartment of the machine is

described in detail in section 39. Detergent

compartment.

Drain valve

This valve is a diaphragm valve that opens and

closes by way of the water pressure. The control

valve is situated next to the water valves.

The drain valve of the machine is described in

detail in section 38. Drain valve.

Drain valve

Detergent compartment

5185

Page 37

11. Regular maintenance

Contents

Daily .......................................................................................................... 3

Every third month ...................................................................................... 3

Page 38

Intentionally blank

Page 39

11. Regular maintenance

11

3

Service

Manual

To keep your machine in proper working order, follow the preventive maintenance

recommendations provided below.

The maintenance interval should be adjusted according to machine usage. The

suggested schedule assumes an 8 hour work day, and a 5 day work week..

Daily

• Check the door and door lock:

- Open the door and try starting the machine. The machine MUST NOT START.

- Close the door, start the machine and try opening the door. It MUST NOT BE

POSSIBLE TO OPEN THE DOOR WHILE THE MACHINE IS OPERATING!

- Check that the door does not leak.

- Clean the door seal, removing any detergent and fluff.

• Check that the drain valve does not leak during the wash cycle.

• Clean out any detergent remaining in the detergent compartment. Rapid advance

through a program and let the water rinse the compartment.

• Inspect liquid chemical tubing and connections for leaks. Repair as necessary.

Every third month (refer this service to qualified personnel)

May only be carried out by authorized personnel.

• Check that the door does not leak.

• Check the drain valve and remove any lint.

• Inspect the interior of the machine (during an actual wash cycle to ensure that no

leaks are noticed) by:

- Turning of the main power switch of the machine.

- Remove the top cover and the protective front and rear plates.

- Cover the detergent dispenser to prevent water from splashing inside the

machine.

- Start a wash program.

- KEEP CLEAR OF MOVING PARTS WHILE MACHINE IS OPERATING!!

Page 40

11. Regular maintenance

11

4

Service

Manual

- Inspect all internal hoses, seals and gaskets for signs of leakage.

Repair as necessary.

- Check that water inlet screens are clean of debris. Dirty screens

result in longer fill times, which reduce productivity.

- Inspect the drive belt. Adjust the tension or replace if necessary (see

section 30. Motor).

- Check that there are no signs of leakage on the floor beneath the

machine. Locate and repair any leak.

- On heated machines, if the heating time is unusually long, check the

heating elements (see section 40. Heating). If the water is very hard,

check whether there are lime deposits on the heating elements.

Decalcify the elements if necessary. Adapt the amount of deliming

agent to the manufacturer’s guidelines.

- Never switch on the heating elements when there is no water in the

machine. This will cause the slow-blow fuse to trigger.

- Inspect the shock absorbers and coil springs. (Only EX- and

H-model).

Page 41

21. Control unit

Contents

Description............................................................................................... 3

Function ................................................................................................... 4

Front control unit ................................................................................. 4

Program OL02..................................................................................... 7

Program OL03..................................................................................... 9

Rear control unit................................................................................ 11

Page 42

Intentionally blank

Page 43

3

21

21. Control unit

Service

Manual

1

Fig.

1

Description

The control unit of the machine consists of the following parts:

• Front control unit

This unit contains an electro-mechanical programme unit A1, a safety

control card for the door lock (door lock control A31), thermostat B1,

level switch B2 and 4 and rotary switch S5.

• Rear control unit

This module contains the main power switch Q1 with a connection for

received voltage, the heat contactor K21 and the communication card

A21 with outputs for e.g. external detergent supply.

5925, 5182, 5916

T1

T2

T3L1N

N

L2

L3

Front control unit

Rear control unit

Q1

Main power switch

K21 Heater contactor

A21

Communication card

K22 Heater contactor

(only larger machines)

X30

X38

X39

X37X28 X31

X27

X33 X34

X21

X20

X24

X26

X11 X12 X13 X14

X92

X97

X91X90

X93

X95

X96

X94

X99

X98

X161 X160 X36

X111

X112 X113 X114

A31

Door lock

controller

S5

Rotary switch

program selector

B1

Thermostat

A1

Programme unit

B2

Level switch

B4

Level switch

wash program

Page 44

21

21. Control unit

4

Service

Manual

2

5925

Front control unit

X30

X38

X39

X37X28 X31

X27

X33 X34

X21

X20

X24

X26

X11 X12 X13 X14

X92

X97

X91X90

X93

X95

X96

X94

X99

X98

X161 X160 X36

X111

X112 X113 X114

A31

Door lock

controller

S5

Rotary switch program selector

B1

Thermostat

A1

Programme

unit

B2

Level

switch

B4

Level switch wash program

Function

Front control unit

Programme unit A1

The programme unit is electromechanical and

has up to 10 fixed programmes (depending on

program).

The programme unit is described in detail in

section 23. Programme unit.

Level guard B2

Control of the water level and turning of the drum

are controlled with a backup guard, to ensure

that the door will not open with water in the drum

or when the drum rotates.

Apart from a level guard on the programme unit

card, there is a level guard B2, connected to the

door lock control A31. This card controls door

locking action as well as the level and drum rpm

speed.

Level guard B4

Controls the water level for low and high level in

wash programs.

Thermostat B1

Controls the wash temperature and closes the

heating relay or steam valve when selected

temperature is reached.

Rotary switch S5

Rotary switch for selecting wash program.

Fig.

2

Fig.

2

Fig.

2

Fig.

2

Page 45

5

21

21. Control unit

Service

Manual

3

5471

Program selector card

Jumpers on program selector card

Jumpers are assembled on the program selector

card. These jumpers can be moved or removed

to obtain new functions for the wash programs.

Program OG01

Jumper on A gives a correct function of valve

Y25 (W3180-3330N, W640-675). Y25 will flush in

both pre wash and in main wash.

Jumper B gives a correct function of valve Y25

(W375-3130N, W620-630). Y25 will flush only in

pre wash and not main wash.

Jumper on C is bleaching function. It is

recommended when compartment 4 is used for

bleaching agent or if bleaching agent is supplied

from a pump unit. There will be a flushing in

compartment 4 during 30 seconds, 3.5 minutes

after selected temperature is reached. Note! The

pump signal, on connection X72:5 will appear 30

seconds before the flushing of compartment 4.

Jumper on D is main wash function. It is

recommended when compartment 4 is used for

main wash detergent or if main wash detergent is

supplied from pump.

Jumper on F gives a correct function of valve

Y12 (W3180-3330N, W640-675). There are no

Y22 valve on these machines.

Jumper on G. (W3180-3330N, W640-675 with

only cold water inlet). The signal for Y25 (hot

inlet) will give cold inlet (Y15) instead.

Jumper on H for the machines (W3180-3330N,

W640-675) without inlet valve Y35 will give cold

inlet (Y15) instead and for the machines (W3753130N, W620-630) without inlet valve Y35 will

give cold inlet (Y11) in compartment 1 instead.

Jumper I (no heat). On machines without heating

or machines with support heating. The wash

program will not stop and wait for the selected

temperature.

Fig.

3

Fig.

4

Page 46

21

21. Control unit

6

Service

Manual

4

6053, 5477

OFF

A

B

C

D

60

40

40

40

40

90

60

60

90

30

Program OG01

I

H

F

D

C

B

A

TERMOSTAT

X23

X36

X35

X191

WATER

NO HEAT

NO Y22

NO Y35

BLEACH

SMALL

DET 2

BIG

12

3

4

56

BOX4

Y25

Y35 Y25

Y22

Y14 Y15

Y13

Y12 Y11

1

23456

1

2

1

2

K21

Y51

12345

6

7

12345123

4

12345

6

1

2

X391

X111

X112

X114

X113

NO Y25

G

3

12X291

7

5

67

6

7

P1

Page 47

7

21

21. Control unit

Service

Manual

Program OL02

Jumper on A gives correct function of Y25 (W3180-3330N, W640-675).

Y25 will flush in pre-wash and in main wash.

Jumper B gives correct function of Y25 (W375-3130N, W620-630). Y25 will

flush in pre wash and not main wash.

Jumper on C is bleaching function. It is recommended when compartment

4 is used for bleaching agent or if bleaching agent is supplied from a pump

unit. There will be a flushing in compartment 4 during 30 seconds, 3.5

minutes after selected temperature is reached. Note! The pump signal, on

connection X72:5 will appear 30 seconds before the flushing of

compartment 4.

Jumper on D is main wash function. It is recommended when compartment

4 is used for main wash detergent of if main wash detergent is supplied

from pump.

Jumper on E gives a correct function of valve Y15 (cold water). The valve

Y15 will open in main wash (W3180-3330N, W640-675).

Jumper on F gives a correct function of valve Y12 (W3180-3330N, W640-

675). There are no Y22 valve on these machines.

Jumper on G. (W3180-3330N, W640-675 with only cold water inlet). The

signal for Y25 (hot inlet) will give cold inlet (Y15) instead.

Jumper on H for the machines (W3180-3330N, W640-675) without inlet

valve Y35 will give cold inlet (Y15) instead and for the machines (W3753130N, W620-630) without inlet valve Y35 will give cold inlet (Y11) in

compartment 1 instead.

Jumper I (no heat). On machines without heating or machines with support

heating. The wash program will not stop and wait for the selected

temperature.

Jumper J (short program). If the jumper isn’t connected the agitation time in

the wash program will be twice as long. Pre wash will be changed from 3 to

6 minutes, main wash from 6 to 12 minutes and rinsing time from 1 to 2

minutes.

Fig.

5

Page 48

21

21. Control unit

8

Service

Manual

5

6054, 5478

4

3

1

5

OFF

2

Program OL02

F

B

A

TERMOSTAT

X23

X36

POWER OUT

NO Y25

BLEACH

SMALL

DET 2

BIG

1234

5

6

Y25

Y35

Y25

Y22

Y14

Y15

Y13

Y12

Y11

12345

612

K21

1234567

12345

1

23

4

12345

6

1

2

X111 X112

X113

X114

X291

12

G

E

Y15

DC

BOX4

H

IJ

NO

Y35NOY22

NO

HEAT

NO

TIME

EXT.

BIG

X191

P2

7

6

7

567

1

2

X391

POWER IN

X35

3

Page 49

9

21

21. Control unit

Service

Manual

Program OL03

Jumper on A gives correct function of Y25 (W3180-3330N, W640-675).

Y25 will flush in pre-wash and in main wash.

Jumper B gives correct function of Y25 (W375-3130N, W620-630). Y25 will

flush only in pre wash and not main wash.

Jumper on C is bleaching function. It is recommended when compartment

4 is used for bleaching agent or if bleaching agent is supplied from a pump

unit. There will be a flushing in compartment 4 during 30 seconds, 3.5

minutes after selected temperature is reached. Note! The pump signal, on

connection X72:5 will appear 30 seconds before the flushing of

compartment 4.

Jumper on D is main wash function. It is recommended when compartment

4 is used for main wash detergent of if main wash detergent is supplied

from pump.

Jumper on E gives correct function of valve Y15 (cold water). The valve

Y15 will open in main wash (W3180-3330N, W640-675).

Jumper on F gives a correct function of valve Y12 (W3180-3330N, W640-

675). There are no Y22 valve on these machines.

Fig.

6

Page 50

21

21. Control unit

10

Service

Manual

6

6055, 5475

w

a

s

h

l

a

v

a

d

o

r

i

n

s

e

a

c

l

a

r

a

d

o

Delicato

Prendas

delicadas

Perm.

press

Cold

Frio

Warm

Templado

Hot Caliente

extract

centrifugado

s

o

a

k

p

r

e

-

l

a

v

a

d

o

Program OL03

F

X161

X36

123456

1

2

345

6

7

8

12

3456

7

123451

2

34

12345

6

X111 X112

X113

X114

D

C

P03

EB

A

1234

X160

OPTIONS

OPTIONS

DISTRIB. CARD

DET 2 BOX4

BLEACH BOX4

Y25 SMALL

Y15 BIG

Y25 BIG

7

6

7

5

6

7

NO Y22

Page 51

11

21

21. Control unit

Service

Manual

7

T1

T2

T3L1N

N

L2

L3

Main power switch Q1

Heating contactor K21

Voltage supply

connector

Heating contactor K22

(only larger machines with

six heating elements)

5182

Front control unit

Main power switch Q1

The main power switch interrupts all received

power phases and is placed on the outside of the

connection box cover.

The cover cannot be removed unless the main

power switch is turned to the 0 position.

The received voltage supply is connected to the

lower screw post of the main power switch, alt.

the terminal connection.

Heating contactor K21

This contactor is only featured on machines with

electric heating.

It activates the three heating elements at the

front, lower part of the outer drum. It is controlled

by the programme unit A1 and thermostat B1.

Heating contactor K22

This contactor is only featured on larger

machines.

It activates the three heating elements, with a

total of four circuits, situated at the front, lower

part of the outer drum. It is controlled by the

programme unit A1 and thermostat B1.

Fig.

7

Fig.

7

Fig.

7

Page 52

21

21. Control unit

12

Service

Manual

8

T1

T2

T3L1N

N

L2

L3

Communication card

5182

Communication card

This communication card contains:

• Fuses F11 and F12 (1.25 A)

These protect the received voltage supply for

the programme unit and door lock controller.

•Output connection blocks

Control signals for connection to external

system such as detergent supply.

Card No. Function

Outputs (110V AC)

X70 see Payment system

X71:1 0 V Door locked (common)

X71:2 L1 Door locked

X72:1 Common

X72:2 Liquid supply 1 (Pre wash)

X72:3 Liquid supply 2 (Main wash)

X72:4 Liquid supply 3 (Softener)

X72:5 Liquid supply 4 (Bleach)

Fig.

8

Fig.

9

9

6052

Card A

X53

X52

X51

X50

X41

X42

X43

X44

X45

X46

X72

X50 X51 Y35 Y25 Y24 Y15 Y13 Y12 Y11 Y14

X71 X70

X81

X47 X48 X49

X81

Page 53

13

21

21. Control unit

Service

Manual

Fig.

10

Option card

The option card is only available on machines

with programme OL03

10

T1

T2

T3L1N

N

L2

L3

Option card

5182, 5475

w

a

s

h

l

a

v

a

d

o

r

i

n

s

e

a

c

l

a

r

a

d

o

Delicato

Prendas

delicadas

Perm.

press

Cold

Frio

Warm

Templado

Hot Caliente

extract

centrifugado

s

o

a

k

p

r

e

-

l

a

v

a

d

o

Page 54

21

21. Control unit

14

Service

Manual

5600

11

12

5601, 5602

There are some possibilities to alter the standard

parameters in the wash programs by moving or

adding jumpers on the option card.

•When adding a jumper on N or M gives warm

rinses instead of cold. M shall be used on

W375-W3130N, W620-630 and N on

W3180N-W3330N and W640-675.

3 spare jumpers

Fig.

11

Fig.

12

Page 55

15

21

21. Control unit

Service

Manual

13

5603

14

5604

15

5605

•When adding a jumper on O there will be no

prewash in the programs.

The timer rapid advances the prewash

automatically. Remember that "Delicate" is

always without prewash.

•When adding a jumper on P there will be two

rinses instead of three. The timer rapid

advances the first rinse.

• If the jumper on Q is removed the main wash

will be extended by three minutes to nine

minutes instead of six.

Fig.

13

Fig.

14

Fig.

15

Page 56

21

21. Control unit

16

Service

Manual

16

5606

• In standard position on R, low level is used in

prewash, main wash and high level in rinses. If

jumper is moved to S it will be high level also in

prewash and mainwash.

Fig.

16

Page 57

26. Level control

Contents

Control and fault tracing........................................................................... 3

Water level check................................................................................ 4

Water level is too high......................................................................... 4

Page 58

Intentionally blank

Page 59

3

26

26. Level control

Service

Manual

1

1198

The level switch is a pressure sensor controlling

two different drum water levels by sensing air

pressure in a hose connected to the drum’s

bottom. When the water rises in the drum and

hose, the air in the hose compresses and, at two

preset pressure levels (shut-off levels), two

different alternating contacts in the pressure

sensor are activated.

When the water drains from the drum, the

contacts switch back to original position, but now

at lower water levels than was required to

activate the contacts when the drum was

being filled. These levels are called minimum

levels. If the water level during washing falls

below the minimum level, water will be added

until the shut-off level is again reached.

Control and fault tracing

All level sensors are factory-set for the various

machines. As a rule, this setting should not be

changed. For that reason, the level controls are

sealed with enamel paint.

A faulty level switch can not be repaired and

should be replaced.

The machine guarantee ceases to be valid

if the level sensor is tampered with.

Fig.

1

Fig.

2

Page 60

26

26. Level control

4

Service

Manual

1417

2

21

24

22

11

12

14

Low levelHigh level

Water level check

Start the machine and select a standard

program. Check low water level for prewash and

main wash according to the illustration. Advance

the program using the START button and

check high water level for rinsing.

Water level is too high

•Check that the hose connecting the level

switch and the drain valve is not obstructed.

When necessary and when the machine is

empty of water, clean the hose by

disconnecting it from the level switch and

blowing air through it.

•Check the hose for holes which can be

caused by the hose rubbing against the

pulley.

•Overfilling can also be caused by burnt

contacts in the level switch. If this is the case,

replace the level switch.

Fig.

2

Page 61

27. Thermostat

Contents

Data ......................................................................................................... 3

Description............................................................................................... 3

Repair instructions ................................................................................... 4

Replacing the thermostat .................................................................... 4

Page 62

Intentionally blank

Page 63

3

27

27. Thermostat

Service

Manual

1453

1

6

X123

5977

1

Data

Range off-on approx. 4°C

Max. temperature for sensor 150°C

Sensor medium Liquid

Description

The thermostat monitors the temperature while

the machine carries out a program. The heating

element contactor is controlled using open and

closed contacts.

The thermostat sensor is located at the lowest

point of the outer drum to the left of the heating

element. A liquid-filled cable (capillary tube) runs

from the sensor to the thermostat, located in the

automatic control unit. The water temperature

controls the liquid expansion and thereby the

activation of the various thermostat contacts.

Temperature selection (contact selection) (90°C,

60°C, 40°C or 30°C) is controlled by the

programmer and the program selector.

Fig.

1

B1

21

X123

3425

31 4111

30° 40° 60° 90°

14 24 34

12 22 32 42 44

16

X123

Page 64

27

27. Thermostat

4

Service

Manual

Repair instructions

All thermostats are factory-set for the various

machines. As a rule, this setting should not be

changed. For that reason, the thermostats are

sealed with enamel paint.

The machine guarantee ceases to be valid

if the thermostat is tampered with.

Replacing the thermostat

•Remove the front panel and pull out the

thermostat sensor.

•Undo the capillary tube strapping and replace

the thermostat. Install the new capillary tube

in the same way as the old one.

Page 65

29. Door and door lock

Contents

Description................................................................................................3

General ................................................................................................3

Function ....................................................................................................4

The door lock locks the door ................................................................4

The door lock unlocks the door ............................................................5

Error codes...........................................................................................6

Reset button.........................................................................................7

Door lock control inputs/outputs...........................................................7

Repairs....................................................................................................10

Emergency opening of door lock........................................................10

Replacing the door lock......................................................................11

Page 66

Intentionally blank

Page 67

3

29

29. Door and door lock

Service

Manual

Fig.

1

Fig.

2

Description

General

The door locks consists of the following:

• Door lock A111, which contains

- An actuator that locks the door lock and

also has two built-in micro switches, S4a

and S4b. The actuator is bi-stable, i.e., it

has two stable positions: locked door and

unlocked door. The actuator must receive a

pulse to lock and unlock the door lock. S4a

and S4b are both closed when the door is

locked.

-A micro switch S3 that is closed when the

door is closed.

- An emergency opening arm/emergency

opening button that can be used to open

the door lock in an emergency.

• Door lock controller A31 situated in the front

control unit of the machine. This card controls

the door lock function and supervises whether

the drum is empty and not turning. It locks and

unlocks the door lock when the programme

unit requests door locking or unlocking.

Actuator (with

micro switch S4a

and S4b)

Micro switch S3

X96 (to door lock control A31)

5368, 6112

Emergency opening arm

1

X30 (to programme

unit A1)

Emergency opening button

X96 (to door lock

control A31)

X30 (to programme

unit A1)

2

Door lock controller A31

5184, 5916

Page 68

29

29. Door and door lock

4

Service

Manual

Fig.

3

3

Function

The door lock locks the door

When the door is closed (closed door lock switch

S3), the programme unit may request door

locking by applying a voltage of 110-240 V on the

door lock controller A31 input X92.

The following check is made by the A31 card

prior to locking of the door:

• No water in drum - input X93 from level

guard B2 is closed = 0 V

• Motor not engaged - input X94 from motor

control A107 open = 5 V

• Drum not turning - no pulses on input X95

from rotation sensor B3.

When the above conditions are met, the card

A31 outputs a closing pulse on output X96 to the

door lock actuator/coil, which then locks the door.

The micro switches S4a and S4b in the actuator/

door lock are closed when the door is locked.

These micro switches feed voltage to:

• The output switches on the programme unit.

The switches control the machine’s drain and

water valves as well as heater switch-on.

• Interlock signal enables motor operation.

Programme operation is now possible.

Door lock

control

A31

Level

guard

B2

M1

Door lock

A41

Programme

unit A1

X92

X31

X96X95X93

X30

X94

Motor

module

A107

Rotation sensor B3

X304

X302

X27

5191 B

X24

Page 69

5

29

29. Door and door lock

Service

Manual

Fig.

4

4

The door lock unlocks the door

The programme unit requests door unlocking by

applying 0 V on input X92 of the door lock

controller.

The following check is made prior to unlocking of

the door:

• No water in drum - input X93 from level

guard B2 is closed = 0 V

• Motor not engaged - input X94 from motor

controller A107 open = 5 V

• Drum not turning - no pulses on input X95

from rotation sensor B3.

When the above conditions are met, the door

lock controller outputs an opening pulse on

output 96 to the door lock actuator/coil, which

then unlocks the door. Micro switches S4a and

S4b now interrupt the relays/switches. The drain,

water valves, heater and motor cannot now be

switched on.

Door lock

control

A31

Level

guard

B2

M1

Door lock

A41

Programme

unit A1

X92

X31

X96X95X93

X30

X94

Motor

module

A107

Rotation sensor B3

X304

X302

X27

X24

Page 70

29

29. Door and door lock

6

Service

Manual

Fig.

5

5

Error codes

The door lock control has three LEDs that show

whether the door lock operates normally or

whether an error has been detected. During

normal operation, the LEDs blink when the drum

is not turning and are off when the drum rotates.

In case of an error, the three LEDs will show the

error condition according to the table below. If an

error disappears, the error code condition

disappears. If the error is still present at the

programme end, the error is automatically

cleared after 5 minutes and the door is unlocked.

LEDs Normal operation

ABC

●●● No error. The drum is not turning

(LEDs blinking)

❍❍❍ No error. The drum is rotating

LEDs Error state

ABC

●●❍ Level guard B2 indicates water in drum

when the door lock is open (input X93

not closed).

❍●● Motor control indicates that motor is

operating when door lock is open

(input X94 not open).

●❍❍ No signal from rotation sensor B3

(frequency input X95 < 0.4 Hz) in spite

of the motor control indicating motor

operation (input X94 open).

❍●❍ No signal from motor control (input

X94 not open) in spite of rotation

sensor B3 indicating motor operation

(frequency input X95 > 0.4 Hz).

●❍● Error in drive circuits for door lock

(output X96) or error in door lock/cable

harness for the door lock.

❍❍● Internal error in the door lock control.

❍ = no lit, ● = lit

LEDs

A B C

Reset button

5184

Page 71

7

29

29. Door and door lock

Service

Manual

Fig.

6

Fig.

5

6

Reset button

The door lock control features a reset button

used to reset the programme routines stored in

the computer. When pressed, any error codes

are erased.

Door lock control inputs/outputs

X90: AC 110-240 V AC feed

X91: Transfer of voltage supply

Feeds the voltage to programme unit A1.

X92: Input from programme unit:

Lock door

Prior to the door lock control locking the door

(output X96), a check is made for any water left

in the drum (input X93 closed) and whether the

drum is not rotating (input X94 open).

Input voltage X96 Function

110-240 V AC: Programme unit requests door locking

0 V: Programme unit requests door

opening

5193

Door lock control A31

X90

X91

1

2

1

2

200240 V

Voltage

supply to A1

Level guard

B2

1

2

12

1

2

X93

X94

X92

12

X31

Programme unit

A111

13

X304

Motor relays

B3

X95

Page 72

29

29. Door and door lock

8

Service

Manual

Fig.

7

5193

7

X93: Input from level guard

If the input indicates “Water in drum” when the

door is not locked, the door cannot be locked.

The LEDs then show the error code ● ● ❍.

Input voltage Function X93

5 V DC: Water in drum (level guard open)

0 V: Drum empty (level guard closed)

X94: Input from motor control

If the input indicates “Motor operating”, the door

cannot be locked. The LEDs then show the error

code ❍ ● ●.

The input signal from X94 is compared with the

signal from the rotation sensor B3 (input X95).

If the motor signal is operating, but the rotation

sensor does not provide a signal, the error code

● ❍ ❍ is shown.

If the rotation sensor indicates motor rotation

when there is no motor signal, the error code

❍ ● ❍ is shown.

Input voltage Function X94

5 V DC: Motor not operating (input closed)

0 V: Motor operating (input open)

Door lock control A31

X90

X91

1

2

1

2

200240 V

Voltage

supply to A1

Level guard

B2

1

2

12

1

2

X93

X94

X92

12

X31

Programme unit

A111

13

X304

Motor relays

B3

X95

Page 73

9

29

29. Door and door lock

Service

Manual

Door lock control A31

X95

1

2

3

Rotation sensor

B3

X96

1

2

Door lock A41

Y80

Unlocks + Locks - +

X96

X95

5184

5194

Fig.

9

Fig.

8

8

9

X95: Input from rotation sensor on motor

shaft

When the motor is operating, a pulse train is

applied on the input.

Input Function

Pin 1: DC 4-10 V feed

Pin 2: 0V

Pin 3: DC 5 V pulse input

X96: Output to door lock

Locks the door lock when the following conditions

are met:

• DC 110-240 V AC on input X92 (programme

unit requests door locking).

• DC 0 V on input X93 (no water in drum).

• DC +5 V on input X94 (motor not operating).

•No pulses on input X95 (drum not rotating).

•No error code present.

Unlocks the door lock when the following

conditions are met:

• DC 0 V on input X92 (programme unit

requests door unlocking).

• DC 0 V on input X93 (no water in drum).

• DC +5 V on input X94 (motor not activated).

•No pulses on input X95 (drum not rotating).

•No error code present.

Voltage Function

17 - 31 V DC, + on pin 1, - on pin 2 Unlocks the door

17 - 31 V DC - on pin 1, + on pin 2 Locks the door

Page 74

29

29. Door and door lock

10

Service

Manual

Repairs

Repair work on the machine should only be

done by specially trained personnel.

Emergency opening of door lock

1. Take down power from the machine by turning

the main power switch to the 0 position.

2. Remove the front cover or top cover. When

replacing the door lock, it is recommended to

remove the front cover.

3. Pull the emergency opening arm to the side.

This retracts the spring-loaded locking pin and

the door lock opens.

Alt. Press down the emergency opening

button.

4. Reset the emergency opening correctly.

Fig.

10

5369, 6111

10

Page 75

11

29

29. Door and door lock

Service

Manual

Replacing the door lock

1. Take down power from the machine by turning the main power switch to

the 0 position.

2. Remove the front cover alt. side pole.

3. Remove the door (two screws in each hinge).

4. Remove the front panel.

5. Remove the door lock (three holding screws).

6. Verify the strap positions on the cable for the lock. Cut the necessary

straps to undo the cables leading to the lock.

7. Undo the connectors.

8. Replace the door lock.

9. Reconnect the new (door) lock.

10. Assemble in reverse order.

11. Strap the cables for the lock according to the notes made in step 6.

Page 76

Intentionally blank

Page 77

30. Motor

Contents

Warnings................................................................................................... 3

Description................................................................................................4

Motor ....................................................................................................4

Principle wiring .....................................................................................5

Motor overload protector ......................................................................6

Repairs .....................................................................................................7

Motor replacement ...............................................................................7

Adjustments ..............................................................................................8

Drive belt tension .................................................................................8

Page 78

Intentionally blank

Page 79

3

30

30. Motor

Service

Manual

Warnings

DANGER

Be careful when measuring capacitors and filter.

Page 80

30

30. Motor

4

Service

Manual

Fig.

1

1

Description

Motor

The motor is fitted in a bridge carrier under the

outer drum. It drives the washing drum using a

drive belt.

The motor is controlled by contactors.

The motor winding is protected against

overloads using a thermal overheating protector

that is automatically reset.

The motor is connected directly to the motor

module via a cable with quick connectors.

5467, 5465

Motor

Rotation sensor

B3

2

5975

Programme unit

A1

Rotation

control card

A31

X24

X94 X97

X95

B3

Motor

Contactors

A107

1 or 3-phase

Thermal

protection

X27 X26

Page 81

5

30

30. Motor

Service

Manual

3

5973

5974

Single phase

Three phase

1

K1

2

4

13

4

3

2

K2

K4

4

13

2

Black

Blue

White

21

22

C1-2

K4

White

Black

Blue

2122C3-6

C3-6

Aux

Main

Wash speed (18-pole) Extract speed (2-pole)

A Only machines with start switch

Note! Some machines may hav overcurrent protection.

This is not shown here.

A

Principle wiring

4

3

6

5

2

1

4

3

6

5

2

1

K1 K2

Black

Blue

White

Black

Blue

White

4

3

6

5

2

1

K4

Note! Some motors are possible to change from Y to D-connection to accomodate different voltages.

Page 82

30

30. Motor

6

Service

Manual

Motor overload protector

The motor is equipped with one or more thermal

overload protectors. The protectors are

connected in series and will trip at a

temperature of 150 ± 5°C.

A burned out motor can be re-wound.

Some single-phase machines are also equipped

with a manual resettable overload protector

mounted on the extract relay in the motor

module. This overload protector protects the

motor during the start-up of the extraction.

4

0304

Fig.

4

Page 83

7

30

30. Motor

Service

Manual

5

Fig.

5

6

Fig.

6

Repairs

Repair work on the machine should only be

done by specially trained personnel.

Motor replacement

Disassembly

1. Take down power from the machine by turning

the main power switch to the 0 position.

2. Remove the rear cover.

3. Undo the bracket for the drain hose connector

from the lower rear piece, then remove the

rear cover.

4. Undo the ground connection from the motor.

5. Remove the drive belt by pulling the belt

towards you while rotating the drum by hand.

6. Undo the motor cable from motor.

7. Undo and remove the motor mounting bolts.

8. Lift out the motor.

Assembly

1. Fit the new motor without locking the

mounting bolts.

2. Fit the drive belt and adjust the belt tension

with the tensioner on one side of the motor.

Se section Adjustments - Drive belt tension for

details.

Main power switch

5916

5465

Rotation sensor

B3

Page 84

30

30. Motor

8

Service

Manual

4741

5466

B, C

A

Adjust drive belt tension if values exceed

those shown in the table.

Retaining screw for drive belt tension

Locking nut

Fig.

7

Fig.

8

7

8

3. Connect the new motor to the cable and use

straps to secure the cable.

4. Connect the motor cable to the motor.

5. Fit the lower rear piece and secure the drain

hose connection with screws.

6. Fit the upper rear piece.

7. Connect the voltage supply and verify that the

motor operates normally.

Adjustments

Drive belt tension

The drive belt is pre-tensioned upon delivery

from the factory.

The drive belt tension should be as follows:

Model Force A Post tensioning B New belt C

(N) (mm) (mm)

W375N 35 8 6

W385N 35 9 8

W3105N 40 8 7

W3130N 40 8 7

W3180N 60 9 7

W3250N 68 8 7

W3330N 45 8 6

To adjust drive belt tension, first undo the motor

retaining screw a couple of turns, then press

down on the motor to achieve proper tensioning.

Lock the locking nut when the tension is correct.

Then lock the retaining screw.

Inspection of the drive belt tension is an

important part of general maintenance.

Adjusting screw

Page 85

38. Drain valve

Contents

Description................................................................................................3

Function ....................................................................................................3

Repairs......................................................................................................4

Disassembly.........................................................................................4

Assembling...........................................................................................5

Page 86

Intentionally blank

Page 87

3

38

38. Drain valve

Service

Manual

Description

The drain valve is situated on a flange at the

bottom of the outer drum and can be accessed

from the front after removing the front cover.

The drain valve consists of the following principal

parts:

• Lower part with rubber diaphragm.

•Piston and cylinder.

•Pressure plate and recoil springs.

•Rubber diaphragm with drain connection.

•Upper part with connection for outer drum.

Function

The drain valve uses the water pressure in the

cold-water inlet to close the valve. A feed hose is

connected between the water inlet and the

control valve.

When the control valve operates (drain valve

should be closed), the control valve opens the

water pressure onto the feed hose, which is

connected to the lower part of the drain valve.

When the lower part is filled with water, the lower

part diaphragm pushes up the piston. The piston

lifts the pressure plate against the drain valve

rubber diaphragm, which in turn forms a seal

against the outer drum, effectively closing the

valve.

When the drain valve should be opened, the

control valve changes position to allow the water

pressure to the lower part of the drain valve to

close, instead opening the return hose to the

drain. The pressure plate recoil springs pull the

pressure plate back, upon which the piston is

pressed back into the cylinder. The water from

the lower part is fed through the feed hose and

the control valve to the drain.

3359

Cylinder

Feed hose

Control valve

Feed hose

Lower part

Diaphragm

Piston

Pressure plate

Rubber

diaphragm

with drain

connection

Return hose

Recoil springs

Drain valve

5916

Principal

diagram

Fig.

1

Fig.

2

1

2

Page 88

38

38. Drain valve

4

Service

Manual

Repairs

Repair work on the machine should only be

done by specially trained personnel.

Disassembly

For repair works on the drain valve, there is

a risk that water still left in the machine may

flood onto the floor. Be sure to dry up any

spilled water since it may cause people to

slip and hurt themselves.

1. Take down power from the machine by turning

the main power switch to the 0 position.

2. Remove the front cover.

3. Disconnect the drain hose from upper part of

the valve.

4. Undo the hose clamp holding the valve rubber

bellows against the sleeve coupling of the

outer drum.

5. Loosen and unscrew the 4 retaining nuts of

the valve a couple of turns (use a socket,

extender and ratchet wrench). Turn the valve

and unhook it from the bolts.

6. Disconnect the pressure hose from the lower

part of the valve.

7. Replace the valve with a new one or replace

the defective part.

Lower part

5916

Main power switch

5222

Fig.

3

Fig.

4

Fig.

5

3

4

Upper part

Piston

Rubber

diaphragm

with drain

connection

Pressure plate

101772

Cylinder

Diaphragm

Recoil spring

Nipple for

connection of

feed hose from

control valve

5

Page 89

5

38

38. Drain valve

Service

Manual

Assembling

1. Connect the pressure hose to the lower part of the valve. Verify that the

hose is not bent or pinched.

2. Fit the rubber bellows onto the sleeve coupling.

3. Hook the valve onto the bolts and turn the valve into position. Secure the

4 retaining bolts of the valve.

4. Secure the hose clamp at the connection of the rubber bellows on the

sleeve coupling.

5. Connect the drain hose to the upper part of the valve.

6. Turn the main power switch to position 1 and verify correct valve

operation and that it does not leak.

7. Reattach the front cover.

Fig.

4

Fig.

5

Fig.

3

Page 90

Intentionally blank

Page 91

39. Detergent compartment

Contents

Description................................................................................................3

Page 92

Intentionally blank

Page 93

3

39

39. Detergent compartment

Service

Manual

Description

The detergent compartment of the machine is

designed for use with powder and liquid

detergent. The compartment is divided into four

sub-compartments as follows:

•Compartment 1 - For pre wash with powder or

liquid detergent.

•Compartment 2 - For main wash with

detergent powder.

•Compartment 3 - Rinse.

•Compartment 4 - Main wash with liquid

detergent or, bleaching-agent.

The connections for incoming water are situated

on the rear side of the compartment.

Compartments 3 and 4 each have one

connector, while compartments 1 and 2 each

have two connectors, one for cold water, the

other for warm water.

The detergent is routed from the bottom of the

compartment to the outer drum through the

combo module immediately behind the

compartment.

To safeguard against overfilling, e.g., due to a

blocked hose on its way to the drum, the combo

module features an overflow drain directly

connected to the drain of the machine.

Detergent compartment

5916

Compartment 2: Main wash, powder detergent

Compartment 1: Pre-wash