Page 1

Operating and installation manual

TD30 RMC - TD50 RMC - TD75 RMC

Aqua Clean

Gas heating

487 18 94 81/04

Wascomat 1999.48

Page 2

Page 3

– Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department,

– Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Tumble dryer

Gas dryers only

3

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

WARNING: For your safety the information in

this manual must be followed to minimize

the risk of fire or explosion or to prevent

property damage, personal injury or death.

Page 4

Page 5

5

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

OPERATING & MAINTENANCE MANUAL

Tumble dryer Type 30 - Type 50 - Type 75

WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE

NEXT PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF YOUR WASCOMAT MACHINE.

PLEASE CHECK THAT THE FOLLOWING INFORMATION APPEARS ON THE MACHINE

DATA PLATE(S).IF THIS INFORMATION IS MISSING, CONTACT WASCOMAT CUSTOMER SERVICE AT 516-371-0700

KEEP THIS MANUAL IN A

SECURE PLACE FOR FUTURE REFERENCE.

Maskindata

Page 6

Page 7

A

7

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

NOTICE TO: OWNERS, OPERATORS AND DEALERS OF WASCOMAT MACHINES.

IMPROPER INSTALLATION AND INADEQUATE MAINTENANCE, POOR HOUSEKEEPING AND

WILLFUL NEGLECT OR BYPASSING OF SAFETY DEVICES MAY RESULT IN SERIOUS ACCIDENTS OR INJURY. TO ASSURE THE SAFETY OF CUSTOMERS AND/OR OPERATORS OF

YOUR MACHINE, THE FOLLOWING MAINTENANCE CHECKS MUST BE PERFORMED ON A

DAILY BASIS.

1. Prior to operation of the machine, check to make certain that all operating instructions and

warning signs are affixed to the machine and legible. (See the following page of this manual

for description and location of the signs.) Missing or illegible signs and labels must

be

replaced immediately. Be sure you have spare signs and labels available at all times.

These can be obtained from your dealer or Wascomat.

2. Check the door safely switch, as follows:

(a) OPEN THE DOOR of the machine and attempt to start in the normal manner:

THE MACHINE(S) SHOULD NOT START!

(b) CLOSE THE DOOR to start machine operation and, while it is operating,

open the door: THE MACHINE(S) SHOULD STOP.

If the machine can operate with the door open, it must be placed out of order until the

necessary repairs are made.

3. DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO BYPASS OR REWIRE ANY OF

THE MACHINE`S SAFETY DEVICES AS THIS CAN RESULT IN SERIOUS ACCIDENTS,

AND WILL VOID YOUR WARRANTY.

4. Be sure to keep the machine(s) in proper working order: Follow all maintenance and

safety procedures. Further information regarding machine safety, service and parts can be

obtained from your dealer or from Wascomat through its Customer Service Department 516/ 371-0700.

All requests for assistance must include the model, serial number and electrical characteristics as

they appear on the machine identification plate.

5. WARNING: DO NOT OPERATE MACHINE(S) WITH SAFETY DEVICES BYPASSED,

REWIRED OR INOPERATIVE!

6. A wiring diagram for your machine is located behind the front panel as shown (A).

Page 8

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

8

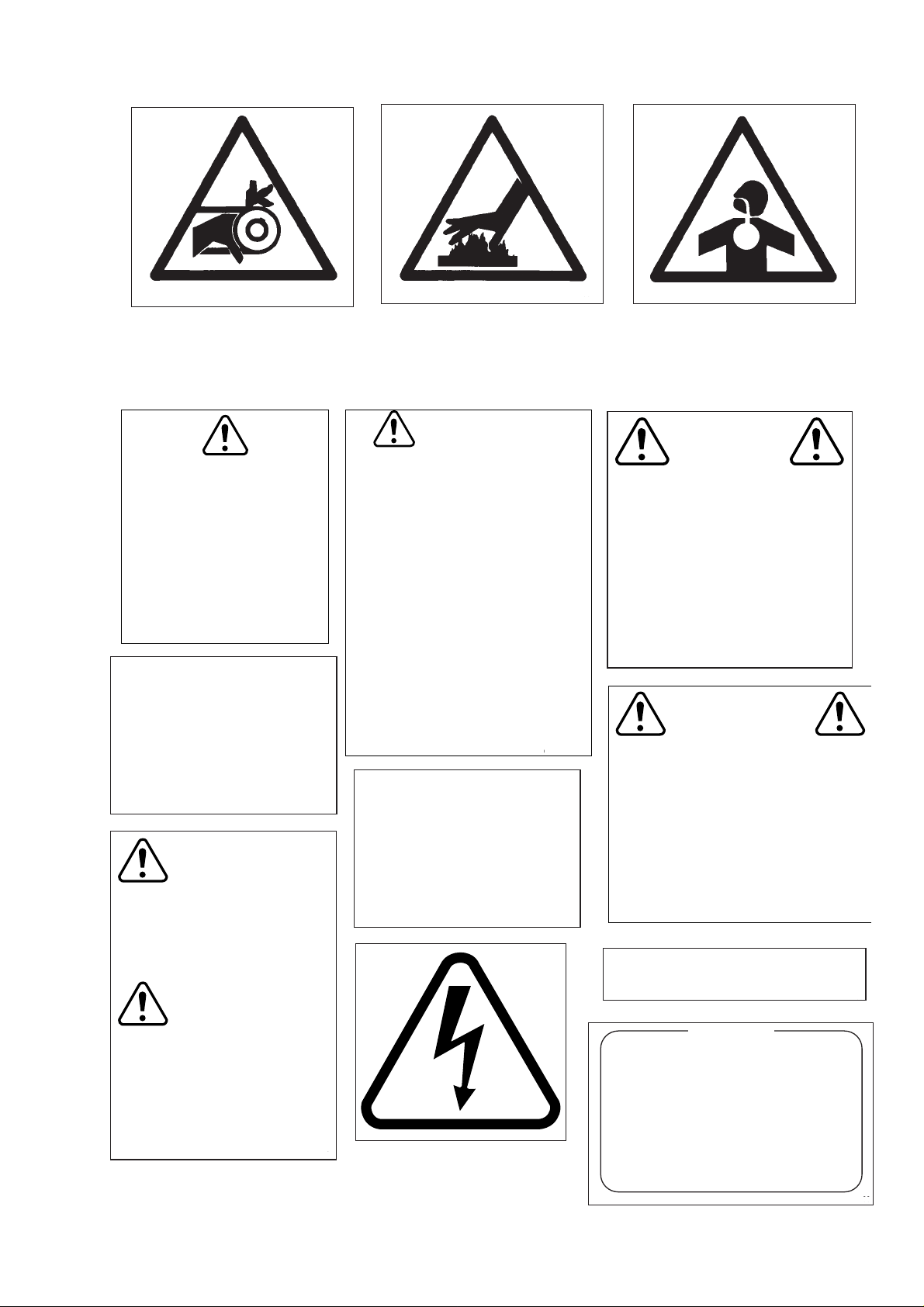

SAFETY AND WARNING SIGNS

Replace If Missing Or Illegible

One or more of these signs must be affixed on each machine.

LOCATED AT THE REAR OF THE MACHINE:

If you need to order more safety or warning

signs, call Wascomat´s parts department at

516-371-2000 or call your local dealer.

487 18 97 32.00

To order replacement parts, call Wascomat’s

parts department at 516.371.2000, or call

your local dealer.

INSTALLATION AND MAINTENANCE WARNINGS

1. This machine should be installed on an uncovered concrete floor, in accordance with the installation

instructions, to reduce the risk of fire and to prevent serious injury and damage to the machine.

2. If installed on a floor of combustible material the floor area below this machine must be covered by

a metal sheet extending to the outer edges of the machine.

3. This machine MUST be connected to a dedicated electrical circuit to which no other lighting unit or

general purpose receptacle is connected. Use copper conductors only.

4. This machine MUST be serviced and operated in compliance with manufacturer’s intructions.

CHECK DOOR EVERY DAY FOR PROPER OPERATION TO PREVENT INJURY OR DAMAGE. IF THE

DOOR INTERLOCK FAILS TO OPERATE PROPERLY, PLACE THE MACHINE OUT OF ORDER UNTIL

THE PROBLEM IS CORRECTED.

5. Disconnect power prior to any servicing of machine.

6. To open the service panel for service on those models on which it is secured by screws and

keylock at the front panel, use the key originally shipped in the drum package. Be certain to

relock after the servicing.

MANUFACTURED BY NYBORG LAUNDRY MACHINES, TOMMERUP, DENMARK.

DISTRIBUTED BY WASCOMAT, INWOOD, NEW YORK, USA

AND BY WASCOMAT OF CANADA, MISSISSAUGA, ONTARIO, CANADA.

SOLD AND SERVICED BY INDEPENDENT WASCOMAT DEALERS.

MACHINE SHOULD NOT BE USED BY CHILDREN

487 18 97 31.02

IMPORTANT

BEFORE CONNECTING POWER OR

HEATING SUPPLIES,

REFER TO MACHINE DATA LABEL

BEHIND FRONT CONTROL PANEL.

For use only in

non-combustible locations

487 18 97 66.00

Page 9

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Must be exhausted to

the outdoors

“Warning”

High temperatures which

could cause severe burns.

Dryer MUST NOT be operated with

guards, outer panels, our service

door/panels removed or not secured

in place.

SAFETY AND WARNINGS SIGNS

487 18 97 33.00

487 18 97 34.00

487 18 97 35.00

DO NOT store or use flammable liquids

near the dryer.

DO NOT put articles soiled with flammable

liquids in dryer.

DO NOT put articles soiled with vegetable

or cooking oils in dryer.

DO NOT put articles containing foam

rubber, plastic or similarly textured

rubberlike materials in dryer.

DO NOT store or use aerosols or cleaning

solvents in the vicinity of the dryer. Some

chemicals used in laundries contain

Chlorine (some dry-cleaning fluids, aerosols

and bleach). When exposed to a flame,

these chemicals may produce toxic fumes

that are harmful to humans and highly

corrosive.

DO NOT reach into dryer until all moving

parts have stopped.

DO NOT let children play in or near dryer.

487 18 97 38.00

WARNING

”Live voltage”

Disconnect electrical power

before servicing

9

LPG conversion kits.

DO NOT OPERATE THIS APPLIANCE

BEFORE READING THEINSTRUCTION

BOOKLET.

DO NOT PLACE ARTICLES ON OR

AGAINST THIS APPLIANCE.

DO NOT STORE CHEMICALS OR

FLAMMABLE MATERIALS, OR SPRAY

AEROSOLS NEAR THIS APPLIANCE.

DO NOT OPERATE WITH PANELS,

COVERS OR GUARDS REMOVED

FROM THIS APPLIANCE.

DO NOT LOAD MATERIALS

CONTAININGFLAMMABLE SOLVENTS

INTO THIS APPLIANCE.

IMPORTANT

DO NOT JUMP WIRES AROUND AIR

SWITCH.

DO NOT TAPE SWITCH DAMPER

SHUT.

DO NOT RESTRICT FLOW OF AIR

TO SWITCH.

WARNING

VALVE CONVERTED FOR USE ON LP

GAS. REGULATOR BLOCKED OPEN!

EXTERNAL REGULATOR REQUIRED!

IMPROPER OPERATION COULD

RESULT IN DEATH OR SERIOUS

INJURY!

MISE EN

487 18 97 36.01

487 18 97 43.00

CAUTION

THIS DRYER MUST BE EXHAUSTED TO

THE OUTDOORS.

INSTRUCTIONS

INSPECT EXHAUST DUCTING EVERY

6 MONTHS AND REMOVE LINT BUILDUP.

487 18 97 42.00

WARNING

PLUMBERS BEWARE WHEN PRESSURE

TESTING!!!

DRYER MUST NOT BE SUBJECTED TO

PRESSURE THAT EXCEEDS

TO DO SO WILL CAUSE GAS LEAKS

WHICH CAN RESULT IN FIRE OR

EXPLOSION.

THIS DRYER AND ITS INDIVIDUAL SHUT-OFF

VALVE MUST BE DISCONNECTED FROM THE

GAS SUPPLY PIPING SYSTEM DURING ANY

PRESSURE TESTING OF THAT SYSTEM AT

TEST PRESSURES IN EXCESS OF 1/2 psig

(3.5 kPa). THIS DRYER MUST BE ISOLATED

FROM THE GAS SUPPLY PIPING SYSTEM BY

CLOSING ITS INDIVIDUAL MANUAL SHUT-OFF

VALVE DURING ANY PRESSURE TESTING OF

THE GAS SUPPLY PIPING SYSTEM AT TEST

PRESSURES EQUAL TO OR GREATER

LINT SCREEN MUST BE CLEANED IN

ACCORDANCE WITH THE MANIFACTURER´S

RECOMMENDED FREQUENCY GUIDELINES

1/2 psig (3.5kPa).

487 18 97 39.00

WARNING

THAN 1/2 psig (3.5 kPa).

487 18 97 37.02

487 18 97 41.00

SOUPAPE CONVERTIE POUR USAGE

SUR GAZ DE PETROLE LIQUEFIE.

REGULATEUR BLOQUE EN POSITION

OUVERTE! REGULATEREXTERNE

NECESSAIRE! UN FONCTIONNEMENT

INAPPROPRIE PEUT PROVOQUERLA

MORT OU DES BLESSURES GRAVES.

GARDE

487 18 97 40.00

487 18 97 45.00

THE DRYER MUST BE USED ONLY FOR DRYING WATER

WARNING

WASHED FABRICS.

HEAT MUST NOT BE USED FOR DRYING FOAM RUBBER

ITEMS OR SIMILARLY TEXTURED RUBBERLIKE

MATERIALS.

DO NOT DRY MOPHEADS OR ARTICLES EXPOSED TO

GASOLINE, KEROSENE, PAINT, WAX, GREASE,

COMBUSTIBLE DETERGENT OR ALL PURPOSE

CLEANERS.

REMOVE ARTICLES BEING DRIED IMMEDIATELY AFTER

TUMBLER STOPS.

THIS DRYER IS NOT TO BE USED IN THE PRESENCE OF

DRY CLEANING SOLVENTS.

487 18 97 44.00

Page 10

IMPORTANT

YOU MUST DISCONNECT and LOCKOUT THE ELECTRIC SUPPLY and THE

GAS SUPPLY or THE STEAM SUPPLY BEFORE ANY COVERS or GUARDS

ARE REMOVED FROM THE MACHINE TO ALLOW ACCESS FOR CLEANING,

ADJUSTING, INSTALLATION, or TESTING OF ANY EQUIPMENT per OSHA

(Occupational Safety and Health Administration) STANDARDS.

WARNING

CHILDREN SHOULD NOT BE ALLOWED TO PLAY ON OR IN THE DRYER(S).

CHILDREN SHOULD BE SUPERVISED IF NEAR DRYER(S) IN OPERATION.

CAUTION

DRYER(S) SHOULD NEVER BE LEFT UNATTENDED WHILE IN OPERATION,

IMPORTANT

Please observe all safety precautions displayed on the equipment and/or speci-

fied in the installation/operators manual included with the dryer.

Dryer(s) must not be installed or stored in an area where it will be

exposed to water and / or weather,

The wiring diagram for the dryer is located in the front electrical control box area.

10

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE,

DO NOT DRY MOP HEADS IN THE DRYER.

DO NOT USE DRYER IN THE PRESENCE OF DRY CLEANING FUMES.

Page 11

11

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Electrical Information

It is your responsibility to have ALL electrical connections (including grounding) made by a properly licensed and competent electrician to assure that the electrical installation is adequate and conforms with local and state regulations or codes.

In the absence of such codes, ALL electrical connections, material, and workmanship must con-

form to the applicable requirements of the NATIONAL ELECTRIC CODE ANSI/NFPA NO. 70 or

the CANADIAN ELECTRICAL CODE, CSA C22.1 - both the latest edition.

IMPORTANT: Failure to comply with these codes or ordinances and/or the requirements

stipulated in this manual can result in personal injury or component failure.

NOTE: Component failure due to improper installation will VOID THE WARRANTY.

IMPORTANT: A separate circuit serving each dryer must be provided. The dryer must be

connected to copper wire only. DO NOT use aluminum wire which could

cause a fire hazard.

NOTE: The use of aluminum wire will VOID THE WARRANTY

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors

can cause improper operation or component failure.

Electric Service

Gas dryers ONLY

IMPORTANT: The dryer must be connected to the electrical supply shown on the data

label affixed to the dryer. In the case of 208 VAC or 240 VAC, the supply

voltage must match the electric service specifications of the data label

exactly. Wire must be properly sized to handle the rated current.

WARNING: 120 VAC, 208 VAC and 240 VAC ARE NOT THE SAME. Any damage

done to dryer components due to improper voltage connections will

VOID THE WARRANTY.

NOTE: On gas dryers, to convert from 120 VAC to 208 VAC or to 240 VAC (or vice

versa), the Direct Spark Ignition (DSI) transformer wiring must be

changed.

Page 12

12

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Gas Information

It is your responsibility to have ALL plumbing connections made by a qualified professional to

insure that the installation is adequate and conforms with local and state regulations or codes. In

the absence of such codes, ALL plumbing connections, material, and workmanship must conform

to the applicable requirements of

the National Fuel Gas Code ANSI Z223.1 or the CAN/CGA-B149, INSTALLATION CODES both the latest edition.

IMPORTANT: Failure to comply with these codes or ordinances, and/ or the requirements

stipulated in this manual, can result in personal injury and improper

operation of the dryer.

The dryer and its individual shut-off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of I/ 2 psig (3.5 kPa). The

dryer must be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or

greater than

1

/2psig (3.5 kPa).

IMPORTANT: Failure to isolate or disconnect the dryer from the gas supply as noted can cause

irreparable damage to the gas valve and will VOID THE WARRANTY.

WARNING: FIRES or EXPLOSION COULD RESULT.

Gas Supply

The gas dryer installation must meet the American National Standard, National Fuel Gas Code

Z223.1-LATEST EDITION, as well as local codes and ordinances and must be done by a qualified

professional,

NOTE: Undersized gas piping will result in ignition problems,

slow drying, increased use of energy, and can create a safety hazard.

The dryer must be connected to the type of heat/ gas indicated on the dryer data label. If this

information does not agree with the type of gas available, do not operate the dryer. Contact your

local dealer or the Wascomat Sales Department.

IMPORTANT: Any burner changes or conversions must be

made by a qualified licensed professional.

The input ratings shown on the dryer data label are for elevations of up to 2,000 feet. The adjustment or conversion of the dryer(s) in the field for elevations over 2,000 feet are made by changing

each burner orifice.

Also for conversion to LPG there are conversion kits.

If these conversions are necessary, contact your local dealer or the Wascomat Sales Department.

Page 13

13

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Technical Gas Data

Natural Gas

The natural gas supply pressure to the dryer must be between 6 and 10 inches water column. If

the pressure is too low, ignition failure and/or slow drying times may result. Excessively high supply pressure will result in erratic operation of the gas valve’s internal pressure regulator. The pressure measured at the pressure tap on the body of the gas valve must be for TYPE 30: 4.2-inches

water column, TYPE 50: 3.2 -inches water column and TYPE 75: 3.2 -inches water column

Liquid Petroleum (L.P.) Gas

Dryers made for use with L.P. gas have the gas valve pressure regulator blocked open, so that the

gas pressure must be regulated upstream of the dryer. The pressure measured at the gas valve

body pressure tap must be 11 inches water column. In accordance with American Gas Association

(AGA) standards, a gas pressure regulator, when installed indoors, must be equipped with a vent

limiter or a vent line must be installed from the gas pressure regulator vent to the outype oors.

The water column pressure must be regulated at the source (L,P. tank), or an external regulator

must be added to each dryer.

Piping/Connections

The dryer is provided with a 1/2” N.P.T. (the model TYPE 75 has a 3/4”) inlet pipe connection extending out the rear area or through the top of the dryer. For ease of servicing, the gas supply line of

each dryer should have its own shut-off valve.

The size of the gas supply line (header) will vary depending on the distance this supply line travels

from the gas meter or, in the case of L.P. gas, the supply tank, the number of tees, other gas-operated appliances, etc. Specific information regarding supply line size should be determined by the

gas supplier.

NOTE: Undersized gas supply piping can create a low or inconsistent gas pressure which

will result in erratic operation of the burner ignition system.

Consistent gas pressure is essential at ALL gas connections. It is recommended that a

3

/4-inch

pipe gas loop be installed in the supply line serving the bank of dryers. An in-line pressure regulator must be installed in the gas supply line (header) if (natural) gas line pressure exceeds 12-inches water column pressure.

IMPORTANT: Water column pressure of TYPE: 30 4.2 -inches water column, TYPE: 50 3.2 -

inches water column and TYPE: 75 3.2 -inches water column for natural gas dry

ers

and 11.0 inches for L.P, dryers is required at the gas valve pressure tap of each

dryer for proper and safe operation.

A1/8” N.P,T. plugged tap, accessible for test gauge connection, must be installed in the main gas

supply line immediately upstream of each dryer.

IMPORTANT: Pipe joint compounds that resist the action of natural gas and L.P. gas

MUST BE used.

WARNING: Test ALL connections for leaks by brushing on a soapy water solution (liquid

detergent also works well). NEVER TEST FOR GAS LEAKS WITH AN OPEN

FLAME.

ALL components / materials must conform to NATIONALFUEL GAS CODE specifications. It is

important that gas pressure regulators meet applicable pressure requirements and that gas meters

are rated for the total amount of appliance Btu’s being supplied.

Page 14

Page 15

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Tumble dryer

Contents:

Instructions for use: ............................................................................17

Diagram of tumble dryer

Manual operation

Aqua Clean wash and drying programs

Error codes

Running hours counter

Maintenance

General installation:............................................................................25

Setup: unpacking, positioning, mechanical installation

Reversing door

Venting

Installation gas heating: .....................................................................31

Machine dimension

Technical data

Electricl installation, function check

Fuse sizes, effects and voltages

Gas installation

Parameter programming:....................................................................45

Switching to programming mode

Adjustable parameters, change machine type

Temperature and time setting, reversing

Cooling time, residual moisture level, extra drying time

Quick view parameter list.

The manufacturer reserves the right to modify design and material

specifications without notice.

Safety instructions

This machine is only intended for drying water-washed garments.

The machine must not be used for drying foam rubber or

foam-like materials.

The machine must not be used for drying *floor mops.

The machine must not be used by children.

The machine must not be hosed down with water.

Mechanical, electrical and gas installations must only be car-

ried out by authorized personnel.

If the machine has a fault, this must be reported as soon as

possible to the person in charge. This is important for your

own safety and for the safety of others.

Machine with gas heating is not to be installed in rooms containing cleaning machines with perchloroethylene,

TRICHLOROETHYLENE or CHLOROFLUOROCONTAINING

HYDROCARBONS as cleaning agents.

*Applies only to mop heads containing polypropylene.

15

Page 16

Page 17

Instructions for use

17

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Diagram of tumble dryer

Door

Cylinder

Filter door

Operating panel

Page 18

Instructions for use

18

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

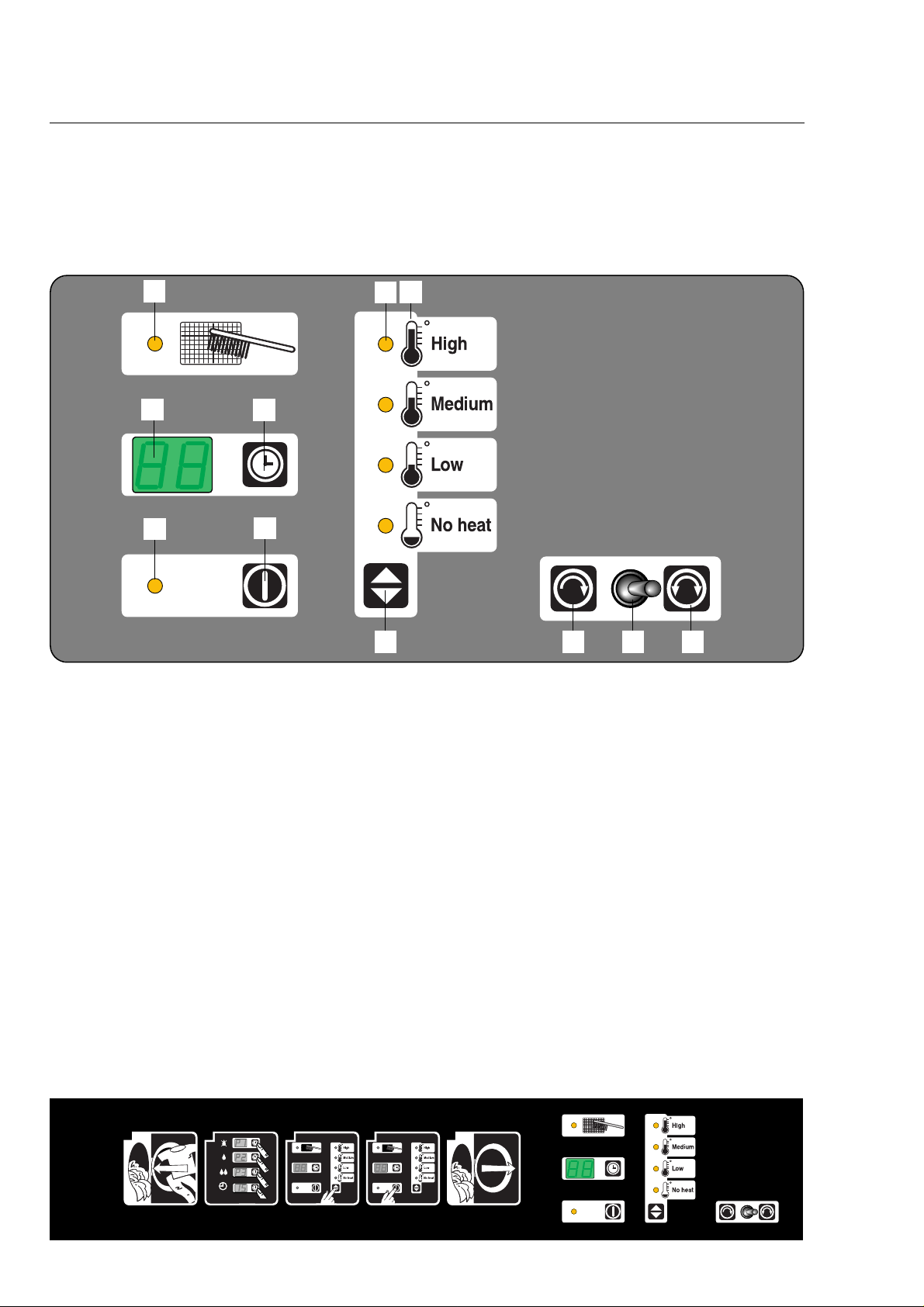

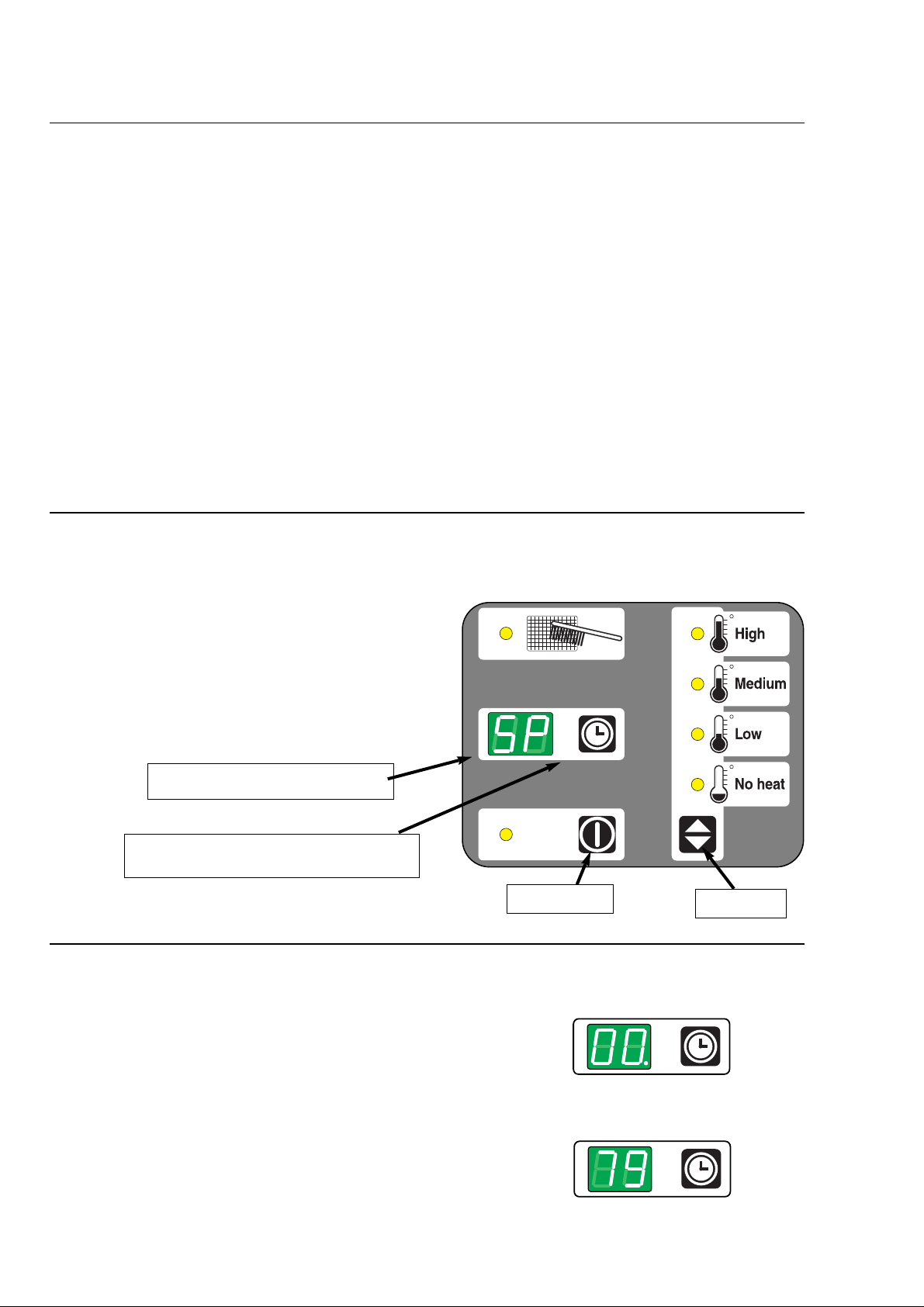

Manual operation with RMC (residual moisture control)

A. Filter: When the lamp is lit, the lint filter must be cleaned.

B. Display indicates program: A1, A2, A3 – or in time control version: drying time/time remaining

C. Operating lamp indicates when machine is in use.

D. Program selection button/drying-time adjuster.

E. Start/stop button.

F. Temperature selection button.

G. Lamps: lit to indicate selected temperature.

H. Temperature.

I. Reversing switch: a = Reversing off

b = Reversing on

A

G

H

B

C

E

F Ia b

D

1

2

15-90 MIN15-90 MIN

33

4 5

Page 19

Instructions for use

19

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Manual operation with RMC (residual moisture control)

Check that

the filter is

clean

Select the

program:

A1, A2, A3

or timer

Start:

Press the start/stop

button

Stop:

Press the

start/stop button or

open the door.

Caution!

Garments may fall

out when the door

is opened.

The last few

minutes of the

drying time are

the cooling-down

period

(the garments are

cooled).

Restart:

Close the door

again and press

the start/stop

button.

Load

garments

into the

machine and

close the door.

Select

temperature

Dryness 1 (see programming

instructions)

Dryness 2 (see programming

instructions)

Dryness 3 (see programming

instructions)

Time control in minutes

Use for durable items, outer garments and

wool

Use for synthetic and delicate textiles

(eg. silk, acetate, angora and rayon)

No-heat setting

The machine will stop

automatically when the

moisture level reaches

the value set for the

selected program.

The machine stops

when the selected time

has ended.

Reversing switch:

Select option, with or without reversing.

OFF

ON

To prevent

wrinkling:

empty the tumble

dryer as soon as

the program has

ended.

If the tumble dryer is not emptied after

the drying time has ended, an anti-wrinkle program is automatically started.

This means that the cylinder rotates at

short intervals, thereby almost completely avoiding wrinkling.

Page 20

Instructions for use

20

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Outer garments

without sensitive linings

Ewac 11-21-31 A2 10-12 % High

Outer garments

with sensitive linings

Ewac 13-23-33 A3 15-18 % High

Active textiles

Sympatex, Goretex, down

Ewac 12-22-32 A1 0-2 % Medium

Delicate garments

Synthetic

Ewac 13-23-33 A2 10-12 % High

Delicate garments

Wool

Ewac 14-24-34 A2 10-12 % High

Delicate garments

Silk

Ewac 15-25-35 A2 10-12 % High

Delicate garments

Acetate,Angora,

Cashmere

Ewac 15-25-35 A3 15-18 % High

Leather & suede (Hang dry after wash) Ewac 16-26-36 20-40 min. Medium

Program Ewac 11-16 for full load (filling factor 1:20)

Program Ewac 21-26 for half load

Program Ewac 31-36 for single garment load

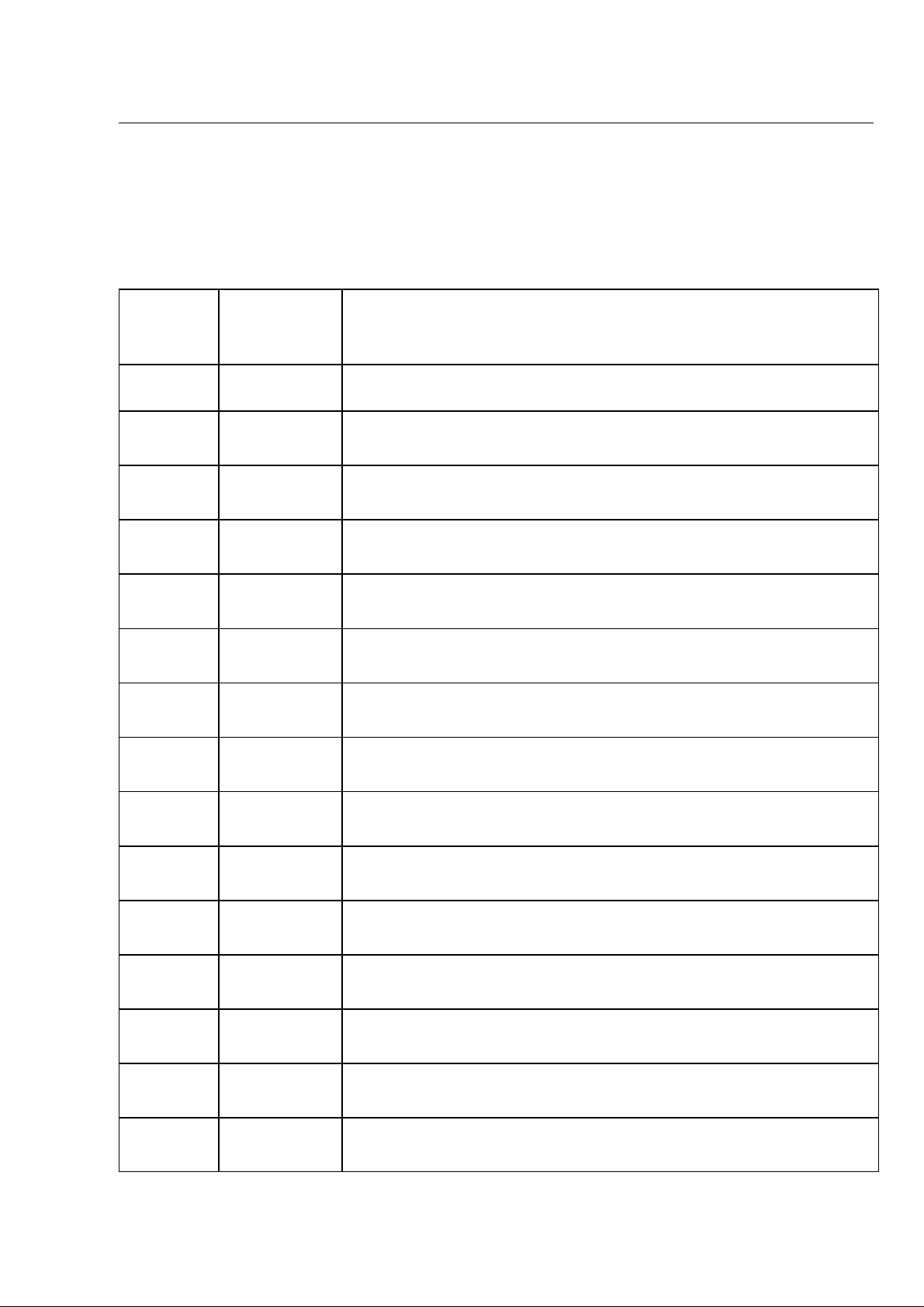

Aqua Clean wash and drying programs

Type of garments

Drying-

program

RMC

%

Temp.

setting

Aqua Clean Washers: 125 EX30c, 225 EX50c, 400 EX90 FC

Aqua Clean Dryers: TD30 RMC, TD50 RMC, TD75 RMC

Aqua Clean

Program

Time

Page 21

Instructions for use

21

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

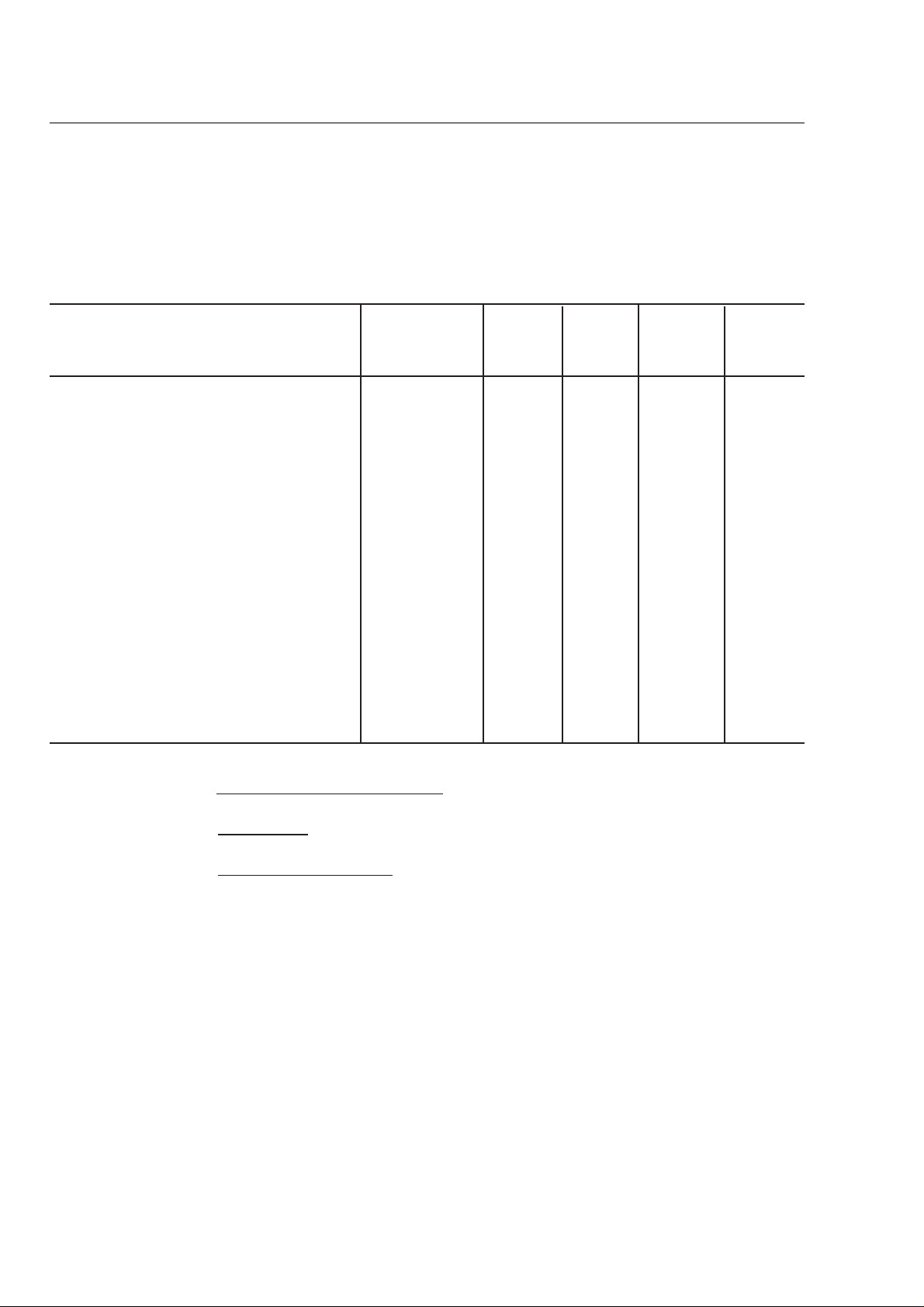

Error codes

These machines feature automatic fault reporting,

displayed in the form of flashing error codes.

F1 = Machine type has not been set.

“F1” is shown after the control circuit board has

been changed or if power is connected to the

machine while the service program is active.

(Machine type should be set in the service program).

F4 = The thermal sensor is disconnected.

Check for loose or broken connections.

Page 22

Instructions for use

22

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Running hours counter

The machine is equipped with a running hour

counter to track the number of hours that the

machine has been in operation.

The running hours read-out (a 6-digit number) is

given in the display.

The total running hour counter valve is shown each

time the power is connected to the machine.

Example of machine having run for 12796 hours:

Switch the machine off and on again.

After approx. 10 seconds

the first two digits of a 6-digit number

01 — — are shown, and at the same time,

lamp A lights up.

After 4 seconds, the lamp and the two digits

are turned off.

After a two-second pause

the next two digits – 27 – show while

lamp B is lit. After 4 seconds, the lamp

and the two digits are turned off.

After a two-second pause

the last two digits, — — 96 are shown,

with lamp C lit, for 4 seconds.

Altogether, the machine has been in

operation for 01-27-96 = 12796 hours.

The machine will complete its power-on testing sequence

and be ready for use after a short time

ON ON

OFF OFF

A

Time:

10 sec.

4 sec.

2 sec.

4 sec.

2 sec.

4 sec.

= 012796

01 -- --

-- -- --

-- 27 --

-- -- --

-- -- 96

B

C

Page 23

Instructions for use

23

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

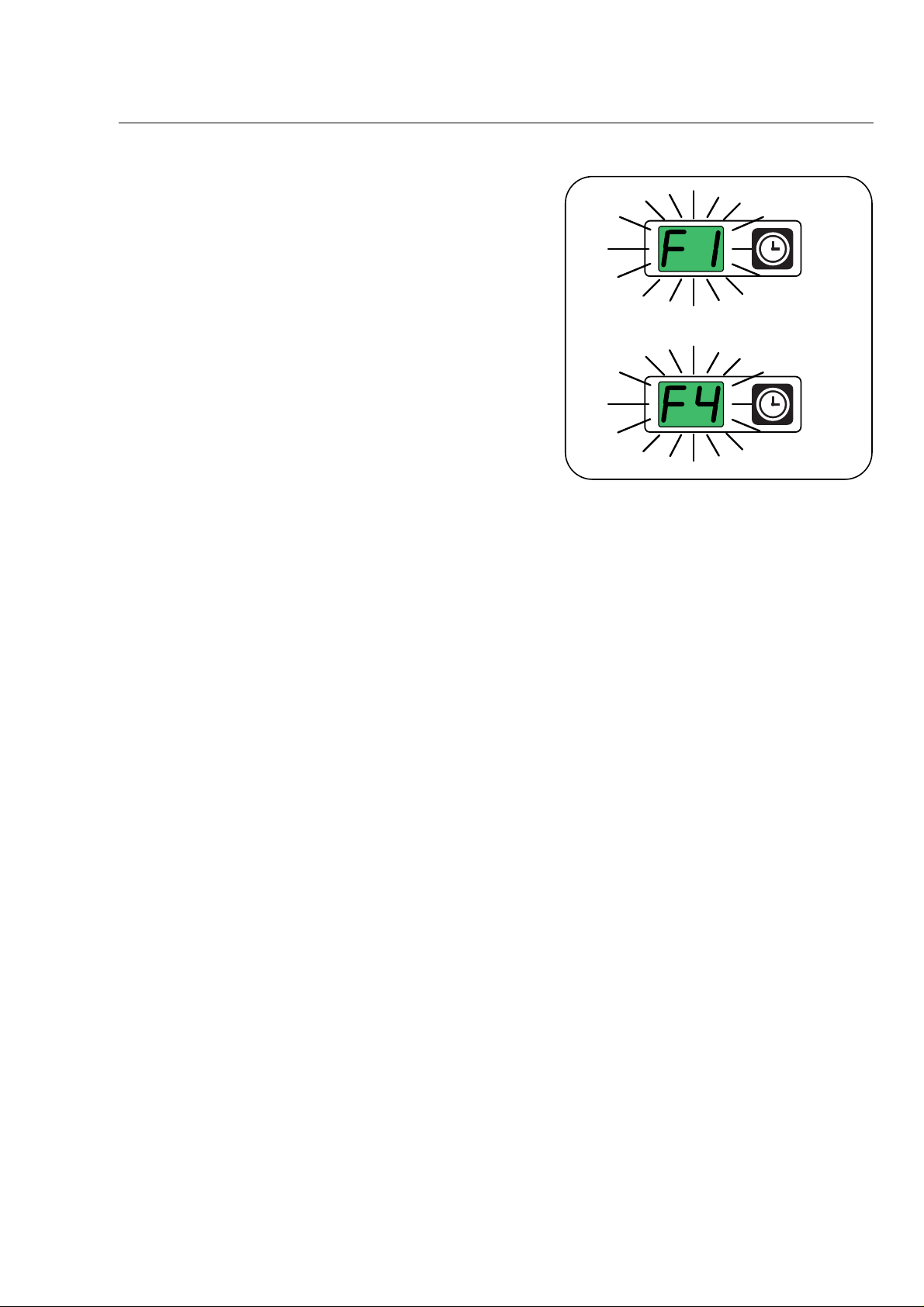

Maintenance

The following should be carried out at regular

intervals, depending on machine usage.

Daily

• Check that the machine does not operate when

the door is open.

• Check that the machine does not start until the

door is closed and the start button has been

pressed.

• Clean the door gasket (use a moist cloth).

• Cleaning of lint filter compartment:

Remove the lint compartment door by opening it

and pulling it upwards. It is not necessary to

remove the lint filter for cleaning. The air system of

the machine ensures that lint and dust settle automatically at the bottom of the filter compartment,

so that they can be removed with a broom or

vacuum-cleaner.

• Check that the lint filter is not damaged.

Quarterly/Semi-annually

• Check that the fresh-air intake at the back of the

machine is not clogged by lint or otherwise

blocked.

• Check that the exhaust system connections are

tight and that the ducts are not clogged by lint or

dust or otherwise blocked.

• Remove the lint filter and check that the fan wheel

is not clogged by lint or otherwise blocked.

• Gently clean the lint filter with warm water and a

soft brush. Allow the filter to dry then re-install it.

1

1

2

2

3

3

To be continued

Page 24

Instructions for use

24

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Maintenance continued

Annually

• Check that the fresh-air intake to the room and

exhaust ducts from the room are not clogged by lint

or dust or otherwise blocked.

Clean, as required, depending on machine usage once a year as a minimum.

• Remove the front panel and finger protector. Clean

all accumulated lint and dust.

• At least once a year a qualified service technician

should check the internal parts of the machine and

thoroughly clean them of lint and dirt.

Lubrication

The motor bearings, idler bearings, and tumbler

bearings are permanently lubricated.

No lubrication is necessary.

4

4

Page 25

General installation

25

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

2

1

Minimum

20”

3/8”

(10)

3/8”

(10)

Minimum 20”

Minimum 6”

Minimum 1.8”

Section A-A

A

A

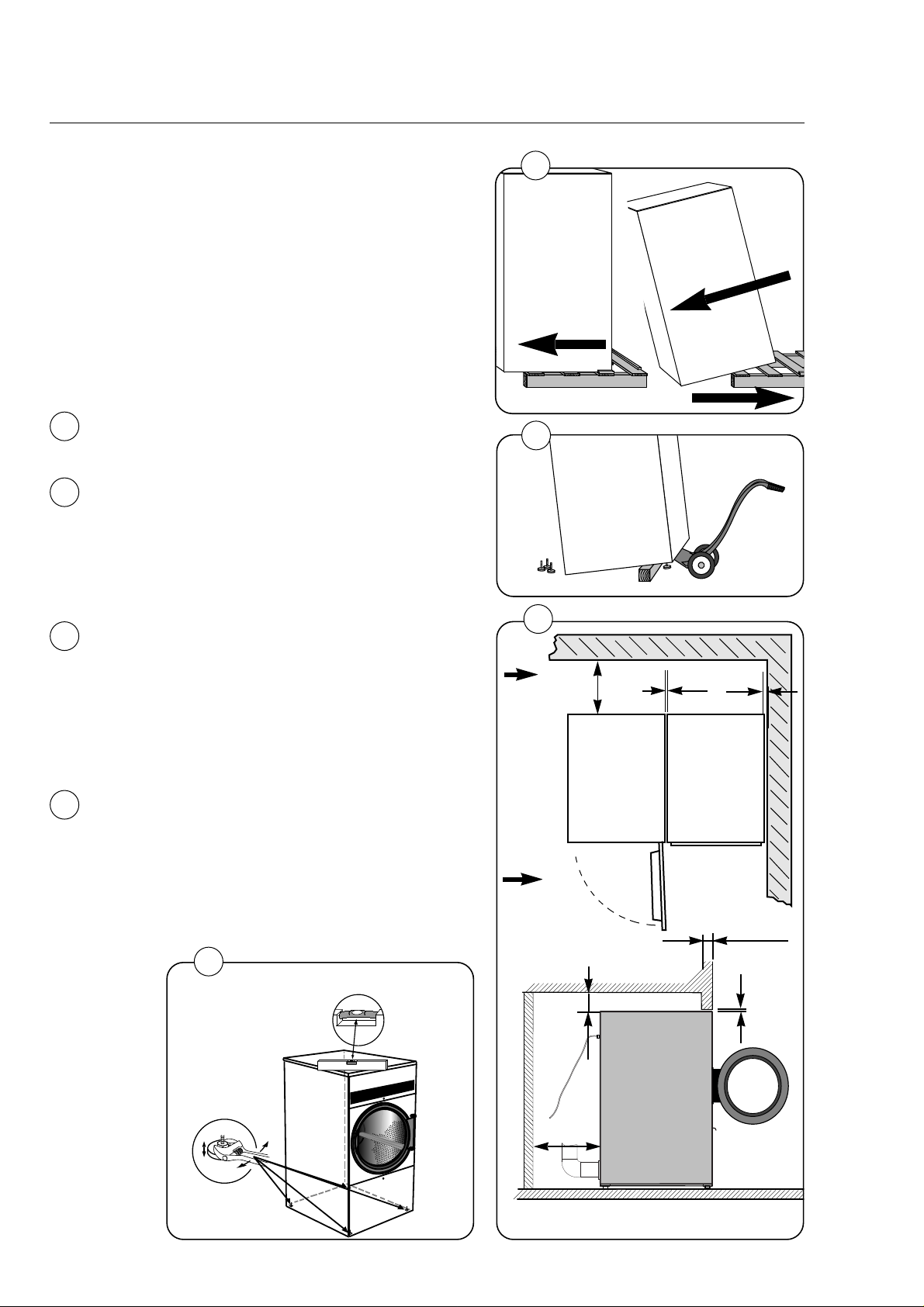

Setup, type 30 and 50

Unpacking

When unpacking the machine, handle it with

care. There are no transport brackets to

remove.

The tumble dryer is fastened to the pallet by

three screws. Remove the two front screws by

opening the filter lid. Remove the back screw by

unscrewing and removing the bottom backplate.

Positioning

Position the tumble dryer so that there is plenty

of room for working, both for the user and for

the service technician.

The distance from the wall or other equipment

behind the tumble dryer should be at least 20”

(500 mm) and the space at the sides at least

3/8” (10 mm).

Note that, for servicing purposes, access to

the rear of the tumble dryer is required.

Mechanical installation

Adjust the machine to make it stand horizontally

and stably on all four feet.

The max. height adjustment of the feet is 5/8”

(15 mm)

Maximum 2”

Page 26

General installation

26

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

1

2

4

Setup, type 75

Unpacking

When unpacking the machine, handle it with

care. There are no transport brackets to

remove.

The tumble dryer is fastened to the pallet by

four screws. Remove the two front screws by

opening the lint filter panel. Remove the two

back screws by unscrewing and removing the

bottom back-plate.

Carefully push the tumble dryer back so that it

can be tipped backwards to allow the pallet to

be pulled out from beneath it.

Put the tumble dryer into position, tipping it up

to install the four supplied feet.

Positioning

Position the tumble dryer so that there is plenty

of room for working, both for the user and for

the service technician.

The distance from the wall or other equipment

behind the tumble dryer should be at least 20”

(500 mm) and the space at the sides at least

3/8” (10 mm).

Note that, for servicing purposes, access to

the rear of the tumble dryer is required.

Mechanical installation

Adjust the machine to make it stand horizontally

and stably on all four feet.

The max. height adjustment of the feet is 5/8”

(15 mm).

1

4

3

2

3

Minimum

20”

3/8”

(10)

3/8”

(10)

Minimum 20”

Minimum 6”

Minimum 1.8”

A

A

Section A-A

Top view

Maximum 2”

Page 27

General installation

27

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

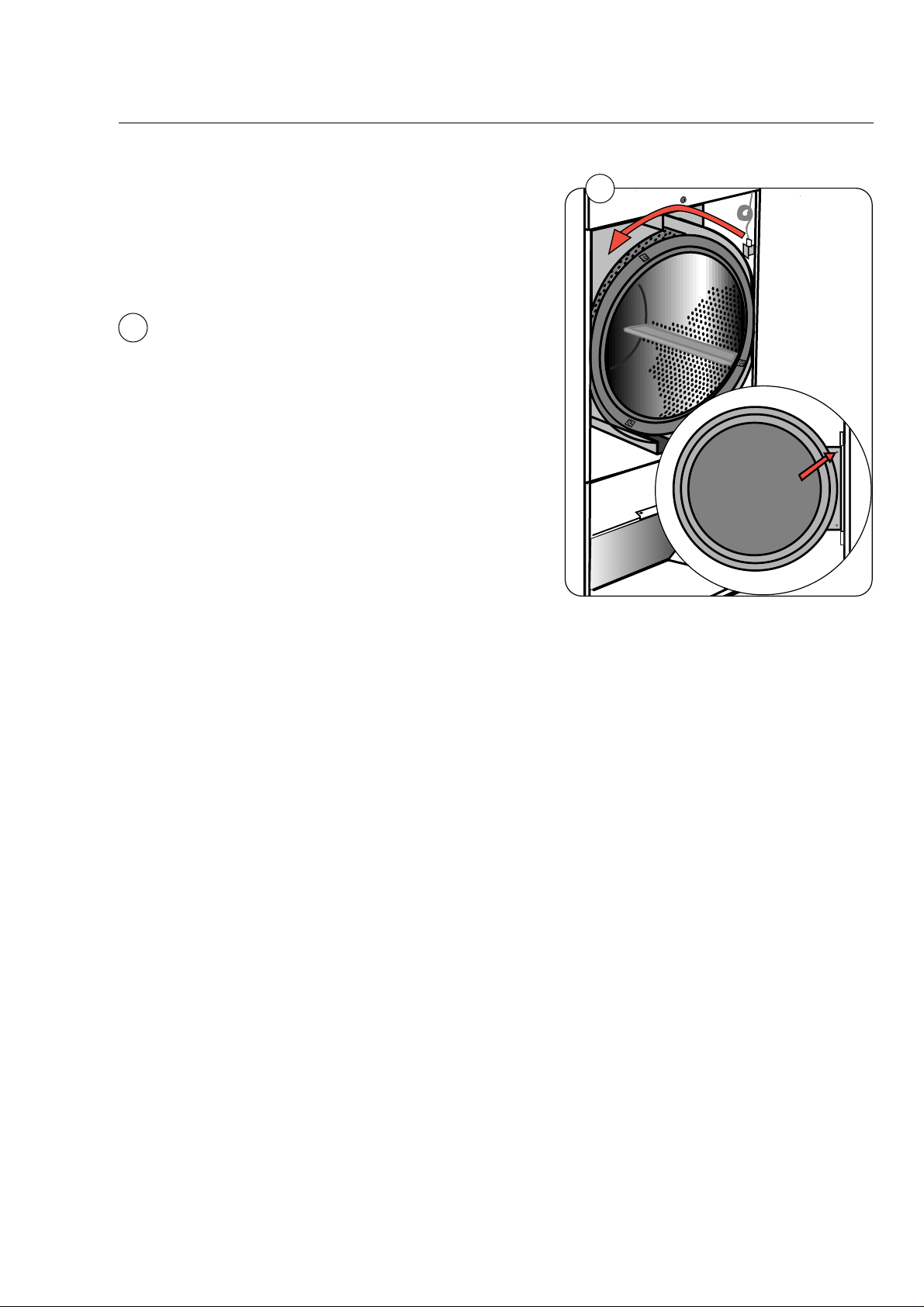

Reversing the door

The tumble dryer is usually delivered with a right

hinged door but the door can easily be changed to

left hinged position.

Dryer door reversal instructions

Disconnect the power supply to the machine.

Remove the screws that secure the center-front

panel to the machine and remove the entire panel

(with the door mounted on it).

Move the door switch to the opposite side of the

machine.

Turn the front panel over and re-mount it.

Unscrew the door-switch pin from the inside of the

hinge flange and move it to the opposite edge of the

flange A. The new pin location must correspond

with the new position of the door switch.

Restore power to the machine and check for proper

operation of the door switch, as follows:

• With the door open, attempt to start the dryer. It

must not start.

• Close the door and start the machine. Open the

door. The dryer must stop.

If the dryer starts with the door open, or fails to stop

when the door is opened during operation, repair or

replace the door switch, as necessary.

11

1

1

A

Page 28

General installation

28

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

A

5

x

A

5 x A

2

1

1

2

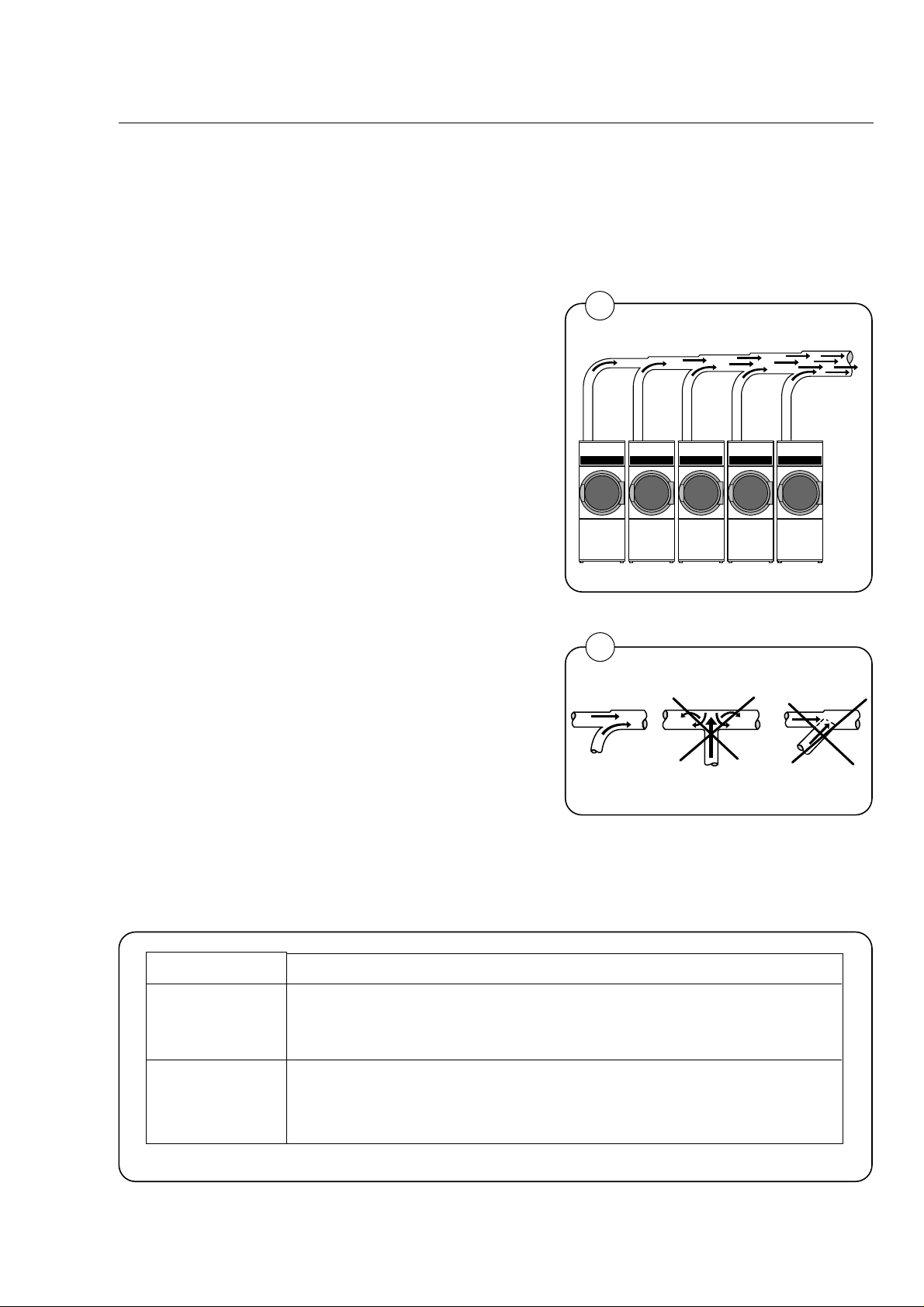

Tumble dryer inlet air requirements

Fresh- air

For maximum efficiency and the shortest possible

drying time, it is important to ensure that fresh air

is able to enter the room from the outside in the

same volume as that blown out of the room. To

avoid a draught in the room, it is advisable to

place the air inlet behind the machine. *The area

of the air inlet opening must be 5 times the size

of the vent pipe area.

The resistance in the grating/slats on the air-inlet

cover plate should not exceed 10 Pa (0.1 mbar).

Type 30: The air consumption is approx.

410 CFM (690 m

3

/h).

Type 50: The air consumption is approx.

680 CFM (1160 m

3

/h).

Type 75: The air consumption is approx.

650 CFM (1100 m

3

/h).

*The area of the inlet opening is the area through

which the air can flow without resistance from

grating/slatted cover.

Note that gratings/slatted covers often block half

of the total fresh air vent area. Remember to take

this into account.

Air principle

The blower creates low pressure in the cylinder,

drawing air into the machine via the heating unit.

The heated air passes through the garments and

the cylinder vents.

Then the air flows out through a lint filter, positioned immediately in front of the blower. After

this, the air is evacuated through the ventilator

and exhaust ducts.

3

Inlet

Outlet

Page 29

General installation

29

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

1 2 3 4 5 6 7 8 9 10

7

3

/4” 11” 12 3/8” 14” 15 3/4” 173/4” 183/4” 195/8” 21” 22”

(200) (280) (315) (355) (400) (450) (475) (500) (535) (560)

1

5

/8 3 1/4 4 7/8 6 1/2 8 1/16 9 5/8 115/16 13 141/2 161/8

(1.05) (0.35) (0.45) (0.60) (0.75) (0.90) (1.05) (1.20) (1.35) (1.50)

Number of tumble

dryers

Exhaust pipe diam-

eter, inches

Required area of

fresh-air inlet,

Square feet (m2 )

(minimum)

Each machine requires a 5

3

/4” x 5 3/4” fresh-air inlet opening. (400 x 400 mm)

When installing several machines on a shared

exhaust duct, increase the area of the duct with

each additional machine, so that each machine

will be working at the same air resistance. Fig. 1

and the table show in simplified form how the

exhaust duct should look.

Note: To keep the air flowing, ensure proper

machine operation, and minimize lint buildup in

the exhaust system, never connect ducts at right

angles, always use gentle bends. See fig. 2.

Tumble dryer exhaust system

Exhaust system for installation of several machines with

a shared exhaust duct

2

1

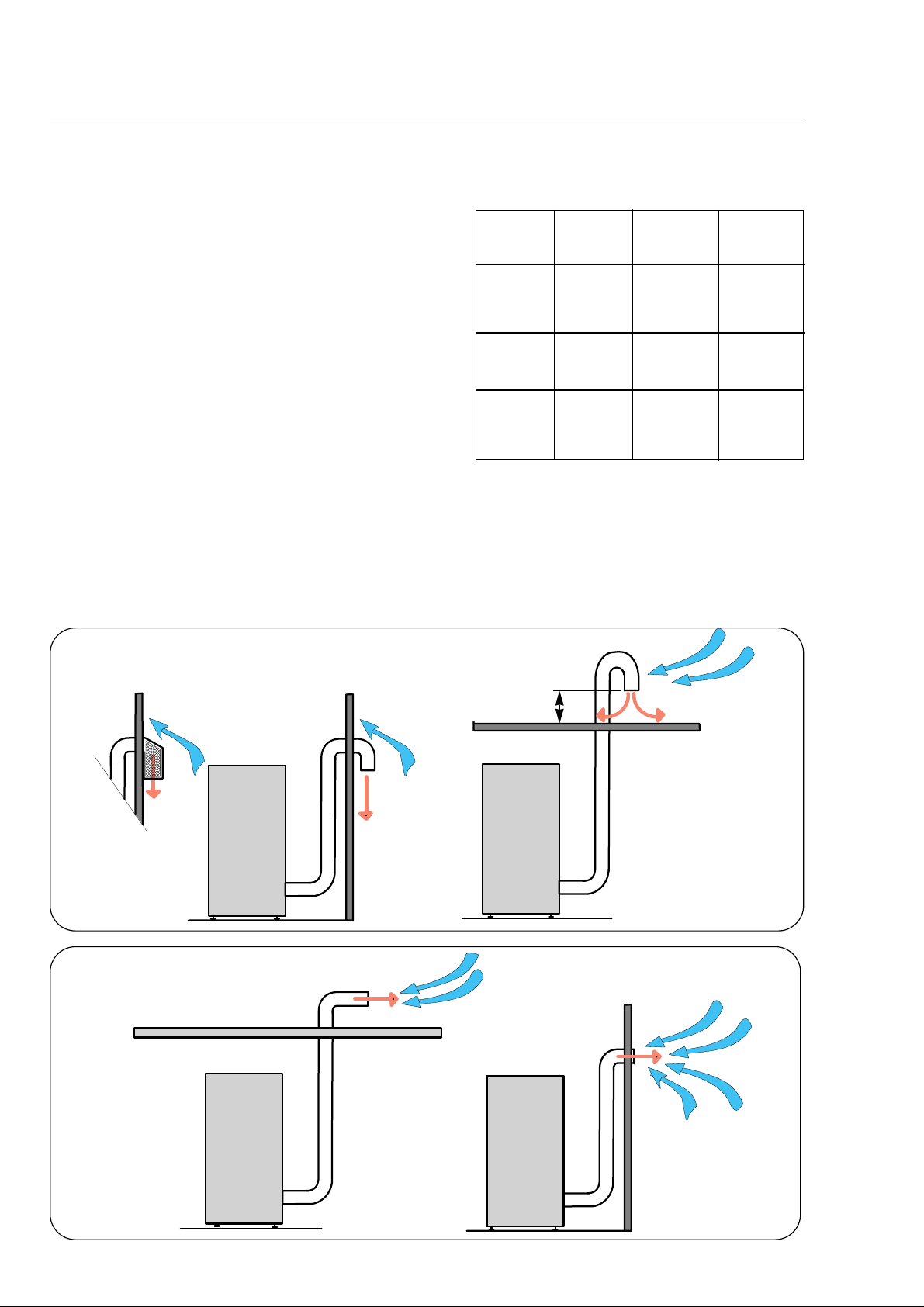

Page 30

General installation

30

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

With With With

1 elbow 2 elbow 3 elbow

TD 30 30 ft 24 ft 18 ft

TD 50 30 ft 24 ft 18 ft

TD 75 100 ft 94 ft 88 ft

Tumble dryer exhaust system

Exhaust duct

It is recommended to connect each machine to a

separate, smooth exhaust duct with the lowest

possible air resistance. The duct must lead into

the open, where lint and steam will not be a hazard. The outlet must be protected against rain

and foreign objects

The exhaust duct must be designed to minimize

backpressure. The end of the exhaust duct must

never be exposed to wind pressure.

Note: In cold areas, condensation may cause

frost damage to the building.

If you have questions relating to the design of

the exhaust system, please contact your local

dealer or Wascomat´s Customer Service

Department.

Acceptable

Exhaust illustrations

Unacceptable

windwind

wind

wind

wind

Minimum

3.5 ft

OR

Maximum duct length

Page 31

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

31

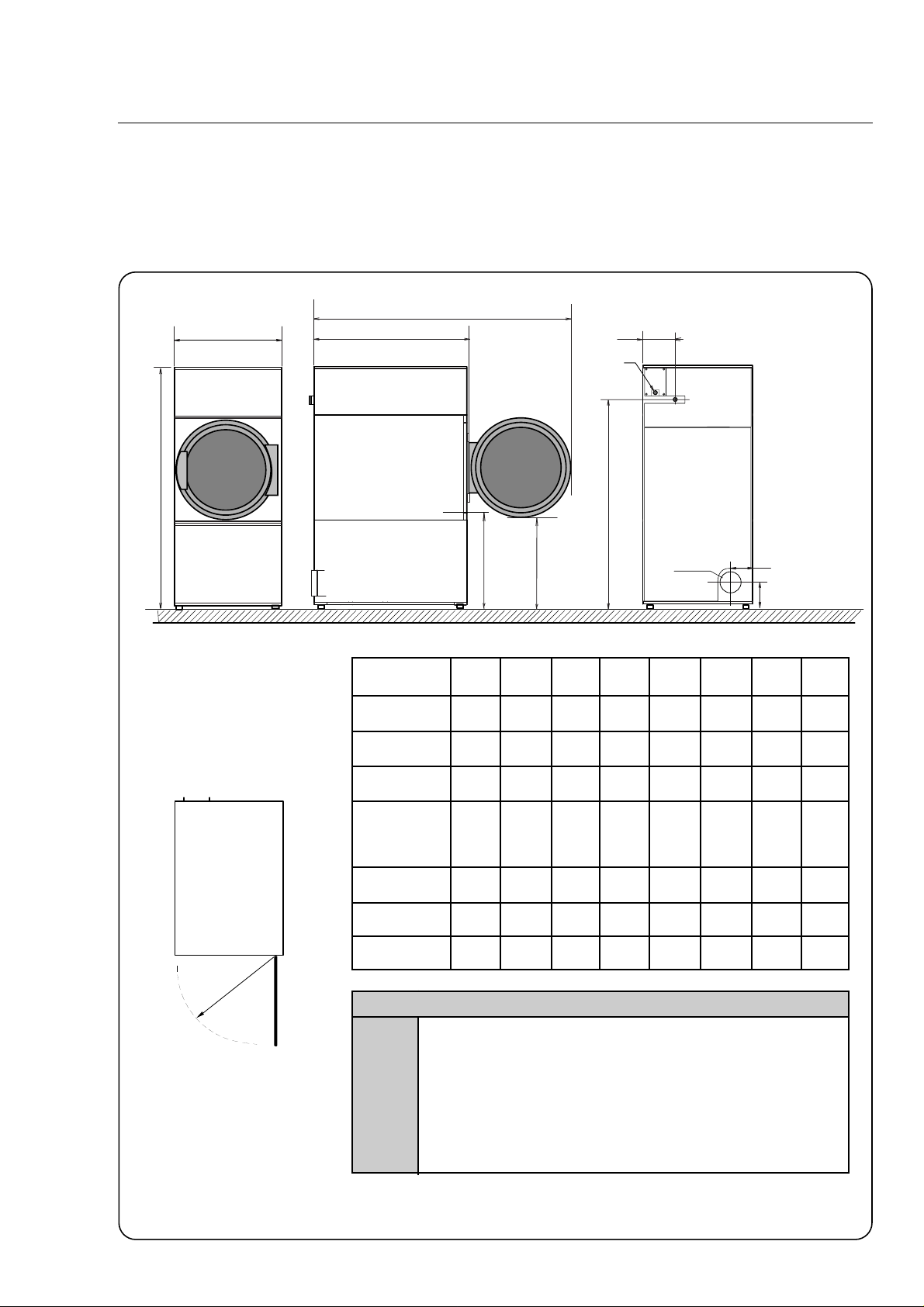

Mashine Dimensions

Ø 8"

I

F

H

A

C

B

E

D

K

J

M

N

D Door opening dia.

G/L Not in use on this model

F/M Gas connection (gas models)

N Electric connection (gas models)

Type 30 Type 50 and 75

22

3

/4”(580) 32”(810)

A B C D E F G H

Type 30 28” 44” 74” 303/4” 281/2” 631/3” - 51/4”

(710) (1120) (1880) (780) (725) (1610) - (135)

Type 50 373/4” 461/2” 781/2” 281/3” 251/2” 68” - 6”

(960) (1180) (1995) (720) (650) (1725) - (155)

Type 75 373/4” 54” 781/2” 281/3” 251/2” 68” - 6”

(960) (1370) (1995) (720) (650) (1725) - (155)

I J K L M N

Type 30 63/4” 28” 711/4” - 9” -

(170) (710) (1810) - (250)

Type 50 83/4” 373/4” 831/2” - 101/2” -

(225) (960) (2120) - (270)

Type 75 83/4” 373/4” 901/2” - 101/2” -

(225) (960) (2300) - (270)

All dimensions given in inches

±

1

/8”

Inch (mm)

Page 32

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

32

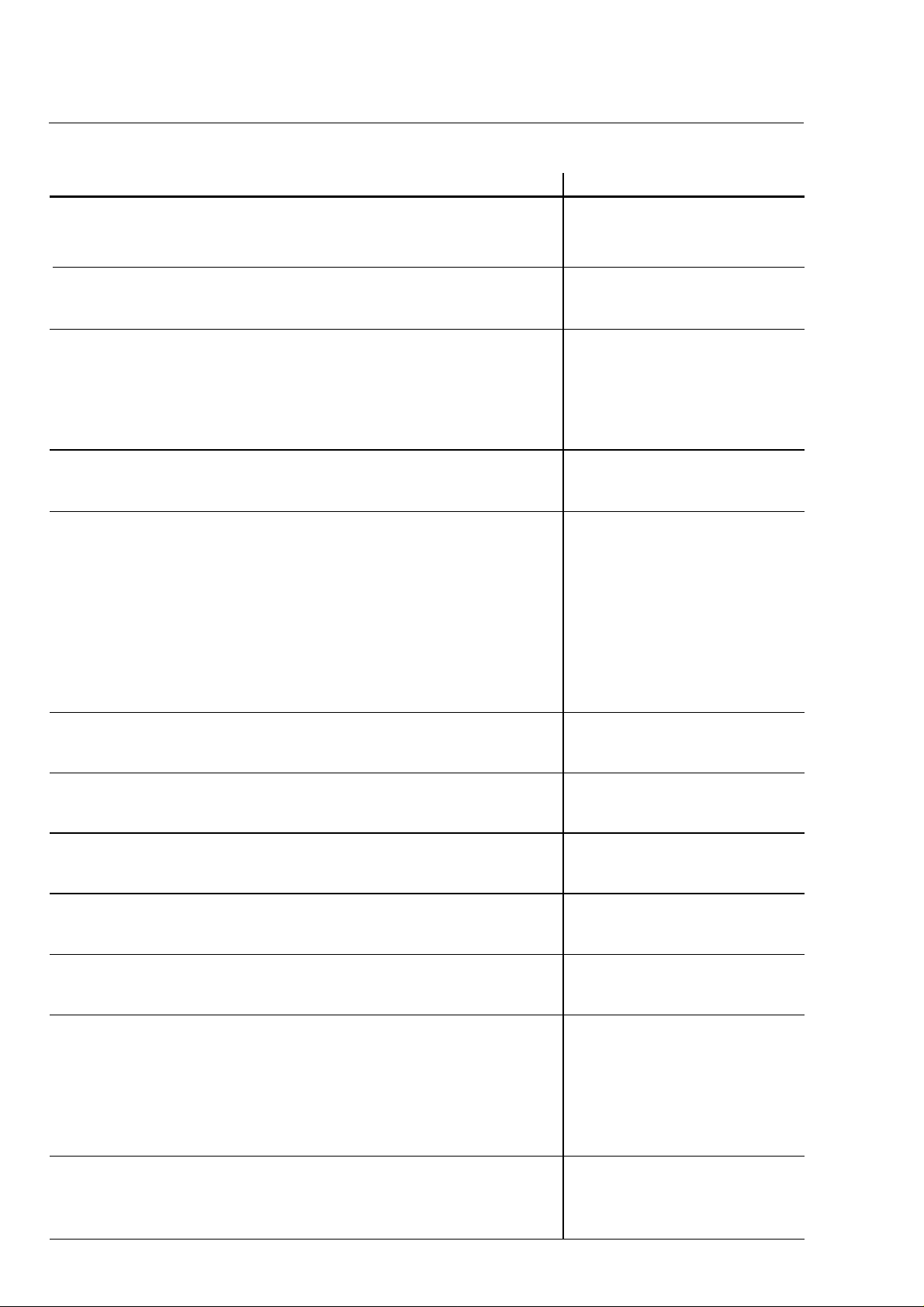

Technical data, type 30

Heating Gas

Cylinder volume: (286 litres) 10.1 cu.ft.

Weight: Net (220 kg) 485 lbs

Cylinder: Diameter (680 mm) 26 3/4”

Depth (790 mm) 31”

Revolutions per minute 44 rpm

G-factor 0.8

Capacity: 13.6 kg 30 lb

Motor single phase: Effect of cylinder/vent motor 0.5hp/ 0.37 kW

Revolutions per minute 60 Hz 1680 rpm

Motor three phase: Effect of cylinder/vent motor 0.5hp/ 0.37 kW

Effect with reverse:

Cylinder 0.5hp/0.37kW

Blower 0.5hp/0.37kW

Revolutions per minute 60 Hz 1680 rpm

Heat effect: Gas heating (21kW) 71600 BTU/h

Air consumption: Gas (690 m

3

/h) 410 cu.ft./min

Pipe connection: Evacuation: (Ø200) Ø 8”

Drop in pressure: Evacuation: (20Pa) max. 0.1” W.C

Gas pipe connection: (ISO 7/1-R1/2) 1/2” NPT

Gas pressure: GNH (Natural gas) Minimum 3.5” W .C.

Maximum 10” W.C.

LPG (L.P.gas) Minimum 8” W.C.

Maximum 13” W.C.

Noise level: < 70 dB (A)

Page 33

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

33

Technical data, type 50

Heating Gas

Cylinder volume: (528 litres) 18.6 cu.ft.

Weight:Net (332 kg) 732 lbs

Cylinder: Diameter (913 mm) 36”

Depth (812 mm) 32”

Revolutions per minute 40 rpm

G-factor 0.8

Capacity: 22.7 kg 50 lb

Motor single phase: Effect of cylinder/vent motor 1.5hp/ 1.1kW

Revolutions per minute 60 Hz 1720 rpm

Motor three phase: Effect of cylinder 0.5hp/0.37 kW

Effect of blower 0.5hp/0.37 kW

Revolutions per minute 60 Hz 1680 rpm

Heat effect: Gas heating (40 kW) 136400 BTU/h

Air consumption: Gas (1160 m

3

/h) 680 cu.ft./min

Pipe connection: Ø 8”

Drop in pressure: Evacuation (60Pa) max. 0.23” W.C.

Gas pipe connection: (ISO 7/1-R1/2) 1/2” N.P.T

Gas pressure: GNH (Natural gas): Minimum 3.5” W.C.

Maximum 10” W.C.

LPG (L.P.gas): Minimum 8” W.C.

Maximum 13” W.C.

Noise level: < 70 dB (A)

Page 34

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

34

Technical data, type 75

Heating Gas

Cylinder volume: (650 litres) 23 cu.ft.

Weight: Net (345 kg) 760 lbs

Cylinder: Diameter (913 mm) 36”

Depth (998 mm) 39 1/4”

Revolutions per minute 44 rpm

G-factor 0.9

Capacity: 34.1 kg 75 lb

Motor single phase: Effect of cylinder motor 1.5hp/1.1 kW

Effect of blower motor 1.0hp/0.75 kW

Cylinder: Revolutions per minute 60 Hz 1720 rpm

Ventilator: Revolutions per minute 60 Hz 3400 rpm

Motor three phase: Effect of cylinder motor 0.5hp/ 0.37kW

Effect of blower motor 1.0hp/0.75 kW

Cylinder: Revolutions per minute 60 Hz 1680 rpm

Ventilator: Revolutions per minute 60 Hz 3400 rpm

Heat effect: Gas heating (44.3 kW) 151200 BTU/h

Air consumption Gas (1100 m

3

/h) 650 cu.ft./min

Pipe connection: Evacuation (Ø200) Ø 8”

Drop in pressure: Evacuation (340 Pa) max. 1.3” W.C.

Gas pipe connection: (ISO 7/1-R3/4) 3/4” NPT

Gas pressure: GNH (Natural gas) Minimum 3.5” W.C.

Maximum 10”W.C.

LPG (L.P.gas) Minimum 8” W.C.

Maximum 13”W.C.

Noise level: < 70 dB (A)

Page 35

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

35

Important

The machine is equipped with a control circuit

transformer with 4 selections for incoming supply Voltages:

120, 200/208, 220/230, and 240V.

Check the transformer taps. The connection of

the primary voltage on the transformer taps

must be exactly the same voltage as specified

on the dryer`s data label.

Connecting the power cable:

A wiring diagram is included with each dryer

showing the wiring connection sequence. The

electrical connections are made at the terminal

block located at the rear top area of the dryer

The dryer is shipped with three (3) connection

points: Voltage 208-240, 120: L1, N and

Ground fig. 2.

Or four (4) connection points: Voltage 208-240:

L1, L2, L3 and Ground fig. 3.

Cable dimension:

Refer to local codes to determine proper size of

power cable.

Circuit breaker raitings are given on the following pages.

Function check see next page

(NB: Correct direction of rotation is important!)

Electrical installation: Gas heating

It is your responsibility to have ALL electrical connections (including grounding)

made by a properly licensed and competent electrician to assure that the electric

installation is adequate and conforms with local and state regulations or codes.

In the absence of such codes, ALL electric connections, material, and workmanship

must conform to the applicable requirements of the NATIONAL ELECTRIC CODE

ANSI/NFPA NO. 70-

or the CANADIAN ELECTRICAL CODE, CSA C22.1 - both

the latest edition.

A separate circuit serving each dryer must be provided. The dryer must be connected to copper wire only. DO NOT use aluminum wire which could cause a fire haard.

L3L3 L2L2 L1L1 NN

L3L3 L2L2 L1L1 NN

2

2

3

3

1

1

Page 36

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

36

Electrical installation

Function check

This proceedure must be carried out by qualified

personnel.

Check that the cylinder is empty and the door is

closed.

Start the machine.

Check that the safety lock is working: The

cylinder, blower and heat must stop if the front

door is opened approximately 2”.

The initial direction of rotation should be clockwise

(see illustration). If the direction is reversed, swap

two powerline phases (on 3 phase machines).

Let the machine operate for 5 minutes on a program that requires heat. Then check whether the

heating is working by opening the front door to

check if heat can be felt inside the drum.

If the above checks are found to be in order, the

dryer is ready for use.

If problems exist, please contact your local dealer

or Wascomat´s Customer Service Department.

Page 37

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

37

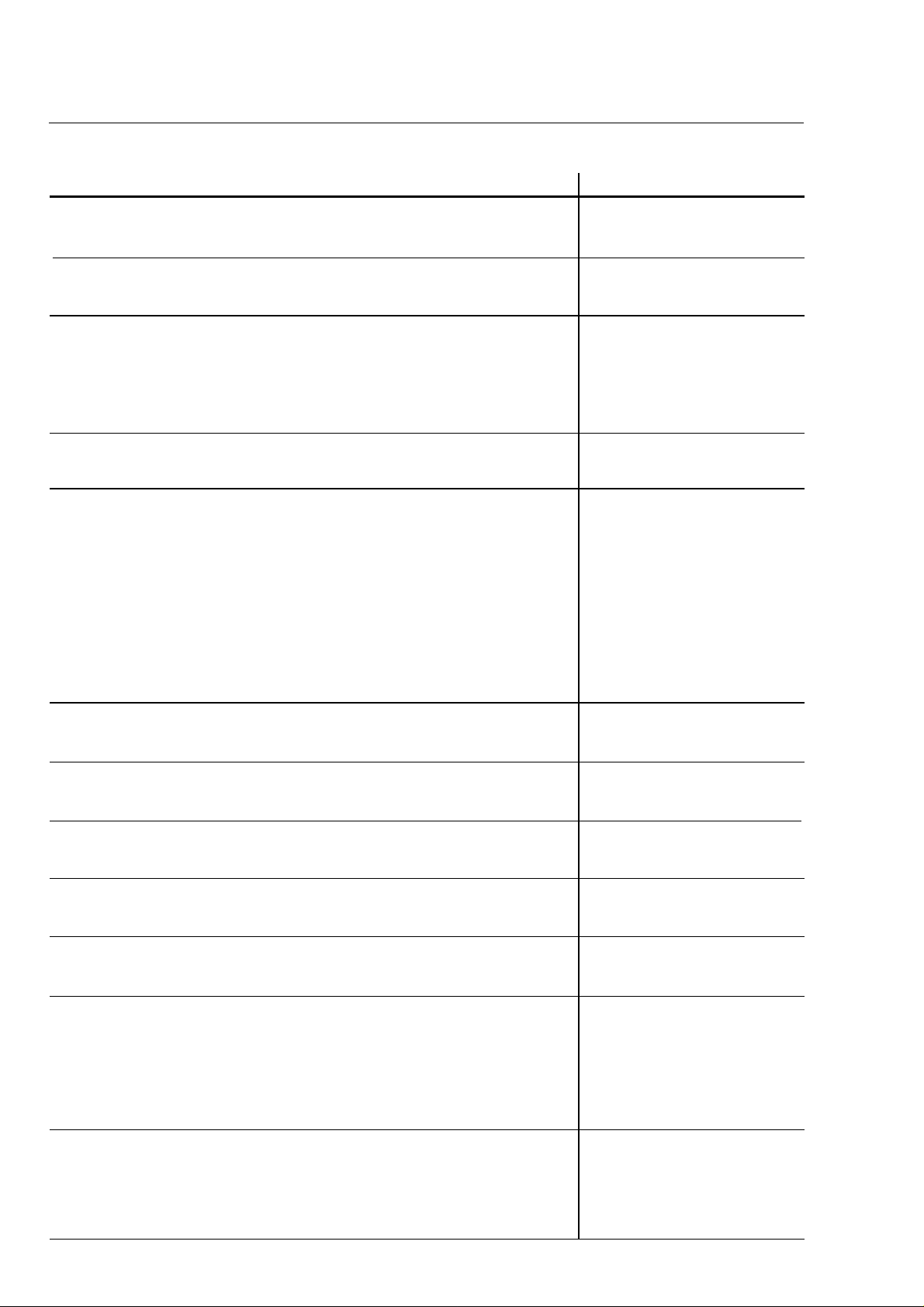

Electrical installation - Tumble dryer type 30

Only

one

cable

for con-

trol and

motor

Gas heating, circuit breaker ratings, power consumption and voltages

208 - 240V 3AC 60 Hz 1.5 kW 15A

208 - 240V 1AC 60 Hz 0.7 kW 15A

120V 1AC 60 Hz 0.7 kW 15A

Voltage

Total

input

Gas

Note: Use common-trip, single-lever circuit breakers only

Circuit

breaker

Page 38

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

38

Electrical installation - Tumble dryer type 50

Only

one

cable

for control and

motor

Gas heating, circuit breaker ratings, power consumption and voltages

208 - 240V 3AC 60 Hz 1.5 kW 15A

208 - 240V 1AC 60 Hz 1.0 kW 15A

120V 1AC 60 Hz 1.0 kW 15A

Voltage Total

input

Gas

Note: Use common-trip, single-lever circuit breakers only

Circuit

breaker

Page 39

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

39

Electrical installation - Tumble dryer type 75

Only

one

cable

for con-

trol and

motor

Gas heating, circuit breaker ratings, power consumption and voltages

208 - 240V 3AC 60 Hz 2.0 kW 15A

208 - 240V 1AC 60 Hz 2.0 kW 15A

120V 1AC 60 Hz 2.0 kW 20A

Voltage Total

input

Gas

Note: Use common-trip, single-lever circuit breakers only

Circuit

breaker

Page 40

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

40

Fit the enclosed manual gas shutoff valve

upstream from the dryer.

The gas connection to the machine should be

sized for to an output of 71600, 136400 or

151200 Btu/h depending upon the size of the

machine.

The machine is fitted with a general gas burner.

The factory nozzle pressure setting corresponds

to the fuel value given on the nameplate.

Note: If converting to a different type of gas,

an appropriate sign (supplied) must replace

the existing plate on the machine.

Check that the nozzle pressure and fuel value

agree with the values given in the table. If not,

contact your gas supplier.

Bleed the pipe system before connecting the

machine.

After connection, test all joints for leaks.

The dryer and its individual shutoff valve must

be disconnected from the gas supply piping system during any pressure testing of that system at

test pressures in excess of 1/2 psig (3.5 kPa).

The dryer must be isolated from the gas supply

piping system by closing its individual manual

shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or greater than 1/2 psig (3.5 kPa).

A minimum

1

/8inch NPT plugged tap, accessible

for test gage connection, must be installed

immediately upstream of the gas supply connections to the dryer.

For gas valves, pressure

and adjustment tables,

see pages regarding gas

valves.

It is your responsibility to have all plumbing connections made by a qualified professional to insure that the gas plumbing installation is adequate and conforms with

local and state regulations or codes. In the absence of such codes, ALL plumbing

connections, material, and workmanship must conform to the applicable requirements of the National Fuel Gas Code ANSI Z223.1-LATEST EDITION.

Gas installation

1

1

Tumble dryer

Pressure regulator

(optional) LPG only

Gas shutoff valve

1

/8” NPT plugged tap

Page 41

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

41

Gas installation

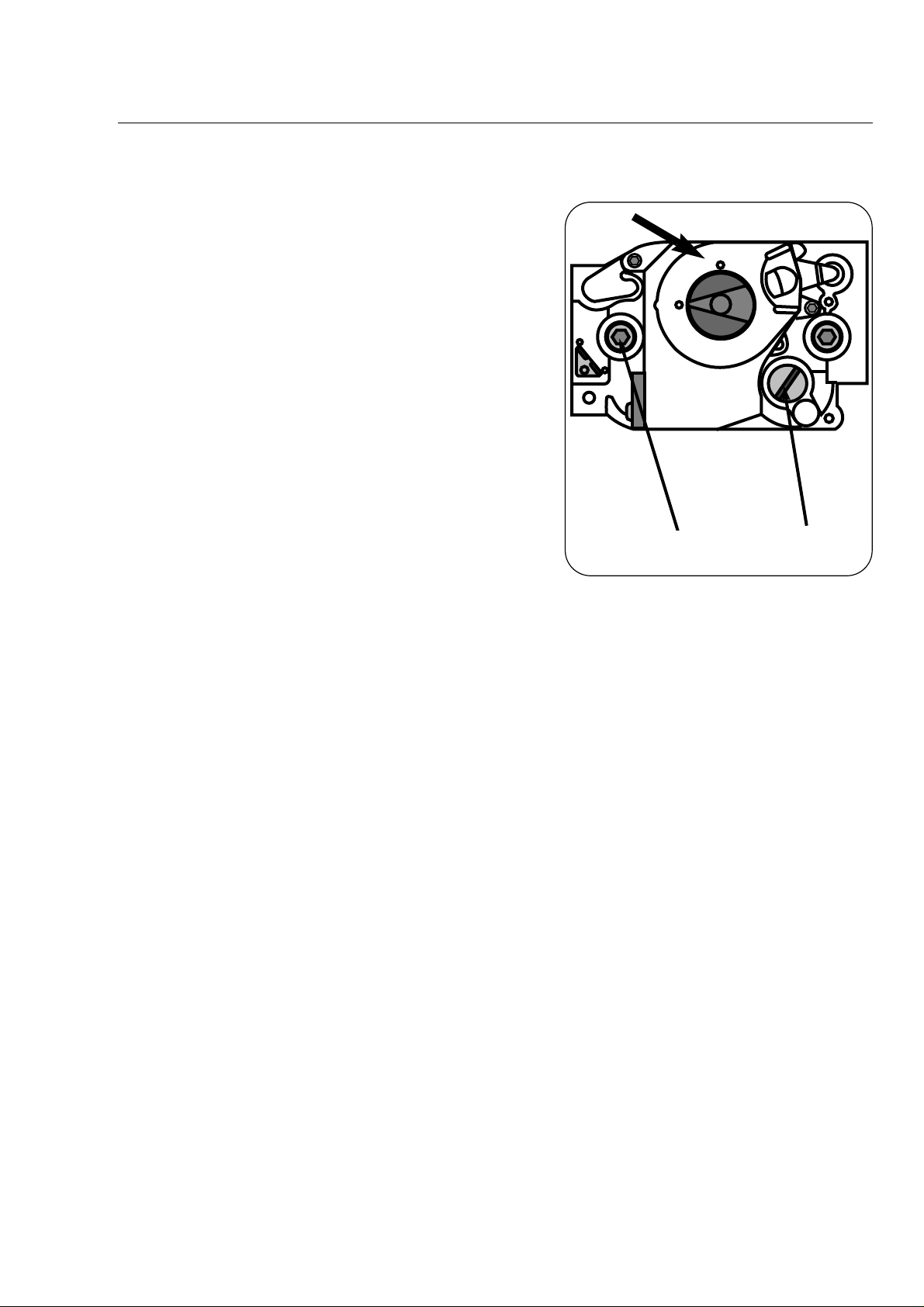

Test run

Turn gas control knob to OFF.

Remove outlet pressure tap plug from gas con-

trol and connect a manometer (pressure gauge)

to the outlet pressure tap (5). (See pages

regarding gas valves).

Turn gas control knob to ON position.

If necessary, adjust pressure regulator screw

under cap screw (3), as follows:

1. Remove pressure regulator adjustment cap

screw.

2. Turn adjustment screw clockwise to increase

or counterclockwise to decrease gas pressure to

main burner.

Select a program with heat and start the

machine.

Check that the gas is burning evenly and with a

bluish flame.

After testing replace cap screw and tighten firmly

to prevent gas leakage. Close the service panel

and place the machine in service.

ON

OFF

3

5

Page 42

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

42

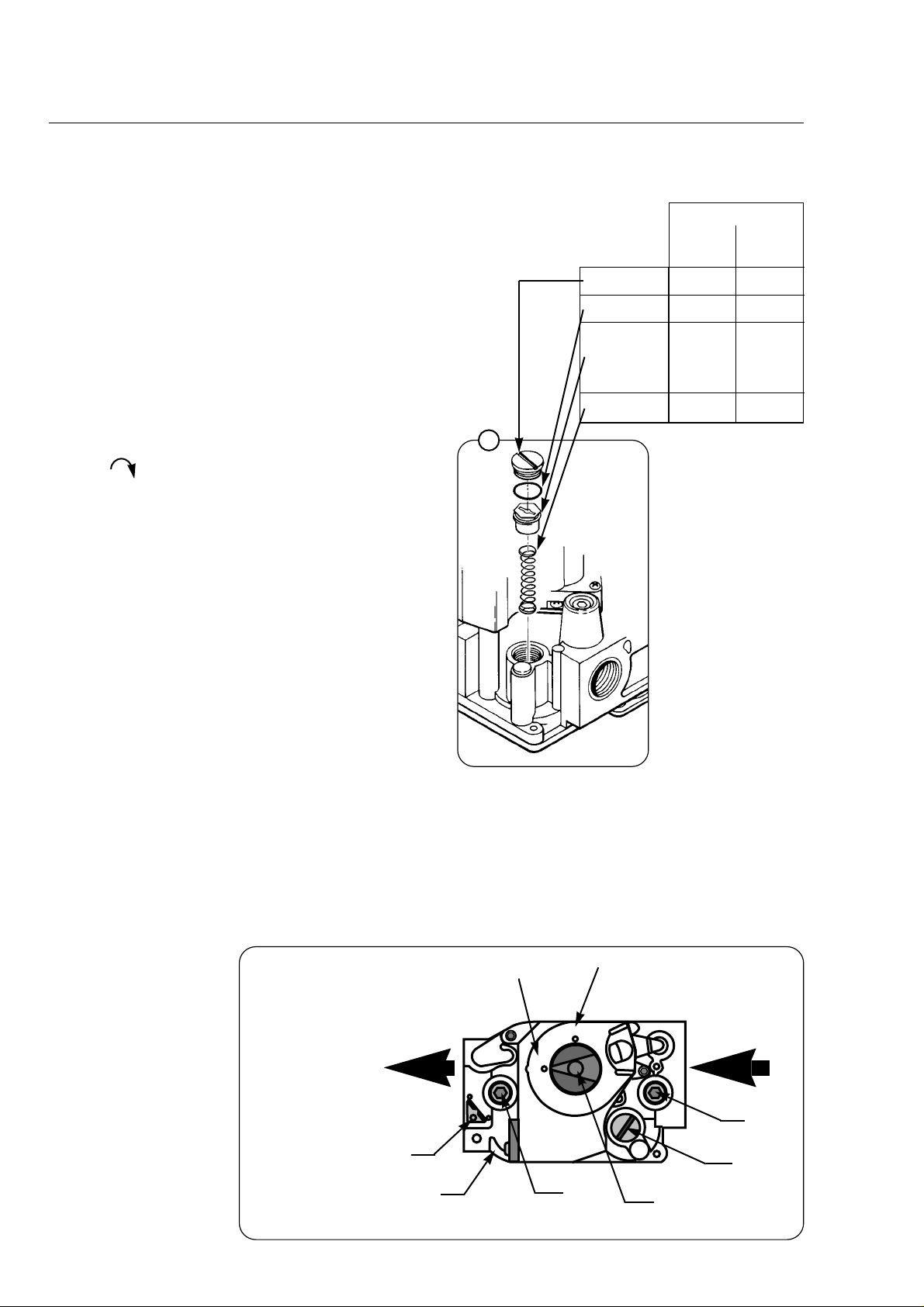

To convert from one gas to another:

1. Turn off gas supply at the appliance service valve.

2. Remove regulator cap screw and pressure regulator adjusting screw. Refer to Fig. 1.

3. Remove the existing spring.

4. Insert the replacement spring. Refer to Fig. 1.

5. Install the new plastic pressure regulator adjustment screw. Assure that the screw top is flush with

the regulator top.

6. Turn pressure regulator adjustment screw clockwise

eleven complete turns. The preliminary pres-

sure setting is approximately

11.0 in. wc (2.7 kPa)

for LP gas regulator 393691

and 3.5 in wc (0.9 kPa)

for natural gas regulator 394588

7. Check the regulator setting using a manometer.

8. Install the new cap screw and O ring.

9. Mount conversion label on the gas control.

Start-up

Gas control knob settings

OFF: Prevents main burner gas flow.

ON: Permits gas flow into gas control.

Main burner gas flow is controlled by thermostat

and automatic valve operators.

Color code for

LP

gas

Natural

gas

Cap screw

O ring

Spring

Pressure

regulator

adjusting

screw

Black

Black

White

Red

Silver

Black

White

Stainless

Steel

1

Gas installation

ON

OFF

2

4

5

6

7

3

1. Nozzle

2. Inlet pressure tap

3. Pressure regulator adjust

ment (Under cap screw)

4. Gas control knob

5. Outlet pressure tap

6. Wiring terminals

7. Ground terminals

Inlet

Outlet

Gas valve

OFF

ON

Page 43

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

43

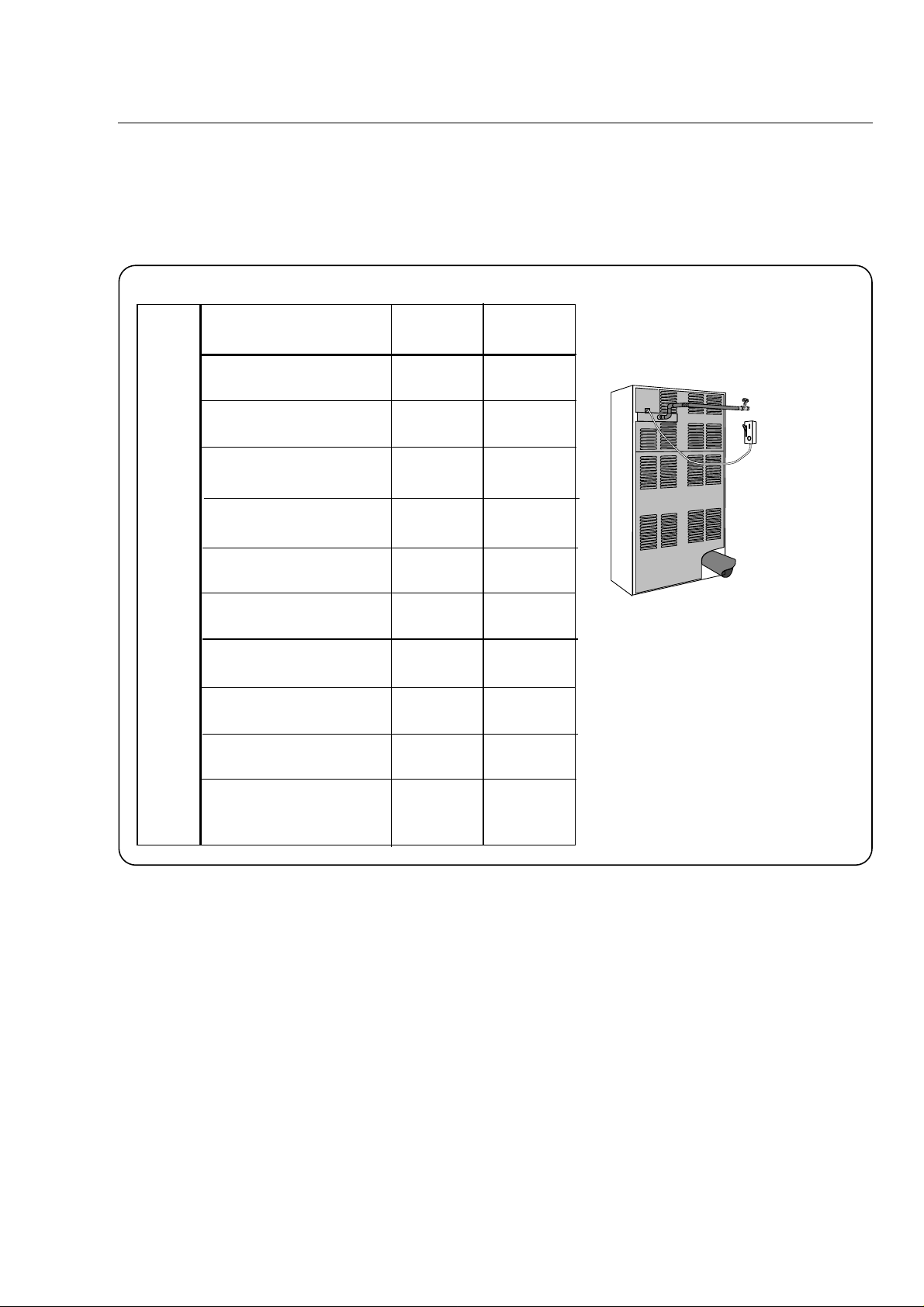

OFF

ON

OFF

ON

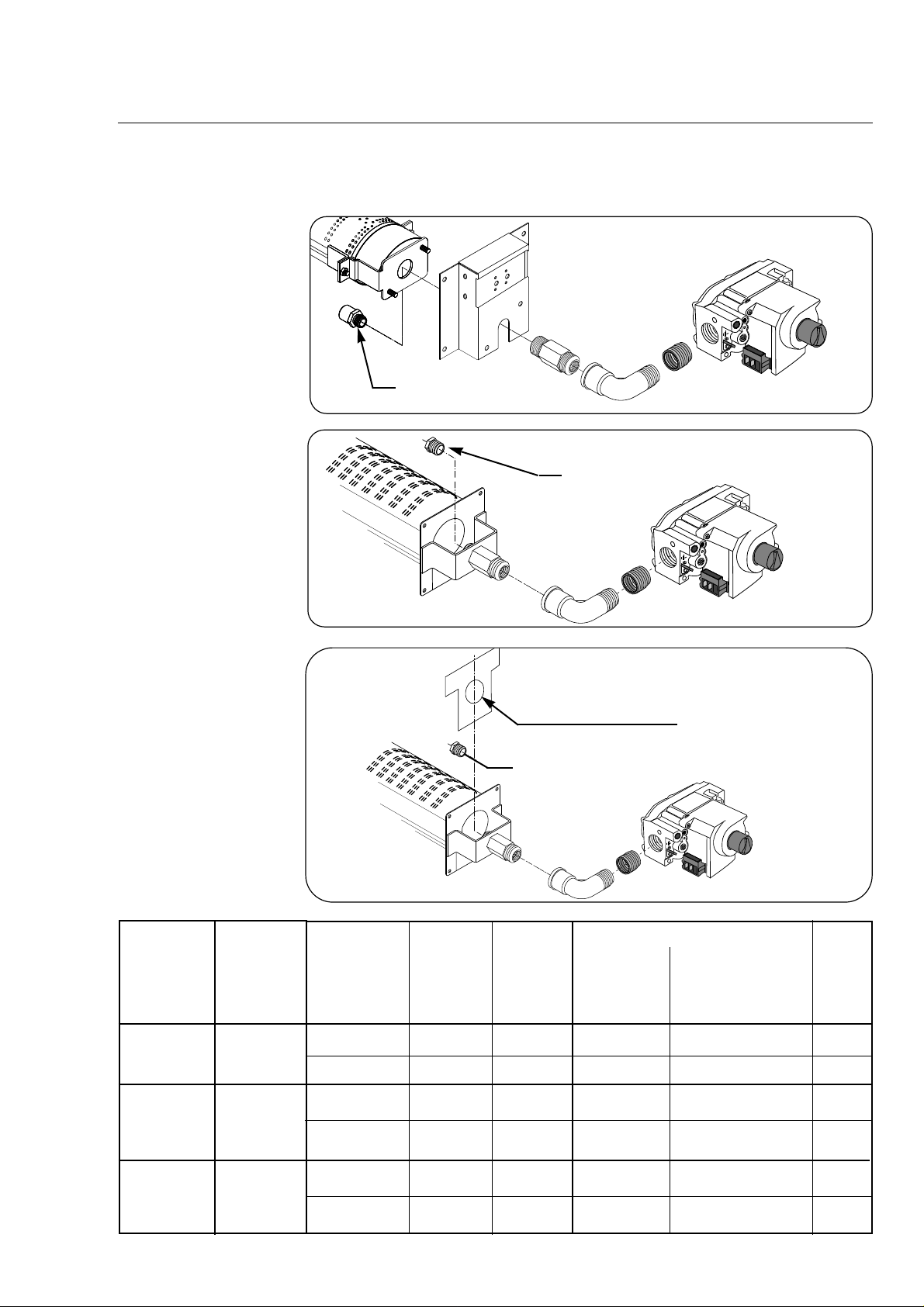

Gas type Upper Upper Gas pressure Ø

calorific wobbe- Inlet Nozzle

value index 2 1

MJ/m3 MJ/m3 inch W.C. inch W.C. mm

LPG 125.81 87.33 11.0 11.0 2.2

GNH 37.78 50.72 7.0 4.2 3.8

LPG 125.81 87.33 11.0 11.0 3.2

GNH 37.78 50.72 7.0 3.2 5.6

LPG 125.81 87.33 11.0 11.0 3.5

GNH 37.78 50.72 7.0 3.2 5.8

Nozzle pressure

(

Outlet pressure tap

)

5

Dryer

type

Heating

power

Type 50

Type 75

136400

151200

Btu/h

Type 30

71600

Dryer type 30

Gas type: LPG

GNH

Dryer type 50

Gas type: LPG

GNH

1

1

Gas installation - tumble dryer type 30, 50 and 75

OFF

ON

Dryer type 75

Gas type: LPG

GNH

Air reducingplate

A must be

mounted when

converting to

LPG and dismounted when

converting to

GNH.

Air reducing plate A

1

Page 44

Installation - gas heating

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

44

Page 45

Parameter programming

45

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

SP

X1

1

77

66

SP

X1

1

77

66

1

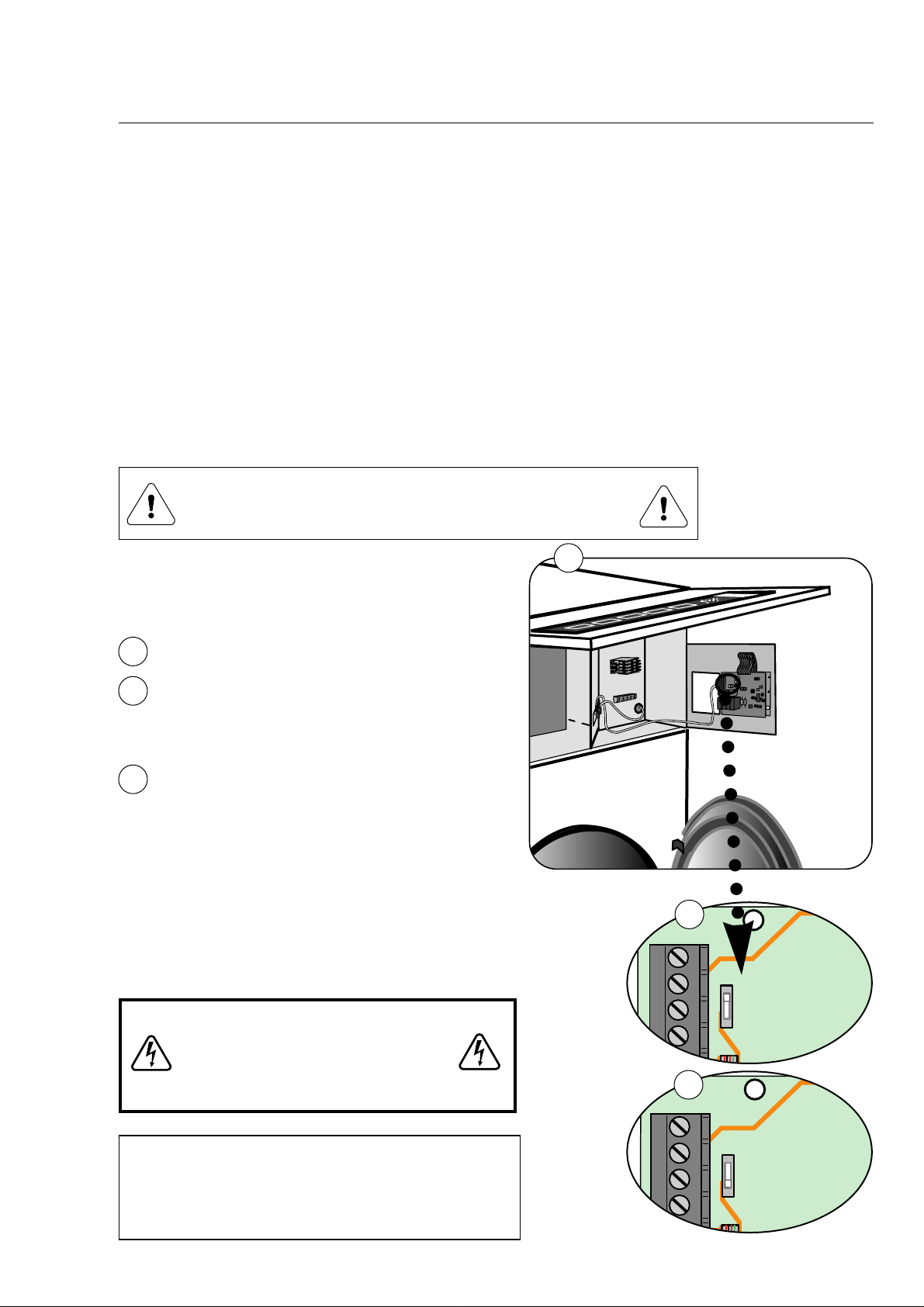

Note !! If Programming is activated

when the machine power is subsequently switched on, a test and diagnosis program will start.

Caution

The control circuit board in this dryer

contains hazardous voltages. Refer

servicing to qualified personnel.

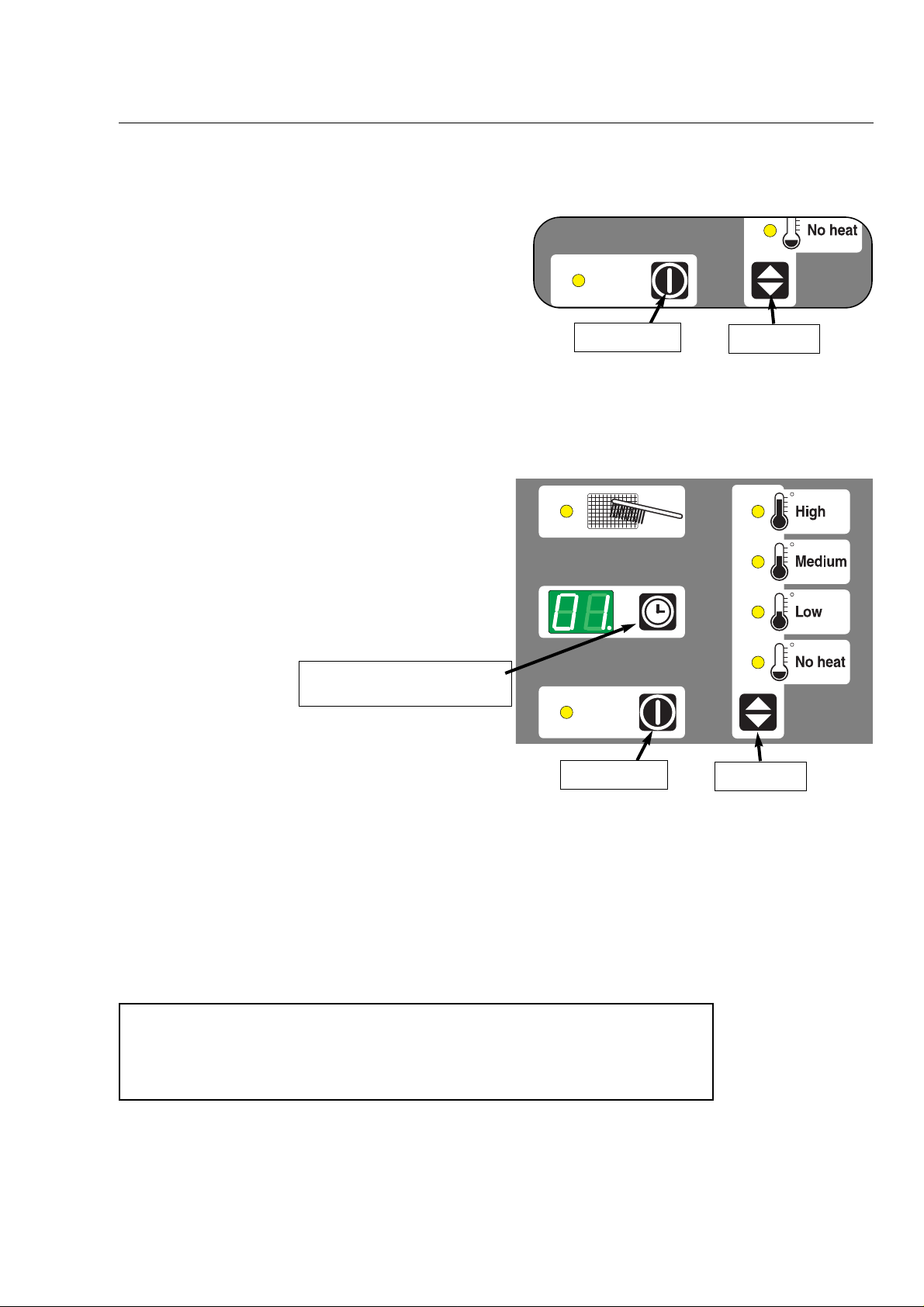

Switching to Programming mode

• Open the loading door (the door must be

kept open).

•

Open the door of the control panel.

• Move the switch on the circuit-board to position SP, fig. 2.

• Program the dryer as described on following

pages.

• End of programming. Move the switch back

to normal mode, fig. 3.

1

2

2

3

3

Programming mode

Normal mode

Programming is only to be carried out by qualified personnel.

The programming mode is used for changing (programming) preset machine values

At the factory, the dryer has been set to specific values for:

Time, temperature, cooling, reversing, etc. These values can

be adjusted in the programming mode.

The parameters must always match to the specific dryer

type.

The machine parameters can be changed by switching the

electronic control to Programming mode. The display will

read SP and the three push-buttons will now be used to

change the programming parameters, (see next page).

Page 46

Parameter programming

46

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

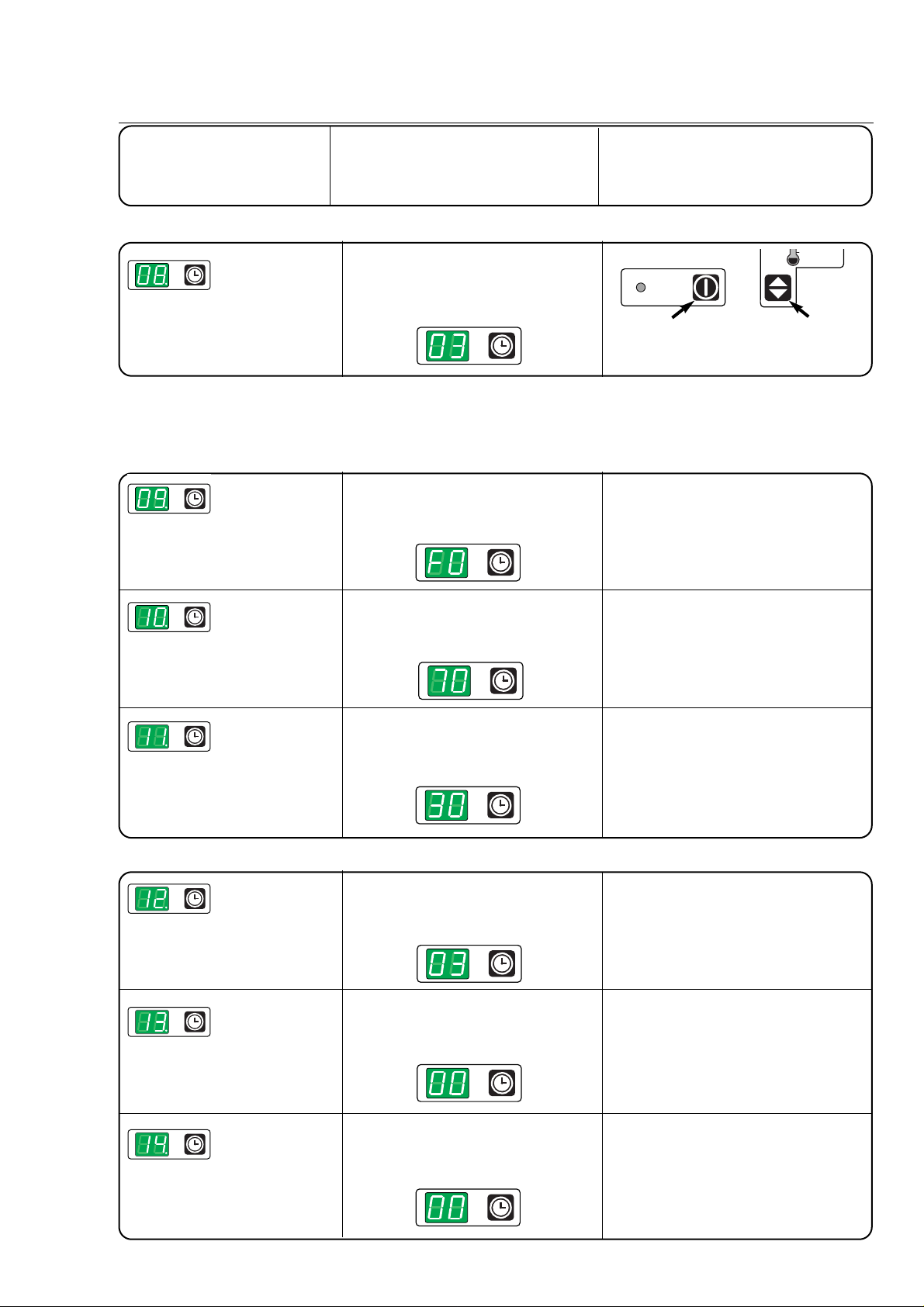

Count down

SP = Parameter Programming

Count up

Clock button:

Shift between different parameters

Control panel switched to Programming

mode.

Change of machine type

Press the clock button; the display will read 00.,

which is the first parameter

(first parameter

00

. = machine type).

The parameter numbers are shown for two seconds with a dot after the last digit.

After two seconds the machine type selected will

be displayed. In this case, where the display reads

79

, the machine is the Aqua Clean dryer with

reversing.

Control panel function in Programming mode

00.

Machine type

01.-03.

Temperature

04.

Temperature hysteresis

05.

Time interval

06.

Max. running time

07.

Running time between reversals

08.

Cooling time

09.-11.

Residual moisture levels

12.-14.

Extra drying time

Adjustable parameters:

Page 47

Parameter programming

47

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Change of machine type, continued

The machine type can be changed

byusing the buttons to count up or

down.

Change of parameters

When the machine type has been selected, push the clock button; parameter no.

01 will come up on the display: After two

seconds a value is shown that can be

changed by means of the count up/down

buttons.

Now press the clock button again; the next

parameter number will come up on the display.

After two seconds a value is shown that can

be changed by means of the count up/down

buttons, etc....

It is possible to scroll the parameters by

pushing the clock button repeatedly.

Clock button,

change to next parameter

Count down

Count up

Count down

Count up

Parameters 01.-14.

are on the following pages

Note! Parameter

06.

= maximum running time for a manual machine. If max-

imum running time on a manual machine is changed e.g. to 30 minutes, the

machine cannot run more than the maximum time, i.e. 30 minutes.

Page 48

Parameter programming

48

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Temperature setting

Reversing

Time setting

Parameter no.

check by pressing

the clock button

Value

can be set after two seconds

Required change: Press the

“count up/down” buttons.

The highest temperature

can be set to a value

between 32°C-85°C.

Factory setting = 85 (=185°F)

Temperature

program High

Count down Count up

The medium temperature

can be set to a value

between 32°C-85°C.

Factory setting = 70 (=158°F)

Temperature

program

Medium

Temperature

hysteresis

Difference

between

heat

on or off

Time interval

Running time

per push

Running time

between reversals

Max. running

time

Temperatureprogram Low

Can be set to a value

between 01°C-10°C.

Factory setting = 02 (=3.6°F)

Can be set to a value

between 0.1 and 90 minutes.

Factory setting = 3.0

Lowest temperature

can be set to a value

between 32°C-85°C.

Factory setting = 50 (=122°F)

From 0.1 to 9.9 minutes the setting can

be changed by increments of

1

/10minute per push.

From 10 to 90 minutes the setting can

be changed by increments of

1 minute per push.

Can be set to a value

between 0.1 and 90 minutes.

Factory setting = 45

Can be set to a value

between 0.1 and 9,9 minutes.

Factory setting = 5.0

From 0.1 to 9.9 minutes the setting

can be changed by increments of

1

/10minute per push.

From 10 to 90 minutes the setting can

be changed by increments of

1 minute per push.

Change the setting by

1

/10minute per push.

Next parameter

Temperature conversion

°C. . . . . . . . °F

32. . . . . . . . 90

38 . . . . . . . 100

43 . . . . . . . 110

49 . . . . . . . 120

54 . . . . . . . 130

60 . . . . . . . 140

71 . . . . . . . 160

85 . . . . . . . 185

Page 49

Parameter programming

49

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Program A1

Program A2

Program A1

Extra drying

time

in minutes

Extra drying

time

in minutes

Program A3

Extra drying

time

in minutes

Residual

moisture level

Program A3

Residual

moisture level

Residual

moisture level

Cooling time

Residual moisture level

The measurement of residual moisture level consists of a combined parameter set for residual moisture + a parameter for extra drying time.

Extra drying time

Cooling time

Running time

without

heat at end of

cycle

Count down Count up

-- --

Can be set to a value

between 00 and 10 minutes.

Factory setting = 03

Can be set to a value

between 05 and F0.

Factory setting F0

Can be set to a value

between 05 and F0.

Factory setting 70

Can be set to a value

between 05 and F0.

Factory setting 30

Can be set to a value

between 00 and 20 minutes.

Factory setting 03

Can be set to a value

between 00 and 20 minutes.

Factory setting 00

Can be set to a value

between 00 and 20 minutes.

Factory setting 00

Extra drying time when the value set

in parameter 09 has been reached.

The values for residual moisture are

given in hexadecimals (05-F0). See

explanation on following page.

Extra drying time when the value set

in parameter 10 has been reached.

Extra drying time when the value set

in parameter 11 has been reached.

Parameter no.

check by pressing

the clock button

Value

can be set after two seconds

Required change: Press the

“count up/down” buttons.

Program A2

Page 50

Parameter programming

50

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

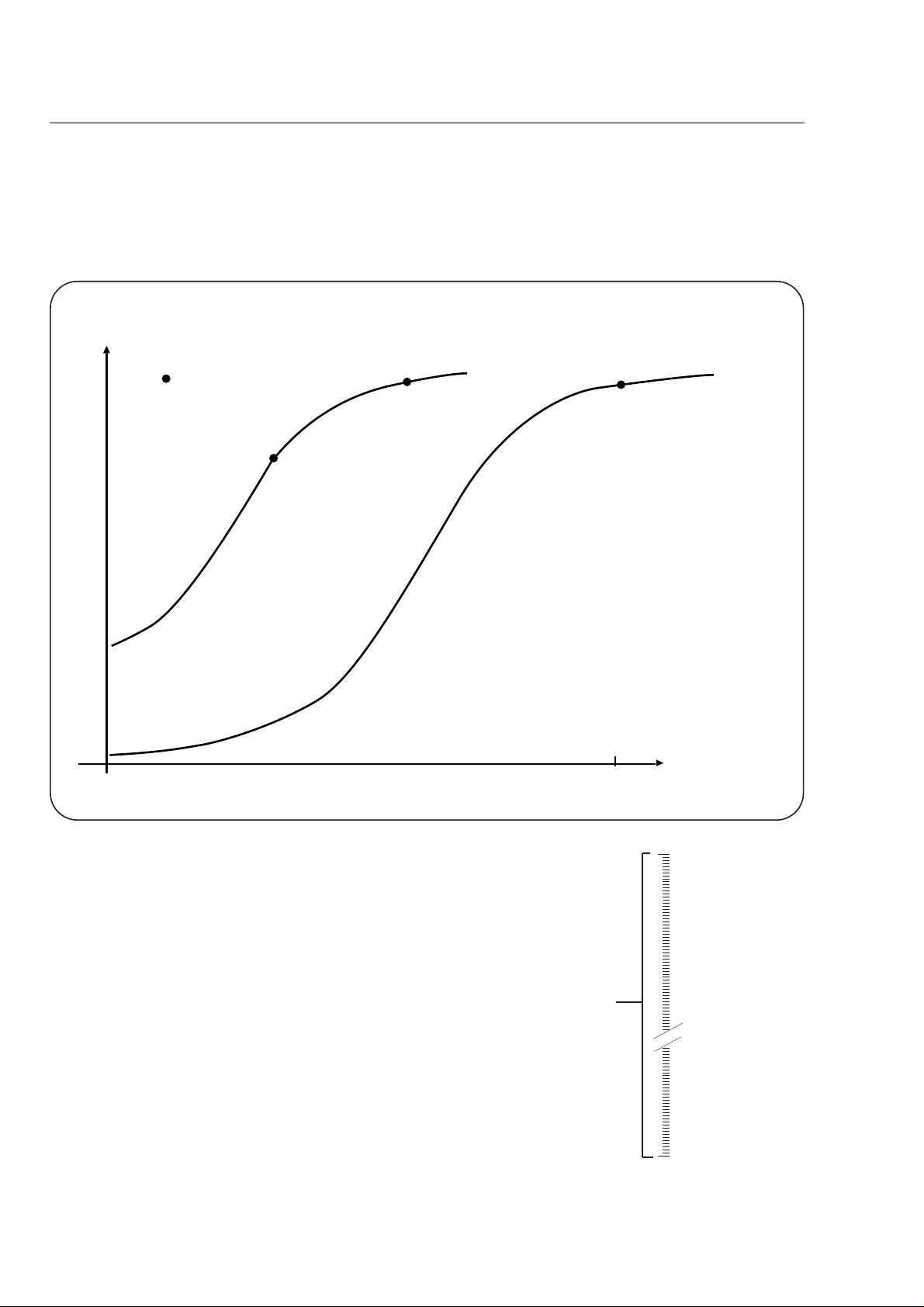

Residual moisture level

Measurement principle

Explanation of Y-axis (hexadecimal)

The values for residual moisture are

shown in the display in so-called hexadecimalformat - a series of numbers covering a

total of 16 values for each digit

(0,1,2,3,. . . . . .9,A,B,C,D,E,F). A total of 236

values can be shown in two digits.

If the clothes are not dry enough, add increments by using the “count up” button.

Total:

236 increments

%

30 20 10

0

A3 A2

A1

Residual moisture level

Curve for A1

= Factory setting

Curve for A2 and A3

25

15 5

F0

0

C0

90

60

30

A3

A2

y-axis

A1

F0

E0

D0

C0

B0

A0

40

30

20

05

00

Page 51

Parameter programming

51

487 18 94 81 - 30/50/75 - Aqua Clean

Wascomat

Quick-view parameter list

The following values are factory settings

Value/setting

00. 79 Machine type, Aqua Clean

01. 85 Program with high temperature (85°C = 185° F)

02. 70 Program with medium temperature (70°C = 158°F)

03. 50 Program with low temperature (50°C=122°F)

04. 02 Temperature hysteresis

05. 3.0 Time interval, running time pr push

06. 45 Max. time

07. 5.0 Running time between reversals

08. 03 Cooling time

09. F0 Moisture level: A1

10. 70 Moisture level: A2

11. 30 Moisture level: A3

12. 03 Extra drying time: A1

13. 00 Extra drying time: A2

14. 00 Extra drying time: A3

Parameter-

number

Parameter

Loading...

Loading...