Page 1

16 CUP 4 QT. FOOD PROCESSOR

With the LIQUILOCK™ SEAL SYSTEM and

CONTINUOUS FEED OPERATION

WFP16SCD

For your safety and continued enjoyment of this product,

always read the instruction book carefully before using.

An que votre appareil vous procure en toute sécurité beaucoup de

satisfaction, lire attentivement le mode d’emploi avant de l’utiliser.

Para su seguridad y para disfrutar plenamente de este producto,

siempre lea las instrucciones cuidadosamente antes de usarlo.

Page 2

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should

always be followed including the following:

1.

READ ALL INSTRUCTIONS.

2. Unplug from outlet when not in use, before putting on

or taking off parts, before removing food from work

bowl, and before cleaning. To unplug, grasp plug when

pulling from electrical outlet. Never pull cord.

3. Unplug from outlet prior to handling or cleaning the unit.

4. Blades are sharp. Handle carefully.

5. Your Waring

kitchen equipment, and like all other kitchen equipment,

extreme care must be used when operating it. Although

training requirements are minimal, only responsible and

prudent individuals should be allowed to operate this food

processor. It should not be used by or near children or

individuals with certain disabilities.

6. To avoid injury, never place cutting blade or disc on base

without rst having put the bowl properly in place.

7. Keep hands as well as spatulas and other utensils away

from moving blades or discs while processing food to

prevent the possibility of severe personal injury or damage

to the food processor. A plastic scraper may be used, but

must be used only when the food processor is not running.

8. To protect against risk of electrical shock, do not put base in

water or other liquids.

9. Avoid contact with moving parts. Never feed food by hand

when slicing or shredding. Always use food pusher.

10. Make sure motor has completely stopped before removing

the cover.

11. Do not operate any appliance with a damaged cord or plug,

or after appliance has been dropped or damaged in any

manner. Return appliance to the nearest authorized service

facility for examination, repair or adjustment.

12. The use of attachments not recommended or sold by

Waring Commercial may cause re, electric shock or injury.

®

Commercial food processor is a piece of

13. Do not use outdoors.

14. Do not let cord hang over edge of table or counter, or touch

hot surfaces.

15. This product is ETL listed for commercial use. Use it only for

food preparation as described in this book.

16. Do not attempt to disable the cover interlock mechanism.

17. Be certain cover is securely locked in place before operating

appliance.

18. If the machine malfunctions for any reason, discard any food

being processed at that time.

19. This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

20. Children should be supervised to ensure that they do not

play with the appliance.

SAVE THESE INSTRUCTIONS

APPROVED FOR

COMMERCIAL USE

2 3

Page 3

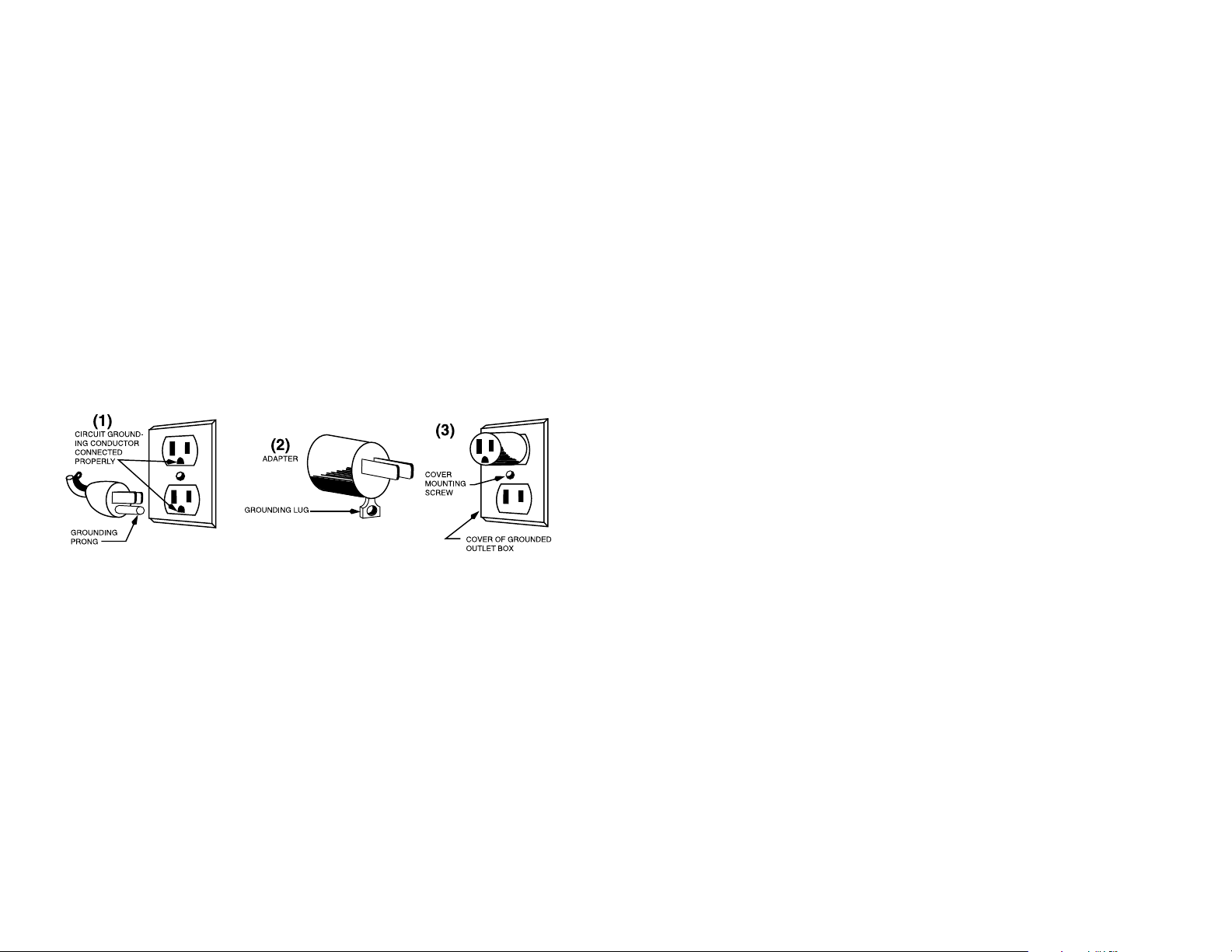

GROUNDING INSTRUCTIONS

For your protection, this appliance is equipped with a

3-conductor cordset.

120 volt units are supplied with a molded 3-prong grounding-type

plug (NEMA 5-15P), and should be used in combination with a

properly connected grounding-type outlet as shown in Figure 1.

If a grounding-type outlet is not available, an adapter as shown in

Figure 2 may be obtained to enable a 2-slot wall outlet to be used

with a 3-prong plug.

As shown in Figure 3, the adapter must be grounded by attaching

its grounding lug under the screw of the outlet cover plate.

CAUTION: Before using an adapter, it must be determined that

the outlet cover plate screw is properly grounded. If in doubt,

consult a licensed electrician. Never use an adapter unless you

are sure it is properly grounded.

INTRODUCTION

Waring® Commercial food processors are the most versatile food

processors in their class, featuring a LiquiLock

enables processing of large volumes of liquid without leakage and

the need to remove the S-blade while pouring. These professional

machines are prime examples of Waring’s seventy-ve years of

industry food service experience, as well as seventy-ve years of

food processing experience.

The WFP16SCD is both ETL and Commercial ETL listed.

This instruction book describes the WFP16SCD, which comes

with a sealed work bowl (also known as a batch bowl) and a

sealed/locked cutter blade (or S-blade) to CHOP, GRIND, PURÉE

and MIX. The patented LiquiLock

®

Seal System allows for

processing large volumes of liquids with no leakage. Additional

discs provided allow for shredding, slicing and whipping directly

in the sealed batch bowl. For large volume processing, the

WFP16SCD includes a continuous feed chute. This option allows

anything processed with an accessory disc to be processed

directly into a separate container. The WFP16SCD is the rst

of the LiquiLock

®

series food processors to introduce dicing

operation making it the most versitile LiquiLock

available.

®

Seal System that

®

food processor

Size, power and convenience

The wide feed tube makes processing high volumes of larger

sized foods convenient and easy. The motor shaft is built for

durability. The housing, work bowl, chute, covers and pushers are

all made from durable polycarbonate for heavy-use conditions

and easy cleanup. The clear bowl and processing covers are

convenient for viewing food processing and are made of

heavy-duty material to withstand heavy-duty use.

4 5

Page 4

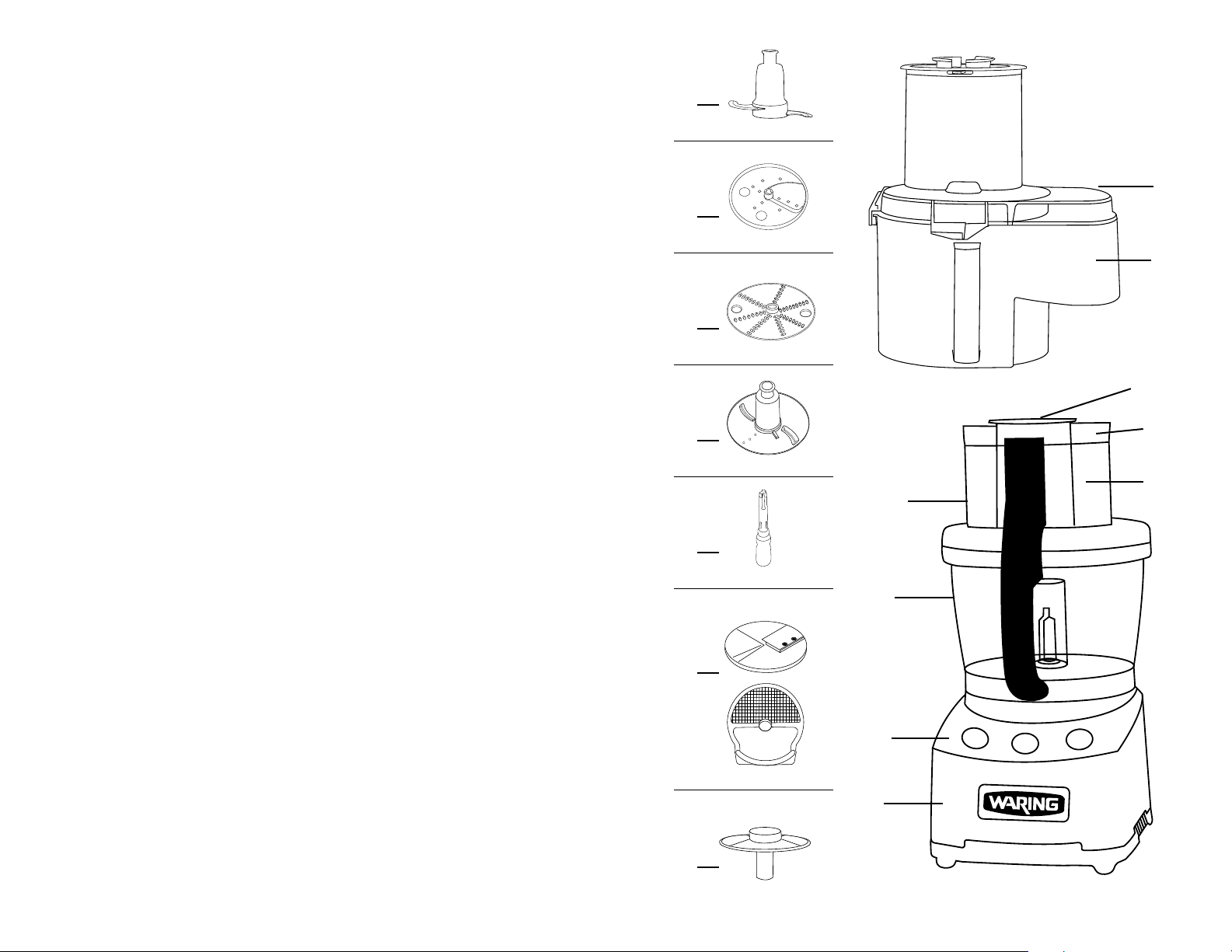

THE PARTS

The Waring WFP16SCD consists of the following standard

parts and accessories:

1. Diecast motor base with vertical heavy-duty shaft

2. Three control bottons

a. OFF

b. ON

c. PULSE

3. Safety interlock (not shown). Prevents machine from

operating until cover is in place

4. Sealed clear 4 quart (16 cups)/3.75L work bowl

5. Sealed clear work bowl cover

a. Small pusher used within the large pusher for smaller

vegetables, pepperoni, etc.

b. Large pusher with full-size and reduced-size feed

options

c. Large feed tube for maximum use of cutting surface

Note: This combination pusher allows use of the entire feed

tube for large foods and provides controlled processing for

small-diameter foods such as carrots, celery and pepperoni.

6. Sealed S-blade (cutter blade) to chop, grind, purée and mix:

Locks in place for liquid processing and easy pouring.

7. Adjustable slicing disc

8. Reversible shredding disc

9. Sealed whipping disc

10. Detachable disc stem for use with adjustable slicing disc and

reversible shredding disc

11. Dicing assembly

3

a.

b.

12. Cleaning brush (not shown)

13. Continuous feed chute

14. Continuous feed chute cover

15. Slinger

16. Dicing grid pick (not shown)

⁄8" slicing blade

3

⁄8" dicing grid

6

8

9

10

11

14

7

13

5a.

5b.

5c.

5

4

11a .

11b.

2

2a.

2b.

2c.

1

15

6 7

Page 5

ASSEMBLY OF BATCH BOWL PARTS

We will use the terms work bowl, batch bowl and cutter bowl

interchangeably throughout this instruction book. They mean the

same thing.

Prior to First Use:

• Clean and sanitize the motor base. Wash, rinse, and sanitize

the work bowl, cover, food pusher, food pusher insert and

accessories.

• Place base on a counter or table near a 3-prong electrical

outlet. Position it so you look at the front of the unit and can see

the control panel. Do not plug in the cord until the processor is

completely assembled.

• Pick up the transparent work bowl, holding it in both hands with

the handle toward you.

• Place the bowl on the base, tting its central tube over the

motor shaft on the base and placing its handle slightly to the

left of back-center (at about a 7 o’clock position).

• Press the bowl down so the lower rim ts around the circular

platform. Turn the bowl counterclockwise as far as it will go. It

will lock into position with the tabs on the sides of the

platform.

Read this if assembling the batch bowl parts to use S-blade

(cutter blade) or whipping disc.

• If processing food with the S-blade or whipping disc, now is the

time to add the food or liquid to the work bowl.

• Do not ll liquid over MAX LIQUID FILL LINE. If too much

liquid is used, it will overow. In this case, stop operation,

remove liquid to below MAX LIQUID FILL LINE and continue

processing.

Read this if assembling batch bowl parts to use accessory

discs in batch bowl.

To assemble the adjustable slicing disc (WFP16S10), you must

remove bowl cover. Position the disc stem over the drive shaft

securely. Next, select the desired thickness setting on your

adjustable slicing disc. There are 16 different positions ranging

from 1–6mm in thickness. Once you’ve set the thickness, position

the plastic receptacle over the disc stem securely. Do not turn on

the unit until the batch bowl is properly assembled with the cover.

To assemble the reversible shredding disc (WFP16S12), you must

remove bowl cover. Position the disc stem over the drive shaft

securely. Next, select the desired shredding blade size. Your

reversible shredding disc has ne shredding blades on one side

and medium shredding blades on the other. Be sure the desired

blade size is facing up, and position the disc on the disc stem

securely. Do not turn on the unit until the batch bowl is properly

assembled with the cover.

• Pick up the S-blade or whipping disc, noting the diagram on

the top of the plastic center. It matches the shape of the motor

shaft.

• Place the S-blade or whipping disc over the tip of the motor

shaft, lining up the inside of the hub with the shaft. Press it

down rmly, rotating the center hub until the blade or disc

assembly is fully seated. It should easily drop into place. Push

rmly to lock and seal S-blade or whipping disc hub in place.

Be sure it is pushed down as far as it will go. If it is not all the

way down, it may become damaged and any liquid may leak.

Push only on the center section (plastic part); never touch the

cutting blade, as it is extremely sharp.

• Check to be sure the blade or disc is all the way down by

turning it back and forth while gently pushing it down. If

properly installed and fully seated, the lower blade will be

positioned just above the inside bottom of the bowl.

8 9

NEVER ATTEMPT TO START THE FOOD PROCESSOR

WITHOUT THE COVER LOCKED INTO POSITION.

Two pushers for feed tube

There is a large food pusher and small food pusher. The large

pusher is for processing larger foods. The small pusher nests in

the large pusher and can be used for smaller products, guiding

long thin vegetables for more precise cuts, or for jobs like slicing

pepperoni. Insert the small food pusher into the large food pusher

opening. Now you are ready to insert the large pusher into the

feed tube opening.

Page 6

DISASSEMBLY OF BATCH BOWL PARTS

ALWAYS UNPLUG THE UNIT BEFORE DISASSEMBLING.

• Remove the large food pusher from the feed tube. Remove the

small pusher from the large pusher.

Disassembly when removing the S-blade or whipping

disc

• Remove the work bowl from the unit by rotating clockwise

(left) to disengage the tabs on the bottom of the bowl platform

from the work bowl. When the bowl handle is on the left

(about 7 o’clock position), you can gently lift the bowl straight

up and out.

It is recommended that you remove the bowl from the motor

base before you remove the S-blade or whipping disc.

NOTE: REMOVE ALL FOOD AND LIQUID BEFORE REMOVING

S-BLADE OR WHIPPING DISC, OR BOWL WILL LEAK.

• To remove the blade or disc, keep a slight downward pressure

on the top center hub of the blade or disc while removing the

bowl from the motor base. This will form a seal to prevent food

particles from spilling into the center tube of the bowl and onto

the motor base or the work surface. Remove all contents from

the batch bowl. Then remove the S-blade or whipping disc

from the bowl by pulling upward to unlock the seal. Handle the

S-blade with caution; the blades are extremely sharp.

Disassembly when removing an accessory disc

• Do not remove the work bowl until the accessory disc is

removed.

• To remove an accessory disc, place your ngers on the outer

edge of two opposite sides of the disc and lift. The disc should

remove easily off the disc stem. If the disc stem stays attached

to the disc, hold the disc in one hand with the stem facing away

from your hand and pull out the disc stem. Be careful not to

scrape your hand on any sharp edges.

• Remove the work bowl from the unit by rotating clockwise (left)

to disengage the tabs on the bottom of the bowl platform

from the work bowl. When the bowl handle is on the left (about

7 o’clock position), you can gently lift the bowl straight up and out.

ASSEMBLY OF CONTINUOUS-FEED CHUTE PARTS

• Clean and sanitize the motor base, and wash, rinse, and sanitize

the continuous-feed chute, cover, slinger disc, food pusher,

food pusher insert and processing tools prior to initial use.

• Place the base on a counter or table near a 3-prong electrical

outlet. Position it so that you are looking at the front of the

unit and can see the control panel. Be certain that the cord

is unplugged. Do not plug in the cord until the processor is

completely assembled.

• Pick up the continuous-feed chute, holding it in both hands with

the chute pointing in the 4-o’clock position and the handle at

the 10-o’clock position. Place the chute on the base, tting its

center opening over the motor shaft.

• Press the chute down so the round lower rim of the chute ts

around the circular platform. Rotate counterclockwise until it

clicks into place and engages the rear interlock.

• Place the slinger (or ejector disc) in the bowl, sliding it over the

metal motor shaft until it reaches the bottom of the chute.

• Select the appropriate accessory disc. Follow directions on

page 9 to attach stem to disc.

• Place the cover on top of the chute with cover locking tab at

left of locking tab on chute. Press down and rotate the cover

until it latches to the tab on the continuous-feed chute. This will

prevent the lid from rising up during processing.

• The interlock tab on the cover will slide into the interlock slot on

the cover and engage the magnetic safety interlock switch. The

interlock switch prevents operation of the machine unless the

cover is in the proper position. With this switch engaged, the

food processor will operate if the power is on and the controls

are turned to ON or PULSE.

• To assemble the dicing assembly (WFP16S13) you may use only

the continuous feed. Do not attempt to use the dicing grid in

the batch bowl. First remove the continuous-feed chute cover

and be sure that the slinger is properly installed (see above for

assembly of continuous-feed chute). Position the dicing grid so

that it ts securely on the tabs of the continuous feed chute.

Guide the stem of the slicing blade through the center hole of

the dicing grid and over the drive shaft. Be sure that the slicing

disc is completely secured on the shaft by spinning the disc

lightly until it is almost ush with the dicing grid. Do not turn on

10 11

Page 7

the unit until the continuous-feed chute is properly assembled

with the cover.

To remove dicing assembly, rst rotate dicing blade counterclockwise and lift up from the edges. Be careful not to touch

the blade when removing dicing assembly as the blades are

very sharp. Next lift the dicing grid. NOTE: Dicing assembly

(WFP16S13) is to be handwashed only. DO NOT PUT

DICING BLADE OR GRID IN DISHWASHER.

NEVER ATTEMPT TO START THE FOOD PROCESSOR

WITHOUT THE CHUTE AND COVER LOCKED INTO

POSITION.

• Insert the small food pusher into the large food pusher opening.

Now you are ready to insert the large pusher into the feed tube

opening.

• Once feed chute is assembled, place separate container under

the feed chute.

DISASSEMBLY OF CONTINUOUS- FEED

CHUTE PARTS

ALWAYS UNPLUG THE CORD BEFORE DISASSEMBLING.

• Turn the cover clockwise until the safety interlock tab on the

cover is disengaged from the safety interlock switch on the

chute, and the tabs are clear of the tabs on the cover.

• Remove the large food pusher from the feed tube. Remove the

small pusher from the large pusher.

• Remove the continuous-feed chute from the motor base. If the

chute is pointing in the 4-o’clock position, just lift it up. If not,

rotate clockwise to disengage the tabs on the bottom of the

chute platform (motor base) from the slots on the bottom of the

continuous-feed chute.

• Use caution removing accessory discs as the blades are

very sharp.

OPERATING THE CONTROLS

• Plug the machine into an electrical outlet. The outlet must be

120V, 6 0Hz.

• There are three control buttons on the base unit.

The three controls are: ON

OFF

PULSE

How they work: ON: Press the ON button to start

the motor.

OFF: Press the OFF button to stop

the motor.

PULSE: To pulse the motor, press the

PULSE button down, then

release. The motor will run as

long as you hold the button

down; it stops when you

release the button.

HOW TO USE

Continuous use

For continuous processing, use the ON button which is located in

the middle.

Pulsing

• For rapid ON/OFF operation, use the PULSE. The motor runs as

long as you hold the button down; it stops when you release the

button.

• You control the duration of each pulse by the amount of time

you hold the button down. You control the frequency of pulses

by the rate at which you press the button.

• Pulsing gives you greater control over consistancy when

chopping, blending and mixing.

• Pulsing is also useful in processing hard foods. Pulse the food

a few times to break it up into smaller parts. Then proceed with

continuous use after the pieces are broken up and easier to

process.

12 13

Page 8

• Always use the PULSE button for pulsing. Never move the

bowl and cover assembly on or off to control pulses. It is less

efcient and could damage the machine.

Large pusher

This pusher is typically used when inserting vegetables

horizontally for longer cuts.

Turning the machine off with the OFF Button.

• Always switch the food processor off by pressing and releasing

the OFF button. This assures that the power is not supplied to

the motor.

• Always switch the food processor off and wait until rotation

stops before removing the cover.

• While the safety interlock switch will turn the machine off if the

bowl is rotated clockwise or the cover is removed while running,

this should not be the means of turning the machine on or off.

• As a safety precaution, always make sure the machine is off by

pressing the OFF button before pushing down the lid.

FOOD PREPARATION

• Prepare all food items to be processed by washing and peeling

as required. Remove pits, stones, and large seeds.

• Cut vegetables, meats, cheeses, etc. into sizes that will t

into either the small or large feed tube for processing with

accessory discs.

• Preparation for slicing: Produce that is long and cylindrical such

as carrots, cucumbers and celery should be cut at at both

ends. This will provide a consistent slice for all food processed.

RESETTING THERMAL PROTECTION

The WFP16SCD Food Processor is equipped with an automatic

reset switch to protect the motor from overheating.

If your food processor stops running under heavy use, press the

OFF button and unplug the power cord. Empty the work bowl of

all its contents and discard. Allow approximately 30 minutes for

the motor to cool down.

Reassemble unit, plug the power cord back into the outlet and

run rst with the bowl empty. Put food into the bowl and continue

processing.

If your food processor does not function properly following

this procedure, discontinue use and contact a Certied Waring

Customer Service Center.

USE INSTRUCTIONS FOR S-BLADE

(CUTTER BLADE)

• The sealed S-blade (cutter blade) is designed for chopping,

grinding, puréeing, blending, mixing or kneading.

• Assemble the bowl and blade as instructed in the section titled

“Assembly of Batch Bowl Parts” (page 8).

FOOD PUSHER SELECTION

The feed tube can be used for adding ingredients while the food

processor is running. However, it is recommended that the food

pushers be left in place whenever possible to prevent splashing

and avoid unwanted additions to the work bowl.

Small pusher

This pusher is typically used when inserting vegetables vertically

for smaller cuts. It should be used when slicing foods such as

carrots, celery, pepperoni, etc. when a consistent, at result is

desired.

14 15

Chopping and mincing

• To chop or mince in the bowl, ll the bowl up to ¾ full.

• To chop or mince most effectively, use the pulse function. This

allows for better control over consistancy. Continue pulsing until

the desired consistency has been reached.

• If chopped foods are processed continuously, the food could

be processed unevenly, i.e., food on the bottom will be nely

chopped and food on the top will be more coarse.

Chopping meat

Cut meat into 1-inch (2.5 cm) pieces to ensure an even chop.

Process no more than 2.25 lb. of meat. Press the PULSE button

Page 9

3 or 4 times at a rate of 1 second on, 1 second off. If the food is

not chopped ne enough, let the processor run continuously for

a few seconds. If the machine has trouble starting, reduce the

amount of meat in the bowl and start again.

Chopping/grating hard cheese

To chop, place up to 2 lb. of uniformly cut 1-inch (2.5 cm) cubes

of chilled cheese into the bowl and pulse. For grated cheese,

pulse until the cheese is in small chunks (pea size), then allow

the processor to run continuously until you have the degree of

grating desired. Cheese with high moisture content can ball up if

processed too long.

Chopping onions, celery, cabbage, etc.

Cut onions in quarters, and other vegetables into 1-inch

(2.5 cm) cubes. Place the cubed food into the work bowl up to the

top of the bowl’s inner tube, and pulse until you reach the desired

consistency.

Note: If you let the blade run too long, the ingredients on the

bottom will become puréed or give you uneven results.

Purée or Mix

To purée tomatoes, vegetables and fruits, make sauces, or mix

and blend ingredients, place the ingredients into the bowl, turn

the unit on and allow it to run continuously until you reach the

desired consistency. Do not let the machine run unattended.

If too much liquid is used, it will overow. In this case, stop

operation, remove liquid to below the MAX FILL LINE and

continue processing.

Do not fill liquid past MAX LIQUID FILL LINE.

ACCESSORY DISC SELECTION AND USE

The food processor disc accessories are made to perform a wide

variety of food processing tasks: slicing, whipping, shredding and

dicing. Four (4) accessory discs are included with the WFP16SCD.

As of this printing they are:

WFP16S10 - Adjustable Slicing Disc

WFP16S11 - Sealed Whipping Disc

WFP16S12 - Reversible Shredding Disc

WFP16S13 - Dicing Assembly

16 17

SLICING OPERATION

• The WFP16SCD comes with an adjustable slicing disc. The

adjustable slicing disc allows you to slice foods anywhere

from 1 to 6mm thick using 16 different slicing positions!

Prior to mounting the disc onto the motor shaft (see page

9 for assembly instructions), use the knob to select desired

thickness. Once you have selected the thickness and mounted

the disc onto the unit, you may secure the cover onto the batch

bowl or continuous fed chute and remove the pusher.

• Prepare all food items to be processed by washing and peeling

as required. Remove pits, stones, and large seeds. Be sure the

food will t into the proper feed chute. Foods such as carrots,

cucumbers, etc., should be cut at at both ends to provide a

consistent slice throughout the whole product.

• With foods like cabbage, lettuce or any product that has an

undesirable core, the core should be removed. Medium size

cabbage or lettuce heads may be cut into thirds to t in the

feed chute. Larger heads may need to be quartered.

• When food preparation is complete, ll the chosen feed tube,

position the pusher, turn the machine on and monitor the

results.

• Never try to slice soft cheese. Use only hard cheese.

Mozzarella may be sliced only when well chilled around 36˚F.

• When sliced food reaches nearly full capacity of the bowl,

remove all sliced food from the bowl.

SHREDDING OPERATION

• The WFP16SCD comes with a reversible shredding disc. Both

sides on this disc produce a perfect shred, one ne, the other

medium. When assembling the shredding disc, note that the

side facing up will be the size shred produced. When the disc

is secured, you may attach the cover on the batch bowl or

continuous feed chute and remove the pusher.

• Prepare all food items to be processed by washing and peeling

as required. Remove pits, stones, and large seeds. Be sure the

food will t into the proper feed chute.

• Select which feed tube to use. Horizontal placement of foods

such as carrots and zucchini will result in a longer shredded

Page 10

product. Using the smaller chute and small pusher with food

inserted vertically will yield a shorter shredded product.

• Never try to shred soft cheese. Use only hard cheese.

Mozzarella may be shredded only when well chilled about 36˚F.

Always use PULSE operation when shredding cheese.

• When shredded food reaches nearly full capacity of the bowl,

remove all shredded food from the bowl.

SEALED WHIPPING DISC OPERATION

• The WFP16SCD comes with a sealed whipping disc. See page

8 for assembly instructions to install the whipping disc. Once

assembled, you are ready to start adding in your favorite

ingredients!

• The whipping disc makes any whipping job easy and quick.

Just pour in heavy cream and your choice of sweetening or

avor, and whip until cream is thick and uffy. For whipping

cream do not use more than 6-cups of heavy cream as it

could expand beyond the MAX FILL LINE during the process.

If cream leaks, stop operation, remove cream to below MAX

LIQUID FILL LINE and continue. Note that the seal will prevent

leaks and spills from the batch bowl cover, however when the

motor is running, the liquid could get whipped out through the

feed tube. To turn your cream into butter, keep whipping until

moisture is mostly separated from cream. Use your choice

of herbs and seasoning to make your own homemade herb

butter.

DICING OPERATION

• The dicing operation requires that product be sliced both

horizontally and vertically by the machine. The smaller the

dice required, the more difcult the cut is to achieve. Soft

or juicy product will tend to mush if the dice is too small or

the produce is too soft. Cheese and meat are the opposite

extreme. Because of the consistency of cheese and meat, it is

not recommended that this kind of product be diced. Damage

could occur to the blades and/or motor and will not be covered

under warranty.

• During the dicing operation, attention should be given to the

nished product. Any food in front of the blade should be

removed before the feed chute is relled. A visible change in

the product will occur when the dicing grid requires cleaning.

The best way to clean the grid is to remove the continuous feed

lid and the slicing plate, and use the dicing grid pick included

to push through any product in between the grid blades.

• When using dicing feature: Select dicing grid and place in chute

on top of indentations on the bowl. Pick up slicing disc and

place on drive shaft so that the blade is ush with the dicing

grid. Pulsing is the best method for this operation.

• When dicing, if the disc gets jammed, remove the lid of the

continuous feed chute rst. Remove any food jammed in the

blade opening, then rotate the slicing plate counterclockwise

slowly to loosen the slicing plate. Reassemble and continue

dicing.

• Dicing assembly is to be hand washed only.

GRATING OPERATION

Waring Commercial offers grating discs as an optional accessory.

For grating, use instructions below.

• Prepare all food items to be processed by washing and peeling

as required. Remove pits, stones, and large seeds. Be sure the

food will t into the proper feed chute.

• Never try to grate soft cheese. Use only hard cheese.

Mozzarella may be grated only when well chilled around 36°F.

• For grating cheese, it is recommended that a slight pulsating

pressure be applied with the pusher, alternating push/no push

until the cheese block is completely grated. Cheese grating

puts more strain on the food processor motor than other tasks

and may cause overheating if too much pressure is applied in

a continuous manner.

• You can typically expect to grate 10 pounds (4.5 kg) of cheese

in about ve (5) minutes.

• After fteen (15) minutes of continuous cheese grating, allow

the machine to cool.

• It is recommended that you plan your food preparation in a

manner that will allow for ve minutes of grating, followed by

ve minutes of food preparation while the machine rests.

• When grated food reaches nearly full capacity of the bowl,

remove all grated food from the bowl.

18 19

Page 11

JULIENNE DISC OPERATION

Waring Commercial offers a julienne disc as an optional accessory.

Follow the instructions below to operate.

• Prepare all food items to be processed by washing and peeling

as required. Remove pits, stones, and large seeds. Be sure the

food will t into the proper feed chute.

• If a long horizontal cut is desired – for example, squash sticks –

the food must be placed in the feed chute horizontally or on its

side. For nely chopped food results – for example, chopped

celery or nely chopped onions, you must insert the vegetables

vertically or standing up. For a very ne chop of onions, quarter

the onion and gravity-feed it through the chute.

Removing processed food from the batch bowl

1. Turn the machine off and wait for the blade to stop moving

before removing the lid and pusher.

2. If the blade holds the bowl locked when the motor stops,

move the handle of the bowl rapidly back and forth – rst

clockwise, then counterclockwise.

3. If using a disc, remove before tilting the bowl, using a spatula

to scrape off any food sticking to it. If using S-blade, it will

stay locked in the bowl when you tilt to pour. Use spatula

to scrape food out of bowl. NEVER USE FINGERS TO

REMOVE FOOD WHILE BLADE IS IN BOWL.

TROUBLESHOOTING

This section describes potential problems and the correct

solutions for them. Problems that cannot be solved with the

guidelines listed below should be referred to one of the Waring

Authorized Service Centers for assistance. A listing of authorized

service agencies is supplied with each Waring food processor.

Unit stops running during processing

• The unit may have overheated. Refer to Resetting Thermal

Protection section (page 15).

• Turn unit off and unplug.

• Remove bowl attachment.

• Remove food being processed from inside the bowl and discard.

• Allow unit to cool for 30 minutes.

• Reassemble unit, and run rst with the bowl empty, then put

food into the bowl and try again.

Unit jams or vibrates excessively

• Turn unit off and unplug.

• Disassemble the batch bowl/accessories.

• Make sure there is no food in S-blade hub (if applicable).

• Clean food off accessory discs (if applicable).

• Reassemble unit, and run rst with the bowl empty, then put

food into the bowl and try again.

Unit will not come up to full speed

• Bowl is overloaded – remove food being processed and reload

using smaller quantities.

If unit does not operate after you have followed the above

• Check outlet to be sure there is current.

• Check to be sure circuit breaker is on.

• Check to be sure the fuse is not blown if there are fuses on this

circuit.

• Call a local Waring service agency.

Unit does not start when assembled correctly

• Pull the plug and try plugging into another outlet.

• Make sure the bowl is properly positioned on the motor base,

that the bowl cover is attached properly, and that the safety

interlock tab on the cover has properly engaged the safety

interlock switch.

• Press ON button.

20 21

If food processor makes grinding noise

• Turn unit off, unplug, disassemble, check bowl and blade to see

if they have been rubbing together.

• If bowl and blade are rubbing, call your authorized Waring

service agency.

Page 12

CLEANING AND MAINTENANCE

Clean the food processor and accessories prior to initial use and

after each use. Do not use harsh abrasive-type cleaners on any

part of the food processor. Cleaning must follow ETL sanitation

guidelines.

Wash the motor shaft with a small brush.

Wash, rinse, sanitize and dry the bowl, cover, small food pusher,

large food pusher, accessory discs, and S-blade prior to initial

use and after use, unless they will be used again immediately.

With the exception of the WFP16S13 dicing assembly, these items

are all dishwasher safe, and may be cleaned and rinsed in the

dishwasher instead of manually in the sink. The dicing assembly

(WFP16S13) grid and slicing blade are to be hand washed only.

Wash and rinse all of the above items after each use.

A stiff bristle brush will help to knock food particles out of the

crevices of the discs and blades before washing. Handle very

carefully as the blades are sharp.

For manual cleaning, it is recommended that you use washing

solutions based on non-sudsing detergents, and chlorine-based

sanitizing solutions that have a minimum chlorine concentration of

100 PPM. The following washing, rinsing, and sanitizing solutions,

or their equivalents, may be used:

SOLUTION PRODUCT DILUTION IN WATER TEMPERATURE

Washing *Ajax® ¼ oz. per Hot 115°F (46°C

Sanitizer 2½ gallons

Cleaner

Powder

Rinsing Plain Water Warm 95°F (35°C)

Sanitizing **Clorox® 1 tablespoon per Cold 50°F

Institutional gallon (10–21°C)

To clean and sanitize the motor base

Clean and sanitize the motor base prior to initial use and after

each use. Unplug the unit, then wipe down the exterior surfaces

of the motor base with cloth or sponge dampened with a soluble

detergent. Next, wipe down with rinse water. Prevent liquid from

running into the motor base by wringing out all excess moisture

from cloth or sponge before using it.

NEVER IMMERSE THE MOTOR BASE IN WATER OR ANY

OTHER LIQUID.

Allow the unit to air-dry before using again.

Never use harsh, abrasive-type cleaners on any part of the

commercial food processor.

*Ajax® is a registered trademark owned by the Colgate-Palmolive Company.

**Clorox® is a registered trademark owned by the Clorox Company.

LIMITED WARRANTY

LIMITED FIVE YEAR MOTOR WARRANTY

LIMITED TWO YEAR PARTS AND LABOR WARRANTY

Waring Commercial warrants that this product’s motor shall be

free from defects in material and workmanship for a period of ve

years from the date of purchase when used with foodstuffs,

nonabrasive liquids (other than detergents) and nonabrasive

semi-liquids, providing it has not been subject to loads in excess

of indicated rating. All other components are warranted for a

period of two years from date of purchase.

Under this warranty, the Waring Commercial division will repair

or replace any part which, upon our examination, is defective in

materials and workmanship, provided the product is delivered

prepaid to the Waring Service Center, 314 Ella T. Grasso Ave.,

Torrington, CT 06790, or any factory-approved service center.

This warranty does not: a) apply to any product that has become

worn, defective, damaged or broken due to use or due to repairs

or servicing by other than the Waring Service Center or a factory

approved service center or due to abuse, misuse, overloading or

tampering; b) cover incidental or consequential damages of any

kind.

This warranty is applicable only to appliances used in the United

States or Canada; this supersedes all other express product

warranty or guaranty statements. For Waring products sold

outside of the U.S. and Canada, the warranty is the responsibility

of the local importer or distributor. This warranty may vary

according to local regulations.

This warranty is void if appliance is used on Direct Current (DC

current).

22 23

Page 13

24 25

Page 14

IMPORTANTES CONSIGNES

DE SÉCURITÉ

L'utilisation d'appareils électriques requiert la prise de précautions

élémentaires, parmi lesquelles les suivantes :

1.

LIRE TOUTES LES INSTRUCTIONS.

2. Débrancher l’appareil après usage et avant toute

manipulation (y compris vider le bol) ou entretien. Saisir

le cordon d’alimentation par la fiche pour le débrancher.

Ne jamais tirer sur le cordon.

3. Débrancher l'appareil avant toute manipulation ou entretien.

4. Les lames sont très coupantes. Manipuler avec précaution.

5. Comme c’est le cas avec tout appareil ménager, il vous

faudra être prudent lorsque vous utilisez le robot de cuisine

Waring

ne devrait être utilisé que par des personnes vigilantes.

Il ne devrait pas être utilisé par ou près d’enfants ou de

personnes souffrant d’un certain handicap.

6. An de prévenir tout risque de blessure, ne jamais installer le

couteau ou les disques avant de vous être assuré que le bol

est bien installé.

7. Tout contact avec le couteau ou le disque alors que

l’appareil est en marche pourrait provoquer des blessures

graves ou bien endommager l’appareil. Maintenir les

mains et les ustensiles loin des éléments en mouvement.

Vous pouvez utiliser une spatule en plastique une fois que

l’appareil est arrêté.

8. An de prévenir tout risque de choc électrique, ne jamais

placer le socle dans l’eau ou tout autre liquide.

9. Éviter tout contact avec les éléments en mouvement. Ne

jamais introduire la main ou les doigts dans l'entonnoir alors

que l'appareil est en marche. Utiliser le poussoir.

10. Attendre que le moteur soit à l’arrêt avant de retirer le

couvercle.

11. Ne pas utiliser l'appareil si le cordon d’alimentation

ou la che sont endommagés, s’il ne fonctionne pas

correctement, s'il est abîmé ou après qu'il soit tombé.

®

Commercial. Bien que simple d’utilisation, ce robot

Envoyer l'appareil à un service après-vente autorisé an qu’il

soit inspecté, réparé ou réglé au besoin.

12. L’utilisation d’accessoires non recommandés ou vendus par

Waring Commercial peut présenter un risque d'incendie,

d'électrocution ou de blessure.

13. Ne pas utiliser l'appareil à l'air libre.

14. Ne pas laisser le cordon pendre au bord d'une table ou

d'un plan de travail, ni entrer en contact avec des surfaces

chaudes.

15. Cet appareil, agréé ETL, est à usage commercial. Ne

l'utiliser que pour la préparation des aliments, tel que décrit

dans ce manuel.

16. Ne pas essayer de forcer le mécanisme de sécurité de

l’appareil.

17. Vérier que le couvercle est bien fermé avant de mettre

l’appareil en marche.

18. En cas de mauvais fonctionnement de l’appareil pendant

l’utilisation, jeter le contenu du bol.

19. Cet appareil ne devrait pas être utilisé par des enfants ou

des personnes souffrant d’un handicap physique, mental

ou sensoriel, ou qui ne disposent pas des connaissances

ou de l'expérience nécessaires, à moins qu'une personne

responsable de leur sécurité leur en ait expliqué le

fonctionnement ou les encadre.

20. Il convient de surveiller les enfants an de s'assurer qu'ils ne

jouent pas avec l'appareil.

GARDER CES INSTRUCTIONS

USAGE COMMERCIAL AUTORISÉ

26 27

Page 15

INSTRUCTIONS DE MISE À LA TERRE

Pour votre protection, votre appareil est doté d'un cordon avec

mise à la terre.

Les appareils de 120V sont équipés d'une che NEMA 5-15P. La

che doit être branchée dans une prise de terre correctement

congurée (Fig. 1).

Vous pouvez utiliser un adaptateur temporaire (Fig. 2) pour

brancher l’appareil dans une prise polarisée jusqu’à ce que vous

fassiez installer une prise de terre par un électricien.

An d'assurer la mise à la terre, la languette de l’adaptateur doit

être xée au boîtier par une vis en métal (Fig. 3).

ATTENTION : Vérier que le boîtier est mis à la terre avant

d'utiliser l'adaptateur. En cas de doute, demander conseil à un

électricien. Ne jamais utiliser un adaptateur, à moins qu'il ne soit

correctement mis à la terre.

INTRODUCTION

Les robots de cuisine Waring Commercial® sont les plus

polyvalents de leur catégorie. Dotés du système d'étanchéité

LiquiLock

liquide sans fuite et de vider le bol sans avoir à retirer la lame.

Ces appareils professionnels sont le fruit de 75ans d'expérience

dans la restauration et 75ans d'expérience dans la préparation

culinaire.

Le WFP16S est agréé "ETL" et "Commercial ETL".

Le WFP16S est équipé d'un bol hermétique et d'un couteau

étanche permettant de HACHER, MOUDRE, RÉDUIRE EN PURÉE

et MÉLANGER/MIXER. Le système d'étanchéité LiquiLock

est un système breveté qui permet de préparer de grands

volumes de liquide, sans fuite. Votre nouveau robot de cuisine

inclut également des disques pour émincer, trancher et battre

directement dans le bol hermétique.

Haute capacité, puissance et commodité

L'entonnoir large permet de préparer une grande quantité

d'aliments plus gros, en moindre temps. L'arbre moteur est solide

et durable. Le socle-moteur, le bol, le couvercle et les poussoirs,

faits en polycarbonate, sont résistants et faciles à nettoyer. Le

bol et le couvercle transparents sont pratiques et conçus pour

résister à l'usage intensif qu'en font les professionnels, jours

après jour.

®

, ils permettent de préparer de grands volumes de

®

28 29

Page 16

PIÈCES

Le robot multifonction WFP16S de Waring Commercial inclut les

pièces et accessoires suivants:

1. Socle moulé sous pression avec arbre moteur à usage

intensif

2. Trois boutons de commande

a. OFF (arrêt)

b. ON (marche)

c. PULSE (pulse)

3. Mécanisme de sécurité (non illustré) empêchant l’appareil de

se mettre en marche si le couvercle n’est pas bien fermé

4. Bol hermétique transparent de 3,75L

5a.

5c.

5.

5b.

5. Couvercle transparent hermétique

a. Large entonnoir, pour réduire le temps de préparation

b. Gros poussoir, idéal pour les gros aliments

c. Petit poussoir, idéal pour les aliments ns (carottes,

céleri, saucisse, etc.)

Remarque: Le petit poussoir s'emboîte dans le gros

poussoir. Ce système de poussoir 2-en-1 permet d'utiliser

l'appareil pour préparer une grande variété d'aliments.

6. Couteau étanche pour couper, hacher, réduire en purée et

mélanger. Évite les fuites et reste en place lorsqu'on vide le

bol.

7. Disque à trancher réglable

8. Disque à émincer réversible

9. Disque à fouetter hermétique

10. Adaptateur amovible pour utilisation avec le disque à trancher

réglable et le disque à émincer réversible

4.

2.

a.

6.

9.

b.

7.

c.

1.

8.

10.

30 31

Page 17

ASSEMBLAGE DU BOL NORMAL

Avant la première utilisation:

• Nettoyer et désinfecter le socle. Laver, rincer et désinfecter le

bol, le couvercle, l’entonnoir, les poussoirs et les accessoires.

• Placer l’appareil sur un plan de travail ou une table, à proximité

d'une prise de courant, et de façon à faire face aux boutons de

commande. Ne pas brancher l'appareil avant d'avoir terminé

l'assemblage.

• Tenir le bol entre les deux mains, la poignée face à vous.

• Aligner l’arbre du moteur avec le cylindre qui se trouve au

centre du bol. La poignée devrait se trouver légèrement du

côté gauche.

• Enfoncer le bol sur le socle, et le tourner dans le sens inverse

des aiguilles d’une montre jusqu’à ce qu’il se bloque.

Installation des disques

Pour installer le disque à trancher réglable (WFP16S10): Retirer le

couvercle. Enfoncer l'adaptateur amovible sur l'arbre du moteur.

Le disque à trancher réglable permet d'obtenir des tranches

de 16 épaisseurs différentes de 1 à 6mm. Régler le disque sur

l'épaisseur voulue. Une fois l'épaisseur réglée, installer le disque

sur l'adaptateur. Fermer le couvercle avant de mettre l'appareil en

marche.

Pour installer le disque à émincer (WFP16S12): Retirer le

couvercle. Enfoncer l'adaptateur sur l'arbre du moteur. Le disque

réversible a deux côté: un côté qui produit des résultats ns,

et un autre qui produit des résultats moyens. Installer le disque

sur l'adaptateur, le côté que vous souhaitez utiliser vers le haut.

Fermer le couvercle avant de mettre l'appareil en marche.

NE JAMAIS ESSAYER DE METTRE L’APPAREIL EN MARCHE

ALORS QUE LE COUVERCLE N'EST PAS BIEN FERMÉ.

Installation du couteau ou du disque à fouetter

• Tenir le couteau/disque par la partie en plastique. Notez son

axe, conçu pour s’emboîter sur l’arbre du moteur.

• Aligner l’axe du couteau/disque à fouetter avec celui du

moteur. Enfoncer, en tournant légèrement jusqu'à ce que le

couteau/disque s'emboîte. Vous ne devriez pas rencontrer

de résistance. Pousser fermement pour bloquer et assurer

l'étanchéité du couteau/disque. Vérier qu'il est bien enfoncé.

S'il ne l'était pas, il pourrait être endommagé et il pourrait y

avoir des fuites. Ne jamais toucher le couteau, celui-ci étant

très aiguisé. Toujours le tenir par la partie plastique.

• Vérier que le couteau/disque est bien engagé, en le faisant

pivoter d'avant en arrière. La lame inférieure du couteau devrait

pratiquement toucher le fond du bol.

• Si vous souhaitez utiliser l’appareil avec le couteau ou

le disque à fouetter, vous pouvez maintenant mettre les

ingrédients dans le bol.

• Ne pas dépasser la ligne "MAX". Les ingrédients liquides

pourraient déborder. Si cela se produisait, arrêter l'appareil,

puis vider partiellement le bol (jusqu'à en dessous de la ligne

MAX) avant de continuer.

32 33

Poussoir 2-en-1

Cet appareil est doté de deux poussoirs: Un gros poussoir qui

s'emboîte directement dans l'entonnoir, et un petit poussoir

qui s'emboîte dans le gros poussoir. Choisir le poussoir désiré.

Utiliser le gros poussoir pour les gros légumes. Utiliser le petit

poussoir pour les aliments requérant une coupe plus précise,

comme par exemple les petits légumes, les légumes ns ou les

saucisses. Introduire le petit poussoir au centre du gros poussoir.

Introduire le gros poussoir dans l'entonnoir.

DÉSASSEMBLAGE DU BOL NORMAL

TOUJOURS DÉBRANCHER L'APPAREIL AVANT DE LE

DÉSASSEMBLER.

• Retirer le gros poussoir de l’entonnoir. Ensuite, retirer le petit

poussoir du gros poussoir.

Désassemblage du couteau ou du disque à fouetter

• Tourner le bol dans le sens des aiguilles d’une montre pour

libérer les pattes de verrouillage. La poignée du bol devrait se

trouver du côté gauche. Soulever alors le bol.

Il est conseillé de retirer le bol du socle-moteur avant

d’enlever le couteau ou le disque à fouetter.

Page 18

REMARQUE: VIDER LE BOL AVANT DE RETIRER LE

COUTEAU OU LE DISQUE À FOUETTER.

• Appuyer sur la partie plastique du couteau/disque tout en

soulevant le bol pour le maintenir en place. Cela évitera que

les aliments dégoulinent sur le socle-moteur ou votre plan

de travail. Vider le bol. Pour retirer le couteau ou le disque

à fouetter du bol, le soulever. Manipuler le couteau avec

précaution. Les lames sont très aiguisées.

Désassemblage des disques

• Retirer le disque avant de retirer le bol.

• Prendre le disque par les bords, entre deux doigts, et le

soulever. Il devrait se dégager sans problème. Pour retirer

l'adaptateur, tenir le disque dans une main, en prenant garde

de ne pas toucher les lames ou les râpes.

• Tourner le bol dans le sens des aiguilles d’une montre pour

libérer les pattes de verrouillage. La poignée du bol devrait se

trouver du côté gauche. Soulever alors le bol.

FONCTIONNEMENT DE L'APPAREIL

• Brancher l’appareil dans une prise électrique de 120V (60 Hz).

• Les boutons de commande se trouvent face à vous.

Les trois boutons de commande sont : ON (marche)

OFF (arrêt)

PULSE (pulse)

Fonctionnement: ON: Appuyer sur ce bouton pour mettre

l'appareil en marche continue.

OFF: Appuyer sur ce bouton une fois pour

éteindre l'appareil.

Appuyer, puis relâcher le bouton PULSE

pour utiliser le mode "pulse". Le moteur

continuera à tourner aussi longtemps que

vous appuierez sur le bouton et s'arrêtera

lorsque vous le relâcherez.

INSTRUCTIONS

Mode continu

Pour utiliser l'appareil en mode continu, appuyer sur le bouton

ON.

Fonction "pulse"

• Pour utiliser la fonction pulse, appuyer sur le bouton PULSE

à plusieurs reprises. Le moteur continuera à tourner aussi

longtemps que vous appuierez sur le bouton et s'arrêtera

lorsque vous le relâcherez.

• La fonction "pulse" vous offre davantage de contrôle, car elle

permet de contrôler le nombre et la durée de chaque pulsation

avec précision. Laisser le temps aux aliments de redescendre

dans le fond du bol entre deux pulsations.

• La fonction "pulse" permet de contrôler la consistance des

aliments que vous hachez ou mixez avec plus de précision.

• La fonction "pulse" est aussi pratique pour hacher/moudre

les aliments durs. Utiliser la fonction "pulse" pour broyer les

aliments. Terminer de hacher en mode continu.

• Toujours utiliser le bouton PULSE pour contrôler les pulsations.

Ne jamais essayer de les contrôler en bougeant le bol ou le

couvercle. Cela pourrait endommager l’appareil.

Arrêt de l’appareil

Toujours éteindre l’appareil en appuyant sur le bouton OFF et

attendre que le couteau ou le disque soit complètement immobile

avant de retirer le couvercle. Cela prendra seulement quelques

secondes.

PRÉPARATION DES ALIMENTS

• Laver et peler les aliments si nécessaire. Enlever les queues,

les pépins et les noyaux.

• Couper les fruits, les légumes, le fromage ou la viande de

façon à ce que les morceaux entrent dans l’entonnoir, ou à la

taille désirée selon l'accessoire utilisé.

34 35

Page 19

• Aliments à couper en rondelles ou en tranches: Couper les

deux bouts des aliments tels que les carottes, les concombres,

le céleri, etc. Vous obtiendrez ainsi de plus belles rondelles.

Hacher ou émincer

• Placer les ingrédients dans le bol, sans dépasser les ¾ de la

hauteur de ce-dernier.

CHOIX DU POUSSOIR

Remarque - Lorsque vous utilisez le couteau:

Il est possible d'introduire des aliments dans l'entonnoir alors que

l'appareil est en marche. Toutefois, il est recommandé de laisser

le gros poussoir en place pour éviter les éclaboussures.

Petit poussoir

Le petit poussoir sert généralement à pousser les aliments

introduits à la verticale dans la goulotte au centre du gros

poussoir. Il permet d'obtenir des morceaux plus petits. Il s'utilise

typiquement pour couper les carottes, le céleri ou les saucisses

en rondelles.

Gros poussoir

Le gros poussoir sert à pousser les aliments introduits à

l’horizontale dans l'entonnoir. Il permet d'obtenir des morceaux

plus longs.

DISPOSITIF DE PROTECTION DU MOTEUR

Cet appareil est équipé d’un dispositif de protection thermique

qui arrête le moteur automatiquement en cas de surchauffe.

Si cela se produisait, arrêter et débrancher l'appareil. Vider le bol

et jeter le contenu. Laisser le moteur refroidir pendant 30 minutes.

Rebrancher l'appareil. Continuer.

Si l'appareil ne fonctionne pas comme il se doit, cesser

l'utilisation et contacter un service après-vente autorisé.

UTILISATION DU COUTEAU

• Le couteau est conçu pour hacher, broyer, réduire en purée,

mixer et pétrir.

• Installer le couteau, comme indiqué dans la section

"Assemblage du bol", avant de mettre les ingrédients dans le

bol.

36 37

• Pour obtenir de meilleurs résultats, utiliser la fonction "pulse".

Cela vous permettra de contrôler la consistance des aliments

avec plus de précision. Continuer jusqu’à obtention de la

consistance désirée.

• L’utilisation du mode continu pour broyer ou hacher pourrait

produire des résultats irréguliers (les ingrédients au fond du bol

sont broyés plus nement).

Hacher de la viande

Pour obtenir des résultats homogènes, couper la viande en

morceaux de 2,5 cm. Ne pas hacher plus de 1kg de viande

à la fois. Presser le bouton PULSE 3 ou 4 fois de suite, à un

rythme d'une seconde entre chaque pulsation. Pour obtenir une

texture plus ne, utiliser le mode continu (ON) pendant quelques

secondes. Si l’appareil a du mal à hacher, retirer un peu de viande

et continuer.

Râper/réduire en poudre du fromage dur

Couper le fromage (bien réfrigéré) en cubes de 2,5 cm et placer

les morceaux dans le bol, sans dépasser la capacité maximale

(900 g). Utiliser la fonction "pulse" pour râper le fromage et

terminer avec le mode continu pour le réduire en poudre. Vous

obtiendrez de meilleurs résultats avec des fromages secs. Les

fromages plus gras ont tendance s’empâter.

Hacher des oignons, du céleri, du chou etc.

Couper les oignons en quartiers et les autres légumes en

morceaux de 2,5 cm. Placer les morceaux dans le bol, sans

dépasser le haut du cylindre en plastique. Utiliser la fonction

"pulse" jusqu’à obtention de la consistance désirée.

Remarque: Ne pas trop hacher. Cela peut produire des résultats

irréguliers ou réduire les ingrédients qui se trouvent au fond du

bol en purée.

Page 20

Réduire en purée ou mixer

Pour réduire fruits et légumes en purée, émulsionner une sauce

ou mixer, mettre les ingrédients dans le bol et utiliser le mode

continu jusqu’à obtention de la consistance désirée. Ne pas

laisser l’appareil sans surveillance pendant le fonctionnement. Si

les ingrédients liquides débordent, c'est que le bol est trop rempli.

Si cela se produisait, arrêter l'appareil, puis vider partiellement le

bol avant de continuer.

NE PAS DÉPASSER LA LIGNE DE REMPLISSAGE MAXIMUM.

Arrêt de l'appareil

• Toujours utiliser le bouton OFF pour éteindre l'appareil. Cela

arrêtera le moteur.

• Éteindre l’appareil et attendre que le couteau soit

complètement immobile avant d’ouvrir le couvercle.

• Le mécanisme de sécurité arrêtera l’appareil si vous tournez

ou enlevez le couvercle. Toutefois, ne vous servez pas de cette

méthode pour arrêter l’appareil.

• Par précaution, toujours appuyer sur le bouton OFF avant

d'ouvrir le couvercle.

CHOIX DU DISQUE

Les disques inclus avec votre appareil sont capables de réaliser

un grand nombre de taches de préparation. Trois disques sont

inclus avec votre appareil. Au moment de l'impression, il s'agit

des accessoires suivants:

WFP16S10 - Disque à trancher réglable

WFP16S11 - Disque à fouetter hermétique

WFP16S12 - Disque à émincer réversible

UTILISATION DU DISQUE À TRANCHER

• Les accessoires accompagnant le WFP16S incluent un disque

à trancher réglable permettant d'obtenir des tranches de

16 épaisseurs différentes, de 1 à 6 mm! Régler l'épaisseur

désirée avant d'installer le disque sur l'arbre du moteur. Une

fois l'épaisseur des tranches réglée et le disque installé, fermer

le couvercle et retirer le poussoir.

• Laver et peler les aliments si nécessaire. Enlever les queues,

les pépins et les noyaux. Couper les aliments en morceaux

si nécessaire. Couper les deux bouts des aliments tels que les

carottes, les concombres, le céleri, etc. Vous obtiendrez ainsi

de plus belles rondelles.

• Retirer le cœur des légumes tels que le chou et la laitue. Les

choux/laitues de taille moyenne devront être coupés en trois

pour rentrer dans l'entonnoir. Les choux/laitues plus gros

devront être coupés en quatre.

• Après avoir préparé les aliments, les introduire dans l'entonnoir

voulu, introduire le poussoir dans l'entonnoir et allumer

l'appareil.

• Ne pas essayer de couper en tranches du fromage mou.

Utiliser du fromage dur uniquement. La Mozzarella peut être

coupée en tranches, mais seulement si elle est très froide.

• Vider le bol une fois que la capacité maximale est atteinte.

UTILISATION DU DISQUE À ÉMINCER

• Les accessoires accompagnant le WFP16S incluent un disque

à émincer réversible. Un côté du disque produit des résultats

ns, l'autre moyens. Installer le disque de façon à ce que le

côté que vous souhaitez utiliser soit vers le haut. Une fois le

disque installé, fermer le couvercle et retirer le poussoir.

• Laver et peler les aliments si nécessaire. Enlever les queues,

les pépins et les noyaux. Couper les aliments en morceaux si

nécessaire.

• Placer les aliments dans l'entonnoir désiré: Horizontalement

pour obtenir des longs bouts ; Verticalement pour obtenir des

petits bouts.

• Ne pas essayer d'émincer du fromage mou. Utiliser du

fromage dur uniquement. La Mozzarella peut être émincée,

mais seulement si elle est très froide. Congeler la Mozzarella

pendant 1 heure avant de l'émincer. Toujours utiliser la fonction

"pulse" pour émincer le fromage.

• Vider le bol une fois que la capacité maximale est atteinte.

38 39

Page 21

UTILISATION DU DISQUE À FOUETTER

• Les accessoires accompagnant le WFP16S incluent un disque

à fouetter hermétique. Installer le disque (voir les instructions en

page 8) avant de mettre les ingrédients dans le bol.

• Le disque à fouetter est facile à utiliser et offre des résultats

rapides. Pour préparer de la crème fouettée, verser simplement

la crème dans le bol et ajouter l'édulcorant ou l'arôme de

votre choix. Fouetter jusqu'à obtention de la consistance

voulue. Ne pas fouetter plus de 1,5L de crème à la fois. Cela

pourrait provoquer des fuites par l'entonnoir malgré le système

d'étanchéité du bol. Pour faire du beurre, fouetter la crème

jusqu'à ce que le petit-lait se sépare. Assaisonner à votre goût

pour préparer du beurre aromatisé.

UTILISATION DU DISQUE À JULIENNE

Les disques à Julienne Waring® Commercial sont en option.

Suivre les instructions ci-dessous pour les utiliser.

• Laver et peler les aliments si nécessaire. Enlever les queues,

les pépins et les noyaux. Couper les aliments en morceaux si

nécessaire.

• Pour couper les aliments (par exemple les courgettes) en

bâtonnets longs, coucher les aliments horizontalement dans

l'entonnoir. Pour couper les aliments (par exemple le céleri ou

les onions) en bâtonnets ns, placer les aliments debout dans

l'entonnoir. Pour couper les oignons très ns, les jeter dans

l'entonnoir alors que l'appareil est en route, un quart à la fois.

UTILISATION DU DISQUE À RÂPER

Les disques à râper Waring® Commercial sont en option. Suivre

les instructions ci-dessous pour les utiliser.

• Laver et peler les aliments si nécessaire. Enlever les queues,

les pépins et les noyaux. Couper les aliments en morceaux si

nécessaire.

• Placer les aliments dans l'entonnoir désiré: horizontalement

pour obtenir des longs bouts ou verticalement pour obtenir des

petits bouts.

Ne pas essayer de râper du fromage mou. Utiliser du fromage dur

uniquement. La Mozzarella peut être râpée, mais seulement si

elle est très froide (environ 2°C).

• Pour éviter que le moteur ne surchauffe, il est conseillé

d'appuyer puis de relâcher le poussoir tour à tour jusqu'à ce

que le fromage soit complètement râpé. Éviter de faire pression

continuellement sur le fromage. Cela pourrait faire surchauffer

le moteur.

• Le robot de cuisine est capable de râper jusqu'à 4,5 kg de

fromage en approximativement 5 minutes.

• Après 15 minutes, laisser l'appareil refroidir.

• Il est conseillé de laisser reposer l'appareil pendant 5 minutes

après 5 minutes d'opération continue.

• Vider le bol une fois que la capacité maximale est atteinte.

Comment vider le bol

1. Éteindre l'appareil et attendre que la lame soit complètement

immobile avant d'ouvrir le couvercle.

2. Retirer le bol du socle-moteur. S'il est bloqué, le tenir par la

poignée et le bouger rapidement de droite à gauche.

3. Si vous utilisez un disque, le retirer avant de vider le bol.

Si vous utilisez le couteau, il restera en place lorsque

vous viderez le bol. Vider le bol à l'aide d'une spatule. NE

PAS INTRODUIRE LES DOIGTS DANS LE BOL SI LE

COUTEAU Y EST.

RÉSOLUTION DE PROBLÈMES

Vous trouverez dans cette section la solution aux problèmes les

plus courants. Si cette liste ne solutionne pas votre problème,

veuillez contacter un service après-vente autorisé. Consulter

la liste des service après-vente autorisés, fournie avec votre

appareil.

L’appareil ne se met pas en marche

• Débrancher l’appareil et le brancher dans une autre prise de

courant.

• Appuyer sur le bouton ON.

• Vérier que le bol est bien en place, que le couvercle est bien

fermé et que les pattes de verrouillage du couvercle sont bien

engagées.

40 41

Page 22

L’appareil s’arrête pendant l’utilisation

• Il se peut que le moteur ait surchauffé. Voir la section

"Dispositif de protection du moteur".

• Éteindre et débrancher l'appareil.

• Retirer le bol du socle.

• Vider le bol.

• Laisser l'appareil refroidir pendant 30 minutes.

• Remettre le bol sur le socle-moteur, refermer le couvercle et

faire fonctionner l’appareil à vide avant de le remplir à nouveau.

L'appareil vibre ou se bloque souvent

• Éteindre et débrancher l'appareil.

• Démonter le bol et les accessoires.

• Vérier que des aliments ne soient pas coincés dans la tige du

couteau (si vous utilisez le couteau).

• Nettoyer le disque (si vous utilisez un disque).

• Remettre le bol sur le socle-moteur, refermer le couvercle et

faire fonctionner l’appareil à vide avant de le remplir à nouveau.

L’appareil n’atteint pas la vitesse maximale

• Le bol est trop chargé. Le vider et recommencer avec un

moindre contenu.

Si l'appareil ne fonctionne toujours pas correctement:

• Vérier que la prise de courant est sous tension.

• Vérier que le disjoncteur est allumé.

• Vérier que le fusible qui alimente la prise n’est pas grillé.

• Appeler le service après-vente de Waring.

NETTOYAGE ET ENTRETIEN

Nettoyer l’appareil et ses accessoires avant de l’utiliser pour

la première fois et après chaque utilisation. Ne pas utiliser de

nettoyants abrasifs. Le nettoyage doit respecter les directives de

ETL Sanitation.

Nettoyer l’arbre du moteur avec une petite brosse.

Laver, rincer, désinfecter et sécher le bol, le couvercle, l'entonnoir,

les poussoirs, le couteau et les disques avant d’utiliser l’appareil

pour la première fois et après chaque utilisation, à moins que

vous ne réutilisiez l’appareil immédiatement. Tous les éléments

sont lavables au lave-vaisselle.

Bien laver et rincer toutes les pièces après chaque utilisation.

Nettoyer le couteau et les disques à l’aide d’une brosse dure

avant de les laver. Le couteau et les disques sont très aiguisés.

Les manipuler avec précaution.

Pour le lavage à la main, nous recommandons l'utilisation d'une

solution de nettoyage à base de détergents non moussants

et d'une solution désinfectante à base de chlore, avec une

concentration minimum de 100 ppm. Vous pouvez utiliser les

solutions suivantes ou leur équivalent:

SOLUTION PRODUIT PROPORTIONS TEMPÉRATURE

Nettoyage Ajax® en poudre 7 g pour Chaude 46°C (115°F)

9,5 L d'eau

Rinçage Eau claire Tiède 35°C (95°F)

Désinfection **Eau de javel Clorox

3,8 L d'eau (50–70°F)

®

1 c. à soupe pour Froide 10–21°C

L’appareil grince

• Éteindre l’appareil, le débrancher, puis vérier si le couteau

touche le bol.

• Si le couteau touche le bol, contacter un service après-vente

autorisé.

42 43

Page 23

Nettoyage du socle-moteur

Nettoyer et désinfecter le socle-moteur avant d’utiliser l’appareil

pour la première fois et après chaque utilisation. Débrancher

l’appareil et essuyer le socle avec une éponge imbibée de

détergent liquide. Essuyer ensuite le socle avec une éponge

imbibée d’eau claire. Bien essorer l’éponge pour éviter que le

liquide ne pénètre dans le boîtier.

NE JAMAIS SUBMERGER LE SOCLE-MOTEUR DANS L'EAU

OU TOUT AUTRE LIQUIDE.

Laisser sécher l’appareil à l’air libre avant de l'utiliser à nouveau.

Ne jamais utiliser de détergents abrasifs pour nettoyer cet

appareil ou ses éléments.

*Ajax® est une marque déposée de Colgate-Palmolive Company.

**Clorox

®

est une marque déposée de Clorox Company.

GARANTIE LIMITÉE

GARANTIE LIMITÉE DE CINQ ANS (MOTEUR)

GARANTIE LIMITÉE DE DEUX ANS (PIÈCES ET MAIN D'OEUVRE)

Waring Commercial garantit le moteur de cet appareil contre tout

vice de matière ou de fabrication pendant une période de cinq

ans suivant sa date d’achat, à condition que l'appareil ait été

utilisé uniquement avec des produits alimentaires, des liquides

non-abrasifs (autres que des détergents) et des semi-liquides

non-abrasifs, à condition que l'appareil n'ait pas été soumis à

des charges excédant sa capacité maximale. Les autres pièces

sont garanties pendant une période de deux ans suivant la date

d'achat.

Au titre de cette garantie, la division Waring Commercial réparera

ou remplacera toute pièce nous paraissant afcher un vice

de matière ou de fabrication. Pour un service au titre de cette

garantie, envoyez l'appareil, port payé, à l'adresse suivante ou

amenez-le à un centre de réparation agréé : Waring Service

Center, 314 Ella T. Grasso Ave., Torrington, CT 06790.

Cette garantie a) n’est pas valable si l’appareil est endommagé,

cassé, détérioré ou s’il afche un vice ou défaut résultant de

l’utilisation, de l’entretien ou de la réparation par des personnes

non autorisées, ou consécutif à l’usage abusif ou inapproprié, à la

surcharge ou à la modication de l'appareil ; b) ne couvre aucun

dommage accessoire ou indirect.

Cette garantie n’est valable que sur les appareils utilisés aux

États-Unis et au Canada et abroge toute autre garantie formelle

ou tout autre accord de garantie. La garantie des produits Waring

vendus en dehors des États-unis et du Canada est à la charge

de l'importateur ou du distributeur local. Les droits de garantie

peuvent varier d’un pays ou d’une région à l’autre.

Brancher cet appareil sur Courant Continu (C.C.) annulera la

garantie.

44 45

Page 24

MEDIDAS DE SEGURIDAD

IMPORTANTES

Siempre que use aparatos eléctricos, debe tomar precauciones

básicas de seguridad, entre las cuales las siguientes:

1.

LEA TODAS LAS INSTRUCCIONES.

2. Desconecte el aparato cuando no esté en uso, antes

de instalar o de remover piezas, antes de vaciar el bol y

antes de limpiarlo. Para desconectar el aparato, agarre

el cable por la clavija. Nunca jale el cable.

3. Desconecte el aparato antes de cualquier manipulación o

mantenimiento.

4. Las cuchillas son muy losas. Manipular con sumo cuidado.

5. Como todo electrodoméstico, su robot de cocina Waring

Commercial debe usarse con mucha precaución. Aunque

no se necesita mucha preparación para operar este aparato,

sólo debería ser usado por personas responsables y

cuidadosas. No debería ser usado por o cerca de niños o

personas con alguna discapacidad.

6. Para reducir el riesgo de heridas, asegúrese de que el

recipiente esté debidamente ensamblado antes de instalar

la cuchilla o el disco.

7. Para reducir el riesgo de herida seria o de daño al aparato,

mantenga las manos y los utensilios alejados de la cuchilla

o del disco durante el funcionamiento. Se podrá usar una

espátula de goma, siempre en cuando el aparato esté

apagado.

8. Para reducir el riesgo de electrocución, no coloque el

bloque-motor en agua u otro líquido.

9. Evite el contacto con las piezas móviles. Nunca introduzca

la mano en la boca de llenado. Siempre utilice el empujador.

10. Espere hasta que el motor se haya detenido completamente

antes de retirar la tapa.

11. No utilice este aparato si el cordón o la clavija estuviesen

dañados, después de que hubiese funcionado mal o que se

hubiese caído o si estuviese dañado. Regrese el aparato a

un centro de servicio autorizado para su revisión, reparación

o ajuste.

46 47

®

12. El uso de accesorios no recomendados o vendidos por

Waring Commercial presenta un riesgo de incendio,

electrocución o herida.

13. No lo utilice en exteriores.

14. No permita que el cordón cuelgue del borde de la encimera

o de la mesa, ni que haga contacto con supercies

calientes.

15. Este aparato está homologado por ETL para uso

comercial. Utilícelo únicamente con el propósito para el

cual fue diseñado, según se describe en este manual de

instrucciones.

16. No intente forzar el mecanismo de seguridad de la tapa.

17. Asegúrese de que la tapa esté debidamente cerrada antes

de encender el aparato.

18. En caso de mal funcionamiento durante el uso, tire el

contenido del bol a la basura.

19. Los niños o las personas que carezcan de la experiencia

o de los conocimientos necesarios para manipular el

aparato, o aquellas cuyas capacidades físicas, sensoriales o

mentales estén limitadas, no deben utilizar el aparato sin la

supervisión o la dirección de una persona responsable por

su seguridad.

20. Asegúrese de que los niños no jueguen con este aparato.

GUARDE ESTAS

INSTRUCCIONES

APROBADO PARA

USO COMERCIAL

Page 25

INSTRUCCIONES DE PUESTA A TIERRA

Para su protección, este aparato está equipado con un cable

eléctrico con conductor de tierra.

Los aparatos de 120V están equipados con clavija tripolar de

conexión con tierra (NEMA5-15P), la cual debe ser conectada a

una toma de corriente puesto a tierra (Fig. 1).

Si una toma de corriente puesta a tierra no está disponible, se

podrá usar un adaptador para conectar el aparato a una toma de

corriente polarizada (Fig. 2).

El adaptador debe ser puesto a tierra mediante un tornillo de

metal que conecte la lengüeta del adaptador a la placa de la

toma de corriente (Fig. 3).

PRECAUCIÓN: Antes de conectar el adaptador, asegúrese de

que la toma de corriente esté puesta a tierra. Si no está seguro,

comuníquese con un electricista. Nunca use un adaptador sin

estar seguro de que la toma de corriente esté puesta a tierra.

INTRODUCCIÓN

Los robots de cocina Waring® Commercial son los aparatos

más versátiles de su categoría. Equipados con el sistema

hermético LiquiLock

líquido sin derrame y vaciar el bol sin tener que retirar la cuchilla.

Estos aparatos profesionales son el resultado de 75 años de

experiencia en la industria de la restauración y 75 años de

experiencia en preparación culinaria.

El WFP16S está homologado "ETL" y "ETL Commercial".

El WFP16S está equipado con un bol hermético y una cuchilla

hermética que permiten PICAR, MOLER, LICUAR y MEZCLAR.

El sistema hermético LiquiLock

permite procesar altas cantidades de líquido sin derrame. Su

nuevo robot de cocina también incluye discos para triturar/rallar,

rebanar y batir directamente en el bol hermético.

Alta capacidad, potencia y comodidad

La boca de llenado ancha permite procesar altas cantidades

de alimentos más grandes, en menos tiempo. El árbol motor

es sólido y duradero. El bloque-motor, el bol, la tapa y los

empujadores, hechos de policarbonato, son resistentes y fáciles

de limpiar. El bol y la tapa transparentes son prácticos y han sido

diseñados para tolerar el uso intensivo de los profesionales, día

tras día.

®

, permiten procesar altas cantidades de

®

es un sistema patentado que

48 49

Page 26

PIEZAS

El robot de cocina WFP16S de Waring Commercial cuenta con

las piezas y los accesorios siguientes:

1. Bloque-motor de fundición con resistente árbol motor

2. Tres controles

a. OFF (apagado)

b. ON (encendido)

c. PULSE (pulso)

3. Sistema de seguridad (no ilustrado) que impide que el

aparato se ponga en marcha a menos que la tapa esté

debidamente cerrada

4. Bol hermético transparente de 3.75 L

5a.

5c.

5.

5b.

5. Tapa transparente hermética

a. Boca de llenado ancha, para reducir el tiempo de

preparación

b. Empujador grande, ideal para los alimentos grandes

c. Empujador pequeño, ideal para los alimentos nos

(zanahorias, apio, salchicha, etc.)

Nota: El empujador pequeño encaja en el empujador grande.

Este sistema de empujadores 2-en-1 permite procesar una

gran variedad de alimentos.

6. Cuchilla hermética para picar, moler, hacer purés y mezclar.