Page 1

W600/

W

900 Modbus

Instruction Manual

WAL C HE M, Iwaki America Inc.

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA :

TEL: 508-429-1110 WEB: www.walchem.com

Page 2

Notice

© 2018 WALCHEM, Iwaki America Inc. (hereinafter “Walchem”)

5 Boynton Road, Holliston, MA 01746 USA

(508) 429-1110

All Rights Reserved

Printed in USA

Proprietary Material

The information and descriptions contained herein are the property of WALCHEM. Such information and

descriptions may not be copied or reproduced by any means, or disseminated or distributed without the

express prior written permission of WALCHEM, 5 Boynton Road, Holliston, MA 01746.

This document is for information purposes only and is subject to change without notice.

Statement of Limited Warranty

WALCHEM warrants equipment of its manufacture, and bearing its identification to be free from defects in

workmanship and material for a period of 24 months for electronics and 12 months for mechanical parts and

electrodes from date of delivery from the factory or authorized distributor under normal use and service and

otherwise when such equipment is used in accordance with instructions furnished by WALCHEM and for the

purposes disclosed in writing at the time of purchase, if any. WALCHEM’s liability under this warranty shall

be limited to replacement or repair, F.O.B. Holliston, MA U.S.A. of any defective equipment or part which,

having been returned to WALCHEM, transportation charges prepaid, has been inspected and determined by

WALCHEM to be defective. Replaceable elastomeric parts and glass components are expendable and are not

covered by any warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESS OR IMPLIED, AS TO

DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE OR USE,

OR ANY OTHER MATTER.

180676 Rev F

October 2018

Page 3

Table of Contents

1.0 SCOPE ............................................................................................................................................................... 1

2.0 INTRODUCTION ................................................................................................................................................ 1

3.0 OVERVIEW ........................................................................................................................................................ 1

3.1 Modbus Settings ..................................................................................................................................................................... 2

4.0 MODBUS/TCP DRIVER ...................................................................................................................................... 2

4.1 Modbus/TCP Protocol ............................................................................................................................................................ 2

4.1.1 MBAP Header .................................................................................................................................................................... 2

4.1.2 Protocol Data Unit ............................................................................................................................................................. 3

4.1.3 Modbus/TCP Function Codes ............................................................................................................................................ 3

4.1.3.1 Function Code 1, Read Coils ..................................................................................................................................... 4

4.1.3.2 Function Code 2, Read Discrete Inputs .................................................................................................................... 4

4.1.3.3 Function Code 3, Read Holding Registers ................................................................................................................ 5

4.1.3.4 Function Code 4, Read Input Registers .................................................................................................................... 5

4.1.3.5 Function Code 5, Write Single Coil ........................................................................................................................... 6

4.1.3.6 Function Code 6, Write Single Holding Register ...................................................................................................... 6

4.1.3.7 Function Code 16, Write Multiple Holding Registers ............................................................................................... 7

4.1.4 Modbus/TCP Exception Error Codes .................................................................................................................................. 7

4.2 TCP/IP Interface ...................................................................................................................................................................... 8

4.3 Data Refresh ........................................................................................................................................................................... 8

4.4 Data Encoding ........................................................................................................................................................................ 8

4.4.1 Coils and Discrete Inputs ................................................................................................................................................... 8

4.4.1.1 Boolean .................................................................................................................................................................... 8

4.4.2 Holding Register and Input Registers ................................................................................................................................. 8

4.4.2.1 16-Bit Word (Boolean) ............................................................................................................................................. 8

4.4.2.2 16-Bit Word (Bitfield) ............................................................................................................................................... 9

4.4.2.3 16-Bit Word (Status) ................................................................................................................................................ 9

4.4.2.4 16-Bit Word (Integer) ............................................................................................................................................... 9

4.4.2.5 32-Bit Value (Integer) ............................................................................................................................................... 9

4.4.2.6 32-Bit Value (Float) .................................................................................................................................................. 9

4.4.2.7 32-Bit Inverse Data Format (Integer or Float) ........................................................................................................ 10

5.0 DATA DICTIONARY .......................................................................................................................................... 10

5.1 Addressing (0- or 1-Based) ................................................................................................................................................... 10

5.2 Address Maps ....................................................................................................................................................................... 10

5.2.1 W600 Controller – I/O Channel Address Maps ................................................................................................................ 11

5.2.2 W900 Controller – I/O Channel Address Maps ................................................................................................................ 12

5.2.3 Alternate Address Maps .................................................................................................................................................. 14

5.3 Type-Specific Address Map .................................................................................................................................................. 15

5.3.1 System Address Map ....................................................................................................................................................... 15

5.3.2 Network Address Map ..................................................................................................................................................... 16

5.3.3 Sensor Input Address Maps ............................................................................................................................................. 17

5.3.3.1 Sensor Input (all types except Analog Input Flowmeter) Address Map ................................................................. 17

5.3.3.2 Analog Input Flowmeter Address Map .................................................................................................................. 18

5.3.4 Digital Input Address Maps .............................................................................................................................................. 19

5.3.4.1 Digital Input / DI State Type Address Map ............................................................................................................. 19

5.3.4.2 Digital Input / Contacting Flow Meter Type Address Map ..................................................................................... 20

5.3.4.3 Digital Input / Paddlewheel Flow Meter Type Address Map ................................................................................. 21

5.3.4.4 Digital Input / DI Counter Type Address Map ........................................................................................................ 22

5.3.4.5 Digital Input / Flow Monitor Type Address Map .................................................................................................... 23

5.3.5 Virtual Input Address Maps ............................................................................................................................................. 24

5.3.5.1 Virtual Input / Calculation & Raw Value Type Address Map .................................................................................. 24

Page 4

5.3.5.2 Virtual Input / Redundant Sensor Type Address Map ........................................................................................... 25

5.3.5.3 Virtual Input / Disturbance Type Address Map ..................................................................................................... 26

5.3.6 Relay Output Address Maps ............................................................................................................................................ 27

5.3.6.1 Relay Output / Manual Control Mode Address Map ............................................................................................. 27

5.3.6.2 Relay Output / On/Off & On/Off Disturbance Control Mode Address Map .......................................................... 28

5.3.6.3 Relay Output / Dual Setpoint Control Mode Address Map .................................................................................... 29

5.3.6.4 Relay Output / Time Proportional Control Mode Address Map ............................................................................ 30

5.3.6.5 Relay Output / Intermittent Sampling Control Mode Address Map ...................................................................... 31

5.3.6.6 Relay Output / Bleed And Feed Control Mode Address Map ................................................................................ 32

5.3.6.7 Relay Output / Bleed Then Feed Control Mode Address Map ............................................................................... 33

5.3.6.8 Relay Output / Flow Timer Control Mode Address Map ....................................................................................... 34

5.3.6.9 Relay Output / Counter Timer Control Mode Address Map .................................................................................. 35

5.3.6.10 Relay Output / Target PPM Control Mode Address Map ....................................................................................... 36

5.3.6.11 Relay Output / PPM By Volume Control Mode Address Map ................................................................................ 37

5.3.6.12 Relay Output / Flow Meter Ratio Control Mode Address Map .............................................................................. 38

5.3.6.13 Relay Output / Volumetric Blend Control Mode Address Map .............................................................................. 39

5.3.6.14 Relay Output / Percent Timer Control Mode Address Map ................................................................................... 40

5.3.6.15 Relay Output / Event Timer Control Mode Address Map ...................................................................................... 41

5.3.6.16 Relay Output / Biocide Timer Control Mode Address Map ................................................................................... 42

5.3.6.17 Relay Output / Spike Control Mode Address Map ................................................................................................. 43

5.3.6.18 Relay Output / Probe Wash Control Mode Address Map ...................................................................................... 44

5.3.6.19 Relay Output / Plating Control Mode Address Map .............................................................................................. 45

5.3.6.20 Relay Output / Plating Follow Control Mode Address Map ................................................................................... 46

5.3.6.21 Relay Output / Lag Output Control Mode Address Map........................................................................................ 47

5.3.6.22 Relay Output / Alarm Control Mode Address Map ................................................................................................ 48

5.3.7 Pulse Relay Output Address Maps ................................................................................................................................... 49

5.3.7.1 Pulse Relay Output / Manual Control Mode Address Map .................................................................................... 49

5.3.7.2 Pulse Relay Output / Pulse Proportional Control Mode Address Map .................................................................. 50

5.3.7.3 Pulse Relay Output / Flow Proportional Control Mode Address Map ................................................................... 51

5.3.7.4 Pulse Relay Output / Pulse PID Control Mode Address Map ................................................................................. 52

5.3.7.5 Pulse Relay Output / Pulse Disturbance Control Mode Address Map ................................................................... 53

5.3.7.6 Pulse Relay Output / Lag Output Control Mode Address Map .............................................................................. 54

5.3.8 Analog Output Address Maps .......................................................................................................................................... 55

5.3.8.1 Analog Output / Manual Control Mode Address Map ........................................................................................... 55

5.3.8.2 Analog Output / Retransmit Mode Address Map .................................................................................................. 56

5.3.8.3 Analog Output / Proportional Control Mode Address Map ................................................................................... 57

5.3.8.4 Analog Output / Flow Proportional Control Mode Address Map .......................................................................... 58

5.3.8.5 Analog Output / PID Control Mode Address Map ................................................................................................. 59

5.3.8.6 Analog Output / Disturbance Control Mode Address Map .................................................................................... 60

5.3.8.7 Analog Output / Lag Output Control Mode Address Map ..................................................................................... 61

5.3.9 Alternate Address Maps .................................................................................................................................................. 62

5.3.9.1 Alternate Sensor Input Address Map ..................................................................................................................... 62

5.3.9.2 Alternate Digital Input Address Map ..................................................................................................................... 63

5.3.9.3 Alternate Virtual Input Address Map ..................................................................................................................... 64

5.3.9.4 Alternate Relay Output Address Map .................................................................................................................... 65

5.3.9.5 Alternate Analog Output Address Map ................................................................................................................. 66

5.3.9.6 Alternate Control Output Address Map ................................................................................................................. 67

5.4 Status Register Codes ........................................................................................................................................................... 68

5.5 Alarm Bitfields ...................................................................................................................................................................... 70

5.5.1 System Alarm Bitfield ...................................................................................................................................................... 70

5.5.2 Network Alarm Bitfield .................................................................................................................................................... 70

5.5.3 Sensor Input Alarm Bitfield ............................................................................................................................................. 71

5.5.4 Digital Input Alarm Bitfield .............................................................................................................................................. 71

5.5.5 Virtual Input Alarm Bitfield .............................................................................................................................................. 72

5.5.6 Relay & Control Output Alarm Bitfield ............................................................................................................................ 72

5.5.7 Analog Output Alarm Bitfield .......................................................................................................................................... 73

Page 5

1.0 SCOPE

This document is a User Interface Specification for the Walchem Modbus/TCP product feature for W600

and W900 Controllers. It contains mapping of the various dynamic variables to their Modbus/TCP

address locations.

This document supports the Modbus/TCP feature on controller software versions 3.01 and higher.

2.0 INTRODUCTION

The Modbus/TCP feature allows the Walchem controller to communicate with PC-based applications

such as WonderWare and Intellution HMI/SCADA programs, Building Energy Management systems,

Distributed Control Systems (DCS), as well as stand-alone HMI devices.

The controller is a Modbus Server, meaning that it can respond to requests from the HMI device. The

controller cannot initiate the flow of information. For example, it will not immediately send a new alarm

message. It will wait until the HMI device requests the current data contained in specific address

locations.

If the HMI device does not directly support the Modbus/TCP protocol, then a protocol translation

gateway may be required to convert from Modbus/TCP to a protocol that the device supports. Please

note that Modbus/RTU requires a serial interface, not Ethernet, and therefore is not directly compatible

with the Walchem controller.

3.0 OVERVIEW

Modbus/TCP, also known as Modbus TCP/IP, is a form of Modbus that uses the TCP/IP layers as a base

for controlling the communications between different devices. This is not to be confused with Modbus

over TCP/IP, which Walchem controllers do not support.

The Modbus/TCP protocol supports multiple types of data transactions, from reading single bits per

transaction, to advanced object-oriented operations. However, to ensure the most compatible system

available, only a basic subset of these functions is supported in the controller.

The official Modbus/TCP protocol supports data addresses 5 digits in length. A de facto extended

standard exists which supports data addresses 6 digits in length. However, to ensure compatibility, the

Modbus/TCP feature supports only 5-digit data address system.

The Modbus/TCP feature supports reading and writing of single-bit Coils and 16-bit Holding Registers, as

well as read-only single-bit Discrete Inputs and 16-bit Input Registers. These data formats allow the

controller to establish blocks that contain all the process variables, set points, alarms, and input/output

status values that are made public to a Modbus/TCP client. These blocks of data are packaged so that it

can be read in 8-bit chunks (for a group of up to 8 Coils or Discrete Inputs) or 16-bit chunks (for a single

Holding Register or Input Register), regardless of the type of data within it. In the following sections, the

formatting, storing, and reading of this data are described.

1

Page 6

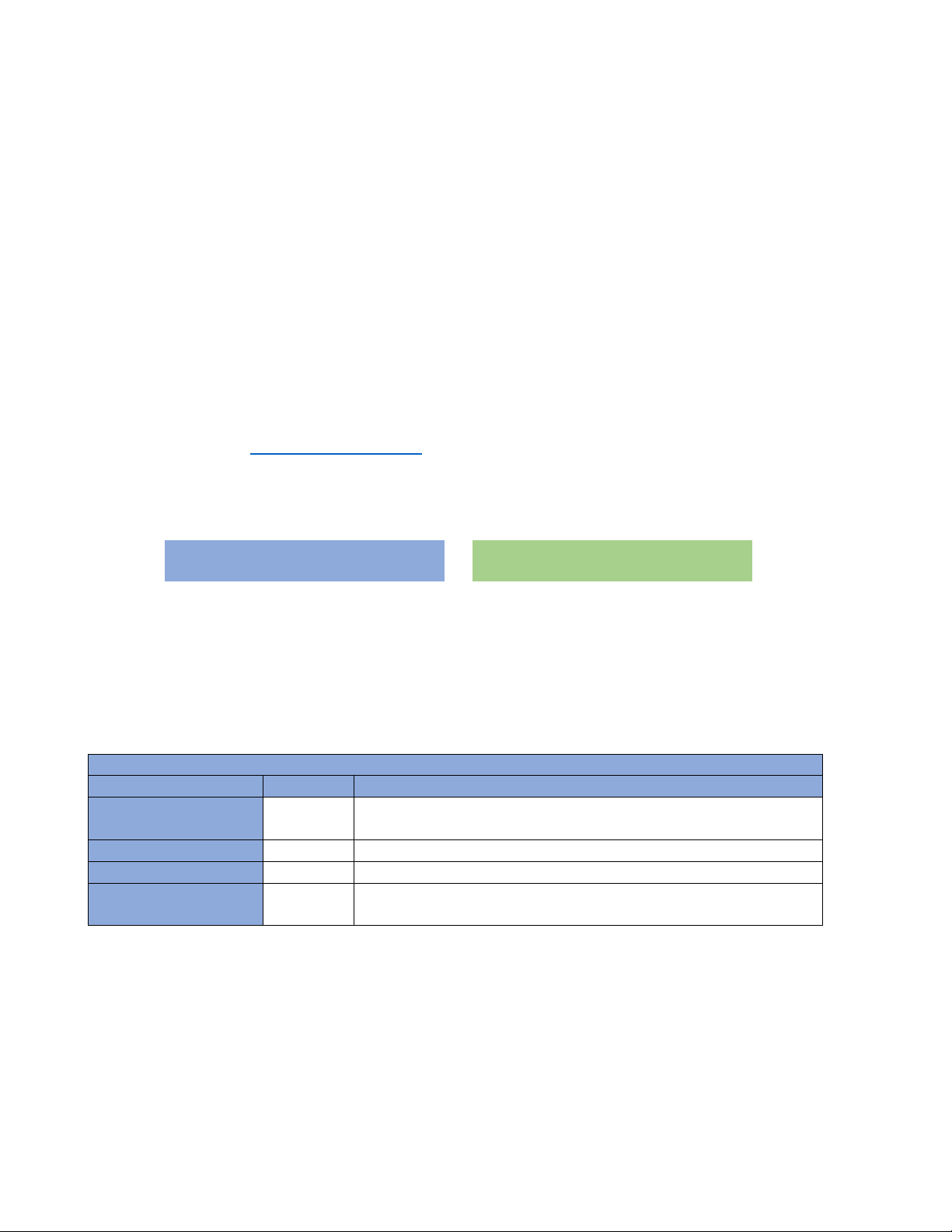

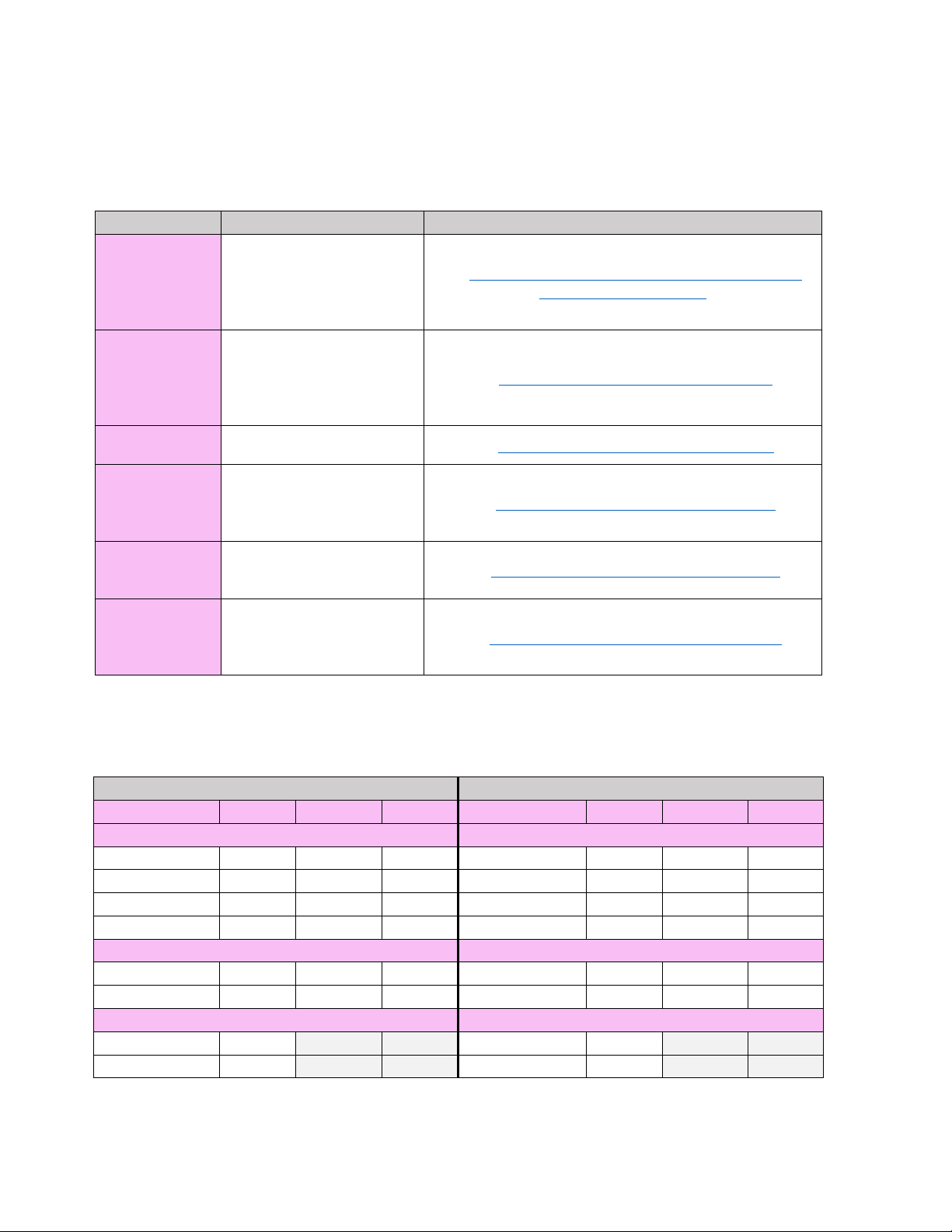

3.1 Modbus Settings

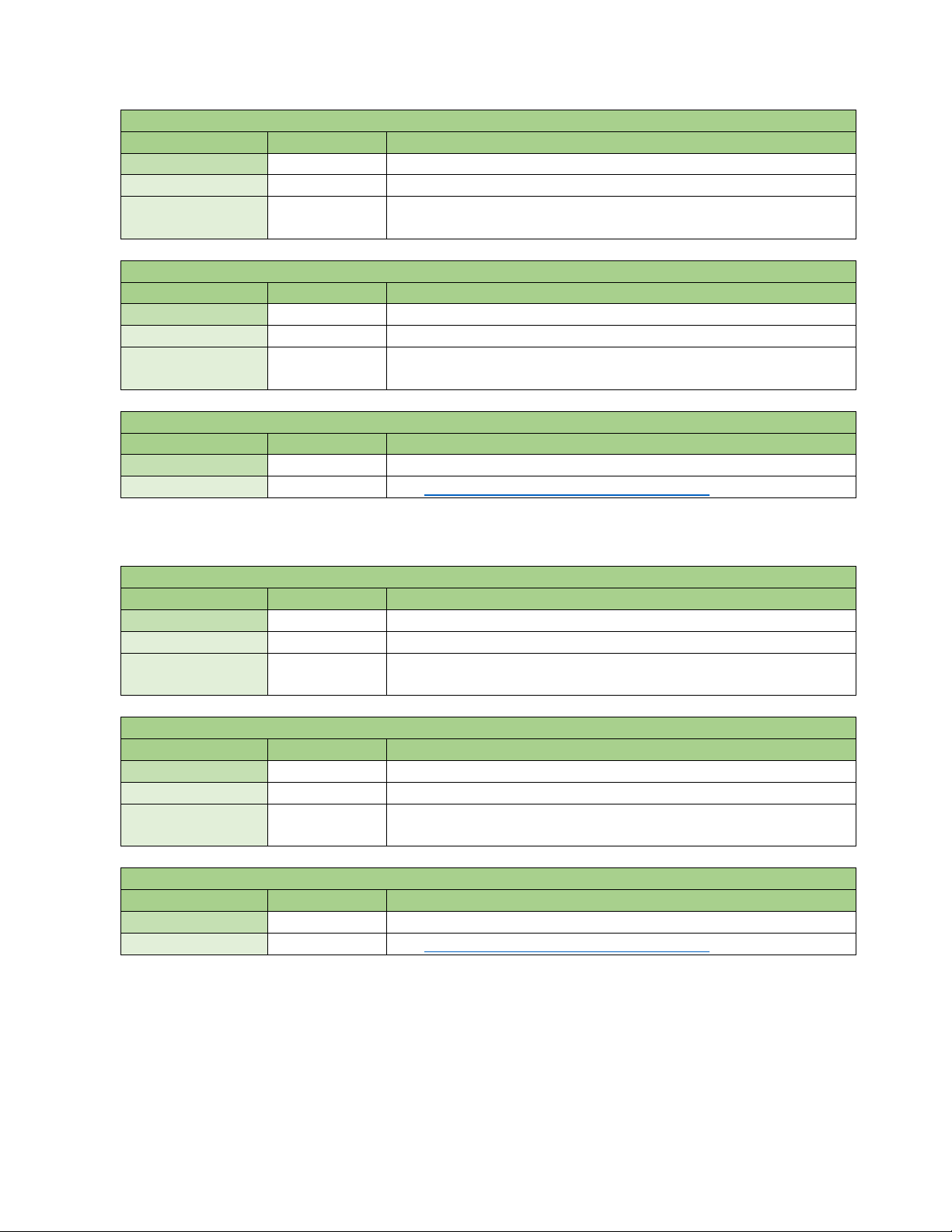

Modbus Application Protocol (MBAP)

Header

Modbus Application Protocol (MBAP) Header

Name

Size

Description

Identification of Request/Response transaction.

Copied from request to response

Protocol Identifier

2 bytes

0 = Modbus protocol.

Length

2 bytes

Number of following bytes (includes the Unit Identifier and PDU)

Identification of Remote Device.

Can be used for broadcasting (unsupported).

Settings relating to the Modbus/TCP feature can be configured in the Remote Communication

Configuration Menu.

The ‘Verbose Logging’ setting is used to generate an Event log entry for every Modbus message into and

out of the controller. The information may be used in conjunction with an HMI log when

troubleshooting communications during commissioning. However, the additional logging adds a

significant load on the controller’s systems. Therefore, this feature should only be enabled temporarily

while actively troubleshooting communications. The setting automatically reverts to Disabled when the

controller is restarted.

Detailed information on the Remote Communication Configuration Menu can be found in the controller

Instruction Manual.

4.0 MODBUS/TCP DRIVER

4.1 Modbus/TCP Protocol

The Modbus protocol, as well as the Modbus/TCP variant, is well documented in the specifications

which are available at http://www.modbus.org

supporting and organizing the Modbus protocol.

The Modbus/TCP Application Data Unit (ADU) consists of 2 distinct sections:

, a website established by the Modbus Organization for

Protocol Data Unit (PDU)

The total size of the ADU is between 9 and 263 bytes, depending on the function code and number of

data addresses requested.

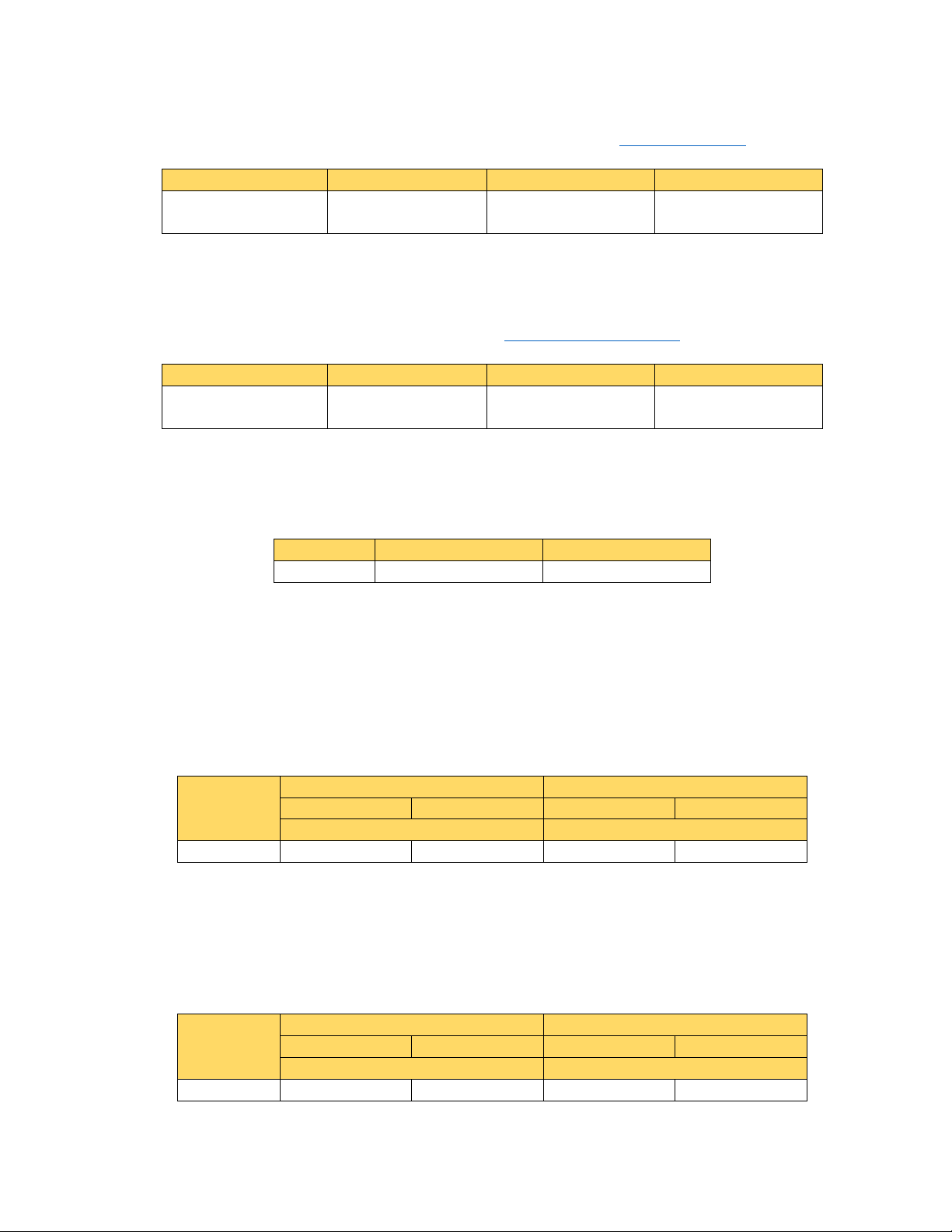

4.1.1 MBAP Header

The Modbus/TCP extension adds 7 additional bytes to the original Modbus protocol, which allows for

the transport over the TCP/IP layers. These 7 bytes make up the MBAP Header:

Transaction Identifier 2 bytes

Unit Identifier 1 byte

The Unit Identifier has a special consideration in the Modbus/TCP implementation. If the value is 0, then

the request is a broadcast message and the packet will be processed, but no response will be generated.

If the value is non-zero, the packet will be processed and a response will be returned.

Normally the Slave ID, which is not present in the Modbus/TCP protocol, will be set in the HMI client

software to 1. The broadcast Unit Identifier address is not supported by the controller; all supported

function codes require a response message at all times.

2

Page 7

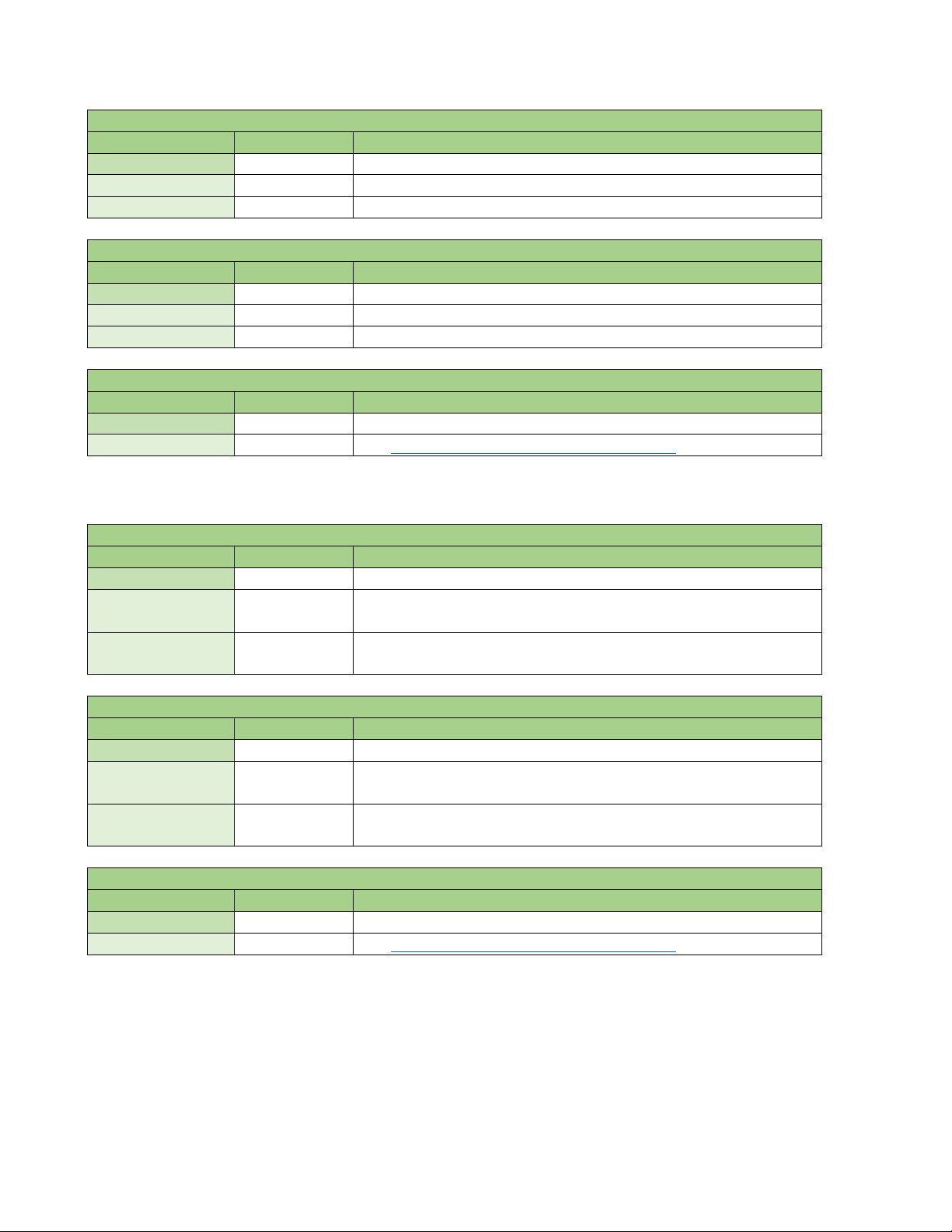

4.1.2 Protocol Data Unit

Protocol Data Unit (PDU)

Name

Size

Description

Function Code identifier.

Can be any of the hexadecimal codes listed in the Function Code table.

1 – 255

byte(s)

Payload for request/response transactions.

Varies depending on function code and number of addresses requested.

Supported Function Codes

Function

Code

Data Address

Range

FC1

(0x01)

Read up to 2000 consecutive 1-bit Coils within a single

request/response cycle.

FC2

(0x02)

Read Discrete

Inputs

Read up to 2000 consecutive 1-bit Discrete Inputs

within a single request/response cycle.

FC3

(0x03)

Read Holding

Registers

Read up to 125 consecutive 16-bit Holding Registers

within a single request/response cycle.

FC4

(0x04)

Read Input

Registers

Read up to 125 consecutive 16-bit Input Registers

within a single request/response cycle.

FC5

(0x05)

Write a single 1-bit Coil within a single

request/response cycle.

FC6

(0x06)

Write Single

Holding Register

Write a single 16-bit Holding Register within a single

request/response cycle.

FC16

(0x10)

Write Multiple

Holding Registers

Write up to 125 consecutive 16-bit Holding Registers

within a single request/response cycle.

The Protocol Data Unit (PDU) is made up of between 2 and 256 bytes, depending on the function and

number of data addresses requested:

Function Code 1 byte

Data Payload

4.1.3 Modbus/TCP Function Codes

The Modbus/TCP Server feature supports the following function codes:

Name Description

Read Coils

0xxxx

1xxxx

4xxxx

3xxxx

Write Single Coil

0xxxx

4xxxx

4xxxx

The consecutive address limitations of the Coils, Discrete Inputs, Holding Registers, and Input Registers

were established for the Modbus/TCP standard to maintain consistency with the original Modbus

protocol standard, even though a TCP/IP packet can contain a larger payload.

The Modbus/TCP feature allows for Function Codes 1 and 2 to be used interchangeably for read

requests. For example, a read coils (FC1) request for data addresses 00605 through 00610 will always

return the same result as a read discrete inputs (FC2) request for data addresses 10605 through 10610.

Likewise, the Modbus/TCP feature allows for Function Codes 3 and 4 to also be used interchangeably for

read requests. For example, a read holding registers (FC3) request for data addresses 40587 through

40590 will always return the same result as a read input registers (FC4) request for data addresses

30587 through 30590. All addresses accessible as a Coil or Discrete Input may also be accessed as a

Holding Register or Input Register.

Only the 4 least significant digits of the data address are explicitly stated in the Modbus message, with

the most significant (5

th

) digit being derived from the function code. However, generally the entire

5-digit data address must be specified in the Tag Database of an HMI.

3

Page 8

4.1.3.1 Function Code 1, Read Coils

Read Coils Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x01).

Starting Address

2 Bytes

The data address of the first Coil to read.

Quantity of Coils

2 Bytes

The number of Coils requested, maximum of 2000 per message.

Read Coils Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x01).

Byte Count

1 Byte

The number of data bytes to follow.

Coil Status

1-125 Bytes

8 Coils per byte, up to 2000 Coils per message.

Read Coils Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x81).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

Read Discrete Inputs Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x02).

Starting Address

2 Bytes

The data address of the first Discrete Input to read.

Quantity of

Discrete Inputs

The number of Discrete Inputs requested, maximum of 2000 per

message.

Read Discrete Inputs Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x02).

Byte Count

1 Byte

The number of data bytes to follow.

Discrete Input

Status

8 Discrete Inputs per byte, up to 2000 Discrete Inputs per

message.

Read Discrete Inputs Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x82).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

4.1.3.2 Function Code 2, Read Discrete Inputs

2 Bytes

1-125 Bytes

4

Page 9

4.1.3.3 Function Code 3, Read Holding Registers

Read Holding Registers Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x03).

Starting Address

2 Bytes

The data address of the first Holding Register to read.

Quantity of

Holding Registers

The total number of Holding Registers requested, maximum of

125 per message.

Read Holding Registers Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x03).

Byte Count

1 Byte

The number of data bytes to follow.

Holding Register

Values

1 Holding Register for every 2 bytes, maximum of 125 Holding

Registers per message.

Read Holding Registers Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x83).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

Read Input Registers Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x04).

Starting Address

2 Bytes

The data address of the first Input Register to read.

Quantity of Input

Registers

The total number of Input Registers requested, maximum of 125

per message.

Read Input Registers Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x04).

Byte Count

1 Byte

The number of data bytes to follow.

Input Register

Values

1 Input Register for every 2 bytes, maximum of 125 Input

Registers per message.

Read Input Registers Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x84).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

2 Bytes

2-250 Bytes

4.1.3.4 Function Code 4, Read Input Registers

2 Bytes

2-250 Bytes

5

Page 10

4.1.3.5 Function Code 5, Write Single Coil

Write Single Coil Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x05).

Coil Address

2 Bytes

The data address of the Coil to which to write.

Coil Value

2 Bytes

The value to write to the Coil (0xFF00 = On, 0x0000 = Off).

Write Single Coil Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x05).

Coil Address

2 Bytes

The data address of the Coil written.

Coil Value

2 Bytes

The value written to the Coil (0xFF00 = On, 0x0000 = Off).

Write Single Coil Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x85).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

Write Single Holding Register Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x06).

Holding Register

Address

Holding Register

Value

Write Single Holding Register Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x06).

Holding Register

Address

Holding Register

Value

Write Single Holding Register Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x86).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

4.1.3.6 Function Code 6, Write Single Holding Register

2 Bytes The data address of the Holding Register to which to write.

2 Bytes The value to write to the Holding Register.

2 Bytes The data address of the Holding Register written.

2 Bytes The value written to the Holding Register.

6

Page 11

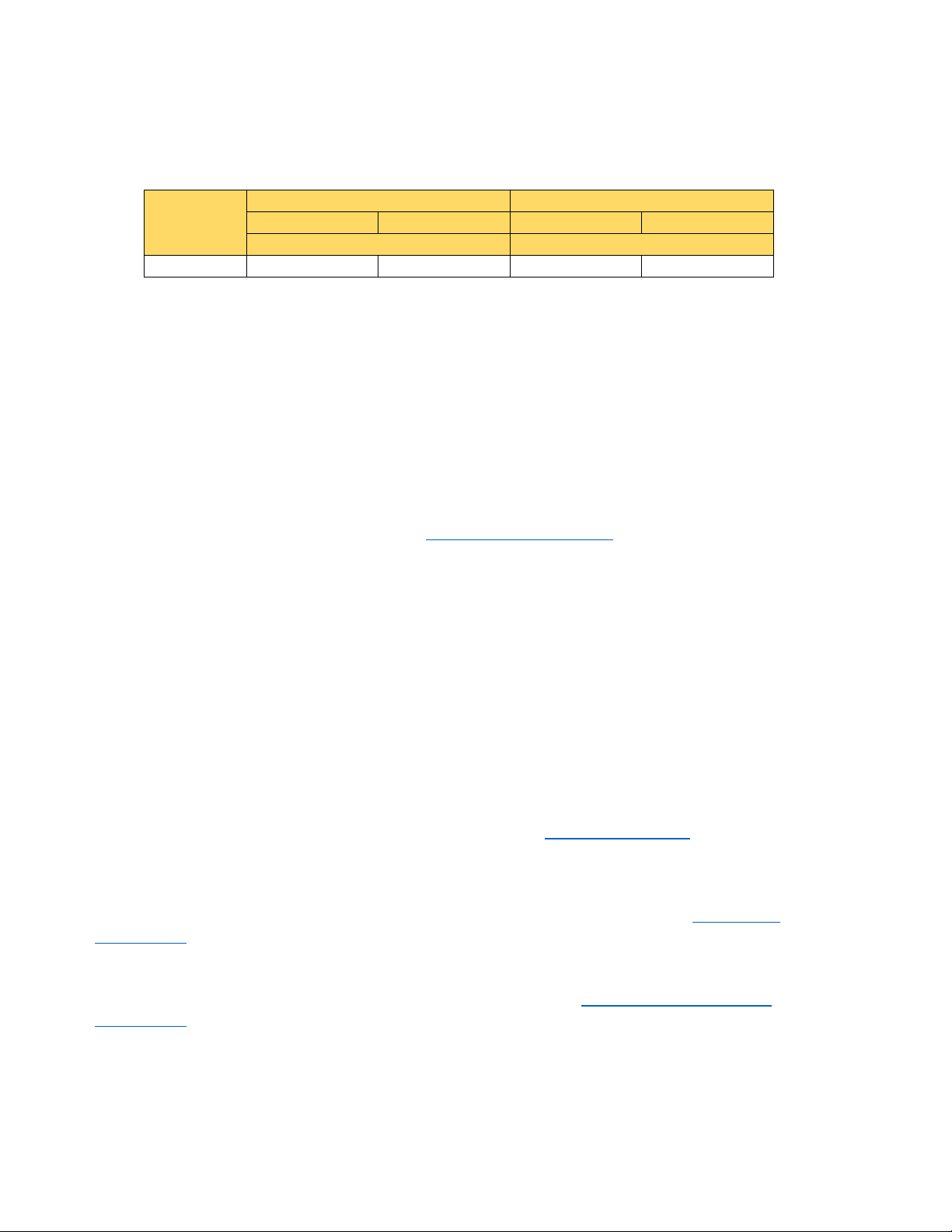

4.1.3.7 Function Code 16, Write Multiple Holding Registers

Write Multiple Holding Registers Request PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x10).

Starting Address

2 Bytes

The data address of the first Holding Register to which to write.

Quantity of

Holding Registers

Byte Count

1 Byte

The number of data bytes to follow.

Holding Register

Values

2 bytes for every Holding Register, maximum of 125 Holding

Registers per message. Write Multiple Holding Registers Response PDU

Name

Size

Description

Function Code

1 Byte

Function Code Identifier (0x10).

Starting Address

2 Bytes

The data address of the Holding Register written.

Quantity of

Holding Registers

Write Multiple Holding Registers Exception PDU

Name

Size

Description

Error Code

1 Byte

0x80 plus Function Code Identifier (0x90).

Exception Code

1 Byte

See 4.1.4 Modbus/TCP Exception Error Codes

Supported Exception Codes

Exception Code

Name

Description

The function code received is not supported in the

controller.

The data address received is not an allowable address within

register requested is not valid for the function.

A value contained in the query data field for a Write

for the function.

An unrecoverable error occurred while the controller was

but the controller could provide a response.

2 Bytes Number of Holding Registers to write.

1-250 Bytes

2 Bytes Number of Holding Registers written.

4.1.4 Modbus/TCP Exception Error Codes

The Modbus/TCP feature supports the following Exception (Error) Codes:

0x01 Illegal Function

0x02 Illegal Data Address

0x03 Illegal Data Value

0x04 Slave Device Failure

When an exception occurs, the Response PDU contains a Function Code of 0x80 plus the original

hexadecimal Function Code.

the controller. This error will only be generated if the first

command is not an allowable value for field. This error will

only be generated if the first register requested is not valid

attempting to perform the requested action. This is a

general exception code indicating that the request was valid,

7

Page 12

4.2 TCP/IP Interface

Byte Value

Coil 1

Coil 2

6 unused bits

0x02

(00000010)

Word Value

Coil Value

Most Significant Byte

Least Significant Byte

0xFF00

(1111111100000000)

0xFF

(11111111)

0x00

(00000000)

Word Value

Bit Value

Most Significant Byte

Least Significant Byte

0x0001

(0000000000000001)

0x00

(00000000)

0x01

(00000001)

The Modbus/TCP interface is attached to the TCP/IP stack that is implemented within the Walchem

controller. When the Modbus feature is Enabled, the controller will listen to all communications that

come in on the Modbus/TCP registered port 502. This port can be changed in the Remote

Communications Menu.

4.3 Data Refresh

To ensure continued connectivity, the Modbus/TCP client should not request data more frequently than

once every 5000 msec. Faster refresh rates are unsupported and may result in unexpected behavior.

4.4 Data Encoding

Modbus uses a ‘big-endian’ representation for addresses and data items. This means that within each

register, when a numerical quantity larger than a single byte is transmitted, the MOST significant byte is

sent first. The following topics describe the different types of encoding and show how the data is

encoded within the Modbus/TCP packet. Most client drivers will extract the data from the packet in the

correct format for use/display within the client environment.

4.4.1 Coils and Discrete Inputs

4.4.1.1 Boolean

Coils and Discrete Inputs can be used for digital input states, relay states, alarm states, and reset buttons

that are representable as a 1 or a 0. All binary data is packed from least significant bit to most significant

bit into a byte containing up to 8 Coils or Discrete Inputs. Bits not containing the value of a Coil or

Discrete Input are space holders and have a value of 0.

0 1 000000

Reset buttons may also be packed as a 16-bit word when using the Write Single Coil function code.

(0xFF00 = On, 0x0000 = Off)

1

4.4.2 Holding Register and Input Registers

4.4.2.1 16-Bit Word (Boolean)

Holding Registers and Input Registers can be used for digital input states, relay states, alarm states, and

reset buttons that are representable as a 1 or a 0. All binary data can be packed into a 16-Bit register,

with the least significant bit of the least significant byte being occupied by the 1-bit value. This is

functionally identical to a 16-bit integer.

1

8

Page 13

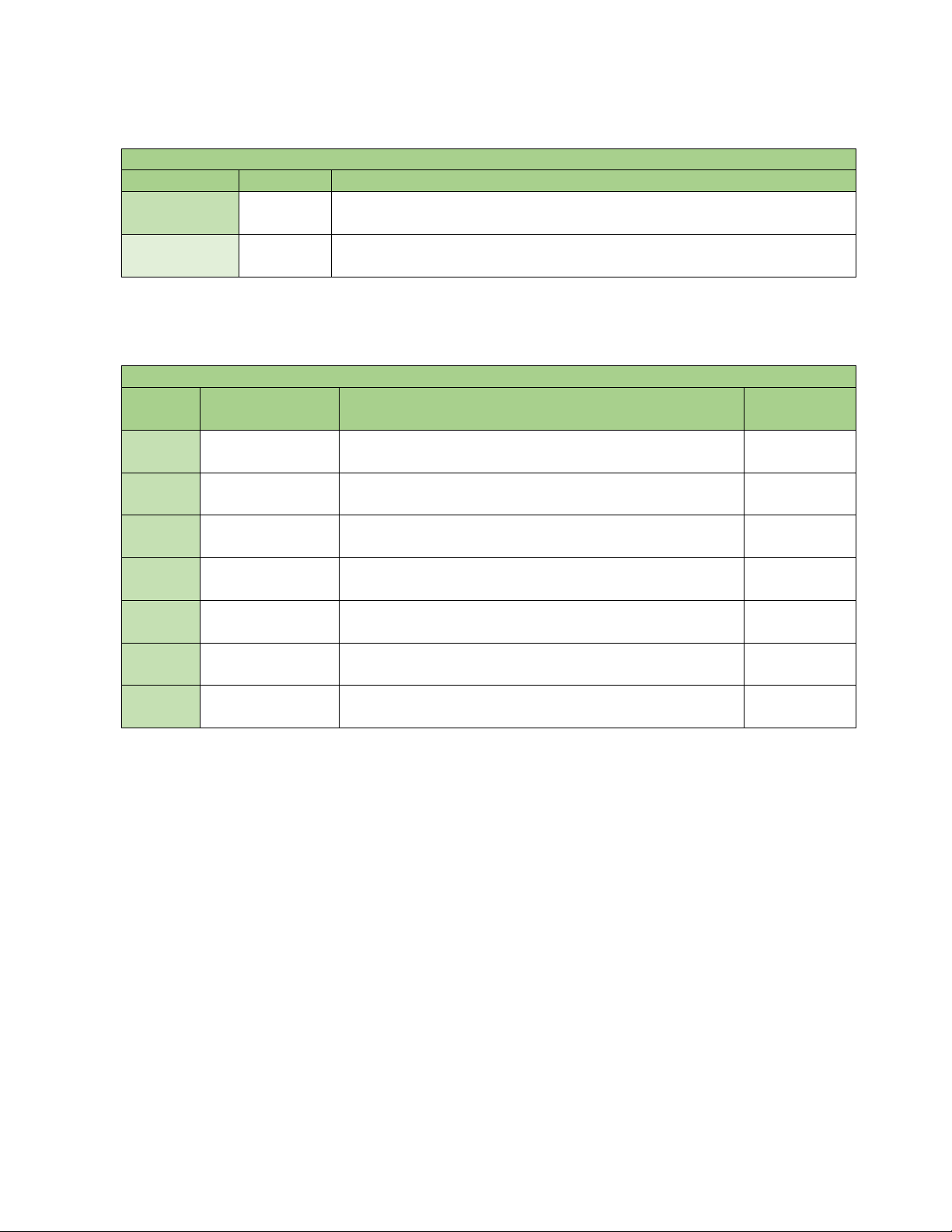

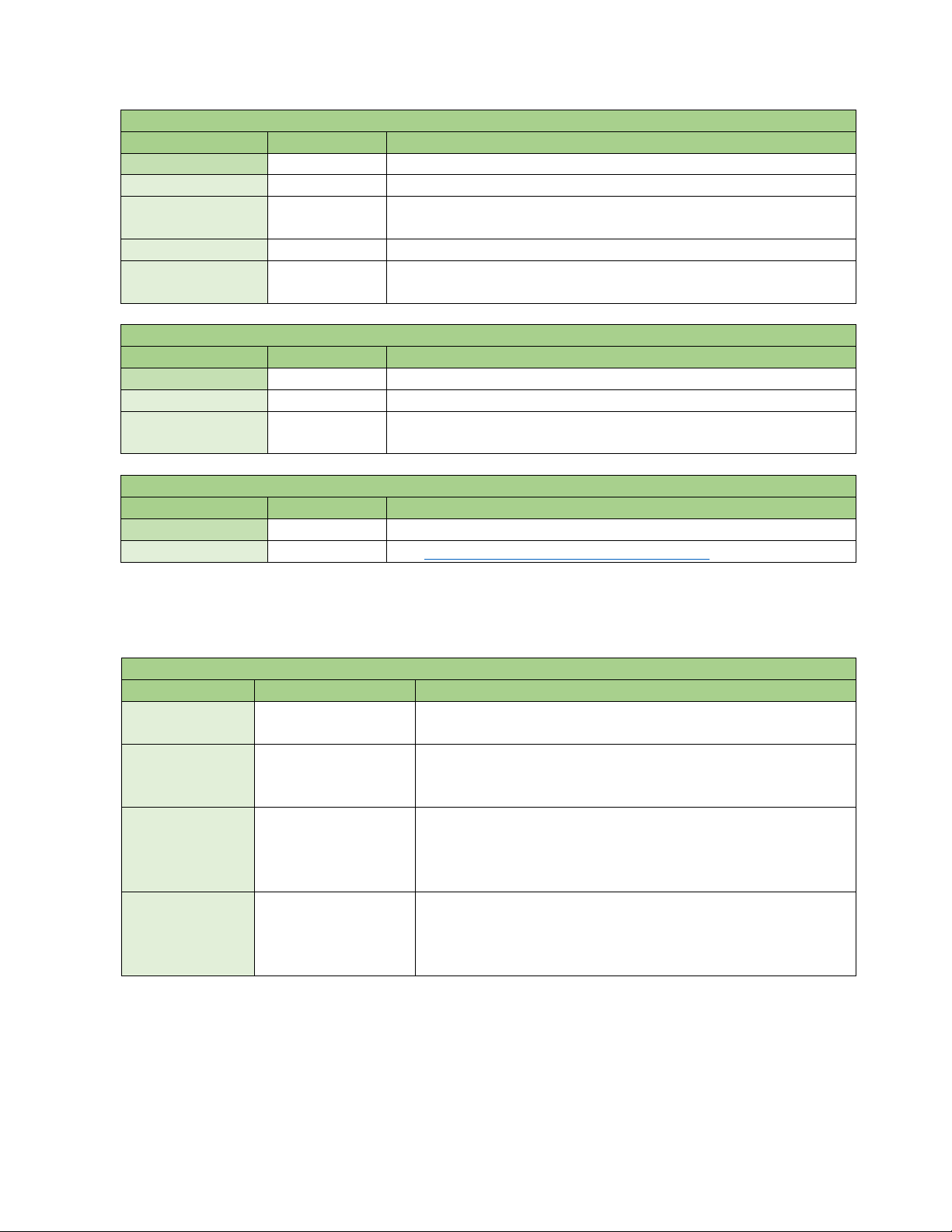

4.4.2.2 16-Bit Word (Bitfield)

Word Value

Alarm Bitfield Value

Most Significant Byte

Least Significant Byte

0x00AA

(0000000010101010)

0x00

(00000000)

0xAA

(10101010)

Word Value

Alarm Bitfield Value

Most Significant Byte

Least Significant Byte

0x00AA

(0000000010101010)

0x00

(00000000)

0xAA

(10101010)

Word Value

Most Significant Byte

Least Significant Byte

0x1234

0x12

0x34

Register 1

Register 2

Most Significant

Least Significant

Most Significant

Least Significant

Least Significant Word

Most Significant Word

0x12345678

0x56

0x78

0x12

0x34

Register 1

Register 2

Most Significant

Least Significant

Most Significant

Least Significant

Least Significant Word

Most Significant Word

0x12345678

0x56

0x78

0x12

0x34

Holding Registers and Input Registers can be used for Alarm Bitfields. An 8-Bit Alarm bitfield is packed

into the least significant byte of a 16-bit register. This is offered as a single-register alternative to

accessing alarm states individually. Bitfields can be decoded in section 5.5 Alarm Bitfields

0xAA

.

4.4.2.3 16-Bit Word (Status)

Holding Registers and Input Registers can be used for enumerated values such as status codes. An 8-Bit

status code is packed into the least significant byte of a 16-bit register. This is functionally identical to

the 16-bit integer. Status codes are defined in section 5.4 Status Register Codes

0xAA

.

4.4.2.4 16-Bit Word (Integer)

Holding Registers and Input Registers can be used for 16-bit integers containing HOA settings, and time

data that don’t require 32-bit integers. All 16-bit integers are unsigned.

4.4.2.5 32-Bit Value (Integer)

Holding Registers and Input Registers can be used for 32-bit integer data containing elapsed time values

and timestamps. The system clock register and all registers containing timestamps use the Unix Time

format, that counts the seconds passed since 12:00:00 am, January 1

wide; therefore, a request message must include 2 consecutive registers to read or write a 32-bit

integer. The 32-bit value is transmitted with the least significant word first, then the most significant

word. All 32-bit integers are unsigned.

Word Value

st

, 1970. Registers are only 16 bits

4.4.2.6 32-Bit Value (Float)

Holding Registers and Input Registers can be used for 32-bit floating point data containing set points,

sensor readings, percentages, deadbands, etc. Registers are only 16 bits wide; therefore, a request

message must include 2 consecutive registers to read or write a 32-bit float. The 32-bit value is

transmitted with the least significant word first, then the most significant word.

Word Value

9

Page 14

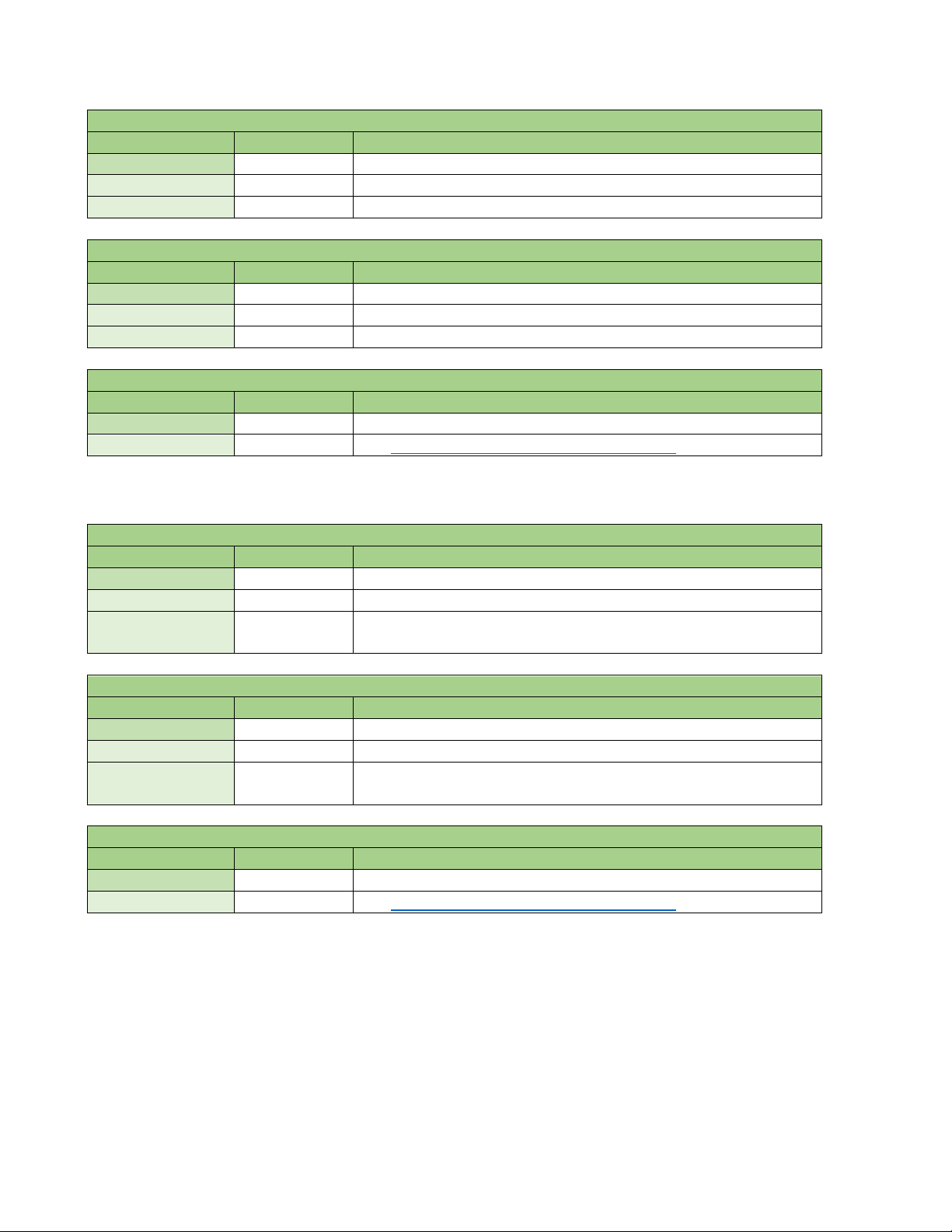

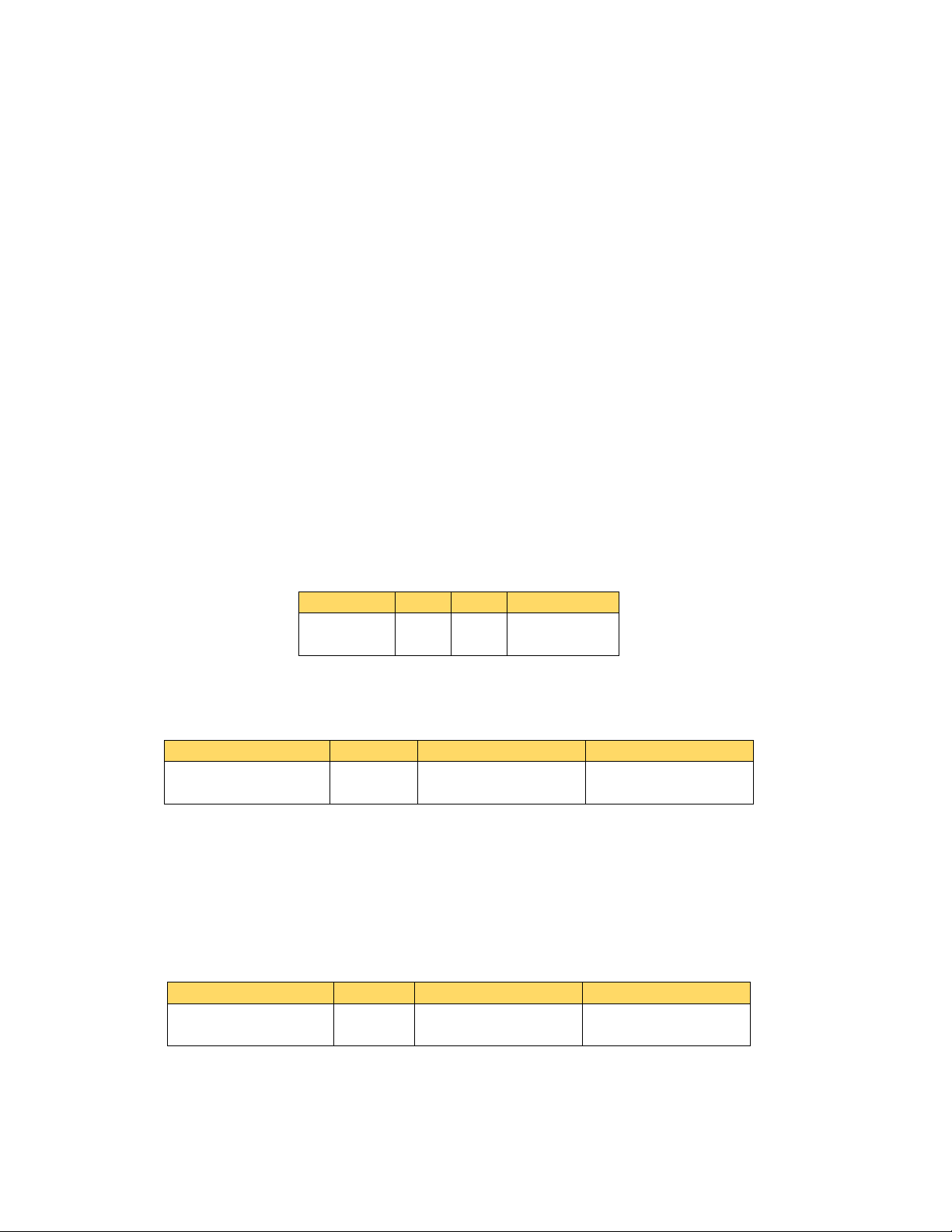

4.4.2.7 32-Bit Inverse Data Format (Integer or Float)

Register 1

Register 2

Most Significant

Least Significant

Most Significant

Least Significant

Most Significant Word

Least Significant Word

0x12345678

0x12

0x34

0x56

0x78

32-bit integers and floats can use an inverse data format, where the contents of registers 1 and 2 are

switched. When inverse data format is selected, the 32-bit value is transmitted with the most significant

word first, then the least significant word. The data format setting can be modified in the Remote

Communications Settings Menu.

Word Value

5.0 DATA DICTIONARY

5.1 Addressing (0- or 1-Based)

The addressing within the Modbus/TCP protocol (that is, the data within the physical packet) is 0-based,

meaning the first element/item to be accessed is referenced by address 0. The Modbus standard for

handling and displaying data is 1-based, meaning the first element/data item to be accessed is

referenced by address 1.

For most client applications, users enter the 1-based number which is converted to 0-based addressing

at the protocol level. The addresses defined in the following address maps below are 1-based, as most

of the client applications work with this method. Register addresses for individual elements are derived

by adding the address offset in the appropriate Type-Specific Address Map

I/O Channel Address Map below.

to the starting address in the

5.2 Address Maps

The address map is a function code-agnostic map that contains all data values that can be accessed as

Coils (0xxxx), Discrete Inputs (1xxxx), Holding Registers (4xxxx), and Input Registers (3xxxx).

The Address Map of the Modbus/TCP feature is modular; valid addresses are determined by the add-on

card configuration of the controller and the task being performed by each Input or Output. Each object

has a block of 36 addresses.

The Modbus/TCP feature allows all addresses to be accessed as registers. On the following address map

tables, values in BOLD can also be accessed as a Coil or Discrete Input.

As examples, to read the ‘Controller Firmware Version’ from the System Address Map

x0037) as an Input Register (FC4), the address indices 2 and 3 must be requested together: Addresses

30039 and 30040.

To read the ‘Low Alarm’ status for Sensor 2-1 in a W600 Controller as a Coil (FC1), the

Address Map indicates the starting address is x0865. Address index 28 must be requested: Address

00893. For the W900 Controller, the ‘Low Alarm’ status for Sensor 2-1 is x1729 + 28 = Address 01757.

To write the ‘Setpoint’ for Relay 3 (set to On/Off control mode) in the

Address Map (staring address x9001) as a Holding Register (FC6), the address indices 6 and 7 must be

used together: Addresses 49007 and 49008.

Relay On/Off Control Mode

(starting address

Sensor Input

10

Page 15

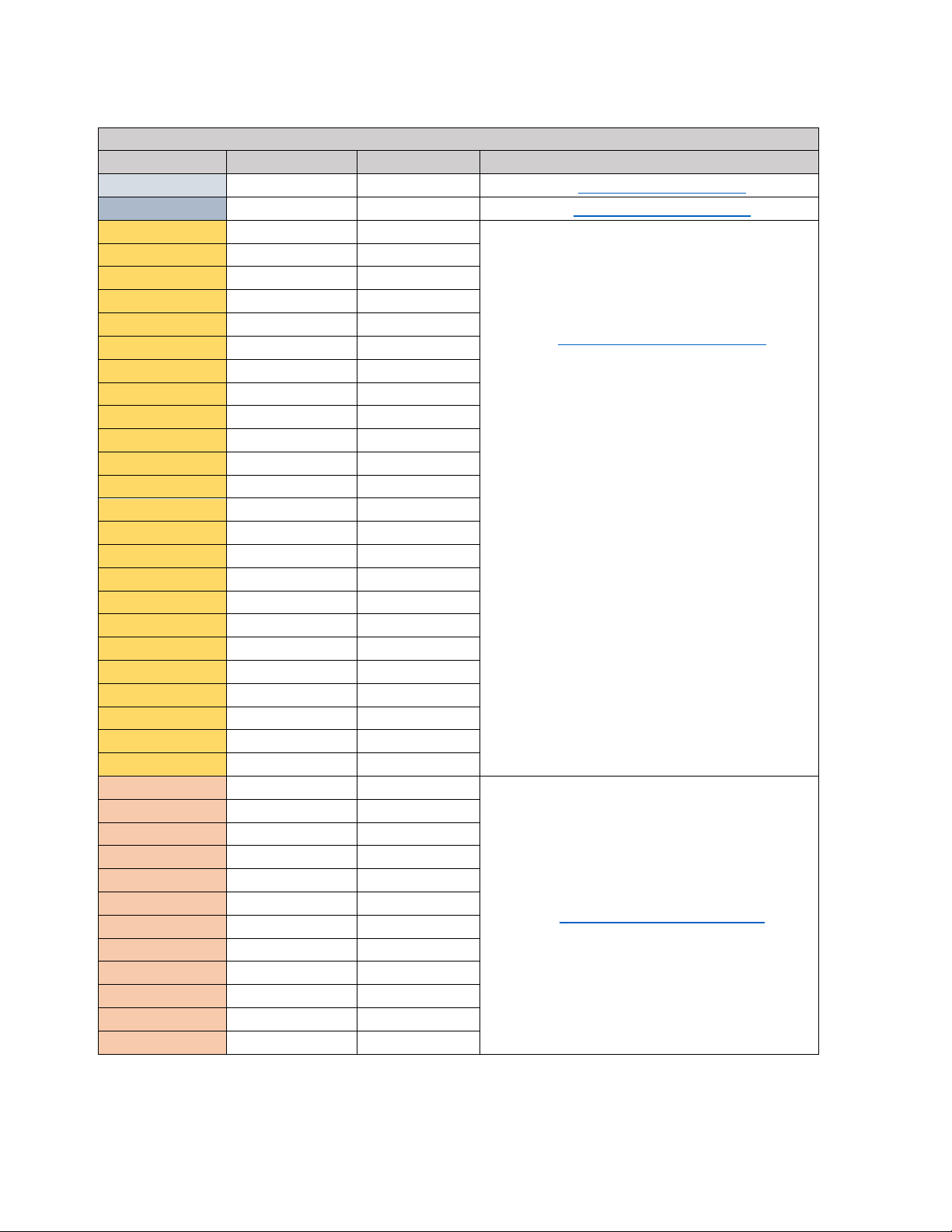

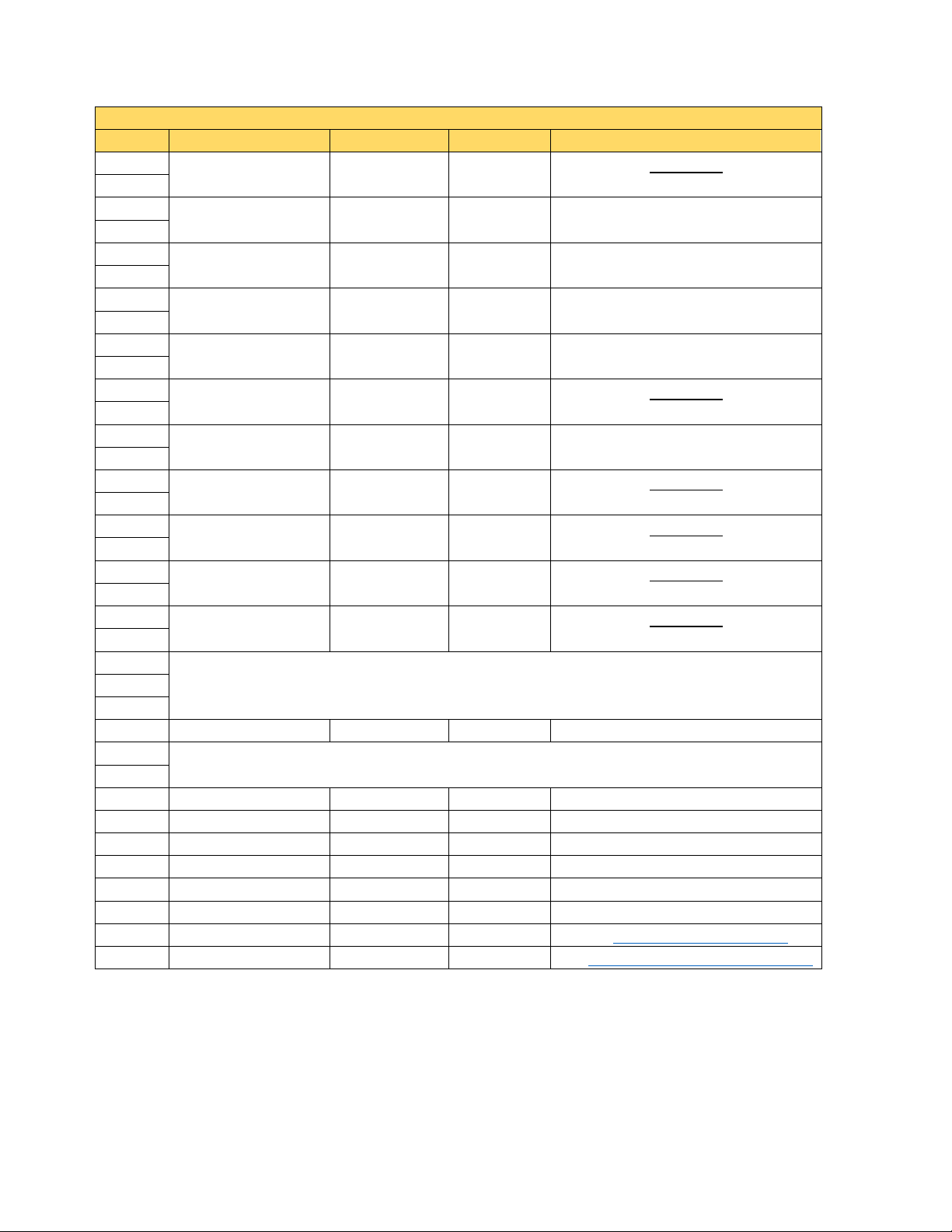

5.2.1 W600 Controller – I/O Channel Address Maps

W600 Controller – I/O Channel Address Map

Starting

Address

Ending

Address

Type-Specific Address Maps

System

Network

Sensor Input 1-1

Sensor Input 1-2

Sensor Input 1-3

Sensor Input 2-1

x0865

x0900

Sensor Input 2-2

x0901

x0936

Sensor Input 2-3

x0937

x0972

Digital Input 1

x0289

x0324

Digital Input 2

Digital Input 3

Digital Input 4

Digital Input 5

Digital Input 6

Virtual Input 1

Virtual Input 2

x5797

x5832

Relay Output 1

x8929

x8964

Relay Output 2

x8965

x9000

Relay Output 3

Relay Output 4

Relay Output 5

Relay Output 6

Analog Output 1

Analog Output 2

The address ranges for each input/output channel in the W600 controller are as follows:

Object

x0037 x0072 See 5.3.1 System Address Map

x0145 x0180 See 5.3.2 Network Address Map

x0577 x0612

x0613 x0648

x0649 x0684

x0325 x0360

x0361 x0396

x0397 x0432

x0433 x0468

x0469 x0504

x5761 x5796

See 5.3.3 Sensor Input Address Maps

See 5.3.4 Digital Input Address Maps

See 5.3.5 Virtual Input Address Maps

See 5.3.6 Relay Output Address Maps

x9001 x9036

x9037 x9072

x9073 x9108

x9109 x9144

x1153 x1188

x1189 x1224

5.3.7 Pulse Relay Output Address Maps

See 5.3.8 Analog Output Address Maps

Or

11

Page 16

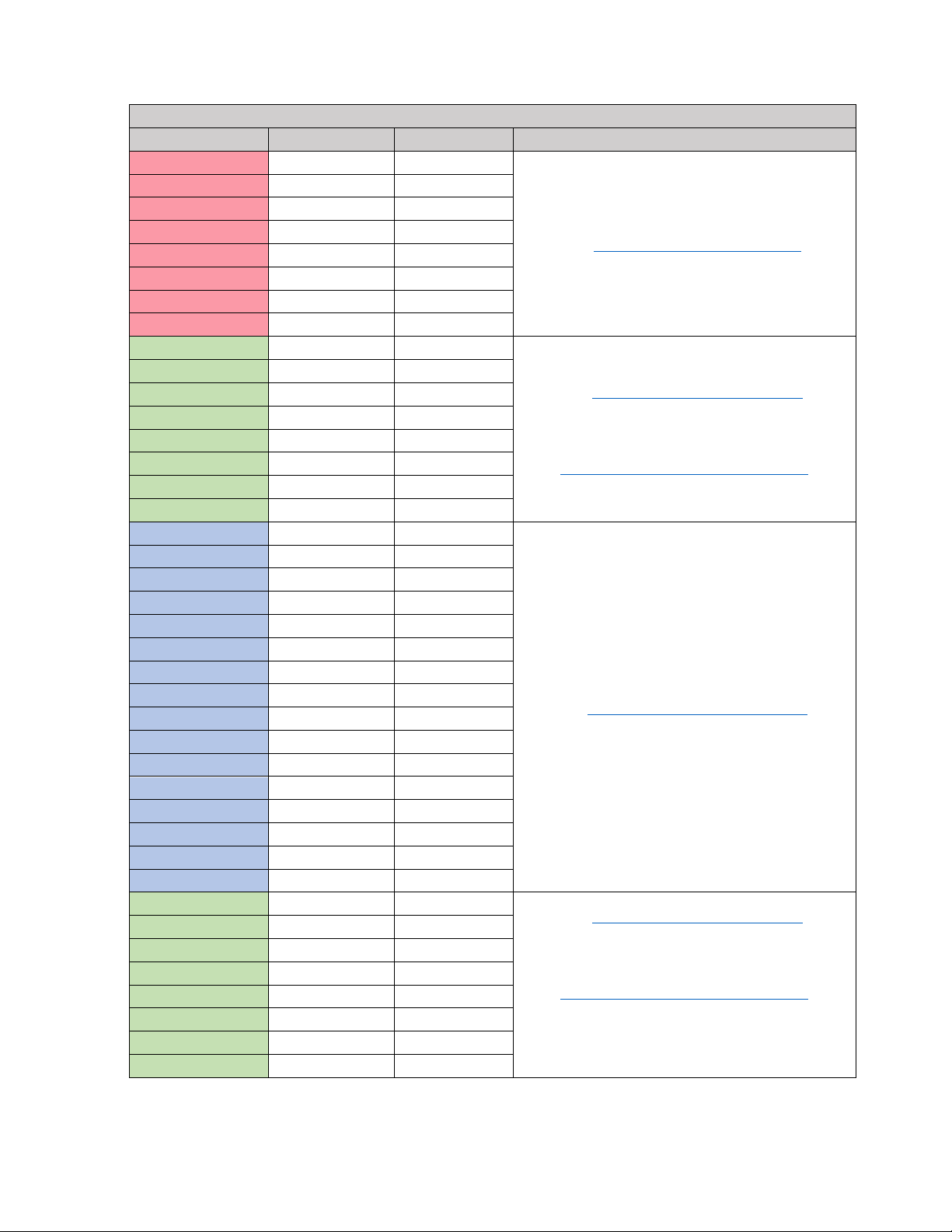

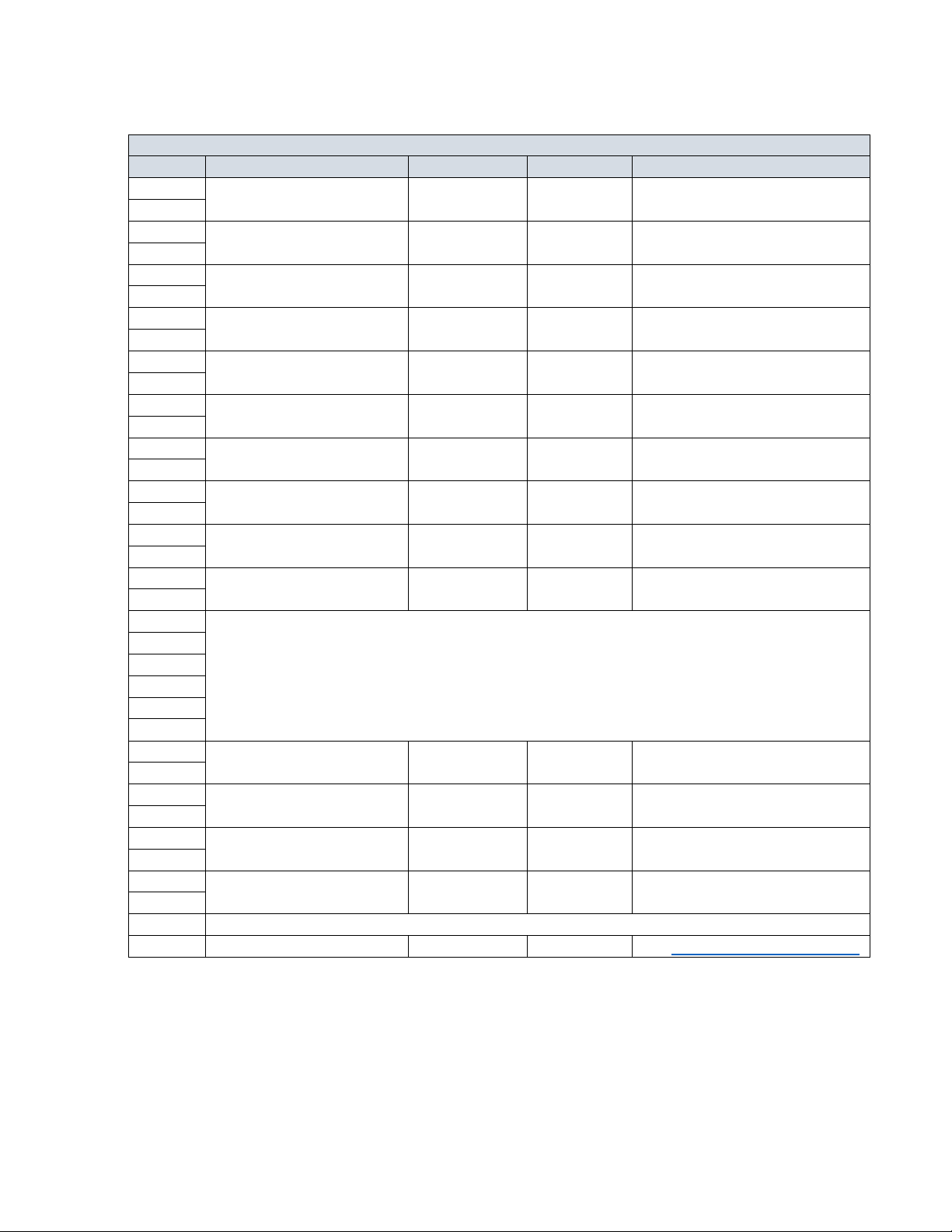

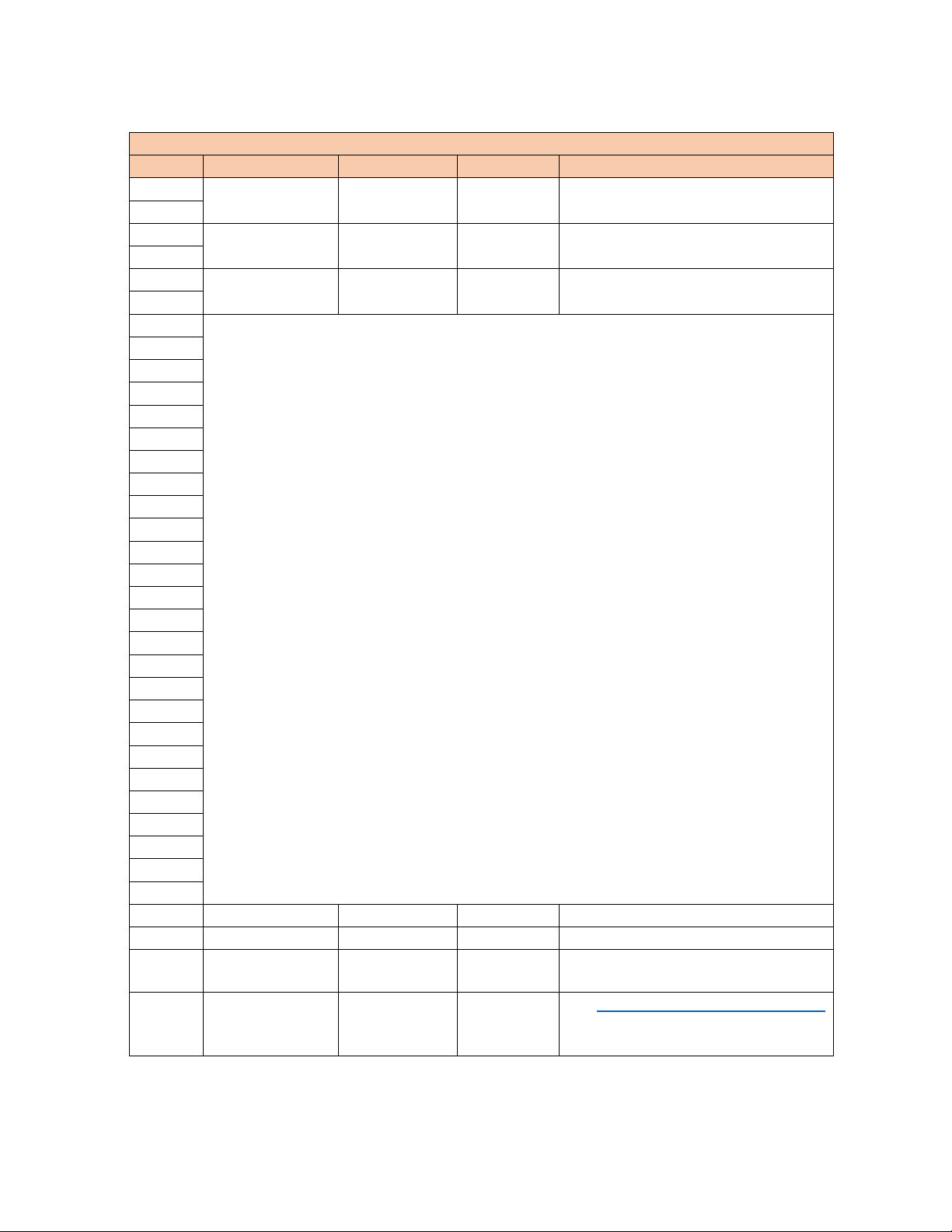

5.2.2 W900 Controller – I/O Channel Address Maps

W900 Controller – I/O Channel Address Map

Type-Specific Address Maps

System

Network

Sensor Input 1-1

Sensor Input 1-2

Sensor Input 1-3

Sensor Input 1-4

x1261

x1296

Sensor Input 1-5

x1297

x1332

Sensor Input 1-6

x1333

x1368

Sensor Input 2-1

Sensor Input 2-2

Sensor Input 2-3

Sensor Input 2-4

Sensor Input 2-5

Sensor Input 2-6

Sensor Input 3-1

Sensor Input 3-2

Sensor Input 3-3

x2377

x2412

Sensor Input 3-4

x2413

x2448

Sensor Input 3-5

x2449

x2484

Sensor Input 3-6

Sensor Input 4-1

Sensor Input 4-2

Sensor Input 4-3

Sensor Input 4-4

Sensor Input 4-5

Sensor Input 4-6

x3061

x3096

Digital Input 1

x0577

x0612

Digital Input 2

x0613

x0648

Digital Input 3

x0649

x0684

Digital Input 4

Digital Input 5

Digital Input 6

Digital Input 7

Digital Input 8

Digital Input 9

Digital Input 10

x0901

x0936

Digital Input 11

x0937

x0972

Digital Input 12

x0973

x1008

The address ranges for each input/output channel in the W900 controller are as follows:

Object Starting Address Ending Address

x0037 x0072 See 5.3.1 System Address Map

x0145 x0180 See 5.3.2 Network Address Map

x1153 x1188

x1189 x1224

x1225 x1260

x1729 x1764

x1765 x1800

x1801 x1836

x1837 x1872

x1873 x1908

x1909 x1944

x2305 x2340

x2341 x2376

x2485 x2520

x2881 x2916

x2917 x2952

x2953 x2988

x2989 x3024

x3025 x3060

See 5.3.3 Sensor Input Address Maps

Note: When using P/N 191918 I/O card with

2 Analog Input + 4 Analog Output channels,

the two (4-20 mA) Sensor Inputs are mapped

from channels 1 and 2 into channels 5 and 6.

For example, if the card is installed in the third

I/O slot, the register address mapping is:

Analog Output 3-1: x2305 to x2340

Analog Output 3-2: x2341 to x2376

Analog Output 3-3: x2377 to x2412

Analog Output 3-4: x2413 to x2448

Sensor Input 3-1: x2449 to x2484

Sensor Input 3-2: x2485 to x2520

x0685 x0720

x0721 x0756

x0757 x0792

x0793 x0828

x0829 x0864

x0865 x0900

12

See 5.3.4 Digital Input Address Maps

Page 17

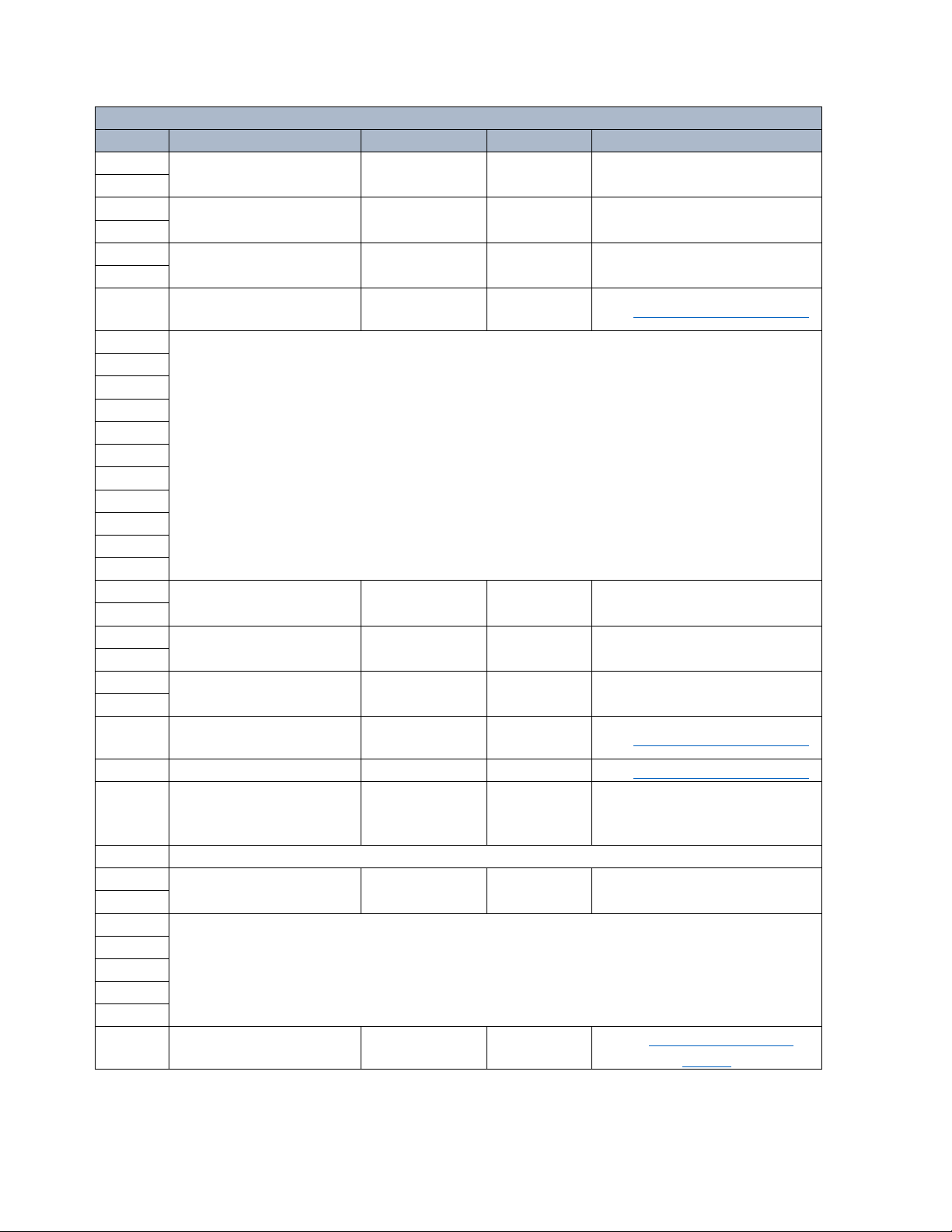

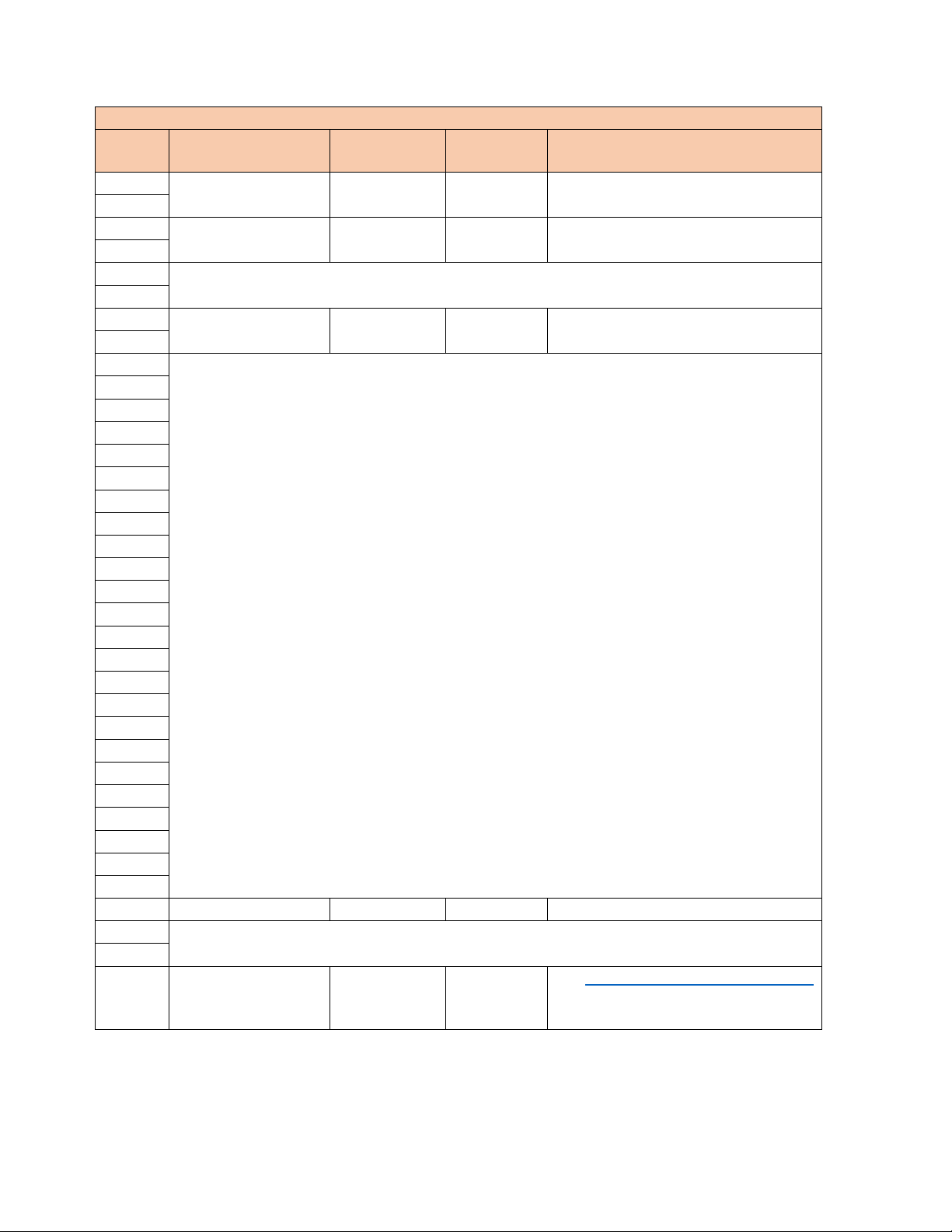

W900 Controller – I/O Channel Address Map

Object

Starting Address

Ending Address

Type-Specific Address Maps

Virtual Input 1

x5761

x5796

Virtual Input 2

x5797

x5832

Virtual Input 3

Virtual Input 4

Virtual Input 5

Virtual Input 6

Virtual Input 7

Virtual Input 8

Relay Output 1

Relay Output 2

x8965

x9000

Relay Output 3

x9001

x9036

Relay Output 4

x9037

x9072

Relay Output 5

Relay Output 6

Relay Output 7

Relay Output 8

x9181

x9144

Analog Output 1-1

Analog Output 1-2

Analog Output 1-3

Analog Output 1-4

x1261

x1296

Analog Output 2-1

x1729

x1764

Analog Output 2-2

x1765

x1800

Analog Output 2-3

x1801

x1836

Analog Output 2-4

Analog Output 3-1

Analog Output 3-2

Analog Output 3-3

Analog Output 3-4

Analog Output 4-1

Analog Output 4-2

x2917

x2952

Analog Output 4-3

x2953

x2988

Analog Output 4-4

x2989

x3024

Control Output 1

Control Output 2

Control Output 3

Control Output 4

Control Output 5

Control Output 6

Control Output 7

x7129

x7164

Control Output 8

x7165

x7200

x5833 x5868

x5869 x5904

x5905 x5940

x5941 x5976

x5977 x6012

x6013 x6048

x8929 x8964

See 5.3.5 Virtual Input Address Maps

x9073 x9108

x9109 x9144

x9145 x9180

x1153 x1188

x1189 x1224

x1225 x1260

x1837 x1872

x2305 x2340

x2341 x2376

x2377 x2412

x2413 x2448

x2881 x2916

See 5.3.6 Relay Output Address Maps

Or

5.3.7 Pulse Relay Output Address Maps

See 5.3.8 Analog Output Address Maps

x6913 x6948

x6949 x6984

x6985 x7020

x7021 x7056

x7057 x7092

x7093 x7128

See 5.3.6 Relay Output Address Maps

Or

5.3.7 Pulse Relay Output Address Maps

Note: Control Outputs share address maps

and alarm bitfields with Relay control modes

13

Page 18

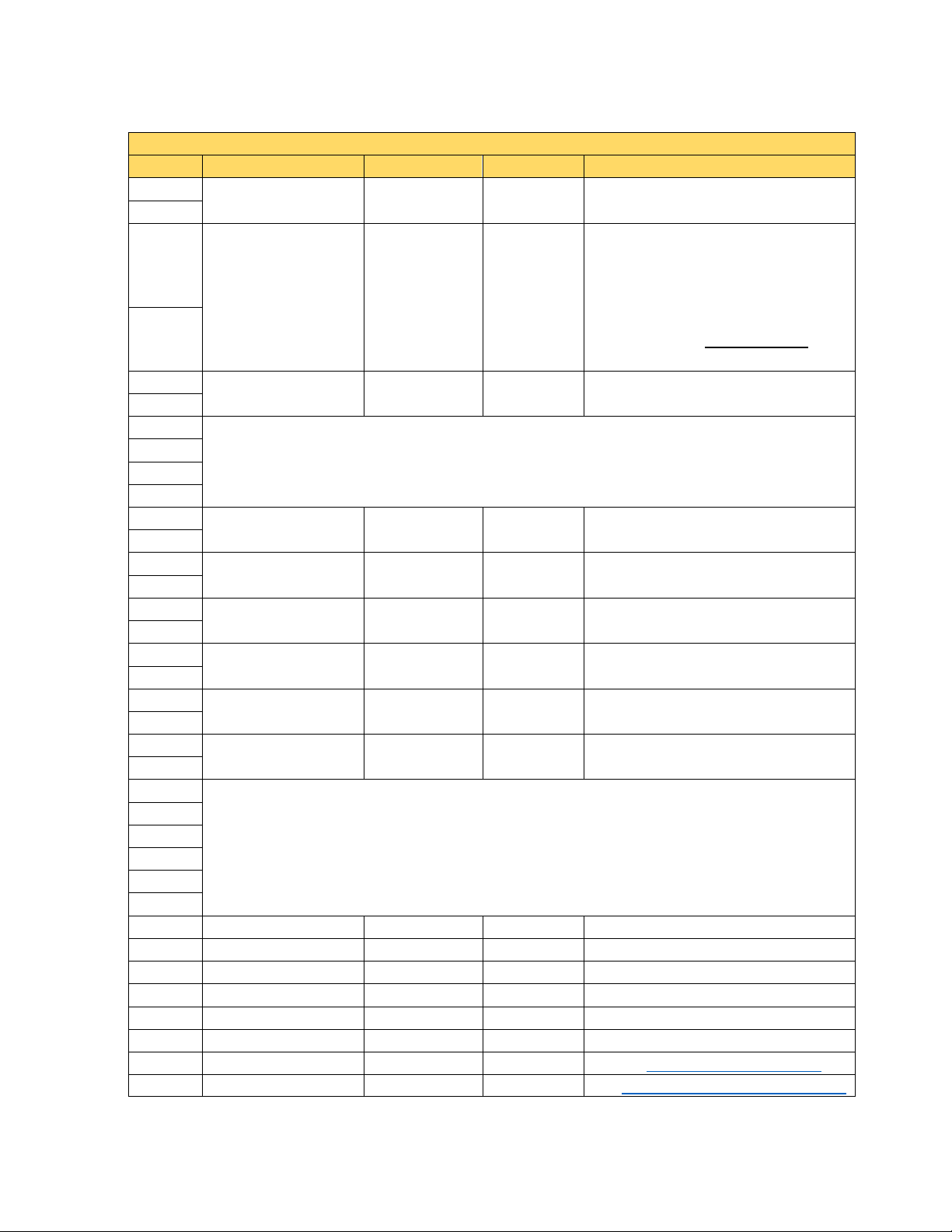

5.2.3 Alternate Address Maps

Primary Value; Status

Calibration Required

DI State; Interlock State

Low, High Alarms

Primary Value; Status

Alarm Bitfield

Relay State

Alarm Bitfield

Output Percent

Alarm Bitfield

Output State

Alarm Bitfield

Scenario #1: I/O Slot 2 Not Populated

Scenario #2: I/O Slot 2 Populated

Channel

Address

Alternate

Address

Channel

Address

Alternate

Address

I/O Slot 1: Dual Sensor Input Card

I/O Slot 1: Dual Sensor Input Card

Sensor Input 1-1

x1153

Sensor 1

x9217

Sensor Input 1-1

x1153

Sensor 1

x9217

Sensor Input 1-2

x1189

Sensor 2

x9219

Sensor Input 1-2

x1189

Sensor 2

x9219

Sensor Input 1-3

x1225

Sensor 3

x9221

Sensor Input 1-3

x1225

Sensor 3

x9221

Sensor Input 1-4

x1261

Sensor 4

x9223

Sensor Input 1-4

x1261

Sensor 4

x9223

I/O Slot 2: Not Populated

I/O Slot 2: Single Sensor Input Card

Sensor Input 2-1

x1729

Sensor 5

x9225

Sensor Input 2-2

x1765

Sensor 6

x9227

I/O Slot 3: Dual Analog Input Card

I/O Slot 3: Dual Analog Input Card

Sensor Input 3-1

x2305

Sensor 5

x9225

Sensor Input 3-1

x2305

Sensor 7

x9229

Sensor Input 3-2

x2341

Sensor 6

x9227

Sensor Input 3-2

x2341

Sensor 8

x9231

The I/O Address Maps in the previous sections are based on the hardware position/slot within the

controller. Alternate Address Maps use software-based, dynamic addressing to provide a more efficient

way to access similar data from different objects. Using these address tables, the same field type is

accessible using consecutive addresses. For example, the primary values for all sensors installed in the

controller can be accessed in a single Modbus FC4 request/response cycle starting at address 39217.

I/O Type Available Objects Type-Specific Alternate Address Map

Sensor Inputs

Digital Inputs

Virtual Inputs

Relay Outputs

Analog Outputs

Control Outputs

Alarm Bitfield

Low, High Alarms

LoLo, HiHi Alarms

Total Time

Flowrate;

Pulse Output Percent

Flow Total

Alarm Bitfield

Time On;

Time On; Status

Output Percent

Time On;

Status

Status

See 5.3.9.1 Alternate Sensor Input / Temperature Input /

Analog Input Address Map

See 5.3.9.2 Alternate Digital Input Address Map

See 5.3.9.3 Alternate Virtual Input Address Map

See 5.3.9.4 Alternate Relay Output Address Map

See 5.3.9.5 Alternate Analog Output Address Map

See 5.3.9.6 Alternate Control Output Address Map

Note that changing I/O card locations can affect the address used to access individual objects. For

example, if a W900 is configured with a Dual SI card in slot 1 and a Dual AI card in slot 3, the alternate

address mappings for the primary values are different if a Single SI card is inserted into slot 2:

14

Page 19

5.3 Type-Specific Address Maps

System Address Map

Address

Name

Data Encoding

Permissions

Value

0

1

2

Controller Firmware

Version

3

4

5

6

Controller Processor

Temperature

7

8

Network Card

Temperature

9

10

Digital Input Card

Temperature (W900 Only)

11

12

13

14

15

16

I/O Card 3 Temperature

(W900 Only)

17

18

I/O Card 4 Temperature

(W900 Only)

19

20

21

22

23

24

25

26

27

28

29

30

31

32

+12 V Supply

(W900 Only)

33

34

35

Alarm Bitfield

16-Bit Bitfield

Read

See 5.5.1 System Alarm Bitfield

5.3.1 System Address Map

Controller Time 32-Bit Integer Read Unix Time

32-Bit Float Read

Date of Last Data Log 32-Bit Integer Read Unix Time

32-Bit Float Read °C

32-Bit Float Read °C

32-Bit Float Read °C

I/O Card 1 Temperature 32-Bit Float Read °C

I/O Card 2 Temperature 32-Bit Float Read °C

32-Bit Float Read °C

32-Bit Float Read °C

Battery Power 32-Bit Float Read Volt

+3.3 V Supply 32-Bit Float Read Volt

+5 V Supply 32-Bit Float Read Volt

32-Bit Float Read Volt

15

Page 20

5.3.2 Network Address Map

Network Address Map

Address

Name

Data Encoding

Permissions

Value

0

1

2

VTouch Last

Configuration Time

3

4

5

VTouch LiveConnect

Status

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

WiFi Channel

(W900 Only)

23

WiFi Security

(W900 Only)

25

WiFi Status (W900 Only)

16-Bit Status

Read

See 5.4 Status Register Codes

Begin Temporary

(W900 Only)

27

28

29

30

31

32

33

34

See 5.5.2 Network Alarm

Bitfield

VTouch Last Data Time 32-Bit Integer Read Unix Time

VTouch Refresh Rate 32-Bit Float Read/Write 1 – 1440 Minutes

32-Bit Integer Read Unix Time

24

6

WiFi Signal Strength

(W900 Only)

WiFi RSSI

(W900 Only)

16-Bit Status Read See 5.4 Status Register Codes

32-Bit Float Read -30 – -100 dBm

32-Bit Float Read 0 – 100%

32-Bit Float Read 1 – 14

16-Bit Status Read See 5.4 Status Register Codes

26

Ad-Hoc Mode Session

Ad-Hoc Mode Time Limit

35 Alarm Bitfield 16-Bit Bitfield Read

(W900 Only)

Boolean Read/Write

32-Bit Float Read/Write

16

Write 1 to Begin Temporary

Ad-Hoc Mode Session

1 – 1440 minutes

Page 21

5.3.3 Sensor Input Address Maps

Sensor Input (all types except Analog Input Flowmeter) Address Map

Address

Name

Data Encoding

Permissions

Value

0

1

Cond: µS/cm before ATC

Temperature: Ω

Corrosion Rate: mpy (Mild Steel)

Imbalance

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Low Alarm

Boolean

Read

1 = Alarm Active

29

High Alarm

Boolean

Read

1 = Alarm Active

30

LoLo Alarm

Boolean

Read

1 = Alarm Active

31

HiHi Alarm

Boolean

Read

1 = Alarm Active

32

Cal Required

Boolean

Read

1 = Alarm Active

33

Input Failure

Boolean

Read

1 = Alarm Active

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

35

Alarm Bitfield

16-Bit Bitfield

Read

See 5.5.3 Sensor Input Alarm Bitfield

5.3.3.1 Sensor Input (all types except Analog Input Flowmeter) Address Map

Primary Value 32-Bit Float Read Sensor Units

2

Active, Cu/Ni: mV

4-20 mA Input: mA

Primary Raw Value 32-Bit Float Read

3

Imbalance: Corrosion Rate

Last Calibration Date 32-Bit Integer Read Unix Time

Deadband 32-Bit Float Read/Write Sensor Units

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

LoLo Alarm Setpoint 32-Bit Float Read/Write Sensor Units

Low Alarm Setpoint 32-Bit Float Read/Write Sensor Units

High Alarm Setpoint 32-Bit Float Read/Write Sensor Units

HiHi Alarm Setpoint 32-Bit Float Read/Write Sensor Units

17

Page 22

5.3.3.2 Analog Input Flowmeter Address Map

Analog Input Flowmeter Address Map (W900 Controller Only)

Address

Name

Data Encoding

Permissions

Value

0

Flow Units

Rate Units

1

2

3

4

5

6

7

8

9

10

Flow Units

Rate Units

11

12

13

14

15

16

17

18

Rate Units

19

20

Flow Units

Rate Units

21

22

23

24

25

Reset Total Flow

Boolean

Read/Write

Write 1 to Reset Flow Total

26

27

28

Low Alarm

Boolean

Read

1 = Alarm Active

29

High Alarm

Boolean

Read

1 = Alarm Active

30

LoLo Alarm

Boolean

Read

1 = Alarm Active

31

HiHi Alarm

Boolean

Read

1 = Alarm Active

32

Cal Required

Boolean

Read

1 = Alarm Active

33

Input Failure

Boolean

Read

1 = Alarm Active

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

35

Alarm Bitfield

16-Bit Bitfield

Read

See 5.5.3 Sensor Input Alarm Bitfield

Primary Value 32-Bit Float Read

Primary Raw Value 32-Bit Float Read mA

Last Calibration Date 32-Bit Integer Read Unix Time

Flow Total 32-Bit Float Read Flow Units

Input Filter 32-Bit Float Read/Write mA

Deadband 32-Bit Float Read/Write

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

LoLo Alarm Setpoint 32-Bit Float Read/Write

Low Alarm Setpoint 32-Bit Float Read/Write

High Alarm Setpoint 32-Bit Float Read/Write

HiHi Alarm Setpoint 32-Bit Float Read/Write

Flow Units

Rate Units

Flow Units

Rate Units

Flow Units

18

Page 23

5.3.4 Digital Input Address Maps

Digital Input / DI State Type Address Map

Address

Name

Data Encoding

Permissions

Value

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Reset Total Time

Boolean

Read/Write

Write 1 to Reset Time

33

DI State

Boolean

Read

0 = Open, 1 = Closed

0 = Inactive

1 = Active Interlock

See 5.5.4 Digital Input Alarm Bitfield

Returns 1 if any alarm is active

5.3.4.1 Digital Input / DI State Type Address Map

Last Reset Date 32-Bit Integer Read Unix Time

Total Time 32-Bit Integer Read Seconds

Cycle Time 32-Bit Integer Read Seconds

34 Interlock State Boolean Read

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

19

Page 24

5.3.4.2 Digital Input / Contacting Flow Meter Type Address Map

Digital Input / Contacting Flow Meter Address Map

Data

Encoding

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Reset Total Flow

Boolean

Read/Write

Write 1 to Reset Flow Total

33

34

See 5.5.4 Digital Input Alarm Bitfield

Returns 1 if any alarm is active

Address Name

Last Reset Date 32-Bit Integer Read Unix Time

Total Flow 32-Bit Float Read Flow Units

Total Flow Alarm

Setpoint

Permissions Value

32-Bit Float Read/Write

0 – 1,000,000,000

Flow Units

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

20

Page 25

5.3.4.3 Digital Input / Paddlewheel Flow Meter Type Address Map

Digital Input / Paddlewheel Flow Meter Address Map

Data

Encoding

0

1

2

3

4

Flow Units

Rate Units

5

6

7

8

9

10

Rate Units

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Reset Total Flow

Boolean

Read/Write

Write 1 to Reset Flow Total

33

34

See 5.5.4 Digital Input Alarm Bitfield

Returns 1 if any alarm is active

Address Name

Last Reset Date 32-Bit Integer Read Unix Time

Total Flow 32-Bit Float Read Flow Units

Current Flowrate 32-Bit Float Read

Total Flow Alarm

Setpoint

Deadband 32-Bit Float Read/Write

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

Low Alarm Setpoint 32-Bit Float Read/Write

High Alarm Setpoint 32-Bit Float Read/Write

Permissions Value

32-Bit Float Read/Write

0 – 1,000,000,000

Flow Units

Flow Units

Flow Units

Rate Units

Flow Units

Rate Units

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

21

Page 26

5.3.4.4 Digital Input / DI Counter Type Address Map

Digital Input / DI Counter Address Map (W900 Controller Only)

Data

Encoding

0

1

2

3

4

Units

Rate Units

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Reset Total

Boolean

Read/Write

Write 1 to Reset Total

33

34

See 5.5.4 Digital Input Alarm Bitfield

Returns 1 if any alarm is active

Address Name

Last Reset Date 32-Bit Integer Read Unix Time

Total Count 32-Bit Float Read Units

Current Rate 32-Bit Float Read

Total Alarm

Setpoint

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

Permissions Value

32-Bit Float Read/Write

0 – 1,000,000,000

Units

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

22

Page 27

5.3.4.5 Digital Input / Flow Monitor Type Address Map

Digital Input / Flow Monitor Address Map

Addres

s

0

1

2

3

4

Flow Units

Rate Units

5

6

7

8

9

10

11

12

13

14

Reprime Time

16-Bit Integer

Read/Write

0 – 3599 Seconds

15

Flow Alarm Delay

16-Bit Integer

Read/Write

10 – 3599 Seconds

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Reset Total Flow

Boolean

Read/Write

Write 1 to Reset Flow Total

33

34

See 5.5.4 Digital Input Alarm Bitfield

Returns 1 if any alarm is active

Name Data Encoding Permissions Value

Last Reset Date 32-Bit Integer Read Unix Time

Total Feed 32-Bit Float Read Flow Units

Current Flowrate 32-Bit Float Read

Totalizer Alarm

Setpoint

32-Bit Float Read/Write

Volume/Contact 32-Bit Float Read/Write

0 – 1,000,000

Flow Units

0.001 – 1000.000

Flow Units / Pulse

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

Flow Alarm Clear 32-Bit Float Read/Write 1 – 100,000 Pulses

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

23

Page 28

5.3.5 Virtual Input Address Maps

Virtual Input / Calculation & Raw Value Type Address Map

Address

Name

Data Encoding

Permissions

Value

0

1

2

3

4

5 6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Low Alarm

Boolean

Read

1 = Alarm Active

29

High Alarm

Boolean

Read

1 = Alarm Active

30

LoLo Alarm

Boolean

Read

1 = Alarm Active

31

HiHi Alarm

Boolean

Read

1 = Alarm Active

32

1 = Out-Of-Range or

Input Failure Alarm Active

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

See 5.5.5 Virtual Input Alarm

Bitfield

5.3.5.1 Virtual Input / Calculation & Raw Value Type Address Map

Primary Value 32-Bit Float Read Virtual Input Units

Deadband 32-Bit Float Read/Write Virtual Input Units

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

LoLo Alarm Setpoint 32-Bit Float Read/Write Virtual Input Units

Low Alarm Setpoint 32-Bit Float Read/Write Virtual Input Units

High Alarm Setpoint 32-Bit Float Read/Write Virtual Input Units

HiHi Alarm Setpoint 32-Bit Float Read/Write Virtual Input Units

33 Misc. Alarm Boolean Read

35 Alarm Bitfield 16-Bit Bitfield Read

24

Page 29

5.3.5.2 Virtual Input / Redundant Sensor Type Address Map

Virtual Input / Redundant Sensor Type Address Map (W900 Controller Only)

Address

Name

Data Encoding

Permissions

Value

0

1

2

3

4

5 6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Deviation Alarm

Boolean

Read

1 = Alarm Active

33

Misc. Alarm

Boolean

Read

1 = Input Failure Alarm Active

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

See 5.5.5 Virtual Input Alarm

Bitfield

Primary Value 32-Bit Float Read Virtual Input Units

Deadband 32-Bit Float Read/Write Virtual Input Units

Deviation Alarm

Setpoint

35 Alarm Bitfield 16-Bit Bitfield Read

32-Bit Float Read/Write Virtual Input Units

25

Page 30

5.3.5.3 Virtual Input / Disturbance Type Address Map

Virtual Input / Disturbance Type Address Map (W900 Controller Only)

Address

Name

Data Encoding

Permissions

Value

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

See 5.5.5 Virtual Input Alarm

Bitfield

Primary Value 32-Bit Float Read Unitless

Minimum Value 32-Bit Float Read/Write Unitless

Maximum Value 32-Bit Float Read/Write Unitless

Smoothing Factor 32-Bit Float Read/Write 0 – 90%

Disturbance Setpoint 32-Bit Float Read/Write Disturbance Input Units

Max Disturbance 32-Bit Float Read/Write Disturbance Input Units

35 Alarm Bitfield 16-Bit Bitfield Read

26

Page 31

5.3.6 Relay Output Address Maps

Relay Output / Manual Control Address Map

Address

Name

Data Encoding

Permissions

Value

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Relay State

Boolean

Read

0 = Off, 1 = On

32

Reset Time Total

Boolean

Read/Write

Write 1 to Reset Time Total

0 = Hand, 1 = Off,

2 = Auto Mode

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

See 5.5.6 Relay Output Alarm Bitfield

Returns 1 if any alarm is active

5.3.6.1 Relay Output / Manual Control Mode Address Map

Time On 32-Bit Integer Read Seconds

Total Time 32-Bit Integer Read Seconds

On Time Delay 32-Bit Integer Read/Write 0 – 86,399 Seconds

Off Time Delay 32-Bit Integer Read/Write 0 – 86,399 Seconds

Hand Time Limit 32-Bit Integer Read/Write 0 – 86,399 Seconds

33 HOA Setting 16-Bit Integer Read/Write

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

27

Page 32

5.3.6.2 Relay Output / On/Off & On/Off Disturbance Control Mode Address Map

Relay Output / On/Off & On/Off Disturbance Control Address Map

Data

Encoding

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Duty Cycle Period

16-Bit Integer

Read/Write

0 – 3599 Seconds

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Reset Output Timeout

Boolean

Read/Write

Write 1 to Reset Output Timeout

31

Relay State

Boolean

Read

0 = Off, 1 = On

32

Reset Time Total

Boolean

Read/Write

Write 1 to Reset Time Total

0 = Hand, 1 = Off,

2 = Auto Mode

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

See 5.5.6 Relay Output Alarm Bitfield

Returns 1 if any alarm is active

Address Name

Time On 32-Bit Integer Read Seconds

Total Time 32-Bit Integer Read Seconds

Setpoint 32-Bit Float Read/Write Input Sensor Units

Deadband 32-Bit Float Read/Write Input Sensor Units

Duty Cycle 32-Bit Float Read/Write 0 – 100%

Permissions Value

On Time Delay 32-Bit Integer Read/Write 0 – 86,399 Seconds

Off Time Delay 32-Bit Integer Read/Write 0 – 86,399 Seconds

Output Time Limit 32-Bit Integer Read/Write 0 – 86,399 Seconds

Hand Time Limit 32-Bit Integer Read/Write 0 – 86,399 Seconds

33 HOA Setting 16-Bit Integer Read/Write

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

28

Page 33

5.3.6.3 Relay Output / Dual Setpoint Control Mode Address Map

Relay Output / Dual Setpoint Control Address Map

Data

Encoding

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Duty Cycle Period

16-Bit Integer

Read/Write

0 – 3599 Seconds

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Reset Output Timeout

Boolean

Read/Write

Write 1 to Reset Output Timeout

31

Relay State

Boolean

Read

0 = Off, 1 = On

32

Reset Time Total

Boolean

Read/Write

Write 1 to Reset Time Total

0 = Hand, 1 = Off,

2 = Auto Mode

34

Status

16-Bit Status

Read

See 5.4 Status Register Codes

See 5.5.6 Relay Output Alarm Bitfield

Returns 1 if any alarm is active

Address Name

Time On 32-Bit Integer Read Seconds

Total Time 32-Bit Integer Read Seconds

Setpoint 1 32-Bit Float Read/Write Input Sensor Units

Setpoint 2 32-Bit Float Read/Write Input Sensor Units

Deadband 32-Bit Float Read/Write Input Sensor Units

Duty Cycle 32-Bit Float Read/Write 0 – 100%

Permissions Value

On Time Delay 32-Bit Integer Read/Write 0 – 86,399 Seconds

Off Time Delay 32-Bit Integer Read/Write 0 – 86,399 Seconds

Output Time Limit 32-Bit Integer Read/Write 0 – 86,399 Seconds

Hand Time Limit 32-Bit Integer Read/Write 0 – 86,399 Seconds

33 HOA Setting 16-Bit Integer Read/Write

35 Alarm Bitfield 16-Bit Bitfield Read

When accessed as a Coil,

29

Page 34

5.3.6.4 Relay Output / Time Proportional Control Mode Address Map

Relay Output / Time Proportional Control Address Map

Data

Encoding

0

1

2

32-Bit

Integer

3

4

32-Bit

Integer

5

6

7

8

9

10

11

12

13

14

32-Bit

Integer

15

16

17

18

19

20

21

22

32-Bit

Integer

23

24

25

26

27

28

29

Reset Output

Timeout

31

Relay State

Boolean

Read

0 = Off, 1 = On

32

Reset Time Total

Boolean

Read/Write

Write 1 to Reset Time Total

16-Bit

Integer

0 = Hand, 1 = Off,

2 = Auto Mode

16-Bit

Status

See 5.5.6 Relay Output Alarm Bitfield

Returns 1 if any alarm is active

Address Name

Time On

Total Time

Cycle Time

Setpoint 32-Bit Float Read/Write Input Sensor Units