Page 1

Modular I/O System

BACnet/IP Controller

750-830

Manual

Technical description,

installation and

configuration

Version 1.0.1

Page 2

2 • General

Copyright © 2008 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

The contents of this documentation are taken in part from the BACnet Standard 135-2004 or are based on the original contents. These contents are subject to copyright.

The following applies to these contents:

©2004, American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org). Reprinted by permission from 2004 ASHRAE

Standard-135. This material may not be copied nor distributed in either paper

or digital form without ASHRAE’s permission.

The following applies for the BACnet logo:

BACnet® is a registered trademark of ASHRAE.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 7 77

Fax: +49 (0) 571/8 87 – 87 77

E-Mail:

tcba@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time.

E-Mail:

documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 3

Content • 3

Content

1 Important Notes ..........................................................................................6

1.1 Legal Principles........................................................................................6

1.2 Standards and Regulations for Operating the 750 Series.........................8

1.3 Symbols.................................................................................................... 9

1.4 Safety Information.................................................................................. 10

1.5 Font Conventions ...................................................................................11

1.6 Number Notation....................................................................................11

1.7 Scope ...................................................................................................... 12

1.8 Abbreviation...........................................................................................12

2 The WAGO-I/O-SYSTEM 750................................................................ 13

2.1 System Description.................................................................................13

2.2 Technical Data........................................................................................ 14

2.3 Manufacturing Number ..........................................................................20

2.4 Component Update.................................................................................21

2.5 Storage, Assembly and Transport ..........................................................21

2.6 Mechanical Setup ...................................................................................22

2.7 Power Supply .........................................................................................30

2.8 Grounding............................................................................................... 41

2.9 Shielding (Screening)............................................................................. 44

2.10 Assembly Guidelines/Standards.............................................................45

3 Fieldbus Controller................................................................................... 46

3.1 BACnet/IP Controller 750-830 ..............................................................46

4 Fieldbus Communication .......................................................................163

4.1 ETHERNET .........................................................................................163

4.2 BACnet/IP ............................................................................................ 192

4.3 MODBUS Functions ............................................................................214

5 I/O Modules ............................................................................................. 245

5.1 Overview ..............................................................................................245

5.2 Process Data Architecture for MODBUS/TCP.................................... 254

6 List of all BACnet Properties in Native Operation..............................275

6.1 Acked_Transitions................................................................................276

6.2 Active_COV_Subscriptions .................................................................277

6.3 Active_Text.......................................................................................... 277

6.4 Alarm_Value ........................................................................................ 278

6.5 APDU_Segment_Timeout.................................................................... 279

6.6 APDU_Timeout.................................................................................... 279

6.7 Application_Software_Version............................................................ 280

6.8 Archive .................................................................................................280

6.9 Backup_Failure_Timeout.....................................................................280

6.10 Change_Of_State_Count......................................................................281

6.11 Change_Of_State_Time .......................................................................281

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 4

4 • Content

6.12 Configuration_Files..............................................................................282

6.13 COV_Increment ...................................................................................282

6.14 Database_Revision ...............................................................................282

6.15 Data_List .............................................................................................. 283

6.16 Daylight_Savings_Status......................................................................283

6.17 Deadband..............................................................................................283

6.18 Description ........................................................................................... 284

6.19 Device_Address_Binding..................................................................... 284

6.20 Device_Type ........................................................................................285

6.21 Effective_Period...................................................................................285

6.22 Elapsed_Active_Time ..........................................................................285

6.23 Event_Enable........................................................................................286

6.24 Event_State........................................................................................... 286

6.25 Event_Time_Stamps.............................................................................286

6.26 Exception_Schedule .............................................................................287

6.27 Feedback_Value ...................................................................................288

6.28 File_Access_Method............................................................................ 288

6.29 File_Size...............................................................................................289

6.30 File_Type.............................................................................................. 289

6.31 Firmware_Revision ..............................................................................289

6.32 High_Limit ...........................................................................................289

6.33 Inactive_Text........................................................................................290

6.34 Last_Restore_Time ..............................................................................290

6.35 Limit_Enable........................................................................................ 291

6.36 List_Of_Object_Property_References ................................................. 291

6.37 Local_Date ........................................................................................... 292

6.38 Local_Time...........................................................................................292

6.39 Location................................................................................................292

6.40 Low_Limit............................................................................................292

6.41 Max_APDU_Length_Accepted ...........................................................293

6.42 Max_Pres_Value ..................................................................................293

6.43 Max_Segments_Accepted.................................................................... 293

6.44 Min_Pres_Value...................................................................................293

6.45 Minimum_Off_Time ............................................................................ 294

6.46 Minimum_On_Time............................................................................. 294

6.47 Model_Name........................................................................................ 294

6.48 Modification_Date................................................................................295

6.49 Notification_Class................................................................................ 295

6.50 Notify_Type .........................................................................................295

6.51 Number_Of_APDU_Retries.................................................................295

6.52 Object_Identifier ..................................................................................296

6.53 Object_List ...........................................................................................296

6.54 Object_Name........................................................................................296

6.55 Object_Type .........................................................................................297

6.56 Out_Of_Service....................................................................................297

6.57 Polarity ................................................................................................. 298

6.58 Present_Value....................................................................................... 299

6.59 Priority_Array ......................................................................................302

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 5

Content • 5

6.60 Priority_For_Writing............................................................................ 302

6.61 Protocol_Object_Types_Supported......................................................302

6.62 Protocol_Revision ................................................................................303

6.63 Protocol_Services_Supported ..............................................................303

6.64 Protocol_Version..................................................................................303

6.65 Read_Only............................................................................................304

6.66 Record_Count....................................................................................... 304

6.67 Reliability ............................................................................................. 304

6.68 Relinquish_Default............................................................................... 305

6.69 Resolution............................................................................................. 306

6.70 Schedule_Default ................................................................................. 306

6.71 Segmentation_Supported......................................................................306

6.72 Status_Flags..........................................................................................307

6.73 System_Status ......................................................................................308

6.74 Time_Delay.......................................................................................... 308

6.75 Time_Of_Active_Time_Reset ............................................................. 309

6.76 Time_Of_State_Count_Reset............................................................... 309

6.77 Units ..................................................................................................... 309

6.78 Update_Interval.................................................................................... 310

6.79 UTC_Offset .......................................................................................... 310

6.80 Vendor_Identifier .................................................................................310

6.81 Vendor_Name ......................................................................................311

6.82 Weekly_Schedule.................................................................................311

7 Protocol Implementation Conformance Statement (PICS) ................312

7.1 PICS Content........................................................................................312

8 Application Examples............................................................................. 313

8.1 Test of MODBUS Protocol and Fieldbus Nodes .................................313

8.2 Visualization and Control Using SCADA Software ............................313

9 Use in Hazardous Environments ........................................................... 316

9.1 Foreword ..............................................................................................316

9.2 Protective Measures .............................................................................316

9.3 Classification Meeting CENELEC and IEC ........................................316

9.4 Classifications Meeting the NEC 500 ..................................................323

9.5 Identification ........................................................................................325

9.6 Installation Regulations........................................................................327

Glossary ........................................................................................................331

Literature List.............................................................................................. 355

Index.............................................................................................................. 356

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 6

6 • Important Notes

Legal Principles

1 Important Notes

This section provides only a summary of the most important safety requirements and notes which will be mentioned in the individual sections. To protect

your health and prevent damage to the devices, it is essential to read and carefully follow the safety guidelines.

1.1 Legal Principles

1.1.1 Copyright

This manual including all figures and illustrations contained therein is subject

to copyright. Any use of this manual which infringes the copyright provisions

stipulated herein, is not permitted. Reproduction, translation and electronic

and phototechnical archiving and amendments require the written consent of

WAGO Kontakttechnik GmbH & Co. KG, Minden. Non-observance will entail the right of claims for damages.

WAGO Kontakttechnik GmbH & Co. KG reserves the right of changes serving technical progress.

All rights developing from the issue of a patent or the legal protection of utility patents are reserved to WAGO Kontakttechnik GmbH & Co. KG. Thirdparty products are always indicated without any notes concerning patent

rights. Thus, the existence of such rights must not be excluded.

1.1.2 Personnel Qualification

The use of the product described in this manual requires special qualifications,

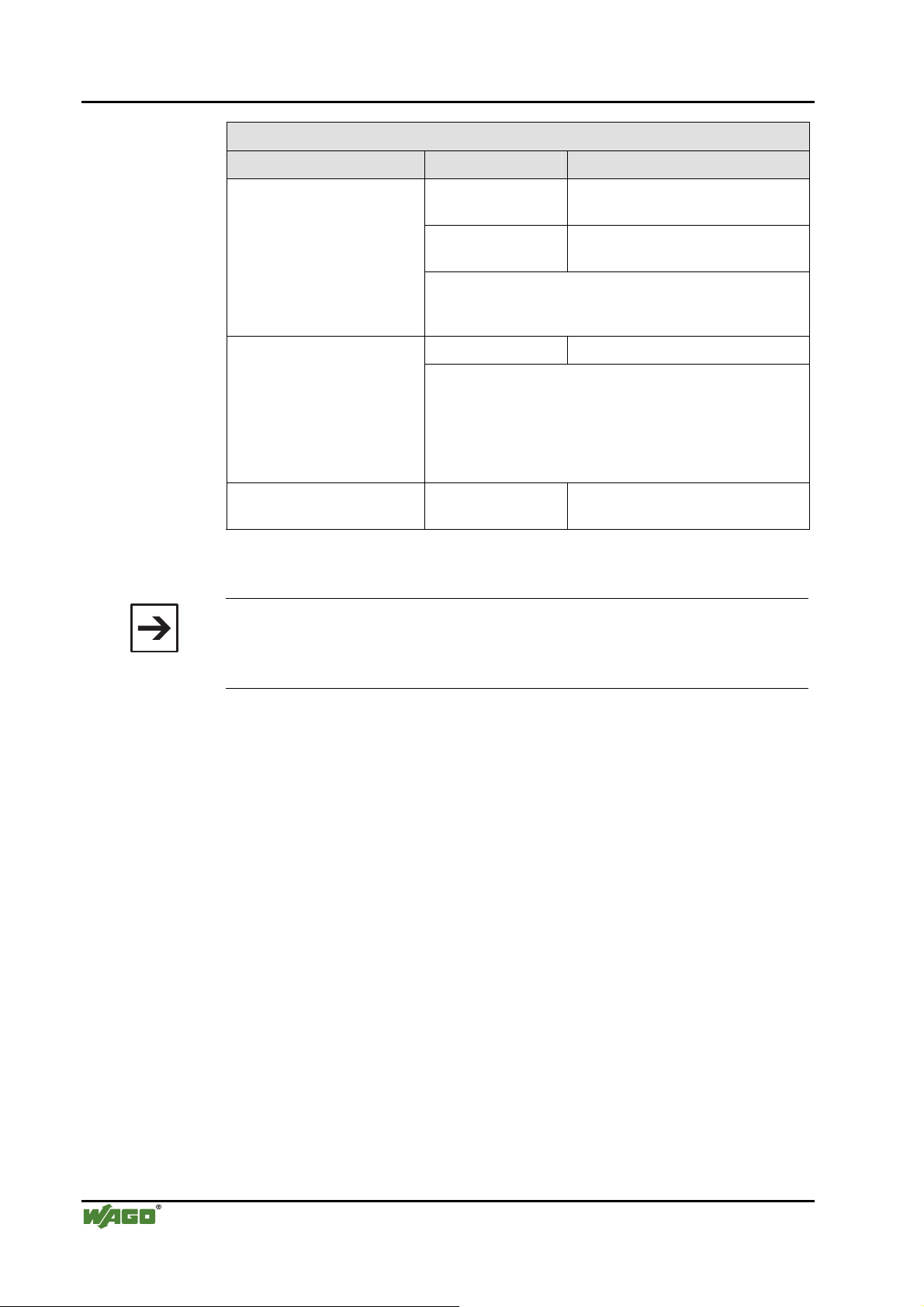

as shown in the following table:

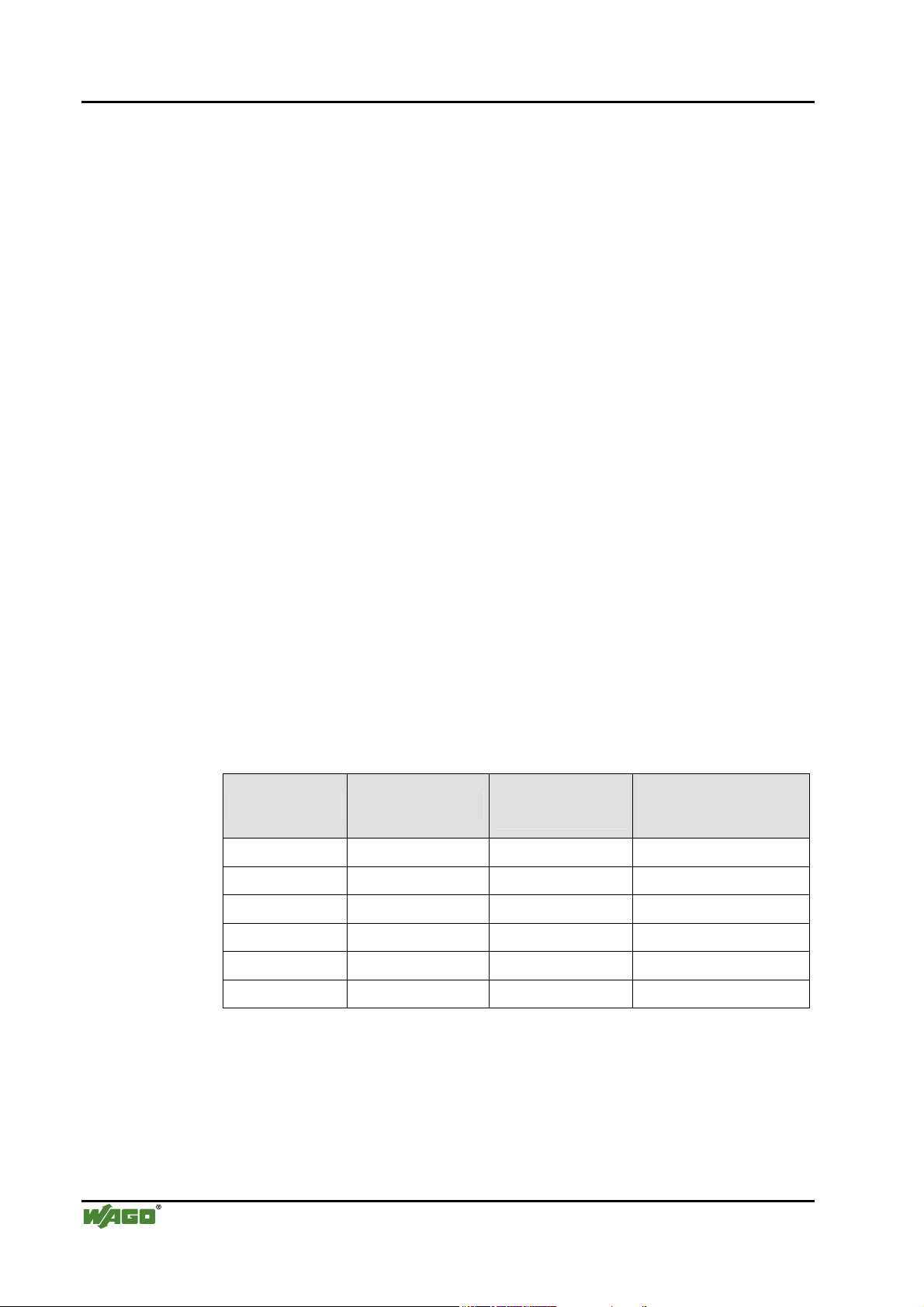

Activity Electrical specialist

Assembly

Commissioning

Programming

Maintenance

Troubleshooting

Instructed personnel*)

X X

X X

X

X X

X

Specialists**) having

qualifications in PLC

programming

Disassembly

*) Instructed persons have been trained by qualified personnel or electrical specialists.

**) A specialist is someone who, through technical training, knowledge and experience,

demonstrates the ability to meet the relevant specifications and identify potential dangers in

the mentioned field of activity.

WAGO-I/O-SYSTEM 750

X X

BACnet/IP Controller

Page 7

Important Notes • 7

Legal Principles

All personnel must be familiar with the applicable standards.

WAGO Kontakttechnik GmbH & Co. KG declines any liability resulting from

improper action and damage to WAGO products and third party products due

to non-observance of the information contained in this manual.

1.1.3 Conforming Use of Series 750

The couplers and controllers of the modular I/O System 750 receive digital

and analog signals from the I/O modules and sensors and transmit them to the

actuators or higher level control systems. Using the WAGO controllers, the

signals can also be (pre-)processed.

The device is designed for IP20 protection class. It is protected against finger

touch and solid impurities up to 12.5mm diameter, but not against water penetration. Unless otherwise specified, the device must not be operated in wet and

dusty environments.

1.1.4 Technical Condition of the Devices

For each individual application, the components are supplied from the factory

with a dedicated hardware and software configuration. Changes in hardware,

software and firmware are only admitted within the framework of the possibilities documented in the manuals. All changes to the hardware or software

and the non-conforming use of the components entail the exclusion of liability

on the part of WAGO Kontakttechnik GmbH & Co. KG.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH & Co.

KG.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 8

8 • Important Notes

Standards and Regulations for Operating the 750 Series

1.2 Standards and Regulations for Operating the 750 Series

Please observe the standards and regulations that are relevant to your installation:

• The data and power lines must be connected and installed in compliance

with the standards to avoid failures on your installation and eliminate any

danger to personnel.

• For installation, startup, maintenance and repair, please observe the accident prevention regulations of your machine (e.g. BGV A 3, "Electrical Installations and Equipment").

• Emergency stop functions and equipment must not be made ineffective.

See relevant standards (e.g. DIN EN 418).

• Your installation must be equipped in accordance to the EMC guidelines

so that electromagnetic interferences can be eliminated.

• Operating 750 Series components in home applications without further

measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information in the section on "WAGO-I/O-SYSTEM 750" ! "System Description" ! "Technical Data".

• Please observe the safety measures against electrostatic discharge according to DIN EN 61340-5-1/-3. When handling the modules, ensure that the

environment (persons, workplace and packing) is well grounded.

• The relevant valid and applicable standards and guidelines concerning the

installation of switch cabinets are to be observed.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 9

Important Notes • 9

Symbols

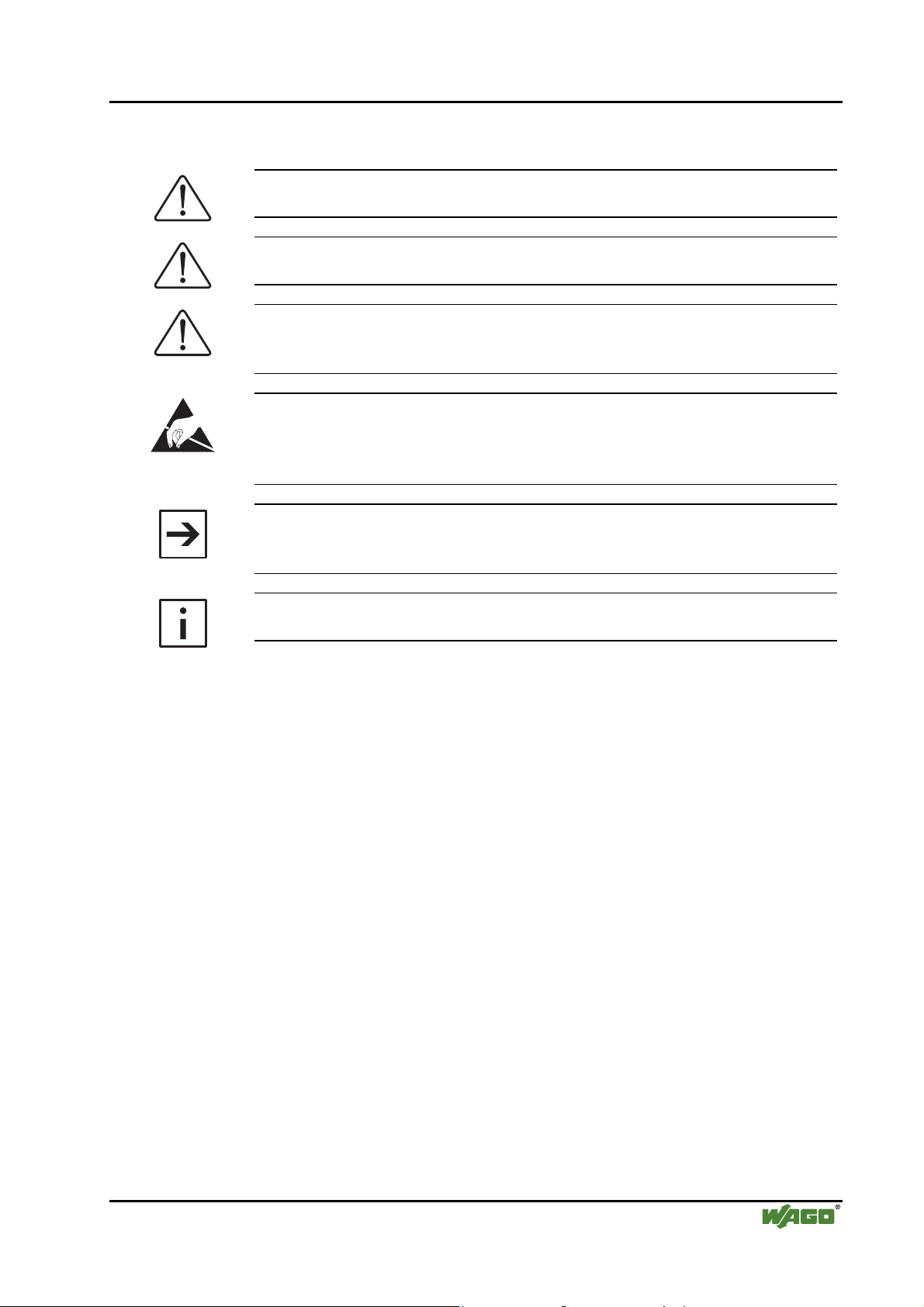

1.3 Symbols

Danger

Always observe this information to protect persons from injury.

Warning

Always observe this information to prevent damage to the device.

Attention

Marginal conditions that must always be observed to ensure smooth and efficient operation.

ESD (Electrostatic Discharge)

Warning of damage to the components through electrostatic discharge. Observe the precautionary measure for handling components at risk of electrostatic discharge.

Note

Make important notes that are to be complied with so that a trouble-free and

efficient device operation can be guaranteed.

Additional Information

References to additional literature, manuals, data sheets and internet pages.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 10

10 • Important Notes

Safety Information

1.4 Safety Information

When connecting the device to your installation and during operation, the following safety notes must be observed:

Danger

The WAGO-I/O-SYSTEM 750 and its components are an open system. It

must only be assembled in housings, cabinets or in electrical operation

rooms. Access is only permitted via a key or tool to authorized qualified personnel.

Danger

All power sources to the device must always be switched off before carrying

out any installation, repair or maintenance work.

Warning

Replace defective or damaged device/module (e.g. in the event of deformed

contacts), as the functionality of field bus station in question can no longer be

ensured on a long-term basis.

Warning

The components are not resistant against materials having seeping and insulating properties. Belonging to this group of materials is: e.g. aerosols, silicones, triglycerides (found in some hand creams). If it cannot be ruled out

that these materials appear in the component environment, then the components must be installed in an enclosure that is resistant against the above mentioned materials. Clean tools and materials are generally required to operate

the device/module.

Warning

Soiled contacts must be cleaned using oil-free compressed air or with ethyl

alcohol and leather cloths.

Warning

Do not use contact sprays, which could possibly impair the functioning of the

contact area.

Warning

Avoid reverse polarity of data and power lines, as this may damage the devices.

ESD (Electrostatic Discharge)

The devices are equipped with electronic components that may be destroyed

by electrostatic discharge when touched.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 11

Important Notes • 11

Font Conventions

Warning

For components with ETHERNET/RJ-45 connectors:

Only for use in LAN, not for connection to telecommunication circuits.

1.5 Font Conventions

italic

Names of paths and files are marked in italic.

e.g.: C:\Programs\WAGO-IO-CHECK

italic

Menu items are marked in bold italic.

e.g.: Save

\

A backslash between two names characterizes the selection of a

menu point from a menu.

e.g.: File \ New

END

Press buttons are marked as bold with small capitals

e.g.:

< >

Keys are marked bold within angle brackets

e.g.: <F5>

Courier

The print font for program codes is Courier.

e.g.: END_VAR

1.6 Number Notation

ENTER

Number code Example Note

Decimal 100 Normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Within inverted commas,

Nibble separated with dots

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 12

12 • Important Notes

Scope

1.7 Scope

This manual describes the field bus independent WAGO I/O SYSTEM 750

with the programmable BACnet/IP Controller.

Item.-No. Description

750-830 BACnet/IP Controller

1.8 Abbreviation

AI

AO

DI

DO

I/O

ID

PFC

Analog Input

Analog Output

Digital Input

Digital Output

Input/Output

Identifier

Programmable Fieldbus Controller

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 13

System Description • 13

Technical Condition of the Devices

2 The WAGO-I/O-SYSTEM 750

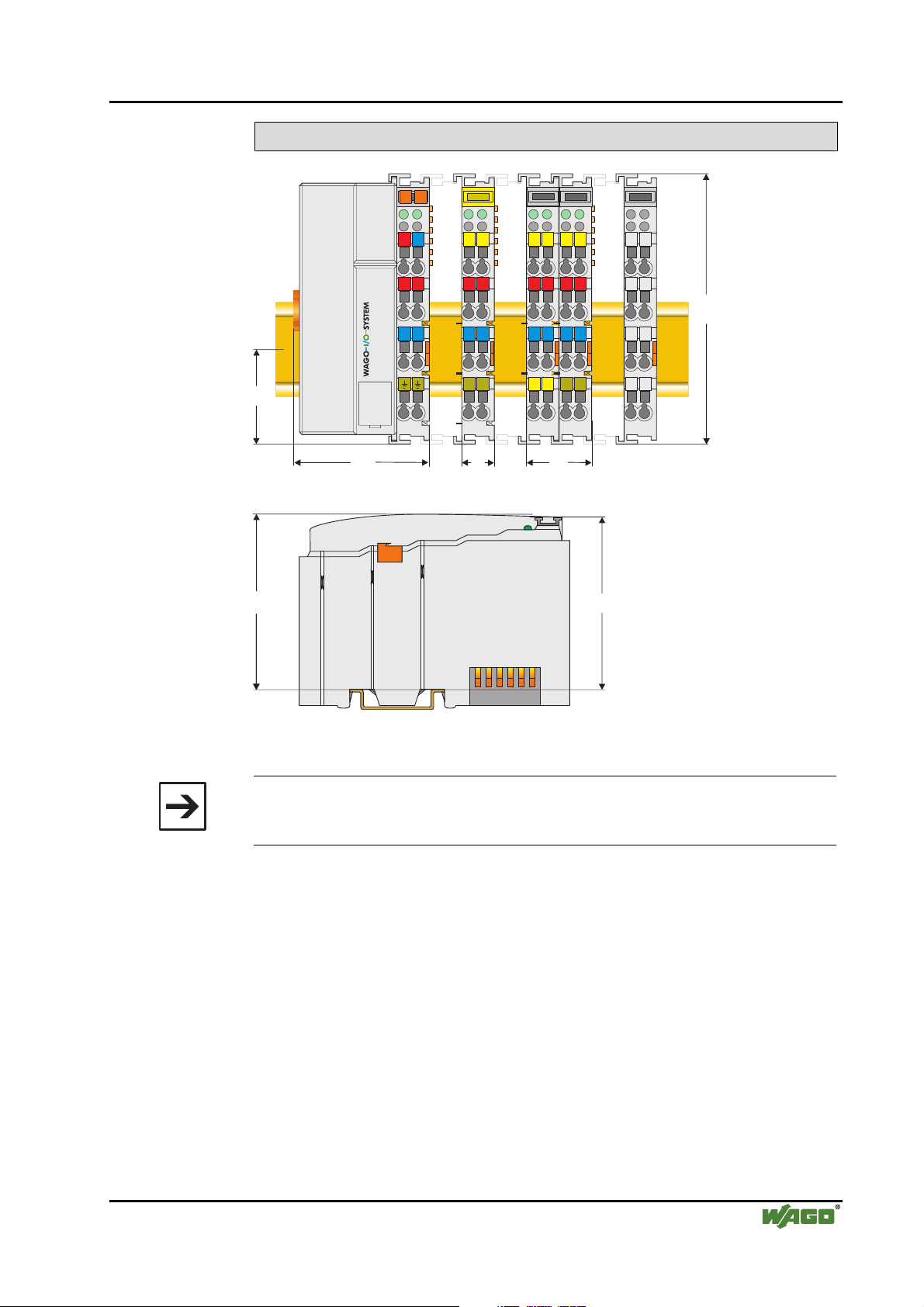

2.1 System Description

The WAGO-I/O-SYSTEM 750 is a modular, field bus independent I/O system. It is comprised of a field bus coupler/controller (1) and connected field

bus modules (2) for any type of signal. Together, these make up the field bus

node. The end module (3) completes the node.

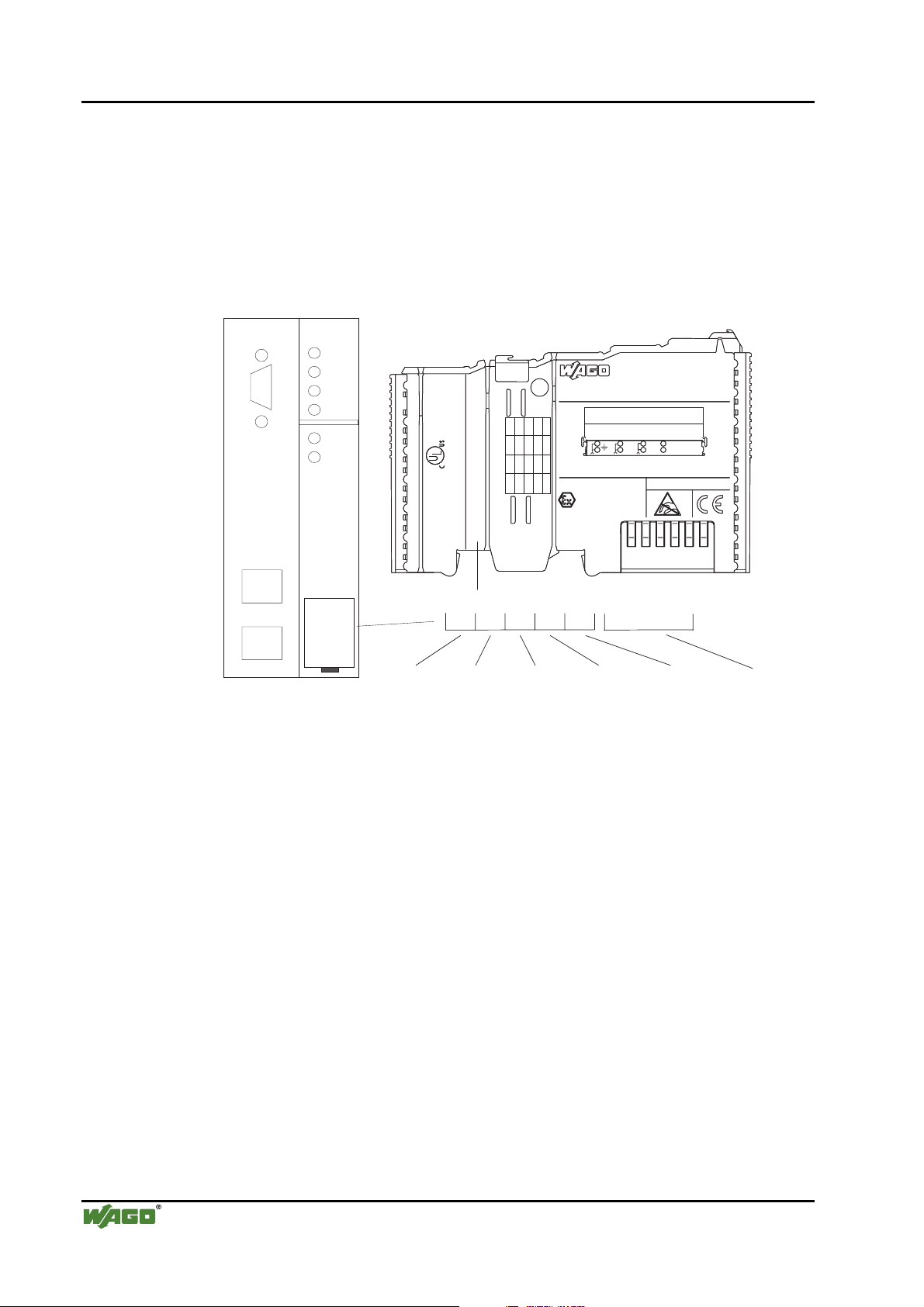

Fig. 2-1: Field bus node g0xxx00x

Couplers/controllers for field bus systems such as PROFIBUS, INTERBUS,

ETHERNET TCP/IP, CAN (CANopen, DeviceNet, CAL), MODBUS, LON

and others are available.

The coupler/controller contains the field bus interface, electronics and a power

supply terminal. The field bus interface forms the physical interface to the

relevant field bus. The electronics process the data of the bus modules and

make it available for the field bus communication. The 24 V system supply

and the 24 V field supply are fed in via the integrated power supply terminal.

The field bus coupler communicates via the relevant field bus. The programmable field bus controller (PFC) enables the implementation of additional

PLC functions. Programming is done with the WAGO I/O PRO CAA in accordance with IEC 61131-3.

Bus modules for diverse digital and analog I/O functions as well as special

functions can be connected to the coupler/controller. The communication between the coupler/controller and the bus modules is carried out via an internal

bus.

The WAGO-I/O-SYSTEM 750 has a clear port level with LEDs for status indication, insertable mini WSB markers and pullout group marker carriers. The

3-wire technology supplemented by a ground wire connection allows for direct sensor/actuator wiring.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 14

14 • Technical Data

Technical Condition of the Devices

2.2 Technical Data

Mechanic

Material Polycarbonate, Polyamide 6.6

Dimensions W x H* x L

* from upper edge of DIN 35 rail

- Coupler/Controller (Standard)

- Coupler/Controller (ECO)

- Coupler/Controller (FireWire)

- I/O module, single

- I/O module, double

- I/O module, fourfold

- 51 mm x 65 mm x 100 mm

- 50 mm x 65 mm x 100 mm

- 62 mm x 65 mm x 100 mm

- 12 mm x 64 mm x 100 mm

- 24 mm x 64 mm x 100 mm

- 48 mm x 64 mm x 100 mm

Installation on DIN 35 with interlock

Modular by double feather key dovetail

Mounting position any position

Marking standard marking label type

group marking label 8 x 47 mm

Connection

Connection type CAGE CLAMP®

Wire range 0.08 mm² ... 2.5 mm², AWG 28-14

Stripped length 8 … 9 mm,

9 … 10 mm for components with pluggable wiring

(753-xxx)

Contacts

Power jumpers contacts blade/spring contact

self-cleaning

Current via power contacts

Voltage drop at I

< 1 V/64 modules

max

10 A

max

Data contacts slide contact, hard gold plated

1.5 µm, self-cleaning

Climatic environmental conditions

Operating temperature 0 °C ... 55 °C,

-20 °C … +60 °C for components with extended

temperature range (750-xxx/025-xxx)

Storage temperature -20 °C ... +85 °C

Relative humidity 5 % … 95 % without condensation

Resistance to harmful substances acc. to IEC 60068-2-42 and IEC 60068-2-43

Maximum pollutant concentration at

relative humidity < 75%

≤ 25 ppm

SO

2

H

S ≤ 10 ppm

2

Special conditions Ensure that additional measures for components are

taken, which are used in an environment involving:

– dust, caustic vapors or gases

– ionization radiation

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 15

Technical Data • 15

Technical Condition of the Devices

Safe electrical isolation

Air and creepage distance acc. to IEC 60664-1

Degree of pollution

2

acc. To IEC 61131-2

Degree of protection

Degree of protection IP 20

Electromagnetic compatibility

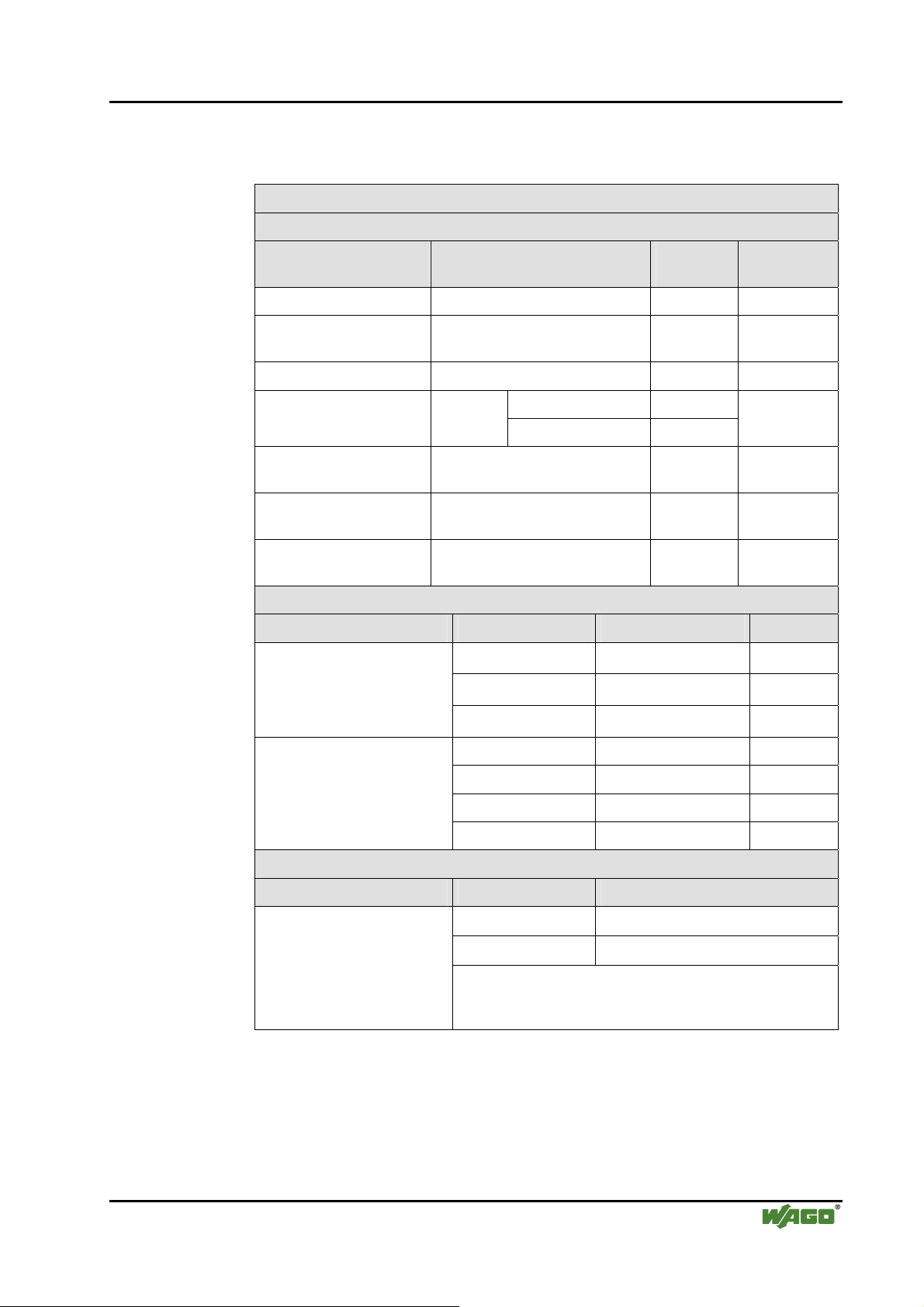

Immunity to interference for industrial areas acc. to EN 61000-6-2 (2001)

Test specification Test values Strength

class

Evaluation

criteria

EN 61000-4-2 ESD 4 kV/8 kV (contact/air) 2/3 B

EN 61000-4-3

10 V/m 80 MHz ... 1 GHz 3 A

electromagnetic fields

EN 61000-4-4 burst 1 kV/2 kV (data/supply) 2/3 B

EN 61000-4-5 surge

-/- (line/line) Data:

B

1 kV (line/earth) 2

ply:

AC supply:

0.5 kV (line/line) 1 DC sup-

0.5 kV (line/earth) 1

1 kV (line/line) 2

2 kV (line/earth) 3

B

B

EN 61000-4-6

RF disturbances

10 V/m 80 % AM

(0.15 ... 80 MHz)

3 A

Emission of interference for industrial areas acc. to EN 61000-6-4 (2001)

Test specification Limit values/[QP]*) Frequency range Distance

79 dB (μV) 150 kHz ... 500 kHz EN 55011 (AC supply,

conducted)

73 dB (μV) 500 kHz ... 30 MHz

40 dB (μV/m) 30 MHz ... 230 MHz 10 m EN 55011 (radiated)

47 dB (μV/m) 230 MHz ... 1 GHz 10 m

Emission of interference for residential areas acc. to EN 61000-6-3 (2001)

Test specification Limit values/[QP]*) Frequency range Distance

EN 55022 (AC supply,

conducted)

66 ... 56 dB (μV) 150 kHz ... 500 kHz

56 dB (μV) 500 kHz ... 5 MHz

60 dB (μV) 5 MHz ... 30 MHz

40 ... 30 dB (μA) 150 kHz ... 500 kHz EN 55022 (DC supply/data,

conducted)

30 dB (μA) 500 kHz ... 30 MHz

30 dB (μV/m) 30 MHz ... 230 MHz 10 m EN 55022 (radiated)

37 dB (μV/m) 230 MHz ... 1 GHz 10 m

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 16

16 • Technical Data

Technical Condition of the Devices

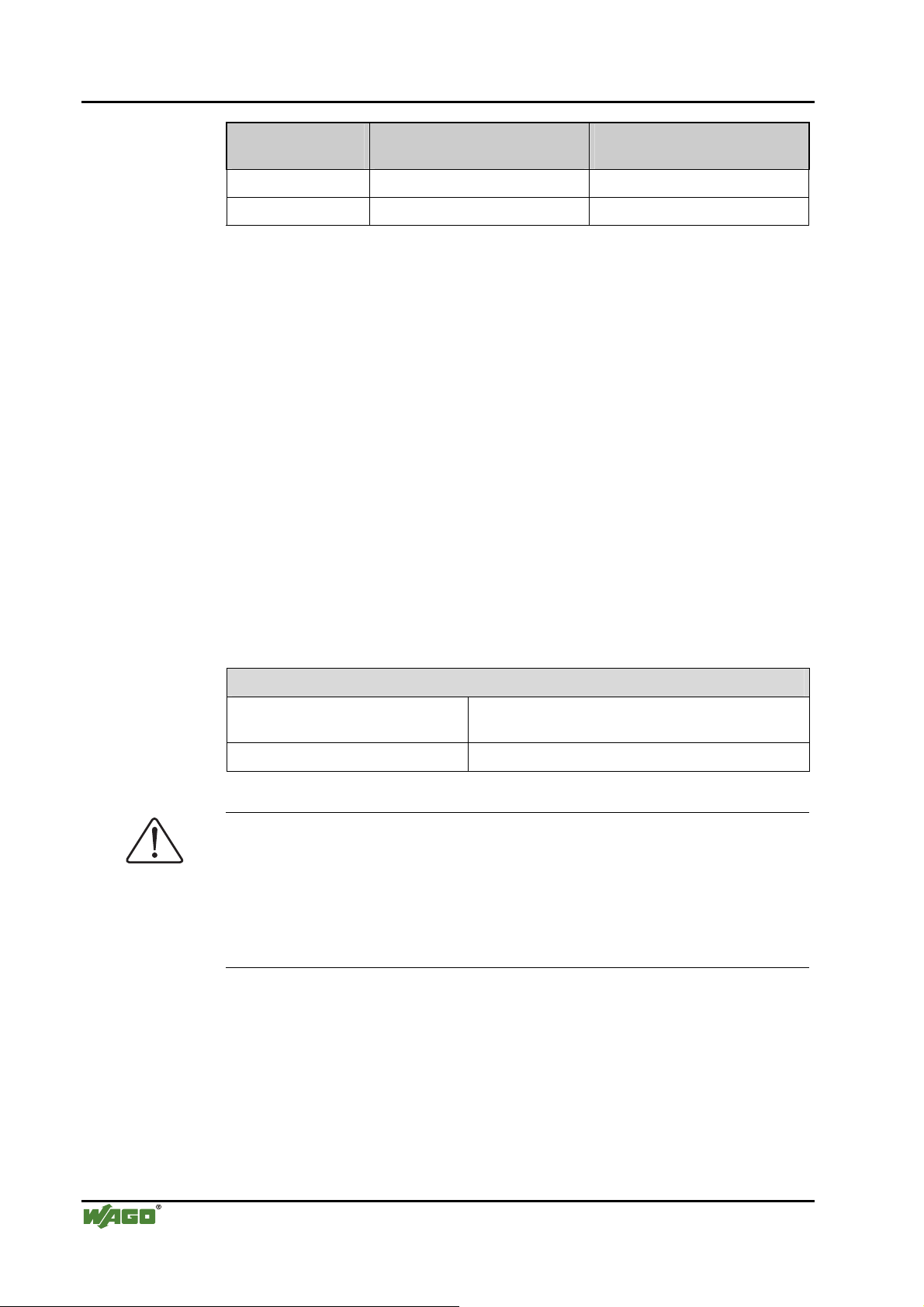

Mechanical strength acc. to IEC 61131-2

Test specification Frequency range Limit value

IEC 60068-2-6 vibration

IEC 60068-2-32 free fall 1 m

*) QP: Quasi Peak

5 Hz ≤ f < 9 Hz

9 Hz ≤ f < 150 Hz

Note on vibration test:

a) Frequency change: max. 1 octave/minute

b) Vibration direction: 3 axes

15 g IEC 60068-2-27 shock

Note on shock test:

a) Type of shock: half sine

b) Shock duration: 11 ms

c) Shock direction: 3x in positive and 3x in negative direction for each of the three mutually perpendicular axes of the

test specimen

1.75 mm amplitude (permanent)

3.5 mm amplitude (short term)

0.5 g (permanent)

1 g (short term)

(module in original packing)

Note

If the technical data of components differ from the values described here, the

technical data shown in the manuals of the respective components shall be

valid.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 17

Technical Data • 17

Technical Condition of the Devices

For Products of the WAGO-I/O-SYSTEM 750 with ship specific approvals

supplementary guidelines are valid:

Electromagnetic compatibility

Immunity to interference acc. to Germanischer Lloyd (2003)

Test specification Test values Strength

class

IEC 61000-4-2 ESD 6 kV/8 kV (contact/air) 3/3 B

IEC 61000-4-3

electromagnetic fields

IEC 61000-4-4 burst 1 kV/2 kV (data/supply) 2/3 A

IEC 61000-4-6

RF disturbances

Type test AF disturbances

(harmonic waves)

Type test high voltage 755 V DC

Emission of interference acc. to Germanischer Lloyd (2003)

Test specification Limit values Frequency range Distance

Type test

(EMC1, conducted)

allows for ship bridge control

applications

10 V/m 80 MHz ... 2 GHz 3 A

0.5 kV (line/line) 1 IEC 61000-4-5 surge AC/DC

Supply:

10 V/m 80 % AM

(0.15 ... 80 MHz)

3 V, 2 W - A

1500 V AC

96 ... 50 dB (μV) 10 kHz ... 150 kHz

60 ... 50 dB (μV) 150 kHz ... 350 kHz

50 dB (μV) 350 kHz ... 30 MHz

1 kV (line/earth) 2

3 A

- -

Evaluation

criteria

A

Type test

(EMC1, radiated)

allows for ship bridge control

applications

except: 24 dB (μV/m) 156 MHz ... 165 MHz 3 m

Mechanical strength acc. to Germanischer Lloyd (2003)

Test specification Frequency range Limit value

IEC 60068-2-6 vibration

(category A – D)

80 ... 52 dB (μV/m) 150 kHz ... 300 kHz 3 m

52 ... 34 dB (μV/m) 300 kHz ... 30 MHz 3 m

54 dB (μV/m) 30 MHz ... 2 GHz 3 m

2 Hz ≤ f < 25 Hz

25 Hz ≤ f < 100 Hz

Note on vibration test:

a) Frequency change: max. 1 octave/minute

b) Vibration direction: 3 axes

± 1.6 mm amplitude (permanent)

4 g (permanent)

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 18

18 • Technical Data

Technical Condition of the Devices

Range of

application

Industrial areas EN 61000-6-4 (2001) EN 61000-6-2 (2001)

Residential areas EN 61000-6-3 (2001)*) EN 61000-6-1 (2001)

*)

The system meets the requirements on emission of interference in residential areas with

the field bus coupler/controller for:

ETHERNET

LonWorks

CANopen

DeviceNet

MODBUS

KNX

BACnet

With a special permit, the system can also be implemented with other field bus couplers/controllers in residential areas (housing, commercial and business areas, small-scale

enterprises). The special permit can be obtained from an authority or inspection office. In

Germany, the Federal Office for Post and Telecommunications and its branch offices

issues the permit.

It is possible to use other field bus couplers/controllers under certain boundary conditions. Please contact WAGO Kontakttechnik GmbH & Co. KG.

Required specification

emission of interference

750-342/-841/-842/-860

750-319/-819

750-337/-837

750-306/-806

750-312/-314/ -315/ -316

750-812/-814/ -815/ -816

750-849

750-830

Required specification

immunity to interference

Maximum power dissipation of the components

Bus modules 0.8 W / bus terminal (total power dissipation, sys-

tem/field)

Field bus coupler/controller 2.0 W / coupler/controller

Warning

The power dissipation of all installed components must not exceed the maximum conductible power of the housing (cabinet).

When dimensioning the housing, care is to be taken that even under high external temperatures, the temperature inside the housing does not exceed the

permissible ambient temperature of 55 °C.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 19

Technical Data • 19

Technical Condition of the Devices

Dimensions

02

01

35

A

B

24V 0V

+

-

A

C

B

D

+

A

C

D

A

C

B

B

D

A

C

D

C

B

D

100

-

51

65

Side view

12

24

Dimensions in mm

64

Fig. 2-2: Dimensions g01xx05e

Note

The illustration shows a standard coupler. For detailed dimensions, please

refer to the technical data of the respective coupler/controller.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 20

20 • Manufacturing Number

Technical Condition of the Devices

2.3 Manufacturing Number

The manufacturing number indicates the delivery status directly after production.

This number is part of the lateral marking on the component.

In addition, starting from calendar week 43/2000 the manufacturing number is

also printed on the cover of the configuration and programming interface of

the field bus coupler or controller.

PROFIBUS

750-333

ITEM-NO.:750-333

ITEM-NO.:750-333

PROFIBUS DP 12 MBd /DPV1

Hansastr. 27

Hansastr. 27

GL

D-32423 Minden

D-32423 Minden

24V DC

24V DC

AWG 28-14

AWG 28-14

55°C max ambient

55°C max ambient

72072

72072

DS

NO

SW

HW

FWL

II3GD

LISTED 22ZA AND 22XM

LISTED 22ZA AND 22XM

0103000203-B000000

0103000203-B060606

II3GD

DEMKO 02 ATEX132273 X

DEMKO 02 ATEX132273 X

EEx nA II T4

EEx nA II T4

PROFIBUS DP 12 MBd /DPV1

-

Power Supply

Field

24 V

+

0V

0V

Power Supply

Power Supply

Electronic

Electronic

PATENTS PENDING

PATENTS PENDING

WAGO - I/O - SYSTEM

Manufacturing Number

1

0

3

01030002

03-B

060606

72072

Calendar

week

Fig. 2-3: Example: Manufacturing Number of a PROFIBUS field bus coupler 750-333

0

Year Software

version

2

0

0

0

3

-B060606

Hardware

Firmware Loader

version

version

Internal

Number

g01xx15e

0

The manufacturing number consists of the production week and year, the software version (if available), the hardware version of the component, the firmware loader (if available) and further internal information for

WAGO Kontakttechnik GmbH & Co. KG.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 21

Component Update • 21

Technical Condition of the Devices

2.4 Component Update

For the case of an Update of one component, the lateral marking on each component contains a prepared matrix.

This matrix makes columns available for altogether three updates to the entry

of the current update data, like production order number (NO; starting from

calendar week 13/2004), update date (DS), software version (SW), hardware

version (HW) and the firmware loader version (FWL, if available).

Update Matrix

Current Version data for: 1. Update 2. Update 3. Update

Production Order

Number

Datestamp

Software index

Hardware index

Firmware loader

index

NO

DS

SW

HW

FWL

" only starting from calendar

" only for coupler/controller

If the update of a component took place, the current version data are registered

into the columns of the matrix.

Additionally with the update of a field bus coupler or controller also the cover

of the configuration and programming interface of the coupler or controller is

printed on with the current manufacturing and production order number.

The original manufacturing data on the housing of the component remain

thereby.

2.5 Storage, Assembly and Transport

Wherever possible, the components are to be stored in their original packaging. Likewise, the original packaging provides optimal protection during

transport.

week 13/2004

When assembling or repacking the components, the contacts must not be

soiled or damaged. The components must be stored and transported in appropriate containers/packaging. Thereby, the ESD information is to be regarded.

Statically shielded transport bags with metal coatings are to be used for the

transport of open components for which soiling with amine, amide and silicone has been ruled out, e.g. 3M 1900E.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 22

22 • Mechanical Setup

Installation Position

2.6 Mechanical Setup

2.6.1 Installation Position

Along with horizontal and vertical installation, all other installation positions

are allowed.

Attention

2.6.2 Total Expansion

In the case of vertical assembly, an end stop has to be mounted as an additional safeguard against slipping.

WAGO item 249-116 End stop for DIN 35 rail, 6 mm wide

WAGO item 249-117 End stop for DIN 35 rail, 10 mm wide

The length of the module assembly (including one end module of 12mm

width) that can be connected to the coupler/controller is 780 mm. When assembled, the I/O modules have a maximum length of 768 mm.

Examples:

• 64 I/O modules of 12 mm width can be connected to one coupler/controller.

• 32 I/O modules of 24 mm width can be connected to one coupler/controller.

Exception:

The number of connected I/O modules also depends on which type of coupler/controller is used. For example, the maximum number of I/O modules

that can be connected to a PROFIBUS coupler/controller is 63 without end

module. The maximum total expansion of a node is calculated as follows:

Warning

The maximum total length of a node without coupler/controller must not exceed 780 mm. Furthermore, restrictions made on certain types of couplers/controllers must be observed (e.g. for PROFIBUS).

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 23

Mechanical Setup • 23

Assembly onto Carrier Rail

2.6.3 Assembly onto Carrier Rail

2.6.3.1 Carrier Rail Properties

All system components can be snapped directly onto a carrier rail in accordance with the European standard EN 50022 (DIN 35).

Warning

WAGO Kontakttechnik GmbH & Co. KG supplies standardized carrier rails

that are optimal for use with the I/O system. If other carrier rails are used,

then a technical inspection and approval of the rail by WAGO Kontakttechnik GmbH & Co. KG should take place.

Carrier rails have different mechanical and electrical properties. For the optimal system setup on a carrier rail, certain guidelines must be observed:

• The material must be non-corrosive.

• Most components have a contact to the carrier rail to ground electro-

magnetic disturbances. In order to avoid corrosion, this tin-plated carrier

rail contact must not form a galvanic cell with the material of the carrier

rail which generates a differential voltage above 0.5 V (saline solution of

0.3% at 20°C) .

• The carrier rail must optimally support the EMC measures integrated into

the system and the shielding of the bus module connections.

• A sufficiently stable carrier rail should be selected and, if necessary, several mounting points (every 20 cm) should be used in order to prevent

bending and twisting (torsion).

• The geometry of the carrier rail must not be altered in order to secure the

safe hold of the components. In particular, when shortening or mounting

the carrier rail, it must not be crushed or bent.

• The base of the I/O components extends into the profile of the carrier rail.

For carrier rails with a height of 7.5 mm, mounting points are to be riveted

under the node in the carrier rail (slotted head captive screws or blind rivets).

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 24

24 • Mechanical Setup

Spacing

2.6.3.2 WAGO DIN Rail

WAGO carrier rails meet the electrical and mechanical requirements.

Item Number Description

210-113 /-112 35 x 7.5; 1 mm; steel yellow chromated; slotted/unslotted

210-114 /-197 35 x 15; 1.5 mm; steel yellow chromated; slotted/unslotted

210-118 35 x 15; 2.3 mm; steel yellow chromated; unslotted

210-198 35 x 15; 2.3 mm; copper; unslotted

210-196 35 x 7.5; 1 mm; aluminum; unslotted

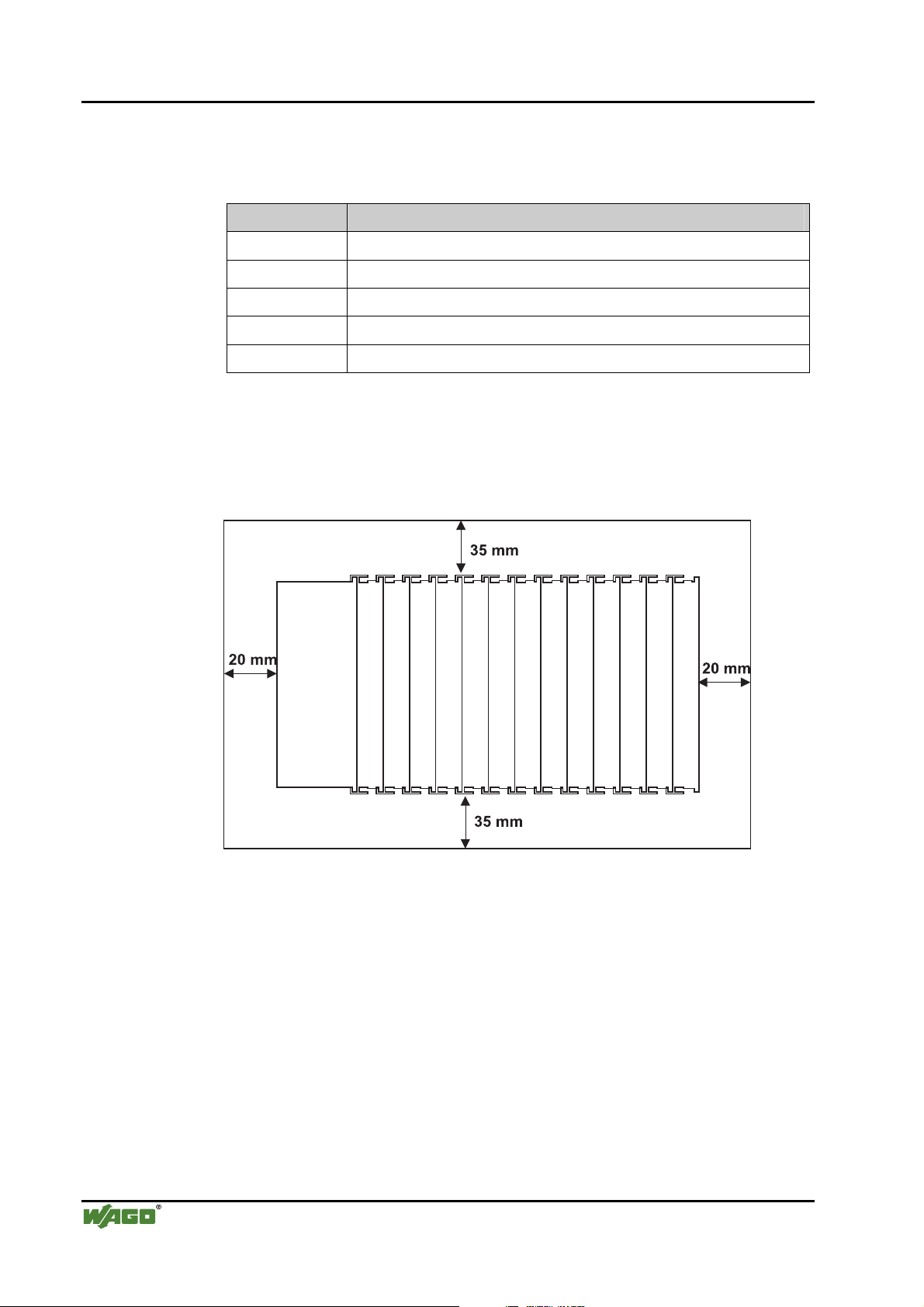

2.6.4 Spacing

The spacing between adjacent components, cable conduits, casing and frame

sides must be maintained for the complete field bus node.

Fig. 2-4: Spacing g01xx13x

The spacing creates room for heat transfer, installation or wiring. The spacing

to cable conduits also prevents conducted electromagnetic interferences from

influencing the operation.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 25

Mechanical Setup • 25

Plugging and Removal of the Components

2.6.5 Plugging and Removal of the Components

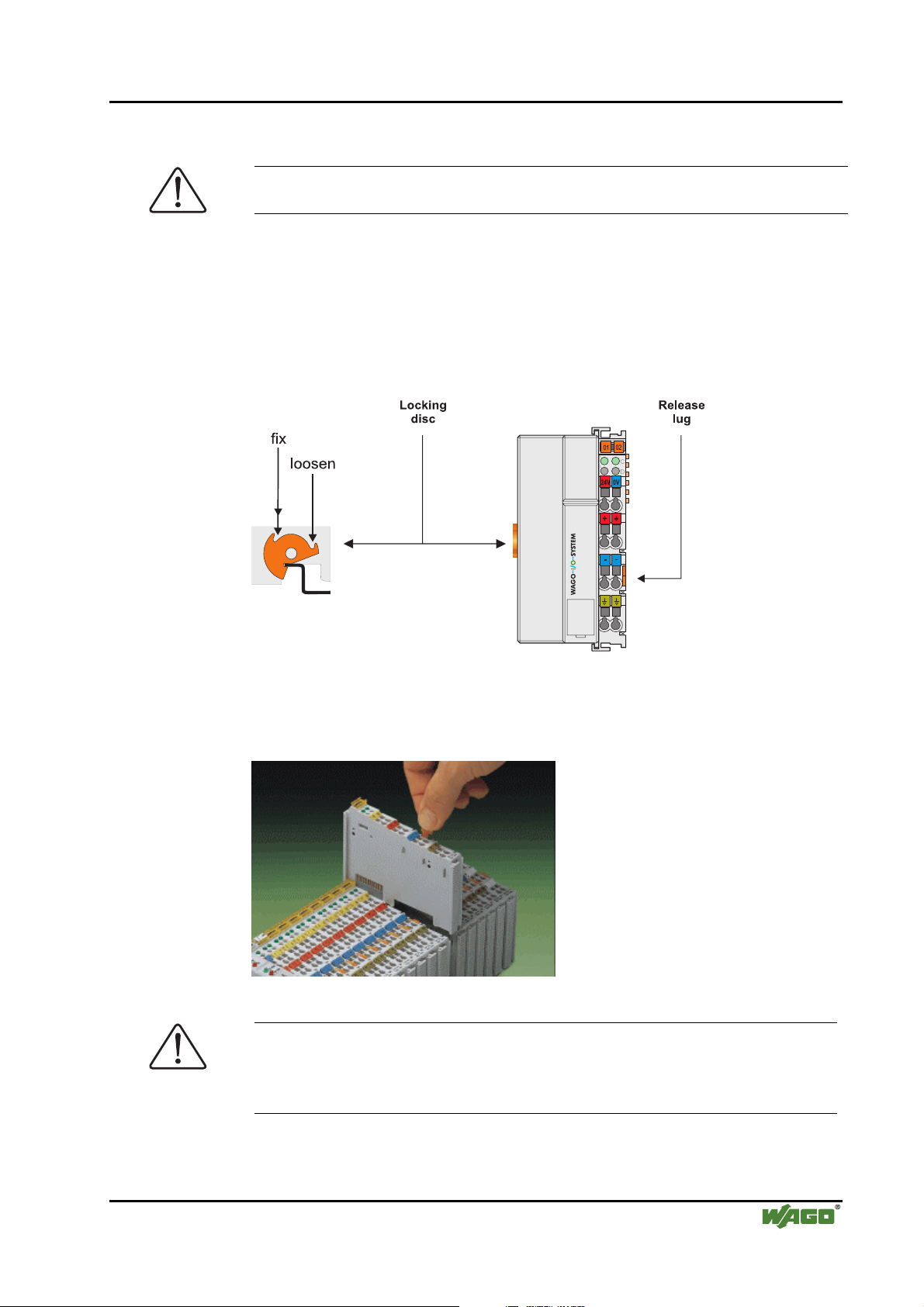

Warning

Before work is done on the components, the voltage supply must be turned off.

In order to safeguard the coupler/controller from jamming, it should be fixed

onto the carrier rail with the locking disc To do so, push on the upper groove

of the locking disc using a screwdriver.

To pull out the field bus coupler/controller, release the locking disc by pressing on the bottom groove with a screwdriver and then pulling the orange colored unlocking lug .

Fig. 2-5: Coupler/Controller and unlocking lug g01xx12e

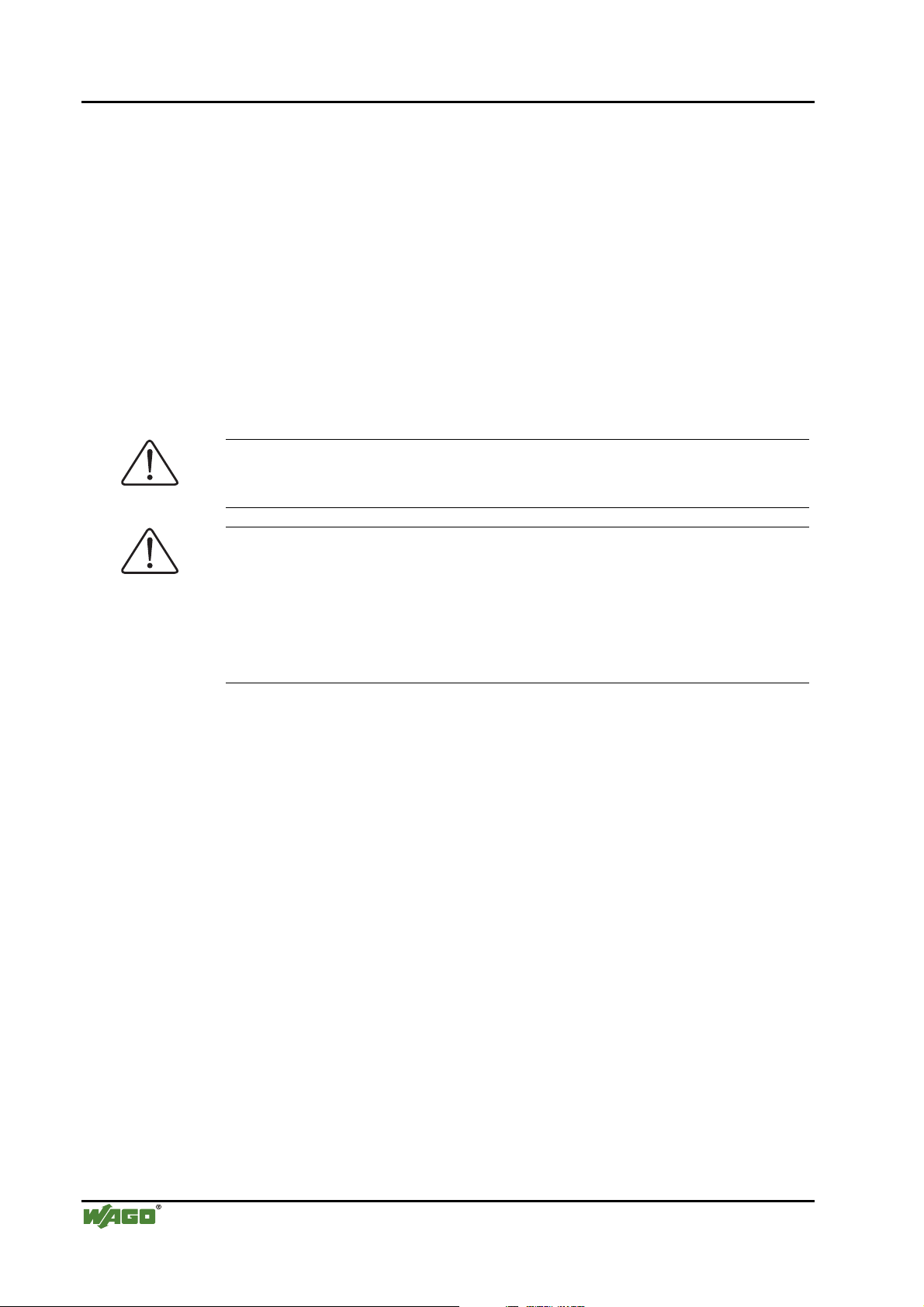

It is also possible to release an individual I/O module from the unit by pulling

an unlocking lug.

Fig. 2-6: removing bus terminal p0xxx01x

Danger

Ensure that an interruption of the PE will not result in a condition which

could endanger a person or equipment!

For planning the ring feeding of the ground wire, please see chapter 2.6.3.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 26

26 • Mechanical Setup

Assembly Sequence

2.6.6 Assembly Sequence

All system components can be snapped directly on a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual components are securely

seated on the rail after installing.

Starting with the coupler/controller, the bus modules are assembled adjacent

to each other according to the project planning. Errors in the planning of the

node in terms of the potential groups (connection via the power contacts) are

recognized, as the bus modules with power contacts (male contacts) cannot be

linked to bus modules with fewer power contacts.

Attention

Always link the bus modules with the coupler/controller, and always plug

from above.

Warning

Never plug bus modules from the direction of the end terminal. A ground

wire power contact, which is inserted into a terminal without contacts, e.g. a

4-channel digital input module, has a decreased air and creepage distance to

the neighboring contact in the example DI4.

Always terminate the field bus node with an end module (750-600).

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 27

Mechanical Setup • 27

Internal Bus/Data Contacts

2.6.7 Internal Bus/Data Contacts

Communication between the coupler/controller and the bus modules as well as

the system supply of the bus modules is carried out via the internal bus. It is

comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Fig. 2-7: Data contacts p0xxx07x

Warning

Do not touch the gold spring contacts on the I/O modules in order to avoid

soiling or scratching!

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the environment (persons, workplace and packing) is well grounded. Avoid touching

conductive components, e.g. data contacts.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 28

28 • Mechanical Setup

Power Contacts

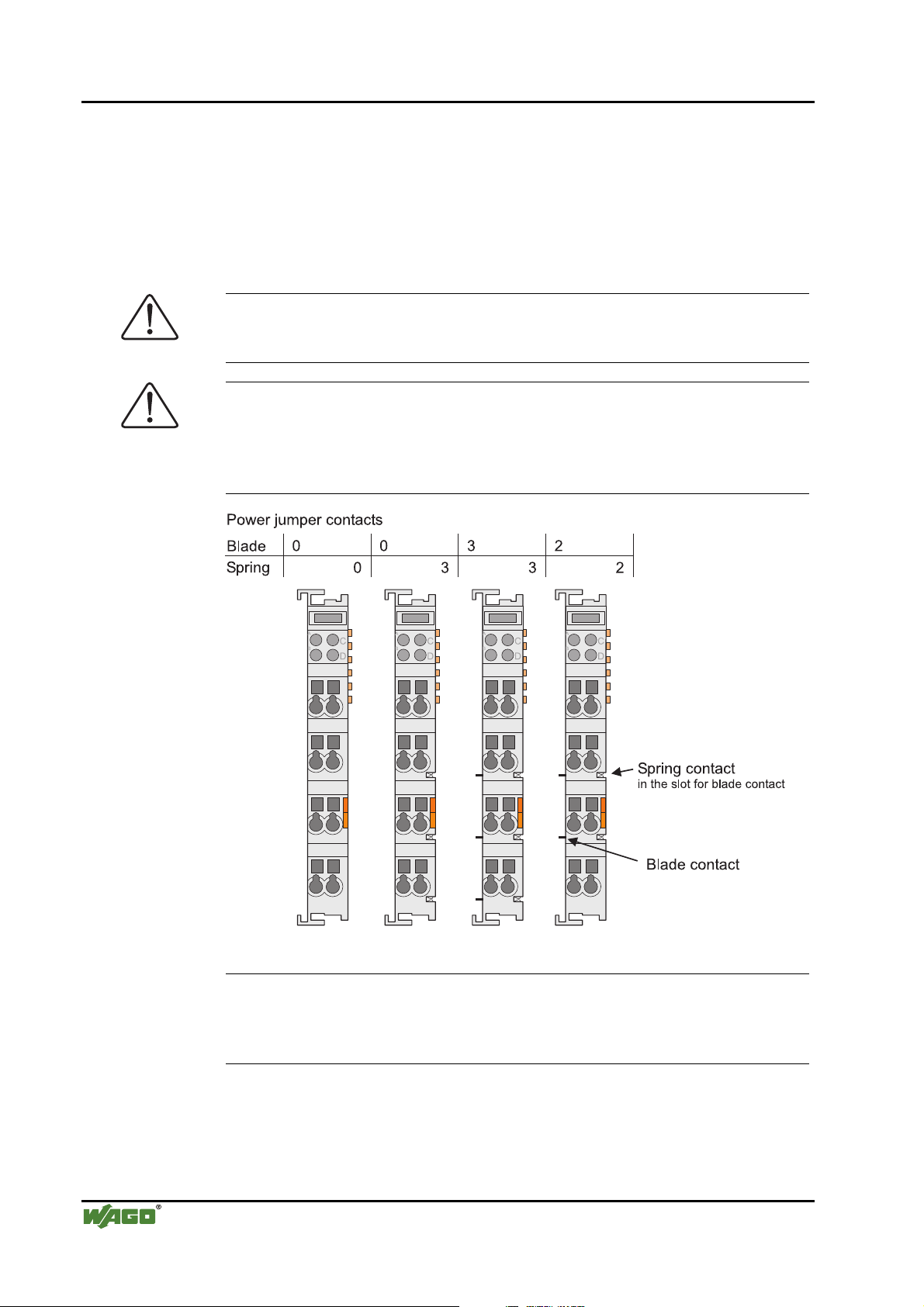

2.6.8 Power Contacts

Self-cleaning power contacts , are situated on the side of the components

which further conduct the supply voltage for the field side. These contacts

come as touchproof spring contacts on the right side of the coupler/controller

and the bus module. As fitting counterparts the module has male contacts on

the left side.

Danger

The male contacts are sharp-edged. Handle the module carefully to prevent

injury.

Attention

Please take into consideration that some bus modules have no or only a few

power jumper contacts. The design of some modules does not allow them to

be physically assembled in rows, as the grooves for the male contacts are

closed at the top.

WAGO-I/O-SYSTEM 750

Fig. 2-8: Example for the arrangement of power contacts g0xxx05e

Recommendation

With the WAGO ProServe® Software smartDESIGNER, the structure of a

field bus node can be configured. The configuration can be tested via the integrated accuracy check.

BACnet/IP Controller

Page 29

Mechanical Setup • 29

Wire Connection

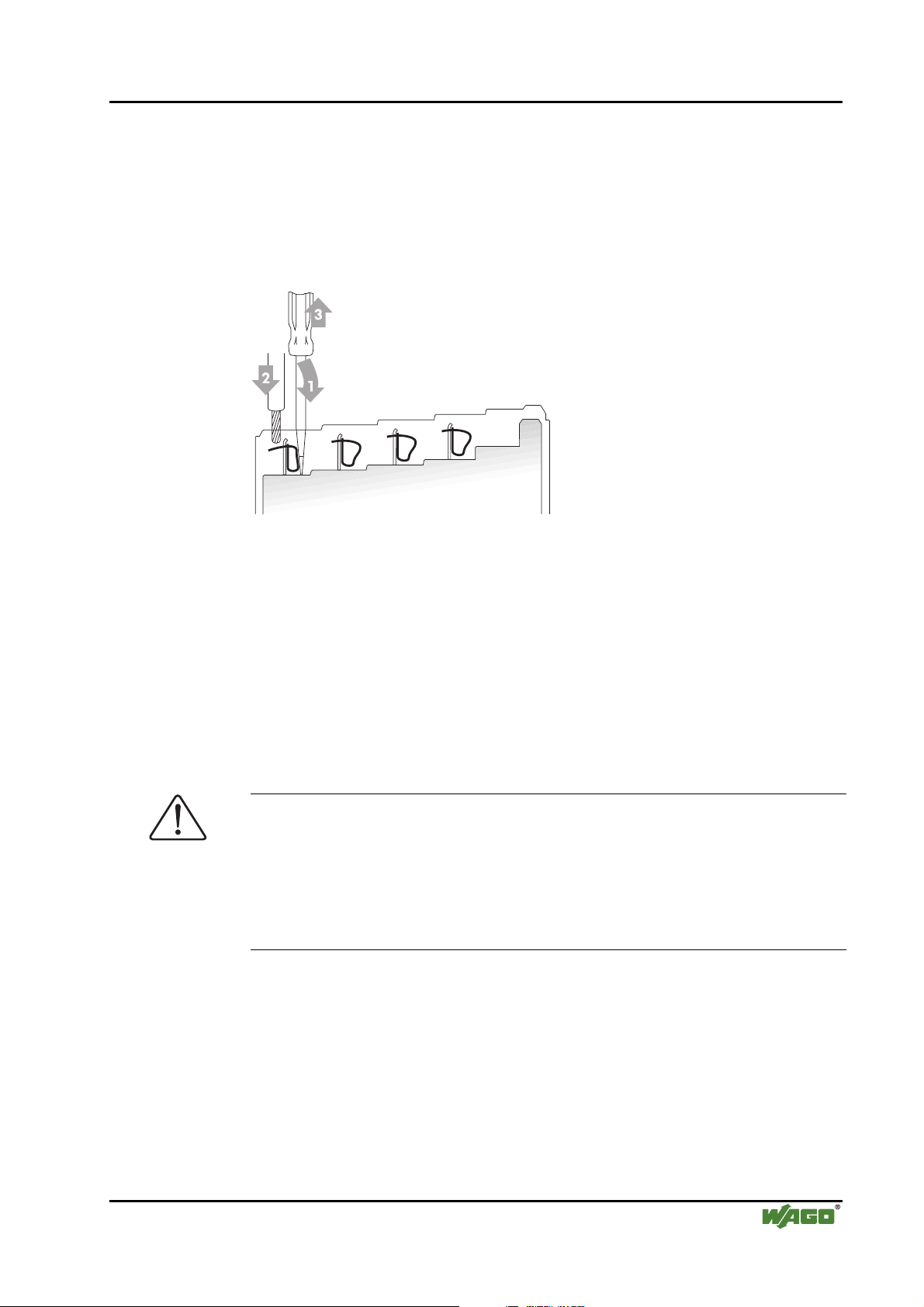

2.6.9 Wire Connection

All components have CAGE CLAMP® connections.

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded

and finely stranded conductors. Each clamping unit accommodates one conductor.

Fig. 2-9: CAGE CLAMP® Connection g0xxx08x

The operating tool is inserted into the opening above the connection. This

opens the CAGE CLAMP®. Subsequently the conductor can be inserted into

the opening. After removing the operating tool, the conductor is safely

clamped.

More than one conductor per connection is not permissible. If several conductors have to be made at one connection point, then they should be made away

from the connection point using WAGO Terminal Blocks. The terminal blocks

may be jumpered together and a single wire brought back to the I/O module

connection point.

Attention

If it is unavoidable to jointly connect 2 conductors, then a ferrule must be used

to join the wires together.

Ferrule:

Length 8 mm

Nominal cross section

1 mm2 for 2 conductors with 0.5 mm2 each

max.

WAGO Product 216-103 or products with comparable properties

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 30

30 • Power Supply

Isolation

2.7 Power Supply

2.7.1 Isolation

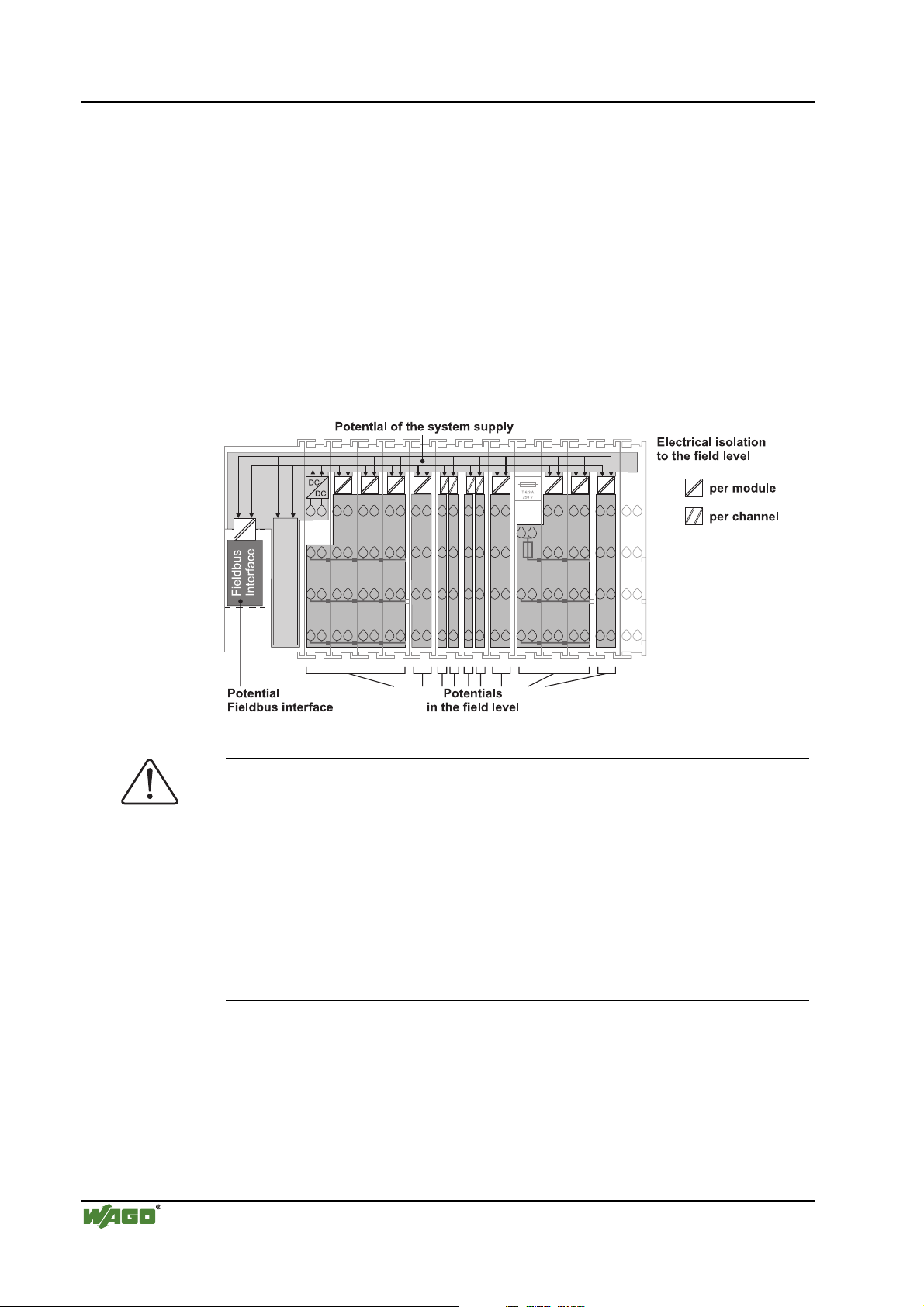

Within the field bus node, there are three electrically isolated potentials.

• Operational voltage for the field bus interface.

• Electronics of the couplers/controllers and the bus modules (internal bus).

• All bus modules have an electrical isolation between the electronics (inter-

nal bus, logic) and the field electronics. Some digital and analog input

modules have each channel electrically isolated, please see catalog.

Fig. 2-10: Isolation g0xxx01e

Attention

The ground wire connection must be present in each group. In order that all

protective conductor functions are maintained under all circumstances, it is

recommended that a ground wire be connected at the beginning and end of a

potential group. (ring format, please see chapter 2.8.3). Thus, if a bus module

comes loose from a composite during servicing, then the protective conductor

connection is still guaranteed for all connected field devices.

When using a joint power supply unit for the 24 V system supply and the

24 V field supply, the electrical isolation between the internal bus and the

field level is eliminated for the potential group.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 31

Power Supply • 31

System Supply

2.7.2 System Supply

2.7.2.1 Connection

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply

(-15 % or +20 %). The power supply is provided via the coupler/controller

and, if necessary, in addition via the internal system supply modules

(750-613). The voltage supply is reverse voltage protected.

Attention

The use of an incorrect supply voltage or frequency can cause severe damage

to the component.

Fig. 2-11: System Supply g0xxx02e

The direct current supplies all internal system components, e.g. coupler/controller electronics, field bus interface and bus modules via the internal

bus (5 V system voltage). The 5 V system voltage is electrically connected to

the 24 V system supply.

Fig. 2-12: System Voltage g0xxx06e

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 32

32 • Power Supply

f

System Supply

Attention

Resetting the system by switching on and off the system supply, must take

place simultaneously for all supply modules (coupler/controller and

750-613).

2.7.2.2 Alignment

Recommendation

A stable network supply cannot be taken for granted always and everywhere.

Therefore, regulated power supply units should be used in order to guarantee

the quality of the supply voltage.

The supply capacity of the coupler/controller or the internal system supply

module (750-613) can be taken from the technical data of the components.

Internal current consumption*)

Residual current for bus terminals*)

*)

cf. catalogue W4 Volume 3, manuals or internet

Example Coupler 750-301:

Current consumption via system voltage:

5 V for electronics of the bus modules and coupler/controller

Available current for the bus modules. Provided by

the bus power supply unit. See coupler/controller

and internal system supply module (750-613)

internal current consumption:350 mA at 5 V

residual current for

bus modules : 1650 mA at 5 V

sum I

: 2000 mA at 5 V

(5V) total

The internal current consumption is indicated in the technical data for each

bus terminal. In order to determine the overall requirement, add together the

values of all bus modules in the node.

WAGO-I/O-SYSTEM 750

Attention

If the sum of the internal current consumption exceeds the residual current

or bus modules, then an internal system supply module (750-613) must be

placed before the module where the permissible residual current was exceeded.

BACnet/IP Controller

Page 33

Power Supply • 33

System Supply

Example:

A node with a PROFIBUS Coupler 750-333 consists of 20 relay modules (750-517) and 10 digital input modules (750-405).

Current consumption:

20* 90 mA = 1800 mA

10* 2 mA = 20 mA

Sum 1820 mA

The coupler can provide 1650 mA for the bus modules. Consequently,

an internal system supply module (750-613), e.g. in the middle of the

node, should be added.

Recommendation

With the WAGO ProServe® Software smartDESIGNER, the assembly of a

field bus node can be configured. The configuration can be tested via the integrated accuracy check.

The maximum input current of the 24 V system supply is 500 mA. The exact

electrical consumption (I

Coupler/Controller

I

= Sum of all the internal current consumption of the connected

(5 V) total

) can be determined with the following formulas:

(24 V)

bus modules

+ internal current consumption coupler/controller

750-613

I

= Sum of all the internal current consumption of the connected

(5 V) total

bus modules

Input current I

(24 V)

=

5 V / 24 V * I

η

= 0.87 (at nominal load)

(5 V) total

/ η

Attention

If the electrical consumption of the power supply point for the 24 V-system

supply exceeds 500 mA, then the cause may be an improperly aligned node

or a defect.

During the test, all outputs, in particular those of the relay modules, must be

active.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 34

34 • Power Supply

Field Supply

2.7.3 Field Supply

2.7.3.1 Connection

Sensors and actuators can be directly connected to the relevant channel of the

bus module in 1/4 conductor connection technology. The bus module supplies

power to the sensors and actuators. The input and output drivers of some bus

modules require the field side supply voltage.

The coupler/controller provides field side power (DC 24V). In this case it is a

passive power supply without protection equipment.

Power supply modules are available for other potentials, e. g. AC 230 V. Likewise, with the aid of the power supply modules, various potentials can be set

up. The connections are linked in pairs with a power contact.

Fig. 2-13: Field Supply (Sensor/Actuator) g0xxx03e

The supply voltage for the field side is automatically passed to the next module via the power jumper contacts when assembling the bus modules .

The current load of the power contacts must not exceed 10 A on a continual

basis. The current load capacity between two connection terminals is identical

to the load capacity of the connection wires.

By inserting an additional power supply module, the field supply via the

power contacts is disrupted. From there a new power supply occurs which

may also contain a new voltage potential.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 35

Power Supply • 35

Field Supply

Attention

Some bus modules have no or very few power contacts (depending on the I/O

function). Due to this, the passing through of the relevant potential is disrupted. If a field supply is required for subsequent bus modules, then a power

supply module must be used.

Note the data sheets of the bus modules.

In the case of a node setup with different potentials, e.g. the alteration from

DC 24 V to AC 230V, a spacer module should be used. The optical separation of the potentials acts as a warning to heed caution in the case of wiring

and maintenance works. Thus, the results of wiring errors can be prevented.

2.7.3.2 Fusing

Internal fusing of the field supply is possible for various field voltages via an

appropriate power supply module.

750-601 24 V DC, Supply/Fuse

750-609 230 V AC, Supply/Fuse

750-615 120 V AC, Supply/Fuse

750-610 24 V DC, Supply/Fuse/Diagnosis

750-611 230 V AC, Supply/Fuse/Diagnosis

Fig. 2-14: Supply module with fuse carrier (Example 750-610) g0xxx09x

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 36

36 • Power Supply

Field Supply

Warning

In the case of power supply modules with fuse holders, only fuses with a

maximum dissipation of 1.6 W (IEC 127) must be used.

For UL approved systems only use UL approved fuses.

In order to insert or change a fuse, or to switch off the voltage in succeeding

bus modules, the fuse holder may be pulled out. In order to do this, use a

screwdriver for example, to reach into one of the slits (one on both sides) and

pull out the holder.

Fig. 2-15: Removing the fuse carrier p0xxx05x

Lifting the cover to the side opens the fuse carrier.

Fig. 2-16: Opening the fuse carrier p0xxx03x

Fig. 2-17: Change fuse p0xxx04x

After changing the fuse, the fuse carrier is pushed back into its original position.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 37

Power Supply • 37

Field Supply

Alternatively, fusing can be done externally. The fuse modules of the WAGO

series 281 and 282 are suitable for this purpose.

Fig. 2-18: Fuse modules for automotive fuses, series 282 pf66800x

Abb. 2-19: Fuse modules for automotive fuses, series 2006 p0xxx13x

Fig. 2-20: Fuse modules with pivotable fuse carrier, series 281 pe61100x

Abb. 2-21: Fuse modules with pivotable fuse carrier, series 2002 p0xxx12x

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 38

38 • Power Supply

Supplementary Power Supply Regulations

2.7.4 Supplementary Power Supply Regulations

The WAGO-I/O-SYSTEM 750 can also be used in shipbuilding or offshore

and onshore areas of work (e. g. working platforms, loading plants). This is

demonstrated by complying with the standards of influential classification

companies such as Germanischer Lloyd and Lloyds Register.

Filter modules for 24-volt supply are required for the certified operation of the

system.

Item No. Name Description

750-626 Supply filter Filter module for system supply and field supply (24 V, 0 V), i.e.

for field bus coupler/controller and bus power supply (750-613)

750-624 Supply filter Filter module for the 24 V- field supply

(750-602, 750-601, 750-610)

Therefore, the following power supply concept must be absolutely complied

with.

WAGO-I/O-SYSTEM 750

Fig. 2-22: Power supply concept g01xx11e

Note

Another potential power terminal 750-601/602/610 must only be used behind

the filter terminal 750-626 if the protective earth conductor is needed on the

lower power contact or if a fuse protection is required.

BACnet/IP Controller

Page 39

Power Supply • 39

Supply Example

2.7.5 Supply Example

Attention

The system supply and the field supply should be separated in order to ensure

bus operation in the event of a short-circuit on the actuator side.

L1

L2

L3

N

PE

a)

1)

b)

c)

1)

d)

System

Supply

Field

Supply

Field

Supply

230V

230V

24V

24V

10 A

750-613

2) 2)

10 A

750-512 750-512750-616 750-513 750-610 750-552 750-600750-612 750-616

750-630750-400 750-410 750-401

Shield (screen) bus

Main ground bus

1) Separation module

recommended

2) Ring-feeding

recommended

a) Power Supply

on coupler / controller

via external Supply

Module

b) Internal System

Supply Module

c) Supply Module

passive

d)

Supply Module

with fuse carrier/

iagnostics

d

Fig. 2-23: Supply example g0xxx04e

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 40

40 • Power Supply

Power Supply Unit

2.7.6 Power Supply Unit

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply

with a maximum deviation of -15 % or +20 %.

Recommendation

A stable network supply cannot be taken for granted always and everywhere.

Therefore, regulated power supply units should be used in order to guarantee

the quality of the supply voltage.

A buffer (200 µF per 1 A current load) should be provided for brief voltage

dips. The I/O system buffers for approx 1 ms.

The electrical requirement for the field supply is to be determined individually

for each power supply point. Thereby all loads through the field devices and

bus modules should be considered. The field supply as well influences the bus

modules, as the inputs and outputs of some bus modules require the voltage of

the field supply.

Attention

The system supply and the field supply should be isolated from the power

supplies in order to ensure bus operation in the event of short circuits on the

actuator side.

WAGO products

Item No.

Description

787-612 Primary switched mode; DC 24 V; 2,5 A

Input nominal voltage AC 230 V

787-622 Primary switched mode; DC 24 V; 5 A

Input nominal voltage AC 230 V

787-632 Primary switched mode; DC 24 V; 10 A

Input nominal voltage AC 230/115 V

288-809

288-810

288-812

288-813

Rail-mounted modules with universal mounting carrier

AC 115 V / DC 24 V; 0,5 A

AC 230 V / DC 24 V; 0,5 A

AC 230 V / DC 24 V; 2 A

AC 115 V / DC 24 V; 2 A

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 41

Grounding • 41

Grounding the DIN Rail

2.8 Grounding

2.8.1 Grounding the DIN Rail

2.8.1.1 Framework Assembly

When setting up the framework, the carrier rail must be screwed together with

the electrically conducting cabinet or housing frame. The framework or the

housing must be grounded. The electronic connection is established via the

screw. Thus, the carrier rail is grounded.

Attention

2.8.1.2 Insulated Assembly

Care must be taken to ensure the flawless electrical connection between the

carrier rail and the frame or housing in order to guarantee sufficient grounding.

Insulated assembly has been achieved when there is constructively no direct

conduction connection between the cabinet frame or machine parts and the

carrier rail. Here the earth must be set up via an electrical conductor.

The connected grounding conductor should have a cross section of at least

4 mm2.

Recommendation

The optimal insulated setup is a metallic assembly plate with grounding connection with an electrical conductive link with the carrier rail.

The separate grounding of the carrier rail can be easily set up with the aid of

the WAGO ground wire terminals.

Item No. Description

283-609 1-conductor ground (earth) terminal block make an automatic contact to

the carrier rail; conductor cross section: 0.2 -16 mm

Note: Also order the end and intermediate plate (283-320).

2

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 42

42 • Grounding

Grounding Function

2.8.2 Grounding Function

The grounding function increases the resistance against disturbances from

electro-magnetic interferences. Some components in the I/O system have a

carrier rail contact that dissipates electro-magnetic disturbances to the carrier

rail.

Fig. 2-24: Carrier rail contact g0 xxx10e

Attention

Care must be taken to ensure the direct electrical connection between the

carrier rail contact and the carrier rail.

The carrier rail must be grounded.

For information on carrier rail properties, please see chapter 2.6.3.2.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 43

Grounding • 43

Grounding Protection

2.8.3 Grounding Protection

For the field side, the ground wire is connected to the lowest connection terminals of the power supply module. The ground connection is then connected

to the next module via the Power Jumper Contact (PJC). If the bus module has

the lower power jumper contact, then the ground wire connection of the field

devices can be directly connected to the lower connection terminals of the bus

module.

Attention

Should the ground conductor connection of the power jumper contacts within

the node become disrupted, e. g. due to a 4-channel bus terminal, the ground

connection will need to be re-established.

The ring feeding of the grounding potential will increase the system safety.

When one bus module is removed from the group, the grounding connection

will remain intact.

The ring feeding method has the grounding conductor connected to the beginning and end of each potential group.

Fig. 2-25: Ring-feeding g0 xxx07e

Attention

The regulations relating to the place of assembly as well as the national regulations for maintenance and inspection of the grounding protection must be

observed.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 44

44 • Shielding (Screening)

General

2.9 Shielding (Screening)

2.9.1 General

The shielding of the data and signal conductors reduces electromagnetic interferences thereby increasing the signal quality. Measurement errors, data transmission errors and even disturbances caused by overvoltage can be avoided.

Attention

Constant shielding is absolutely required in order to ensure the technical

specifications in terms of the measurement accuracy.

The data and signal conductors should be separated from all high-voltage

cables.

The cable shield should be potential. With this, incoming disturbances can be

easily diverted.

The shielding should be placed over the entrance of the cabinet or housing in

order to already repel disturbances at the entrance.

2.9.2 Bus Conductors

The shielding of the bus conductor is described in the relevant assembly

guidelines and standards of the bus system.

2.9.3 Signal Conductors

Bus modules for most analog signals along with many of the interface bus

modules include a connection for the shield.

Note

For a better shield performance, the shield should have previously been

placed over a large area. The WAGO shield connection system is suggested

for such an application.

This suggestion is especially applicable if the equipment can have even current or high impulse formed currents running through (for example initiated

by atmospheric discharge).

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 45

Assembly Guidelines/Standards • 45

WAGO Shield (Screen) Connecting System

2.9.4 WAGO Shield (Screen) Connecting System

The WAGO Shield Connecting system includes a shield clamping saddle, a

collection of rails and a variety of mounting feet. Together these allow many

different possibilities. See catalog W4 volume 3 chapter 10.

Fig. 2-26: WAGO Shield (Screen) Connecting System p0xxx08x, p0xxx09x, and p0xxx10x

Fig. 2-27: Application of the WAGO Shield (Screen) Connecting System p0xxx11x

2.10 Assembly Guidelines/Standards

DIN 60204, Electrical equipping of machines

DIN EN 50178 Equipping of high-voltage systems with electronic

components (replacement for VDE 0160)

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 46

46 • BACnet/IP Controller 750-830

Description

3 Fieldbus Controller

3.1 BACnet/IP Controller 750-830

3.1.1 Description

The 750-830 BACnet Controller connects the WAGO-I/O-SYSTEM with the

BACnet protocol. The 750-830 Controller complies with the BACnet device

profile "BACnet Building Controller" B-BC in accordance with DIN EN ISO

16484-5 and has 3 functions available internally:

1. Native server: For each channel, appropriate BACnet objects are gen-

erated automatically for the digital, analog input and output modules

that are connected to the controller.

2. Application server: Other supported BACnet objects can be created

via the IEC 61131-3 programming environment.

3. Application client: Using the client functionality, objects and their

properties can be accessed by other BACnet devices.

Access to BACnet/IP networks is provided by the controller's RJ45 interface.

The RS232 interface can be used as a standard RS232 or (beginning with

software version 2) as a BACnet-PTP connection to other PTP-capable

BACnet devices.

The 750-830 BACnet/IP Controller is based on an ETHERNET controller and

supports the corresponding functions:

All input signals from the sensors are combined. After connecting the controller, all of the I/O modules on the node are determined and a local process image is created from these. Analog and specialty module data is sent via words

and/or bytes; digital data is sent bit by bit.

The local process image is divided into two data zones containing input and

output data areas. The data of the analog modules are written into the process

image in the order of their position after the controller.

The bits of the digital modules are combined into words and then also mapped

onto the analog modules in the process image. If the number of digital inputs

and outputs is greater than 16 bits, the controller automatically begins a new

word.

According to IEC -61131-3 programming, the processing of the process data

occurs on location in the PFC. The link results created by this can be output

directly to the actors or transmitted via the bus to the higher-order controller.

The controller can then optionally communicate with higher-order systems either via 10/100 Mbit/s (ETHERNET), "100BaseTX" or "10BaseT".

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 47

BACnet/IP Controller 750-830 • 47

Compatibility

An application program can be created using the WAGO-I/O-PRO CAA software, based on IEC 61131-3. The controller provides 512 KB of program

memory, 256 KB of data memory and 24 KB of retain memory for this purpose. Start-up and configuration of the BACnet/IP Controller is performed using the Windows-compliant WAGO BACnet Configurator.

For communication via BACnet, the BACnet/IP and BACnet/PTP protocols

are supported. Process data are also sent via MODBUS/TCP(UDP). HTTP,

BootP, DHCP, DNS, SNTP, FTP, SNMP V1 and SMTP are used for administration and diagnosis.

The programmer can program clients and servers via an internal socket-API

for all transport protocols (TCP, UDP, etc.) with functional modules. Library

functions are available for function expansion. With the IEC 61131-3 library

"SysLibRTC.lib," for example, a buffered real time clock with date, time

(resolution 1 second), alarm functions, and a timer is incorporated. This clock

is supplied with auxiliary power during a power failure.

This controller is based on a 32-Bit CPU with multitasking capabilities, i.e.

several programs can be executed semi-simultaneously.

An internal server is available for Web-based applications.

Information on configuration is also stored as HTML pages in the fieldbus

controller and can be read using a customary web browser (web-based Management-System). In addition, internal HTML pages can also be stored using

an implemented file system.

3.1.2 Compatibility

Additional Information

To get the current software version for programming and configuring the

Controller 750-830, go to our website at http://www.wago.com ! Service !

Documentation ! WAGO-I/O-SYSTEM759 ! WAGO-I/O-PRO

Additional Information

You can find the BACnet Configurator on the internet on the website

http://www.wago.com Service ! Downloads ! Building Automation !

BACnet Downloads.

The documentation for the BACnet Configurator can be found under Service

! Documentation ! WAGO-I/O-SYSTEM 750 ! Fieldbus Coupler and

Programmable Fieldbus Controller ! 750-830.

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 48

48 • BACnet/IP Controller 750-830

Hardware

3.1.3 Hardware

3.1.3.1 View

BACnet/IP

fieldbus

connection

RJ45

fieldbus

connection

RS232

service interface

as a configuration and

programming interface

(flap open)

LINK

ACT

BT

MS

NS

I/O

USR

A

B

0

50-83

7

01

24V 0V

++

_

_

02

C

D

mode switch

power supply status

- system

- power contacts

data contacts

24V

bus coupler power supply

0V

24V

power contacts supply

0V

power contacts

Fig. 3-1: BACnet/IP Controller G083000e

The controller in detail:

• A power supply unit for the system supply and power jumper contacts for

the field supply via bus modules.

• Two fieldbus connections (RJ45 and RS232)

• LEDs as status display of the operation, the bus communication, the oper-

ating voltages as well as for error messages and diagnostics

• Service interface, alternative for programming and configuration (see

3.1.3.5)

• Operating mode switch (see

3.1.3.6)

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 49

BACnet/IP Controller 750-830 • 49

Hardware

3.1.3.2 Power Supply

The power supply is derived from modules with CAGE CLAMP® connections. 24 V power supply (see Fig. 3-1) for system power and power to the

field side.

The integrated power supply provides the required power to the electronics

and the bus modules.

An electrically isolated power supply is provided to the fieldbus interface.

DC

DC

1

5

24V/0V

2

6

24 V

24 V

0V

10 nF

DC

DC

I/O

MODULES

24 V

3

7

ELECTRONIC

FiELDBUS

INTERFACE

FiELDBUS INTERFACE

ELECTRONIC

750-830

0V

4

8

0V

10 nF

Fig. 3-1: Power Supply G083001e

WAGO-I/O-SYSTEM 750

BACnet/IP Controller

Page 50

50 • BACnet/IP Controller 750-830

Hardware

3.1.3.3 Fieldbus Connection

The connection to the fieldbus is made via an RJ45 connector, which is also

called a "Western plug." Wiring for the RJ45 socket on the fieldbus controller