Page 1

2 year

TexPerfect

Guarantee

2 Jahre

Garantie

525

GB/D

Page 2

a

5-15 cm

20-30 cm

TexPerfect Flexio 525

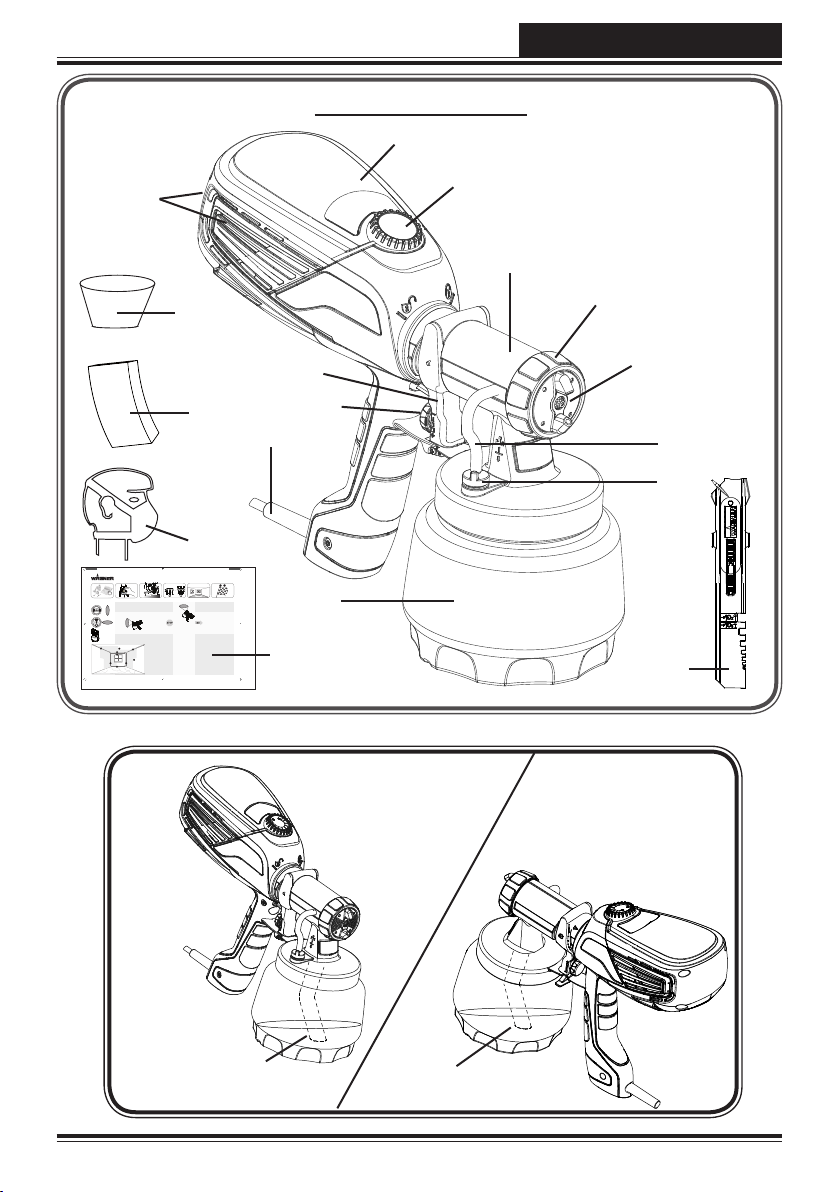

OVERVIEW / ÜBERSICHT

6

7

15

16

17

WallPerfect Flexio 585 I-Spray

A B C D E F

– +

I-Spray

1

2

1

1

3

4

3

3

3

2333118_Testposter_W577.indd 1 19.11.2012 14:22:56

Testposter

I-Spray

-

1 4

Cover up !

+

20-30 cm

5

4

3

8

1/2

9

10

13

12

11

18

Materialnr. 233 3118 EBSS

14

b

A

B

Page 3

TexPerfect Flexio 525

click

c

a

b

1

2

A B C

Page 4

TexPerfect Flexio 525

20-30 cm

1

A

B

1

Page 5

TexPerfect Flexio 525

1.

2.

1

2

3

3

1

2

Page 6

SPARE PARTS / ERSATZTEILE

TexPerfect Flexio 525

6

5

34

7

8

9

12

10

1

3

2

1

4

..........................................................................1 - 17

GB

........ ........................................................................18 - 35

D

............................................. 38

++

Page 7

TexPerfect Flexio 525

GB

Translation of the original operating instructions

MANY THANKS FOR PLACING YOUR TRUST IN US

We would like to congratulate you on purchasing this brand product from Wagner;

we are sure that you will enjoy working with it greatly.

Please read the Operating Manual carefully and observe the safety information

before starting the device. Store the Operating Manual in a safe place close to the

product in case it needs to be used by someone else.

We would be happy to be of assistance if you have any questions, suggestions or requests.

Please contact us via the phone number included on the back page or via our homepage,

www.wagner-group.com/service.

Contents

1. Explanation of symbols used .....................................................2

2. General Safety Instructions ......................................................2

3. Safety Instructions for Spray Guns ................................................5

4. Description/ Scope of delivery ...................................................6

5. Coating Materials Suitable for Use ................................................6

6. Coating Materials Not Suitable for Use ............................................6

7. The following materials can only be processed with optional accessories ..........6

8. Preparation of the workplace .....................................................7

9. Preparing the wall ...............................................................7

10. Preparation of the Coating Material .............................................7

11. Start-up ........................................................................8

12. Selecting the Spray Setting .....................................................8

13. Adjusting the Material Volume (Fig. 6) ...........................................9

14. Setting the Amount of Air (Fig. 7) ................................................9

15. Spray Technique ................................................................9

16. Interruption of Work ..........................................................10

17. Taking Out of Operation and Cleaning .........................................10

18. Maintenance ................................................................. 12

19. Spare Parts ...................................................................12

20. Accessories ................................................................... 13

21. Correction of Malfunctions ....................................................14

22. Technical Data ................................................................ 15

23. Environmental protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

24. Important Note regarding Product Liability! ................................... 16

2 year guarantee ................................................................. 17

1

Page 8

GB

i

TexPerfect Flexio 525

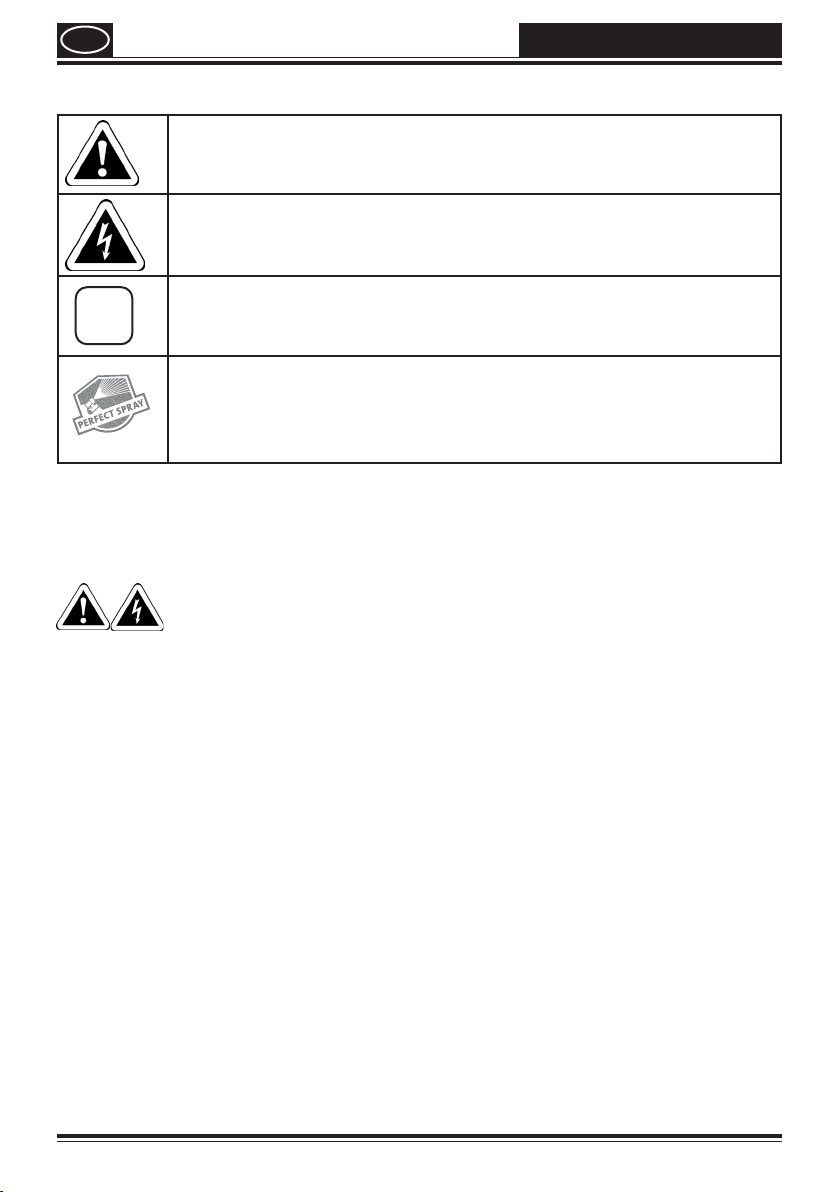

1. Explanation of symbols used

This symbol indicates a potential danger for you or for the device.

Under this symbol you can nd important information on how to

avoid injuries and damage to the device.

Danger of electrical shock

Indicates tips for use and other particularly useful information.

This symbol identies devices and accessory devices that

are suitable for processing ne plaster, structured paint and

undercoats. If a material bears this logo, it is particularly well suited

for use with the relevant device.

2. General Safety Instructions

WARNING! Read all safety notications and instructions. Failure to comply with the safety

notications and instructions provided may result in electric shock, re and/or

serious injury. The term "power tool" used below covers both mains-operated

power tools (with mains lead) and accumulator-operated power tools (without

mains lead).

1. Safety at the workplace

a) Keep your workplace clean and well lit. Disorder or unlit workplaces may result in

accidents.

b) Never use the tool in hazardous areas that contain ammable liquids, gases

or dusts. Power tools generate sparks that can ignite the dust or vapors.

c) Keep children and other persons away when using the power tool. You can

lose control of the tool if you are distracted.

2. Electrical Safety

a) The tool plug must t into the socket. The plug may not be modied in any

form. Do not use adaptor plugs together with protective-earthed tools.

Unmodied plugs and suitable sockets reduce the risk of an electric shock.

2

Page 9

TexPerfect Flexio 525

b) Avoid physical contact with earthed surfaces such as pipes, heating

elements, stoves and refrigerators. The risk through electric shock increases if

your body is earthed.

c) Keep the equipment away from rain and moisture. The risk of an electric shock

increases if water penetrates electrical equipment.

d) Do not misuse the mains lead by carrying the tool by the lead, hanging it

from the lead or by pulling on the lead to remove the plug. Keep the lead

away from heat, oil, sharp edges or moving tool parts. Damaged or twisted

leads increase the risk of an electric shock.

e) If you work outdoors with a power tool, only use extension cables suitable

for outdoor use. The use of an extension lead that is suitable for outdoors reduces

the risk of an electric shock.

f) If you cannot avoid using the tool in a damp environment, use a residual

current operated circuit-breaker. Using a residual current operated circuit-breaker

avoids the risk of electric shock.

3. Safety of Persons

a) Be attentive. Pay attention to what you are doing and work sensibly with

a power tool. Do not use the tool if you are tired or under the inuence of

drugs, alcohol or medication. Just a moment of inattentiveness while using the

tool can lead to serious injuries.

GB

b) Wear personal safety equipment and always wear safety goggles Wearing

personal protective equipment, such as dust mask, non-slip safety shoes, safety helm

or ear protection, depending on the type of power tools, reduces the risk of injury.

c) Avoid accidental starting-up. Make sure that the electric tool is switched o

before you connect it to the power supply, pick it up or carry it. Accidents can

occur if you carry the power tool while your nger is on the switch or if you connect

the power tool to the power supply which it is on.

d) Remove setting tools or wrenches before switching on the power tool. A tool

or wrench that is in a rotating tool part can lead to injuries.

e) Avoid an unnatural posture. Ensure that you are standing securely and

have your balance at all times. This ensures that you can control the tool better in

unexpected situations.

f) Wear suitable clothing. Do not wear wide clothing or jewellery. Keep your

hair, clothes and gloves away from moving parts. Loose clothing, jewellery or

long hair can be caught in moving parts.

3

Page 10

GB

g) This device can be used by children over the age of 8 as well as by people

with restricted physical, sensory or mental abilities or who have little

experience or knowledge about it, providing they are supervised or

instructed on how to use the device safely and what risks are involved.

Children may not play with the device. User maintenance and cleaning may not be

carried out by children unattended.

TexPerfect Flexio 525

4. Usage and treatment of the electric tool

a) Do not overload the tool. Use the power tool designed for the work that you

are doing. You work better and safer in the specied performance range if you use

the suitable power tool.

b) Do not use power tools whose switch is defective. A power tool that cannot be

switched on or o is dangerous and has to be repaired.

c) Remove the plug from the socket before carrying out tool settings, changing

accessories or putting the tool away. This precautionary measure prevents

unintentional starting of the tool.

d) Store unused power tools so that they are inaccessible to children. Do not

let persons use the tool who are not familiar with it or who have not read

these instructions. Power tools are dangerous when they are used by inexperienced

persons.

e) Take proper care of your tools. Check whether the moving parts function

trouble-free and do not jam, whether parts are broken or damaged so that

the tool function is impaired. Have damaged parts repaired before using

the tool. Many accidents have their origin in power tools that have been maintained

badly.

f) Use the power tool, accessories, insert tools, etc. in accordance with these

instructions and in a fashion specied for this special tool type. Take the

working conditions and the activity to be carried out into consideration. The

use of power tools for purposes other than the intended ones can lead to dangerous

situations.

5. Service

a) Have your tool repaired only by qualied specialist personnel and only with

original spare parts. This ensures that the tool safety is maintained.

b) If the supply cord is damaged, it must be replaced by the manufacturer or it’s

service agent or a similarly qualied person in order to avoid a safety hazard.

4

Page 11

TexPerfect Flexio 525

GB

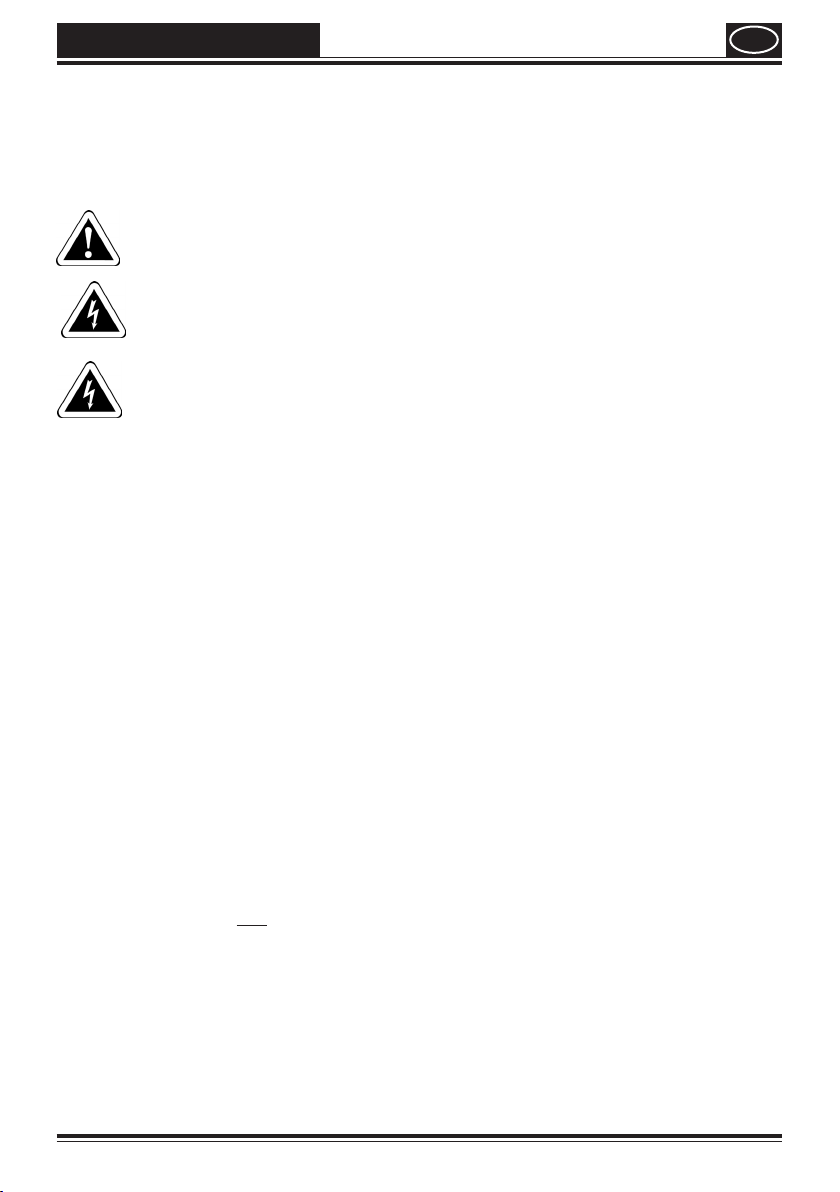

3. Safety Instructions for Spray Guns

Caution! Wear breathing equipment: Paint mist and solvent vapors are damaging to

•

health. Always wear breathing equipment and only work in well ventilated rooms or

using supplementary ventilating equipment. It is advisable to wear working clothing,

safety glasses, ear protection and gloves.

CAUTION: DANGER OF INJURY!

Never point the spray stream towards human beings or animals.

Sockets and plugs must be masked. Risk of an electric shock as a

consequence of sprayed material entering the socket!

Attention! Never operate the device if the nozzle seal is either

damaged or missing. If the nozzle seal is either missing or damaged

liquids can enter the device and increase the risk of an electric shock.

Check the nozzle seal before each use.

Do not use the spray guns to spray ammable substances.

•

The spray guns are not to be cleaned with ammable solvents.

•

Caution against dangers that can arise from the sprayed substance and observe the

•

text and information on the containers or the specications given by the substance

manufacturer.

Do not spray any liquid of unknown hazard potential.

•

The device may not be used in workplaces covered by the explosion-protection

•

regulations.

To avoid the hazard of explosion when spraying, provide for eective natural or

•

articial ventilation.

There must be no sources of ignition such as, for example, open res, smoke of lit

•

cigarettes, cigars and tobacco pipes, sparks, glowing wires, hot surfaces, etc. in the

vicinity during spraying.

When working with the Flexio 525 indoors as well as outdoors ensure that no solvent

•

vapors are sucked in by the spray gun.

The spray gun is not a toy; children must therefore not be allowed to handle it or play

•

with it.

Before working on the spray gun remove the power plug from the socket.

•

Cover areas that are not to be sprayed. When working keep in mind that wind, for

•

example, may transport paint mist over great distances and cause damage.

Never open the device yourself in order to carry out repairs in the electrical system!

•

The units may only be used with a functional valve. If paints rises in the ventilating

•

hose (Fig. 1, item 13) do not operate the unit further! Dismantle and clean the

ventilating hose, valve and diaphragm and replace the diaphragm if necessary.

Do not lay the spray gun on its side.

•

The device is equipped with a thermal release which disconnects the device in case of

•

overheating. In this case, turn o the device, remove the plug and let the device cool

5

Page 12

GB

down for at least 1/2 hour. Eliminate the cause of heating, e.g. soiled air lter, slots for

air intake covered.

With original WAGNER accessories and spare parts, you have the guarantee that

all safety regulations are fullled.

TexPerfect Flexio 525

4. Description/ Scope of delivery

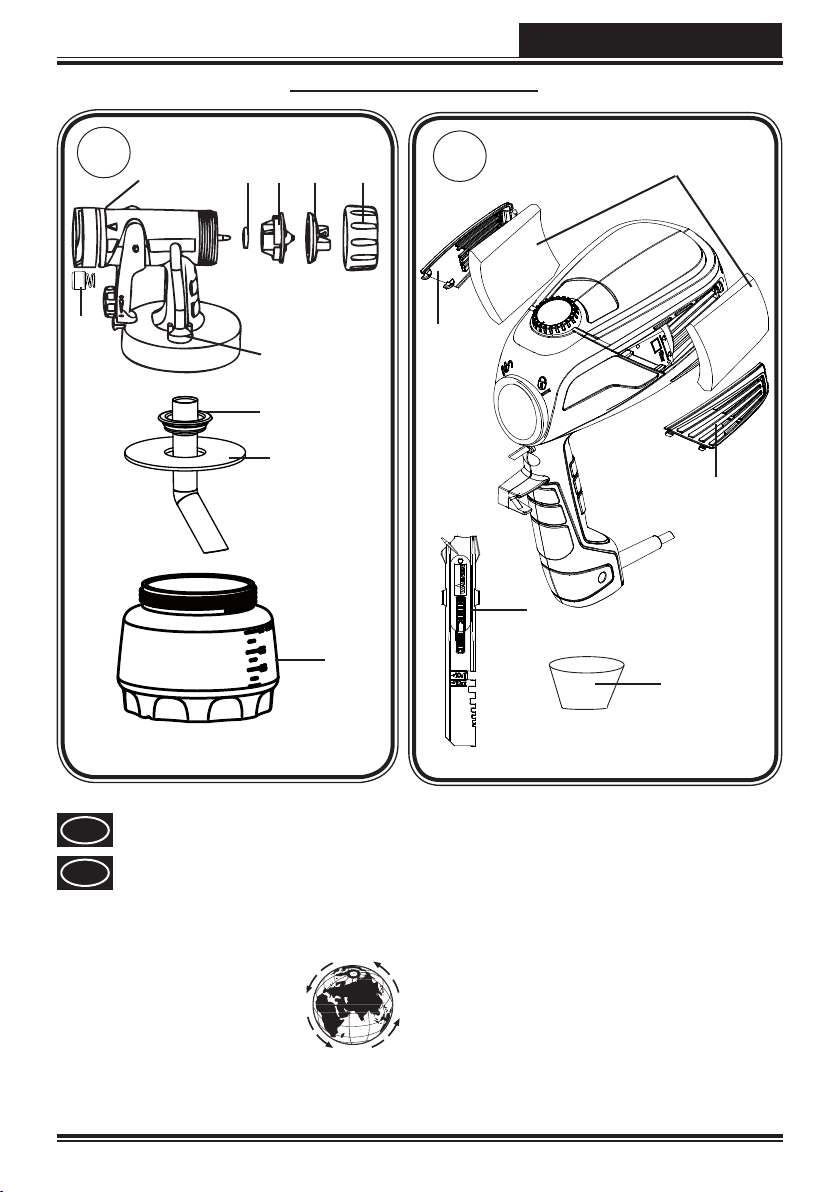

Description/ Scope of delivery (Fig. 1)

1) Air cap 2) Nozzle

3) Union nut 4) TexPerfect spray attachment

5) Air volume control 6) Spray gun rear part

7) Air lter cover (right + left) 8) Trigger

9) Material volume adjustment 10) Mains lead

11) Container 12) Valve

13) Ventilating hose 14) Stirring rod

15) Feed hopper (2 pcs.) 16) Replacement air lter (2 pcs.)

17) Breathing mask (FFP2) 18) Practice poster

19) Replacement nozzle seal* 20) Lubricating grease*

* This is inside the container: remove it before starting operations!

5. Coating Materials Suitable for Use

Mansory paint (only outdoor use)

Fine plaster (maximum grain size 1 mm), structured paint, undercoats, sealing primer

6. Coating Materials Not Suitable for Use

Materials that contain highly abrasive components (grain size bigger than 1 mm), caustic

solutions and acidic coating substances. Flammable materials.

7. The following materials can only be processed with

optional accessories

Interior wall paint (dispersions and latex paint)

Water- and solvent-based paints, nishes, primers, 2-component paints, clear nishes,

automotive nishes, staining sealers and wood sealer-preservatives.

6

Page 13

TexPerfect Flexio 525

GB

8. Preparation of the workplace

Sockets and plugs must be masked. Risk of an electric shock as a

consequence of sprayed material entering the socket!

Mask all the areas and objects that are not to be spray painted, or

remove them from the work area. No liability is assumed for damage

due to overspray. Silicate paint corrodes glass and ceramic surfaces

upon contact! All such surfaces must therefore be completely covered.

Pay attention to the quality of the adhesive tape used.

Do not use excessively strong adhesive tape on wallpaper and painted

i

surfaces, in order to avoid damaging these surfaces when removing the

tape. Remove adhesive tape slowly and evenly; do not use jerky movements.

Do not leave adhesive tape on surfaces any longer than necessary, in order

to minimise the possibility of residues when removing.

Also observe the adhesive tape manufacturer's instructions.

9. Preparing the wall

The spray result depends heavily on the smoothness and cleanliness of

i

the surface to be sprayed. Fine plaster cannot be used to level bumps or

holes in the wall. Therefore the surface should be carefully prepared and

kept free of dust.

Depending on the surface, it might be necessary to apply a suitable sealing primer/

undercoat before spraying the ne plaster on the wall. Please observe the information

about this that is provided by the manufacturer of the material.

10. Preparation of the Coating Material

Spray material that is at least at room temperature provides a better spray

i

result.

The Flexio 525 is perfect for spraying mansory paint, ne plaster, structured paint and

undercoats either undiluted or partially diluted. Detailed information is available in the

technical data sheet of the manufacturer ( Internet download).

1.

Stir the material thoroughly and dilute it in the container as per the recommended

dilution (an agitator is recommended for stirring).

Thinning recommendation

Sprayed material

Mansory paint, undercoats, sealing primer undiluted

Fine plaster dilute by 0-5%

Structured paint observe manufacturer's instructions

7

Page 14

GB

2. If the feed rate is too low even at maximum flow setting, dilute in steps of 5 - 10 %

until the feed rate meets your requirements (observe the maximum permitted

dilution as stipulated by the manufacturer).

TexPerfect Flexio 525

11. Start-up

Before connecting to the mains supply, be sure that the supply voltage is identical with

the value given on the rating plate.

Unscrew the container from the spray gun.

•

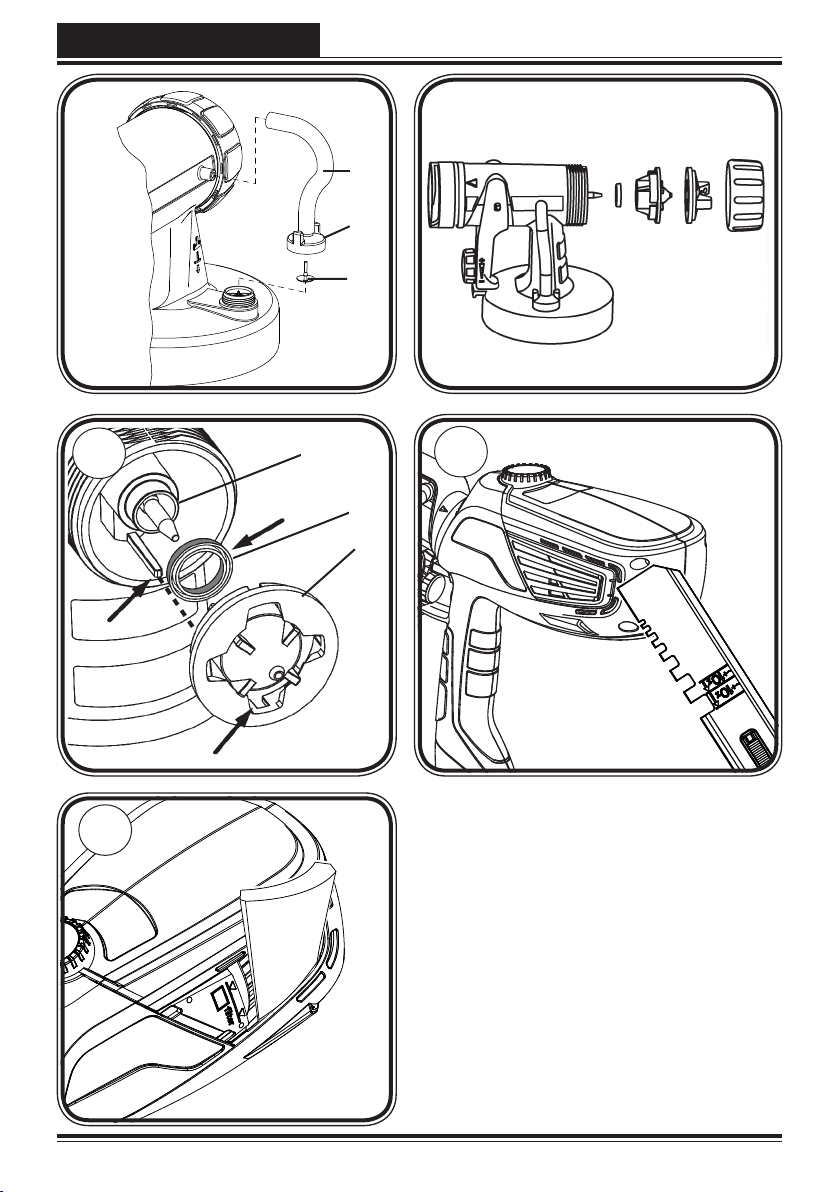

Aligning suction tube. (Fig. 2)

•

If the suction tube is positioned correctly, the container contents can be sprayed without

almost any residue.

When working on lying objects: Turn the suction tube forwards. (Fig. 2 A)

Spraying work when working on overhead objects: Turn the suction tube rearwards.

(Fig. 2 B)

Place the container on a paper base and pour in the prepared coating substance with the

•

aid of the feed hopper included in the scope of supply (Fig. 1, 15). Screw the container

tightly onto the spray gun.

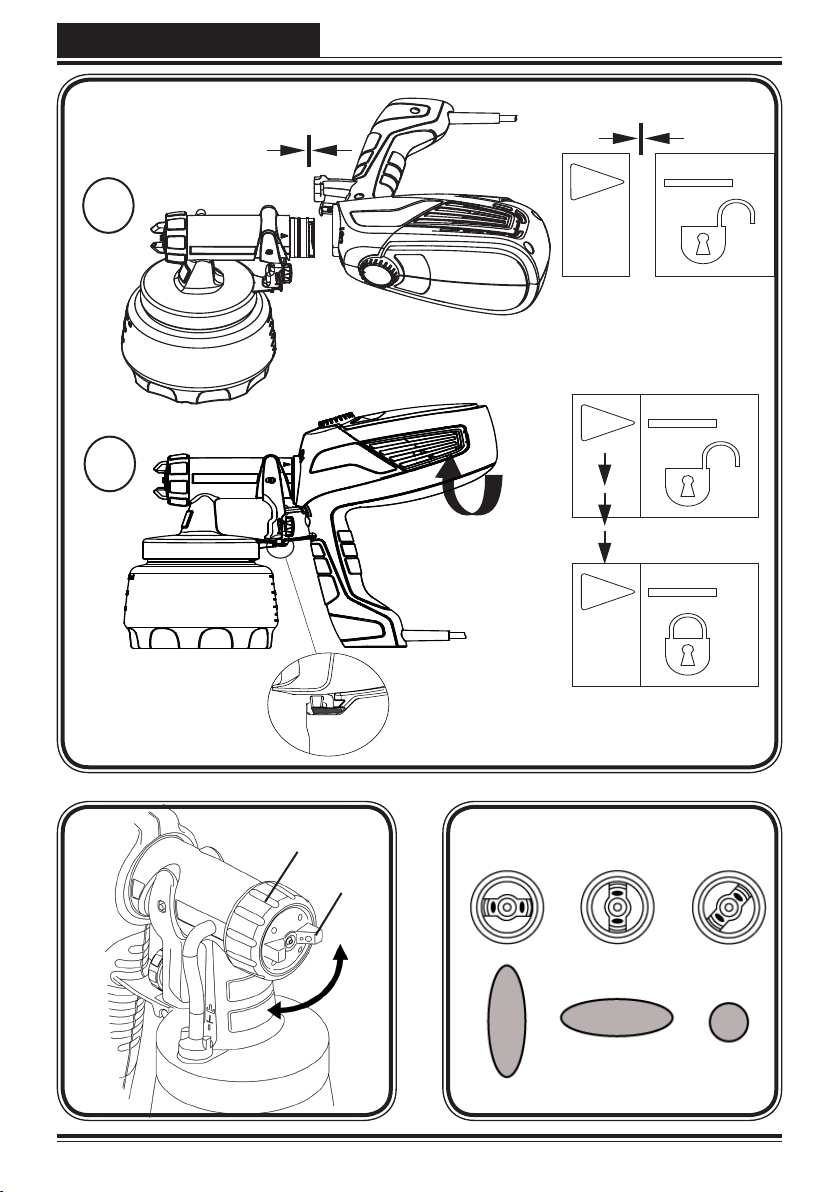

Connect the front part with the rear part of the gun (Fig. 3).

•

Put the machine down only on a level, clean surface. Otherwise the machine could tip

•

over!

Pull the trigger. The Flexio 525 has a two-stage trigger. In the rst stage the turbine is

•

started. If the trigger guard is pressed further, the material is transported.

Adjust the spray setting on the spray gun.

•

The enclosed practice poster is ideal for familiarising yourself with

operation of the spray gun. After trying out the rst spray coatings, it

i

makes sense to test it further on cardboard or a similar surface in order

to nd out the right ow rate of paint and air for the best spray pattern.

Detailed information about these settings can be found in chapter 12-14.

12. Selecting the Spray Setting

WARNING! Danger of injury! Never pull the trigger guard while adjusting

the air cap.

With the union nut (g. 4, 1) slightly unscrewed, turn the air cap (2) to the desired spray

setting position (arrow). Then tighten the union nut.

Fig. 3 A = vertical at jet

Fig. 3 B = horizontal at jet

Fig. 3 C = circular jet

8

for applying the material horizontally

for applying the material vertically

for corners, edges and hard-to-reach

surfaces

Page 15

TexPerfect Flexio 525

GB

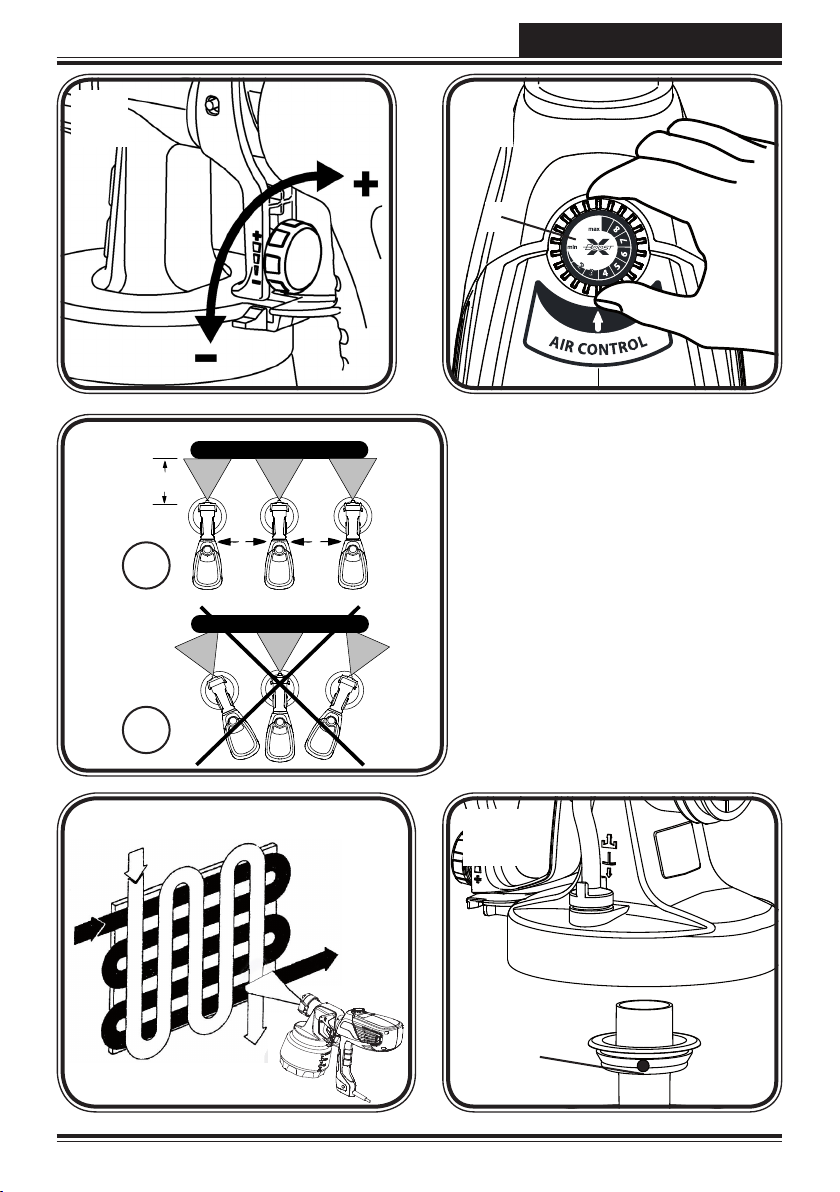

13. Adjusting the Material Volume (Fig. 6)

Set the material volume by turning the regulator on the trigger guard of the spray gun.

lower material volume turn anti-clockwise (-)

higher material volume turn clockwise (+)

14. Setting the Amount of Air (Fig. 7)

Depending on the viscosity of the material to be sprayed and the nish of the

i

object to be coated, it may be advisable to vary the amount of air. Very low viscosity

materials do not have to be atomised with the maximum amount of air. In this case it

is advisable to reduce the amount of air and thus minimize the spray vapour.

This also applies for the use of the low-scale and radiator/detail spray attachment

(accessory).

Turn the air quantity regulator (g. 7, 1) until the level you want is above the arrow.

thin paint

thick paint (e.g. interior wall paint)

Level min to 6

Level 6 to max

15. Spray Technique

General

The spray result depends heavily on the smoothness and cleanliness of the

i

surface to be sprayed. Therefore the surface should be carefully prepared and

kept free of dust.

Cover all surfaces not to be sprayed.

•

Important: Start at the edge of the area to be sprayed. Start the spray

movement rst of all, and then press the trigger. Avoid interruptions

i

within the area to be sprayed.

The spray movement should come from the arm, not just from the wrist. This ensures

•

that a uniform distance is maintained between the spray gun and the spray surface

during the spray operation.

Fig. 8 A: CORRECT Even distance to the object.

Fig. 8 B: INCORRECT An uneven distance will result in uneven paint application.

Move the spray gun evenly cross-wise or up-and-down, depending on the spray

•

pattern setting.

An even movement of the spray gun results in an even surface quality.

•

9

Page 16

GB

Important: Wipe o the nozzle and air cap regularly

to make sure they do not get blocked.

i

Undercoats, sealing primer

Select a distance of about 15-20 cm and a low ow rate.

•

Mansory paint, ne plaster, structured paint

Select a distance of 15-20 cm, depending on the desired spray jet width.

•

For masonry paint select a medium or high ow rate.

•

For ne plaster, the material ow should be adjusted to the grain size. When using

•

larger grain sizes (e.g. 1 mm) a high ow rate should be set.

Apply the masonry paint and ne plaster in a criss-cross movement (g. 9).

•

If necessary, spray another 1-2 layers (allowing the material to dry rst).

With ne plaster the nal result cannot be evaluated until it has dried. Therefore

i

wait about 20-30 minutes until the rst layer is dry before you start touchingup the wall.

The ow rate for ne plaster is lower than when using undercoat.

i

You therefore work more slowly in order to attain an even application.

TexPerfect Flexio 525

16. Interruption of Work

Turn the machine o.

•

With ne plaster, observe the maximum processing time (usually 20-30 minutes). If

•

the spray attachment is not used for a slightly longer period, clean it, as the material is

hard to remove once dry.

During longer breaks, vent the container by briey opening and then closing it again.

•

Clean nozzle openings after an interruption in operation.

•

17. Taking Out of Operation and Cleaning

Proper cleaning is the prerequisite for problem-free operation of the paint application

device. No warranty claims are accepted in case of improper or no cleaning.

Never hold the spray gun rear part under water or immerse it into liquids.

Clean the housing only with a moistened cloth.

With mansory paint, ne plaster, structured paint and undercoats we

i

recommend using warm water for cleaning.

10

Page 17

TexPerfect Flexio 525

1)

Unplug the power plug. Vent the container in case of longer breaks and after the work

has been terminated. This can be done by briey turning open and then closing the

container or by pulling the trigger guard and letting the paint into the original paint

container.

2)

Divide the spray gun. Press the hook (Fig. 3 b "click") slightly downwards. Turn the gun

front part and gun rear part against each other and take them apart.

3) Unscrew the container. Empty any remaining coating material back into the material

tin.

4)

Preclean the container and feed tube with a brush. Clean the ventilating bore

(Fig. 10, 1).

5)

Pour water into the container. Screw the container back on.

Do not use ammable materials for cleaning purposes.

6) Assemble the gun again (Fig. 3).

7) Insert the power plug, turn on the machine and spray the water into a container or a

cloth.

8) Repeat the above procedure until the water emerging from the nozzle is clear.

9) Turn o the machine and remove the plug.

10)

Divide the spray gun. Press the hook (Fig. 3 b "click") slightly downwards. Turn the gun

front part and gun rear part against each other and take them apart.

11) Screw of the container and empty it. Pull out the suction tub with container seal.

CAUTION! Never clean seals, diaphragm and nozzle or air holes of the spray gun with metal

objects.

The ventilation hose and diaphragm are only solvent-resistant to a limited

extent. Do not immerse in solvent, only wipe.

12) Pull the ventilating hose (Fig.11, 1) at the top from the gun body. Screw o the valve

cover (2). Remove the diaphragm (3). Clean all the parts carefully.

13) Unscrew the union nut and remove the air cap and nozzle. Clean the air cap, nozzle

seal and nozzle with a brush and water (Fig. 12).

14) Clean the outside of the spray gun and container with a cloth soaked in water.

15) Assemble the parts again (see “Assembly”).

GB

Assembly

The unit may only be operated with an integer diaphragm (Fig. 11, 3).

1) Place the diaphragm (Fig. 11 ,3) with the pin facing upwards on the bottom section

of the valve. Also see the marking on the gun body.

2) Place on the valve cover (Fig. 11 ,2) and screw it closed.

3) Place the ventilating hose (Fig. 11, 1) on the valve cover and on the nipple at the gun

body.

Attention! Never operate the device if the nozzle seal is either damaged or

missing. If the nozzle seal is either missing or damaged liquids can enter

the device and increase the risk of an electric shock.

4)

Push the nozzle seal (g. 13, 1) over the needle (3); the groove (slot) should point

towards you.

11

Page 18

GB

5) Put the nozzle onto the gun body and nd the correct position by turning it.

6) Put the air cap onto the nozzle and tighten it using the union nut.

7) Place the container seal from below on the suction tube and slide it over the collar,

while turning the container seal slightly.

8) Insert the suction tube with container seal in the gun body.

TexPerfect Flexio 525

18. Maintenance

WARNING! Never operate the machine without the air filter;

dirt could be sucked in and interfere with the function of the

machine. Check the air filter after each use for contaminants.

Disconnect plug before changing parts.

1) Open the air lter lid with the help of the stirring rod. (Fig. 14)

2) Pull out the air lter and replace it if necessary, depending on how soiled it is.

3) First, push the new air lter into the bottom part of the compartment. (Fig. 15)

4)

Next push it completely into the compartment.

In order to push the air lter into the compartment completely, we recommend using

the stirring rod.

In order to mount the gun more easily apply lubricating grease (enclosed) liberally

to the O-ring at the gun front part. (Fig. 16, 5 ).

19. Spare Parts

Spare Parts List: TexPerfect spray attachment (Fig. 16)

Pos. Designation Order No.

TexPerfect spray attachment complete with 1300 ml container 2345 792

1 Union nut 2343 966

2 Air cap 2343 965

3 Nozzle 2343 963

4 Nozzle seal (2 pcs.) 2304 433

5 O-ring 0417 308

6 Feather with cap 2343 967

7 Ventilating hose, valve cover, diaphragm 2304 027

8 Suction tube 2328 922

9 Container seal 2328 919

10 Container with cover 1300 ml 2305 155

12

Page 19

TexPerfect Flexio 525

GB

Spare Parts List Flexio 525 (Fig. 17)

Pos. Benennung Best. Nr.

1 Air lter cover (right + left) 2335 172

2 Air lter set (2 pcs.) 2333 123

3 Stirring rod 2304 419

4 Feed hopper (3 pcs.) 2304 028

Lubricating grease (no g.) 2315 539

20. Accessories

The new CLICK&PAINT SYSTEM with additional spray attachments and accessories

oers the right tool for each work.

Accessories (not included in the delivery)

Name Order No.

HVLP handle extension

For easier coating of ceilings and horizontal objects. 2307 678

Brilliant spray attachment incl. 600 ml container

Optimised nozzle and air guidance for brilliant paint results 0417 932

Small-scale spray attachment incl. 250 ml container

For ligree objects, detailed and creative work. 0417 918

Perfect Spray spray attachment incl. 1400 ml container

Rapid working at larger objects such as timber houses, garage doors,

etc.

Detail / Radiator spray attachment incl. 600 ml container

For inaccessible places, such as radiators, cupboard corners, recesses

etc.

WallPerfect I-Spray spray attachment incl. 1800 ml container

For processing interior wall paint and high-viscosity coating materials. 2326 477

0417 917

0417 915

Further information about the WAGNER range of products for renovating is available

under www.wagner-group.com

13

Page 20

GB

TexPerfect Flexio 525

21. Correction of Malfunctions

Problem Cause Remedy

No coating material

emerges from the

nozzle

Coating material

drips from the

nozzle

Atomisation too

coarse

Spray jet pulsates

Coating material

causes "paint tears"

Too much fog of

coating material

(Overspray)

Nozzle clogged

•

Feed tube clogged

•

Material volume setting turned

•

too far to the left (-)

Feed tube loose

•

No pressure build-up in container

•

Ventilating bore (Fig. 10,1)

•

clogged

Nozzle loose

•

Nozzle worn

•

Nozzle seal is missing or worn

•

Coating material assembly at air

•

cap, nozzle or needle

Coating material too thick

•

Material volume too large

•

Material volume adjusting screw

turned too far to the right (+)

Nozzle contaminated

•

Air lter heavily soiled

•

Too little pressure build-up in

•

container

Amount of air too low

•

Coating material in container

•

running out

Air lter heavily soiled

•

Nozzle seal is missing or worn

•

Too much coating material

•

applied.

Distance to the object too large

•

Too much coating material

•

applied

Amount of air too high

•

➞ Clean

➞ Clean

➞ Turn to the right (+)

➞ Insert

➞ Tighten container

➞ Clean

➞ Tighten

➞ Change

➞ Insert an intact nozzle

seal

➞ Clean

➞ Dilute

➞ Turn material volume

adjusting screw to the

left (-)

➞ Clean

➞ Change

➞ Tighten container

➞ Increase air quantity

➞ Rell

➞ Change

➞ Insert an intact nozzle

seal

➞ Turn material volume

adjusting screw to the

left (-)

➞ Leave it to dry and

then sand down

➞ Reduce distance

➞ Turn material volume

adjusting screw to the

left (-)

➞ Decrease air quantity

14

Page 21

TexPerfect Flexio 525

GB

Problem Cause Remedy

Paint in the

ventilating hose

Poor covering

capacity on the wall

Device does not

function

Diaphragm soiled

•

Diaphragm defective

•

Spray material is too cold

•

Highly absorbent surface or paint

•

with poor covering capacity

Distance too large

•

Device overheated ➞ Unplug the power

•

➞ Clean the diaphragm

➞ Replace the diaphragm

➞ The material you are

spraying should be at

room temperature

➞ Cross spray (Fig. 9)

➞ Closer to the object

plug, let the device

cool down approx. 30

minutes, check the air

lter, do not cover the

intake slots

22. Technical Data

Technical Data

Max. viscosity: 4000 mPas

Power source: 230 V, ~ 50 Hz

Power consumption: 630 W

Atomizing output: 25 W (min), 200 W (max)

Max. ow rate (ne plaster): 450 g / min

Double insulation:

Sound pressure level*: 74 dB (A); Uncertainty K = 4 dB

Sound pressure output*: 87 dB (A); Uncertainty K = 4 dB

Oscillation level*: < 2.5 m/s²; Uncertainty K = 1.5 m/s²

Weight: 1.9 kg

* Measured in accordance with EN 60745-1

Information about the oscillation level

The specied oscillation level has been measured according to a standard test

procedure and can be used to compare against electric tools.

The oscillation level is also for determining an initial assessment of the vibrational

strain.

Attention! The vibration emission value can dier from the specied value when the

electric tool is actually in use, depending on how the electric tool is being used. It is

necessary to specify safety measures to protect the operating personnel. These measures

15

Page 22

GB

are based on an estimated shutdown during the actual conditions of use (all parts of the

operating cycle are taken into consideration here, for example periods when the electric

tool is switched o, and, when it is switched on but running without any load).

TexPerfect Flexio 525

23. Environmental protection

The device and all accessories and packaging have to be recycled in an

environmentally friendly manner. Do not dispose of the appliance with

household waste. Support environmental protection by taking the appliance

to a local collection point or obtain information from a specialist retailer.

Leftover paint and solvents may not be emptied into drains, the sewage system

or disposed of as household rubbish. It has to be disposed of separately as

special waste. Please pay special attention to the instructions on the product

packaging.

24. Important Note regarding Product Liability!

According to an EU directive, the manufacturer is only liable without limitation for faults

in the product if all parts come from the manufacturer or have been approved by the

manufacturer and have been mounted to the device and are operated properly. If thirdparty accessories or spare parts are used, the manufacturer is exonerated wholly or partly

from his/her liability if use of the third-party accessories or spare parts have caused a

defect in the product.

16

Page 23

TexPerfect Flexio 525

GB

2 year guarantee

The guarantee runs for two years, counting from the date of sale (sales slip). It covers

and is restricted to free-of-charge rectication of faults which are demonstrably

attributable to the use of faulty materials in manufacture, or assembly errors; or freeof-charge replacement of the defective parts. The guarantee does not cover incorrect

use or commissioning or tting or repair work which is not stated in our operating

instructions. Wearing parts are also excluded from the guarantee. The guarantee

excludes commercial use. We expressly reserve the right to full the guarantee. The

guarantee expires if the tool is opened up by persons other than WAGNER service

personnel. Transport damage, maintenance work and loss and damage due to faulty

maintenance work are not covered by the guarantee. Under any guarantee claim,

there must be proof of purchase of the tool through submission of the original receipt.

Wherever legally possible, we exclude all liability for injury, damage or consequential

loss, especially if the tool has been used for a purpose other than that stated in the

operating instructions, commissioned or repaired other than in accordance with our

operating instructions or if repairs are performed by someone who is unqualied.

We reserve the right to perform any repairs in excess of those stated in our operating

instructions. In case of guarantee or repair, please refer to your point of sale.

Warning

If the supply cord of this appliance is damaged, it

must only be replaced by a repair shop appointed by

the manufacturer, because special purpose tools are

required.

Warning: Do not connect the blue or brown wire to the

earth terminal of the plug! The wires in this mains lead

are coloured in accordance with the following code:

blue = neutral brown = live

As the colours of the wires in the mains lead of this

appliance may not correspond with the coloured

markings identiying the terminals in your plug,

proceed as follows:

Should the moulded plug have to be replaced, never

re-use the defective plug or attempt to plug it into a

dierent 13 A socket. This could result in an electric

shock.

Should it be necessary to exchange the fuse in the plug

only use fuses approved by ASTA in accordance with

BS 1362. 5 Amp fuses may be used.

To ensure that the fuse and fuse carrier are correctly

mounted please observe the provided markings or

colour coding in the plug.

After changing the fuse, always make sure that the

fuse carrier is correctly inserted. Without the fuse carrier,

it is not permissible to use the plug.

The correct fuses and fuse carriers are available from

your local electrical supplies stockist.

17

Page 24

D

TexPerfect Flexio 525

Originalbetriebsanleitung

HERZLICHEN DANK FÜR IHR VERTRAUEN

Wir gratulieren Ihnen zum Erwerb dieses Markenproduktes von Wagner und sind

überzeugt, dass es Ihnen viel Freude bereiten wird.

Bitte lesen Sie vor Inbetriebnahme die Bedienungsanleitung genau durch und

beachten Sie die Sicherheitshinweise. Bewahren Sie die Bedienungsanleitung bitte

sorgfältig auf und legen Sie sie dem Produkt bei, falls Sie es einmal weitergeben sollten.

Für Fragen, Anregungen und Wünsche stehen wir Ihnen gerne unter der auf der Rückseite

angegebenen Rufnummer oder der Internetseite www.wagner-group.com/service zur

Verfügung.

Inhalt

1. Erklärung der verwendeten Symbole ........................................... 19

2. Allgemeine Sicherheitshinweise ................................................ 19

3. Sicherheitshinweise für Spritzpistolen ..........................................22

4. Beschreibung/ Lieferumfang ...................................................23

5. Verarbeitbare Beschichtungsstoe .............................................24

6. Nichtverarbeitbare Beschichtungsstoe ........................................24

7. Folgende Materialien lassen sich nur mit optionalen Zubehör verarbeiten .......24

8. Vorbereitung des Arbeitsplatzes ................................................ 24

9. Vorbereitung der Wand ........................................................ 25

10. Vorbereitung des Beschichtungsstoes .......................................25

11. Inbetriebnahme .............................................................. 25

12. Einstellung des gewünschten Spritzbildes .................................... 26

13. Einstellung der Materialmenge (Abb. 6) .......................................26

14. Einstellung der Luftmenge (Abb. 7) ............................................ 27

15. Spritztechnik . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

16. Arbeitsunterbrechung ....................................................... 28

17. Außerbetriebnahme und Reinigung ...........................................28

18. Wartung .....................................................................30

19. Ersatzteile .................................................................... 30

20. Zubehör .....................................................................31

21. Behebung von Störungen ....................................................32

22. Technische Daten ............................................................. 33

23. Umweltschutz ................................................................ 34

24. Wichtiger Hinweis zur Produkthaftung! ........................................ 34

2 Jahre Garantie .................................................................35

18

Page 25

TexPerfect Flexio 525

i

D

1. Erklärung der verwendeten Symbole

Dieses Symbol weist auf eine potenzielle Gefahr für Sie bzw. das

Gerät hin. Unter diesem Symbol nden Sie wichtige Informationen,

wie Sie Verletzungen und Schäden am Gerät vermeiden.

Gefahr eines elektrischen Schlages

Kennzeichnet Anwendungstipps und andere besonders nützliche

Hinweise.

Mit diesem Symbol gekennzeichnete Geräte und Zubehöre sind für die

Verarbeitung von Feinputz, Strukturfarbe und Grundierung geeignet.

Trägt ein Material dieses Logo ist es für die Verwendung mit dem

entsprechenden Gerät besonders gut geeignet.

2. Allgemeine Sicherheitshinweise

Achtung! Sämtliche Anweisungen sind zu lesen. Fehler bei der Einhaltung der nachstehend

aufgeführten Anweisungen können elektrischen Schlag, Brand und/oder

schwere Verletzungen verursachen. Der nachfolgend verwendete Begri

“Elektrowerkzeug” bezieht sich auf netzbetriebene Elektrowerkzeuge (mit

Netzkabel) und auf akkubetriebene Elektrowerkzeuge (ohne Netzkabel).

1. Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet. Unordnung oder

unbeleuchtete Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Gerät nicht in explosionsgefährdeter Umgebung,

in der sich brennbare Flüssigkeiten, Gase oder Stäube benden.

Elektrowerkzeuge erzeugen Funken, die den Staub oder die Dämpfe entzünden

können.

c) Halten Sie Kinder und andere Personen während der Benutzung des

Elektrowerkzeugs fern. Bei Ablenkung können Sie die Kontrolle über das Gerät

verlieren.

2. Elektrische Sicherheit

a) Der Anschlussstecker des Gerätes muss in die Steckdose passen. Der Stecker

darf in keiner Weise verändert werden. Verwenden Sie keine Adapterstecker

gemeinsam mit schutzgeerdeten Geräten. Unveränderte Stecker und passende

Steckdosen verringern das Risiko eines elektrischen Schlages.

19

Page 26

D

b) Vermeiden Sie Körperkontakt mit geerdeten Oberächen, wie von Rohren,

Heizungen, Herden und Kühlschränken. Es besteht ein erhöhtes Risiko durch

elektrischen Schlag, wenn Ihr Körper geerdet ist.

c) Halten Sie das Gerät von Regen oder Nässe fern. Das Eindringen von Wasser in

ein Elektrogerät erhöht das Risiko eines elektrischen Schlages.

d) Zweckentfremden Sie das Kabel nicht, um das Gerät zu tragen, aufzuhängen

oder um den Stecker aus der Steckdose zu ziehen. Halten Sie das Kabel

fern von Hitze, Öl, scharfen Kanten oder sich bewegenden Geräteteilen.

Beschädigte oder verwickelte Kabel erhöhen das Risiko eines elektrischen Schlages.

e) Wenn Sie mit einem Elektrowerkzeug im Freien arbeiten, verwenden Sie

nur Verlängerungskabel, die auch für den Außenbereich geeignet sind. Die

Anwendung eines für den Außenbereich geeigneten Verlängerungskabels verringert

das Risiko eines elektrischen Schlages.

f) Wenn der Betrieb des Gerätes in feuchter Umgebung nicht vermeidbar

ist, verwenden Sie einen Fehlerstromschutzschalter. Der Einsatz eines

Fehlerstromschutzschalters verhindert das Risiko eines elektrischen Schlages.

TexPerfect Flexio 525

3. Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen Sie mit

Vernunft an die Arbeit mit einem Elektrowerkzeug. Benutzen Sie das Gerät

nicht, wenn Sie müde sind oder unter dem Einuss von Drogen, Alkohol

oder Medikamenten stehen. Ein Moment der Unachtsamkeit beim Gebrauch des

Gerätes kann zu ernsthaften Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und immer eine Schutzbrille.

Das Tragen persönlicher Schutzausrüstung, wie Staubmaske, rutschfeste

Sicherheitsschuhe, Schutzhelm oder Gehörschutz, je nach Art und Einsatz des

Elektrowerkzeuges, verringert das Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetriebnahme. Vergewissern Sie

sich, dass das Elektrowerkzeug ausgeschaltet ist, bevor Sie es an die

Stromversorgung anschließen, es aufnehmen oder tragen. Wenn Sie beim

Tragen des Geräts den Finger am Schalter haben oder das Gerät eingeschaltet an die

Stromversorgung anschließen, kann dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie das

Gerät einschalten. Ein Werkzeug oder Schlüssel, der sich in einem drehenden

Geräteteil bendet, kann zu Verletzungen führen.

e) Vermeiden Sie eine abnormale Körperhaltung. Sorgen Sie für einen sicheren

Stand und halten Sie jederzeit das Gleichgewicht. Dadurch können Sie das

Gerät in unerwarteten Situationen besser kontrollieren.

20

Page 27

TexPerfect Flexio 525

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern von sich

bewegenden Teilen. Lockere Kleidung, Schmuck oder lange Haare können von sich

bewegenden Teilen erfasst werden.

g) Dieses Gerät kann von Kindern ab 8 Jahren und darüber sowie von Personen

mit verringerten physischen, sensorischen oder mentalen Fähigkeiten oder

Mangel an Erfahrung und Wissen benutzt werden, wenn sie beaufsichtigt

oder bezüglich des sicheren Gebrauchs des Gerätes unterwiesen wurden

und die daraus resultierenden Gefahren verstehen. Kinder dürfen nicht mit

dem Gerät spielen. Reinigung und Benutzer-Wartung dürfen nicht von Kindern ohne

Beaufsichtigung durchgeführt werden.

4. Verwendung und Behandlung des Elektrowerkzeugs

a) Überlasten Sie das Gerät nicht. Verwenden Sie für Ihre Arbeit das dafür

bestimmte Elektrowerkzeug. Mit dem passenden Elektrowerkzeug arbeiten Sie

besser und sicherer im angegebenen Leistungsbereich.

b) Benutzen Sie kein Elektrowerkzeug, dessen Schalter defekt ist. Ein

Elektrowerkzeug, das sich nicht mehr ein- oder ausschalten lässt, ist gefährlich und

muss repariert werden.

c) Ziehen Sie den Stecker aus der Steckdose, bevor Sie Geräteeinstellungen

vornehmen, Zubehörteile wechseln oder das Gerät weglegen. Diese

Vorsichtsmaßnahme verhindert den unbeabsichtigten Start des Geräts.

D

d) Bewahren Sie unbenutzte Elektrowerkzeuge außerhalb der Reichweite

von Kindern auf. Lassen Sie Personen das Gerät nicht benutzen, die mit

diesem nicht vertraut sind oder diese Anweisungen nicht gelesen haben.

Elektrowerkzeuge sind gefährlich, wenn Sie von unerfahrenen Personen benutzt

werden.

e) Pegen Sie das Gerät mit Sorgfalt. Kontrollieren Sie, ob bewegliche

Geräteteile einwandfrei funktionieren und nicht klemmen, ob Teile

gebrochen oder so beschädigt sind, dass die Funktion des Gerätes

beeinträchtigt ist. Lassen Sie beschädigte Teile vor dem Einsatz des

Gerätes reparieren. Viele Unfälle haben ihre Ursache in schlecht gewarteten

Elektrowerkzeugen.

f) Verwenden Sie Elektrowerkzeug, Zubehör, Einsatzwerkzeuge

usw. entsprechend diesen Anweisungen und so, wie es für diesen

speziellen Gerätetyp vorgeschrieben ist. Berücksichtigen Sie dabei die

Arbeitsbedingungen und die auszuführende Tätigkeit. Der Gebrauch von

Elektrowerkzeugen für andere als die vorgesehenen Anwendungen kann zu

gefährlichen Situationen führen.

21

Page 28

D

5. Service

a) Lassen Sie Ihr Gerät nur von qualiziertem Fachpersonal und nur mit

Original-Ersatzteilen reparieren. Damit wird sichergestellt, dass die Sicherheit des

Geräts erhalten bleibt.

b) Wenn die Netzanschlussleitung dieses Gerätes beschädigt wird, muss

sie durch den Hersteller oder seinen Kundendienst oder eine ähnlich

qualizierte Person ersetzt werden, um Gefährdungen zu vermeiden.

TexPerfect Flexio 525

3. Sicherheitshinweise für Spritzpistolen

Achtung! Atemschutz tragen: Farbnebel und Lösungsmitteldämpfe sind gesundheits-

•

schädlich. Nur in gut belüfteten Räumen oder bei künstlicher Belüftung arbeiten.

Das Tragen von Arbeitskleidung, Schutzbrille, Gehörschutz und Handschuhen wird

empfohlen.

ACHTUNG VERLETZUNGSGEFAHR!

Niemals die Pistole auf sich, Personen oder Tiere richten.

Steckdosen und Schalter unbedingt abkleben.

Gefahr eines elektrischen Schlages durch eindringendes Sprühmaterial!

Achtung! Gerät niemals mit beschädigter oder fehlender Düsendichtung

betreiben. Bei fehlender oder beschädigter Düsendichtung kann

Flüssigkeit in das Gerät eindringen und dadurch das Risiko eines

elektrischen Schlages erhöhen.

Überprüfen Sie die Düsendichtung vor jeder Benutzung.

Die Spritzpistolen dürfen nicht zum Sprühen brennbarer Stoe verwendet werden.

•

Die Spritzpistolen dürfen nicht mit brennbaren Lösungsmitteln gereinigt werden.

•

Achten Sie auf die Gefahren die von dem versprühten Sto ausgehen können und

•

beachten Sie ebenfalls die Aufschriften auf den Behältern oder die vom Hersteller des

Stoes angegebenen Hinweise.

Versprühen Sie keinerlei Stoe von denen Sie die Gefährlichkeit nicht kennen.

•

In Betriebsstätten, die unter die Explosionsschutz-Verordnung fallen, dürfen die

•

Spritzpistolen nicht benutzt werden.

Um Explosionsgefahr bei Spritzarbeiten zu vermeiden, muss für eine gute natürliche

•

oder künstliche Lüftung gesorgt werden.

Beim Spritzen dürfen in der Umgebung keine Zündquellen vorhanden sein, wie

•

z. B. oenes Feuer, Rauchen von Zigaretten, Funken, glühende Drähte und heiße

Oberächen.

Beim Arbeiten mit dem Gerät Flexio 525 in Räumen wie auch im Freien darauf achten,

•

dass keine Lösemitteldämpfe vom Gerät angesaugt werden.

22

Page 29

TexPerfect Flexio 525

Die Spritzpistole ist kein Spielzeug. Lassen Sie deswegen Kinder nicht mit der

•

Spritzpistole hantieren oder spielen.

Vor allen Arbeiten an der Spritzpistole den Netzstecker aus der Steckdose ziehen.

•

Decken Sie nicht zu spritzende Flächen ab. Beachten Sie beim Arbeiten, dass z. B.

•

durch Wind, Farbnebel über größere Distanzen verfrachtet werden kann und dadurch

Schäden verursacht werden können.

Önen Sie das Gerät nie selbst um Reparaturen im elektrischen Bereich auszuführen!

•

Das Gerät darf nur mit funktionsfähigem Ventil betrieben werden. Wenn Farbe

•

in den Belüftungsschlauch (Abb. 1, 13) steigt, Gerät nicht weiter betreiben!

Belüftungsschlauch, Ventil und Membran demontieren, reinigen und ggf. Membran

ersetzen.

Spritzpistole nicht legen

•

Das Gerät ist mit einer Thermosicherung ausgestattet, welche das Gerät bei Überhitzung

•

abschaltet. In diesem Falle Gerät ausschalten, Netzstecker ziehen und das Gerät mind. 30

Minuten abkühlen lassen. Überhitzungsursache abstellen, z. B. verschmutzter Luftlter,

abgedeckte Schlitze zur Luftansaugung.

Mit original WAGNER Zubehör und Ersatzteilen haben Sie die Gewähr, dass alle

Sicherheitsvorschriften erfüllt sind.

D

4. Beschreibung/ Lieferumfang

Beschreibung/ Lieferumfang (Abb. 1)

1) Luftkappe 2) Düse

3) Überwurfmutter 4) Sprühaufsatz TexPerfect

5) Luftmengenregulierung 6) Spritzpistole Hinterteil

7) Luftlterabdeckung (rechts + links) 8) Abzugsbügel

9) Materialmengenregulierung 10) Netzkabel

11) Behälter 12) Ventil

13) Belüftungsschlauch 14) Rührstab

15) Einfülltrichter (2 Stk.) 16) Ersatzluftlter (2 Stk.)

17) Atemschutzmaske (FFP2) 18) Ersatzdüsendichtung*

19) Ersatzdüsendichtung* 20) Gleitfett

* Bendet sich im Behälter, vor Inbetriebnahme entfernen!

23

Page 30

D

TexPerfect Flexio 525

5. Verarbeitbare Beschichtungsstoe

Mansory Paint (nur bei Anwendungen im Freien)

Feinputz (maximale Korngröße 1 mm), Strukturfarbe, Grundierung, Sperrgrund

6. Nichtverarbeitbare Beschichtungsstoe

Materialien die stark schmirgelnde Bestandteile enthalten (Korngröße größer als 1mm),

Laugen und säurehaltige Beschichtungsstoe.

Brennbare Beschichtungsstoe.

7. Folgende Materialien lassen sich nur mit optionalen

Zubehör verarbeiten

Innenwandfarbe (Dispersionen und Latexfarbe)

Lösemittelhaltige und wasserverdünnbare Lackfarben, Lasuren, Grundierungen,

2-Komponenten Lacke, Klarlacke, Kraftfahrzeug-Decklacke, Beizen und

Holzschutzmittel.

8. Vorbereitung des Arbeitsplatzes

Steckdosen und Schalter unbedingt abkleben. Gefahr eines

elektrischen Schlages durch eindringendes Sprühmaterial!

Decken Sie alle nicht zu sprühende Flächen und Objekte ab, bzw.

entfernen Sie diese aus dem Arbeitsbereich. Für Schäden durch

Farbnebel (Overspray) wird keine Haftung übernommen.

Silikatfarbe verätzt bei Kontakt Glas- und Keramikächen! Alle

entsprechenden Oberächen müssen daher unbedingt komplett

abgedeckt werden.

24

Achten Sie auf die Qualität des verwendeten Abklebebandes.

Verwenden Sie auf Tapeten und gestrichenen Untergründen kein zu stark

i

haftendes Klebeband, um Beschädigungen beim Entfernen zu vermeiden.

Entfernen Sie Klebebänder langsam und gleichmäßig; keinesfalls ruckartig.

Lassen Sie Flächen nur so lange wie nötig abgeklebt, um mögliche

Rückstände beim Entfernen zu minimieren.

Beachten Sie auch die Hinweise des Klebebandherstellers.

Page 31

TexPerfect Flexio 525

D

9. Vorbereitung der Wand

Das Spritzergebnis hängt entscheidend davon ab, wie glatt und sauber

i

die Oberäche vor dem Spritzen ist. Mit Feinputz können keine

Unebenheiten oder Löcher beseitigt werden. Deshalb die Oberäche

sorgfältig vorbehandeln und staubfrei halten.

Abhängig vom Untergrund kann es notwendig sein, vor dem Sprühen des Feinputzes

einen geeigneten Sperrgrund auf die Wand aufzutragen. Beachten Sie hierzu auch die

Angaben des Materialherstellers

10. Vorbereitung des Beschichtungsstoes

Sprühmaterial mit mindestens Zimmertemperatur führt zu einem besseren

Sprühergebnis.

i

Mit der Flexio 525 können Mansory Paint, Feinputze, Strukturfarbe und Grundierungen

unverdünnt oder geringfügig verdünnt versprüht werden. Detailierte Informationen

können Sie dem technischen Datenblatt des Farbherstellers entnehmen ( Internet

Download).

1. Rühren Sie das Material gründlich auf und verdünnen Sie es im Gebinde gemäß der

Verdünnungsempfehlung (zum Umrühren wird ein Rührwerk empfohlen).

Verdünnungsempfehlung

Spritzmaterial

Mansory Paint, Grundierung, Sperrgrund unverdünnt

Feinputz 0 -5 % verdünnen

Strukturfarben Herstellerangaben beachten

2.

Ist die Fördermenge auch bei maximaler Mengeneinstellung zu gering,

schrittweise 5 - 10 % verdünnen bis die Fördermenge Ihren Anforderungen

entspricht (maximal zulässige Verdünnung gemäß Herstellerangaben beachten).

11. Inbetriebnahme

Vor Anschluss an das Stromnetz darauf achten, dass die Netzspannung mit der Angabe

auf dem Leistungsschild übereinstimmt.

Behälter von der Spritzpistole abschrauben

•

Steigrohr ausrichten (Abb. 2). Bei richtiger Position des Steigrohres kann der

•

Behälterinhalt fast ohne Rest verspritzt werden.

Bei Arbeiten an liegenden Objekten: Steigrohr nach vorne drehen. (Abb. 2 A)

Spritzarbeiten bei über Kopf Objekten: Steigrohr nach hinten drehen. (Abb. 2 B)

Behälter auf Papierunterlage stellen und vorbereiteten Beschichtungssto mit Hilfe des

•

im Lieferumfang enthaltenen Einfülltrichters (Abb. 1, 16) einfüllen. Behälter fest an die

Spritzpistole anschrauben.

25

Page 32

D

Vorder- und Hinterteil der Pistole miteinander verbinden (Abb 3)

•

Gerät nur auf ebener und sauberer Fläche abstellen. Gerät kann sonst umkippen!

•

Abzugsbügel betätigen. Die Flexio 525 hat einen 2-stugen Abzugsbügel. In der ersten

•

Stufe wird die Turbine gestartet. Wird der Abzugsbügel weiter gedrückt, wird Material

gefördert.

Spritzbild an der Spritzpistole einstellen

•

Das beiliegende Übungsposter ist ideal, um sich mit der Bedienung der

Sprühpistole vertraut zu machen. Nach diesen ersten Sprühversuchen,

i

ist es zweckmäßig auf Karton oder ähnlichem Untergrund eine

Sprühprobe durchzuführen, um die Material- und Luftmenge für ein

optimales Spritzbild zu ermitteln.

Detaillierte Informationen zu diesen Einstellungen nden Sie in den

folgenden Kapiteln 12 -14.

TexPerfect Flexio 525

12. Einstellung des gewünschten Spritzbildes

WARNUNG! Verletzungsgefahr! Niemals während der Einstellung der

Luftkappe den Abzugsbügel ziehen.

Bei leicht gelöster Überwurfmutter (Abb. 4, 1) die Luftkappe (2) in die gewünschte

Spritzbild-Position drehen (Pfeil). Danach Überwurfmutter wieder festziehen.

Abb. 5 A = senkrechter Flachstrahl

Abb. 5 B = waagrechter Flachstrahl

Abb. 5 C = Rundstrahl

für horizontalen Materialauftrag

für vertikalen Materialauftrag

für Ecken und Kanten sowie schwer

zugängliche Flächen

13. Einstellung der Materialmenge (Abb. 6)

Materialmenge durch Drehen der Regulierung am Abzugsbügel der Pistole festlegen.

weniger Materialmenge

mehr Materialmenge

26

gegen den Uhrzeigersinn drehen (-)

im Uhrzeigersinn drehen (+)

Page 33

TexPerfect Flexio 525

D

14. Einstellung der Luftmenge (Abb. 7)

Je nach Viskosität (Flüssigkeit) des zu versprühenden Materials und der

Beschaenheit des zu beschichtenden Objektes, kann es vorteilhaft sein die

i

Luftmenge zu variieren. Sehr dünnüssige Materialien müssen nicht mit der

maximalen Luftmenge zerstäubt werden. Es ist ratsam hier die Luftmenge

zu reduzieren und dadurch den Sprühnebel zu minimieren. Dies gilt auch

für die Verwendung des Kleinmengen- und Heizkörper/Detailsprühaufsatzes

(Zubehör).

Drehen Sie den Luftmengenregler (Ab. 7, 1) bis sich die gewünschte Stufe über dem Pfeil

bendet.

dünnüssige Materialien

dicküssige Materialien (z.B. Innenwandfarbe)

Stufe min - 6

Stufe 6 - max

15. Spritztechnik

Allgemeines

Das Spritzergebnis hängt entscheidend davon ab, wie glatt und sauber die

Oberäche vor dem Spritzen ist. Deshalb die Oberäche sorgfältig vorbehandeln

i

und staubfrei halten.

Nicht zu spritzende Flächen abdecken.

•

Wichtig: Am Rand der Spritzäche beginnen. Zuerst mit der

Sprühbewegung beginnen und dann den Abzugsbügel drücken.

i

Unterbrechungen innerhalb der Spritzäche vermeiden.

Die Spritzbewegung sollte nicht aus dem Handgelenk, sondern aus dem Arm

•

kommen. Somit bleibt während des Spritzvorgangs immer der gleiche Abstand

zwischen Spritzpistole und Fläche gewährleistet.

Abb. 8 A: RICHTIG gleichmäßiger Abstand zum Objekt

Abb. 8 B: FALSCH ungleichmäßiger Abstand erzeugt ungleichmäßigen

Farbauftrag

Bewegen Sie die Spritzpistole gleichmäßig quer oder auf und ab, je nach

•

Spritzbildeinstellung.

Eine gleichmäßige Spritzpistolenführung ergibt eine einheitliche Oberächenqualität.

•

Wichtig: Düse und Luftkappe während der

Benutzung regelmäßig abwischen, um ein

i

Verstopfen der Düse zu verhindern.

27

Page 34

D

Grundierung/ Sperrgrund

Wählen Sie einen Abstand von ca. 15-20 cm und eine niedrige Materialmengenein-

•

stellung.

Mansory Paint/ Feinputz/ Strukturfarbe

Wählen Sie einen Abstand von ca. 15-20cm je nach gewünschter Spritzstrahlbreite.

•

Wählen Sie bei Mansory Paint eine mittlere bis hohe Materialmengeneinstellung.

•

Bei Feinputz sollte die Materialmenge an die Korngröße angepasst werden. Bei

•

größeren Korngrößen (z.B. 1 mm) sollte daher eine hohe Materialmenge eingestellt

werden.

Tragen Sie Mansory Paint und Feinputz im Kreuzgang auf (Abb. 9). Sprühen Sie bei

•

Bedarf noch 1-2 weitere Bahnen (zuerst Antrocknen lassen).

Das Sprühergebnis lässt sich bei Feinputz erst nach dem Trocknen nal

i

beurteilen. Warten Sie daher zuerst ca. 20-30 Minuten bis die erste Schicht

trocken ist, bevor Sie Nachbesserungen durchführen.

Die Fördermenge bei Feinputz ist geringer als bei Grundierung.

i

Arbeiten Sie daher langsamer, um einen gleichmäßigen Auftrag zu

erreichen.

TexPerfect Flexio 525

16. Arbeitsunterbrechung

Gerät ausschalten.

•

Beachten Sie bei Feinputz die maximale Verarbeitungszeit (in der Regel 20-30

•

Minuten). Reinigen Sie bei längeren Pausen den Sprühaufsatz, da sich getrocknetes

Material schwerer entfernen lässt.

Bei längeren Pausen Behälter durch kurzes Aufdrehen und anschließendem

•

Verschließen entlüften.

Nach der Arbeitsunterbrechung Düsenönungen reinigen.

•

17. Außerbetriebnahme und Reinigung

Eine sachgemäße Reinigung ist Voraussetzung für den einwandfreien Betrieb des

Farbauftragsgerätes. Bei fehlender oder unsachgemäßer Reinigung werden keine

Garantieansprüche übernommen.

WARNUNG: Pistolen-Hinterteil niemals unter Wasser halten oder in

Flüssigkeit tauchen. Gehäuse nur mit getränktem Tuch reinigen.

Bei der Verarbetung von Mansory Paint, Feinputz, Strukturfarbe und

i

Grundierung empfehlen wir zur Reinigung warmes Wasser.

1) Netzstecker ziehen. Bei längeren Pausen und nach Beendigung der Arbeit Behälter

entlüften. Dies kann durch kurzes aufdrehen und anschließendem verschließen

28

Page 35

TexPerfect Flexio 525

des Behälters oder durch Betätigung des Abzugsbügels und Ablassen der Farbe ins

Originalgebinde geschehen.

2)

Pistole teilen. Haken (Abb. 3 b “click”) leicht nach unten drücken.

Pistolen-Vorderteil und Pistolen-Hinterteil gegeneinander verdrehen und auseinander

nehmen.

3) Behälter abschrauben. Restlicher Beschichtungssto in Materialdose zurückleeren

4)

Behälter und Steigrohr mit Pinsel vorreinigen. Entlüftungsbohrung reinigen.

(Abb.10,1)

5)

Wasser in den Behälter einfüllen. Behälter anschrauben.

Verwenden Sie zur Reinigung keine brennbaren Materialien.

6) Pistole wieder zusammenbauen (Abb. 3).

7)

Netzstecker einstecken, Gerät einschalten und Wasser in einen Behälter oder ein Tuch

spritzen.

8) Den obigen Vorgang wiederholen, bis an der Düse klares Wasser austritt.

9) Gerät ausschalten und Netzstecker ziehen.

10)

Pistole teilen. Haken (Abb. 3 b “click”) leicht nach unten drücken.

Pistolen-Vorderteil und Pistolen-Hinterteil gegeneinander verdrehen und auseinander

nehmen.

11) Behälter abschrauben und entleeren. Steigrohr mit Behälterdichtung herausziehen.

ACHTUNG! Dichtungen, Membran und Düsen- oder Luftbohrungen der

Spritzpistole niemals mit spitzen metallischen Gegenständen reinigen.

Belüftungsschlauch und Membran sind nur bedingt lösemittelbeständig.

Nicht in Lösemittel einlegen sondern nur abwischen.

12) Ist der Belüftungsschlauch (Abb. 11, 1) innen verschmutz, diesen oben vom

Pistolenkörper abziehen. Ventildeckel (2) aufschrauben. Membran (3) entnehmen.

Alle Teile sorgfältig reinigen.

13)

Überwurfmutter abschrauben, Luftkappe und Düse abnehmen. Luftkappe,

Düsendichtung und Düse mit Pinsel und Wasser reinigen. (Abb.12)

14) Spritzpistole und Behälter außen mit einem in Wasser getränktem Tuch reinigen.

15) Teile wieder zusammenbauen (siehe “Zusammenbau”).

D

Zusammenbau

Gerät darf nur mit unversehrter Membran (Abb. 11, 3) betrieben werden.

1) Membran (Abb. 11, 3) mit Stift nach oben auf das Unterteil des Ventils setzen. Siehe

hierzu auch Markierung auf dem Pistolenkörper.

2) Ventildeckel (Abb. 11, 2) vorsichtig aufsetzen und zuschrauben.

3)

Belüftungsschlauch (Abb. 11, 1) auf Ventildeckel und auf Nippel am Pistolenkörper

stecken.

Achtung! Gerät niemals mit beschädigter oder fehlender Düsendichtung

betreiben. Bei fehlender oder beschädigter Düsendichtung kann Flüssigkeit

in das Gerät eindringen und dadurch das Risiko eines elektrischen Schlages

erhöhen.

29

Page 36

D

4) Düsendichtung (Abb. 13, 1) über die Nadel (3) schieben, die Nut (Schlitz) muss dabei

zu Ihnen zeigen.

5) Düse auf den Pistolenkörper stecken und durch Drehen die richtige Position nden.

6) Luftkappe auf Düse stecken und mit Überwurfmutter festziehen.

7)

Behälterdichtung von unten auf das Steigrohr stecken und bis über den Bund schieben.

Dabei Behälterdichtung leicht drehen.

8) Steigrohr mit Behälterdichtung in Pistolenkörper stecken.

TexPerfect Flexio 525

18. Wartung

Achtung! Gerät niemals ohne Luftlter betreiben, es könnte Schmutz

angesaugt werden und den Betrieb des Gerätes beeinflussen.

Überprüfen Sie den Luftlter nach jeder Benutzung auf Verschmutzung.

Vor dem Wechsel Netzstecker ziehen.

1) Luftlter Abdeckung mit Hilfe des Rührstabes önen. (Abb. 14)

2) Luftlter herausziehen und je nach Verschmutzung den Luftlter auswechseln.

3) Schieben Sie den neuen Luftlter zuerst in die Unterseite des Faches. (Abb. 15)

4)

Drücken Sie ihn anschließend vollständig in das Fach.

Um den Luftlter vollständig in das Fach zu drücken, empehlt sich die Benutzung

des Rührstabes.

Zum leichteren Montieren der Pistole, tragen Sie bitte nach dem Reinigen großzügig

Gleitfett (ist beigelegt) am O-Ring des Sprühaufsatzes (Abb. 16, 5) auf.

19. Ersatzteile

Ersatzteilliste Sprühaufsatz TexPerfect (Abb. 16)

Pos. Benennung Best. Nr.

Sprühaufsatz TexPerfect kpl. mit Behälter 1300 ml 2345 792

1 Überwurfmutter 2343 966

2 Luftkappe 2343 965

3 Düse 2343 963

4 Düsendichtung (2 Stk.) 2304 433

5 O-Ring 0417 308

6 Feder mit Kappe 2343 967

7 Belüftungsschlauch, Ventildeckel, Membran 2304 027

8 Steigrohr 2328 922

9 Behälterdichtung 2328 919

10 Behälter (1300 ml) mit Deckel 2305 155

30

Page 37

TexPerfect Flexio 525

D

Ersatzteilliste Flexio 525 (Abb. 17)

Pos. Benennung Best. Nr.

1 Luftlter Abdeckung (links und rechts) 2335 172

2 Luftlter (2 Stk.) 2333 123

3 Rührstab 2304 419

4 Einfülltrichter (3 Stk.) 2304 028

Gleitfett (ohne Abb.) 2315 539

Ersatzteilbestellung

: 0180 5 59 24 637 (14 Cent/Min. aus dem deutschen Festnetz, Mobilfunk max.

42 Cent/ Min)

Email: hotline@wagner-group.com

20. Zubehör

Das neue CLICK&PAINT SYSTEM bietet mit weiteren Sprühaufsätzen und Zubehör

für jede Arbeit das richtige Werkzeug.

Zubehör (nicht im Lieferumfang enthalten)

Benennung Best. Nr.

HVLP Griverlängerung

Zur einfacheren Beschichtung von Decken und liegenden Objekten 2307 678

Brilliant Sprühaufsatz incl. Behälter 600 ml

Optimierte Düse und Luftführung für brillante Lackierergebnisse

Kleinmengen Sprühaufsatz incl. Behälter 250 ml

Für ligrane Gegenstände, detaillierte und kreative Arbeiten.

Perfect Spray Sprühaufsatz incl. Behälter 1400 ml

Zügiges Arbeiten für größere Objekte wie Holzhäuser, Garagentore etc.

Detail- und Heizkörper Sprühaufsatz mit Verlängerung

incl. Behälter 600 ml

Für schwer erreichbare Stellen, z. B. Heizkörper, Schrankecken, Nischen etc.

WallPerfect I-Spray Sprühaufsatz inkl. Behälter 1800 ml

Zur Verarbeitung von Innenwandfarbe.

Weitere Informationen zur WAGNER-Produktpalette rund ums Renovieren unter

www.wagner-group.com

0417 932

0417 918

0417 917

0417 915

2326 477

31

Page 38

D

TexPerfect Flexio 525

21. Behebung von Störungen

Störung Ursache Abhilfe

Kein

Beschichtungsstoaustritt an der Düse

Beschichtungssto

tropft an der Düse

nach

Zu grobe

Zerstäubung

Spritzstrahl pulsiert

BeschichtungsstoLäufer

Düse verstopft

•

Steigrohr verstopft

•

Materialmengen-Einstellung

•

zu weit nach links gedreht (-)

Steigrohr lose

•

Kein Druckaufbau im Behälter

•

Entlüftungsbohrung

•

(Abb. 10, 1) verstopft

Düse lose

•

Düse verschlissen

•

Düsendichtung fehlt oder

•

verschlissen

Beschichtungssto-Aufbau an

•

Luftkappe, Düse oder Nadel

Beschichtungssto zu

•

dicküssig

Materialmenge zu groß

•

Materialmengen-Einstellschraube zu weit nach rechts

gedreht

Düse verunreinigt

•

Luftlter stark verschmutzt

•

Zu geringer Druckaufbau im

•

Behälter

Zu geringe Luftmenge

•

Beschichtungssto im

•

Behälter geht zu Ende

Luftlter stark verschmutzt

•

Düsendichtung fehlt oder

•

verschlissen

Zuviel Beschichtungssto

•

aufgetragen

➞ Reinigen

➞ Reinigen

➞ Nach rechts drehen (+)

➞ Einstecken

➞ Behälter anziehen

➞ Reinigen

➞ Anziehen

➞ Auswechseln

➞ Intakte Düsendichtung

einsetzen

➞ Reinigen

➞ Verdünnen

➞ Materialmengen-

Einstellschraube nach

links drehen (-)

➞ Reinigen

➞ Auswechseln

➞ Behälter anziehen

➞ Luftmenge erhöhen

➞ Nachfüllen

➞ Auswechseln

➞ Intakte Düsendichtung

einsetzen

➞

Materialmengeneinstellschraube nach links

drehen (-)

➞ Trocknen lassen und

dann abschleifen

32

Page 39

TexPerfect Flexio 525

Störung Ursache Abhilfe

Zuviel

BeschichtungsstoNebel (Overspray)

Material im

Belüftungsschlauch

Schlechte Deckkraft

an der Wand

Gerät funktioniert

nicht

Abstand zum Spritzobjekt zu

•

groß

Zuviel Beschichtungssto-

•

Auftrag

Zu hohe Luftmenge

•

Membran verschmutzt

•

Membran defekt

•

Sprühmaterial zu kalt

•

Stark saugender Untergrund

•

oder Farbe mit schlechter

Deckkraft

Abstand zu groß

•

Gerät überhitzt ➞ Netzstecker ziehen,

•

➞ Spritzabstand

verringern

➞

Materialmengeneinstellschraube nach links

drehen (-)

➞ Luftmenge verringern

➞ Membran reinigen

➞ Membran ersetzen

➞ Sprühmaterial sollte

zuerst Zimmertemperatur haben

➞ Im Kreuzgang sprühen

(Abb. 9)

➞ Näher ans Objekt

Gerät 30 Minuten

abkühlen lassen,

Luftlter prüfen,

Ansaugschlitze nicht

abdecken

D

22. Technische Daten

Technische Daten

Max. Viskosität: 4000 mPas

Spannung: 230 V, ~ 50 Hz

Leistungsaufnahme: 630 W

Zerstäubungsleistung : 25 W (min), 200 W (max)

Max. Fördermenge (Feinputz): 450 g / min

Doppelisolation:

Schalldruckpegel*: 74 dB (A); Unsicherheit K = 4 dB

Schallleistungspegel* 87 dB (A); Unsicherheit K = 4 dB

Schwingungspegel* < 2,5 m/s² Unsicherheit K = 1,5 m/s²

Gewicht: 1,9 kg

* Gemessen nach EN 60745-1

33

Page 40

D

TexPerfect Flexio 525

Information zum Schwingungspegel

Der angegeben Schwingungspegel ist nach einem genormten Prüfverfahren

gemessen worden und kann zum Vergleich von Elektrowerkzeugen verwendet werden.

Der Schwingungspegel dient auch zu einer einleitenden Einschätzung der

Schwingungsbelastung.

Achtung! Der Schwingungsemissionswert kann sich während der tatsächlichen Benutzung

des Elektrowerkzeuges vom Angabewert unterscheiden, abhängig von der Art und Weise,

in der das Elektrowerkzeug verwendet wird. Es ist notwendig, Sicherheitsmaßnahmen

zum Schutz der Bedienperson festzulegen, die auf einer Abschätzung der Aussetzung

während der tatsächlichen Benutzungsbedingungen beruhen (hierbei sind alle Anteile des

Betriebszyklus zu berücksichtigen, beispielsweise Zeiten, in denen das Elektrowerkzeug

abgeschaltet ist, und solche, in denen es zwar eingeschaltet ist, aber ohne Belastung

läuft).

23. Umweltschutz

Das Gerät samt Zubehör und Verpackung sollte einer umweltgerechten

Wiederverwertung zugeführt werden. Geben Sie das Gerät bei der Entsorgung nicht in

den Hausmüll. Unterstützen Sie den Umweltschutz und bringen Sie deshalb Ihr Gerät

zu einer örtlichen Entsorgungsstelle oder erkundigen Sie sich im Fachhandel.

Farbreste und Lösungsmittel dürfen nicht in die Kanalisation, das Abusssystem

oder den Hausmüll geschüttet werden. Diese sind als Sondermüll separat zu

entsorgen. Beachten Sie dazu die Hinweise auf den Produktverpackungen.

24. Wichtiger Hinweis zur Produkthaftung!

Nach dem seit 01.10.1990 geltenden Produkthaftungsgesetz haftet der Hersteller für sein

Produkt bei Produktfehlern uneingeschränkt nur dann, wenn alle Teile vom Hersteller

stammen oder von diesem freigegeben wurden, die Geräte sachgemäß montiert und

betrieben werden. Bei Verwendung von fremdem Zubehör und Ersatzteilen kann die

Haftung ganz oder teilweise entfallen, wenn die Verwendung des fremden Zubehörs oder

der fremden Ersatzteile zu einem Produktfehler führt.

34

Page 41

TexPerfect Flexio 525

D

2 Jahre Garantie

Die Garantie beträgt 2 Jahre, gerechnet vom Tag des Verkaufes (Kassenbon).

Sie umfasst und beschränkt sich auf die kostenlose Behebung der Mängel, die

nachweisbar auf die Verwendung nicht einwandfreien Materials bei der Herstellung

oder Montagefehler zurückzuführen sind oder kostenlosen Ersatz der defekten Teile.

Verwendung oder Inbetriebnahme, sowie selbständig vorgenommene Montagen oder

Reparaturen, die nicht in unserer Bedienungsanleitung angegeben sind, schließen

eine Garantieleistung aus. Dem Verschleiß unterworfene Teile sind ebenfalls von der

Garantie ausgeschlossen. Die Garantieleistung schließt den gewerblichen Einsatz

aus. Die Garantieleistung behalten wir uns ausdrücklich vor. Die Garantie erlischt,

wenn das Gerät von anderen Personen als dem WAGNER Service - Personal geönet

wurde. Transportschäden, Wartungsarbeiten sowie Schäden und Störungen durch

mangelhafte Wartungsarbeiten fallen, nicht unter die Garantieleistungen. Der Nachweis

über den Erwerb des Gerätes muss bei Inanspruchnahme der Gewährleistung durch

Vorlage des Originalbeleges geführt werden. Soweit gesetzlich möglich, schließen

wir jede Haftung für jegliche Personen,- Sach- oder Folgeschäden aus, insbesondere,

wenn das Gerät anders als für den in der Bedienungsanleitung angegebenen

Verwendungszweck eingesetzt wurde, nicht nach unserer Bedienungsanleitung in

Betrieb genommen oder instandgesetzt oder Reparaturen selbständig von einem

Nichtfachmann ausgeführt wurden. Reparaturen oder Instandsetzungsarbeiten, die

weitergehen als in dieser Bedienungsanleitung angegeben, behalten wir uns im Werk

vor. Im Garantie- bzw. Reparaturfall wenden Sie sich bitte an Ihre Verkaufsstelle.

Sehr geehrter WAGNER-Kunde,

unser Service-Zentrum bietet Ihnen die beste Unterstützung durch unsere Hotline,

die wir für Sie unter der Telefon Nummer 0180 5 59 24 637 (14 Cent/Min. aus dem

deutschen Festnetz, Mobilfunk max. 42 Cent/Min) geschaltet haben.

Unsere Experten garantieren Ihnen schnelle Hilfe und kompetente Auskunft. Sie geben